Trane VUVE Installation and Maintenance Manual

Installation, Operation,

and Maintenance

Vertical Unit Ventilator

Classroom Unit Ventilator—Model VUV

Models |

“A” and later Design Sequence |

VUVE |

750 cfm—1500 cfm |

SAFETY WARNING

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are attached to the equipment.

January 2013 |

UV-SVN03F-EN |

Warnings, Cautions and Notices

Warnings, Cautions, and Notices. Note that warnings, cautions, and notices appear at appropriate intervals throughout this manual. Warnings are provide to alert installing contractors to potential hazards that could result in death or personal injury. Cautions are designed to alert personnel to hazardous situations that could result in personal injury, while notices indicate a situation that could result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this machine depend upon the strict observance of these precautions.

Read this manual thoroughly before operating or servicing this unit.

ATTENTION: Warnings, Cautions, and Notices appear at appropriate sections throughout this literature. Read these carefully:

WARNING

WARNING

CAUTIONs

CAUTIONs

NOTICE:

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury. It could also be used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only

Important

Environmental Concerns!

Scientific research has shown that certain man-made chemicals can affect the earth’s naturally occurring stratospheric ozone layer when released to the atmosphere. In particular, several of the identified chemicals that may affect the ozone layer are refrigerants that contain Chlorine, Fluorine and Carbon (CFCs) and those containing Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all refrigerants containing these compounds have the same potential impact to the environment. Trane advocates the responsible handling of all refrigerants-including industry replacements for CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are important to the environment, our customers, and the air conditioning industry. All technicians who handle refrigerants must be certified. The Federal Clean Air Act (Section 608) sets forth the requirements for handling, reclaiming, recovering and recycling of certain refrigerants and the equipment that is used in these service procedures. In addition, some states or municipalities may have additional requirements that

must also be adhered to for responsible management of refrigerants. Know the applicable laws and follow them.

WARNING

WARNING

Contains Refrigerant!

System contains oil and refrigerant under high pressure. Recover refrigerant to relieve pressure before opening the system. See unit nameplate for refrigerant type. Do not use non-approved refrigerants, refrigerant substitutes, or refrigerant additives.

Failure to follow proper procedures or the use of nonapproved refrigerants, refrigerant substitutes, or refrigerant additives could result in death or serious injury or equipment damage.

WARNING

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified personnel. Improperly installed and grounded field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST follow requirements for field wiring installation and grounding as described in NEC and your local/state electrical codes. Failure to follow code could result in death or serious injury.

WARNING

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical hazards.

•Before installing/servicing this unit, technicians MUST put on all PPE required for the work being undertaken. ALWAYS refer to appropriate MSDS sheets and OSHA guidelines for proper PPE.

•When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS sheets and OSHA guidelines for information on allowable personal exposure levels, proper respiratory protection and handling instructions.

•If there is a risk of arc or flash, technicians MUST put on all PPE in accordance with NFPA 70E or other country-specific requirements for arc flash protection, PRIOR to servicing the unit.

Failure to follow instructions could result in death or serious injury.

© 2013 Trane All rights reserved |

UV-SVN03F-EN |

Warnings, Cautions and Notices

WARNING

WARNING

Hazard of Explosion and Deadly Gases!

Never solder, braze or weld on refrigerant lines or any unit components that are above atmospheric pressure or where refrigerant may be present. Always remove refrigerant by following the guidelines established by the EPA Federal Clean Air Act or other state or local codes as appropriate. After refrigerant removal, use dry nitrogen to bring system back to atmospheric pressure before opening system for repairs. Mixtures of refrigerants and air under pressure may become combustible in the presence of an ignition source leading to an explosion. Excessive heat from soldering, brazing or welding with refrigerant vapors present can form highly toxic gases and extremely corrosive acids. Failure to follow all proper safe refrigerant handling practices could result in death or serious injury.

Introduction

Important: Equipment is shipped FOB (Free On Board) at the manufacturer. Therefore, freight claims for damages against the carrier must be initiated by the receiver.

Trademarks

ComfortLink, EarthWise, Rover, Tracer, Tracer Summit, Trane, and the Trane logo are trademarks or registered trademarks of Trane in the United States and other countries. All trademarks referenced in this document are the trademarks of their respective owners.

BACnet is a registered trademark of American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE); Echelon, LonTalk, and LONWORKS are registered trademarks of Echelon Corporation; Energizer is a registered trademark of Eveready Battery Company, Inc.; National Electrical Code, National Fire Protection Association, and NEC are registered trademarks of the National Fire Protection Association.

UV-SVN03F-EN |

3 |

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . 8

Unit Description . . . . . . . . . . . . . . . . . . . . . 8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . 10

Dimensions and Weights . . . . . . . . . . . . . . . . 11

Unit Location and Clearances . . . . . . . . . 11

. . . . . . . . . . . . . . . . . 18

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . 19

Jobsite Inspection . . . . . . . . . . . . . . . . . . 19

Jobsite Storage . . . . . . . . . . . . . . . . . . . . 19

Installation—Mechanical . . . . . . . . . . . . . . . . 20

Wall Box Installation . . . . . . . . . . . . . . . . 20

General Installation Checks . . . . . . . . . . . 20

Location Considerations . . . . . . . . . . . . . 21

Unit Mounting . . . . . . . . . . . . . . . . . . . . . 21

Installation—Piping . . . . . . . . . . . . . . . . . . . . . 24

Piping Installation . . . . . . . . . . . . . . . . . . . 24

Refrigerant Piping . . . . . . . . . . . . . . . . . . 25

Steam Piping . . . . . . . . . . . . . . . . . . . . . . 25

Modulating Water Valves (Option) . . . . . 25

Heating Coils with Direct Expansion Cooling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation—Sensors . . . . . . . . . . . . . . . . . . . 29

Control Options . . . . . . . . . . . . . . . . . . . . . . 29

Installing Wall-Mounted Wired Sensors . 30

Location Considerations . . . . . . . . . . . . . 31

Location Considerations for Wireless zone sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fan Mode Switch Installation . . . . . . . . . 31 Zone Sensor Installation . . . . . . . . . . . . . 31

Wireless Sensors . . . . . . . . . . . . . . . . . . . . . 32

Address Setting . . . . . . . . . . . . . . . . . . . . 32

Observing the Receiver for Readiness to Associate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Associating the Sensor to the Receiver . 33

Testing Signal Strength and Battery Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configuring the Wireless Display Sensor (Model WDS only) . . . . . . . . . . . . . . . . . . .35

Sensor Operations . . . . . . . . . . . . . . . . . . .37

Wireless Sensor Specifications . . . . . . . . .40

Installation—Electrical . . . . . . . . . . . . . . . . . . .42

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Electrical Wiring . . . . . . . . . . . . . . . . . . . . .42

Electric Heat (Option) . . . . . . . . . . . . . . . . .43

DX System . . . . . . . . . . . . . . . . . . . . . . . . .43

Split System Start-Up . . . . . . . . . . . . . . . .43

ECM Overview and Setup . . . . . . . . . . . . . . . .45

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

General Information . . . . . . . . . . . . . . . . . . .45

Trane BLDC Motor . . . . . . . . . . . . . . . . . . .45

ECM Engine Controller . . . . . . . . . . . . . . .45

Standard Adapter Board . . . . . . . . . . . . . .46

CSTI Adapter Board . . . . . . . . . . . . . . . . . .46

Installation and Initial Setup . . . . . . . . . . . .47

Installation and Initial Setup . . . . . . . . . . .47

Adjustment and Configuration of the Engine

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Status Display . . . . . . . . . . . . . . . . . . . . . . .50

Initial Setup and Configuration . . . . . . . . .55

Configuration . . . . . . . . . . . . . . . . . . . . . . . . .55

Configuring the ECM Engine Controller . .55

Configuring the ECM Engine Board . . . . .60

Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Setting the Time Clock . . . . . . . . . . . . . . . .65

Wired Controllers—Communication Wiring 67

Wiring Installation (ZN520) . . . . . . . . . . . . .67

Device Addressing . . . . . . . . . . . . . . . . . . .67

Recommended Communication Wiring Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Wiring Installation (Tracer UC400) . . . . . . .67

Wiring Overview Outline . . . . . . . . . . . . . .68

General Instructions . . . . . . . . . . . . . . . . . .68

BACnet MS/TP Link . . . . . . . . . . . . . . . . . .68

Power Supply . . . . . . . . . . . . . . . . . . . . . . .69

Pre-Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4 |

UV-SVN03F-EN |

Pre-Start-up Checklist . . . . . . . . . . . . . . . |

71 |

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. . . |

72 |

Tracer ZN520 Unit Startup . . . . . . . |

. . |

. . . |

72 |

Tracer UC400 Unit Startup . . . . . . |

. . |

. . . |

72 |

General Information . . . . . . . . . . . . . |

. |

. . . |

72 |

Fan Mode Switch Operation . . . . . . |

. |

. . . |

72 |

Tracer ZN520 Operation . . . . . . . . . |

. |

. . . |

72 |

UC400 Controller Operation . . . . . . |

. |

. . . |

73 |

Tracer ZN520 Sequence of Operation |

. . . |

73 |

|

Cooling Operation (Tracer ZN520) . . . . . |

74 |

||

Fan Mode Operation (Tracer ZN520) |

. . . 75 |

||

UC400 Sequence of Operation . . . . . |

. |

. . . |

80 |

Power-up Sequence (UC400) . . . . . |

. |

. . . |

80 |

Random Start (UC400) . . . . . . . . . . . |

. |

. . . |

80 |

Occupancy Modes (UC400) . . . . . . . |

. |

. . . |

80 |

Timed Override Control (UC400) . . |

. |

. . . |

81 |

Zone Temperature Control (UC400) . . . . 81 |

|||

Discharge Air Tempering (UC400) |

. . . . . 82 |

||

Heating or Cooling Mode (UC400) |

. . . . . 82 |

||

Entering Water Temperature Sampling Func- |

|||

tion (UC400) . . . . . . . . . . . . . . . . . . . |

. |

. . . |

82 |

Fan Operation (UC400) . . . . . . . . . . |

. |

. . . |

82 |

Exhaust Control (UC400) . . . . . . . . . |

. |

. . . |

83 |

Valve Operation (UC400) . . . . . . . . . |

. |

. . . |

83 |

Modulating Outdoor/Return Air Damper |

|

||

(UC400) . . . . . . . . . . . . . . . . . . . . . . . |

. |

. . . |

84 |

Two-position Control Of A Modulating Out- |

|||

door Air Damper (UC400) . . . . . . . . |

. |

. . . |

85 |

Electric Heat Operation (UC400) . . . |

. |

. . . |

85 |

Dehumidification Operation (UC400) |

. . . 85 |

||

Peer-to-peer Communication (UC400) . . 85 |

|||

Unit Protection Strategies (UC400) . |

. |

. . . |

85 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . |

. |

. . . |

87 |

Service Access . . . . . . . . . . . . . . . . . |

. |

. . . |

87 |

Periodic Maintenance . . . . . . . . . . . |

. |

. . . |

87 |

Preventive Maintenance . . . . . . . . . |

. |

. . . |

89 |

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. . . |

90 |

Troubleshooting Checklist . . . . . . . . |

. |

. . . |

90 |

Output Testing and Diagnostics (Tracer |

|

||

ZN520) . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. . . |

91 |

Output Testing and Diagnostics (UC400) . 95

Output Testing (UC400) . . . . . . . . . . . . . . .95

Diagnostics (UC400) . . . . . . . . . . . . . . . . .95

Troubleshooting (Wireless Controls) . . . . .96

Troubleshooting (Tracer ZN520) . . . . . . .102

Troubleshooting (UC400) . . . . . . . . . . . .103

Troubleshooting (ECM) . . . . . . . . . . . . . .105

General Information (ECM) . . . . . . . . . . .106

Troubleshooting Information (ECM) . . .106

Replacing ECM Components . . . . . . . . . . . .108

Circuit Modules Replacement Notes/Work Instructions . . . . . . . . . . . . . . . . . . . . . . . . .109

Softsetting the IMC Address of an ECM Engine Module . . . . . . . . . . . . . . . . . . . . . . .110

UV-SVN03F-EN |

5 |

Model Number Descriptions

Vertical Unit

Ventilator Model

Number

Digits 1, 2, 3 — Unit

Configuration

VUV= Vertical Unit Ventilator

Digit 4 — Development

Sequence

E

Digits 5, 6, 7 — Nominal Airflow

075 = |

750 cfm |

100 = |

1000 cfm |

125 = |

1250 cfm |

150 = |

1500 cfm |

Digit 8 — Voltage (Volts/Hz/

Phase)

0 |

= |

115/60/1 |

1 |

= |

208/60/1 |

2 |

= |

230/60/1 |

3 |

= |

208/60/3 |

4 |

= |

460/60/3 |

7 |

= |

277/60/1 |

8 |

= |

230/60/3 |

Digit 9 — Open Digit = 0

Digits 10, 11 — Current Design

Sequence

Digit 12 — Face & Bypass

Y |

= |

Yes, Include Damper |

N |

= |

No Damper |

Digit 13 — Unit Arrangement

1= Return Air Front / Fresh Air Back

2= 100% Return Air Front

3= 100% Fresh Air Back

4= Dynamic Air Barrier

5= ERS-Compatible w/RH Connection

6= ERS-Compatible w/LH Connection

Digit 14 — Preheat / Reheat /

Changeover

A= 4-Pipe Preheat (RH Clg/LH Htg)

B= 4-Pipe Preheat (LH Clg/RH Htg)

C= 4-Pipe Reheat (RH Clg/LH Htg)

D= 4-Pipe Reheat (LH Clg/RH Htg)

E= 2-Pipe (RH Connections)

F= 2-Pipe (LH Connections)

Digit 15 — Cooling / 2-Pipe Coil

0 = None

B= 2-Row, 12 F.P.I.

C= 2-Row, 16 F.P.I.

D= 3-Row, 12 F.P.I.

E= 3-Row, 16 F.P.I.

F= 4-Row, 12 F.P.I.

G= 4-Row, 14 F.P.I.

H= 3-Row, 16 F.P.I, EarthWise™ Coil

J = 3-Row, DX (R-410A) Cooling Coil

Digit 16 — Heating Coil

0 = None

A= 1-Row, 12 F.P.I.

B= 2-Row, 12 F.P.I.

C= 2-Row, 16 F.P.I.

D= 3-Row, 12 F.P.I.

E= 3-Row, 16 F.P.I.

F= 4-Row, 12 F.P.I.

G= 4-Row, 14 F.P.I.

H= 3-Row, 16 F.P.I, EarthWise Coil

K= Steam Low

L= Steam High

M= Electric Heat - Low

N= Electric Heat - Med

P= Electric Heat - High

Digit 17 — Motor

0 = ECM

1= ECM & Low Acoustic Option

2= ECM & Low FLA Option

3= ECM & Low Acoustic & Low FLA Option

Digit 18 — Other Motor Items

A |

= |

None |

B |

= |

Toggle |

C |

= |

Circuit Breaker |

Digit 19 — 2- or 3-Way Valve - Cooling Changeover Coil

0 = None

2= 2-Way; 3-Point Floating

3= 3-Way; 3-Point Floating

4= 2-Way; 2–10 Volt

5= 3-Way; 2–10 Volt

6= Isolation Valve; 2-Way

7= Isolation Valve; 3-Way

Digit 20 — CV - Cooling or Changeover Coil

0 = None

L= Low Cv

M= Medium Cv

H= High Cv

Digit 21 — 2- or 3-Way Valve - Preheat or Reheat Heating Coil

0 = None

2= 2-Way; 3-Point Floating

3= 3-Way; 3-Point Floating

4= 2-Way; 2–10 Volt

5= 3-Way; 2–10 Volt

6= Isolation Valve; 2-Way

7= Isolation Valve; 3-Way

Digit 22 — CV - Preheat or Reheat Heating Coil

0 = None

L= Low Cv

M= Medium Cv

H= High Cv

Digit 23 — Discharge

Arrangement

0 = Opening Only, No Grille

A= Discharge Grille

B= Double Deflection Discharge Grille

C= Grille Discharge with Wire Mesh

Digit 24 — Outside Air Damper

Control

0 = None

A= 3-Wire Actuator

B= 2–10 Volt Actuator

Digit 25 — Face and Bypass

Damper Control

0 = None

A= 3-Wire Actuator

B= 2–10 Volt Actuator

Digit 26 — Controls

0 = None, Unit-Mounted Speed

Switch

2= Customer Supplied Terminal Interface (CSTI)

3= CSTI w/Low Temp Detection

4= Tracer™ ZN520

5= Tracer ZN520 w/Time Clock

6= Tracer ZN520 w/Fan Status

7= Tracer UC400

8= Tracer UC400 w/Time Clock

Digit 27 — Unitor WallMounted Controls

0 |

= |

None |

1 |

= |

Unit-Mounted |

2 |

= |

Wall-Mounted |

3= Unit-Nounted Fan Speed Switch & Wall-Mounted Temperature Sensor

4= Wireless Zone Sensor

Note: The wall-mounted room sensor is ordered as separate line item in Job Configurator.

Digit 28 — Internal or External Set Point

0 |

= |

None |

1 |

= |

Internal |

2 |

= |

External |

3 |

= |

Digital Display |

Digit 29 — Timed Override

0 |

= |

No |

1 |

= |

Yes |

Digit 30 — Exhaust Control

A= No Exhaust Control with 3-Speed Supply Fan

B= Exhaust Control with 2-Speed Supply Fan

C= No Exhaust Control with 1-Speed Supply Fan (DX/EH Units)

D= Exhaust Control with 1-Speed Supply Fan (DX/EH Units)

Digit 31 — DDC Programming

0 = None

1= Humidity Sensor Programming

2= CO2 Sensor Programming

Note: The humidity and CO2 sensor must be ordered as a separate line item in Job Configurator.

6 |

UV-SVN03F-EN |

Model Number Descriptions

Digit 32 — Unit Depth

A= Standard (16-5/8 in.)

B= 21-1/4 in. Depth with Baffle

C= 21-1/4 in. Depth with Full Sheet Metal Back and Baffle

D= 21-1/4 in. Depth with 25 in. High Falseback

E= 21-1/4 in. Depth with 26 in. High Falseback

F= 21-1/4 in. Depth with 27 in. High Falseback

G= 21-1/4 in. Depth with 28 in. High Falseback

H= 21-1/4 in. Depth with 29 in. High Falseback

J = 21-1/4 in. Depth without Baffle

Note: Selection “J” should be applied if OA opening is raised above standard baffle location.

Digit 33 — End Covers

0 = None

1= 16-5/8 in. Depth without Cutouts

2= 16-5/8 in. Depth with 3 x 7-1/4 in. Cutout

4= 21-1/4 in. Depth without Cutouts

5= 21-1/4 in. Depth with 3 x 7-1/4 in. Cutout

6= 21-1/4 in. Depth with 3-1/4 in. x 16-7/8 in. Cutout

Digit 34 — Front Panel

1= Standard Front Panel

2= Heavy Gauge Front Panel

Digit 35 — Subbase

0 |

= |

No Subbase |

2 |

= |

2 in. Subbase |

4 |

= |

4 in. Subbase |

6 |

= |

6 in. Subbase |

Digit 36 — Piping Package

0 = None

1= Ball Valves & P/T Ports

2= Ball Valve & Circuit-Setter with P/T Ports

3= Ball Valve, Circuit-Setter with P/T Ports & Strainer

Digit 37 — Flow Control -

Cooling/Changeover Coil

0 = None

Digit 38 — Flow Controls -

Heating Coil

0 = None

Digit 39 — Auxiliary Drain Pan -

Piping

Y = Yes, Auxiliary Drain Pan

N = No Auxiliary Drain Pan

Digit 40 — Crossover Piping

0 |

= |

None |

1 |

= |

Internal |

2= External 1-3/8 in. Crossover Piping

3= External 2-1/8 in. Crossover Piping

Digit 41 — Filter

1= Standard Throwaway Filter

2= MERV 8 Filter

3= MERV 13 Filter

Digit 42 — Color

1= Deluxe Beige

2= Cameo White

3= Soft Dove

4= Stone Gray

5= Driftwood Gray

UV-SVN03F-EN |

7 |

General Information

Unit Description

Unit Nameplate. The unit nameplate is located in the left hand end pocket, behind the control box. It includes the unit model number, serial number, electrical characteristics, and other pertinent unit data.

Factory Shipment. Before shipment, each unit is leaktested and run-tested for proper control operation.

Access. A three-panel front access of the unit ventilator allows for speedy set-up during field commissioning. This design allows for the end pocket of the unit ventilator to be open while the fan (airside) section stays closed.

End Pockets. Access for piping and controls is made through the unit ventilator’s end pockets.

Coil Connections. The coil headers and drain connections are made within the unit chassis to allow a tight seal and help prevent air leakage around the coil. The connection sizes vary dependent upon type of coil combination specified.

Coil type |

Size (in.) |

|

|

Hydronic cooling (main) coil or |

3/4 in. nominal |

Heating/cooling changeover coil |

7/8 in. ID |

|

|

Heating (auxiliary) coil |

1/2 in. nominal |

|

5/8 in. ID |

|

|

Steam heating coil |

1 in. FNPT |

|

|

Direct expansion coil |

3/8 in. OD liquid |

|

7/8 in. OD suction |

|

|

Unit Drain Pan. The drain pan is dual-sloped for effective condensate removal. It is made from a noncorrosive material to help eliminate issues associated to leaking or standing water. It may be easily removed for cleaning. The drain pan connection size for all Trane VUVE models is 7/8 in. OD.

Motor. Motors for the VUVE model do not include an external fan bearing on the end of the fan shaft. This helps avoid issues related to fan bearing maintenance (oiling is not needed), and/or bearing replacement.

Filters. Filter sizing for the unit ventilator are an off-the- shelf design to reduce or help eliminate local stocking of the filters. Options include throwaway filters, MERV 8, and MERV 13 filters.

Sliding Fan Deck. Convenient access to the fan motor and wheels for maintenance and serviceability may be made through Trane’s easy-slide fan deck design.

Note: Ground wire must be reconnected if removed for service of fan deck.

Outside-Air/Return-Air Dampers. The outside-air/ return-air damper is a one piece, linkage free design resulting in a superior air-tight seal.

Options

Field-Installed Controls (Option). The unit comes equipped with a fan speed switch, damper blade (only), and an optional low temperature detection.

Customer Supplied Terminal Interface (CSTI)

(Option). Units containing the end device control design will incorporate a pre-wired, selected control components to a terminal strip for wiring a field-provided controller and temperature sensor.

Note: For controller operation malfunction of any nonTrane, field installed controls, consult the literature or technical support of the controls manufacturer.

Tracer ZN520 Control Package (Option). The Tracer ZN520 electronic digital controller is a factory installed, tested and commissioned LonTalk® certified design. It may be used in a stand-alone control scheme, or as part of a building automation system. The controller is pre-wired to Trane selected control components best suited for room comfort. For more information on the Tracer ZN520 unit controller operation and service issues, refer to CNT-SVX04A-EN (Installation, Operation, and Programming Guide: Tracer ZN520 Unit Controller), or the most recent version.

Tracer UC400 Control Package (Option). The Tracer UC400 electronic digital controller is a factory installed, tested and commissioned BACnet® certified design. The Tracer UC400 operates as a single zone VAV controller and ramps fan speed based on space load. It may be used in a stand-alone control scheme, or as part of a building automation system. The controller is mounted, pre-wired, and pre-programmed to selected control components best suited for room comfort. For more information on the Tracer UC400 unit controller operation and service issues, refer to BAS-SVX48B-EN (Installation, Operation, and Programming Manual: Tracer UC400 Programmable Controller), or the most recent version.

OA/RA Actuator (Option). The OA/RA actuator provides true spring-return operation for positive close-off of the OA/RA damper. The spring return system of the actuator closes the outside damper if power is lost to the building. When ordered with factory controls, the actuator is a 3-point floating design. A 2 to 10 Vdc actuator is available when other than Trane controls are specified. Refer to Table 1, p. 9 for OA/RA technical data.

Note: Because the damper actuator is a spring return type an inner spring will close the damper upon loss of power. If the need to service or replace the actuator is required, the spring must be “loaded” for the damper to function properly. The term loaded means that the blade must be held in the return air position upon replacement of the actuator.

8 |

UV-SVN03F-EN |

General Information

Face and Bypass Actuator (Option). The face and bypass damper actuator incorporates a direct couple design. It provides electronic protection against overload. A limit switch is not included, nor required as part of the design. When reaching the damper end position, the actuator automatically stops. The gears can be manually disengaged with a button on the housing. Refer to Table 2, p. 9 for face and bypass actuator specifications.

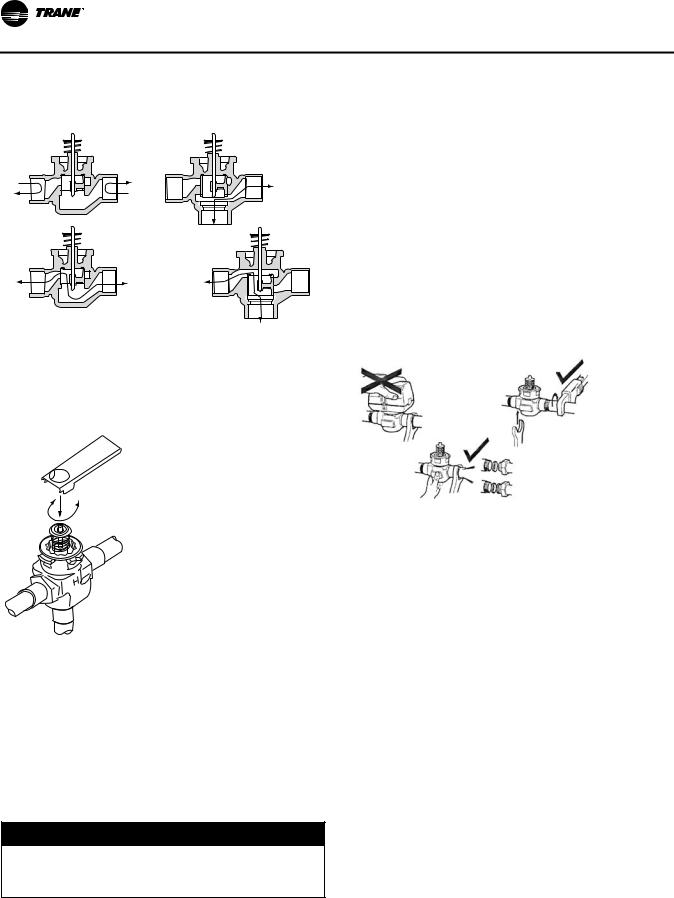

Modulating Water Valves (Option). The modulating control valve provides optimum control of hot and chilled water flow in various heating and cooling applications.

They are designed to provide sinusoidal valve actuator travel and operate silently, resisting water hammer.

The actuator on the valve is a 24V, 3-point floating type. Refer to Table 3 for modulating water valve specifications.

Isolation Valve (Option). The isolation valve is a two position 24V, spring return type valve. It provides added control in heating and cooling applications when used in conjunction with the face and bypass damper.

On heating coils, and two-pipe changeover applications, the valve is normally open to help prevent the coil from freezing in-case of power loss.

For cooling, the valve is normally closed and opens when there is a call for cooling. Refer to Table 4, p. 9 for isolation valve specifications.

Table 1. |

OA/RA actuator specification |

||

|

|

|

|

|

|

|

|

|

Power supply |

24 Vac ±20% 50/60 Hz |

|

|

|

|

24 Vac ±10% |

|

|

|

|

|

Power consumption |

Running: 2.5 W |

|

|

|

|

Holding: 1 W |

|

|

|

|

|

Transformer sizing |

5 VA (class 2-power source) |

|

|

|

|

|

|

Overload protection |

Electronic throughout 0° to 95° rotation |

|

|

|

|

|

|

Control signal |

2 to 10 Vdc |

|

|

|

|

3-point floating with Trane controls |

|

|

|

|

|

Angle of rotation |

Maximum 95° |

|

|

|

|

Adjustable with mechanical stop |

|

|

|

|

|

Torque |

|

35 in·lb |

|

|

|

|

|

Direction of rotation |

Spring return reversible with cw/ccw |

|

|

|

|

mounting |

|

|

|

|

|

Position indication |

Visual indicator, 0° to 95° |

|

|

|

|

|

|

Noise level |

|

Running: 30 dB |

|

|

|

|

Table 2. Face-bypass actuator specification

|

|

|

|

|

Power supply |

24 Vac ± 20% 50/60 Hz |

|

|

|

24 Vac ± 10% |

|

|

Power consumption |

2 W |

|

|

|

|

|

|

Transformer sizing |

3 VA (class 2-power source) |

|

|

|

|

|

|

Angle of rotation |

Maximum 95-degree |

|

|

|

Adjustable with mechanical stop |

|

|

|

|

|

|

Torque |

35 in./lb |

|

|

|

|

|

|

Direction of rotation |

Reversible with switch L/R |

|

|

|

|

|

|

Position indication |

Clip-on indicator |

|

|

|

|

|

|

Manual override |

External push button |

|

|

|

|

|

|

Noise level |

Less than 35 dB |

|

|

|

|

|

|

Control signal |

3-point floating |

|

|

|

|

|

Table 3. Mod. water valve specification |

|||

|

|

|

|

|

|

|

|

|

Power supply |

|

24 Vac - 50/60 Hz |

|

Power consumption |

|

4 W |

|

|

|

|

|

Max. duty cycle |

|

15% |

|

|

|

|

|

Operating ambient temp. |

0 to 65°C |

|

|

|

|

32 to 150°F |

|

|

|

|

|

Min./max. fluid temp. |

|

1 to 95°C |

|

|

|

34 to 203°F |

|

|

|

|

|

Operating pressure |

|

Max. - 4 bar (60 psi) |

|

differential |

|

|

|

|

|

|

|

Pressure rating |

|

Static - 20 bar (300 psi) |

|

|

|

Burst - 100 bar (1500 psi) |

|

|

|

|

|

Flow characteristic |

|

Linear |

|

|

|

|

Table 4. Isolation valve specification

|

|

Power supply |

24 Vac - 50/60 Hz |

Power consumption |

5 W |

|

|

Max. fluid temp. |

94°C |

|

200°F |

|

|

Min. fluid temp. |

1°C |

|

34°F |

|

|

Max. operating pressure |

300 psi |

|

|

Max. close-off pressure |

1/2 in. = 30 psi |

|

3/4 in. = 20 psi |

|

1 in. = 15 psi |

|

|

UV-SVN03F-EN |

9 |

ECM Application Notes

The new Trane BLDC system has some notable differences to traditional designs.

RPM Mode

The motors are programmed from the factory to run in rpm mode and will not change rpm based on external static pressure, except at the performance limits of the motor/controller. For ducted units, the units are shipped with the rpm set for 0.2 in. ESP for High, Medium, and Low speeds. The speeds can for high, medium, and low operation, but should not be changed for the electric heat actuation speeds.

Generally, the fans deliver less cfm for the same rpm, if the static is increased and the power will decrease. The fan will deliver more cfm for the same rpm, if the static is decreased and the fan power will increase. A unit with high static configuration should not be used to free-deliver air (i.e., with no ducting attached).

Field Power Wiring

Note: This product uses an electronic variable speed motor control, which includes a line reactor to minimize power line harmonic currents. It is recommended that good wiring practices be followed to manage building electrical power system harmonic voltages and currents to avoid electrical system problems or other equipment interaction.

Performance Boundaries

While the speeds of the fan motors can be adjusted, never program a fan speed higher than 1700 rpm, or lower than 450 rpm. In many cases, units configured for high-static operation will not achieve the desired rpm if the ESP of the unit is too low, or the unit is allowed to “free-discharge.” The ECM engine contains settings that will limit the output power of the motor under these overload conditions. If the motors cannot achieve rpm close to the target for a specific period of time, the unit will disable electric heat and fanstatus indicators.

MCA/MFS and Power Draw

The Trane BLDC motors have variable output but are shipped at specific settings to deliver proper performance and reliability. The power draw indicated in the catalogue indicates the power consumed when applied properly (as shipped and with the nominal ESP applied). However, the nameplate of the unit indicates the maximum input draw of the motor, as the motor settings can be changed to draw more power.

Electric Heat Relays

For quiet operation, the new BLDC units employ power relays instead of definite purpose contactors for electric heat actuation. The coils of multiple relays are hooked in parallel to simulate a multi-pole contactor, as shown in Figure 1. In Figure 1, two sets of three relays are used to

perform the function of a two 3-pole contactors.

Figure 1. Sample arrangement: electric heat relay

Troubleshooting Other Unit Functions

In some cases, the normal or abnormal operation of the BLDC system may interact with other components in the system. Generally, verification of the engine and adapter boards’ wiring and configuration should be checked if there are unexplained abnormalities in other areas of the unit:

1.Valve operation

2.Electric Heat operation

3.Changeover sensor operation

4.Damper operation

5.Condensate overflow switch

A high degree of protection is provided on electric heat units. If electric heat fails to actuate, it may be because of one of the following events:

1.Fans are failing to meet target speed. If a second motor is not present, all settings for speeds for Motor 2 should be set to 0000.

2.Hot water may be available in the changeover coil.

3.The connection to analogue input 1 on the Tracer ZN controller may be reversed in polarity.

4.Target speeds for motors may be set too high:

a.The parameter may be set incorrectly.

b.The parameter may be set incorrectly.

10 |

UV-SVN03F-EN |

Dimensions and Weights

Unit Location and Clearances

Locate the unit in an indoor area. The ambient temperature surrounding the unit must not be less than 45°F. Do not locate the unit in areas subject to freezing.

NOTICE:

Equipment Damage!

Do not locate the unit in areas subject to freezing. Pipes could burst at lower temperature resulting in equipment damage.

Attention should be given to service clearance and technician safety. The unit should contain enough space for service personnel to perform maintenance or repair. Provide sufficient room to make water, and electrical connection(s).

Table 5. VUVE general data

WARNING

WARNING

Electrocution and Fire Hazards with Improperly Installed and Grounded Field Wiring!

Improperly installed and grounded field wiring poses FIRE & ELECTROCUTION hazards. To avoid these hazards, you MUST follow requirements for field wiring installation and grounding as described in NEC and your local/state electrical codes. All field wiring MUST be performed by qualified personnel.

Failure to follow these requirements could result in death or serious injury.

A 36-inch clearance at the unit front is sufficient for maintenance and service of the equipment.

|

|

|

|

Unit size |

|

|

|

|

|

|

|

|

|

Description |

|

0750 |

1000 |

|

1250 |

1500 |

|

|

|

|

|

|

|

Unit length w/o end covers (in.) |

|

69 |

81 |

|

93 |

105 |

|

|

|

|

|

|

|

Unit depth - standard (in.) |

|

16-5/8 |

16-5/8 |

|

16-5/8 |

16-5/8 |

Unit depth - with false back (in.) |

|

21-1/4 |

21-1/4 |

|

21-1/4 |

21-1/4 |

|

|

|

|

|

|

|

Unit height - standard (in.) |

|

30 |

30 |

|

30 |

30 |

|

|

|

|

|

|

|

Shipping weight (lb) |

|

320 |

405 |

|

450 |

470 |

|

|

|

|

|

|

|

Nominal filter size (in.) and quantity |

|

14 x 20 x 1 (2) |

14 x 24 x 1 (1) |

|

14 x 20 x 1 (2) |

14 x 24 x 1 (2) |

|

|

|

14 x 30 x 1 (1) |

|

14 x 24 x 1 (1) |

14 x 30 x 1 (1) |

|

|

|

|

|

|

|

Dynamic air filter nominal size (in.) and quantity |

|

7 x 42 x 1 (1) |

7 x 54 x 1 (1) |

|

7 x 66 x 1 (1) |

7 x 78 x 1 (1) |

|

|

|

|

|

|

|

Drain connection size (in.) |

|

7/8 I.D. hose |

7/8 I.D. hose |

|

7/8 I.D. hose |

7/8 I.D. hose |

|

|

|

|

|

|

|

Fan type / quantity |

|

FC / 2 |

FC / 2 |

|

FC / 4 |

FC / 4 |

|

|

|

|

|

|

|

Motor data |

|

|

|

|

|

|

Quantity |

1 |

1 |

|

2 |

2 |

|

Horsepower (each) |

1/4 |

1/4 |

|

1/4 |

1/4 |

|

|

|

|

|

|

|

|

Coil volume (gal) |

|

|

|

|

|

|

Coil type A |

0.178 |

0.228 |

|

0.277 |

0.327 |

|

|

B |

0.311 |

0.410 |

|

0.510 |

0.610 |

|

C |

0.311 |

0.410 |

|

0.510 |

0.610 |

|

D |

0.444 |

0.571 |

|

0.704 |

0.931 |

|

E |

0.444 |

0.571 |

|

0.704 |

0.931 |

|

F |

0.610 |

0.809 |

|

1.014 |

1.213 |

|

G |

0.610 |

0.809 |

|

1.014 |

1.213 |

|

H |

0.395 |

0.593 |

|

0.742 |

0.837 |

|

|

|

|

|

|

|

Table 6. |

Control Methodology |

|

|

|

Fan Speed |

|

|

FSS |

3 or infinite(a) |

CSTI |

3 or infinite(a) |

ZN520 |

3 |

|

|

UC400 |

Infinite |

(a) With a field-supplied 2–10 Vdc controller.

Table 7. Control Sequences

|

Fan Speeds |

|

|

DX operation(a) |

1 |

Electric heat operation(a) |

1 |

Sidewall Exhaust(b) |

2 |

ERSA(b) |

2 |

(a)Fan speed during sequence operation.

(b)Unit Ventilator when operating with option.

UV-SVN03F-EN |

11 |

Dimensions and Weights

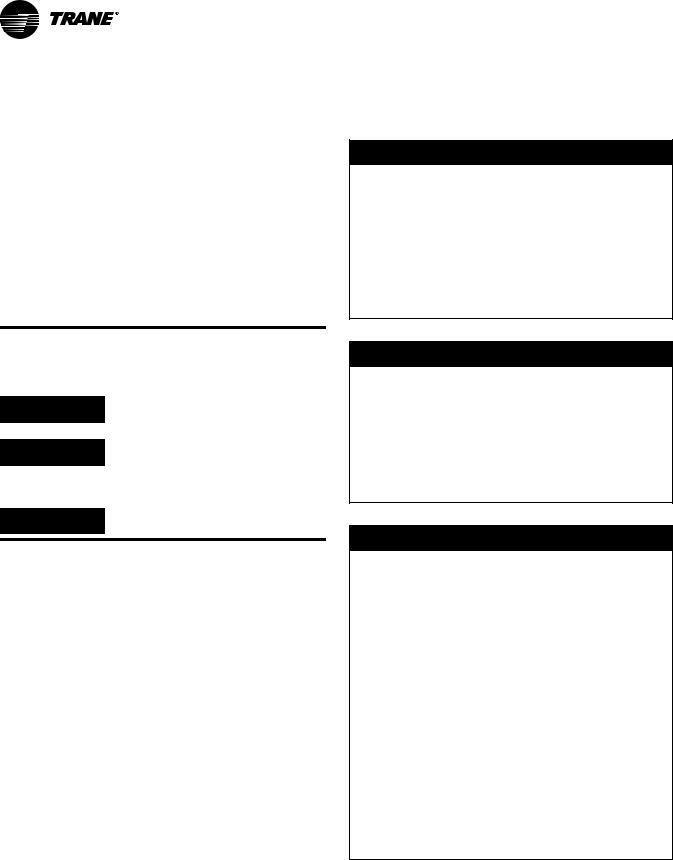

Figure 2. Standard depth unit

(4)K.O. FOR PIPING OR ELECTRICAL

|

|

A |

|

5 3/4" |

|

|

|

5" |

|

|

|

22 5/8" |

|

|

|

12 1/2" |

|

|

|

|

|

FRESH AIR OPENING (OPTIONAL) |

3 3/4" |

2 1/4" |

9" |

B |

3/4" |

8 1/8" |

|||

|

13 1/2" |

|

12 1/4" |

|

|

|

16 5/8" |

|

|

2 3/8" |

|

|

|

PIPE |

|

|

CHASE |

|

7/8" O.D. |

|

30" |

DRAIN CONN. |

7/8" O.D. |

|

|

|

|

|

AUX. |

|

|

DRAIN CONN. |

|

|

(optional) |

|

9 1/4" |

|

|

5 1/4" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

2 1/2" |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

7" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

11" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

14 3/8" |

|

|

|

|

|

|

|

2 1/4" |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

BACK VIEW |

SIDE VIEW |

|

|

(2)9" x 9"[229mm x 229mm] |

|

13" |

KNOCKOUTS IN BOTTOM |

|

|

|

2 1/4" |

|

|

2" |

|

|

|

|

3 3/4" |

16 5/8" |

|

10 7/8" |

|

|

TOP VIEW

|

GRILLE |

|

|

|

UNIT MOUNTED |

UNIT SIZE |

NO. FANS |

A |

B |

FAN SWITCH |

||||

(OPTIONAL) |

|

|

|

|

|

075 |

2 |

69" |

42" |

|

100 |

2 |

81" |

54" |

|

FRONT OF UNIT |

|

|

|

|

125 |

4 |

93" |

66" |

|

150 |

4 |

105" |

78" |

RETURN AIR

(OPTIONAL)

NOTE:

1. THE UNIT LENGTH DOES NOT INCLUDE 5/8" END PANELS.

2. THE POWER CONNECTION IS MADE IN THE LEFT HAND END POCKET FOR ALL OPTIONS BUT ELECTRIC HEAT.

3. THE POWER CONNECTION FOR ELECTRIC HEAT OPTION IS MADE IN THE RIGHT HAND END POCKET.

12 |

UV-SVN03F-EN |

Dimensions and Weights

Figure 3. Falseback unit

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

21 1/4" |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 5/8" |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 3/8" |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 3/4" |

|

|

|

|

|

(4)K.O. FOR PIPING |

|

|

7/8" O.D. |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

PIPE |

|||||||||||||||||||

|

|

|

|

|

|

|

|

OR ELECTRICAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

DRAIN CONN. |

CHASE |

|||

5" |

|

|

|

7/8" O.D. 30 |

|

|

|

|

AUX. |

||

|

|

|

|

||

22 5/8" |

|

|

|

DRAIN CONN. |

|

|

18" |

1/4"9 |

1/4"5 |

(optional) |

|

12 1/2" |

2 |

/2 |

|||

|

|

|

|

|

|

FRESH AIR OPENING (OPTIONAL) |

3 3/4" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7" |

|

|

|

|

|

|

|

|

|

|

|||

2 1/4" |

|

|

|

|

9" |

|

|

|

|

B |

|

|

|

|

|

8 1/8" |

3/4" |

|

|

|

11" |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 3/8" |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 1/4" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 1/2" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 1/4" |

||||||

|

|

|

|

|

|

|

|

|

BACK VIEW |

|

|

|

|

|

|

|

|

|

SIDE VIEW |

|||||||||||||||

|

|

|

STEP-DOWN |

21 1/4" |

|

|

|

IS IN 1" |

|

|

|

|

INCREMENTS |

16 5/8" |

|

|

|

|

|

|

(2)9" x 9"[229mm x 229mm] |

|

|

2 3/8" |

|

|

|

|

|

13" |

KNOCKOUTS IN BOTTOM |

|

|

|

|

|

|

|

|

2 1/4" |

|

FALSEBACK |

|

|

|

|

3 3/4" |

|

30" |

|

|

|

C |

|

2" |

|

|

|

|

|

|

18" |

|

|

|

|

10 7/8" |

|

|

|

|

|

|

|

|

|

|

|

2 1/2" |

TOP VIEW |

|

|

|

14 3/8" |

FALSEBACK |

|

|

2 1/4" |

|

|

|

|

|

|

|

SIDE VIEW |

|

|

|

Depicting Step-down |

||

|

|

|

Falseback |

|

UNIT SIZE NO. FANS |

A |

B |

C |

|

FRONT OF UNIT |

|

|

|

|

075 |

2 |

69" |

42" |

25" to 29" |

100 |

2 |

81" |

54" |

25" to 29" |

RETURN AIR |

|

|

|

|

(OPTIONAL) |

4 |

93" |

66" |

25" to 29" |

125 |

||||

150 |

4 |

105" |

78" |

25" to 29" |

NOTE:

STEP-DOWN FALSEBACK

STEP-DOWN

FALSEBACK

FOR RETROFIT

APPLICATIONS

WHERE WINDOW SEAL MAY INTERFERE

WITH UNIT INSTALLATION

(OPTIONAL)

1.THE UNIT LENGTH DOES NOT INCLUDE 5/8" END PANELS.

2.THE POWER CONNECTION IS MADE IN THE LEFT HAND END POCKET FOR ALL OPTIONS BUT ELECTRIC HEAT.

3.THE POWER CONNECTION FOR ELECTRIC HEAT OPTION IS MADE IN THE RIGHT HAND END POCKET.

4.THE UNIT SHOWN INCLUDES THE INSULATED HORIZONTAL BAFFLE OPTION.

UV-SVN03F-EN |

13 |

Dimensions and Weights |

|

|

|

|

|

|

Figure 4. |

Dynamic air barrier unit |

|

|

|

|

|

|

|

(4)K.O. FOR PIPING |

|

|

|

|

|

|

OR ELECTRICAL |

|

|

|

|

|

|

A |

|

21 1/4" |

|

|

|

|

|

16 5/8" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 3/8 |

|

|

5 3/4" |

|

|

|

PIPE |

|

|

|

|

|

|

|

CHASE |

|

5" |

|

|

|

7/8" O.D. |

|

30" |

|

|

|

|

DRAIN CONN. |

|

|

|

|

|

|

7/8" O.D. |

||

|

|

|

|

|

||

22 5/8" |

|

|

|

|

AUX. |

|

|

RETURN AIR OPENING |

|

|

DRAIN CONN. |

||

|

|

|

|

|

(optional) |

|

12 1/2" |

|

|

|

9 1/4" |

|

|

|

|

FRESH AIR OPENING |

3 3/4" |

5 1/4" |

2 |

/2 |

|

|

|

|

|

||

|

|

|

3/4" |

7" |

|

|

2 1/4" |

9" |

B |

11" |

|

|

|

8 1/8" |

14 3/8" |

2 1/4" |

||||

|

|

|

|

|||

|

13 1/2" |

|

12 1/4" |

|

||

|

|

|

|

|

||

BACK VIEW |

SIDE VIEW |

(2)9" x 9"[229mm x 229mm] KNOCKOUTS IN BOTTOM

2 1/4" |

FALSEBACK |

2" |

|

|

3 3/4" |

|

10 7/8" |

13" |

|

TOP VIEW

FALSEBACK

UNIT SIZE |

NO. FANS |

A |

B |

|

|

|

|

075 |

2 |

69" |

42" |

|

|

|

|

100 |

2 |

81" |

54" |

|

|

|

|

125 |

4 |

93" |

66" |

|

|

|

|

150 |

4 |

105" |

78" |

|

|

|

|

NOTE:

1. THE UNIT LENGTH DOES NOT INCLUDE 5/8" END PANELS.

2. THE POWER CONNECTION IS MADE IN THE LEFT HAND END POCKET FOR ALL OPTIONS BUT ELECTRIC HEAT.

3. THE POWER CONNECTION FOR ELECTRIC HEAT OPTION

IS MADE IN THE RIGHT HAND END POCKET.

BARRIER

14 |

UV-SVN03F-EN |

Dimensions and Weights

Figure 5. End covers

UV-SVN03F-EN |

15 |

Dimensions and Weights

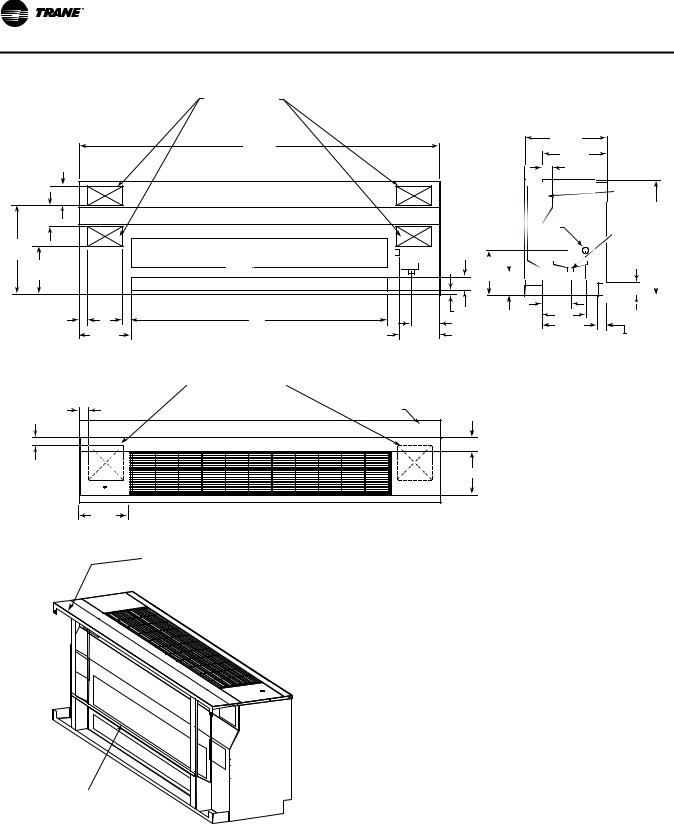

Figure 6. Wall boxes

16 |

UV-SVN03F-EN |

|

|

Dimensions and Weights |

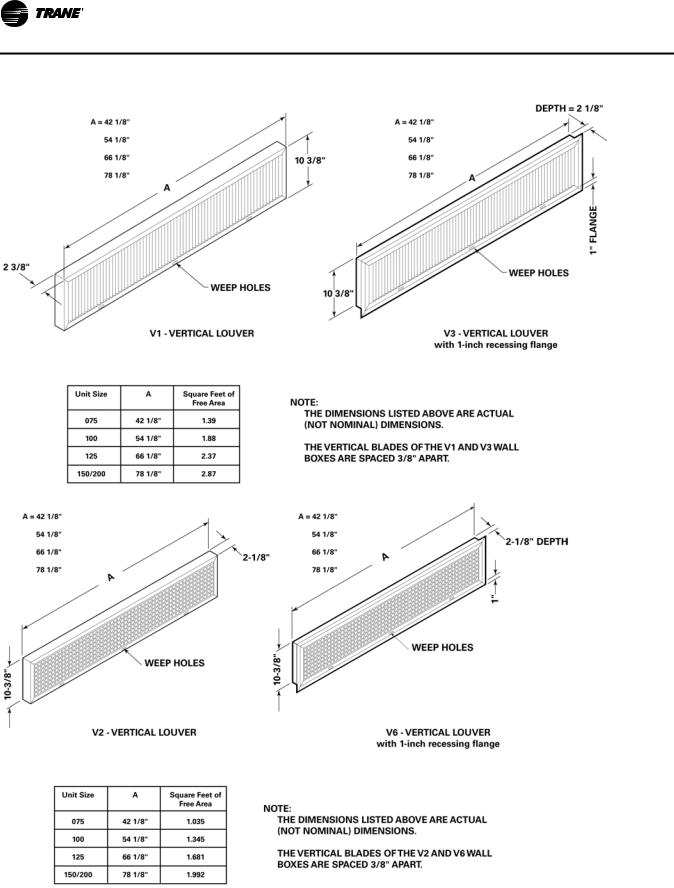

|

Figure 7. |

Crossover piping |

|

|

16 5/8" DEPTH UNIT |

|

|

|

|

|

7/8" I.D. FIELD |

|

|

FLUSH |

CONN.W/ SHUT |

1 1/2" |

|

OFF VALVE |

RETURN |

|

|

|

|

3" |

|

|

S R |

|

|

|

|

SUPPLY |

|

|

3 1/2" |

24" |

|

|

4 1/2" |

|

|

|

19 3/8" |

|

|

|

|

|

|

|

TOP VIEW |

3 5/8" |

|

|

|

5 3/8" |

21 1/4" DEPTH UNIT |

SIDE VIEW |

||

|

|

||

|

|

7/8" I.D. FIELD |

1 1/4" |

|

FLUSH |

CONN. W/ SHUT |

|

|

RETURN |

||

|

OFF VALVE |

||

|

|

||

|

|

|

3" |

|

|

|

SUPPLY |

|

|

S R |

|

|

|

|

24" |

|

|

|

19 3/8" |

|

|

3 1/2" |

|

|

|

4 1/2" |

|

|

|

TOP VIEW |

8 1/4" |

|

|

|

|

|

|

|

10" |

SIDE VIEW

Note: 1-3/8 in. OD and 2-1/8 in. ID crossover piping

1.Crossover piping is available for all 2- or 4-pipe coils selections. Trane provides the crossover for the hot water only. The crossover pipe is factory insulated with 3/8 in.-thick insulation.

2.Expansion compensation between the factory piping package and the crossover piping is achieved using a flex hose rated at 250 psi working pressure. Flex hose is only available with factory mounted piping packages.

3.Expansion compensation for the crossover piping must be handled external to the unit ventilator.

4.Crossover connections terminate in the same end pocket as the heating coil on all 2- and 4-pipe coils.

UV-SVN03F-EN |

17 |

Receiving and Handling

The unit ventilator is packaged in clear stretch wrap and protective cardboard.

Note: Before unwrapping, make a visual inspection of the unit for any damage that may have occurred during shipping. All orders are shipped FOB (Freight on Board) from the factory, therefore any claims must be made with the delivering carrier.

Following visual inspection, carefully begin the following procedures:

1.Carefully remove the stretch wrap and the top cardboard cover.

2.Remove remaining cardboard blocking.

3.Remove the bottom access panel with a 7/32-in. Allen wrench.

4.Verify nameplate sales order number is correct.

5.Remove shipping bracket from the lower rear corners of the unit and shipping skid. Access to the screws holding unit to the skid is obtained inside the unit.

Figure 8. Shipping skid removal

6.Rotate fan wheels manually. Wheels should move freely and be in proper alignment. Visually inspect the fan area for obstructions or shipping damage.

7.Remove all applicable knock-outs for coil piping and electrical connections (see Figure 2, p. 12 through Figure 4, p. 14).

18 |

UV-SVN03F-EN |

Pre-Installation

Jobsite Inspection

Always perform the following checks before accepting a unit:

1.Verify that the nameplate data matches the data on the sales order and bill of lading (including electrical data).

2.Verify that the power supply complies with the unit nameplate specifications.

3.Visually inspect the exterior of the unit, for signs of shipping damage. Do not sign the bill of lading accepting the unit(s) until inspection has been completed. Check for damage promptly after the unit(s) are unloaded. Once the bill of lading is signed at the jobsite, the unit(s) are now the property of the SOLD TO party and future freight claims MAY NOT be accepted by the freight company.

Jobsite Storage

This unit is intended for indoor use only. To protect the unit from damage due to the elements, and to prevent possible IAQ contaminant sources from growing.

1.Place the unit(s) on a dry surface or raise above the ground to assure adequate air circulation beneath the unit.

2.Cover the unit(s) with a water proof tarp to protect them from the elements.

NOTICE:

Microbial Growth!

Wet interior unit insulation can become an amplification site for microbial growth (mold), which may cause odors and damage to the equipment and building materials. If there is evidence of microbial growth on the interior insulation, the insulation should be removed and replaced prior to operating the system.

3.Make provisions for continuous venting of the covered units to prevent moisture from standing on the unit(s) surfaces.

4.Do not stack units.

UV-SVN03F-EN |

19 |

Installation—Mechanical

Wall Box Installation

The following instructions are general recommendations for installing wall intake boxes. Consult the architectural plans for specific requirements.

Additional materials required to complete any specific installations (such as duct connections, metal mounting plates, or flanges) are not furnished by Trane.

For best results, all air intake boxes should be removable from outside of the building. Weep holes must be at the bottom to permit free drainage. A positive air and moisture seal should be provided around all edges.

General Instructions. Trane wall boxes are illustrated in the dimensional section of this manual. Dimensions are actual, and may be used to define the wall opening.

Vertical louvers in the wall intake box provide extra strength for a high load bearing capacity. The lintel may be omitted on masonry wall installations.

Weep holes are provided in the outside face of the bottom channel in the wallbox frame. Install all wall boxes to permit free drainage through the weep holes to the outside of the building.

All wallboxes are furnished with diamond pattern expanded aluminum bird screen.

Note: V1 and V2 (vertical) wall models are all unflanged. H2, V3, and V6 are flanged.

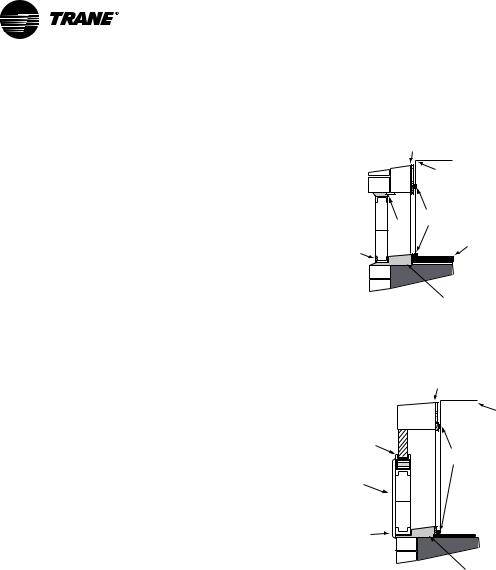

Installation in Masonry Walls. A typical method of installing the wall box in a masonry wall opening is shown in Figure 9.

Grout the top and bottom of the wall box frame as noted. A sloped water dam located in the space between the unit and wall facilitates moisture drainage. Grouting at the ends of the intake box will complete the seal between the wall box frame and the masonry opening.

Installation in Curtain Walls. In all cases, the wall intake box should be caulked to provide a tight, weatherproof seal (see Figure 10).

Note: A minimum of 2-1/8 in. of clearance must be maintained between the exterior wall and back of the unit. Failure to provide this gap will not allow the wall box to fit properly.

Figure 9. Masonry wall installation

Interior Wall w/ sheetrock

Outside |

|

Unit |

Wall |

|

|

|

|

|

|

|

Rubber |

|

Grout |

Seals |

|

|

|

Weep |

|

Floor |

Holes |

|

|

Water dam sloped toward exterior

Figure 10. Flanged wall box installation in 2-in. curtain wall

Interior Wall w/ sheetrock

Outside |

|

Wall |

Unit |

Caulking

Rubber

Seals

Flanged wallbox

Weep

Holes

Water dam sloped toward exterior

General Installation Checks

The checklist below is a summary of the steps required to successfully install a unit. This checklist is intended to acquaint the installing personnel with procedures required in the installation process. It does not replace the detailed instructions called out in the applicable sections of this manual.

1.Carefully remove the stretch wrap and top cardboard cover. Check the unit for shipping damage and material shortage; file a freight claim and notify appropriate sales representation. If end panels have been ordered, the panel will already be mounted to the unit.

Note: The unit ventilator is packaged in clear stretch wrap to allow for immediate visual inspection. A protective cardboard cover helps prevent scratching and other cosmetic blemishes during transport.

2.Remove remaining cardboard blocking.

3.Remove the unit’s left front panel to verify nameplate/ sales order number is correct. It is located behind the control box.

20 |

UV-SVN03F-EN |

Installation—Mechanical

4.Remove shipping bracket from the lower rear corners of the unit to separate the unit from the skid. Access to the screws holding the bracket to the skid is obtained inside the unit.

5.Rotate the fan wheels manually. The wheels should move freely and be in proper alignment. Visually inspect the fan area for obstructions or shipping damage.

6.Remove all applicable knockouts for coil piping and electrical connections.

Location Considerations

Selecting the appropriate location for installing a unit is very important. The following factors should be considered:

WARNING

WARNING

Heavy Object!

Floor structure must be strong enough to support the weight of the unit. Consult the structural plans, and have a structural engineer ensure the floor can withstand the weight of the unit. Inadequate structural support could result in unit falling.

Failure to follow recommendations could result in death or serious injury.

1.Floor design must have sufficient structure to withstand the weight of the unit while allowing for openings in the floor for a return air duct, electrical and piping supply lines fed through the floor. Refer to “Dimensions and Weights,” p. 11 for unit weights.

2.Wall space design should allow the unit to be mounted to the wall securely. The wall surface behind the unit should be smooth and level. Wall and floor moldings should be removed prior to installation. A wall slightly out of level may cause problems with unconditioned air leaking into the room. Remove any object projecting more then 1/8 in. (0.3175 cm) from the wall surface.

Note: Additional gasket or furr strips may be installed to accommodate for an uneven wall.

3.There are two removable knock-outs in the rear of the unit, on either end, for piping and electrical supply lines. A pipe chase is located in the upper back portion of the unit for crossover piping. The outside air opening is located in the lower back of the unit and the path to the wallbox on the outside wall should be unobstructed.

4.The physical layout of the room should accommodate any accessories ordered with the unit. Conditioned air is distributed through the grille on top of the unit and returned through the return air grille on the bottom of the unit. Avoid placing any objects that may obstruct either grille or interfere with airflow.

5.Internal access to the unit is provided by the removable front panel. Sufficient space should be allowed to lift the panel for maintenance purposes.

6.Ensure the floor surface is level.

Note: The unit leveling legs can be adjusted to accommodate slight out-of-level installation surfaces.

Unit Mounting

Note: All wall intake boxes should be installed prior to mounting the unit ventilator. Refer to p. 20 for wall box installation instructions.

The 1/2 in. mounting or anchoring holes are located on the back of the unit on each end (see Figure 11, p. 22).

Note: All mounting fasteners are to be provided by the installer.

UV-SVN03F-EN |

21 |

Installation—Mechanical

Figure 11. Mounting hole location

E |

F |

C |

C |

|

B |

B |

|

A

A D

D

|

|

A |

B |

C |

D |

E |

F |

075 |

Standard unit (no falseback) |

1.31 |

13.50 |

2.75 |

66.39 |

10.38 |

45.64 |

|

Standard falseback |

1.00 |

2.13 |

26.00 |

67.00 |

10.00 |

47.00 |

|

29 in. stepdown falseback |

1.00 |

2.13 |

24.44 |

67.00 |

10.00 |

47.00 |

|

28 in. stepdown falseback |

1.00 |

2.13 |

23.44 |

67.00 |

10.00 |

47.00 |

|

27 in. stepdown falseback |

1.00 |

2.13 |

22.44 |

67.00 |

10.00 |

47.00 |

|

26 in. stepdown falseback |

1.00 |

2.13 |

21.44 |

67.00 |

10.00 |

47.00 |

|

25 in. stepdown falseback |

1.00 |

2.13 |

20.44 |

67.00 |

10.00 |

47.00 |

100 |

Standard unit (no falseback) |

1.31 |

13.50 |

2.75 |

78.39 |

10.38 |

57.64 |

|

Standard falseback |

1.00 |

2.13 |

26.00 |

79.00 |

10.00 |

59.00 |

|

29 in. stepdown falseback |

1.00 |

2.13 |

24.44 |

79.00 |

10.00 |

59.00 |

|

28 in. stepdown falseback |

1.00 |

2.13 |

23.44 |

79.00 |

10.00 |

59.00 |

|

27 in. stepdown falseback |

1.00 |

2.13 |

22.44 |

79.00 |

10.00 |

59.00 |

|

26 in. stepdown falseback |

1.00 |

2.13 |

21.44 |

79.00 |

10.00 |

59.00 |

|

25 in. stepdown falseback |

1.00 |

2.13 |

20.44 |

79.00 |

10.00 |

59.00 |

125 |

Standard unit (no falseback) |

1.31 |

13.50 |

2.75 |

90.39 |

10.38 |

69.64 |

|

Standard falseback |

1.00 |

2.13 |

26.00 |

91.00 |

10.00 |

71.00 |

|

29 in. stepdown falseback |

1.00 |

2.13 |

24.44 |

91.00 |

10.00 |

71.00 |

|

28 in. stepdown falseback |

1.00 |

2.13 |

23.44 |

91.00 |

10.00 |

71.00 |

|

27 in. stepdown falseback |

1.00 |

2.13 |

22.44 |

91.00 |

10.00 |

71.00 |

|

26 in. stepdown falseback |

1.00 |

2.13 |

21.44 |

91.00 |

10.00 |

71.00 |

|

25 in. stepdown falseback |

1.00 |

2.13 |

20.44 |

91.00 |

10.00 |

71.00 |

150 |

Standard unit (no falseback) |

1.31 |

13.50 |

2.75 |

102.39 |

10.38 |

81.64 |

|

Standard falseback |

1.00 |

2.13 |

26.00 |

103.00 |

10.00 |

83.00 |

|

29 in. stepdown falseback |

1.00 |

2.13 |

24.44 |

103.00 |

10.00 |

83.00 |

|

28 in. stepdown falseback |

1.00 |

2.13 |

23.44 |

103.00 |

10.00 |

83.00 |

|

27 in. stepdown falseback |

1.00 |

2.13 |

22.44 |

103.00 |

10.00 |

83.00 |

|

26 in. stepdown falseback |

1.00 |

2.13 |

21.44 |

103.00 |

10.00 |

83.00 |

|

25 in. stepdown falseback |

1.00 |

2.13 |

20.44 |

103.00 |

10.00 |

83.00 |

WARNING

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper center of gravity lift point. To avoid dropping of unit, reposition lifting point if unit is not level. Failure to properly lift unit could result in death or serious injury or possible equipment or property-only damage.

7.Set the unit into selected location and adjust leveling legs if necessary to ensure level fit.

Note: Care should be taken when handling the unit to ensure that the front return air grille does not bend.

8.Push the unit tightly against the wall to compress the seal on the back edge of the unit and intake opening. Anchor the unit by using the 1/2 in. mounting holes in both end pockets.

Units containing a falseback: The falseback unit ventilator contains mounting holes located on the

falseback metal. Use these holes rather than the holes located in the unit’s end pockets.

Note: Ensure the unit is level. Coils and drain pans inside the unit are pitched properly for draining before shipment.

9.Ensure the unit rests tightly against the wall. Check for proper seal and that air does not leak underneath the unit.

Subbase (Option)

A subbase may be used to increase the unit height and aid in leveling the unit. The subbase is shipped separately for field installation. Slots and leveling screws are provided on the subbase.

1.Remove the leveling legs provided with the unit (see Figure 12).

22 |

UV-SVN03F-EN |

Installation—Mechanical

Figure 12. Subbase with leveling legs

Unit Base

Weld

Weld

Nuts

2"- 6" Subbase

For leveling legs

2.Set the unit on the subbase and fasten with four, 3/8 in. x 16 ft x 1 in. hex head cap screws and 3/8 in. lock washers.

Note: Hex screws and lock washers are provided by the factory. They are located in a baggy and are used to attach the base to the unit ventilator.

Pre-drilled slots in the subbase flange will line up with the weld nuts in the bottom of the unit.

3.The bottom of the subbase has weld nuts in four slots. Place the leveling legs in those slots and level the unit.

End Panels

When ordered as an option, end covers ship already attached to the vertical unit ventilator. The following section is for installing end covers purchased as an addon.

It is recommended end panels be installed on the unit ventilator after all piping, wiring and accessory installation is completed. To install the end panel:

1.Insert the four factory provided metal studs into the four pre-mounted nuts on the inside of the panel.

2.Align each stud with the four pre-drilled holes on the side of the unit.

3.Secure the panel to the unit by fastening with the four factory provided nuts.

4.Do not overtighten screws.

NOTICE:

Equipment Damage!

Do not run units for any length of time without all panels and filters properly installed. Failure to do so could result in equipment failure.

UV-SVN03F-EN |

23 |

Installation—Piping

Piping Installation

Before installation of piping package, the shipping bracket holding the piping in place, must be removed.

Proper installation of piping is necessary to provide efficient coil operation and to prevent damage during operation. Follow standard piping practices and include all accessories as necessary.

Piping connection knockouts are shown in “Dimensions and Weights,” p. 11. Field connection types and sizes for unit coils are listed in Table 8. These sizes are provided for field piping connection.

Table 8. |

Coil data for field piping |

|

|

|

|

|

|

Coil type |

|

Connection location |

Field connection size |

|

|

|

|

4-pipe chilled water / |

Left or right (opposite |

7/8 in. OD / 5/8 in. OD |

|

hot water |

|

ends) |

|

|

|

|

|

2-pipe changeover coil |

Left or right |

7/8 in. OD |

|

|

|

|

|

Hot water only |

Left or right |

7/8 in. OD |

|

|

|

|

|

Steam |

|

Left or right |

1 in. MPT |

|

|

|

|

Chilled water / electric |

Left cooling |

7/8 in. OD |

|

heat |

|

|

|

|

|

|

|

Chilled water / steam |

Left or right |

7/8 in. OD / 1 in. MPT |

|

|

|

|

|

DX |

|

Left |

7/8 in. suction, 3/8 in. |

|

|

|

|

DX / hot water |

Left cooling / right |

7/8 in. suction, |

|

|

|

heating |

3/8 in. / 5/8 in. OD |

|

|

|

|

DX / steam |

|

Left cooling / right |

7/8 in. suction, |

|

|

heating |

3/8 in. / 1 in. MPT |

|

|

|

|

DX / electric heat |

Left cooling / right |

7/8 in. suction, |

|

|

|

heating |

3/8 in. / NA |

|

|

|

|

A 7/8 in. OD condensate drain connection is provided on the chilled water supply end of the unit.

1.Attach a flexible condensate drain hose over the drain pan connection and secure with a hose clamp.

The drain pan on the vertical is vacuum-molded with a drain connection and P-trap on the cooling coil, connection side.

Note: Condensate removal to the main system should be made through the bottom of the unit ventilator. If other location for condensate removal is desired, a specific field cut-out for the connection should be made in the back of the unit ventilator. To help avoid cold air infiltration, the field cut-out should only be large enough to allow for the condensate hose to exit the unit.

To field reverse the slope of a vertical unit drain pan:

2.Slide out fan deck (disconnecting the condensate line and fan plug will release fan deck for sliding).

3.Remove pipe clamp that hold the p-trap to the drain pan.

4.Remove clips that hold the drain pan in-place.

5.Lift and rotate the drain pan.

6.Reconnect p-trap to the drain pan and replace clips to secure the pan to the fan deck.

7.After the condensate drain piping has been completed, check water flow to ensure the system properly carries and away all condensate accumulation.