Installation

Owner

Diagnostics

Tracer

Unit Ventilator

®

ZN.520 for Classroom

UV-SVP01A-EN

Installation of New Units

1. Follow all instruction for

installation of classroom unit

ventilators as detailed in UVIOM-1 (Installation Operation

Maintenance manual).

2. Disconnect power or disable

the circuit breaker to unit.

3. Run communication link wire

when required. (See wiring

diagram in the unit).

4. Install zone sensor when

required. (See wiring diagram

in the unit and zone sensor

submittals).

5. Reapply power.

6. Check for GREEN Status LED

operation to ensure power

has been made to the TracerTM

ZN.520 unit controller.

Start-up Procedures

7. Check for YELLOW Comm LED

operation to help ensure communication has been made to

the Tracer ZN.520 unit controller when required.

Peel IDENTIFICATION TAG from

unit and place in the Appendix of

this document, or on building

plans for future location use. The

actual room location on the tag

may be hand written.

UV-SVP01A-EN 5

Power Up Sequence

Manual output test can be initiated

at any time in the power up sequence or during normal operation.

When 24 VAC power is initially applied to the controller, the following sequence occurs:

1. Green Status LED turns on.

2. All outputs are controlled Off.

3. The controller reads input values to determine initial values.

4. Standalone control is assumed

unless occupancy data is communicated.

5. Random start timer expires (5

to 30 seconds, random).

Start-up Procedures

6. Power-up control Wait feature

is applied. When power up

control Wait is enabled, the

controller waits 120 seconds to

allow ample time for communicated control data to arrive.

If, after 120 seconds, the controller does not receive a communicated occupancy request,

the unit assumes standalone

operation.

7. All modulating valves and

damper calibrate closed, face

and bypass damper calibrate

to bypass (when present).

8. Normal operation begins after

290 (potentially) seconds have

passed.

Note: Manual output test can

be initiated at any time .

6 UV-SVP01A-EN

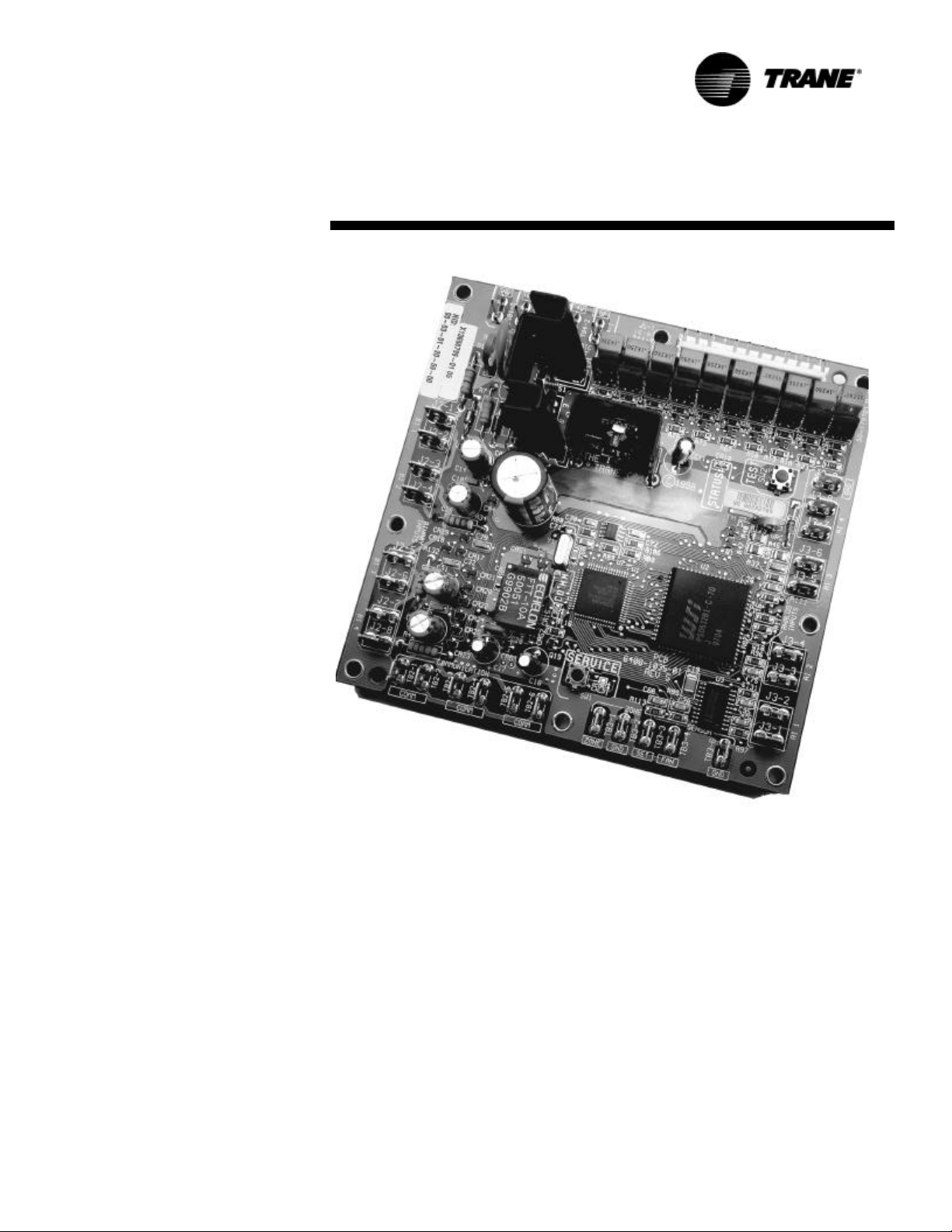

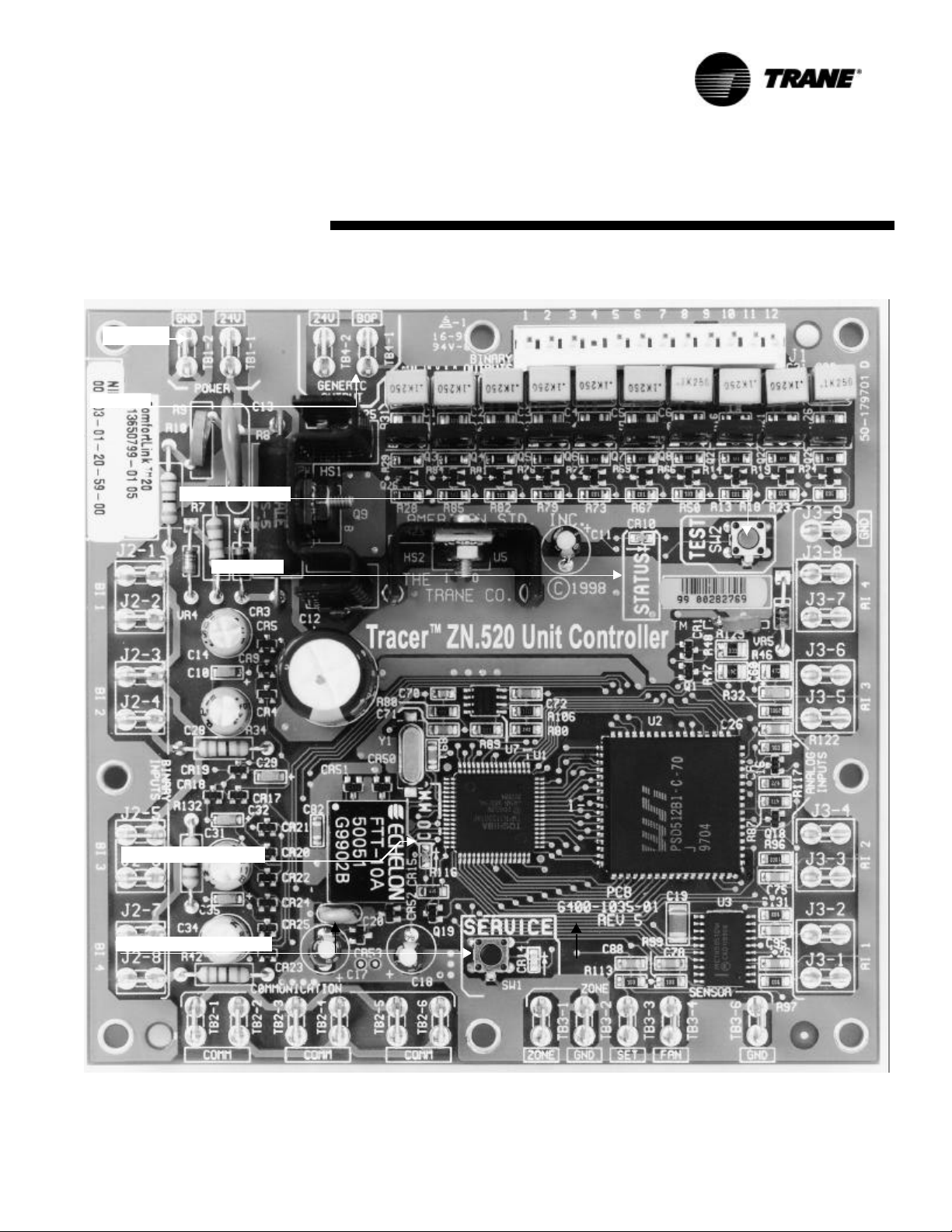

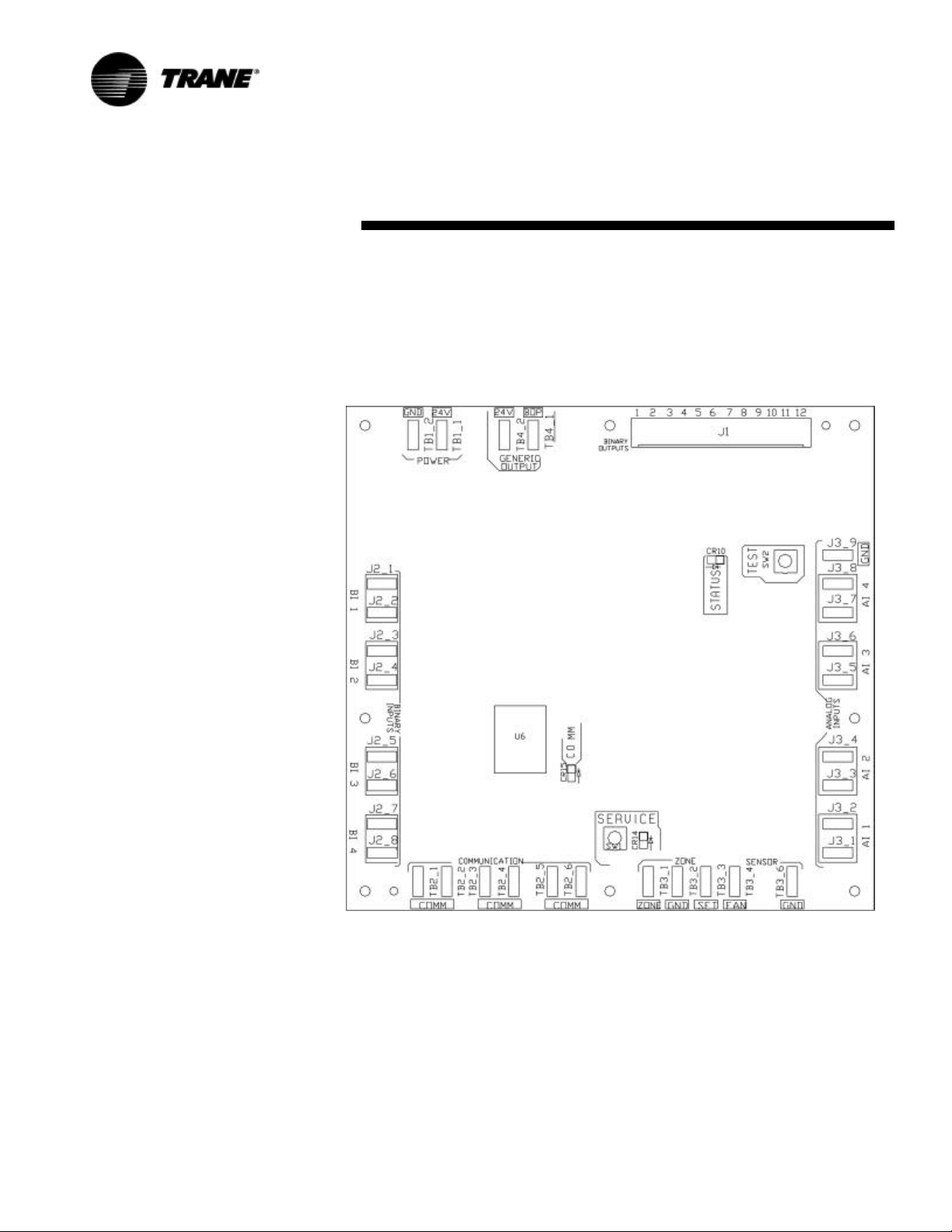

Tracer® ZN.520

Overview

The Trane® Tracer® ZN.520 controller is a factory-installed and

commissioned, direct-digital

controller (DDC) offering for

classroom unit ventilator systems. (See Figure 1: “Tracer

ZN.520 Control Board”) The Tracer ZN.520 can also be applied to

other Trane® interoperable HVAC

equipment, including the fan coil

and blower coil products. (For

more information see, Table 1:

Tracer™ ZN.520 Unit Controller

features and coil availability, on

page 8 for more information.) For

more information regarding the

application of the Tracer ZN.520

to other Trane products, contact

the appropriate local Trane sales

office.

Trane offers a complete solution

to space comfort control with the

flexibility of Integrated Comfort

System (ICS) and stand-alone

control packages. The ICS control

package combines HVAC equipment and building management

into one environmental comfort

system.

Integrating the Tracer ZN.520 on

classroom unit ventilators, and

tying them to a Tracer Summit®

system will provide a complete

building management system.

The stand-alone control package

offers the features and functionality of the direct digital control

without a front-end building automation system, while providing

future considerations for ICS.

Equipment problems can often be

diagnosed on each unit without

having to access the unit componets. These diagnostics can be received remotely via a modem with

a Tracer Summit building automation system, thus reducing the

number of actual on-site service

calls; through the Rover® service

tool connected to a communication jack located inside the Trace

zone sensor; or connected to the

unit.

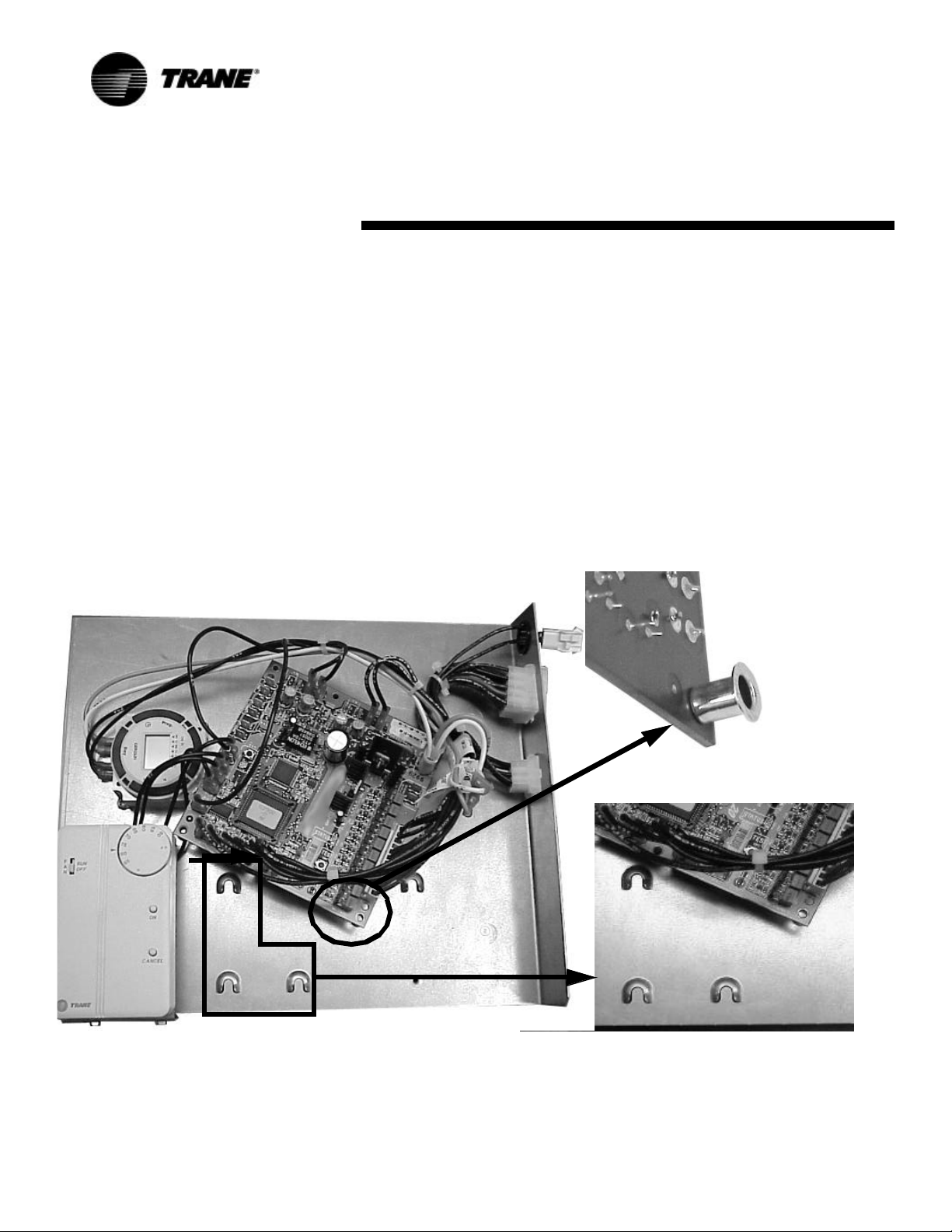

General Information

Figure 1: Tracer ZN.520 Control Board

The Tracer ZN.520 is factorymounted, tested, wired, configured and commissioned for the selected application.

The Tracer ZN.520 configuration

has flexible point and product configurations. For example, with

point configuration, a specific binary point can be configured to accept input from either a time clock

or some type of generic device.

UV-SVP01A-EN 7

General Information

Table 1: Tracer™ ZN.520 Unit Controller features and coil availability

Entering

Water

Temperature

Sampling

Coil

Multiple

Fan Speeds

Dehumid-

ification

Auto

Damper

Adjust

Face and

Bypass

Damper

Valve

Control

Economizer

Damper

Auxiliary

2

Heat

2-pipe changeover X X X X X X X

2-pipe hot water

only

X X X X X X

2-pipe steam only X X X X X

2-pipe changeover/

electric heat

X X X X X X X

2-pipe cool only X X X X

2-pipe cool only/

electric heat

4-pipe hot water/

chilled water

4-pipe changeover X X X X

4-pipe steam/chilled

water

1

X

X X X X

X1 X X X

3

3

X X X

X X X X

X X X X X

Electric heat only X X

DX/hot water X

DX/steam X

1

1

1

X

1

X

X X X

X X X

DX/electric heat X X

DX cooling only X

1. Multiple fan speeds are available in hydronic units only.

2. Auxiliary heat is designed to bring on baseboard heat as the second stage of heating. The baseboard heat must be the same type as the

unit heating coil.

3. Units with face bypass dampers cannot actively dehumidify.

8 UV-SVP01A-EN

Power

Generic

Controller Circuit Board

Features

Auto Test Button

Status LED

Communications LED

Service Button and LED

Communications

Figure 2: Tracer ZN.520 unit controller circuit board

UV-SVP01A-EN 9

Zone Sensor Connections

Controller Features

Each Tracer ZN.520 unit controller

circuit board is equipped with enhancements to help facilitate service, testing, and diagnosis.

Each board has

q Manual test button,

q Status LED,

q Communication status LED,

q Service button,

q Quick terminal connectors, and

q Easy to read screen printing.

(See Figure 1: “Tracer ZN.520

Control Board”).

Service

The Trane Tracer ZN.520 unit controller is serviced using Rover®, the

ICS software service too. Rover is

designed to support the Tracer

ZN.520 unit controller on the classroom unit ventilator.

For “remote” access to the communicating units, the zone sensors

offered with the Tracer ZN.520

have a telephone style (RJ-11) connector allowing field connection

between Rover and the zone sensor; however, the RJ-11 connector

must be connected to the terminals

TB2-5 and TB2-6 on the Tracer

ZN.520 unit controller. (See Figure

3: “Rover service tool connected to

the RJ-11 communication jack in a

zone sensor”)

The zone sensor may also be used

when trying to locate a unit. By

pressing the O N button on the zone

sensor for 5 seconds or using the

“wink” command in Rover, the circuit board receives the signal causing the Communication LED to

“wink”. Winking allows visual

identifier on the board for service

technicians.

The Tracer ZN.520 also includes

features such as a test output to

manually test all of the end devices

and color coded wires (i.e. red for

heating valves and blue for cooling

valves) to aid in the troubleshooting process.(See “Manual Output

Test” on page48, for more information.)

Figure 3: Rover service tool connected to the RJ-11 communication jack in a zone sensor

Typical Components

A typical classroom unit ventilator

system with a DDC package consists of the following physical components, in addition to the

mechanical equipment:

q Tracer ZN.520—contains the

sensor input circuits, service

adjustments, microprocessor

control electronics, and

communications hardware.

10 UV-SVP01A-EN

Power is supplied by a

separately mounted 24 VAC\90

VA transformer.

q Sensor Modules—a variety of

analog sensors that provide

temperature and optional

humidity sensing and CO2

sensor; and an operator

interface to the Tracer ZN.520

for operating modes, status,

and temperature setpoints.

q Standard End Devices—a

variety of devices that help to

gather information, control

capacity, and provide

ventilation are used by the

Tracer ZN.520 in its control

algorithm to condition the

space to the desired

temperature and relative

humidity level. (See “Standard

End Devices ” on page13, for

more information.)

Communication Configurations

Note: The Tracer ZN.520 is a

configured controller. It will

not operate without a valid

downloaded configuration

file.

The Tracer ZN.520 controller supports ICS and peer-to-peer communications as well as standalone operation. A number of control features may be configured at

the factory or by using the Rover

service tool. (See “Configuration”

on page32, for more information.)

Integrated Comfort

System

Note: The Tracer ZN.520

controller may only be used

with Tracer Summit version

11.0 or greater with a Comm5

communications card.

Classroom unit ventilators can operate as part of a large building automation system controlled by

Tracer Summit. The Tracer ZN.520

is linked directly to the Tracer

Summit via a twisted pair communication wire. Each Tracer Summit

building automation system can

connect to a maximum of 120

Tracer ZN.520 controllers.

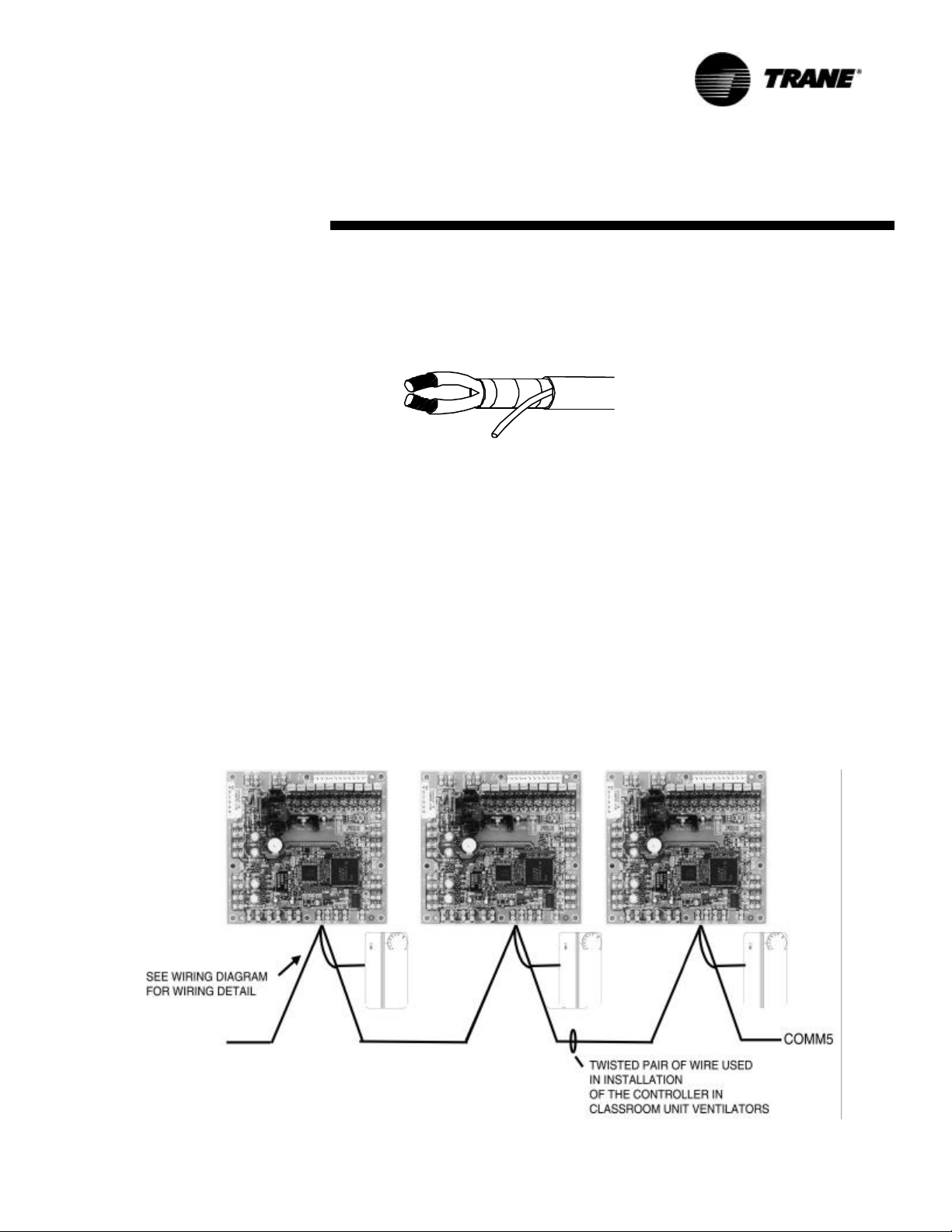

Figure 4: Communications link wire

The ICS system allows for complete communication with the

classroom unit ventilators via

Tracer ZN.520 unit controller. All

points connected to the Tracer

ZN.520 may be observed from the

Tracer Summit front-end controller. The Tracer Summit can also

initiate an alarm on a loss of performance or equipment malfunctions.

The ICS system also allows all of

the classroom unit ventilators to

share information without the

presence of hardwired sensors at

each unit. Some typical shared

points include outside air temperature, entering water temperature,

and occupancy schedules.

Peer-to-Peer

Communications

On a peer-to-peer communication

system, multiple Tracer ZN.520

controllers may share data, via a

twisted pair communication wire,

without the need for a Tracer Summit system. (See Figure 5: “Peer-

to-peer communication connections”)

Peer-to-peer communications allows features such as master/slave

operation, in which multiple units

operate off of a single zone sensor.

This is typically seen in large spaces requiring multiple units.

The Rover service tool is required

to set up peer-to-peer communications.

Figure 5: Peer-to-peer communication connections

UV-SVP01A-EN 11

Communication Configurations

Stand-Alone

In a stand-alone configuration,

commands for operation are determined based on input from the

zone sensor, humidity sensor, and

factory- or field-mounted timeclock.(See Figure 6: “Typical class-

room unit ventilator installation ”)

q The timeclock is wired to the

Tracer ZN.520 to index the unit

between occupied and

unoccupied modes.

q A unit-mounted, analog,

outside-air temperature sensor

is used to initiate the dry bulb

economizer and freeze

avoidance routines.

q On changeover units, a unit-

mounted, analog, entering

water temperature sensor is

used to automatically control

the system in the heat/cool

mode.

These sensors are required for

proper system operation and are

provided as standard on standalone units.

Figure 6: Typical classroom unit ventilator

installation

Communication Interface

Important! To help ensure

optimal performance of the

Rover service tool, please use

the latest version. To obtain

the latest version contact your

local Trane sales representtative or service technician.

Note: Refer to the Tracer

system manuals for more

information on communications.

The Tracer ZN.520 communicates

via Comm5 (LonTalk) to a building

management system, the Rover

service tool, and other unit controllers on the communications link.

Each Tracer ZN.520 requires a

unique address for the system to

operate properly. Every Tracer

ZN.520 has this address (Neuron

ID) embedded in the microprocessor, which eliminates the need for

field-addressing of the units. Each

unit also ships from the factory

with a unit identification tag. (See

“Location Identifier ” on page38,

for more information.)

Building automation system

Trane offers a state-of the art frontend building automation system

designed to coordinate and monitor Trane equipment and controllers: Tracer Summit.

The Tracer Summit system allows

the user to monitor and/or change

Tracer ZN.520:

q status, parameters, sensor data,

diagnostics, and internal

variables; and

q setpoints, operating modes,

and outputs.

Service tool

Trane also offers a service tool to

work in conjunction with the Tracer

Summit system or with peer-topeer and stand-alone systems: the

Rover service tool.

Communication to the Tracer

ZN.520, or multiple controllers, can

also be accomplished by using the

ICS software service tool.

A personal computer running Rover may be directly connected to a

standalone Tracer ZN.520; connected to the communications jack

in the Trane zone sensor; or connected to a communicating unit’s

Tracer ZN.520 unit controller, to access all of the units on a communicating link.

Rover allows the user to interface

with the Tracer ZN.520, but will not

allow any advanced control (e.g.

equipment scheduling or trending). To purchase a copy of the ICS

software service tool, contact the

BAS department at your local

Trane dealer.

Interoperability

Trane has lead the industry with

BACnet interoperability and Trane

is now expanding the realm of interoperable solutions by offering

LonMark certified unit controllers.

The Tracer ZN.520 controller conforms to the LonMark Space Comfort Controller profile. (See

“Appendix—Data Lists” on

page64, for more information.)

This allows the ZN.520 to be used

as a unit controller on other control

systems that support LonTalk and

the SCC profile. Now building owners have more choices and design

engineers have more flexibility to

meet the challenges of building automation.

12 UV-SVP01A-EN

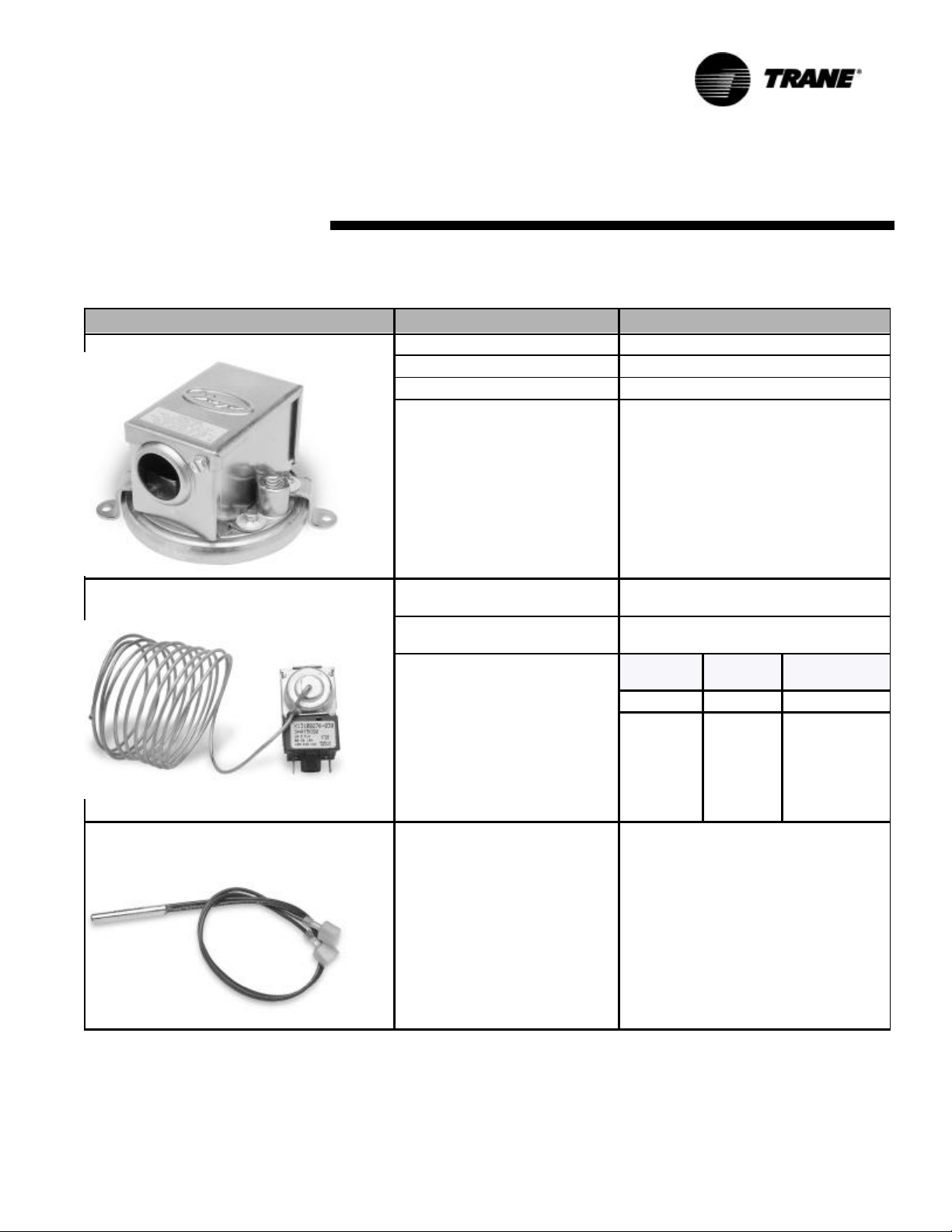

Standard End Devices

Table 2: End Device Specifications

Device Characteristic Description

Fan Status Switch Material Contact Blade—Pilot duty rated

Operating Temperature Range -40°F/250°F (-40°C/120°C)

Contact Form SPST-NO

Preset Fan status - 0.07”

Low Temperature Detection Switch (Freezestat)

OutsideAir Sensor/discharge AirSensor/Entering

Water Temperature Sensor/Unit Mounted, Zone

Return-air Temperature Sensor

Trip Temperature:

Release Temperature

Rating—Auto Reset

Sensing Element

36°F ± 2°F

(2°C + - 1.11°C)

44°F ± 3°F

(6.67°C + - 1.67°C)

Pilot Duty

(24 VAC)

FLA 10.0 5.0

LRA 60.0 30.0

Thermistor 10 KOhms @ 77°F ± 1.8°F (25°C

±1°C)

120 VAC 240 VAC

UV-SVP01A-EN 13

Standard End Devices

Table 2: End Device Specifications

Device Characteristic Description

Outside Air Actuator Description Three-point floating with spring return

Ambient Temperature Rating -25°F to 125°F

Power Consumption 5 VA

Torque 35 in-lbs.

Drive Time 90 seconds, 95 degree stroke

Face and Bypass Actuator Description Three-point floating

Ambient Temperature Rating 32°F to 122°F

Power Consumption 3 VA

Torque 35 in-lbs.

Drive Time 80-110 seconds, 95 degree stroke

2-way Control Valve Description Three-point modulating

Ambient Temperature Rating 140°F at 95% relative humidity

Drive Time 50 seconds

Max Pressure 400 psi water

Close Off Varied by size and Cv

Temperature Water 200°F maximum

14 UV-SVP01A-EN

Standard End Devices

Table 2: End Device Specifications

Device Characteristic Description

3-way Control Valve Description Three-point modulating

Ambient Temperature Rating 140°F at 95% relative humidity

Drive Time 50 seconds

Max Pressure 400 psi water

Close Off Varied by size and Cv

Temperature Water 200°F maximum

Time clock Size 2.83'' x 4.0'' x 2.06''

Power Consumption 4.4 VA

Switch SPDT dry contacts, silver cadmium oxide

Switch Rating 16A 250V resistive, 1000 Watts tungsten

Minimum Switching Current 100mA,230V

Shortest Switching Time 1 minute

Ambient Temperature Range -14°F to 131°F

Wiring Connections Screw terminals suitable for #10 to #24 AWG

Backup Seven day capacitor backup

Zone sensor

Zone Sensor Wiring Size And

Maximum Lengths

16-22 AWG: up to 200 feet

UV-SVP01A-EN 15

Standard End Devices

Table 2: End Device Specifications

Device Characteristic Description

Humidity Sensor Sensing Element Polymer capacitive

Sensing Element Accuracy: ± 5% over 20-95% RH @ 77ºF

Range 0 to 99% RH

Operating Temperature Range 0°F to 140ºF

Max Supply Voltage 24VDC

Output Characteristics 4 to 20 MA for 0-100% RH

Drift Rate Less than 1% per year

CO2 Sensor Sensing Element Accuracy: ± 100ppm full scale

Range 0-2000 ppm

Operating Temperature Range 59°F to 95ºF

Supply Voltage 24VAC

Output Characteristics 0-10 VDC for 0-2000 ppm

Power consumption 10 VA

Drift Rate ±5% full scale over four years

Fan Relay

Contact Rating

Terminals 0.25 quick connect

Contact material Silver-Cadium Oxide

Coil 24 vac 2.7 va

16 UV-SVP01A-EN

20 amps at 120/240 vac

3/4 hp at 120 vac

1 1/2 hp at 240 vac

20 amps @ 28 vdc

DPDT

Table 2: End Device Specifications

Device Characteristic Description

Control Transformer

Standard End Devices

Type N.E.C. Class 2

Primary Voltage 120 vac

Secondary voltage

24 vac at 90 va

Manual reset

4amp fuse in 24-volt circuit

UV-SVP01A-EN 17

Specifications

Dimensions

Tracer ZN.520 board and mounting

hardware:

• Height: 5.25 inches (133 mm.)

• Width: 5.50 inches (140 mm)

• Depth: 2.25 inches (57 mm)

Power Requirements

• 18 to 32 VAC (24 VAC nominal)

• 50 or 60 Hz

• 570 mA AC

Operating Environment

Installation and Wiring

• 32° to 140°F (0× to 60°C)

• 5% to 95% relative humidity,

non-condensing

Storage Environment

• -40° to 185°F (-40° to 85°C)

• 5% to 95% relative humidity,

non-condensing

Agency Listings

• UL and CUL 916 Energy Management System

• Agency Compliance IEC 10004-2 (ESD), IEC 1000-4-4(EFT),

IEC 1000-4-5 (Surge)

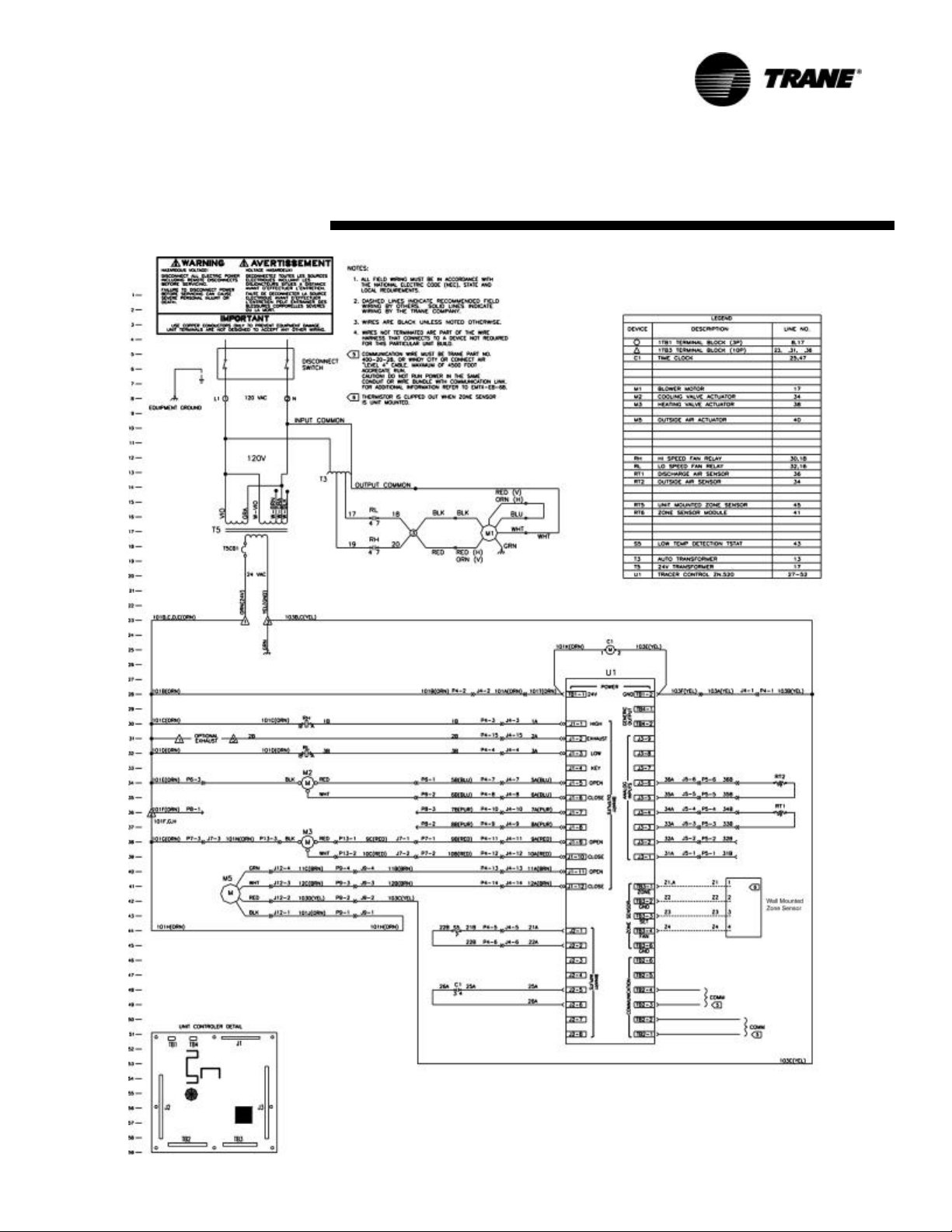

Figure 7: Tracer ZN.520 circuit board

schematic

18 UV-SVP01A-EN

Installation and Wiring

Binary Inputs

Each binary input associates an input signal of 0 VAC with open contacts and 24 VAC with closed

contacts.

Table 3: Binary inputs (typically 24 mA AC)

Description Terminals Terminal Function

Binary input 1

(BI 1)

Binary input 2

(BI 2)

Binary input 3

(BI 3)

Binary input 4

(BI 4)

J2-1 24 VAC

J2-2 Input

J2-3 24 VAC

J2-4 Input

J2-5 24 VAC

J2-6 Input

J2-7 24 VAC

J2-8 Input

UV-SVP01A-EN 19

Binary Outputs

Outputs are load side switching triacs. The triac acts as a switch, either making or breaking the circuit

between the load (valve, damper,

contactor, relay) and ground.

Table 4: Binary outputs

Installation and Wiring

Description Terminals

Fan high J1-1 12 VA

Fan medium,

Exhaust fan

Fan low J1-3 12 VA

No connection J1-4 (Key) — — —

Cool open, face bypass cool valve

DX, 2-position cooling valve, BI 5

Cool close J1-6 12 VA

Face/bypass damper open J1-7 12 VA

Face/bypass damper close J1-8 12 VA

Heat open

Face bypass isolation valve,

2-position heating valve

Electric heat 1st stage

Heat close

Electric heat 2nd stage

Economizer damper open J1-11 12 VA

Economizer damper close J1-12 12 VA

J1-2 12 VA

J1-5 12 VA

J1-9 12 VA

J1-10 12 VA

Output

Rating

Load Energized Load De-energized

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

1 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

24 VAC RMS

(typical)

Generic/baseboard Heat Binary Output

Table 5: Generic binary outputs

Description Terminals Output

Rating

Generic/ baseboard heat output TB4-1 12 VA 1 VAC RMS

24VAC TB4-2 12 VA NA NA

20 UV-SVP01A-EN

Load Energized Load De-energized

(typical)

24 VAC RMS

(typical)

Installation and Wiring

Analog Inputs

Table 6: Analog inputs

Description Terminals Function Range

Zone TB3-1 Space temperature input 5° to 122°F

Ground TB3-2 Analog ground NA

Set TB3-3 Setpoint input 40° to 115°F

Fan TB3-4 Fan switch input 4821 to 4919 Ω (Off)

Ground TB3-6 Analog ground NA

Analog Input 1 J3-1 Entering water temperature -40° to 212°F (-40° to 100°C)

J3-2 Analog ground NA

Analog Input 2 J3-3 Discharge air temperature -40° to 212°F (-40° to 100°C)

J3-4 Analog ground NA

Analog Input 3 J3-5 Outdoor air temperature / Generic

temperature

J3-6 Analog ground NA

Analog Input 4 J3-7 Power port 4-20 mA

J3-8 Universal input

Generic 4-20ma

Humidity

CO2

J3-9 Analog ground NA

(-15° to 50°C)

(4.4° to 46.1°C)

2297 to 2342 Ω (Auto)

10593 to 10807 Ω (Low)

13177 to 13443 Ω (Medium)

15137 to 16463 Ω (High)

-40° to 212°F (-40° to 100°C)

0 – 100%

0 – 100%

0 – 2000ppm

UV-SVP01A-EN 21

Mounting

The Tracer ZN.520 circuit board is

mounted in the left-hand end pocket for all classroom unit ventilator

configurations. The sheet metal

mounting plate has raised embosses to accept the mounting feet on

the circuit board. (See Figure 8:

“Classroom unit ventilator control

box with close-up of horseshoe

embosses and circuit board

mounting feet. ”) This design al-

lows the Tracer ZN.520 controller

to be secured with a minimal number of sheet metal screws.

Installation and Wiring

Figure 8: Classroom unit ventilator control box with close-up of horseshoe embosses and circuit board mounting feet.

22 UV-SVP01A-EN

Installation and Wiring

The mounting position on the vertical classroom unit ventilator

configuration allows complete access to the Tracer ZN.520 by removing the front panel. (See

Figure 9: “Vertical classroom unit

ventilator end pocket”) The

mounting plate swings out of the

way with the removal of a single

screw to allow access to the components behind the control board.

The mounting plate on the hori-

zontal classroom unit ventilator configuration is designed to

slide out with the removal of a single screw for complete access to

the Tracer ZN.520. (See Figure 10:

“Horizontal classroom unit ventilator end pocket”) The location of

the control board on this unit configuration allows complete access

to the other components in the

end pocket when the front panel is

removed.

For additional convenience, quick

connects and modular wire harnesses are used on the control

board and mounting plate. (See

Figure 11: “Quick connects to control board in the classroom unit

ventilator”) These quick connects

help facilitate ease of wiring devices (e.g., zone sensor) to the control

board, and helps add accessibility

to major components.

Figure 11: Quick connects to control board

in the classroom unit ventilator

Figure 9: Vertical classroom unit ventilator

end pocket

Figure 10: Horizontal classroom unit

ventilator end pocket

UV-SVP01A-EN 23

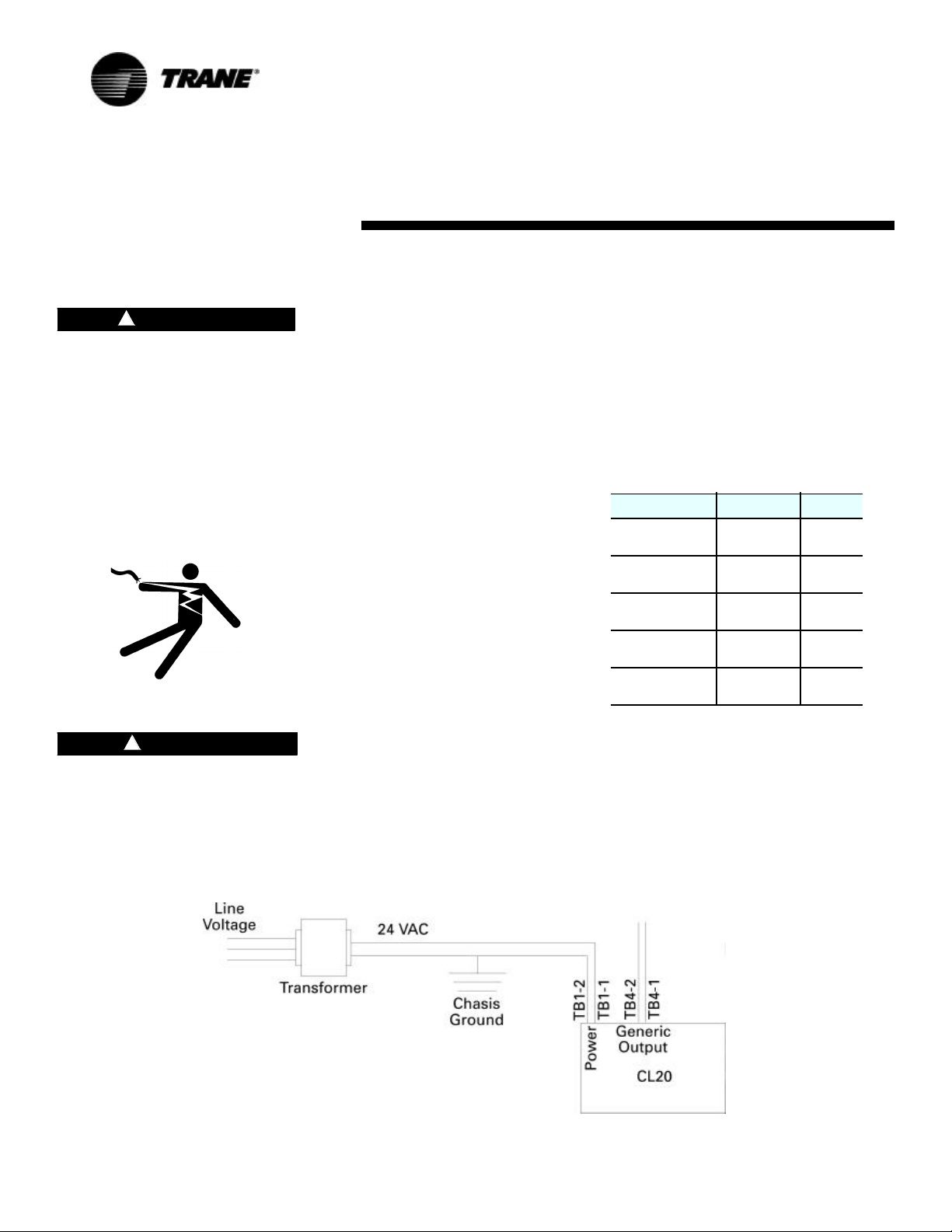

Installation and Wiring

Wiring

!

WARNING

Warning! Disconnect all electrical power before servicing

unit to prevent injury or

death due to electrical shock.

Use copper conductors only.

The use of aluminum or

other incorrect types of wire

may result in overheating

and equipment damage.

!

CAUTION

Caution: To prevent damage

to the unit ventilator, refer to

the diagram provided on the

inside of the unit's access

panel for specific wiring infor-

mation. All controls are wired

at the factory. Single point

power, zone sensor, and

communication wiring is to

be installed by the contractor.

Important! All wiring must

comply with state, local, and

federal guidelines. Contact the

appropriate local agency for

furthur information.

Important! Wires for

temperature sensors,

communication lines, 24 VAC,

and contact closure sensing

inputs should not be bundled

with or run near high voltage

wiring.

q Power wiring must be

separated from the Tracer

ZN.520 and all low voltage

wires. External input wires

should be run in separate

conduits from high voltage

wires.

q Wires connected to pin headers

should be formed and routed

so as to cause minimum strain

on the Tracer ZN.520

connector.

q A minimum of 1.5" clearance

(from the pin centerline) for

wires up to 16 AWG is

recommended for bending and

forming wires.

q All sensor and input circuits are

at or near ground potential. Do

not connect any sensor or input

circuit to an external ground

connection.

q A close-coupled ground

connection is required for the

Tracer ZN.520. T

q Table 7: Tracer ZN.520 Wiring

Requirements, shows Tracer

ZN.520 wire types and lengths.

Table 7: Tracer ZN.520 Wiring

Requirements

Application Wire Type Length

Contact Closure 18 AWG

24 VAC 16-22 AWG

Thermostat 16-22 AWG

Zone

Sensor

Communications

16-22 AWG

Belden 8760

or equivalent

Up to

1000 ft.

Up to

1000 ft.

Up to

1000 ft.

Up to

200 ft.

Up to

5000 ft.

Power

The Tracer ZN.520 controller is

powered by 24 VAC. (See Table 7:

“Tracer ZN.520 Wiring Requirements”)A total of two 1/4-inch

quick-connect terminals are provided for 24 VAC connection to the

board.

Figure 12: Power connection to the Tracer ZN.520 unit controller

24 UV-SVP01A-EN

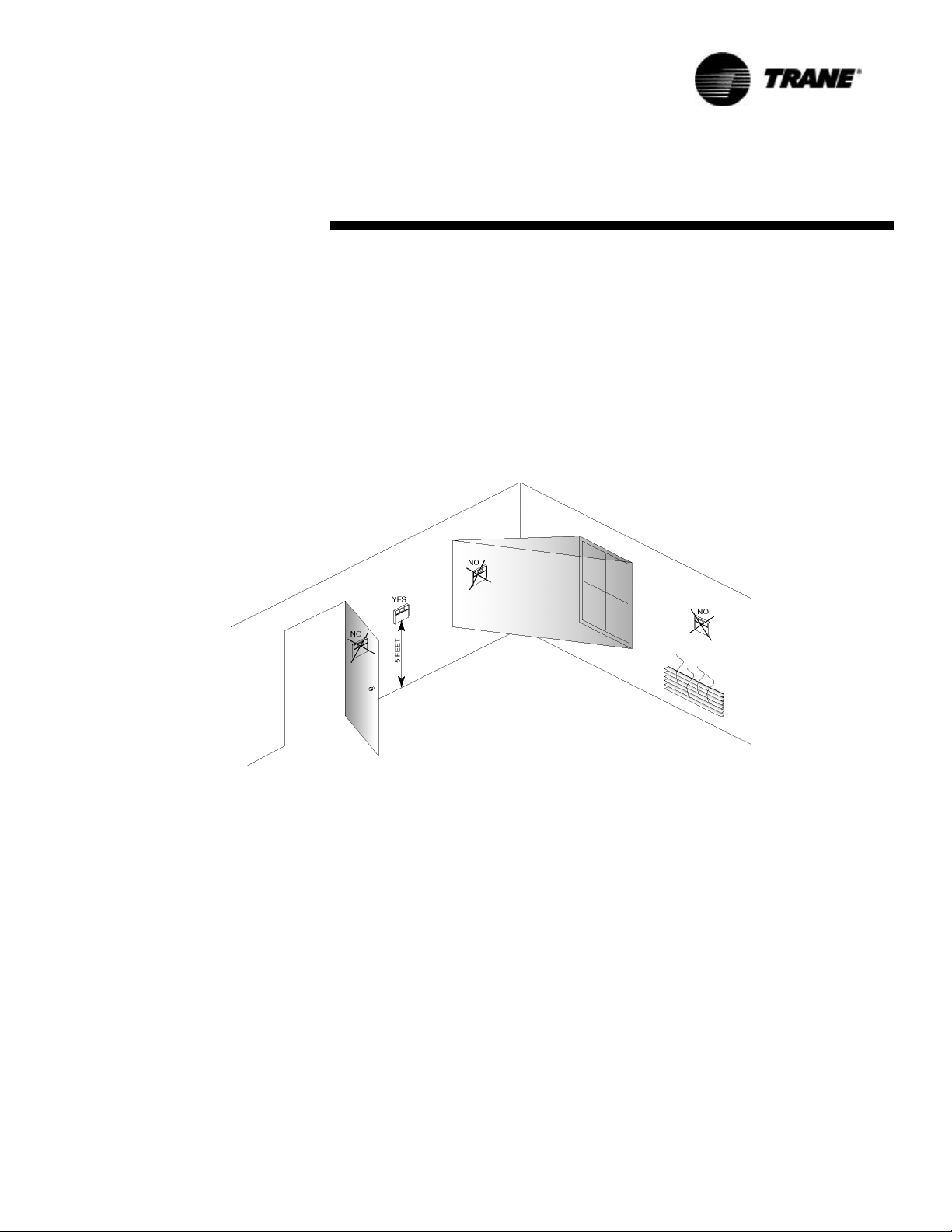

Installation and Wiring

Installing the WallMounted Zone Sensor

(Optional)

Zone sensor location is an important element of effective room

control and comfort.

The best sensor location is typically on a wall, remote from the

HVAC unit. Readings at this location assure that the desired setpoint is achieved across the space,

not just near the unit itself.

Note: It may be necessary to

subdivide the zone with

multiple units to ensure

adequate control and comfort

throughout the space.

The following are typical areas

where the zone sensor should NOT

be mounted:

q Near drafts or “dead spots”

(e.g., behind doors or corners);

q Near hot or cold air ducts;

q Near radiant heat (e.g., heat

emitted from appliances or the

sun);

q Near concealed pipes or

chimneys;

q On outside walls or other non-

conditioned surfaces; or

q In air flows from adjacent

zones or other units.

Figure 13: Proper zone sensor placement

Note: All zone sensor wiring

will be done in the factory

unless zone sensor options are

selected to be wall mounted.

When a unit-mounted speed

switch is selected with a wallmounted zone sensor, the contractor must disconnect the cooling

setpoint on the unit mounted sensor if the wall mounted cooling

setpoint is used. The zone signal

will be cut at the factory. The unitmounted speed switch cannot be

used as a zone sensor.

THe communications link is not

connected in the factory. Communications should be wired to the

wall-mounted sensor.

UV-SVP01A-EN 25

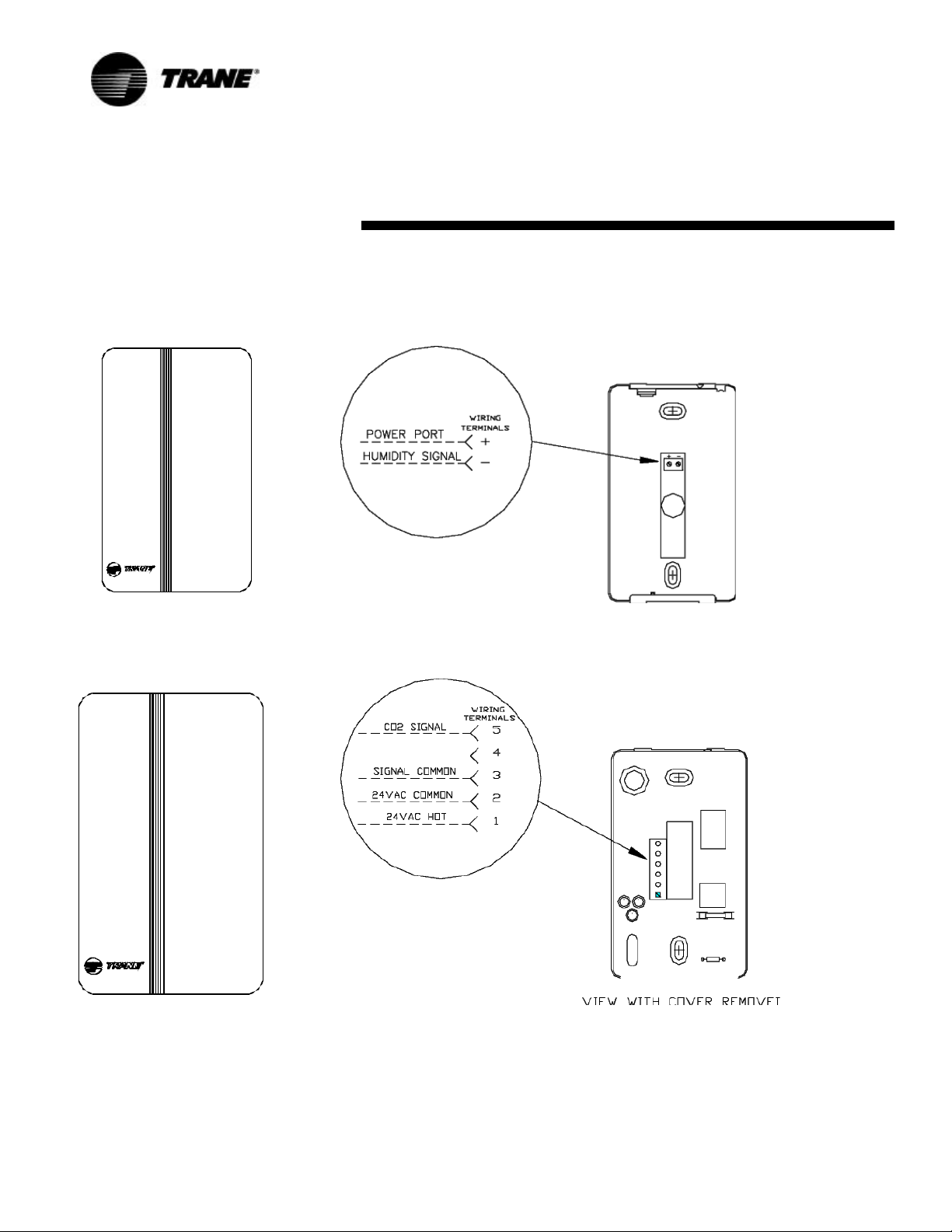

Humidity and CO2 Sensors

Humidity and CO2 sensors should

be mounted in a similar location as

the zone sensor.

Installation and Wiring

Figure 14: Relative humidity sensor

Figure 15: CO2 Sensor

26 UV-SVP01A-EN

Typical Wiring Diagram—Wall

Mounted Zone Sensor

UV-SVP01A-EN 27

Typical Wiring Diagram—Unit

Mounted Zone Sensor

28 UV-SVP01A-EN

Typical Wiring Diagram—Unit

Mounted Switch, Wall Mounted Sensor

UV-SVP01A-EN 29

Input/Output Summary

Input/Output Summary

The following lists all possible binary and analog inputs and outputs available for the classroom

unit ventilator applications. Some

of the points listed may be mutually exclusive and some are optional.

(See Table 8: Input and output

summary)

Table 8: Input and output summary

Input Description

Binary Inputs

Occupancy/Generic

J1-1 Fan High Speed

J1-3 Fan Low Speed

(Modulating valve/DX/

J1-6 Cooling Close

J1-7 Face and Bypass Damper

J1-8 Face and Bypass Damper

Binary Outputs

J1-9 Heat Open (Modulating

valve/Isolation valve) or 1st

Stage Electric Heat

J1-10 Heat Close or 2nd Stage

J1-11 Economizer Damper

J1-12 Economizer Damper

TB4-1 Generic/Baseboard

Most binary inputs and outputs are

wired from the factory based on

unit configuration and options. If

the generic inputs and outputs are

to be used, wiring connections are

made at the 1/4” quick-connect terminals provided.

Analog inputs from a wall-mounted zone sensor, humidity sensor,

CO2 sensor, or a generic device

Freezestat

Fan Status

J1-2 Exhaust Fan

J1-5 Cooling Open

Isolation valve)

Open

Close

Electric Heat

Open

Close

Heat

TB4-2 24 VAC

must be wired to the 1/4” quickconnect terminals provided. Most

other analog inputs will be wired

from the factory.

30 UV-SVP01A-EN

Table 8: Input and output summary

Input Description

Analog Inputs

Entering Water Temperature

Discharge Air Temperature

Outdoor Air Temperature/

Input/Output Summary

Zone Temperature

Setpoint

Fan Speed

Generic

Generic/Humidity/CO2 (4-

20mA)

UV-SVP01A-EN 31

Configuration

Note: The Tracer Zn.520 unit

controller only supports

cascade control by controlling

the discharge air temperature.

Therefore, the controller

requires both a space

temperature input and a

discharge air temperature

input.

Table 9: Typical applications supported

Configuration Type of valve Options

2-pipe cooling only

2-pipe heating only ü ü ü ü

2-pipe changeover

4-pipe

4-pipe changeover ü ü ü ü

2-pipe face bypass heating only ü

2-pipe face bypass changeover ü

4-pipe face bypass ü

DX cooling only

DX cooling, 2-pipe heating

DX cooling, electric heating

Electric heat only (1 or 2 stage)

1. Isolation valves are 2-position only.

Trane configures the Tracer®

ZN.520 Unit Controller at the factory per the selected unit configuration. The controller is applied

classroom unit ventilator configurations that support modulating

valves, 2-position valves, economizer damper (modulating only),

direct expansion (DX) cooling, 1-

Modulating 2 position

ü ü ü ü

ü ü ü ü ü

ü ü ü ü

1

1

1

NA NA

ü ü ü ü

NA NA

NA NA

and 2 -stage electric heat, faceand-bypass damper, baseboard

heat, dehumidification, and generic I/O. The controller also supports HIG H and LOW fan speeds

with exhaust fan output on 1- and

2-speed fan applications.

Electric Heat

(1 or 2 stage)

Economizer

Damper

Baseboard

Heat

ü ü

ü ü

ü ü

ü

ü ü ü

ü ü ü

Configurable parameters

Rover service tool uses the unit

type to determine and download

many other aspects of the unit configuration, such as the default analog input configuration, the default

binary input configuration, and the

default binary output configuration.

Cooling source

q None

q Hydronic (main coil

changeover)

q Dedicated hydronic

q DX

32 UV-SVP01A-EN

Heating source

q None

q Hydronic

q Dedicated hydronic

q Steam

q Electric heat

q Hydronic (main coil

changeover) + dedicated

hydronic (auxiliary coil)

q Hydronic (main coil

changeover)

Configuration

Binary Outputs

1

Table 10: Binary output summary

Binary output Classroom unit ventilator Valid range

J1-1 Fan high NA

J1-2 Exhaust fan or none NA

J1-3 Fan low NA

J1-4 (Key) NA

Cooling valve open NA

J1-5

Face bypass cool isolation valve Normally open or normally closed

2-position cooling Normally open or normally closed

2

2

DX NA

J1-6 Cooling valve close NA

J1-7 Face bypass damper open NA

J1-8 Face bypass damper close NA

Heating valve open NA

J1-9

J1-10

Face bypass heat isolation valve Normally open or normally closed

Electric heat stage 1 NA

2-position heating Normally open or normally closed

Heating valve close NA

Electric heat stage 2 NA

2

2

J1-11 Outdoor air damper open NA

J1-12 Outdoor air camper close NA

TB4-1/TB4-2 Terminals Output Rating Load Energized Load De-energized

Generic/baseboard heat output TB4-1

24 VAC TB4-2

12 VA 1 VAC RMS (typical) 24 VAC RMS (typical)

1. Trane’s Rover service tool uses the unit type to determine and download the proper default binary output configuration.

2. The normally open/closed configuration item refers to the inactive state of the controlled end device (such as an 2-position cooling valve

output).

UV-SVP01A-EN 33

Configuration

Binary Inputs

Table 11: Binary input summary

Binary input Configuration Valid range

BI 1 Low coil temperature detection or not used

BI 2 Not used

BI 3 Occupancy, generic, or not used

BI 4 Fan status or not used

1. Trane Rover service tool uses the unit type to determine and download the proper default binary input configuration.

Analog Inputs

Table 12: Analog input summary

Analog input Configuration Calibration range

Zone Space temperature

Fan Fan switch NA

AI 1 Entering water temperature NA

AI 2 Discharge air temperature NA

AI 3

AI 4

1. Trane Rover service tool uses the unit type to determine and download the proper default analog input configuration.

2. Analog input 3 (AI 3) configured as generic temperature input does not affect unit operation. When configured, the Tracer™ ZN.520 Unit

Controller communicates the generic temperature value to Rover or Tracer Summit and displays it as generic temperature.

1

1

Set Setpoint (hardwired)

Outdoor air temperature or generic temperature input

(Note 2)

Humidity, CO2 or generic

4-20mA input

Normally open

Normally closed

Normally open

Normally closed

Normally open

Normally closed

Normally open

Normally closed

+/- 10.0°F

(0.1°F resolution)

+/- 10.0°F

(0.1°F resolution)

NA

NA

34 UV-SVP01A-EN

Configuration

Fan Configuration

Table 13: Fan configuration ranges

Fan configuration Default Valid range

Fan operation in heating Continuous

Fan operation in cooling Continuous

Number of fan speeds Varies

Configurable fan speed heating Varies

Configurable fan speed cooling Varies

2

2

2

Zone sensor fan switch Enable Disable or enable

End Device Configurations

Continuous (during occupied)

Cycling with capacity (unoccupied)

Continuous (during occupied)

Cycling with capacity (unoccupied)

1, 2

Off, low, high, auto

Off, low, high, auto

Table 14: End device ranges

Default Valid range

Main, cooling/changeover valve stroke time Varies

Entering water sampling Varies

Auxiliary, heating valve stroke time Varies

Outdoor air damper stroke time Varies

2

2

2

2

30 - 360 seconds

Disable or enable

30 to 360 seconds

30 to 360 seconds

Occupied outdoor air damper minimum position 15% 0 to 100%

Occupied standby outside air damper minimum

position

Alternate minimum outside air damper position

for low fan speed

15% 0 to 100%

40% 0 to 100%

Economizer enable temperature 55°F 30 to 70°F

Exhaust fan enable setpoint

1

9%

0 to 100%, 101% disables the

exhaust fan

Face-and-bypass damper stroke time 65 seconds 30-360 seconds

1. The exhaust fan is energized when the outdoor air damper is equal to or greater than the exhaust fan enable point, and the exhaust fan

is turned off when the outdoor air damper is 10% less than the exhaust fan enable point.

2. Varies with unit configuration.

UV-SVP01A-EN 35

Configuration

Setpoints

Table 15: Setpoint defaults

Setpoint Default Valid range

Occupied heating setpoint 71°F 40 to 115°F

Occupied cooling setpoint 74°F 40 to 115°F

Occupied standby heating setpoint 67 °F 40 to 115°F

Occupied standby cooling setpoint 78 °F 40 to 115°F

Unoccupied heating setpoint 60°F 40 to 115°F

Unoccupied cooling setpoint 85°F 40 to 115°F

Heating setpoint low limit

Cooling setpoint low limit

Heating setpoint high limit

Cooling setpoint high limit

Thumbwheel setpoint Enable Disable or enable

1. The heating and cooling setpoint high and low limits only apply to the occupied and occupied standby setpoints and are never applied

to the unoccupied setpoints.

1

1

1

1

40°F 40 to 115°F

40°F 40 to 115°F

105°F 40 to 115°F

110°F 40 to 115°F

Discharge Air Limits

Table 16: Discharge air limit ranges

Default Valid range

Low limit

Control point high limit

Control point low limit

1

2

2

38 °F 30 to 50°F

150 °F 38 to 150°F

45 °F 35 to 150°F

1. The low limit is the temperature at which the controller shuts down the unit to prevent the coil from freezing.

2. The control algorithm is limited to calculating this discharge air temperature based on capacity request.

Freeze Avoidance

Table 17: Freeze avoidance setpoint range

Default Valid range

Freeze avoidance setpoint

The controller disables freeze avoidance when the outdoor air temperature rises 3 °F above the freeze avoidance setpoint.

1

40 °F 20 to 60°F

36 UV-SVP01A-EN

Configuration

Occupied Bypass Timer

Table 18: Bypass timer range

Default Valid range

Occupancy bypass timer

1. The occupied bypass timer is used for timed override applications.

1

120 Minutes

Power-Up Control Wait

Table 19: Control wait timer

Default Valid range

Power up control wait (2 minutes) 120 seconds Disable or enable

0 to 240 minutes

(1 minute resolution)

Maintenance Timers

Table 20: Maintenance timer range

Default Valid range

Maintenance timer 0 0 to 10,000 hours

UV-SVP01A-EN 37

Unit Identification

Tag

The unit identification tag is factory

mounted and provided for easy

identification of an installed unit. It

contains model number, tagging,

and location information.

The top portion of the unit identification tag remains permanently affixed to the unit for identification

purposes. The bottom portion of

the tag provides pertinent information that is removable to be placed

on building plans or in “ Appendix—Location Identifier” on

page68. This provides identification history about the unit’s location for quick reference.

These tags provide information

about

q unit serial number;

q NID (neuron identification

number)—The NID is similar to

the serial number of the unit

but is specific to the

identification of the Tracer

ZN.520 unit controller circuit

board; and

q unit location—The location

identification is a customer

defined, clear English

description, of the unit’s

physical location. This is a 27

character description, including

spaces, of the location. For

example, if the location

identification for a unit is

“Conference Room 101”, the

ZN.520, Rover (the Trane

Comm 5 service tool), and

Tracer Summit, will recognize

this clear English description.

If location identification is not defined, it will default to the unit serial number. This unit identification

tag provides some information so

the user has multiple references to

the unit. The blank location is provided for field modification in case

the unit is moved from the initial

location.

Location Identifier

Figure 16: Unit identification tag

Winking

Winking a device causes the green

status LED on the device selected

to blink at a rate of twice per second for approximately 10 seconds.

This feature is useful when a discrepancy in device location exists.

As part of the troubleshooting process, one person can WINK the device while another can observe the

blinking and verify the device’s

physical location.

Important! If the status LED on

the ZN.520 does not blink, the

device may not be

communicating or it may not

be the device you selected

according to the stored

address.

A Tracer ZN.520 unit controller

may be set to wink by

q holding the ON button on the

zone sensor for 5 seconds

q using Rover, Trane’s

communication service tool

38 UV-SVP01A-EN

Unit Operation

Power-Up

When 24 VAC is initially applied to

the controller, the following sequence of events occurs:

q Green status LED turns ON .

q All outputs are controlled OFF.

q The controller reads input

values to determine initial

values.

q Random-start timer expires (5

to 30 seconds).

q When POWER-UP CONTROL WAIT

is enabled, the controller waits

0-120 seconds (depending on

configuration) to allow ample

time for communicated control

data to input. If the controller

does not receive communicated information, standalone

control is assumed.

q All modulating valves and

dampers calibrate closed.

q NORMAL operation begins.

Occupancy

The valid occupancy modes for the

Tracer ZN.520 controller are:

q OCC UPIED - Normal operating

mode for occupied spaces or

daytime operation.

q UNOCCUPIED - Normal

operating mode for

unoccupied spaces or

nighttime operation.

q OCC UPIED STANDBY - Mode

used to reduce the heating and

cooling demands, while

providing ventilation, during

the occupied hours when the

space is vacant or unoccupied.

q OCC UPIED BYPASS -Used to

temporarily place the unit into

the occupied operation.

The occupancy mode can be hardwired to the controller via the occupancy binary input or

communicated to the controller.

OCC UPIED mode

When the controller is in the OC CU-

PIED mode, the unit attempts to

maintain the space temperature at

the active occupied heating or

cooling setpoint.

OCC UPIED mode is the default

mode of the Tracer ZN.520 controller.

UNOCCUPIE D mode

When the controller is in the UN-

OCC UPIED mode, the unit attempts

to maintain space temperature at

the stored unoccupied heating or

cooling setpoint (i.e., configurable through Tracer Summit or

the Rover service tool) regardless

of the presence of a hardwired or

communicated setpoint. When

the space temperature exceeds

the stored unoccupied setpoint,

the controller brings on 100% of

the primary heating or cooling capacity.

The UNOCC UPIED mode can be initiated through a hardwired signal

to the occupancy binary input or

by a communicated request.

OCC UPIED STANDBY mode

The OC CUPIED STANDBY mode allows the unit to operate at a heating or cooling setpoint between

the occupied and unoccupied setpoints to help maintain the environment while decreasing energy

consumption.

This mode decreases the ventilation for heating or cooling during

brief periods of vacancy in the

space. Unit operation in this mode

is similar to the occupied mode except for the different heating and

cooling setpoints and a different

outside air damper position.

The OC CUPIED STANDBY mode is

initiated only when occupancy is

communicated to the Tracer

ZN.520 controller and the hardwired signal to the occupancy input is calling for unoccupied

operation.

OCC UPIED BYPASS mode

The OCCUPIED BY PASS mode is

used to transition the unit from the

UNOCCUPIED mode to the OCC U-

PIE D mode for a period of time

from 0 to 4 hours (configurable

through Rover. Default=RUN). The

controller can be placed in OC CU-

PIE D BYPASS mode by either com-

municating an occupancy request

of BYPASS or by using the TIMED

OVE RRIDE (i.e., ON) button on the

Trane zone sensor.

ON and CANCEL Buttons

Some Trane zone sensors have ON

and CANCEL buttons for timed over-

ride operation. Pressing the ON

button on the zone sensor when

the unit is in the UNOCC UPIED

mode initiates the OCC UPIED BY-

PASS mode and initializes the by-

pass timer. The CANCEL button is

used to send the unit back into UN-

OCC UPIED mode before the bypass

timer has expired.

The ON button may also be used

for the unit identification or the

“WINK” feature. (See “Winking”

on page38.for more information.)

When the Tracer ZN.520 controller

is connected to a Tracer Summit

system or the Rover service tool,

the ON button may be used in place

of the service pin for easy unit

identification.

Heating And Cooling

Changeover Logic

The Tracer™ ZN.520 Unit Controller can receive communicated requests for heating or cooling

operation. The communicated

variable nviApplicMode is used to

communicate the requests for the

controller's operating mode based

on the following values:

0 = Auto (mode determined by

controller)

1 = Heat (uses heating

setpoints)

2 = Morning Warm-up

3 = Cool (uses cooling

setpoints)

UV-SVP01A-EN 39

Unit Operation

4 = Night Purge (air

changeover) not supported

5 = Pre-cool (morning cool

down)

6 = Off (no unit operation

allowed)

7 = Test (special test mode)

8 = Emergency Heat not

supported

9 = Fan Only (no heating or

cooling allowed)

All other enumerations will be interpreted as Auto.

As the controller automatically determines its heating or cooling

mode, it changes from cool to heat

or from heat to cool, while the error

(integrated over time between the

active setpoint and the space tem-

perature) is (900 °Fh Sec). Integra-

tion only begins once the heating

and cooling capacity is equal to 0%

or the discharge air temperature is

being limited by the discharge air

temperature control limits.(See

Figure 17: “Heat/Cool Changeover

logic”).

Figure 17: Heat/Cool Changeover logic

If the measured space temperature

is 69 °F and the active cooling setpoint is 72 °F, the error between

the space temperature and the setpoint is three degrees. If the same

error exists for one minute (60 seconds), the integration term is

(3 °Fh60 Sec) or (180 °Fh Sec).

The Tracer™ ZN.520 Unit Controller changes from heating to cooling and cooling to heating when

the integration term exceeds

(900 °FhSec). Along with satisfying the integration for heating and

cooling changeover, the measured

space temperature must fall outside the setpoint range. This

means the space temperature

must be greater than the active

40 UV-SVP01A-EN

cooling setpoint or lower than the

active heating setpoint.

Example: If the cooling setpoint is

75°F and the heating setpoint

70°F, any space temperature

greater than 75°F or less than 70°F

is outside the setpoint range.

Once the integration term is satisfied and the space temperature is

outside the setpoint range, the

controller changes modes. However, before the unit's heating or

cooling capacity ramps up, the

controller checks to make sure it is

capable of heating or cooling.

For some units, heating and cooling capability exists with local resources such as electric heat or

compressors. For these units, central heating or cooling plan operation is not required for heating or

cooling because they are capable

of providing their own local heating or cooling.

For 2-pipe changeover and 4-pipe

changeover units with hydronic capacity, heating and cooling is provided through hydronic. For those

hydronic, central heating or cooling plant operation is required for

the unit to deliver heating or cooling. To determine whether the central plant is providing the desired

water temperature, an entering

water temperature sensor (either

hardwired or communicated) must

be present.

Unit Operation

The entering water must be five

degrees or more above the space

temperature to allow hydronic

heating, and five degrees or more

below the space temperature to allow hydronic cooling.

If the desired water temperature is

available, the unit begins normal

heating and cooling operation. If

the measured entering water temperature is not adequate for the

desired heating or cooling, the

controller begins the entering water temperature sampling logic.

The Tracer™ ZN.520 Unit Controller operates the modulating valves

and dampers based on a heating

or cooling capacity calculated by

the control algorithm. The control

algorithm calculates the heating or

cooling capacity based on the

measured space temperature, the

active setpoint and the discharge

air temperature. When the measured space temperature is within

the active heating and cooling setpoints, the heating and cooling capacity approaches zero.

Cooling Operation

During the C OOLING mode, the

Tracer ZN.520 controller attempts

to maintain the space temperature

at the active cooling setpoint.

Based on the controller’s occupancy mode, the active cooling setpoint is one of the following:

q Occupied cooling setpoint

q Occupied standby cooling

setpoint

q Unoccupied cooling setpoint

The controller uses the measured

space temperature, the active

cooling setpoint, and discharge air

temperature along with the control algorithm to determine the requested cooling capacity of the

unit (0-100%). The outputs are controlled based on the unit configuration and the requested cooling

capacity.

Heating Operation

During the H EATING mode, the

Tracer ZN.520 controller attempts

to maintain the space temperature

at the active heating setpoint.

Based on the controller’s occupancy mode, the active heating setpoint is one of the following:

q Occupied heating setpoint

q Occupied standby heating

setpoint

q Unoccupied heating setpoint

The controller uses the measured

space temperature, the active

heating setpoint, and discharge air

temperature along with the control algorithm to determine the requested heating capacity of the

unit (0-100%). The outputs are controlled based on the unit configuration and the requested heating

capacity.

Fan Operation

For multiple fan speed applications, the Tracer ZN.520 controller

allows separate default fan speeds

to be configured for heating and

cooling modes. When the fan

mode switch is in the AUTO position or no hardwired input exists,

the fan operates at the configured

default fan speed (i.e, HIGH).

The Tracer ZN.520 controller also

allows the default fan speed to be

configured as AU TO. When the fan

speed switch is in the AUTO position and the default fan speed is

configured as AU TO, the unit may

change fan speeds based on the

requested heating or cooling capacity. In this mode, the unit fan

will operate at LOW speed until the

requested capacity requires HIGH

fan speed operation to maintain

space comfort.

The fan mode request can be either hardwired or communicated

to the Tracer ZN.520 controller.

When both are present, the communicated request has priority

over the hardwired input. Additional flexibility in the controller al-

lows the fan speed switch to be

disabled. When this occurs, the

unit will operate at the default fan

speed unless a communicated request is present.

During OCCUPIE D, OCCUPIED

STANDBY , and OCCUPIED BYPASS

modes, the fan will normally operate continuously at the appropriate fan speed. The fan will only be

O FF in these modes when the MAN-

UAL OUTPUT TEST has been initiat-

ed, a latching diagnostic is

present, or the communicated or

hardwired fan speed is OFF. (See

“Manual Output Test” on

page48.for more information.)

During the UNOCCUPIED mode, the

unit fan is controlled OFF. When ca-

pacity is required to maintain the

unoccupied heating or cooling setpoint, the unit fan is controlled to

high speed regardless of a hardwired or communicated fan speed.

Table 21: Absolute two-speed fan

switch points

Fan Speed

Change

Low to High 2.00 °F

High to Low 1.25 °F

Absolute

Temperature Error

Fan Off Delay

When a heating output is controlled off, the Tracer™ ZN.520

Unit Controller automatically

holds the fan on for an additional

30 seconds. This 30-second delay

gives the fan time to blow off any

residual heat from the heating

source, such as a steam coil. When

the unit is heating, the fan off delay is normally applied to control

the fan; otherwise, the fan off delay does not apply.

Fan Start On High Speed

On a transition from off to any other fan speed, the Tracer™ ZN.520

Unit Controller automatically

starts the fan on high speed and

runs the fan at high speed for 0.5

UV-SVP01A-EN 41

Unit Operation

seconds. This provides the ample

torque required to start all fan motors from the off position.

Exhaust fan/damper

operation

This binary point is a shared point

with medium fan speed. For this

point to be used for exhaust control, the controller must be configured for a 1- or 2-speed fan. The

exhaust fan/damper is coordinated

with the unit fan and outdoor

damper operation. The exhaust

output is energized only when the

unit fan is operating and the outdoor damper position is greater

than or equal to the configurable

exhaust enable point. The exhaust

fan output is disabled when the

outdoor air damper position drops

10% below the exhaust enable

point. If the enable point is less

than 10%, the unit turns on at the

enable point and off at 0.

Valve Operation

Modulating Valves

The Tracer ZN.520 controller supports one or two modulating

valves for hydronic heating and

cooling operation. The main valve/

coil is used for cooling only, heat/

cool changeover (2-pipe applications), or cooling (4-pipe applications). The auxiliary valve/coil

provides heating in 4-pipe and

heating only applications.

At power-up, the Tracer ZN.520

controller drives the modulating

valves to the closed position. The

controller calibrates to the full

closed position by overdriving the

actuator 135%. Whenever the controller requests a valve position of

zero or 100%, the controller overdrives the actuator 135% regardless of the current valve position.

Face-and-Bypass

Isolation Valves

Face-and-bypass units may use

isolation valves to prevent unwanted water flow in the coil. This eliminates problems such as radiant

heat or excessive condensate in 2pipe systems.

In 4-pipe applications, the isolation

valves are used to prevent conflicting capacities within the unit.

Face-and-Bypass

Damper Operation

Note: The Face-and-bypass

actuator is located in the righthand end pocket of the

classroom unit ventilator.

The Tracer ZN.520 controller actuates a face-and- bypass damper to

modulate a percentage of air to the

face of the coil to maintain space

comfort. When a requested capacity is present, the unit modulates

the damper to allow more air to the

face of the coil. An averaging sensor is used on the discharge air to

provide accurate capacity control.

Figure 18: Horizontal unit with face-and-bypass damper option.

42 UV-SVP01A-EN

Unit Operation

Figure 19: Vertical unit with face-andbypass damper operations

Upon power-up, the controller calibrates the face-and-bypass damper to the full bypass position by

overdriving the damper actuator.

During normal operation, whenever the Tracer ZN.520 controller

generates a face-and-bypass

damper position request of zero or

100%, the unit calibrates the actuator by overdriving the damper actuator 135%.

Entering Water

Temperature

Sampling

Units with 4-pipe changeover and

2-pipe changeover require an entering water temperature to determine if the appropriate water

temperature is present for the requested mode (heating or cooling). This temperature may be

communicated in an ICS system or

hardwired to the Tracer ZN.520

controller for standalone applications.

When a unit uses 2-way modulating valves, it is possible for the water near the entering water

temperature sensor to migrate towards ambient temperature. The

Tracer ZN.520 controller has a water sampling feature for these applications. When the sensed water

temperature is not sufficient for

the requested heat/cool mode

(5°F above the zone temperature

for heating or 5°F below the zone

temperature for cooling), the controller drives the valve fully open.

The controller then monitors the

water temperature until the appropriate temperature is sensed or

until the three minute time limit

expires. If the water temperature is

acceptable for the requested capacity, the unit continues normal

operation. If the three minute timer expires and the water temperature is still unsuitable, the unit

closes the valve and waits one

hour before invoking the sampling

feature again.

Table 22: Water assumption chart

Unit Configuration

2-pipe Heating valve Hot

2-pipe cooling valve Cold

2-pipe H/C valve with

auto changeover enabled

2-pipe H/C valve with

auto changeover

disabled

1. Assumption based on absence of a valid

entering water temperature

Temperature

Assumed

Hot

Cold

1

Modulating Outdoor

Air Operation

The Tracer ZN.520 controller operates a modulating (3-wire floating)

outdoor air damper actuator according to the effective occupancy, outdoor air temperature, space

temperature, effective setpoint,

discharge air temperature, and

discharge air temperature set-

point. Default minimum damper

positions are provided and can be

changed for occupied and occupied standby modes, or for low

speed operation. The controller

can also receive a communicated

outdoor air damper minimum position from Tracer Summit. A communicated minimum position

from Tracer Summit has priority

over all configured setpoints.

During the OC CUPIED mode the

outdoor air damper will always be

controlled to the effective minimum position unless ASHRAE Cycle I, ASHRAE Cycle II, or

economizing modes are active.

Figure 20: OA/RA actuator mounting for

the vertical unit ventilator

Figure 21: Figure 2: OA/RA actuator

mounting for the horizontal unit ventilator

UV-SVP01A-EN 43

Unit Operation

Automatic Outdoor Air

Damper Adjustment

The Tracer ZN.520 controller is capable of using different minimum

outdoor air damper positions for

high and low fan speeds, which are

configurable. This allows the ventilation rate to be maintained when

switching between fan speeds.

Note: The typical reduction in

airflow between high and low

fan speeds is 25%, however, if

precise control is desired, an

air balancer should be

consulted.

Economizer

Operation

Note: When there is a request

for 0% or 100% actuator

position, the actuator will

overdrive the actuator 135% to

help maintain calibration.

With a valid outdoor air temperature (hardwired or communicated),

Tracer ZN.520 uses the modulating

economizer damper as the highest

priority source of cooling.

The controller initiates the economizer function if the outdoor air

temperature is cold enough to be

used for free cooling capacity. If

the outdoor air temperature is less

than the economizer enable setpoint (absolute dry bulb), the controller modulates the outdoor air

damper between the minimum position and 100% to control the

amount of cooling capacity. When

the outdoor air temperature rises

5°F above the economizer enable

setpoint, the outdoor air damper

returns to its minimum position

and mechanical cooling is initiated.

ASHRAE Cycle I

ASHRAE Cycle I admits 100% outdoor air except during the warm up

cycle or the unoccupied mode. To

set up the Tracer ZN.520 controller

for ASHRAE Cycle I conformance,

set the occupied outdoor air damper minimum position to 100%.

44 UV-SVP01A-EN

ASHRAE Cycle II

The Tracer ZN.520 controller conforms to ASHRAE Cycle II by allowing the modulating outdoor air

damper to maintain a minimum

position during the occupied mode

unless economizing is enabled or

the space temperature falls more

than 3°F below the effective setpoint.

If the space temperature falls more

than 2°F below the setpoint, the

outdoor air damper will begin to

close. When the space temperature

hits 3°F below the setpoint, the

outdoor air damper is completely

closed.

Figure 22: ASHRAE cycle 2

DX Operation

Tracer ZN.520 supports direct expansion (DX) compressor operation for cooling only.

The controller does not allow both

the DX compressor and economizer to operate at the same time. This

prevents problems where the entering air temperature is too low

for the evaporator coil to operate

as designed.

Tracer ZN.520 also includes a fixed

minimum on/off time of 3 minutes

for compressor operation to prevent short cycling of the compressor.

Electric Heat

Operation

The Tracer ZN.520 controller supports 1 or 2 stages of electric heat

control.

To control space temperature,

electric heat is cycled to control the

discharge air temperature. The rate

of cycling is dependent on the load

in the space and the temperature of

the incoming fresh air.

Baseboard Heat

Operation

The Tracer ZN.520 controller can

be configured to support one stage

of baseboard heat. A 2 position

valve or an electric heat contactor

will be energized at 2.5°F below

the effective heating setpoint. The

baseboard heat is de-energized at

1°F below the effective heating

setpoint.

The unit will provide heating capacity as required regardless of the

presence of baseboard heat. If the

unit can not maintain the space

temperature, the baseboard heat

will come on as a secondary stage.

If baseboard heat is to be used as

the primary source of heating, the

discharge air high limit should be

set to a moderate temperature.

This will allow the ventilation air to

be tempered and avoid a “drafty”

feeling. The baseboard heat will

then operate as the heating capacity for the space.

In the UNOCC UPIED mode, the

baseboard heat and unit heating

capacity are brought on simultaneously as needed to maintain the

unoccupied setpoint.

Exhaust Fan

Operation

The exhaust fan is coordinated

with the unit fan and outdoor air

damper operation. The exhaust fan

output is energized only when the

unit fan is operating and the outdoor air damper position is greater

Unit Operation

than or equal to the configurable

exhaust enable setpoint. This is

useful for exhaust fans designed

to offset the added economizer

ventilation.

The exhaust fan is disabled when

the outdoor air damper position

drops 10% below the exhaust enable point. If the exhaust fan enable setpoint is less than 10%, the

Tracer ZN.520 controller energizes

the exhaust fan at the enable point

and disables it when the outdoor

air damper closes.

Output Overrides

Manual Output Test

Manual output test allows the binary outputs to be energized in a

predefined sequence.(For more in-

formation see, Manual Output

Test, on page 48 for more informa-

tion.)

Water Valve Override

To enable quicker water balancing, the controller allows a user to

specify the desired state of all water valves. The values supported

are:

q Open all valves

q Close all valves

The valves in the system will remain open for two hours or until

normal operation is resumed.

The Tracer Summit or the Rover

service tool is required to access

this feature.

Fan Status

There are two ways to do fan status monitoring:

1. The status of the fan is

reported based on the state of

the binary output(s) dedicated

to fan control. The fan status

is reported as HIG H or LOW

whenever the corresponding

binary output is directed ON.

The fan status is reported as

OFF when none of the fan out-

puts are directed ON.

2. The Tracer ZN.520 controller

has a binary input available

for a fan status device (current

sensing relay or differential

pressure switch) which can

provide feedback of fan operation. If the device does not

indicate fan operation after 1

minute, a unit shutdown is initiated, and the unit is latched

OFF.

Filter Status/

Maintenance Timer

The unit filter status\maintenance

timer is based on the cumulative

run hours of the unit fan. The controller compares the fan run time

against an adjustable fan run hour

limit and recommends unit maintenance as required.

The Rover service tool is used to

edit the maintenance required setpoint time. Once the setpoint limit

is exceeded, the controller generates a MAIN TENANCE REQUIRED informational diagnostic. When the

maintenance required setpoint

time is set to zero, the controller

disables this feature.

You can use the Trace Summit or

the Rover service tool to clear the

MAINTENANC E REQUIRED informa-

tional diagnostic. Once the diagnostic is cleared, the controller

resets the fan run time to zero and

begins accumulating fan run

hours again.

Note: If at any time the unit

loses power, the timer is reset

to zero.

Other Modes

DEHUMIDIFICATION

Note: If the unit is in the

unoccupied mode, the

dehumidification routine will

not operate

Dehumidification is possible when

mechanical cooling is available;

the heating capacity is in the reheat position; and the space relative humidity setpoint is valid.

The controller starts dehumidifying the space when the space humidity exceeds the humidity

setpoint. The controller continues

to dehumidify until the sensed humidity falls below the setpoint minus the relative humidity offset.

The controller uses the cooling

and reheat coils simultaneously to

dehumidify the space. When dehumidifying, the discharge air

temperature is controlled to maintain the space temperature at the

current setpoint.

Economizing is disabled during

the dehumidification mode.

Note: While in the

dehumidification mode, if

there is a call for capacity by

the unit, the zone temperature

setpoint will take priority over

the relative humidity

setpoints.

DEFROST

For defrost operation, a sensor is

wired in series with the DX cooling

relay. When a defrost condition is

detected, the condensing unit is

disabled, and the unit is placed in

the DEFROST mode.

During DEFROST the condensing

unit is O FF the outside air damper

is set to the minimum positions,

and the fan will continue to operate as continuous. The unit will remain in the DEFROST mode until

the senor resets at 48°F. The unit

will return to NORMAL operation after the mode is discontinued.

FRE EZE AVOIDANCE

FRE EZE AVOIDANCE is used as low

ambient temperature protection,

and is only invoked when the fan is

O FF. This includes the UNOCCUPIED

mode when there is no call for capacity, or any other time the fan is

UV-SVP01A-EN 45

Unit Operation

OFF due to a safety or command.

The controller enters the FRE EZE

AVOIDANCE mode when an out-

door air temperature is present

(communicated or hardwired) and

it is below the freeze avoidance setpoint (configurable). The controller

disables freeze avoidance when

the outdoor air temperature rises

3°F above the freeze avoidance

setpoint.

When the controller is in the freeze

avoidance mode:

q All water valves are driven

open to allow water flow

through the coil

q Fan is OFF

q Face-and-bypass damper

(when present) is in full BYPASS

q DX and electric heat are OFF

MORNING WARM-UP

The Tracer ZN.520 controller keeps

the modulating outdoor air damper closed anytime during the OCCU-

PIED mode when the space

temperature is 3°F or more below

the heating setpoint.

The damper remains closed indefinitely during morning warm-up

until the space temperature is within 2°F of the effective heating setpoint. The unit runs at full capacity

until setpoint is met.

COOL-DOWN

The Tracer ZN.520 controller keeps

the modulating outdoor air damper closed for up to one hour at every transition from UNOC CUPIED to

OC CUPIED mode when the space

temperature is 3°F or more above

the cooling setpoint.

The damper remains closed during

cool-down until the space temperature is within 2°F of the effective

cooling setpoint. The unit runs at

full capacity until setpoint is met.

Data Sharing—LonWorks

Tracer ZN.520 allows peer-to-peer

data communication through the

use of LonWork’s technology. Data

such as space temperature setpoint, occupancy, etc. can be

shared from a master controller to

a peer controller over a twisted pair

of communication wire with or

without the presence of a front end

building management system.

(See Figure 23: “Simple data sharing application ”) This ability al-

lows units to operate with the

same data to prevent conflicting

control.

Data sharing is established

through the use of “bindings”.

Bindings are set up through the

Rover service tool.

The Tracer ZN.520 controller includes a network variable for master/slave operation. This variable

includes all of the information required for the slave units to operate with master controller. (See

Figure 24: “More complex data

sharing application”)

For more information on establishing bindings, see the Rover service

tool manual. For a complete listing

on shared points see “Appendix—

Data Lists” on page64.

Figure 23: Simple data sharing application

46 UV-SVP01A-EN

Unit Operation

Figure 24: More complex data sharing application

UV-SVP01A-EN 47

Unit Operation

Power-Up

When 24 VAC is initially applied to

the controller, the following sequence of events occurs:

q Green status LED turns ON .

q All outputs are controlled OFF.

q The controller reads input

values to determine initial

values.

q Random-start timer expires (5

to 30 seconds).

q When POWER-UP CONTROL WAIT

is enabled, the controller waits

0-120 seconds (depending on

configuration) to allow ample

time for communicated control

data to input. If the controller

does not receive communicated information, standalone

control is assumed.

q All modulating valves and

dampers calibrate closed.

q NORMAL operation begins.

Occupancy

The valid occupancy modes for the

Tracer ZN.520 controller are:

q OCC UPIED - Normal operating

mode for occupied spaces or

daytime operation.

q UNOCCUPIED - Normal

operating mode for

unoccupied spaces or

nighttime operation.

q OCC UPIED STANDBY - Mode

used to reduce the heating and

cooling demands, while

providing ventilation, during

the occupied hours when the

space is vacant or unoccupied.

q OCC UPIED BYPASS -Used to

temporarily place the unit into

the occupied operation.