Trane WSHP Installation and Maintenance Manual

Installation, Operation,

and Maintenance

Water Source Heat Pump

Axiom™ High Efficiency Vertical Stack — GET

¾-3Tons-60Hz

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of

heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training.

Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury.

When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that

are attached to the equipment.

November 2013

WSHP-SVX10B-EN

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note thatwarnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provide to alert

installing contractors to potentialhazards that could result

in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that

could result in equipment or property-damage-only

accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

Read this manual thoroughlybefore operating or servicing

this unit.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read

these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situationthat could resultin

equipment or property-damage only

Contains Refrigerant!

System contains oil and refrigerant under high

pressure. Recover refrigerant to relieve pressure before

opening the system. See unit nameplate for refrigerant

type. Do not use non-approved refrigerants, refrigerant

substitutes, or refrigerant additives.

Failure to follow proper procedures or the use of nonapproved refrigerants, refrigerant substitutes, or

refrigerant additives could result in death or serious

injury or equipment damage.

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

WARNING

WARNING

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

© 2013Trane All rights reserved WSHP-SVX10B-EN

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all Personal ProtectiveEquipment (PPE)

recommended for the work being undertaken.

ALWAYSrefer to appropriate MSDS sheets and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a risk of arc or flash, technicians MUST put

on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit.

Failure to follow recommendations could result in death

or serious injury.

WARNING

Revision Summary

WSHP-SVX10B-EN (15 November 2013)

• WPRD Chassis Model Number change

WSHP-SVX10B-EN (18 June 2013)

• Add ECM motor

Trademarks

Trane and theTrane logo are trademarks or registered

trademarks ofTrane in the United States and other

countries.Trane is a business of Ingersoll Rand. All

trademarks referenced in this document are the

trademarks of their respective owners.

Warnings, Cautions and Notices

WSHP-SVX10B-EN 3

Table of Contents

Model Number Descriptions .............. 5

General Information ..................... 7

Pre-Installation .......................... 8

Dimensions and Weights ................. 9

Installation ............................. 12

Electrical Data .......................... 21

Pre-Start-up ............................ 22

Checklist ............................ 22

Initial Unit Start-up ................... 22

Operating Pressures .................... 23

Start-up ................................ 26

Maintenance ........................... 27

Troubleshooting ........................ 28

Unit Wiring ............................ 30

Warranty ............................... 34

4 WSHP-SVX10B-EN

Model Number Descriptions

Vertical High-Rise Cabinet

WSHP

Digits 1-3: Unit Configuration

GET = High Efficiency Vertical High Rise

Heat Pump

Digit 4: Development Sequence

E = R-410A

Digits 5-7: Nominal Size (Tons)

009=¾Tons

012=1Tons

015=1¼Tons

018=1½Tons

024 = 2Tons

036 = 3Tons

Digit 8: Voltage (Volts/Hz/Phase)

1 = 208/60/1

2 = 230/60/1

7 = 265/60/1

Digit 9: Heat Exchanger

1 = Copper Water Coil

2 = Cupro-Nickel Water Coil

3 = Copper Water Coil with Isolation

Valve and Low Flow Control

4 = Cupro- Nickel Water Coil with

Isolation Valve and Low Flow Control

5 = Copper Water Coil with Isolation

Valve and High Flow Control

6 = Cupro-Nickel Water Coil with Isolation

Valve and High Flow Control

Digit 10: Current Design

Sequence

Digit 11: Refrigeration Circuit

0 = Heating and Cooling Circuit

Digit 12: Blower Configuration

1 = Free Discharge - PSC motor

2 = Ducted Discharge - PSC motor

3 = Free Discharge w/1" Flange -

PSC motor

4 = Free Discharge w/3" Flange -

PSC motor

5 = ECM motor w/o flange

6 = ECM motor w/1" flange

7 = ECM motor w/3" flange

8 = Chassis only/No motor (ECM Control)

9 = Chassis only/No motor (PSC Control)

Digit 13: Freeze Protection

A = 20° freezestat

B = 35° freezestat

Digit 14: Open Digit

0 = Open

S = Special

Digit 15: Supply Air

Arrangement

0 = No Supply Air Arrangement

1 = Back and Front Supply Air

2 = Back and Left Supply Air

3 = Back and Right Supply Air

4 = Front and Left Supply Air

5 = Front and Right Supply Air

6 = Left and Right Supply Air

7 = Back, Front and Right Supply Air

8 = Back, Front and Left Supply Air

9 = Front, Right and Left Supply Air

B = Back Supply Air

L = Left Supply Air

R = Right Supply Air

T =Top Supply Air

F = Front Supply Air

Digit 16: Return Air

Arrangement

0 = No Return Air Door (Field Provided)

1 = Flush with Wall, Acoustic Hinged

Return Air Door with Keyless Entry

2 = Flush with Wall, Acoustic Hinged

Return Air Door with Keylock Entry

Digit 17: Control Types

D = Deluxe 24V Controls

C =Tracer™ ZN510 Controls

Digit 18: Thermostat Sensor

Location

0 = Wall Mounted Location

Digit 19: Fault Sensors

0 = No Fault Sensors

1 = Condensate Overflow Sensor

2 = Filter MaintenanceTimer

3 = Condensate Overflow and Filter

MaintenanceTimer

Digit 20-22: Open Digits

Digit 23: Unit Mounted

Disconnect

0 = No Unit Mounted Switch

C =Toggle Switch Only

D =Toggle Switch with Fuses

Digit 24: Filter Type

1 = 1-inchThrowaway Filter

Digit 25: Acoustic Arrangement

0 = Enhanced Sound Attenuation

1 = Deluxe Sound Attenuation

Digit 26: Factory Configuration

3 = R-410A Cabinet

Digit 27: Paint Color

8 = Polar White

Digit 28: Outside Air Option

0 = No Outside Air

Digit 29: Piping Arrangement

B = Back Riser Location

L = Left Hand Riser Location

R = Right Hand Riser Location

Digit 30: Riser Type

0 = No Riser

L =Type L Riser

M=Type M Riser

Digit 31: Supply Riser

0 = No Riser

B = 1" Dia. Riser with Insulation

C = 1¼" Dia. Riser with Insulation

D = 1½" Dia. Riser with Insulation

E = 2 Dia. Riser with Insulation

F = 2½" Dia. Riser with Insulation

G = 3" Dia. Riser with Insulation

2 = 1" Dia. Riser

3 = 1¼" Dia. Riser

4 = 1½" Dia. Riser

5 = 2" Dia. Riser

6 = 2½" Dia. Riser

7 = 3" Dia. Riser

Digit 32: Return Riser

0 = No Riser

B = 1" Dia. Riser with Insulation

C = 1¼" Dia. Riser with Insulation

D = 1½" Dia. Riser with Insulation

E = 2" Dia. Riser with Insulation

F = 2½" Dia. Riser with Insulation

G = 3" Dia. Riser with Insulation

2 = 1" Dia. Riser

3 = 1¼" Dia. Riser

4 = 1½" Dia. Riser

5 = 2" Dia. Riser

6 = 2½" Dia. Riser

7 = 3" Dia. Riser

Digit 33: Condensate Riser

0 = No Riser

B = 1" Dia. Riser with Insulation

C = 1¼" Dia. Riser with Insulation

D = 1½" Dia. Riser with Insulation

E = 2" Dia. Riser with Insulation

F = 2½" Dia. Riser with Insulation

G = 3" Dia. Riser with Insulation

2 = 1" Dia. Riser

3 = 1¼" Dia. Riser

4 = 1½" Dia. Riser

5 = 2" Dia. Riser

6 = 2½" Dia. Riser

7 = 3" Dia. Riser

WSHP-SVX10B-EN 5

Model Number Descriptions

Digit 34, 35, 36: Riser Length

000 = No Riser

096 = 96" Riser Length

097 = 97" Riser Length

098 = 98" Riser Length

099 = 99" Riser Length

100 = 100" Riser Length

101 = 101" Riser Length

102 = 102" Riser Length

103 = 103" Riser Length

104 = 104" Riser Length

105 = 105" Riser Length

106 = 106" Riser Length

107 = 107" Riser Length

108 = 108" Riser Length

109 = 109" Riser Length

110 = 110" Riser Length

111 = 111" Riser Length

112 = 112" Riser Length

113 = 113" Riser Length

114 = 114" Riser Length

115 = 115" Riser Length

116 = 116" Riser Length

117 = 117" Riser Length

118 = 118" Riser Length

119 = 119" Riser Length

120 = 120" Riser Length

Vertical High-Rise Chassis

WSHP

Digits 1-3: Unit Configuration

GET = High Efficiency Vertical High Rise

Heat Pump (cabinet with blower/motor)

Digit 4: Development Sequence

E = R-410A

Digits 5-7: Nominal Size (Tons)

009=¾Tons

012=1Tons

015=1¼Tons

018=1½Tons

024 = 2Tons

036 = 3Tons

Digit 8: Voltage (Volts/Hz/Phase)

1 = 208/60/1

2 = 230/60/1

7 = 265/60/1

Digit 9: Heat Exchanger

1 = Copper Water Coil

2 = Cupro-Nickel Water Coil

3 = Copper Water Coil with Isolation

Valve and Low Flow Control

4 = Cupro- Nickel Water Coil with Isolation

Valve and Low Flow Control

5 = Copper Water Coil with Isolation

Valve and High Flow Control

6 = Cupro-Nickel Water Coil with Isolation

Valve and High Flow Control

Digit 10: Current Design

Sequence

Digit 11: Refrigeration Circuit

0 = Heating and Cooling Circuit

Digit 12: Blower Configuration

1 = Free Discharge - PSC motor

2 = Ducted Discharge - PSC motor

3 = Free Discharge w/1" Flange -

PSC motor

4 = Free Discharge w/3" Flange -

PSC motor

5 = ECM motor w/o flange

6 = ECM motor w/1" flange

7 = ECM motor w/3" flange

8 = Chassis only/No motor (ECM Control)

9 = Chassis only/No motor (PSC Control)

Digit 13: Freeze Protection

0 = None or Standard

A = 20° Freezestat

B = 35° Freezestat

Digit 14: Open Digit

0 = Open

Digit 15: Supply Air

Arrangement

0 = No Supply Air Arrangement

1 = Back and Front Supply Air

2 = Back and Left Supply Air

3 = Back and Right Supply Air

4 = Front and Left Supply Air

5 = Front and Right Supply Air

6 = Left and Right Supply Air

7 = Back, Front and Right Supply Air

8 = Back, Front and Left Supply Air

9 = Front, Right and Left Supply Air

B = Back Supply Air

L = Left Supply Air

R = Right Supply Air

T =Top Supply Air

F = Front Supply Air

Digit 16: Return Air

Arrangement

0 = No Door (Chassis Only)

1 = Flush with Wall, Acoustic Hinged

Return Air Door with Keyless Entry

2 = Flush with Wall, Acoustic Hinged

Return Air Door with Keylock Entry

Digit 17: Control Types

0 = Basic Controls for WPRD Retrofit

Chassis

D = Deluxe 24V Controls

C =Tracer™ ZN510 Controls

Digit 18: Thermostat Sensor

Location

0 = Wall Mounted Location

Digit 19: Fault Sensors

0= No Fault Sensors

1 = Condensate Overflow Sensor

2 = Filter Maintenance Timer

3 = Condensate Overflow and Filter

MaintenanceTimer

Digit 20-22: Open Digits

Digit 23: Unit Mounted

Disconnect

0 = No Unit Mounted Switch

C = Switch Only

D = Switch with Fuses

Digit 24: Filter Type

1 = 1-inchThrowaway Filter

Digit 25: Acoustic Arrangement

0 = Enhanced Sound Attenuation

1 = Deluxe Sound Attenuation

Digit 26: Factory Configuration

2 = R-410A Chassis

R = WPRD Retrofit Chassis

Digit 27: Paint Color

8 = Polar White

Digit 28: Outside Air Option

0 = No Outside Air

Digit 29: Piping Arrangement

B = Back Riser Location

L = Left Hand Riser Location

R = Right Hand Riser Location

Digit 30: Riser Type

0 = No Riser (Chassis Only)

Digit 31: Supply Riser

0 = No Riser (Chassis Only)

Digit 32: Return Riser

0 = No Riser (Chassis Only)

Digit 33: Condensate Riser

0 = No Riser (Chassis Only)

Digit 34, 35, 36: Riser Length

000 = No Riser (Chassis Only)

6 WSHP-SVX10B-EN

General Information

Blower/Motor

The blower and motor is located inside the unit cabinet.

The blower and motor may be removed from the cabinet

through the chassis opening. After removing the chassis,

the blower assembly is strapped into the unit cabinet

through a single metal, flexible bracket. We refer to this

bracket as a housing belly bracket. After detaching one

screw at the bottom/front edge of the bracket, the housing

and motor are free to be lifted from the fan deck.

Compressor Nameplate

The nameplate for the compressors are located on the

compressor shell.

Controls

A 75 VA transformer is factory supplied on this unit

configuration. See wiring diagram on chassis access panel

for field wiring connection to the 24V mechanical

thermostat.

Deluxe 24V Controls

Units containing the Deluxe 24V control design will

incorporate a microprocessor-based control board.The

Trane microprocessor board is factory wired to a terminal

strip to provide all necessary terminals for field

connection.The deluxe board is equipped with a random

start relay, anti-short cycle timer, brown out protection,

compressor disable, unit safety control, diagnostics and a

generic relay (which may be available for field use). See

p. 14 for diagnostic information.

Power wiring is made at the contactor.The wiring is fed

through the left or right conduittube, and intothe cabinet’s

control box (contactor).

Schrader Connections

Connections for the low and high side of the refrigeration

system are located conveniently on the chassis’ front

beneath a sheet metal plate.

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and run tested for proper control

operation.

Unit Nameplate

The unit nameplate is located at the front of the unit. It

includes the unit model number, serial number, electrical

characteristics,refrigerant charge, and otherpertinent unit

data.

Water Connections

½" or ¾" water connections are located on the chassis’s

upper section and clearly labeled for water-in/out hose to

riser hook-up.

Water-to-Refrigerant Coils

The co-axial water-to-refrigerant heat exchanger for the ¾

ton through 3 ton equipment is constructed of copper or

cupro-nickel (option) for the water section and stainless

steel for the refrigeration section.

The heat exchanger is leak tested to assure there is no

cross leakage between the water and refrigerant gas.

ZN510 Controls

Units incorporating the ZN510 control option design will

include a digital LonTalk™ certified control board.The

control board will support such options as: random start

delay, heating/cooling status,occupied/unoccupied mode

and fan/filter status.

Power wiring is made at the contactor.The wiring is fed

through the left or right conduittube, and intothe cabinet’s

control box (contactor). See manual WSHP-IOP-2 for

diagnostic information.

Sound Attenuation

Sound attenuation is applied as a standard feature in the

product design.The enhanced reduction package includes

a heavy gage base plate, and gasket/insulation around the

compressor enclosure.

An optional deluxe sound reduction package is also

available. It includes a heavy gage base plate, gasket and

insulation around the compressor enclosure, and

vibration isolation between the chassis and cabinet. An

additional dampening treatment is applied around the

compressor enclosure to achieve greater acoustical

reductions.

WSHP-SVX10B-EN 7

Pre-Installation

WARNING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or repair will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. Glass wool fibers could result in respiratory,

skin or eye irritation.

Jobsite Inspection

Always perform the following checks before accepting a

unit:

1. Verify that the nameplate data matches the data on the

sales order and bill of lading (including electrical data).

2. Verify that the power supply complies with the unit

nameplate specifications.

3. Visually inspect the exterior of the unit, for signs of

shipping damage. Do not sign the bill of lading

accepting the unit(s) until inspection has been

completed. Check for damage promptly after the

unit(s) are unloaded. Once the billof lading is signed at

the jobsite, the unit(s) are now the property of the

SOLDTO party and future freight claims MAY NOT be

accepted by the freight company.

4. Verify that the refrigerant charge has been retained

during shipment by use of gauges. Schrader taps are

located external to the cabinet on the ¾-3 ton

equipment.

5. After assuring that charge has been retained, reinstall

the schrader caps to assure that refrigerant leakage

does not occur.

Jobsite Storage

NOTICE:

Microbial Growth!

Wet interior unit insulation can become an

amplification site for microbial growth (mold), which

may cause odors and damage to the equipment and

building materials. If there is evidence of microbial

growth on the interior insulation, the insulation should

be removed and replaced prior to operating the system.

This unit is intended for indoor useonly.To protect the unit

from damage due to the elements, and to prevent possible

IAQ contaminant sources from growing, the unitshould be

stored indoors. If indoor storage is not possible, the

following provisions for outdoor storage must be met:

1. Place the unit(s) on a dry surface or raise above the

ground to assure adequate air circulation beneath the

unit.

2. Cover the unit(s) with a water proof tarp to protect

them from the elements.

3. Make provisionsfor continuous venting of the covered

units to prevent moisture from standing on the unit(s)

surfaces. Wet interior unit insulation can become an

amplification site for microbial growthwhich has been

determined to be a cause of odors and serious health

related indoor air quality problems.

4. Store refrigeration units (chassis) units in the normal

UP orientation to maintain oil in the compressor.

Cabinet configurations may be stored as crated.

5. Do not stack units.

8 WSHP-SVX10B-EN

Dimensions and Weights

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in death or serious injury

or possible equipment or property-only damage.

Table 1. Unit weights

Size

009 135 115

012 135 115

015 175 150

018 175 150

024 225 195

036 225 195

009 88 78

012 107 97

015 112 102

018 117 107

024 174 164

036 190 180

Shipping weight with

pallet (lb)

Cabinet

Chassis

Shipping weight

without pallet (lb)

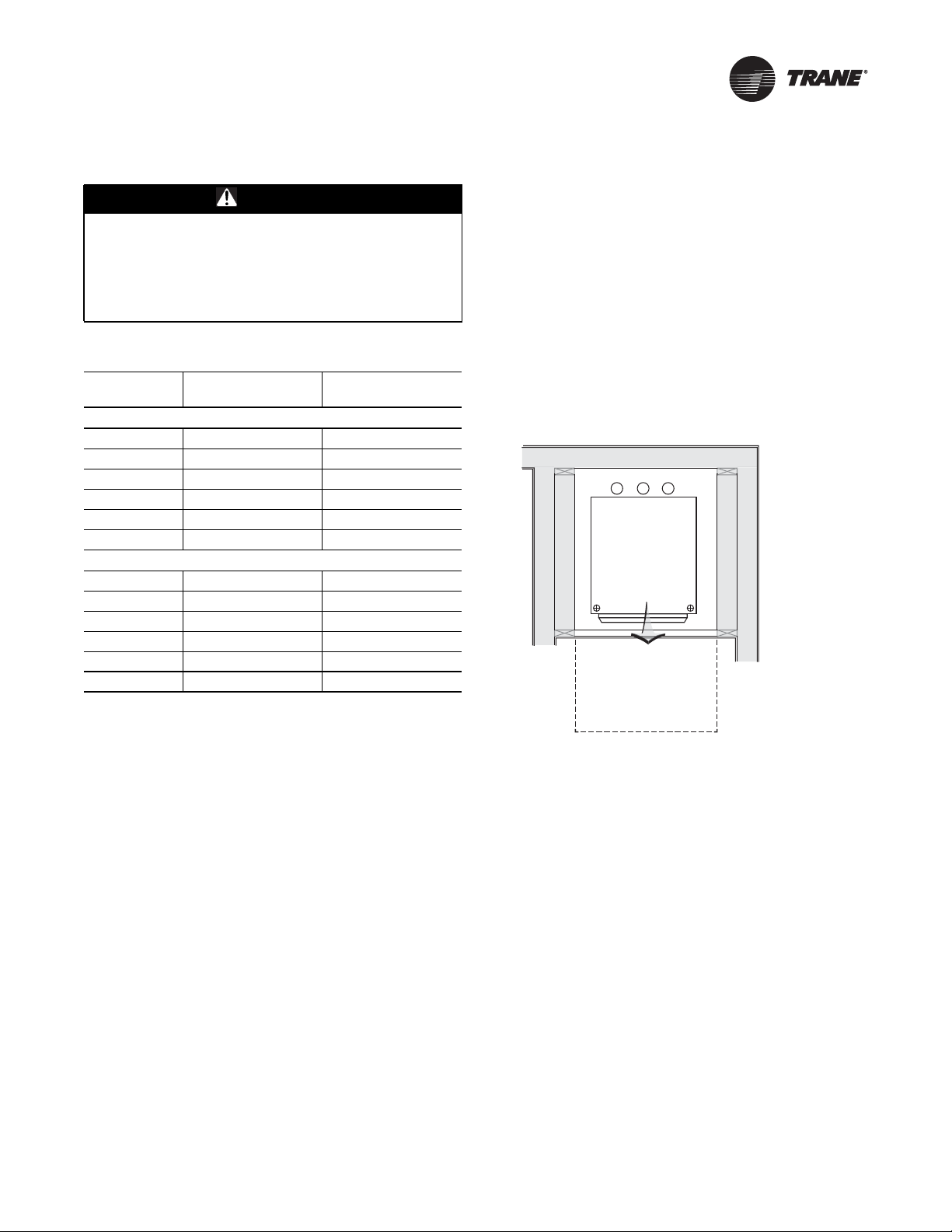

Unit Location and Clearances

Locate the unit in an indoor area.The ambient

temperature surrounding the unit must not be less than

45°F. Do not locate the unit in areas subject to freezing.

Attention should be given to service clearance and

technician safety.The unit chassis should be easily

removed from the cabinet in all applications.There must

be enough space for service personnel to perform

maintenance or repair. Provide sufficient room to make

water, and electrical connection(s). Local and national

codes should be followed in providing electrical power

connections.

Figure 1. Mechanical clearances

RSD

ALLOW 36" (914 mm)

AT UNIT FRONT FOR

CHASSIS REMOVAL

WSHP-SVX10B-EN 9

Dimensions and Weights

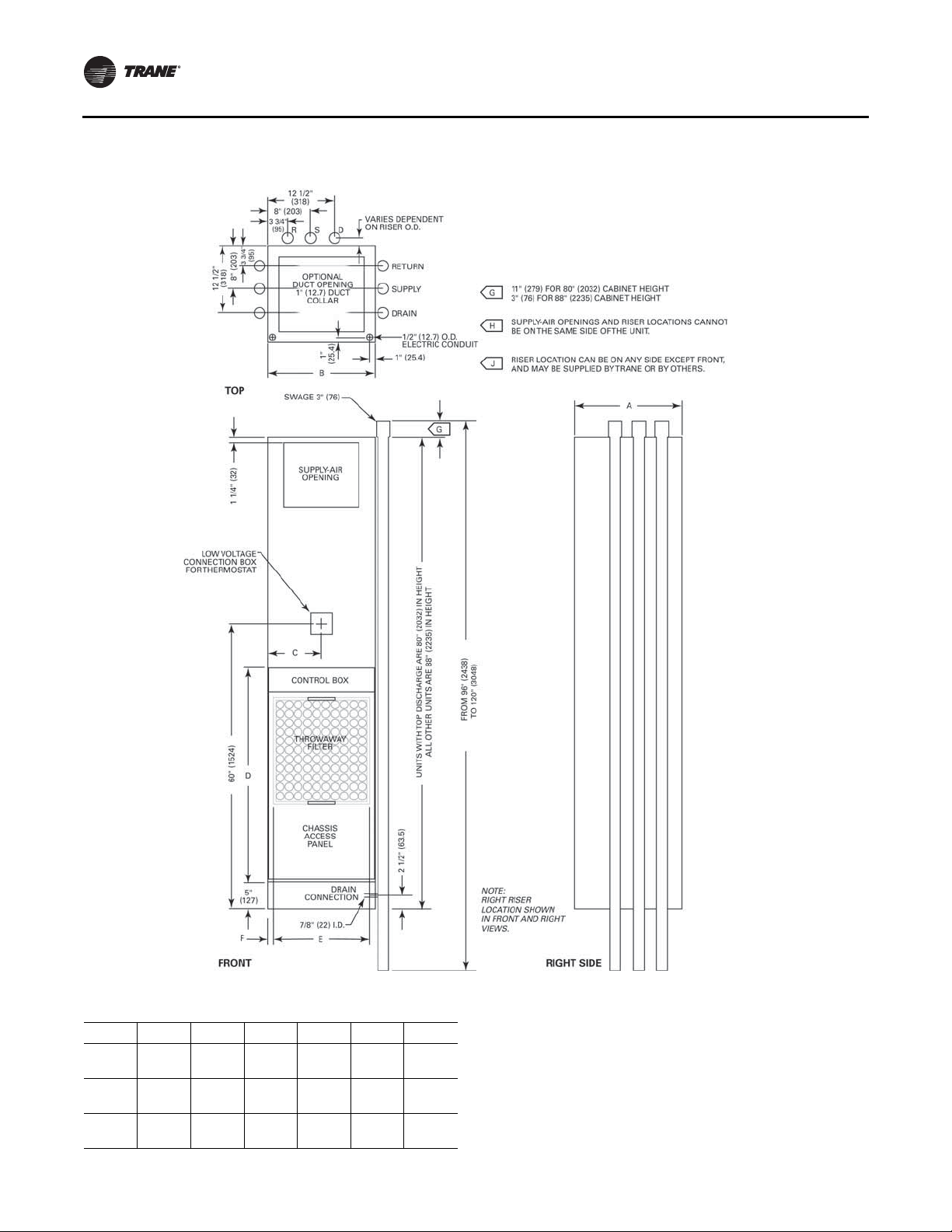

Figure 2. GET 009-036

Table 2. GET 009-036

GET A B C D E F

009, 012

015-018

024-036

16¼"

(413)

18"

(457)

24"

(610)

10 WSHP-SVX10B-EN

16¼"

(413)

20"

(508)

24"

(610)

8 1/8"

(206)

10"

(254)

12"

(305)

39 1/8"

(994)

40 5/8"

(1032)

49 5/8"

(1260)

14¾"

(375)¾"(19)

18¾"

(476)¾"(19)

22 5/8"

(575)¾"(19)

Dimensions and Weights

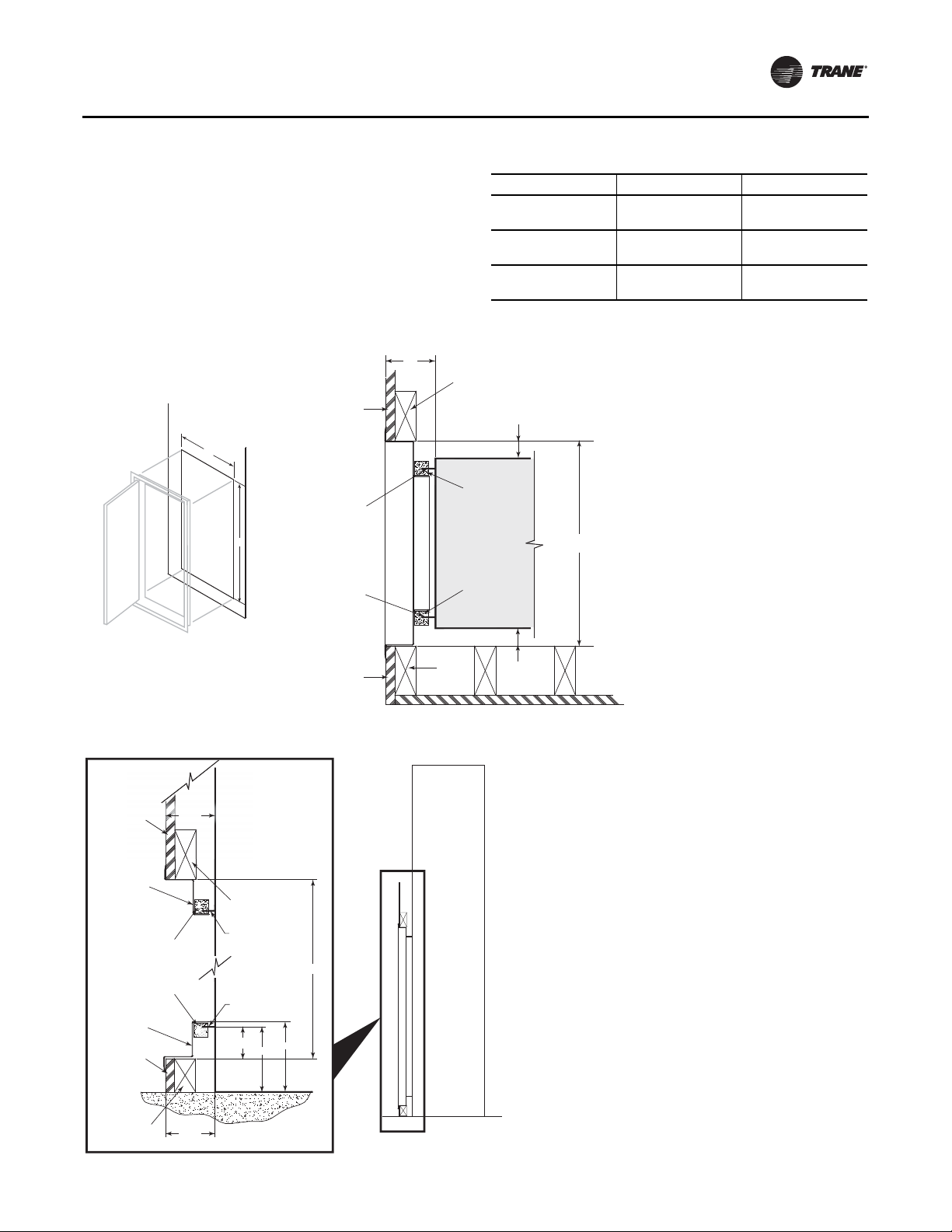

Return Air (hinged) Acoustical Door

The hinged acousticaldoor is recessedinto the wall so that

the door is flush with the surface of the wall.

The opening through the wall for the door assembly must

be centered with the return-air opening of the unit cabinet.

For full installing instructions of the return-air acoustical

door, see p. 14.

Figure 3. Return air (hinged) acoustical door

3 1/2” ±3/8”

SHEETROCK

A

RETURN AIR OPENING

FLANGE ON CABINET

B

RETURN AIR

DOOR FLANGE

RETURN AIR OPENING

FLANGE ON CABINET

Table 3. Return air hinged acoustical door

Unit Size A B

2“ X 4” STUD

1“ X 1” CLOSED

CELL INSULATION

CABINET

1“ X 1” CLOSED

CELL INSULATION

1 1/4”

+1/2”/-0”

009

012

015

018

024

036

A

19¼”

(489)

23¼”

(591)

27 1/8”

(689)

44 1/8”

(1121)

45¼”

(1149)

54 5/8”

(1387)

SHEETROCK

RETURN AIR

DOOR FRAME

1“ X 1” CLOSED

CELL INSULATION

1“ X 1” CLOSED

CELL INSULATION

RETURN AIR

DOOR FRAME

SHEETROCK

FLOOR

SHEET ROCK

OPENING

3 1/2” ±3/8”

K

2 X 4 STUD

RETURN-AIR OPENING

FLANGE ON CABINET

RETURN-AIR OPENING

FLANGE ON CABINET

2 1/4“

4 5/8“

CABINET

SHEETROCK

Note:

Finished wall and framing should not

touch the unit cabinetry.

B

5“

2“ X 4”

STUD

CABINET

1 1/4”

+1/2”/-0”

TOP VIEW

1 1/2” X 2 3/8”

3 1/2” ±3/8”

SIDE VIEW

WSHP-SVX10B-EN 11

Loading...

Loading...