Supermicro SuperChassis 743TQ-865B operation manual

SC743 Chassis

SC743TQ-865B-SQ |

SC743T-665B |

SC743T-R760(B) |

SC743TQ-R760(B) |

SC743T-500B |

SC743i-665B |

SC743S1-R760(B) |

SC743TQ-865(B) |

SC743i-500B |

SC743i-R760(B) |

SC743S2-R760(B) |

SC743i-465B |

SC743TQ-903B |

SC743AC-668B |

SC743AC-1200B-SQ |

USER’S MANUAL

Revision 1.3

Chassis SC743 User's Manual

The information in this User’s Manual has been carefully reviewed and is believed to be accurate. The vendor assumes no responsibility for any inaccuracies that may be contained in this document, and makes no commitment to update or to keep current the information in this manual, or to notify any person or organization of the updates. Please Note:

For the most up-to-date version of this manual, please see our website at www.supermicro.com.

Super Micro Computer, Inc. ("Supermicro") reserves the right to make changes to the product described in this manual at any time and without notice. This product, including software and documentation, is the property of Supermicro and/ or its licensors, and is supplied only under a license. Any use or reproduction of this product is not allowed, except as expressly permitted by the terms of said license.

IN NO EVENT WILL Super Micro Computer, Inc. BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL, SPECULATIVE OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OR INABILITY TO USE THIS PRODUCT OR DOCUMENTATION, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN PARTICULAR, SUPER MICRO COMPUTER, INC. SHALL NOT HAVE LIABILITY FOR ANY HARDWARE, SOFTWARE, OR DATA STORED OR USED WITH THE PRODUCT, INCLUDING THE COSTS OF REPAIRING, REPLACING, INTEGRATING, INSTALLING OR RECOVERING SUCH HARDWARE, SOFTWARE, OR DATA.

Any disputes arising between manufacturer and customer shall be governed by the laws of Santa Clara County in the State of California, USA. The State of California, County of Santa Clara shall be the exclusive venue for the resolution of any such disputes. Supermicro's total liability for all claims will not exceed the price paid for the hardware product.

FCC Statement: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the manufacturer’s instruction manual, may cause harmful interference with radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case you will be required to correct the interference at your own expense.

California Best Management Practices Regulations for Perchlorate Materials: This Perchlorate warning applies only to products containing CR (Manganese Dioxide) Lithium coin cells. “Perchlorate Material-special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate”.

WARNING: Handling of lead solder materials used in this product may expose you to lead, a chemical known to the State of California to cause birth defects and other reproductive harm.

The products sold by Supermicro are not intended for and will not be used in life support systems, medical equipment, nuclear facilities or systems, aircraft, aircraft devices, aircraft/emergency communication devices or other critical systems whose failure to perform be reasonably expected to result in significant injury or loss of life or catastrophic property damage. Accordingly, Supermicro disclaims any and all liability, and should buyer use or sell such products for use in such ultra-hazardous applications, it does so entirely at its own risk. Furthermore, buyer agrees to fully indemnify, defend and hold Supermicro harmless for and against any and all claims, demands, actions, litigation, and proceedings of any kind arising out of or related to such ultra-hazardous use or sale.

Manual Revision 1.3

Release Date: August 31, 2017

Unless you request and receive written permission from Super Micro Computer, Inc., you may not copy any part of this document. Information in this document is subject to change without notice. Other products and companies referred to herein are trademarks or registered trademarks of their respective companies or mark holders.

Copyright © 2017 by Super Micro Computer, Inc.

All rights reserved.

Printed in the United States of America

2

Preface

Preface

About this Manual

This manual is written for professional system integrators and PC technicians. It provides information for the installation and use of the chassis. Installation and maintenance should be performed by experienced technicians only.

This document lists compatible parts available when this document was published. Refer to the Supermicro web site for updates on supported parts and configurations.

This manual may be periodically updated without notice. Check the Supermicro website for possible updates.(http://www.supermicro.com).

Notes

Information on this and other chassis is available on the Supermicro website.

•Supermicro product manuals: http://www.supermicro.com/support/manuals/

•Product safety info: http://www.supermicro.com/about/policies/safety_information.cfm

If you have any questions, please contact our support team at: support@supermicro.com.

Warnings

Special attention should be given to the following symbols used in this manual.

Warning! Indicates important information given to prevent equipment/property damage or personal injury.

Warning! Indicates high voltage may be encountered when performing a procedure.

Warning! Indicates high voltage may be encountered when performing a procedure.

3

Chassis SC743 User's Manual

|

Contents |

|

Chapter 1 Introduction |

|

|

1.1 |

Overview............................................................................................................................... |

7 |

1.2 |

Unpacking the System.......................................................................................................... |

8 |

1.3 |

System Features................................................................................................................... |

8 |

1.4 |

Chassis Features.................................................................................................................. |

9 |

|

Control Panel....................................................................................................................... |

9 |

|

Front Features................................................................................................................... |

10 |

|

Rear Features.................................................................................................................... |

11 |

1.5 |

Where to Get Replacement Components........................................................................... |

12 |

1.6 |

Returning Merchandise for Service.................................................................................... |

12 |

Chapter 2 Rack Mount Installation |

|

|

2.1 |

Overview............................................................................................................................. |

13 |

2.2 |

Preparing for Rack Mounting.............................................................................................. |

13 |

|

Choosing a Setup Location............................................................................................... |

13 |

|

Rack Precautions............................................................................................................... |

13 |

|

Server Precautions............................................................................................................ |

14 |

|

Rack Mounting Considerations.......................................................................................... |

14 |

|

Ambient Operating Temperature.................................................................................... |

14 |

|

Airflow............................................................................................................................. |

14 |

|

Mechanical Loading....................................................................................................... |

14 |

|

Circuit Overloading......................................................................................................... |

15 |

|

Reliable Ground............................................................................................................. |

15 |

2.3 |

Chassis Preparation............................................................................................................ |

16 |

2.4 |

Installing the Rails............................................................................................................... |

17 |

|

Identifying the Rails .......................................................................................................... |

17 |

|

Releasing the Inner Rails.................................................................................................. |

17 |

|

Installing the Inner Rails.................................................................................................... |

18 |

|

Assembling and Installing the Outer Rails........................................................................ |

19 |

2.5 |

Installing the Server into the Rack...................................................................................... |

20 |

|

Removing the Chassis from the Rack............................................................................... |

21 |

2.6 |

Control Panel Orientation................................................................................................... |

22 |

4

Preface

Chapter 3 Maintenance and Component Installation |

|

3.1 Removing Power................................................................................................................. |

24 |

3.2 Accessing the System......................................................................................................... |

25 |

3.3 Chassis Components.......................................................................................................... |

26 |

Storage Drives................................................................................................................... |

26 |

Drive Indicators ............................................................................................................. |

26 |

Installing the Standard 3.5" Drives................................................................................. |

27 |

Configuring the 5.25" Drive Bays...................................................................................... |

29 |

Additional Storage Drives in a Mobile Rack.................................................................. |

32 |

Installing Expansion Cards................................................................................................ |

34 |

System Cooling.................................................................................................................. |

35 |

Chassis Fans.................................................................................................................. |

35 |

Air Shroud...................................................................................................................... |

36 |

Power Supply..................................................................................................................... |

37 |

465, 500, 665, 668, 865 and 1200 Watt Power Supplies................................................. |

37 |

Installing the Power Supply............................................................................................ |

37 |

760 Watt Power Supply..................................................................................................... |

39 |

Installing the Power Supply............................................................................................ |

39 |

Appendix A Power Supply Specifications |

|

Appendix B Standardized Warning Statements for AC Systems |

|

Appendix C BPN-SAS-743TQ Backplane Specifications |

|

Appendix D BPN-SAS3-743A Backplane Specifications |

|

Appendix E SATA-743 Backplane Specifications |

|

5

Chassis SC743 User's Manual

|

Contacting Supermicro |

Headquarters |

|

Address: |

Super Micro Computer, Inc. |

|

980 Rock Ave. |

|

San Jose, CA 95131 U.S.A. |

Tel: |

+1 (408) 503-8000 |

Fax: |

+1 (408) 503-8008 |

Email: |

marketing@supermicro.com (General Information) |

|

support@supermicro.com (Technical Support) |

Website: |

www.supermicro.com |

Europe |

|

Address: |

Super Micro Computer B.V. |

|

Het Sterrenbeeld 28, 5215 ML |

|

's-Hertogenbosch, The Netherlands |

Tel: |

+31 (0) 73-6400390 |

Fax: |

+31 (0) 73-6416525 |

Email: |

sales@supermicro.nl (General Information) |

|

support@supermicro.nl (Technical Support) |

|

rma@supermicro.nl (Customer Support) |

Website: |

www.supermicro.nl |

Asia-Pacific |

|

Address: |

Super Micro Computer, Inc. |

|

3F, No. 150, Jian 1st Rd. |

|

Zhonghe Dist., New Taipei City 235 |

|

Taiwan (R.O.C) |

Tel: |

+886-(2) 8226-3990 |

Fax: |

+886-(2) 8226-3992 |

Email: |

support@supermicro.com.tw |

Website: |

www.supermicro.com.tw |

6

Chapter 1: Introduction

Chapter 1

Introduction

Supermicro's SC743 chassis series is optimized for the latest Intel Xeon processor and is also compatible with previous generation Intel and AMD single/dual processor-based motherboards.

Utilizing redundant, high-efficiency power supplies (95+%) and eight hot-swap 3.5" drive bays, this chassis offers reliable performance with problem-free maintenance. Designed with 100% cooling redundancy using a combination of high-performance fans, the chassis minimizes the probability of system downtime or performance degradation from thermal-related issues.

With seven tool-less PCIe expansion slots, and 6-pin power connectors supporting up to three high-end graphics cards, and it is quick to configure and easy to operate. Optionally, this tower can be converted to mount in a standard rack.

1.1 Overview

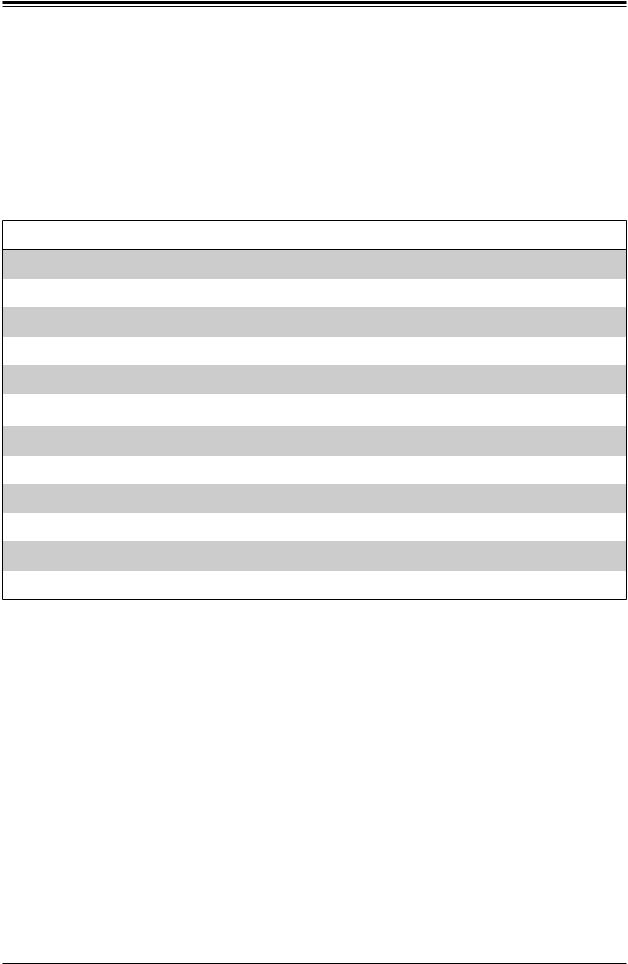

This chapter provides a brief outline of the functions and features of the SC743 chassis. Models are listed below.

SC743 Chassis Models

|

Model |

HDD |

I/O Slots |

Power Supply |

|

|

SC743AC-1200B-SQ |

8x SAS3/SATA |

7x FF |

1200W |

|

|

|

||||

|

SC743TQ-903B |

8x SAS3/SATA |

7x FF |

903W |

|

|

|

||||

|

SC743TQ-865B-SQ |

8x SAS/SATA |

7x FF |

865W |

|

|

|

||||

|

SC743TQ-865B |

8x SAS/SATA |

7x FF |

865W |

|

|

SC743TQ-R760 / |

8x SAS/SATA |

7x FF |

760W |

|

|

SC743TQ-R760B |

|

|||

|

|

|

|

|

|

|

SC743S2-R760 / |

8x SCA Dual |

7x FF |

760W |

|

|

SC743S2-R760B |

Channel |

|

||

|

|

|

|

||

|

SC743S1-R760 / |

8x SCA |

7x FF |

760W |

|

|

SC743S1-R760B |

|

|||

|

|

|

|

|

|

|

SC743T-R760 / |

8x SATA |

7x FF |

760W |

|

|

SC743T-R760B |

|

|||

|

|

|

|

|

|

|

SC743i-R760 / |

8x Fixed |

7x FF |

760W |

|

|

SC743i-R760B |

|

|||

|

|

|

|

|

|

|

SC743AC-668B |

8x SAS3/SATA |

7x FF |

668W |

|

|

SC743T-665B |

8x SAS/SATA |

7x FF |

665W Super Quiet |

|

|

SC743i-500B |

8x Fixed |

7x FF |

500W |

|

|

SC743T-500B |

8x SATA |

7x FF |

500W |

|

|

SC743i-465 / |

8x Fixed |

7x FF |

465W Low Noise |

|

|

SC743i-465B |

|

|||

|

|

|

|

|

|

7

Chassis SC743 User's Manual

1.2 Unpacking the System

Inspect the box in which the chassis was shipped, and note if it was damaged. If any equipment appears damaged, file a damage claim with the carrier who delivered it.

1.3 System Features

The following table provides you with an overview of the main features of the SC743.

System Features

Chassis

SC743

Drives Bays

Up to eight SAS3/SATA3 3.5" hot-swap drives, or optionally, 2.5" drives with converter

Cooling

Three 8-cm, 4-pin PWM mid-chassis fans; two 8-cm exhaust fans; one airflow shroud (-SQ models have two 8-cm fans and one 9-cm fan for super quiet performance)

Expansion Slots

Seven PCI-Express full-height slots

Form Factor

4U tower; optional rack mounting rails

Dimensions

(WxHxD) 17.3 x 7.0 x 38.2 in. (438 x 178 x 970 mm)

8

Chapter 1: Introduction

1.4 Chassis Features

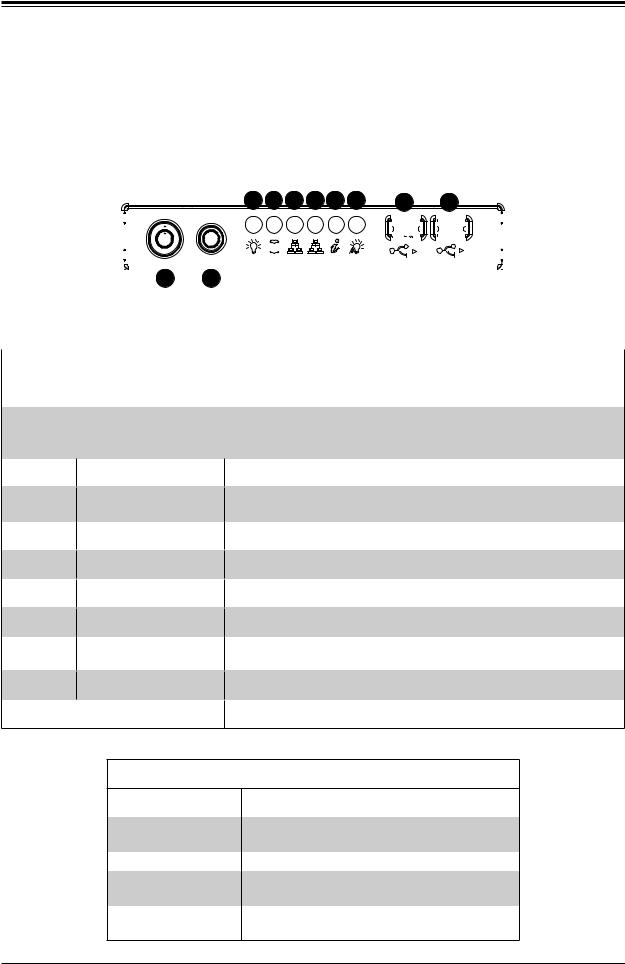

Control Panel

Power switches and status LEDs are located on the control panel on the front of the chassis.

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

Figure 1-1. Control Panel View |

|||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control Panel Features |

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

Feature |

|

Description |

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

The main power button is used to apply or remove power from the power supply |

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||

1 |

Power Button |

|

to the server. Turning off system power with this button removes the main power |

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

but maintains standby power. |

||||||||||||||||||||||||||||||||||||

2Reset Button

3Power LED

4HDD LED

5NIC1 LED

6NIC2 LED

7Information LED

8Power Fail LED

9USB0 Port

10 |

USB1 Port |

|

|

The reset button is used to reboot the system.

Indicates power is being supplied to the system power supply. This LED should normally be illuminated when the system is operating.

Indicates hard drive activity when flashing.

Indicates network activity on LAN port 1 when flashing.

Indicates network activity on LAN port 2 when flashing.

See table below for details.

This LED flashes to indicate one of the redundant power supply modules has failed. The flashing light should be accompanied by an audible warning.

USB 3.0 port

USB 3.0 port

Information LED

Status

Continuously on and red

Blinking red (1Hz)

Solid blue

Blinking blue

Description

An overheat condition has occurred.

(This may be caused by cable congestion.)

Fan failure, check for an inoperative fan.

Local UID has been activated. Use this function to locate the server in a rackmount environment.

Remote UID is on. Use this function to identify the server from a remote location.

9

Chassis SC743 User's Manual

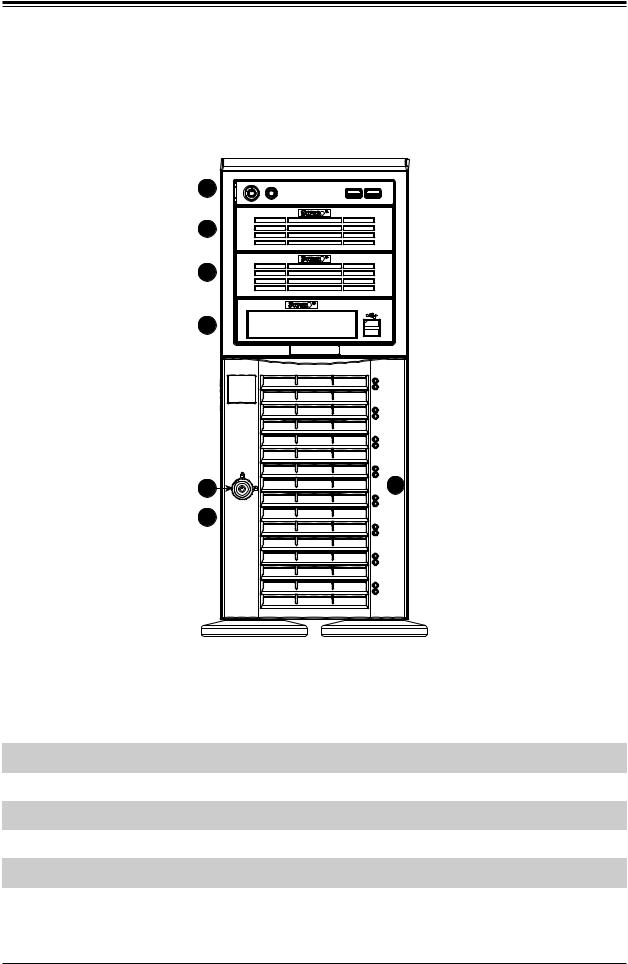

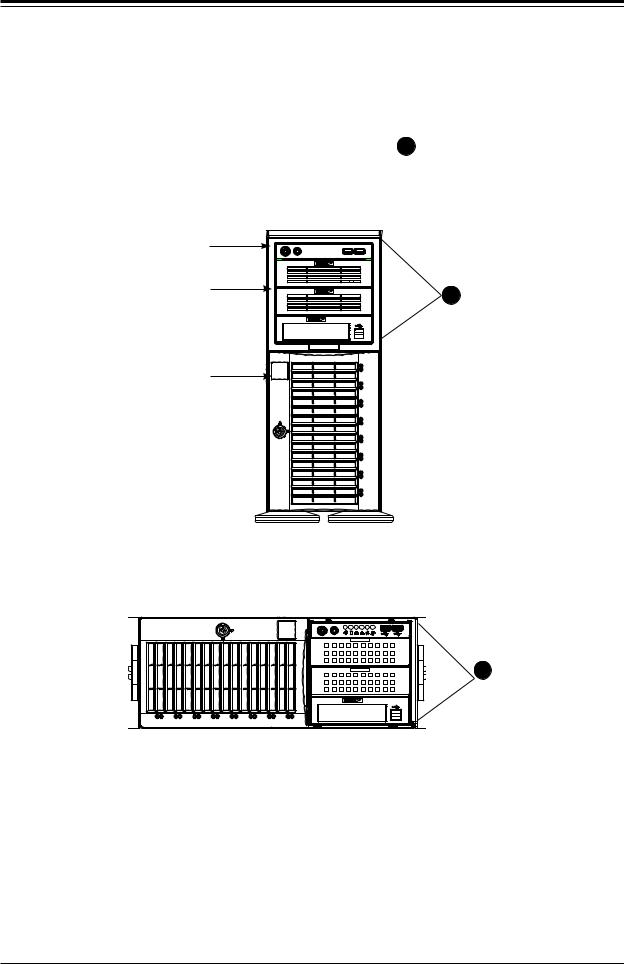

Front Features

The SC743 is a tower chassis. See the illustration below for the features included on the front of the chassis.

1

2

2

2

3 |

5 |

4 |

|

|

|

Figure 1-2. Chassis Front View |

|

|

|

|

|

|

|

|

Front Chassis Features |

|

|

|

|

Item |

Feature |

|

Description |

1 |

Control Panel |

|

Front control panel with LEDs and buttons (see preceding page) |

|

|||

2 |

Peripheral Drive Bays |

|

Three 5.25" bays for optional peripherals such as a DVD drive |

|

|||

3 |

Lock |

|

Front bezel lock |

|

|||

4 |

Drive Bays |

|

Eight 3.5" bays for hot-swap hard drives behind front bezel |

|

|||

5 |

Drive Indicators |

|

Eight pairs of LED status indicators for drives |

|

|||

|

|

|

|

10

Chapter 1: Introduction

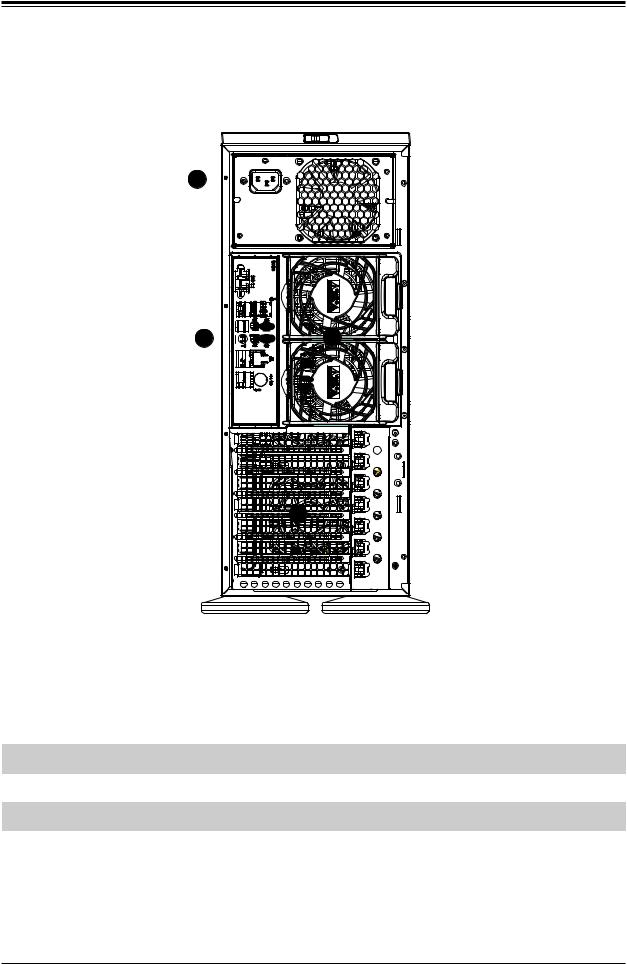

Rear Features

The illustration below shows the features included on the rear of the chassis.

1 |

|

2 |

3 |

|

4 |

|

|

Figure 1-3. Chassis Rear View |

|

|

|

|

|

|

|

|

Rear Chassis Features |

|

|

|

|

Item |

Feature |

|

Description |

1 |

Power Supply |

|

Most models have P/S 2 power supplies |

|

|||

2 |

I/O Back Panel |

|

Rear I/O ports (see Section 4.3) |

|

|||

3 |

Fans |

|

Two 8-cm exhaust fans |

|

|||

4 |

Expansion Slots |

|

Seven PCI-E expansion card slots |

|

|||

|

|

|

|

11

Chassis SC743 User's Manual

1.5 Where to Get Replacement Components

If you need replacement parts for your system, to ensure the highest level of professional service and technical support, purchase exclusively from our Supermicro Authorized Distributors/System Integrators/Resellers. A list can be found at: http://www.supermicro.com. Click the "Where to Buy" link.

1.6 Returning Merchandise for Service

A receipt or copy of your invoice marked with the date of purchase is required before any warranty service will be rendered.You can obtain service by calling your vendor for a Returned Merchandise Authorization (RMA) number. When returning to the manufacturer, the RMA number should be prominently displayed on the outside of the shipping carton, and mailed prepaid or hand-carried. Shipping and handling charges will be applied for all orders that must be mailed when service is complete.

For faster service, RMA authorizations may be requested online (http://www.supermicro.com/ support/rma/).

Whenever possible, repack the chassis in the original Supermicro carton, using the original packaging material. If these are no longer available, be sure to pack the chassis securely, using packaging material to surround the chassis so that it does not shift within the carton and become damaged during shipping.

This warranty only covers normal consumer use and does not cover damages incurred in shipping or from failure due to the alteration, misuse, abuse or improper maintenance of products.

During the warranty period, contact your distributor first for any product problems.

12

Chapter 2 Rack Mount Installation

Chapter 2

Rack Mount Installation

2.1 Overview

This chapter provides instructions for preparing and mounting your chassis in a rack. By default, the chassis is shipped configured as a tower. The tower top cover and bottom feet must be removed to mount in a rack. Also, the control panel/drive module should be rotated

90 degrees.

Mounting rails are optional for this system. Be sure you have received the correct rail kit for your server.

2.2 Preparing for Rack Mounting

Choosing a Setup Location

•The system should be situated in a clean, dust-free area that is well ventilated.Avoid areas where heat, electrical noise and electromagnetic fields are generated.

•Leave at least 25 inches clearance in front of the rack to open the front door completely.

•Leave approximately 30 inches of clearance in the back of the rack to allow for sufficient airflow and access for servicing.

•It should be a restricted access location, such as a dedicated equipment room or a service closet.

•This product is not suitable for use with visual display workplace devices acccording to §2 of the German Ordinance for Work with Visual Display Units.

Rack Precautions

•Ensure that the leveling jacks on the bottom of the rack are extended to the floor so that the full weight of the rack rests on them.

•In single rack installations, stabilizers should be attached to the rack. In multiple rack installations, the racks should be coupled together.

•Always make sure the rack is stable before extending a server or other component from the rack.

13

Chassis SC743 User's Manual

•You should extend only one server or component at a time; extending two or more simultaneously may cause the rack to become unstable.

•When initially installing the server to a rack, test that the rail locking tabs engage to prevent the server from being overextended. Have a rack lift in place as a precaution in case the test fails.

Server Precautions

•Review the electrical and general safety precautions in Appendix B.

•Determine the placement of each component in the rack before you install the rails.

•Install the heaviest server components at the bottom of the rack first and then work your way up.

•Use a regulating uninterruptible power supply (UPS) to protect the server from power surges and voltage spikes and to keep your system operating in case of a power failure.

•Allow any drives and power supply modules to cool before touching them.

•When not servicing, always keep the front door of the rack and all covers/panels on the servers closed to maintain proper cooling.

Rack Mounting Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating temperature of the rack environment may be greater than the room's ambient temperature. Therefore, consideration should be given to installing the equipment in an environment compatible with the manufacturer’s maximum rated ambient temperature (TMRA).

Airflow

Equipment should be mounted into a rack so that the amount of airflow required for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does not arise due to uneven mechanical loading.

14

Chapter 2 Rack Mount Installation

Circuit Overloading

Consideration should be given to the connection of the equipment to the power supply circuitry and the effect that any possible overloading of circuits might have on overcurrent protection and power supply wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this concern.

Reliable Ground

A reliable ground must be maintained at all times. To ensure this, the rack itself should be grounded. Particular attention should be given to power supply connections other than the direct connections to the branch circuit (i.e. the use of power strips, etc.).

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

•This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack.

•If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

•Slide rail mounted equipment is not to be used as a shelf or a work space.

15

Chassis SC743 User's Manual

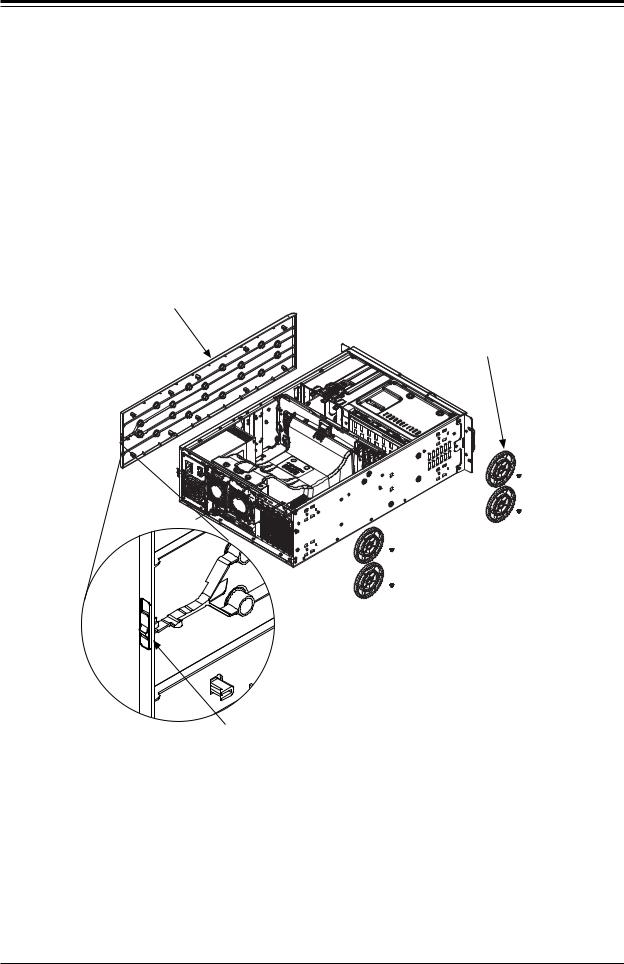

2.3 Chassis Preparation

The chassis is shipped with the tower top cover and feet installed. Both must be removed for before installing the rails.

Removing the Tower Top Cover

1.Locate the chassis cover lock (blue lever) at the rear of the chassis cover.

2.Slide the chassis cover lock to the right and push chassis cover forward.

3.Lift the chassis top cover off the chassis.

Tower Top Cover

Chassis Feet

Chassis Cover Lock

Figure 2-1. Remove Feet and Chassis Top Cover

Removing the Chassis Feet

1.Place the chassis on its side.

2.Remove the screw holding a chassis foot in place.

3.The foot lock is a tab located in the center of the foot. It prevents the foot from sliding. Using a flat head screwdriver, gently lift the foot lock upward and slide the foot toward the rear of the chassis.

16

Chapter 2 Rack Mount Installation

2.4 Installing the Rails

There are a variety of rack units on the market, which may require a slightly different assembly procedure. Do not use a two post "telco" type rack. This rail set fits a rack between 26" and 35.9" deep.

The following is a basic guideline for installing the system into a rack with the rack mounting hardware provided. You should also refer to the installation instructions that came with the specific rack you are using.

Identifying the Rails

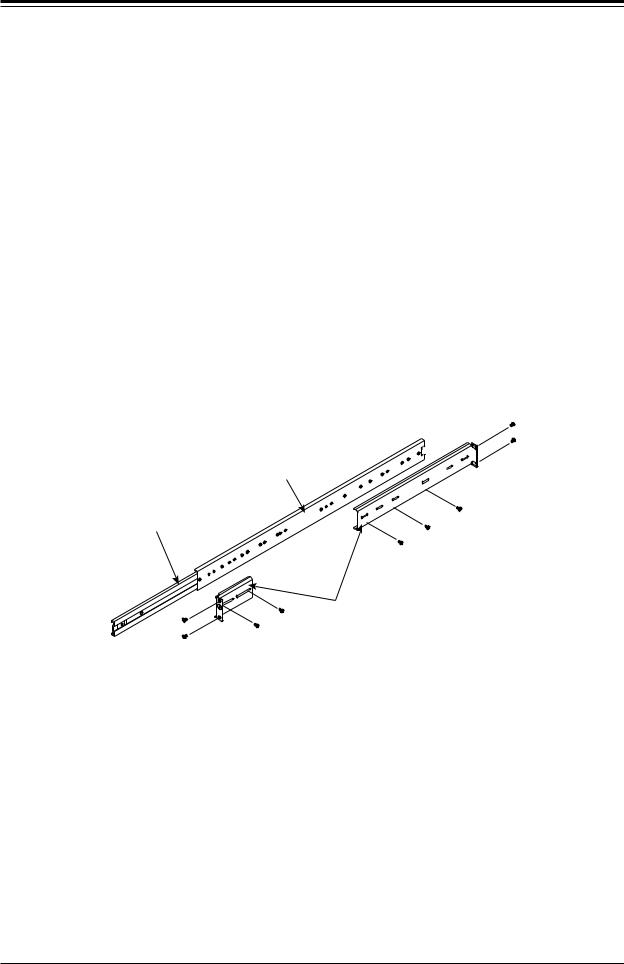

The optional rackmount kit includes two rack rail assemblies, one for each side. Each of these assemblies consist of several sections: an inner fixed rail that secures to the chassis, an outer rack rail that secures to the rack, a middle rail that slides within the outer rail, and two brackets that attach the outer rail to the rack. The brackets are specific to the left and right side, and front and back, and labeled.

Outer rail

Inner rail

Rail brackets

Figure 2-2. Identifying the Sections of the Rack Rails

Releasing the Inner Rails

The inner rails must be removed from the outer rails to install onto the chassis. To remove the inner rail, pull it out as far as possible until it clicks to a stop. Depress the locking lever on the inner rail next to the middle rail to pull the inner rail completely out.

17

Chassis SC743 User's Manual

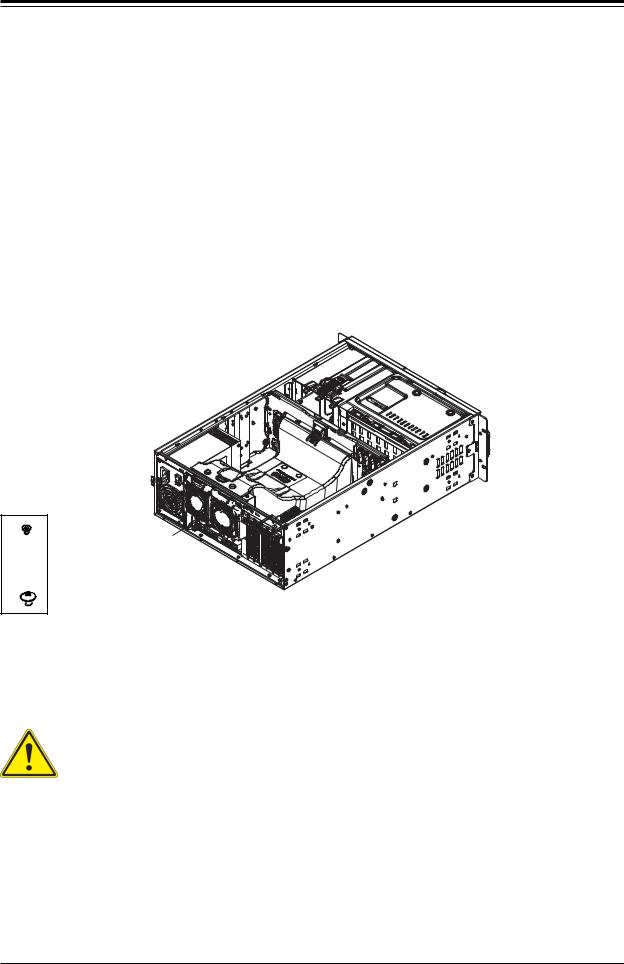

Installing the Inner Rails

Identify the left and right inner rails.

1.Attach the handles to the front sides of the chassis with three screws each.

2.Position the inner rails along the side of the chassis making sure the screw holes line up.

3.Screw the rail securely to the side of the chassis.

Screw for Handles

Screw for Inner Rails

Figure 2-3. Installing the Chassis Rails

Warning: Do not pick up the server with the front handles. They are designed to pull the system from a rack only.

18

Chapter 2 Rack Mount Installation

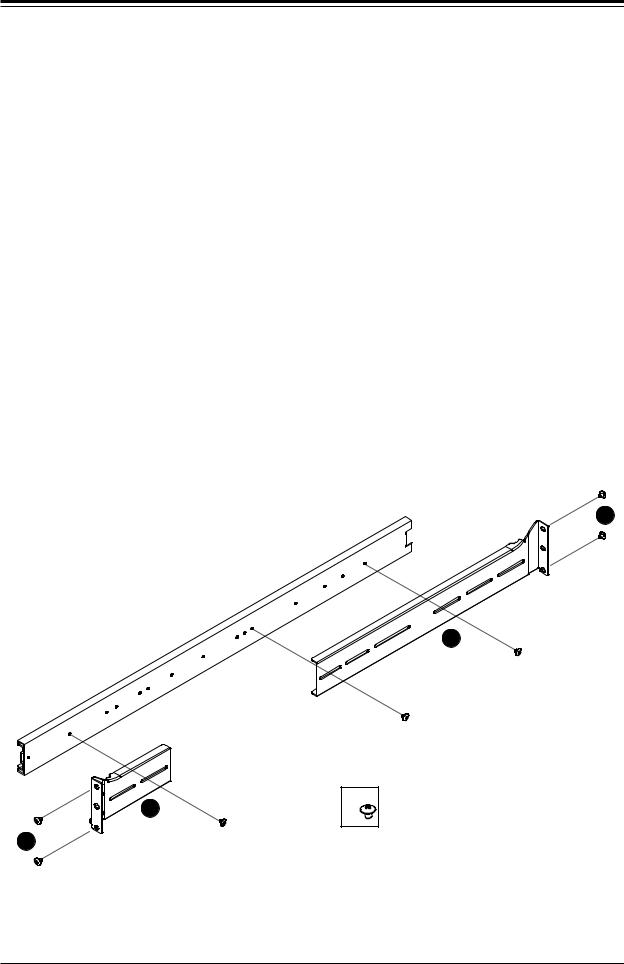

Assembling and Installing the Outer Rails

Each outer rail comes in three sections that require assembly before mounting onto the rack.

1.Find the outer rail mounting brackets in the chassis accessory box.

•A pair of long brackets for the rear of each rail

•A pair of short brackets for the front of each rail

Note that the brackets are labeled as to front, rear, and up. They are specific for the left and right rails.

2.Secure the front (short) bracket onto the outer rail with M5 screws.

3.Mount the rear (long) bracket onto the outer rail at the approximate position to fit your rack. Use two or three M5 screws into holes that are convenient. Leave the screws just loose enough that the bracket can slide.

4.Install the outer rail assembly onto your rack. Adjust the outer rail to the exact depth of the rack by sliding the rear bracket. Then use screws and fasteners to secure the outer rail to the front and rear rack posts.

5.Further tighten the screws holding the rear bracket to the rail.

4

3

2 |

Screw for Outer Rail |

|

Brackets |

4

Figure 2-4. Assembling the Outer Rails

19

Chassis SC743 User's Manual

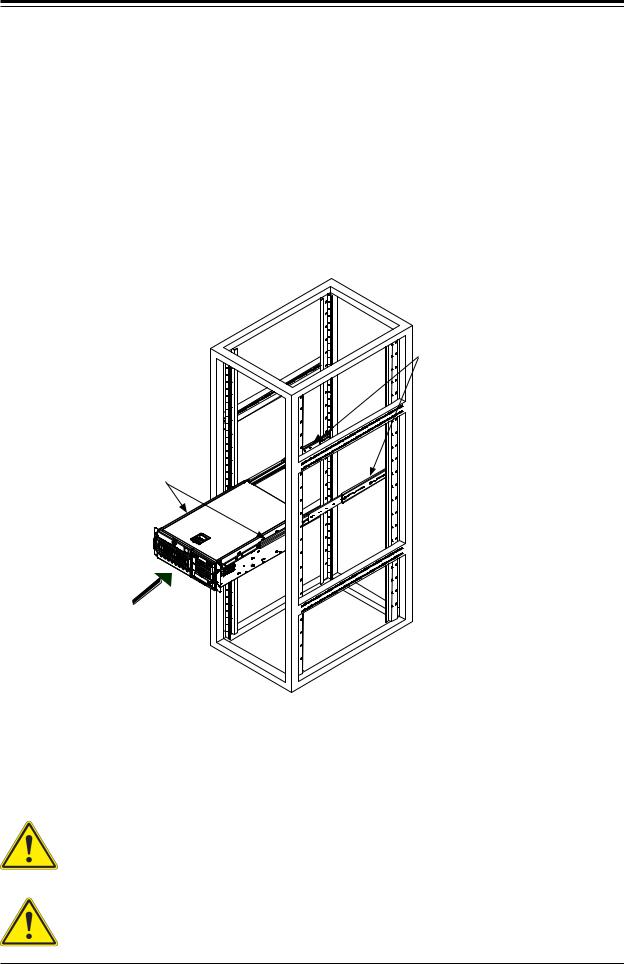

2.5 Installing the Server into the Rack

After attaching rails to both the chassis and the rack, slide the server into the rack.

1.Pull the middle rail out of the front of the outer rail and make sure that the ball bearing shuttle is locked at the front of the middle rail.

2.Align the rear of the inner (chassis) rails with the front of the outer (rack) rails and slide the inner rails into the outer rails until the server is completely in the rack.

3.Insert and tighten the thumbscrews that hold the front of the server to the rack.

Outer Rail

Assemblies

Inner Rails

Figure 2-5. Installing the Server into a Rack

Note: Figure is for illustrative purposes only.Always install servers to the bottom of a rack first.

Warning: Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack to tip over.

When initially installing the server to a rack, test that the rail locking tabs engage to prevent the server from being overextended. Have a rack lift in place as a precaution in case the test fails.

20

Chapter 2 Rack Mount Installation

Removing the Chassis from the Rack

Caution! It is dangerous for a single person to off-load the heavy chassis from the rack without assistance. Be sure to have sufficient assistance supporting the chassis when removing it from the rack. Use a lift.

1.Pull the chassis forward out the front of the rack until it stops.

2.Find the release lever on each side of the chassis on the inner rails. Release the chassis by simultaneously and lifting the left lever and pushing down the right lever. Continue to pull the chassis out of the rack.

Warning: In any instance of pulling the system from the rack, always use a rack lift and follow all associated safety precautions.

Slide rail mounted equipment is not to be used as a shelf or a work space.

Slide rail mounted equipment is not to be used as a shelf or a work space.

21

Chassis SC743 User's Manual

2.6 Control Panel Orientation

The server can be configured for either tower or server rack orientation. It is shipped in tower mode and can be immediately used as desktop server. To use it in a rack, rotate the module that contains the control panel and the three drive trays ( 1 in Figure 2-6) 90 degrees.

Note that two of the 5.25" drives may be replaced by a mobile rack containing eight 2.5" storage drives.

Control Panel |

|

5.25" Drive Trays |

1 |

|

Control Panel/

Drive Module

Default Hard

Disk Drive Bays

Figure 2-6. Chassis in Tower Mode (Default Configuration)

Control Panel/

Drive Module

1

Figure 2-7. Chassis in Rack Mount Mode

22

Chapter 2 Rack Mount Installation

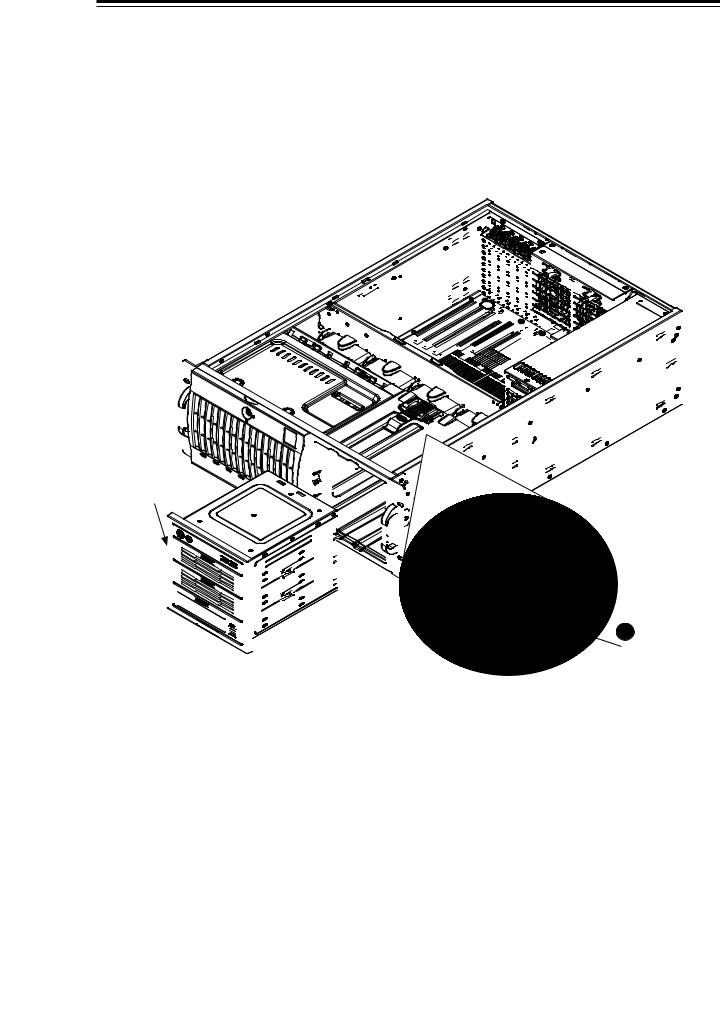

Rotating the Control Panel/Drive Module for Rack Mounting

1.Power down the system as described in section 3.1 and open the chassis cover.

2.Disconnect any cables from the back of the Control Panel/Drive Module.

3.Push the module release lever to unlock the module.

Control Panel/

Drive Module

in Rack Mount

Orientation

3

Module Release Lever

Figure 2-8. Rotating the Control Panel/Drive Module

4.Grasp the edges of the module and pull it from the chassis.

5.Rotate the module 90 degrees so that the control panel is on top.

6.Reinsert the module into the chassis and reconnect the cables.

Caution: Use caution when working around the backplane. Do not touch the module backplane with any metal objects and make sure no ribbon cables touch the backplane or obstruct the holes, which aid in proper airflow.

23

Chassis SC743 User's Manual

Chapter 3

Maintenance and Component Installation

This chapter provides instructions on installing and replacing main system components. To assure compatibility, only use components that match the specifications or part numbers given.

Installation or replacement of most components require that power first be removed from the system.

3.1 Removing Power

Use the following procedure to ensure that power has been removed from the system. This step is necessary when removing or installing non-hot-swap components.

1.Use the operating system to power down the system.

2.After the system has completely shut down, disconnect both the AC power cords from the power strip or outlet.

3.Disconnect the power cords from both the power supply modules.

24

Chapter 3: Maintenance and Component Installation

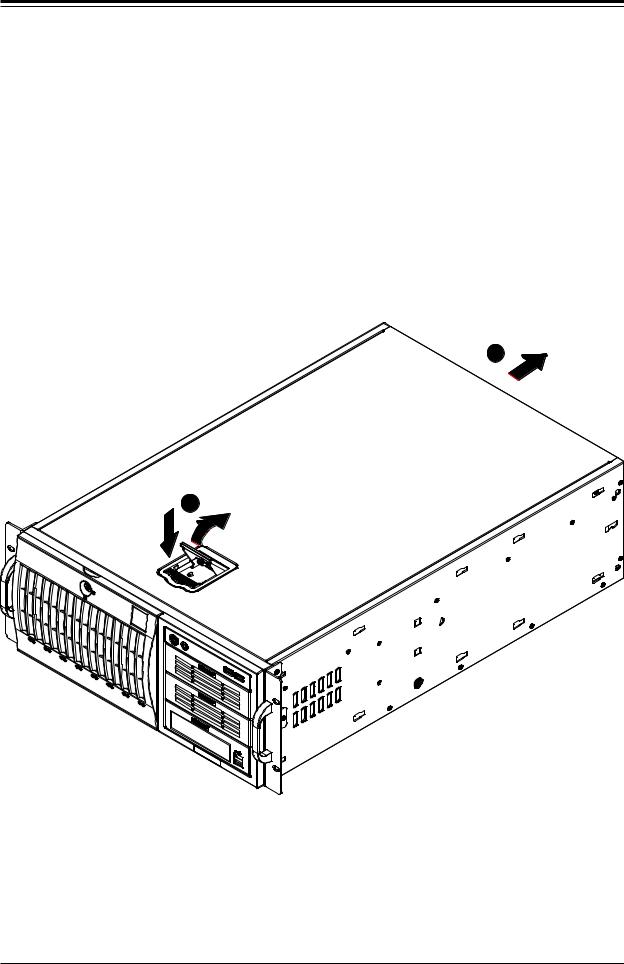

3.2 Accessing the System

The chassis offers a removable side cover (top, if rack mounted) which allows access to the internal components.

Removing the Side Cover

1.Locate the latch on the cover, depress where it says "push," then lift the latch to release the cover.

2.Slide the cover to the rear and off.

12

11

Figure 3-1. Removing the Chassis Cover

25

Loading...

Loading...