Snorkel TB60 User Manual

P/N 0082168

January, 2001

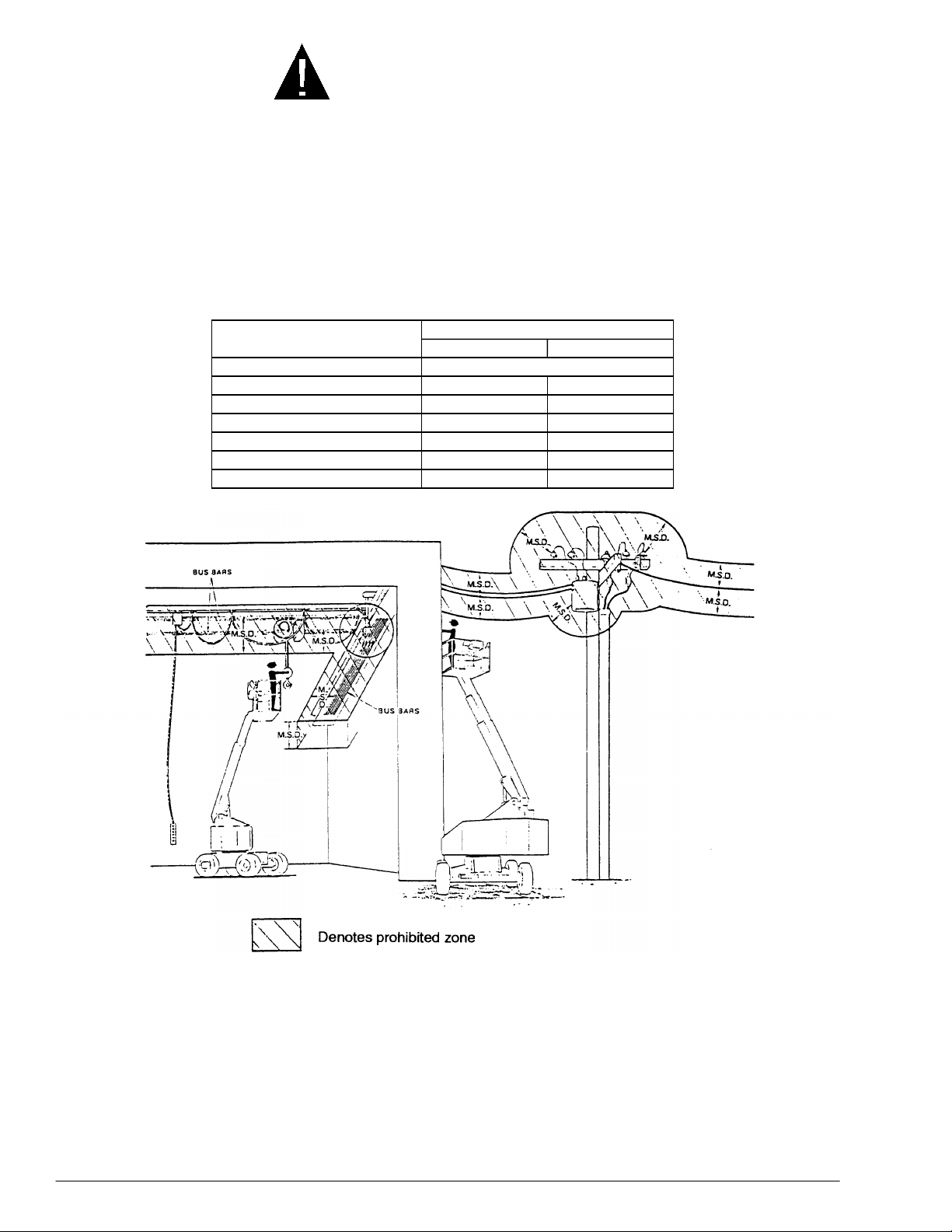

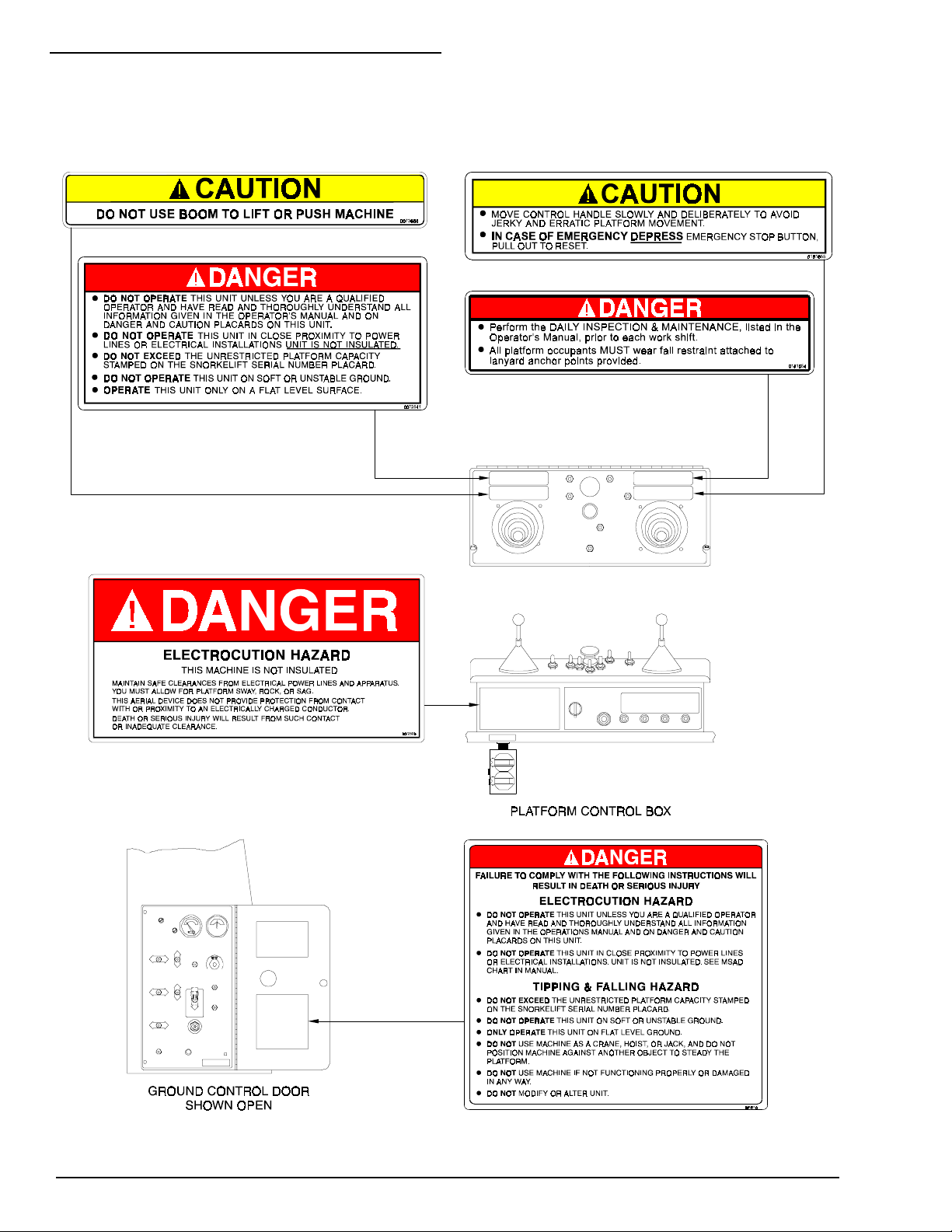

DANGER

ELECTRICAL HAZARD

The TB 60 is an all metal boom, NOT ELECTRICALLY INSULATED, aerial work platform. Do

not operate it near ELECTRICAL conductors. Regard all conductors as being energized. Use

the table and figure below to determine safe clearance from electrical conductors. Table 1 and

Figure 3 are reprinted courtesy of Scaffold Industry Association, ANSI/SIA A92.5, page 23.

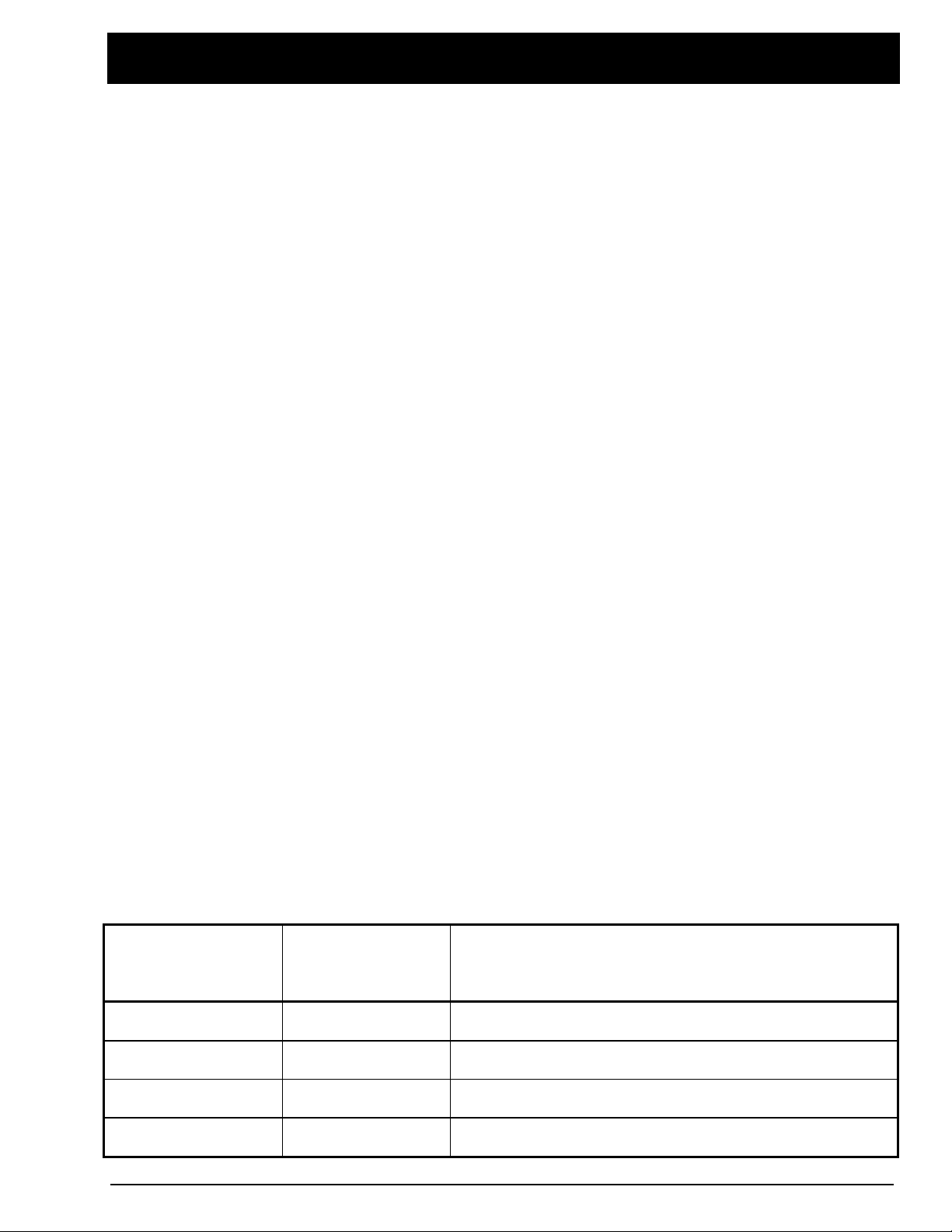

Table 1 - Minimum safe approac h di stance (M.S.A.D.)

to energized (exposed or insulated power lines

Voltage range

(phase to phase)

0 to 300V Avoid contact

Over 300V to 50KV 10 3.05

Over 50KV to 200KV 15 4.60

Over 200KV to 350KV 20 6.10

Over 350KV to 500KV 25 7.62

Over 500KV to 750KV 35 10.67

Over 750KV to 1000KV 45 13.72

Minimum safe approach di stance

(Feet) (Meters)

Danger: - Do not allow machine personnel or conductive

materials inside prohibited zone.

- Maintain M.S.A.D. from all energized lines and parts

as well as those shown.

- Assume all electrical parts and wires are energized

unless known otherwise.

Caution: - Diagrams shown are only for purposes of illustrating

M.S.A.D. work positions, not all work positions.

Figure 3 - Minimum Safe Approach Distance (M.S.A.D.)

P/N 0082168

DANGER

ELECTRICAL HAZARD

THE TB 60 AERIAL WORK PLATFORM IS NOT

ELECTRICALLY INSULATED.

If the platform, booms, or any other conductive part of a TB 60 contacts a highvoltage electrical conductor, the result can be

persons on or near the machine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH

DISTANCES ON THE OPPOSITE PAGE.

Be sure to allow for sag and sway in the wires and the work platform.

If a TB 60 comes in contact with a live electrical conductor, the entire machine

can be charged. If that happens, you should remain on the machine and not

contact any other structure or object within reach. That includes the ground,

adjacent buildings, poles, and any object not a part of the TB 60. Such contact

could make your body a conductor to the other object creating an electrical

shock hazard resulting in

or leave the TB 60 until you are sure the electricity has been turned off.

SERIOUS INJURY

SERIOUS INJURY

DEATH

or

. Do not attempt to enter

or

DEATH

for

If a TB 60 is in contact with a live conductor, the platform operator

others on the ground in the vicinity of the TB 60 to

machine, since their bodies can also form a path for electricity to ground thus

creating an electrical shock hazard with possible

DEATH

Do not attempt to operate the TB 60 ground controls when the platform, booms,

or any other conducting part of a TB 60 is in contact with electrical wires or if

there is an immediate danger of such contact.

Regard all conductors as energized.

Personnel working on or near a TB 60 must be continuously aware of electrical

hazards, recognizing that

an electrical wire does occur.

.

SERIOUS INJURY

or

STAY AWAY

ELECTROCUTION

DEATH

can result if contact with

MUST

from the

and

warn

P/N 0082168

i

TABLE OF CONTENTS

INTRODUCTION.................................................................iii

SIGNS...........................................................................iii

QUALIFIED OPERATORS............................................iii

MAINTENANCE............................................................iii

RESPONSIBILITIES OF PARTIES.............................. iv

ADDITIONAL INFORMATION...................................... iv

1. SAFETY ......................................................................1 - 1

SAFE OPERATION...................................................1 - 1

Pre-start Inspection.................................................1 - 1

Work Place Inspection and Practices.....................1 - 1

Electrocution...........................................................1 - 2

Tipover & Falling Hazards.......................................1 - 2

Crushing .................................................................1 - 2

GENERAL SAFETY PRECAUTIONS........................1 - 2

Personnel Precautions............................................1 - 2

Operator General Precautions................................1 - 2

Mounting & Dismounting Precautions.....................1 - 3

Starting and Stopping Precautions.........................1 - 3

Operating Precautions............................................1 - 3

Operator Maintenance Precautions........................1 - 3

Fuel Handling Precautions......................................1 - 3

SAFETY DECALS & PLACARDS..............................1 - 3

2. SAFETY DEVICES......................................................2 - 1

TILT ALARM & LEVEL SENSOR...............................2 - 1

EMERGENCY STOP SWITCHES.............................2 - 1

LANYARD ANCHOR POINTS...................................2 - 2

GRAVITY GATE........................................................2 - 2

FOOT SWITCH..........................................................2 - 2

GROUND OPERATION SWITCH..............................2 - 3

SELF-CLOSING GATE (option).................................2 - 3

OPERATOR HORN (option)......................................2 - 3

FLASHING LIGHT (option)........................................2 - 3

PLATFORM WORK LIGHTS (option)........................2 - 4

DRIVING LIGHTS (option).........................................2 - 4

MOTION WARNING ALARM (option)........................ 2 - 4

GFCI OUTLET (option)..............................................2 - 4

GUARDRAILS (option) ..............................................2 - 4

3. SPECIFICATIONS ......................................................3 - 1

GENERAL SPECIFICATIONS...................................3 - 1

PLATFORM SPECIFICATIONS.................................3 - 1

ENGINE DATA...........................................................3 - 2

ENGINE OIL CHARTS...............................................3 - 2

OVERALL DIMENSIONS...........................................3 - 3

WORKING ENVELOPE.............................................3 - 4

SERIAL NUMBER LOCATIONS................................3 - 5

CHASSIS NOMENCLATURE....................................3 - 5

TURNTABLE AND BOOM NOMENCLATURE..........3 - 5

4. GAUGES & CIRCUIT BREAKERS.............................4 - 1

GAUGES ...................................................................4 - 1

FILTER MINDER.....................................................4 - 1

TEMPERATURE.....................................................4 - 1

AMPS......................................................................4 - 1

HOURS...................................................................4 - 1

Fuel.........................................................................4 - 2

Hydraulic Oil Level..................................................4 - 2

Hydraulic Oil Temperature......................................4 - 2

Hydraulic Oil Filter ..................................................4 - 3

Engine Oil...............................................................4 - 3

CIRCUIT BREAKERS................................................4 - 4

5. SIRENS & AUTOMATIC SHUT-OFFS........................5 - 1

SIRENS .....................................................................5 - 1

AUTOMATIC SHUT-OFFS........................................5 - 1

6. CONTROLS................................................................ 6 - 1

GROUND-CONTROL PANEL...................................6 - 2

PLATFORM-CONTROL BOX....................................6 - 4

7. OPERATION...............................................................7 - 1

CONTROL STATIONS..............................................7 - 1

STARTING FROM THE GROUND-

CONTROL PANEL....................................................7 - 1

Pre-start Conditions................................................ 7 - 1

Starting (from the ground) ...................................... 7 - 2

STARTING FROM THE PLATFORM-

CONTROL BOX.........................................................7 - 3

Pre-start Conditions................................................ 7 - 3

Starting (from the platform).....................................7 - 4

MOVING THE PLATFORM........................................7 - 5

MOVING THE TB 60.................................................7 - 8

STEERING................................................................7 - 8

125 V AC OUTLET AT THE PLATFORM..................7 - 9

8. EMERGENCY OPERATION.......................................8 - 1

EMERGENCY STOP.................................................8 - 1

EMERGENCY POWER.............................................8 - 1

Used from ground-control panel.............................8 - 1

Used from platform-control box..............................8 - 2

EMERGENCY BLEED-DOWN..................................8 - 3

9. STOWING & TRANSPORTING..................................9 - 1

STOWING .................................................................9 - 1

TRANSPORTING......................................................9 - 1

Trailering.................................................................9 - 1

Securing to a Transport Vehicle.............................9 - 2

Towing....................................................................9 - 4

10. DAILY INSPECTION & MAINTENANCE................10 - 1

DAILY INSPECTION AND MAINTENANCE.........10 - 1

PLACARDS AND DECALS INSPECTION CHART...10 - 10

PLACARDS AND DECALS INSPECTION DWG........10 - 11

11. TROUBLESHOOTING............................................ 11 - 1

12. OPTIONS................................................................12 - 1

OPERATOR HORN..............................................12 - 1

PLATFORM WORK LIGHTS................................12 - 1

DRIVING LIGHTS.................................................12 - 1

COLD WEATHER START KIT .............................12 - 2

Deutz Engine.....................................................12 - 2

Ford Engine.......................................................12 - 2

HYDRAULIC SYSTEM COLD WEATHER

WARM-UP KIT .....................................................12 - 2

AC GENERATOR.................................................12 - 3

MOTION WARNING ALARM................................12 - 3

AIR LINE TO PLATFORM....................................12 - 3

GFCI OUTLET......................................................12 - 4

FLASHING LIGHT................................................12 - 4

SELF-CLOSING GATE.........................................12 - 4

SPARK ARRESTOR.............................................12 - 4

LIFTING LUGS.....................................................12 - 5

TOW KIT...............................................................12 - 5

13. FIRE FIGHTING & HAZARDOUS

CHEMICAL CONTAINMENT..................................13 - 1

ANTIFREEZE (UN 1993)...................................... 13 - 1

BATTERY, LEAD/ACID (UN 2794).......................13 - 1

DIESEL FUEL (NA 1993) .....................................13 - 1

FOAM IN TIRES...................................................13 - 1

GASOLINE (UN 1203)..........................................13 - 2

HYDRAULIC OIL (UN 1270).................................13 - 2

LIQUEFIED PETROLEUM GAS (UN 1075)..........13 - 2

MOTOR OIL (UN 1270)........................................13 - 2

INDEX..............................................................................I - 1

WARRANTY ..........................................(inside back cover)

ii

P/N 0082168

INTRODUCTION

INTRODUCTION

The most important chapter in t his manual is

“1. SAFETY.” Take time, now, to study it

closely. The information in that chapt er m ight

save your life or prevent serious injury.

SIGNS

The following two conventions are used

throughout this manual.

1. This sign

DANGER

means:

is involved

2. This sign

Attention! Become alert! Your safety

.

CAUTION

means one of two things: (1) an act ion, about t o

be performed, is potentially hazardous and

might result in minor per sonal inj ur y if not done

correctly, or (2) an action, about to be

performed, can damage the TB 60 if not done

correctly.

QUALIFIED OPERATORS

The TB 60 aerial platfor m has built-in safety

features and has been factory tested for

compliance with Snorkel specifications and

industry standards. However, any personnellifting device can be potentially dangerous in

the hands of untrained or careless operat or s.

The following rules will help ensure the

safety of personnel and help prevent

needless downtime because of damaged

equipment.

1. Only TRAINED and AUTHORIZED operators

shall be permitted to operate the eq uipm ent .

2. All manufacturer’s operating instructions and

safety rules and all employers’ safety rules and

all OSHA and other government safety rules

must be strictly adhered to.

3. Repairs and adjustments shall be made only

by QUALIFIED TRAINED maintenance

personnel.

4. No modification shall be made to the

equipment without prior written consent of

Snorkel.

5. You must make a pre-star t inspection of the

TB 60 at the beginning of each shift. A

malfunctioning machine must not be used.

6. You must make an inspection of the work

place to locate possible hazards before

operating the TB 60.

DANGER

Misuse of this machine can result in DEATH

or SERIOUS INJURY.

Do not operate this equipment unless you

are TRAINED and AUTHORIZED and have

read and thoroughly understand all

information given in this Operator’s Manual

and on all DANGER and CAUTION signs on

the machine.

Training is essential and must be performed by

a QUALIFIED person. Become proficient in

knowledge and actual operation before using

the TB 60 on the job. You must be tr ained and

authorized to perform any funct ions of the TB

60. Operation of the T B 60 m ust be within the

scope of the machine specifications.

Before operating the TB 60 you must read and

understand the operating instruct ions in this

manual as well as the decals, warnings, and

instructions on the machine itself.

Before operating the TB 60 you must be

AUTHORIZED by the person in charge to

do so.

P/N 0082168

MAINTENANCE

Every person who maintains, inspects, tests, or

repairs these machines, and every person

supervising any of these functions, must be

properly trained.

This Operator’s Manual provides a daily

inspection procedure that will help you keep

your TB 60 in good operating condition. Do not

perform other maint enance unless you are a

TRAINED mechanic, QUALIFIED t o work on

the TB 60. Call QUALIFIED maint enance

personnel if you find problems or malfunctions.

iii

INTRODUCTION

Information contained in this manual concerns

only current TB 60’s, and the right is reserved

to make changes at any time without obligation.

RESPONSIBILITIES OF PARTIES

It is imperative that all owners and users of the

TB 60 read, understand, and confor m to all

applicable regulations. Ultimate com pliance to

OSHA regulations is the responsibility of the

employer using the equipment.

ANSI Standard A92.5 identifies r equirements of

all parties who might be involved with BoomSupported Elevating Work Platfor m s .

ADDITIONAL INFORMATION

For additional information, contact your local

dealer, or write:

Snorkel International, I nc.

P.O. Box 1160

St. Joseph, MO 64502-1160 USA

816-364-0317

http://www.snorkelusa.com

A reprint of the

Dealers, Owners, Users, O per at ors, Lessors

and Lessees of ANSI/SIA A92.5-1992 BoomSupported Elevating Work Platf o r m s”

available from Snorkel dealers or from the

factory upon request.

Copies are also available from:

Scaffold Industry Association

20335 Ventura Blvd. Suite 310

Woodland Hills, CA 91364- 2471 USA

“Manual of Responsibilities for

is

iv

P/N 0082168

1. SAFETY

1. SAFETY

SAFE OPERATION

The following safety inf o r m a t ion is vitally

important for safe operation of the TB 60. Failure

to follow these instructions can result in personal

injury or DEATH.

Pre-start Inspection

Prior to each shift, t he TB 60 shall be given a

visual inspection and function test. See the

“DAILY INSPECTION & MAINT ENANCE”

chapter in this manual for a list of items to

inspect and test.

Do not operate the TB 60 unless you are trained

and authorized, understand the operation

characteristics of the TB 60, and have inspected

and tested all functions to be sure they are in

proper working order. See the “DAI LY

INSPECTION & MAINTENANCE” chapter.

Work Place Inspection and Practices

Do not use the TB 60 as a ground for welding.

Ground to the work piece.

Before the TB 60 is used, and during use, check

the area in which the TB 60 is to be used for

possible hazards such as, but not limited to:

• drop-offs or holes,

• side slopes,

• bumps and floor obstructions,

• debris,

• overhead obstructions and electrical

conductors,

• hazardous locations,

• inadequate surface and support to withstand

all load forces imposed by the aerial platform

in all operating configur at ions,

• wind and weather conditions,

• presence of unauthorized persons,

• other possible unsafe conditions.

Before using the aerial plat form in any hazardous

(classified) location, make cer tain it is approved

and of the type required by ANSI/ NFPA 505 for

use in that particular location.

A recommended safety practice is to have

personnel that are trained in the operation of the

emergency controls working in the imm ediat e

area of the TB 60 to assist the platform operator

in the event of an emergency.

When moving the platform, check the clear ance

around the TB 60 to avoid contact with structures

or other hazards. Always look in the direction of

motion.

Keep ground personnel from under t he platform

when the platform is raised.

Secure all accessories, containers, tools, and

other materials in the platform to prevent them

from accidentally falling or being kicked off the

platform.

Do not engage in any form of “horseplay” or

“stunt driving” while operating the TB 60.

Do not permit riders on the machine anyplace

other than on the platform .

Remove all loose objects stored in or on the

machine, particularly in the platfo r m . Rem o ve all

objects which do not belong in or on the

machine.

When other moving equipment is in the area,

take special precautions to comply with local

regulations regarding warnings.

Never steady the platform by positioning it

against another platfor m .

Do not operate a TB 60 that is not functioning

properly, or has been damaged, until the

machine has been repaired by a qualified

maintenance person.

Do not operate a TB 60 that does not have all its

decals and placards attached and legible.

Drive the machine with care and at speeds

compatible with conditions. Use extra caution

when driving over rough ground, on slopes, and

when turning.

Know and understand the job site traffic-flow

patterns and obey the flagmen, r oad signs, and

signals.

P/N 0082168

Watch for bystanders and never allow anyone to

be under, or to reach through, the machine and

its equipment while operating.

1 - 1

1. SAFETY

Electrocution

The TB 60 is an all-metal boom, NO NINSULATED, aerial work-platform. Do not

operate it near ELECTRICAL conductors.

Regard all conductors as being energized.

Do not operate outside during a thunderst or m.

Tipover & Falling Hazards

Do not operate a TB 60 from a posit ion on

trucks, trailers, railway cars, floating vessels,

scaffolds, or similar equipment unless the

application is approved in writing by Snorkel.

If the platfor m or elevating assembly becomes

caught, snagged, or otherwise prevented from

normal motion by an adjacent structure or other

obstacles such that control reversal does not f r ee

the platform, r em o ve all personnel from the

platform before attempts are made to fr ee the

platform using gr ound controls.

It is best not to transf er from the platform to

another structure or from t he st r uct ur e to the

platform, unless that is t he safest way to do the

job. Judge each situation separately tak ing the

work environment into account. If it is necessary

to transfer from the platform to anot her structure

the following guidelines apply:

• Where possible, place t he work plat form over

a roof or walking structur e to do the transfer.

• Transfer your anchorage from one structure to

another before you step across.

Care shall be taken to prevent rope, elect r ic

cords, and hoses, etc., fr om becoming entangled

in the aerial platform.

Raise the platform only when the TB 60 is on

level ground.

Maintain a firm footing on t he platform floor.

Climbing on the guard rails is pr ohibit ed.

Do not use ladders, planks, or other devices to

extend or increase your work position from the

platform.

Do not jerk the controls. Move the controls slowly

and deliberately to avoid jerky and erratic

operation. Always stop the controls in the neutral,

off, position before going in the opposite

direction.

Do not use the boom for any purpose other than

to position personnel, their tools, and materials.

Do not use the TB 60 as a crane, hoist, or j ack.

Do not operate the TB 60 in winds, or wind

gusts, of 28 mph (45 km/hr) or more.

Do not add anything to the TB 60 that will

increase the wind loading (billboards, banners,

flags, etc).

Crushing

Always look in the direction of travel. Avoid

overhead obstructions.

Never cover the floor grating or ot her wise

obstruct your view below.

• Remember that you might be transferring to a

structure where

required.

• Use the platform entrance, do not climb over

the guardrails.

All platform occupants MUST wear a fall r estraint

device connected to a lanyard anchor point.

Do not exceed the unrestricted platfor m capacit y

as indicated on the capacity placards at the

platform and ground-control panel.

Do not raise the boom if the T B 60 is on soft

ground. Operate the boom only on a f ir m sur face

capable of withstanding all load forces imposed

by the aerial platform in all operat ing conditions.

Do not carry loads from any point outside of t he

platform.

1 - 2

personal fall arrest

is

Make sure the area below the platform is f r ee of

personnel before lowering.

GENERAL SAFETY PRECAUTIONS

Personnel Precautions

If you encounter any suspected malfunction of

the aerial platform, or any hazard or pot entially

unsafe condition relating to capacity, int ended

use, or safe operation, cease operat ion and seek

assistance from management.

Operator General Precautions

Make sure that all protective guards, cowlings,

and doors are in place and secure.

Be sure the guardrail system, including t he gate,

is in place and secure.

P/N 0082168

1. SAFETY

Mounting & Dismounting Precautions

Use three points of support when gett ing on or

off the platf orm (two hands and one foot or a

similar set of points). Keep t he plat form clean.

Do not jump off t he m achine.

Do not dismount while the machine is in motion.

Starting and Stopping Precautions

Do not start until all personnel are clearly away

from the machine.

Before leaving the operator’s stat ion, place the

machine in the stowed position.

When leaving the m achine par ked or

unattended, remove the starter key from the

MASTER key switch, set the BATTERY switch to

OFF, then lock the BATTERY switch closed.

Operating Precautions

Do not modify the TB 60 in any way.

When parts or com ponents are replaced, they

shall be identical or equivalent to original Snor kel

parts or components.

Do not override any of the safety feat ur es of the

TB 60.

Limit travel speeds according to conditions. Take

into account: grade, surface, congestion,

visibility, side slope, location of personnel, and

other hazards.

Operator Maintenance Precautions

Do not use your hand to search for hydraulic oil

leaks. High pressure hydraulic oil can easily cut

and penetrate your skin — a very serious injury

that requires immediate at t ention by a medical

specialist trained in that type of injur y. Use a

piece of cardboard or wood to search for

hydraulic oil leaks.

Do not attempt repairs unless you are trained.

Refer to manuals and experienced repair

personnel for help.

Charge batteries in a well-ventilated area free of

flame, sparks, or ot her hazards t hat might cause

fire or explosion.

Use extreme caution when removing radiator

caps. Park the machine and let it cool down

before opening a pressurized compartment.

Fuel Handling Precautions

Do not smoke or permit open f lam es while

fueling or near f ueling operations.

Never remove the fuel cap or refuel a g asoline

engine while the engine is running or hot. Never

allow fuel to spill on hot machine components.

Maintain control of the fuel filler nozzle when

filling the tank.

Do not fill the fuel tank to capacity. Allow room

for expansion.

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely. If the fuel cap

is lost, replace it with an approved cap from

Snorkel. Use of a non-approved cap without

proper venting may result in pressurization of the

tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for

the operating season.

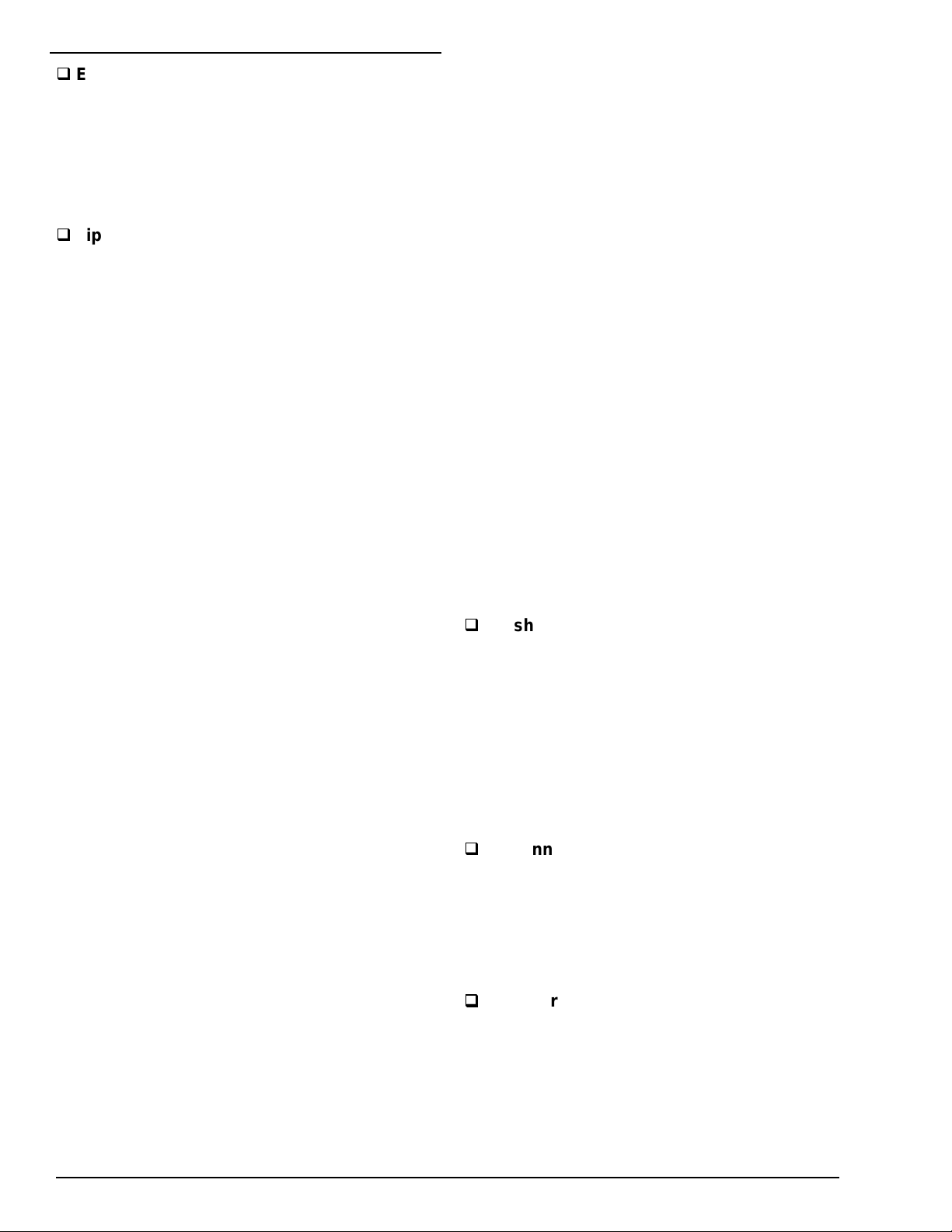

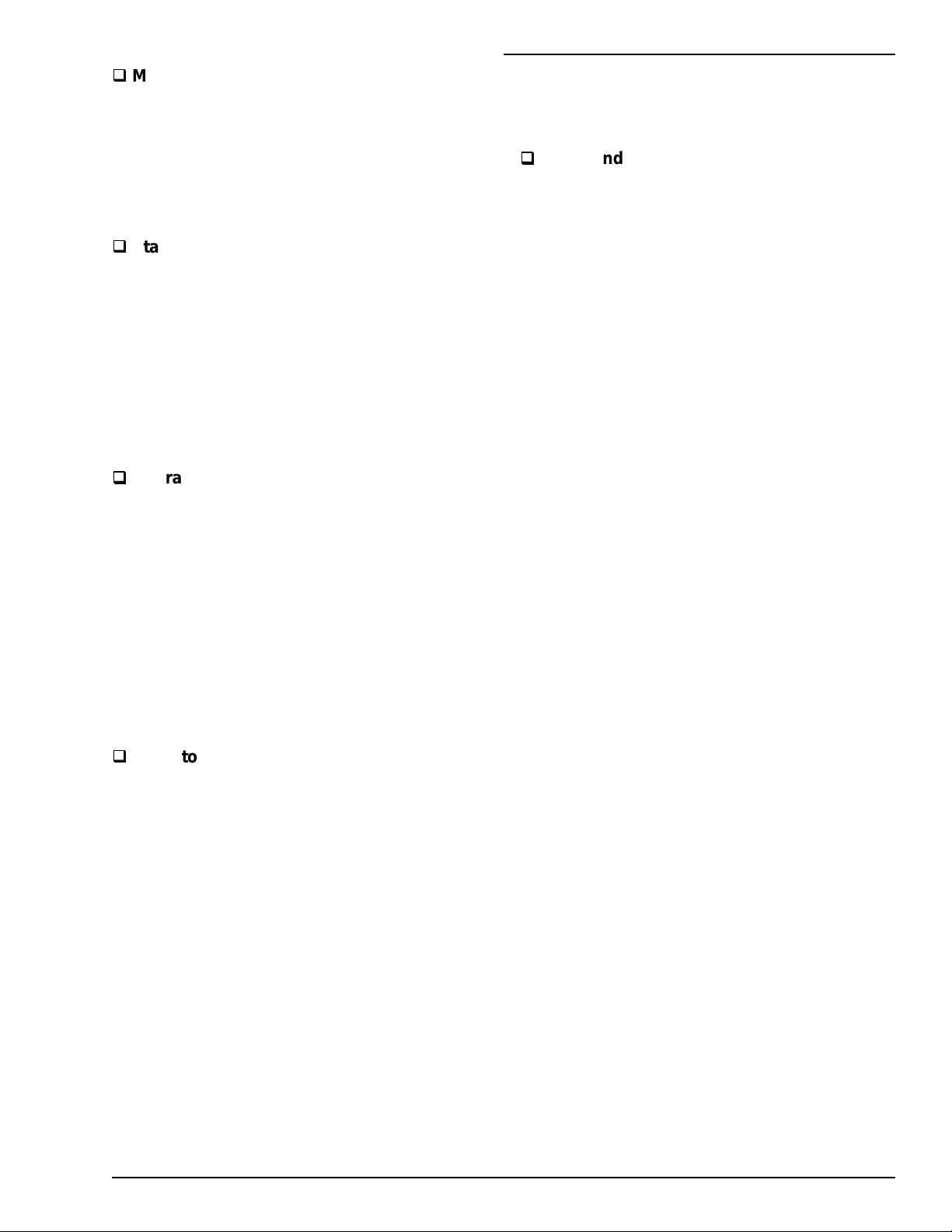

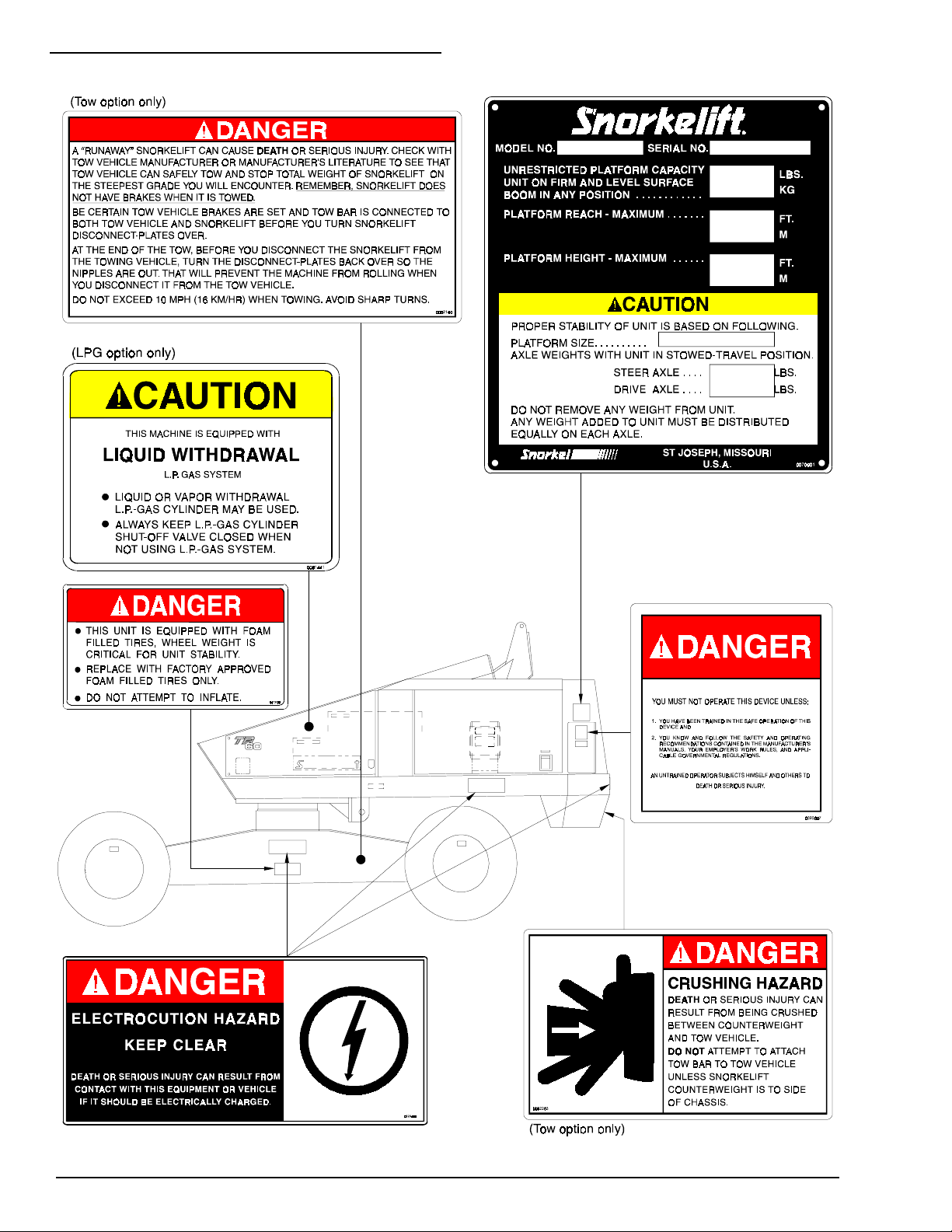

SAFETY DECALS & PLACARDS

There are several safety decals and placards on

the TB 60. Their locations and descriptions are

shown in this section. Take time to study them.

Be sure that all the safety decals and placards

on the TB 60 are legible. Clean or replace them if

you cannot read the words or see the pictures.

Clean with soap & water and a soft cloth. Do not

use solvents.

You must replace a decal or placard if it is

damaged, missing, or cannot be r ead. If it is on a

part that is replaced, make sur e a new decal or

placard is installed on the replaced part. See

your Snorkel dealer for new decals and placards.

Refer to PLACARDS AND DECALS

INSPECTION CHART and DRAWING in t he

“DAILY INSPECTION AND MAINT ENANCE”

chapter for part number s, locat ion, and r equired

quantities of all placards and decals.

P/N 0082168

1 - 3

1. SAFETY

Refer to PLACARDS AND DECALS INSPECTION CHART and DRAWING in the “DAILY

INSPECTION AND MAINTENANCE” chapter for part numbers, locations, and required

quantities of all placards and decals.

1 - 4

P/N 0082168

1. SAFETY

P/N 0082168

1 - 5

1. SAFETY

1 - 6

P/N 0082168

2. SAFETY DEVICES

2. SAFETY DEVICES

For emergency-operation controls and

procedures, see the “EMERGENCY

OPERATION” chapter in t his m anual.

The devices listed in this chapter are safety

devices. They are on a TB 60 to increase safety

in the work place for both the operat or and ot her

people near a TB 60. Do not by-pass, disable,

modify, or ignore any of these devices. Check

them carefully at the start of each work shift to

see that they are in working order (see “DAI LY

INSPECTION & MAINTENANCE” chapter) . I f

any is found to be defective, remove the TB 60

from service immediately until a q ualified service

technician can make repairs.

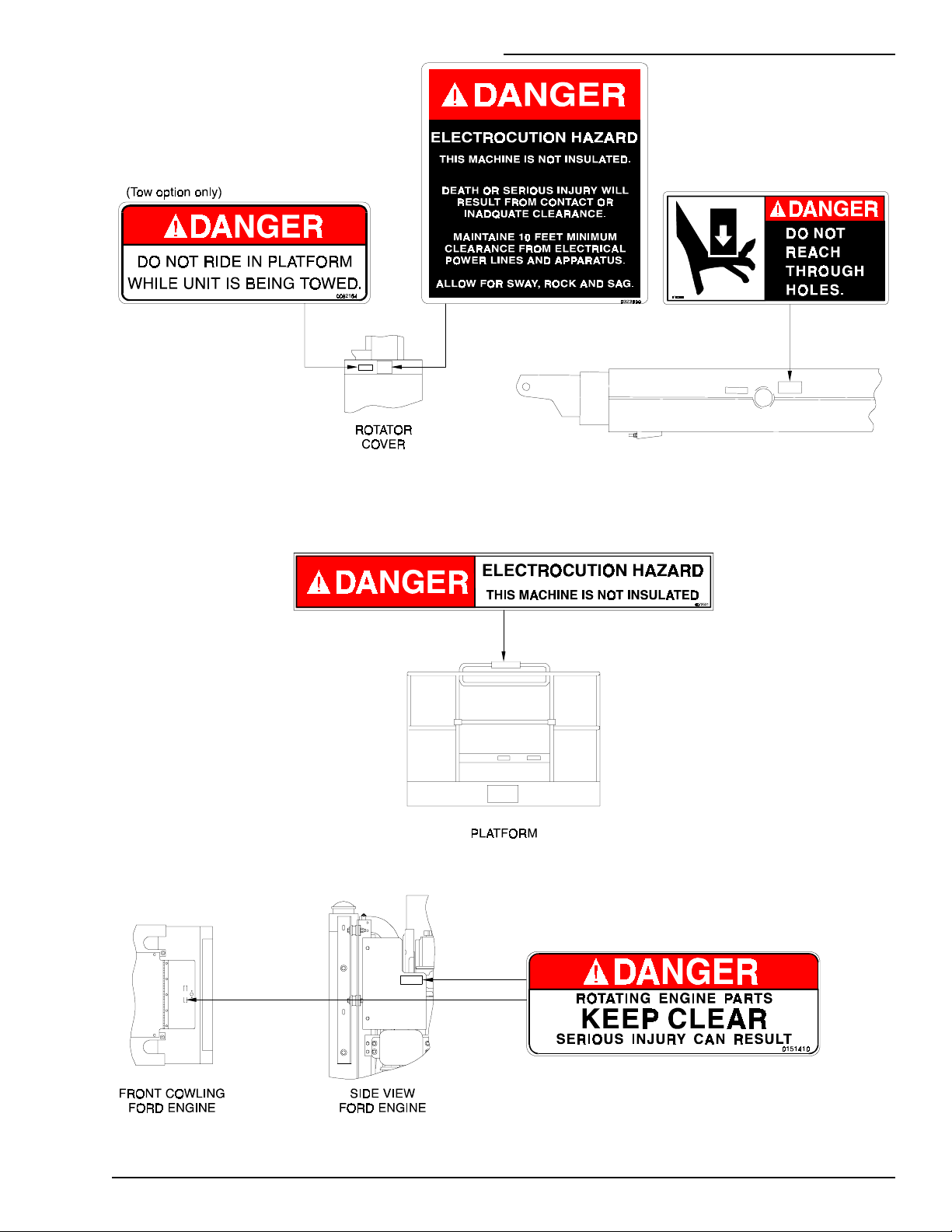

TILT ALARM & LEVEL SENSOR

There are two tilt alarm sirens on a TB 60.

When you are in control of a TB 60 and you hear

its two-toned siren, you should immediately:

1. Stop using the DRIVE controller st ick on

the platform-control box.

2. Completely retract and complet ely lower the

booms.

3. Use the platform-control box DRIVE

controller to move the TB 60 to a level surface

or more firm gr ound before extending or

raising the booms again.

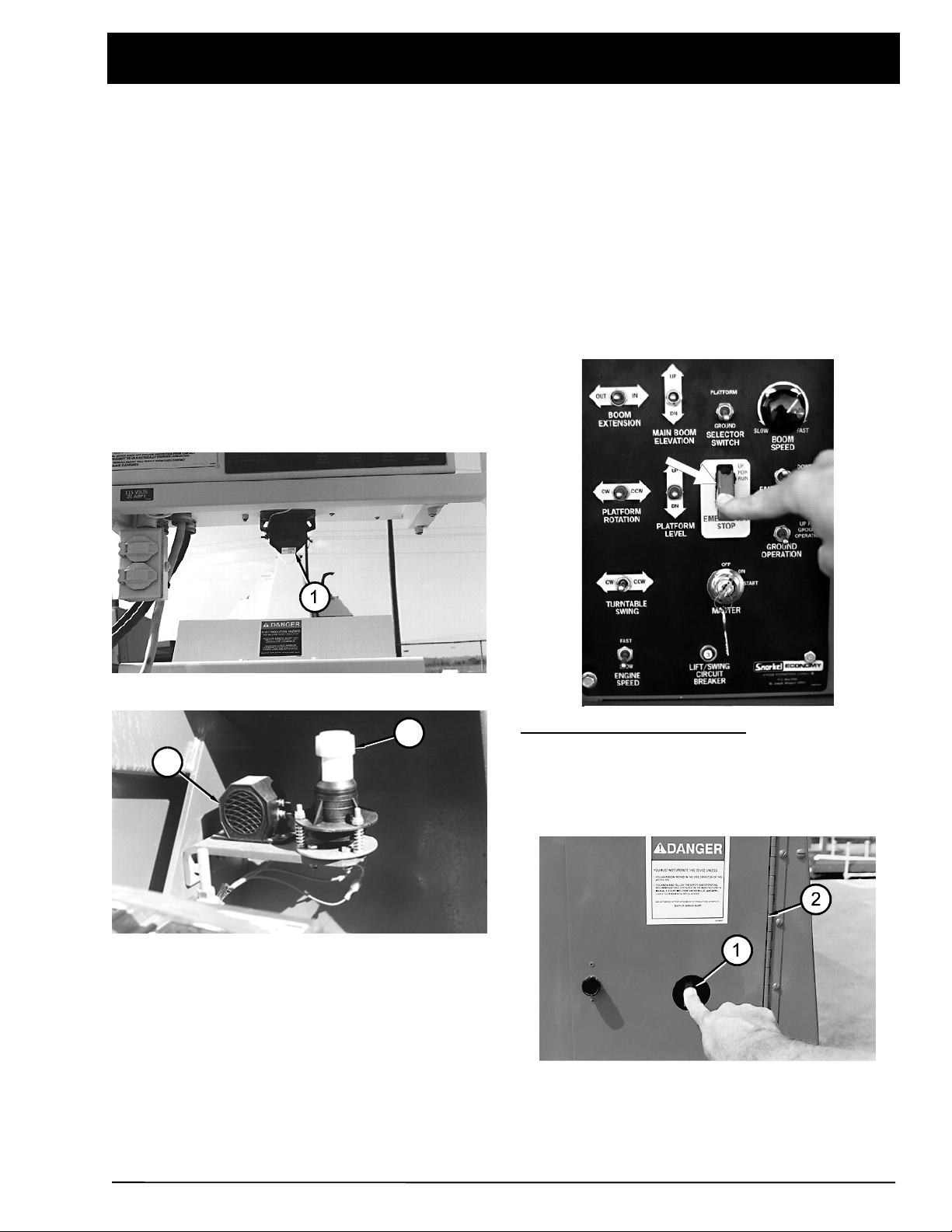

EMERGENCY STOP SWITCHES

One (1) is located under the platform-control box.

3

2

One (2) is located in the turntable next to t he

level sensor (3).

The sirens will both, simultaneously, emit a t wotoned sound (high-low-high-low...) if the TB 60 is

tilted more than 5° and the booms ar e not

completely retracted and completely down. Af t er

the sirens begin to sound, if t he t ilt continues to

increase, the TB 60 can turn over.

At the ground-control panel: Press the red

EMERGENCY STOP cover down, at any time,

under any conditions, and the entire machine

stops, the engine turns of f, the brakes set, and

nothing moves. This switch must be up for

anything on the TB 60 to work.

The ground-control panel EMERG ENCY STOP

switch (1) can also be used with the door (2)

closed.

P/N 0082168

2 - 1

2. SAFETY DEVICES

At the platform-control box: Press the large

red EMERGENCY STOP button down and the

entire machine stops, the engine tur ns off, the

brakes set, and nothing moves. This switch must

be pulled to its up (or out) position t o cont rol the

TB 60 from the platform.

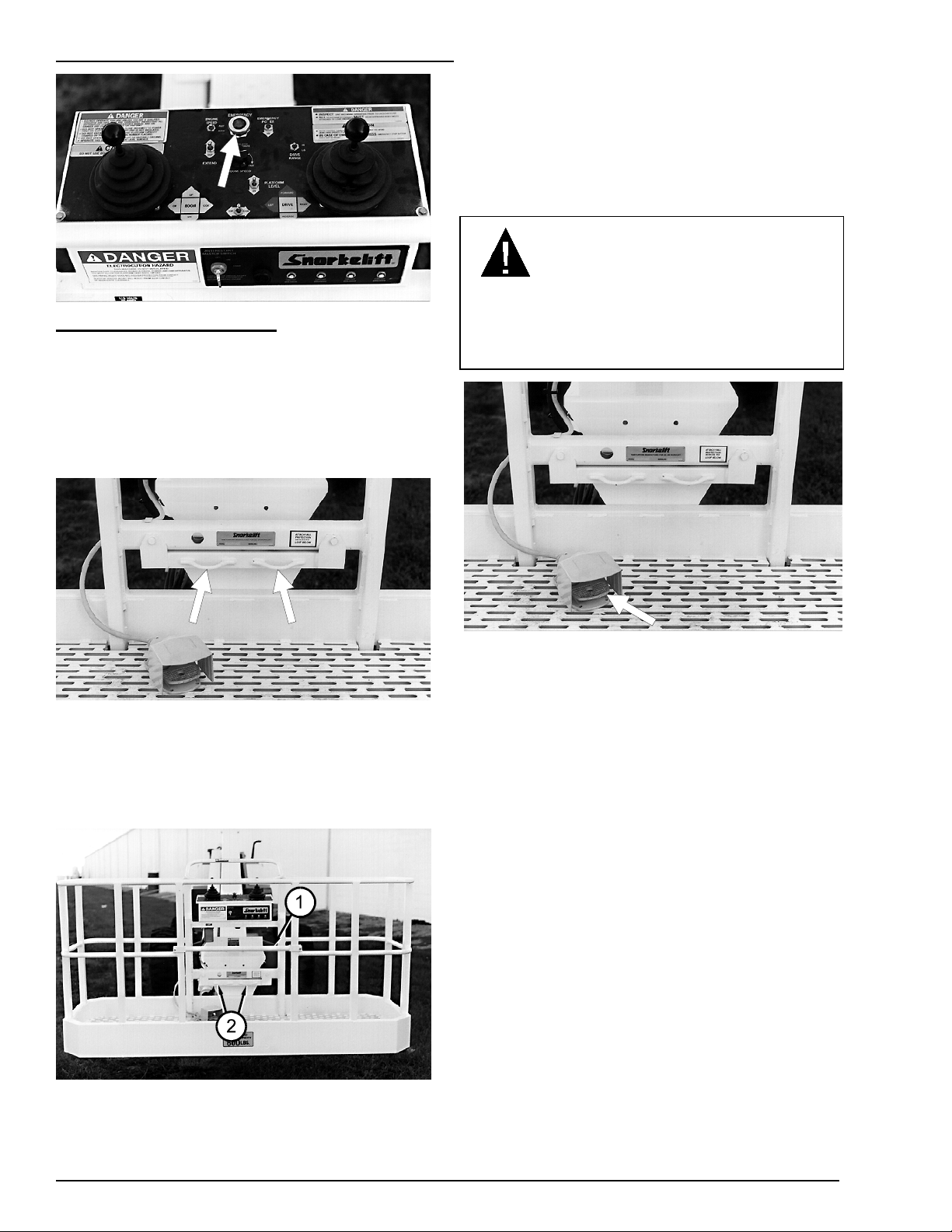

LANYARD ANCHOR POINTS

leave the platform. Raise the gate and step

under it onto the platform . Once you have

entered the platform and at tached your fall

restraint lanyard to an anchor point (2), check to

see that the gravity gate (1) has fallen back into

place.

FOOT SWITCH

DANGER

Serious injury can result from sudden stops.

To avoid sudden stops, do not remove your

foot from the foot switch while t he TB 60 is in

motion.

All personnel on the platform should att ach t heir

fall restraint lanyards to one of the lanyard

anchor points.

GRAVITY GATE

The gravity gate (1) is the place in the platform

guardrail system where you should enter and

The foot switch prevents the platf or m from

moving if something accidentally pushes one of

the platform-moving controls on the platformcontrol box. (Stepping on the foot switch is an

action that must be performed, at the same time

as another action, to make the plat form move.)

2 - 2

P/N 0082168

GROUND OPERATION SWITCH

2. SAFETY DEVICES

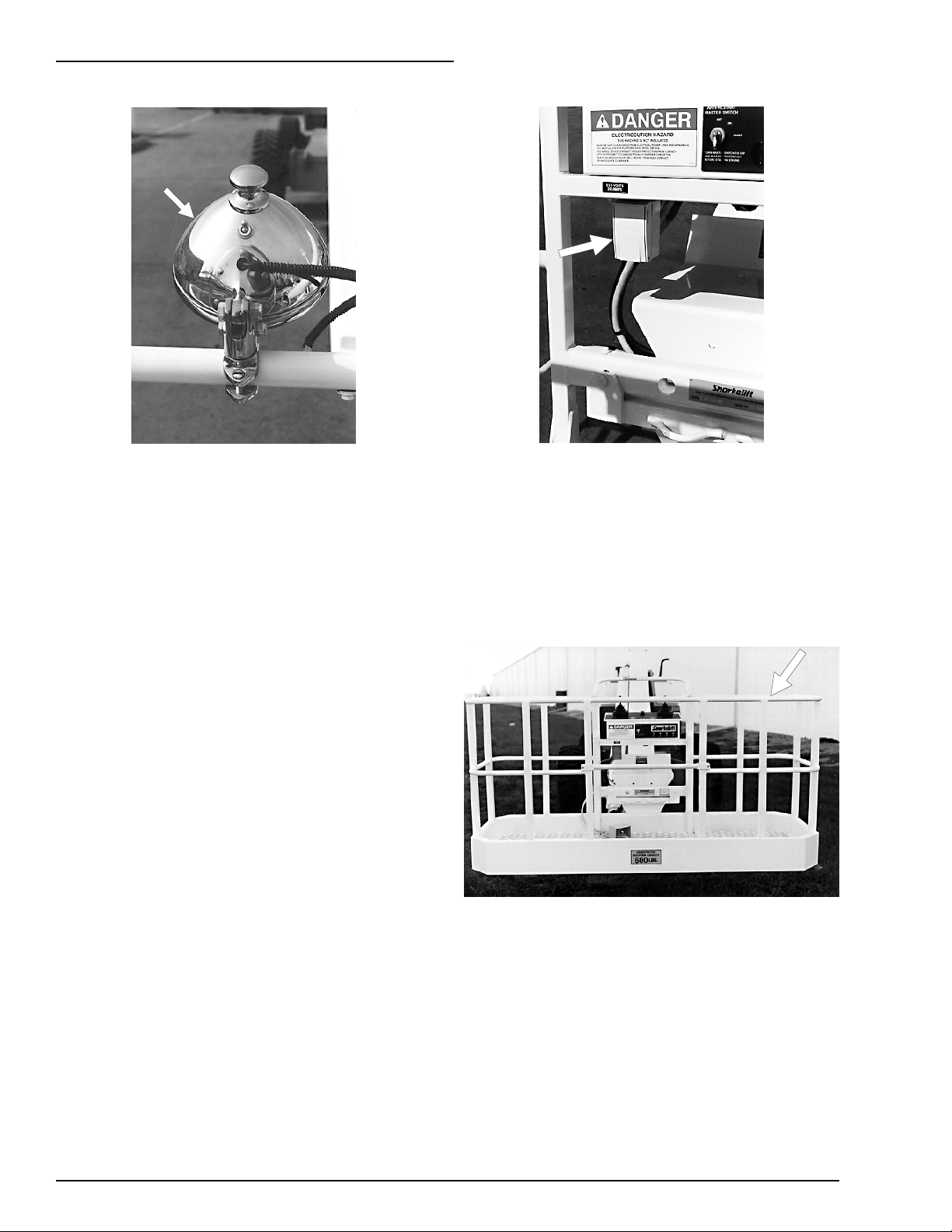

OPERATOR HORN (option)

GROUND OPERATION

The

platform fr om moving if something accident ally

pushes one of the platform-moving switches at

the ground-control panel. (I t is an action that

must be performed, at t he sam e time as another

action, to make the platform move.)

SELF-CLOSING GATE

switch prevents the

(option)

The operator

the platform-control box. It is used primarily to

get the attention of people on the ground when

you are working aloft. The horn itself is located

next to the level sensor, it is the same horn used

to sound the tilt alarm. For the horn to work the

BATTERY

switches, on the ground-control panel, must be

set as indicated:

SELECTOR SWITCH

EMERGENCY STOP

MASTER

FLASHING LIGHT (option)

HORN

switch must be ON and the following

..........................ON

button is on the right side of

.......PLATFORM

.......pulled out

The self-closing g ate is designed to automatically

close after you enter or leave the platf or m. It

helps prevent people from falling off the platfor m .

P/N 0082168

The flashing light alerts people that the TB 60 is

present. The light flashes at about one flash per

second anytime the

STOP

are all ON. There is no ON/OFF switch f or t he

flashing light.

(at the ground), and

BATTERY, EMERGENCY

MASTER

switches

2 - 3

2. SAFETY DEVICES

PLATFORM WORK LIGHTS

The platform work lig ht s are located on top the

platform guardrail. Use the lights to improve

visibility when you are working aloft in dimly lit

areas. Do not use the platform work lights to

drive on public thoroughfares.

(option)

GFCI OUTLET

The GFCI (ground fault circuit interrupt ) is

located under the platform-control box. The GFCI

protects against short circ uit s to ground. When

there is a short to ground the G FCI automatically

shuts off power the way a circuit breaker would.

(option)

For more informat ion about platform work light s

see the “OPTIONS” chapter .

DRIVING LIGHTS

Two 30 watt headlights are located on top of the

front cowling, two 25 watt blinking t aillights are

on the sides of the rear cowlings. Dr iving lights

help improve your visibility and help others see

you when you are driving on dimly lit work sites.

Driving lights are not f or driving on public

thoroughfares.

For more informat ion about dr iving lights see the

“OPTIONS” chapter .

MOTION WARNING ALARM

The motion warning alarm emits a loud beeping

sound at ground level anytime the

DRIVE/STEER

REVERSE. This alarm alerts people on t he

ground that the TB 60 is traveling along the

ground. The alarm it self is below the wiring box,

inside the front-right side of the turntable.

controller is in FORWARD or

(option)

(option)

For more information about t he GFCI see the

“OPTIONS” chapter .

GUARDRAILS

The guardrails help protect you f r om falling off

the platform. Be sure t he guardrails are properly

installed and that the gate is in place.

2 - 4

P/N 0082168

3. SPECIFICATIONS

3. SPECIFICATIONS

The Snorkelift TB 60 is a boom-supported

elevating work-platform built to conform t o th e

following standards:

OSHA Paragraph 1910.67 Title 29, C.F.R.

Vehicle-Mounted Elevating and Rotating Work

Platforms - Labor.

OSHA Paragraph 1926.556 Title 29, C.F.R Aerial

Lifts - Construction.

ANSI Standard A92.5, Boom-Supported

Elevating Work Platforms.

CSA Standard CAN3-B354.4-M82, Boom-type

Elevating Work Platforms.

GENERAL SPECIFICATIONS

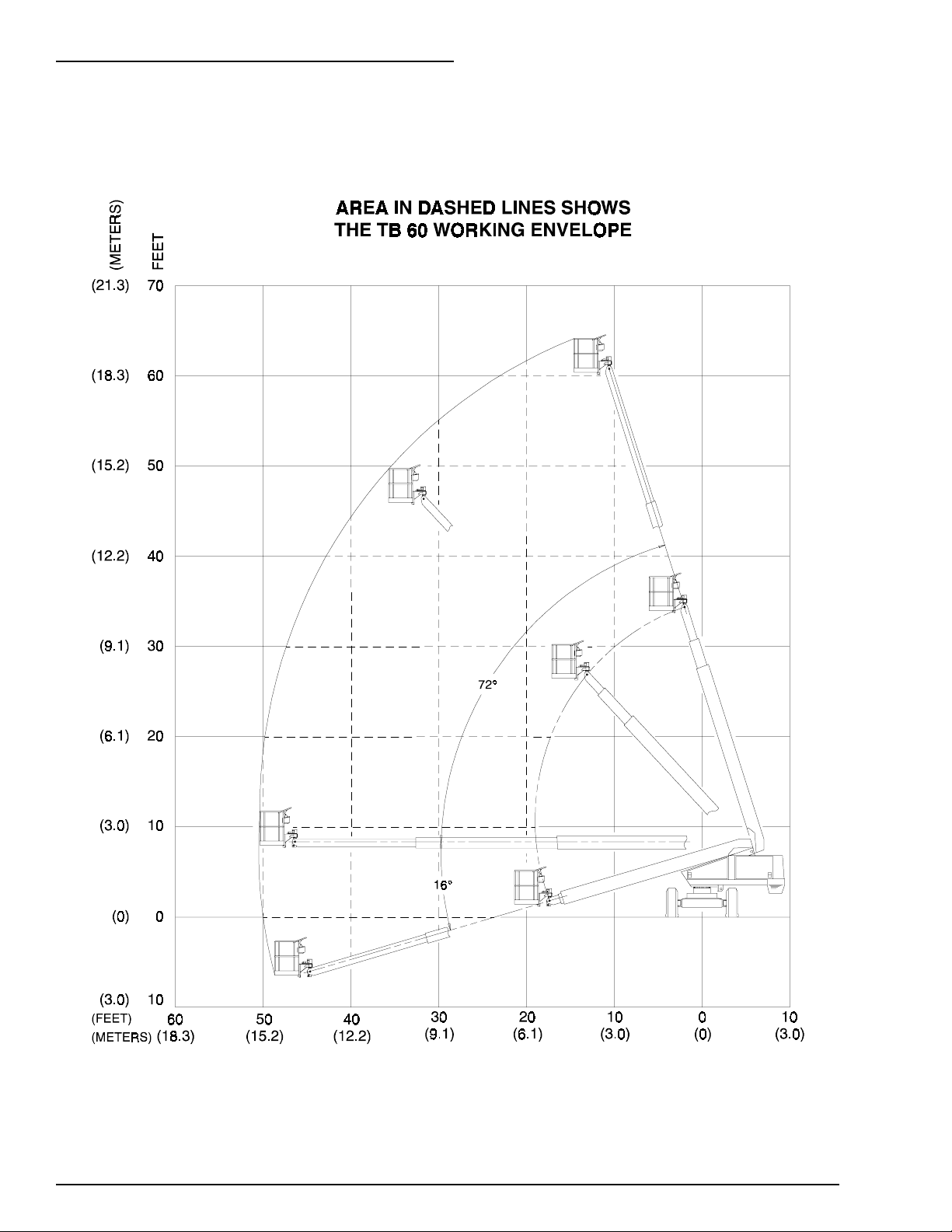

Working height (nominal) ...... 66 ft - 0 in (20.1 m)

Platform height (maximum) ... 60 ft - 0 in (18.3 m)

Platform rea ch (maximum).... 50 ft - 0 in (15.2 m)

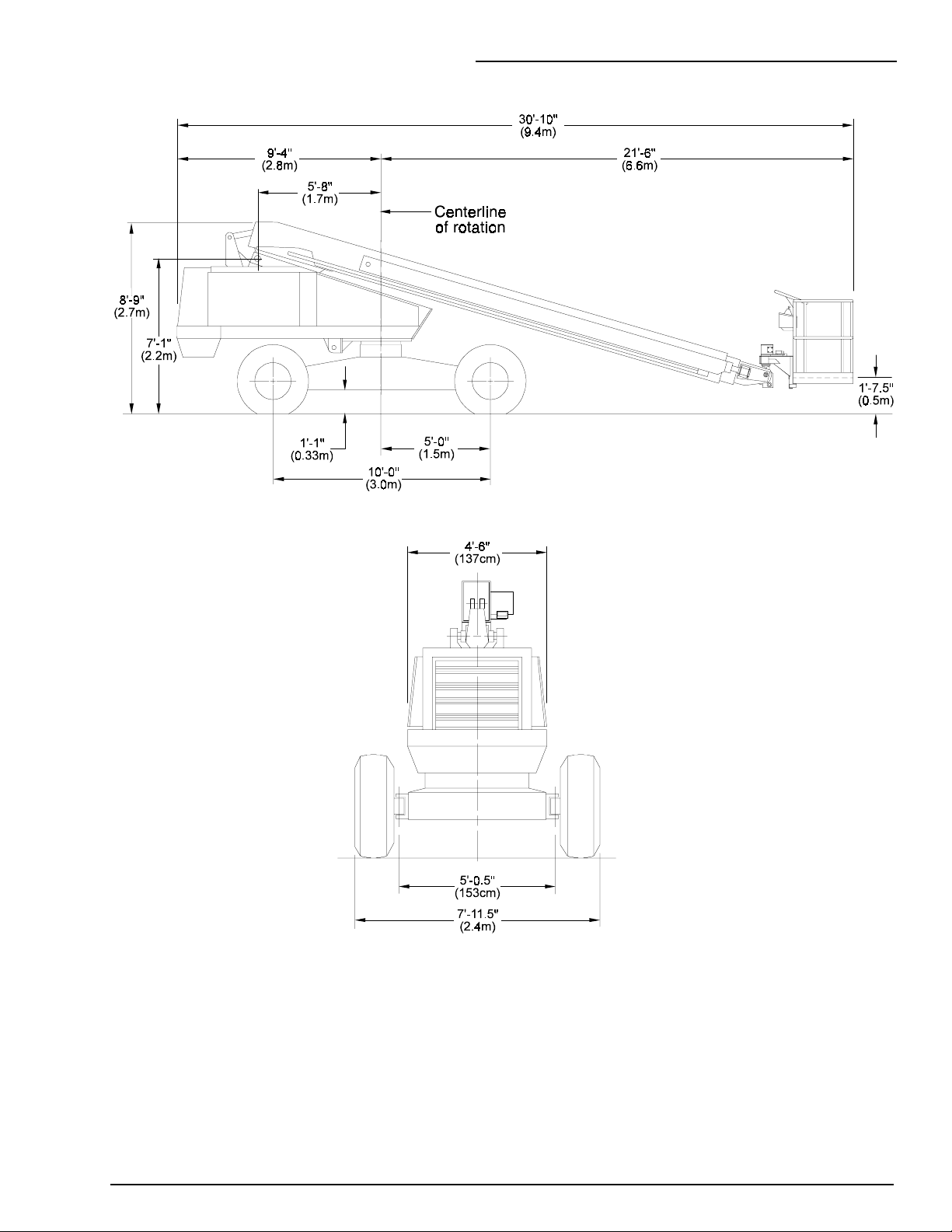

Length

(

booms down and retracted

Width...................................... 8 ft - 0.5 in (2.5 m)

Height

(booms down and retraced) .... 8 ft - 9 in (2.7 m)

Wheelbase.............................. 10 ft - 0 in (3.0 m)

Ground clearance........................... 13 in (33 cm)

Weight (approximate)......... 20,700 lbs (9,389 kg)

Ground pressure, max............... 64 psi (442 kPa)

Wheel lo a d, max . sing le........10,600 lbs (4,808 kg)

Boom elevation.................+72°/-16° to horizontal

Gradeability .................................................. 25%

Travel speeds:

booms down and retracted .. 3.0 mph ( 4.8 km/hr)

booms up and/or extended.... 1 mph (1.6 km/hr)

) .. 30 ft - 10 in (9.4 m)

Turning radius, inside................ 15 ft 5 in (4.7 m)

Tires......................... 15 x 19 .5 in (3 8 X 5 0 c m) , 1 2 ply

Electrical system.. 12 V dc (neg. chassis ground)

Environmental operating ranges:

ambient air temperature.............. 0°F to +110°F

................................................. (-18°C to +43° C)

wind speed (maximum gust

or continuous)...................... 28 mph (45 km/hr)

Fuel tank capacity:

standard gasoline

or diesel........................ 40 gal USA (151 liters)

optional LPG.................... 43.5 lbs USA (20 kg)

optional gasoline or diesel

(Used when LPG cylinder is mounted

inside the turntable, in front of the

gasoline or diesel tank.) ... 20 gal USA (76 liters)

Hydraulic oil tank capaci ty.. 26.1 gal USA (99 liters)

Maximum hydraulic oil temperature

(at tank) ....................................... 200°F (93°C)

Hydraulic oil system

capacity ........................ 35 gal USA (132 liters)

Hydraulic oil and grade

Above 10°F (-13°C)Mobil DTE-13M (ISO VG32)

Below 10°F (-13°C) Mobil DTE-11M (ISO VG15)

Hydraulic system

maximum pressure ....... 2,500 psi (17,250 kPa)

Boom movement times

(complete range of movement):

Turntable Swing

CW or CCW (360°): ............... 85 - 95 seconds

Platform Rotation

CW or CCW (180°): ............... 16 - 20 seconds

Main Boom Elevation

UP:......................................... 40 - 45 seconds

DOWN:.................................. 40 - 45 seconds

Boom Extension

OUT:...................................... 60 - 70 seconds

IN:.......................................... 50 - 60 seconds

PLATFORM SPECIFICATIONS

SIZE

PLATFORM

standard steel 30 x 60 (76 x 152)

optional steel 30 x 92 (76 x 233)

optional aluminum 30 x 60 (76 x 152)

optional aluminum 30 x 92 (76 x 233)

P/N 0082168

inches (cm)

Unrestricted rated work load (total weight of personnel,

tools, and materials that the platform is designed to carry

above its floor -- same as UNRESTRICTED PLATFORM

CAPACITY)

Rated work load: 500 lbs (227 kg)

Rated number of occupants: 2 people

Rated work load: 500 lbs (227 kg)

Rated number of occupants: 2 people

Rated work load: 660 lbs (300 kg)

Rated number of occupants: 2 people

Rated work load: 600 lbs (273 kg)

Rated number of occupants: 2 people

3 - 1

3. SPECIFICATIONS

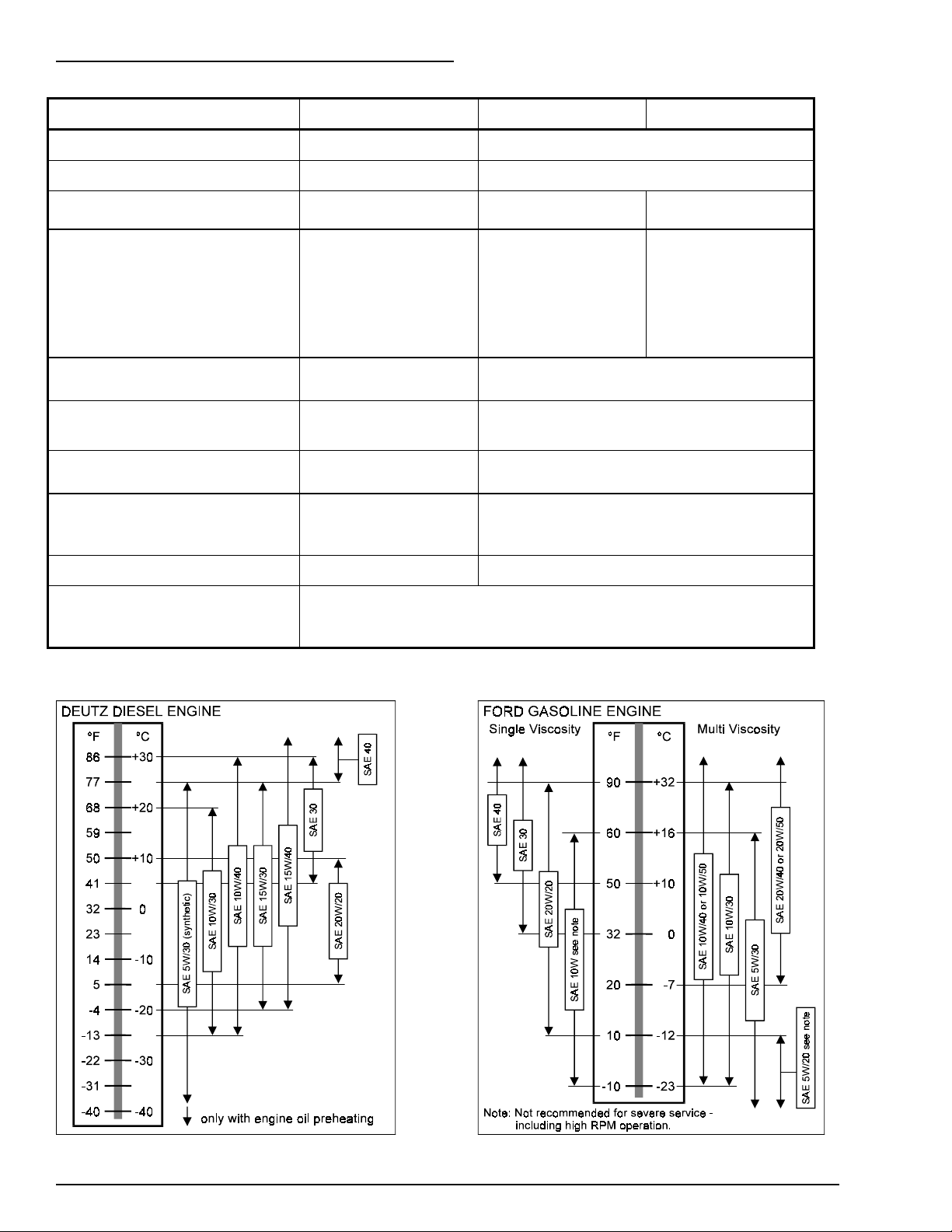

ENGINE DATA

ENGINE MAKE DEUTZ FORD (gasoline) FORD (LPG)

MODEL F4L-1011F LRG-423

COOLANT air 50% water + 50% ethylene glycol

FUEL

FUEL GRADE

diesel

DIN 51 601.

BS 2869: A1 and A2.

ASTM D 975-81:

1-D and 2-D.

W-F-800C: DF-A,

DF-1, and DF-2.

gasoline

leaded or unleaded

83 octane

(motor method).

LPG (liquefied

petroleum gas)

HD5

Gas Processors

Association

Standard 2140.

Category: special

duty propane.

OPERATING TEMPERATURE

OIL SUMP CAPACITY 10.5 qt USA

OIL FILTER CAPACITY

OIL GRADE

OIL WEIGHT see chart below see chart below

RUNNING TIME

(one tank fuel)

ENGINE OIL CHARTS

172°F - 203°F

(78°C - 95°C)

(10 liters)

0.5 qt USA

(0.5 liters)

API: CC/SE CC/SF

CD/SE CD/SF

CE/SF CE/SG

Any tank of fuel (regardless of whether it is LPG, gasoline, or

diesel) will last an entire eight hour shift, under normal working

conditions.

160°F - 190°F

(71°C - 88°C)

4 qt USA

(3.8 liters)

1 qt USA

(0.95 liters)

API: SH or SG

3 - 2

P/N 0082168

OVERALL DIMENSIONS

3. SPECIFICATIONS

P/N 0082168

3 - 3

3. SPECIFICATIONS

WORKING ENVELOPE

3 - 4

P/N 0082168

3. SPECIFICATIONS

3

)

SERIAL-NUMBER LOCATIONS

Serial Numbers are located in five places.

1. Above the ground-control panel on a placard.

(The last four digits are month and year shipped.)

2. On the back-right of the counterweight.

CHASSIS NOMENCLATURE

3. Above the lanyard anchor points on a placard.

(Last four digits are mo. and yr. shipped.)

TURNTABLE AND BOOM

NOMENCLATURE

4. Below the drain hole in the turntable.

5. At the weld on the rear of the chassis. (Fourwheel drive machines have the serial number

stamped on top the chassis just behind the

rotation-bearing turret.)

P/N 0082168

NOTE: If the turntable is rotated 180° its

FRONT is above the REAR of the chassis.

- 5 (3 - 6 blank

3 - 5

4. GAUGES & CIRCUIT BREAKERS

4. GAUGES & CIRCUIT BREAKERS

GAUGES

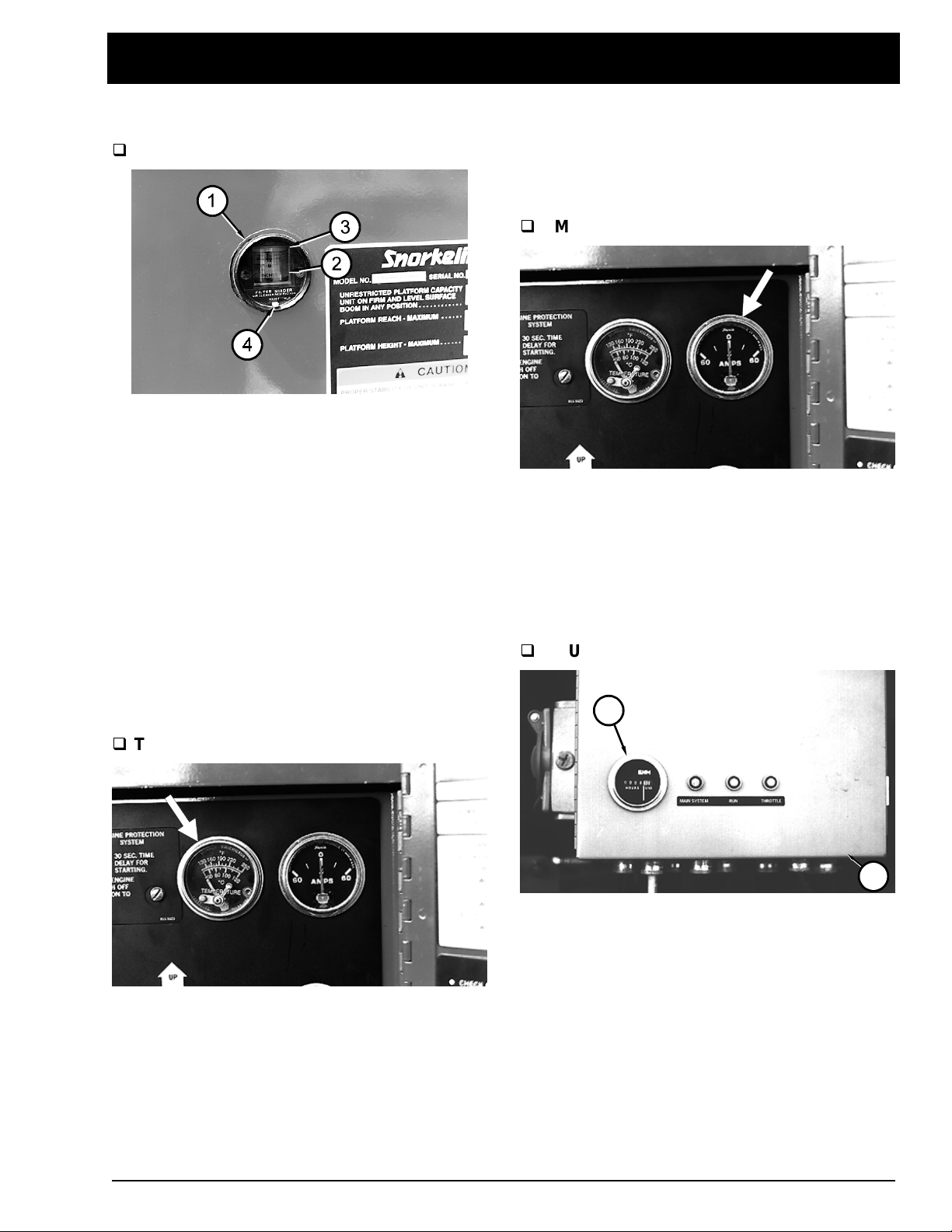

FILTER MINDER

The air filter g auge (1) (FILTER MINDER) is

located just above the ground-control panel. The

gauge measures the vacuum (air pressur e)

between the intake manifold and t he air filter. As

the filter clogs, t he vacuum increases (pressure

drops). As the vacuum increases, the yellow

indicator disk (2) raises toward the red ar ea ( 3)

of the sight glass. When the yellow disk reaches

the red, it’s time to chang e the air filter.

The indicator disk (2) stays at it s highest setting,

it does not go to the bottom of the sight glass

when the engine is turned off. After the f ilt er is

changed, press the small RESET button (4) t o

reset the indicator disk to the bottom of the sight

glass.

The TEMPERATURE gauge for Deutz engines

shows the temperature of the engine oil as the oil

leaves the oil filter. The t ypical operat ingtemperature range for a Deutz engine is 172°F to

203°F (78°C to 95°C).

AMPS

The AMPS gauge shows the electric current

from the alternator t o the battery(ies). When the

engine is running, the needle in the AMPS gauge

should not be to the left of “ 0. ” Under normal

operating conditions, after the engine has been

running for a few minutes, this gauge should

read “0.”

HOURS

1

TEMPERATURE

The TEMPERATURE gauge is located at the top

of the ground-control panel. For Ford engines it

shows the temperature of the water-ant ifreeze

mixture in the engine block. The t ypical

operating-temperatur e r ange for Ford engines is

160°F to 190°F (71°C to 88°C).

P/N 0082168

2

The HOURS gauge (1) is located on the wiring

box (2), to the left of the ground-control panel

(behind the cowling door). The HOURS gauge is

basically an electric clock. It accumulates tim e

when the BATTERY, EMERGENCY STOP (at

the ground), and MASTER switches are all in the

ON position. The HOURS g auge cannot be

reset. Use it to tell when it is time for 150 hour or

500 hour maintenance.

4 - 1

4. GAUGES & CIRCUIT BREAKERS

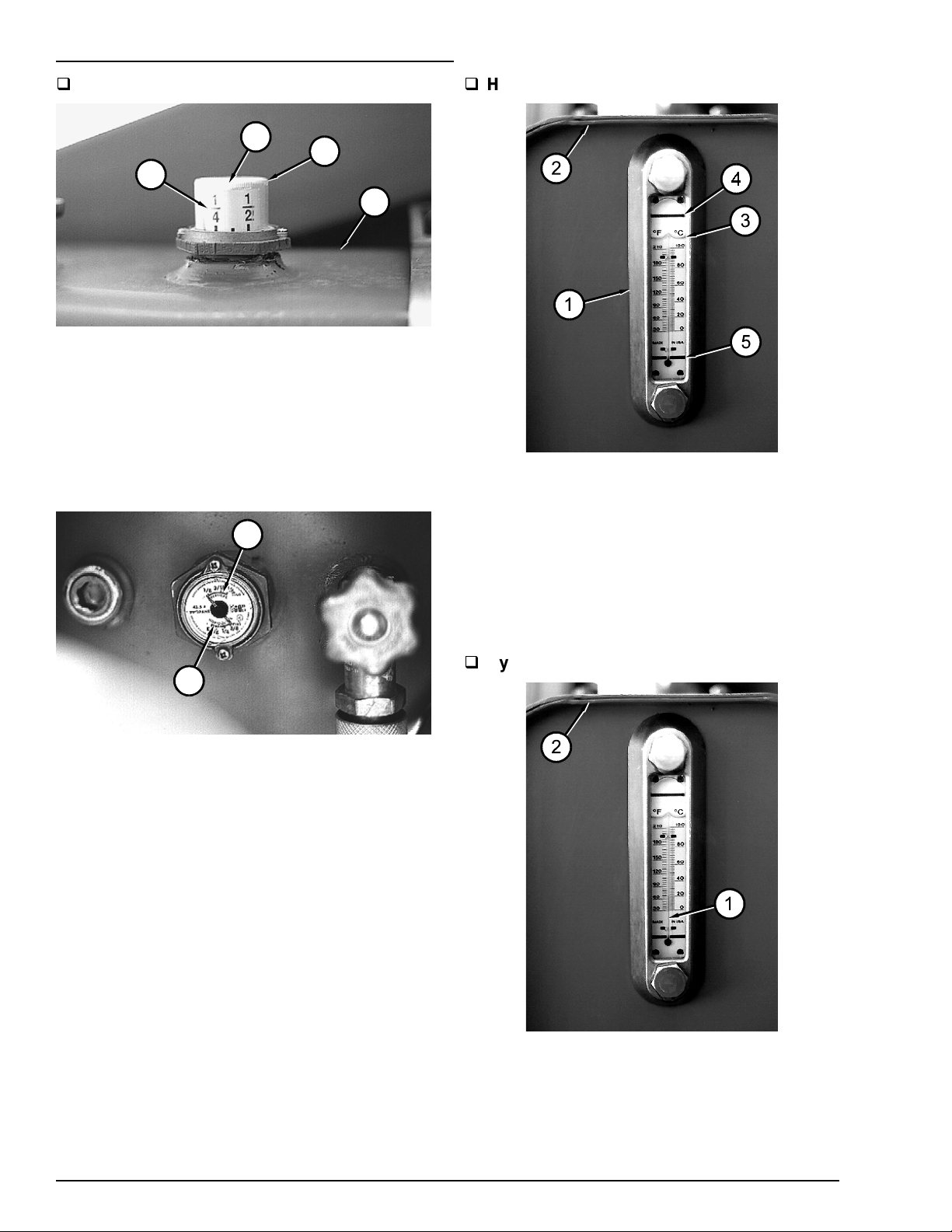

Fuel

Hydraulic Oil Level

3

1

4

2

The fuel gauge (1) is locat ed on top of the

gasoline or diesel fuel tank (2). Read it at the line

(3) in the clear plastic window (4). It reads in

fractions-of-a- full-tank. The tank shown is a little

less than 3/8 full.

NOTE: Do not run a diesel fuel tank dry. Air in

the fuel line makes a diesel engine hard to

start.

1

The hydraulic-oil level gauge (1) is on the end of

the hydraulic oil tank (2). It shows the actual level

of oil inside the tank. Read it only when the

booms are completely down and completely

retracted. Otherwise, the lift and/or extend

cylinders become large reservoirs for hydraulic

oil and the oil level in the tank will be low. The oil

level (3) should be between the HIGH mark (4)

and LOW mark (5).

2

(OPTION - LPG) LPG t anks have two fuel

gauges (1) (2) on top. One measures correctly

when the tank is standing on end (VERTICAL)

the other measures correctly when the tank is

laying down (HORIZONTAL). Both read in

fractions-of-a- full-tank. Tanks on TB 60’s are

mounted horizontally. Therefore, you should read

the HORIZONTAL scale (2). This one is over 3/8

full.

Hydraulic Oil Temperature

The hydraulic-oil temperature gauge (1) is

located inside the hydraulic-oil level gauge. It

measures the temperature of the oil in the tank

(2). The temperatur e should not exceed 200°F

(93°C). If it does, r educe your dr iving speed or

stop the TB 60 to let the hydraulic oil cool.

4 - 2

P/N 0082168

Loading...

Loading...