Snorkel X33RT User Manual [en, de, es, fr, it]

Operator Manual

This first section of the Operator manual is the English language version.

Betriebsanleitung

Im zweiten Abschnitt dieser Betriebsanleitung finden Sie die Deutsche Version.

Manuel Utilisateur

La troisième section de ce manuel est la version en langue Française.

Manual del Usuario

El apartado cuarto de este manual del usuario corresponde a la versión en Español.

Manuale d’Uso

La quinta sezione di questo manuale d'uso è la versione in lingua Italiana.

Bedieningshandleiding

Het zesde deel van de Bedieningshandleiding is de Engelstalige versie.

(EN) Manual part number 508401-001 for serial numbers 70810 to current.

(DE) Bestellnummer 508401-001 ab Seriennummer 70810 fortlaufend.

(FR) Manuel Pièce numéro 508401-001 pour numéro série 70810 jusqu'au

numéro courant.

(ES) El número de referencia para el manual es el 508401-001 para los

números de serie del 70810 hasta el actual.

(IT) Manuale Ricambi Numero 508401-001 per Numeri di Serie da 70810

all’attuale.

(NL) Handboek onderdeelnummer 508401-001 voor de serienummers van

70810 tot de huidige.

Jan 08

X-27-33-RT

Serial N umbers NZ 70810 - C urrent

ENGLISH

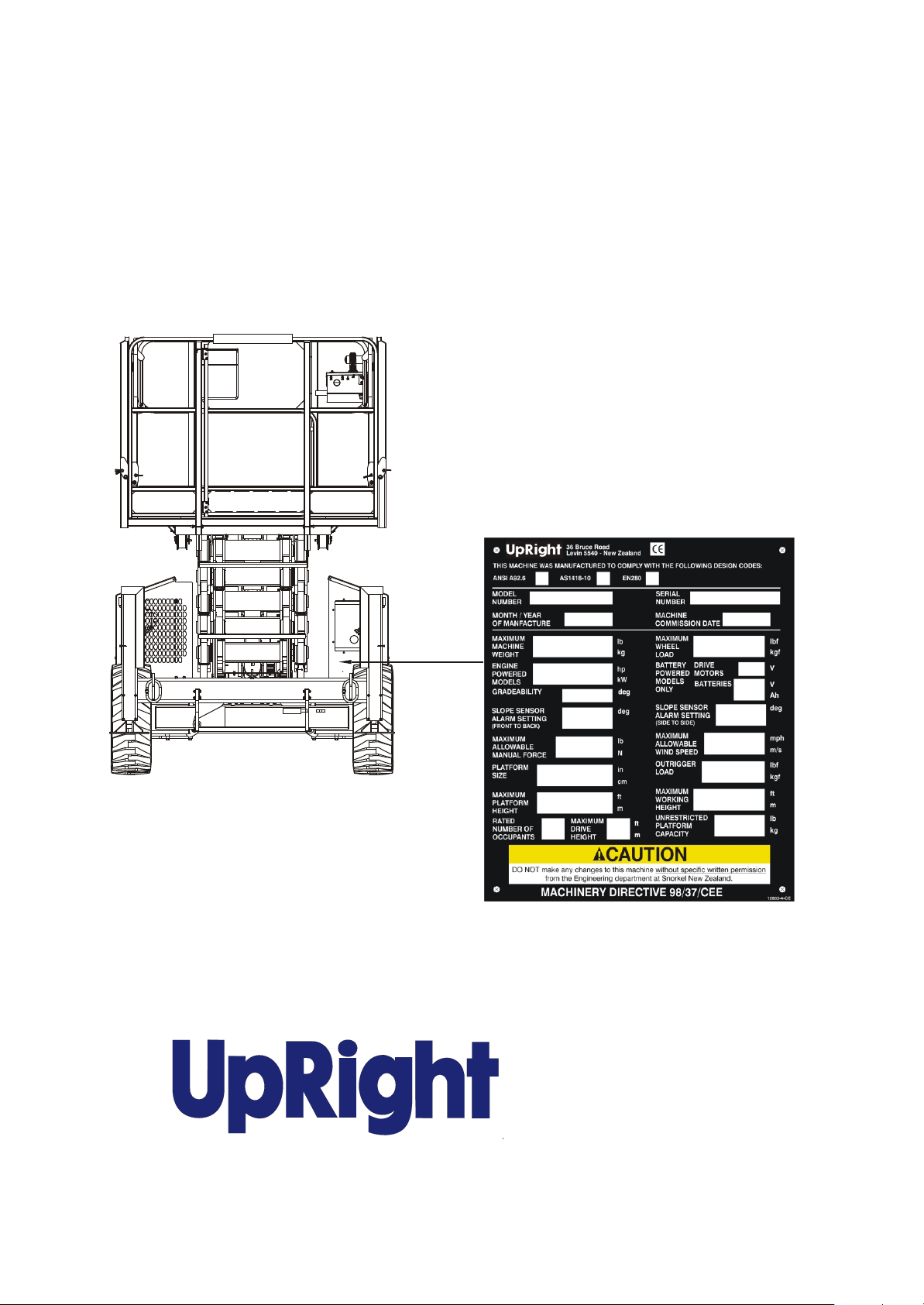

When con tact ing UpRight for ser vice or parts in formation, be sure to in clude the MODEL and SERIAL

NUMBERS from the equip ment name plate.

POWERED ACCESS

www.upright.com

Up Right Pow ered Ac cess HQ

Vigo Cen tre

Birtley Road

Wash ing ton

Tyne & Wear

NE38 9DA

Tel: +44 (0) 845 1550 057

Fax: +44 (0) 845 1557 756

OPERATION MANUAL

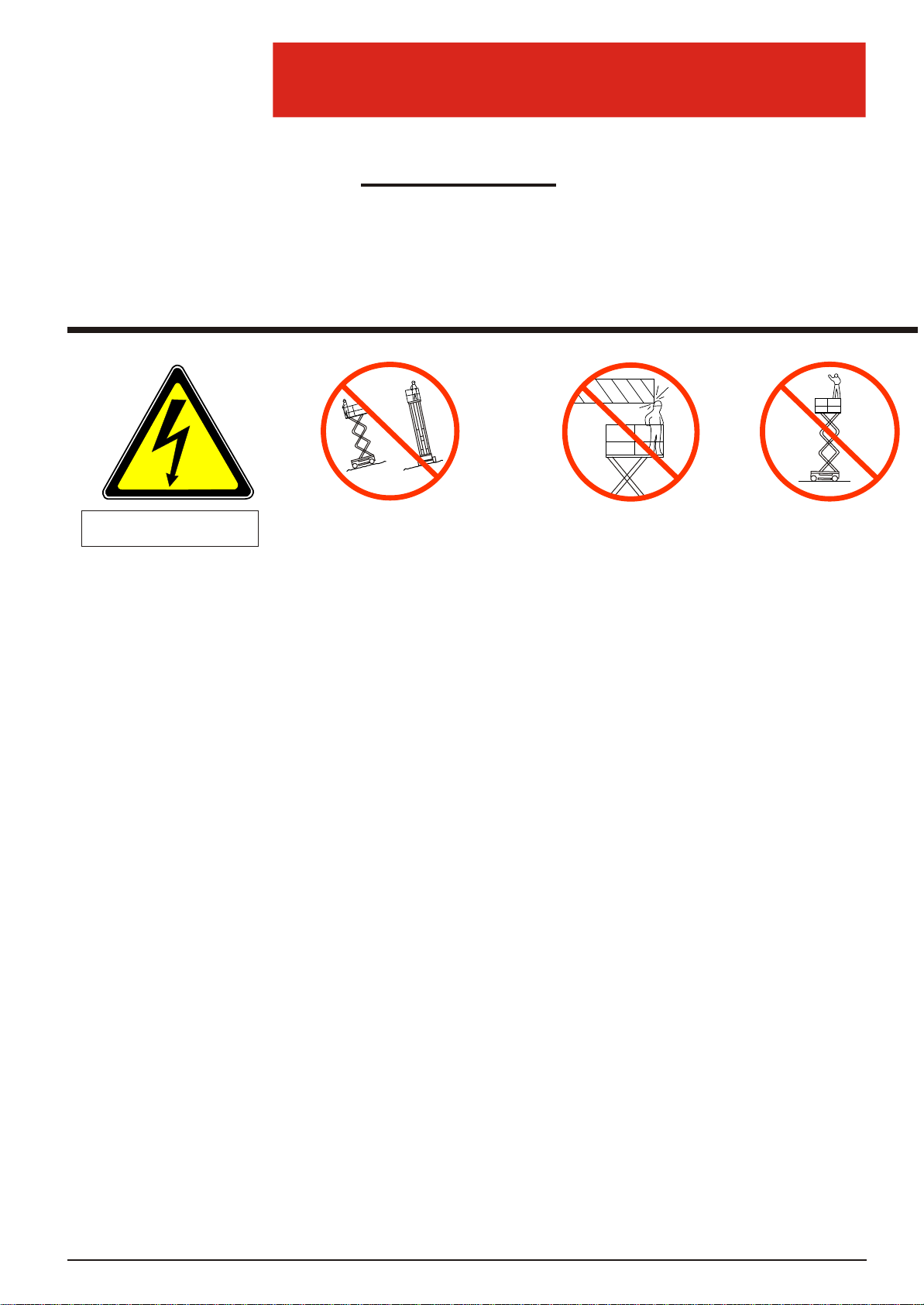

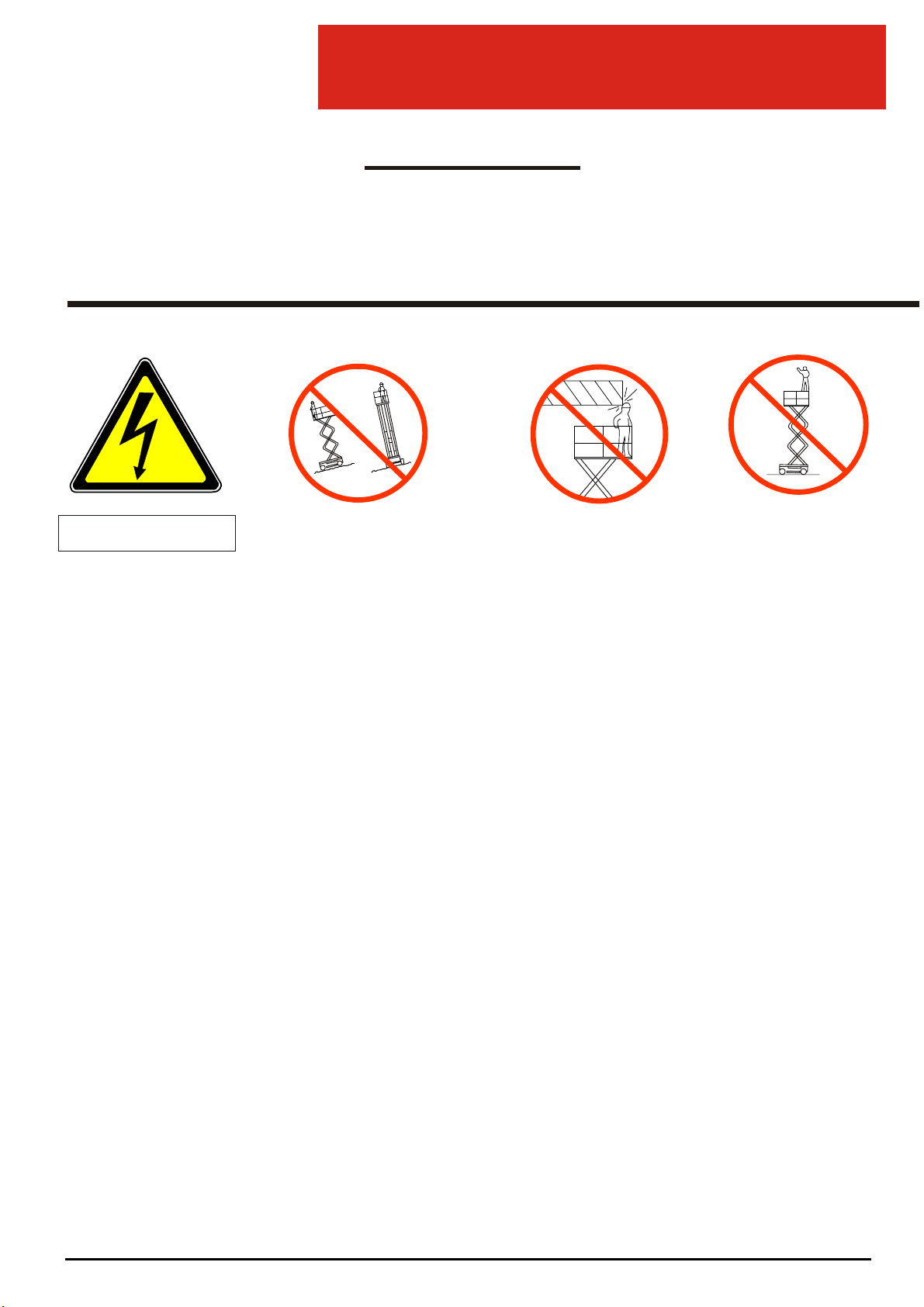

Electrocution Hazard

Tip Over Hazard

Collision Hazard

Fall Hazard

This machine is not

insulated

NEVER elevate the platform or drive

the machine while elevated unless

the machine is on a firm, level surface

NEVER position the platform

without first checking for overhead

obstructions or other hazards

NEVER climb, stand or sit on

platform guardrails or midrail

WARNING

All per son nel shall care fully read, un der stand and fol low all safety rules and op er at ing

in struc tions be fore op er at ing or per form ing main te nance on any Up Right ae rial work plat form.

Safety Rules

USE OF THE AERIAL WORK PLATFORM: This ae rial work plat form is in tended to lift peo ple and their tools as well as the ma te rial

used for the job. It is de signed for re pair and as sem bly jobs and as sign ments at over head workplaces (ceil ings, cranes, roof struc tures, build ings etc.). All other uses of the ae rial work plat form are pro hib ited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this rea son it is im per a tive to keep a safe dis tance from live parts of

elec tri cal equip ment!

Ex ceed ing the spec i fied per mis si ble max i mum load is pro hib ited! See "Spe cial Lim i ta tions" on page 4 for de tails.

The use and op er a tion of the ae rial work plat form as a lift ing tool or a crane (lift ing of loads from be low up wards or from up high on

down) is pro hib ited!

NEVER ex ceed the man ual force al lowed for this ma chine. See "Spe cial Lim i ta tions" on page 4 for de tails.

DISTRIBUTE all plat form loads evenly on the plat form.

NEVER op er ate the ma chine with out first sur vey ing the work area for sur face haz ards such as holes, drop-offs, bumps, curbs, or de -

bris; and avoid ing them.

OPERATE ma chine only on sur faces ca pa ble of sup port ing wheel loads.

NEVER op er ate the ma chine when wind speeds ex ceed this ma chine's wind rat ing. See "Beau fort Scale" on page 4 for de tails.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to de ac ti vate all pow ered func tions.

IF ALARM SOUNDS while the plat form is el e vated, STOP, care fully lower the plat form. Move ma chine to a firm level sur face.

Climb ing up the rail ing of the plat form, stand ing on or step ping from the plat form onto build ings, steel or pre fab con crete struc tures,

etc., is pro hib ited!

Dis man tling the swing gate or other rail ing com po nents is pro hib ited! Al ways make cer tain that the swing gate is closed and se curely locked!

It is pro hib ited to keep the swing gate in an open po si tion (held open with tie straps) when the plat form is raised!

To ex tend the height or range by plac ing lad ders, scaf folds or sim i lar de vices on the plat form is pro hib ited!

NEVER per form ser vice on the ma chine while the plat form is el e vated with out block ing the el e vat ing as sem bly.

INSPECT the ma chine thor oughly for cracked welds, loose or miss ing hard ware, hy drau lic leaks, loose wire con nec tions, and dam -

aged ca bles or hoses be fore us ing.

VERIFY that all la bels are in place and leg i ble be fore us ing.

NEVER use a ma chine that is dam aged, not func tion ing prop erly, or has dam aged or miss ing la bels.

To by pass any safety equip ment is pro hib ited and pres ents a dan ger for the per sons on the ae rial work plat form and in its work ing

range.

NEVER charge bat ter ies near sparks or open flame. Charg ing bat ter ies emit ex plo sive hy dro gen gas.

Mod i fi ca tions to the ae rial work plat form are pro hib ited or per mis si ble only at the ap proval by UpRight.

AFTER USE, se cure the work plat form from un au tho rized use by turn ing the keyswitch off and re mov ing the key.

Operation Manual Page 1

Introduction .........................................................3

CONTENTS

General Description...................................................3

Platform Capacity ...................................................4

Manual Force ......................................................4

Beaufort Scale .....................................................4

Lift Overload Alarm..................................................4

Controls and Indicators ...............................................5

Pre-Operational Safety Inspection.......................................6

System Function Inspection............................................7

Operation ...........................................................8

Platform Extension ..................................................8

Travel With The Platform Lowered......................................8

Steering...........................................................8

Elevating The Platform ...............................................8

Travel With The Platform Elevated .....................................9

Lowering The Platform ...............................................9

Levelling The Platform ...............................................9

Emergency Lowering ...............................................10

Fold Down Guardrails...............................................11

Fold Down Procedure..........................................11

Erection Procedure............................................11

Towing or Winching .................................................12

Parking Brake Release..............................................12

After Use Each Day ................................................12

Hour Meter .......................................................12

Transporting The Work Platform .......................................13

Preparation For Shipment ...........................................13

Lifting By Crane ...................................................13

By Forklift ........................................................13

Driving or Winching Onto a Truck .....................................13

Maintenance ........................................................14

Blocking The Elevating Assembly .....................................14

Scissor Brace Installation.......................................14

Scissor Brace Stowage ........................................14

Battery Maintenance................................................15

Battery Charging .............................................15

Inspection and Maintenance Schedule ............................16

Daily Preventative Maintenance Checklist ...............................16

Labels .............................................................18

Specifications.......................................................19

Page 2 Operation Manual

Introduction

INTRODUCTION

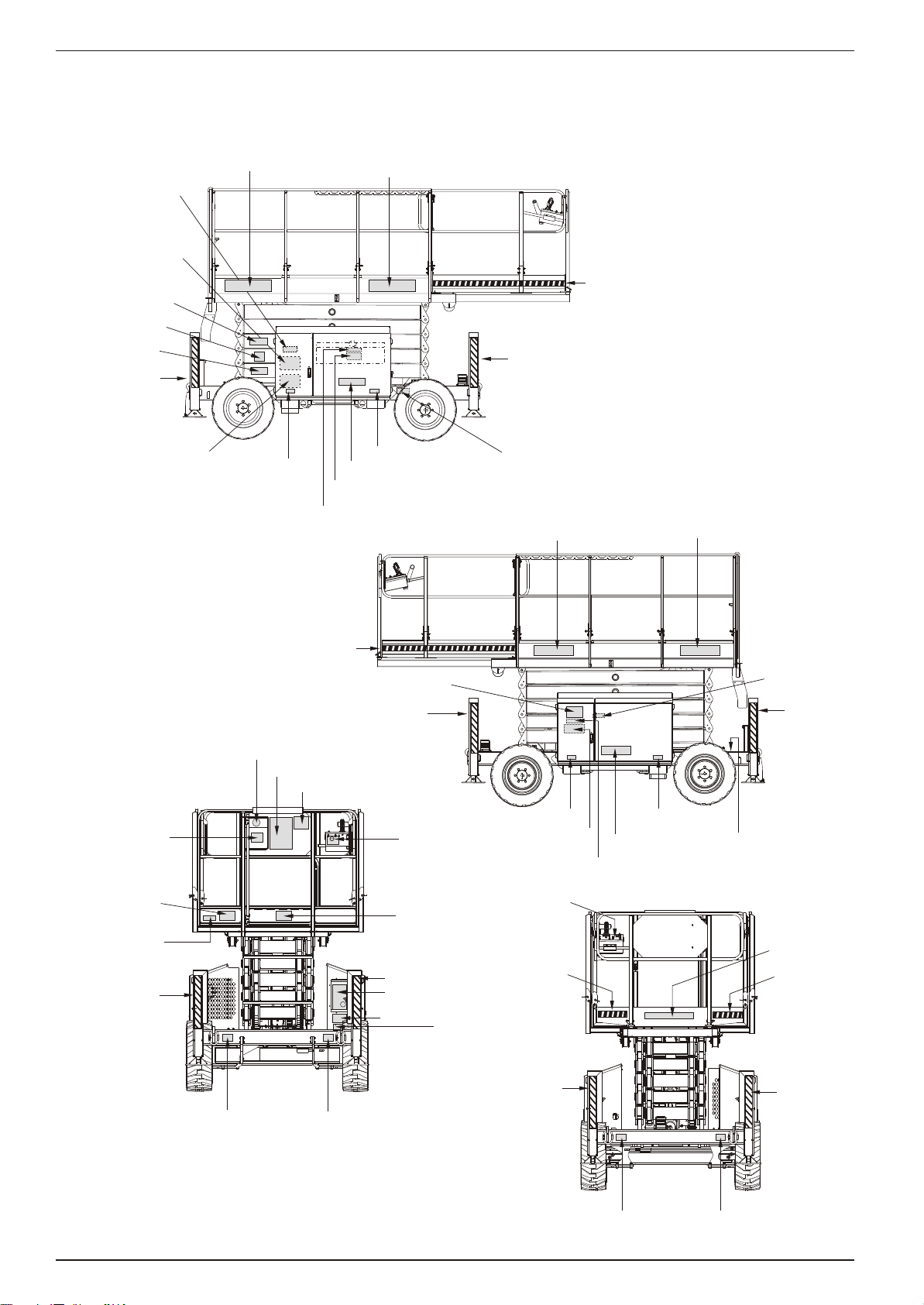

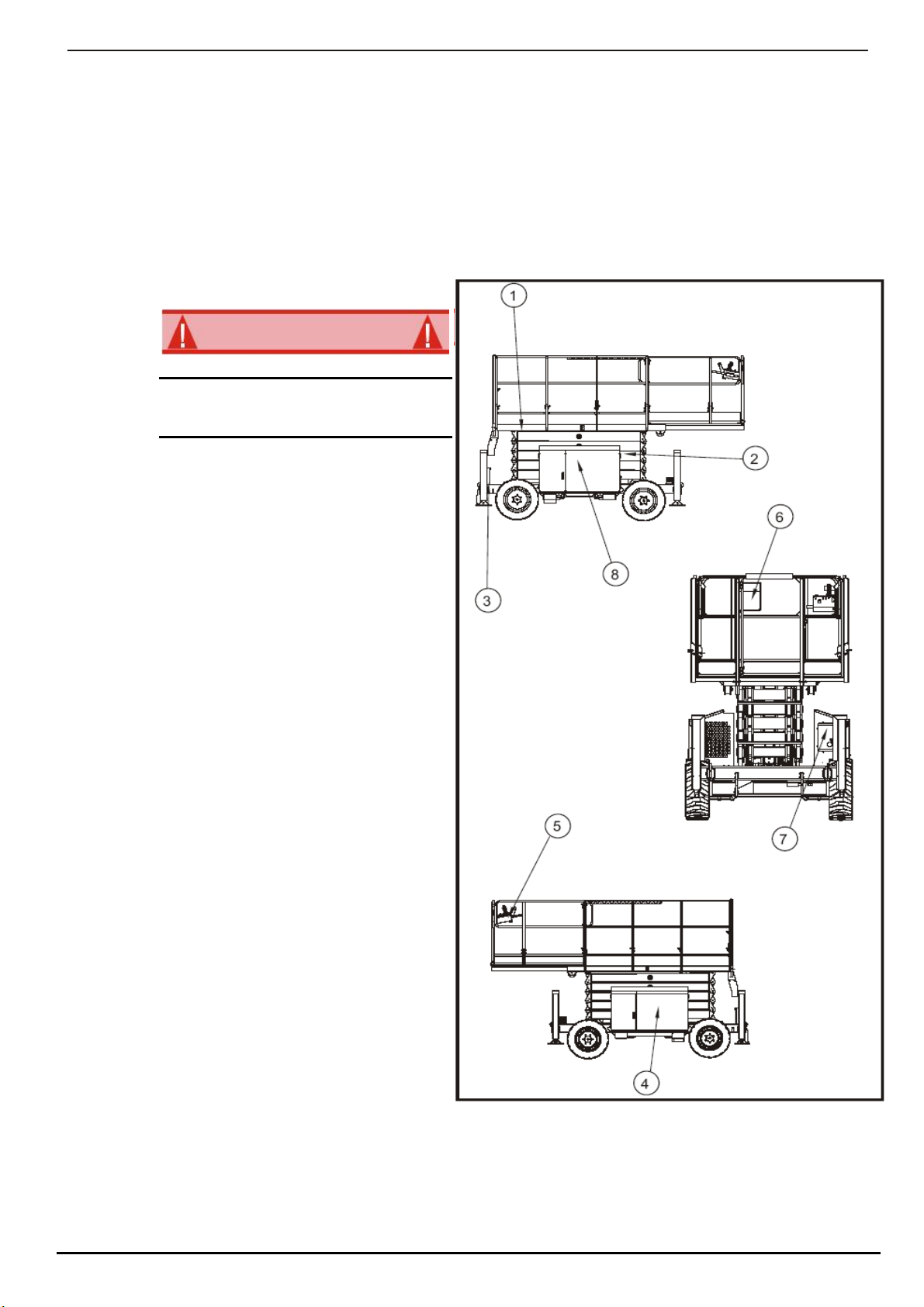

GENERAL DESCRIPTION

1

3

5

7

2

4

6

8

W A R N I N G

This man ual cov ers op er a tion of the X-27-33-RT Se ries Self-Pro pelled Rough Ter rain

Work Plat forms. This man ual must be stored on the ma chine at all times.

1. Platform

DO NOT use the main te nance plat form

with out guard rails prop erly as sem bled

and in place

Figure 1

2. Elevating Assembly

3. Chassis

4. Engine

5. Platform Controls

6. Manual Case

7. Chassis Controls

8. Hydraulic Fluid Reservoir

Operation Manual Page 3

Special Limitations

SPECIAL LIMITATIONS

D A N G E R

PLATFORM CAPACITY

D A N G E R

MANUAL FORCE

D A N G E R

BEAUFORT SCALE

BEAUFORT

SCALE

WIND SPEED

GROUND CONDITIONS

m/s km/h ft/s mph

3 3.4~5.4 12.5~19.4 11.5~17.75 5~12.0 Papers and thin branches move, flags wave.

4 5.4~8.0 19.4~28.8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small

5 8.0~10.8 28.8~38.9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are

6 10.8~13.9 38.9~50.0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is

7 13.9~17.2 50.0~61.9 45.5~56.5 31~38.5 Whole trees sway. It is difficult to walk against the

branches sway.

apparent in ponds or swamps.

difficult to open an umbrella.

wind.

LIFT OVERLOAD ALARM

D A N G E R

Travel with the plat form raised is lim ited to creep speed range.

El e vat ing the Work Plat form is lim ited to firm, level sur faces only.

The el e vat ing func tion shall ONLY be used when the work plat form is lev eled and on a firm sur face.

The max i mum ca pac ity for the MACHINE, in clud ing oc cu pants is de ter mined by model and op tions, and is listed in "Spec i fi ca tions" on page 19.

DO NOT ex ceed the max i mum plat form ca pac ity or the plat form oc cu pancy lim its for this ma chine.

Man ual force is the force ap plied by the oc cu pants to ob jects such as walls or other struc tures out side the work plat form.

The max i mum al low able man ual force is lim ited to 200 N (45 lbs.) of force per oc cu pant, with a

max i mum of 400 N (90 lbs.) for two or more oc cu pants.

DO NOT ex ceed the max i mum amount of man ual force for this ma chine.

Never op er ate the ma chine when wind speeds ex ceed 25 km/h (15 mph) [Beau fort scale 4].

Page 4 Operation Manual

If a load which is greater than the safe work ing load is pres ent in the bas ket all ma chine func tions

will cease to op er ate and an acous tic warn ing will sound. In or der to re turn to nor mal op er a tion a

load equal to or less than the safe work ing load must be pres ent in the bas ket.

Never op er ate the ma chine with a plat form load greater than the rated ca pac ity.

Contro ls and Indi cato rs

C

ON T R OL S A ND

I

NDI C AT OR S

9

9

3

3

11

11

5

5

13

7

7

15

2

2

10

10

4

4

12

12

12

12

12

6

6

14

8

8

16

1

1

Emergency S top Switch

Emergency S top Switch

1.

1.

S tart Switch

S tart Switch

2.

2.

Glow Plug/Choke

Glow Plug/Choke Indicator Light

3.

3.

Glow Plug/Choke Indicator Light

Glow Plug/Choke

4.

4.

Safety Control

Lift Indicator Light

5.

5.

Joystick Controller

Plat form Lif t/Lower Switch

6.

6.

S teering Rocker Switch

Fuel Selector Switch (When Option Fitted)

7.

7.

Lift/Drive Selector

Ground/Plat form Selector

8.

8.

S peed Selector

Contact Breaker

9.

9.

Lift Indicator Light

Hour Meter

10.

10.

Drive Indicator Light

Water T emperature Gauge

11.

11.

Manual S tabiliser Switches

Ammeter Gauge

12.

12.

Auto Level / Auto S tow Switch13.

Horn Switch14.

Oil Pressure W arning Light15.

Plat form Overload Indicator Light

PLA TFORM CONTROLS

16.

GROUND/CHASSIS CONTROLS

Figure 2: Contr ols and Indic ators

Opera tion Manua l Page 5

Pre-Operation Safety Inspection

PRE-OPERATIONAL SAFETY INSPECTION

NOTE: Care fully read, un der stand and fol low all safety rules, op er at ing in struc tions, la bels

and Na tional safety In struc tions/Re quire ments. per form the fol low ing steps each day be fore use.

1. Open cabinets and inspect for

damage, fluid leaks or missing

parts.

Figure 3: Hydraulic Tank

2. Check the level of the hydraulic

fluid with the platform fully

lowered. The hydraulic reservoir is

located in the Control Cabinet.

The fluid must be above the

minimum line. Add hydraulic fluid

if necessary.

3. Check the fluid level in the starter

battery is correct.

4. Check the level of the Diesel fuel

with the engine switched off. The fuel tank is located in the Engine Cabinet. Add fuel as

required.

5. Check that all the guardrails are in place and all the fasteners are properly tightened.

6. Inspect the machine thoroughly for cracked welds and structural damage, loose or missing

hardware, hydraulic leaks, damaged control cable, loose wire connections and wheel bolts.

Page 6 Operation Manual

System Function Inspection

SYSTEM FUNCTION INSPECTION

W A R N I N G

Re fer to Fig ure 2 (Page 5) for the lo ca tions of var i ous con trols and in di ca tors.

STAND CLEAR of the work plat form while per form ing the fol low ing checks.

Be fore op er at ing the work plat form, sur vey the work area for sur face haz ards such as holes,

drop-offs, bumps and de bris.

Check in ALL di rec tions, in clud ing above the work plat form, for ob struc tions and elec tri cal con duc tors.

1. Move the machine, if necessary, to an unobstructed and level area to allow for full elevation.

2. Pull Chassis Emergency Stop Switch to the ON position.

3. Pull Platform Emergency Stop Switch to the ON position.

4. Visually inspect the elevating assembly, lift cylinder, cables, and hoses for cracked welds and

structural damage, loose hardware, hydraulic leaks, loose wire connections, and erratic

operation. Check for missing or loose parts.

5. Turn the key on and start the engine.

6. Select GROUND operation on the platform/ground switch.

7. Hold the platform LIFT/LOWER switch up to the rise position and fully elevate the platform.

8. Partially lower the platform by pushing the platform lift/lower switch down and check for

proper operation of the audible lowering alarm.

9. Pull the Emergency Lowering control to check for proper operation. When the platform is

lowered, release the knob.

10. Push the chassis Emergency Stop Switch to check for proper operation. All machine

functions should be disabled. Pull the Emergency Stop Switch to allow normal operation to

resume.

11. Check that the route is clear of obstacles (persons, obstructions, holes, and drop-offs, bumps

and debris), is level, and is capable of supporting the wheel loads.

12. Mount the platform and properly close the entrance gate.

13. Check the operation of the stabilisers. Use the AUTO LEVEL switch to set the stabilisers and

ensure that the LIFT ENABLE LIGHT comes on. Select AUTO STOW to fully retract the

stabilisers.

14. Check the operation of the stabilisers in MANUAL MODE. Operate each of the individual

Stabiliser Switches to see that they both extend and retract individual stabilisers.

15. Select DRIVE mode.

NOTE: Use both HI and LOW drive when per form ing the fol low ing step.

16. While engaging the Interlock Switch, move the Control Handle to FORWARD, then

REVERSE, to check for speed control

17. Push the Steering Switch RIGHT, then LEFT, to check for steering control.

18. Select LIFT mode. Grasp the Control Handle, engaging the Interlock Switch, and pull it back

to check platform lift controls. Raise the platform to full elevation.

19. Push forward on the Control Handle. The platform should descend and the audible lowering

alarm should sound.

20. Push the Platform Emergency Stop Switch to check for proper operation. All machine

functions should be disabled. Pull out the Platform Emergency Stop switch to allow normal

operation to resume.

Operation Manual Page 7

Operation

OPERATION

STARTING THE ENGINE

TRAVEL WITH THE PLATFORM LOWERED

STEERING

ELEVATING THE PLATFORM

Be fore op er at ing the work plat form, en sure that the Pre-Op er a tion Safety In spec tion has been

com pleted and that any de fi cien cies have been cor rected. Never op er ate a dam aged or mal -

func tion ing ma chine.

The op er a tor must be thor oughly trained on this ma chine.

1. Turn the key on at the ground control position.

2. Mount the platform and close the entry gate.

3. Turn the start switch to ON.

4. Depress and hold the COLD START button for approximately 5 seconds.

5. Turn the start switch to the start position.

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps,

and debris), is level, and is capable of supporting the wheel loads.

2. Verify that the engine is started and the Chassis Emergency Stop Switch in ON (pulled out).

3. Mount the platform and properly close the entrance gate.

4. Check clearances above, below, and to the sides of the platform.

5. Pull the Platform Emergency Stop Switch out to the ON position.

6. Select DRIVE mode.

NOTE: Choose be tween hi speed drive (rab bit) and low speed (tur tle)

7. Engage the Interlock Switch and move the Control Handle FORWARD or REVERSE to

travel in the desired direction. the speed of the machine will vary depending how far from

centre the Control Handle is moved.

1. Turn the drive/Lift Switch to DRIVE

2. While engaging the Interlock Switch, push the Steering Switch to RIGHT or LEFT to turn the

wheels in the desired direction. Observe the tires while maneuvering the work platform to

ensure proper direction.

NOTE: Steer ing is not self-cen ter ing. Wheels must be re turned to the straight ahead po si -

tion by op er at ing the Steer ing Switch.

1. Select a firm, level surface.

2. Select LIFT mode.

3. While engaging the Interlock Switch, pull the Control Handle backward.

4. If the machine is not level the tilt alarm will sound, the lift enable light will not illuminate, and

the machine will not lift or drive.

5. If the tilt alarm sounds the platform must first be fully lowered, and either the machine

moved to more level ground or the stabilisers used to level the machine.

Page 8 Operation Manual

Operation

TRAVEL WITH THE PLATFORM ELEVATED

LOWERING THE PLATFORM

LEVELLING THE PLATFORM

LEVELLING THE PLATFORM MANUALLY

LEVELLING THE PLATFORM AUTOMATICALLY

NOTE: The ma chine will travel at re duced speed when the plat form is el e vated

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and

debris), is level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of the platform.

3. Select DRIVE mode.

4. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to

travel in the desired direction. The speed of the machine will vary depending on how far from

centre the Control Handle is moved.

5. If the machine is not level the tilt alarm will sound, the lift enable light will not illuminate, and

the machine will not lift or drive. If the tilt alarm sounds the platform must be lowered and the

machine moved to a firm level surface before attempting to re-elevate the platform.

1. Select LIFT mode.

2. Check around the base of the platform to ensure that no one is in contact with the machine.

Engage the Interlock Switch and push forward on the Control Handle to lower the platform.

3. The platform will stop when it reaches approximately 1 metre from the stowed position and an

alarm will sound. Inspect around the machine to ensure no one is in contact with the machine.

After a pre-set delay continue to lower the platform as in step 2.

NOTE: The plat form can be lev elled ei ther man u ally or au to mat i cally by set ting the sta bi lis ers. It is

also pos si ble to use a com bi na tion of man ual levelling and auto lev el ling. For ex am ple the ma chine

can be man u ally lev elled part way and then "auto lev elled".

The en gine must be run ning and the ma chine set for plat form op er a tion.

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and

debris), is level, and is capable of supporting the loads.

2. Check clearances above, below, and to the sides of the platform.

3. Pull and hold the Stabiliser Switches backwards (one at a time) until all four stabilisers

contact the ground.

4. Visually check the level bubble to determine which stabilisers must be further extended to

level the platform.

5. When the Lift Indicator Light comes on the platform can be safely raised.

1. Check that the route is clear of obstacles (persons, obstructions, holes, drop-offs, bumps, and

debris), is level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of the platform.

3. Press and hold the Auto Level Switch down to the auto level position until all movement stops

and the Lift Enable Light illuminates.

Operation Manual Page 9

Operation

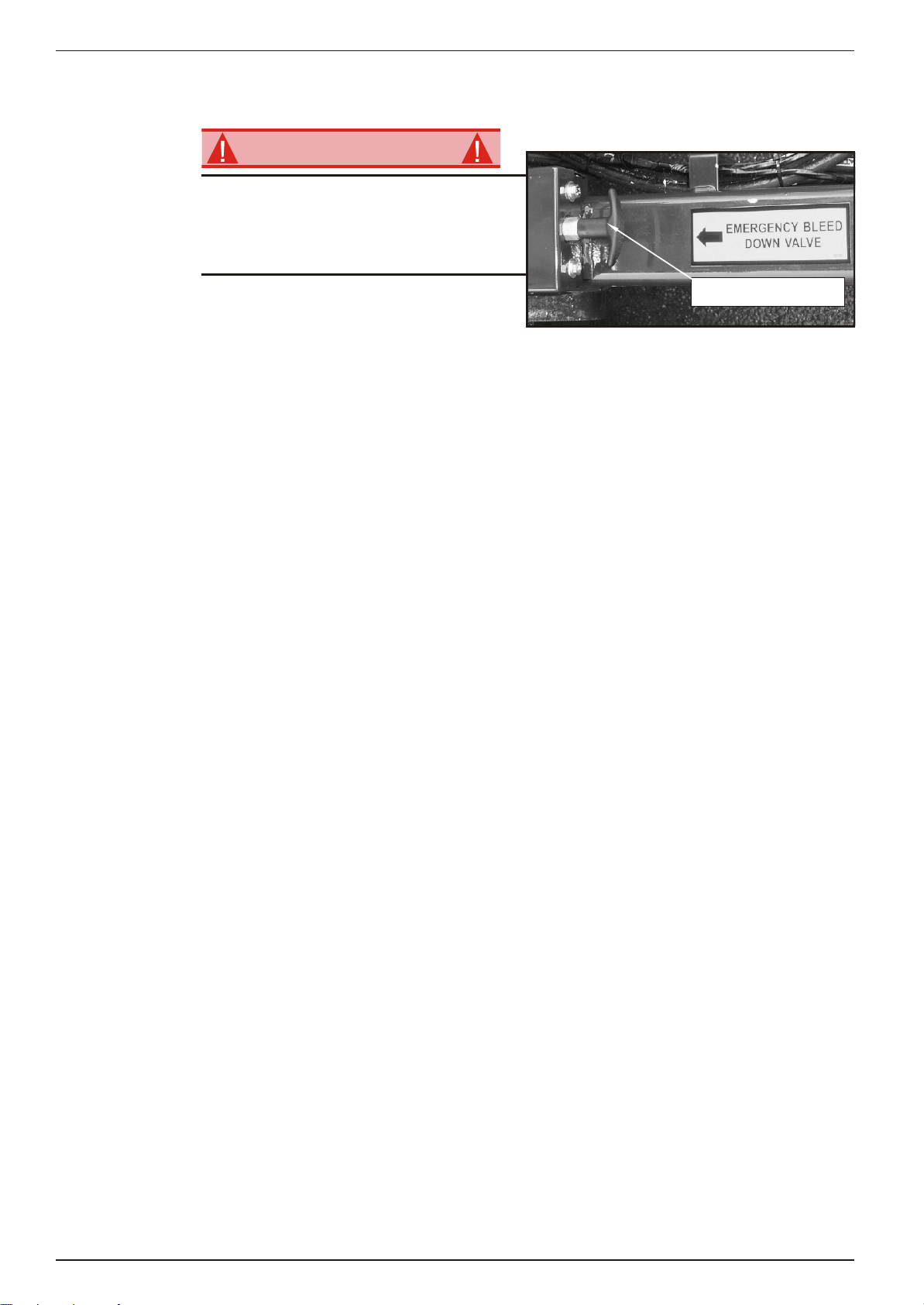

EMERGENCY LOWERING

W A R N I N G

EMERGENCY LOWERING

HANDLE

Figure 4: Emergency Lowering

If the plat form should fail to lower, NEVER

climb down the el e vat ing as sem bly.

Stand clear of the el e vat ing as sem bly while

op er at ing the Emer gency Low er ing

Con trol.

1. Check around the base of the platform to ensure that no one is in contact with the machine.

2. To lower the platform, pull on the handle until the platform is fully lowered.

Page 10 Operation Manual

Operation

FOLD DOWN GUARDRAILS

FOLD DOWN PROCEDURE

ERECTION PROCEDURE

D A N G E R

NOTE: Guard rails must be re turned to proper po si tion be fore us ing the ma chine.

1. Undo the cables from the control box and remove the two "grip clips". Remove the control box

and store it securely.

2. Pull out the two pins at the base of the front guardrail and lift it out of the 2 locking clevis

fixtures at the top on each side.

3. Lay the front guardrail on the deck of the platform.

4. Repeat steps 2 and 3 for the rear guardrail.

5. Working with either side guardrail, remove the two pins from the extension deck guardrail and

fold it over onto the deck. Repeat this for the extension guardrail on the other side.

6. Remove the 4 pins from one of the side guardrails and fold this down on to the deck. Repeat

the procedure for the other side.

1. Raise the side guardrails and insert locking pins.

2. Raise the extension deck guardrails and insert the locking pins.

3. Lift the rear guardrail into position aligning the two clevis fixtures and pull/push it securely into

place. Insert the two locking pins.

4. Repeat step 3 for the front guardrail.

5. Reattach the control box with the two "grip clips" and reattach the control cables.

Be fore en ter ing the plat form, guard rails must be se curely fas tened in

their proper po si tion.

Operation Manual Page 11

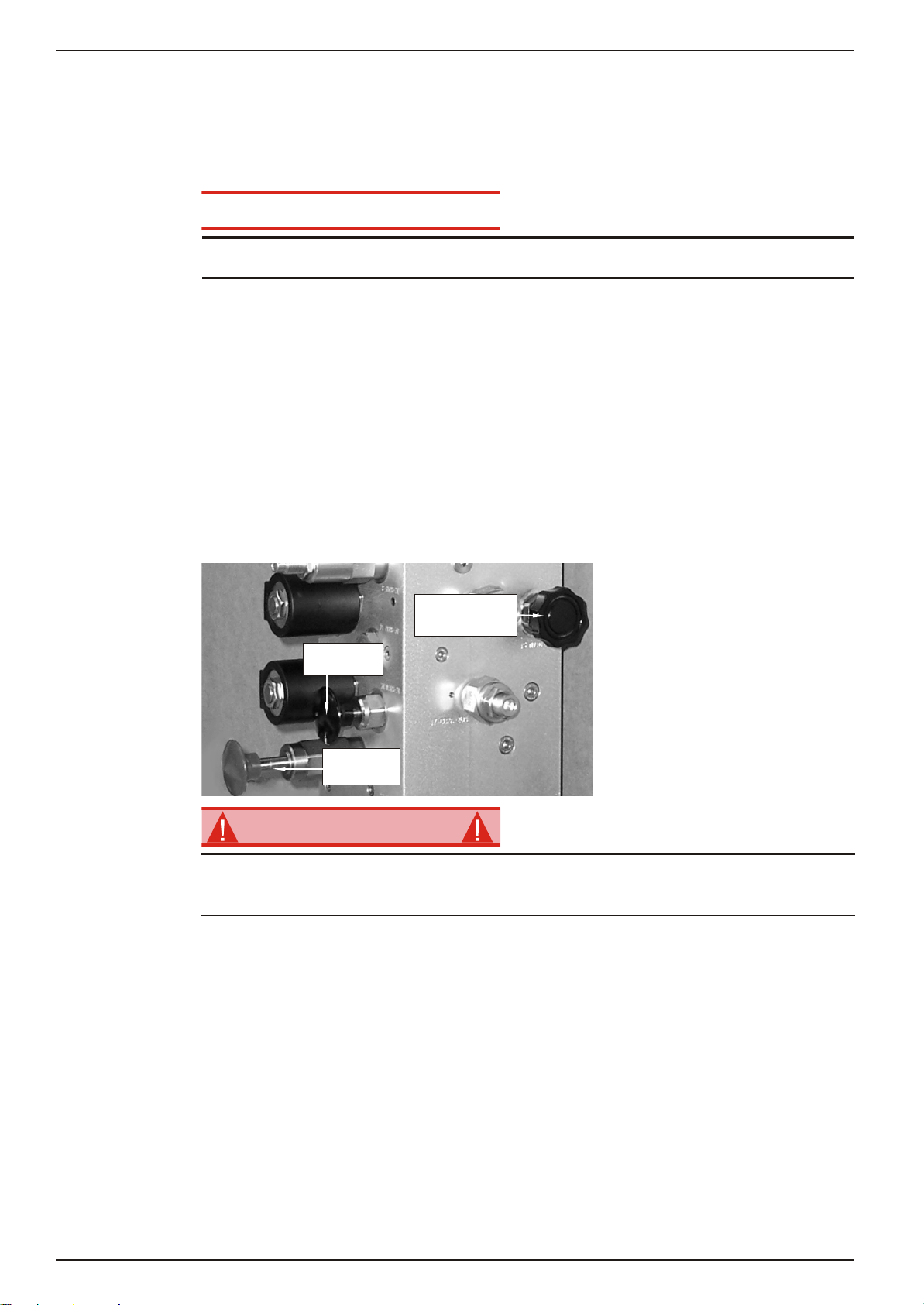

Towing or Winching

TOWING OR WINCHING

C A U T I O N

BRAKE RELEASE PUMP

FREE-WHEEL

VALV E

HAND

PUMP

RE-SET

KNOB

W A R N I N G

AFTER USE EACH DAY

HOUR METER

Per form the fol low ing only when the ma chine will not op er ate un der its own power and it is nec es sary to move the ma chine or when winch ing onto a trans port ve hi cle (see "Trans port ing the Work

Plat form" on page 13).

DO NOT tow or winch the ma chine faster than 2 mph (3.2 km/hr), (0.9m/s), (3ft./s). Faster

speeds will dam age drive com po nents and void the war ranty.

Per form the fol low ing only when the ma chine will not op er ate un der it's own power and it is nec es sary to move the ma chine or when tow ing the ma chine up a grade or onto a trailer to trans port.

1. At the ground control box set the Emergency Stop switch to off, turn the Main Power switch

to off and remove the key.

2. Inside the Hydraulic Compartment, open the Free-Wheeling Valve by turning

counterclockwise until the knob stops.

3. To Release the Brakes, Pump the Hand-Pump 5-10 times. The brakes will now be released

and the machine is ready to be towed, pushed, or winched.

4. Once the machine has been safely towed pull the Re-set Knob to re-apply the brakes, and

close the Free-Wheel Valve by turning fully clockwise.

Figure 5: Brake Release Pump

Never tow faster than 0.9 m/sec (3 ft./sec.).

Never op er ate the work plat form with the park ing brakes re leased. Se ri ous in jury or dam age

could re sult.

1. Ensure that the platform is fully lowered and that all four stabilisers are fully retracted.

2. Park the machine on a firm level surface, preferably under cover, secure against vandals,

children and unauthorized operation.

3. Turn the Battery Switch to OFF and padlock it.

4. Turn the Ground Key Switch to OFF and remove the Key to prevent unauthorized

operation.

Page 12 Operation Manual

The hour me ter can be read from the Ground Con trol Box.

Transporting the Work Platform

TRANSPORTING THE WORK PLATFORM

PREPARATION FOR SHIPMENT

LIFTING BY CRANE

BY FORKLIFT

D A N G E R

FRONT TIE DOWN

AND LIFTING LUGS

REAR TIE DOWN

AND LIFTING LUGS

FORKLIFT POCKETS

(Both sides of machine)

DRIVING OR WINCHING ONTO

A TRUCK OR TRAILER

C A U T I O N

1. Fully lower the platform.

2. Turn OFF the Main Power Switch and remove the key.

3. Turn the battery switch to OFF and padlock it.

1. Secure straps to chassis tie down/lifting lugs only.

2. Place the platform onto the transport vehicle in the transport position.

3. Chock the wheels.

4. Secure the work platform to the transport vehicle with chains or straps of adequate load

capacity attached to the chassis tie down/lifting lugs.

Forklifting is for trans port only.

See spec i fi ca tions for weight of work plat form and be cer tain that the fork lift is of ad e quate ca pac ity to lift the work plat form.

Fork lift from the side us ing the 'built in' fork lift pock ets.

Figure 6: Transporting

NOTE: Do not winch faster than 0.9 m/s (3 ft/s).

1. Move the machine onto the trailer.

A.

To Drive the machine onto the transport

vehicle:

i. Move the work platform up the ramp and into

the transport position.

ii. Set the wheels straight and turn off the

machine.

iii. Chock the wheels

B.

To Winch the machine onto the transport

vehicle.

i. Move the platform up to the ramp.

ii. Attach the winch cable to the tie down/lifting

lugs.

iii. Release the parking brakes (refer to "Towing or

Winching" on page 12).

iv. Winch the platform into transport position.

v. Chock the wheels.

vi. Reset the parking brakes.

2. Secure the work platform to the transport vehicle with chains or straps of adequate load

capacity attached to the chassis tie down/lifting lugs.

Overtightening of the chains or straps at tached to the Tie Down/Lift ing Lugs may re sult in dam age to the work plat form.

Operation Manual Page 13

Maintenance

MAINTENANCE

W A R N I N G

BLOCKING THE

ELEVATING ASSEMBLY

INSTALLATION

REMOVAL

Never per form ser vice while the plat form is el e vated with out first block ing the el e vat ing as sem bly.

DO NOT stand in the el e vat ing as sem bly area while de ploy ing or stor ing the brace.

Figure 7: Scissor Brace

1. Park the work platform on firm level ground and

leave the engine running.

2. Ensure the Ground Emergency Stop Button is

pulled to the ON position.

3. Using the Ground Controls raise the scissor arm

assembly sufficiently to raise the Scissor Prop to

a vertical position.

4. Using the Ground Controls lower the scissor

arm assembly until it is firmly resting on the

prop.

1. Using the Ground Controls raise the scissor arm assembly until the safety prop can be

removed.

2. Place the scissor arm prop back into it's cradle.

3. Lower the scissor arm assembly until it reaches its stowed position.

Page 14 Operation Manual

Maintenance

BATTERY MAINTENANCE

W A R N I N G

BATTERY CHARGING

Haz ard of ex plo sive gas mix ture. Keep sparks, flame, and smok ing ma te rial away from bat tery.

Al ways wear safety glasses when work ing near bat ter ies.

bat tery fluid is highly cor ro sive. thor oughly rinse away any spilled fluid with clean wa ter.

Al ways re place bat ter ies with othe cor rect type or man u fac turer ap proved re place ments.

●

Check the battery fluid level daily, especially if the work platform is being used in a

warm dry climate.

●

If electrolyte level is lower than 10mm (3/8") above the plates add distilled water only.

DO NOT use tap water with high mineral content, as this will shorten battery life.

●

Keep the terminals and tops of the battery clean.

●

refer to the Service manual to extend battery life and for complete service instructions.

The bat tery is charged while the en gine is run ning.

Operation Manual Page 15

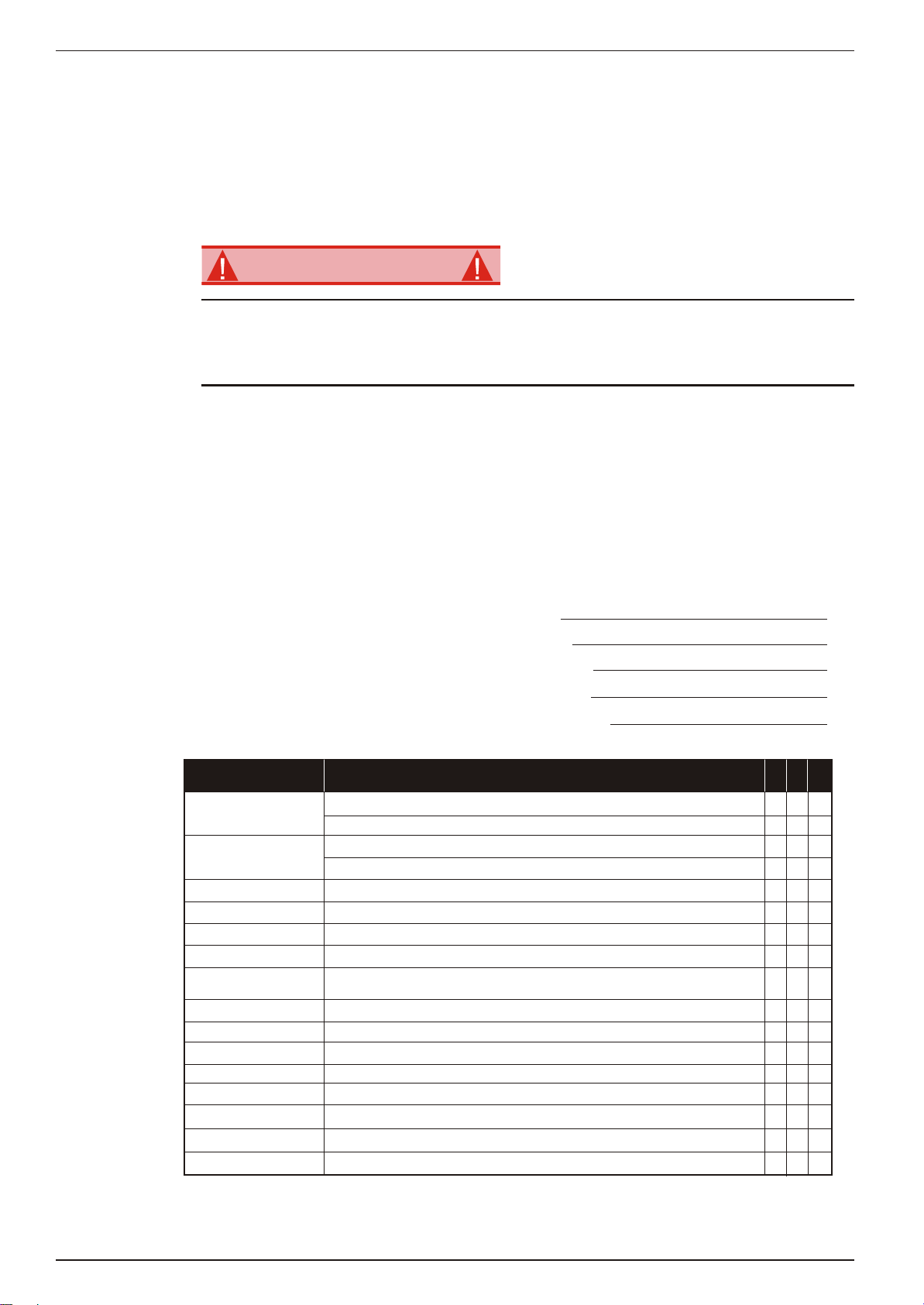

Inspection and Maintenance Schedule

DAILY PREVENTATIVE MAINTENANCE CHECKLIST

W A R N I N G

INSPECTION AND MAINTENANCE SCHEDULE

MAINTENANCE TABLE KEY

Y = Yes/Acceptable

PREVENTATIVE MAINTENANCE REPORT

N = No/Not Acceptable

R = Repaired/Acceptable

Date:

Owner:

Model No:

Serial No:

Serviced By:

INSPECTION OR SERVICES

RNY

COMPONENT

Battery

Check electrolyte level

Check battery condition

Chassis

Check hoses for pinch or rubbing points

Check welds for cracks

Check the exterior of the cable for pinching, binding or wear

Control Cable

Controls

Check switch operation

Drive Motors

Check for operation and leaks

Elevating Assembly

Inspect for structural cracks

Emergency Lowering

Assembly

Operate the emergency lowering mechanism and check for serviceability

Entire Machine

Check for and repair collision damage

Hydraulic Fluid

Check fluid level

Hydraulic Pump

Check for hose fitting leaks

Hydraulic System

Check for leaks

Labels

Check for peeling, missing, or unreadable labels and replace

Platform Deck & Rails

Check welds for cracks

Tires and Wheels

Check for damage

Platform Deck & Rails

Check condition of deck

The Com plete In spec tion con sists of pe ri odic vi sual and op er a tional checks, along with

pe ri odic mi nor ad just ments that as sure proper per for mance. daily in spec tion will pre vent

ab nor mal wear and pro long the life of all sys tems. The in spec tion and main te nance

sched ule should be per formed at the spec i fied in ter vals. in spec tion and main te nance

shall be per formed by per son nel who are trained and fa mil iar with me chan i cal and elec tri cal pro ce dures.

Be fore per form ing pre ven ta tive main te nance, fa mil iar ize your self with the op er a tion of the ma chine.

Al ways block the el e vat ing as sem bly when ever it is nec es sary to per form main te nance while

the plat form is el e vated.

The daily pre ven ta tive main te nance check list has been de signed for ser vice and main te nance.

Please pho to copy this page and use the check list when in spect ing the ma chine.

Page 16 Operation Manual

Daily Preventative Maintenance Checklist

NOTES:

Operation Manual Page 17

Labels

LABELS

12671

569295

300700

12816

12815-2

Inside Cabinet

Inside Cabinet

0323897

58365-6

9223-3

569295

12814

451986

96924-9

96924-9

476706

9223-3

560272

12689

96924-9

569295

12699

9223-3

605726

476706

9208

621486

12753

569295

12671

569295

621486

621486

9223-3

12815-4

Inside Cabinet

Inside Cabinet

Inside Cabinet

Inside Cabinet

Inside Cabinet

621486

9751

12574

1843

562246

451986

9223-3

0083427

0083427

0083427

0083427

9223-3

9223-3

9223-3

560240

300699

0070901E

0073298

96924-9

These la bels shall be pres ent and in good con di tion be fore op er at ing the work plat form. Be sure to

read, un der stand and fol low these la bels when op er at ing the work plat form.

Page 18 Operation Manual

Specifications

SPECIFICATIONS

X 27-RT

Nominal working height

Roll out deck size

Drive speed (below 2.4m)

Drive speed (above 2.4m)

Safe working load - Main deck

(Roll out deck not extended)

Safe working load - Main deck

Roll out deck extended - Roll out deck

Platform size

Stowed height

Stowed height (hand rails folded down)

Overall length

Overall width

Gradeability

Lift time

Turning radius (inner)

Turning radius (outer)

Maximum wind speed (12.5m/s)

Insulation rating

Tyres - Poly filled loader lug

Overall weight

Ground clearance

Maximum sound level at platform

10.28m 33' 9”

1200mm 48”

0 to 4.5kph 0 to 2.8mph

0 to 0.9kph 0 to 0.6mph

580kg 1280lbs

460kg

120kg

2.73 x 1.65m 8’ 11” x 5’ 5”

2.5m 8' 2"

1.7m 5' 8"

3.36m 11’ 0”

1.7m 5' 8"

35%

26 seconds

2.83m 9’ 3”

4.6m 15’ 1”

45km/h 28mph

Nil

27" x 10.5" x 15"

2800kg 6272lbs

350mm 13.8”

86db

1015lbs

265lbs

X-33-RT

Nominal working height

Roll out deck size

Drive speed (below 2.4m)

Drive speed (above 2.4m)

Safe working load - Main deck

(Roll out deck not extended)

Safe working load - Main deck

Roll out deck extended - Roll out deck

Platform size

Stowed height

Stowed height (hand rails folded down)

Overall length

Overall width

Gradeability

Lift time

Turning radius (inner)

Turning radius (outer)

Maximum wind speed (12.5m/s)

Insulation rating

Tyres - Poly filled loader lug

Overall weight

Ground clearance

Maximum sound level at platform

12.12m 39' 2”

1200mm 48”

0 to 4.5kph 0 to 2.8mph

0 to 0.35kph 0 to 0.22mph

450kg 990lbs

330kg

120kg

2.73 x 1.65m 8’ 11” x 5’ 5”

2.7m 8' 10"

2.0m 6' 6"

3.36m 11’ 0”

1.77m 5' 9"

35%

50 seconds

2.38m 7’ 8”

4.75m 15’ 6”

45km/h 28mph

Nil

27" x 10.5" x 15"

3620kg 7964lbs

350mm 13.8”

86db

726lbs

264lbs

Spec i fi ca tions are sub ject to change with out no tice. Hot weather or heavy use may af fect per for mance. Re fer to the Ser vice Man ual for com plete

parts and ser vice in for ma tion. This ma chine meets or ex ceeds all ap pli ca ble re quire ments of OSHA and ANSI A92.6

Operation Manual Page 19

X-27-33-RT

Seriennummern NZ 70810 - aktuelles Modell

DEUTSCH

Stellen Sie sicher, dass Sie die MODELL- und SERIENNUMMERN auf dem Gerätetypenschild angeben,

wenn Sie sich mit Upright bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzen.

UpRight Powered Access HQ

POWERED ACCESS

www.upright.com

Vigo Centre

Birtley Road

Washington

Tyne & Wear

NE38 9DA

Tel: +44 (0) 845 1550 057

Fax: +44 (0) 845 1557 756

BETRIEBSANLEITUNG

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Betriebsanleitungen gründlich durchlesen, verstehen und

befolgen, bevor sie an irgendeiner Upright-Hocharbeitsbühne Wartungsarbeiten ausführen oder die

Arbeitsbühne in Betrieb nehmen.

Sicherheitsrichtlinien

Lebensgefahr durch

Stromschlag

Diese Maschine ist nicht

isoliert!

Kippgefahr Kollisionsgefahr

NIEMALS die Plattform ausfahren oder die

Maschine mit ausgefahrener Plattform

fortbewegen, wenn sich die Maschine nicht auf

einer festen, ebenen Fläche befindet.

Plattform NIEMALS in Position bringen,

ohne vorher sicherzustellen, dass der

Bereich über der Plattform frei von

Hindernissen und anderen Gefahren ist.

Gefahr des

Herunterfallens

NIEMALS auf das obere oder mittlere

Gestänge des Plattformgeländers klettern

und auch nicht darauf stehen oder sitzen.

VERWENDUNG DER HUBARBEITSPLATTFORM: Diese Hubarbeitsplattform dient zum Anheben von Personen und deren

Werkzeug sowie von Material, das für bestimmte Arbeiten erforderlich ist. Sie wurde speziell für Reparatur- und Montagearbeiten

sowie für Einsatzbereiche konzipiert, die sich oberhalb der Mitarbeiter befinden, sodass die Mitarbeiter nach oben gerichtet

arbeiten müssen (z. B. Decken, Kräne, Dachstrukturen, Gebäude etc.). Jede andere Verwendung der Hocharbeitsbühne ist strikt

verboten!

DIESE HUBARBEITSPLATTFORM IST NICHT ISOLIERT! Aus diesem Grund müssen Sie von stromführenden Teilen

elektrischer Anlagen einen Sicherheitsabstand einhalten!

Es ist verboten, die angegebene zulässige Maximallast zu überschreiten.Siehe Abschnitt "Besondere Einschränkungen" auf

Seite 4 für weitere Einzelheiten hierzu.

Es ist streng verboten, die Hocharbeitsbühne als Hubwerkzeug oder Kran einzusetzen (d. h. um Lasten von unten nach oben

oder von oben nach unten zu befördern).

Die für diese Maschine zulässige manuelle Kraft NIEMALS überschreiten. Siehe Abschnitt "Besondere Einschränkungen" auf

Seite 4 für weitere Einzelheiten hierzu.

VERTEILEN Sie die gesamte Plattformlast gleichmäßig auf der Plattform.

Vor Inbetriebnahme der Maschine IMMER ZUERST die Aufstellfläche im Arbeitsbereich auf Gefahren wie Bodenlöcher,

ausgelaufene Flüssigkeiten, Bodenerhebungen, Kanten oder Schutt untersuchen und diese umgehen bzw. beseitigen.

BEDIENEN Sie die Maschine nur auf Flächen, die das Gewicht der Maschine tragen können.

Maschine NIEMALS in Betrieb nehmen, wenn die tatsächliche Windgeschwindigkeit höher ist als die Windgeschwindigkeit, für die

die Maschine ausgelegt ist. Siehe "Beaufort-Skala" auf Seite 4 für weitere Einzelheiten hierzu.

IM NOTFALL NOT-AUS-Schalter drücken, um alle strombetriebenen Funktionen zu deaktivieren.

WENN EIN ALARMSIGNAL ERTÖNT, während die Plattform angehoben ist, HALTEN SIE SOFORT AN, und senken Sie die

Plattform vorsichtig ab. Fahren Sie die Maschine auf einen festen, ebenen Untergrund.

Das Hochsteigen auf den Schienen der Plattform, das Stehen oder Steigen von der Plattform auf Gebäude, Stahl- oder

Betonstrukturen von Fertighäusern usw. ist verboten!

Das Schwingtor oder andere Komponenten des Schutzgeländers zu demontieren ist verboten! Vergewissern Sie sich immer,

dass das Schwingtor geschlossen und sicher verriegelt ist!

Es ist verboten, das Schwingtor geöffnet zu halten (z. B. mit Befestigungsgurten), wenn die Plattform ausgefahren wird!

Das Erweitern der Höhe oder der Reichweite durch die Verwendung von Leitern, Gerüsten oder ähnlichen Hilfsmitteln auf der

Plattform ist verboten!

Führen Sie bei angehobener Plattform NUR DANN Wartungsarbeiten an der Maschine aus, wenn Sie die Hubeinheit blockiert

haben.

UNTERSUCHEN Sie die Maschine vor Gebrauch gewissenhaft nach gerissenen Schweißnähten, losen oder fehlenden

Befestigungselementen, Hydrauliklecks, losen Drahtverbindungen und beschädigten Kabeln oder Schläuchen.

ÜBERPRÜFEN Sie vor dem Gebrauch, dass alle Etiketten richtig angebracht und lesbar sind.

Verwenden Sie

Etiketten aufweist.

Betriebsanleitung Seite 1

NIEMALS eine Maschine, die beschädigt ist, nicht ordnungsgemäß funktioniert oder beschädigte bzw. fehlende

Das Umgehen einer Sicherheitseinrichtung ist verboten und stellt eine Gefahr für die Personen auf der Hubarbeitsplattform und

innerhalb des Arbeitsbereichs dar.

Laden Sie die Batterien NIEMALS in der Nähe von offenen Flammen oder Funkenbildung auf. Beim Aufladen von Batterien wird

explosives Wasserstoffgas freigesetzt.

Modifikationen an der Hubarbeitsplattform sind verboten bzw. dürfen nur mit der Zustimmung von UpRight durchgeführt

werden.

Sichern Sie die Arbeitsplattform NACH GEBRAUCH gegen unbefugte Benutzung, indem Sie den Schlüsselschalter ausschalten

und den Schlüssel abziehen.

Seite 2 Betriebsanleitung

I NHALT

Einführung

Allgemeine Beschreibung 4

Tragfähigkeit der Plattform 5

Manuelle Kraft 5

Beaufort-Skala 5

Alarm bei Überlastung der Hubeinheit 5

Bedienelemente und Anzeigen 6

Sicherheitsprüfung vor der Inbetriebnahme 7

Überprüfung der Systemfunktionen 8

Bedienung 9

Plattformverlängerung 9

Fahren mit abgesenkter Plattform 9

Lenkung 9

Anheben der Plattform 9

Fahren mit ausgefahrener Plattform 10

Absenken der Plattform 10

Nivellieren der Plattform 10

Notabsenkung 11

Einklappen der Schutzgitter 12

Einklappen 12

Montageanleitung 12

Ziehen oder Winden 13

Lösen der Feststellbremse 13

Nach dem täglichen Gebrauch 13

Betriebsstundenzähler 13

Transport der Arbeitsbühne 14

Vorbereitung 14

Anheben mit einem Kran 14

Per Gabelstapler 14

Fahren oder Ziehen der Maschine auf einen Lastwagen 14

Wartung 15

Blockieren der Hubvorrichtung 15

Installation der Scherenklammer 15

Verstauen der Scherenklammer 15

Wartung der Batterie 16

Aufladen der Batterie 16

Inspektions- und Wartungsplan 17

Checkliste für tägliche präventive Wartungsarbeiten 17

Etiketten 19

Technische Daten 20

Betriebsanleitung Seite 3

4

Einführung

E INFÜHRUNG

Dieses Handbuch beschreibt Einsatz und Bedienung der selbstfahrenden Arbeitsbühnen für schwierige

Gelände der Serie X-27-33-RT. Das Handbuch muss immer bei der Maschine aufbewahrt werden.

A LLGEMEINE B ESCHREIBUNG

1. Plattform

WARNUNG

Hocharbeitsbühne NICHT ohne korrekt

montiertes und angebrachtes Schutzgeländer verwenden.

2. Hubvorrichtung

Abbildung 1

3. Fahrwerk

4. Motor

5. Plattform-Bedienelemente

6. Handbuchfach

7. Fahrwerk-Bedienelemente

8. Behälter für Hydraulikflüssigkeit

5

7

Seite 4 Betriebsanleitung

Loading...

Loading...