Snorkel TL37J User Manual

Operation MANUAL

TL37J

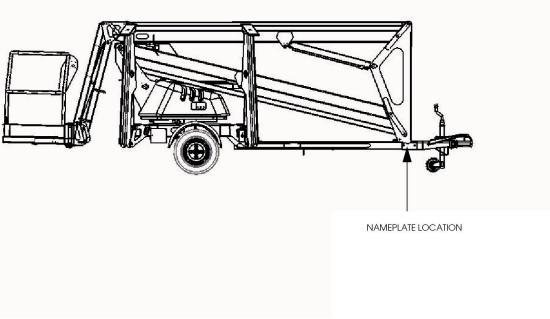

When contacting Snorkel for service orparts information, always include the MODEL and SERIAL NUMBER from the machine namplate.

The serial number is stmped into the chassis above the machine nameplate.

e.g. 7 # # #

www.snorkellifts.com

WARNING

Allpersonnelshallcarefullyread,understandandfollowallsafetyrulesandoperatinginstructions

before operating or performing maintenance on any Snorkel platform.

Safety Rules

Electrocution Hazard |

Tip Over Hazard |

Collision Hazard |

Fall Hazard |

THIS MACHINE IS NOT

INSULATED!

NEVER elevate the platform or move the machine while elevated. Always level the machine with the outriggers before elevating the platform.

NEVERpositionthe platform without first checking for overhead obstructions or other hazards.

NEVER climb, stand, or sit on platform guardrails or midrail.

Always check the outriggers before entering the platform

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures, buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Platform Capacity” on page 7 for details. The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See page 11 for details. DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 12 for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc., is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed and securely locked!

It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited! NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas. Modifications to the aerial work platform are prohibited or permissible only at the approval by Snorkel.

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

CONTENTS

|

Page |

Introduction |

4 |

Description of Equipment |

5 |

Technical Specification |

6 |

Working Envelope |

7 |

Operator Requirements |

8 |

Warning Notices |

9 |

. Beaufort Scale |

10 |

Towing Instructions |

11 |

Pre-Start Checks |

13 |

Batteries, & Power Pack |

15 |

Setting Up |

16 |

Extending Structure |

18 |

. Basket Controls |

18 |

. Ground Controls |

19 |

Safety Harness |

20 |

Emergency Controls |

|

. Emergency Stops |

20 |

. Emergency Lower (Aided) |

21 |

. Emergency Lower (Unaided) |

22 |

. Emergency Slew |

22 |

. Cage Overload |

23 |

. Emergency Battery Isolation |

24 |

Stowing the Machine |

25 |

2

CONTENTS

Maintenance |

Page |

|

|

. Daily Checks |

26 |

. Weekly and Monthly Checks |

27 |

. Slew Drive and Limit Switches |

28 |

Trailer lights |

29 |

Appendices |

|

App’1 Petrol/Bi-fuel Option. |

30 |

App’2 Generator Option. |

31 |

App’3 Mains connection. |

32 |

3

INTRODUCTION

The Snorkel TL37J’s unique combination of strength, versatility and simplicity, have made it an instant leader in its class.

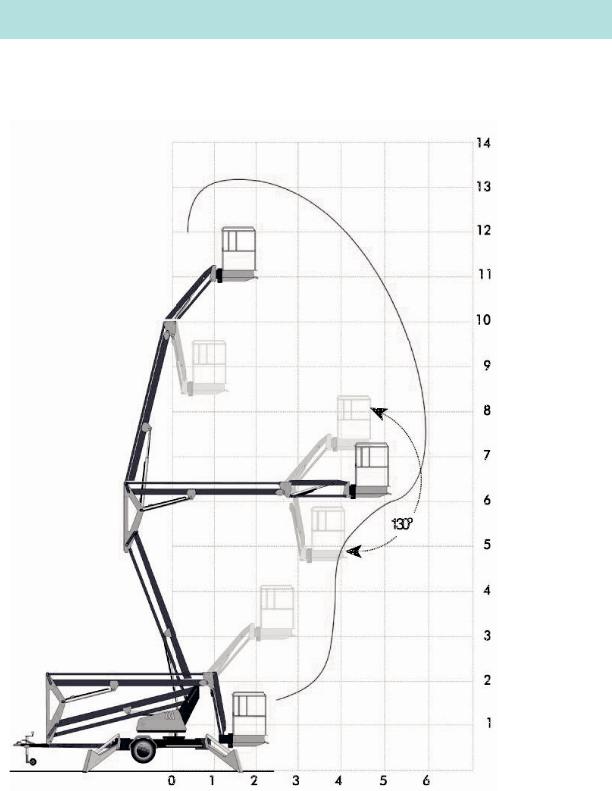

Its exceptional working envelope, despite the low towing weight, is achieved thanks to our innovative boom design.

The third flick boom, with 130 DEGREES working arc, guarantees access to the most hard to reach places, while the 90 DEGREES basket rotation provides the precision positioning that is vital for working in tight spaces.

Snorkel has a global reputation for innovation and a proud heritage in the design and manufacture of high quality powered equipment.

The company was founded in the UK more than 25 years ago, on the principle of constantly improving service excellence for end users.

Every model in our growing range of versatile, trailer mounted units is a class leader and together they have set new industry benchmarks.

Our commitment to research and design, plus 250,000sq ft of same site fabrication, build and support capacity, mean Snorkel can offer complete solutions to meet even the most demanding access applications.

Snorkel has third party accreditation to quality standard ISO 9001 and the full range proudly carries the CE mark, complying with or exceeding all relevant standards and EC directives.

SNORKEL is a member of the IPAF

International Powered Access Federation.

To ensure you are fully aware of safety and operational information, the following symbols are used throughout this manual;

This type of box contains, Points of operation to NOTE.

The information contained in this type of box contains, WARNING text. It gives Warnings about the risk of Damage to equipment, and possibly personnel.

The information contained in this type of box contains, DANGER text. It gives Warnings about the risk of PERSONAL INJURY to the operator and or others.

4

DESCRIPTION OF EQUIPMENT

The Snorkel TL37J is of the parallel linkage vertical boom design, mounted on either a road towable trailer, or on industrial bogie chassis . The unique yet very simple boom configuration gives the maximum safety and control ability combined with a robust construction to withstand a heavy working environment.

The TL37J machine is designed for two man capacity with 215 kg S.W.L.

The machine incorporates a bottom boom with tie rod, a short vertical boom and a top boom with tie rod. The TL37J has also an independent hydraulically operated Flick-Out Boom and

Rotating Cage for extra manoeuvrability.

The hydraulic system is of a fail-safe design throughout, with built-in hydraulic lock valves on all the rams as a precaution against hose failure. The machine is controlled by means of proportional manual lever operated valves. These valves are located at both the base and in the cage, as standard.

Emergency lower valves are fitted as standard to allow the machine to be lowered from the Base. Additionally, a hand pump is fitted in the cage for emergency operation.

Thehydraulicallyoperatedoutriggersarefittedwithloadsensinginterlocks,topreventthebooms being raised without the outriggers being extended and under load. An interlock prevents the hydraulic outriggers being accidentally retracted while the booms are raised. A simple system of

warning lights show the power is on and each of the outriggers is under load.

Performance.

Maximum Working Height |

13.1 m |

|

Maximum Working Outreach |

5.9 m |

|

Capacity (2-man working) |

215 kg |

|

Slewing Arc |

700° |

|

Airborne Noise Emissions |

(Battery) |

70 dB(A) |

|

(Engine) |

100 dB(A) |

|

(Diesel) |

103 dB(A) |

Construction Standards.

The machine complies fully with the requirements of the following EEC Directives: Directive 98/37/EC, the ‘Machinery Directive’.

Directive 89/336/EEC, as amended – the ‘Electromagnetic Compatibility Directive’. Directive 73/23/EEC, as amended – the ‘Low Voltage Directive’.

The machine is designed and tested in accordance with all relevant B.S.I. and European Standards including EN280.

5

TECHNICAL SPECIFICATION

Cage Dimensions |

|

|

Length |

|

1.20m |

Width |

|

0.80m |

Guard-rail Height |

|

1.10m |

Toe-board Height |

|

0.15m |

Operating Dimensions |

|

|

Maximum Working Height |

|

13.10m |

Maximum Cage Height |

|

11.10m |

Maximum Outreach ( From centre of rotation ) |

5.90m |

|

Travel Dimensions |

|

|

Towing Length |

|

6.43m |

Closed Width |

|

1.48m |

Closed Height |

|

1.95m |

Weight (Battery Model) |

|

1450kg (unladen) |

Operating Parameters |

|

|

Safe Working Load |

|

215 kg |

Maximum Horizontal Pull |

|

400 N |

Maximum Wind Speed |

|

12.5 ms-1 |

Rotation |

|

700° |

Cage Slew |

|

90° |

Equipment |

|

|

Bottom Ram |

Double acting: |

Bore Ø 60.0 mm |

|

|

Rod Ø 40.0 mm |

Top Ram |

Double acting: |

Bore Ø 60.0 mm |

|

|

Rod Ø 40.0 mm |

Flick Ram |

Double acting: |

Bore Ø 60.0 mm |

|

|

Rod Ø 40.0 mm |

Stabiliser Ram |

Double acting: |

Bore Ø 70.0 mm |

|

|

Rod Ø 40.0 mm |

Bottom & Top Ram Lock Valves |

Pilot operated over centre valves |

|

Control Valve (Cage) |

Monoblock unit consisting of five double acting spools |

|

Control Valve (Ground) |

Monoblock unit consisting of four double acting |

|

|

spools |

|

Control Valve (Stabiliser) |

Monoblock unit consisting of four double acting |

|

|

spools |

|

Bushes |

Acetol resin polymer with sintered bronze base (DX) |

|

Pivot Pins |

Stainless Steel Bright Bar |

|

|

To Grade BS970 303 S31 CW |

|

6

WORKING ENVELOPE

Height in Meters

Reach in Meters

7

OPERATOR REQUIREMENTS

1.To operate the machine you must be medically fit and have no problems with eyesight or hearing.

2.You must have a good head for heights.

3.Your primary concern must be the safe operation of the work platform, the safety of the people working with you, and the safety of other persons in your working area.

4.You must be familiar with the contents of this manual, and at no time attempt to operate the machine beyond the recommended limits.

5.The proper care of the work platform is a major factor in ensuring the safety of those who work with it.

6.You must not misuse the machine or ignore or interfere with the devices that have been provided to maintain safety.

7.Operation of the machine should be restricted to personnel who have been authorised to operate the equipment and have received proper training.

8

Loading...

Loading...