Snorkel A62JRT User Manual

OPERATORS

MANUAL

Part Number 104850-000 December 2012

Serial number 000000 and after

Table of Contents

Table of Contents |

|

Declaration of Conformity............................................ |

2 |

Wheel Orientation Information.................................... |

3 |

Safety Rules................................................................ |

4 |

Introduction................................................................. |

5 |

Component Identification............................................ |

5 |

Special Limitations...................................................... |

6 |

Platform Capacity..................................................... |

6 |

Manual Force........................................................... |

6 |

Platform Overload Sensing System......................... |

6 |

Beaufort Scale......................................................... |

6 |

Controls and Indicators............................................... |

7 |

Battery Disconnect Switch.......................................... |

8 |

Lower Controls............................................................ |

8 |

Preheat Button......................................................... |

8 |

Start Switch.............................................................. |

8 |

Emergency Stop Button........................................... |

8 |

Controls Selector Switch.......................................... |

8 |

Ground Operation Switch......................................... |

8 |

Rotation Switch........................................................ |

8 |

Riser Switch............................................................. |

8 |

Boom Elevation Switch............................................ |

8 |

Boom Extension Switch........................................... |

8 |

Jib Articulation Switch.............................................. |

9 |

Platform Level Switch.............................................. |

9 |

Platform Rotation Switch.......................................... |

9 |

Engine/Emergency Power Switch............................ |

9 |

Hydraulic Oil Warm-Up Switch................................. |

9 |

Circuit Breaker Reset Buttons..................................... |

9 |

Upper Controls.......................................................... |

10 |

Preheat Switch....................................................... |

10 |

Start Switch............................................................ |

10 |

Emergency Stop Button......................................... |

10 |

Boom Joystick........................................................ |

10 |

Drive Joystick......................................................... |

10 |

Drive Range Switch............................................... |

11 |

Boom Speed Knob................................................. |

11 |

Riser Switch........................................................... |

11 |

Boom Extension Switch......................................... |

11 |

Jib Articulation Switch............................................ |

11 |

Platform Level Switch............................................ |

11 |

Platform Rotation Switch........................................ |

11 |

Engine/Emergency Power Switch.......................... |

11 |

Horn Switch............................................................ |

11 |

Platform Foot Switch.............................................. |

11 |

AC Generator Switch............................................. |

12 |

Hydraulic Oil Warm-Up Switch............................... |

12 |

Pre-Operation Safety Inspection............................... |

12 |

System Function Inspection...................................... |

13 |

Operation.................................................................. |

14 |

Cold Weather Start-Up........................................... |

14 |

Hydraulic System Cold Weather Warm-Up............ |

14 |

Hydraulic System Warm-Up Switch....................... |

14 |

Manually Warming The Hydraulic System............. |

14 |

Preparing for Operation......................................... |

15 |

Lower Controls....................................................... |

15 |

Upper Controls....................................................... |

15 |

Boom Operation..................................................... |

15 |

Driving and Steering.............................................. |

16 |

Drive Speeds......................................................... |

16 |

Pivoting Front Axle................................................. |

17 |

All Motion Alarm..................................................... |

17 |

Electrical Power Outlet........................................... |

17 |

AC Generator......................................................... |

17 |

Air Line................................................................... |

17 |

Emergency Lowering............................................. |

17 |

Lower Controls.................................................... |

18 |

Upper Controls.................................................... |

18 |

After Use Each Day............................................... |

18 |

Transporting the Machine......................................... |

19 |

Preparing for Transportation.................................. |

19 |

By Crane................................................................ |

19 |

By Truck................................................................. |

19 |

Storage...................................................................... |

19 |

Maintenance.............................................................. |

20 |

Hydraulic Fluid....................................................... |

20 |

Check Hydraulic Fluid............................................ |

20 |

Engine.................................................................... |

20 |

Oil Level................................................................. |

20 |

Battery Maintenance.............................................. |

20 |

Inspection and Maintenance Schedule..................... |

21 |

Daily Preventative Maintenance Checklist................ |

22 |

Preventative Maintenance Report.......................... |

22 |

Specifications............................................................ |

23 |

A62JRT – 104850-000 |

1 |

000-104850 – A62JRT

Model |

Modello |

|

|

A62JRT |

|

Modell |

Verticaal model |

|

|

|

|

|

|

|

|

||

Modele |

Malli |

|

|

|

|

Modelo |

|

|

|

|

|

Serial number |

Serienummer |

|

|

|

|

Matricola |

Numero de serie |

|

|

||

|

|||||

Sarajanumero |

Matricola |

|

|

|

|

Notified body |

|

Powered Access |

|||

Notifizierte Stelle |

|

Certification Ltd (PAC) |

|||

Organisme notifie |

|

Applethwaite Lodge, The Common |

|||

Organismo notificado |

|

Windermere |

|||

Aangemelde instantie |

|

Cumbria |

|||

Myndighet |

|

LA23 1JQ |

|||

Avendte harmoniserte standarder |

United Kingdom |

||||

Udpeget organ |

|

Notified body number 0545 |

|||

Asiasta on tehty ilmoitus seuraaville tahoille

Ente Notificatore

EC Type Examination Certificate number

EC-Typenprufung Zertifikat-Nr

Examen type CE Numero de Certificat

Inspeccion tipo CE Numero de certificado

Attestato di certificazione CE nr

Onderzoek van het type EC Certificaatnummer

EU typkontroll Certifieringsnummer

EF-typeproving Sertifikatnummer

EF-typegodkendelse Nummer pa typeattest

EU-tyyppitarkastuksen nr.

Signed for Snorkel

Manufacturing Quality Manager |

Date |

Gary Bradbury

Powered Access

Vigo Centre

Washington

Tyne and Wear

NE38 9DA

England

EC Declaration of Conformity of Machinery 2006/42/EC EC-Konformitätserklärung für Maschinen 2006/42/EC

Declaration De Conformite CE pour les Machines 2006/42/EC Declaracion De Conformidad CE Para Maquinaria 2006/42/EC Dichiarazione Di Conformità CE Per Le Macchine 2006/42/EC CE Conformiteitsverklaring voor Machinerie 2006/42/EC

EU Deklaration Avseende Överensstammelse För Maskinutrustning 2006/42/EC

EF-Samsvarserklaering For Maskiner 2006/42/EC EF-Overensstemmelseserklaering for Maskiner 2006/42/EC EU Vaatimustenmukaisuusvakuutus 2006/42/EC

Manufacturer |

|

Snorkel, |

Hersteller |

Fabrikant |

Vigo Centre, Washington, |

Fabricant |

Tillverkare |

Tyne and Wear, England |

Fabricante |

Produsent |

Tel: +44 (0) 845 1557 755 |

Fabbricante |

Valmistaja |

Fax: +44 (0) 845 1557 756 |

Authorized Representative |

|

|

Autorisierte Vertretung |

|

|

Representant autorise |

|

|

Representante autorizado |

|

|

Mandatario |

|

|

Erkend vertegenwoordiger |

|

|

Auktoriserad representant |

|

|

Autorisert representant |

|

|

Represenentant |

|

|

Valtuutettu edustaja |

|

|

Description |

|

Aerial Work Platform |

Bezeichnung |

|

Arbeitsbühne |

Description |

|

Plate-forme elevatrice de personnel |

Descripcion |

|

Platforma aerea de trabajo con motor |

Descrizione |

|

Piattaforma di sollevamento motorizzata |

Beschrijving |

|

Mechanisch aangedreven werkplatform |

Beskrivning |

|

Höj-och sänkbar arbetsplattform |

Beskrivelse |

|

Selvgående arbetsplattform |

Beskrivelse |

|

Motordrevet lofteplatform |

Kuvaus |

|

Konevoimalla toimiva nostolava |

|

|

Selvgående personarbetslift |

WARNING

WARNING

SAFETY NOTICE

PLEASE READ BEFORE USE

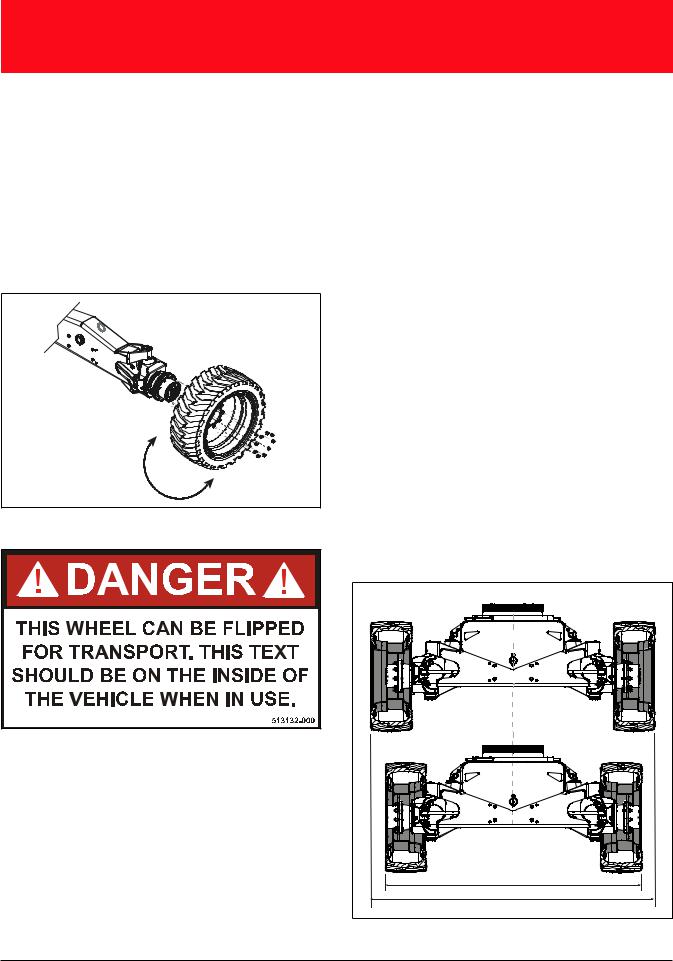

If this machine has been transported in a container the wheels will have been flipped to get it into the container. This will make the machine narrower than the design intent. The machine may be driven with the wheels flipped to load & unload but only ever when in the stowed position. The machine must not be used for a job of work until the wheels have been flipped back round to their correct position.

180°

Figure 1 – Correct Wheel Orientation

Figure 2 – Wheel Position Decal

The distance between the outer edge of the right wheel to the outer edge of the left wheel should be 2390mm (94 in) when the wheels are correctly orientated. Refer to Figure 3.

To flip the wheel back to the correct orientation (refer to Figure 1), use the following instructions.

1.Safely jack the machine.

2.Loosen the 9 retaining lug nuts.

3.Safely remove the wheel from the hub.

4.Flip the wheel 180° so that decal 513132-000 is facing on the inside of the wheel. Refer to Figure 2.

5.Safely fit the wheel back onto the hub.

6.Hand tighten the 9 retaining lug nuts and lower the machine from the jack.

7.Dry torque the lug nuts to 150 ft lbs in a non-circular pattern.

W O R K IN G /ELEVATIN G PO SITIO N |

TR A N SPO R TATIO N PO SITIO N |

2190m m |

2390m m |

Figure 3 – Wheel Position Distance

A62JRT – 104850-000 |

3 |

Introduction

SAFETY RULES

Warning

Warning

All personnel shall carefully read, understand and follow all safety rules and operating instructions before operating or performing maintenance on any Snorkel aerial work platform.

Electrocution Hazard |

Tip Over Hazard |

Collision Hazard |

Fall Hazard |

|

8 |

|

|

|

3 |

|

|

|

B |

|

|

|

A |

|

|

|

t |

|

|

|

h |

|

|

|

g |

|

|

|

i |

|

|

|

R |

|

|

|

p |

|

|

|

U |

|

|

THIS MACHINE IS |

NEVER elevate the platform |

NEVER position the platform |

NEVER climb, stand, or sit |

NOT INSULATED! |

or drive the machine while |

without first checking for |

on platform guardrails or |

|

elevated unless the machine |

overhead obstructions or |

midrail. |

|

is on a firm, level surface |

other hazards. |

|

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures, buildings etc.). Uses or alterations to the aerial work platform must be approved by Snorkel.

THIS AERIAL WORK PLATFORM IS NOT INSULATED! Refer to applicable national/governmental/local regulations for safe approach distances.

Exceeding the specified permissible maximum load is prohibited! See “Platform Capacity” on page 6 for details. The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” on page 6 for details. DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 6 for details.

Do not operate the aerial platform in windy or gusty conditions. Do not add anything to the aerial platform that will increase the wind loading such as billboards, banners, flags, etc.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc., is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed! It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited! NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas. Modifications to the aerial work platform are prohibited or permissible only at the approval by Snorkel.

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to national traffic regulations.

Certain inherent risks remain in the operation of this machine despite utilizing proper design practices and safeguarding.

Harness attachment points are provided in the platform and the manufacturer recommends the usage of a fall restraint harness, especially where required by national safety regulations.

Care must be taken to ensure that the machines meets the requirements of stability during use, transportation, assembly, dismantling when out of service, testing, or foreseeable breakdowns.

In the event of an accident or breakdown see “Emergency Lowering” on page 17, do not operate the aerial platform if it is damaged or not functioning properly. Qualified maintenance personnel must correct the problem before putting the aerial platform back into service.

A62JRT – 104850-000

Introduction

Introduction

This manual covers the A62JRT Aerial Work Platform.

This manual must be stored on the machine at all times.

Read, Understand and follow all safety rules and operating instructions before attempting to operate the machine.

When contacting Snorkel for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped at the rear of the chassis.

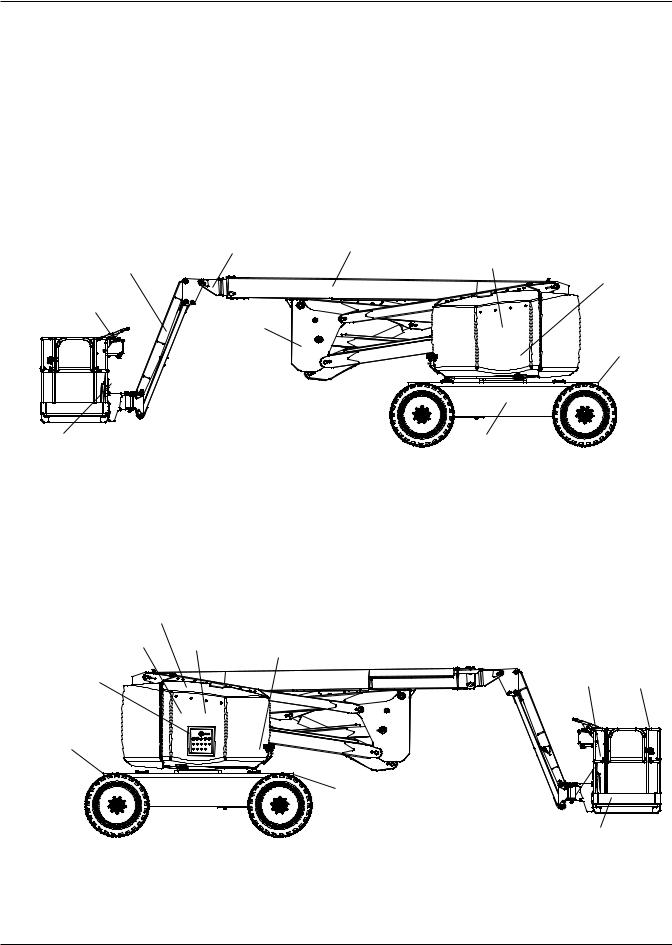

Component Identification

Tip Boom |

Main Boom |

|

Jib |

Engine |

Battery |

|

|

Disconnect |

Upper Controls

Riser Boom

Pivoting

Front Axle

Operator’s |

Chassis |

Manual |

Steer Wheels |

|

|

Rear |

Front |

Right Side

Hydraulic Fluid Filter |

|

|

Hydraulic Fluid Tank |

Fuel Tank |

Battery |

|

|

|

Lower |

Lanyard |

|

Anchors |

Platform |

|

Controls |

|

|

Tie-Down/Lifting Lugs |

|

|

Top Front of Chassis |

|

|

Tie-Down/Lifting Lugs |

Jib |

|

Top Rear of Chassis |

|

|

|

Platform |

|

Steer Wheels |

Foot Switch |

|

Front |

Rear |

Left Side

A62JRT – 104850-000 |

5 |

Special Limitations

Special Limitations |

The system will remain in error mode until the excess |

Travel with the platform raised is limited to creep speed |

load is removed from the platform and the emergency |

range. Elevating the platform is limited to firm, level |

stop button or start switch is cycled off and back on, |

surfaces only. |

resetting the system. At that time, the machine functions |

|

are operational. |

Danger

The elevating function shall ONLY be used when the work platform is level and on a firm surface.

The work platform is NOT intended to be driven over uneven, rough, or soft terrain.

Platform Capacity

Two people and tools may occupy the platform. The maximum platform capacity for the aerial platform is stated in the “Specifications” on page 23.

Caution

The emergency power system is for emergency lowering and stowing only. The length of time the pump can be operated depends on the capacity of the battery. Do not use this system for normal operation.

If the platform overload sensing system is tripped while operating the machine or if the system is in error mode and can not be reset, the emergency power system may still be used for emergency machine operation from either the lower or upper controls.

Danger

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

Manual Force

Manual force is the force applied by the occupants to objects such as walls or other structures outside the work platform.

The maximum allowable manual force is limited to 200 N (45 lbs) of force per occupant, with a maximum of 400 N (90 lbs) for two occupants.

Danger

DO NOT exceed the maximum amount of manual force for this machine.

Platform Overload Sensing System

All functions are stopped from the upper and lower controls, when the platform overload limit is exceeded. The horn will sound intermittently and the platform overload light will blink until the excess load is removed from the platform. At that time, the machine functions are again

operational.

If the platform becomes significantly overloaded, or if an upward force on the platform exceeds approximately 2225 N (500 lb), the system will enter into error mode, stopping all functions from the upper and lower controls. The horn will then sound constantly and the overload light will stay illuminated at the upper and lower controls.

Danger

The aerial platform can tip over if it becomes unstable. Death or serious injury will result from a tip-over accident. Do not exceed the capacity values indicated on the platform rating placard.

The overload sensing system is not active when the machine is being driven with the booms in the stowed position. This allows the machine to be driven without the system sensing an overload due to rough ground conditions.

To eliminate repeated tripping of the system during machine operation, there is a five second delay in machine functions following:

•starting the engine.

•removing excess load from the platform.

Beaufort Scale

Never operate the machine when wind speeds exceed 12.5 m/s (28mph) [Beaufort scale 6]. Refer to Figure 1.

BEAUFORT |

|

WIND SPEED |

|

GROUND CONDITIONS |

||

RATING |

m/s |

km/h |

ft/s |

mph |

||

|

||||||

3 |

3,4~5,4 |

12,25~19,4 |

11.5~17.75 |

7.5~12.0 |

Papers and thin branches move, flags wave. |

|

4 |

5,4~8,0 |

19,4~28,8 |

17.75~26.25 |

12.0~18 |

Dust is raised, paper whirls up, and small branches sway. |

|

5 |

8,0~10,8 |

28,8~38,9 |

26.25~35.5 |

18~24.25 |

Shrubs with leaves start swaying. Wave crests are apparent in ponds |

|

or swamps. |

||||||

|

|

|

|

|

||

6 |

10,8~13,9 |

38,9~50,0 |

35.5~45.5 |

24.5~31 |

Tree branches move. Power lines whistle. It is difficult to open an |

|

|

|

|

|

|

umbrella. |

|

7 |

13,9~17,2 |

50,0~61,9 |

45.5~56.5 |

31.~38.5 |

Whole trees sway. It is difficult to walk against the wind. |

|

Figure 1 – Beaufort Scale

A62JRT – 104850-000

Loading...

Loading...