Snorkel S3246 CE User Manual

OperOper

OperOper

Oper

aa

aa

a

tor’tor’

tor’tor’

tor’

ss

ss

s

ManualManual

ManualManual

Manual

Part Number 0410063EE

July, 2005

The aerial platform is not electrically insulated. Death or serious injury will result from con-

tact with, or inadequate clearance from, an energized conductor.

Do not go closer than the minimum safe approach distance as defined by the Minimum Safe

Approach Distance section in Chapter 3 – Safety.

Regard all conductors as energized.

Allow for electrical wire sag and aerial platform sway .

If the platform, scissors structure, or any part of the aerial platform contacts a high-voltage electrical

conductor, the entire machine can become electrically charged.

If that happens, remain on the machine and do not contact any other structure or object. This includes

the ground, adjacent buildings, poles, and any other objects that are not part of the aerial platform.

Such contact could make your body a conductor to the other object, creating an electrical shock

hazard resulting in death or serious injury .

If an aerial platform is in contact with an energized conductor the platform operator must warn ground

personnel in the vicinity to stay away . Their bodies can conduct electricity creating an electrical shock

hazard resulting in death or serious injury .

Do not approach or leave the aerial platform until the electricity has been turned off.

Do not attempt to operate the lower controls when the platform, scissors structure, or any part of the

aerial platform is in contact with a high-voltage electrical conductor or if there is an immediate danger

of such contact.

Personnel on or near an aerial platform must be continuously aware of electrical hazards, recognizing

that death or serious injury can result from contact with an energized conductor .

S2646/3246 – 0410063EE

Table of Contents

Chapter 1 – Introduction

Aerial Platform Features............................................ 1

Options .....................................................................1

Operator’s Manual..................................................... 1

Safety Alerts ............................................................. 1

Operation .................................................................. 1

Maintenance .............................................................2

Owner and User Responsibilities............................... 2

Additional Information ................................................2

Chapter 2 – Specifications

Component Identification ...........................................3

General Specifications S2646....................................4

Aerial Platform ....................................................... 4

Platform ................................................................. 4

Function Speed...................................................... 4

Drive System ......................................................... 4

Drive/Lift Level Sensor Interlock.............................. 4

Tires ...................................................................... 4

Electrical System .................................................. 4

Hydraulic System .................................................. 4

Ambient Air T emperature Operating Range............. 4

Maximum Wind Speed........................................... 4

Vibration ................................................................ 4

Sound Threshold .................................................... 4

General Specifications S3246....................................5

Aerial Platform ....................................................... 5

Platform ................................................................. 5

Function Speed...................................................... 5

Drive System ......................................................... 5

Drive/Lift Level Sensor Interlock.............................. 5

Tires ...................................................................... 5

Electrical System .................................................. 5

Hydraulic System .................................................. 5

Ambient Air T emperature Operating Range............. 5

Maximum Wind Speed........................................... 5

Vibration ................................................................ 5

Sound Threshold .................................................... 5

Chapter 3 – Safety

Electrocu tion Hazards...............................................7

Minimum Safe Approach Distance.............................7

Prestart Inspection ....................................................8

Work Place Inspection and Practices........................8

Operation .................................................................. 8

Tip-Over and Falling Hazards.....................................8

Electrical System ...................................................... 9

Hydraulic System......................................................9

Placards and Decals .................................................9

Chapter 4 – Safety Devices

Emergency Stop Controls ....................................... 11

Drive Motion Alarm .................................................. 11

Pothole Protector Skids .......................................... 1 1

Drive/Lift Pothole Protector Interlock........................ 12

Drive/Lift Level Sensor Interlock ...............................12

Lowering Alarm........................................................ 12

Lowering Interrupt.................................................... 12

Emergency Lowering Handle ...................................12

Safety Prop .............................................................12

Guardrails ............................................................... 13

Horn ........................................................................ 13

Tilt Alarm.................................................................13

Overload Protection .................................................13

Flashing Light ......................................................... 13

Chapter 5 – Gauges and Displays

Hour Meter .............................................................. 15

Ammeter .................................................................15

Battery Condition Indicator ...................................... 15

Chapter 6 – Batteries

General Maintenance .............................................. 17

Charging ................................................................. 17

Chapter 7 – Controls

Battery Disconnect Switch ...................................... 19

Lower Controls ........................................................ 19

Emergency Stop Button....................................... 19

Control Selector Switch ....................................... 19

Platform Raise/Lower Switch ............................... 19

Upper Controls ........................................................ 19

Emergency Stop Button....................................... 20

Drive/Lift Selector Switch ..................................... 20

Joystick ............................................................... 20

Interlock............................................................... 20

Steer Switch ........................................................ 20

Drive Range Switch .............................................. 20

Horn Button ......................................................... 20

Battery Condition Indicator ................................... 20

Chapter 8 – Prestart Inspection

Operator’s Manual................................................... 21

Electrical System .................................................... 21

Battery Fluid Level ............................................... 21

Battery T erminals................................................. 21

Battery Charger.................................................... 21

Safety Prop .............................................................22

Cables and Wiring Harness..................................... 22

Hydraulic System....................................................23

Fluid Level............................................................ 23

Hoses and Fittings............................................... 23

Free-Wheeling V alve ............................................ 23

Tires and Wheels ....................................................24

Ground Strap........................................................... 24

Lower Control Station ..............................................24

Operating Controls ............................................... 24

Emergency Stop .................................................. 24

Table of Contents

S2646/S3246 – 0410063EE

Lowering Alarm and Interrupt ...................................24

Pothole Protector Interlock ......................................24

Emergency Lowering............................................... 25

Structures ............................................................... 25

Weldments .......................................................... 25

Slide Pads ........................................................... 26

Fasteners ............................................................ 26

Upper Control Station ..............................................26

Guardrail System................................................. 26

Platform Extension .............................................. 26

Swing-Down Rails ................................................ 27

Brakes ................................................................. 27

Operating Controls ............................................... 27

Emergency S top .................................................. 27

Horn..................................................................... 27

Lowering Alarm and Interrupt ...................................28

Drive Motion Alarm ..................................................28

Flashing Light ......................................................... 28

Battery Condition Indicator ...................................... 28

Placards and Decals ...............................................28

Prestart Inspection Checklist .................................. 31

Chapter 9 – Operation

Preparing for Operation............................................33

Lower Controls ........................................................ 33

Upper Controls ........................................................ 33

Driving ..................................................................... 34

Drive Range Switch .............................................. 34

Drive S peeds ........................................................ 34

Drive/Lift Level Sensor Interlock............................ 35

Steering...................................................................35

Platform .................................................................. 35

Raising and Lowering ........................................... 35

Lowering Interrupt................................................. 35

Overload Protection.............................................. 35

Extending ............................................................ 36

Swing-Down Rails ................................................ 36

Swing-Out Trays ..................................................... 37

Wallboard Loading .................................................. 37

Chapter 10 – Stowing and Transporting

Stowing ...................................................................39

Transporting ............................................................ 39

Lifting With a Forklift ............................................ 39

Winching ............................................................. 39

Driving.................................................................. 40

Hoisting ............................................................... 41

Securing for Transport.......................................... 42

Chapter 1 1 – Emergency Operation

Emergency Lowering............................................... 43

Towing..................................................................... 43

Chapter 12 – Troubleshooting

Troubleshooting Chart ............................................. 45

Appendix A – Glossary

Limited Warranty

S2646/S3246 – 0410063EE 1

Chapter 1 – Introduction

Aerial Platform Features

The aerial platform is a self-propelled scissors lift that

has been designed to raise personnel, their tools, and

material to the workstation. The S2646 has one hydrau-

lic cylinder to raise and lower the platform and the S3246

has two cylinders. A hydraulic motor on each of the front

wheels provides power to move the aerial platform.

The standard machine includes the following features.

• Proportional drive and lift up control

• Drivable at full height

• Drive motion alarm

• Non-marking tires

• Automatic pothole protection system

• Level sensor with drive/lift interlock

• Hour meter

• Manual lowering valve

• Lockable battery disconnect switch

• Tie-down lugs

• Lifting lugs

• Heavy duty battery charger with ammeter

• Swing-out hydraulic and electrical component trays

• Non-slip metal platform floor

• 0.9 m (3′) platform extension

• Swing-down platform rails

• 125 volt AC electrical outlet with GFCI

• Scissor arm safety support prop

• Lowering alarm

• Removable upper controls

• Horn

• Forklift loadable from three sides

• Rear forklift pockets

• Platform entry gate with gravity gate

• Keyed control selector switch

• Five year limited warranty

The aerial platform has been manufactured to conform to

European Directive 98/37/EC and European Standard

EN280.

Options

The following options may be provided on the machine.

• Flashing light

• Battery condition indicator

Operator’s Manual

This manual provides information for safe and proper op-

eration of the aerial platform. Because it covers more

than one model, some figures may only represent what

is actually on the machine. Read and understand the

information in this Operator’s Manual before operating

the aerial platform on the job.

Additional copies of this manual may be ordered from

Snorkel. Supply the model and manual part number from

the front cover to assure that the correct manual will be

supplied.

All information in this manual is based on the latest prod-

uct information at the time of publication. Snorkel reserves

the right to make product changes at any time without

obligation.

Safety Alerts

A safety alert symbol is used throughout this manual to

indicate danger, warning, and caution instructions. Fol-

low these instructions to reduce the likelihood of per-

sonal injury and property damage. The terms danger,

warning, and caution indicate varying degrees of personal

injury or property damage that can result if the instruc-

tion is not followed.

ADanger

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury .

This signal word is to be used in the most extreme

situations.

AWarning

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury .

ACaution

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate in-

jury. It may also be used to alert against unsafe

practices.

Notes

Notes are used to provide special information or helpful

hints to assist in aerial platform operation, but do not

indicate a hazardous situation.

Operation

The aerial platform has built-in safety features and has

been factory tested for compliance with Snorkel specifi-

cations and industry standards. However , any personnel

lifting aerial platform can be potentially dangerous in the

hands of untrained or careless operators.

AWarning

The potential for an accident increases when the

aerial platform is operated by personnel who are

not trained and authorized. Death or serious injury

can result from such accidents. Read and under-

stand the information in this manual and on the plac-

ards and decals on the machine before operating

the aerial platform on the job.

Training is essential and must be performed by a quali-

fied person. Become proficient in knowledge and actual

operation before using the aerial platform on the job. Y ou

must be trained and authorized to perform any functions

of the aerial platform. Operation of the aerial platform must

be within the scope of the machine specifications.

Chapter 1 – Introduction

2 S2646/S3246 – 0410063EE

The operator bears ultimate responsibility for following all

manufacturer’s instructions and warnings, regulations and

safety rules of their employer and/or any state or federal

law.

Maintenance

Every person who maintains, inspects, tests, or repairs

the aerial platform must be qualified to do so. Following

the daily prestart inspection in this Operator’s Manual

will help keep the aerial platform in optimum working con-

dition. Other maintenance functions must be performed

by maintenance personnel who are qualified to work on

the aerial platform.

Do not modify this aerial platform without prior written

consent of the Snorkel Engineering Department. Modifi-

cation may void the warranty, adversely af fect stability , or

affect the operational characteristics of the aerial plat-

form.

Owner and User Responsibilities

All owners and users of the aerial platform must read,

understand, and comply with all applicable regulations.

Ultimate compliance to national safety regulations is the

responsibility of the user and their employer.

Additional Information

For additional information contact your local dealer or

Snorkel at:

Snorkel International

P.O. Box 1160

St. Joseph, MO 64502-1160 USA

785-989-3000

http://www.snorkelusa.com

S2646/S3246 – 0410063EE 3

Chapter 2 – Specifications

Component Identification

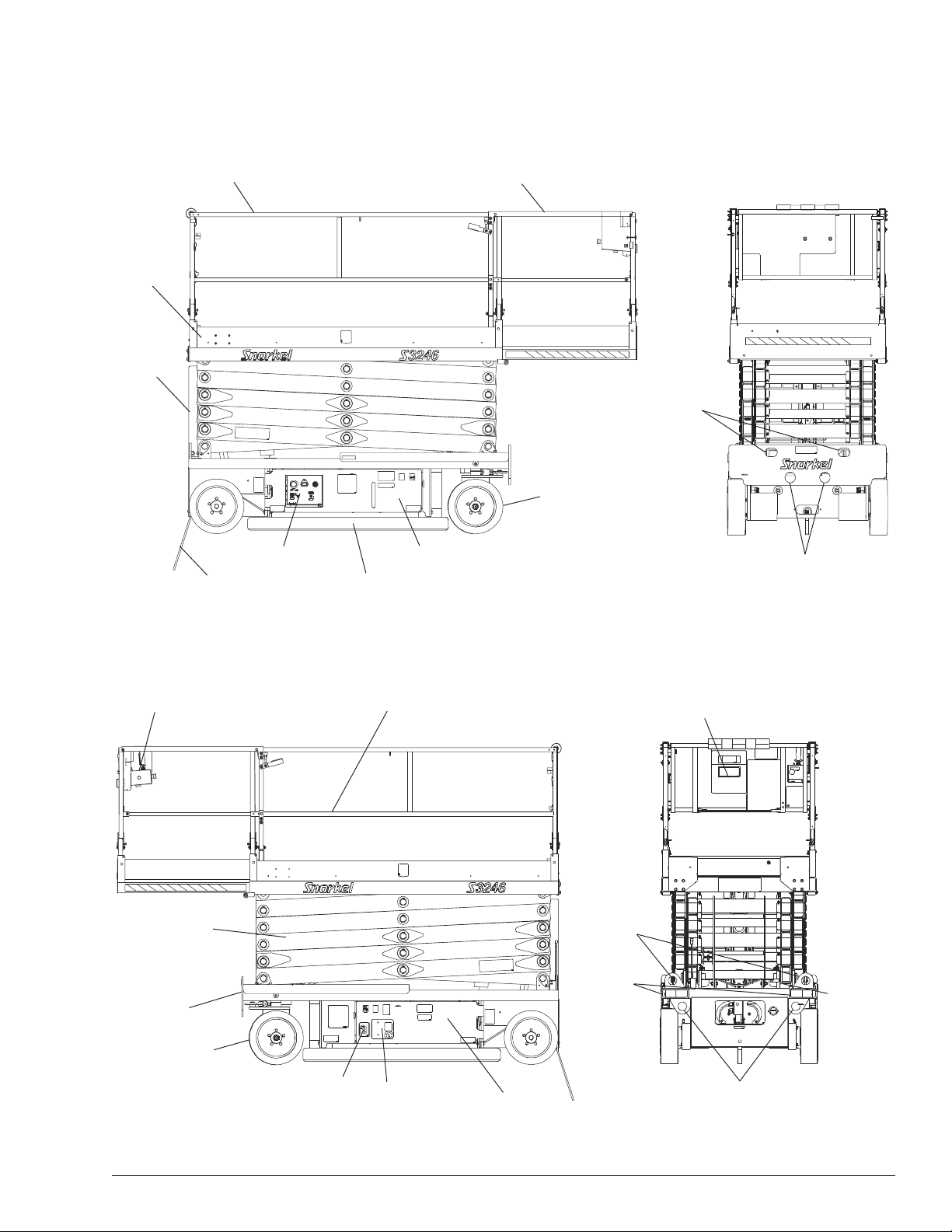

Chassis

Battery Charger

Upper Controls

Platform

Platform Extension Deck

Left Side

Battery Tray

Battery Disconnect

Switch

Pothole Protector Skid

Operator’s

Manual

Scissors

Structure

Guardrails

Toeboards

Entry Step

Ground Strap

Right Side

Rear

Front

Lower Controls

Hydraulic Tray

Lifting Lugs

Tie-down Lugs

Drive and Steer

Wheels

Drive and Steer

Wheels

Forklift

Pockets

Lifting Lugs

Emergency

Lowering

Handle

Tie-down Lugs

Chapter 2 – Specifications

4 S2646/S3246 – 0410063EE

General Specifications S2646

Aerial Platform

Working height 9.75 m (32′)

Maximum platform height 7.9 m (26′)

Turning radius

Inside 25.4 cm (10″)

Outside 2.5 m (101″)

Wheelbase 1.9 m (75″)

Ground clearance

Pothole protector raised 10.1 cm (4″)

Pothole protector lowered 2.5 cm (1″)

Maximum wheel load 1 125 kg (2,480 lbs)

Maximum ground pressure 11.7 kg/cm² (166 p si)

Weight, GVW

Approximate 2359 kg (5,200 lbs)

Stowed wid th 1 16.8 cm (46″)

Stowed length 254 cm (100″)

Stowed height

Guardrails raised 236.2 cm (93″)

Guardrails lowered 167.6 cm (66″)

Platform

Dimensions

Main 1 14.3 cm x 238.7 cm (45″ x 94″)

Extension 104.1 cm x 91.4 cm (41″ x 36″)

Total length with extension 330.2 cm (130″)

Rated work load

Total 453.5 kg (1,000 lb)

Extension 113.3 kg (250 lb)

Maximum number of occupants

Outside 1 person

Inside 3 people

Function Speed

Platform raise 25 to 35 seconds

Platform lower 50 to 60 seconds

High drive

Platform lower than 2.1 to 2.4 m (7 to 8 feet)

3.2 km/h (0 to 2 mph)

Low drive

Platform higher than 2.1 to 2.4 m (7 to 8 feet)

0.8 km/h (0 to 0.5 mph)

Drive System

St andard Two wheel drive

Gradeability 25%

Maximum drive height 10.9 m (26′)

Drive/Lift Level Sensor Interlock

Side-to-side 2 degrees

Front-to-rear 4 degrees

Tires

Nonmarking solid rubber 40.6 cm x 12.7 cm (16″ x 5″)

Electrical System

V olta ge 24 V DC negative chassis ground

Source Four - 6 V 240 amp hour batteries

Fluid recommended distilled water

Charger 40 amp

Hydraulic System

Maximum pressure 21,373.75 kPa (3,100 psi)

Reservoir capacity 34 l (9 US gal)

System capacity 35 l (9.25 US gal)

Maximum operating temperature 71°C (160°F)

Hydraulic fluid recommended

Above -13°C (10°F) Mobil DTE-13M (ISO VG32)

Below -13°C (10°F) Mobil DTE-11M (ISO VG15)

Ambient Air Temperature Operating Range

Celsius -18°C to 43°C

Fahrenheit 0°F to 1 10°F

Maximum Wind Speed

Gust or steady 12.5 m/s (28 mph)

Vibration less than 2.5 m/sec

2

Sound Threshold below 70 dB(A)

Chapter 2 – Specifications

S2646/S3246 – 0410063EE 5

General Specifications S3246

Aerial Platform

Working height 1 1.58 m (38′)

Maximum platform height 9.75 m (32′)

Turning radius

Inside 25.4 cm (10″)

Outside 2.5 m (101″)

Wheel base 1.9 m (75″)

Ground clearance

Pothole protector raised 10.1 cm (4″)

Pothole protector lowered 2.5 cm (1″)

Maximum wheel load 1328 kg (2,928 lbs)

Maximum ground pressure 13.8 kg/cm² (196 psi)

Weight, GVW

Approximate 3003 kg (6,620 lbs)

Stowed wid th 1 16.8 cm (46″)

Stowed length 254 cm (100″)

Stowed height

Guardrails raised 251.4 cm (99″)

Guardrails lowered 182.8 cm (72″)

Platform

Dimensions

Main 45″ x 94″ (1 14.3 cm x 238.7 cm)

Extension 41″ x 36″ (104.1 cm x 91.4 cm)

Total length with extension 130″ (330.2 cm)

Rated work load

T otal 317.5 kg (700 lb)

Extension 113.3 kg (250 lb)

Maximum number of occupants

Outside 1 person

Inside 2 people

Function Speed

Platform raise 40 to 50 seconds

Platform lower 50 to 60 seconds

High drive

Platform lower than 2.1 to 2.4 m (7 to 8 feet)

3.2 km/h (0 to 2 mph)

Low drive

Platform higher than 2.1 to 2.4 m (7 to 8 feet)

0.8 km/h (0 to 0.5 mph)

Drive System

Standard Two wheel drive

Gradeability 25%

Maximum drive height 9.75 m (32′)

Drive/Lift Level Sensor Interlock

Side-to-side 2 degrees

Front-to-rear 4 degrees

Tires

Nonmarking solid rubber 40.6 cm x 12.7 cm (16″ x 5″)

Electrical System

Vo ltage 24 V DC negative chassis ground

Source Four - 6 V 240 amp hour batteries

Fluid recommended distilled water

Charger 40 amp

Hydraulic System

Maximum pressure 21,373.75 kPa (3,100 psi)

Reservoir capacity 34 l (9 US gal)

System capacity 35 l (9.25 US gal)

Maximum operating temperature 71°C (160°F)

Hydraulic fluid recommended

Above -13°C (10°F) Mobil DTE-13M (ISO VG32)

Below -13°C (10°F) Mobil DTE-11M (ISO VG15)

Ambient Air Temperature Operating Range

Celsius -18°C to 43°C

Fahrenheit 0°F to 110°F

Maximum Wind Speed

Gust or steady 12.5 m/s (28 mph)

Vibration less than 2.5 m/sec

2

Sound Threshold below 70 dB(A)

Chapter 2 – Specifications

6 S2646/S3246 – 0410063EE

S2646/S3246 – 0410063EE 7

Chapter 3 – Safety

Knowledge of the information in this manual, and proper

training, provide a basis for safely operating the aerial

platform. Know the location of all controls and how they

operate to act quickly and responsibly in an emergency .

Safety devices reduce the likelihood of an accident. Never

disable, modify, or ignore any safety device. Safety alert s

in this manual indicate situations where accidents may

occur.

If any malfunction, hazard or potentially unsafe condition

relating to capacity, intended use, or safe operation is

suspected, stop aerial platform operation and seek as-

sistance.

The operator bears ultimate responsibility for following all

manufacturer’s instructions and warnings, regulations and

safety rules of their employer and/or any state or federal

law.

Electrocution Hazards

The aerial platform is made of metal components and is

not insulated. Regard all conductors as energized. Do

not operate outside during a thunderstorm.

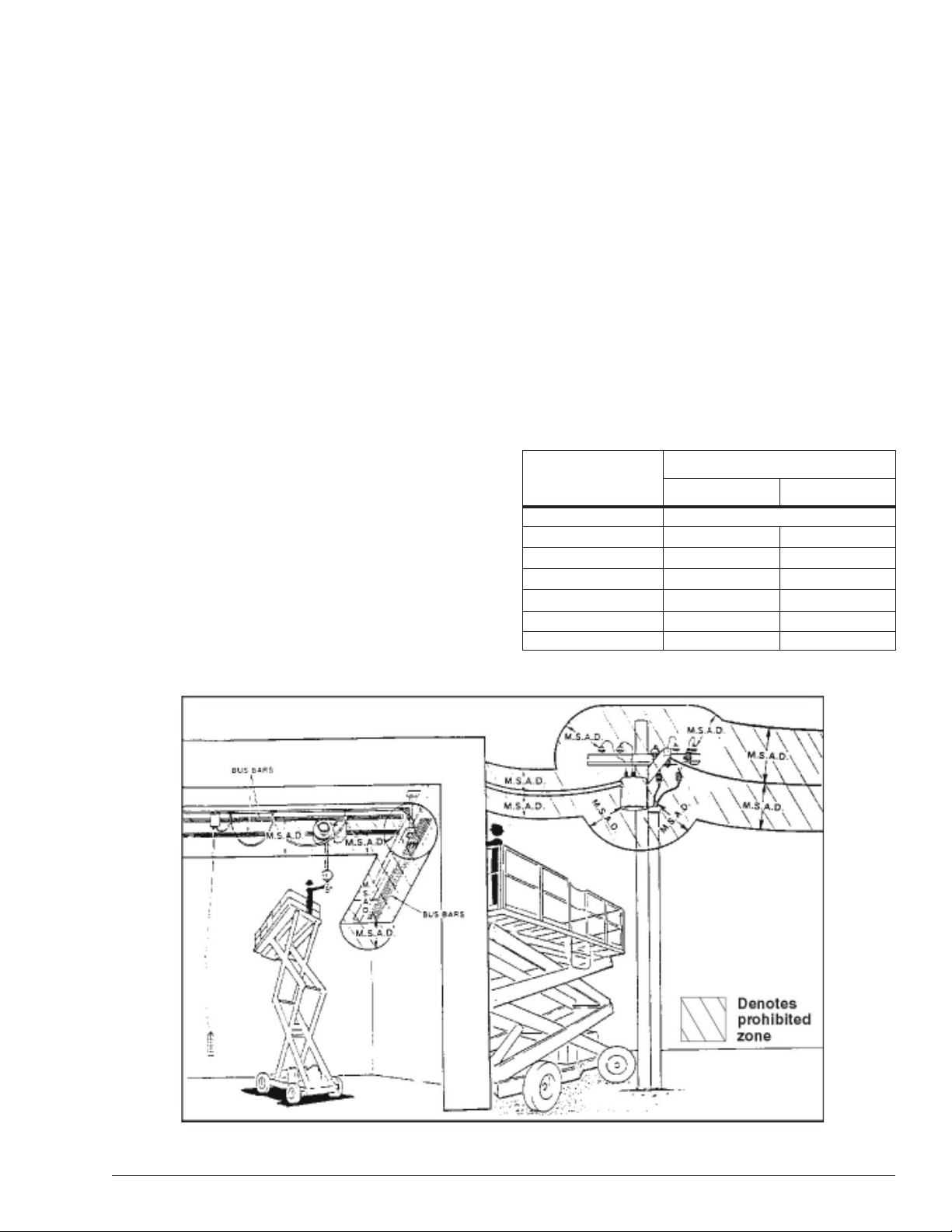

Minimum Safe Approach Dist ance

Minimum safe approach distances to energized power

lines and their associated parts must be observed while

operating the aerial platform.

ADanger

The aerial platform is not electrically insulated.

Death or serious injury will result from contact with,

or inadequate clearance from, an energized con-

ductor. Do not go closer than the minimum safe

approach distance as defined by ANSI or national

safety regulations.

ANSI publications define minimum distances that must

be observed when working near bus bars and energized

power lines. T able 1 and Figure 4 are reprinted courtesy

of Scaffold Industry Association, ANSI/SIA A92.6.

Table 1 – Minimum Safe Approach Distance

Figure 4 – Minimum Safe Approach Distance

Minimum Safe Approach Distance

V oltage Range

(Phase to Phase)

0 to 300V

Over 300V to 50kV

Over 50kV to 200kV

Over 200kV to 350kV

Over 350kV to 500kV

Over 500kV to 750kV

Over 750kV to 1000kV

Feet Meters

Avoid Contact

10

15

25

20

35

45

3.05

4.60

6.10

7.62

10.67

13.72

Chapter 3 – Safety

8 S2646/S3246 – 0410063EE

Prestart Inspection

Perform a prestart inspection before each shift as de-

scribed in Chapter 8. Do not use the aerial platform on

the job unless you are trained and authorized to do so.

Work Place Inspection and Practices

Do not use the aerial platform as a ground connection

when welding. The welding ground clamp must be at-

tached to the same structure that is being welded. Elec-

trical current flow can be very intense, causing serious

internal damage to some components.

Inspect the area before and during aerial platform use.

The following are some potential hazards that may be in

the work place.

• Debris

• Slopes

• Drop-offs or holes

• Bumps and floor obstructions

• Overhead obstructions

• Unauthorized persons

• High voltage conductors

• Wind and weather conditions

• Inadequate surface and support to withstand load

forces applied by the aerial platform in all operating

configurations

Before using the aerial platform in any hazardous (classi-

fied) location, make certain it is approved and of the type

required by ANSI/NFPA 505 for use in that particular lo-

cation.

Know and understand the job site traffic-flow patterns and

obey the flagmen, road signs, and signals.

While operating the aerial platform, a good safety prac-

tice is to have qualified personnel in the immediate work

area to:

• Help in case of an emergency.

• Operate emergency controls as required.

• Watch for loss of control by platform operator.

• Warn the operator of any obstructions or hazards

that may not be obvious to them.

• Watch for soft terrain, sloping surfaces, drop-offs, etc.

where stability could be jeopardized.

• Watch for bystanders and never allow anyone to be

under the platform, or to reach through the scissor

arms while operating the aerial platform.

ADanger

Pinch points may exist between moving compo-

nents. Death or serious injury will result from be-

coming trapped between components, buildings,

structures, or other obstacles. Make sure there is suf-

ficient clearance around the machine before mov-

ing the chassis or platform. Allow sufficient room

and time to stop movement to avoid contact with

structures or other hazards.

Always look in the direction of movement. Drive with care

and at speeds compatible with the work place conditions.

Use caution when driving over rough ground, on slopes,

and when turning. Do not engage in any form of horse-

play or permit riders any place other than in the platform.

Secure all accessories, containers, tools, and other ma-

terials in the platform to prevent them from accidentally

falling or being kicked off the platform. Remove all ob-

jects that do not belong in or on the aerial platform.

Never steady the platform by positioning it against an-

other platform.

Do not operate the aerial platform if it is damaged or not

functioning properly. Qualified maintenance personnel must

correct the problem before putting the aerial platform back

into service.

Operation

Use three points of support when entering or exiting the

platform. For example, use two hands and one foot when

climbing into the platform.

Make sure the area below the platform is free of person-

nel before lowering.

Keep both feet positioned firmly on the platform floor.

Operate the controls slowly and deliberately to avoid jerky

and erratic operation. Always stop the controls in neutral

before going in the opposite direction.

Do not dismount while the aerial platform is in motion or

jump off the platform.

Properly stow the aerial platform and secure it against

unauthorized operation at the end of each work day , be-

fore transporting, or if it is left unattended.

Tip-Over and Falling Hazards

Operate the aerial platform only on a firm, flat, level sur-

face capable of withstanding all load forces imposed by

the aerial platform in all operating conditions. Refer to the

General Specifications chart for the maximum wheel load,

maximum floor pressure, and drive/lift level sensor inter-

lock information. Raise the platform only when the aerial

platform is on level ground.

ADanger

The aerial platform can tip over if it becomes un-

stable. Death or serious injury will result from a tip-

over accident. Do not drive or position the aerial

platform for elevated use near any drop-off, hole,

slope, soft or uneven ground, or other tip-over haz-

ard. Do not raise the platform in wind speeds above

12.5 m/s (28 mph).

Do not operate the aerial platform within 1.2 m (4′) of any

drop-off or hole.

Chapter 3 – Safety

S2646/S3246 – 0410063EE 9

Do not raise the platform in winds above 12.5 m/s (28

mph).

Do not add anything to the aerial platform that will in-

crease the wind loading such as billboards, banners, flags,

etc.

Never operate the aerial platform without all parts of the

guardrail system in place. Make sure the platform gate

and the gravity gate are closed. Make sure that all pro-

tective guards, cowlings, and doors are securely fastened.

Do not exceed the platform capacity as indicated on the

platform rating placard on the platform. Do not carry loads

that extend beyond the platform guardrails without prior

written consent from Snorkel.

Do not operate the aerial platform from trucks, trailers,

railway cars, floating vessels, scaffolds, or similar equip-

ment unless the application is approved in writing by

Snorkel.

Do not use the aerial platform as a crane, hoist, jack, or

for any purpose other than to position personnel, tools,

and materials.

Do not climb on the guardrails or use ladders, planks, or

other devices to extend or increase the work position

from the platform.

Take care to prevent rope, electrical cords, and hoses,

etc., from becoming caught in or on the aerial platform. If

the platform or scissors structure becomes caught on an

adjacent structure or other obstacle and is prevented from

normal motion, reverse the control to free the platform. If

control reversal does not free the platform, evacuate the

platform before attempting to free it.

It is best not to transfer from the platform to another struc-

ture or from the structure to the platform, unless that is

the safest way to do the job. Judge each situation sepa-

rately taking the work environment into account. If it is

necessary to transfer from the platform to another struc-

ture the following guidelines apply:

1. If you are using a fall restraint, transfer your anchor-

age from one structure to the other before stepping

across.

2. Remember that you might be transferring to a struc-

ture where personal fall arrest is required.

3. Use the platform entrance, do not climb over or

through the guardrails.

Electrical System

Charge the batteries in a well-ventilated area free of flame,

sparks, or other hazards that might cause fire or explo-

sion.

Do not operate any of the aerial platform functions while

the battery charger is plugged in.

AWarning

Batteries give off hydrogen and oxygen that can

combine explosively . Death or serious injury could

result from a chemical explosion. Do not smoke or

permit open flames or sparks when checking the

batteries.

Battery acid can damage the skin and eyes. Seri-

ous infection or reaction can result if medical treat-

ment is not given immediately. Wear face and eye

protection when working near the batteries.

Batteries contain sulfuric acid that can damage your eyes

or skin on contact. Wear a face shield, rubber gloves,

and protective clothing when working around batteries. If

acid contacts your eyes, flush immediately with clear

water and get medical attention. If acid contacts your

skin, wash off immediately with clear water .

Hydraulic System

The hydraulic system contains hoses with hydraulic fluid

under pressure.

ADanger

Hydraulic fluid escaping under pressure can have

enough force to inject fluid into the flesh. Serious

infection or reaction will result if medical treatment

is not given immediately . In case of injury by escap-

ing hydraulic fluid, seek medical attention at once.

Do not place your hand or any part of your body in front of

escaping hydraulic fluid. Use a piece of cardboard or wood

to search for hydraulic leaks.

Placards and Decals

The aerial platform is equipped with placards and decals

that provide instruction for operation and accident pre-

vention. Do not operate the aerial platform if any placards

or decals are missing or not legible.

Chapter 3 – Safety

10 S2646/S3246 – 0410063EE

S2646/S3246 – 0410063EE 11

Chapter 4 – Safety Devices

This aerial work platform is manufactured with safety de-

vices, placards, and decals to reduce the likelihood of an

accident. For the safety of all personnel, do not disable,

modify , or ignore any safety device. Safety devices are

included in the daily prestart inspection.

AWarning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury can result from such accidents. Do not alter ,

disable, or override any safety device.

If any safety devices are defective, remove the aerial plat-

form from service until qualified maintenance personnel

can make repairs.

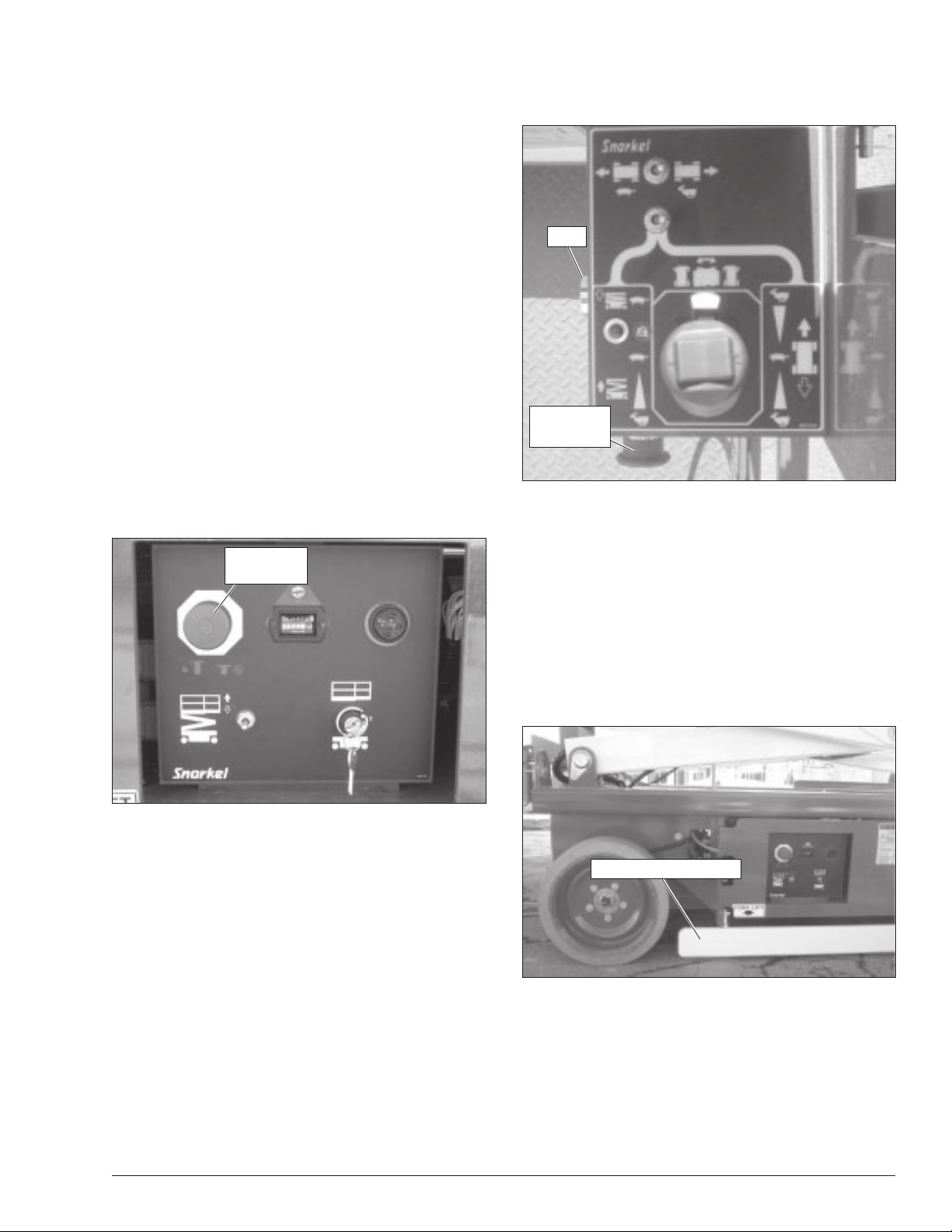

Emergency Stop Controls

There is an emergency stop control at the lower and up-

per controls.

At the lower controls, the emergency stop is a two-posi-

tion push button (refer to Figure 4.1).

Figure 4.1 – Lower Controls

Push the emergency stop button in to disconnect power

to all control circuits. Pull the button out to restore power.

Note

The lower controls override the upper controls. If the up-

per control emergency stop button is engaged, the lower

controls can still be used to operate the aerial platform.

At the upper controls, the emergency stop is a two-posi-

tion push button (refer to Figure 4.2).

Push the emergency stop button in to disconnect power

to the upper control circuits. Pull the button out to re-

store power.

Figure 4.2 – Upper Controls

Drive Motion Alarm

When the joystick is moved out of neutral to drive the

aerial platform, the alarm emits a loud beeping sound to

warn personnel in the work area to stand clear .

Pothole Protector Skids

The pothole protector skids automatically lower when the

platform is elevated approximately 61 cm (24″). Ground

clearance is reduced from 10.1 cm (4″) to 2.5 cm (1″)

when the skids lock into position (refer to Figure 4.3).

Figure 4.3 – Pothole Protector Skids

ADanger

The aerial platform can tip over if it becomes un-

stable. Death or serious injury will result from a tip-

over accident. Do not drive or position the aerial

platform for elevated use within 1.2 m (4

′′

′′

′) of any

drop-off, hole, or other tip-over hazard.

Pothole Protector Skid

Emergency

Stop Button

Emergency

Stop Button

Horn

Chapter 4 – Safety Devices

12 S2646/3246 – 0410063EE

Center the control in neutral to reset the lowering func-

tion, then continue to lower the platform.

Emergency Lowering Handle

The emergency lowering handle may be used to lower

the platform if there is a malfunction in the hydraulic or

electrical system. The handle is mounted at the rear of

the aerial platform (refer to Figure 4.4).

Figure 4.4 – Emergency Lowering Handle

The emergency lowering handle may be used to lower

the scissors arms onto the safety prop before inspecting

the machine. Pull the handle outward to lower the plat-

form. Push the handle all the way back in after lowering

the platform.

Safety Prop

The safety prop (refer to Figure 4.5) is used to support

the scissors structure when access to the scissors arm

components or the chassis is required. Always use the

safety prop when the platform is raised during inspection

and maintenance.

Figure 4.5 – Safety Prop

This protection system limits the tilt angle if a wheel is

driven into a drop-off or hole. This greatly reduces the

likelihood of the aerial platform tipping over .

The pothole protection system is for added protection

and does not justify operating near drop-offs or holes.

Drive/Lift Pothole Protector Interlock

The aerial platform drive and lift functions are interlocked

through a limit switch that senses whether or not the

pothole protection linkage is locked into position. The

drive/lift pothole interlock operates when the platform is

elevated approximately 2.1 to 2.4 m (7 to 8 feet).

If an obstruction under the skids, or some other impair-

ment prevents the skids from locking into position, the

drive and lift functions will not operate and an alarm will

sound.

Lower the platform and remove the obstruction when the

drive/lift pothole protector interlock alarm sounds.

Drive/Lift Level Sensor Interlock

The aerial platform drive and lift functions are interlocked

through a level sensor system. The drive/lift level sensor

interlock operates when the platform is elevated approxi-

mately 2.1 to 2.4 m (7 to 8 feet).

If the chassis is tilted more than two degrees side-to-

side or four degrees front-to-rear, the drive and lif t func-

tions will not operate and an alarm will sound.

Lower the platform and drive to a level surface when the

drive/lift level sensor alarm sounds.

The drive/lift level sensor system is for added protection

and does not justify operating on anything other than firm,

flat, level surfaces.

Lowering Alarm

When the joystick is moved out of neutral to lower the

platform, the alarm emits a loud beeping sound to warn

personnel in the work area to stand clear .

ADanger

Pinch points exist on the scissors structure. Death

or serious injury will result if the scissors structure

lowers onto personnel within the scissors arms or

under the raised platform. Stand clear while rais-

ing and lowering the platform.

Be careful when lowering the platform. Keep hands and

fingers away from the scissors structures components.

Lowering Interrupt

When the platform is lowered to about 1.5 m (5′) lowering

stops. The platform will not lower for five seconds regard-

less of the control position to allow personnel to clear the

area of the scissors before the platform completely low-

ers.

Safety Prop

Emergency Lowering Handle

Chapter 4 – Safety Devices

S2646/3246 – 0410063EE 13

Guardrails

The guardrail system includes a top rail, mid rail, and

toeboards around the sides of the platform (refer to Fig-

ure 4.6).

Figure 4.6 – Platform

An entry gate allows for access to the platform for load-

ing work materials. The gate is part of the guardrail sys-

tem and must be securely fastened after loading and

entering the platform.

Horn

The horn may be used to warn personnel on the ground.

The horn is operational when the machine is set up for

operation from the upper controls.

Tilt Alarm

An alarm will sound if the aerial platform chassis is out of

level more than two degrees side-to-side or four degrees

front-to-rear when the platform is raised.

ADanger

The aerial platform can tip over if it becomes un-

stable. Death or serious injury will result from a tip-

over accident. Do not drive or position the aerial

platform for elevated use near any drop-off, hole,

slope, soft or uneven ground, or other tip-over haz-

ard.

Completely lower the platform and then drive to a level

surface when the tilt alarm sounds.

The tilt alarm is for added protection and does not justify

operating on anything other than firm, flat, level surfaces.

Overload Protection

When the load in the platform is near or at rated capac-

ity, an alarm will sound and the red light on the upper

controls (refer to Figure 4.7) will flash.

Figure 4.7 – Upper Controls

The alarm and light warn the operator that the platform is

close to becoming overloaded. All functions remain fully

operational.

ADanger

The aerial platform can tip over if it becomes un-

stable. Death or serious injury will result from a tip-

over accident. Do not exceed the capacity values

indicated on the platform rating placard.

If the platform is fully lowered and is overloaded, when it

is elevated just past 1.8 m (6′), a control module will stop

the lift and drive functions and the alarm will sound and

the warning light will flash. The platform can still be low-

ered to remove the excess load.

If the platform is elevated just past 1.8 m (6′) and material

is added to the platform overloading it, a control module

will stop the lift, drive and lower functions and the alarm

will sound and the warning light will flash. In this case,

remove the load in excess of rated capacity and cycle

the emergency stop button at the upper controls to re-

turn to normal operation.

Flashing Light

An optional red or amber flashing light may be located at

the rear of the aerial platform. The flashing light warns

personnel that the aerial platform is in the area.

The light flashes at about one flash per second when the

machine is set up for operation from the upper controls.

Toeboard

Top Rail

Mid Rail

Entry Gate

Overload Warning Light

Chapter 4 – Safety Devices

14 S2646/3246 – 0410063EE

Loading...

Loading...