Snorkel A46JRT User Manual

Table of Contents

Table of Contents |

|

Declaration of Conformity............................................ |

2 |

Safety Rules................................................................ |

3 |

Introduction................................................................. |

4 |

Component Identification............................................ |

4 |

Special Limitations...................................................... |

5 |

Platform Capacity..................................................... |

5 |

Manual Force........................................................... |

5 |

Platform Overload Sensing System......................... |

5 |

Beaufort Scale......................................................... |

5 |

Controls and Indicators............................................... |

6 |

Battery Disconnect Switch....................................... |

6 |

Lower Controls and Indicators................................. |

6 |

Upper Controls and Indicators................................. |

6 |

Battery Disconnect Switch.......................................... |

7 |

Lower Controls............................................................ |

7 |

Preheat Button......................................................... |

7 |

Start Button.............................................................. |

7 |

Emergency Stop Button........................................... |

7 |

Controls Selector Switch.......................................... |

7 |

Ground Operation Switch......................................... |

7 |

Rotation Switch........................................................ |

7 |

Riser Switch............................................................. |

7 |

Boom Elevation Switch............................................ |

7 |

Boom Extension Switch........................................... |

7 |

Jib Articulation Switch.............................................. |

7 |

Platform Level Switch.............................................. |

8 |

Platform Rotation Switch.......................................... |

8 |

Engine/Emergency Power Switch............................ |

8 |

Hydraulic Oil Warm-Up Switch................................. |

8 |

Circuit Breaker Reset Buttons..................................... |

8 |

Upper Controls............................................................ |

9 |

Preheat Switch......................................................... |

9 |

Start Switch.............................................................. |

9 |

Emergency Stop Button........................................... |

9 |

Drive Joystick........................................................... |

9 |

Steer Switch............................................................. |

9 |

Drive Range Switch................................................. |

9 |

Boom Speed Knob................................................... |

9 |

Rotation Switch...................................................... |

10 |

Riser Switch........................................................... |

10 |

Boom Elevation Switch.......................................... |

10 |

Boom Extension Switch......................................... |

10 |

Jib Articulation Switch............................................ |

10 |

Platform Level Switch............................................ |

10 |

Platform Rotation Switch........................................ |

10 |

Engine/Emergency Power Switch.......................... |

10 |

Horn Switch............................................................ |

10 |

Platform Foot Switch.............................................. |

10 |

AC Generator Switch............................................. |

10 |

Hydraulic Oil Warm-Up Switch............................... |

10 |

Pre-Operation Safety Inspection............................... |

12 |

System Function Inspection...................................... |

13 |

Operation.................................................................. |

14 |

Cold Weather Start-Up........................................... |

14 |

Hydraulic System Cold Weather Warm-Up............ |

14 |

Hydraulic System Warm-Up Switch....................... |

14 |

Manually Warming The Hydraulic System............. |

14 |

Preparing for Operation......................................... |

15 |

Lower Controls....................................................... |

15 |

Upper Controls....................................................... |

15 |

Boom Operation..................................................... |

15 |

Driving and Steering.............................................. |

16 |

Drive Speeds......................................................... |

16 |

Pivoting Front Axle................................................. |

17 |

All Motion Alarm..................................................... |

17 |

Electrical Power Outlet........................................... |

17 |

AC Generator......................................................... |

17 |

Air Line................................................................... |

17 |

Emergency Lowering............................................. |

17 |

Lower Controls....................................................... |

18 |

Upper Controls....................................................... |

18 |

After Use Each Day............................................... |

18 |

Transporting the Machine......................................... |

19 |

Preparing for Transportation.................................. |

19 |

By Crane................................................................ |

19 |

By Transport Vehicle.............................................. |

19 |

Maintenance.............................................................. |

20 |

Hydraulic Fluid....................................................... |

20 |

Check Hydraulic Fluid............................................ |

20 |

Engine.................................................................... |

20 |

Oil Level................................................................. |

20 |

Battery Maintenance.............................................. |

20 |

Inspection and Maintenance Schedule..................... |

21 |

Daily Preventative Maintenance Checklist................ |

22 |

Preventative Maintenance Report.......................... |

22 |

Specifications............................................................ |

23 |

Aerial Platform....................................................... |

23 |

Platform.................................................................. |

23 |

Function Speed...................................................... |

23 |

Drive System.......................................................... |

23 |

Tires....................................................................... |

23 |

Electrical System................................................... |

23 |

Hydraulic System................................................... |

23 |

Engine.................................................................... |

23 |

Fuel Tank Capacity................................................ |

23 |

Ambient Air Temperature Operating Range........... |

23 |

Maximum Wind Speed........................................... |

23 |

Vibration................................................................. |

23 |

Sound Power Level................................................ |

23 |

Sound Pressure Level............................................ |

23 |

Working Envelope.................................................. |

23 |

AB46RT – 0260228 |

1 |

EC DECLARATION OF CONFORMITY

FOR MACHINERY

MACHINERY:

Powered Aerial Platform known as:

Type: |

Snorkel A46JRT |

Serial Number: |

A46JRT-04-XXXXXX |

The machine specified above conforms to the following provisions:

Machinery directive 2006/42/EC (using document EC Community Legislation on Machinery and taking guidance from EN280:2001 + Amendment A2:2009)

Council Directive 2004/108/EC on Electromagnetic Compatibility Council Directive 2006/95/EC on Low Voltage Equipment Safety

Council Directive 2000/14/EC on Noise Emission in the Environment by Equipment for use Outdoors

|

As performed in accordance with EN 3744:1995 |

||

|

Measured sound power level |

91 dB Min |

|

|

100 dB Max |

||

|

|

|

|

|

Guaranteed sound power level |

100 dB |

|

|

|

|

|

Type approval in accordance with |

Powered Access Certification LTD |

||

2006/42/EC performed by: |

P. O. Box 98, Windermere |

||

|

|

Cumbria, LA23 1WF, UK |

|

|

|

Notified Body Identification Number: 0545 |

|

E. C. Type Examination Certificate No:

Authorized Representative in |

The Tanfield Group, PLC |

European Union: |

Vigo Centre, Birtley Road |

|

Washington, Tyne & Wear |

|

NE38 9DA, UK |

Note: Modification of the specified unit renders this declaration invalid.

A46JRT – 0260228

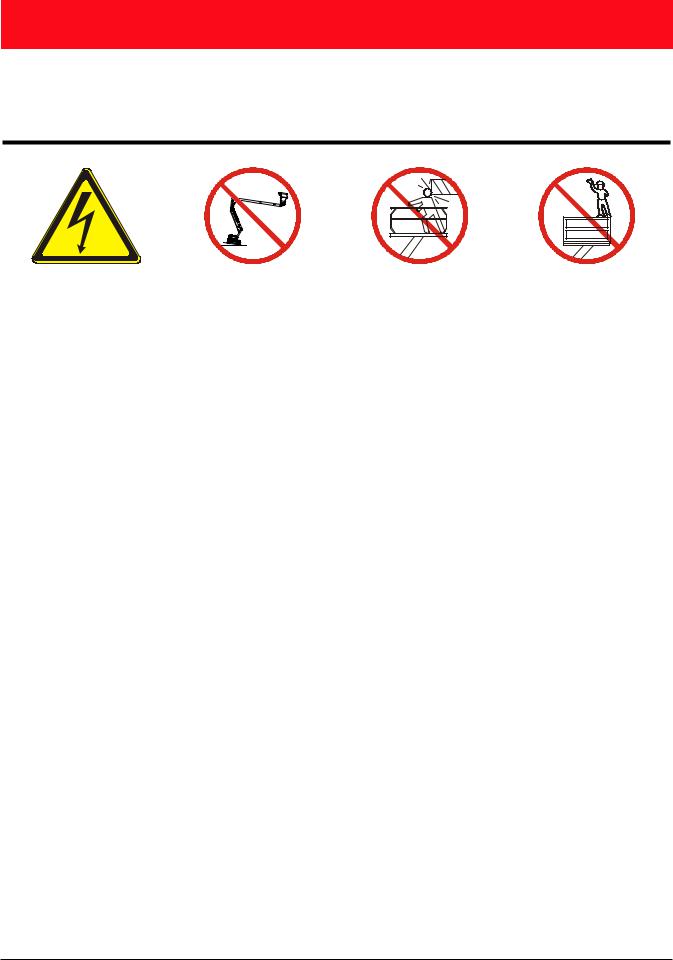

SAFETY RULES

Warning

Warning

All personnel shall carefully read, understand and follow all safety rules and operating instructions before operating or performing maintenance on any Snorkel aerial work platform.

Electrocution Hazard |

Tip Over Hazard |

Collision Hazard |

Fall Hazard |

|

8 |

|

|

|

3 |

|

|

|

B |

|

|

|

A |

|

|

|

t |

|

|

|

h |

|

|

|

g |

|

|

|

i |

|

|

|

R |

|

|

|

p |

|

|

|

U |

|

|

THIS MACHINE IS |

NEVER elevate the platform |

NEVER position the platform |

NEVER climb, stand, or sit |

NOT INSULATED! |

or drive the machine while |

without first checking for |

on platform guardrails or |

|

elevated unless the machine |

overhead obstructions or |

midrail. |

|

is on a firm, level surface |

other hazards. |

|

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures, buildings etc.). Uses or alterations to the aerial work platform must be approved by Snorkel.

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Platform Capacity” on page 5 for details. The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” on page 5 for details. DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 5 for details.

Do not operate the aerial platform in windy or gusty conditions. Do not add anything to or take anything into the aerial platform that will increase the wind loading such as billboards, banners, flags, etc.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc., is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed! It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited! NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas. Modifications to the aerial work platform are prohibited or permissible only at the approval by Snorkel.

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to national traffic regulations.

Certain inherent risks remain in the operation of this machine despite utilizing proper design practices and safeguarding.

Harness attachment points are provided in the platform and the manufacturer recommends the usage of a fall restraint harness, especially where required by national safety regulations.

Care must be taken to ensure that the machines meets the requirements of stability during use, transportation, assembly, dismantling when out of service, testing, or foreseeable breakdowns.

In the event of an accident or breakdown see “Emergency Lowering” on page 17, do not operate the aerial platform if it is damaged or not functioning properly. Qualified maintenance personnel must correct the problem before putting the aerial platform back into service.

A46JRT – 0260228 |

3 |

Introduction

Introduction

This manual covers the A46JRT Aerial Work Platform.

This manual must be stored on the machine at all times.

Read, understand and follow all safety rules and operating instructions before attempting to operate the machine.

When contacting Snorkel for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of the chassis at the front of the machine.

Component Identification

|

Main Boom |

|

|

Tip Boom |

|

Riser Boom |

Jib |

|

Lanyard |

||

|

||

|

Anchors |

|

Lower |

Operator |

|

Controls |

Manual |

|

Front |

Platform |

|

Foot Switch |

||

Fuel Tank |

Power to Platform Inlet |

|

Nameplate Location |

||

Tie-Down/Lifting Lugs |

||

Battery Disconnect |

||

Rear |

||

Switch |

||

|

Left Side |

|

Upper Controls |

Power to Platform Outlet |

Platform |

|

Tie-Down Lugs |

|

Riser |

|

Engine Compartment |

Hydraulic Fluid Filter |

Engine • Hydraulic Pump • Battery |

|

Level Sensor • Drive Valve Block |

|

Hydraulic Reservoir |

Pivoting Front Axle |

Rear |

|

Chassis |

Tie-Down/Lifting Lugs |

|

Front |

Right Side

A46JRT – 0260228

Special Limitations

Special Limitations

Travel with the platform raised is limited to creep speed range. Elevating the platform is limited to firm, level surfaces only.

Danger

The elevating function shall ONLY be used when the work platform is level and on a firm surface.

Platform Capacity

Two people and tools may occupy the platform. The maximum platform capacity for the aerial platform is stated in the “Specifications” on page 23.

Danger

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

Manual Force

Manual force is the force applied by the occupants to objects such as walls or other structures outside the work platform.

The maximum allowable manual force is limited to 200 N (45 lb) of force per occupant, with a maximum of 400 N (90 lb) for two occupants.

Danger

DO NOT exceed the maximum amount of manual force for this machine.

Platform Overload Sensing System

All functions are stopped from the upper and lower controls, when the platform overload limit is exceeded. The horn will sound intermittently and the platform overload light will blink until the excess load is removed from the platform. At that time, the machine functions are again

operational.

If the platform overload sensing system is tripped while operating the machine, the emergency power system may still be used for emergency machine operation.

Danger

The aerial platform can tip over if it becomes unstable. Death or serious injury will result from a tip-over accident. Do not exceed the capacity values indicated on the platform rating placard.

The overload sensing system is not active when the machine is being driven with the booms in the stowed position. This allows the machine to be driven without the system sensing an overload due to rough ground conditions.

Beaufort Scale

Never operate the machine when wind speeds exceed 12.5 m/s (28 mph) [Beaufort scale 6]. Refer to Figure 1.

Caution

The emergency power system is for emergency lowering and stowing only. The length of time the pump can be operated depends on the capacity of the battery. Do not use this system for normal operation.

BEAUFORT |

|

WIND SPEED |

|

GROUND CONDITIONS |

||

RATING |

m/s |

km/h |

ft/s |

mph |

||

|

||||||

3 |

3,4~5,4 |

12,25~19,4 |

11.5~17.75 |

7.5~12.0 |

Papers and thin branches move, flags wave. |

|

4 |

5,4~8,0 |

19,4~28,8 |

17.75~26.25 |

12.0~18 |

Dust is raised, paper whirls up, and small branches sway. |

|

5 |

8,0~10,8 |

28,8~38,9 |

26.25~35.5 |

18~24.25 |

Shrubs with leaves start swaying. Wave crests are apparent in ponds |

|

or swamps. |

||||||

|

|

|

|

|

||

6 |

10,8~13,9 |

38,9~50,0 |

35.5~45.5 |

24.5~31 |

Tree branches move. Power lines whistle. It is difficult to open an |

|

|

|

|

|

|

umbrella. |

|

7 |

13,9~17,2 |

50,0~61,9 |

45.5~56.5 |

31.~38.5 |

Whole trees sway. It is difficult to walk against the wind. |

|

Figure 1 – Beaufort Scale

A46JRT – 0260228 |

5 |

Controls and Indicators

Controls and Indicators

The operator shall know the location of each control and indicator and have a thorough knowledge of the function and operation of each before attempting to operate the machine.

1

18.Main control circuit breaker

19.Platform overload light

37 |

34 |

22 |

35 |

25 |

|

|

|

|

32 |

33 |

|

|

29 |

|

|

|

|

|

|

|

|

|

|

26 |

|

|

27 |

28 |

30 |

31 |

23 |

24 |

|

Figure 2 – Battery Disconnect Switch

1. Battery disconnect switch

4 |

|

|

5 |

3 |

2 |

16 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

14 |

|

|

|

|

|

19 |

|

|

|

8 |

|

9 |

|

|

11 |

6 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

7 |

15 |

|

|

13 |

12 |

|

|

|

|

|

|

|

Figure 3 – Lower Controls and Indicators

2.Preheat button

3.Start button

4.Emergency stop button

5.Controls selector switch

6.Ground operation switch

7.Rotation switch

8.Riser switch

9.Boom elevation switch

10.Boom extension switch

11.Jib articulation switch

12.Platform level switch

13.Platform rotation switch

14.Engine/emergency power switch

15.Hour meter

16.Relays circuit breaker

17.Switches circuit breaker

36

21 |

20 |

|

Figure 4 – Upper Controls and Indicators

20.Preheat switch

21.Start switch

22.Emergency stop button

23.Drive joystick

24.Steer switch

25.Drive range switch

26.Boom speed knob

27.Rotation switch

28.Riser switch

29.Boom elevation switch

30.Boom extension switch

31.Jib articulation switch

32.Platform level switch

33.Platform rotation switch

34.Engine/Emergency power switch

35.Horn

36.Upper control circuit breaker

37.Platform overload light

Danger

Pinch points may exist between moving components. Death or serious injury will result from becoming trapped between components, buildings, structures, or other obstacles. Make sure all personnel stand clear while operating the aerial platform.

•Controls to position the platform are located on the lower control panel on the turntable and on the upper control panel in the platform.

•Controls to drive the aerial platform are located on the upper control panel only.

A46JRT – 0260228

Controls and Indicators

Battery Disconnect Switch

The battery disconnect is located at the left rear of the chassis (refer to Figure 2).

The battery disconnect removes electrical power from all electrically controlled functions when in the off position.

•Place the switch in the on position to electrically connect the battery to the electrical system.

Caution

Only authorized personnel should operate the aerial platform. Unqualified personnel may cause injury to coworkers or property damage. Lock the battery disconnect switch in the off position before leaving the aerial platform unattended.

•Lock the battery disconnect switch in the off position to prevent unauthorized use of the aerial platform.

Lower Controls

The lower controls (refer to Figure 3) are located on the left side of the turntable. Boom and platform functions can be operated from the lower controls.

Preheat Button

The preheat button (refer to Figure 3) is a two-position, black push button. This button operates the glow plugs to aid in starting the engine when the start switch is in the on position.

•When the engine is warmed up or the ambient temperature is above 10°C (50°F), it is not necessary to operate the glow plugs before starting the engine.

•When the ambient temperature range is 10°C (50°F) to -5°CF (23°), press and hold the preheat button for five seconds before starting the engine.

•When the ambient temperature is below -5°C (23°F), press and hold the preheat button for ten seconds before starting the engine.

Start Button

The start button (refer to Figure 3) works like an automobile ignition switch.

•Push the start button until the engine starts, then release it to on.

•If the engine dies, the control switch must be turned to off before the engine can be restarted.

An alarm sounds when the switch is turned on to warn others that the machine engine is being started.

Emergency Stop Button

The emergency stop (refer to Figure 3) is a two-position, red push button.

•Push the button inward to disconnect power to all control circuits.

• Pull the button outward to restore power.

Controls Selector Switch

Use the controls switch (refer to Figure 3) to select between lower control and upper control operation.

•Place the switch in the upward position to operate the aerial platform from the upper controls.

•Place the switch in the downward position for lower control operation.

Ground Operation Switch

Hold the ground operation switch (refer to Figure 3) upward continually to operate the machine from the lower controls. The engine speed increases when the switch is held upward. This switch is spring returned to the off position.

Rotation Switch

The rotation switch (refer to Figure 3) is used to rotate the turntable in a clockwise or counterclockwise direction. The switch is spring returned to the center off position.

•Hold the switch to the right to rotate the turntable counterclockwise.

•Hold the switch to the left to rotate the turntable clockwise.

Riser Switch

The riser switch (refer to Figure 3) is used to raise or lower the riser booms. The switch is spring returned to the center off position.

•Hold the switch upward to raise the riser booms.

•Hold the switch downward to lower the riser booms.

Boom Elevation Switch

The boom elevation switch (refer to Figure 3) is used to raise or lower the main boom. The switch is spring returned to the center off position.

•Hold the switch upward to raise the main boom.

•Hold the switch downward to lower the main boom.

Boom Extension Switch

The boom extension switch (refer to Figure 3) is used to extend or retract the booms. The switch is spring returned to the center off position.

•Hold the switch to the right to extend the booms.

•Hold the switch to the left to retract the booms.

Jib Articulation Switch

The jib switch (refer to Figure 3) is used to raise or lower the jib. The switch is spring returned to the center off position.

• Hold the switch upward to raise the jib.

A46JRT – 0260228 |

7 |

Loading...

Loading...