Skil 5755 Instruction Manual

SM 2610934975 05-06 5/17/06 10:03 AM Page 1

SM 2610934975 05-06 5/17/06 10:03 AM Page 1

!2610934975!

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

5755

Call Toll Free for |

Pour obtenir des informations |

Llame gratis para |

Consumer Information |

et les adresses de nos centres |

obtener información |

& Service Locations |

de service après-vente, |

para el consumidor y |

|

appelez ce numéro gratuit |

ubicaciones de servicio |

1-877-SKIL999 (1-877-754-5999) www.skil.com

For English Version |

Version française |

Versión en español |

See page 2 |

Voir page 14 |

Ver la página 26 |

SM 2610934975 05-06 5/17/06 10:03 AM Page 2

SM 2610934975 05-06 5/17/06 10:03 AM Page 2

Power Tool Safety Rules

|

|

Read and understand all instructions. Failure to follow all instructions listed |

|||

|

! WARNING |

||||

|

|

below, may result in electric shock, fire and/or serious personal injury. |

|||

|

|

||||

|

|

|

SAVE THESE INSTRUCTIONS |

||

|

|

Work Area |

|

When operating a power tool outside, use |

|

Keep your work area clean and well lit. |

an outdoor extension cord marked "W-A" |

||||

Cluttered benches and dark areas invite |

or "W." These cords are rated for outdoor use |

||||

accidents. |

|

|

and reduce the risk of electric shock. Refer to |

||

Do not operate power tools in explosive |

“Recommended sizes of Extension Cords” in |

||||

the Accessory section of this manual. |

|||||

atmospheres, such as in the presence of |

Personal Safety |

||||

flammable liquids, gases, or dust. Power |

|||||

tools create sparks which may ignite the dust |

Stay alert, watch what you are doing and |

||||

or fumes. |

|

|

use common sense when operating a |

||

Keep by-standers, children, and visitors |

power tool. Do not use tool while tired or |

||||

away while operating a power tool. |

under the influence of drugs, alcohol, or |

||||

Distractions can cause you to lose control. |

medication. A moment of inattention while |

||||

|

Electrical Safety |

operating power tools may result in serious |

|||

|

personal injury. |

||||

Double Insulated tools are equipped with a |

Dress properly. Do not wear loose clothing |

||||

polarized plug (one blade is wider than the |

or jewelry. Contain long hair. Keep your |

||||

other.) This plug will fit in a polarized outlet |

hair, clothing, and gloves away from |

||||

only one way. If the plug does not fit fully |

moving parts. Loose clothes, jewelry, or |

||||

in the outlet, reverse the plug. If it still does |

long hair can be caught in moving parts. |

||||

not fit, contact a qualified electrician to |

Keep handles dry, clean and free from oil and |

||||

install a polarized outlet. Do not change |

grease. |

||||

the plug in any way. Double Insulation |

Avoid accidental starting. Be sure switch is |

||||

eliminates the need for the three wire |

|||||

grounded power cord and grounded power |

“OFF” before plugging in. Carrying tools with |

||||

supply system. Before plugging in the tool, be |

your finger on the switch or plugging in tools |

||||

certain the outlet voltage supplied is within the |

that have the switch “ON” invites accidents. |

||||

voltage marked on the nameplate.Do not use |

Remove adjusting keys or wrenches before |

||||

“AC only” rated tools with a DC power supply. |

turning the tool “ON”. A wrench or a key that |

||||

Avoid body contact with grounded |

is left attached to a rotating part of the tool may |

||||

surfaces such as pipes, radiators, ranges |

result in personal injury. |

||||

and refrigerators. There is an increased risk |

Do not overreach. Keep proper footing and |

||||

of electric shock if your body is grounded. If |

balance at all times. Proper footing and |

||||

operating the power tool in damp locations is |

balance enables better control of the tool in |

||||

unavoidable, a Ground Fault Circuit Interrupter |

unexpected situations. |

||||

must be used to supply the power to your tool. |

Use safety equipment. Always wear eye |

||||

Electrician’s rubber gloves and footwear will |

|||||

protection. Dust mask, non-skid safety shoes, |

|||||

further enhance your personal safety. |

|||||

hard hat, or hearing protection must be used |

|||||

Don't expose power tools to rain or wet |

|||||

for appropriate conditions. |

|||||

conditions. Water entering a power tool will |

Tool Use and Care |

||||

increase the risk of electric shock. |

|||||

Do not abuse the cord. Never use the cord |

Use clamps or other practical way to |

||||

to carry the tools or pull the plug from an |

secure and support the workpiece to a |

||||

outlet. Keep cord away from heat, oil, sharp |

stable platform. Holding the work by hand or |

||||

edges or moving parts. Replace damaged |

against your body is unstable and may lead to |

||||

cords immediately. Damaged cords increase |

loss of control. |

||||

the risk of electric shock. |

|

|

|||

-2-

SM 2610934975 05-06 5/17/06 10:03 AM Page 3

SM 2610934975 05-06 5/17/06 10:03 AM Page 3

Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

Do not use tool if switch does not turn it “ON” or “OFF”. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control. Any alteration or modification is a misuse and may result in a dangerous condition.

Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools. Develop a periodic maintenance schedule for your tool.

Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool, may become hazardous when used on another tool. Service

Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury. For example: internal wires may be misplaced or pinched, safety guard return springs may be improperly mounted.

When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of electric shock or injury. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

|

|

|

|

||

|

|

Safety Rules for Circular Saws |

|||

|

|

Keep hands away from |

open position. If saw is accidentally dropped, |

||

|

! DANGER |

||||

|

|

cutting area and blade. Keep |

lower guard may be bent. Raise the lower guard |

||

|

|

||||

your second hand on auxiliary handle, or |

only with the Lower Guard Lift Lever and make |

||||

motor housing. If both hands are holding the |

sure it moves freely and does not touch the |

||||

saw, they cannot be cut by the blade. Hold the |

blade or any other part, in all angles and depths |

||||

saw firmly to prevent loss of control.Figures in |

of cut. |

||||

this manual illustrate typical hand support of the |

Check the operation of the lower guard |

||||

saw.NEVER place your hand behind the saw |

|||||

blade since kickback could cause the saw to |

spring. If the guard and the spring are not |

||||

jump backwards over your hand. |

operating properly, they must be serviced |

||||

Keep your body positioned to either side of |

before use. Lower guard may operate |

||||

sluggishly due to damaged parts, gummy |

|||||

the saw blade, but not in line with the saw |

|||||

deposits, or a buildup of debris. Disconnect the |

|||||

blade. KICKBACK could cause the saw to jump |

|||||

backwards. (See “Causes and Operator |

plug from power source. Periodically remove |

||||

Prevention of Kickback.”) |

the blade, clean the upper, lower guards and |

||||

Do not reach underneath the work. The |

the hub area with kerosene and wipe it dry, or |

||||

blow it clean with compressed air. |

|||||

guard cannot protect you from the blade below |

|||||

Lower guard should be retracted manually |

|||||

the work. Do not attempt to remove cut material |

|||||

when blade is moving. |

only for special cuts such as “Pocket Cuts” |

||||

Check lower guard for proper closing before |

and “Compound Cuts”. Raise lower guard |

||||

each use. Do not operate saw if lower guard |

by Lower Guard Lift Lever. As soon as blade |

||||

does not move freely and close instantly. |

enters the material, lower guard must be |

||||

Never clamp or tie the lower guard into the |

released. For all other sawing, the lower guard |

||||

|

|

|

should operate automatically. |

||

-3-

SM 2610934975 05-06 5/17/06 10:03 AM Page 4

SM 2610934975 05-06 5/17/06 10:03 AM Page 4

Always observe that the lower guard is covering the blade before placing saw down on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch is released.

NEVER hold piece being cut in your hands or across your leg. It is important to support the work properly to minimize body exposure, blade binding, or loss of control.

Hold tool by the insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or it own cord. Contact with a "live" wire will also make exposed metal parts of the tool “live” and shock the operator.

When ripping always use a rip fence or straight edge guide. This improves accuracy of cut and reduces the chance for blade binding.

Always use blades with correct size and shape (diamond vs. round) arbor holes.

Blades that do not match the mounting hardware of the saw will run eccentrically, causing loss of control and will not allow proper vari-torque engagement.

Never use damaged or incorrect blade washers or bolts. The blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation.

The blade washers and the bolt on your saw have been designed to work as a “VARITORQUE CLUTCH”.Understand the operation and settings of the VARI-TORQUE CLUTCH, because the proper setting of the CLUTCH, combined with firm handling of the saw will allow you to control KICKBACK.

Do not run the saw while carrying it at your side. Lower guard may be opened by a contact with your clothing. Accidental contact with the spinning saw blade could result in serious personal injury.

Depending upon use, the switch may not last the life of the saw. If the switch should fail in the “OFF” position, the saw may not start. If it should fail while the saw is running, the saw may not shut off. If either occurs, unplug the saw immediately and do not use until repaired.

This circular saw should not be mounted to a table and converted to a table saw. Circular saws are not designed or intended to be used as table saws.

CAUSES AND OPERATOR PREVENTION

OF KICKBACK:

Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator.

When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and jump back toward the operator.

Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below:

Maintain a firm grip with both hands on the saw and position your body and arm to allow you to resist KICKBACK forces.

KICKBACK forces can be controlled by the operator, if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the saw from the work or pull the saw backward while the blade is in motion or KICKBACK may occur. Investigate and take corrective action to eliminate the cause of blade binding. Wet lumber, green lumber or pressure treated lumber require special attention during cutting operation to prevent KICKBACK.Avoid cutting nails.Inspect for and remove all nails from lumber before cutting.

When restarting a saw in a workpiece, center the saw blade in the kerf and check that saw teeth are not engaged into the material. If saw blade is binding, it may walk up

-4-

SM 2610934975 05-06 5/17/06 10:03 AM Page 5

SM 2610934975 05-06 5/17/06 10:03 AM Page 5

or KICKBACK from the workpiece as the saw is restarted.

Support large panels to minimize the risk of blade pinching and KICKBACK. Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides, near the line of cut and near the edge of the panel. See “Cutting Large Sheets” in this manual.

Do not use dull or damaged blade.

Unsharpened or improperly set blades produce narrow kerf causing excessive friction, blade binding and KICKBACK.

Blade depth and bevel adjusting locking knobs must be tight and secure before making cut. If blade adjustment shifts while cutting, it may cause binding and KICKBACK.

Using the saw with an excessive depth of cut setting increases loading on the unit and susceptibility to twisting of the blade in the kerf. It also increases the surface area of the blade available for pinching under conditions of kerf close down.

Use extra caution when making a “Pocket Cut” into existing walls or other blind areas.

The protruding blade may cut objects that can cause KICKBACK.

! Some dust created by power sanding, sawing, grinding,WARNINGdrilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

-5-

SM 2610934975 05-06 5/17/06 10:03 AM Page 6

SM 2610934975 05-06 5/17/06 10:03 AM Page 6

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbols |

|

|

|

|

|

|

||

|

IMPORTANT: Some of the following symbols may be used on your tool. Please study them |

||||||||||||||

|

and learn their meaning. Proper interpretation of these symbols will allow you to operate the |

||||||||||||||

|

tool better and safer. |

|

|

|

|

|

|

|

|

||||||

|

Symbol |

Name |

|

Designation/Explanation |

|

|

|

|

|

|

|||||

|

|

|

V |

Volts |

|

Voltage (potential) |

|

|

|

|

|

|

|||

|

|

|

A |

Amperes |

|

Current |

|

|

|

|

|

|

|||

|

|

|

Hz |

Hertz |

|

Frequency (cycles per second) |

|

||||||||

|

|

|

W |

Watt |

|

Power |

|

|

|

|

|

|

|||

|

|

|

kg |

Kilograms |

|

Weight |

|

|

|

|

|

|

|||

|

|

min |

Minutes |

|

Time |

|

|

|

|

|

|

||||

|

|

|

s |

Seconds |

|

Time |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Diameter |

|

Size of drill bits, grinding wheels, etc. |

|

|||||

|

|

|

n0 |

No load speed |

|

Rotational speed, at no load |

|

||||||||

|

.../min |

Revolutions or reciprocation per minute |

Revolutions, strokes, surface speed, |

|

|||||||||||

|

|

|

|

|

|

|

|

|

orbits etc. per minute |

|

|

|

|

|

|

|

0 |

|

|

|

Off position |

|

Zero speed, zero torque... |

|

|||||||

|

1, 2, 3, ... |

Selector settings |

|

Speed, torque or position settings. |

|

||||||||||

|

I, II, III, |

|

|

Higher number means greater speed |

|

||||||||||

|

0 |

|

|

|

|

Infinitely variable selector with off |

|

Speed is increasing from 0 setting |

|

||||||

|

|

|

|

|

|

|

Arrow |

|

Action in the direction of arrow |

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

Alternating current |

|

Type or a characteristic of current |

|

|||||

|

|

|

|

|

|

|

Direct current |

|

Type or a characteristic of current |

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

Alternating or direct current |

|

Type or a characteristic of current |

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

Class II construction |

|

Designates Double Insulated |

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

Construction tools. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthing terminal |

|

Grounding terminal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Warning symbol |

|

Alerts user to warning messages |

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

Ni-Cad RBRC seal |

|

Designates Ni-Cad battery recycling |

|

|||||

|

|

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates |

This symbol designates |

|

|

|

|

|

|

||

|

|

|

|

|

|

that this tool is listed to |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

that this tool is listed by |

Canadian Standards by |

This symbol |

|||||||

|

|

|

|

|

|

Underwriters Laboratories. |

Underwriters Laboratories. |

||||||||

|

|

|

|

|

|

|

|

|

|

designates |

|||||

|

|

|

|

|

|

This symbol designates |

This symbol designates that |

that |

|||||||

|

|

|

|

|

|

this tool is listed by |

this tool |

||||||||

|

|

|

|

|

|

that this tool is listed by |

Underwriters Laboratories, |

complies |

|||||||

|

|

|

|

|

|

the Canadian Standards |

and listed to Canadian |

to NOM |

|||||||

|

|

|

|

|

|

Association. |

Standards by Underwriters |

Mexican |

|||||||

|

|

|

|

|

|

|

|

Laboratories. |

Standards. |

||||||

-6-

SM 2610934975 05-06 5/17/06 10:03 AM Page 7

SM 2610934975 05-06 5/17/06 10:03 AM Page 7

|

Functional Description and Specifications |

|

! |

Disconnect the plug from the power source before making any |

|

WARNING assembly, adjustments or changing accessories. Such preventive safety |

||

measures reduce the risk of starting the tool accidentally. |

|

|

|

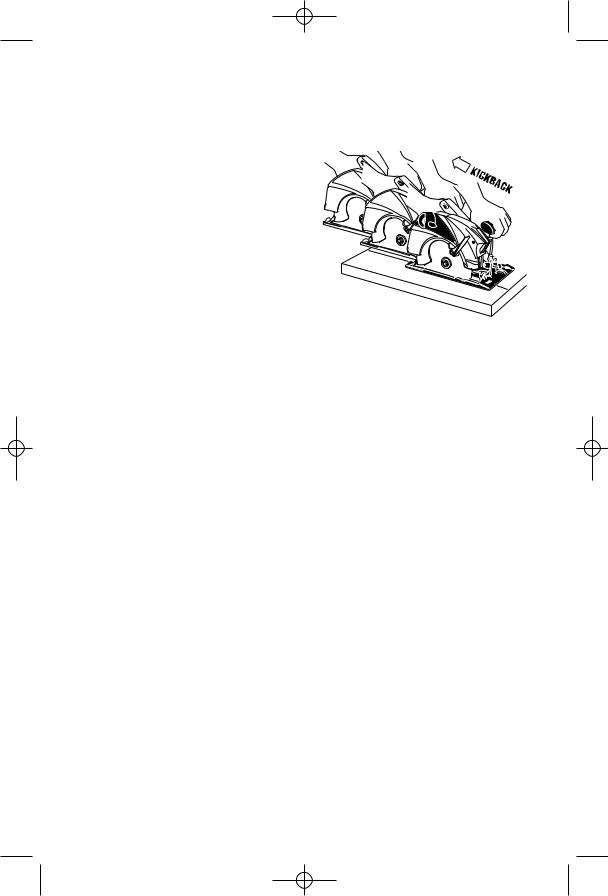

Circular Saw |

|

|

FIG. 1 |

|

|

SAFETY SWITCH |

|

|

DUST PORT |

LASER LIGHT |

|

UPPER |

ADJUSTMENT SCREW |

|

|

|

|

GUARD |

AUXILIARY |

|

|

HANDLE |

|

|

CALIBRATED |

|

LOWER |

BEVEL |

|

QUADRANT |

|

GUARD LIFT |

|

|

|

LEVER |

BEVEL |

|

|

ADJUSTMENT |

|

|

KNOB |

FOOT

LOWER

GUARD

DEPTH

SCALE

LOCK BUTTON

DEPTH ADJUSTMENT

LEVER

|

|

BLADE WRENCH & |

|

|

|

STORAGE AREA |

|

Maximum Capacities |

7-1/4" |

|

|

Blade |

Depth of cut at 90° |

2-7/16" |

|

Blade arbor hole |

Round |

Depth of cut at 45° |

1-15/16" |

NOTE: For tool specifications refer to the nameplate on your tool.

-7-

SM 2610934975 05-06 5/17/06 10:03 AM Page 8

SM 2610934975 05-06 5/17/06 10:03 AM Page 8

|

|

|

|

Assembly |

|

|||

ATTACHING THE BLADE |

|

5. |

Reinstall OUTER WASHER. First tighten |

|||||

! WARNING |

Disconnect |

the plug from |

BLADE STUD finger tight, then TIGHTEN |

|||||

the power source before |

BLADE STUD 1/8 TURN (45˚) WITH THE |

|||||||

making any assembly, adjustments or |

WRENCH PROVIDED. |

|||||||

changing accessories. Such preventive |

Do not use wrenches with longer handles, |

|||||||

safety measures reduce the risk of starting |

since it may lead to over tightening of the blade |

|||||||

the tool accidentally. |

|

|

|

stud. |

|

|||

1. Press the lock button and turn wrench until |

|

|

VARI-TORQUE CLUTCH |

|||||

lock button engages. Saw shaft is now locked. |

This clutching action is provided by the friction |

|||||||

Continue to depress button, turn wrench |

of the OUTER WASHER against the BLADE |

|||||||

counter-clockwise and remove BLADE STUD |

and permits the blade shaft to turn when the |

|||||||

and OUTER WASHER (Fig. 2). |

|

blade encounters excessive resistance. When |

||||||

2. Retract the lower guard all the way up into |

the BLADE STUD is properly tightened (as |

|||||||

the upper guard. While retracting the lower |

described in No. 5 of Attaching The Blade), the |

|||||||

guard, check operation and condition of the |

blade will slip when it encounters excessive |

|||||||

LOWER GUARD SPRING. |

|

|

|

resistance, thus reducing saw’s tendency to |

||||

3. Make sure the saw teeth and arrow on the |

KICKBACK. |

|||||||

blade point in the same direction as the arrow |

One setting may not be sufficient for cutting all |

|||||||

on the lower guard. |

|

|

|

materials. If excessive blade slippage occurs, |

||||

4. Slide blade through slot in the foot and |

tighten the blade stud a fraction of a turn more |

|||||||

(less than 1/8 turn). OVERTIGHTENING THE |

||||||||

mount it against the INNER WASHER on the |

||||||||

BLADE STUD NULLIFIES THE EFFECTIVE- |

||||||||

shaft. Be sure the large diameter of the OUTER |

||||||||

NESS OF THE CLUTCH. |

||||||||

washer lays flush against the blade. |

|

|||||||

|

|

|

|

|||||

|

|

|

|

FIG. 2 |

|

|

||

|

|

|

|

|

|

|

LOWER GUARD |

|

|

DUST |

|

|

|

|

|

SPRING |

|

|

|

|

|

|

|

|

||

|

PORT |

|

|

|

|

|

BLADE SHAFT |

|

|

|

|

|

|

|

|

||

LOWER GUARD |

|

|

|

|

|

|

||

LIFT LEVER |

|

|

|

|

|

|

||

OUTER WASHER |

|

|

|

|

|

|

||

Large Diameter |

|

|

|

|

|

|

||

Faces Blade |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

LOCK BUTTON |

|

Tighten |

|

|

INNER WASHER |

|

LOWER |

|||

|

|

|

|

|||||

|

|

|

Large Diameter |

|

|

GUARD |

||

BLADE |

Loosen |

|

|

Faces Blade |

|

|

|

|

BLADE |

|

|

|

|

||||

STUD |

|

|

|

|

|

|||

-8-

SM 2610934975 05-06 5/17/06 10:03 AM Page 9

SM 2610934975 05-06 5/17/06 10:03 AM Page 9

|

|

Operating Instructions |

|

|

|||

|

|

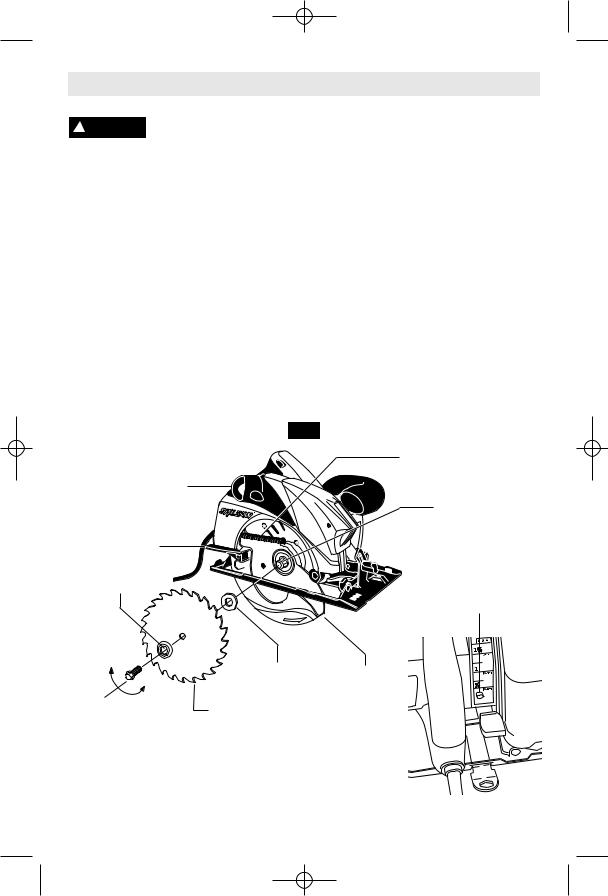

DEPTH ADJUSTMENT |

|

|

|

||

Disconnect plug from power source. Loosen |

desired. Check desired depth (Fig. 3). |

||||||

the depth adjustment lever located between |

Not more than one tooth length of the blade |

||||||

the guard and handle of saw. Hold the foot |

should extend below the material to be cut, for |

||||||

down with one hand and raise or lower saw by |

minimum splintering (Fig. 4). |

|

|

||||

the handle. Tighten lever at the depth setting |

|

|

|

|

|

||

|

|

FIG. 3 |

|

|

|

|

FIG. 4 |

|

|

DEPTH |

|

|

|

|

|

|

|

SCALE |

|

|

|

|

|

|

|

DEPTH |

|

|

|

|

|

|

|

ADJUSTMENT |

|

|

|

|

|

|

|

LEVER |

|

|

|

|

|

|

|

BLADE WRENCH, |

|

ONE TOOTH LENGTH SHOULD |

|||

|

|

& STORAGE |

|

|

PENETRATE WOOD FOR |

||

|

|

AREA |

|

|

MINIMUM SPLINTERING |

||

|

|

SAFETY SWITCH |

|

90° CUTTING ANGLE CHECK |

|||

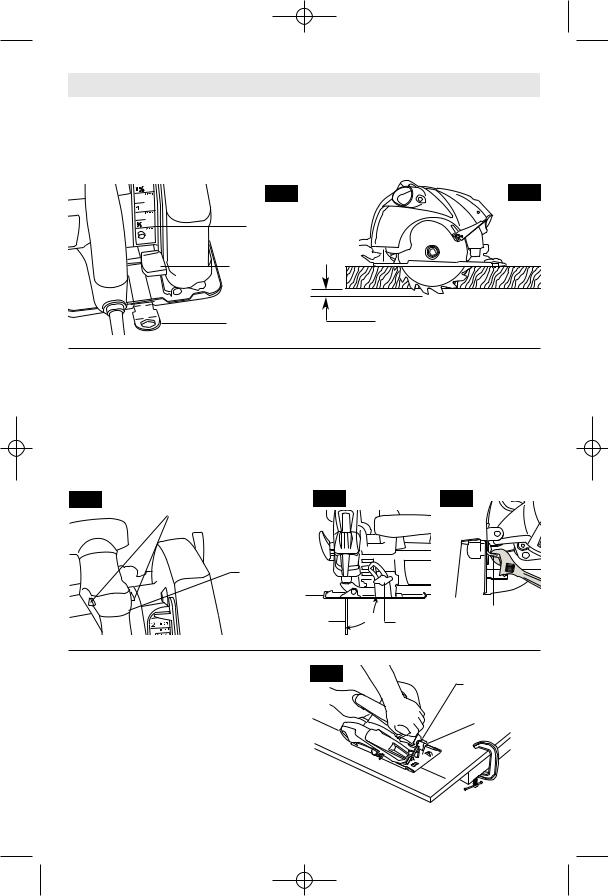

The safety switch is designed to prevent |

Disconnect plug from power source. Set foot |

||||||

accidental starts. To operate safety switch, |

to maximum depth of cut setting. Loosen |

||||||

press the release button with your thumb on |

bevel adjustment knob, set to 0° on quadrant, |

||||||

either side of handle to disengage the lock, |

retighten knob and check for 90° angle |

||||||

then pull the trigger (Fig. 5). When the trigger |

between the blade and bottom plane of foot |

||||||

is released the button will engage the safety |

with a square (Fig. 6). If adjustment is |

||||||

switch automatically, and the trigger will no |

necessary, tilt foot to 45°, tighten bevel |

||||||

longer operate. (See Switch & General Cuts |

adjustment knob and bend "TAB" with an |

||||||

on page 10.) |

|

adjustable wrench or pliers (Fig. 7). |

|||||

FIG. 5 |

|

RELEASE |

FIG. 6 |

|

FIG. 7 |

||

|

|

BUTTON |

|

|

|

|

|

|

|

TRIGGER |

|

|

|

|

|

|

|

FOOT |

|

|

BEVEL |

|

TAB |

|

|

BLADE |

90º |

|

|||

|

|

ADJUSTMENT |

|

||||

|

|

|

|

|

KNOB |

|

|

|

BEVEL ADJUSTMENT |

FIG. 8 |

|

|

|

|

|

Disconnect plug from power source. The foot |

|

|

|

|

QUADRANT |

||

can be adjusted up to 45° by loosening the |

|

|

|

|

BEVEL |

||

bevel adjustment knob at the front of the saw. |

|

|

|

|

|||

Align to desired angle on calibrated quadrant. |

|

|

|

ADJUSTMENT |

|||

Then tighten bevel adjustment knob (Fig. 8). |

|

|

|

|

KNOB |

||

Because of the increased amount of blade |

|

|

|

|

|

||

engagement in the work and decreased stability of the foot, blade binding may occur. Keep the saw steady and the foot firmly on the workpiece.

-9-

SM 2610934975 05-06 5/17/06 10:03 AM Page 10

SM 2610934975 05-06 5/17/06 10:03 AM Page 10

|

ADJUSTABLE LASER LINE GUIDE |

becomes significantly harder to turn the |

|||||||||||||||||||

|

|

When adjusting the laser |

screw. Overturning the adjustment screw may |

||||||||||||||||||

|

! WARNING |

||||||||||||||||||||

|

line guide you will need to |

cause the adjustment system to break or |

|||||||||||||||||||

|

have the saw |

plugged into a power source. |

cause the adjustment screw to fall out of the tool. |

||||||||||||||||||

Pay attention to the placement of the saw |

|

|

|

|

|

|

|

|

LASER RADIATION. AVOID |

||||||||||||

! |

DANGER |

||||||||||||||||||||

blade with respect to your hands and body |

|

|

DIRECT EYE EXPOSURE. |

||||||||||||||||||

and avoid accidental actuation of the |

DO NOT stare into the laser light source. |

||||||||||||||||||||

power switch. |

Accidental start-up of the saw |

Never aim light at another person or object |

|||||||||||||||||||

may cause injury. |

other than the workpiece. Laser light can |

||||||||||||||||||||

Your tool is equipped with a laser line guide |

damage your eyes. |

||||||||||||||||||||

that will turn on whenever the tool is plugged |

|

|

|

|

|

|

|

|

|

DO NOT use tinted glasses |

|||||||||||

! |

WARNING |

|

|||||||||||||||||||

in and the safety switch release button is |

|

|

|

to enhance the laser light. |

|||||||||||||||||

pushed in. The two laser lines are set to the |

Tinted glasses will reduce overall vision for the |

||||||||||||||||||||

kerf of the blade supplied and indicate the |

application and interfere with the normal |

||||||||||||||||||||

outer edges of the blade. If you use a blade |

operation of the tool. |

||||||||||||||||||||

with a different kerf the laser lines will need to |

|

|

|

|

|

|

|

|

|

Never aim the beam at a |

|||||||||||

be adjusted to match the kerf of the new |

! |

WARNING |

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

workpiece with a reflective |

|||||||

blade. You should adjust the laser lines to |

surface. Bright shiny reflective sheet steel or |

||||||||||||||||||||

whichever side of the blade the user would |

|||||||||||||||||||||

similar reflective surfaces are not |

|||||||||||||||||||||

prefer the cut line to be on. The laser guide |

|||||||||||||||||||||

recommended for laser use. Reflective |

|||||||||||||||||||||

does not need to be adjusted for bevel cuts |

|||||||||||||||||||||

surfaces could direct the beam back toward |

|||||||||||||||||||||

after it is aligned for straight 90° cuts. |

|||||||||||||||||||||

the operator. |

|

|

|

|

|

|

|

|

|

|

|||||||||||

If using the laser line guide for cutting you do |

|

|

|

Use of controls or adjustments |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||||

not need the line guide incorporated in the foot |

! |

CAUTION |

|

|

|

||||||||||||||||

|

|

|

or performance of procedures |

||||||||||||||||||

as it may be in a different setting than the |

other than those specified herein may result in |

||||||||||||||||||||

laser line guide. |

|

|

|

||||||||||||||||||

|

|

|

hazardous radiation exposure. |

||||||||||||||||||

The laser light guide is a class IIIA laser with a |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

The use of optical instruments |

||||||||||||

maximum output power of 5.0 mWatts and |

! |

CAUTION |

|

|

|

||||||||||||||||

conforms to 21 CFR 1040.10 and 1040.11. |

|

|

|

|

|

|

|

|

|

with this product will increase |

|||||||||||

eye hazards. |

|

|

|||||||||||||||||||

TO ADJUST: |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Use a flat head screwdriver to turn the |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

FIG. 9 |

|

|

|

|

|

|

|

|

|

|

||||||||||

adjustment screw located on the side of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

laser module (Fig. 9). Turn on the laser line |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LASER LIGHT |

|||||

guide by pressing the safety switch and rotate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

the adjustment screw until the laser line is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ADJUSTMENT |

|||||

aligned. There is no need to power the saw |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCREW |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

“on” while adjusting the light beam. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

The Laser line guide has a limited amount of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

travel. Do not continue to turn the adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

screw after the line stops moving or if it |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

SWITCH |

To turn tool “ON”, press the release button |

|

|

When starting the tool, |

with your thumb on either side of handle to |

|

! WARNING |

|||

hold it with both hands. |

disengage the lock, then squeeze the trigger |

||

The torque from the motor can cause the tool |

switch. To turn the tool “OFF”, release the |

||

to twist. |

|

trigger switch, which is spring loaded and will |

|

-10-

SM 2610934975 05-06 5/17/06 10:03 AM Page 11

SM 2610934975 05-06 5/17/06 10:03 AM Page 11

return to the off position automatically and lock |

||

the trigger. |

|

|

Your saw should be running at full speed |

||

BEFORE starting the cut, and turned off only |

||

AFTER completing the cut. To increase switch |

||

life, do not turn switch on and off while cutting. |

||

When cutting across the grain, the fibers of |

||

the wood have a tendency to tear and lift. |

||

Advancing the saw slowly minimizes this |

||

effect. For a finished cut, a cross cut blade or |

||

miter blade is recommended. |

||

|

GENERAL CUTS |

|

Always hold the saw handle with one hand |

||

and the auxiliary handle or housing with the |

||

other. |

Always be sure either hand |

|

|

! WARNING |

|

|

does not interfere with the |

|

free movement of the lower guard.Maintain |

||

a firm grip and operate the switch with a |

||

decisive action. Never force the saw. Use light |

||

and continuous pressure. |

||

|

|

After completing a cut and |

|

! WARNING |

|

|

the trigger has been |

|

released, be aware of the necessary time it takes for the blade to come to a complete stop during coast down. Do not allow the saw to brush against your leg or side, since the lower guard is retractable, it could catch on your clothing and expose the blade. Be aware of the necessary blade exposures that exist in both the upper and lower guard areas.

When cutting is interrupted, to resume cutting: squeeze the trigger and allow the blade to reach full speed, re-enter the cut slowly and resume cutting.

|

CUTTING MASONRY/METAL |

|

|||||

This tool is not recommended for continuous |

|||||||

and general usage with metal or masonry cut- |

|||||||

off wheels. If you use your saw for cutting |

|||||||

these materials, use the appropriate wheel for |

|||||||

the material being cut. |

|

|

|

||||

When cutting masonry, do not cut a depth of |

|||||||

more than 1/4 inch (6 mm). Make successive |

|||||||

passes to achieve desired depth. Apply a light |

|||||||

forward pressure. Do not overload motor. |

|||||||

Disconnect plug from power source and clean |

|||||||

dust from air vents frequently. Metal cutting is |

|||||||

done at full depth. |

|

|

|

||||

|

|

|

|

Clean guards frequently to |

|||

|

! WARNING |

|

|

||||

|

|

|

assure a rapid return of |

||||

lower guard. |

|

|

|||||

The lower guard may become |

|||||||

sluggish when cutting masonry materials. |

|||||||

|

|

|

|

Abrasive Cut Off Wheels |

|||

|

! WARNING |

||||||

|

|

|

must have a maximum |

||||

safe operating speed greater than the “no |

|||||||

load RPM” marked on the tool’s |

|||||||

nameplate. Wheels running over the rated |

|||||||

speed can fly apart and cause injury. |

|

||||||

|

|

|

|

Do not use the abrasive |

|||

|

! WARNING |

|

|||||

|

|

|

cut |

off |

wheel |

near |

|

flammable materials. |

Sparks from the |

||||||

wheel could ignite these materials. |

|

||||||

|

|

|

|

This |

machine is |

not |

|

|

! WARNING |

|

|

||||

|

|

|

intended to be used with |

||||

Wet Diamond Wheels. Using water or other liquid coolants with this machine may result in electrocution or shock. Use of Dry Diamond Wheels is acceptable.

POCKET CUTS

Disconnect the plug from the power source before making adjustments. Set depth adjustment according to material to be cut. Tilt saw forward with cutting guide notch lined up with the line you’ve drawn. Raise the lower guard, using lift lever and hold the saw by the front and rear handles (Fig. 10).

With the blade just clearing the material to be cut, start the motor. Gradually lower the back end of saw using the front end of the foot as the hinge point. WARNING: As blade starts cutting the material, release the lower guard immediately. When the foot rests flat on the surface being cut, proceed cutting in forward direction to end of cut. WARNING: Allow blade to come to a complete stop before lifting the saw from cut. Also, never pull the saw

backward since blade will climb out of the material and KICKBACK will occur. Turn saw around and finish the cut in the normal manner, sawing forward. If corners of your pocket cut are not completely cut through, use a jigsaw or hand saw to finish the corners.

FIG. 10

FOOT

LINE

GUIDE

-11-

SM 2610934975 05-06 5/17/06 10:03 AM Page 12

SM 2610934975 05-06 5/17/06 10:03 AM Page 12

CUTTING LARGE SHEETS

Large sheets and long boards sag or bend, depending on support. If you attempt to cut without leveling and properly supporting the piece, the blade will tend to bind, causing KICKBACK and extra load on the motor (Fig. 11).

Support the panel or board close to the cut, as shown in (Fig. 12). Be sure to set the depth of the cut so that you cut through the sheet or board only and not the table or work bench. The two-by-fours used to raise and support the work should be positioned so that the broadest sides support the work and rest on the table or bench. Do not support the work with the narrow sides as this is an unsteady arrangement. If the sheet or board to be cut is too large for a table or work bench, use the supporting two-by-fours on the floor and secure.

FIG. 11

WRONG

RIGHTF . 12

RIP CUTS

The combination blade provided with your saw is for both cross cuts and rip cuts. Ripping is cutting lengthwise with the grain of the wood. Rip cuts are easy to do with a rip fence (Fig. 13). Rip Fence is available as an accessory (not included). To attach fence, insert fence through slots in foot to desired width as shown and secure with the wing nut (not included).

|

WING |

FIG. 13 |

|

|

|

|

NUT |

|

|

|

DESIRED |

|

|

WIDTH |

|

|

OF CUT |

RIP |

|

|

FENCE |

|

|

RIP BOARD GUIDE

When rip cutting large sheets, the rip fence may not allow the desired width of cut. Clamp or nail a straight piece of 1" lumber to the sheet as a guide (Fig. 14). Use the right side of the foot against the board guide.

FIG. 14

RIP

BOARD

GUIDE

DESIRED LINE

OF CUT

-12-

Loading...

Loading...