Skil 7500 User Manual

SM 2610930928 6-05 6/1/05 9:10 AM Page 1

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

7500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Call Toll Free |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pour renseignement des |

Llame gratis para |

||||||

for Consumer Information |

|

consommateurs et centres |

obtener información |

|||||

& Service Locations |

|

de service, appelez au |

para el consumidor y |

|||||

|

|

|

numéro gratuit : |

ubicaciones de servicio |

||||

1-877-SKIL999 (1-877-754-5999) www.skil.com

For English |

Parlez-vous français? |

¿Habla español? |

See page 2 |

Voir page 13 |

Ver página 24 |

SM 2610930928 6-05 6/1/05 9:10 AM Page 2

General Safety Rules

! WARNING Read all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury. The term “power tool” in

all of the warnings listed below refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

SAVE THESE INSTRUCTIONS

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

Do not use AC only rated tools with a DC power supply. While the tool may appear to work, the electrical components of the AC rated tool are likely to fail and create a hazard to the operator.

If operating the power tool in damp locations is unavoidable a Ground Fault Circuit Interrupter (GFCI) must be used to supply the power to your tool. GFCI and personal protection devices like electrician’s rubber gloves and footwear will further enhance your personal safety.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

Use safety equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

Avoid accidental starting. Ensure the switch is in the off-position before plugging in. Carrying power tools with your finger on the switch or plugging in power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of these devices can reduce dustrelated hazards.

-2-

SM 2610930928 6-05 6/1/05 9:10 AM Page 3

Keep handles dry, clean and free from oil and grease. Slippery hands cannot safely control the power tool.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tools operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc., in accordance with these instructions and in the manner intended for the particular type of power tool, taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a hazardous situation.

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be careful not to disassemble any portion of the tool since internal wires may be misplaced or pinched or safety guard return springs may be improperly mounted. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

SAVE THESE INSTRUCTIONS

Belt Sander Safety Rules

Hold tool by insulated gripping surfaces when performing a operation where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator.

Never leave the trigger locked “ON”. Before plugging the tool in, check that the trigger lock is “OFF”. Accidental start-ups could cause injury.

Unplug the sander before changing accessories. Accidental start-ups may occur if sander is plugged in while changing an accessory.

Keep your fingers and clothing away from the belt. They could get cut or wedged between the pulley, belt and motor housing.

Properly adjust tracking of belt to avoid it overhanging the housing. A running belt overhanging its housing can cause severe lacerations.

Be aware of the location and setting of the Switch "Lock-ON" Button. If the switch is locked "ON", be ready for emergency situations to switch it "OFF", by first pulling the trigger then immediately releasing it without pressing the "Lock-ON" button.

-3-

SM 2610930928 6-05 6/1/05 9:10 AM Page 4

Keep the cord to the side away from pulleys. The cord can be dragged into belt housing and become entangled with the pulleys.

Clamp or secure workpiece when sanding. Clamping the workpiece prevents it from being ejected from under the sander and leaves both hands to control the tool.

Clamp or secure sander if it is inverted and bench mounted for use as a table sander. Always use edge stop or guide when sanding short or small workpieces.

Fingers or clothing can be dragged into pulley and housing area.

Do not wet sand with this sander. Liquids entering the motor housing is an electrical shock hazard.

Your tool is equipped with a dust canister, empty it frequently, after completion of sanding and before storing the sander. Be extremely careful of dust disposal, materials in fine particle form may be explosive. Do not throw sanding dust on an open fire. Combustion from mixture of varnishes, lacquers, polyurethane, oil or water with dust particles can occur if there is a static discharge, spark introduced in the box, or excessive heat.

Portable belt sanders are not intended to be permanently mounted as a bench or table sander. There are accessories available

which can convert certain portable belt sanders for occasional stationary use. If such accessories are used always clamp or secure sander when inverted and bench mounted for use as a table sander. Be aware of switch location and know how to shut off the tool in emergency situations. Always follow directions included with the accessory. Use sanding fence, stop or guide when sanding short or small workpieces.

! WARNING Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

-4-

SM 2610930928 6-05 6/1/05 9:10 AM Page 5

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol |

Name |

Designation/Explanation |

|||||

|

|

V |

Volts |

Voltage (potential) |

|||

|

|

A |

Amperes |

Current |

|||

|

|

Hz |

Hertz |

Frequency (cycles per second) |

|||

|

|

W |

Watt |

Power |

|||

|

|

kg |

Kilograms |

Weight |

|||

|

min |

Minutes |

Time |

||||

|

|

s |

Seconds |

Time |

|||

|

|

|

|

|

|

Diameter |

Size of drill bits, grinding wheels, etc. |

|

|

n0 |

No load speed |

Rotational speed, at no load |

|||

.../min |

Revolutions or reciprocation per minute |

Revolutions, strokes, surface speed, |

|||||

|

|

|

|

|

|

|

orbits etc. per minute |

0 |

|

|

|

Off position |

Zero speed, zero torque... |

||

1, 2, 3, ... |

Selector settings |

Speed, torque or position settings. |

|||||

I, II, III, |

|

Higher number means greater speed |

|||||

0 |

|

|

|

|

Infinitely variable selector with off |

Speed is increasing from 0 setting |

|

|

|

|

|

|

|

Arrow |

Action in the direction of arrow |

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

Alternating current |

Type or a characteristic of current |

|

|

|

|

|

|

Direct current |

Type or a characteristic of current |

|

|

|

|

|

|

||

|

|

|

|

|

|

Alternating or direct current |

Type or a characteristic of current |

|

|

|

|

|

|

||

|

|

|

|

|

|

Class II construction |

Designates Double Insulated |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Construction tools. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthing terminal |

Grounding terminal |

|

|

|

|

|

|

||

|

|

|

|

|

|

Warning symbol |

Alerts user to warning messages |

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

Ni-Cad RBRC seal |

Designates Ni-Cad battery recycling |

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed to Canadian Standards by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, and listed to Canadian Standards by Underwriters Laboratories.

This symbol designates that

this tool complies to NOM Mexican Standards.

-5-

SM 2610930928 6-05 6/1/05 9:10 AM Page 6

|

Functional Description and Specifications |

|

|

Disconnect the plug from the power source before making any |

|

! WARNING |

||

assembly, adjustments or changing accessories. Such preventive safety |

||

|

measures reduce the risk of starting the tool accidentally.

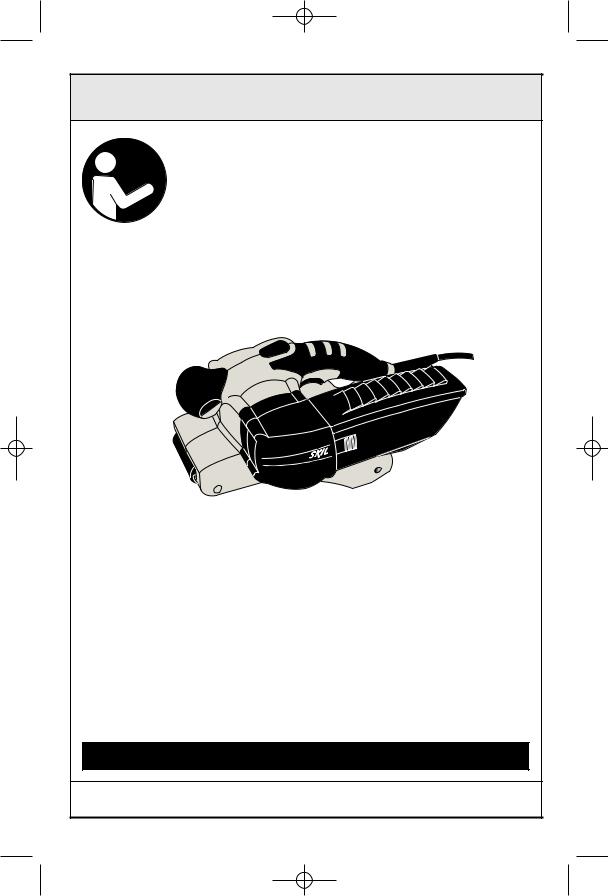

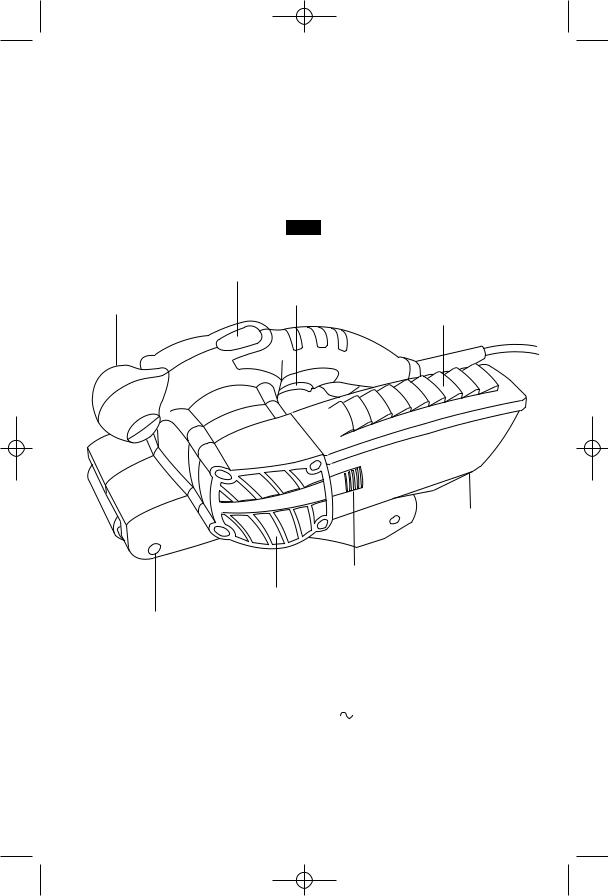

Belt Sander

AUXILIARY

HANDLE

AUTO-TRACK

ADJUSTMENT

SCREW

FIG. 1

“LOCK-ON”

BUTTON

ON/OFF

TRIGGER

MICROFILTER

DUST CANISTER LID

MICROFILTER

DUST

CANISTER

RELEASE TABS

VENTILATION

OPENINGS

Model number |

7500 |

Voltage rating |

120 V 50 - 60Hz |

Amperage rating |

6 A |

No load speed |

n0 1050 SFPM |

Belt size |

3" x 18" |

-6-

SM 2610930928 6-05 6/1/05 9:10 AM Page 7

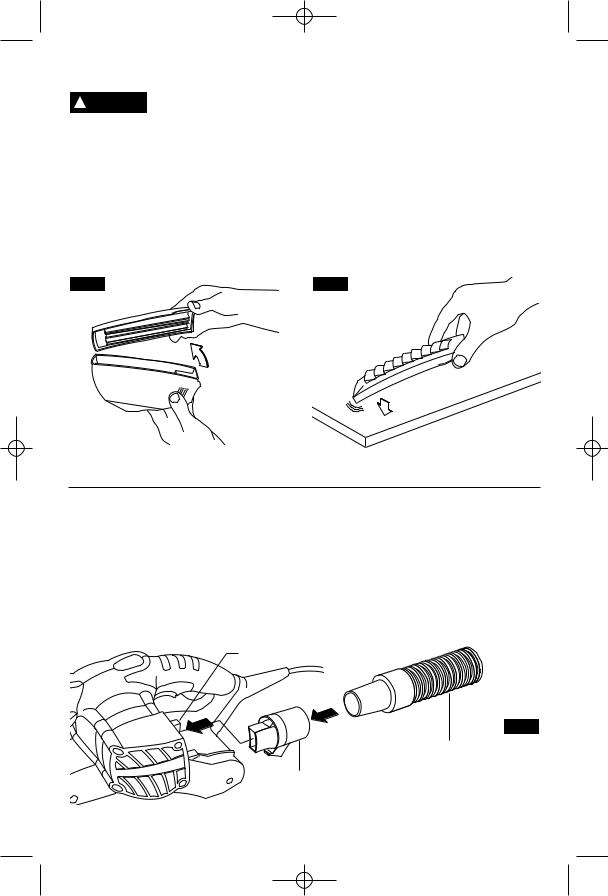

Assembly

REMOVING AND INSTALLING

SANDING BELTS

! WARNING To prevent personal injury, always disconnect the plug

from the power source before removing or installing the belt.

Keep your fingers and clothing away from the belt. They could get cut or wedged between the pulley, belt and motor housing.

TO REMOVE BELT

1. Place sander on it’s side and move lever in direction of arrow to retract front pulley and release belt tension (Fig. 2).

2. With the sander on it’s side and the open side facing you, you can easily remove the belt.

TO INSTALL BELT

1.While the sander is still on it’s side with the front pulley retracted and locked, insert the new belt around both pulleys and over the metal plate. If belt has directional marks, be sure the arrow on the inside of belt is pointing in the direction of rotation as indicated on housing.

2.Then push lever back to its original position to return tension to the belt.

REAR PULLEY |

BELT TENSION RELEASE LEVER |

FIG. 2 |

DIRECTION |

|

|

OF TRAVEL |

|

|

|

FRONT PULLEY |

|

|

METAL PLATE |

|

DIRECTION OF TRAVEL

MICROFILTER DUST CANISTER

The integral dust extraction system collects sanding dust in canister supplied with your sander. For maximum efficiency, the dust canister should be emptied frequently during operation.

REMOVING AND INSTALLING DUST

CANISTER

To remove dust canister: squeeze release tabs on both sides of canister and simply pull away from the tool (Fig. 3).

To install dust canister: align dust port with hole in canister and push canister onto tool until it locks into place.

DUST PORT |

MICROFILTER |

FIG. 3 |

DUST CANISTER LID |

MICROFILTER

DUST

CANISTER

RELEASE TABS

-7-

SM 2610930928 6-05 6/1/05 9:10 AM Page 8

CLEANING AND EMPTYING THE DUST CANISTER

! WARNING |

Your tool is equipped with |

a dust canister, empty it |

frequently, after completion of sanding and before storing the sander. Be extremely careful of dust disposal, materials in fine particle form may be explosive. Do not throw sanding dust on an open fire. Combustion from mixture of varnishes, lacquers, polyurethane, oil or water with dust particles can occur if there is a static discharge, spark introduced in the box, or excessive heat.

To empty canister, hold canister and maintain a firm grip. Firmly push upward on tab on corner of lid, and remove from canister (Fig. 4). Knock excess dust out of the microfilter, or remove dust with your fingers or a soft brush (Fig. 5). You may notice that all the dust may not come out of the canister. This will not affect sanding performance but will reduce dust collection efficiency.

NOTE: Do not wash the micro filter with soap and water. Dust may become more firmly lodged in the pores, which will reduce dust collection, and damage the micro filter.

FIG. 4 |

FIG. 5 |

VACUUM ADAPTER

For maximum dust collection when the dust canister has been removed, use the vacuum adapter supplied and a shop vacuum cleaner.

INSTALLING VACUUM ADAPTER

To install vacuum adapter: Remove dust canister (Fig. 3). Align dust port with hole in

vacuum adapter and push onto tool until firmly seated (Fig. 6). Attach 1-1/4" vacuum hose to the vacuum adapter.

To remove vacuum adapter: Grasp vacuum adapter and pull away from tool.

DUST PORT

FIG. 6

VACUUM

HOSE

VACUUM

ADAPTER

-8-

SM 2610930928 6-05 6/1/05 9:10 AM Page 9

Operating Instructions

TRIGGER SWITCH AND “LOCK-ON” |

FIG. 7 |

“LOCK-ON” |

ON/OFF |

|

BUTTON |

||||

|

TRIGGER |

|||

Your tool can be turned “ON” or “OFF” by |

|

BUTTON |

||

|

|

|

||

squeezing or releasing the trigger. Your tool is |

|

|

|

|

also equipped with “Lock-ON” button located |

|

|

|

|

just above the trigger that allows continuous |

|

|

|

|

operation without holding the trigger (Fig. 7). |

|

|

|

TO LOCK SWITCH “ON”: Squeeze trigger, depress button and release trigger.

TO UNLOCK THE SWITCH: Squeeze trigger and release it without depressing the “LockON” button.

! WARNING If the “Lock-ON” button is continuously being de-

pressed, the trigger cannot be released.

AUTO-TRACK SYSTEM |

FIG. 8 |

Your sander features the automatic belt control system which keeps the belt running in the center of the pulleys after initial adjustment. The system has been preset at the factory but may require adjustment when belts are changed or an older belt stretches.

ADJUSTING THE AUTO-TRACK SYSTEM

1.Plug in the cord with the tool OFF.

2.Hold handle of sander with one hand and tilt back until belt is off work and the sander is resting on the bottom heel of the housing.

3.Turn tool ON by pressing the trigger.

4.For best performance the belt should be in line with the outer edge of the rear pulley. If the

belt deviates more than 1/8 inch from the outside of the sander, adjust the belt position by turning the auto-track adjustment screw, (Fig. 8) until the belt returns to the proper position.

1/8” MAXIMUM

AUTO-TRACK ADJUSTMENT SCREW

SELECTING THE SANDING BELT

It is very important that you select the proper belt for each particular application. To do this you should understand the method of marking or coding on the back of most belts. “CLOSED COAT” means the surface is densely covered with as much grit as the adhesive will hold. “OPEN COAT” means the grit has been

applied evenly, but openly to the surface. An “open coat” will not clog or fill as readily as “closed coat”. In general, aluminum oxide abrasive belts are best for woodworking because they are tougher and last longer. Sanding belts should be stored in a cool, dry place. Do not store near heat or near a window where the sun can reach them.

-9-

SM 2610930928 6-05 6/1/05 9:10 AM Page 10

3" x 18" BELTS AVAILABLE FROM SKIL

TYPE OF MATERIAL |

|

|

REMARKS |

|

|

|

|

|

|

|

GRIT SIZE |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

Coarse |

|

Medium |

|

|

Fine |

|

Very Fine |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36 |

80 |

100 Grit |

||||||||||||

|

WOOD FINISHING: |

This is a “closed |

60 |

||||||||||||||||||

|

New or unfinished |

|

|

coat” belt and has a |

|

|

|

Grit |

|

|

|

Grit |

|

|

Grit |

|

|

No. |

|

||

|

wood, plastics, resins. |

|

|

white colored |

|

|

|

No. |

|

|

|

No. |

|

|

No. |

|

|

73108 |

|

||

|

NON-FERROUS |

|

|

backing for |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

73105 |

|

|

73106 |

|

|

73107 |

|

|

120 Grit |

|

||||||

|

METALS: Such as lead, |

|

|

identification. The |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

|

||||

|

copper, solder and |

|

|

abrasive used is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

73109 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

aluminum. |

|

|

aluminum oxide. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

PAINT REMOVING: |

|

|

|

Similar to above |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

36 |

60 |

|

|

|

|

|

|

|

||||||||

|

For removing varnish, |

|

|

|

belts but “open |

|

|

|

|

Grit |

|

|

|

Grit |

|

|

|

|

|

|

|

|

lacquer and paint, |

|

|

|

coat”. Aluminum |

|

|

|

|

No. |

|

|

|

No. |

|

|

|

|

|

|

|

|

also for resinous or |

|

|

|

oxide grits |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

73110 |

|

|

|

73111 |

|

|

|

|

|

|

|

||

|

green wood. |

|

|

|

are wider apart. |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 Belts per package

FLUSH SANDING

Your sander has been designed to allow convenient flush sanding on the right side of the sander.

Sanding Tips

TECHNIQUE

Grasp the handles firmly. Start the sander with the belt off the work (NOTE: never start or stop the tool with the belt in contact with the work surface). Place the heel of the sander on the work first. Then, with a forward motion, begin the sanding stroke as the machine is lowered onto the work surface. This will prevent gouging. Keep the sander moving so that your work will be smooth and even. The stroke is simply a back-and-forth movement with most of the sanding done on the pull movement. Use a light touch. The weight of the belt sander is the only pressure required. Too much pressure will slow the work by overloading the motor and reducing belt speed. The result will be decreased sanding efficiency. Sand slowly and systematically and, when you stop, lift the sander from the surface before stopping the tool.

WOOD FINISHING

Take care to select belts wisely. For initial smoothing of rough lumber, use coarse or very coarse grit and sand with the grain. On very uneven or hard wood, sand diagonally (across the grain). Be careful to avoid gouging. Now switch to medium grit belt and sand with the grain. This will provide a relatively level and smooth finish. Now insert a fine grit belt for final finishing. Always sand with the grain to remove scratches left by coarser belts. Keep the sander moving in long, light strokes during finishing operations. As a final touch, experienced sanders will often insert a “used” fine belt to provide a smooth surface for filling, sealing, brushing or spraying.

REFINISHING COATED WOOD

Your belt sander will also help remove old paint, varnish or lacquer; however, if the coating consists of several layers, remove as much as possible with a paint solvent or varnish remover before using the belt sander. Use a hand scraper to remove the residue left by the solvent and allow surface to dry completely before sanding.

-10-

SM 2610930928 6-05 6/1/05 9:10 AM Page 11

For fast removal, start with a coarse grit, open coat belt. Change to closed coat belts, using medium grits as the material shows through the coating. When the covering is thin, use medium grit to avoid scratching the material. Use short, light strokes, moving the sander rapidly. Excessive pressure or steady sanding in one place will burn the coating and load the belt.

METAL FINISHING

For ferrous metals such as steel, stainless steel, iron, etc., use coarse grit open coat belts

or coarse to fine grit closed coat belts, depending on the finish desired. Non-ferrous metals such as aluminum, solder, brass, bronze, etc., can also be sanded. Beeswax or tallow are recommended as lubricants for metal sanding, polishing or satin finishing to minimize belt loading and to lengthen belt life. To use, simply rub the lubricant on the belt from time to time. SAE No. 10 or 20 lubricating oil can also be used to assure a smooth scratch free surface. Just wipe the oil on the surface prior to sanding.

GUIDE FOR WOOD SANDING OPERATION

SANDING |

PURPOSE |

ABRASIVE |

|

METHOD OF SANDING |

||||||

OPERATION |

|

|

|

|

TO USE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ROUGH |

|

|

|

|

Open Coat |

|

|

|

|

|

|

To level out uneven |

|||||||||

|

|

|

|

Sanding diagonally to start |

||||||

|

|

surfaces. |

|

|

Coarse Grit |

|

and finish up sanding |

|

||

|

|

|

|

|

|

|

parallel with the grain. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PREPARATORY |

|

To smooth the |

Open Coat |

|

|

|

|

|||

|

|

Sanding parallel with the |

||||||||

|

|

rough sanding |

Medium Grit |

|

wood grain. |

|

||||

|

|

preparatory to finish |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

sanding. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

FINISH |

|

|

|

Open or |

|

|

|

|||

|

The last sanding in |

|

Sanding parallel with the |

|||||||

|

|

preparing the bare |

|

Closed Coat |

|

wood grain. |

|

|||

|

|

wood for coating. |

|

Fine Grit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove all sanding dust thoroughly before coating. Use a soft brush or a vacuum cleaner and hose to remove all dust from seams or crevices.

-11-

Loading...

Loading...