SHARP QT-CD180BL, QT-CD180RD, QT-CD180S, QT-CD180WH Service Manual

QT-CD180

CONTENTS

Page

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)....................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

FITTING OF DIAL POINTER ............................................................................................................................................. 3

OPERATION MANUAL ...................................................................................................................................................... 4

DISASSEMBLY.................................................................................................................................................................. 5

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 6

ADJUSTMENT ................................................................................................................................................................... 8

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 11

TYPES OF TRANSISTOR ............................................................................................................................................... 11

SCHEMATIC DIAGRAM .................................................................................................................................................. 12

WIRING SIDE OF P.W.BOARD....................................................................................................................................... 14

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 16

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... 17

FUNCTION TABLE OF IC................................................................................................................................................ 21

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (FOR U.S.A. ONLY)

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified should

be used.

SERVICE MANUAL

SHARP CORPORATION

No. S1102QTCD180/

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

QT-CD180(BL)

QT-CD180(RD)

QT-CD180(S)

QT-CD180(WH)

PORTABLE CD STEREO SYSTEM

MODEL

QT-CD180

– 2 –

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

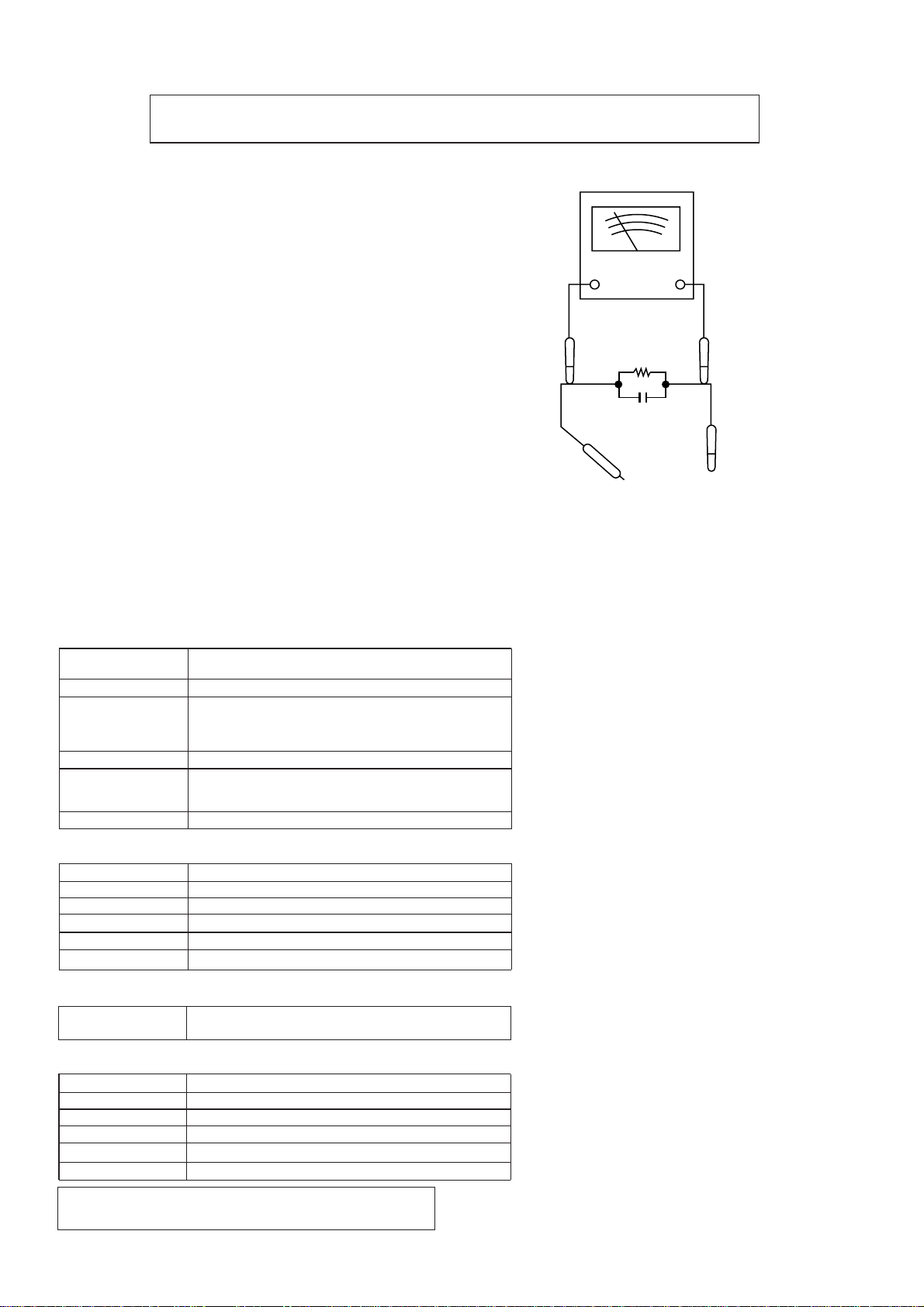

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the chassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment

covers or shields, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

having a return path to the chassis (antenna, metal cabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)

All check must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

SPECIFICATIONS

Specifications for this model are subject to change without

prior notice.

AC SCALE

VTVM

1.5k ohms

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

■

Tape recorder

Frequency response

Signal/noise ratio

Wow and fiutter

Motor

Bias system

Erase system

50 - 14,000 Hz (Normal tape)

50 dB

0.25 % (WRMS)

DC 9 V electric governor

AC bias

Magnet erase

■

Compact disc player

Type

Signal readout

Audio channels

Filter

D/A converter

Wow and flutter

Compact disc

Non-contact, 3-beam semi-conductor laser pickup

2

8-time oversampling digital filter

1-bit D/A converter

Unmeasurable (less than 0.001% W. peak)

■

General

AC 120 V, 60 Hz

DC 9 V [“D” size (UM/SUM-1, R20 or HP-2) battery x 6]

11 W

3-1/8" (8 cm) full-range speaker x 2

5.5 lbs. (2.5 kg) without batteries

Power source

Power consumption

Output power

Speakers

Dimensions

Weight

FM; 87.5 - 108 MHz

AM; 530 - 1,720 kHz

■

Radio

Frequency range

FTC; 2.0 W min. RMS per channel into 4 ohms from 150

Hz to 20 kHz, with no more than 10 % total harmonic

distortion.

RMS; 2.3 W/CH (DC operation, 10 % T.H.D)

Width; 14-6/8" (376 mm)

Height; 5-7/8" (150 mm)

Depth; 9" (230 mm)

QT-CD180

– 3 –

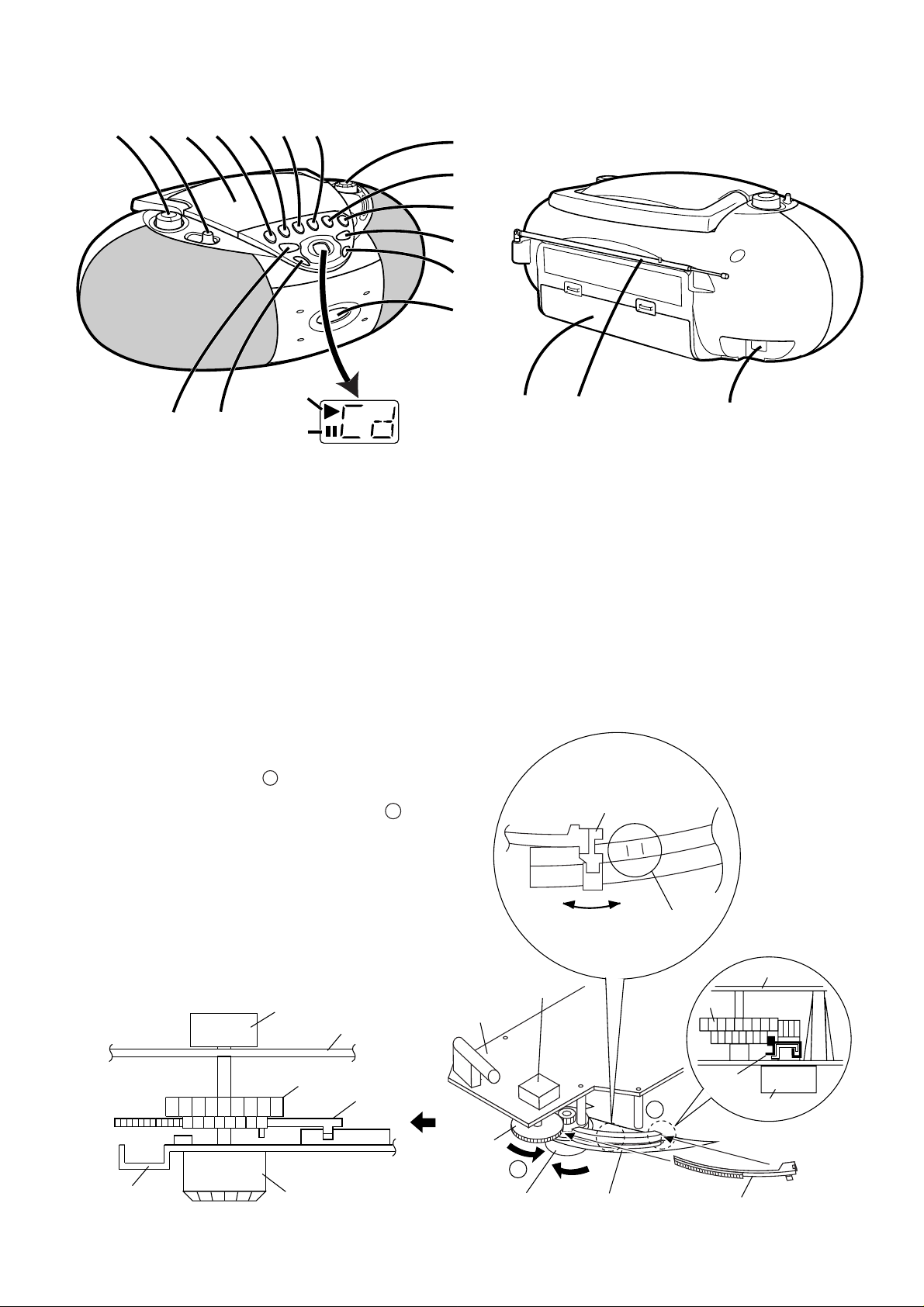

NAMES OF P ARTS

FITTING OF DIAL POINTER

Setting method of the dial pointer

1. Remove the front cabinet. (Refer to Fig.5-2 on page 5,

"Disassembly method".)

2. Remove the dial pointer.

3. Insert the dial pointer from A of the top cabinet so that it

engages with the drum gear.

4. Fully turn the drum in the opposite direction of B and set

it to the FL marks.

5. Reassemble the front cabinet.

Figure 3-1

Drum

Drum

Dial

Pointer

Dial

Pointer

Tuning Knob

Tuning Knob

Main PWB

Main PWB

Main PWB

Top Cabinet

Top Cabinet

Variable

Capacitor

Variable

Capacitor

A

B

Drum

Dial

Pointer

Tuning Knob

FL Mark

Dial Pointer

FH

FL

1234567

8

9

10

11

12

13

14 15

16

17

10. (TAPE) Record Button

11. (CD) Play/Pause Button

12. (CD) Track Up/Cue Button

13. Cassette Compartment

14. (CD) Stop Button

15. (CD) Track Down/Review

Button

16. (CD) Play Indicator

17. (CD) Pause Indicator

01. Volume Control

02. Function Switch

03. CD Compartment

04. (TAPE) Pause Button

05. (TAPE) Stop/Eject Button

06. (TAPE) Fast Forward Button

07. (TAPE) Rewind Button

08. Tuning Control

09. (TAPE) Play Button

18

19

20

18. Battery Compartment

19. FM Telescopic Rod Antenna

20. AC Power input Socket

QT-CD180

– 4 –

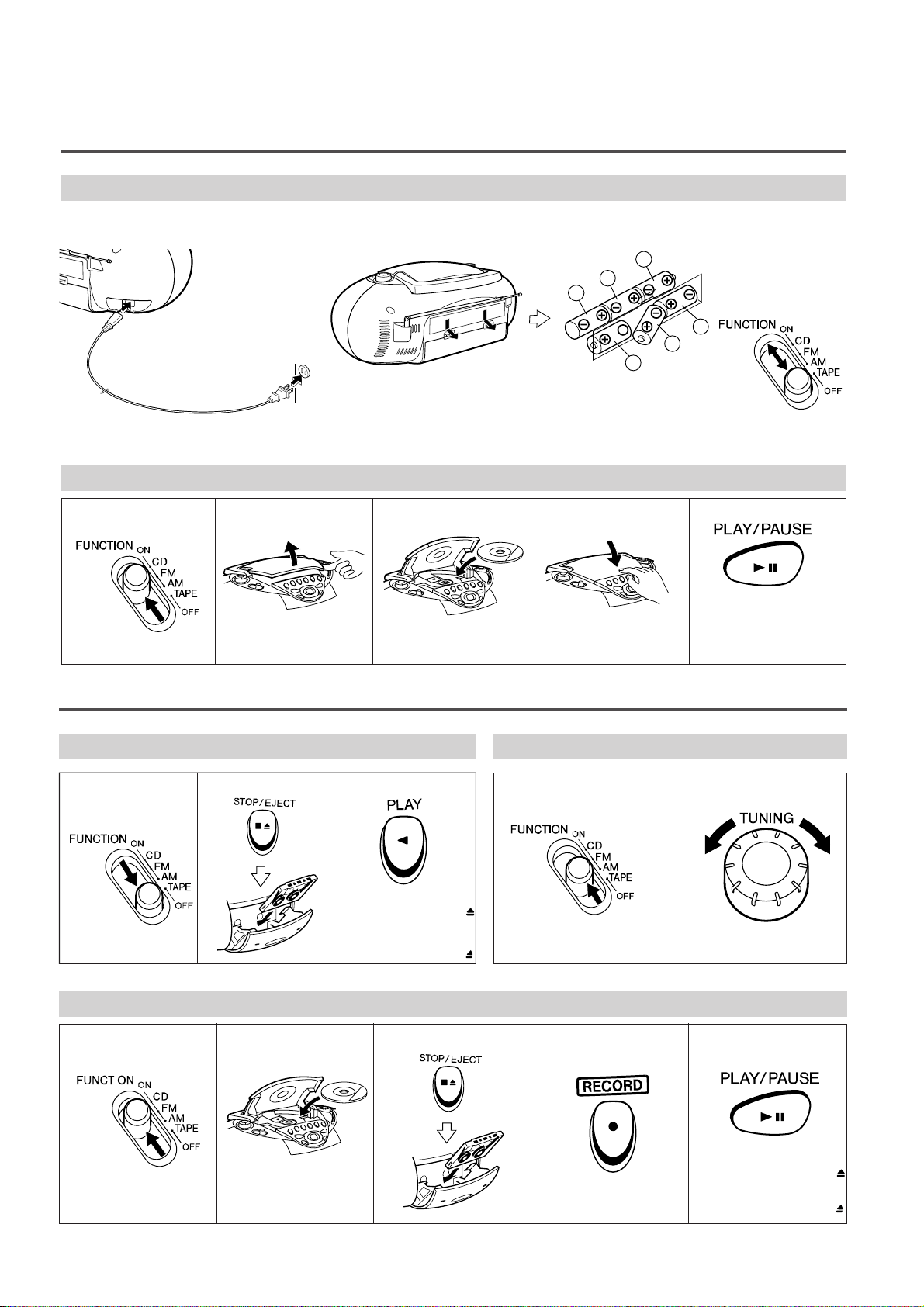

OPERATION MANUAL

Quick Guide /

Guía rápida

■ Operation with AC power

■

Funccionamiento con corriente alterna

■ Operation with batteries

■

Funccionamiento con pilas

To an AC outlet

A un tomacorriente de CA

T o AC INPUT

A la toma AC INPUT

AC 120 V, 60 Hz

120 V de CA, 60 Hz

● 6 “D” size batteries (UM/SUM-1, R20, HP-2 or similar)

● Batteries are not included.

●

6 pilas del tamaño “D” (UM/SUM-1, R20, HP-2 o similares)

●

Las pians no están incluidas.

5

4

6

1

3

2

■ Turning the power

ON and OFF

■

Conexión (ON) y

desconexión (OFF)

de la alimentación

● Label side up.

●

Con el lado de la etiqueta

encarada hacia arriba.

To stop playback

Press the STOP ■ button.

Para detener la

reproducción

Pulse el botón STOP

■

.

123 45

1

Preparation for use /

Preparación para su uso

2

Listening to a CD /

Audictión de CD

123

To stop playback

Press the STOP/EJECT ■

button.

Para detener la

reproducción

Pulse el botón STOP/EJECT

■

.

12

12

● Load the disc to be

recorded.

●

Introduzca el disco que

va a grabar.

To stop recording

Press the STOP/EJECT ■

button.

Para detener la grabación

Pulse el botón STOP/EJECT

■

.

3

Listening to a tape /

Audictión de una cinta

4

Listening to the radio /

Audic

tión de la radio

5

Recording from a CD /

Grabaciones de CD

4

3

5

QT-CD180

– 5 –

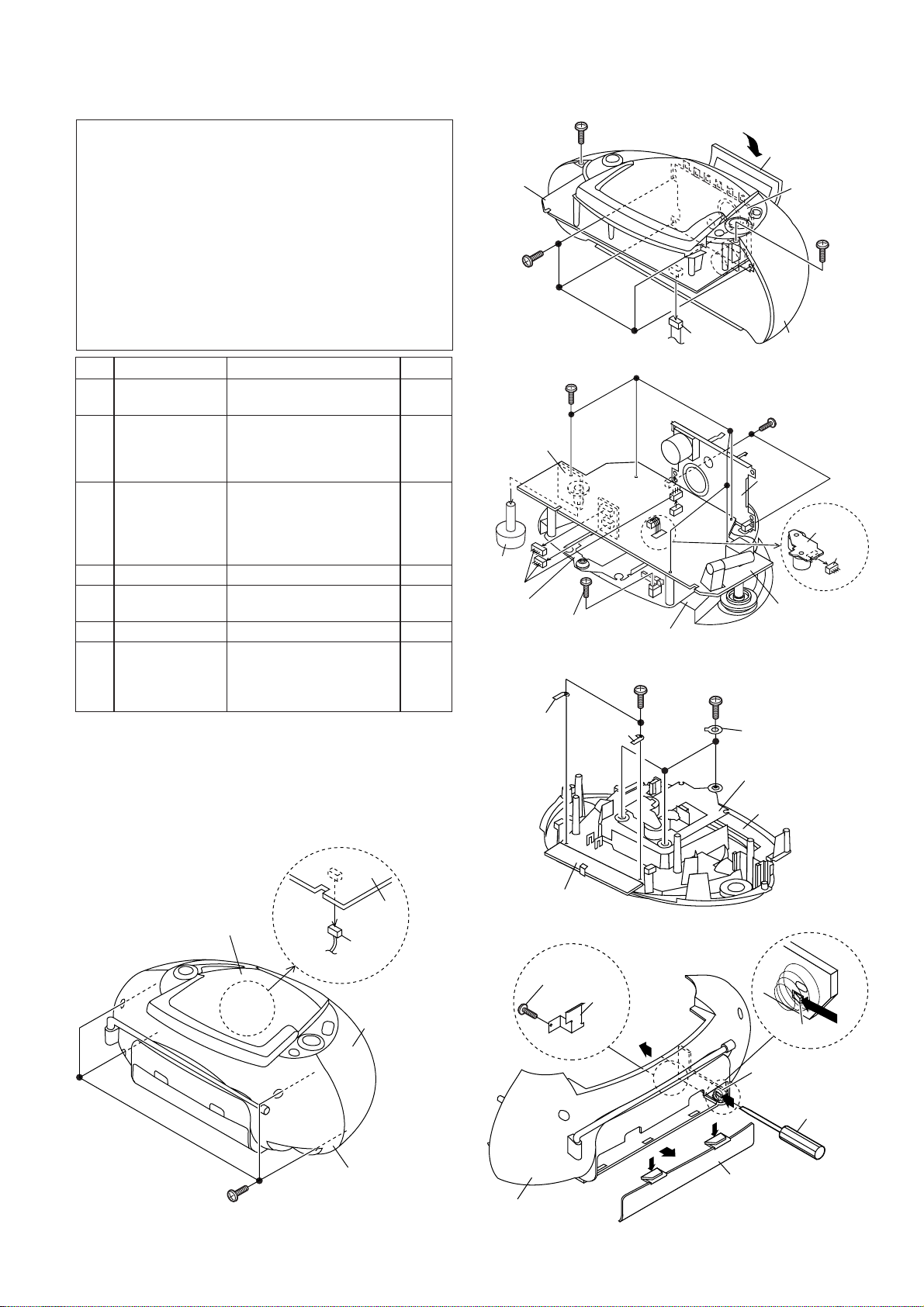

1 Rear Cabinet 1. Screw ................... (A1) x4 5-1

2. Socket .................. (A2) x1

2 Front Cabinet 1. Open the cassette holder 5-2

2. Socket .................. (B1) x1

3. Screw ................... (B2) x4

4. Screw ................... (B3) x2

3 Main PWB 1. Knob..................... (C1) x1 5-3

(With CD Control 2. Socket .................. (C2) x3

PWB) 3. Screw ................... (C3) x5

(Note) 4. Screw ................... (C4) x1

5. Socket .................. (C5) x1

4 Tape Mechanism 1. Screw ................... (D1) x2 5-3

5 CD Control PWB 1. Screw ................... (E1) x2 5-4

(With Main PWB) 2. Bracket................. (E2) x2

6 CD Mechanism 1. Screw ................... (F1) x3 5-4

7 Power PWB 1. Battery Lid............(G1) x1 5-5

2. Screw ................... (G2) x1

3. Bracket ................. (G3) x1

4. Hook..................... (G4) x1

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep it safe and ensure excellent

performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need

to be removed when disassembling the unit. After

servicing the unit, be sure to rearrange the leads

where they were before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

Figure 5-3

Figure 5-1

Figure 5-2

Figure 5-5

Figure 5-4

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

(G2)x1

ø3x10mm

Rear Cabinet

Power PWB

Driver

(G4)x1

(G1)x1

(G3)x1

Front Cabinet

Rear Cabinet

Top Cabinet

Main

PWB

(A2)x1

(A1)x4

ø3x14mm

(B3)x1

ø3x8mm

(B2)x4

ø3x10mm

(B3)x1

ø3x8mm

Tape

Mechanism

Front Cabinet

Main

PWB

Open

Cassette

Holder

(B1)x1

(F1)x3

ø2.5x10mm

CD Mechanism

CD Control

PWB

Top Cabinet

PWB

Washer x3

(E1)x2

ø3x10mm

(E2)x1

(E2)x1

(C3)x5

ø3x10mm

(D1)x2

ø3x8mm

(C4)x1

ø2.5x10mm

(C5)x1

(C2)x3

(C1)x1

Volume

PWB

Tape

Mechanism

CD Mechanism

CD Motor

PWB

Main PWB

Top Cabinet

QT-CD180

– 6 –

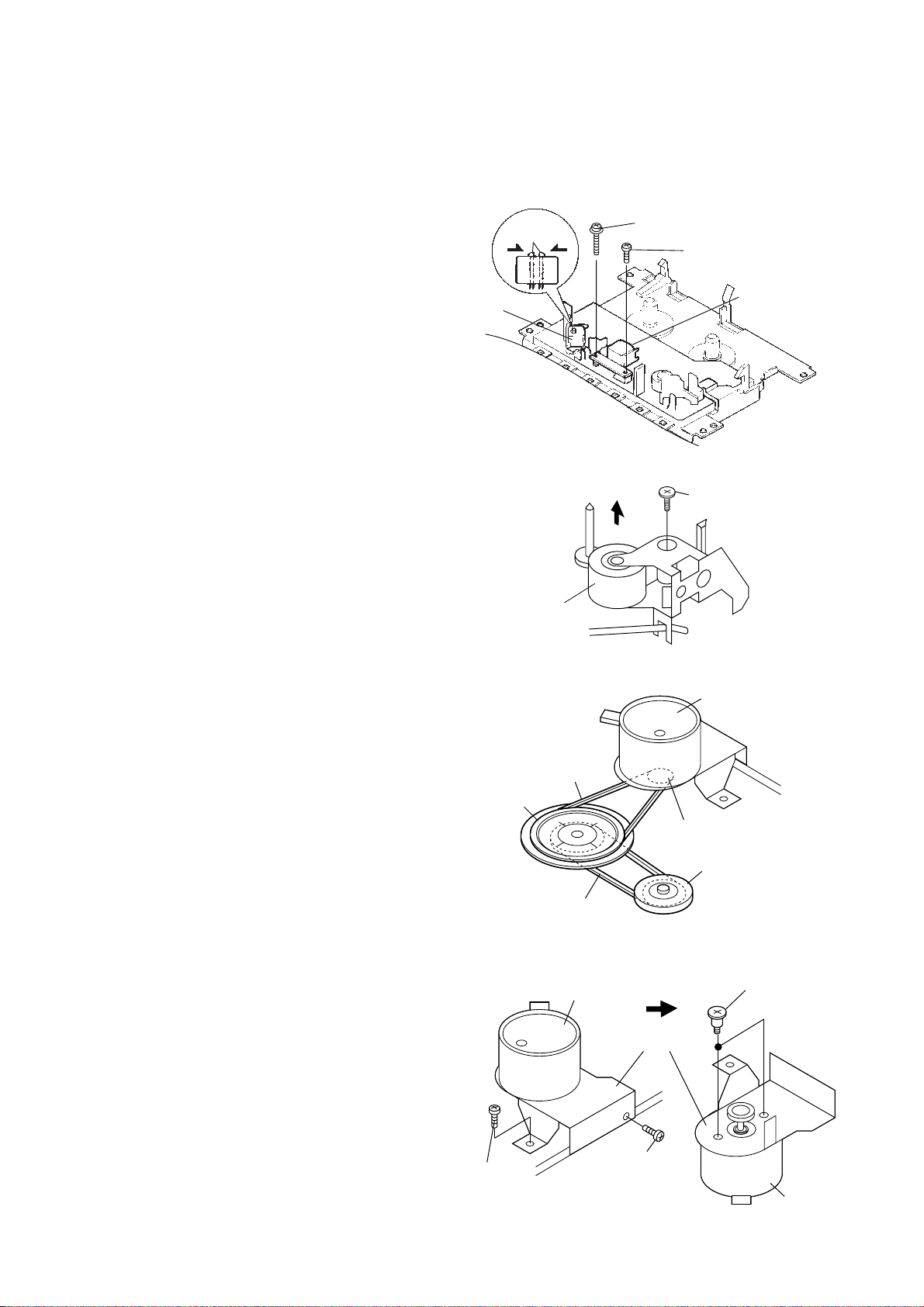

TAPE MECHANISM SECTION

Perform steps 1 to 4 of the disassembly method to remove the

tape mechanism. (See page 5.)

How to remove the record / playback and erase

heads (See Fig. 6-1.)

1. Remove the screws (A1) x 2 pcs., to remove the record/

playback head.

2. Remove the hooks (A2) x 2 pcs., toward the center

position as shown in Fig. 6-1. and then extract the erase

head upward.

Note:

After replacing the heads and performing the azimuth

adjustment, be sure to apply screwlock.

How to remove the pinch roller (See Fig. 6-2.)

1. Remove the screw (B1) x 1 pc., and remove the pinch roller

upwards.

How to remove the belts (See Fig. 6-3.)

1. Remove the main belt (C1) x 1 pc., from the motor

pulley.

2. Remove the FF/REW belt (C2) x 1 pc., from the REW/FF

roller.

3. Put on the belts in the reverse order of removal.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

How to remove the motor

(See Fig. 6-4.)

1. Remove the main belt. (See Fig. 6-3.)

2. Remove the screws (D1) x 2 pcs., to remove the motor

bracket.

3. Remove the screws (D2) x 2 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor bracket

angle.

Figure 6-1

Figure 6-2

Figure 6-3

Figure 6-4

(A1) x1

ø2x7mm

(A1) x1

ø2x3mm

Record/Playback

Head

Erase Head

Hook

(A2)x2

REMOVING AND REINSTALLING THE MAIN PARTS

Pinch Roller

(B1) x1

ø1.5x2.5mm

Motor Bracket

Motor

Motor

(D2)x2

Special

Screw

(D1) x1

ø2.5x4mm

(D1) x1

ø2.5x4mm

Motor

REW/FF

Roller

Flywheel

FF/REW Belt

(C2)x1

Main Belt

(C1)x1

Motor Pulley

QT-CD180

– 7 –

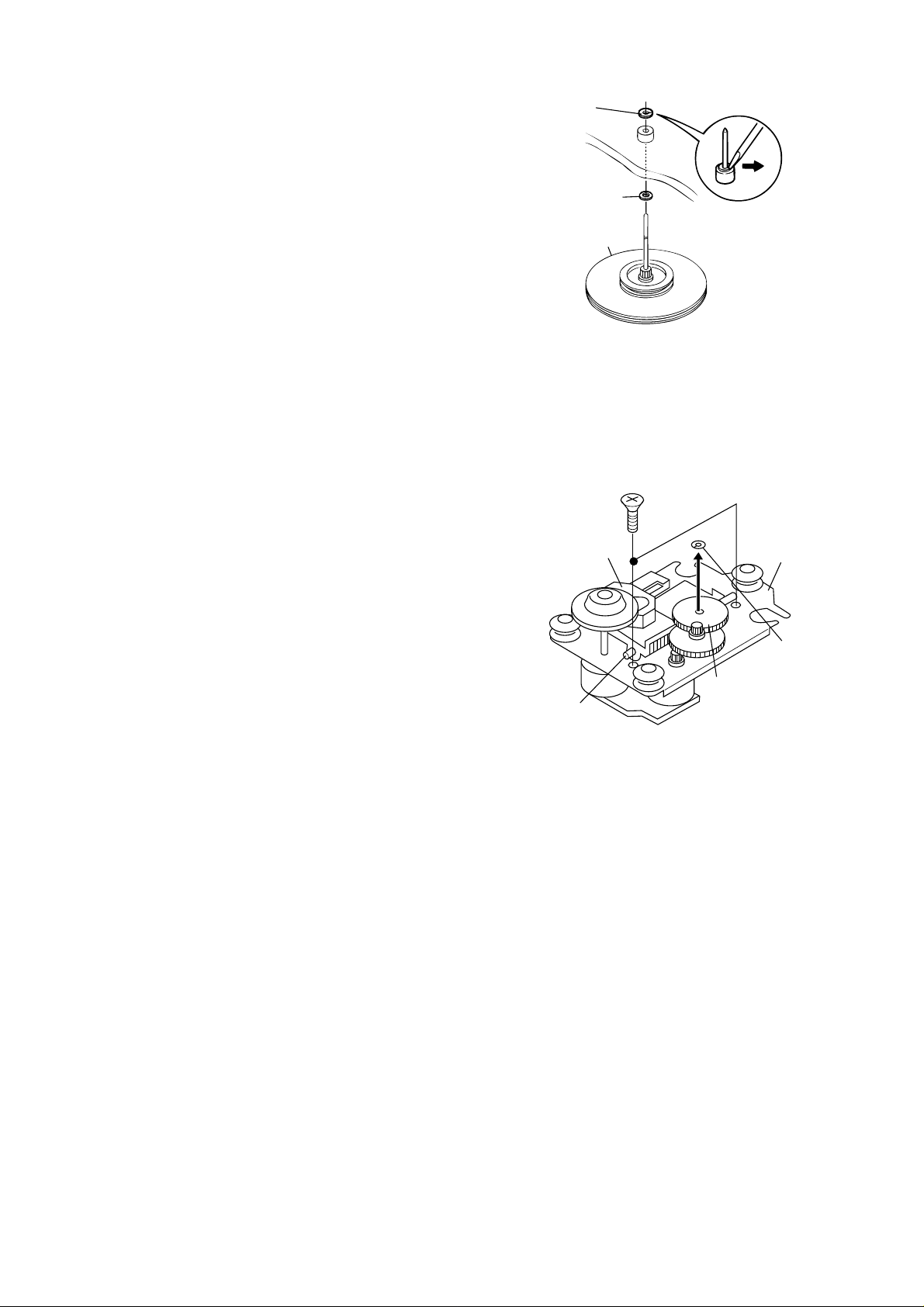

CD MECHANISM SECTION

Perform steps 1 to 6 of the disassembly method to remove the

CD mechanism. (See page 5.)

How to remove the pickup (See Fig. 7-2.)

1. Remove the screws (A1) x 2 pcs., to remove the shaft

(A2) x1 pc.

2. Remove the stop washer (A3) x1 pc., to remove the gear

(A4) x 1 pc.

3. Remove the pickup.

Stop

Washer

(A3) x1

CD

Mechanism

Gear

(A4) x1

Shaft

(A2) x1

Pickup

(A1) x2

ø2.6 x6mm

Figure 7-2

Figure 7-1

(E1) x 1

Stop Washer

Washer

Flywheel

How to remove the flywheel (See Fig. 7-1.)

1. Remove the belt. (See Fig. 6-3.)

2. Remove the stop washer (E1) x 1 pc., with a small

precision screwdriver to extract the flywheel from the

capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

QT-CD180

– 8 –

MECHANISM SECTION

• Driving Force Check

PLAY: TW-2412 Over 80 g

Torque Meter

Specified Value

• Torque Check

Torque Meter

Specified Value

Play: TW-2111 30 to 60 g.cm

Fast Forward: TW-2231 55 to 140 g.cm

Rewind: TW-2231 55 to 140 g.cm

• Tape Speed

MTT-111 Variable 3,000 ± 90 Hz Output: Speaker

resistor in Terminal

motor. (M601) (CNP201 Load

resistance: 4 ohms)

Instrument

Connection

Specified

Value

Test

Tape

TAPE SECTION

Position of each switch or control

Volume control Max

Function switch Tape/Power Off

• Bias Oscillation

Adjustment Point

• Playback Amplifier Sensitivity Check

Instrument Connection

Test Tape

MTT-118 1.1 V ± 3 dB Speaker Terminal

(Load resistance: 4 ohms)

Specified Value

ADJUSTMENT

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• FM IF/RF

FM Detection T2

FM fL: L2

Band Coverage fH: TC2

FM Tracking fL: 88.0 MHz: L1

fH: 108.0 MHz: TC1

Test Stage

Specified

Value/Adjusting

Point

Instrument

Connection

Input: Pin 1 of IC1

Output: Pin 18 of IC1

Input: Antenna

Output: Speaker

Terminal (CNP201

Load resistance: 4

ohms)

• AM IF/RF

AM IF T3 Input: Antenna

Output: Pin 18 of IC1

AM fL: L4 Input: Antenna

Band Coverage fH: TC4 Output: Speaker

AM Tracking fL: 600 kHz: L3 Terminal (CNP201

fH: 1,400 kHz: TC3 Load resistance: 4

ohms)

Test Stage

Specified

Value/Adjusting

Point

Instrument

Connection

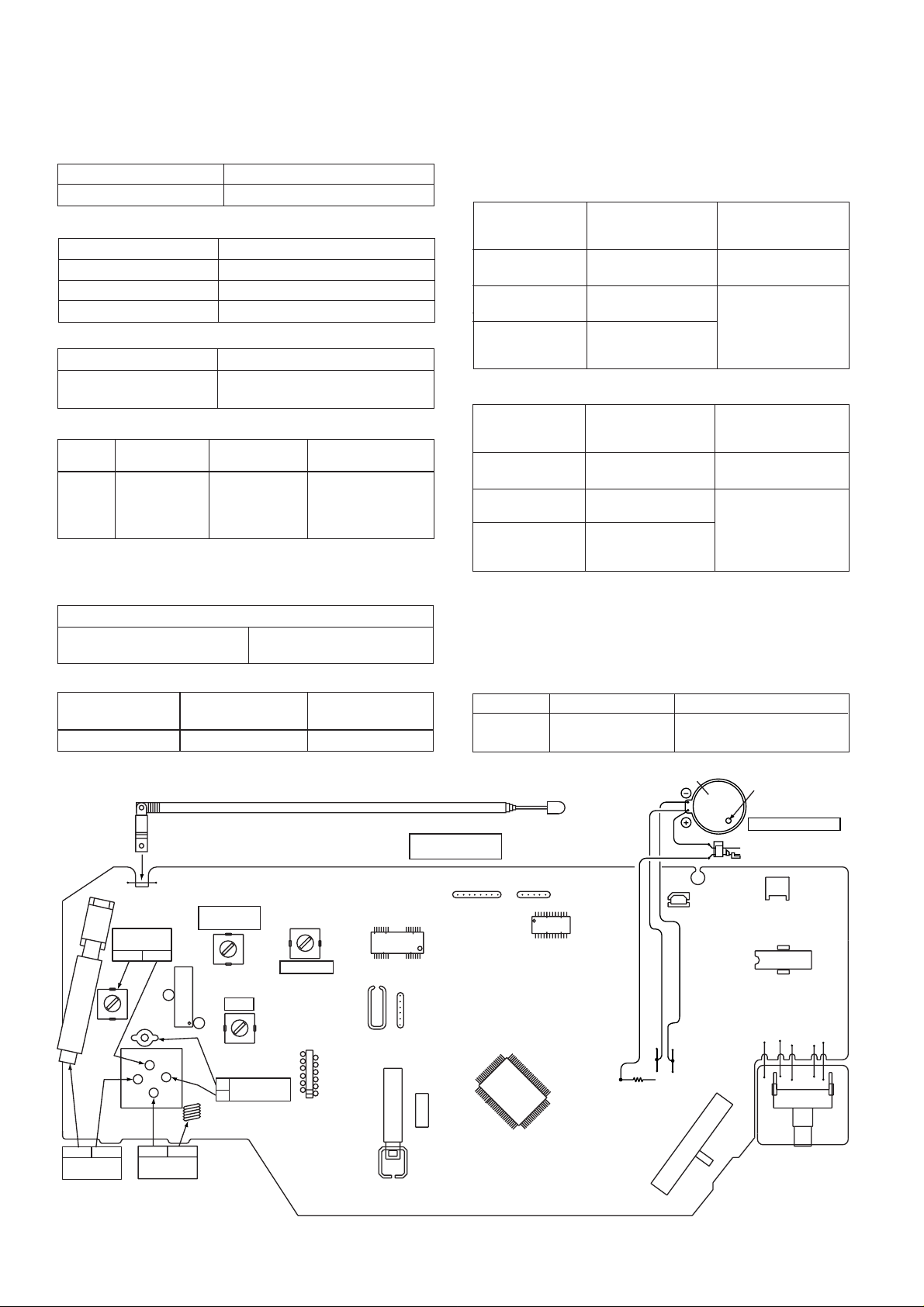

Figure 8 ADJUSTMENT POINTS

• Head Azimuth

Torque Meter

Specified Value

MTT-114 Output: Speaker Terminal

(CNP201 Load resistance: 4 ohms)

Adjusting

Point

Specified Value

Instrument

Connection

L301 80 kHz ± 6 kHz Pin 1 of CNP101

M601

TAPE MOTOR

SW601

TAPE MAIN

TAPE MECHANISM

Variable resistor

in motor

VR201

SW201

CNP101

SW102

L1

L4

L2

IC1

T3

IC101

BI803

IC201

CNP602

BI802

BI801

L301

T2

1

1

TC4

TC2

TC1

TC3

FM ROD ANTENNA

MAIN PWB

1

13

18

AM BAND

COVERAGE

fL

fH

AM IF

FM

DETECTION

12

24

BIAS OSC.

AM

TRACKING

fL

fH

L3

AM BAR

ANTENNA

1

12

11

2

2

3

4

1

23

2

FM BAND

COVERAGE

L3

IC802

IC803

1

14

15

IC801

1

12

13

24

CNP201

28

fH

fL

FM

TRACKING

fH

fL

QT-CD180

– 9 –

CD SECTION

Since this CD system incorporates the following automatic adjustment function, when the pickup is replaced, it is not necessary

to readjust it.

Since this CD unit does not need adjustment, the combination of PWB and laser pickup unit is not restricted.

TEST MODE

While holding down the "Stop" and "Up" button at same time, move the FUNCTION switch to "CD".

Start

Note

1. When the CD LID switch is in the OFF position, (CD LID is open) the unit will be able to enter the test mode.

However, can use the "UP/CUE" and "DOWN/REVIEW" button only.

2. You can only move the pickup.

3. The LCD display should be the same as it is for normal CD operations.

Operation

The use of the "UP/CUE" button will move the pickup to the outermost position.

The use of the "DOWN/REVIEW" button will move the pickup to the innermost position.

After connecting of the 10 kohm resistor between IC802 27 pin and GND and holding down the "Stop" and "Up"

button at same time, move the FUNCTION switch to "CD".

Start

Display

LCD MODE

1. Before the laser light up, CD LID switch (SW801) terminals have to be short with the solder.

Resistor of 330ohm is put from 27 pin of IC802, and you must connect it to GND of PWB. (Refer to PWB of Figure9-1.)

PREPARATION FOR LASER LIGHT UP

Figure 9-1

1. Remove the front cabinet according to the disassembly method.

2. Short the TP of the Figure 9-1 to turn on the CD LID switch (SW810).

3. While holding down the "Stop" and "Up" button at same time, move the FUNCTION switch to "CD".

4. Open the CD LID and press the PLAY button. The laser lights up for a few seconds. (At this time, the pickup lens moves

up and down and adjusts the focus to check if there is a disc or not.)

LASER LIGHTING CONFIRMATION

TP

1

5

10

12

13

15

20

24

7

10

20

8

21

22

1

5

8

1

5

25

28

1

16

E

C

B

1234

C847

C844

C853

C846

C855

X801

C84

0

IC801

C820

C863

C829

R829

C819

R830

R806

R851

R852

C842

C839

C838

R824

R820

C841

C830

R805

C828

BI802

C804

C816

R802

C801

R804

C815

C802

BI801

Q801

C817

R801

C835

C834

R853

C807

IC802

R839

R862

R844

R846

C824

R861

CNP101

C843

R821

C825

R843

C823

R826

C827

R827

C826

C833

R828

FW806

C106

R106

SW102

IC803

BI803

805

1

5

10

15

20

25

30

31

35

40

45

50

51

55

60

65

70

75

80

81

85

90

95

100

A

B

C

D

H

G

F

E

SW102

RECORD/PLAYBACK

PLAY

REC.

1

10

330 ohm

Resistor

GND

27pin

MAIN

PWB-A1

OPEN/CLOSE

SW810

CD LID

SWITCH

BR

BR

GY

GY

GY

GY

GY

H

QT-CD180

– 10 –

1. In Power OFF state, set the Function switch to ON, keeping to be pressed the "Stop" and "Up" button at same time.

After CD initialize finish. The CD TEST mode is set, and the LCD indicate to the total tracks of the disc. Release the PLAY button.

The CD TEST mode is set when the LCD indicate to " 1".

Then cut the above circuit.

2. In above TEST mode state, press once the PLAY button.

The laser is light up when LCD indicate to "cd".

SETTING METHOD FOR LASER LIGHT UP

Figure 10

SETTING FOR MAXIMUM LASER POWER

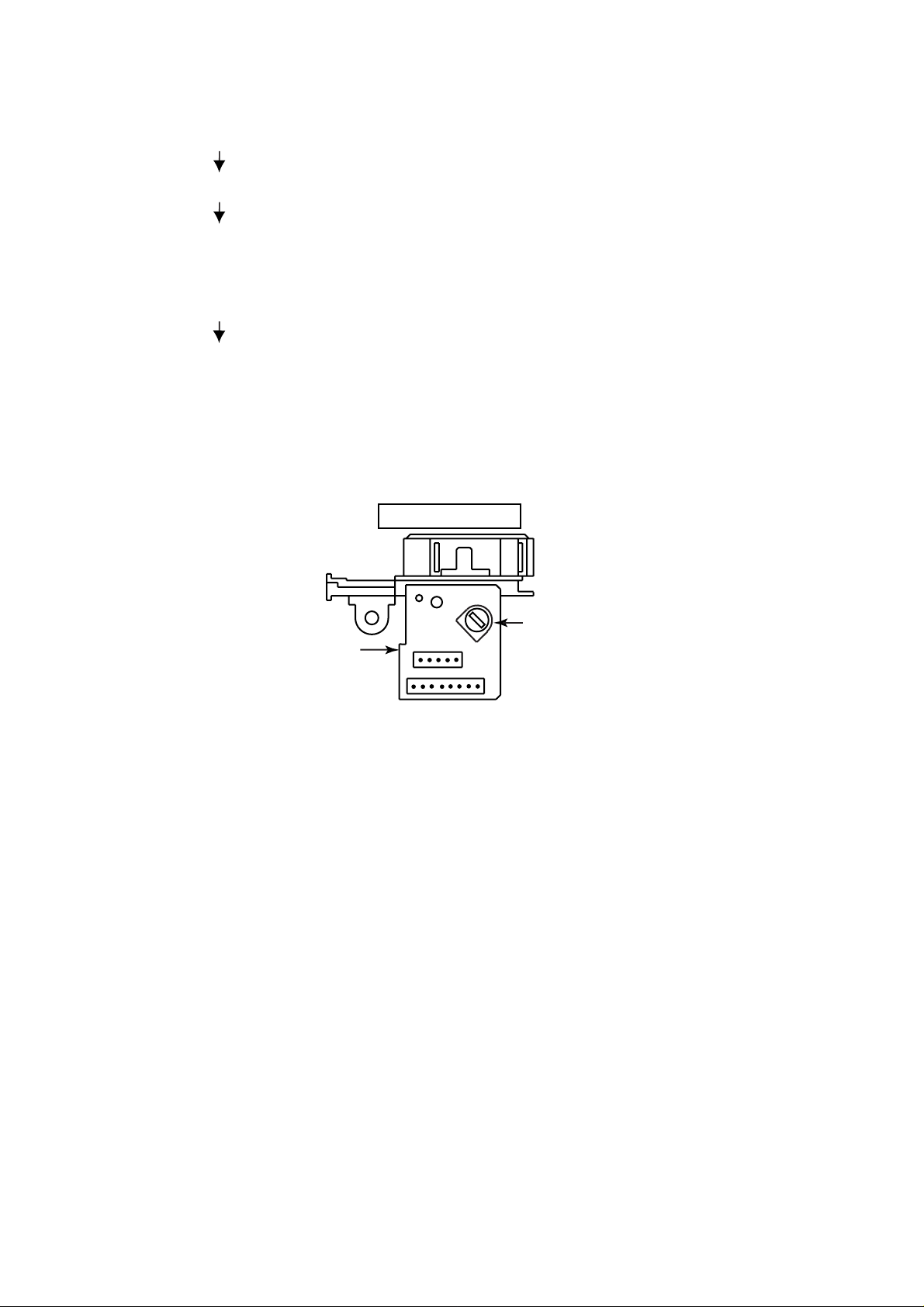

1. In above laser light up state, adjust the variable resistor (VR1A) on pickup PWB to maximum laser power.

Maximum laser power : Rotate the variable resistor (VR1A) to clockwise.

Note :

The TEST mode is cleared by Power OFF.

PICKUP UNIT

Variable Resistor

VR1A

Pickup PWB

Loading...

Loading...