Sharp QT-CD141, QT-CD161 User Manual

QT-CD161/141

SERVICE MANUAL

No. S5929QTCD161/

QT-CD161(S)

QT-CD141(BK)

• In the interests of user-safety the set should be restored to its original condition and only parts identical to those specified should be used.

Illustration: QT-CD161

CONTENTS |

|

|

Page |

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)....................................................................................................... |

2 |

SPECIFICATIONS ............................................................................................................................................................. |

2 |

NAMES OF PARTS ........................................................................................................................................................... |

3 |

REMOTE CONTROL .......................................................................................................................................................... |

3 |

DISASSEMBLY .................................................................................................................................................................. |

4 |

REMOVING AND REINSTALLING THE MAIN PARTS ..................................................................................................... |

5 |

ADJUSTMENT ................................................................................................................................................................... |

6 |

NOTES ON SCHEMATIC DIAGRAM ................................................................................................................................ |

9 |

TYPES OF TRANSISTOR ................................................................................................................................................. |

9 |

WAVEFORMS OF CD CIRCUIT ...................................................................................................................................... |

10 |

BLOCK DIAGRAM ........................................................................................................................................................... |

11 |

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD ............................................................................................. |

14 |

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... |

23 |

FUNCTION TABLE OF IC................................................................................................................................................ |

27 |

PARTS GUIDE/EXPLODED VIEW |

|

PACKING OF THE SET (FOR U.S.A. ONLY) |

|

DIFFERENCE BETWEEN QT-CD161 AND QT-CD141

SECTION |

QT-CD161 |

QT-CD141 |

REMOTE CONTROL

HEADPHONE SOCKET

SHARP CORPORATION |

This document has been published to be used |

for after sales service only. |

|

– 1 – |

The contents are subject to change without notice. |

QT-CD161/141

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER TO THE OPERATION MANUAL.

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the following safety checks.

1.Inspect all lead dress to make certain that leads are not pinched or that hardware is not lodged between the chassis and other metal parts in the audio product.

2.Inspect all protective devices such as insulating materials, cabinet, terminal board, adjustment and compartment covers or shields, mechanical insulators etc.

3.To be sure that no shock hazard exists, check for leakage current in the following manner.

*Plug the AC line cord directly into a 120 volt AC outlet.

*Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15μF capacitor in series with all exposed metal cabinet parts and a known earth ground, such as conduit or electrical ground connected to earth ground.

*Use a VTVM or VOM with 1000 ohm per volt, or higher, sensitivity to measure the AC voltage drop across the resistor (See diagram).

*Connect the resistor connection to all exposed metal parts having a return path to the chassis (antenna, metal cabinet, screw heads, knobs and control shafts, escutcheon, etc.) and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

AC SCALE

1.5k ohms

10W

0.15 µ F |

|

|

TEST PROBE |

CONNECT TO |

|

TO EXPOSED |

KNOWN EARTH |

|

METAL PARTS |

||

GROUND |

||

|

All check must be repeated with the AC line cord plug connection reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp. AC.) or more is excessive and indicates a potential shock hazard which must be corrected before returning the audio product to the owner.

SPECIFICATIONS

● General

Power source: AC 120 V, 60 Hz

|

DC 12 V [ "D" size (UM/SUM-1, |

|

R20 or HP-2) battery × 8] |

|

DC 3 V [ "AA" size (UM/SUM-3, |

|

R6 or HP-7) battery × 2 for tuner |

|

memory] |

Power |

Stand-by; 1.5 W |

consumption: Power on; 20 W

Output power: FTC; 2.0 W min. RMS per channel

|

into 8 ohms from 150 Hz to 20 |

|

kHz, with no more than 10 % total |

|

harmonic distortion. |

|

RMS; 2.3 W/CH |

|

(DC operation, 10 % T.H.D.) |

Speakers: |

4" (10 cm) full-range speaker x 2 |

Output |

Headphones; 16-50 ohms |

terminals: |

(recommended; 32 ohms) |

Dimensions: |

Width; 18-15/16" (480 mm) |

|

Height; 6-1/16" (153 mm) |

|

Depth; 10" (254 mm) |

Weight: |

7.1 lbs. (3.2 kg) without batteries |

● Radio |

|

Frequency |

FM; 87.5 - 108 MHz |

range: |

AM; 530 - 1,720 kHz |

● Tape recorder

Frequency |

|

response: |

50 - 14,000 Hz (Normal tape) |

Signal/noise |

|

ratio: |

50 dB |

Wow and |

|

flutter: |

0.25 % (WRMS) |

Motor: |

DC 12 V electric governor |

Bias system: |

AC bias |

Erase |

|

system: |

Magnet erase |

● Compact disc player |

|

Type: |

Compact disc |

Signal |

Non-contact, 3-beam semi-con- |

readout: |

ductor laser pickup |

Audio |

|

channels: |

2 |

Quantization: |

16-bit linear quantization |

Filter: |

4-times oversampling digital filter |

D/A |

|

converter: |

1-bit D/A converter |

Wow and |

Unmeasurable |

flutter: |

(less than 0.001% W. peak) |

Specifications for this model are subject to change without prior notice.

– 2 –

QT-CD161/141

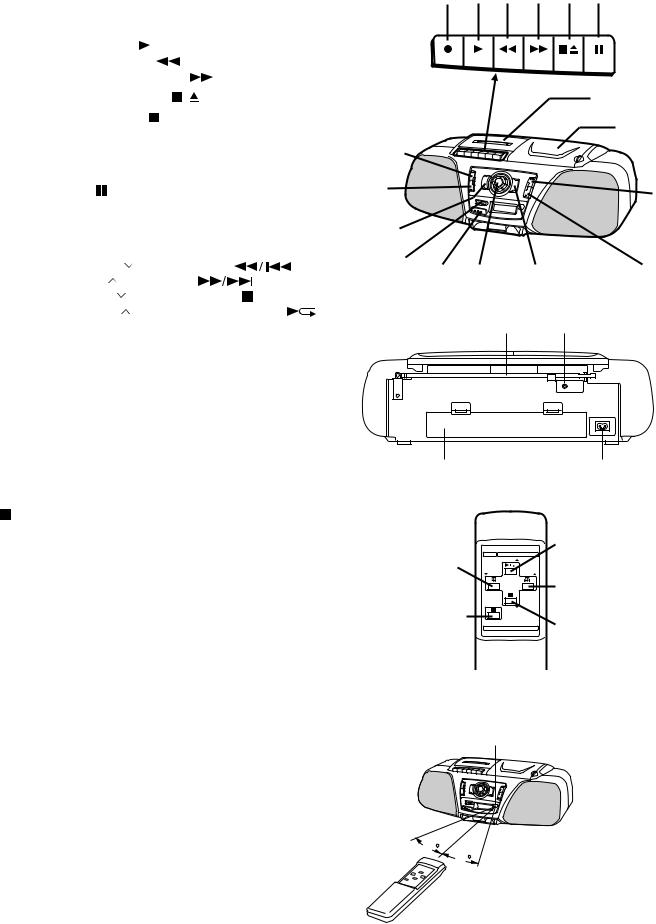

NAMES OF PARTS

1. Cassette Compartment |

3 4 5 6 7 8 |

2.CD Compartment

3.(TAPE) Record Button:

4. |

(TAPE) Play Button: |

|

|

|

||

5. |

(TAPE) Rewind Button: |

|

|

|

||

6. |

(TAPE) Fast Forward Button: |

|

|

|

||

7. |

(TAPE) Stop/Eject Button: / |

|

|

1 |

||

8. |

(TAPE) Pause Button: |

|

|

2 |

||

|

|

|

|

|

||

|

|

|

9 |

|

|

|

9. |

Band/Pause: |

|

10 |

|

15 |

|

10. |

Tuner Memory |

|

|

|

||

|

|

|

|

|||

11. |

Volume |

|

16 |

|

|

|

12. |

Power, On/Function Switch |

|

|

|||

13. |

Extra Bass Button: X-BASS |

12 |

|

|

||

14. |

(CD) Track Down: |

/Review Button: |

|

14 |

||

15. |

(CD) Track Up: |

/Cue Button: |

13 11 |

17 |

||

|

||||||

16. |

(TUNER)Tuning: |

/(CD) Stop Button: |

|

|

|

|

17. |

(TUNER) Tuning: |

/(CD) Play/Repeat Button: |

|

|

|

|

|

18 |

19 |

18. |

FM Telescopic Rod Aerial |

|

19. |

Headphone Socket (QT-CD161 Only) |

|

20. |

Battery Compartment |

|

21. |

AC Power Input Socket |

|

Remote control (QT-CD161 ONLY)

1.(TUNER) Tuning:  /(CD) Play/Repeat Button:

/(CD) Play/Repeat Button:

2.(CD) Track Down:  /Review Button:

/Review Button:

3.Band/Pause:

4.(CD) Track Up:  /Cue Button:

/Cue Button:

5.(TUNER)Tuning:  /(CD) Stop Button:

/(CD) Stop Button:

20 |

21 |

1

2

4

3

5

REMOTE CONTROL (QT-CD161 ONLY)

Notes concerning use:

●Replace the batteries if the operating distance is reduced or if the operation becomes erratic.

●Periodically clean the transmitter LED on the remote control and the sensor on the main unit with a soft cloth.

●Exposing the sensor on the main unit to strong light may interfere with operation. Change the lighting or the direction of the unit.

●Keep the remote control away from moisture, excessive heat, shock, and vibrations.

Sensor Remote

15 |

8" - 20' |

|

(0.2 m - 6 m) |

||

15 |

||

|

0,2 m - 6 m |

– 3 –

QT-CD161/141

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure excellent performance:

1.Take cassette tape and compact disc out of the unit.

2.Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

3.Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing the unit, be sure to rearrange the leads where they were before disassembling.

4. Take sufficient care on static electricity of integrated circuits and other circuits when servicing.

(B2)x1

ø3x10mm |

|

Top Cabinet |

(B1)x1 |

|

STEP |

REMOVAL |

|

PROCEDURE |

FIGURE |

|

|

|

|

|

|

|

1 |

Rear Cabinet |

1. Screw ................. |

(A1) x10 |

4-1 |

|

|

|

2. Socket .................. |

(A2) x1 |

4-2 |

|

|

|

|

|

|

|

2 |

Top Cabinet |

1. |

Knob ..................... |

(B1) x1 |

4-2 |

|

(with CD Mechanism/ |

2. Screw ................... |

(B2) x3 |

|

|

|

Tape Mechanism/ |

3. |

Socket .................. |

(B3) x1 |

|

|

Main PWB) |

|

|

|

|

|

|

|

|

|

|

3 |

Main PWB/ |

1. |

Screw ................... |

(C1) x9 |

4-3,5-1 |

|

Switch PWB/ |

2. Socket .................. |

(C2) x4 |

4-3,5-1 |

|

|

Headphones PWB |

3. |

Soldering .............. |

(C3) x3 |

4-3 |

|

(QT-CD161 Only) |

|

|

|

|

|

|

|

|

|

|

4 |

Tape Mechanism |

1. |

Screw ................... |

(E1) x4 |

5-1 |

|

|

|

|

|

|

5 |

CD Mechanism |

1. Screw ................... |

(F1) x3 |

5-1 |

|

|

|

|

|

|

|

6 |

Terminal PWB |

1. Screw ................... |

(G1) x5 |

5-2 |

|

|

|

2. Hook ..................... |

(G2) x1 |

|

|

|

|

|

|

|

|

7 |

Battery PWB |

1. |

Hook ..................... |

(H1) x2 |

5-3 |

|

|

|

|

|

|

Front Cabinet

(B2)x2 ø3x10mm

(B2)x2 ø3x10mm

(A2)x1 (B3)x1 Front Cabinet

Main PWB

Figure 4-2

(C1)x6 (C2)x1 ø3x10mm

(C1)x2

ø3x10mm

Switch

PWB

PWB

(A1)x1 |

|

Headphones |

|

PWB |

|

(A1)x6 ø3x12mm |

|

|

|

(C3)x3 |

|

ø3x20mm |

|

Main PWB |

|

|

|

(A1)x3 |

Rear Cabinet |

(C2)x2 |

|

||

|

Top Cabinet |

|

ø3x12mm |

|

Figure 4-3

Figure 4-1

– 4 –

QT-CD161/141

(E1)x4 |

(G2)x1 |

|

ø3x10mm |

||

|

|

|

|

|

Push |

|

(F1)x3 |

|

|

|

|

ø2.5x10mm |

|

Driver |

|

Tape |

|

|

|

(G1)x2 |

Mechanism |

|

|

|

|

|

|

|

Rear Cabinet |

ø3x10mm |

|

|

|

|

|

|

|

|

|

(G1)x1 |

|

|

|

|

ø3x10mm |

Top Cabinet |

|

(C1)x1 |

|

|

|

ø2.5x8mm |

|

|

|

CD Mechanism |

(C2)x1 |

|

|

|

|

|

|

|

|

Terminal PWB

Figure 5-1 |

(G1)x2 |

|

ø3x10mm |

||

|

||

|

Figure 5-2 |

|

|

Rear Cabinet |

Pull

(H1)x1 |

|

(H1)x1 |

|

|

|

|

Battery PWB |

Pull |

|

|

Figure 5-3

REMOVING AND REINSTALLING THE MAIN PARTS

CD MECHANISM SECTION

Perform steps 1, 2, 3 and 5 of the disassembly method to remove the CD mechanism.

How to remove the pickup (See Fig. 5-4.)

1.Remove the screws (A1) x 2 pcs., to remove the shaft (A2) x1 pcs.

2.Remove the stop washer (A3) x1 pcs., to remove the gear (A4) x 1 pcs.

3.Remove the pickup.

(A1) x2 ø2.6 x6mm

Pickup

CD

Mechanism

Stop

Washer

Shaft

(A3) x1

(A3) x1

(A2) x1  Gear

Gear

(A4) x1

Figure 5-4

– 5 –

QT-CD161/141

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter |

Specified Value |

|

|

PLAY: TW-2412 |

Over 120 g |

|

|

• Torque Check

Torque Meter |

Specified Value |

|

|

Play: TW-2111 |

25 to 65 g.cm |

|

|

Fast Forward: TW-2231 |

60 to 130 g.cm |

|

|

Rewind: TW-2231 |

60 to 130 g.cm |

|

|

• Head Azimuth |

|

Torque Meter |

Specified Value |

|

|

MTT-114 |

Output: Speaker Terminal |

|

(CNP201 Load resistance: 8 ohms) |

|

|

• Tape Speed

Test |

Adjusting |

Specified |

Instrument |

Tape |

Point |

Value |

Connection |

MTT-111 |

In motor |

3,000 ± 90 Hz |

Output: Speaker |

|

|

|

Teaminal |

|

|

|

(CNP201 Load |

|

|

|

resistance: 8 ohms) |

|

|

|

|

TAPE SECTION

Position of each switch or control

Volume control |

Max |

Function switch |

Tape/Power Off |

X-BASS |

On |

|

|

• Bias Oscillation

Adjustment Point |

Specified Value |

Instrument |

|

|

Connection |

|

|

|

L301 |

82 kHz ± 6 kHz |

Pin 2 of CNP201 |

|

– 6 kHz |

|

|

|

|

• Playback Amplifier Sensitivity Check

Test Tape |

Specified Value |

Instrument Connection |

|||||

MTT-118 |

1.8 V ± 3 dB |

|

Speaker Terminal |

||||

|

|

|

|

(Load resistance: 8 ohms) |

|||

|

|

|

FM ROD ANTENNA |

|

|

||

AM TRACKING |

AM BAND |

|

|

|

|||

fL |

fH |

|

COVERAGE |

|

|

MAIN PWB |

|

|

|

|

|

T2 |

|

R26 |

TP2 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

VR1 |

|

|

TC1 |

L4 |

FM DET. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

19 |

17 |

13 |

L3 |

|

TP1 |

IC2 |

VCO |

|||

AM BAR |

|

|

|||||

|

1 |

|

|

|

|||

ANTENNA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R7 |

|

|

|

|

|

|

|

FM IF |

L2 |

|

|

T3 |

|

|

L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AM IF |

|

||

|

FM RF |

T1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

IC1 |

FM BAND |

|

|

|

|

|

|

COVERAGE |

|

|

|

||

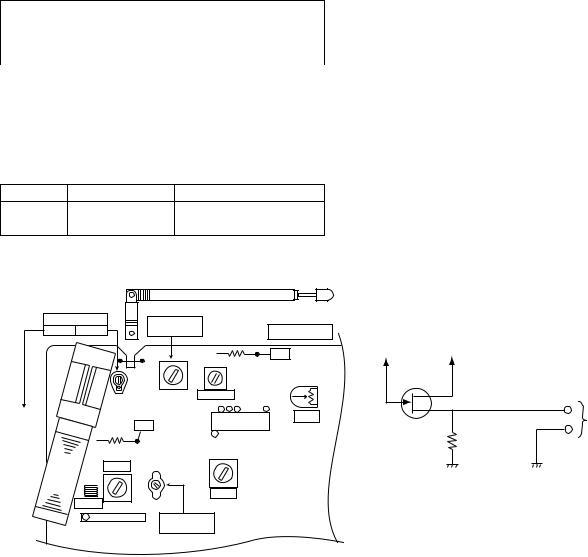

TUNER SECTION

fL: Low-range frequency fH: High-renge frequency

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test Stage |

Frequency |

Frequency |

Setting/ |

Instrument |

|

|

Display |

Adjusting |

Connection |

|

|

|

Parts |

|

Band |

— |

87.5 MHz |

(fL): L2 |

*1 |

Coverage |

|

|

2.0 ± 0.1 V |

|

|

|

|

|

|

RF |

90.0 MHz |

90.0 MHz |

L1 |

*2 |

|

(10~30 dB) |

|

|

|

|

|

|

|

|

*1. Input: Antenna, |

Output: TP1 |

*2. Input: Antenna, |

Output: Speaker Terminal |

• Detection

Signal generator: 10.7 MHz, FM sweep generator

Test |

Frequency |

Frequency |

Setting/ |

Instrument |

Stage |

|

Display |

Adjusting |

Connection |

|

|

|

Parts |

|

IF |

10.7 MHz |

98.00 MHz |

T1(Turn |

Input: Pin 1 of |

|

|

|

the core of |

IC1 |

|

|

|

T1 fully |

Output: TP2 |

|

|

|

counter- |

|

|

|

|

clockwise. |

|

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage |

Frequency |

Frequency |

Setting/ |

Instrument |

|||

|

|

|

|

Display |

Adjusting |

Connection |

|

|

|

|

|

|

|

Parts |

|

IF |

450 kHz |

|

1,720 kHz |

T3 |

*1 |

||

|

|

|

|

|

|

|

|

Band |

— |

|

530 kHz |

(fL): L4 |

*3 |

||

Coverage |

|

|

|

|

1.4 ± 0.05 V |

|

|

|

|

|

|

|

|

|

|

Tracking |

600 kHz |

|

600 kHz |

(fL): L3 |

*2 |

||

|

1,400 kHz |

1,400 kHz |

(fH):TC1 |

|

|||

|

|

|

|

|

|

|

|

*1. Input: Antenna, |

Output: Pin19 of IC2 |

|

|||||

*2. Input: Antenna, |

Output: Speaker Terminal |

|

|||||

*3. Input: Input is not connected, Output: TP1 |

|

||||||

• VCO Frequency |

|

|

|

|

|||

|

|

|

|

|

|

||

Adjusting Point |

|

|

Specified |

|

Instrument |

||

|

|

|

|

Value |

|

Connection |

|

|

|

|

|

|

|||

VR1 |

|

76 kHz ± 200 Hz |

|

Pin 13, pin 21 and |

|||

|

|

|

|

|

|

ground of IC2 |

|

|

|

|

|

|

|

|

|

Note:

After preparing the test circuit shown in Fig. 6-1, connect the Pin 13, Pin 21 and ground of the IC2 with the test circuit, and measure the value. At this time, apply a standard unmodulated signal input and adjust the VCO.

Pin 13 of IC2 Pin 21 of IC2 |

|

||

G |

D |

FET : 2SK19 or 2SK54 |

|

|

|

||

|

|

|

|

|

S |

|

TO FREQUENCY |

|

|

|

COUNTER |

10 kohm

Figure 6-1 VCO FREQUENCY TEST CIRCUIT

Figure 6-2 ADJUSTMENT POINTS

– 6 –

QT-CD161/141

TURNING ON THE TEST MODE

The types of test mode for this microcomputer and specific test mode turning-on procedure are as follows. Only the unit key is used. The remote control key is not valid. The power must be turned on while two keys are held down.

(1)CD test mode function

The power is turned while the (PRESET  ) and STOP (TUNING

) and STOP (TUNING  ) keys are held down.

) keys are held down.

(2)Tuner test mode function

The power is turned on while the (PRESET  ) and PAUSE (BAND) keys are held down.

) and PAUSE (BAND) keys are held down.

(3)LCD test mode function

The power is turned on while the (PRESET  ) and MEMORY keys are held down.

) and MEMORY keys are held down.

CD TEST MODE

When the CD test mode is turned on, the CD pickup is moved to the innermost periphery, and the following indication appears. The operation of CD test mode is as follows.

Indication

(1)The CD pickup is moved with the unit UP key and DOWN key. UP key: The pickup is slid to the outer periphery.

DOWN key: The pickup is slid to the inner periphery. However, when it reaches the innermost periphery, it does not move further inward.

(2)When the PLAY key is pressed in stop state, the laser diode turns on if CD lid is closed.

Indication

(3) When the PLAY key is pressed in laser ON state, playback is started from the current position of pickup.

Indication

The current playback track No. and time are indicated.

(4)When the STOP key is pressed during playback, the laser goes out and playback is stopped, and the process returns to step

(1). (The pickup position does not change.)

(5)When the MEMORY key is pressed during playback, tracking servo ON/OFF is performed. (Even if the playback is stopped in servo OFF state, the servo is turned on when the playback is restored.)

Indication |

The current pickup position and time are indicated. (When the |

|

pickup is moved with the UP/DOWN key, the time at that point is indicated.)

Others

While the CD lid is open (LID-SW = "H"), the test mode is turned on but the operations of step (2) and subsequent steps are not performed. The operation of step (1) is performed.

Contents of error display

Error display |

Contents of an error |

|

Er |

01 |

when TOC information cannot be read normally. |

Er |

02 |

When a PU-IN SW detection error occurs. |

TUNER TEST MODE

The tuner test mode is intended to store the measurement frequency for adjustment and inspection in the preset memory CH without frequency adjustment in the case of tuner adjustment in the production line.

When the power is turned on while the PRESET  (DOWN) key and BAND (PAUSE) key are held down together, the frequency for adjustment measurement of destination (specified according to AREA terminal) is preset-stored in the preset memory CH. (The frequency to be preset-stored for specific destination is as shown in the next page.)

(DOWN) key and BAND (PAUSE) key are held down together, the frequency for adjustment measurement of destination (specified according to AREA terminal) is preset-stored in the preset memory CH. (The frequency to be preset-stored for specific destination is as shown in the next page.)

– 7 –

QT-CD161/141

In the tuner test mode the band is FM, and the mode is FM STEREO in case of start-up.

As with the ordinary mode, when the PRESET  key is pressed for 1ch of preset memory CH, maximum CH is set. When the PRESET

key is pressed for 1ch of preset memory CH, maximum CH is set. When the PRESET  key is pressed for maximum CH of preset memory CH, 1ch is set.

key is pressed for maximum CH of preset memory CH, 1ch is set.

The BAND key is valid. As in the ordinary mode, the band/FM MONO/STEREO mode can be switched.

To exit from the tuner test mode, turn off the power to the microcomputer.

Indication

The indication is the same as that of ordinary operation. However, when the test mode is turned on, the indication shown left lights for one second.

Preset frequencies for various destinations (random preset memory)

BAND (CH) |

U.S.A. |

EUROPE |

GENERAL 1 |

GENERAL 2 |

1 |

FM 87.5M |

FM 87.50M |

FM 87.50M |

FM 87.5M |

|

|

|

|

|

2 |

FM 108.0M |

FM 108.00M |

FM 108.00M |

FM 108.0M |

3 |

FM 98.0M |

FM 98.00M |

FM 98.00M |

FM 98.0M |

4 |

FM 90.0M |

FM 90.00M |

FM 90.00M |

FM 90.0M |

5 |

FM 106.0M |

FM 106.00M |

FM 106.00M |

FM 106.0M |

6 |

AM 530K |

AM 522K |

AM 531K |

AM530K |

7 |

AM1720K |

AM1620K |

AM1602K |

AM1620K |

8 |

AM 990K |

AM 990K |

AM 990K |

AM 990K |

9 |

AM600K |

AM 603K |

AM 603K |

AM 600K |

10 |

AM 1400K |

AM 1404K |

AM 1404K |

AM 1404K |

11 |

|

|

|

|

12 |

|

|

|

|

13 |

|

|

|

|

14 |

|

|

|

|

15 |

|

|

|

|

16 |

|

|

|

|

17 |

|

|

|

|

18 |

|

|

|

|

19 |

|

|

|

|

20 |

|

|

|

|

21 |

|

|

|

|

22 |

|

|

|

|

23 |

|

|

|

|

24 |

|

|

|

|

25 |

|

|

|

|

26 |

|

|

|

|

27 |

|

|

|

|

28 |

|

|

|

|

29 |

|

|

|

|

30 |

|

|

|

|

Note: |

|

|

|

|

The unit shown in table is Hz. K is x1000. M is x1,000,000.

The slash indicates that data are not stored in the memory.

FM is stereo mode.

LCD TEST MODE

When the LCD test mode is turned on, all the segments of LCD light.

Indication

– 8 –

QT-CD161/141

NOTES ON SCHEMATIC DIAGRAM

•Resistor:

To differentiate the units of resistors, the symbol as K and M are used: the symbol K means 1000 ohm and the symbol M means 1000 kohm and the resistor without any symbol is an ohm resistor. The resistor designated "Fusible" is a fuse type resistor

•Capacitor:

To indicate the unit of capacitor, a symbol P is used: this symbol P means micro-micro-farad and the unit of the capacitor without such a symbol is microfarad. As to electrolytic capacitor, the expression “capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation (ML): Mylar type

(P.P.): Polypropylene type

•The indicated voltage in each section is the one measured by Digital Multimeter between such a section and the chassis with no signal given.

1.Tuner

( ): AM mode

Marking except for ( ): FM mode

2.CD

( ): Play mode

Marking except for ( ): Stop state

3.Deck section

( ): Record mode

Marking except for ( ): Playback mode Display / Control section:

( ): Active state

Marking except for ( ): CD Function mode at stop state

•Schematic diagram and Wiring Side of P.W.Board for this model are subject to change for improvement without prior notice.

•Parts marked with “  ” (

” (

) are important for

) are important for

maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

REF. NO |

DESCRIPTION |

POSITION |

|

|

|

SW102 |

RECORD/PLAYBACK |

PLAYBACK |

|

|

|

SW201 |

FUNCTION/POWER |

TAPE—TUNER— CD/ |

|

|

OFF—ON |

|

|

|

SW202 |

X-BASS |

OFF—ON |

|

|

|

SW501 |

TUNER UP |

OFF—ON |

|

|

|

SW502 |

TUNER DOWN |

OFF—ON |

|

|

|

SW503 |

BAND |

OFF—ON |

REF. NO |

DESCRIPTION |

POSITION |

|

|

|

SW504 |

MEMORY |

OFF—ON |

|

|

|

SW505 |

PRESET DOWN |

OFF—ON |

SW506 |

PRESET UP |

OFF—ON |

|

|

|

SW507 |

CD LID OPEN/CLOSE |

OFF—ON |

|

|

|

SW601 |

TAPE MAIN |

OFF—ON |

|

|

|

SW702 |

PICKUP IN |

OFF—ON |

|

|

|

FRONT

VIEW

E C B (S)(G)(D)

(1) (2) (3)

KTA1266 GR

KTA1273 Y

KTC3194 Y

KTC3199 GR

KTC8050 D

KRA102 M

KRA109 M

KRC104 M

KRC107 M

Figure 9 TYPES OF TRANSISTOR

– 9 –

QT-CD161/141

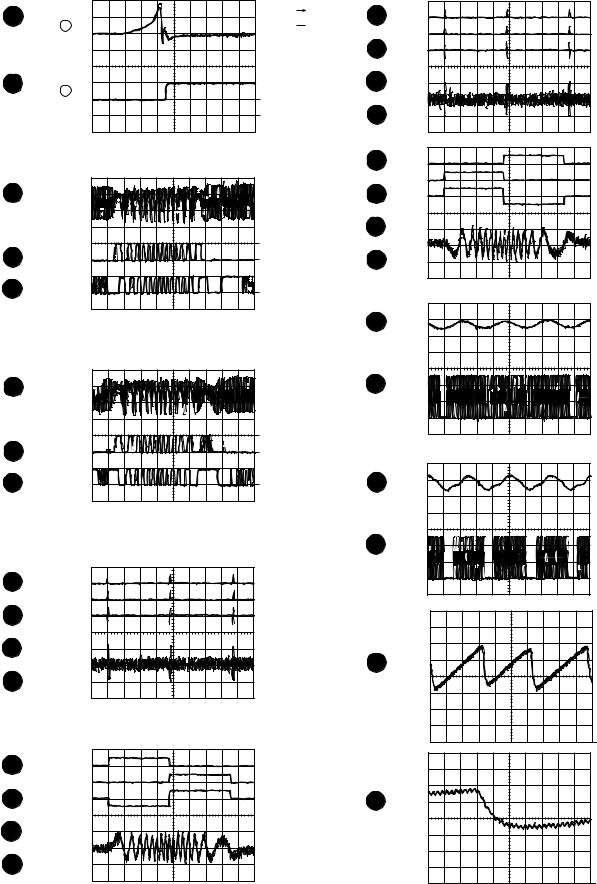

WAVEFORMS OF CD CIRCUIT

1 |

5ms |

STOP |

PLAY |

0.50 V |

|

|

|

|

IC801 20 F.E |

FOCUS |

SERCH |

5ms 2 5.0 V

IC801 54 DRF

3

1

3 |

0.5ms |

CUE |

|

|

|||

1.00 V |

|

||

|

HF |

|

|

|

|

1 |

|

4 |

0.5ms |

2 |

|

5.0 V |

|||

|

|||

|

HFL |

|

|

5 |

0.5ms |

3 |

|

5.0 V |

|||

|

|||

|

TES |

|

3 |

0.5ms |

REVIEW |

|

|

|||

1.00 V |

|

||

H.F |

|

||

|

|

||

|

|

1 |

|

4 |

0.5ms |

2 |

|

5.0 V |

|||

|

|||

|

HFL |

|

|

5 |

0.5ms |

3 |

|

5.0 V |

|||

|

|||

|

TES |

|

6 |

50ms |

CUE |

|

10.0 V |

|||

|

|||

|

JP+ |

|

|

7 |

50ms |

|

|

10.0 V |

|

||

|

|

||

|

JP- |

|

|

8 |

50ms |

|

|

0.50 V |

|

||

|

JP |

|

|

9 |

50ms |

|

|

1.00 V |

|

||

|

|

||

|

TE |

|

6 |

0.5ms |

10.0 V |

|

JP+ |

7 |

0.5ms |

10.0 V |

|

|

JP- |

8 |

0.5ms |

0.50 V |

|

|

JP |

9 |

0.5ms |

1.00 V |

|

|

TE |

6 |

50ms |

REVIEW |

|

10.0 V |

|||

|

|||

|

JP+ |

|

|

7 |

50ms |

|

|

10.0 V |

|

||

|

JP- |

|

|

8 |

50ms |

|

|

0.50 V |

|

||

|

JP |

|

|

9 |

50ms |

|

|

1.00 V |

|

||

|

TE |

|

|

6 |

0.5ms |

|

|

10.0 V |

|

||

|

JP+ |

|

|

7 |

0.5ms |

|

|

10.0 V |

|

||

|

JP- |

|

|

8 |

0.5ms |

|

|

0.50 V |

|

||

|

JP |

|

|

9 |

0.5ms |

|

|

1.00 V |

|

||

|

TE |

|

|

10 |

20ms |

PLAY |

|

1.00 V |

|||

NORMAL DISC |

|||

SPO |

|||

|

TN0=01 |

||

|

|

||

11 |

20ms |

|

|

2.00 V |

|

||

CLV+ |

|

||

|

|

||

10 |

50ms |

PLAY |

|

1.00 V |

TCD-712 (140mm) |

||

|

SPO |

TN0=01 |

|

11 |

50ms |

|

|

2.00 V |

|

||

|

CLV+ |

|

|

|

|

PLAY |

|

|

|

TCD-712 |

|

12 |

5s |

|

|

100mV |

|

||

SLD |

|

||

|

|

||

|

|

1 |

|

12 |

0.5s |

|

|

100mV |

|

||

|

SLD |

|

|

|

|

1 |

– 10 –

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

QT-CD161/141 |

|

|

|

|

|

|

|

|

|

TO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+7.4V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(CD) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

64 63 62 51 |

37 |

46 39 38 33 32 |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

LCHO |

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

43 XVDD |

|

|

|

|

8 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

+5V |

|

23 VDD |

|

|

|

|

|

CQCK. COIN RWC. WRQ |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|||||

|

|

|

6 VVDD |

|

IC802 |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

LC78622E |

|

53 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

SERVO/SIGNAL |

54 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

55 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

CONTROL |

|

|

|

|

|

|

|

|

|

||||

|

|

|

45 XIN |

|

|

56 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

RES. |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

57 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

58 |

|

|

|

|

|

|

|

|

|

|

XL801 |

16.93MHz |

44 |

XOUT |

EFMO EFMIN CLV+ CLV– V/P HFL |

TES |

TOFF TGL |

JP+ JP– SQOUT. |

61 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1 |

SELIAL CONTROL |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

9 10 12 13 14 15 16 17 18 19 20 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+7.4V |

|

|

|

|

||

|

|

|

|

|

|

|

|

44 43 40 |

~ |

32 |

|

|

DAT, |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

SLI SLC CV+ |

|

JP– |

DRF |

54 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CL, |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

CE 53 |

|

1 |

30 |

7 8 9 22 25 24 |

|||||||

|

|

|

|

|

|

|

|

LA9240M SERVO AMP. |

|

|

DAT 52 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CL 51 |

|

|

|

|

|

|

|

|

||

|

|

|

62 |

LDD |

|

|

|

|

CLK |

50 |

CONSTANT |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

DEF 49 |

|

|

IC803 |

|

|

||||||||

|

|

|

|

IC801 |

|

|

VOLTAGE |

Q804 |

|

|

|

|

||||||||

+5V |

|

|

64 |

VCC1 |

|

|

|

|

REGULATOR |

|

|

LA6541 |

|

|||||||

|

|

|

|

|

|

|

|

FOCUS/TRACKING |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

SLD 29 |

|

+5V |

3 |

/SPIN/SLIDE |

|||||||

LASER |

Q801 |

|

|

|

|

|

|

SLEQ 28 |

|

|

13 |

|

DRIVER |

|

||||||

|

|

|

|

|

|

SPO 27 |

|

|

29 |

|

|

|

|

|

||||||

DRIVER |

|

FIN2 FIN1 |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

SL– SL+ |

FD 16 |

|

|

28 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

E F |

|

|

TO 15 |

|

|

18 |

|

|

|

|

|

|||||

|

|

|

|

1 |

2 |

3 |

4 |

|

|

30 31 |

|

|

|

|

25 26 20 21 |

5 |

6 |

10 11 |

||

|

PICKUP UNIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M |

|

|

M |

|

|

|

|

|

|

|

|

FOCUS COIL |

|

TRACKING COIL |

|

|

|

|

|

M701 |

|

|

M702 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPIN |

|

|

SLIDE |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

|

MOTOR |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TO MAIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TO MAIN |

|

|

|

|

SECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SECTION |

|

|

|

|

|

|

Figure 11 BLOCK DIAGRAM (1/3)

– 11 –

Loading...

Loading...