SEW-Eurodrive Varimot 16-46 Series, D 16, D 26, D 36, DF16D Operating Instructions Manual

...

Gearmotors \ Industrial Gear Units \ Drive Electronics \ Drive Automation \ Services

Explosion-Proof

VARIMOT

and Accessories

Edition 11/2006

11529016 / EN

®

Variable Speed Gear Units

O

perating

I

nstructions

SEW-EURODRIVE – Driving the world

Contents

1 Important Information about the Operating Instructions .............................. 4

1.1 Explanation of symbols ............................................................................. 6

2 Safety Notes ...................................................................................................... 7

2.1 Safety notes for the use of VARIMOT

®

3 VARIMOT

in Explosion-Proof Version .......................................................... 8

3.1 Unit design ............................................................................................... 8

3.2 Unit designation ........................................................................................ 9

3.3 Nameplate............................................................................................... 10

3.4 Overview of mounting options................................................................. 11

4 Installation ....................................................................................................... 12

4.1 VARIMOT

4.2 VARIMOT

®

in category 2G ..................................................................... 12

®

in categories 3G and 3D...................................................... 13

4.3 Permitted overhung loads without primary gear unit............................... 13

4.4 Before you begin..................................................................................... 16

4.5 Preliminary work...................................................................................... 16

4.6 Installation............................................................................................... 17

4.7 Gear units with solid shafts ..................................................................... 19

®

..................................................... 7

5 Startup.............................................................................................................. 21

5.1 Installation and setup of optional equipment........................................... 21

6 Inspection and Maintenance .......................................................................... 32

6.1 Inspection and maintenance intervals..................................................... 32

6.2 Before you begin..................................................................................... 33

6.3 Checking torsional play........................................................................... 33

6.4 Checking the friction ring......................................................................... 34

6.5 Replacing the friction ring........................................................................ 35

6.6 Measuring the temperature of the anti-friction bearing ........................... 36

6.7 Completing the inspection/maintenance process ................................... 37

7 Operation and Service .................................................................................... 38

7.1 Customer service .................................................................................... 38

7.2 Malfunction of VARIMOT

®

speed gear units........................................... 38

7.3 WEXA/WEX speed monitor..................................................................... 39

8 Declaration of Conformity .............................................................................. 40

8.1 Variable speed gear units category 2G, VARIMOT

8.2 Variable speed gear units category 3G and 3D,

VARIMOT

®

series 16-46......................................................................... 41

®

series 16-46 ......... 40

9 Index................................................................................................................. 42

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

3

1

Important Information about the Operating Instructions

1 Important Information about the Operating Instructions

Introduction You must follow the information in the operating instructions to ensure trouble-free oper-

ation and for the fulfillment of any rights to claim under the limited warranty. Read the

operating instructions before you start working with the unit.

Make sure that the operating instructions are available to persons responsible for the

system and its operation, as well as to persons who work independently on the unit.

Also observe other technical documents, contracts for delivery or other agreements.

Intended use

Qualified personnel

VARIMOT

systems and may only be used in accordance with the information provided in SEWEURODRIVE's technical documentation and the information given on the nameplate.

It corresponds to valid standards and regulations and meet the requirements of

EC Directive 94/9/EC and the EC Directive for Machinery 98/37/EC.

Gear unit loads other than those specified and areas of application other than industrial

and commercial systems can only be used after consultation with SEW-EURODRIVE.

Any application other than those mentioned is considered non-intended use.

A drive motor connected to the VARIMOT

inverter.

VARIMOT

material. Consequently, assembly, installation, startup and service work may only be

performed by trained personnel who are aware of the potential hazards.

Personnel must possess the required qualifications for the relevant task and be familiar

with the:

• Assembly

• Installation

•Startup

•Operation

• Maintenance

• Servicing

of the product.

Personnel must carefully read the operating instructions, in particular the safety notes

section, and understand and comply with them.

®

variable speed gear units are intended for commercial and industrial

®

may not be operated on the frequency

®

variable speed gear units represent a potential hazard for persons and

4

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

Important Information about the Operating Instructions

Exclusion of liability

You must comply with the information contained in these operating instructions to

ensure safe operation of the VARIMOT

specified product characteristics and performance requirements.

SEW-EURODRIVE GmbH & Co KG assumes no liability for injury to persons or damage

to equipment or property resulting from non-observance of these operating instructions.

In such cases, any liability for defects is excluded.

Product names and trademarks

The brands and product names contained within these operating instructions are trademarks or registered trademarks of the titleholders.

Waste disposal (Please follow the current instructions):

• Housing parts, gears, shafts and anti-friction bearings of the gear unit must be disposed of as steel scrap. This also applies to gray-cast iron parts if there is no special

collection.

• Collect waste oil and dispose of it according to the regulations in force.

®

1

variable speed gear unit and to achieve the

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

5

1

Important Information about the Operating Instructions

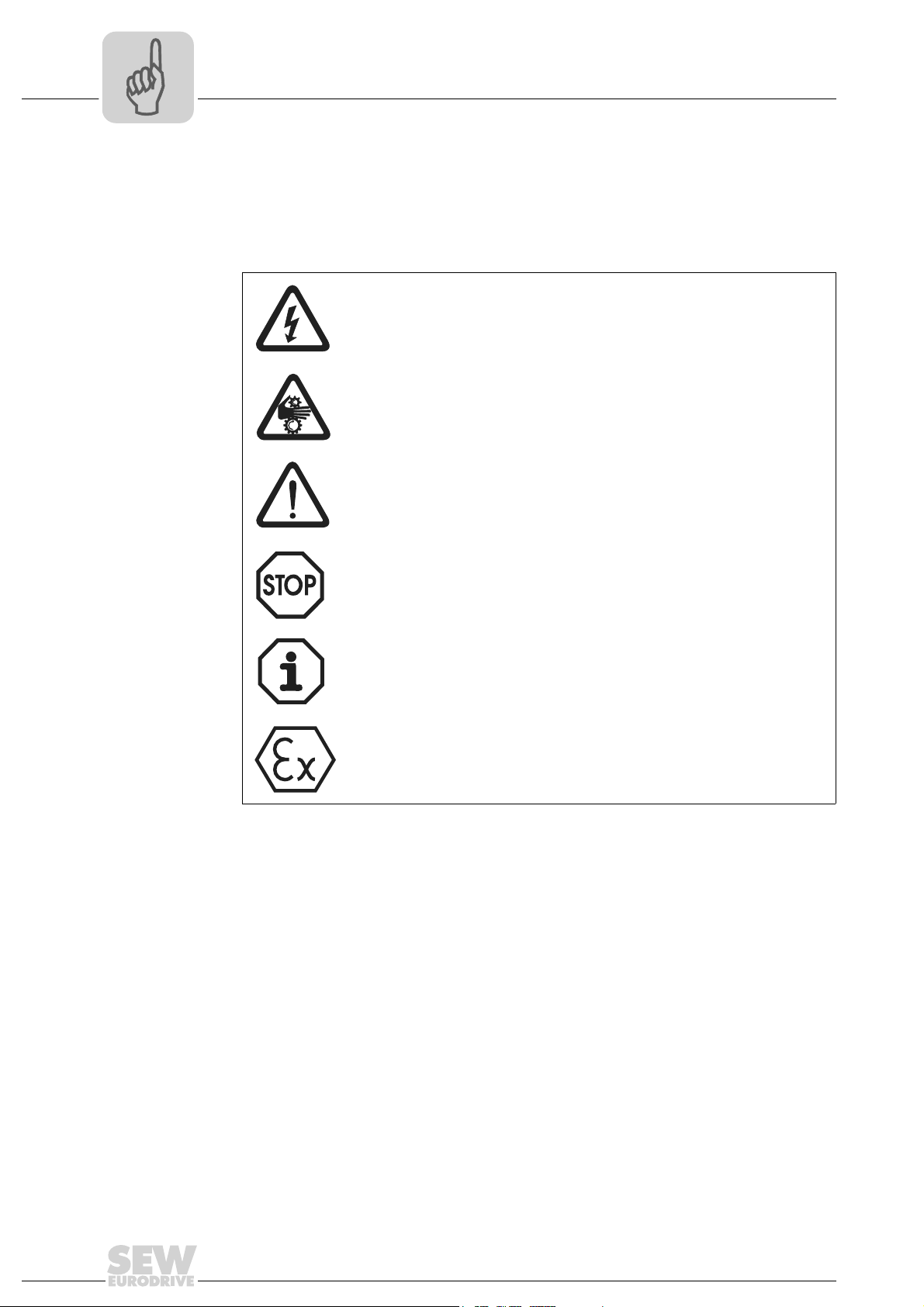

Explanation of symbols

1.1 Explanation of symbols

The operating instructions contain important information that deals with general and

operational safety. This information is emphasized in particular with the following

symbols.

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard

Possible consequences: Severe or fatal injuries.

Hazardous situation

Possible consequences: Slight or minor injuries.

Harmful situation

Possible consequences: Damage to the drive and the environment.

Tips and useful information.

Important information about explosion protection.

6

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

2 Safety Notes

Safety Notes

Safety notes for the use of VARIMOT®

2

2.1 Safety notes for the use of VARIMOT

The following safety notes apply to variable speed gear units.

When using variable speed gearmotors, also refer to the safety notes for gear units

and motors in the relevant operating instructions.

Take into consideration the supplementary safety notes in the individual sections

of these operating instructions.

Explosive gas mixtures or dust concentrations when combined with hot, live, and

moving parts of electrical machinery can cause serious injury or death.

Assembly, connection, startup, maintenance and repair work on the VARIMOT

variable speed gear units and the optional electrical components may only be

performed by qualified personnel while taking the following into account:

• These operating instructions

• Warning and instruction labels on the variable speed gear unit/variable speed gearmotor

• All other project planning documents, operating instructions and wiring diagrams

belonging to the drive

• The specific regulations and requirements for the system

• National/regional regulations on explosion protection, safety, and prevention of accidents that are currently in effect

®

®

Optional

equipment

Optional equipment complies with existing standards and regulations:

• EN 50014

• EN 50018 for protection type "d"

• EN 50019 for protection type "e"

• EN 50020 intrinsically safe "i"

• EN 50281-1-1/EN 50281-1-2 "Electrical apparatus for use in the presence of

combustible dust"

In addition to general installation guidelines, the following regulations in accordance with

ElexV 1 (or other national regulations) must be observed for electrically operated

options:

• EN 60079-14 "Electrical apparatus for explosive gas atmospheres"

• EN 50281-1-2 "Electrical apparatus for use in the presence of combustible dust"

• DIN VDE 105-9 "Operating electrical equipment" or other national regulations

• DIN VDE 0100 "Erection of power installations with rated voltages below 1000 V" or

other national regulations

• System-specific regulations

Technical data and information on approved conditions on site can be found on the

nameplate and in these operating instructions.

These details must be strictly observed.

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

7

3

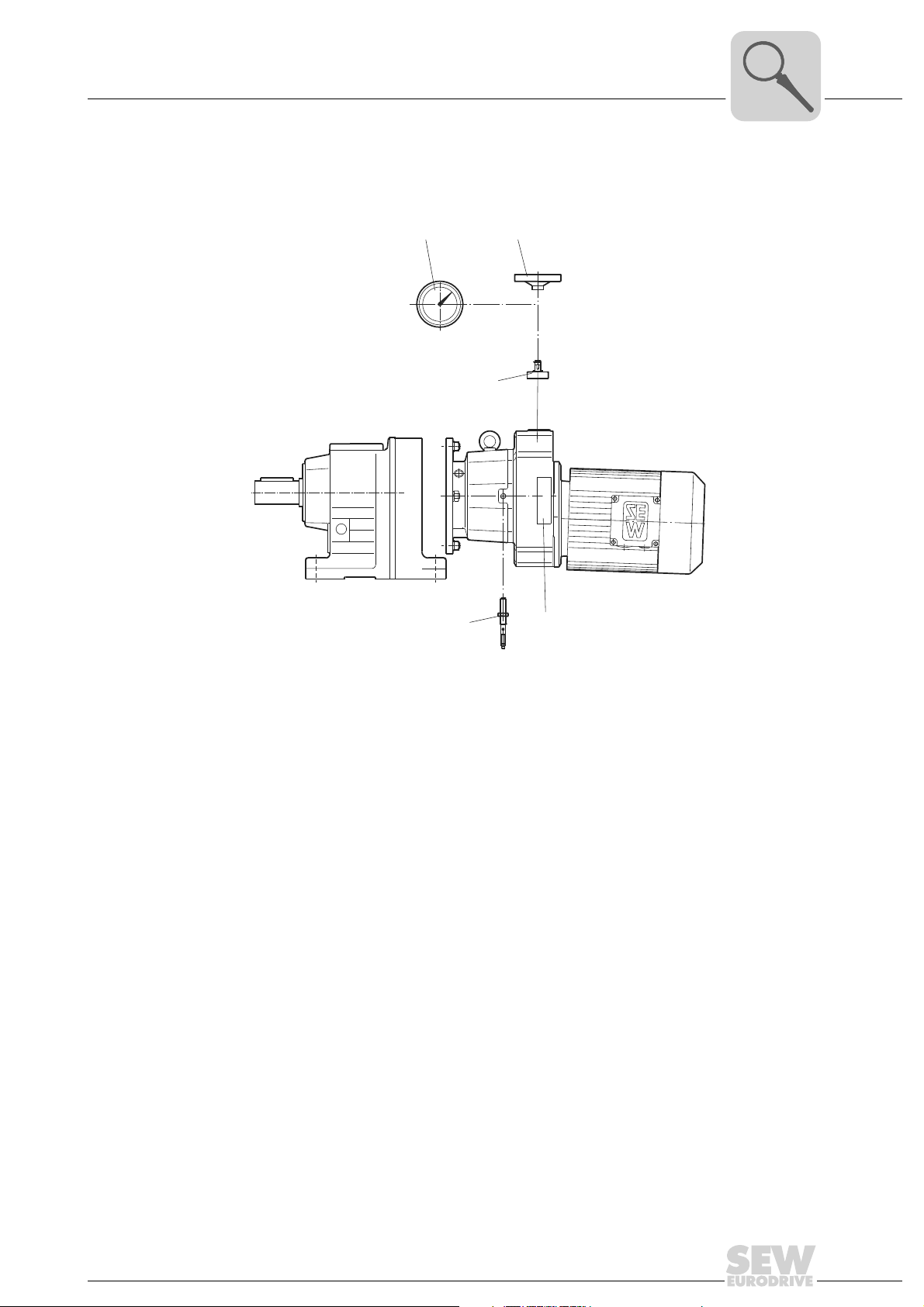

[1]

[9]

[5]

[4][6] [10]

[7]

[3]

[8]

VARIMOT® in Explosion-Proof Version

Unit design

3 VARIMOT® in Explosion-Proof Version

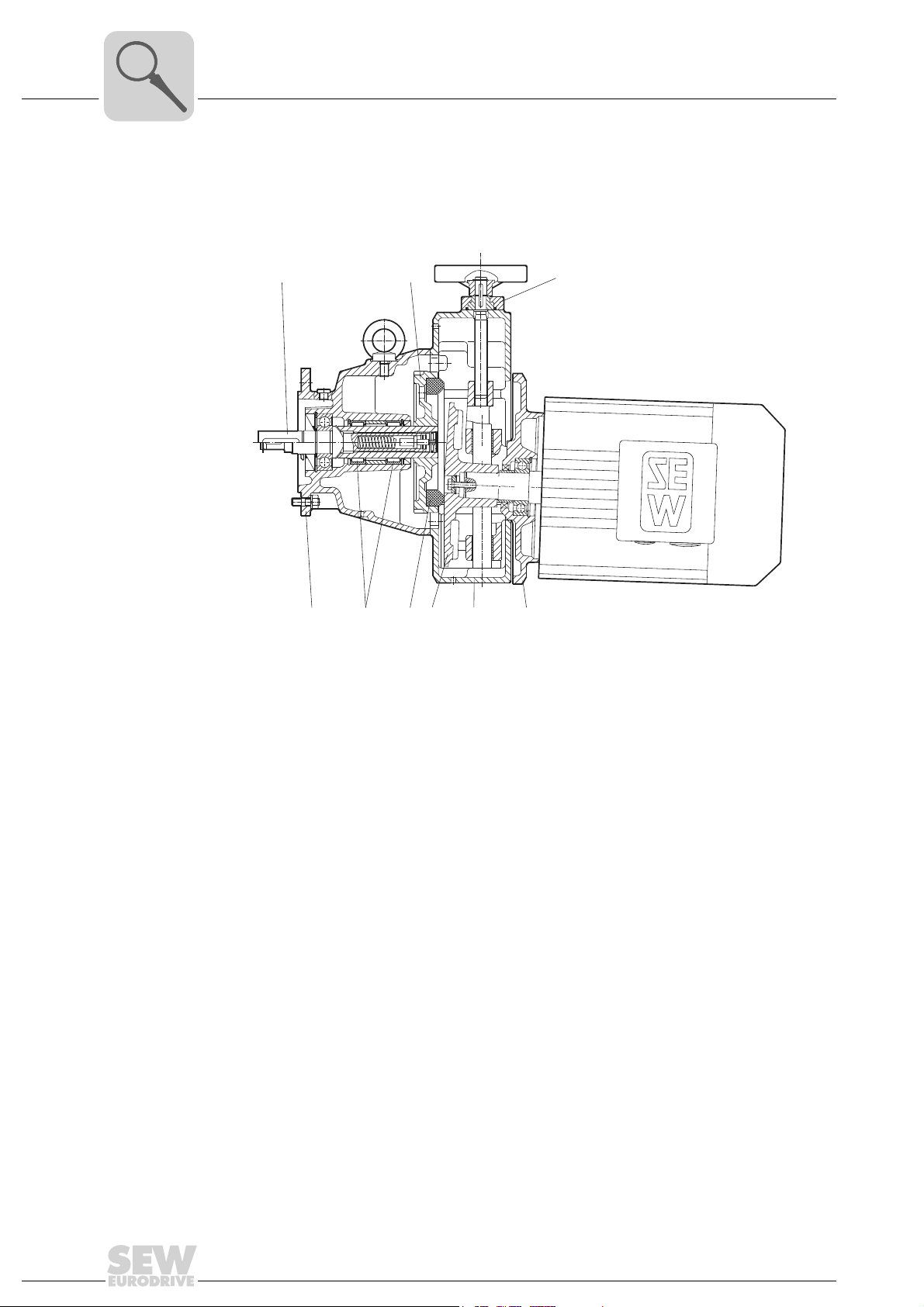

3.1 Unit design

Fig. 1: VARIMOT® in explosion-proof version

52018AXX

[1] Complete output shaft

[3] Plate

[4] Adjusting plate

[5] Housing cover

[6] Drive disk

[7] Needle bearing

[8] Housing with tapped hole

[9] Complete hollow shaft

[10] Friction ring

8

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

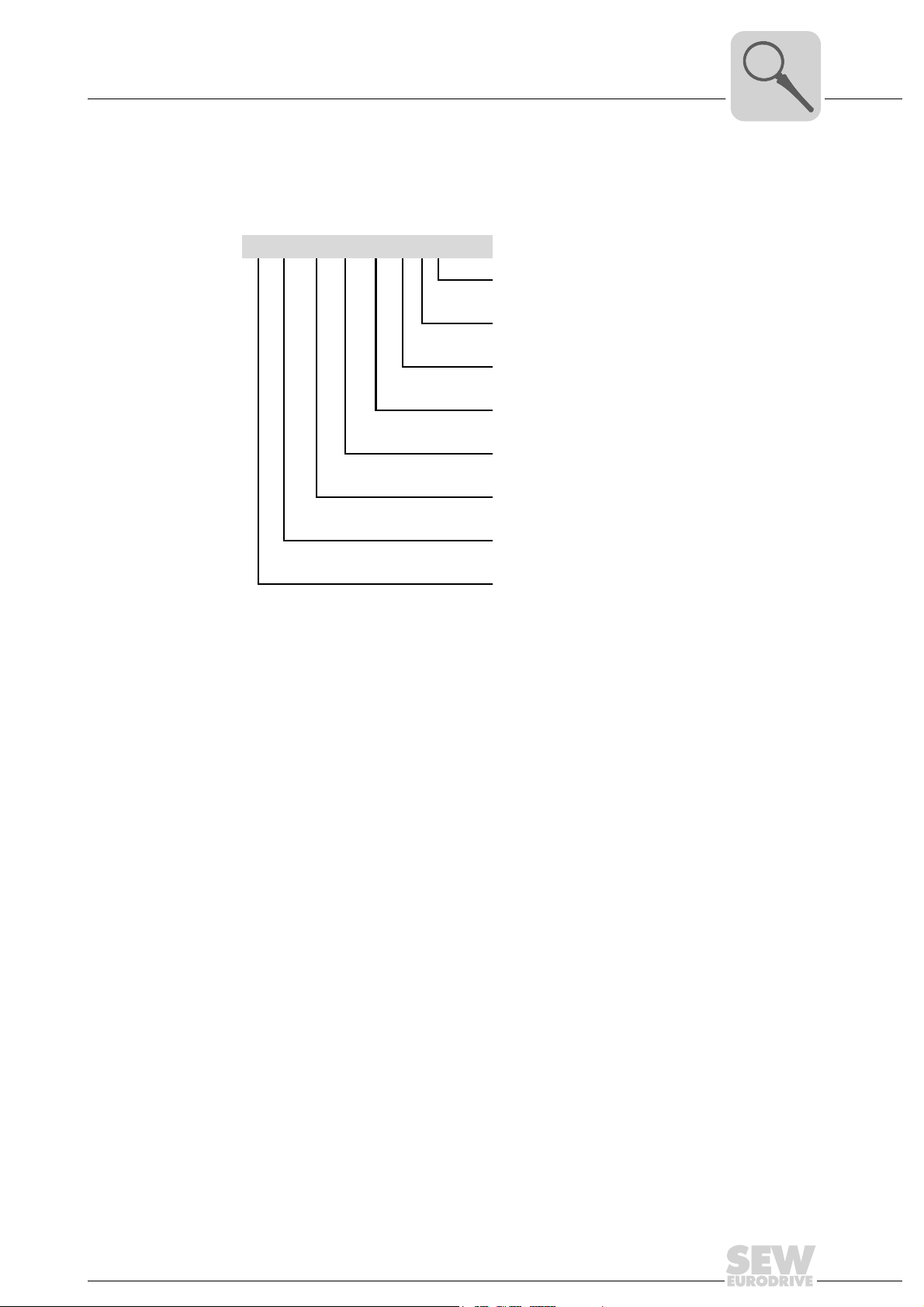

3.2 Unit designation

The following diagram shows the type code structure:

DV 26B WEX II2G eDT 90L 4 TF

VARIMOT® in Explosion-Proof Version

Unit designation

Temperature sensor

Number of motor poles

Motor size

Motor series

Explosion-proof version according to ATEX 100a

Speed monitor

3

VAR IMOT

indicates wet version

VAR IMOT

version

®

variable speed gear unit size B

®

variable speed gear unit series flange

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

9

3

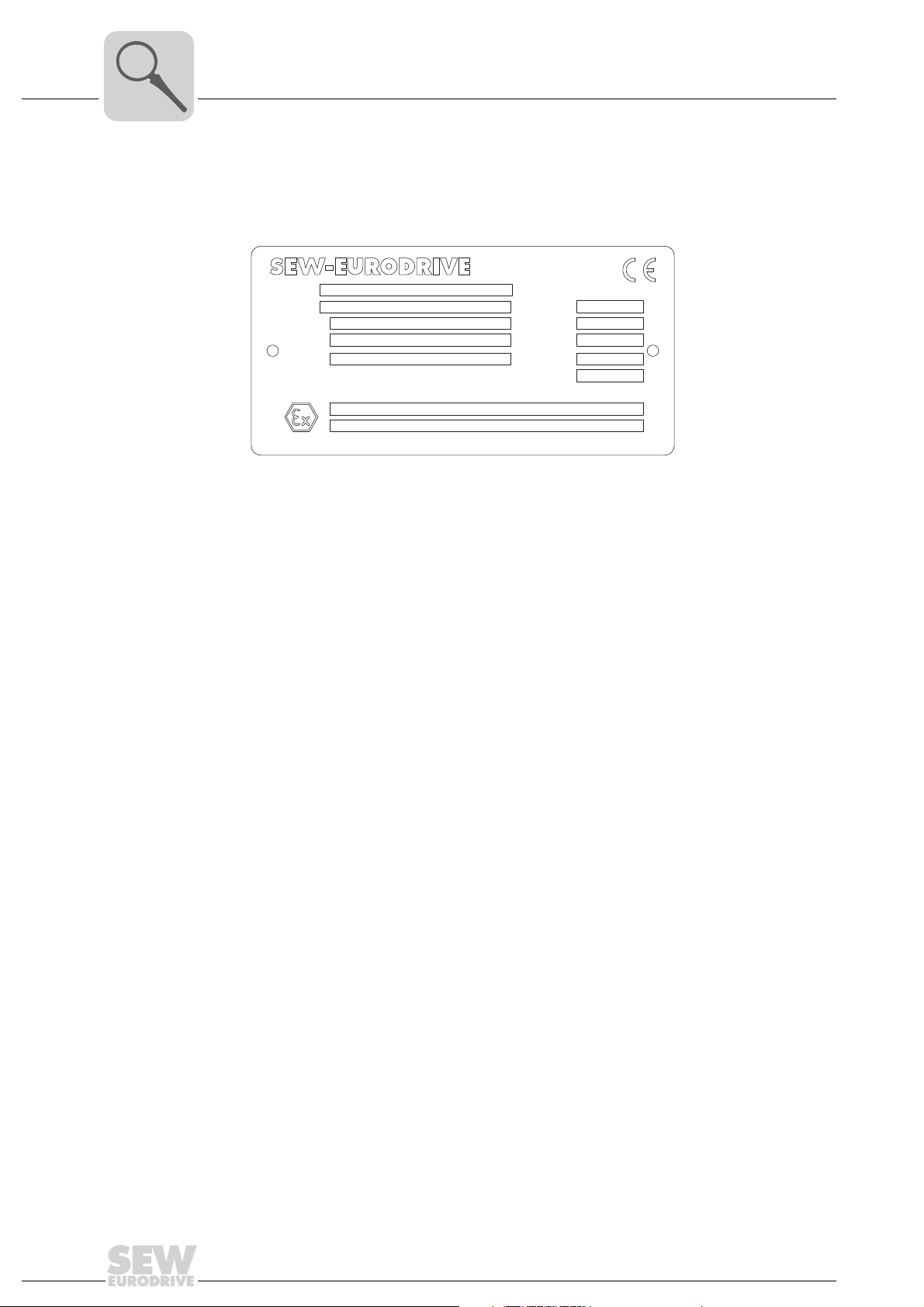

3.3 Nameplate

Example

VARIMOT® in Explosion-Proof Version

Nameplate

Bruchsal / Germany

DF36/A/IGEX/II2G

Typ

01.1151703702.0001.06

Nr.

159/798

r/min

n

a

M

Nm

84/38

a

IM

M4

Bedienungsanleitung muss beachtet werden

Zum Einbau in Komplettantrieb

RX77 D36/IGEX/II2G eDV112M4/C

II2G / T3

Lagerfett synth. KHC2R

Fig. 2: Nameplate

R

n

P

kg

i

Made in Germany 150 881 4.10

1:

5

r/min

e

1440

3.6

kW

e

104.242

=

168

60417AXX

Typ Type code

Nr. Sales order number

Minimum and maximum output speed

n

a

Output torque at minimum and maximum output speed

M

a

IM Mounting position

R Control range

Input speed

n

e

Input power

P

e

kg Weight

i Gear ratio

10

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

VARIMOT® in Explosion-Proof Version

3.4 Overview of mounting options

Overview of mounting options

3

[2]

[5]

Fig. 3: Overview of mounting options

[3]

[1]

[4]

52019AXX

[1] Adjustment device with free shaft end NV

[2] Adjustment device with handwheel and position indication HS

[3] Adjustment device with handwheel (standard version)

[4] Indicator scale

[5] Voltage encoder IGEX

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

11

4

Installation

VARIMOT® in category 2G

4 Installation

Strictly observe the safety notes on page 7 when installing the variable speed

gear unit.

4.1 VARIMOT® in category 2G

General

information

Designation "X" • If the designation "X" appears after the certification number on the declaration of

Temperature class • VARIMOT

Ambient

temperature

Output power and

output torque

Speed monitoring • VARIMOT

• SEW explosion-proof variable speed gear units of the VARIMOT® D/DF 16-46 series

and VARIMOT

group II, category 2G (explosive gas atmosphere). These units are intended for use

in zones 1 and 2.

• A standard feature of the SEW-EURODRIVE explosion-proof variable speed gear

units of the VARIMOT

conformity or the EC prototype test certificate, this indicates the certificate contains

special conditions for safe application of the variable gear unit.

approved for temperature class T3. The temperature class of the variable speed gear

unit is indicated on the nameplate.

• VARIMOT

of –20°C (–4°F) to +40°C (+104°F).

• It is essential that nominal values of output power and/or output torque are maintained.

speed monitoring device. The speed monitor must be correctly installed and adjusted

(see Sec. "Startup", Speed monitoring).

Verify the speed monitoring function before startup.

®

D/DF 16-46B series meet the design requirements of equipment

®

series is a tapped hole for installing a voltage encoder.

®

variable speed gear units, category 2G (explosive gas atmosphere) are

®

variable speed gear units may only be used at an ambient temperature

®

variable speed gear units in category 2G may only be operated with a

12

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

VARIMOT® in categories 3G and 3D

F

R

d

l

l/2

4.2 VARIMOT® in categories 3G and 3D

General

information

Temperature class • VARIMOT

Surface

temperature

Ambient

temperature

Output power and

output torque

• SEW-EURODRIVE explosion-proof variable speed gear units of the VARIMOT

D/DF 16-46 and VARIMOT® D/DF 16-46B series meet the design requirements of

equipment group II, categories 3G (explosive gas atmosphere) and 3D (explosive

dust atmospheres). These units are intended for use in zones 2 and 22.

• A standard feature of the SEW-EURODRIVE explosion-proof variable speed gear

units of the VARIMOT

®

variable speed gear units of category 3G (explosive gas atmosphere)

®

series is a tapped hole for installing a voltage encoder.

are approved for temperature class T3. The temperature class of the variable speed

gear unit is indicated on the nameplate.

• The maximum surface temperature of VARIMOT

gory 3D (explosive dust atmosphere) may not exceed 200 °C (392 °F). The system

operator must guarantee that a possible accumulation of dust will not exceed a

maximum thickness of 5 mm, in accordance with EN 50281-1-2.

• VARIMOT

®

variable speed gear units may only be used at an ambient temperature

of –20°C (–4°F) to +40°C (+104°F).

• It is essential that nominal values of output power and/or output torque are

maintained.

Installation

®

variable speed gear units, cate-

4

®

If an overload condition of the VARIMOT® as category 3G or 3D unit cannot be

ruled out during normal operation, a VARIMOT

monitor must be used (see Sec. "Startup", Speed monitoring).

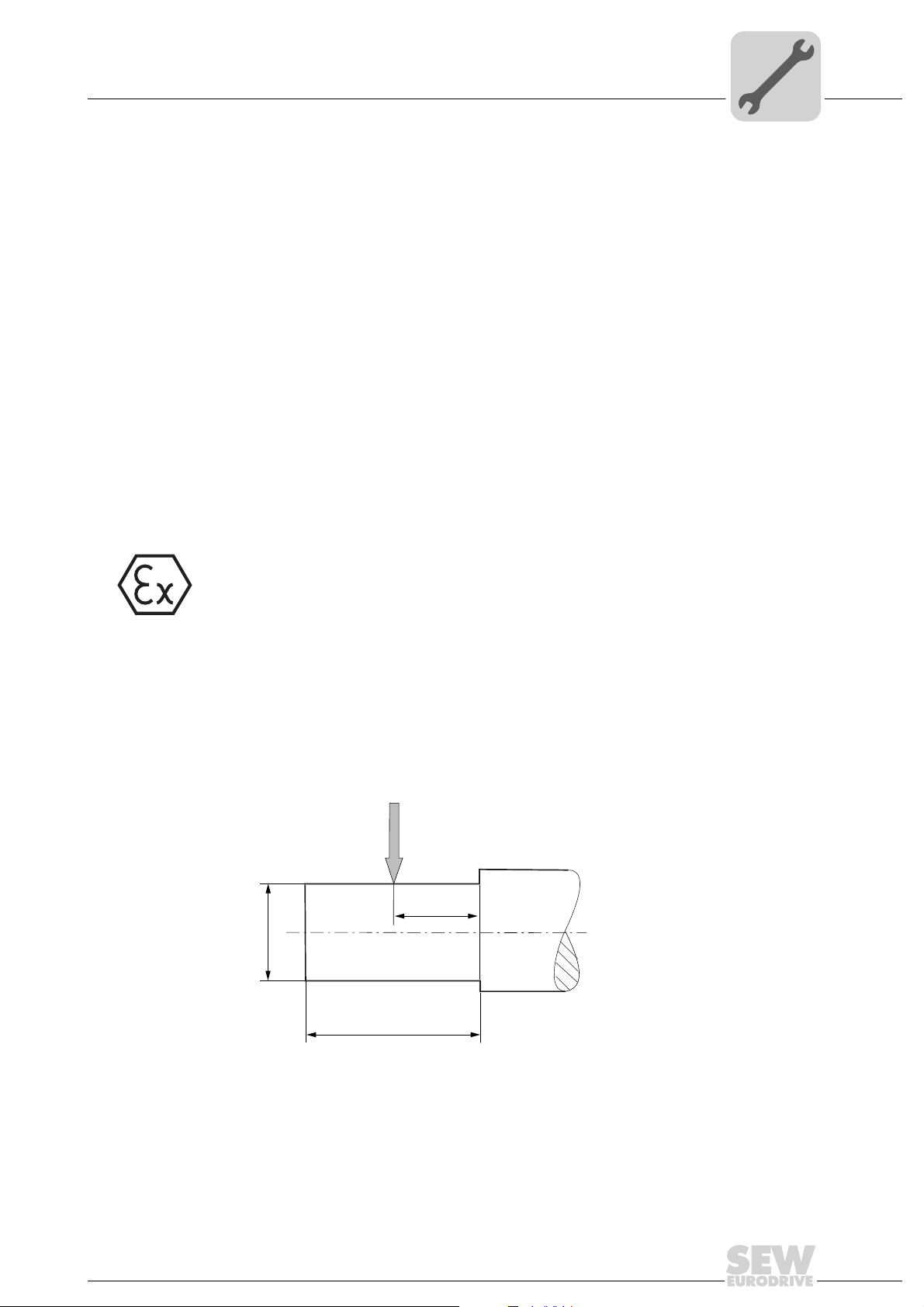

4.3 Permitted overhung loads without primary gear unit

Definition of force

application of

overhung loads

The development of the overhung load depicted in the diagrams refers to a point of

application at mid-point of the shaft extension as indicated in Figure 1. If force is applied

to areas other than the center of the shaft end, consult SEW-EURODRIVE for permitted

lateral forces.

®

unit with a functioning speed

Fig. 4: Definition of force application of overhung loads

F

[N] = permitted overhung load point of application at mid-point of shaft extension.

R

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

50248AXX

13

4

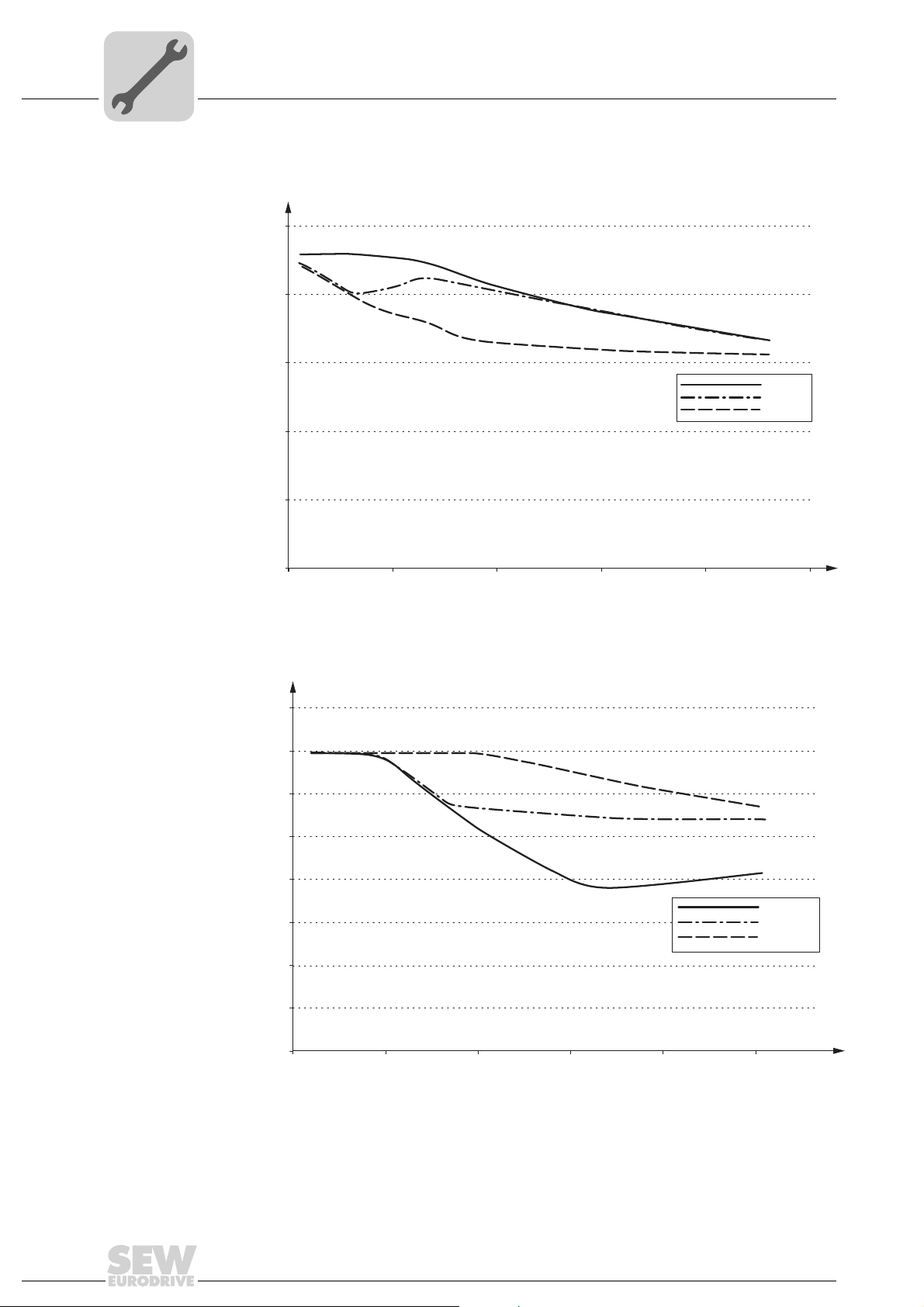

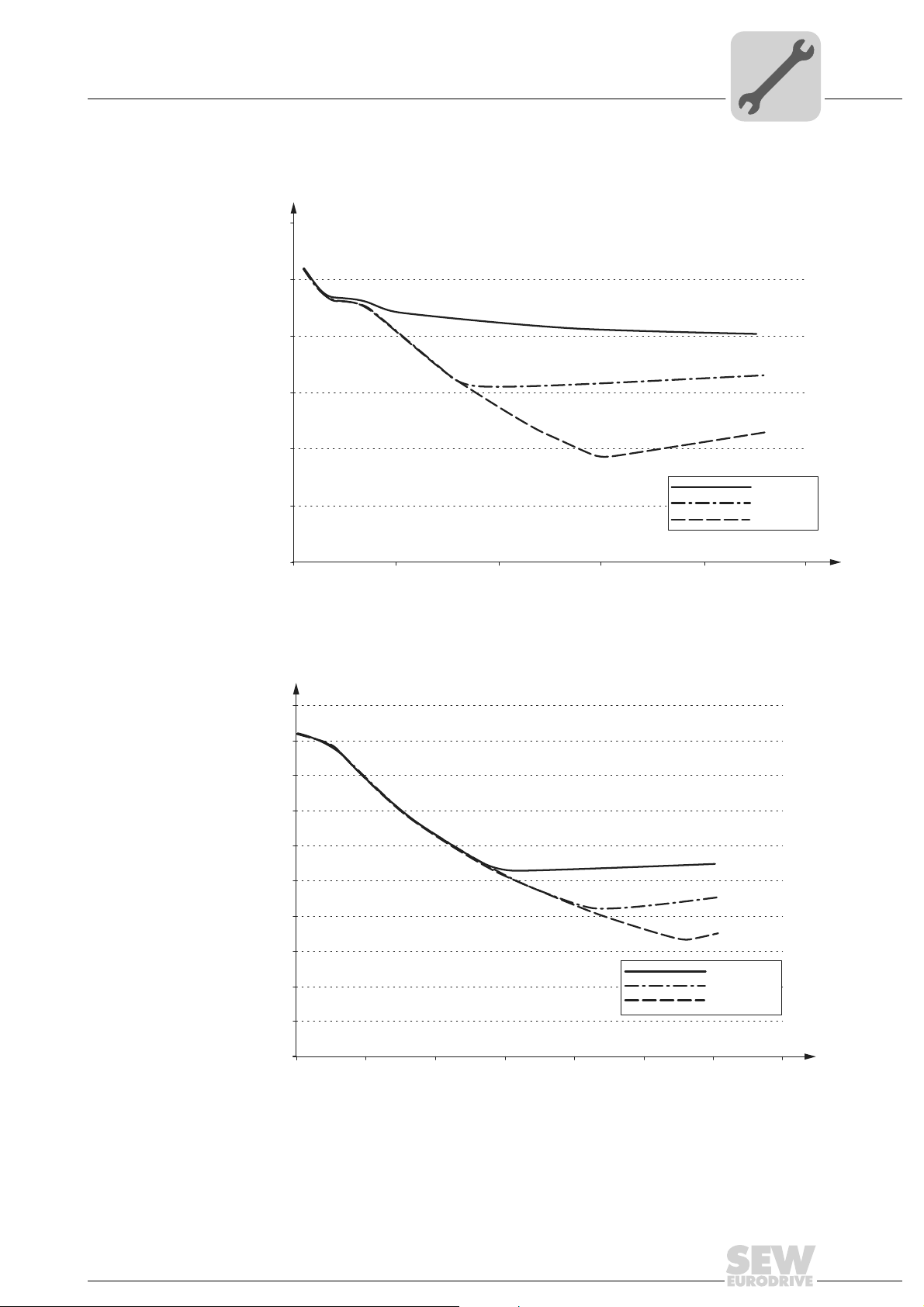

VARIMOT® D16

n [1/min]

FR [N]

0

500

1000

1500

2000

2500

300 600 900 1200 1500 1800

DT71D4

DT80K4

DT80N4

Installation

Permitted overhung loads without primary gear unit

FR [N]

4000

3500

3000

2500

2000

1500

1000

500

0

300 600 900 1200 1500 1800

VARIMOT® D26

51908AXX

DV100M4

DT90L4

DT90S4

n [1/min]

51909AXX

14

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

Installation

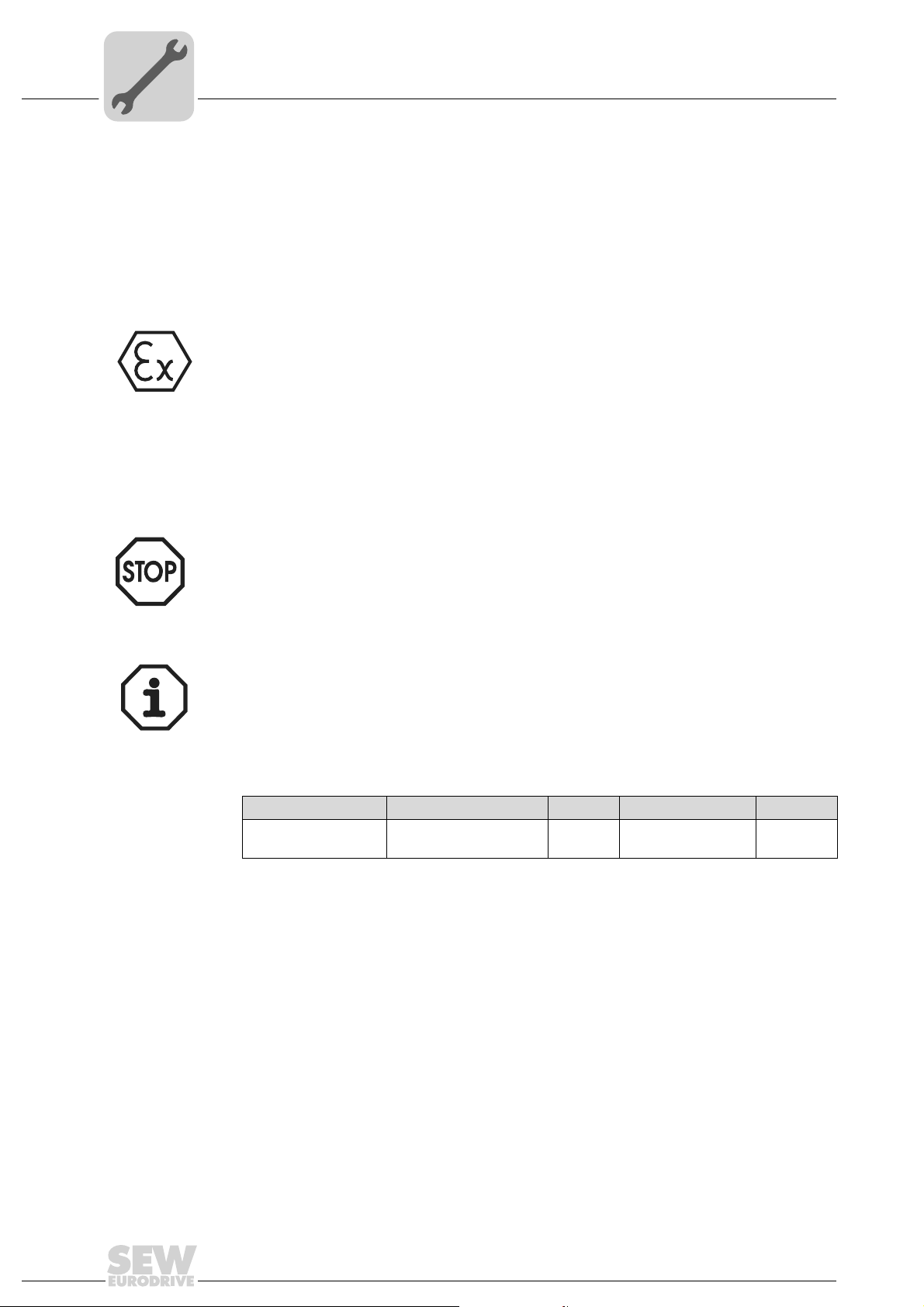

FR [N]

VARIMOT® D36

n [1/min]

0

1000

2000

3000

4000

5000

6000

300 600 900 1200

1500

1800

DV100L4

DV112M4

DV132S4

[

]

Permitted overhung loads without primary gear unit

4

FR [N]

10000

9000

8000

7000

6000

5000

4000

3000

2000

1000

0

400 600 800 1000 1200 1400 1600 1800

VARIMOT® D46

DV132M4

DV132ML4

DV160M4

51911AXX

1/min

n

51912AXX

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

15

4

4.4 Before you begin

Installation

Before you begin

The drive

may only be

installed if

• The information on the nameplate of the drive matches the approved on-site explosion application range (equipment group, category, zone, temperature class or maximum surface temperature).

• The information on the nameplate of the drive matches the voltage supply system.

• The drive is undamaged (no damage caused by transportation or storage).

• It is certain that the following requirements have been met:

• Ambient temperature between –20 °C (–4 °F) and +40 °C (+104 F°)

• No oils, acids, gas, vapors, radiation, potentially explosive atmospheres, etc.

• Enclosure has been verified.

4.5 Preliminary work

Variable speed

gear units

Risk of material damage

Do not let the solvent come into contact with the sealing lips of the oil seals or on

the wide V-belt.

The output shafts and flange surfaces must be thoroughly cleaned of anti-corrosion

agents, contamination or such (use a commercially available solvent).

Anti-friction

bearing grease

Please note:

• The service life of the lubricant in the bearings is reduced if the unit is stored for

à 1 year.

Ambient temperature Base Original filling Brand

Gear unit anti-friction

bearing

–20 °C (–4 °F) to +40 °C

(+104 °F)

Synthetic Mobiltemp SHC 100 Mobil

16

Operating Instructions – Explosion-Proof VARIMOT® Variable Speed Gear Units and Accessories

Loading...

Loading...