SEW-Eurodrive DFS Series, CFM71M, CFM71S, CFM Series, CFM90S Operating Instructions Manual

...

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Drive Technology \ Drive Automation \ System Integration \ Services

DFS/CFM Synchronous Servomotors

Edition 11/2008

Operating Instructions

11354313 / EN

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SEW-EURODRIVE – Driving the world

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Contents

Contents

1 General Notes...................................................................................................... 5

1.1 How to use the operating instructions......................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.3 Rights to claim under limited warranty ........................................................ 6

1.4 Exclusion of liability..................................................................................... 6

2 Safety Notes ........................................................................................................ 7

2.1 General information .................................................................................... 7

2.2 Target group ............................................................................................... 8

2.3 Designated use ........................................................................................... 8

2.4 Other applicable documentation ................................................................. 9

2.5 Transportation/storage................................................................................ 9

2.6 Installation/assembly................................................................................... 9

2.7 Electrical installation ................................................................................. 10

2.8 Startup/operation ...................................................................................... 10

2.9 Inspection/maintenance ............................................................................ 10

2.10 Disposal .................................................................................................... 10

3 Motor Structure ................................................................................................. 11

3.1 DFS synchronous servomotor – general structure ................................... 11

3.2 CFM synchronous servomotor – general structure................................... 12

3.3 Nameplate, unit designation and serial number........................................ 13

4 Mechanical Installation..................................................................................... 17

4.1 Required tools/resources .......................................................................... 17

4.2 Before you begin....................................................................................... 17

4.3 Preliminary work ....................................................................................... 17

4.4 Installing the motor.................................................................................... 19

4.5 Mounting tolerances.................................................................................. 20

5 Electrical Installation ........................................................................................ 21

5.1 Assembling the connector......................................................................... 21

5.2 Wiring notes .............................................................................................. 21

5.3 Connecting the motor and encoder system using SM../SB..

plug connectors......................................................................................... 22

5.4 Dimensioning the cable cross section....................................................... 23

5.5 Power cables for DFS motors ................................................................... 27

5.6 Power cables for CFM motors .................................................................. 32

5.7 Feedback cable for resolver...................................................................... 41

5.8 Feedback cable for HIPERFACE

5.9 Forced cooling fan cable........................................................................... 56

5.10 Cable specification of motor cables for DFS and CFM motors ................. 58

5.11 Cable specification of feedback cables for DFS and CFM motors............ 62

5.12 Connecting the motor via the terminal box ............................................... 64

5.13 Connecting the BR brake (CFM motor) .................................................... 69

5.14 Connecting the B brake (DFS56 motor).................................................... 80

5.15 Accessory equipment................................................................................ 84

®

encoders............................................ 47

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Contents

6 Startup................................................................................................................ 90

6.1 Prerequisites for startup............................................................................ 90

7 Malfunctions ...................................................................................................... 91

7.1 Motor malfunctions.................................................................................... 91

7.2 Malfunctions when operated with a servo inverter.................................... 91

7.3 Brake malfunctions .................................................................................. 92

8 Inspection/Maintenance ................................................................................... 93

8.1 Safety notes regarding inspection/maintenance ....................................... 93

8.2 Inspection intervals ................................................................................... 94

8.3 Inspection work for the B brake (DFS)...................................................... 94

8.4 Inspection work for the B brake (CFM) ..................................................... 95

9 Technical Data................................................................................................. 100

9.1 Main technical data of the servomotors .................................................. 100

9.2 Plug connectors ...................................................................................... 105

9.3 Connection with terminal box.................................................................. 105

9.4 Work done, braking torques.................................................................... 106

9.5 Brake coil resistance............................................................................... 106

9.6 BR brake – operating currents ................................................................ 107

10 Appendix.......................................................................................................... 108

10.1 Crimping tools ......................................................................................... 108

10.2 SM11/SB11 power connector assembly (for DFS56 servomotor) .......... 111

10.3 Assembly of SM5./SM6. and SB5./SB6. power connectors.................... 114

10.4 Assembly of signal plug connectors (resolver/HIPERFACE

10.5 Wiring diagrams for DFS/CFM synchronous servomotors...................... 118

10.6 Wiring diagram for CFM motors with power connector ........................... 119

10.7 Wiring diagram for CFM motors with signal connector ........................... 119

10.8 Wiring diagram for CFM motors with terminal box.................................. 121

10.9 Wiring diagram for DFS motors with power connector ........................... 123

10.10 Wiring diagram for DFS motors with signal connector............................ 123

10.11 Wiring diagram for DFS motors with terminal box .................................. 125

10.12 Wiring diagram for VR forced cooling fan ............................................... 127

®

)................ 115

11 Address List .................................................................................................... 128

Index................................................................................................................. 137

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions – DFS/CFM Synchronous Servomotors

How to use the operating instructions

1 General Notes

1.1 How to use the operating instructions

The operating instructions are an integral part of the product and contain important information for operation and service. The operating instructions are written for all employees who assemble, install, startup, and service this product.

The operating instructions must be accessible and legible. Make sure that persons responsible for the system and its operation, as well as persons who work independently

on the unit, have read through the operating instructions carefully and understood them.

Consult SEW-EURODRIVE if you have any questions or if you require further information.

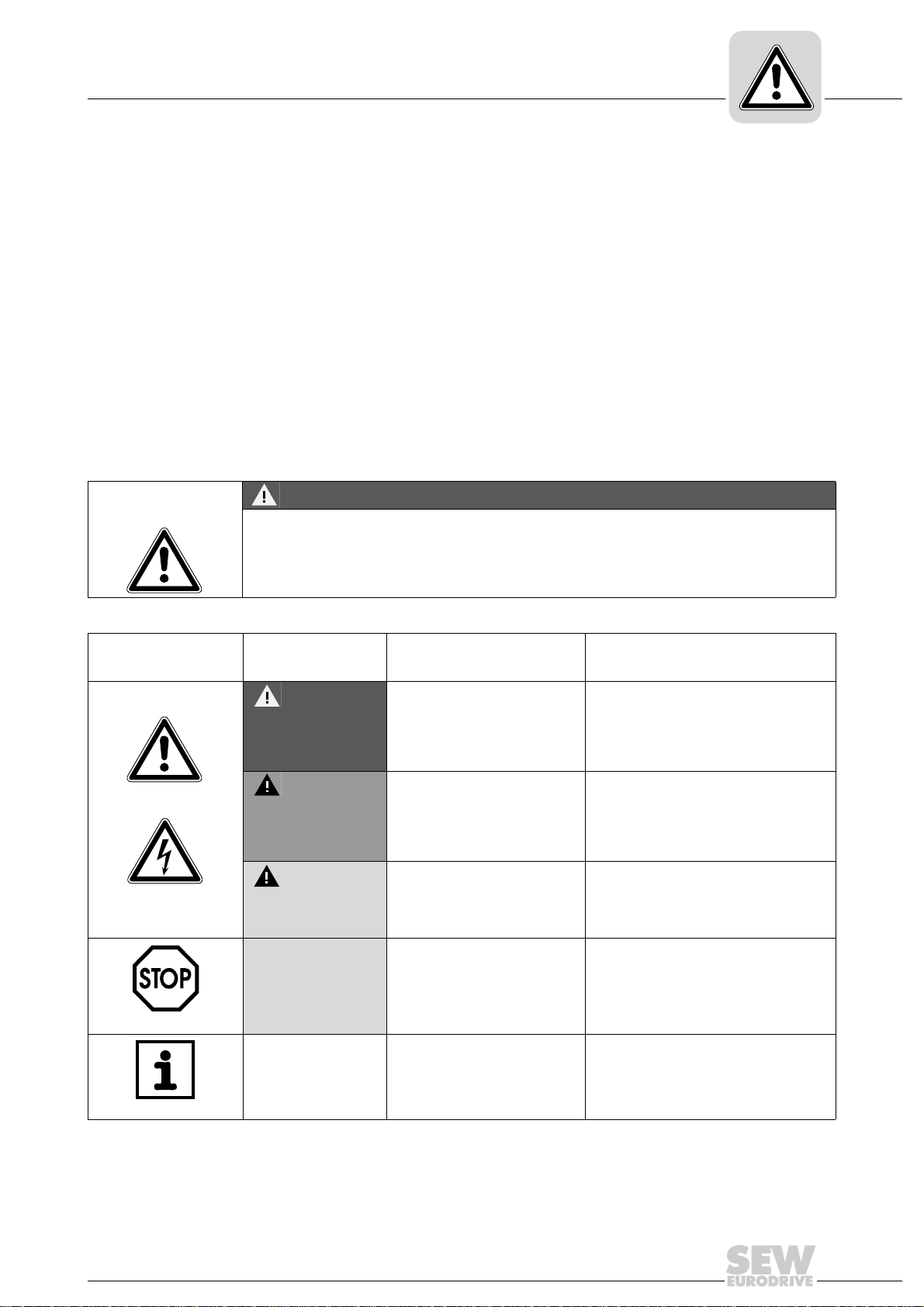

1.2 Structure of the safety notes

The safety notes in these operating instructions are structured as follows:

Symbol SIGNAL WORD

Nature and source of hazard.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the hazard.

General Notes

1

Symbol Signal word Meaning Consequences if

disregarded

Example:

General danger

Specific danger,

e.g. electric shock

DANGER Imminent danger Severe or fatal injuries

WARNING Possible hazardous situation Severe or fatal injuries

CAUTION Possible hazardous situation Minor injuries

NOTICE Potential damage to property. Damage to the drive system or its environ-

ment

TIP Useful information or tip.

Simplifies handling of the drive

system.

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

1

General Notes

Rights to claim under limited warranty

1.3 Rights to claim under limited warranty

Adhering to the operating instructions is a prerequisite for fault-free operation and the

fulfillment of any right to claim under warranty. Therefore, read the operating instructions

before you start working with the unit.

1.4 Exclusion of liability

You must comply with the information contained in these operating instructions to ensure safe operation of the electric motors and to achieve the specified product characteristics and performance features. SEW-EURODRIVE does not assume liability for injury to persons or damage to equipment or property resulting from non-observance of

these operating instructions. In such cases, any liability for defects is excluded.

6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions – DFS/CFM Synchronous Servomotors

2 Safety Notes

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

observed. Make sure that persons responsible for the plant and its operation, as well as

persons who work independently on the unit, have read through the operating instructions carefully and understood them. If you are unclear about any of the information in

this documentation, please contact SEW-EURODRIVE.

2.1 General information

DANGER

Servomotors, gearmotors and gear units may have live, uninsulated, and sometimes

moving or rotating parts as well as hot surfaces during operation.

Severe or fatal injuries.

• All work related to transportation, storage, setup/mounting, connection, startup,

maintenance and repair may only be carried out by qualified personnel, in strict

observation of:

– The relevant detailed operating instructions

– Warning and safety signs on the motor/gearmotor All other project planning

documents, operating instructions and wiring diagrams belonging to the drive

– The specific regulations and requirements for the system

– The national/regional regulations governing safety and the prevention of

accidents

• Never install damaged products

• Immediately report any damages to the shipping company

Safety Notes

General information

2

Removing the required protection cover or the housing without authorization, improper

use as well as incorrect installation or operation may result in severe injuries to persons

or damage to property.

Refer to the documentation for additional information.

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

2

2.2 Target group

Safety Notes

Target group

Any mechanical work may only be performed by adequately qualified personnel. Qualified personnel in this context are persons who are familiar with the setup, mechanical

installation, trouble shooting and maintenance for this product. Further, they are qualified as follows:

• Completed apprenticeship in the field of mechanical engineering (e.g. mechanic or

mechatronic technician).

• They are familiar with these operating instructions.

Any electric work may only be performed by adequately qualified personnel. Qualified

electricians in this context are persons who are familiar with the electronic installation,

startup, trouble shooting and maintenance for this product. Further, they are qualified as

follows:

• Completed apprenticeship in the field of electrical engineering (e.g. electric or

mechatronic technician).

• They are familiar with these operating instructions.

Any activities regarding transportation, storage, operation, and disposal must be carried

out by persons who have been instructed appropriately.

2.3 Designated use

The designated use refers to the procedure specified in the operating instructions.

DFS/CMP synchronous servomotors are drive motors designed for use in industrial and

commercial systems. Motor utilization other than that specified (refer to nameplate) and

areas of application other than industrial and commercial systems can only be used after

consultation with SEW-EURODRIVE.

The DFS/CFM synchronous servomotors meet the requirements stipulated in the low

voltage guideline 2006/95/EC. Do not take the unit into operation until you have established that the end product complies with the Machinery Directive 98/37/EC.

You must observe the technical data and information on the connection requirements

as provided on the nameplate and in the documentation.

The following applications are prohibited unless the unit is explicitly designed for such

use:

• Use in potentially explosive atmospheres

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions – DFS/CFM Synchronous Servomotors

2.4 Other applicable documentation

The following publications and documents have to be observed as well:

• "SPIROPLAN

• "Low Backlash Geared Servomotors (BSF.., PSF..)" catalog

• Operating instructions of the inverter for motors powered by inverters

• Corresponding wiring diagrams

®

W Gear Units, R..7, F..7, K..7, S..7 Series" operating instructions

2.5 Transportation/storage

Follow the instructions on transportation, storage and proper handling.

Immediately upon receipt, inspect the shipment for any damage that may have occurred

during transportation. Inform the shipping company immediately in the event of damage.

If you notice any transport damage, do not startup the motor, consult the

SEW-EURODRIVE Service.

Remove securing devices used for transportation prior to startup.

Safety Notes

Other applicable documentation

2

Tighten installed transportation eyebolts. They are designed to only carry the weight of

the motor/gearmotor; do not attach any additional loads.

The installed lifting eyebolts comply with DIN 580. The loads and regulations specified

in this standard must always be observed. If the gearmotor has 2 suspension eye lugs

or lifting eyebolts, then you should also use both suspension eye lugs for attaching

transport ropes. In this case, the tension force vector of the slings must not exceed a 45°

angle according to DIN 580.

Store the servomotor in a dry, dust-free environment if it is not to be installed straight

away.

2.6 Installation/assembly

Comply with the instructions in section 4, "Mechanical Installation" and section 5, "Electrical Installation".

The units must be installed and cooled according to the regulations and specifications

in the corresponding documentation.

Protect the synchronous servomotors from excessive strain. Ensure that components

are not deformed, particularly during transportation and handling.

The following applications are prohibited unless the unit is explicitly designed for such

use:

• Use in potentially explosive atmospheres

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

2

Safety Notes

Electrical installation

2.7 Electrical installation

Perform electrical installation according to the respective applicable laws, regulations

and standards (e.g. cable cross sections, fusing, protective conductor connection). For

any additional information, refer to the applicable documentation.

Observe the wiring information and differing data on the nameplate.

Observe the notes in sec. 5, "Electrical Installation".

2.8 Startup/operation

Whenever changes to normal operation occur, such as increased temperatures, noise,

vibrations, determine the cause and consult the manufacturer.

Observe the notes in section 6, "Startup".

2.9 Inspection/maintenance

2.10 Disposal

Observe the notes in section 8, "Inspection/Maintenance".

This product consists of:

•Iron

•Aluminum

• Copper

• Plastic

• Electronic components

Dispose the individual components in accordance with the material structure and

the regulations in force.

10

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

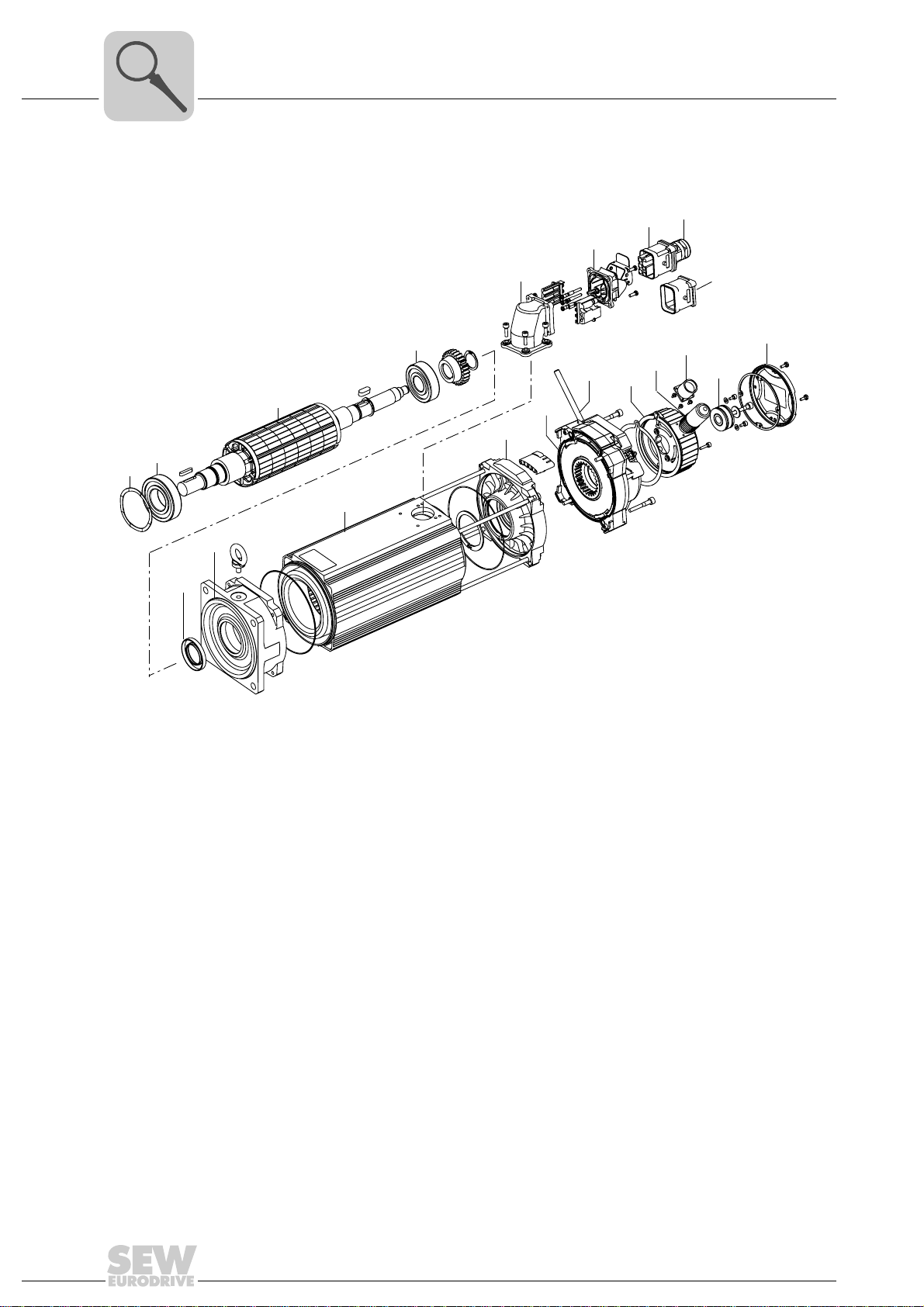

DFS synchronous servomotor – general structure

3 Motor Structure

TIP

The following illustrations are intended to explain the general structure. They are to

facilitate the assignment of components to the spare parts list. Deviations are possible

depending on the motor size and version!

3.1 DFS synchronous servomotor – general structure

Motor Structure

3

[316] [321] [1] [10][7] [11] [304]

[1] Rotor [304] Housing cover

[7] Flanged endshield [305] Resolver

[10] Retaining ring [313] Locking plate

[11] Grooved ball bearing [314] Pin contact power/brake

[16] Stator [316] Power connector, complete

[42] B-side endshield [318] Flange socket complete

[44] Grooved ball bearing [319] Pin contact signal

[106] Oil seal without key [321] Signal connector, complete

[220] Absolute encoder [550] Complete brake

[313]

[314]

[318]

[319]

[305][42][44][550][16][106]

AS1H / ES1H

[220]

[304]

413859723

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

3

Motor Structure

CFM synchronous servomotor – general structure

3.2 CFM synchronous servomotor – general structure

[313]

[316]

[317]

[105]

[11]

[106]

[7]

[1]

[16]

[44]

[42]

[312]

[550]

[660]

[737]

[321]

[327]

[304]

[318]

[305]

413861259

[1] Rotor [312] Connector housing

[7] Flanged endshield [313] Locking plate

[11] Grooved ball bearing [316] Power connector, complete

[16] Stator [317] Socket contact

[42] B-side endshield [318] Flange socket complete

[44] Grooved ball bearing [321] Signal connector, complete

[105] Shim washer [327] Cover

[106] Oil seal [550] Complete brake

[304] Housing cover [660] Release lever

[305] Resolver [737] Encoder housing

12

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Nameplate, unit designation and serial number

3.3 Nameplate, unit designation and serial number

3.3.1 Nameplate

Example: CFM 71M /BR /TF /RH1M synchronous brake motor

76646 Bruchsal/Germany

Typ

CFM71M/BR/TF/RH1L/SB50

Nr.

01.1234567890.0001.07

M

Motor

0

n

N

U

Sys

Bremse

Getriebe

M

i

a pk

:1

Nm

6,5

r/min

3000

V

400

V

230

IM

B5

Nm

I

max

Iso.Kl.

Nm

14

n

a pk

I

0

A

4,3

17,2

Permanentmagnet

A

155 (F)

Gleichrichter

/

n

BME

e pk

Motor Structure

3 IEC60034

IP

65

˚C

-20...+40

r/min

13,0

kg

3

0199 081 0.13

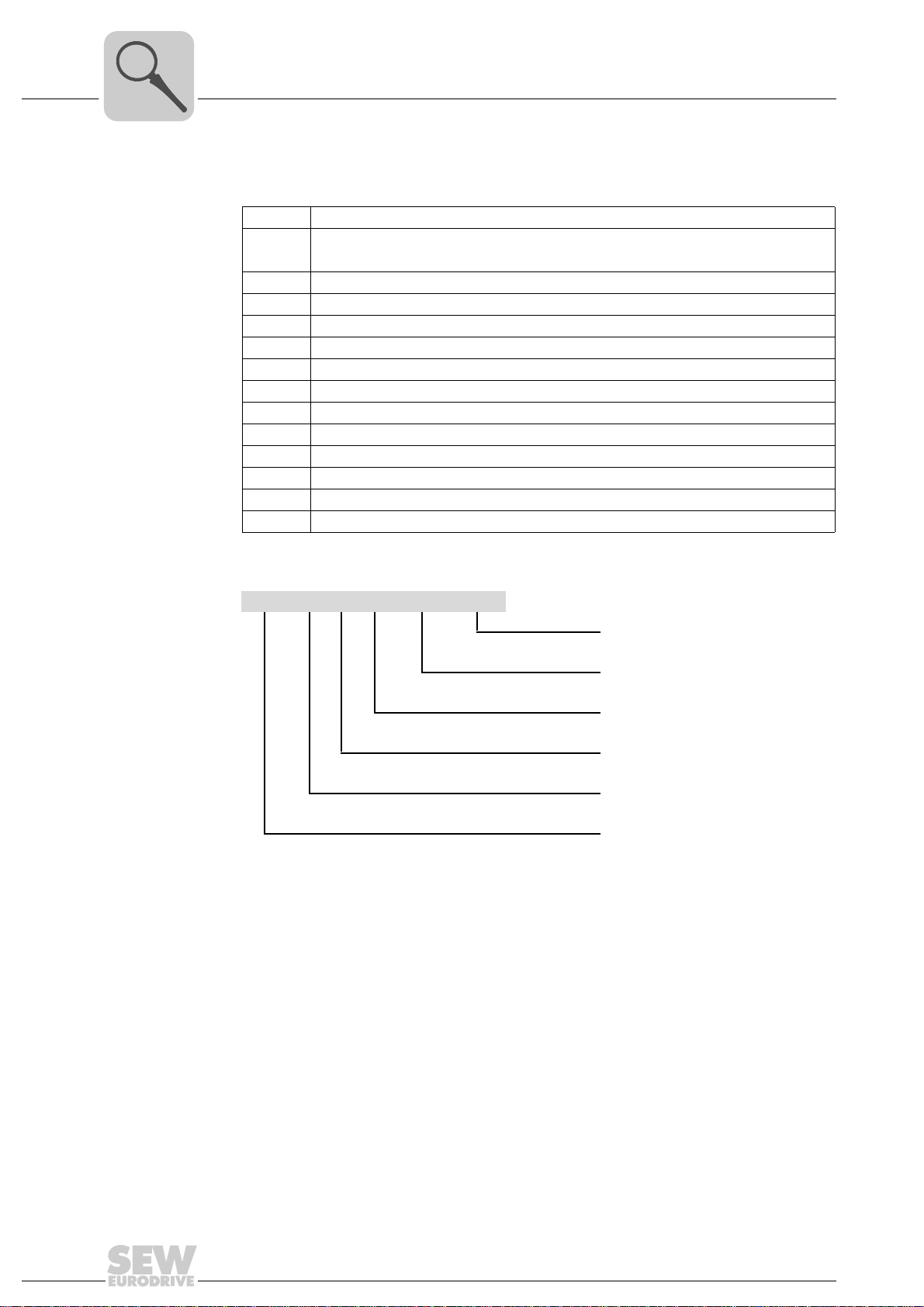

3.3.2 DFS/CFM unit designations

Synchronous servomotors

DS... Motor for mounting to size 56 gear units

DFS... Size 56 in flange-mounted version

CM... Motor for mounting to gear units of sizes 71/90/112

CFM... Sizes 71/90/112 in flange-mounted version

Standard equipment for synchronous servomotors

/SM.0 Motor plug connector (socket on motor end only)

/SB.0 Plug connector motor + brake (socket on motor end only)

/RH1M Resolver

/RH1L Resolver for brake motors

/TF Thermistor (PTC resistor)

/KTY Temperature sensor

Umrichterbetrieb

Made in Germany

685748747

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

3

Motor Structure

Nameplate, unit designation and serial number

Synchronous servomotor options

/B Size 56 disk brake

/BR Size 71/90/112 disk brake

/HR . . manual brake release with automatic re-engaging function sizes 71/90/112

/SM.. Motor plug connector with code number for size and connection cross section

SB.. Plug connector for motor + brake with code number for size and connection cross section

®

/ES1H HIPERFACE

/AS1H HIPERFACE

/AV1H HIPERFACE

/AV1Y Multi-turn SSI encoder, solid shaft, size 56

/AK0H Multi-turn SSI encoder, solid shaft, size 56

/EK0H HIPERFACE

/VR Forced cooling fan

/KK Terminal box

/KK5 Terminal box for radial encoder

/KK6 Terminal box for axial encoder

single-turn encoder, spreadshaft, size 56/71/90/112

®

multi-turn encoder, spreadshaft, size 56/71/90/112

®

multi-turn encoder, solid shaft, size 56/71/90/112

®

single-turn encoder, spread shaft, size 56

3.3.3 Sample unit designation: DFS synchronous brake motor

DFS 56L /B /TF /RH1M /SM11

Plug connector (motor option)

Resolver as standard equipment

TF thermistor as standard equipment

Brake (motor option)

Size 56L

Flange-mounted motor DFS series

14

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Nameplate, unit designation and serial number

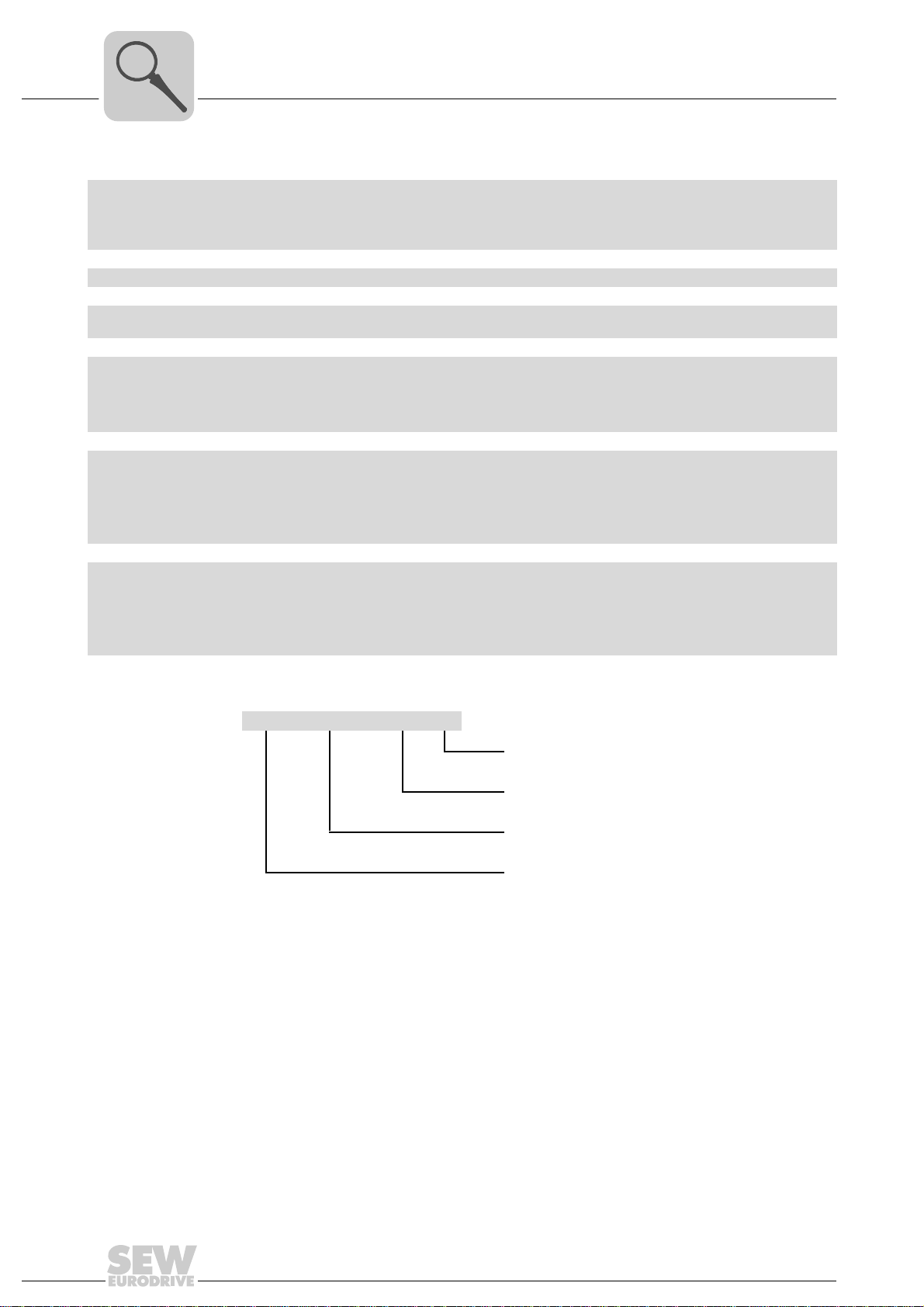

3.3.4 Sample unit designation: CFM synchronous brake motor

CFM 112S /BR /TF /AS1H /SB50

3.3.5 Scope of delivery for SEW-EURODRIVE motors

The scope of delivery for SEW-EURODRIVE servomotors includes for standard mo-

tors:

Motor Structure

Plug connector as standard

Motor option HIPERFACE® multi-turn

encoder

TF thermistor as standard equipment

Brake (motor option)

Size 112S

Flange-mounted motor CFM series

3

Delivery with order confirmation

Delivery with drive 1 x Motor according to order confirmation

Pre-fabricated cable 1 x Bag with loose parts including conductor end sleeves and cable lugs for connection to

Forced cooling fan 1 x Power connector

Plug connector 1 x Encoder connector (radial or axial)

1 x Operating instructions in the language of the corresponding country, if requested. When ordering

several servo gear units, the customer can reduce the number of operating instructions.

1 x Safety notes for startup, if requested

1 x Spare parts list if requested

SEW-EURODRIVE inverters.

1 x Power socket

4 x Hex head screw

4 x Square nut

10 x Crimp socket contacts for encoder connector for core cross sections of 0.25 mm2 to 0.5 mm2.

1 x SM50 mating connector for motor power cable

4 x Crimp socket contacts for power connection for core cross sections of 1.5, 2.5, 4, 6 or 10 mm

2

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

15

3

Motor Structure

Nameplate, unit designation and serial number

The scope of delivery for SEW-EURODRIVE servomotors includes for brakemotors:

Delivery with order confirmation

Delivery with drive 1 x Motor according to order confirmation

Pre-fabricated cable 1 x Bag with loose parts including conductor end sleeves and cable lugs for connection to

Brake 1 x AC-operated BME brake rectifier for DIN rail mounting, or alternatively:

Forced cooling fan 1 x Power connector

Plug connector 1 x Encoder connector (radial or axial)

1 x Operating instructions in the language of the corresponding country, if requested. When ordering

several servo gear units, the customer can reduce the number of operating instructions.

1 x Safety notes for startup, if requested

1 x Spare parts list if requested

SEW-EURODRIVE inverters

- BMP, BMH or BMK brake rectifier

- BSG brake control unit at a voltage of DC 24 V

1 x Manual release lever if brake with manual release was ordered

1 x Power socket

4 x Hex head screw

4 x Square nut

4 x Mounting bracket

10 x Crimp socket contacts for encoder connector for core cross sections of 0.25 mm2 to 0.5 mm

1 x SB50 mating connector for motor power and brake cable

4 x Crimp socket contacts for power connection for core cross sections of 1.5, 2.5, 4, 6 or 10 mm

3 x Crimp socket contacts for brake connection for core cross sections of 1 mm2 or 1.5 mm

2

2

2

3.3.6 Example: Serial number

01. 301234568. 0001. 03

Final two digits of the year of manufacture

Unit serial number (4 digits)

Order number (10 digits)

Sales organization

16

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4 Mechanical Installation

4.1 Required tools/resources

• Standard tools

• Mounting device

• Operation with conductor end sleeves: Crimping tool and conductor end sleeves

• Crimping tool for plug connectors

• Removal tool

4.2 Before you begin

The drive may only be installed if

• The specifications on the drive's nameplate and/or the output voltage of the

frequency inverter match the voltage supply system

• The drive is undamaged (no damage caused by transportation or storage).

Mechanical Installation

Required tools/resources

4

• You are certain that the following requirements have been fulfilled:

– Ambient temperature between –20 °C and +40 °C

– No oil, acid, gas, vapors, radiation, etc.

– Installation altitude max. 1000 m above sea level

– Special designs: Drive configured in accordance with the ambient conditions

4.3 Preliminary work

Motor shaft ends must be thoroughly cleaned of anti-corrosion agents, contamination or

similar (use a commercially available solvent). Make sure that the solvent does not come

into contact with the bearing or sealing rings as it may damage the material.

NOTICE

The bearing and the sealing rings can be damaged if exposed to solvents.

Potential damage to property.

• Protect the bearing and sealing rings from exposure to solvents.

4.3.1 Installation after extended storage

• Note that the service life of the lubricant in the ball bearings is reduced by 10% per

year after the first year of storage.

• Check whether the motor has absorbed moisture as a result of being stored for a long

time. Measure the insulation resistance for this purpose (measuring voltage

DC 500 V).

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

4

Mechanical Installation

Preliminary work

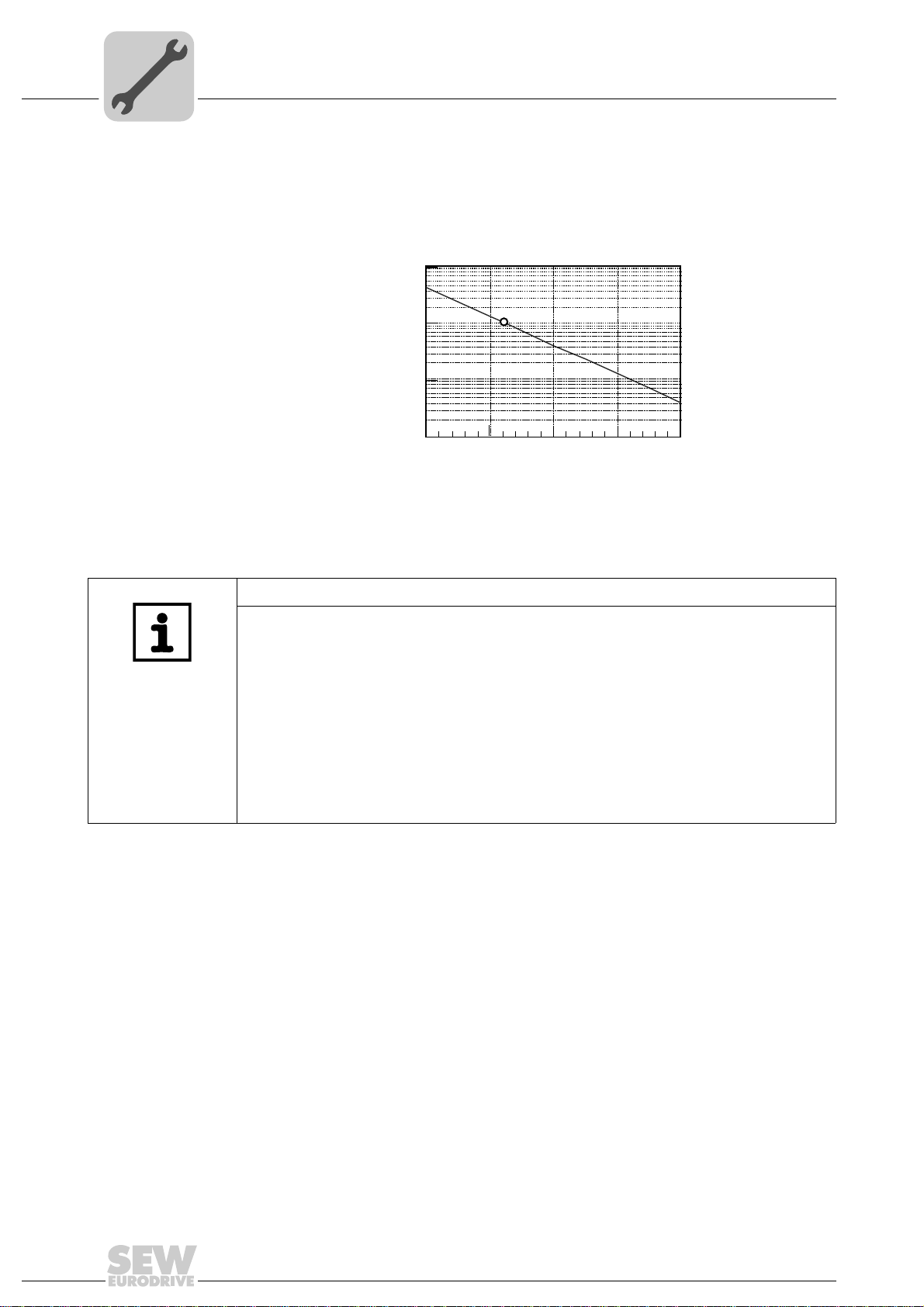

The insulation resistance (see following figure) varies greatly depending on the temperature. The motor must be dried if the insulation resistance is not adequate.

The following figure shows the insulation resistance depending on the temperature.

[MΩ]

100

4.3.2 Drying the motor

TIP

Insulation resistance too low:

→ Servomotor has absorbed moisture

Measure:

• Use hot air to heat up the motor.

• Open the motor compartment enough for moisture to escape from the inside.

Next check whether:

• The wiring space is dry and clean.

• The connections and fastening parts are free from corrosion.

• The joint seal is functioning.

• The cable glands are tight, otherwise clean or replace them.

10

0,1

[1]

1

0

20

40

60

80

[°C]

413914507

18

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4.4 Installing the motor

NOTICE

Improper mounting may result in damages to the motor.

Potential damage to property.

• Only install the motor in the specified mounting position on a level, vibration-free,

and torsionally rigid support structure.

• Align the motor and the driven machine carefully to avoid placing any unacceptable

strain on the output shafts.

• Observe permitted overhung and axial loads → "Low Backlash Servo Gearmotors

(BSF.., PSF..)" catalog.

• Do not butt or hammer the shaft end.

NOTICE

Vertical designs with VR forced-cooling fan can get damaged by foreign objects or

moisture.

Potential damage to property.

• Protect vertical designs with VR forced-cooling fan with corresponding covers.

Mechanical Installation

Installing the motor

4

If a forced cooling fan is used, ensure there is sufficient clearance around the unit to

allow for adequate cooling. Make sure that the unit does not suck in hot outgoing air from

other units.

Components with a keyway to be mounted belatedly on the shaft must be balanced

using a half key. Motor shafts may be balanced with a half key (vibration level "N" to

EN/IEC 600 34). You must not operate the motor without a key.

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

4

Mechanical Installation

Mounting tolerances

4.4.1 Installation in damp locations or in the open

• Try to arrange the motor and encoder connection so that the connector cables do not

point upwards.

• Coat the threads of the cable glands and filler plugs with sealing compound and

tighten them properly. Then coat them again.

• Clean the sealing surfaces of the connector (motor and/or encoder connection)

before reassembly.

• Replace any brittle seals.

• If necessary, restore the anticorrosive paint coat.

• Check that the degree of protection is maintained.

4.5 Mounting tolerances

Shaft end Flanges

Diameter tolerance according to EN 50347

•ISO k6

• Center bore in accordance with DIN 332, shape

DR..

Centering shoulder tolerance in accordance with

EN 50347

•ISO j6

20

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5 Electrical Installation

DANGER

Risk of injury due to electric shock.

Severe or fatal injuries.

• It is essential to comply with the safety notes in section 2 during installation.

• Use switch contacts in utilization category AC-3 to EN 60947-4-1 for connecting

the motor and the brake.

• When motors are powered from inverters, you must adhere to the wiring

instructions issued by the inverter manufacturer.

• Observe the operating instructions for the servo inverter.

5.1 Assembling the connector

NOTICE

If the connector is tightened when it is installed in the wrong position, the insulator could

slip, causing irreparable damage.

Potential damage to property.

Note the following when plugging in the power and signal connectors:

• Check that the connector is installed in the correct position.

• Check that the detent on the connector is positioned correctly.

• Make sure that the connector lock can be turned without having to apply too much

force.

Electrical Installation

Assembling the connector

5

5.2 Wiring notes

5.2.1 Protection against interference by brake controllers

Do not route unshielded brake cables alongside switched-mode power cables, since

brake controllers may cause interference.

Switched-mode power cables include in particular:

• Output cables from frequency inverters and servo inverters, converters, soft start

units and brake units

• Supply cables to braking resistors and similar.

5.2.2 Thermal motor protection

Install the connecting lead of the TF/KTY separately from other power cables, maintaining a distance of at least 200 mm. Collective installation is only permitted if either the

TF / KTY cable or the power cable is shielded.

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

21

5

Electrical Installation

Connecting the motor and encoder system using SM../SB.. plug connectors

5.3 Connecting the motor and encoder system using SM../SB.. plug connectors

The DFS/CFM motors are supplied with the SM../SB.. plug connector system. In the

basic version, SEW-EURODRIVE delivers DFS/CFM motors with a flange socket on the

motor end and without mating connector. The encoder system is connected using a separate 12-pin round plug connector. The standard encoder cable entry is axial for the DFS

motor and radial for the CFM motor.

5.3.1 Cable cross section

Make sure that the type of cable complies with the applicable regulations. The rated currents are specified on the nameplate. The cable cross sections that can be used are

listed in the following table.

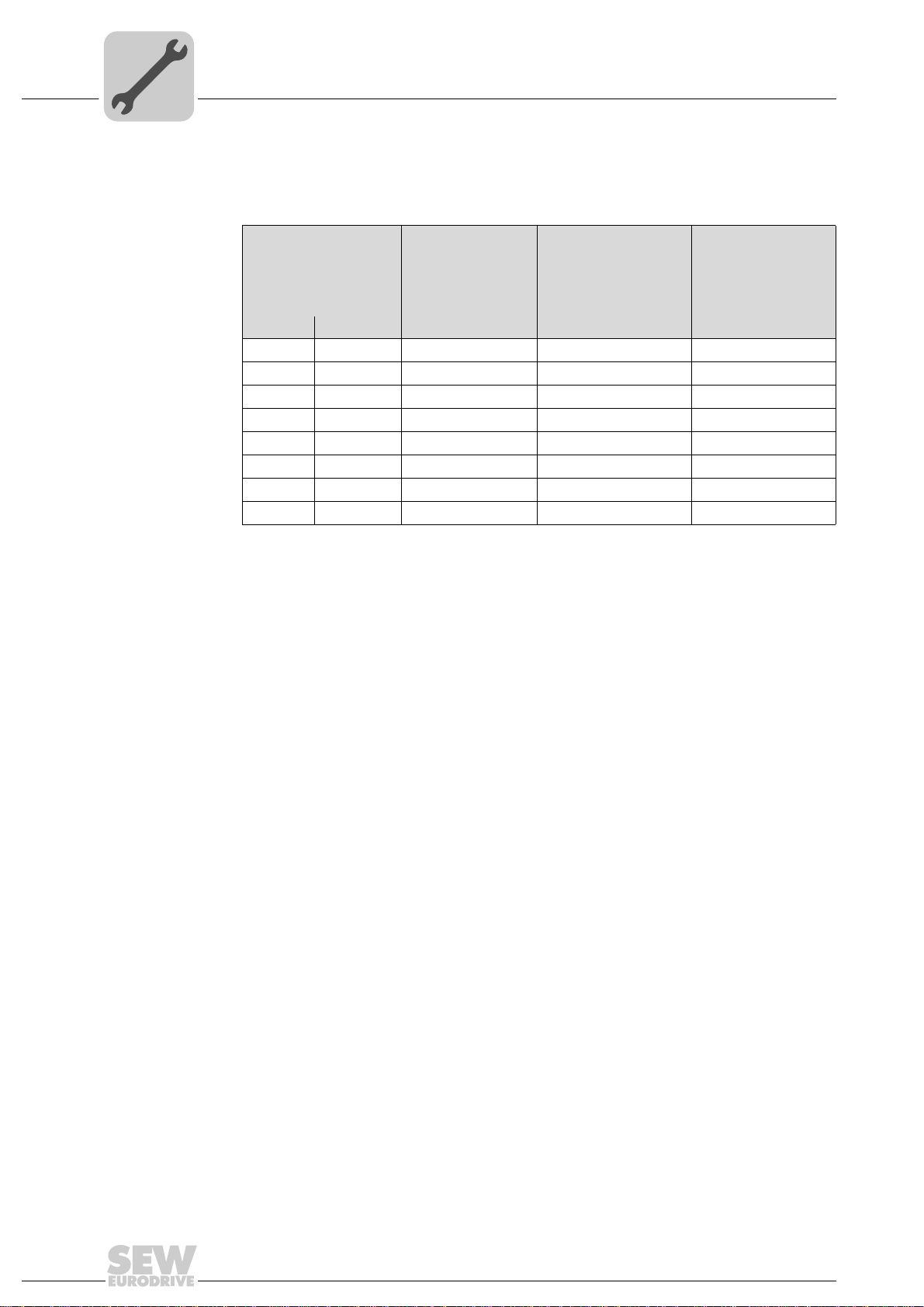

Typ e Cable type Cable cross section

[mm2] [AWG]

SM11/SM51/SM61

SM52/SM62 4 x 2.5 mm

SM54/SM64 4 x 4 mm

SM56/SM66 4 x 6 mm

SM59/SM69 4 x 10 mm

SB11

SB51/SB61 4 x 1.5 mm

SB52/SB62 4 x 2.5 mm

SB54/SB64 4 x 4 mm

SB56/SB66 4 x 6 mm

SB59/SB69 4 x 10 mm

Motor cable

Brakemotor cable

4 x 1.5 mm

4 x 1.5 mm

2

2

2

2

2

2

+ 2 x 1 mm

2

+ 3 x 1 mm

2

+ 3 x 1 mm

2

+ 3 x 1 mm

2

+ 3 x 1.5 mm

2

+ 3 x 1.5 mm

2

AWG 16

AWG 14

AWG 12

AWG 10

AWG 8

2

AWG 16 + AWG 18

2

AWG 16 + AWG 18

2

AWG 14 + AWG 18

AWG 12 + AWG 18

2

AWG 10 + AWG 16

2

AWG8 + AWG16

5.3.2 Prefabricated cables

Pre-fabricated cables are available from SEW-EURODRIVE to connect the SM../SB..

plug connector system. The core designation and contact assignment are listed in the

following tables.

Observe the following when you assemble the cables yourself:

• Section 10 describes the assembly of the SM1./SB1., SM5./SM6., SB5./SB6 power

connectors and the signal connector.

• The socket contacts for the motor connection are designed as crimp contacts. Only

use suitable tools for crimping.

• Strip the insulation of the leads according to section 10.

• Use suitable removal tools to remove incorrectly installed socket contacts.

• Install the insulator in the signal connectors on the motor end at "zero" degree (center

position). Observe this coding on the cable end.

• Cable relief according to EN 61984 and EN 60529 is influenced by the tightening

torque of the screw. The tightening torque must be matched to the cable.

22

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Dimensioning the cable cross section

5.4 Dimensioning the cable cross section

5.4.1 Cable dimensioning according to EN 60402

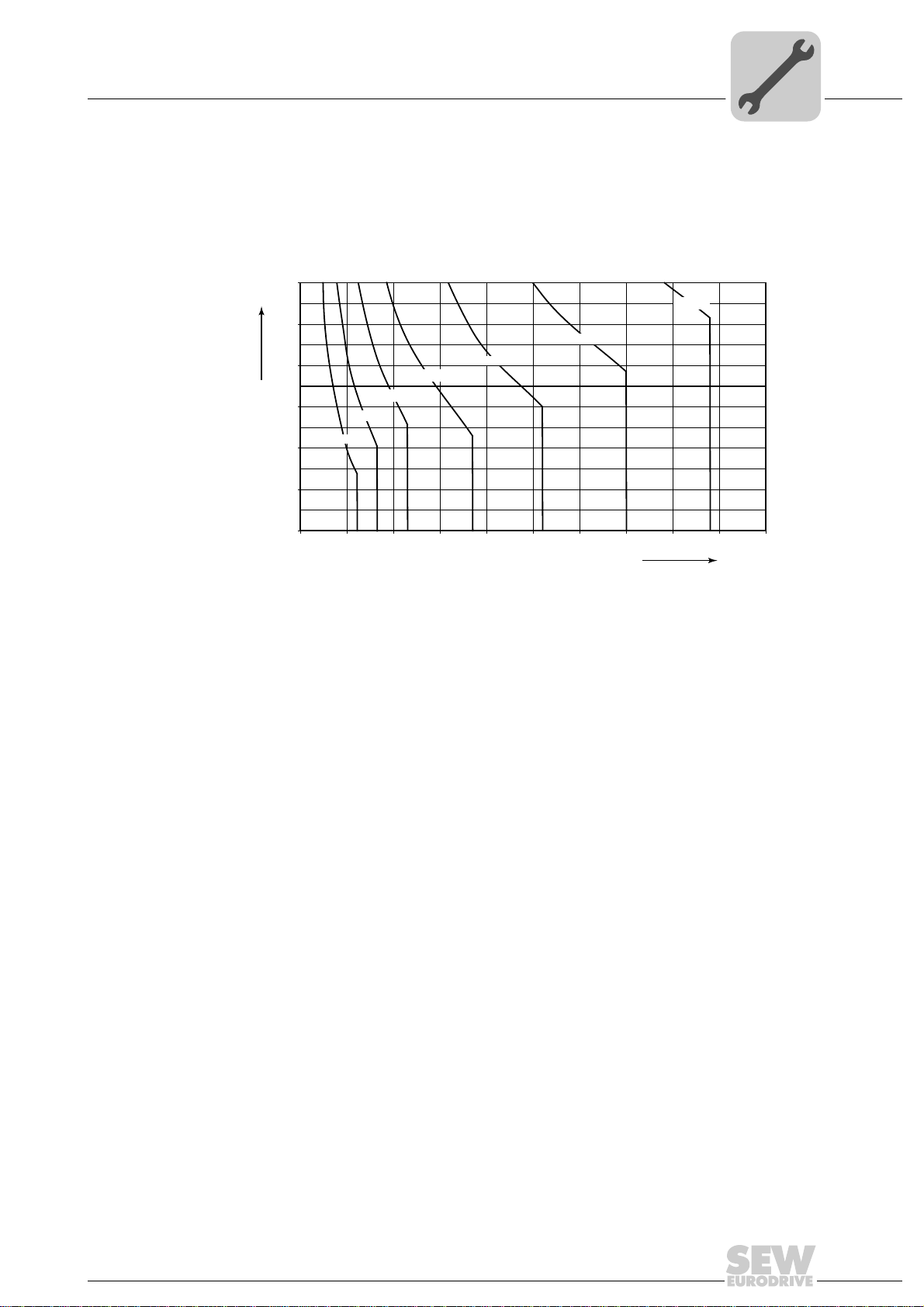

The following figure shows the minimum required cable cross section depending on

cable length l [m] and current I [A].

150

130

110

100

90

70

50

2,5 mm²

1,5 mm²

6 mm²

4 mm²

10 mm²

Electrical Installation

25 mm²

16 mm²

5

30

010 2030405060708090100

Hybrid cables with cross sections of 1.5 mm

dered from SEW-EURODRIVE.

I [A]

576701195

2

(AWG 16) to 10 mm2 (AWG 8) can be or-

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

23

5

5.4.2 Cable load table

Electrical Installation

Dimensioning the cable cross section

Cable load through current I in [A] according to EN 60204-1 table 5, ambient temperature 40 °C.

Triple-core, plas-

Cable cross section

[mm2] [AWG] [A] [A] [A]

1,5 AWG 16 12,2 15,2 16,1

2,5 AWG 14 16,5 21,0 22

4 AWG 12 23 28,0 30

6 AWG 10 29 36,0 37

10 AWG 8 40 50,0 52

16 AWG 6 53 66,0 70

25 AWG 4 67 84,0 88

35 AWG 2 83 104,0 114

tic-sheathed cable

in

Duct or cable

Triple-core, plastic-

sheathed cable on

top of each other on

wall

Triple-core, plastic-

sheathed cable

next to each other,

horizontal

These data are merely recommended values and are no substitute for the detailed

project planning of the cables depending on the concrete application considering the

applicable regulations.

Observe the voltage drop that occurs along the cable in particular with the DC 24 V

brake coil when dimensioning the cross sections for the brake cable. The accelerator

current is decisive for the calculation.

24

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Dimensioning the cable cross section

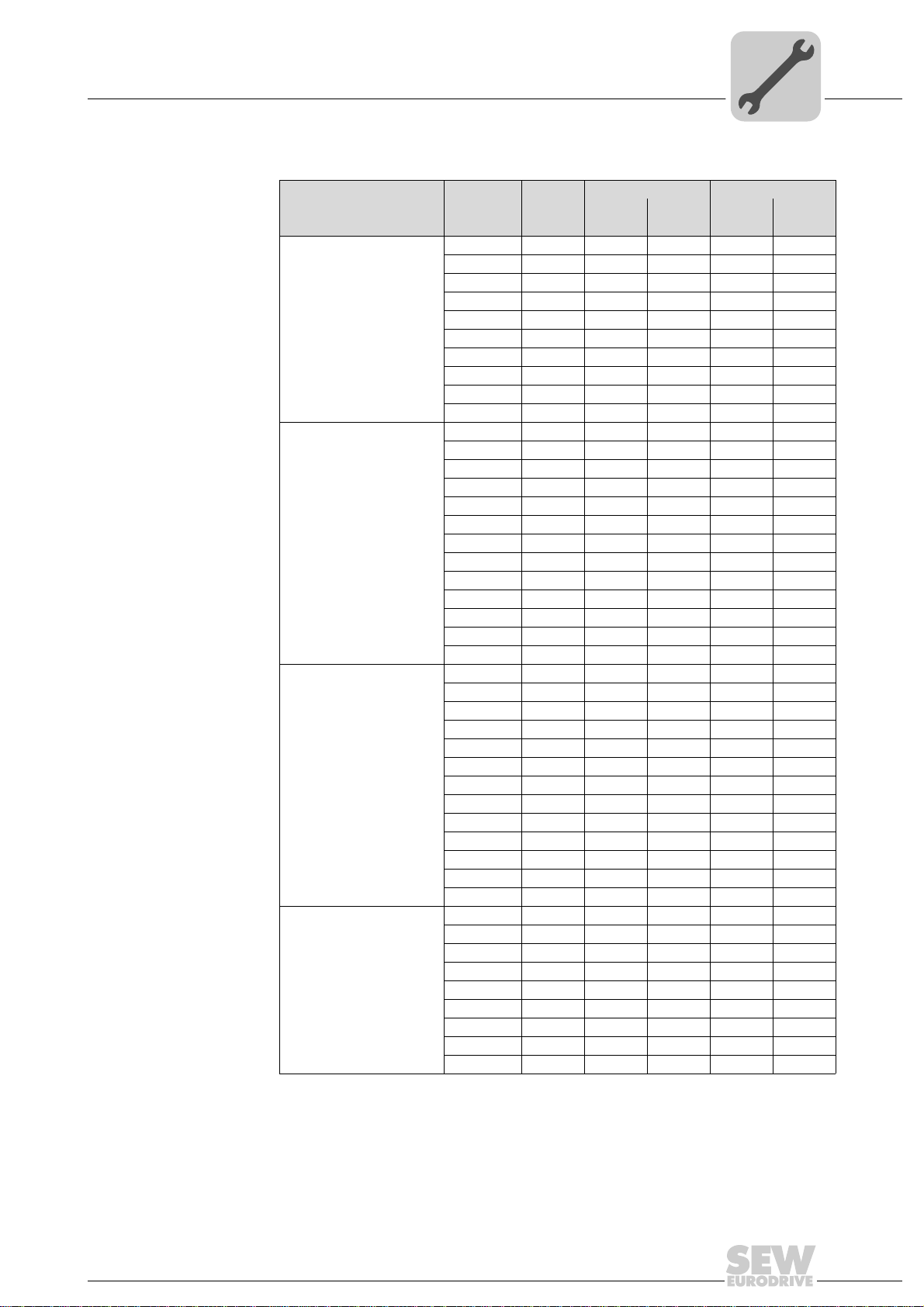

5.4.3 Assignment of servomotor and cable cross section

Electrical Installation

5

Rated speed nN [rpm] Motor

CFM71S 5 2.2 51 / 61 3.95 51 / 61

CFM71M 6.5 3 51 / 61 5.3 51 / 61

CFM71L 9.5 4.2 51 / 61 7.4 52 / 62

CFM90S 11 4.9 51 / 61 8.7 52 / 62

2000

3000

4500

6000

1) For UL application only with terminal box

CFM90M 14.5 6.9 51 / 61 12.1 54 / 64

CFM90L 21 9.9 51 / 61 17.1 56 / 66

CFM112S 23.5 10 51 / 61 18.0 56 / 66

CFM112M 31 13.5 52 / 62 24.5 59 / 69

CFM112L 45 20 54 / 64 35.5 59 / 69

CFM112H 68 30.5 59 / 69 – –

DFS56M 1 1.65111.6511

DFS56L 22.4112.411

DFS56H 42.811 – –

CFM71S 5 3.3 51 / 61 5.9 51 / 61

CFM71M 6.5 4.3 51 / 61 7.6 52 / 62

CFM71L 9.5 6.2 51 / 61 11.1 54 / 64

CFM90S 11 7.3 51 / 61 12.7 54 / 64

CFM90M 14.5 10.1 51 / 61 17.4 56 / 66

CFM90L 21 14.4 52 / 62 25.5 59 / 69

CFM112S 23.5 15 52 / 62 27 59 / 69

CFM112M 31 20.5 54 / 64 35 59 / 69

CFM112L 45 30 59 / 69 48 –

CFM112H 68 43 – – –

DFS56M 11.6511 – –

DFS56L 22.411 – –

DFS56H 4411––

CFM71S 5 4.9 51 / 61 8.5 52 / 62

CFM71M 6.5 6.6 51 / 61 11.3 54 / 64

CFM71L 9.5 9.6 51 / 61 17.1 56 / 66

CFM90S 11 11.1 51 / 61 18.9 56 / 66

CFM90M 14.5 14.7 52 / 62 26 59 / 69

CFM90L 21 21.6 54 / 64 39 59 / 69

CFM112S 23.5 22.5 54 / 64 38.5 59 / 69

CFM112M 31 30 56 / 66 54 –

CFM112L 45 46 59 / 69

CFM112H 68 66 – – –

DFS56M 11.6511 – –

DFS56L 22.7511 – –

DFS56H 45.311 – –

CFM71S 5 6.5 51 / 61 11.6 54 / 64

CFM71M 6.5 8.6 51 / 61 14.1 54 / 64

CFM71L 9.5 12.5 52 / 62 21.5 59 / 69

CFM90S 11 14.5 52 / 62 23.5 59 / 69

CFM90M 14.5 19.8 54 / 64 37 59 / 69

CFM90L 21 29.5 56 / 66 51 –

M

[Nm]

0

400 V 230 V

I

0

[A] [A]

SM

SB

I

1)

––

0

SM

SB

1)

1)

1)

1)

The suggested cross sections for 230 V are sufficient for NFPA 79 and UL 508

(without 1). Further DFS/230 V motor variants are available on request

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

25

5

Electrical Installation

Dimensioning the cable cross section

TIP

The assignments of SM/SB plug connectors are not binding. Given the dynamic properties in the system, other cross sections can also be implemented.

26

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Electrical Installation

Power cables for DFS motors

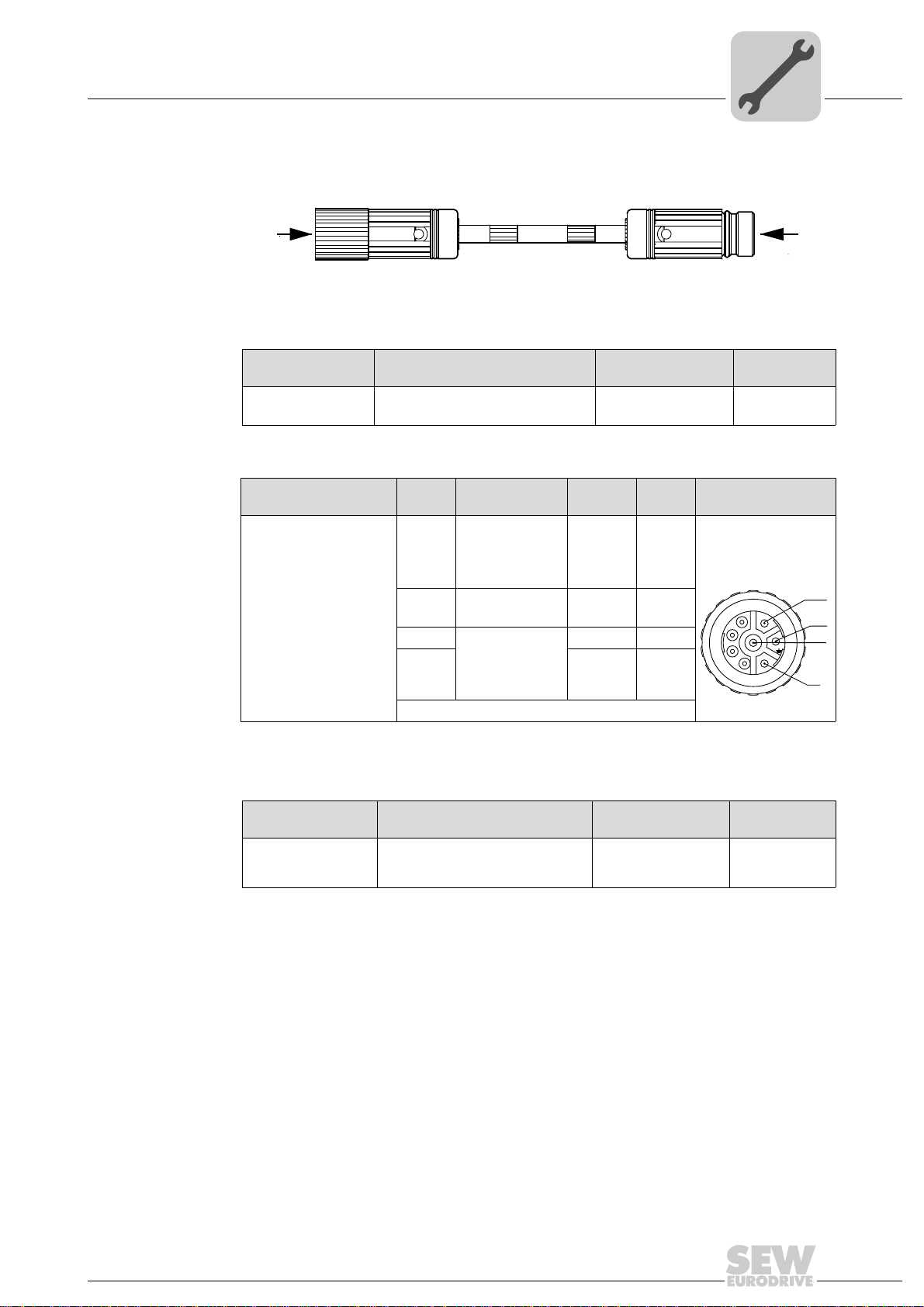

5.5 Power cables for DFS motors

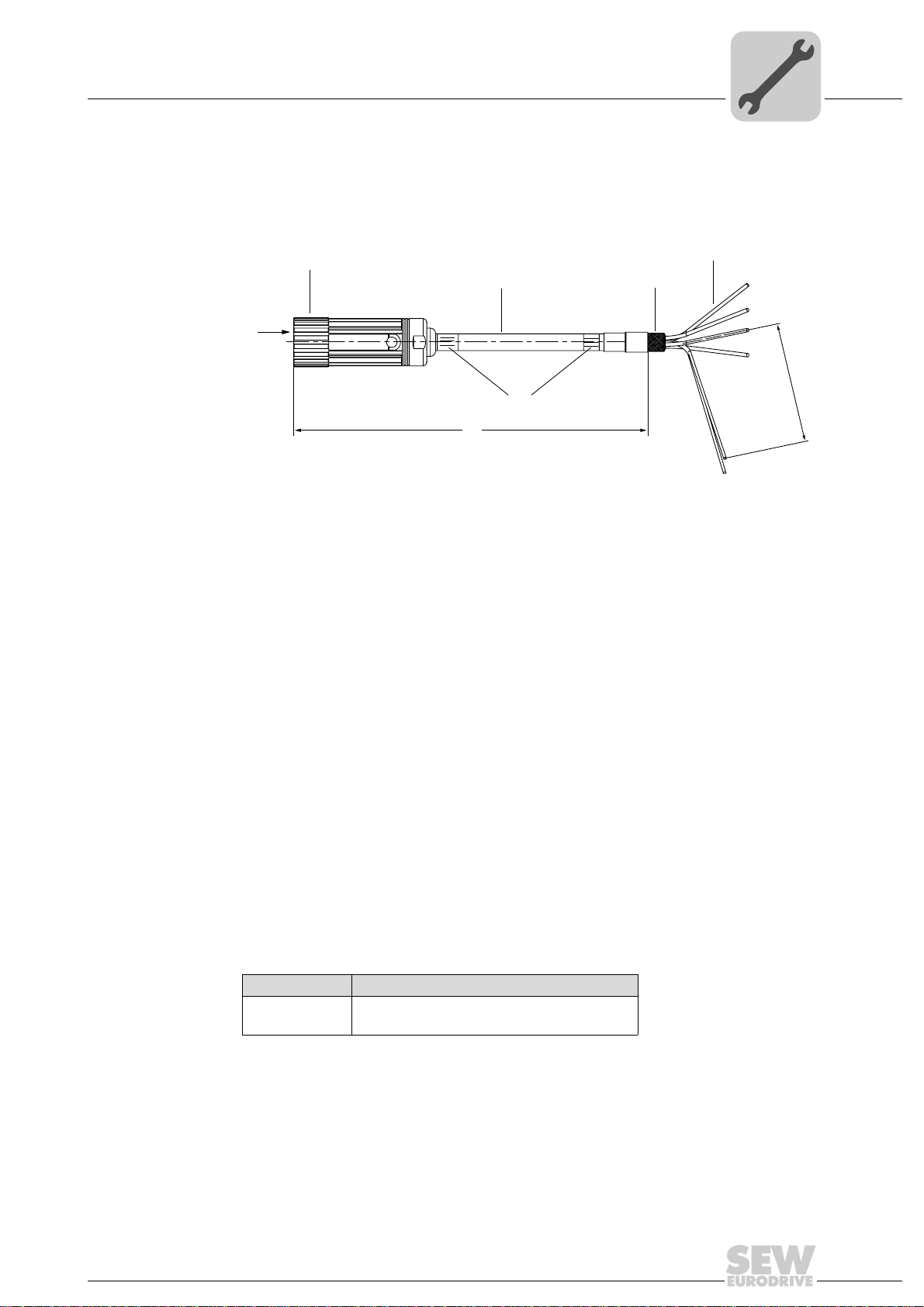

5.5.1 Structure of the motor cables and brakemotor cables for DFS motors

The following figure shows the structure of the motor cables and brakemotor cables:.

5

[1]

[2]

X

[3]

[4]

Connector: Intercontec BSTA 078

[1]

SEW-EURODRIVE logo printed on cable

[2]

Nameplate

[3]

Cable length ≤ 10 m: Tolerance +200 mm

[4]

Cable length ≥ 10 m: Tolerance +2%

Permitted line length according to the technical documents.

Prefabricated cable end for inverter

[5]

Required loose parts are supplied with the cable.

Shielding 20 mm, pulled back approximately + 5 mm

[6]

[5]

[6]

500 ±5

413916043

Motor side The motor cables on the motor side consist of an 8-pin plug connector and socket con-

tacts.

The shield is connected in the connector housing according to EMC requirements. All

plug connectors seal the plug on the cable end with a lamellar seal and ensure cable

relief according to EN 61884.

Inverter side The individual cable cores of the motor and brakemotor cables are exposed and the

shield is prepared for connection in the control cabinet. The cable for the inverter end

has yet to be assembled. The loose parts required are supplied with the cable in a separate bag.

Loose parts The following loose parts are supplied in accordance with the core cross sections for

connection to the power terminals on the inverter:

Bag no. Content

2

1

4 x conductor end sleeves 1.5 mm

4 x M6 U-shaped cable lugs 1.5 mm

, insulated

2

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

27

5

Electrical Installation

Power cables for DFS motors

5.5.2 Motor cable for DFS motors

DFS motor cable

X

DFS motor cable types

413917579

Plug connector type Number of cores and cable cross

SM11 4 × 1.5 mm

SM11 4 × 1.5 mm

DFS motor cable – pin assignment

Plug connector

View X

BSTA 078

0198 6740

8-pole with

socket contacts

W1

PE

2

V1

U1

section

2

(AWG 16) Fixed installation 0590 4544

2

(AWG 16) Cable carrier

Pin Cable core color Assigned Extra

1 (BK) Black U Bag of loose

2 (GN/YE) Green/yellow PE

3 (BK) Black W

4 (BK) Black V

D

3

C

4

B

A

1

Installation Part number

installation

0590 6245

parts

DFS motor cable – alternative plug connector

Plug connectors for power supply with socket contacts (complete).

Plug connector type Number of cores and cable

SM11 4 × 1.5 mm

28

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

cross section

2

Operating Instructions – DFS/CFM Synchronous Servomotors

(AWG 16)

Installation

Fixed installation /

cable carrier installa-

tion

Part number

0198 6740

5.5.3 DFS motor cable – extension cable

Y

Extension cable for DFS motor cable:

X

DFS motor cable – types of extension cables

Electrical Installation

Power cables for DFS motors

5

413920651

Plug connector type Number of cores and cable cross

section

2

SM11 4 × 1.5 mm

(AWG 16)

DFS motor extension cable – pin assignment

Plug connector

View X

BSTA 078

0198 6740

8-pin with socket contacts

Pin Cable core color Assigned Pin Plug connector

(BK/WH)

1

Black with

white lettering

U, V, W

2

(GR/YE)

Green/yellow

3(BK/WH)

4V4

Black with

white lettering

U, V, W

Extension cable for DFS motor cable – alternative plug connector

Plug connector with pins (complete) for motor extension cable.

Installation Part number

Cable carrier

installation

1333 2457

View Y

BKUA 199

U1

PE 2

W3

1333 2430

8-pin with pin contacts

D

3

C

4

2

B

1

A

W/3

PE

V/2

U/1

Plug connector type Number of cores and cable cross

section

2

SM11 4 × 1.5 mm

(AWG 16)

Installation

Fixed installation /

cable carrier installa-

tion

Part number

1333 2430

Operating Instructions – DFS/CFM Synchronous Servomotors

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

29

Loading...

Loading...