SEW Eurodrive DHE41B, DHF41B, DHR41B, DHE21B, DHF21B User Manual

...

Drive Technology \ Drive Automation \ System Integration \ Services

Manual

Controllers

DHE21B / DHF21B / DHR21B (standard)

DHE41B / DHF41B / DHR41B (advanced)

Edition 03/2010 |

16897226 / EN |

SEW-EURODRIVE—Driving the world

Contents

Contents

1 |

General Information ............................................................................................ |

6 |

||

|

1.1 |

How to use the documentation ................................................................... |

6 |

|

|

1.2 |

Structure of the safety notes ....................................................................... |

6 |

|

|

|

1.2.1 |

Meaning of the signal words ........................................................ |

6 |

|

|

1.2.2 |

Structure of section safety notes ................................................. |

6 |

|

|

1.2.3 |

Structure of embedded safety notes............................................ |

6 |

|

1.3 |

Right to claim under warranty ..................................................................... |

7 |

|

|

1.4 |

Exclusion of liability..................................................................................... |

7 |

|

|

1.5 |

Copyright |

..................................................................................................... |

7 |

2 |

Safety Notes ........................................................................................................ |

8 |

|

|

2.1 |

Other applicable documentation ................................................................. |

8 |

|

2.2 |

Bus systems................................................................................................ |

8 |

|

2.3 |

Safety functions .......................................................................................... |

8 |

|

2.4 |

Hoist applications........................................................................................ |

8 |

|

2.5 |

Disposal ...................................................................................................... |

9 |

3 |

Introduction |

....................................................................................................... |

10 |

|

|

3.1 |

General ..................................................................................information |

10 |

|

|

|

3.1.1 ............................................................... |

Content of this manual |

10 |

|

|

3.1.2 .......................................................... |

Additional documentation |

10 |

|

3.2 |

Overview .............................................................................of controllers |

11 |

|

|

|

3.2.1 |

Freely programmable motion and logic controller |

|

|

|

............................................................................. |

(MOVI - PLC ® ) |

11 |

|

|

3.2.2 ................................. |

Configurable application controller (CCU) |

11 |

|

3.3 |

Controller .............................................................................DH.21B/41B |

12 |

|

|

|

3.3.1 ..................................................................................... |

Features |

12 |

|

|

3.3.2 .............................................................................. |

Device types |

12 |

|

|

3.3.3 ...................................... |

Overview of communication interfaces |

12 |

|

|

3.3.4 ................................................................................ |

Engineering |

13 |

|

|

3.3.5 ........................... |

System buses CAN 1, CAN 2 and Ethernet 1 |

14 |

|

|

3.3.6 ......................................... |

RS485 interfaces COM1 and COM2 |

14 |

|

|

3.3.7 .................................................................................. |

Ethernet 2 |

14 |

|

|

3.3.8 .......................................................... |

Binary inputs and outputs |

14 |

|

|

3.3.9 ........................................................................ |

Diagnostic LEDs |

14 |

4 Assembly and Installation Notes..................................................................... |

15 |

||

4.1 |

Installation options of DH.21B/41B ........................................................... |

15 |

|

4.2 |

Installing the DH.21B/41B option in MOVIDRIVE® MDX61B.................... |

15 |

|

|

4.2.1 |

Before you start ......................................................................... |

15 |

|

4.2.2 |

Basic procedure for installing or removing an option card in |

|

|

|

MOVIDRIVE® MDX61B ............................................................. |

16 |

4.3 |

Installing the DH.21B/41B option in MOVIDRIVE® MDX61B.................... |

17 |

|

4.4 |

Installing the DH.21B/41B option in the MOVIAXIS® master module ....... |

17 |

|

|

4.4.1 |

Functional description of terminals X5a / X5b |

|

|

|

(MOVIAXIS® master module) .................................................... |

17 |

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

Contents

4.5 Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit .... |

19 |

||

|

4.5.1 |

Description of terminals and LEDs ............................................ |

19 |

|

4.5.2 |

RS485 interface COM1 connection (connector X24)................. |

19 |

|

4.5.3 |

Connecting CAN 1 system bus/voltage supply (X26) ................ |

20 |

|

4.5.4 |

LED when installing in MOVITRAC®/stand-alone unit............... |

21 |

4.6 |

Shielding and routing bus cables .............................................................. |

22 |

|

4.7 |

Installing the DH.21B/41B option .............................................................. |

23 |

|

|

4.7.1 |

Functional description of terminals, DIP switches and LEDs..... |

23 |

|

4.7.2 |

Connecting binary inputs and outputs (X31 terminal)................ |

24 |

|

4.7.3 |

Connnection to system bus CAN 2 (X32) / CAN 1 (X33)........... |

25 |

|

4.7.4 |

RS485 interface connection (X34)............................................. |

26 |

|

4.7.5 |

System bus Ethernet 1 connection (X36) .................................. |

27 |

|

4.7.6 |

Ethernet 2 interface connection (X37) ....................................... |

27 |

|

4.7.7 |

LEDs of the DH.21B/41B option ................................................ |

27 |

|

4.7.8 |

DIP switch S1 ........................................................................... |

29 |

|

4.7.9 |

SD memory card types OMH41B-T. and OMC41B-T................ |

30 |

4.8 |

Installing the DHF21B/41B option............................................................. |

32 |

|

|

4.8.1 |

Functional description of terminals, DIP switches and LEDs..... |

32 |

|

4.8.2 |

Connecting PROFIBUS (X30P) ................................................. |

33 |

|

4.8.3 |

LEDs in PROFIBUS mode......................................................... |

34 |

|

4.8.4 |

Connecting DeviceNet (X30D)................................................... |

35 |

|

4.8.5 |

LEDs in DeviceNet mode........................................................... |

36 |

|

4.8.6 |

Connecting SEW safety bus (X38) ............................................ |

38 |

4.9 |

Installing the DHR21B/41B option ............................................................ |

39 |

|

|

4.9.1 |

Functional description of the terminals, DIP switches |

|

|

|

and LEDs................................................................................... |

39 |

|

4.9.2 |

Connecting the DHR21B/41B controller to the |

|

|

|

Ethernet network........................................................................ |

40 |

|

4.9.3 |

Setting DIP switches 20 and 21................................................. |

40 |

|

4.9.4 |

The integrated Ethernet switch.................................................. |

41 |

|

4.9.5 |

TCP / IP addressing and subnets.............................................. |

42 |

|

4.9.6 |

LEDs in PROFINET mode ......................................................... |

44 |

|

4.9.7 |

Setting IP address parameters via DCP .................................... |

45 |

|

4.9.8 |

LEDs in EtherNet/IP and Modbus/TCP mode............................ |

46 |

|

4.9.9 |

Setting IP address parameters .................................................. |

47 |

4.10 |

Engineering interfaces of the DH.21B/41B option .................................... |

49 |

|

5 Project Planning and Startup with MOVITOOLS® MotionStudio .................. |

50 |

||

5.1 |

About MOVITOOLS® MotionStudio .......................................................... |

50 |

|

|

5.1.1 |

Tasks ......................................................................................... |

50 |

|

5.1.2 |

Establishing communication with other units ............................. |

50 |

|

5.1.3 |

Executing functions with the units.............................................. |

50 |

5.2 |

First steps ................................................................................................. |

50 |

|

|

5.2.1 |

Starting the software and creating a project .............................. |

50 |

|

5.2.2 |

Establishing communication and scanning the network ............ |

51 |

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Contents

5.3 |

Connection mode...................................................................................... |

52 |

|

|

5.3.1 |

Overview.................................................................................... |

52 |

|

5.3.2 |

Selecting the communication mode (online or offline) ............... |

53 |

5.4 |

Communication via USB ........................................................................... |

54 |

|

|

5.4.1 |

Connecting the unit with the PC via USB .................................. |

54 |

|

5.4.2 |

Installing the driver..................................................................... |

55 |

|

5.4.3 |

Configuring USB communication............................................... |

56 |

|

5.4.4 |

USB communication parameters ............................................... |

57 |

5.5 |

Communication via Ethernet..................................................................... |

58 |

|

|

5.5.1 |

Direct communication ................................................................ |

58 |

|

5.5.2 |

Address Editor ........................................................................... |

59 |

|

5.5.3 |

Configuring the communication channel via Ethernet ............... |

62 |

|

5.5.4 |

Setting communication parameters for SMLP ........................... |

64 |

|

5.5.5 |

Communication parameters for SMLP....................................... |

65 |

|

5.5.6 |

Communication ports used........................................................ |

65 |

5.6 |

Executing functions with the units............................................................. |

66 |

|

|

5.6.1 |

Parameterizing units .................................................................. |

66 |

|

5.6.2 |

Reading or changing unit parameters........................................ |

66 |

|

5.6.3 |

Starting up units (online)............................................................ |

67 |

5.7 |

Configuration and startup of the drives ..................................................... |

68 |

|

5.8 |

Configuration and startup in the PLC Editor ............................................. |

68 |

|

5.9 |

Replacing the unit ..................................................................................... |

68 |

|

6 Error Diagnostics .............................................................................................. |

69 |

||

6.1 |

Diagnostic procedure CAN 1/CAN 2 system bus...................................... |

69 |

|

7 Technical Data and Dimension Drawings....................................................... |

70 |

||

7.1 |

General technical data .............................................................................. |

70 |

|

7.2 |

DHE21B/41B option.................................................................................. |

71 |

|

7.3 |

DHF21B/41B option .................................................................................. |

73 |

|

7.4 |

DHR21B/41B option.................................................................................. |

74 |

|

7.5 |

Stand-alone unit........................................................................................ |

74 |

|

7.6 |

Dimension drawings for stand-alone unit DH.21B/41B/UOH..B ............... |

75 |

|

|

7.6.1 |

Dimension drawing for DHE21B/41B / UOH11B ....................... |

75 |

|

7.6.2 |

Dimension drawing for DHF/DHR21B/41B / UOH21B............... |

76 |

Index |

................................................................................................................... |

|

77 |

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

General Information |

|

How to use the documentation |

||

|

1 General Information

1.1How to use the documentation

The manual is part of the product and contains important information on operation and service. The manual is written for all employees who assemble, install, startup, and service the product.

The manual must be accessible and legible. Make sure that persons responsible for the system and its operation, as well as persons who work independently on the unit, have read through the manual carefully and understood it. If you are unclear about any of the information in this documentation, or if you require further information, contact SEWEURODRIVE.

1.2Structure of the safety notes

1.2.1Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes, notes on potential risks of damage to property, and other notes.

Signal word |

Meaning |

Consequences if disregarded |

DANGER |

Imminent danger |

Severe or fatal injuries |

|

|

|

WARNING |

Possible dangerous situation |

Severe or fatal injuries |

|

|

|

CAUTION |

Possible dangerous situation |

Minor injuries |

|

|

|

NOTICE |

Possible damage to property |

Damage to the drive system or its |

|

|

environment |

|

|

|

INFORMATION |

Useful information or tip: Simplifies the |

|

|

handling of the drive system. |

|

|

|

|

1.2.2Structure of section safety notes

Section safety notes do not apply to a specific action, but to several actions pertaining to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

•Measure(s) to prevent the danger.

1.2.3Structure of embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard. Possible consequence(s) if disregarded.

SIGNAL WORD Nature and source of hazard. Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

General Information

Right to claim under warranty

1.3Right to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited warranty is that you adhere to the information in the documentation. Therefore, read the manual before you start operating the device.

Make sure that the manual is available to persons responsible for the plant and its operation as well as to persons who work independently on the device. You must also ensure that the documentation is legible.

1.4Exclusion of liability

You must observe this documentation and the documentation of the connected devices from SEW-EURODRIVE to ensure safe operation and to achieve the specified product characteristics and performance requirements. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions. In such cases, any liability for defects is excluded.

1.5Copyright

© 2009 – SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use of this document, in whole or in part.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

1

7

2

8

Safety Notes

Other applicable documentation

2 Safety Notes

2.1Other applicable documentation

•Read through this document carefully before you commence installation and startup of the DH.21B/41B options.

The following publications and documents apply to the connected units:

•Operating instructions for the units (such as for MOVIDRIVE® B, MOVITRAC® B, MOVIAXIS®)

•Only electrical specialists are allowed to perform installation and startup observing

the relevant accident prevention regulations and the operating instructions of the connected units (such units are, for example, MOVIDRIVE® MDX60B/61B, MOVITRAC® B, MOVIAXIS®).

•For units with functional safety, also observe the corresponding manual "Functional Safety" or "Safe Disconnection – Conditions".

•You must adhere to the information in the documentation as a prerequisite to faultfree operation and fulfillment of warranty claims.

2.2Bus systems

The DH.21B and DH.41B options support various bus systems. A bus system makes it possible to adapt frequency inverters to the particulars of the machinery within wide limits. As with all bus systems, there is a danger of invisible, external (as far as the inverter is concerned) modifications to the parameters which give rise to changes in the unit behavior. This may result in unexpected, though not uncontrolled, system behavior.

2.3Safety functions

MOVIDRIVE® MDX60B/61B and MOVITRAC® B inverters may not perform any safety functions without higher-level safety systems. Use higher-level safety systems to ensure protection of equipment and personnel. For safety applications, ensure that the information in the following publications is observed: "Safe Disconnection for MOVIDRIVE® MDX60B/61B / MOVITRAC® B".

2.4Hoist applications

MOVIDRIVE® MDX60B/61B, MOVITRAC® B and MOVIAXIS® must not be used as a safety device in hoist applications.

Use monitoring systems or mechanical protection devices as safety equipment to avoid possible damage to property or injury to people.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Safety Notes |

2 |

|

Disposal |

||

|

2.5Disposal

Observe the applicable national regulations.

Dispose of the following materials separately in accordance with the country-specific regulations in force, as:

•Electronics scrap

•Plastic

•Sheet metal

•Copper

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Introduction |

|

General information |

||

|

3 Introduction

3.1General information

3.1.1Content of this manual

This user manual describes the following:

•How to install the DH.21B/41B options in MOVIDRIVE® MDX61B

•Interfaces and LEDs of the DH.21B/41B options

•How to install the DH.21B/41B options in MOVIDRIVE® MDX61B and MOVITRAC® B inverters, in MOVIAXIS® servo inverters, and in stand-alone housings

•Engineering access to the DH.21B/41B options

•Project planning and startup of DH.21B/41B options

3.1.2Additional documentation

To be able to configure and start up the DH.21B/41B options simply and effectively, you should also order the following publications in addition to this manual:

•"DHF21B/41B Controller PROFIBUS DP-V1 and DeviceNet Fieldbus Interfaces" manual

•"DHR21B/41B Controller PROFINET IO, EtherNet/IP, Modbus TCP/IP Fieldbus Interfaces" manual

•MOVIDRIVE® MDX60/61B system manual

•MOVITRAC® B system manual

•MOVIAXIS® system folder

When used as freely programmable motion and logic controller with SD card OMH41B:

•"MOVI-PLC® Programming in the PLC Editor" system manual

The "MOVI-PLC® Programming in the PLC Editor" system manual contains instructions for IEC 61131-3 compliant programming.

•"MPLCMotion_MDX and MPLCMotion_MX Libraries for MOVI-PLC®" manual

•"MPLCMotion_MC07 and MPLCMotion_MM Libraries for MOVI-PLC®" manual

The library relevant manuals describe the motion libraries for controlling MOVIDRIVE® MDX60B/61B, MOVIAXIS®, MOVITRAC® B, and MOVIMOT® inverters.

When used as configurable application controller with SD card OMC41B:

•Manuals for the respective application modules

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

10 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Introduction |

3 |

|

Overview of controllers |

||

|

3.2Overview of controllers

3.2.1Freely programmable motion and logic controller (MOVI-PLC®)

The controller can be operated as freely programmable motion and logic controller MOVI-PLC® when using SD cards of the type OMH41B. MOVI-PLC® is a series of programmable motion and logic controllers. It allows drive solutions, logic processes and sequence controls to be automated simply and efficiently using IEC 61131-3 compliant programming languages.

• MOVI-PLC® is a universal solution because it is able to control the entire portfolio of SEW inverters and offers a simple upgrade to a more powerful MOVI-PLC® version due to the fact that all possible programs can be executed.

|

• MOVI-PLC® is scalable due to several different hardware platforms (standard, |

|

advanced, etc.) and modular software concepts (libraries for numerous applications). |

|

• MOVI-PLC® is powerful due to extensive technologies (such as electronic cam, |

|

synchronous operation) and the control of demanding applications (such as material |

|

handling). |

Performance class |

• DH.21B controllers enable coordinated single axis movements and integration of |

MOVI-PLC® |

external inputs/outputs as well as Drive Operator Panels (DOP). The DH.21B.. option |

standard |

is therefore suitable for use as a module controller or stand-alone controller for |

|

machines of medium complexity. |

Performance class |

• The DH.41B controller is characterized by a great variety of interfaces and a higher |

MOVI-PLC® |

performance level, which allows complex calculations and interpolated movements, |

advanced |

for example. The DH.41B option is therefore suitable for the automation of cells and |

|

machines. The integrated Ethernet interface enables direct connection of the |

|

DH.41B controller to the control level. |

3.2.2Configurable application controller (CCU)

The controller can be used as configurable application controller (CCU) by using SD cards of the type OMC41B. Only standardized application modules created by SEW-EURODRIVE can be executed. The application modules can be started up quickly and conveniently by graphical configuration. A defined process data interface provides this functionality to a higher-level controller. A process data monitor with control mode is available to support the startup procedure.

CCU standard |

The "CCU standard" performance class is intended for application modules with single- |

|

performance class |

axis functionality and medium response times. A maximum of 16 axes can be connected |

|

|

to a configurable application controller. The following application modules are available |

|

|

and can be started up using the AxisConfigurator tool. |

|

|

• |

Speed specification |

|

• |

Cam positioning |

• Bus positioning with 6 process data

• Single-axis universal module

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Introduction |

|

Controller DH.21B/41B |

||

|

Performance class The "CCU advanced" performance class is intended for application modules with single- CCU advanced axis and multi-axis functionality and fast response times. The following application

modules are available:

•Single-axis functionality:

–Speed specification

–Cam positioning

–Bus positioning 6 process data

–Single-axis universal module

•Multi-axis functionality:

–SyncCrane

–Energy-efficient SRU

3.3Controller DH.21B/41B

3.3.1Features

Two types of DH.21B/41B controllers are available:

•As option card DH.21B/41B for MOVIDRIVE® B and MOVITRAC® B inverters (only DHE21B/41B) and for MOVIAXIS® servo inverters

•In stand-alone housing DH.21B/41B UOH.1B prepared for installation on a mounting rail.

3.3.2Device types

Three types of DH.21B/41B controllers are available, which differ in the fieldbus interfaces:

DH.21B/41B type |

Fieldbus interfaces |

DHE21B/41B |

Ethernet TCP/IP, UDP |

|

|

DHF21B/41B |

Ethernet TCP/IP, UDP, PROFIBUS DP-V1, DeviceNet |

|

|

DHR21B/41B |

Ethernet TCP/IP, UDP, PROFINET, EtherNet/IP, ModbusTCP/IP |

|

|

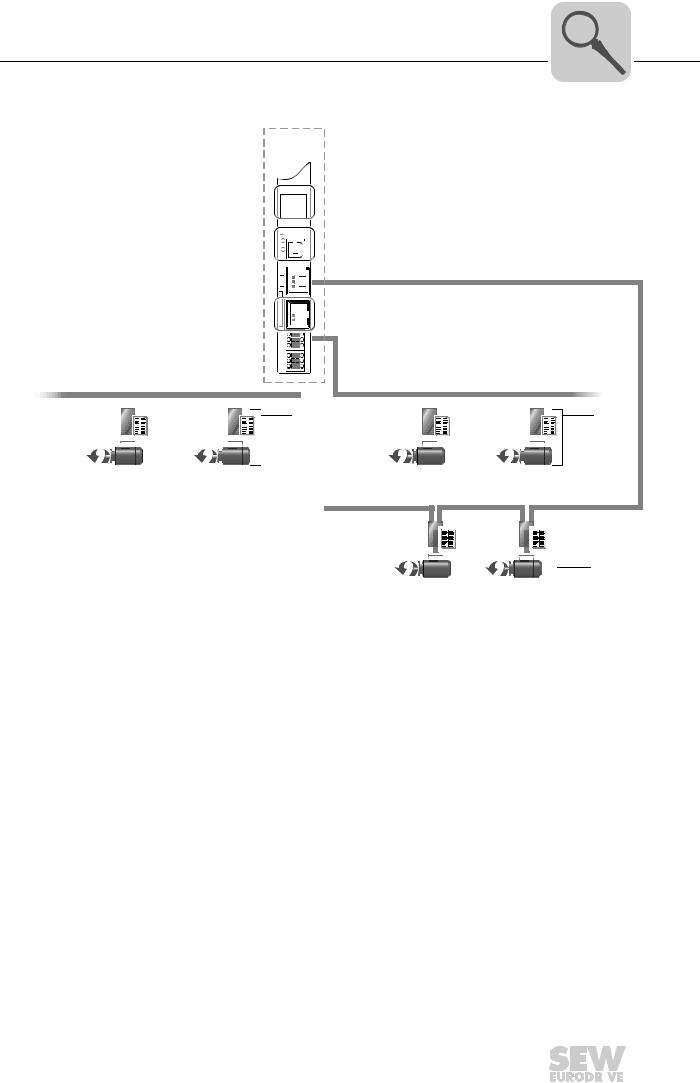

3.3.3Overview of communication interfaces

The DH.21B/41B option is equipped with numerous communication interfaces.

The two system bus interfaces CAN 1 and CAN 2 are primarily used for connecting and controlling several inverters and for integrating decentralized I/O modules.

You can operate this machine module on a higher-level controller using the integrated fieldbus interface.

An operator terminal (e.g. DOP11B) or a MOVIMOT® gearmotor with integrated frequency inverter is connected to the RS485 interfaces.

SEW drives and SEW I/O modules with EtherCAT interface can be connected to the SBUSPLUS® system bus interface.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

12 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Introduction |

3 |

|

Controller DH.21B/41B |

||

|

X34

1

2

2

3

4

4

5

6

6

[4]

[4]

[1]

[1]

SBUSPLUS*

[1]

[1]

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SBUS (CAN1) |

|

|

|

|

SBUS (CAN2) |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[2] |

|

|

|

|

|

|

|

|

|

|

|

|

|

[2] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EtherCAT

[3]

2384673547

[1]Engineering interface USB (X35) and Ethernet 2 (X37)

[2]SEW inverter with SBus interface (X32/X33)

[3]SEW inverter with EtherCAT interface (X36)

[4]2 × RS485 interfaces (X34)

3.3.4Engineering

Engineering of the DH.21B/41B option includes the following activities:

•Configuration

•Parameterization

•Programming (only MOVI-PLC®)

These activities are carried out using the MOVITOOLS® MotionStudio engineering software. The software has a number of useful features for startup and diagnostics of all SEW-EURODRIVE units. The DH.21B/41B option is connected with the engineering PC via

•Ethernet communication interface (X37)

•USB interface (X35)

•Engineering channels of the fieldbus system used

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

13 |

|

|

|

|

|

|

|

|

|

|

|

|

3

14

Introduction

Controller DH.21B/41B

3.3.5System buses CAN 1, CAN 2 and Ethernet 1

You can use the DH.21B/41B option to control a machine module by connecting several inverters via the system bus. The DH.21B/41B option controls all drives within the machine module and in this way takes load off the higher-level controller (e.g. machine/ system PLC). You can connect a total of maximum 16 units to the DH.21B option, and a total of maximum 64 units to the DH.41B option via system buses CAN 1, CAN 2, and Ethernet 1:

•MOVITRAC® B frequency inverter

•MOVIDRIVE® MDX60B/61B drive inverter

•MOVIAXIS® servo inverter

•Gearmotor with integrated frequency inverter MOVIMOT® (Fieldbus interface DeviceNet MFD... required)

•I/O coupler (OCC11B/OCE11B)

3.3.6RS485 interfaces COM1 and COM2

Connect one of the following devices each to the RS485 interfaces COM1 or COM2:

•DOP11B operator terminal

•MOVIMOT® gearmotor with integrated frequency inverter

3.3.7Ethernet 2

You can implement the following functions and connections using the Ethernet 2 communication interface:

•Connection of a DOP11B operator terminal

•PC visualization (e.g. OPC interface)

•Connection to master level

3.3.8Binary inputs and outputs

Binary inputs and outputs enable you to switch actuators (e.g. valves) and evaluate binary input signals (e.g. sensors).

3.3.9Diagnostic LEDs

The LEDs of the DH.21B/41B options indicate the following states:

•Voltage supply of the binary inputs and outputs

•General state of the DH.21B/41B options

•State of the control program

•State of the fieldbus interface (DHF/DHR)

•State of the Ethernet interface

•State of both CAN interfaces

You can connect operator terminals to perform diagnostics. It is recommended to connect an operator terminal to the communication interface Ethernet 2.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Assembly and Installation Notes |

4 |

|

Installation options of DH.21B/41B |

||

|

4 Assembly and Installation Notes

4.1Installation options of DH.21B/41B

Observe the following installation instructions:

INFORMATION

•You can insert the DH.21B/41B option in the MOVIDRIVE® MDX61B inverter. Do not insert it in the MOVIDRIVE® MDX60B inverter.

•Option cards can only be installed or removed for MOVIDRIVE® MDX61B sizes 1 to 6.

•The installation or removal of option cards for MOVIDRIVE® MDX61B size 0 inverters must only be carried out by SEW-EURODRIVE engineers.

•The installation or removal of the DH.21B/41B option in MOVIAXIS® as well as the installation of the stand-alone housing DH.21B41B/UOH..B must only be carried out by SEW-EURODRIVE engineers.

4.2Installing the DH.21B/41B option in MOVIDRIVE® MDX61B

•You must insert the DHE21B/DHE41B option into the fieldbus slot of MOVIDRIVE® MDX61B. If the fieldbus slot is not available, you can plug the DHE21B/41B option into the expansion slot.

•You must insert the DHF21B/DHR21B and DHF41B/DHR41B options into the expansion slot of MOVIDRIVE® MDX61B. It cannot be installed in MOVIDRIVE® MDX61B size 0.

4.2.1Before you start

Read the following notes before installing or removing DH.21B/41B options:

•Disconnect the inverter from power. Switch off the DC 24 V and the line voltage.

•Before touching the DH.21B/41B option, take appropriate measures (discharge strap, conductive shoes, etc.) to protect it from electrostatic charge.

•Before installing the DH.21B/41B option, remove the keypad and the front cover.

•After installing the DH.21B/41B option, replace the front cover and the keypad.

•Keep the DH.21B/41B option in its original packaging until immediately before you are ready to install it.

•Hold the DH.21B/41B option only by its edges. Do not touch any of the components.

•Never place the DH.21B/41B option on a conductive surface.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Assembly and Installation Notes |

|

Installing the DH.21B/41B option in MOVIDRIVE® MDX61B |

||

|

4.2.2Basic procedure for installing or removing an option card in MOVIDRIVE® MDX61B

2.

1.

3.

4

2102036363

1.Remove the retaining screws holding the card retaining bracket. Pull the card retaining bracket out evenly from the slot (do not twist!).

2.Remove the retaining screws of the black cover plate on the card retaining bracket. Remove the black cover plate.

3.Position the option card onto the retaining bracket so that the retaining screws fit into the corresponding bores on the card retaining bracket.

4.Insert the retaining bracket with the installed option card into the slot, pressing slightly so it is seated properly. Secure the option card retaining bracket with the retaining screws.

5.Follow the instructions in reverse order when removing the option card.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

16 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Assembly and Installation Notes |

4 |

|

Installing the DH.21B/41B option in MOVIDRIVE® MDX61B |

||

|

4.3Installing the DH.21B/41B option in MOVIDRIVE® MDX61B

INFORMATION

The DH.21B/41B option is installed as described in the "Installation options of DH.21B/ 41B" chapter. The DH.21B/41B option is powered via MOVIDRIVE® MDX61B. A separate voltage supply is only required for the binary inputs and outputs (connector X31). For wiring the system bus, connect the X33 plug (CAN 1) or X32 (CAN 2) of the DH.21B/41B option with X12 of MOVIDRIVE® MDX61B.

4.4Installing the DH.21B/41B option in the MOVIAXIS® master module

INFORMATION

The DH.21B/41B option is installed as described in the "Installation options of DH.21B/ 41B" chapter. For wiring the system bus, connect connector X33 (CAN 1) or X32 (CAN 2) of the DH.21B/41B option with X9 (signal bus of the MOVIAXIS® supply module or of a MOVIAXIS® axis module), or with X12 (CAN 2 bus of a MOVIAXIS® axis module). The MOVIAXIS® master module provides additional connections that are described in the following section.

4.4.1Functional description of terminals X5a / X5b (MOVIAXIS® master module)

MOVIAXIS® master |

Designation |

Terminal |

|

Function |

||||||

module MXM |

|

|||||||||

|

|

|

|

|

||||||

|

|

|

|

|

|

X5b connector |

X5b:1 |

|

DC 24 VE |

Voltage supply for control electronics |

|

|

|

|

|

X5b |

|

X5b:2 |

|

DGND |

Reference potential for control electronics |

|

|

1 |

|

|

|

|

||||

|

|

|

|

|

X5b:3 |

|

DC 24 VB |

Voltage supply for brake |

||

|

|

2 |

|

|

|

|

|

|||

|

|

3 |

|

|

|

|

X5b:4 |

|

BGND |

Reference potential for brake connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

X5a |

Terminal X5a |

X5a:1 |

|

DC 24 VE |

Voltage supply for control electronics |

|||

|

|

|

|

|

|

|||||

|

|

1 |

|

|

|

X5a:2 |

|

DGND |

Reference potential for control electronics |

|

|

|

2 |

|

|

|

|

|

|||

|

|

|

|

|

|

X5a:3 |

|

DC 24 VB |

Voltage supply for brake |

|

|

|

3 |

|

|

|

|

|

|||

|

|

4 |

|

|

|

|

X5a:4 |

|

BGND |

Reference potential for brake connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2107418379 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

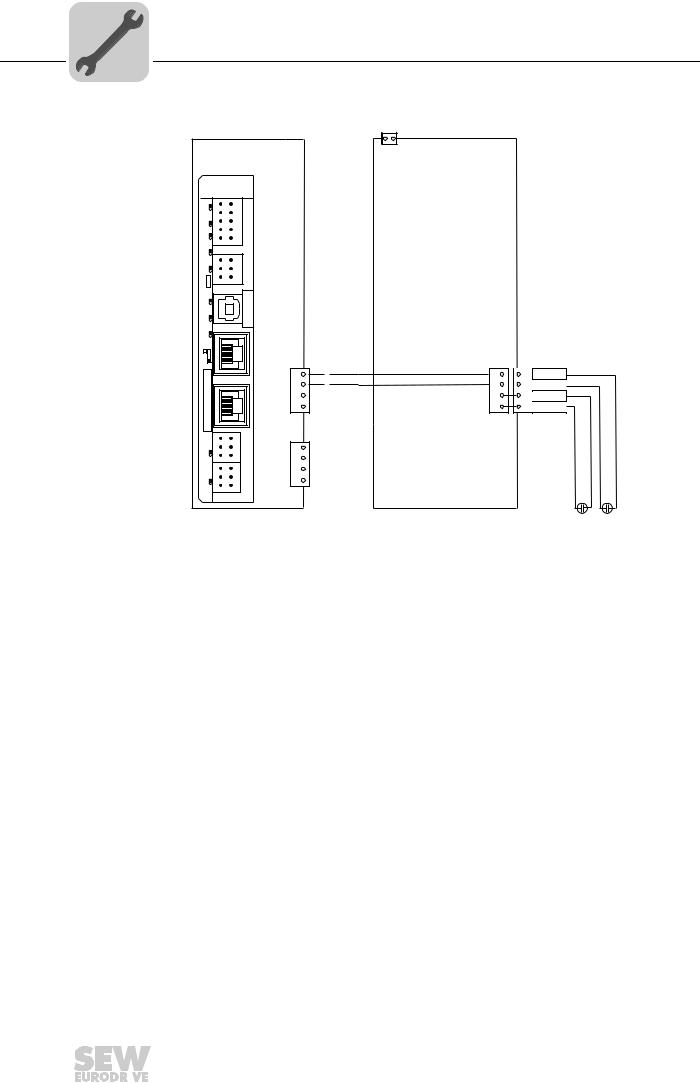

•The terminals X5a and X5b are connected in parallel. In this way, the voltage supply of the MOVIAXIS® master module can be provided from the right to X5b or from below to X5a. With connection to X5a, further modules can be connected via X5b

(e.g. supply module, axis module). The voltage supply for the brake (X5a/b:3,4) is fed through the MOVIAXIS® master module.

•The DH.21B/41B option can be supplied from the MOVIAXIS® switched-mode power supply (MXS) or from an external voltage source. To do so, connect X5 between the individual units.

•If the DH.21B/41B option is connected with DC 24 V from the MOVIAXIS® switchedmode power supply, the functioning of the DH.21B/41B option is maintained after

disconnection from the power supply. This is the case if the DC link voltage is maintained or an external DC 24 V supply is present from the MOVIAXIS® switchedmode power supply.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

17 |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Assembly and Installation Notes |

|

Installing the DH.21B/41B option in the MOVIAXIS® master module |

||

|

Wiring diagram

External DC 24 V

MOVIAXIS® |

|

+ - |

MOVIAXIS® |

|

|

|

|||

master module MXM |

X16 |

switched-mode |

|

|

|

||||

DHE41B |

|

|

power supply MXS |

|

|

|

|||

|

|

|

|

|

|

||||

L10 |

1 |

2 |

|

|

|

|

|

|

|

3 |

4 |

X31 |

|

|

|

|

|

|

|

L9 |

5 |

6 |

|

|

|

|

|

|

|

7 |

8 |

|

|

|

|

|

|

||

L8 |

9 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L7 |

1 |

2 |

X34 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

L6 |

3 |

4 |

|

|

|

|

|

|

|

|

5 |

6 |

|

|

|

|

|

|

|

L4 L5 T1 |

X35 |

Version |

|

|

|

|

|

|

|

3 |

2 |

|

|

|

|

|

|

||

4 |

1 |

|

|

|

|

|

|

||

X36 |

|

|

|

|

|

|

|||

L3 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

S1 |

|

|

|

X5b |

|

X5a |

X5b |

|

|

|

X37 |

|

1 |

|

1 |

1 DC 24VE |

|

|

|

|

|

2 |

|

2 |

2 DGND |

|

|

||

|

|

|

|

|

|

|

|||

|

|

|

|

3 |

|

3 |

3 DC 24VB |

|

|

|

|

|

|

4 |

|

4 |

4 BGND |

|

|

XM |

1 |

1 |

X32 |

X5a |

|

|

|

|

|

2 |

2 |

1 |

|

|

|

|

|

||

L2 |

3 |

3 |

|

2 |

|

|

|

|

|

|

1 |

1 |

X33 |

3 |

|

|

|

|

|

L1 |

2 |

2 |

4 |

|

|

|

|

|

|

3 |

3 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

DC 24 V for |

+ |

- |

|

|

|

|

|

|

brake power supply - |

|||

DC 24 V supply

+ for control electronics

2107421323

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

18 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Assembly and Installation Notes |

4 |

|

Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit |

||

|

4.5Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit

INFORMATION

The DH.21B/41B option is installed as described in the "Installation options of DH.21B/ 41B" chapter. The option card slot MOVITRAC® B and the stand-alone unit provide additional connections for the DH.21B/41B option. These connections are described below.

4.5.1Description of terminals and LEDs

Front view |

|

LED |

|

|

|||||||||||

MOVITRAC® B/ |

Designation |

|

Function |

||||||||||||

stand-alone unit |

|

Terminal |

|

|

|||||||||||

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

LED |

H1 |

|

Reserved |

|

|

|

|

|

|

|

|

H1 |

|

H2 |

|

Reserved |

|||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

H2 |

X24 connector: |

X24:4 |

DGND |

Reference potential COM 1 |

|||

|

|

|

|

|

|

|

|

RS485 COM 1 |

X24:3 |

RS– |

Signal RS485– |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

(RJ10 socket) |

X24:2 |

RS+ |

Signal RS485+ |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

X24 |

|

X24:1 |

5 V |

Voltage output DC +5 V |

|||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2108468363 |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Side view |

Designation |

Terminal |

|

Function |

|||||||||||

Stand-alone unit |

|

||||||||||||||

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

X26 connector: |

X26:1 |

CAN 1H |

System bus CAN 1 high |

|

|

|

|

|

|

|

|

|

|

|

|

CAN 1 and |

X26:2 |

CAN 1L |

System bus CAN 1 low |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

X26 |

|

voltage supply |

X26:3 |

DGND |

Reference potential control/CAN1 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

(plug-in |

X26:4 |

Reserved |

- |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

|

terminal) |

X26:5 |

Reserved |

- |

||

2108496651 |

|

||||||||||||||

|

X26:6 |

DGND |

Reference potential control/CAN1 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

X26:7 |

DC 24 V |

Voltage supply for controller |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.5.2RS485 interface COM1 connection (connector X24)

The connectors X24 and X34:1/3/5 are connected in parallel. You can connect a DOP11B operator terminal at X24. If X24 is unassigned, you can connect an operator terminal or a gearmotor with integrated MOVIMOT® frequency inveter to X34:1/3/5.

For more information, refer to "RS485 interface connection (X34)".

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

19 |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Assembly and Installation Notes |

|

Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit |

||

|

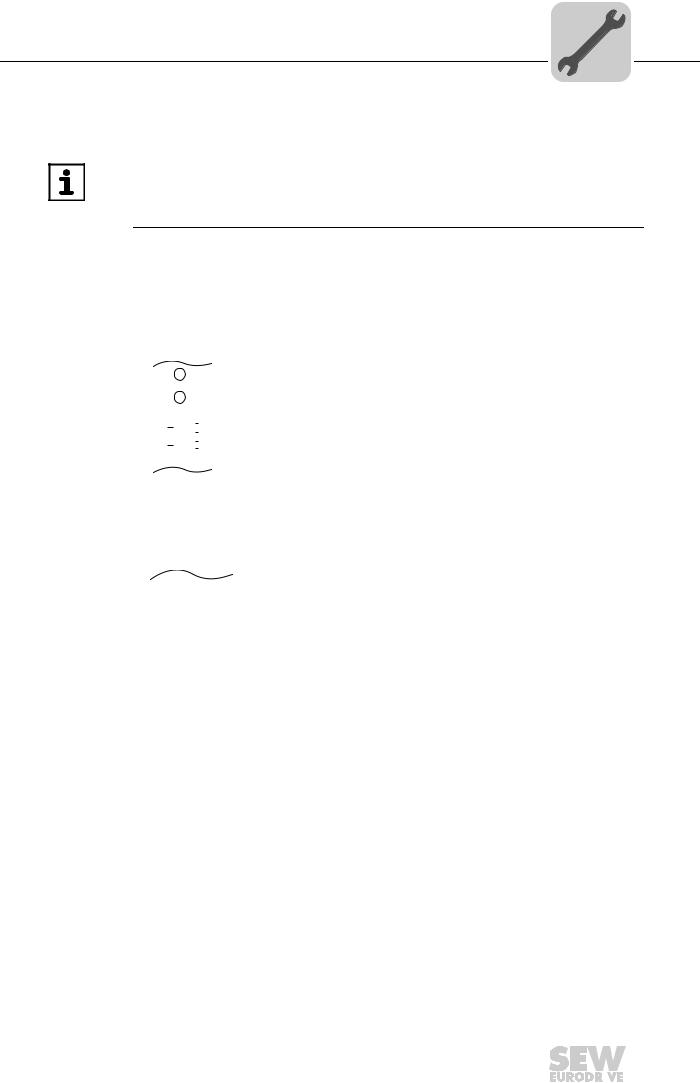

4.5.3Connecting CAN 1 system bus/voltage supply (X26)

X26:1/2/3 and connector X33 are connected in parallel. The DH.21B/41B option in the compact controller is supplied with voltage via X26:6/7.

The DHE21B/41B option can be supplied with the required voltage by MOVITRAC® B. To do so, connect X26:3 (6)/7 with X46:3 (6)/7 or with X12:9/8. If MOVITRAC® B supplies the DHE21B/41B option with DC 24 V, then the functions of the DHE21B/41B option are also ensured after disconnection from the supply system. This requires an external DC 24 V supply to X12:8/9 of MOVITRAC® B.

|

|

MOVITRAC® B |

DHE41B |

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

L10 |

1 |

2 |

|

|

|

|

|

|

|

|

3 |

4 |

X31 |

|

|

|

|

|

|

|

|

L9 |

7 |

8 |

|

|

|

|

|

|

|

|

|

5 |

6 |

|

|

|

|

|

|

|

|

L8 |

9 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L7 |

1 |

2 |

X34 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

L6 |

3 |

4 |

|

|

|

|

|

|

|

|

|

5 |

6 |

|

|

|

|

|

|

|

|

T1 |

X35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

S2 |

L5 |

3 |

2 |

|

|

||

|

|

4 |

1 |

|

|

|||||

|

|

L4 |

|

|

||||||

|

|

|

ON |

|

|

X36 |

|

|

||

|

|

|

|

|

L3 |

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

X44 |

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FSC11B |

|

|

|

X37 |

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

X45 |

X46 |

|

|

|

|

|

|

|

|

|

H L 1 |

2 3 4 5 6 |

7 |

XM |

2 |

2 |

X32 |

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

|

|

|

|

L2 |

3 |

3 |

|

|

|

|

|

|

|

|

L1 |

1 |

1 |

X33 |

120Ω |

|

|

|

|

|

|

2 |

2 |

|||

|

|

|

|

|

|

|

3 |

3 |

|

|

|

|

|

|

|

|

|

|

H1 |

|

|

|

|

|

|

|

|

|

|

H2 |

|

|

|

|

|

|

|

|

|

X24 |

|

|

|

|

|

|

|

|

|

|

X26 |

|

|

|

|

|

X12 |

|

|

|

1 2 3 4 5 6 7 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

+ |

|

4 |

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

DC 24V = |

|

6 |

|

|

|

|

|

|

|

|

- |

24V IO |

7 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

||

|

GND |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2108499339

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

20 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Assembly and Installation Notes |

4 |

|

Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit |

||

|

SC11 System bus +, CAN high SC12 System bus -, CAN low

GND, CAN GND

Compact controller |

||||

DHE41B |

|

|||

L10 |

1 |

2 |

|

|

3 |

4 |

X31 |

|

|

L9 |

7 |

8 |

|

|

|

5 |

6 |

|

|

L8 |

9 |

10 |

|

|

|

|

|

|

|

L7 |

1 |

2 |

X34 |

|

|

|

|||

L6 |

3 |

4 |

|

|

|

5 |

6 |

|

|

T1 |

X35 |

|

|

|

|

|

|

|

|

L5 |

3 |

2 |

|

|

4 |

1 |

|

|

|

L4 |

|

|

||

X36 |

|

|

||

L3 |

|

|

||

|

|

|

|

|

S1 |

|

|

|

|

|

X37 |

|

|

|

XM |

2 |

2 |

X32 |

|

|

1 |

1 |

|

|

L2 |

3 |

3 |

|

|

L1 |

1 |

1 |

X33 |

120Ω |

3 |

3 |

|||

|

2 |

2 |

|

|

|

|

H1 |

|

|

|

|

H2 |

|

|

|

|

X24 |

|

|

SEW drive |

X26 |

|

|

|

|

|

|

||

1 2 3 4 5 6 7 |

||||

|

|

|

|

DC +24 V |

|

|

|

|

GND |

2108502027

4.5.4LED when installed in MOVITRAC®/stand-alone unit

LED H1, H2 |

LEDs H1 and H2 are reserved. |

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Assembly and Installation Notes |

|

Shielding and routing bus cables |

||

|

4.6Shielding and routing bus cables

Only use shielded cables and connection elements that also meet the requirements of category 5, class 2 in compliance with IEC 11801 edition 2.0.

Correct shielding of the bus cable attenuates electrical interference that can occur in industrial environments. The following measures ensure the best possible shielding:

•Manually tighten the mounting screws on the connectors, modules, and equipotential bonding conductors.

•Use only connectors with a metal housing or metallized housing.

•Connect the shielding in the connector over a wide surface area.

•Apply the shielding of the bus cable on both ends.

•Route signal and bus cables in separate cable ducts. Do not route them parallel to power cables (motor leads).

•Use metallic, grounded cable racks in industrial environments.

•Route the signal cable and the corresponding equipotential bonding close to each other using the shortest possible route.

•Avoid using plug connectors to extend bus cables.

•Route the bus cables closely along existing grounding surfaces.

NOTICE

In case of fluctuations in the ground potential, a compensating current may flow via the bilaterally connected shield that is also connected to the protective earth (PE). In such a case, make sure you supply adequate equipotential bonding in accordance with relevant VDE regulations.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

22 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Assembly and Installation Notes |

4 |

|

Installing the DH.21B/41B option |

||

|

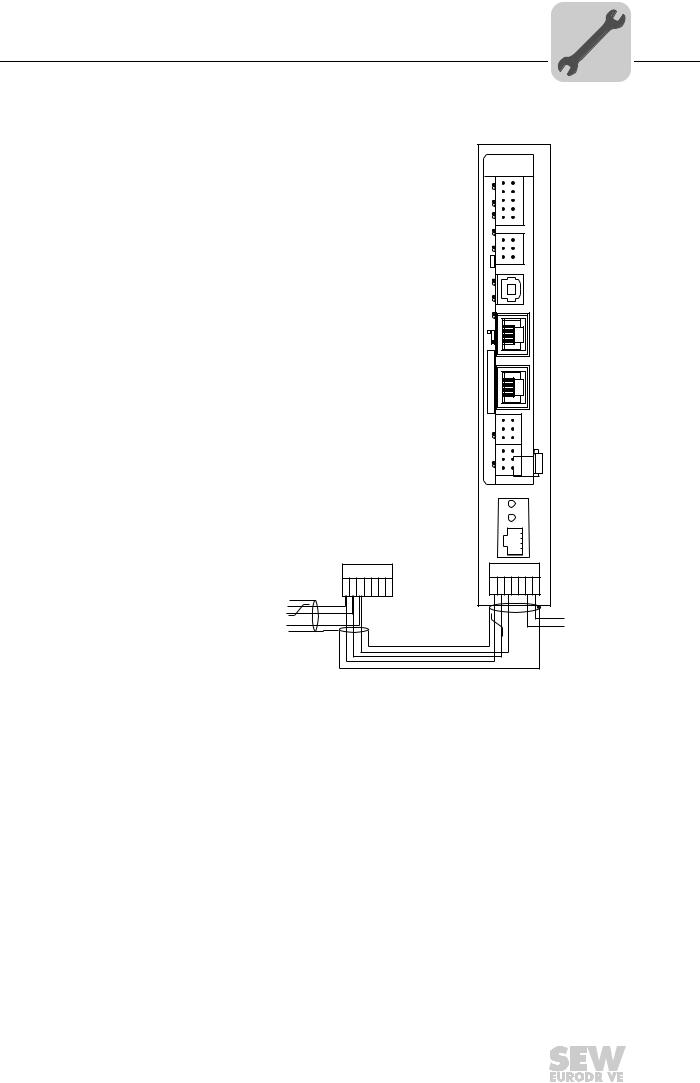

4.7Installing the DH.21B/41B option

4.7.1Functional description of terminals, DIP switches and LEDs

Front view |

|

|

|

Designation |

LED |

|

Function |

||||||

DH.21B/41B |

DIP switch |

|

|||||||||||

option |

|

|

|

|

|

|

|

Terminal |

|

|

|||

|

|

|

|

|

|

|

|

|

LED |

LED 10 |

|

24 V / I/O OK |

State of voltage supply I/O |

|

|

|

|

|

|

|

|

|

|

LED 9 |

|

DIO0/1 |

State of input or output DIO 0/1 |

|

|

|

|

|

|

|

|

|

|

LED 8 |

|

DIO2/3 |

State of input or output DIO 2/3 |

|

|

|

|

|

|

|

|

|

|

LED 7 |

|

DIO4/5 |

State of input or output DIO 4/5 |

|

|

L10 |

1 |

|

2 |

|

|

|

|

|

|||

|

|

3 |

|

4 |

|

|

|

|

LED 6 |

|

DIO6/7 |

State of input or output DIO 6/7 |

|

|

|

L9 |

5 |

|

6 |

X31 |

|

|

|||||

|

|

7 |

|

8 |

|

LED 5 |

|

User LED |

Freely programmable |

||||

|

|

L8 |

9 |

|

10 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

LED 4 |

|

PLC state |

State of control firmware |

|

|

|

L7 |

|

|

|

|

|

|

|

|

|||

|

|

1 |

|

2 |

X34 |

|

LED 3 |

|

IEC progr. state |

State of control program |

|||

|

|

|

|

|

|

||||||||

|

|

L6 |

3 |

|

4 |

|

|

||||||

|

|

|

5 |

|

6 |

|

|

|

|

LED 2 |

|

CAN 2 state |

State of CAN 2 system bus |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

T1 |

|

X35 |

|

|

|

|

LED 1 |

|

CAN 1 state |

State of CAN 1 system bus |

|

|

|

L5 |

3 |

2 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

4 |

1 |

|

|

|

Terminal X31: |

X31:1 |

|

+24 V input |

Voltage input DC +24 V |

||

|

|

L4 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L3 |

|

X36 |

|

|

|

Binary inputs and outputs |

X31:2 |

|

BZG 24 V |

Reference potential for binary signals |

|

|

|

|

|

|

|

|

|

|

(plug-in terminals) |

X31:3 |

|

DIO 0 |

Binary input or output (DIO 0) |

|

|

|

|

|

|

|

|

|

|

X31:4 |

|

DIO 1 |

Binary input or output (DIO 1) |

|

S1 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

X31:5 |

|

DIO 2 |

Binary input or output (DIO 2) |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

X37 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

X31:6 |

|

DIO 3 |

Binary input or output (DIO 3) |

|

|

|

|

|

|

|

|

|

|

X31:7 |

|

DIO 4 |

Binary input or output (DIO 4) |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

X31:8 |

|

DIO 5 |

Binary input or output (DIO 5) |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

XM |

1 |

|

1 |

X32 |

|

X31:9 |

|

DIO 6 |

Binary input or output (DIO 6) |

||

|

|

2 |

|

2 |

|

|

|||||||

|

|

L2 |

3 |

|

3 |

|

|

|

|

X31:10 |

|

DIO 7 |

Binary input or output (DIO 7) |

|

|

|

1 |

|

1 |

X33 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

|

|

L1 |

3 |

|

3 |

Terminal X34: |

X34:1 |

|

RS+ |

Signal RS485+ (COM 1) |

|||

|

|

|

2 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RS485 interfaces COM1, COM2 |

X34:2 |

|

RS+ insulated |

Signal RS485+ insulated (COM 2) |

|

|

|

|

|

|

|

|

|

|

||||

2102456075 |

(plug-in terminals) |

X34:3 |

|

RS– |

Signal RS485– (COM 1) |

||||||||

|

|

|

|

|

|

|

|

|

|

X34:4 |

|

RS– insulated |

Signal RS485– insulated (COM 2) |

|

|

|

|

|

|

|

|

|

|

X34:5 |

|

DGND |

Reference potential (COM 1) |

|

|

|

|

|

|

|

|

|

|

X34:6 |

|

GND insulated |

Reference potential (COM 2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X35 terminal: |

X35:1 |

|

USB +5 V |

|

|

|

|

|

|

|

|

|

|

USB connection |

X35:2 |

|

USB– |

Standard USB-B assignment |

|

|

|

|

|

|

|

|

|

|

X35:3 |

|

USB+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

X35:4 |

|

DGND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X36 terminal: |

X36 |

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet 1 connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

System bus (RJ45 socket) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard Ethernet assignment |

|

|

|

|

|

|

|

|

|

X37 terminal: |

X37 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Ethernet 2 connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

(RJ45 socket) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X32 terminal: |

X32:1 |

|

BZG_CAN 2 |

Reference potential for system bus |

|

|

|

|

|

|

|

|

|

CAN 2 system bus |

X32:2 |

|

CAN 2H |

CAN 2 |

|

|

|

|

|

|

|

|

|

(electrically isolated) |

X32:3 |

|

CAN 2L |

System bus CAN 2 high |

|

|

|

|

|

|

|

|

|

(plug-in terminals) |

|

|

|

System bus CAN 2 low |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X33 terminals: |

X33:1 |

|

DGND |

Reference potential for system bus |

|

|

|

|

|

|

|

|

|

CAN 1 system bus |

X33:2 |

|

CAN 1H |

CAN 1 |

|

|

|

|

|

|

|

|

|

(plug-in terminals) |

X33:3 |

|

CAN 1L |

System bus CAN 1 high |

|

|

|

|

|

|

|

|

|

|

|

|

|

System bus CAN 1 low |

|

|

|

|

|

|

|

|

|

DIP switch |

S1 |

|

Up |

Default IP address (192.168.10.4) |

|

|

|

|

|

|

|

|

|

|

Down |

IP parameter from SD memory card |

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Assembly and Installation Notes |

|

Installing the DH.21B/41B option |

||

|

4.7.2Connecting binary inputs and outputs (X31 terminal)

Terminal X31 provides eight binary inputs or outputs (e.g. for controlling external actuators/sensors).

X31

1

2

2

3

4

4

5

6

6

7

8

8

9

10

10

2102458763

Binary inputs |

• The binary inputs are electrically isolated by optocouplers. |

|

• The permitted input voltages are defined according to IEC 61131. |

|

+13 V – +30 V = "1" = contact closed |

|

–3 V – +5 V = "0" = contact open |

Binary outputs |

• The binary outputs are electrically isolated by optocouplers. |

|

• The binary outputs are short-circuit proof but not interference-voltage-proof. |

|

• The maximum permitted output current is 150 mA per binary output. All eight binary |

|

outputs can be operated simultaneously with this current. |

|

|

|

NOTICE |

|

The supply voltage must be present on X31:1/2 when using binary inputs and outputs. |

|

The DH.21B/41B option might be damaged. In this case, the specified function of the |

|

binary inputs and outputs is no longer ensured. |

|

If the supply voltage is switched off, you must switch off all other voltages at X31:1 to |

|

10, e.g. DC 24 V of switches and sensors at the binary inputs. |

|

|

|

• To prevent dangerous voltage peaks from occurring, do not connect inductive loads |

|

to the supply voltage or the binary inputs or outputs without free running diodes. |

Cable specification • Only connect cables with a minimum core cross section of 0.25 mm2 (AWG23) and a maximum core cross section of 1 mm2 (AWG18). Clamping without conductor end sleeves is possible in accordance with IEC 60999.

•Choose the type and core cross section of the connected cable in dependency of the required cable length and the load expected from your application.

For more information on binary inputs or outputs, refer to the "Technical Data" chapter.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

24 |

|

|

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced) |

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...