Page 1

ILA1B, ILA1F, ILA1R

Lexium Integrated Drive

Product manual

V2.00, 09.2008

0198441113562, V2.00, 09.2008

Page 2

Important information ILA1B, ILA1F, ILA1R

Important information

This manual is part of the product.

Carefully read this manual and observe all instructions.

Keep this manual for future reference.

Hand this manual and all other pertinent product documentation over to

all users of the product.

Carefully read and observe all safety instructions and the chapter "Before you begin - safety information".

Some products are not available in all countries.

For information on the availability of products, please consult the catalog.

Subject to technical modifications without notice.

All details provided are technical data which do not constitute warranted

qualities.

Most of the product designations are registered trademarks of their respective owners, even if this is not explicitly indicated.

2 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 3

ILA1B, ILA1F, ILA1R Table of Contents

Table of Contents

Important information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Writing conventions and symbols. . . . . . . . . . . . . . . . . . . . . . . 9

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Unit overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Components and interfaces . . . . . . . . . . . . . . . . . . . . . 12

1.3.1 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3.2 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Name plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5 Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.6 Documentation and literature references . . . . . . . . . . . 17

1.7 Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . 18

1.8 TÜV certificate for functional safety. . . . . . . . . . . . . . . . 19

2 Before you begin - safety information. . . . . . . . . . . . . . . . . . . 21

2.1 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3 Hazard categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4 Basic information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5 Functional safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 Standards and terminology . . . . . . . . . . . . . . . . . . . . . . 25

3 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.1 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.2 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.3 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.1 Supply Voltage VDC at CN1. . . . . . . . . . . . . . . . . . . 32

3.4.2 Fieldbus at CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.3 Reference value supply to CN2 . . . . . . . . . . . . . . . . 33

3.4.4 Fieldbus at CN3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.5 24V signals to CN4. . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4.6 STO safety function at CN5 and CN6. . . . . . . . . . . . 33

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 3

Page 4

Table of Contents ILA1B, ILA1F, ILA1R

3.5 Conditions for UL 508C . . . . . . . . . . . . . . . . . . . . . . . . 34

4 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 Functional safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 Engineering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 External power supply units . . . . . . . . . . . . . . . . . . . . . 37

5.1.1 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 Ground design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3 Safety function STO ("Safe Torque Off"). . . . . . . . . . . . 40

5.3.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.3 Requirements for using the safety function . . . . . . . 41

5.3.4 Application examples STO. . . . . . . . . . . . . . . . . . . . 43

5.4 Monitoring functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1 Electromagnetic compatibility, EMC . . . . . . . . . . . . . . . 46

6.2 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3.1 Wiring examples . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.3.2 Overview of all connections . . . . . . . . . . . . . . . . . . . 51

6.3.3 Connection via cable entry. . . . . . . . . . . . . . . . . . . . 52

6.3.4 Connection with industrial connectors . . . . . . . . . . . 55

6.3.5 Connection of VDC supply voltage . . . . . . . . . . . . . 55

6.3.6 PROFIBUS DP connection . . . . . . . . . . . . . . . . . . . 58

6.3.7 CAN connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.8 RS485 connection . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.3.9 24V signal interface connection. . . . . . . . . . . . . . . . 69

6.3.10 Connection of STO safety function . . . . . . . . . . . . . 70

6.3.11 Connection of reference signals for CAN or RS485. 72

6.3.12 Connection of reference signals for PROFIBUS DP 74

6.4 Connection accessories . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.1 Accessory "Insert kit, 3x I/O" . . . . . . . . . . . . . . . . . . 77

6.4.2 Accessory "Insert kit, 2x I/O, 1x STO in" . . . . . . . . . 77

6.4.3 Accessory "Insert kit, 1x STO in, 1x STO out" . . . . . 77

6.4.4 Accessory "Insert kit, 4x I/O, 1x STO in, 1x STO out" . .

78

6.5 Checking wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.1 Preparing for commissioning . . . . . . . . . . . . . . . . . . . . 82

7.2 Running commissioning . . . . . . . . . . . . . . . . . . . . . . . . 83

7.2.1 First setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.2.2 Starting 24V signal interface . . . . . . . . . . . . . . . . . . 84

7.2.3 Setting parameters for encoder . . . . . . . . . . . . . . . . 88

4 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 5

ILA1B, ILA1F, ILA1R Table of Contents

7.2.4 Testing safety functions . . . . . . . . . . . . . . . . . . . . . . 90

7.2.5 Releasing the holding brake manually . . . . . . . . . . . 90

7.2.6 Testing with relative positioning . . . . . . . . . . . . . . . . 91

7.2.7 Optimizing the motor behavior . . . . . . . . . . . . . . . . . 92

7.3 Lexium CT commissioning software . . . . . . . . . . . . . . . 94

7.3.1 Firmware update via fieldbus . . . . . . . . . . . . . . . . . . 95

7.4 Controller optimization with step response . . . . . . . . . . 96

7.4.1 Controller structure . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.4.2 Checking and optimizing default settings . . . . . . . . . 97

7.4.3 Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.4.4 Optimizing the speed controller . . . . . . . . . . . . . . . . 99

7.4.5 Setting the Posicast filter . . . . . . . . . . . . . . . . . . . . 102

7.4.6 Optimizing the position controller . . . . . . . . . . . . . . 103

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.1.1 Default parameter values . . . . . . . . . . . . . . . . . . . . 105

8.1.2 External monitoring signals . . . . . . . . . . . . . . . . . . 105

8.1.3 Positioning limits. . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.1.4 Internal monitoring signals . . . . . . . . . . . . . . . . . . . 108

8.1.5 Operating states and state transitions . . . . . . . . . . 111

8.1.6 Operating-mode-specific status information . . . . . . 112

8.1.7 Other status information . . . . . . . . . . . . . . . . . . . . . 113

8.2 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.2.1 Operating mode Jog . . . . . . . . . . . . . . . . . . . . . . . . 116

8.2.2 Operating mode Profile velocity . . . . . . . . . . . . . . . 118

8.2.3 Operating mode Profile position . . . . . . . . . . . . . . . 120

8.2.4 Operating mode Homing. . . . . . . . . . . . . . . . . . . . . 122

8.2.5 Operating mode Electronic gear. . . . . . . . . . . . . . . 129

8.3 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.3.1 Definition of the direction of rotation . . . . . . . . . . . . 133

8.3.2 Motion profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.3.3 Quick Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8.3.4 Programmable inputs and outputs . . . . . . . . . . . . . 135

8.3.5 Fast position capture . . . . . . . . . . . . . . . . . . . . . . . 139

8.3.6 Standstill window . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.3.7 Function of the holding brake . . . . . . . . . . . . . . . . . 142

9 Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . 145

9.1 Error indication and troubleshooting . . . . . . . . . . . . . . 145

9.1.1 Diagnostics via commissioning software . . . . . . . . 145

9.1.2 Diagnostics via fieldbus . . . . . . . . . . . . . . . . . . . . . 145

9.1.3 Operation state and error indication . . . . . . . . . . . . 150

9.1.4 Reset error message . . . . . . . . . . . . . . . . . . . . . . . 150

9.1.5 Error classes and error response . . . . . . . . . . . . . . 151

9.1.6 Causes of errors and troubleshooting. . . . . . . . . . . 151

9.2 Overview of error numbers . . . . . . . . . . . . . . . . . . . . . 154

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 5

Page 6

Table of Contents ILA1B, ILA1F, ILA1R

10 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

10.1 Representation of parameters . . . . . . . . . . . . . . . . . . 157

10.2 Overview Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 158

10.3 Parameter groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

10.3.1 Parameter group "CAN" . . . . . . . . . . . . . . . . . . . . . 159

10.3.2 Parameter group "Capture" . . . . . . . . . . . . . . . . . . 159

10.3.3 Parameter group "Commands" . . . . . . . . . . . . . . . 160

10.3.4 Parameter group "Config" . . . . . . . . . . . . . . . . . . . 161

10.3.5 Parameter group "Control". . . . . . . . . . . . . . . . . . . 163

10.3.6 Parameter group "ErrMem0" . . . . . . . . . . . . . . . . . 163

10.3.7 Parameter group "Gear". . . . . . . . . . . . . . . . . . . . . 164

10.3.8 Parameter group "Homing" . . . . . . . . . . . . . . . . . . 165

10.3.9 Parameter group "I/O" . . . . . . . . . . . . . . . . . . . . . . 166

10.3.10 Parameter group "Manual". . . . . . . . . . . . . . . . . . . 167

10.3.11 Parameter group "Motion" . . . . . . . . . . . . . . . . . . . 168

10.3.12 Parameter group "Profibus" . . . . . . . . . . . . . . . . . . 168

10.3.13 Parameter group "ProgIO0" . . . . . . . . . . . . . . . . . . 169

10.3.14 Parameter group "PTP" . . . . . . . . . . . . . . . . . . . . . 170

10.3.15 Parameter group "RS485" . . . . . . . . . . . . . . . . . . . 171

10.3.16 Parameter group "Settings" . . . . . . . . . . . . . . . . . . 172

10.3.17 Parameter group "Status" . . . . . . . . . . . . . . . . . . . 173

10.3.18 Parameter group "VEL" . . . . . . . . . . . . . . . . . . . . . 177

11 Accessories and spare parts . . . . . . . . . . . . . . . . . . . . . . . . . 179

11.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

11.2 Gearboxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

12 Service, maintenance and disposal . . . . . . . . . . . . . . . . . . . . 181

12.1 Service address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

12.2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

12.2.1 Lifetime STO safety function . . . . . . . . . . . . . . . . . 182

12.3 Replacing units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

12.4 Shipping, storage, disposal. . . . . . . . . . . . . . . . . . . . . 183

6 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 7

ILA1B, ILA1F, ILA1R Table of Contents

13 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1 Units and conversion tables . . . . . . . . . . . . . . . . . . . . 185

13.1.1 Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1.2 Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1.3 Force. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1.4 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1.5 Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.1.6 Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.1.7 Moment of inertia . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.1.8 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.1.9 Conductor cross section . . . . . . . . . . . . . . . . . . . . . 186

13.2 Terms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . 187

14 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 7

Page 8

Table of Contents ILA1B, ILA1F, ILA1R

8 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 9

ILA1B, ILA1F, ILA1R Writing conventions and symbols

Writing conventions and symbols

Work steps If work steps must be performed consecutively, this sequence of steps

is represented as follows:

쮿 Special prerequisites for the following work steps

왘 Step 1

컅 Specific response to this work step

왘 Step 2

If a response to a work step is indicated, this allows you to verify that the

work step has been performed correctly.

Unless otherwise stated, the individual steps must be performed in the

specified sequence.

Bulleted lists The items in bulleted lists are sorted alphanumerically or by priority. Bul-

leted lists are structured as follows:

• Item 1 of bulleted list

• Item 2 of bulleted list

–Subitem for 2

–Subitem for 2

• Item 3 of bulleted list

Making work easier Information on making work easier is highlighted by this symbol:

Sections highlighted this way provide supplementary

information on making work easier.

Parameters Parameters are shown as follows:

Gruppe.Name Index:Subindex

SI units SI units are the original values. Converted units are shown in brackets

behind the original value; they may be rounded.

Example:

Minimum conductor cross section: 1.5 mm

2

(AWG 14)

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 9

Page 10

Writing conventions and symbols ILA1B, ILA1F, ILA1R

10 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 11

ILA1B, ILA1F, ILA1R 1 Introduction

1 Introduction

1.1 About this manual

This manual is valid for all ILA1B, ILA1F, ILA1R standard products. This

chapter lists the type code for this product. The type code can be used

to identify whether your product is a standard product or a customized

model.

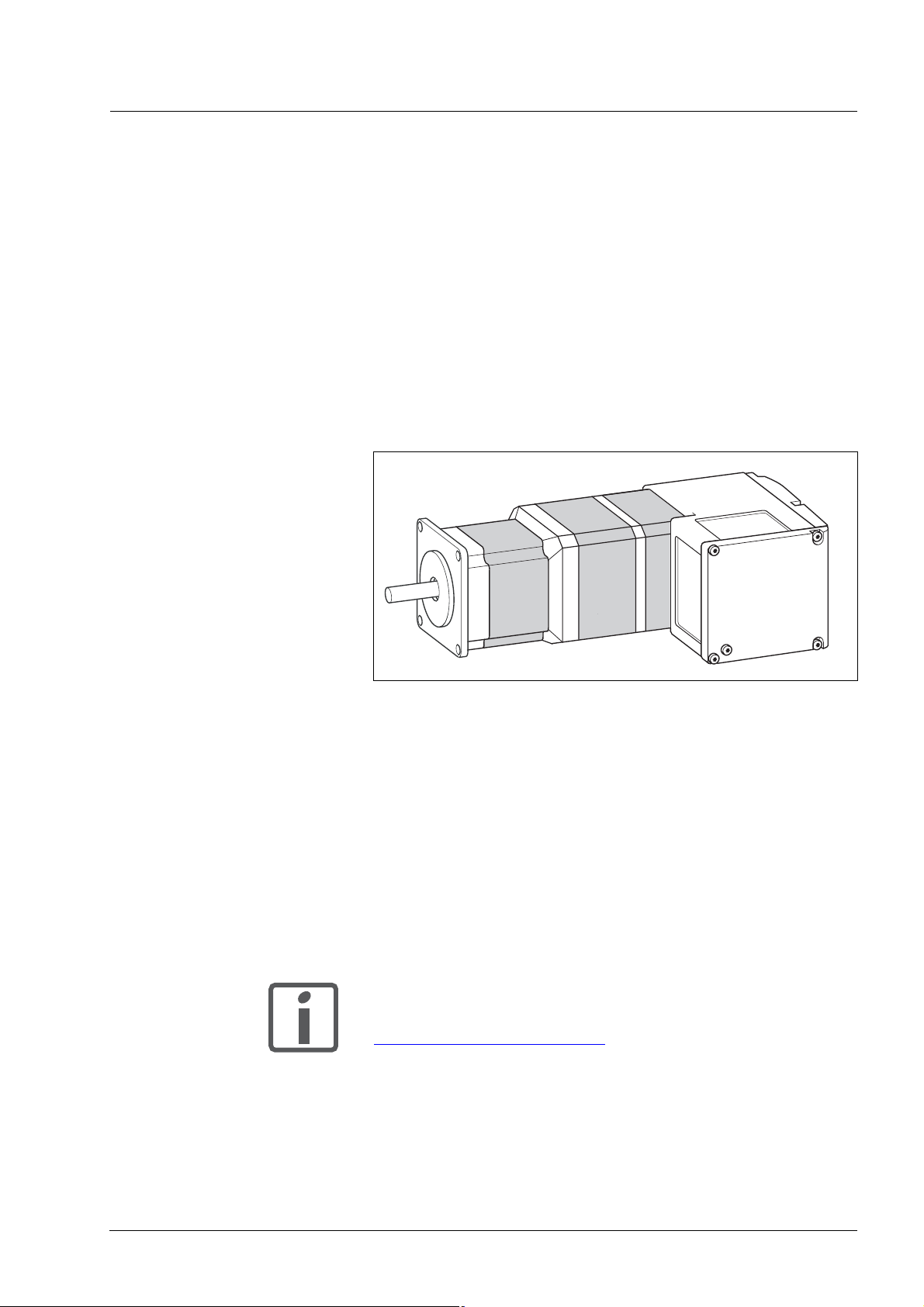

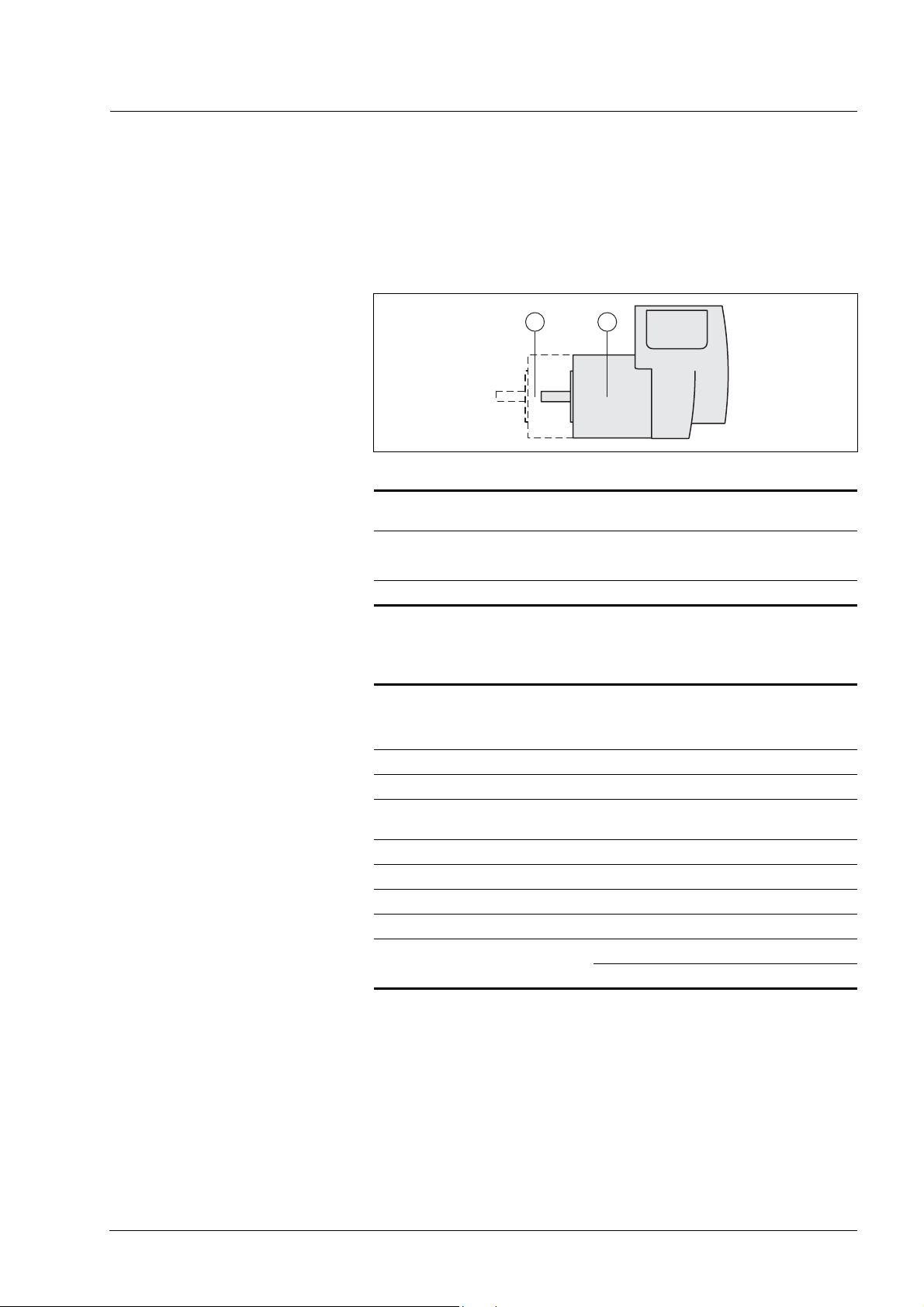

1.2 Unit overview

Figure 1.1 Device overview

The "Lexium Integrated Drive" consists of a motor and integrated electronics. The product integrates interfaces, control electronics, a holding

brake (optional) and the power stage.

Reference value supply The "Lexium Integrated Drive" moves the motor according to the com-

mands recieved by a fieldbus master, e.g. a PLC or a PC.

Safety function The integrated safety function STO (IEC 61800-5-2) meets the require-

ments of Safety Integrity Level SIL2. The safety function allows for a category 0 stop as per EN 60204-1 without external power contactors. It is

not necessary to interrupt the supply voltage. This reduces the system

costs and the response times.

The STO safety function is available as of device revision RS10 (see

nameplate).

Using the library considerably facilitates controlling the

device. The library is available for download from the

Internet.

http://www.schneider-electric.com

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 11

Page 12

1 Introduction ILA1B, ILA1F, ILA1R

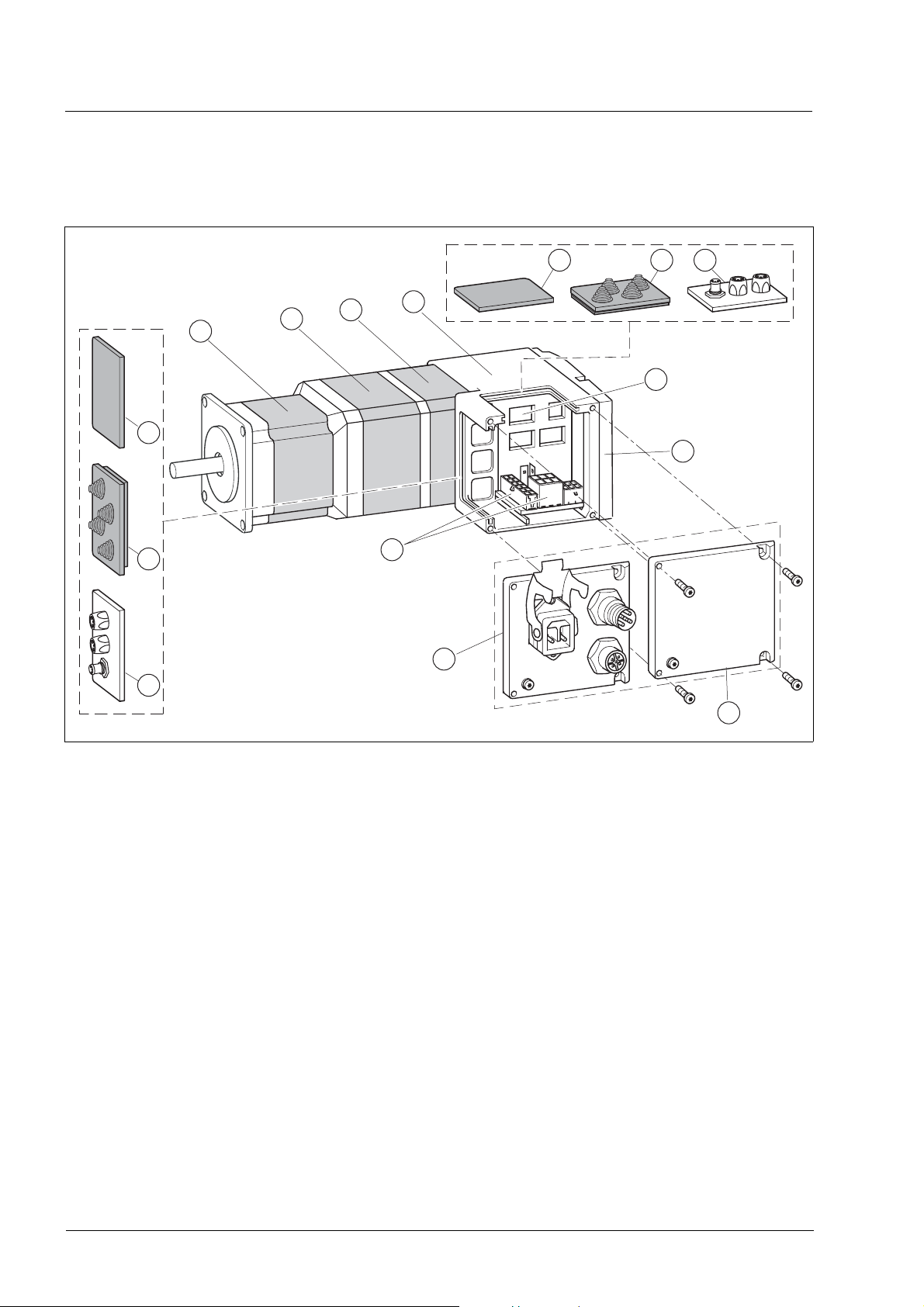

1.3 Components and interfaces

6 75

1

2

5

6

7

3

4

8

9

12

11

10

Figure 1.2 Components and interfaces

(1) Synchronous AC servo motor

(2) Holding brake (optional)

(3) Encoder

(4) Electronics housing

(5) Insert for sealing (accessory)

(6) Insert with cable entry (accessory)

(7) I/O insert with industrial connector (accessory)

(8) Switches for settings

(9) Cover of electronics housing, must not be removed

(10) Cover of connector housing, to be removed for installation

(11) Cover with industrial connector for Vdc supply voltage and IN/

OUT fieldbus connection (optional)

(12) Electrical interfaces

12 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 13

ILA1B, ILA1F, ILA1R 1 Introduction

1.3.1 Components

Motor The motor is a brushless AC synchronous servo motor with 3-phase

technology. The motor has a high power density due to the use of the latest magnetic materials and an optimized design.

Encoder The standard drive system operates with a singleturn encoder.

The singleturn encoder has an internal resolution of 16384 increments

per revolution.

The drive system can optionally be equipped with a multiturn encoder.

The multiturn encoder covers a range of 4096 motor revolutions.

Electronics The electronic system comprises control electronics and power stage.

They have a common power supply and are not galvanically isolated.

The drive can be parameterized and controlled via the fieldbus interface.

4 digital 24V signals are also available. Each of them can be used as an

input or output.

Holding brake The drive can optionally be equipped with an integrated holding brake.

The holding brake is controlled automatically.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 13

Page 14

1 Introduction ILA1B, ILA1F, ILA1R

1.3.2 Interfaces

Standard available interfaces:

Supply voltage VDC The supply voltage VDC supplies the control electronics and the power

stage.

The ground connections of all interfaces are galvanically

connected. For more information see chapter 5.2 "Ground

design". This chapter also provides information on

protection against reverse polarity.

Fieldbus interface Functions:

• Profibus DP connection

• CAN bus connection

• RS485 bus connection

The fieldbus interface is used for parameterizing and controlling the

drive. The fieldbus interface allows the drive to be integrated into a fieldbus network and controlled by a master such as a PLC.

The drive can be commissioned via any of the above interfaces. This requires, for example, a PC with a suitable fieldbus converter (e.g. USBCAN). The commissioning software is available for PCs; it supports the

various fieldbus versions.

The firmware can be updated via any of the interfaces.

24 V signal interface 4 digital 24V signals are available. Each of them can be used as an input

or outputs.

The 24V signals are availab le to the master controller. However, it is

also possible to parameterize special functions such as connection of

limit switches.

14 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 15

ILA1B, ILA1F, ILA1R 1 Introduction

1.4 Name plate

The nameplate contains the following data:

1

2

3

4

5

6

7

Figure 1.3 Nameplate

IL ...

I ...

U

N

M

N

I

max

n

N

DOM

Insulation class

T

ambmax

PR

ID

SN

Rev

made in Germany

(1) Type code

(2) Type code (old designation)

(3) Nominal voltage

(4) Nominal torque

(5) Maximum input current

(6) Nominal speed

(7) Date of manufacture

(8) Thermal class

(9) Maximum ambient air temperature

(10) Software revision

(11) Hardware revision

(12) Firmware number

(13) Material number

(14) Serial Number

RS

8

9

10

USC

11

12

13

14

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 15

Page 16

1 Introduction ILA1B, ILA1F, ILA1R

1.5 Type code

ILA 1F57 1PB1A0--

Motor

ILA = Servo motor

Supply voltage

1 = 24 ... 36 V

Communication interface

B = PROFIBUS DP

F = CANopen DS301

R = RS485

Size

57 = 57 mm

DC

Length

1 = 1 stack

2 = 2 stacks

Winding

P = Medium speed of rotation/medium torque

T = High speed of rotation/low torque

Connection version

B = Printed circuit board connector

C = Industrial connector

Position capture

1 = Servo Singleturn

2 = Servo Multiturn

Holding brake

A = Without holding brake

F = With holding brake

Gearbox

0 = Without gearbox

1)

.

2)

Reserved

1) Not available in combination with the holding brake option

2) Not available in combination with the servo multiturn option.

Customized product In the case of a customized product, position 9 is an "S".

Positions 10 ... 13 are the number of the customized product.

Example: IL••••••S1234--

16 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 17

ILA1B, ILA1F, ILA1R 1 Introduction

1.6 Documentation and literature references

The following manuals belong to this product:

• Product manual, describes the technical data, installation, commissioning and all operating modes and functions.

• Fieldbus manual, description required to integrate the product into

a fieldbus.

Source product manuals The current product manuals are available for download from the Inter-

net.

http://www.schneider-electric.com

Source EPLAN Macros For easier engineering, macro files and product master data are availa-

ble for download from the Internet at:

http://www.schneider-electric.com

Additional literature We recommend the following literature for more in-depth information:

• Ellis, George: Control System Design Guide. Academic Press

• Kuo, Benjamin; Golnaraghi, Farid: Automatic Control Systems. John

Wiley & Sons

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 17

Page 18

1 Introduction ILA1B, ILA1F, ILA1R

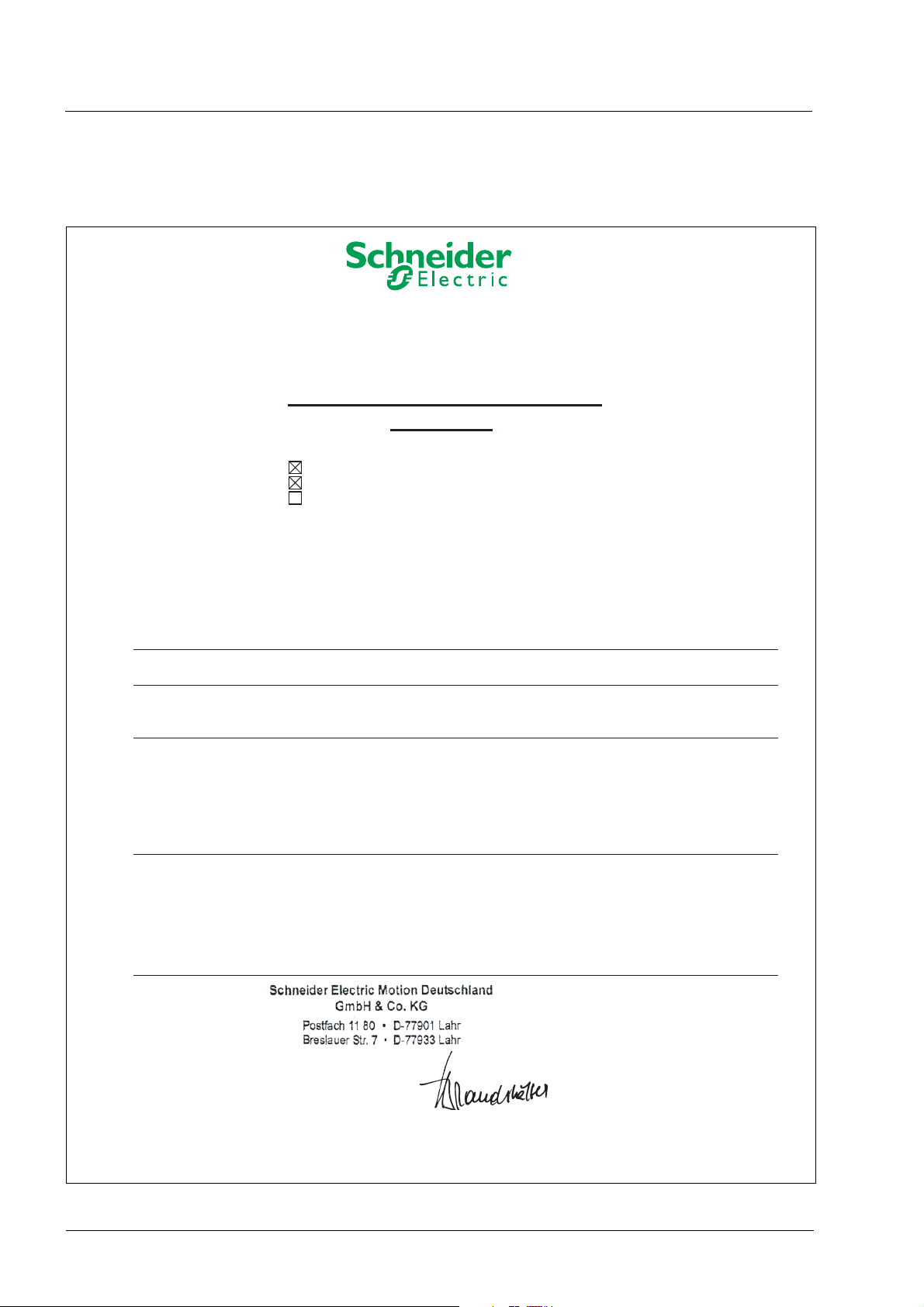

1.7 Declaration of conformity

SCHNEIDER ELECTRIC MOTION DEUTSCHLAND GmbH & Co. KG

Breslauer Str. 7 D-77933 Lahr

EC DECLARATION OF CONFORMITY

EAR 2008

Y

according to EC Directive Machinery 98/37/EC

according to EC Directive EMC 2004/108/EC

according to EC Directive Low Voltage 2006/95/EC

We declare that the products listed below meet the requirements of the mentioned EC

Directives with respect to design, construction and version distributed by us. This

declaration becomes invalid with any modification on the products not authorized by us.

Designation: Motors with integrated control electronics

Type: ILA, ILE, ILS

Product number: 0x6600xxxxxxx, 0x6610xxxxxxx, 0x66206xxxxxx, 0x66307xxxxxx

0x6640xxxxxxx, 0x66606xxxxxx, 0x66707xxxxxx

Applied

harmonized

standards,

especially:

EN ISO 13849-1:2006, Performance Level "d" (category 3)

EN 61800-3:2004, second environment

EN 62061:2005, SILcl 2

EN 61508:2001, SIL 2

Applied

national standards

UL 508C

Product documentation

and technical

specifications,

especially:

Company stamp:

Date/ Signature: 10 July 2008

Name/ Department: Wolfgang Brandstätter/Development

18 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 19

ILA1B, ILA1F, ILA1R 1 Introduction

1.8 TÜV certificate for functional safety

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 19

Page 20

1 Introduction ILA1B, ILA1F, ILA1R

20 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 21

ILA1B, ILA1F, ILA1R 2 Before you begin - safety information

2 Before you begin - safety information

2.1 Qualification of personnel

Only appropriately trained persons who are familiar with and understand

the contents of this manual and all other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must have sufficient technical training,

knowledge and experience and be able to foresee and detect potential

hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical and electronic equipment of the

entire system in which the product is used.

All persons working on and with the product must be fully familiar with all

applicable standards, directives, and accident prevention regulations

when performing such work.

2.2 Intended use

This product is a motor with an integrated drive and intended for industrial use according to this manual.

The product may only be used in compliance with all applicable safety

regulations and directives, the specified requirements and the technical

data.

Prior to using the product, you must perform a risk assessment in view

of the planned application. Based on the results, the appropriate safety

measures must be implemented.

Since the product is used as a component in an entire system, you must

ensure the safety of persons by means of the design of this entire system (e.g. machine design).

Operate the product only with the specified cables and accessories. Use

only genuine accessories and spare parts.

The product must NEVER be operated in explosive atmospheres (hazardous locations, Ex areas).

Any use other than the use explicitly permitted is prohibited and can result in hazards.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 21

Page 22

2 Before you begin - safety information ILA1B, ILA1F, ILA1R

2.3 Hazard categories

Safety instructions to the user are highlighted by safety alert symbols in

the manual. In addition, labels with symbols and/or instructions are attached to the product that alert you to potential hazards.

Depending on the seriousness of the hazard, the safety instructions are

divided into 4 hazard categories.

@ DANGER

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

@ WARNING

WARNING indicates a potentially hazardous situation, which, if not

avoided, can result in death, serious injury, or equipment damage.

@ CAUTION

CAUTION indicates a potentially hazardous situation, which, if not

avoided, can result in injury or equipment damage.

CAUTION

CAUTION used without the safety alert symbol, is used to address

practices not related to personal injury (e.g. can result in equipment

damage).

22 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 23

ILA1B, ILA1F, ILA1R 2 Before you begin - safety information

2.4 Basic information

@ DANGER

UNINTENDED CONSEQUENCES OF EQUIPMENT OPERATION

When the system is started, the drives are usually out of the operator's view and cannot be visually monitored.

• Only start the system if there are no persons in the hazardous

area.

Failure to follow these instructions will result in death or serious

injury.

@ WARNING

UNEXPECTED MOVEMENT

Drives may perform unexpected movements because of incorrect wiring, incorrect settings, incorrect data or other errors.

Interference (EMC) may cause unpredictable responses in the system.

• Carefully install the wiring in accordance with the EMC requirements.

• Switch off the voltage at the inputs STO_A

(PWRR_B

switching on and configuring the drive system.

• Do NOT operate the drive system with unknown settings or data.

• Perform a comprehensive commissioning test.

Failure to follow these instructions can result in death or serious

injury.

) to avoid an unexpected restart of the motor before

(PWRR_A) and STO_B

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 23

Page 24

2 Before you begin - safety information ILA1B, ILA1F, ILA1R

@ WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are EMERGENCY

STOP, overtravel stop, power outage and restart.

• Separate or redundant control paths must be provided for critical

functions.

• System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

• Observe the accident prevention regulations and local safety

guidelines.

• Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death or serious

injury.

1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control

and to NEMA ICS 7.1 (latest edition), Safety Standards for Construction and

Guide for Selection, Installation for Construction and Operation of AdjustableSpeed Drive Systems.

1)

2.5 Functional safety

@ CAUTION

UNEXPECTED BEHAVIOR AND DESTRUCTION OF SYSTEM COMPONENTS

When you work on the wiring and when you unplug or plug in connectors, this may cause unexpected behavior and destruction of system

components.

• Switch the power supply off before working on the wiring.

Failure to follow these instructions can result in injury or equipment damage.

Using the safety functions integrated in this product requires careful

planning. For more information see chapter5.3 "Safety function STO

("Safe Torque Off")" on page 40.

24 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 25

ILA1B, ILA1F, ILA1R 2 Before you begin - safety information

2.6 Standards and terminology

Technical terms, terminology and the corresponding descriptions in this

manual are intended to use the terms or definitions of the pertinent

standards.

In the area of drive systems, this includes, but is not limited to, terms

such as "safety function", "safe state", "fault", "fault reset", "failure", "error", "error message", "warning", "warning message", "alarm", etc.

Among others, these standards include:

• IEC 61800 series: "Adjustable speed electrical power drive systems"

• IEC 61800-7 series: "Adjustable speed electrical power drive systems - Part 7-1: Generic interface and use of profiles for power drive

systems - Interface definition"

• IEC 61158 series: "Industrial communication networks - Fieldbus

specifications"

• IEC 61784 series: "Industrial communication networks - Profiles"

• IEC 61508 series: "Functional safety of electrical/electronic/programmable electronic safety-related systems"

Also see the glossary at the end of this manual.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 25

Page 26

2 Before you begin - safety information ILA1B, ILA1F, ILA1R

26 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 27

ILA1B, ILA1F, ILA1R 3 Technical Data

3 Technical Data

This chapter contains information on the ambient conditions and on the

mechanical and electrical properties of the device family and the accessories.

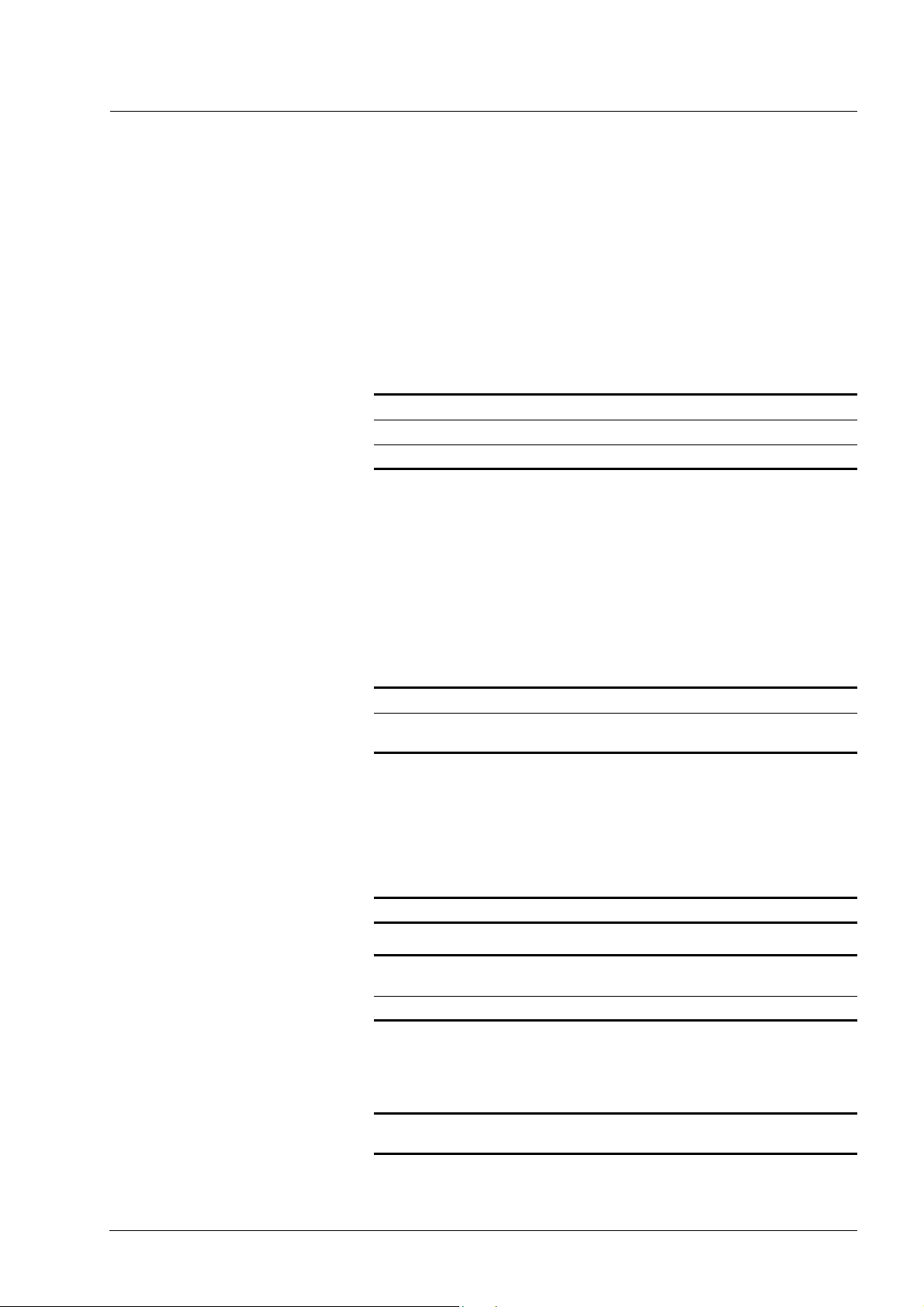

3.1 Certifications

Product certifications:

Certified by Assigned number Validity

TÜV Nord SAS-1728/08 2013-01-09

UL File E 153659

Certified safety function This product has the following certified safety function:

• Safety function STO "Safe Torque Off" (IEC 61800-5-2)

3.2 Ambient conditions

Ambient temperature during

operation

Ambient conditions transportation

and storage

Temperature

The maximum permissible ambient temperature during operation depends on the distance between the devices and the required power. Observe the pertinent instructions in the chapter Installation.

Operating temperature

Operating temperature with cur-

rent reduction of 2% per Kelvin

1) Limit values with flanged motor (steel plate 300x300x10 mm)

2) If the product is to be used in compliance with UL 508C, note the information pro-

vided in chapter 3.5 "Conditions for UL 508C".

1) 2)

[°C] 0 ... 50

[°C] 50 ... 65

1)

The environment during transport and storage must be dry and free from

dust. The maximum vibration and shock load must be within the specified limits.

Temperature [°C] -25 ... +70

Max. temperature of power

1)

stage

Max. temperature of motor

1) Can be read via parameter

2) Measured on the surface

2)

[°C] 105

[°C] 110

Relative humidity The following relative humidity is permissible during operation:

Relative humidity (non-condensing)

0198441113562, V2.00, 09.2008

[%] 15 ... 85

Lexium Integrated Drive 27

Page 28

3 Technical Data ILA1B, ILA1F, ILA1R

Installation altitude The installation altitude is defined as height above sea level.

Installation altitude [m] ≤1000

Vibration and shock

EMC

Vibartion, sinusoidal As per IEC/EN 60068-2-6

Shock, semi-sinusoidal As per IEC/EN 60068-2-27:

Emission IEC/EN 61800-3: Class C2

Noise immunity IEC/EN 61800-3: Second environment

0.15 mm (from 10 Hz ... 60 Hz)

20 m/s2 (from 10 Hz ... 500 Hz)

2

150 m/s

EN 61000-6-4

EN 55022: Class A

(11 ms)

28 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 29

ILA1B, ILA1F, ILA1R 3 Technical Data

3.3 Mechanical data

3.3.1 Degree of protection

IP degree of protection The product has the following IP degree of protection as per EN 60529.

1 2

Figure 3.1 IP degree of protection

Item Degree of

protection

1 Shaft bushing

Shaft bushing with GBX gear (accessory)

2 Housing, except shaft bushing IP54

IP41

IP54

The total degree of protection is determined by the component with the

lowest degree of protection.

Overview of IP degrees of

protection

First digit Second digit

Protection against intrusion of

objects

0 No protection 0 No protection

1 External objects >50 mm 1 Vertically falling dripping water

2 External objects >12 mm 2 Dripping water falling at an angle

3 External objects >2.5 mm 3 Spraying water

4 External objects >1 mm 4 Splashing water

5 Dust-protected 5 Water jets

6 Dust-tight 6 Heavy sea

Protection against intrusion of water

(75 ° ... 90 °)

7Immersion

8Submersion

Degree of protection if STO is used You must ensure that conductive substances cannot get into the product

(pollution degree 2). If you use the safety function and conductive substances get into the product, the safety function may become inoperative.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 29

Page 30

3 Technical Data ILA1B, ILA1F, ILA1R

3.3.2 Mounting position

Mounting position The following mounting positions are defined and approved as per EN

60034-7:

• IM B5 drive shaft horizontal

• IM V1 drive shaft vertical, shaft end down

• IM V3 drive shaft vertical, shaft end up

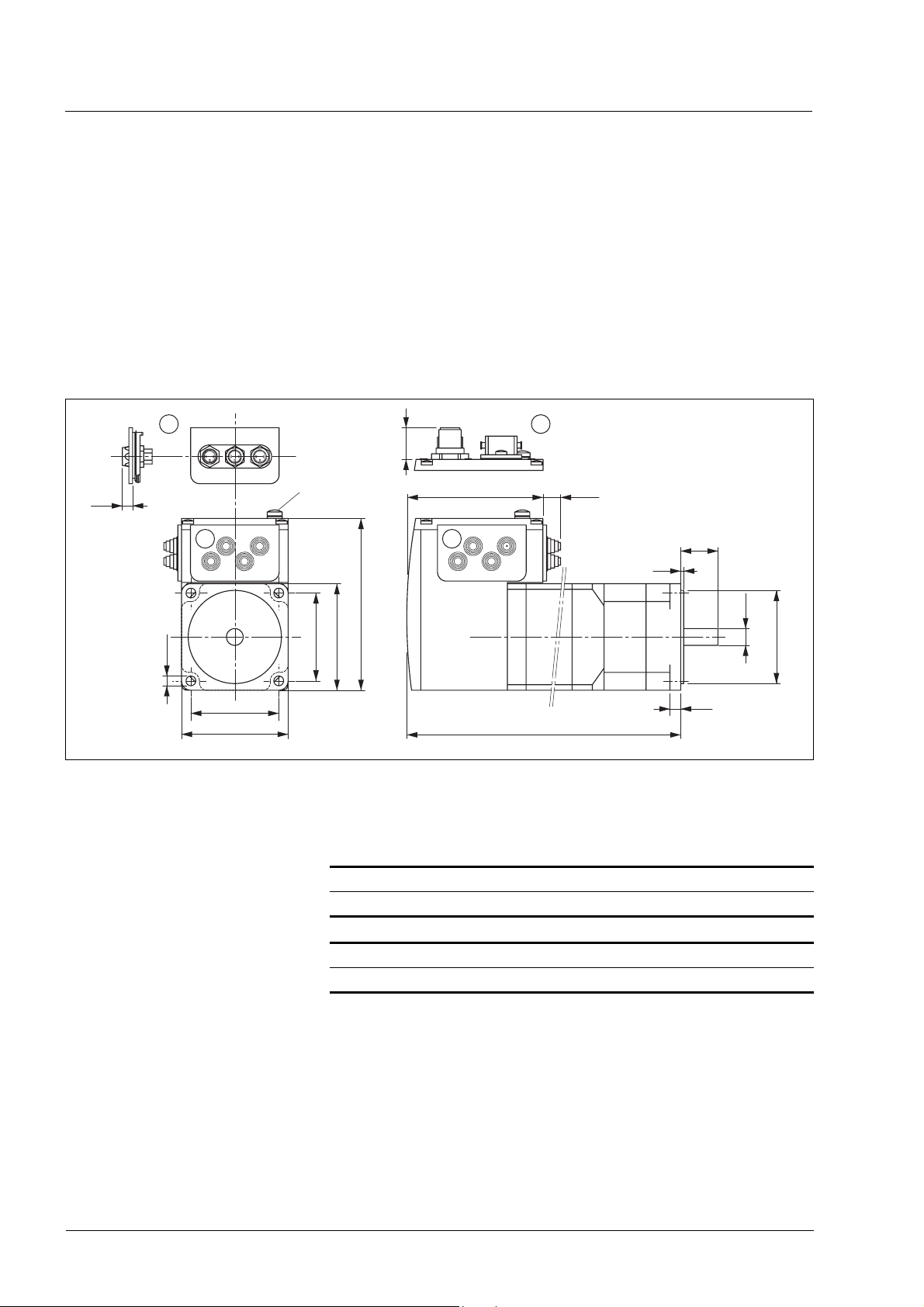

3.3.3 Dimensions

2 3

17

5.5

M4

1 1

92.2

57.2

Ø 5.2

47.14

57.2

47.14

Figure 3.2 Dimensions

(1) Insert with cable entry (accessory)

(2) Insert kit (accessory)

(3) Industrial connector (option)

Total length L

ILA••571... ••1A0 ••2A0 ••1F0

L [mm] 145.3 179.3 190.8

73

9.5

20

1.6

Ø9 j6

Ø 50 h8

5.8

L

ILA••572... ••1A0 ••2A0 ••2F0

L [mm] 163.8 197.8 209.3

30 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 31

ILA1B, ILA1F, ILA1R 3 Technical Data

3.4 Electrical Data

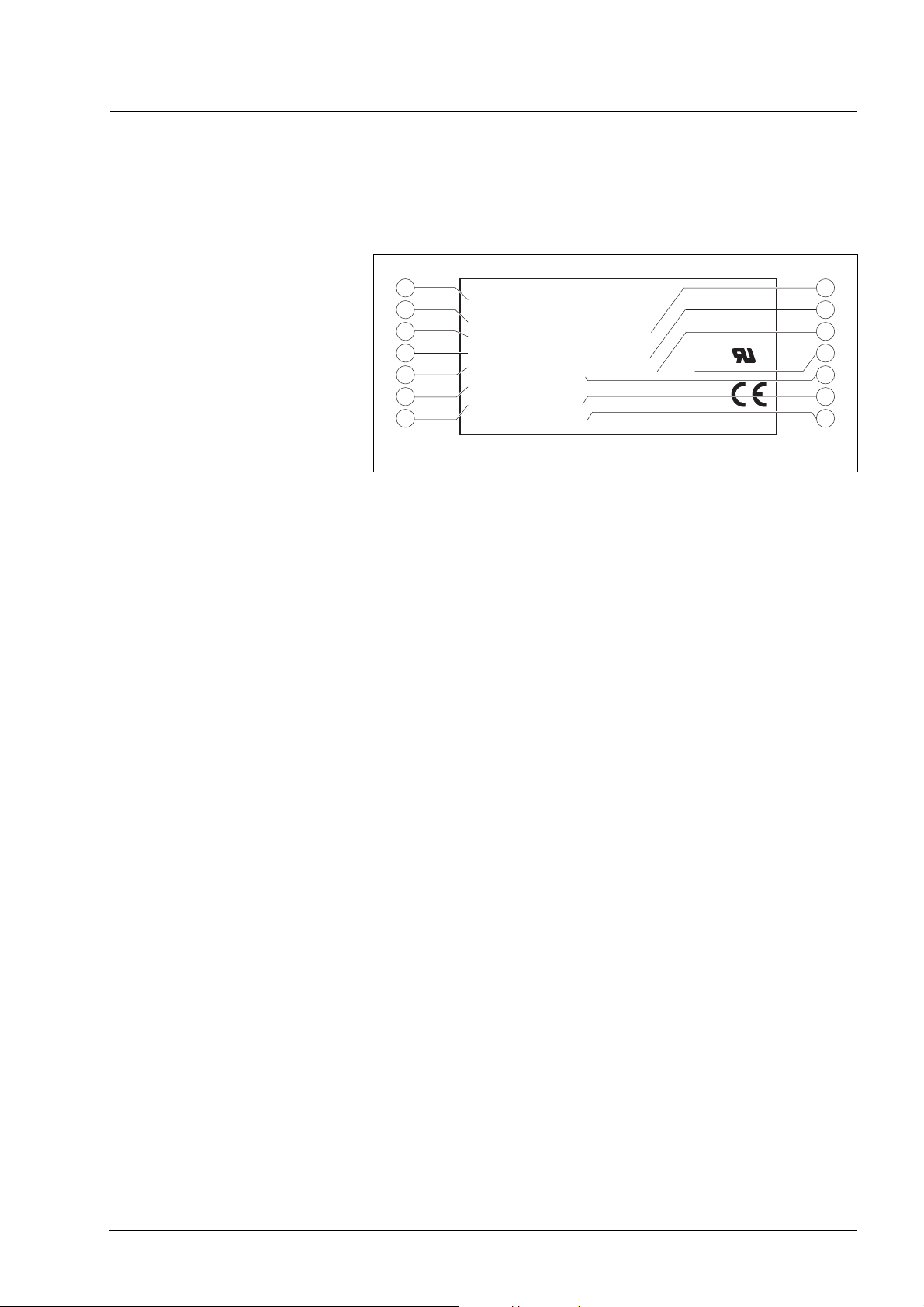

Overview of printed circuit board

connectors

Figure 3.3 Overview of printed circuit board connectors

3.4.1 Supply Voltage VDC at CN1

Nominal voltage [Vdc] 24 / 36 24 / 36

Limit values [V

Ripple at nominal voltage [Vpp] ≤3.6 ≤3.6

Max. continuous current input

Winding type P

Winding type T

Peak input current

Winding type P

Winding type T

Fuse to be connected upstream

1) The actual power requirement is often significantly lower, because the maximum

possible motor torque is usually not required for operation of a system.

2) See chapter 5.1.1 "Supply voltage"

71

82

9 3

10 4

11 5

12 6

0VDC

CN1

VDC

123

456

dc

1)

2)

[A]

[A]

[A] ≤16 ≤16

CN5

1

2

CN6

123

456

CN4CN3CN2

ILA1•571 ILA1•572

] 18 ... 40 18 ... 40

5

7.5

7

11

7

7.5

8.5

9

Inrush current current Charging current for capacitor C=1500 µF

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 31

Page 32

3 Technical Data ILA1B, ILA1F, ILA1R

3.4.2 Fieldbus at CN2

CAN bus signals The CAN bus signals comply with the ISO 11898 standard and are not

galvanically isolated.

Transmission rate [kBaud] 50 / 100 / 125 / 250 / 500 / 800 /

Transmission protocol CANopen as per DS301

1000

Profibus signals The Profibus signals comply with the RS485 standard and are galvani-

cally isolated.

Transmission rate [kBaud] 9.6 / 19.2 / 45.45 / 93.75 / 187.5 /

500 / 1500 / 3000 / 6000 / 12000

Transmission protocol Profibus DP V0

3.4.3 Reference value supply to CN2

Pulse/direction, A/B/I input signals Reference signals for operating mode Electronic Gear

Symmetrical Conforming to RS422

Input frequency pulse/direction [kHz] ≤200

Input frequency A/B [kHz] ≤200

3.4.4 Fieldbus at CN3

RS485 signals The RS485 signals conform to the RS485 standard and are not galvan-

ically isolated.

3.4.5 24V signals to CN4

Signal inputs The signal inputs are galvanically connected to 0VDC and not protected

Transmission rate [kBaud] 9.6 / 19.2 / 38.4

Transmission protocol Manufacturer-specific protocol

against reverse polarity.

Logic 0 (U

Logic 1 (U

Input current (typical at 24V) [mA] 2

Debounce time IO0 ... IO3 [ms] 0.1

Debounce time IO2 and IO3

1) When the function "Fast Position Capture is used"

) [V] -3 ... +4.5

low

) [V] +15 ... +30

high

1)

[ms] 0.01

32 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 33

ILA1B, ILA1F, ILA1R 3 Technical Data

Signal outputs The signal outputs are galvanically connected to 0VDC and short-circuit

protected.

Nominal voltage [V] 24

Voltage range [V] 23 ... 25

Maximum current (total) [mA] 200

Maximum current per output [mA] 100

Suitable for inductive loads [mH] 1000

3.4.6 STO safety function at CN5 and CN6

The signal inputs are galvanically connected to 0VDC.

Data for maintenance plan and

safety calculations

Logic 0 (U

Logic 1 (U

Input current STO_A (PWRR_A)

(typical at 24V)

Input current STO_B

(typical at 24V)

Debounce time [ms] 1

Detection of signal difference

between STO_A (PWRR_A) and

STO_B

Response time (until shutdown of

power stage)

Permitted test pulse width of

upstream devices

) [V] -3 ... +4.5

low

) [V] +15 ... +30

high

[mA] ≤10

(PWRR_B)

(PWRR_B)

[mA] ≤3

[s] ≥1

[ms] <50

[ms] <1

Use the following data of the STO safety function for your maintenance

plan and the safety calculations:

Lifetime (IEC 61508) 20 years

SFF (IEC 61508)

Safe Failure Fraction

HFT (IEC 61508)

Hardware Fault Tolerance

Type A subsystem

Safety integrity level

IEC 61508

IEC 62061

PFH (IEC 61508)

Probability of Dangerous Hardware Failure per Hour

PL (ISO 13849-1)

Performance Level

MTTF

(EN 13849-1)

d

Mean Time to Dangerous Failure

DC (EN 13849-1)

Diagnostic Coverage

[%] 66

1

SIL2

SILCL2

[1/h] 1.84*10

d (Category 3)

4566 years

[%] 90

-9

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 33

Page 34

3 Technical Data ILA1B, ILA1F, ILA1R

3.5 Conditions for UL 508C

If the product is used to comply with UL 508C, the following conditions

must be met:

Ambient temperature during

operation

Pollution degree Use in an environment with pollution degree 2.

Power supply Use only power supply units that are approved for overvoltage category

Wiring Use only 60/75 °C copper conductors.

Surrounding air temperature [°C] 0 ... +50

Surrounding air temperature with

current reduction of 2% per Kelvin

III.

[°C] 50 ... 65

34 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 35

ILA1B, ILA1F, ILA1R 4 Basics

4Basics

4.1 Functional safety

Automation and safety engineering are two areas that were completely

separated in the past but recently have become more and more integrated. Engineering and installation of complex automation solutions

are greatly simplified by integrated safety functions.

Usually, the safety engineering requirements depend on the application.

The level of the requirements results from the risk and the hazard potential arising from the specific application.

Working with IEC 61508

IEC 61508 standard The standard IEC 61508 "Functional safety of electrical/electronic/pro-

grammable electronic safety-related systems" covers the safety-related

function. It is not only one single component but the entire function chain

(e.g. from the sensor through the logical processing unit to the actuator)

that is considered as one single unit. This function chain must meet the

requirements of the specific safety integrity level as a whole. Systems

and components that can be used in various applications for safety tasks

with comparable risk levels can be developed on this basis.

SIL, Safety Integrity Level The standard IEC 61508 defines 4 safety integrity levels (SIL) for safety

functions. SIL1 is the lowest level and SIL4 is the highest level. A hazard

and risk analysis serves as a basis for determining the required safety

integrity level. This is used to decide whether the relevant function chain

is to be considered as a safety function and which hazard potential it

must cover.

PFH, Probability of a dangerous

hardware failure per hour

To maintain the safety function, the IEC 61508 standard requires various levels of measures for avoiding and controlling faults, depending on

the required SIL. All components of a safety function must be subjected

to a probability assessment to evaluate the effectiveness of the measures implemented for controlling faults. This assessment determines the

PFH (probability of a dangerous failure per hour) for a safety system.

This is the probability per hour that a safety system fails in a hazardous

manner and the safety function cannot be correctly executed. Depending on the SIL, the PFH must not exceed certain values for the entire

safety system. The individual PFH values of a function chain are added;

the total PFH value must not exceed the maximum value specified in the

standard.

SIL PFH at high demand or continuous demand

4 ≥10-9 ... <10

3 ≥10-8 ... <10

2 ≥10-7 ... <10

1 ≥10-6 ... <10

-8

-7

-6

-5

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 35

Page 36

4 Basics ILA1B, ILA1F, ILA1R

HFT and SFF Depending on the SIL for the safety system, the IEC 61508 standard re-

quires a specific hardware fault tolerance HFT in connection with a specific proportion of safe failures SFF (safe failure fraction). The hardware

fault tolerance is the ability of a system to execute the required safety

function in spite of the presence of one or more hardware faults. The

SFF of a system is defined as the ratio of the rate of safe failures to the

total failure rate of the system. According to IEC 61508, the maximum

achievable SIL of a system is partly determined by the hardware fault tolerance HFT and the safe failure fraction SFF of the system.

SFF HFT type A subsystem HFT type B

subsystem

012 012

< 60% SIL1 SIL2 SIL3 --- SIL1 SIL2

60% ... <90% SIL2 SIL3 SIL4 SIL1 SIL2 SIL3

90% ... < 99% SIL3 SIL4 SIL4 SIL2 SIL3 SIL4

≥99% SIL3 SIL4 SIL4 SIL3 SIL4 SIL4

Fault avoidance measures Systematic errors in the specifications, in the hardware and the soft-

ware, usage faults and maintenance faults of the safety system must be

avoided to the maximum degree possible. To meet these requirements,

IEC 61508 specifies a number of measures for fault avoidance that must

be implemented depending on the required SIL. These measures for

fault avoidance must cover the entire life cycle of the safety system, i.e.

from design to decommissioning of the system.

36 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 37

ILA1B, ILA1F, ILA1R 5 Engineering

5 Engineering

This chapter contains information on the application of the product that

is vital in the design phase.

5.1 External power supply units

@ DANGER

ELECTRIC SHOCK CAUSED BY INCORRECT POWER SUPPLY UNIT

The VDC and +24VDC supply voltages are connected with many exposed signal connections in the drive system.

• Use a power supply unit that meets the PELV (Protective Extra

Low Voltage) requirements.

• Connect the negative output of the power supply unit to PE

(ground).

Failure to follow these instructions will result in death or serious

injury.

5.1.1 Supply voltage

General The power supply unit must be rated for the power requirements of the

drive. The input current can be found in the technical data.

The actual power requirements are often significantly lower because the

maximum possible motor torque is usually not required for normal operation of a system.

When designing the system, note that the input current of the drive is

higher during the motor acceleration phase than during constant movement.

Protection against reverse polarity In the case of reverse polarity, the supply voltage is short-circuited. The

drive is continuous short circuit-proof up to a short-circuit current of a

maximum of 15 A. If the power is supplied by a transformer power supply

unit, several hundred amperes may flow for a short period of time in the

event of reverse polarity; the drive is rated for this and will not be damaged.

Fuse: a circuit-breaker (16 A, trip characteristic B) or a blade fuse (FKS,

max. 15 A) or a fuse (5 mm x 20 mm, 10 A slow-blow).

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 37

Page 38

5 Engineering ILA1B, ILA1F, ILA1R

Regeneration condition Note the following for drives with large external mass moments of inertia

or for highly dynamic applications:

Motors return regeneration energy during deceleration. The DC bus can

store a limited amount of energy in the capacitors. Connecting additional

capacitors to the DC bus increases the amount of energy that can be

stored.

If the capacity of the capacitors is exceeded, the excess energy must be

discharged via internal or external braking resistors. If the energy is not

discharged, an overvoltage monitor will shut off the power stage.

Overvoltages can be limited by adding a braking resistor with a corresponding braking resistor controller. This converts the regenerated energy to heat energy during deceleration.

Braking resistor controllers can be found in chapter 11 "Accessories and

spare parts". See the product manual for a description of the braking resistor controller.

@ CAUTION

LOSS OF CONTROL DUE TO REGENERATION CONDITION

Regeneration conditions resulting from braking or external driving

forces may increase the VDC supply voltage to an unexpected level.

Components not rated for this voltage may be destroyed or cause misoperation.

• Verify that all VDC consumers are rated for the voltage occurring

during regeneration conditions (for example limit switches).

• Use only power supply units that will not be damaged by regeneration conditions.

• Use a braking resistor controller, if necessary.

Failure to follow these instructions can result in injury or equipment damage.

24V signal power supply A constant 24V signal power supply is available for the sensor system.

It must not be connected in parallel with the 24V signal power supply of

a different drive.

38 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 39

ILA1B, ILA1F, ILA1R 5 Engineering

5.2 Ground design

The ground connections of all interfaces are galvanically connected, including the ground for the VDC supply voltage.

The module interfaces with galvanic isolation such as Profibus are exceptions to this.

The following points must be considered when you wire the drives in a

system:

• The voltage drop in the VDC power supply lines must be kept as low

as possible (less than 1 V). At higher ground potential differences

between different drives, the communication / control signals may

be affected.

• If the distance between the system components is greater, it is recommended to use decentralized power supply units close to the

individual drives to supply the VDC voltage. However, the ground

connections of the individual power supply units must be connected

with the largest possible conductor cross section.

• The internal 24V signal power supply must not be connected in parallel with the internal 24V signal power supply of a different drive.

• If the master controller (e.g. PLC, IPC etc.) does not have galvanically isolated outputs for the drives, you must verify that the current

of the VDC supply voltage has no path back to the power supply unit

via the master controller. Therefore, the master controller ground

may be connected to the VDC supply voltage ground at a single

point only. This is usually the case in the control cabinet. The

ground contacts of the various signal connectors in the drive are

therefore not connected; there is already a connection via the VDC

supply voltage ground.

• If the controller has a galvanically isolated interface for communication with the drives, the ground of this interface must be connected

to the signal ground of the first drive. This ground may be connected

to a single drive only to avoid ground loops. This also applies to a

galvanically isolated CAN connection.

Equipotential bonding conductors Potential differences can result in excessive currents on the cable

shields. Use equipotential bonding conductors to reduce currents on the

cable shields.

The equipotential bonding conductor must be rated for the maximum

current flowing. Practical experience has shown that the following conductor cross sections can be used:

•16mm

length of 200 m

•20mm

of more than 200 m

2

(AWG 4) for equipotential bonding conductors up to a

2

(AWG 4) for equipotential bonding conductors with a length

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 39

Page 40

5 Engineering ILA1B, ILA1F, ILA1R

5.3 Safety function STO ("Safe Torque Off")

See page 35 for information on using the IEC 61508 standard..

5.3.1 Definitions

Safety function STO (IEC 61800-5-2)The safety function STO ("Safe Torque Off", "Safe Torque Off") shuts off

the motor torque safely. It is not necessary to interrupt the supply voltage. There is no monitoring for standstill.

"Power Removal" The STO safety function ("Safe Torque Off") is also known as "Power

Removal".

Category 0 stop (EN 60204-1) Stopping by immediate removal of power to the machine actuators (i.e.

an uncontrolled stop).

Category 1 stop (EN 60204-1) Controlled stop with power available to the machine actuators to achieve

the stop. Power is not interrupted until the stop is achieved.

5.3.2 Function

The STO safety function integrated into the product can be used to implement an "EMERGENCY STOP" (EN 60204-1) for category 0 stops.

With an additional, approved EMERGENCY STOP module, it is also

possible to implement category 1 stops.

Function principle The STO safety function is triggered via 2 redundant inputs. The circuits

of the two inputs must be separate so that there are always two channels.

The switching process must be simultaneous for both inputs (skew <1s).

The power stage is disabled and an error message is generated. The

motor can no longer generate torque and coasts down without braking.

A restart is possible after resetting the error message with a "Fault Reset".

The power stage is disabled and an error message is generated if only

one of the two inputs is switched off or if the skew is too great. This error

message can only be reset by switching off the product.

40 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 41

ILA1B, ILA1F, ILA1R 5 Engineering

5.3.3 Requirements for using the safety function

@ WARNING

LOSS OF SAFETY FUNCTION

Incorrect usage may cause a hazard due to the loss of the safety function.

• Observe the requirements for using the safety function.

Failure to follow these instructions can result in death or serious

injury.

Category 0 stop During a category 0 stop, the motor coasts down in an uncontrolled way.

If access to the machine coasting down involves a hazard (results of the

hazard and risk analysis), you must take appropriate measures.

Category 1 stop A controlled stop must be triggered with a category 1 stop. The control-

led stop is not monitored by the drive system; in the case of a power outage or an error, the stop may not be performed correctly. Final shutoff of

the motor is achieved by switching off the two inputs of the STO safety

function. The shutoff is usually controlled by a standard EMERGENCY

STOP module with a safe time delay.

Behavior of holding brake Triggering the STO safety function means that the delay time for motors

with holding brake is not effective. The motor cannot generate holding

torque to bridge the time to application of the holding brake. Especially

in the case of vertical axes it is important to verify whether additional

measures are required to avoid lowering of the load.

Vertical axes, external forces If external forces act on the motor (vertical axis) and an unwanted move-

ment, for example caused by gravity, could cause a hazard, the motor

must not be operated without additional measures for fall protection, corresponding to the required safety.

Unintended restart Note that a master controller must not trigger an unintended restart after

restoration of power (e.g. after a power outage).

Degree of protection if STO is used You must ensure that conductive substances cannot get into the product

(pollution degree 2). If you use the safety function and conductive substances get into the product, the safety function may become inoperative.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 41

Page 42

5 Engineering ILA1B, ILA1F, ILA1R

Protected cable installation If short circuits or cross circuits can be expected in connection with the

two signals of the STO safety function and if they are not detected by upstream devices, protected cable installation is required.

In the case of an unprotected cable installation, the two signals of the

STO safety function may be connected to external voltage if a cable is

damaged. If the two signals are connected to external voltage, the STO

safety function is no longer operative.

Protected cable installation possibilities:

• Use separate cables for two signals. Any additional wires in these

cables may only carry voltages according to PELV.

• Use a shielded cable. The grounded shield is designed to dissipate

the external voltage in the case of damages and to trip the fuse in

this way.

• Use a separately grounded shield. If there are other wires in the

cable, the two signals must be isolated from these wires by a

grounded, separate shield.

Data for maintenance plan and

safety calculations

Use the following data of the STO safety function for your maintenance

plan and the safety calculations:

Lifetime (IEC 61508) 20 years

SFF (IEC 61508)

Safe Failure Fraction

HFT (IEC 61508)

Hardware Fault Tolerance

Type A subsystem

Safety integrity level

IEC 61508

IEC 62061

PFH (IEC 61508)

Probability of Dangerous Hardware Failure per Hour

PL (ISO 13849-1)

Performance Level

(EN 13849-1)

MTTF

d

Mean Time to Dangerous Failure

DC (EN 13849-1)

Diagnostic Coverage

[%] 66

1

SIL2

SILCL2

[1/h] 1.84*10

d (Category 3)

4566 years

[%] 90

-9

Hazard and risk analysis As a system manufacturer you must conduct a hazard and risk analysis

of the entire system. The results must be taken into account in the application of the STO safety function.

The type of circuit resulting from the analysis may differ from the following application examples. Additional safety components may be required. The results of the hazard and risk analysis always have priority.

42 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 43

ILA1B, ILA1F, ILA1R 5 Engineering

5.3.4 Application examples STO

Example of category 0 stop Application without EMERGENCY STOP module, category 0 stop.

24V

24V

EMERGENCY

STOP

Figure 5.1 Example of category 0 stop

Please note:

• When the EMERGENCY STOP switch is tripped, this initiates a

category 0 stop

Example of category 1 stop Application with EMERGENCY STOP module, category 1 stop.

ENABLE

FAULT RESET

SPS/

CNC

Lexium

integrated

drive

STO_A (PWRR_A)

STO_B (PWRR_B)

24V 24V

24V24V 24V

Preventa

XPS-AV

Y+

Y64

Y74

Y84

Delayed

Undelayed

38

48

04

14

24

S11

S12

S13

S14

A2A1

EMERGENCY

STOP

37

47

57 58

03

13

23

S31

S21

S22

S32

Figure 5.2 Example of category 1 stop

Please note:

• The master controller must immediately trigger a controlled stop,

e.g. via the "Quick Stop" function.

• The inputs STO_A

switched off with a time delay. The delay is set at the EMERGENCY

STOP safety module. If the motor has not yet stopped when the

delay time has elapsed, it coasts down in an uncontrolled way

(uncontrolled stop).

ENABLE

FAULT RESET

SPS/CNC

Lexium

integrated

drive

STO_A (PWRR_A)

STO_B (PWRR_B)

(PWRR_A) and STO_B (PWRR_B) must be

• The specified minimum current and the permissible maximum current of the relay must be observed if the relay outputs of the EMERGENCY STOP module are used.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 43

Page 44

5 Engineering ILA1B, ILA1F, ILA1R

5.4 Monitoring functions

The monitoring functions in the product can help to guard the system

and reduce the risks involved in a system misoperation. These monitoring functions may not be used to protect persons.

The following monitoring functions are available:

Monitoring Task

Data link Error response if the link becomes inoperative

Limit switch signals Monitors for permissible range of travel

2

I

t limitation Power limitation in event of overloading

Tracking error Monitors for difference between actual motor position and reference position

STOP switch signal Stops motor with "Quick Stop"

Overvoltage and undervoltage Monitors for overvoltage and undervoltage of the supply voltage

Motor overload Monitors for excessively high current in the motor phases

Overtemperature Monitors the device for overtemperature

44 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 45

ILA1B, ILA1F, ILA1R 6 Installation

6 Installation

@ WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are EMERGENCY

STOP, overtravel stop, power outage and restart.

• Separate or redundant control paths must be provided for critical

functions.

• System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

• Observe the accident prevention regulations and local safety

guidelines.

• Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death or serious

injury.

1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control

and to NEMA ICS 7.1 (latest edition), Safety Standards for Construction and

Guide for Selection, Installation for Construction and Operation of AdjustableSpeed Drive Systems.

1)

@ CAUTION

RISK OF INJURY WHEN REMOVING CIRCUIT BOARD PLUGS

• When removing them note that the connectors must be unlocked.

– Supply voltage VDC:

Unlock by pulling at the plug housing

– Miscellaneous:

Unlock by pressing the locking lever

• Always hold the plug to remove it (not the cable).

Failure to follow these instructions can result in injury or equipment damage.

The chapter Engineering contains basic information that

you should know before starting the installation.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 45

Page 46

6 Installation ILA1B, ILA1F, ILA1R

6.1 Electromagnetic compatibility, EMC

@ WARNING

SIGNAL AND DEVICE INTERFERENCE

Signal interference can cause unexpected responses of device.

• Install the wiring in accordance with the EMC requirements.

• Verify compliance with the EMC requirements.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

This drive system meets the EMC requirements according to the standard IEC 61800-3, if the described measures are implemented during installation. If it is operated outside this scope, note the following:

@ WARNING

HIGH-FREQUENCY INTERFERENCE

In a domestic environment this product may cause high-frequency interference that may require action to suppress interference.

EMC measures Effect

Keep cables as short as possible. Do not

install unnecessary cable loops, use short

cables from the star point in the control cabinet to the external ground connection.

Ground the product via the motor flange or

with a ground strap to the ground connection

at the cover of the connector housing.

Ground shields of digital signal wires at both

ends by connecting them to a large surface or

via conductive connector housings.

Connect large surface areas of cable shields,

use cable clamps and ground straps

Reduces capacitive and inductive interference.

Reduces emissions, increases

immunity.

Reduces interference affecting

the signal wires, reduces emissions

Reduces emissions.

The following cables must be shielded:

• Fieldbus cable

• STO safety function,

see the requirements in chapter 5.3.3 "Requirements for using the

safety function".

The following cables do not need to be shielded:

• Supply voltage VDC

• 24 V signal interface

46 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 47

ILA1B, ILA1F, ILA1R 6 Installation

Equipotential bonding conductors Potential differences can result in excessive currents on the cable

shields. Use equipotential bonding conductors to reduce currents on the

cable shields.

The equipotential bonding conductor must be rated for the maximum

current flowing. Practical experience has shown that the following conductor cross sections can be used:

•16mm

length of 200 m

•20mm

of more than 200 m

2

(AWG 4) for equipotential bonding conductors up to a

2

(AWG 4) for equipotential bonding conductors with a length

6.2 Mechanical installation

@ CAUTION

HOT SURFACES

Depending on the operation, the surface may heat up to more than

100°C (212°F).

• Do not allow contact with the hot surfaces.

• Do not allow flammable or heat-sensitive parts in the immediate

vicinity.

• Consider the measures for heat dissipation described.

• Check the temperature during test runs.

Failure to follow these instructions can result in injury or equipment damage.

@ CAUTION

MOTOR DAMAGE AND LOSS OF CONTROL

Shock or strong pressure applied to the motor shaft may destroy the

motor.

• Protect the motor shaft during handling and transportation.

• Avoid shocks to the motor shaft during mounting.

• Do not press parts onto the shaft. Mount parts to the shaft by

glueing, clamping, shrink-fitting or screwing.

Failure to follow these instructions can result in injury or equipment damage.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 47

Page 48

6 Installation ILA1B, ILA1F, ILA1R

@ WARNING

MOTOR WITHOUT BRAKING EFFECT

If power outage and faults cause the power stage to be switched off,

the motor is no longer stopped by the brake and may increase its

speed even more until it reaches a mechanical stop.

• Verify the mechanical situation.

• If necessary, use a cushioned mechanical stop or a suitable

brake.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

@ WARNING

LOSS OF BRAKING FORCE DUE TO WEAR OR HIGH TEMPERATURE

Applying the holding brake while the motor is running will cause excessive wear and loss of the braking force. Heat decreases the braking force.

• Do not use the brake as a service brake.

• Note that "EMERGENCY STOPS" may also cause wear

• At operating temperatures of more than 80°C (176°F), do not

exceed a maximum of 50% of the specified holding torque when

using the brake.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

To install a drive in locations difficult to access, it may be

useful to carry out the electrical installation first and then

install the fully wired drive.

Heat dissipation The motor may become very hot, e.g. in the case of incorrect arrange-

ment of multiple motor. The surface temperature of the motor must not

exceed 110 °C during continuous operation.

• Verify that the maximum temperature is not exceeded.

• Verify that there is sufficient heat dissipation, e.g. by means of good

ventilation or heat dissipation via the motor flange.

Mounting The motor is designed to be mounted using four M5 screws. The motor

flange must be mounted on a flat surface to avoid mechanical tension

from being transmitted to the housing.

Painted surfaces have an insulating effect. During mounting verify that

the motor flange is mounted in such a way as to allow for good conductivity (electrical and thermal).

Mounting distances No minimum clearances are required for installation. However, note that

the motor can become very hot.

Observe the bending radii of the cables used.

Ambient conditions Observe the permissible ambient conditions.

48 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 49

ILA1B, ILA1F, ILA1R 6 Installation

6.3 Electrical installation

@ WARNING

UNEXPECTED BEHAVIOR CAUSED BY FOREIGN OBJECTS

Foreign objects, deposits or humidity can cause unexpected behavior.

• Keep foreign objects from getting into the product.

• Do not remove the cover of the electronics housing. Only remove

the connector housing cover.

• Verify correct seat of seals and cable entries.

Failure to follow these instructions can result in death, serious

injury or equipment damage.

@ WARNING

LOSS OF SAFETY FUNCTION CAUSED BY FOREIGN OBJECTS

Conductive foreign objects, dust or liquids may cause the STO safety

function to become inoperative.

• You may not use the STO safety function unless you have protected the system against contamination by conductive substances.

Failure to follow these instructions can result in death or serious

injury.

@ CAUTION

DAMAGE TO SYSTEM COMPONENTS AND LOSS OF CONTROL

Interruptions of the negative connection of the controller supply voltage can cause excessively high voltages at the signal connections.

• Do not interrupt the negative connection between the power supply unit and load with a fuse or switch.

• Verify correct connection before switching on.

• Do not connect the controller supply voltage or change its wiring

while the is supply voltage present.

Failure to follow these instructions can result in injury or equipment damage.

The chapter Engineering contains basic information that

you should know before starting the installation.

The drive is equipped with parameter switches in the

connector housing. Set the parameter switches before

connecting the cables, because after connection they are

difficult to access.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 49

Page 50

6 Installation ILA1B, ILA1F, ILA1R

6.3.1 Wiring examples

The following figure shows a typical wiring example. The limit switches

and the reference switch are supplied via the internal 24V signal power

supply.

Lexium

integrated

drive

~

VDC

+

-

VDC

0VDC

CN4.6

+

LIMN

UBC60

STO_A (PWRR_A)

STO_B (PWRR_B)

CN4.1

CN4.4

CN5.1

CN5.2

CN4.3

CN4.5

CN4.2

+

LIMP

+

-

REF

Figure 6.1 Wiring example

The UBC60 braking resistor controller is available as an accessory, see

chapter 11 "Accessories and spare parts".

50 Lexium Integrated Drive

0198441113562, V2.00, 09.2008

Page 51

ILA1B, ILA1F, ILA1R 6 Installation

6.3.2 Overview of all connections

Overview of printed circuit board

connectors

The following figure shows the pin assignment of the interfaces with the

connector housing cover open.

CN5

1

2

71

82

9 3

10 4

11 5

12 6

0VDC

CN1

VDC

123

456

CN6

123

456

CN4CN3CN2

Figure 6.2 Overview of all connections

Connection Assignment

CN1 Supply voltage VDC

CN2 Interface for PROFIBUS DP and operating mode Electronic

CN3 Interface for CAN or RS485

CN4 24 V signal interface

CN5 Interface for STO safety function

CN6 Jumper for disabling STO safety function

Gear (reference signals)

The drive can be connected via cable entries or industrial connectors.

For connection via cable entries see page 52.

For connection via industrial connectors see page 55.

0198441113562, V2.00, 09.2008

Lexium Integrated Drive 51

Page 52

6 Installation ILA1B, ILA1F, ILA1R

6.3.3 Connection via cable entry

The cable specifications and pin assignments can be found in the chapters that describe the connections.

Preparing and fastening cables

1

A

70mm

10mm

2

D

Figure 6.3 Fastening the cable in the cable entry

B

C

(1) Unshielded cable

(2) Shielded cable

왘 Trim the cable bushings to fit the cable.

NOTE: The specified degree of protection IP54 can only be

achieved with properly trimmed cable bushings.

왘 (A) Strip the jacket of all cables; length 70 mm.

왘 (B) Shorten the shield to a rest of 10 mm.

왘 (C) Slide the shield braiding back over the cable jacket.

왘 (D) Loosen the strain relief.

왘 Push the cables though the strain relief.

왘 Glue EMC shielding foil around the shield.

왘 Pull the cable back to the strain relief.

왘 Fasten the strain relief.

Mounting connectors The table below lists the parts and data required for assembly. Connec-

tor housings and crimp contacts are included in the accessories kit. See

also chapter 11 "Accessories and spare parts".

Only use the special tool listed in the Accessories chapter

to release single crimp contacts from the connector

housing.

52 Lexium Integrated Drive