Schneider Electric iEM3200, iEM3300, iEM3100 User Manual

iEM3100 / iEM3200 / iEM3300 series

Energy meters

User manual

DOCA0005EN-04

04/2014

www.schneider-electric.com

iEM3100 / iEM3200 / iEM3300 series user manual

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you have

any suggestions for improvements or amendments or have found errors in this publication, please

notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical,

including photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using

this product. For reasons of safety and to help ensure compliance with documented system data, only

the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions

must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2014 Schneider Electric. All rights reserved.

DOCA0005EN-04 3

Safety information

iEM3100 / iEM3200 / iEM3300 series user manual

Important information

Read these instructions carefully and look at the equipment to become familiar with the device

before trying to install, operate, service or maintain it. The following special messages may

appear throughout this bulletin or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates that an electrical

hazard exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death or

serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in minor or

moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety alert symbol shall not

be used with this signal word.

Please note

Electrical equipment should be installed, operated, serviced and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of the

use of this material.

A qualified person is one who has skills and knowledge related to the construction, installation, and

operation of electrical equipment and has received safety training to recognize and avoid the hazards

involved.

4 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual

Notices

FCC Part 15 notice

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

DOCA0005EN-04 5

About the book

iEM3100 / iEM3200 / iEM3300 series user manual

Document scope

This manual is intended for use by designers, system builders and maintenance technicians with an

understanding of electrical distribution systems and monitoring devices.

Validity note

The meters are used to measure the amount of active energy consumed by an installation or a part of

an installation.

This function meets the requirements for:

• consumption monitoring,

• evaluation of energy items (cost, accounting, etc.).

This function may also satisfy the power-saving incentives implemented by many countries.

Related documents

Title of documentation Reference number

Installation sheet: iEM3100 / iEM3110 / iEM3115 S1B46581 / S1B62907

Installation sheet: iEM3150 / iEM3155 S1B46583 / S1B62908

Installation sheet: iEM3200 / iEM3210 / iEM3215 S1B46598 / S1B62910

Installation sheet: iEM3250 / iEM3255 S1B46602 / S1B62911

Installation sheet: iEM3135 HRB68964 / HRB72100

Installation sheet: iEM3165 HRB68991 / HRB72106

Installation sheet: iEM3175 HRB68988 / HRB72103

Installation sheet: iEM3235 HRB68995 / HRB72108

Installation sheet: iEM3265 HRB69003 / HRB72111

Installation sheet: iEM3275 HRB68999 / HRB72109

Installation sheet iEM3310 / iEM3350 HRB91204 / HRB91205

Installation sheet iEM3335 / iEM3355 / iEM3365 / iEM3375 HRB91202 / HRB91203

You can download these technical publications and other technical information from www.schneiderelectric.com.

6 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual

Contents

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview of meter functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3 Hardware and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DIN rail mounting and dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Input, output and communications wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power system wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 4 Front panel display and meter setup . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Data display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Multi Tariff feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Meter status information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The device clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Modifying parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Configuration mode menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 5 Communications via Modbus RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . 51

Modbus communication overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Modbus functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Command interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Modbus register list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Read Device Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 6 Communications via LonWorks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

LonWorks communications overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

LonWorks communication implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Standard network variable types (SNVTs) and configuration properties for reading

data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Meter configuration properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Echelon LonMaker plug-in for data display and meter configuration . . . . . . . . . . . 71

DOCA0005EN-04 7

iEM3100 / iEM3200 / iEM3300 series user manual

Chapter 7 Communications via M-Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

M-Bus communications overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

M-Bus protocol support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

M-Bus protocol implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Variable data structure telegram information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Telegram information for data records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Telegram information for meter configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

M-Bus tool for data display and meter configuration . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 8 Communications via BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

BACnet communications overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

BACnet protocol support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

BACnet communications implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

BACnet object and property information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 9 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Environmental characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Measurement accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

MID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Internal clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Modbus communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

LonWorks communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

M-Bus communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

BACnet communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Chapter 10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Diagnosis screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Diagnostic codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 11 Power, energy and power factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Power (PQS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Energy delivered (imported) / energy received (exported) . . . . . . . . . . . . . . . . . . . . 106

Power factor (PF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Power factor register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Safety precautions

Chapter 1 Safety precautions

Installation, wiring, testing and service must be performed in accordance with all local and national

electrical codes.

Carefully read and follow the safety precautions outlined below.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices.

See NFPA 70E in the USA or applicable local standards.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Turn off all power supplying this device and the equipment in which it is installed before working

on the device or equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Before performing visual inspections, tests, or maintenance on this equipment, disconnect all

sources of electric power. Assume that all circuits are live until they have been completely

de-energized, tested and tagged. Pay particular attention to the design of the power system.

Consider all power supply sources, particularly the potential for backfeed.

• Replace all devices, doors and covers before turning on power to this equipment.

• Do not exceed the device’s ratings for maximum limits.

Failure to follow these instructions will result in death or serious injury.

WARNING

UNINTENDED OPERATION

Do not use the meter for critical control or protection applications where human or equipment safety

relies on the operation of the control circuit.

Failure to follow these instructions can result in death, serious injury or equipment damage.

WARNING

INACCURATE DATA RESULTS

• Do not rely solely on data displayed on the front panel or in software to determine if the device is

functioning correctly or compliant with all applicable standards.

• Do not use data displayed on the front panel or in software as a substitute for proper workplace

practices or equipment maintenance.

Failure to follow these instructions can result in death, serious injury or equipment damage.

DOCA0005EN-04 9

Safety precautions iEM3100 / iEM3200 / iEM3300 series user manual

10 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Overview

Chapter 2 Overview

What is in this chapter?

This chapter contains the following topics:

Overview of meter functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overview of meter functions

The meters provide the essential measurement capabilities (for example, current, voltage, and

energy) required to monitor a 1- or 3-phase electrical installation.

The key features of the meters are:

• measurement of active and reactive energy,

• Multi Tariffs (up to 4) controlled by internal clock, digital inputs or communication,

• MID compliance for many of the meters,

• pulse outputs,

• display (current, voltage, and energy measurements),

• communications via Modbus, LonWorks, M-Bus or BACnet protocols.

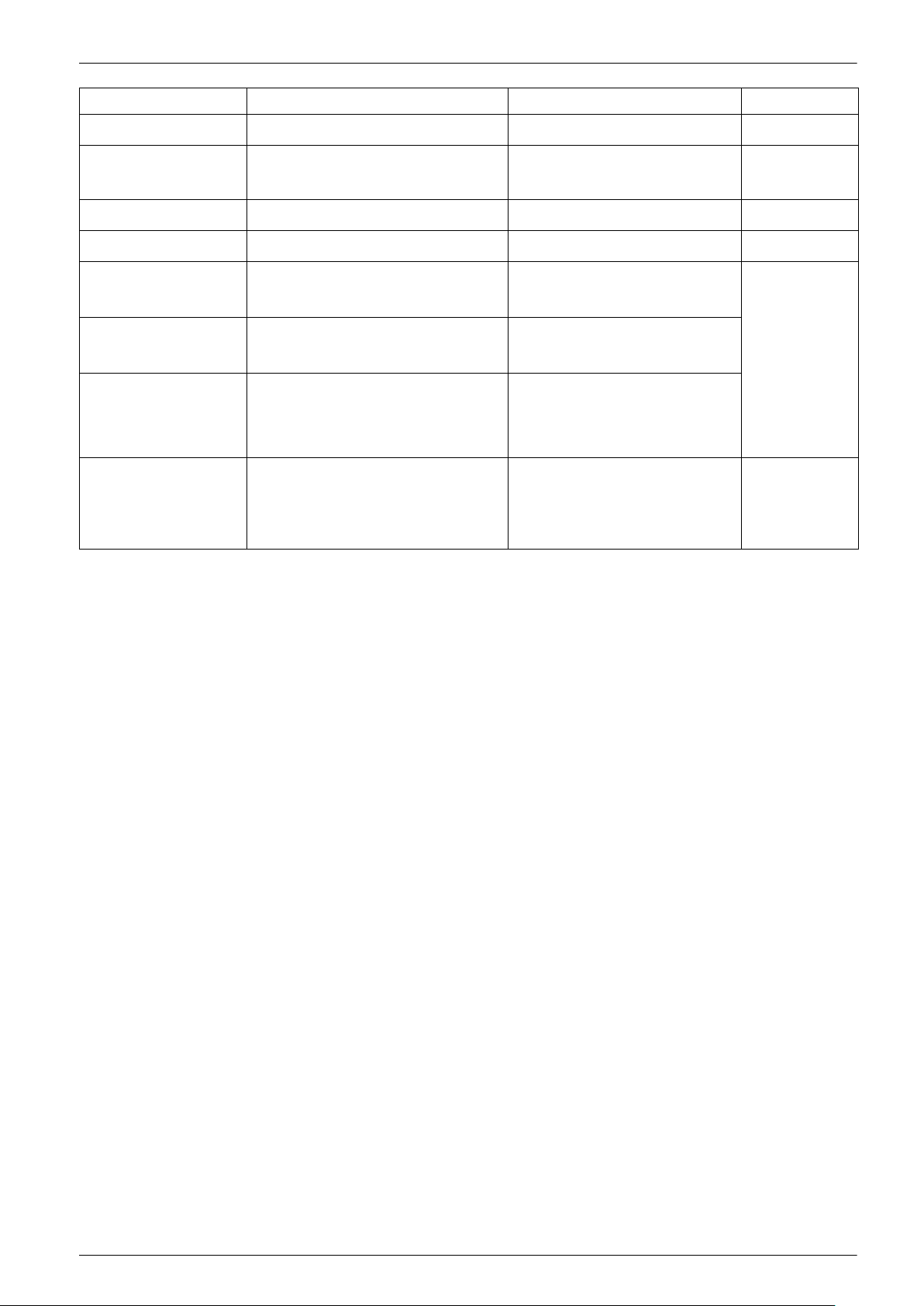

Main characteristics

63 A meters

Function

Direct measurement (up to 63 A)

Active Energy measurement accuracy class (total and

partial kWh)

Four Quadrant Energy measurements

Electrical measurements (I, V, P, ...)

Controlled by internal clock

Multi Tariff

Measurement display (number of lines)

Digital inputs

Digital outputs

Overload alarm

Communications

MID compliant

Width (18 mm module in DIN rail mounting)

Controlled by digital input(s)

Controlled by communications

Programmable (status, tariff

control, or input monitoring)

Tariff control only

Programmable (energy pulsing

or overload alarm)

Pulse output only

Modbus

LonWorks

M-Bus

BACnet

iEM3135

iEM3150

iEM3155

iEM3165

iEM3100

iEM3110

iEM3115

11111111

––– –

–––

––44–444

––42–222

–––4–444

33333333

–––1–111

––2–––––

–––1–11–

–1––––––

––– –

––––––

–––––––

––– ––––

–––––– –

– –

55555555

iEM3175

DOCA0005EN-04 11

Overview iEM3100 / iEM3200 / iEM3300 series user manual

125 A meters

Function

iEM3335

iEM3350

iEM3355

iEM3365

Direct measurement (up to 125 A)

Active Energy measurement accuracy class (total and partial

kWh)

Four Quadrant Energy measurements

Electrical measurements (I, V, P, ...)

Controlled by internal clock

Multi Tariff

Controlled by digital input(s)

Controlled by communications

Measurement display (number of lines)

Digital inputs (programmable for status, tariff control, or input

monitoring)

Programmable (energy pulsing or

Digital outputs

overload alarm)

Pulse output only

Overload alarm

Modbus

LonWorks

Communications

M-Bus

BACnet

MID compliant

Width (18 mm module in DIN rail mounting)

iEM3300

iEM3310

1111111

–– –

––

––4–444

––2–222

––4–444

3333333

––1–111

––1–11–

–1–––––

–– –

–––––

––––––

–– ––––

––––– –

– –

7777777

iEM3375

1 A / 5 A meters

Function

Measurement inputs through CTs (1 A, 5 A)

Measurement inputs through VTs

Active Energy measurement accuracy class (total and

partial kWh)

Four Quadrant Energy measurements

Electrical measurements (I, V, P, ...)

Controlled by internal clock

Multi Tariff

Measurement display (number of lines)

Digital inputs

Digital outputs

Controlled by digital input(s)

Controlled by communications

Programmable (status, tariff

control, or input monitoring)

Tariff control only

Programmable (energy pulsing

or overload alarm)

Pulse output only

iEM3200

iEM3210

iEM3215

iEM3235

iEM3250

iEM3255

iEM3265

iEM3275

–––

0.5S 0.5S 0.5S 0.5S 0.5S 0.5S 0.5S 0.5S

––– –

–––

––44–444

––42–222

–––4–444

33333333

–––1–111

––2–––––

–––1–11–

–1––––––

12 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Overview

Function

iEM3200

iEM3210

iEM3215

iEM3235

iEM3250

iEM3255

iEM3265

Overload alarm

Modbus

LonWorks

––– –

––––––

–––––––

Communications

M-Bus

BACnet

MID compliant

Width (18 mm module in DIN rail mounting)

––– ––––

–––––– –

– –

55555555

Typical applications

This range is a cost effective solution to monitor feeder circuits. These meters can monitor energy

consumption by usage, by zone or by feeder in the cabinet. They can be used to monitor feeders in a

main switchboard or to monitor the main in a distribution cabinet.

iEM31•• and iEM33•• series

iEM3275

Functions Advantages

Can directly measure feeders up to:

iEM31••: 63 A

iEM33••: 125 A

Embedded current transformers (CTs)

Adapted to be installed with Acti9 iC65 (iEM31••) or Acti9 C120

(iEM33••) circuit breakers

Can be used for single-phase multi-circuit monitoring 3 single feeders can be monitored with a single meter

iEM32•• series

Functions Advantages

CT and VT connection Can be used in low or medium voltage applications

Flexible configuration Can be adapted to any distribution network with or without neutral

Typical applications

The following table presents some of the functions of the different meters, the advantages and main

applications.

Functions Advantages Applications Meter

Total and partial energy counters Energy usage monitoring

Internal clock Saves the date and time of last reset

Pulse output with a configurable

pulse weight of up to 1 pulse per

1 Wh

Manages up to four tariffs,

controlled by the digital input(s),

internal clock or communications

(depending on meter model)

Measures essential electrical

parameters like current, average

voltage and total power.

Collect pulses from the meter with a Smartlink

system, PLC or any basic acquisition system

Categorize energy consumption into On Peak and Off

Peak, working days and weekends, or by different

electricity sources (for example, from the utility and

an electrical generator)

Instantaneous measurements help you monitor the

imbalance between phases.

Total power allows you to monitor the feeder load

level.

Saves installation time and space in the cabinet

No wiring to manage

Clear distribution network

Can be used in three-phase systems with or without neutral

Sub-billing management

Metering applications

Provides the timestamp of the last reset of the

partial energy accumulation

Remote monitoring of energy consumption

Integrate the meter in to a system monitoring of

a large number of devices

Energy demand management

Sub-billing management

Identification of local energy consumption

behavior by zone, by usage or by feeder

Monitoring of feeders or any sub-cabinet

All

All (except iEM3100 /

iEM3200 / iEM3300)

iEM3110 / iEM3310 /

iEM3210

iEM3115 / iEM3135 /

iEM3155 / iEM3165 /

iEM3175

iEM3215 / iEM3235 /

iEM3255 / iEM3265 /

iEM3275

iEM3335 / iEM3355 /

iEM3365 / iEM3375

iEM3135 / iEM3155 /

iEM3165 / iEM3175

iEM3235 / iEM3255 /

iEM3265 / iEM3275

iEM3335 / iEM3355 /

iEM3365 / iEM3375

DOCA0005EN-04 13

Overview iEM3100 / iEM3200 / iEM3300 series user manual

Functions Advantages Applications Meter

M-Bus communications

Modbus communications

BACnet communications

LonWorks communications

Four quadrant calculation

Measurement of active, reactive

and apparent energy.

Programmable digital input

Programmable digital output

Communicate advanced parameters using

M-Bus protocol

Communicate advanced parameters using Modbus

protocol

Communicate advanced parameters using BACnet

MS/TP protocol

Communicate advanced parameters using LonWorks

communications

Identification of imported and exported active and

reactive energy allows you to monitor energy flow in

both directions: delivered from the utility and

produced on-site

Allows you to monitor energy consumption and

production

Can be programmed to:

Count pulses from other meters (gas, water, etc.)

Monitor an external status

Reset the partial energy accumulation and start a

new period of accumulation

Can be programmed to:

be an active energy (kWh) pulse output, with a

configurable pulse weight

Alarm on a power overload at a configurable pickup

setpoint

M-Bus network integration

Modbus network integration

BACnet network integration

LonWorks network integration

Ideal for facilities with back-up generators or

green power capabilities (for example, solar

panels or wind turbines)

Manage energy consumption and make

informed investment to reduce your energy bill

or penalties (for example, installing capacitor

banks)

This allows for monitoring of:

WAGES

Intrusion (for example, doors opening) or

equipment status

Energy usage

This allows you to:

Collect pulses from the meter with a Smartlink

system, PLC or any basic acquisition system

Monitor power levels at a detailed level and to

help detect an overload before the circuit

breaker trips

iEM3135 / iEM3235 /

iEM3335

iEM3150 / iEM3155

iEM3250 / iEM3255

iEM3350 / iEM3355

iEM3165 / iEM3265 /

iEM3365

iEM3175 / iEM3275 /

iEM3375

iEM3135 / iEM3155 /

iEM3165/ iEM3175

iEM3235 / iEM3255 /

iEM3265 / iEM3275

iEM3335 / iEM3355 /

iEM3365 / iEM3375

iEM3135 / iEM3155 /

iEM3165

iEM3235 / iEM3255 /

iEM3265

iEM3335 / iEM3355 /

iEM3365

14 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

Chapter 3 Hardware and installation

What is in this chapter?

This chapter contains the following topics:

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DIN rail mounting and dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Input, output and communications wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power system wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dimensions

iEM31•• and iEM32•• meters

A Without communications

B With communications

mm

in

mm

in

N’N

ON

500 /kWh

OK

N’N

90

3.54

iEM33•• meters

ON

200 /kWh

Config

L2’

L2’

87

3.43

45

ESC

Reset

1.77

95.0

3.74

L3’ L3 L2 L1’ L1

101.5

4.00

63.5

2.50

69

2.71

A Without communications

B With communications

93.8

3.70

45

1.77

103.2

OK

ESC

Reset

Config

L3’ L3 L2 L1’ L1L1

4.06

108.4

4.27

63.8

126.0

4.96

69.3

2.73

2.51

DOCA0005EN-04 15

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

Hardware overview

All meters: Meter sealing points

All meters have sealing covers and sealing points to help prevent access to inputs and outputs and

current and voltage connections.

A Sealing points

B Sealable covers

ESC

OK

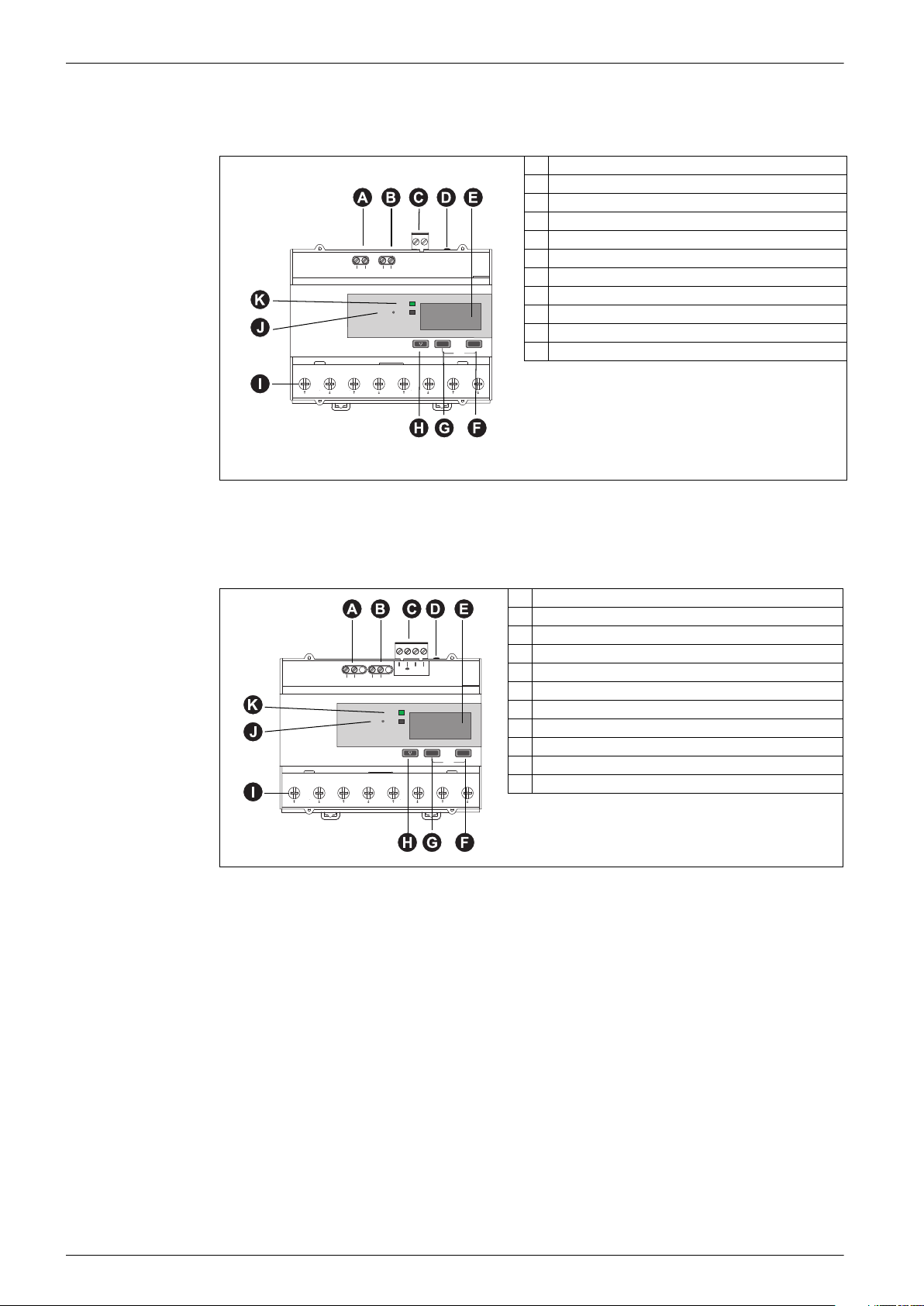

iEM3100 / iEM3110 / iEM3115 - Direct measurement up to 63 A

The various features of the iEM3100 / iEM3110 / iEM3115 are shown in the diagram below:

A Digital inputs for tariff control (iEM3115)

B Display for measurement and configuration

C Pulse output for remote transfer (iEM3110)

D Cancel

E Confirm

C/-

T2

T1

ON

500 /kWh

OK

N’N

Config

L2’

S0+ S0-

ESC

Reset

F Scroll

G Current and voltage inputs (direct measurement up to 63 A)

H Energy pulsing LED (used to verify accuracy)

I Status LED: on/off, error

L3’ L3 L2 L1’ L1

16 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

iEM3135 - Direct measurement up to 63 A and M-Bus communications

The various features of the iEM3135 are shown in the diagram below:

A Digital input

B Digital output

C Communication port

D Communications LED

M-Bus

C/-

C

DI

DO

ON

500 /kWh

OK

Config

N’N

L2’

E Display for measurement and configuration

F Cancel

G Confirm

H Scroll

I Current and voltage inputs (direct measurement up to 63 A)

J Energy pulsing LED (used to verify accuracy)

K Status LED: on/off, error

ESC

Reset

L3’ L3 L2 L1’ L1

iEM3150 / iEM3155 / iEM3165 - Direct measurement up to 63 A and Modbus or BACnet communications

The various features of the iEM3150 / iEM3155 / iEM3165 are shown in the diagram below:

A Digital input (iEM3155/iEM3165)

B Digital output (iEM3155/iEM3165)

C Communication port

D Communications LED

E Display for measurement and configuration

F Cancel

G Confirm

H Scroll

I Current and voltage inputs (direct measurement up to 63 A)

J Energy pulsing LED (used to verify accuracy)

K Status LED: on/off, error

C/- DI

0V D1/+D0/-

N.C.

500 /kWh

RS485

ON

OK

ESC

Reset

Config

N’N

L3’ L3 L2 L1’ L1

L2’

CDO

N.C.

DOCA0005EN-04 17

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

iEM3175 - Direct measurement up to 63 A and LonWorks communications

The various features of the iEM3175 are shown in the diagram below:

A Digital input

B Communication port

C Communications / LonWorks operations LED

D Service pin

E Display for measurement and configuration

F Cancel

G Confirm

H Scroll

I Current and voltage inputs (direct measurement up to 63 A)

J Neuron ID

K Energy pulsing LED (used to verify accuracy)

L Status LED: on/off, error

C/-

DI

500 /kWh

Neuron ID: 000000000000

S/N:0000000000

LON

Service

ON

OK

ESC

Reset

Config

N’N

L3’ L3 L2 L1’ L1

L2’

iEM3200 / iEM3210 / iEM3215 - Measurement with CTs

The various features of the listed meters (CTs 1 A or 5 A) are shown in the diagram below:

A Digital inputs for tariff control (iEM3215)

B Display for measurement and configuration

C Pulse out for remote transfer (iEM3210)

D Current inputs (CTs 1 A or 5 A)

C/-

T2

T1

ON

5000 /kWh

OK

(I1) (I2) (I3)

VnV3V2V1

Config

ESC

Reset

S0+ S0-

S2 S1 S1 S2 S1 S2

E Cancel

F Confirm

G Scroll

H Voltage inputs

I Energy pulsing LED (used to verify accuracy)

J Status LED: on/off, error

18 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

iEM3235 - Measurement with CTs and M-Bus communications

The various features of the iEM3235 (CTs 1 A or 5 A with M-Bus communications) are shown in the

diagram below:

A Digital input

B Digital output

C Communication port

D Communications LED

M-Bus

C/-

C

DI

DO

ON

5000 /kWh

OK

ESC

Reset

Config

(I1) (I2) (I3)

VnV3V2V1

S2 S1 S1 S2 S1 S2

E Display for measurement and configuration

F Current inputs (CTs 1 A and 5 A)

G Cancel

H Confirm

I Scroll

J Voltage inputs

K Energy pulsing LED (used to verify accuracy)

L Status LED: on/off, error

iEM3250 / iEM3255 / iEM3265 - Measurement with CTs and Modbus or BACnet communications

The various features of the iEM3250 / iEM3255 / iEM3265 (CTs 1 A or 5 A with Modbus or BACnet

communication) are shown in the diagram below:

A Digital input (iEM3255/iEM3265)

B Digital output (iEM3255/iEM3265)

C Communication port

D Communications LED

E Display for measurement and configuration

0V D0/- D1/+

C/-

C

N.C.

DI

N.C.

DO

5000 /kWh

RS485

ON

OK

(I1) (I2) (I3)

VnV3V2V1

Config

ESC

Reset

S2 S1 S1 S2 S1 S2

F Current inputs (CTs 1 A and 5 A)

G Cancel

H Confirm

I Scroll

J Voltage inputs

K Energy pulsing LED (used to verify accuracy)

L Status LED: on/off, error

DOCA0005EN-04 19

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

iEM3275 - Measurement with CTs and LonWorks communications

The various features of the iEM3275 (CTs 1 A or 5 A with LonWorks communications) are shown in

the diagram below:

A Digital input

B Communication port

C Communications / LonWorks operation LED

D Service pin

E Display for measurement and configuration

F Current inputs (CTs 1 A and 5 A)

G Cancel

H Confirm

I Scroll

J Voltage inputs

K Neuron ID

L Energy pulsing LED (used to verify accuracy)

M Status LED: on/off, error

C/-

DI

5000 /kWh

Neuron ID: 000000000000

S/N: 0000000000

LON

ON

OK

(I1) (I2) (I3)

VnV3V2V1

Config

ESC

Reset

S2 S1 S1 S2 S1 S2

iEM3300 / iEM3310 - Direct measurement up to 125 A

The various features of the iEM3300 / iEM3310 are shown in the diagram below:

A Display for measurement and configuration

B Pulse output for remote transfer (iEM3310)

C Cancel

S0+S0-

ON

200 /kWh

OK

ESC

Reset

Config

N’N

L2’

L3’ L3 L2 L1’ L1L1

D Confirm

E Scroll

F Current and voltage inputs (direct measurement up to 125 A)

G Energy pulsing LED (used to verify accuracy)

H Status LED: on/off, error

20 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

iEM3335 - Direct measurement up to 125 A and M-Bus communications

The various features of the iEM3335 are shown in the diagram below:

A Digital input

B Digital output

C Communication port

D Communications LED

E Display for measurement and configuration

C/-DIC

DO

ON

200 /kWh

OK

ESC

Reset

Config

N’N

L2’

L3’ L3 L2 L1’ L1L1

F Cancel

G Confirm

H Scroll

I Current and voltage inputs (direct measurement up to 125 A)

J Energy pulsing LED (used to verify accuracy)

K Status LED: on/off, error

iEM3350 / iEM3355 / iEM3365 - Direct measurement up to 125 A and Modbus or BACnet communications

The various features of the iEM3350 / iEM3355 / iEM3365 are shown in the diagram below:

A Digital input (iEM3355 / iEM3365)

B Digital output (iEM3355 / iEM3365)

C Communication port

0V D1/+D0/-

DO

200 /kWh

RS485

ON

OK

ESC

Reset

Config

L2’

L3’ L3 L2 L1’ L1L1

C/-DIC

N’N

D Communications LED

E Display for measurement and configuration

F Cancel

G Confirm

H Scroll

I Current and voltage inputs (direct measurement up to 125 A)

J Energy pulsing LED (used to verify accuracy)

K Status LED: on/off, error

DOCA0005EN-04 21

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

iEM3375 - Direct measurement up to 125 A and LonWorks communications

The various features of the iEM3375 are shown in the diagram below:

A Digital input

B Communication port

C Communications / LonWorks operations LED

D Service pin

E Display for measurement and configuration

F Cancel

G Confirm

H Scroll

I Current and voltage inputs (direct measurement up to 125 A)

J Neuron ID

K Energy pulsing LED (used to verify accuracy)

L Status LED: on/off, error

Neuron ID: 000000000000

S/N:0000000000

N’N

C/-

DI

ON

200 /kWh

Service

OK

ESC

Reset

Config

L2’

L3’ L3 L2 L1’ L1L1

DIN rail mounting and dismounting

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices.

See NFPA 70E in the USA or applicable local standards.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Turn off all power supplying this device and the equipment in which it is installed before working

on the device or equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors and covers before turning on power to this equipment.

• Do not exceed the device’s ratings for maximum limits.

Failure to follow these instructions will result in death or serious injury.

Mounting the meter on a DIN rail

1. Position the 2 upper slots on the rear of the meter onto the DIN rail.

DANGER

2. Press the meter against the DIN rail until the locking mechanism engages. The meter is now

attached to the rail. Make sure that the device is not tilted following installation.

22 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

Click!

Dismounting the meter from a DIN rail

1. Use a flat-tip screwdriver ( 6.5 mm / 0.25 in) to lower the locking mechanism and release the

meter.

2. Lift the meter out and up to free it from the DIN rail.

DOCA0005EN-04 23

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

Input, output and communications wiring

This section describes the wiring of the digital inputs, digital and pulse outputs and the

communications (as applicable).

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices.

See NFPA 70E in the USA or applicable local standards.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Turn off all power supplying this device and the equipment in which it is installed before working

on the device or equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors and covers before turning on power to this equipment.

• Do not exceed the device’s ratings for maximum limits.

Failure to follow these instructions will result in death or serious injury.

WARNING

UNINTENDED OPERATION

Do not use the meter for critical control or protection applications where human or equipment safety

relies on the operation of the control circuit.

Failure to follow these instructions can result in death, serious injury or equipment damage.

Related topics

• See “Power system wiring” on page 26 for information on wiring the voltage and current

connections.

Pulse output wiring: iEM3110 / iEM3210 / iEM3310

Rin

5 – 30 V DC

• The pulse output is compatible with S0 format.

• The pulse output can be directly connected to a 24 V DC (< 30 V DC) input on a Zelio or

Twido PLC.

• The pulse output indicates the primary consumption with consideration of transformer ratios.

• For other concentrators, if V DC/Rin > 15 mA, add a resistor Radd = (V DC/0.01) - Rin

Radd

-+

S0+ S0-

Digital input wiring: iEM3115 / iEM3215

11 – 40 V DC

-+

C/- T1

T2

24 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

Digital input wiring: iEM3135 / iEM3155 / iEM3165 / iEM3175 / iEM3235 / iEM3255 / iEM3265 / iEM3275 / iEM3335 / iEM3355 / iEM3365 / iEM3375

11 – 40 V DC

-+

C/-

DI

N.C.

• The digital input and output are electrically independent.

Digital output wiring: iEM3135 / iEM3155 / iEM3165 / iEM3235 / iEM3255 / iEM3265 / iEM3335 / iEM3355 / iEM3365

5 – 40 V DC

-

-

/+ +/

Load

C

N.C.

DO

• The programmable digital output is compatible with S0 format when configured as a pulse output.

• The digital output is polarity-independent.

• The digital input and output are electrically independent.

Modbus RS-485 communications wiring: iEM3150 / iEM3155 / iEM3250 / iEM3255 / iEM3350 / iEM3355

0 V

D0 = A’ / Rx-, A / TxD1 = B’ / Rx+, B / Tx+

0V D0/- D1/+

BACnet RS-485 communications wiring: iEM3165 / iEM3265 / iEM3365

0 V

D0 = A’ / Rx-, A / TxD1 = B’ / Rx+, B / Tx+

0V D0/- D1/+

M-Bus communications wiring: iEM3135 / iEM3235 / iEM3335

• The M-Bus communications connection is polarity-independent.

DOCA0005EN-04 25

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

LonWorks communications wiring: iEM3175 / iEM3275 / iEM3375

Service

• The LON communications connection is polarity-independent.

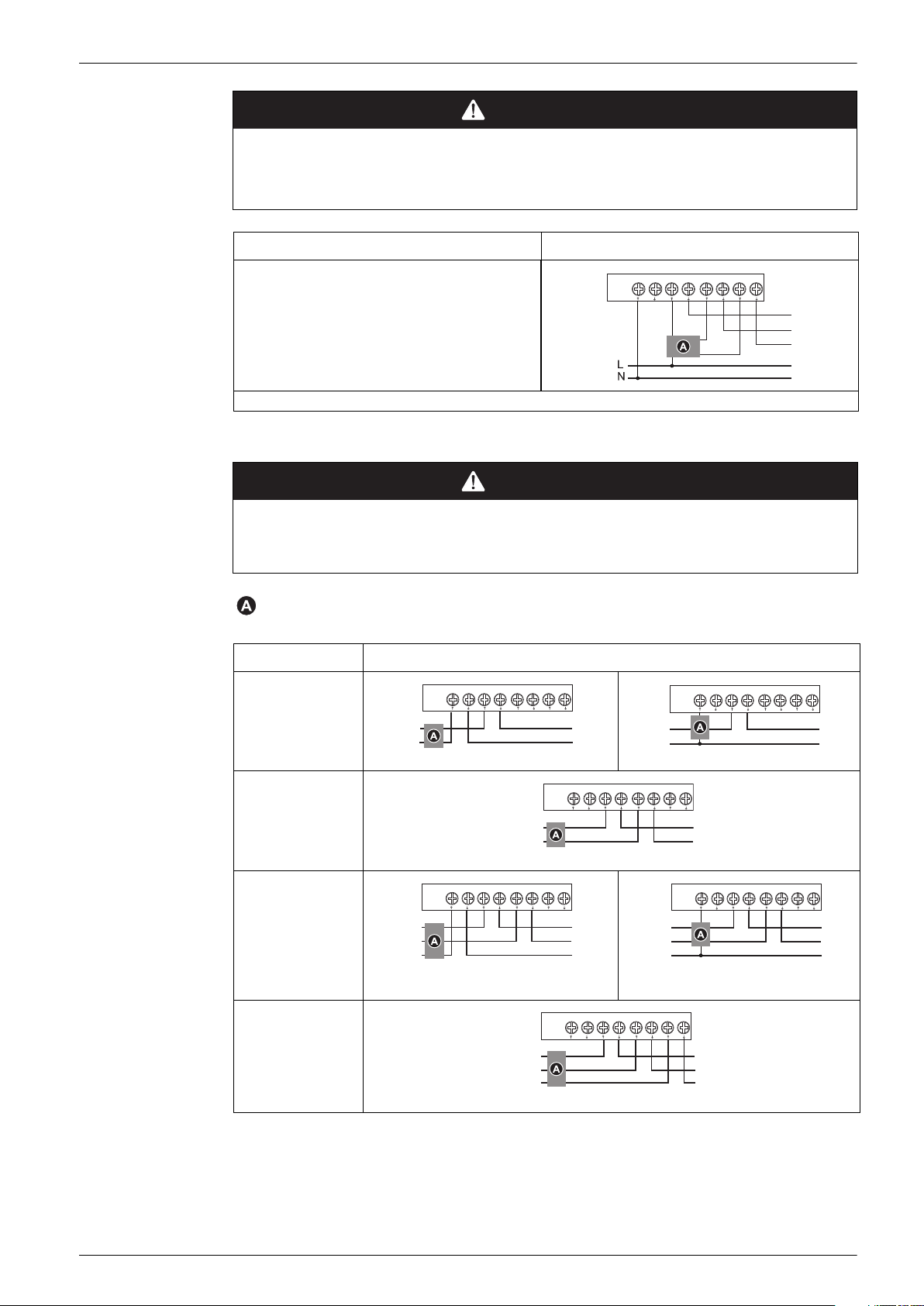

Power system wiring

The diagrams below illustrate how to connect the meters to a single-phase or three-phase 3-wire or

4-wire power system.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices.

See NFPA 70E in the USA or applicable local standards.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Turn off all power supplying this device and the equipment in which it is installed before working

on the device or equipment.

• Always use a properly rated voltage sensing device to confirm power is off.

• Replace all devices, doors and covers before turning on power to this equipment.

• Do not exceed the device’s ratings for maximum limits.

Failure to follow these instructions will result in death or serious injury.

Voltage input protection

The meter’s voltage inputs must be wired to fuses/breakers and a disconnect switch. If using a voltage

transformer (VT), both primary and secondary sides of the VT must be fused and switched.

• Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the

operator.

• Fuses / circuit breakers must be:

— installed in accordance with all local and national electrical codes and standards, and

— rated for the installation voltage, available fault current, and sized for connected loads.

• Fuse for neutral is required if the source neutral connection is not grounded.

Current input protection for 1 A and 5 A meters

For all connected current inputs on 1 A and 5 A meters with external CTs, use a CT shorting block to

short-circuit the secondary leads of the CTs before removing the current input connections to the

meter.

NOTE: Ground any unused current inputs on 1 A and 5 A meters.

iEM31•• and iEM33•• devices associated with a contactor

Connection requirements for iEM3100 / iEM3110 / iEM3115 / iEM3135 / iEM3150 / iEM3155 /

iEM3165 / iEM3175 / iEM3300 / iEM3310 / iEM3335 / iEM3350 / iEM3355 / iEM3365 / iEM3375:

• When the meter is associated with a contactor, connect the meter upstream of the contactor.

• The meter must be protected by a circuit breaker.

26 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

LL

iEM

iEM

Load Load

Related topics

• See “Input, output and communications wiring” on page 24 for information on wiring the digital

inputs, digital or pulse outputs and communications for your device.

63 A direct measurement meter wiring

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Do not allow the total additive current flowing through the device to exceed 63 A.

Failure to follow these instructions will result in death or serious injury.

Fuses and disconnect switch

Power system Wiring

NN’ L3L2’L2L1’L1 L3’

1PH2W L-N

1PH2W L-L

1PH3W L-L-N

3PH3W

L

N

277 V L-N

NN’ L3L2’L2L1’L1 L3’

L1

L2

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L1

L2

N

277 V L-N

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L1

L2

L3

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L

N

L1

L2

N

277 V L-N

NN’ L3L2’L2L1’L1 L3’

277 V L-N

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L1

L2

L3

N

277 V L-N

480 V L-L

3PH4W

NN’ L3L2’L2L1’L1 L3’

L1

L2

L3

N

277 V L-N

480 V L-L

DOCA0005EN-04 27

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Do not connect N’ to the load when setting the wiring type on the meter to 1PH4W Multi L-N.

Failure to follow these instructions will result in death or serious injury.

Power system Wiring

NN’ L3L2’L2L1’L1 L3’

1PH multiple loads with neutral (1PH4W Multi L-N)

1

The 1PH4W Multi L-N wiring type is only available on the iEM3135, iEM3150, iEM3155, iEM3165 and iEM3175.

1

125 A direct measurement meter wiring

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Do not allow the total additive current flowing through the device to exceed 125 A.

Failure to follow these instructions will result in death or serious injury.

Fuses and disconnect switch

Power system Wiring

1PH2W L-N

NN’ L3L2’L2L1’L1 L3’

L

N

277 V L-N

NN’ L3L2’L2L1’L1 L3’

L

N

277 V L-N

1PH2W L-L

1PH3W L-L-N

3PH3W

NN’ L3L2’L2L1’L1 L3’

L1

L2

N

277 V L-N

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L1

L2

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L1

L2

N

277 V L-N

480 V L-L

NN’ L3L2’L2L1’L1 L3’

L1

L2

L3

480 V L-L

28 DOCA0005EN-04

iEM3100 / iEM3200 / iEM3300 series user manual Hardware and installation

Power system Wiring

NN’ L3L2’L2L1’L1 L3’

L1

L2

L3

N

277 V L-N

480 V L-L

3PH4W

NN’ L3L2’L2L1’L1 L3’

L1

L2

L3

N

277 V L-N

480 V L-L

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Do not connect N’ to the load when setting the wiring type on the meter to 1PH4W Multi L-N.

Failure to follow these instructions will result in death or serious injury.

Power system Wiring

NN’ L3L2’L2L1’L1 L3’

1PH multiple loads with neutral (1PH4W Multi L-N)

1

1

The 1PH4W Multi L-N wiring type is only available on the iEM3335, iEM3350, iEM3355, iEM3365 and iEM3375.

5 A / 1 A meter wiring

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Never short the secondary of a voltage transformer (VT).

• Never open circuit a current transformer (CT); use the shorting block to short circuit the leads of

the CT before removing the connection from the meter.

• Always use grounded external CTs for current inputs.

Failure to follow these instructions will result in death or serious injury.

Single-phase systems with CTs

250 mA fuses and disconnect switch

Shorting block

Power system Wiring

V1 V2 V3Vn

(I1) (I3)(I2)

1PH2W L-N

S1 S2

277 V L-N

DOCA0005EN-04 29

Hardware and installation iEM3100 / iEM3200 / iEM3300 series user manual

Power system Wiring

1PH2W L-L

1PH3W L-L-N

1PH multiple loads with neutral

(1PH4W Multi L-N)

1

V1 V2 V3Vn

L1

L2

(I1)

S1

S2

480 V L-L

S1

(I1)

S2

S1 S2

V1 V2 V3Vn

L1

L2

N

277 V L-N

480 V L-L

2CTs 3CTs

V1 V2 V3Vn

(I1) (I3)(I2)

(I3)(I2)

(I3)(I2)

V1 V2 V3Vn

(I1) (I3)(I2)

277 V L-N

1

The 1PH4W Multi L-N wiring type is only available on the iEM3235, iEM3250, iEM3255, iEM3265 and iEM3275

Three-phase systems with CTs

250 mA fuses and disconnect switch

Shorting block

indicates wiring for a balanced system

Power system Wiring

1 CT 2CTs 3CTs

V1 V2 V3Vn

3PH3W

480 V L-L

1 CT 2 CTs 3CTs

V1 V2 V3Vn

480 V L-L

277 V L-N

V1 V2 V3Vn

480 V L-L

V1 V2 V3Vn

V1 V2 V3Vn

V1 V2 V3Vn

3PH4W

277 V L-N

277 V L-N

277 V L-N

30 DOCA0005EN-04

Loading...

Loading...