Page 1

Installation Instructions

CompactLogix 5370 L2 Controllers

Catalog Numbers 1769-L24ER-QB1B, 1769-L24ER-QBFC1B,

1769-L27ERM-QBFC1B

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which ca n cause internal damage and

affect normal operation. Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Before You Begin

Consider the following before installing a CompactLogix 5370 L2 controller:

• The control system includes a controller, an embedded power supply,

and embedded I/O points.

• The embedded power supply is a 24V DC input, isolated power supply.

• You must connect an external Class 2 or SELV-approved power supply

to provide 24V DC power to the system.

• The controllers have embedded I/O points. You wire the input and

output points via a removable connector.

• The controller supports the use of Compact I/O

1769 CompactBus backplane as local expansion modules.

• You must terminate the end of the CompactBus via a 1769-ECR right

end cap.

modules on the local

Page 2

2 CompactLogix 5370 L2 Controllers

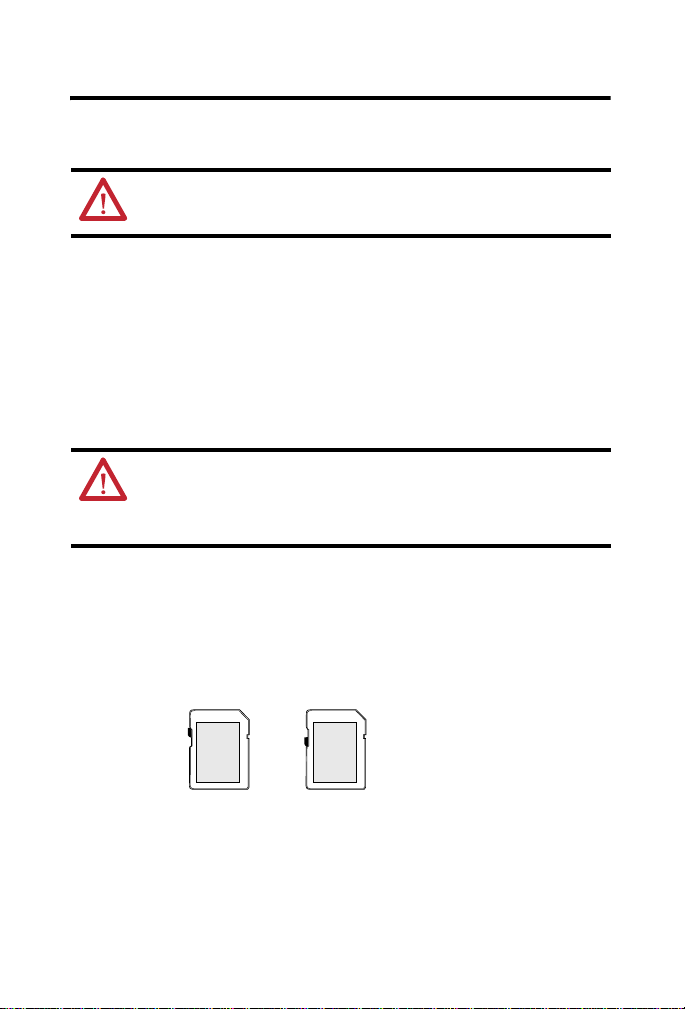

Unlocked Locked

32005-M

• You cannot remove nor install Compact I/O modules while the

controller is powered.

ATTENTION: CompactLogix 5370 L2 control systems do not support removal and

insertion under power (RIUP). Removing a 1769 Compact I/O module or end cap will

generate a controller fa ult and may also result in damage to system components.

Install the Secure Digital Card

The CompactLogix 5370 L2 controller is shipped from the factory with the

1784-SD1 SD card installed.

Complete these steps to re-install an SD card that has been removed from the

controller back into the controller or if installing a new SD card into the

controller.

WARNIN G: When you insert or remove the SD card while power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Verify that the SD card is locked or unlocked according to your

preference before installation. Consider the following points:

– If the card is unlocked, the controller can write data to it or read data

from it.

– If the card is locked, the controller can only read data from it.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 3

CompactLogix 5370 L2 Controllers 3

32253-M

32254-M

32255-M

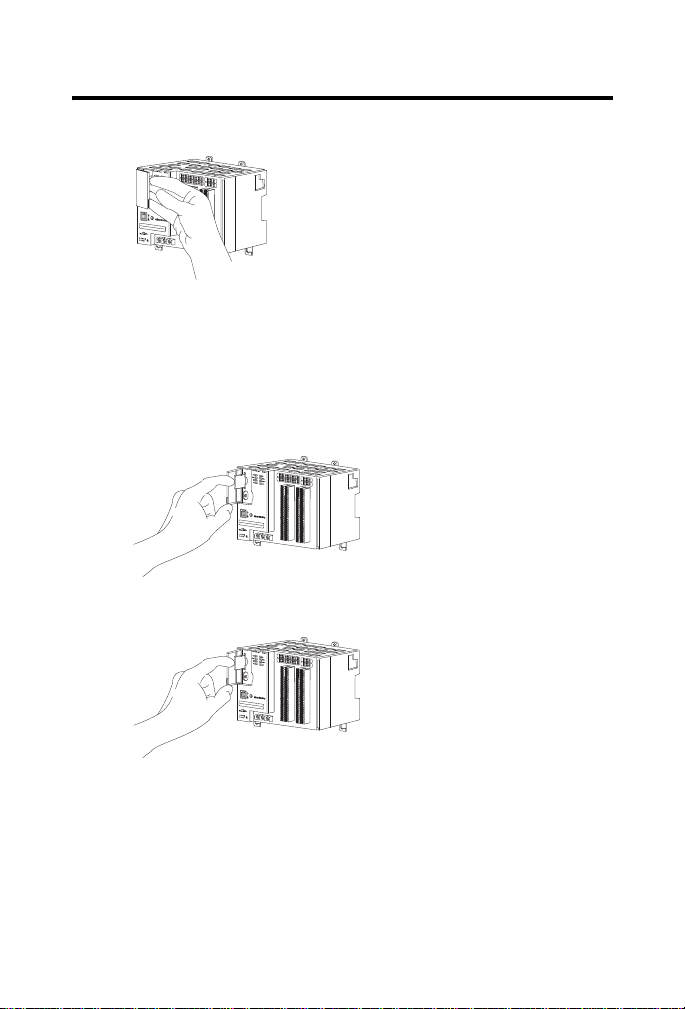

2. Open the door for the SD card.

3. Insert the SD card into the SD card slot.

You can install the SD card in one orientation only. The beveled corner

should be at the bottom. If you feel resistance when inserting the SD

card, pull it out and change the orientation.

4. Gently press the card until it clicks into place.

5. Close the SD card door.

We recommend you close the SD card door during system operation.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 4

4 CompactLogix 5370 L2 Controllers

Mount the System

Mount a CompactLogix 5370 L2 control system on a DIN rail or a panel.

WARNIN G: When used in a Class I, Division 2, hazardous location, this

equipment must be mounted in a suitable enclosure with proper wiring

method that complies with the governing electrical codes.

Available DIN Rails

ATT ENT IO N: This product is grounded through the DIN rail to chassis ground. Use

zinc-plated yellow-chromate steel DIN rail to assure proper grounding. The use of other

DIN rail materials (for example, aluminum or plastic) that can corrode, oxidize, or are

poor conductors, can result in improper or intermittent grounding. Secure DIN rail to

mounting surface approximately every 200 mm (7.8 in.) and use end-anc hors

appropriately.

You can mount the CompactLogix 5370 L2 controller on these DINrails:

• EN 50 022 - 35 x 7.5 mm (1.38 x 0.30 in.)

• EN 50 022 - 35 x 15 mm (1.38 x 0.59 in.)

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 5

CompactLogix 5370 L2 Controllers 5

Bottom

Top

CompactLogix 5370 L2

Controller with

Embedded Power

Supply and I/O Points

End Cap

50 mm

(2 in.)

50 mm

(2 in.)

50 mm

(2 in.)

50 mm

(2 in.)

Side Side

Compa ct I/O Mod ule

Compa ct I/O Mod ule

Compa ct I/O Mod ule

Compa ct I/O Mod ule

00:00:BC:2E:69:F6

L24ER

01234567

8 9 10 11 12 13 14 15

01234567

8 9 10 11 12 13 14 15

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

DC IN

DC OUT

QB1B

118.00 mm

(4.65 in.)

115.00 mm

(4.53 in.)

35.00 mm (1.38 in.)

105.00 mm

(4.13 in.)

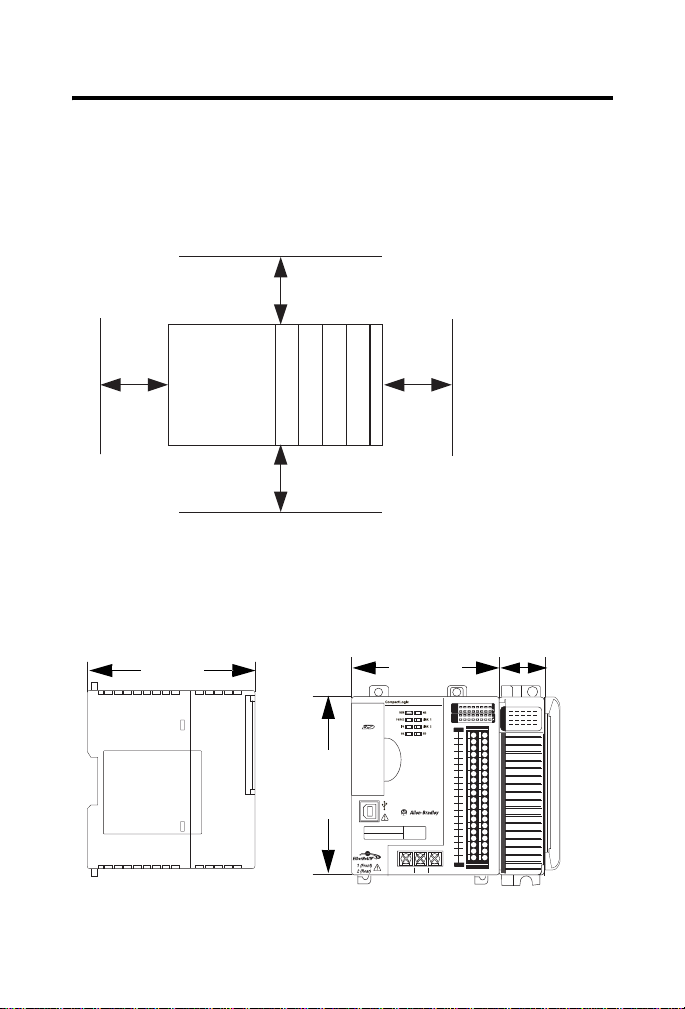

Minimum Spacing

Maintain spacing from enclosure walls, wireways, and adjacent equipment.

Allow 50 mm (2 in.) of space on all sides, as shown. This provides ventilation

and electrical isolation.

System Dimensions

This graphic shows system dimensions for the 1769-L24ER-QB1B controller.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 6

6 CompactLogix 5370 L2 Controllers

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

QBFC1B

105.00 mm

(4.13 in.)

118.00 mm

(4.65 in.)

35.00 mm (1.38 in.)

140.00 mm

(5.51 in.)

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

105.00 mm

(4.13 in.)

118.00 mm

(4.65 in.)

35.00 mm (1.38 in.)

140.00 mm

(5.51 in.)

This graphic shows system dimensions for the 1769-L24ER-QBFC1B

controller.

This graphic shows the system dimensions for the 1769-L27ERM-QBFC1B

controller.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 7

CompactLogix 5370 L2 Controllers 7

IMPORTANT

TIP

TIP

Mount the Controller on a Panel

Use two M4 or #8 panhead screws to mount the controller. Mounting screws are

required on every module. Use this procedure to use the assembled modules as a

template for drilling holes in the panel.

Due to module mounting hole tolerance, it is important to follow these procedures.

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of

all module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel and check for proper hole

alignment.

The grounding plate, that is, where you install the mounting screws, grounds

the module when it is panel-mounted.

6. Use the mounting screws to attach the modules to the panel.

If you are mounting more modules, mount only the last one of this group and

put the others aside. This reduces remounting time when you are drilling and

tapping the next group of modules.

7. Repeat steps 1…6 for any remaining modules.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 8

8 CompactLogix 5370 L2 Controllers

Mount the Controller on the DIN Rail

You can mount the controller on the following DIN rails:

• EN 50 022 - 35 x 7.5 mm (1.38 x 0.30 in.)

• EN 50 022 - 35 x 15 mm (1.38 x 0.59 in.)

ATTENTION: This product is grounded through the DIN rail to chassis ground. Use zinc

plated yellow- chromate steel DIN rail to assure proper grounding. The use of other DIN

rail materials (for example, aluminum or plastic) that can corrode, oxidize, or are poor

conductors, can result in improper or intermittent grounding. Secure DIN rail to

mounting surface approximately every 200 mm (7.8 in.) and use end-anchors

appropriately.

1. Hook the DIN rail latch at the top of the back of the controller on the

DIN rail.

2. Swing the controller downward until it touches the DIN rail and press

the controller against the DIN rail until it clicks in place.

The click verifies that controller is locked on the DIN rail.

Ground the System

ATT EN TI ON : This product is intended to be mounted to a well-grounded mounting

surface such as a metal panel. Additional grounding connections from the power

supply's mounting tabs or DIN rail (if used) are not required unless the mounting

surface cannot be grounded.

Refer to Industrial Automation Wiring and Grounding Guidelines, Rockwell Automation

publication 1770-4.1

, for additional information.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 9

CompactLogix 5370 L2 Controllers 9

01234567

8 9 10 1112 13 14 15

01234567

8910

A0B0 Z0

A1B1 Z1

0 2FUSE

13OK

1112 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCOM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

32256-M

32257-M

01234567

8 9 1011 12 1314 15

01234567

8910

A0B0 Z0

A1B1 Z1

0 2FUSE

13OK

1112 13 1415

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCOM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

Install the Controller

Complete these steps to install the controller.

1. Pull the bottom locking tabs out.

2. Hook the top of the controller on the DIN rail.

3. Swing it downward until the controller is flush against the DIN rail and

push it down against the DIN rail.

4. Push the controller against the DIN rail until the bottom DIN rail lock

on the back of the controller clicks, locking the controller in place.

5. Push the locking tabs in.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 10

10 CompactLogix 5370 L2 Controllers

32258-M

32267-M

6. Slide the 1769-ECR end cap onto the right side of the controller.

The covering covers the exposed interconnections on the right side of

the controller.

ATTENTION: Failure to use a protective covering could result in equipment damage or

injury from electric shock.

7. Push the end cap locking mechanism to the right to lock it onto

the controller.

Connect Power to the Controller

You must connect an external Class 2 or SELV-listed power supply to the

controller’s embedded power supply. The external power supply converts

115/230V AC power to 24V DC.

WARNIN G: Do not connect directly to line voltage. Line voltage must be

supplied by a suitable, approved isolating transformer or power supply having

short circuit capacity not exceeding 100 VA maximum or equivalent.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 11

CompactLogix 5370 L2 Controllers 11

Consider these points before completing the steps in this section:

• An external power supply must reside in the same enclosure as the

CompactLogix 5370 L2 controller.

If the external power supply and controller are located in separate

enclosures, an electrical arc can occur when power is applied.

• Not all Class 2 or SELV-listed power supplies are certified for use in all

applications, for example, use in both nonhazardous and hazardous

environments.

Before installing an external power supply, consult all specification and

certification information to verify that you are using an acceptable

external power supply.

• Yo u must wire power according to the wiring specifications, for example,

the maximum screw torque on a power supply terminal, listed in the

CompactLogix 5370 L2 Controllers Product Information Sheet,

publication 1769-PC010

.

Complete these steps to connect power to the CompactLogix 5370 L2

control system.

1. Verify that the external power supply is installed properly.

2. If appropriate, verify that the power setting on the supply is configured

to match the voltage source and that the supply is not powered.

3. Connect a wire to a +24V DC terminal on the external power supply.

WARNI NG: If you connect or disconnect wiring while the field-side power is

on, an electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

4. Strip 8 mm (0.31 in.) insulation from the end of the wire that you will

connect to the +24VDC terminal on the controller.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 12

12 CompactLogix 5370 L2 Controllers

IMPORTANT

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 1213 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

01234567

8 9 10 11 12 1314 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 1213 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

5. Connect the wire to the +24VDC terminal on the controller.

6. Connect a wire to a -24V DC terminal on the external power supply.

7. Strip 8 mm (0.31 in.) insulation from the end of the wire that you will

connect to the COM terminal on the controller.

8. Connect the wire to the COM terminal on the controller.

If your application requires a power control device, for example, a switch or relay,

between the external power supply and the CompactLogix 5370 L2 controller’s

embedded power supply to control when the controller is powered, you must install

the power control device at the +24VDC terminal on the controller.

If you install the power control device at the COM terminal, the CompactLogix 5370

L2 controller may not power up or power down properly.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

The previous section describes how to wire terminals +24VDC and COM on the

CompactLogix 5370 L2 controller. They are the only terminals you wire to power the

CompactLogix 5370 L2 control system.

You should only use the FG terminal as appropriate when connecting a field device to

the controller.

Page 13

CompactLogix 5370 L2 Controllers 13

00:00:BC:2E:69:F6

L24ER

01234567

8 9 10 11 12 13 14 15

01234567

8 9 10 11 12 13 14 15

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

DC IN

DC OUT

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

DC IN

DC OUT

QB1B

Digital

Input

Point s

Digital

Output

Point s

Wire Embedded I/O Modules

CompactLogix 5370 L2 controllers provide embedded I/O modules as

described in the following table.

Cat. No.

Sourcing

24V DC

Digital

Input

Point s

Sinking

24V DC

Digital

Output

Points

High

Speed

Counters

High

Speed

Counter

Output

Point s

Universal

Analog

Input

Points

1769-L24ER-QB1B 16 16 - - - -

1769-L24ER-QBFC1B 4 4 4 2

1769-L27ERM-QBFC1B

Yo u must wire the embedded I/O modules according to the wiring

specifications, for example, wiring insulation stripping length, listed in the

CompactLogix 5370 L2 Controllers Product Information Sheet, publication

1769-PC010

.

The following graphic shows the embedded digital I/O module terminations

on a 1769-L24ER-QB1B. The digital I/O module terminations on the

1769-L24ER-QBFC1B and 1769-L27ERM-QBFC1B controllers are the same.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Analog

Output

Points

Page 14

14 CompactLogix 5370 L2 Controllers

01234567

8 9 10 1112 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 1213 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCO M

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

OUT

2

HSC

The following graphic shows the embedded analog I/O module terminations

on the 1769-L27ER-QB1B controller. The embedded analog I/O module

terminations on the 1769-L24ER-QBFC1B controller are the same.

V

V

in

in

0+

2+

I

I

in

in

0+

2+

V/I

V/I

in

in

0-

2V

CJC

in

+

3+

I

CJC

in

3+

V

V/I

in

in

1+

3-

V/I

I

in

in

1-

1+

V

V

OUT

OUT

1+

0+

I

I

OUT

in

0+

1+

COMCOM

ANALOG

00:00:BC:2E:69:F6

+24VDC COM FG

L27ERM

QBFC1B

01234567

8 9 10 11 12 13 14 15

SINK\

24VDC

SOURCE

01234567

24VDC

SOURCE

8910

DC IN

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

COM

0

1

NC

NC

+V

+V

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

COM

0

1

DC OUT

A0 B0 Z0

INOUT

DC

A1 B1 Z1

INPUT

COUNTER

0 2 FUSE

DC

HIGH SPEED

OUTPUT

13OK

11 1213 14 15

HSC

A0+

A0-

B0+

B0-

Z0+

Z0-

A1+

A1-

B1+

B1-

Z1+

Z1-

+V

+V

OUT

OUT

2

0

OUT

0UT

1

3

COMCO M

V

V

in

in

0+

2+

I

I

in

in

0+

2+

V/I

V/I

in

in

0-

2V

CJC

in

+

3+

I

CJC

in

3+

V

V/I

in

in

1+

3V/I

I

in

in

1-

1+

V

V

OUT

OUT

0+

1+

I

I

OUT

in

0+

1+

COMCOM

ANALOG

The following graphic shows the embedded high-speed counter module

terminations on the 1769-L27ER-QB1B controller. The embedded high-speed

counter module terminations on the 1769-L24ER-QBFC1B controller are

the same.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 15

CompactLogix 5370 L2 Controllers 15

L27ERM

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 1213 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCOM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

QBFC1B

L27ERM

01234567

8 9 10 11 1213 14 15

01234567

8910

A0B0 Z0

A1B1 Z1

0 2 FUSE

13OK

1112 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCOM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

QBFC1B

Wiring the Embedded I/O Modules

Complete these steps to wire the input and output points on the

CompactLogix 5370 L2 controller.

1. Verify that the control system is not powered.

2. Strip 10 mm (0.39 in.) insulation from the end of the wire.

3. Push the wire into the connector hole until it is securely in place.

If your wire is too thin to push into the connector hole for secure

placement, we recommend that you connect the wire to a ferrule and

then insert it into the connector hole.

4. Repeat step 2

for all embedded I/O wires needed in your application.

To remove a wire from the removable connector, complete these steps.

1. Verify that the control system is not powered.

2. Use a small screwdriver to push on the spring release clip and pull the

wire out.

Rockwell Automation Publication 1769-IN090A-EN-P - April 2012

Page 16

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical i nformation on the Web to assist you in using its prod ucts.

At http://www.rockwellautomation.com/support

code and links to software service packs, and a MySupport feature that you can customize to make the best use of these tools.

You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowled gebase

support chat and forums, sof tware updates, and to sign up for product notification updates.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the informatio n that's contained in this

manual. You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/support/americas/phone_en.html

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufact uring

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the pho ne

number above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs bette r. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

, you can find technical manuals, technical and applic ation notes, sample

for FAQs, technical information,

.

at

, available at http://www.rockwellautomation.com/literature/.

, or contact your

sm

Allen-Bradley, CompactLogix, Compact I/O, CompactBus, Rockwell Software, Rockwell Automation, and TechConnect are

trademarks of Rockwell Automation, Inc.

Trademarks not belonging to R ockwell Automation are property of their respective companies.

Publication 1769-IN090A-EN-P - April 2012 PN-147159

Copyright © 2012 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...