Page 1

Quick Start

CompactLogix 5370 L2 Controllers

Catalog Numbers 1769-L24ER-QB1B, 1769-L24ER-QBFC1B, 1769-L27ERM-QBFC1B

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Compact I/O, CompactLogix, ControlFLASH, FactoryTalk, FLEX, Integrated Architecture, Kinetix, KwikLink, Logix5000, PanelView, POINT I/O, PowerFlex, Rockwell Software, Rockwell Automation,

RSLinx, R SLogix, RSNetWorx, Stratix 6000, Studio 5000, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

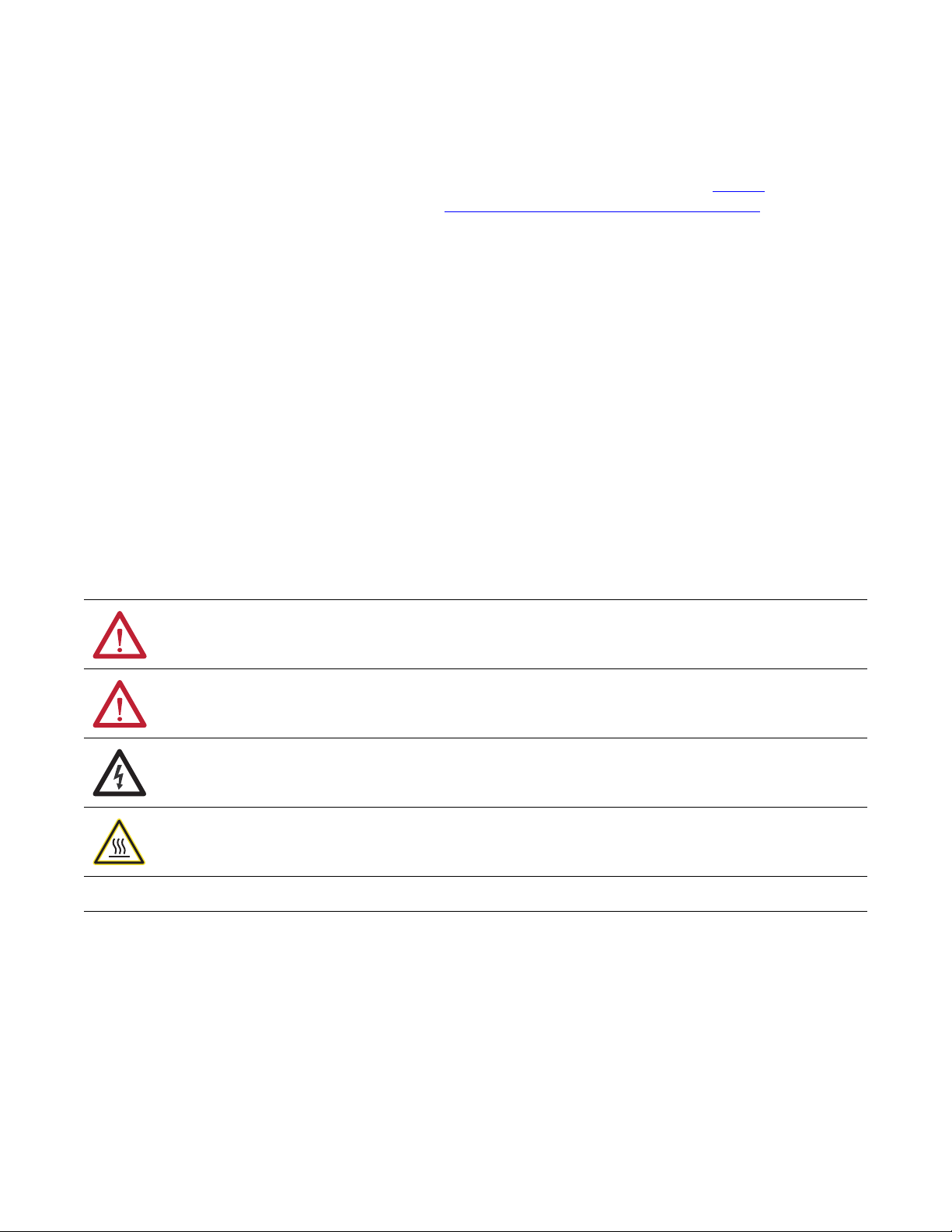

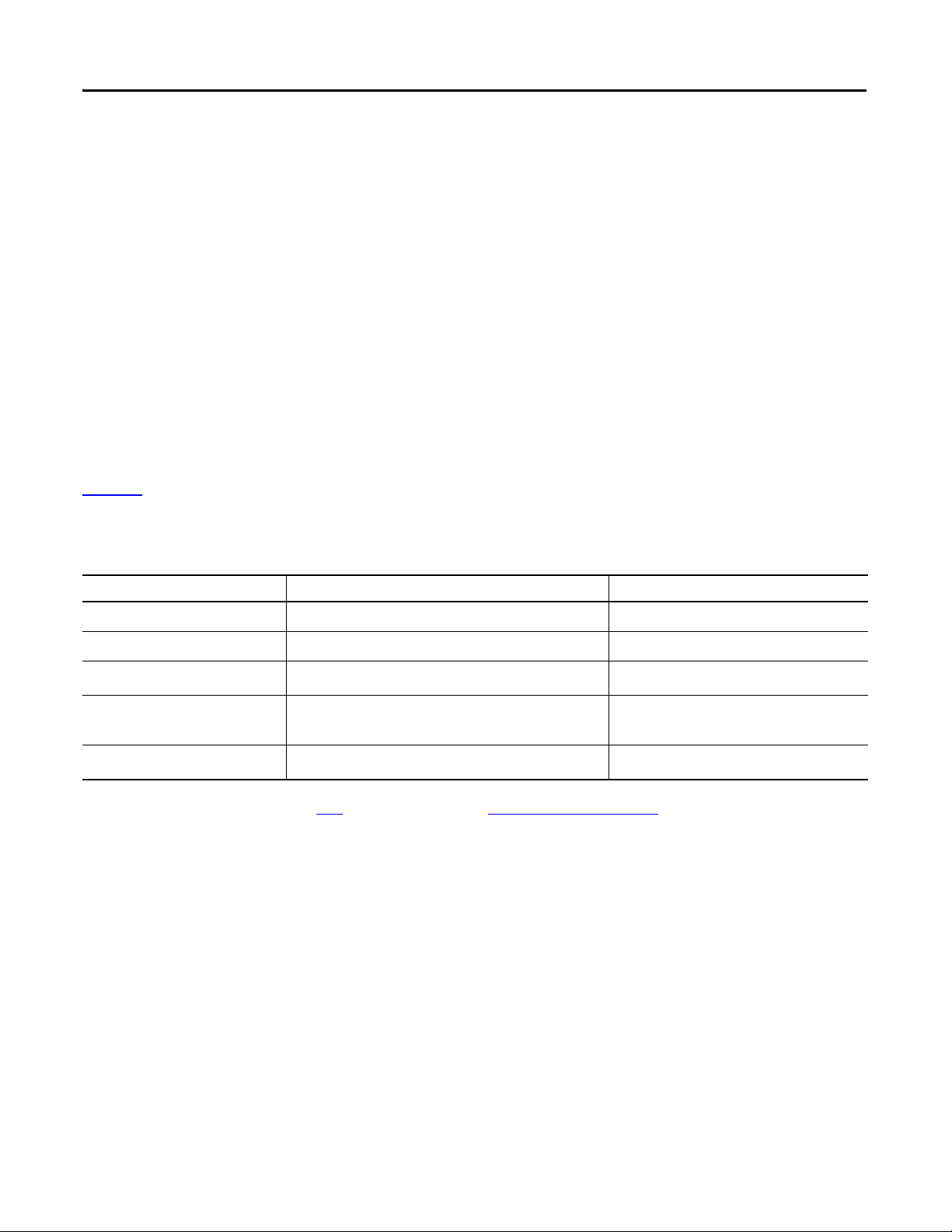

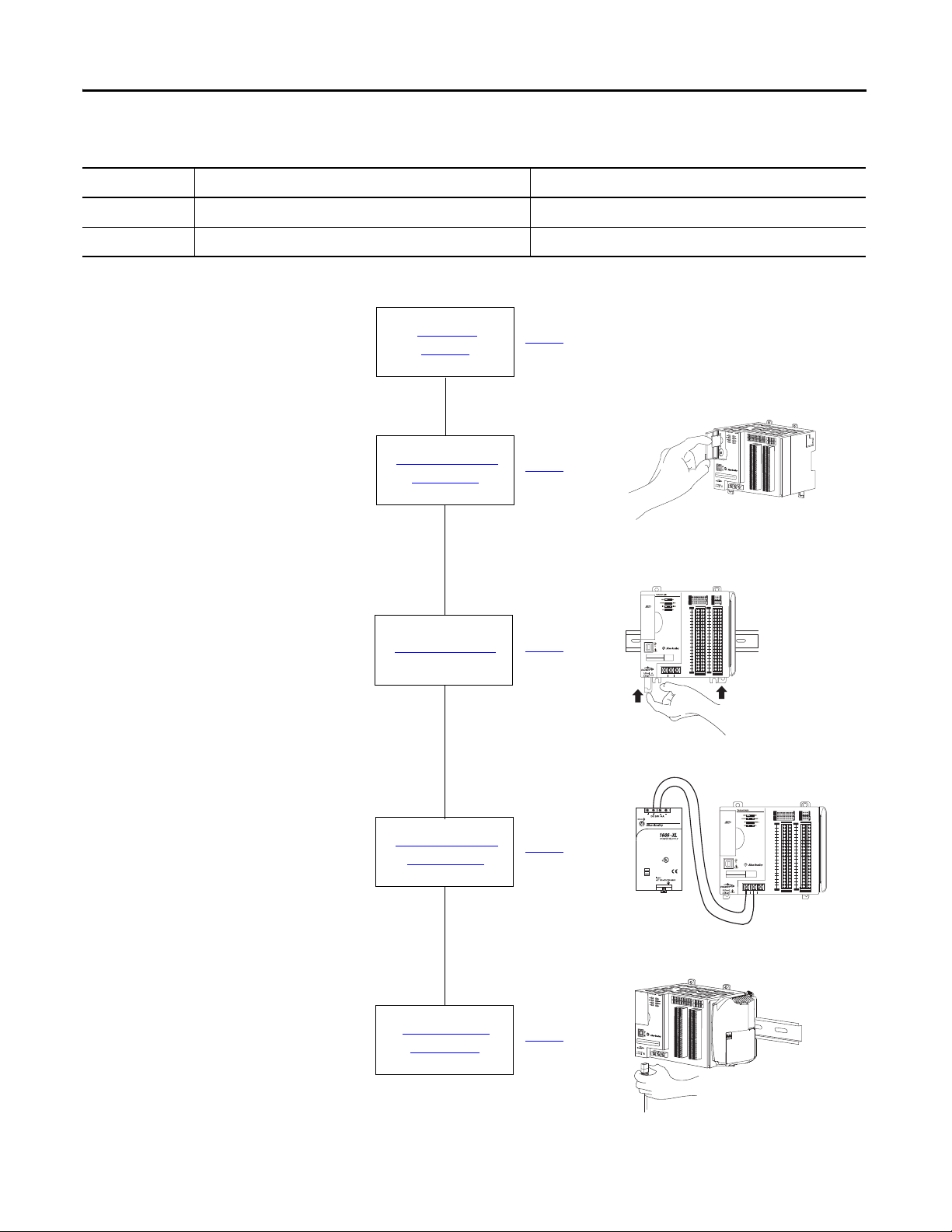

Follow the path that matches your hardware and network configuration.

Create a Logix Designer

Project

Prepare the CompactLogix 5370 L2

Controller Hardware

Prepare the Computer and Load

Controller Firmware

Configure the EtherNet/IP

Network

Configure the DeviceNet

Network

Required

Required

Optional

Required

page 17

page 31

page 47 page 53

page 63

Optional

POINT I/O™

Modules

Kinetix® 350

Drive

Power Flex® 40

Drive

PowerFlex 70

Drive

Panel View

™

Plus Terminal

For more information on using each optional

device, see Table 1 on page 11

.

L27ERM

QBFC1B

00:00:BC:2E:69:F6

+24VDC COM FG

Where to Start

L27ERM

QBFC1B

00:00:BC:2E:69:F6

+24VDC COM FG

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 3

Page 4

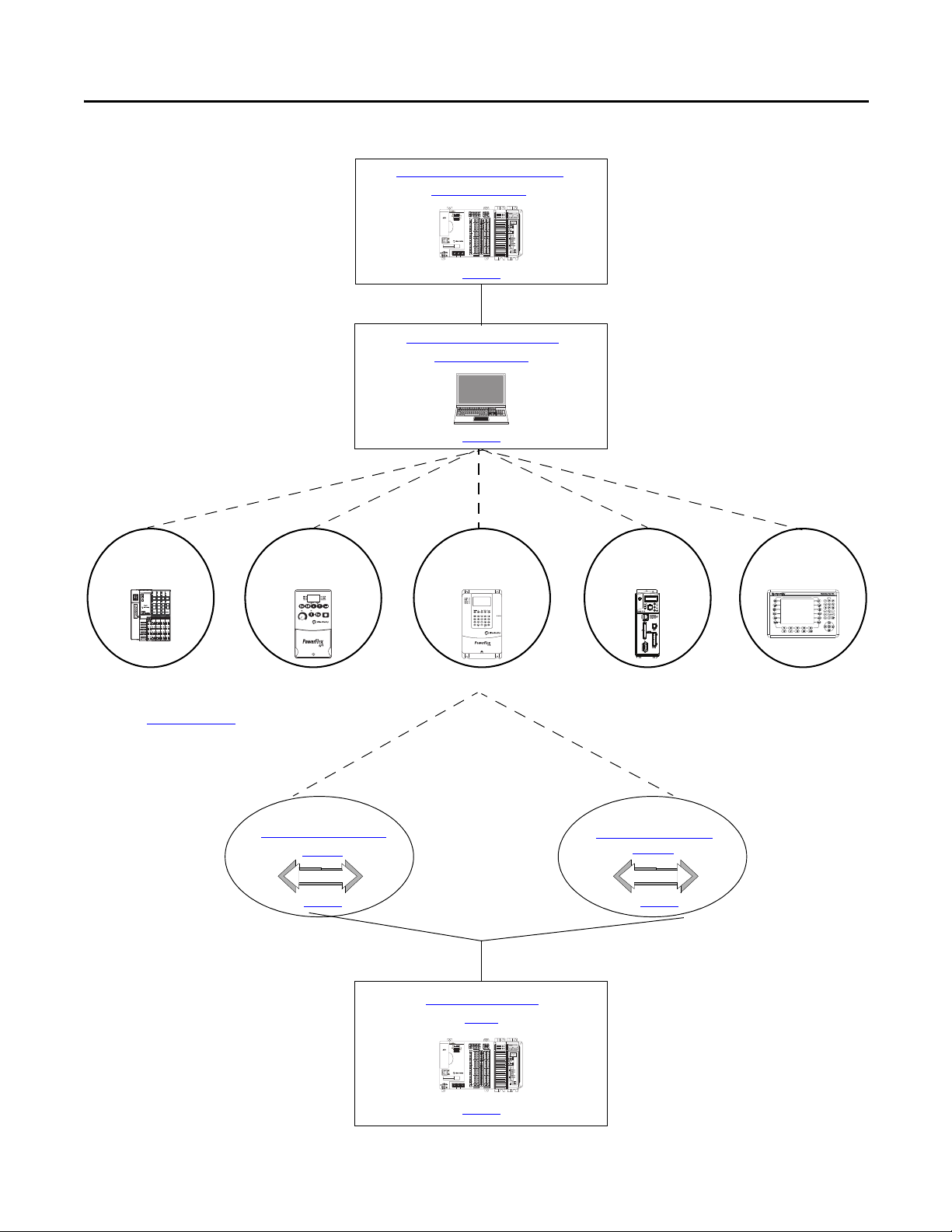

Where to Start

Power Flex 40 Dri ve

Stratix 6000™ Switch

CompactLogix™ 5370

L2 Control System

PanelVie w Plus

Ter minal with

Built-in

EtherNet/IP Port

Compu ter

Distributed POINT I/O Modules with

1734-AENT Adapter

Star Network Topology

Application Configuration

Kinetix 350 Drive

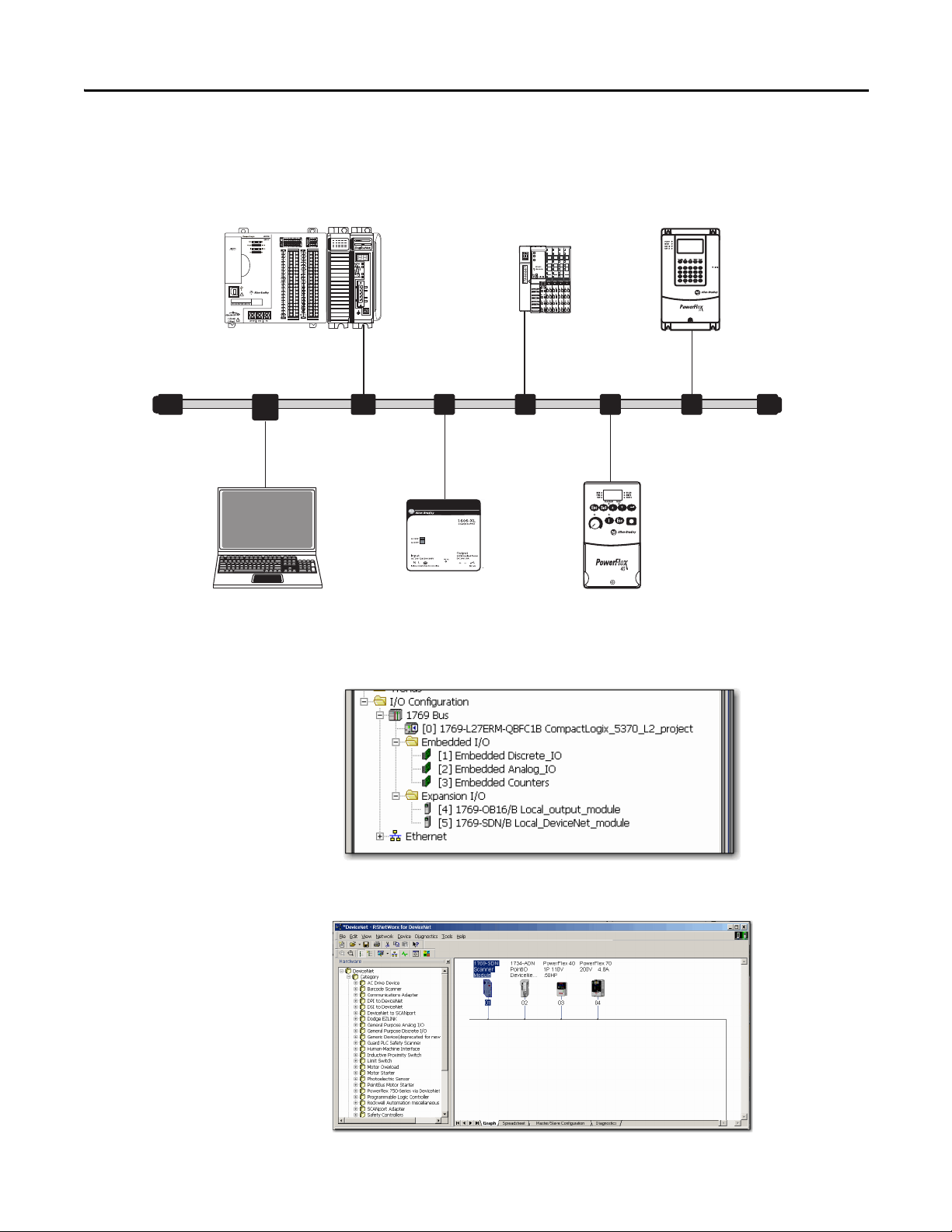

How Hardware Is Connected

This quick start, in use with the additional quick starts listed in Tabl e 1 on pa g e 11, describes

possible control systems shown in Figure 1

Figure 1 - CompactLogix 5370 L2 Controller in a Star Network Topology

and Figure 2.

78

56

34

1

2

00:00:BC:2E:69:F6

+24VDC COM FG

+24VDC COM FG

L27ERM

A0B0 Z0

01234567

A0B0 Z0

INOUT

01234567

DC

A1B1 Z1

8 9 10 11 12 13 14 15

SINK\

24VDC

INPUT

INOUT

SOURCE

DC

QBFC1B

A1B1 Z1

8 9 10 11 12 13 14 15

SINK\

24VDC

INPUT

SOURCE

COUNTER

0 2 FUSE

DC

01234567

HIGH SPEED

COUNTER

02FUSE

24VDC

DC

01234567

HIGH SPEED

OUTPUT

SOURCE

24VDC

13OK

OUTPUT

SOURCE

8910

1112 13 14 15

13OK

1112 13 14 15

8910

DC IN

HSC

A0+

A0-

00

08

B0+

B0-

01

09

Z0+

Z0-

02

10

A1+

A1-

03

11

B1+

B1-

04

12

Z1+

Z1-

05

13

+V

+V

06

14

OUT

OUT

07

15

2

0

OUT

0UT

COM

COM

1

3

0

1

COMCOM

NC

NC

V

V

in

in

+V

+V

0+

2+

I

I

in

in

00

08

2+

0+

V/I

V/I

in

in

01

09

0-

2V

CJC

in

02

10

+

3+

I

CJC

in

03

11

3+

V

V/I

in

in

04

12

1+

3V/I

I

in

in

05

13

1-

1+

V

V

OUT

OUT

06

14

1+

0+

I

I

OUT

in

07

15

0+

1+

COM

COM

COMCOM

0

1

ANALOG

DC OUT

4 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 5

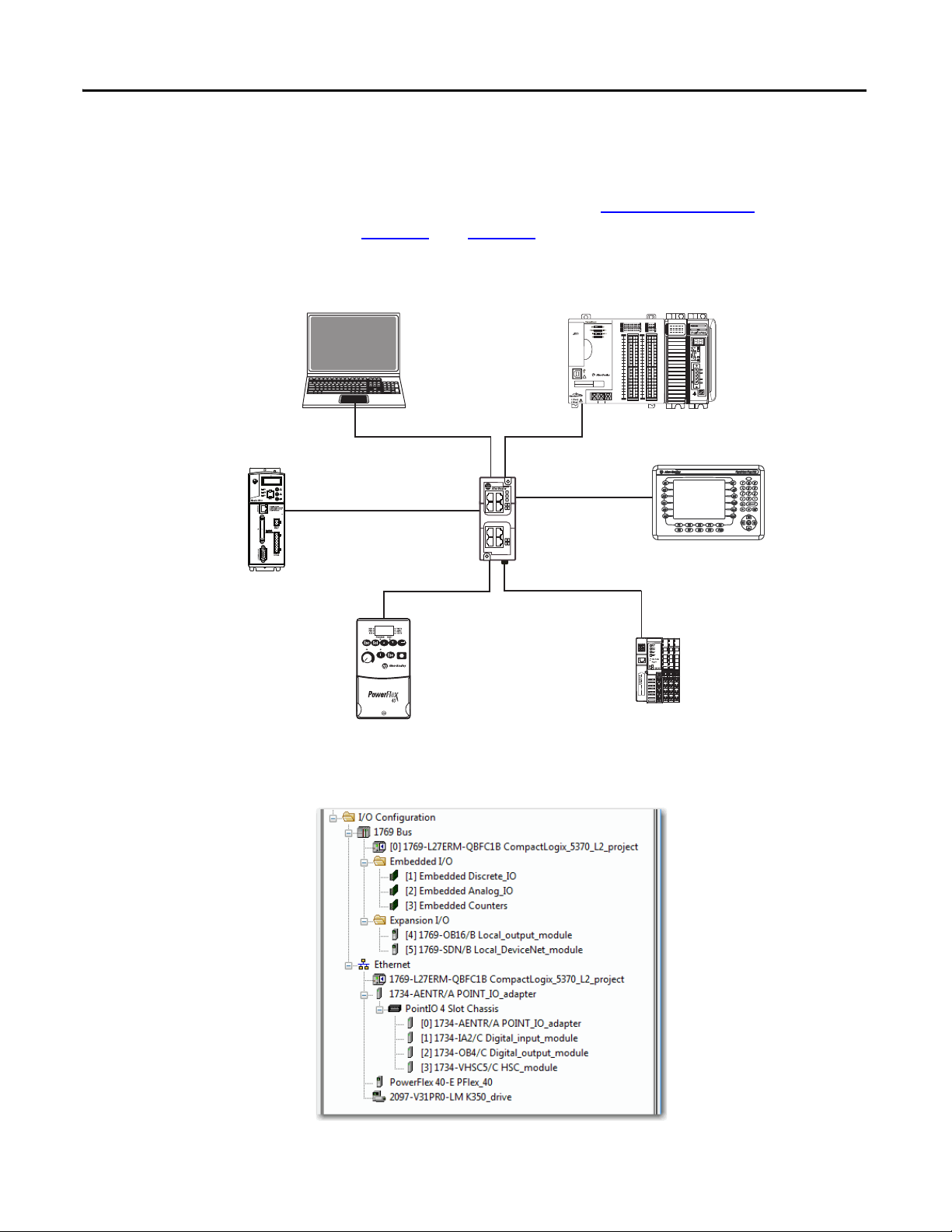

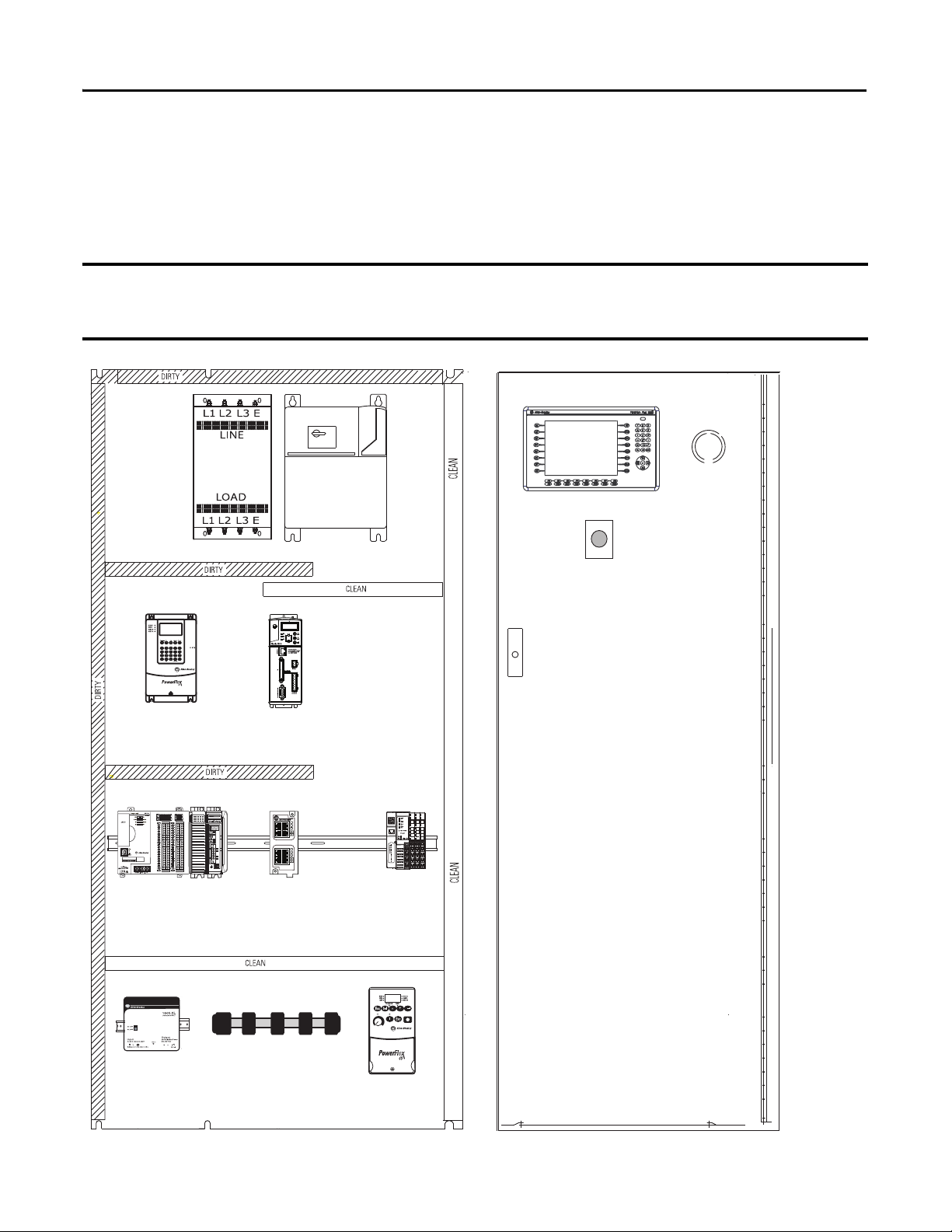

Figure 2 - CompactLogix 5370 L2 Controllers with a DeviceNet Network

PowerFlex 70 Drive with

20-COMM-D Adapter

PowerFlex 40 Drive with

22-COMM-D Adapter

Computer with

1784-U2DN Cable

Distributed POINT I/O Modules with

1734-ADN Adapter

1606-XLDNET4

DeviceNet Power Supply

CompactLogix 5370 L2

Control System with

1769-SDN Module

Application Configuration

Network Configuration

in RSNetWorx™ for

DeviceNet Software

Where to Start

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 5

Page 6

Where to Start

IMPORTANT

AC Line Filter

PowerFlex 70 Drive

PowerFlex 40 Drive

Kinetix 350 Drive

Line Interface

Module

DeviceNet Power Supply

DeviceNet KwikLink™ System

CompactLogix 5370 L2

Control System

Ethernet

Switch

Distributed POINT I/O

Modules

Through-the-door

Disconnect

PanelView Plus Terminal

E-Stop Push Button

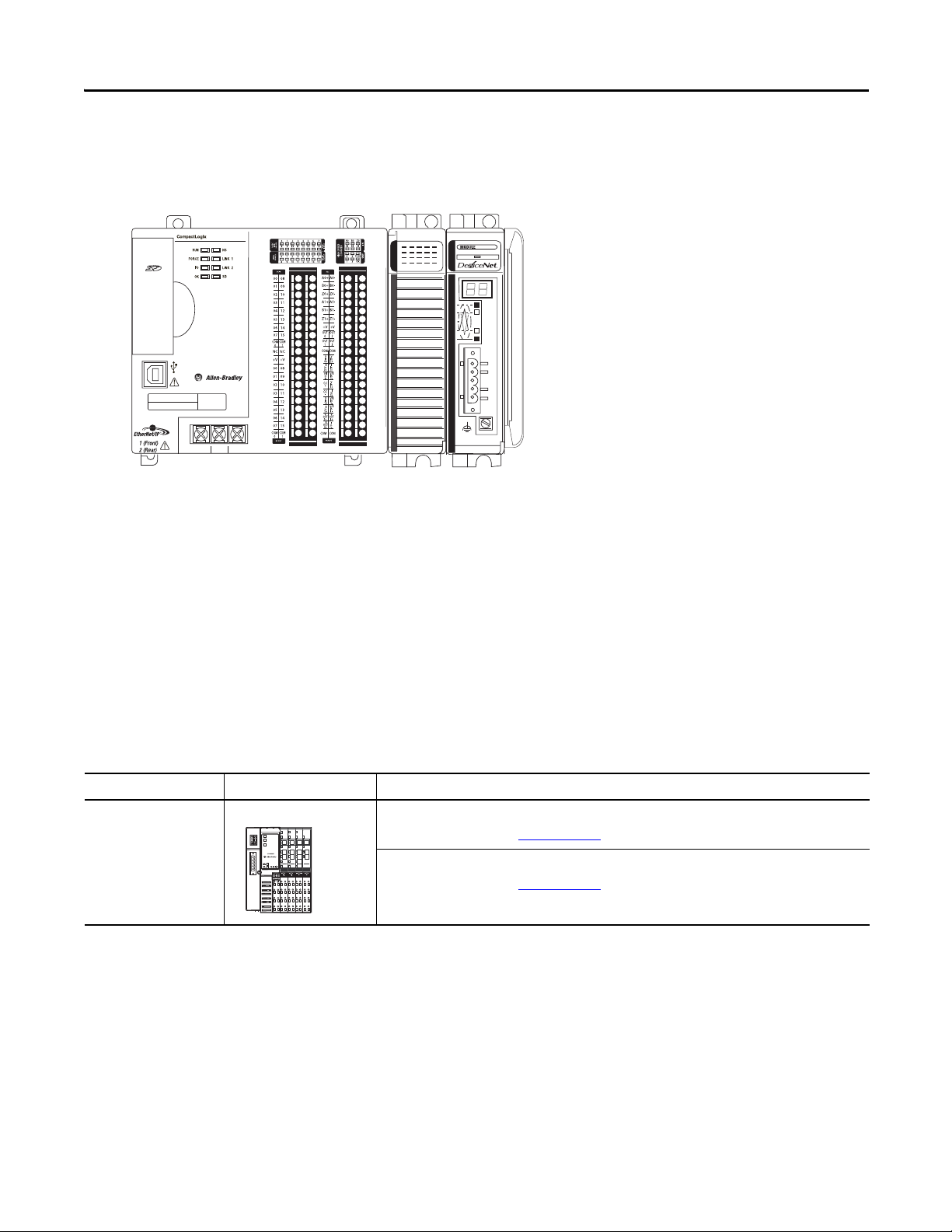

Sample Panel Layout

The sample panel layout shows the orientation of an example CompactLogix 5370 L2 control

system using EtherNet/IP networks and DeviceNet networks.

The specific layout of CompactLogix 5370 L2 control systems varies by application. The following graphic is an example

panel layout. The graphic shows a PowerFlex 40 drive used on a DeviceNet network. You can also use a PowerFlex 40

drive on an EtherNet/IP network.

6 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 7

Table of Contents

Preface

Prepare the CompactLogix 5370 L2

Controller Hardware

About the CompactLogix 5370 L2 Controllers . . . . . . . . . . . . . . . . . . . . . 10

Choose to Integrate Optional Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Required Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Install the Secure Digital Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connect Power to the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Make Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Make a USB Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Make an EtherNet/IP Network Connection. . . . . . . . . . . . . . . . . . . . 28

Make a DeviceNet Network Connection . . . . . . . . . . . . . . . . . . . . . . . 29

Prepare the Computer and Load

Controller Firmware

Configure the EtherNet/IP Network

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Install the Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Installation of ControlFLASH Software . . . . . . . . . . . . . 36

Configure an EtherNet/IP Driver in RSLinx Classic Software . . . . . . . 37

Set the IP Address for the Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Load the Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Install Additional Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Assign an IP Address to the Controller over a USB Connection. . . . . . 50

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 7

Page 8

Table of Contents

Chapter 4

Configure the DeviceNet Network

Create a Logix Designer Project

Understanding Other

Application Options

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Apply Power to the DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Set the 1769-SDN Scanner Module’s Node Address. . . . . . . . . . . . . . . . . 57

Create a DeviceNet Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 5

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Create a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configure the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Add the Local Expansion Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Add the 1769-SDN Scanner Module (optional) . . . . . . . . . . . . . . . . . . . . 71

Add Ladder Logic to Use the Local 1769-OB16 Module. . . . . . . . . . . . . 74

Download the Project to the Controller and Test the Logic . . . . . . . . . . 77

Appendix A

DLR Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Integrated Motion on the EtherNet/IP Network. . . . . . . . . . . . . . . . . . . . 82

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

8 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 9

Preface

IMPORTANT

This quick start describes how to use CompactLogix 5370 L2 controllers to install a simple

CompactLogix 5370 L2 control system and execute a task with a local expansion 1769

Compact I/O™ output module. The programming examples included are not complex, and offer

solutions to verify that devices are functioning and communicating properly.

Consider the following points:

• A typical CompactLogix 5370 L2 control system includes more components than listed in this quick start. For

example, you can use 1734 POINT I/O modules over an EtherNet/IP network in a CompactLogix 5370 L2 control

system. Other quick starts describe how to use additional components with your control system.

For a list of quick starts describing how to use other components in Logix5000™ control systems, see Choose to

Integrate Optional Devices on page 11.

• Not all tasks described in this quick start are required to complete the final task, that is, use ladder logic to test a

1769-OB16 output module as described beginning on page 63. For example, you do not need a DeviceNet

configuration file to test the module.

We expect that you might attempt to complete additional tasks with your control system by using the publications

listed on page 11. When you use those publications, some assumptions are made. For example, if you use a

PanelView Plus terminal over an EtherNet/IP network in a CompactLogix 5370 L2 control system, you must have

already created an Logix Designer project and assigned an IP address to the controller.

If you complete all of the tasks described in this quick start, you can easily complete the tasks described in the

publications listed on page 11.

The following topics are described in this quick start:

• Installing hardware for a basic CompactLogix 5370 L2 control system

• Installing software required for the basic CompactLogix 5370 L2 control system

• Installing and configuring an EtherNet/IP network and a DeviceNet network

• Creating a Logix Designer project

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 9

Page 10

Preface

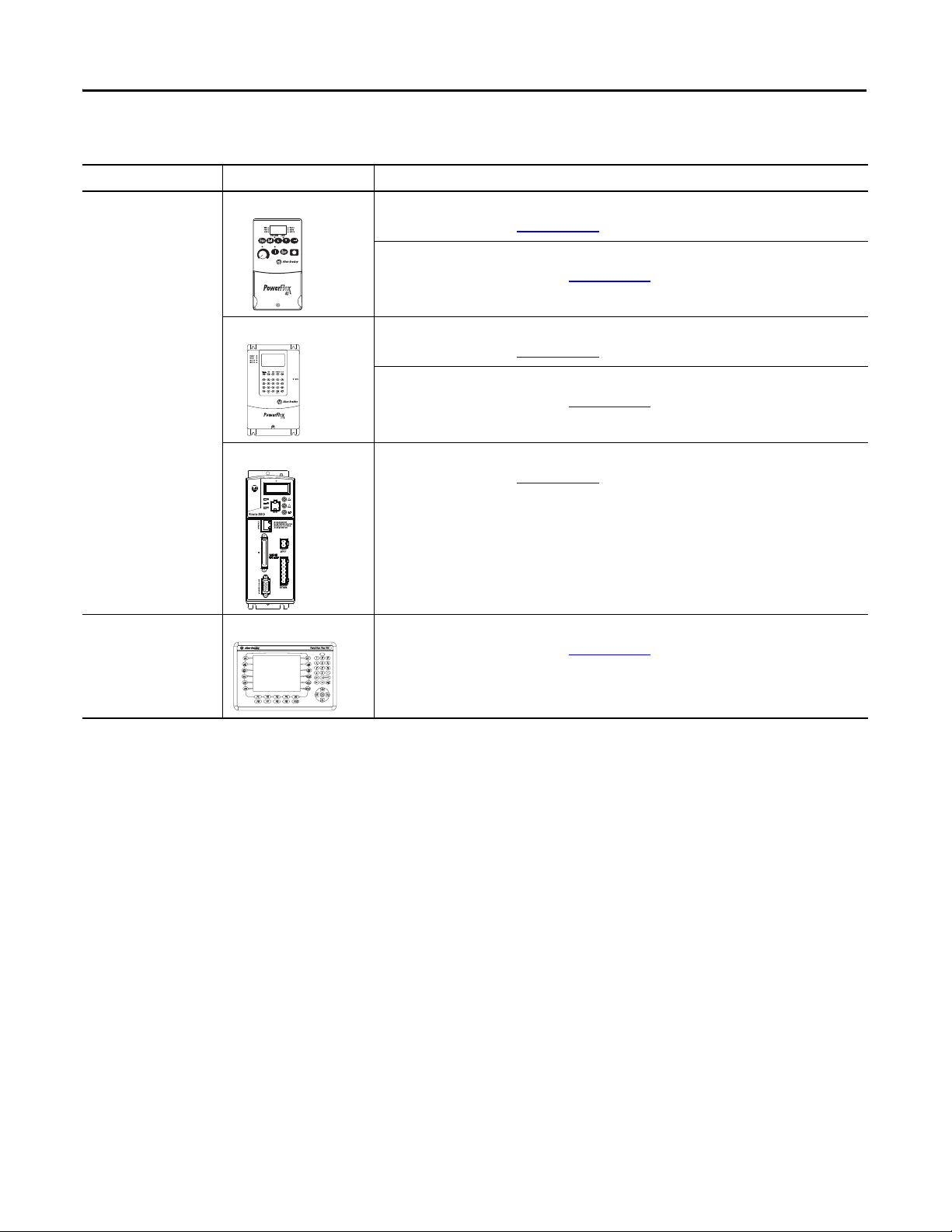

About the CompactLogix 5370 L2 Controllers

These CompactLogix 5370 L2 controllers are available:

• 1769-L24ER-QB1B

• 1769-L24ER-QBFC1B

• 1769-L27ERM-QBFC1B - This controller is used in this quick start.

These features are available on CompactLogix 5370 L2 controllers:

• Secure Digital (SD) card for nonvolatile memory storage

• Network connections:

– USB (single port)

– EtherNet/IP network - Device-level ring (DLR), linear, and star topologies are available.

For more information on these topologies, see the Ethernet Design Considerations

Reference Manual, publication ENET-RM002

– DeviceNet network - Via a 1769-SDN scanner module

• I/O module options:

– 1769 Compact I/O modules as local expansion module

– Control of distributed I/O modules over a DeviceNet or EtherNet/IP network

• Support for Integrated Motion on the EtherNet/IP network with the

.

1769-L27ERM-QBFC1B controller only

For more information on using the 1769-L27ERM-QBFC1B controller in an application

that includes Integrated Motion on the EtherNet/IP network, see Appendix A on page 79

.

10 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 11

Preface

+24VDC COM FG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

This graphic shows a CompactLogix 5370 L2 control system that matches the system you will

install after completing steps.

Choose to Integrate Optional Devices

You can integrate multiple optional devices into a CompactLogix 5370 L2 control system. You

can use these devices on DeviceNet or EtherNet/IP networks.

This table describes optional devices you might use in a CompactLogix 5370 L2 control

controller system and what resources to use for each.

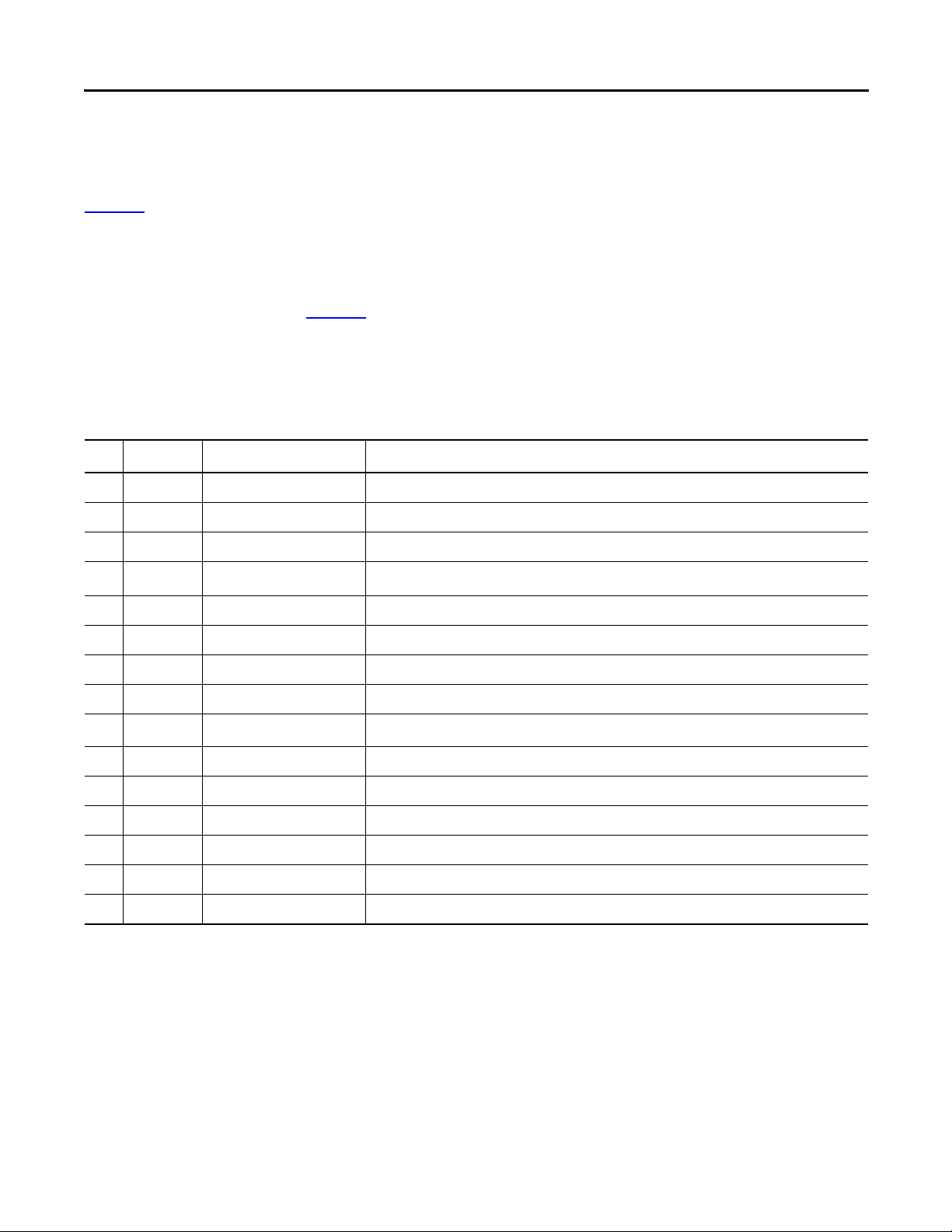

Table 1 - Devices in Logix5000 Control System

Device Type Product Line

Distributed I/O POINT I/O Logix5000 Control Systems: Connect POINT I/O Modules over a DeviceNet Network

(1)

Additional Resource with More Information

Quick Start, publication IASIMP-QS026

Logix5000 Control Systems: Connect POINT I/O Modules over an EtherNet/IP Network

Quick Start, publication IASIMP-QS027

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 11

Page 12

Preface

Table 1 - Devices in Logix5000 Control System

Device Type Product Line

(1)

Additional Resource with More Information

Drives PowerFlex40 Logix5000 Control Systems: Connect PowerFlex 40 Drives over a DeviceNet Network

Quick Start, publication IASIMP-QS028

Logix5000 Control Systems: Connect PowerFlex 40 Drives over an EtherNet/IP

Network Quick Start, publication IASIMP-QS029

PowerFlex 70 Logix5000 Control Systems: Connect PowerFlex 70 Drives over a DeviceNet Network

Quick Start, publication IASIMP-QS030

Logix5000 Control Systems: Connect PowerFlex 70 Drives over an EtherNet/IP

Network Quick Start, publication IASIMP-QS031

Kinetix 350 Logix5000 Control Systems: Connect Kinetix 350 Drives over an EtherNet/IP Network

Quick Start, publication IASIMP-QS032

HMI terminals PanelView Plus Logix5000 Control Systems: Connect PanelView Plus Terminals over an EtherNet/IP

Network Quick Start, publication IASIMP-QS033

(1) You can use other I/O modules, drives, and HMI terminals in Logix5000 control systems. These product lines are used for example purposes.

12 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 13

Preface

Studio 5000 Environment

The Studio 5000™ Engineering and Design Environment combines engineering and design

elements into a common environment. The first element in the Studio 5000 environment is the

Logix Designer application. The Logix Designer application is the rebranding of RSLogix™ 5000

software and will continue to be the product to program Logix5000™ controllers for discrete,

process, batch, motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell Automation

engineering design tools and capabilities. It is the one place for design engineers to develop all the

elements of their control system.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 13

Page 14

Preface

Required Software

Before attempting to complete any of the tasks described in this publication, verify that your

computer meets the following operating system and service pack compatibility requirements:

• Microsoft Windows 7 Professional (64-bit) with Service Pack 1

• Microsoft Windows 7 Home Premium (64-bit) with Service Pack 1

• Microsoft Windows 7 Home Premium (32-bit) with Service Pack 1

• Microsoft Windows Server 2008 R2 Standard Edition with Service Pack 1

If your computer does not meet the operating system and service pack compatibility

requirements, perform the necessary upgrades before continuing.

Ta b l e 2

lists the software used in this quick start. Specific software requirements are listed at the

beginning of each chapter.

Table 2 - Software Used in This Quick Start

Software Minimum Version Required

Studio 5000 21.00.00 Yes

Logix Designer application 21.00.00 Yes

RSLinx® Classic

ControlFLASH™ 12.00.00 - Automatically installed with Studio 5000

RSNetWorx for DeviceNet 21.00.00

(1) Installing RSNetworx for DeviceNet is only required if the automation system includes a DeviceNet network. We recommend that you install RSNetWorx for DeviceNet software to use with devices on a

DeviceNet network as described in publications listed in Tab le 1

3.51.00 Yes

Ye s

installation

No

. For more information, see Chapter 4, Configure the DeviceNet Network on page 53.

(1)

14 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 15

Preface

Parts List

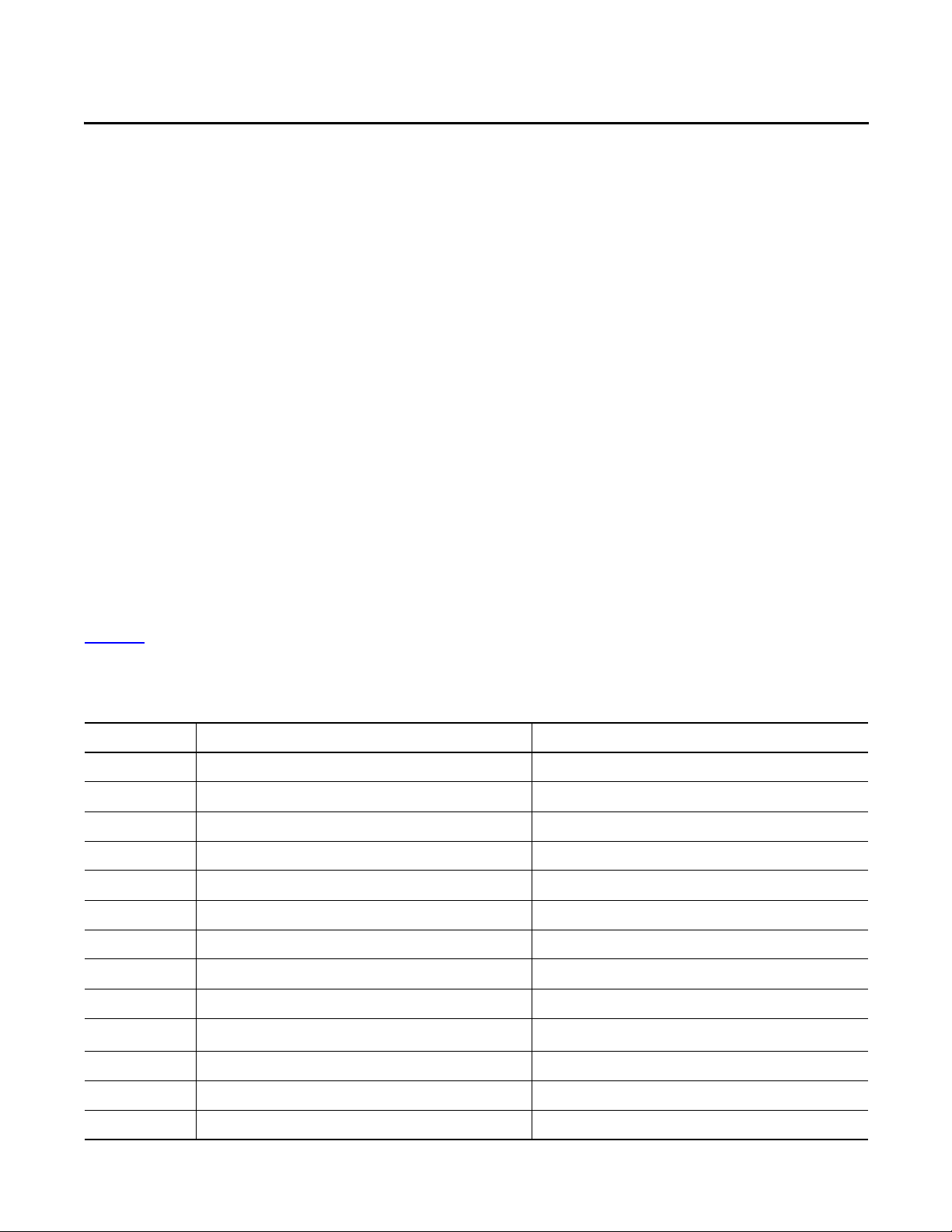

Ta b l e 3 lists the hardware used in this quick start. The minimum hardware you need depends on

the options and examples you choose to complete.

For example, if you do not intend to use a DeviceNet network to complete tasks described in

some publications listed in Ta b l e 1

, you do not need the hardware related to installing a

DeviceNet network.

Specific hardware requirements are listed at the beginning of each chapter.

Table 3 - Parts Used with This Quick Start

Quantity Cat. No. Description

2 or 3 N/A DIN rail (steel, not aluminum)

1 1769-L27ERM-QBFC1B CompactLogix 5370 L2 controller

1 1769-OB16 Compact 16-point 24V DC sourcing output module

1

1 1783-EMS08T Stratix 6000 Ethernet managed switch

1 1606-XLDNET4 Standard switched-mode power supply

1 1585J-M8PBJM-2 RJ45-to-RJ45 patchcord Ethernet cables

1 - USB cable with Type B receptacle

1

1 1485C-P1E75 KwikLink flat cable, 75 m (246 ft)

1769-ECR

1769-SDN

(1)

Compact I/O right end cap/terminator

Compact I/O DeviceNet scanner

2 1485A-T1E4 KwikLink terminator/resistor

1 1485P-P1E4-R5 KwikLink sealed micro connector

1 1485K-P1F5-C KwikLink QD cordset micro right-angle male

1 1606-XLDNET8 DeviceNet power supply

1 1485T-P1E4-B1 KwikLink power tap module

(1) This part ships with the CompactLogix 5370 L2 controller.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 15

Page 16

Preface

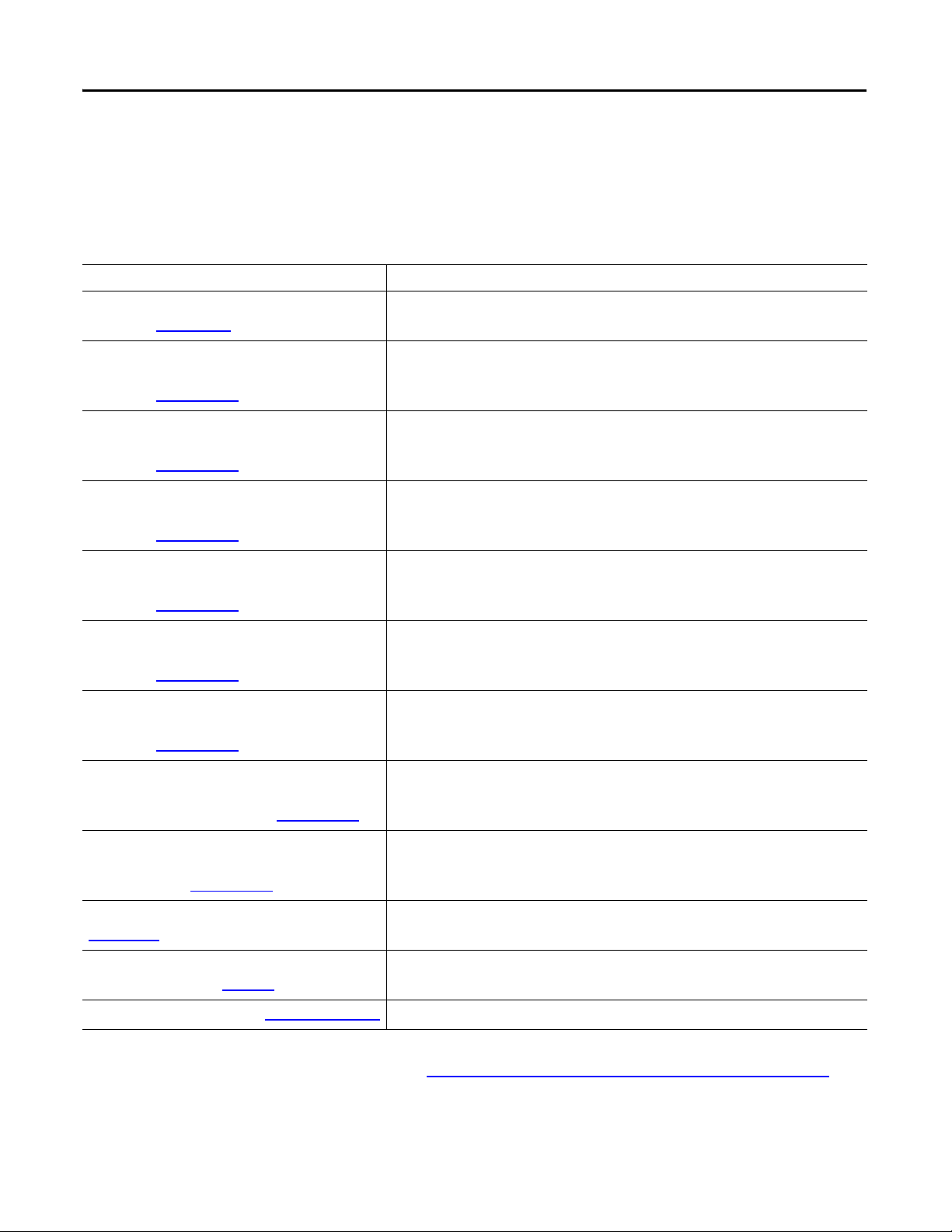

Additional Resources

These documents contain additional information concerning related products from

Rockwell Automation.

Resource Description

CompactLogix 5370 Controllers User Manual,

publication 1769-UM021

Logix5000 Control Systems: Connect POINT I/O

Modules over a DeviceNet Network Quick Start,

publication IASIMP-QS026

Logix5000 Control Systems: Connect POINT I/O

Modules over an EtherNet/IP Network Quick Start,

publication IASIMP-QS027

Logix5000 Control Systems: Connect a PowerFlex

40 Drive over a DeviceNet Network Quick Start,

publication IASIMP-QS028

Logix5000 Control Systems: Connect a PowerFlex

40 Drive over a EtherNet/IP Network Quick Start,

publication IASIMP-QS029

Logix5000 Control Systems: Connect a PowerFlex

70 Drive over a DeviceNet Network Quick Start,

publication IASIMP-QS030

Logix5000 Control Systems: Connect a PowerFlex

70 Drive over an EtherNet/IP Network Quick Start,

publication IASIMP-QS031

Describes how to design, install, operate, and troubleshoot a CompactLogix 5370

control system.

Describes basic steps required to include distributed POINT I/O modules over a

DeviceNet network in a Logix5000 control system, including hardware, firmware,

and software considerations.

Describes basic steps required to include distributed POINT I/O modules over an

EtherNet/IP network in a Logix5000 control system, including hardware, firmware,

and software considerations.

Describes basic steps required to include PowerFlex 40 drives over a DeviceNet

network in a Logix5000 control system, including hardware, firmware, and

software considerations.

Describes basic steps required to include PowerFlex 40 drives over an EtherNet/IP

network in a Logix5000 control system, including hardware, firmware, and

software considerations.

Describes basic steps required to include PowerFlex 70 drives over a DeviceNet

network in a Logix5000 control system, including hardware, firmware, and

software considerations.

Describes basic steps required to include PowerFlex 70 drives over an EtherNet/IP

network in a Logix5000 control system, including hardware, firmware, and

software considerations.

Logix5000 Control Systems: Connect a Kinetix 350

Multi-axis Servo Drive System over an EtherNet/IP

Network Quick Start, publication IASIMP-QS032

Logix5000 Control Systems: Connect a PanelView

Plus Terminal over an EtherNet/IP Network Quick

Start, publication IASIMP-QS033

ControlFLASH Firmware Upgrade Kit, publication

1756-QS105

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at http://www.rockwellautomation.com/literature/

Describes basic steps required to include Kinetix 350 Multi-axis Servo drives over

an EtherNet/IP network in a Logix5000 control system, including hardware,

firmware, and software considerations.

Describes basic steps required to include PanelView Plus terminals over an

EtherNet/IP network in a Logix5000 control system, including hardware, firmware,

and software considerations.

Provides details regarding the installation of ControlFLASH software and execution

of firmware upgrades.

Provides general guidelines for installing a Rockwell Automation® industrial

system.

. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

16 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 17

Chapter 1

Prepare the CompactLogix 5370 L2 Controller Hardware

This chapter describes the hardware required to install your CompactLogix 5370 L2 system.

Before You Begin

Determine which networks your control system uses. You can use CompactLogix 5370 L2

controllers on an EtherNet/IP network and on a DeviceNet network.

What You Need

Ta b l e 4 lists the hardware components used in this chapter. The parts listed in this table are done

so with the assumption that you will install an EtherNet/IP and DeviceNet network.

Table 4 - Parts Used with This Quick Start

Quantity Cat. No. Description

1 or more N/A DIN rail (steel, not aluminum)

1 1769-L27ERM-QBFC1B CompactLogix 5370 L2 controller

1 1606-XLDNET8 DeviceNet power supply

1 1769-ECR Compact I/O end cap/terminator

2 or more 1585J-M8PBJM-2 RJ45-to-RJ45 patchcord Ethernet cables

1 - USB cable with Type B receptacle

1 1783-EMS08T Stratix 6000 Ethernet managed switch

1 1606-XLDNET4 Standard switched-mode power supply

1 1769-OB16 Compact 16-point 24V DC sourcing output module

1

1769-SDN

Compact I/O DeviceNet scanner

1 1485C-P1E75 KwikLink flat cable, 75 m (246 ft)

2 1485A-T1E4 KwikLink terminator/resistor

2 or more 1485P-P1E4-R5 KwikLink sealed micro connector

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 17

Page 18

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

18WM

IND.CONT.EO.

US LISTED

NEC Class 2

Power Supply

NL

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

1112 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0B0 Z0

A1B1 Z1

0 2 FUSE

13OK

1112 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCOM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0B0 Z0

A1B1 Z1

0 2 FUSE

13OK

1112 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COMCOM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

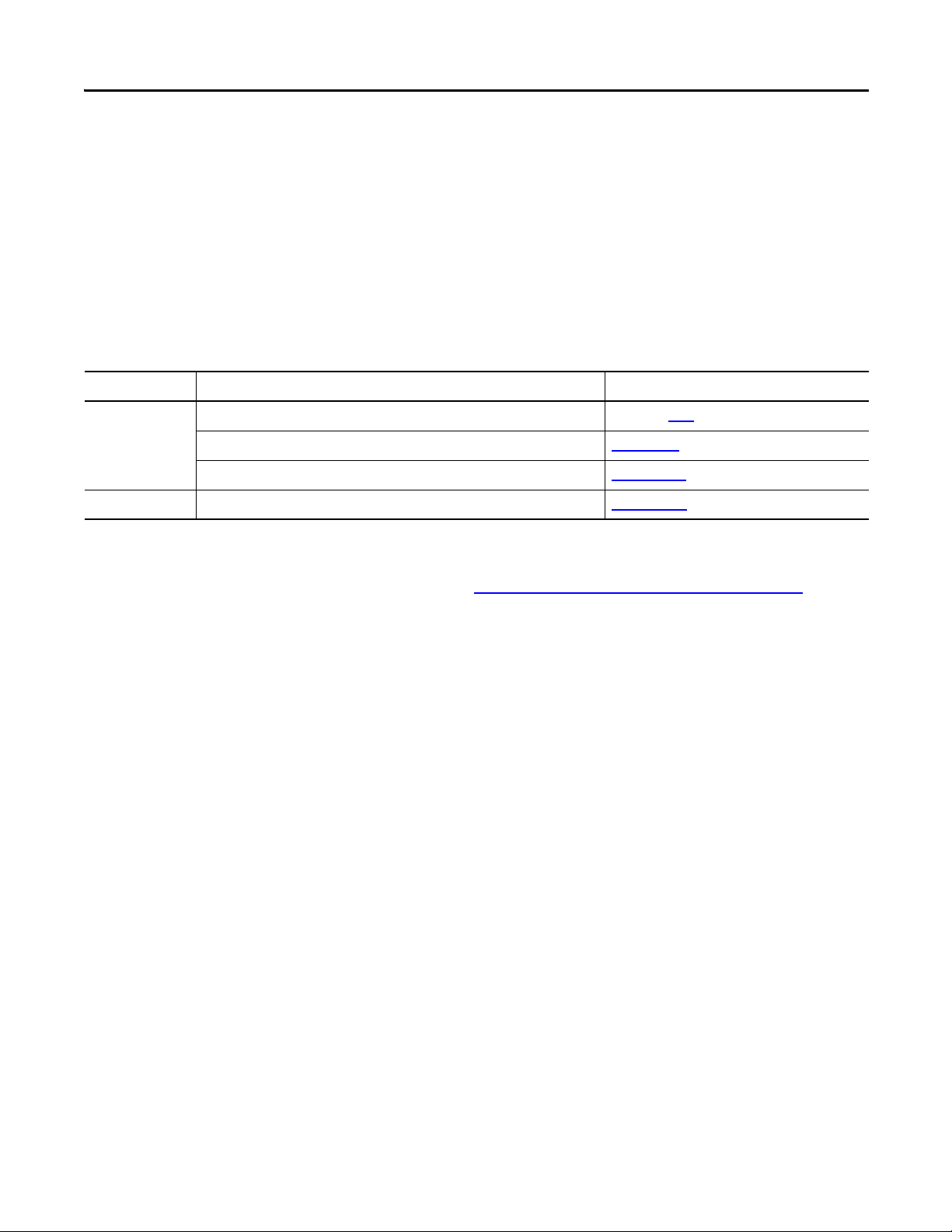

Install the Secure

Digital Card

Install the System

Connect Power to

the Controller

page 20

Make Network

Connections

page 27

page 22

page 25

Install the

Network

page 19

Table 4 - Parts Used with This Quick Start

Quantity Cat. No. Description

1 or more 1485K-P1F5-C KwikLink QD cordset micro right-angle male

1 1485T-P1E4-B1 KwikLink power tap module

Follow These Steps

18 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 19

Prepare the CompactLogix 5370 L2 Controller Hardware Chapter 1

Install the Network

Before you install your CompactLogix 5370 L2 control hardware, you must install the network

on which it will operate, that is, an EtherNet/IP or DeviceNet network.

For more information on installing either of these networks, see the publications listed in the

following table.

Table 5 - Network Publications

Network Publication Title Publication Number

EtherNet/IP EtherNet/IP Media Planning and Installation Manual NA - Click here to access the publication

Stratix 6000 Ethernet Managed Switches Installation Instructions 1783-IN004

Stratix 6000 Ethernet Managed Switch User Manual 1783-UM001

DeviceNet DeviceNet Media Design and Installation Guide DNET-UM072

The publications listed previously describe how to install the communication network and not

how to connect your controller to the network. Make Network Connections on page 27

describes how to connect your controller to the networks.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 19

Page 20

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

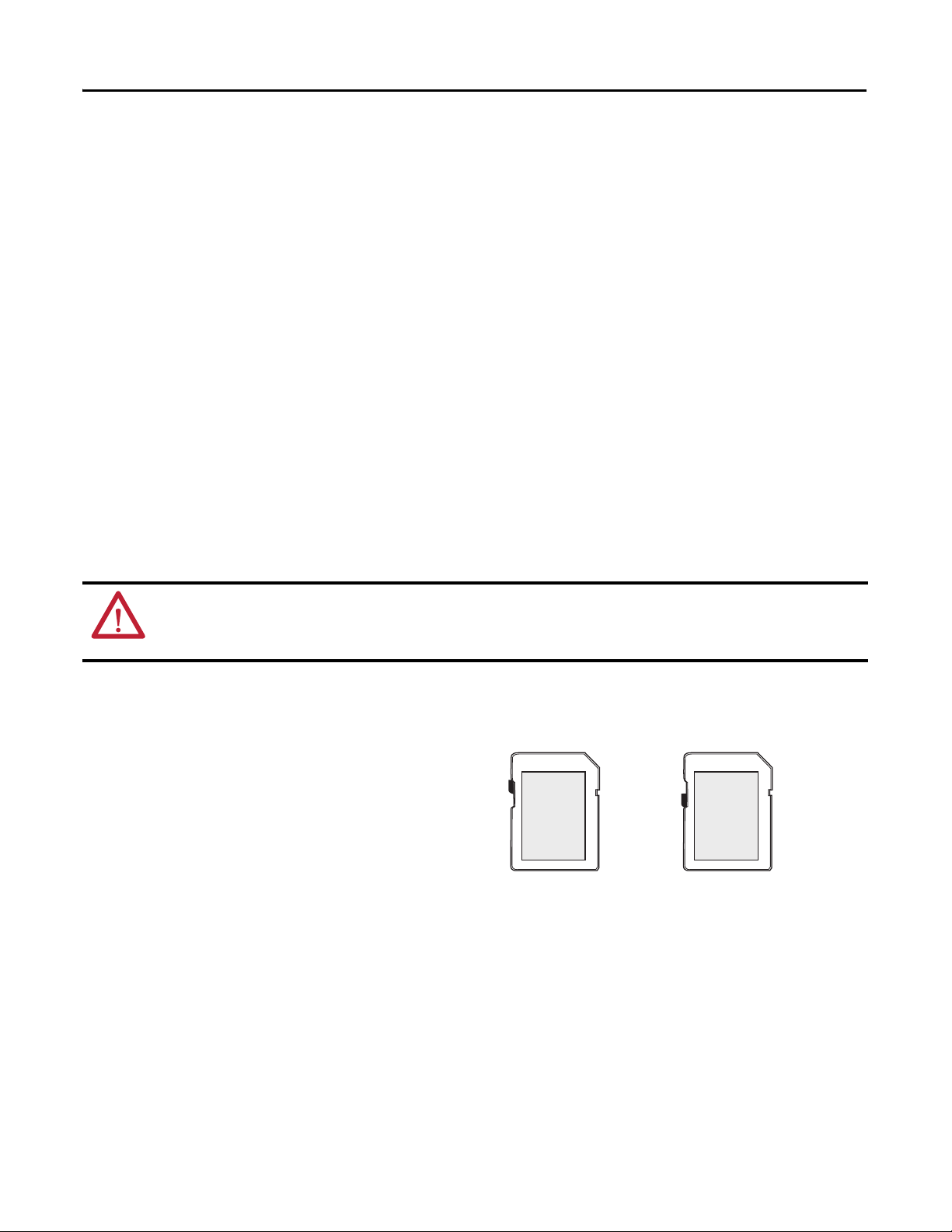

Unlocked Locked

Install the Secure Digital Card

The Secure Digital (SD) card provides nonvolatile storage for the CompactLogix 5370 L2

controller. You can use the SD card for multiple functions in your application, for example,

storing Logix Designer projects on the SD card or loading Logix Designer projects from an

SD card.

The following SD cards are available with for use with your CompactLogix 5370 L2 controller:

• 1784-SD1 card - 1 Gb of memory

• 1784-SD2 card - 2 Gb of memory

The CompactLogix 5370 L2 controllers are shipped from the factory with the 1784-SD1 SD

card installed.

Complete the following steps to re-install an SD card that has been removed from the controller

back into the controller or if installing a new SD card into the controller.

WARNING: When you insert or remove the SD card while power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Verify that the SD card is locked or unlocked according to your preference.

Consider these points when

deciding whether to lock the card

before installation:

• If the card is unlocked, the

controller can write data to it or

read data from it.

• If the card is locked, the controller can only read data from it.

20 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 21

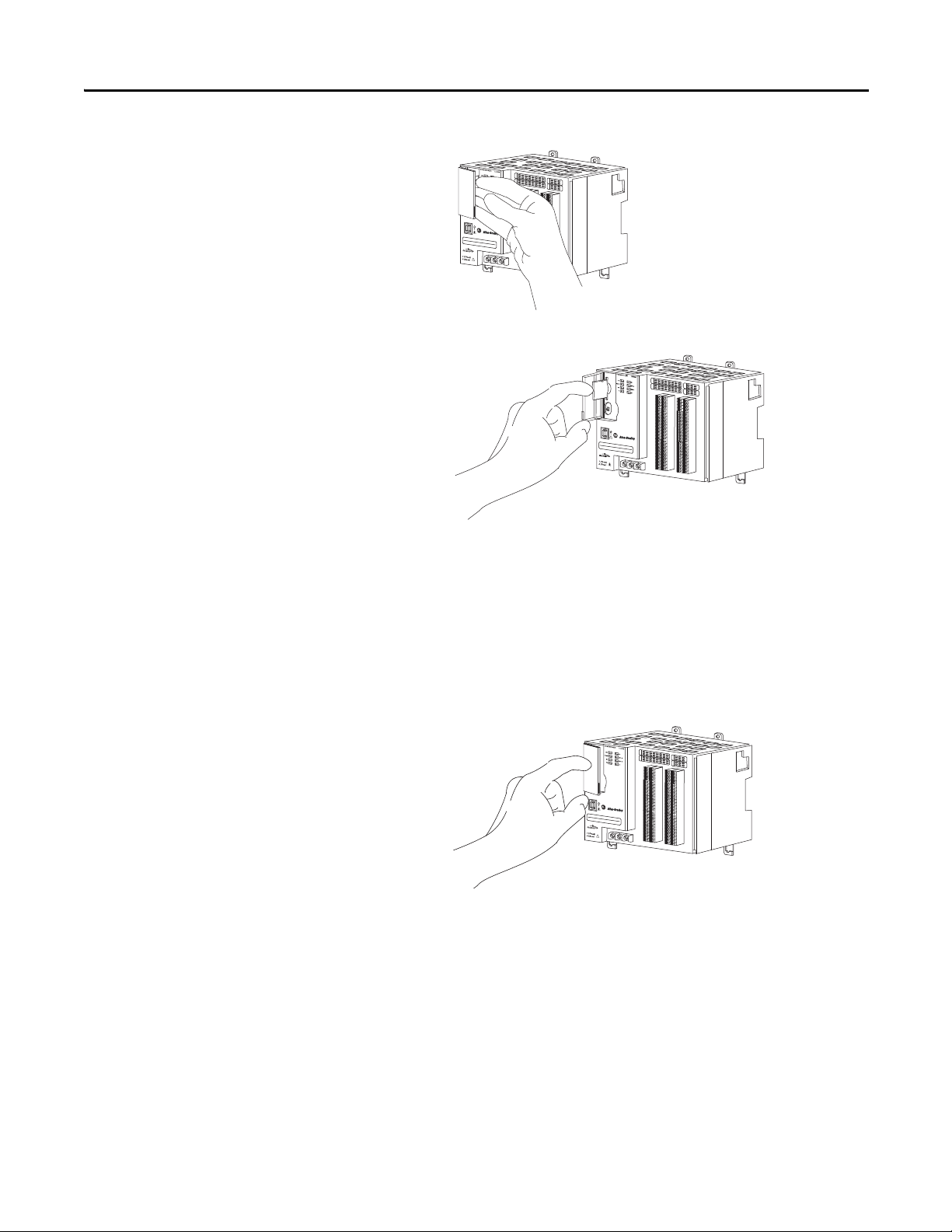

2. Open the door for the SD card.

3. Insert the SD card into the SD

card slot.

You can install the SD card in one

orientation only. You can install

the SD card in one orientation

only—with the beveled corner at

the top. An orientation logo is

Prepare the CompactLogix 5370 L2 Controller Hardware Chapter 1

printed on the card.

If you feel resistance when inserting the SD card, pull it out and change the orientation.

4. Gently press the card until it clicks into place.

5. Close the SD card door.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 21

Page 22

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

32256-M

32257-M

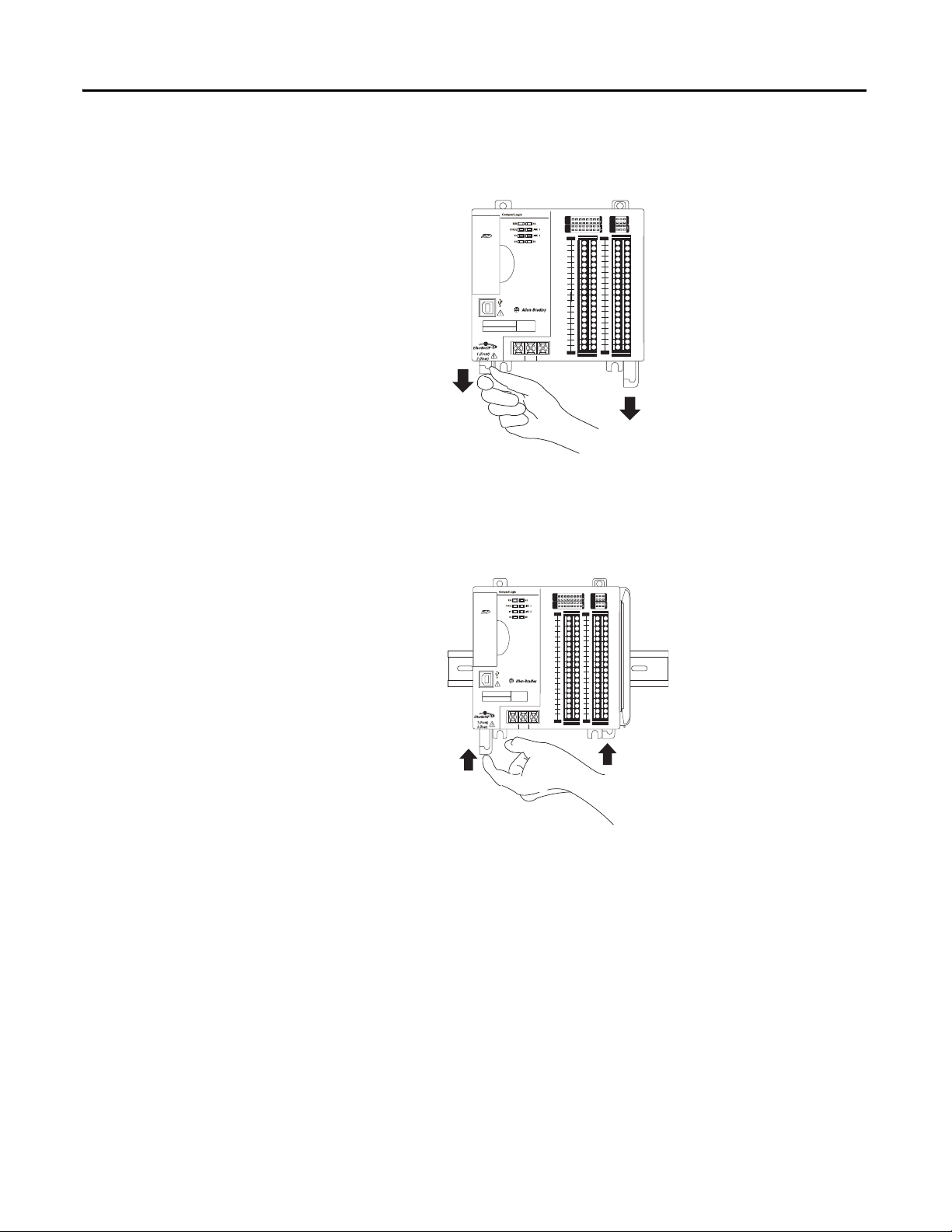

Install the System

1. Pull the bottom locking tabs out.

2. Hook the top of the controller on

the DIN rail.

3. Swing it downward until the

controller is flush against the DIN

rail and push it down against the

DIN rail.

4. Push the controller against the

DIN rail until the bottom DIN rail locks on the back of the controller click, locking the

controller in place.

5. Push the locking tabs in.

00:00:BC:2E:69:F6

+24VDC COM FG

L27ERM

QBFC1B

01234567

8 9 10 11 12 13 14 15

SINK\

24VDC

SOURCE

01234567

24VDC

SOURCE

8910

DC IN

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

COM

0

1

NC

NC

+V

+V

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

COM

0

1

DC OUT

11 12 13 14 15

A0 B0 Z0

INOUT

DC

A1 B1 Z1

INPUT

COUNTER

0 2 FUSE

DC

HIGH SPEED

OUTPUT

13OK

HSC

A0+

A0-

B0+

B0-

Z0+

Z0-

A1+

A1-

B1+

B1-

Z1+

Z1-

+V

+V

OUT

OUT

2

0

OUT

0UT

1

3

COM COM

V

V

in

in

0+

2+

I

I

in

in

0+

2+

V/I

V/I

in

in

0-

2-

V

CJC

in

+

3+

I

CJC

in

3+

V

V/I

in

in

1+

3-

V/I

I

in

in

1-

1+

V

V

OUT

OUT

1+

0+

I

I

OUT

in

0+

1+

COMCOM

ANALOG

22 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 23

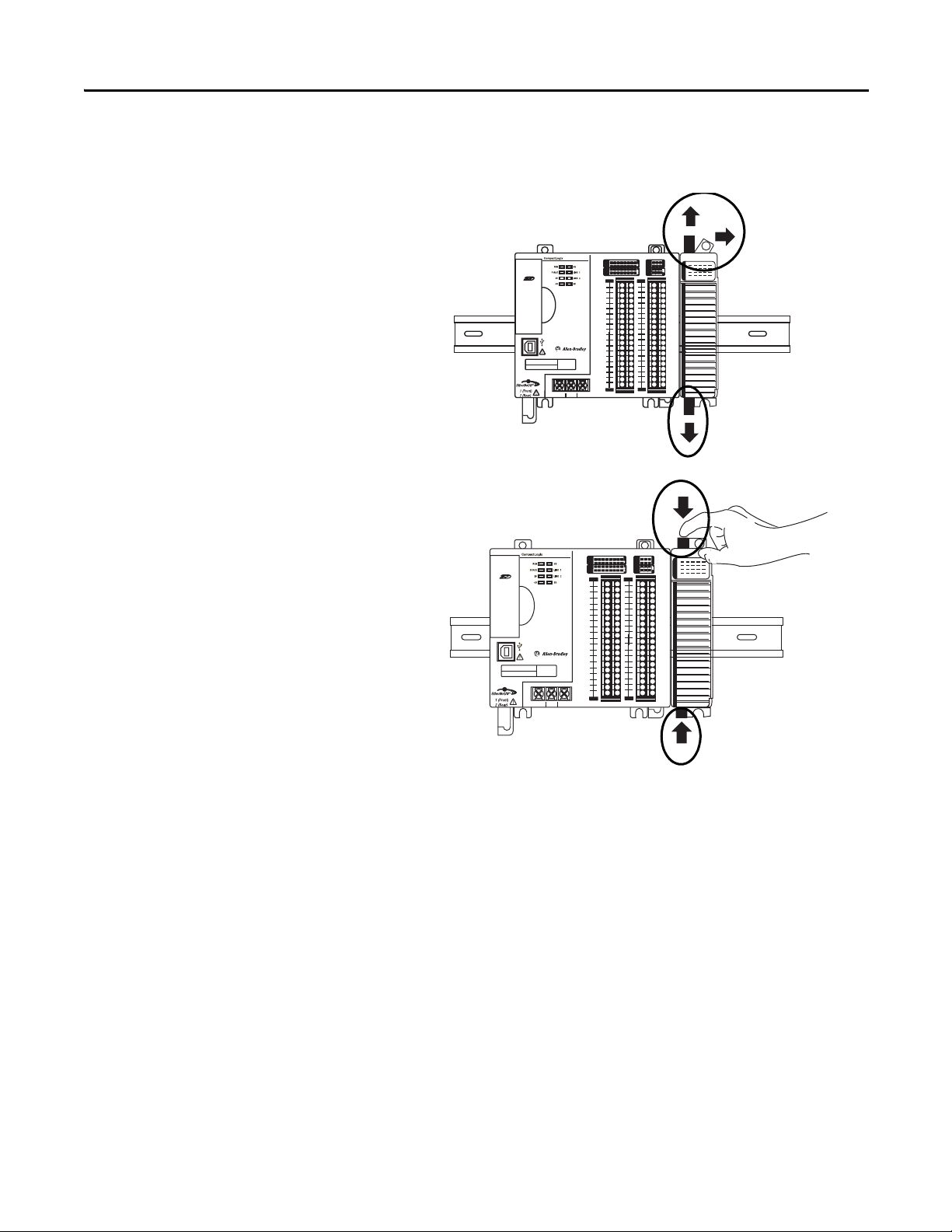

6. Install the 1769-OB16 output module.

a. Make sure the output module’s

locking tabs are pulled out and

the module’s bus lever is in the

unlocked position, that is,

leaning to the right.

b. Use the upper and lower

tongue-and-groove slots to

secure the output module and

power supply together.

c. Move the output module back

along the tongue-and-groove

Prepare the CompactLogix 5370 L2 Controller Hardware Chapter 1

00:00:BC:2E:69:F6

+24VDC COM FG

L27ERM

QBFC1B

24VDC

COM

NC

+V

COM

01234567

8 9 10 11 12 13 14 15

SINK\

SOURCE

01234567

24VDC

SOURCE

8910

DC IN

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

0

1

NC

+V

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

0

1

DC OUT

11 12 13 14 15

A0 B0 Z0

INOUT

DC

A1 B1 Z1

INPUT

COUNTER

0 2 FUSE

DC

HIGH SPEED

OUTPUT

13OK

HSC

A0+

A0-

B0+

B0-

Z0+

Z0-

A1+

A1-

B1+

B1-

Z1+

Z1-

+V

+V

OUT

OUT

0

2

OUT

0UT

1

3

COM COM

V

V

in

in

2+

0+

I

I

in

in

0+

2+

V/I

V/I

in

in

0-

2V

CJC

in

+

3+

I

CJC

in

3+

V

V/I

in

in

1+

3-

V/I

I

in

in

1-

1+

V

V

OUT

OUT

1+

0+

I

I

OUT

in

0+

1+

COMCOM

ANALOG

slots until the bus connectors

line up with each other.

d. Move the output module’s bus

lever fully to the left until it

locks.

e. Push the locking tabs in.

00:00:BC:2E:69:F6

+24VDC COM FG

L27ERM

QBFC1B

SINK\

24VDC

SOURCE

24VDC

SOURCE

DC IN

00

01

02

03

04

05

06

07

COM

0

NC

+V

00

01

02

03

04

05

06

07

COM

0

DC OUT

01234567

8 9 10 11 12 13 14 15

01234567

8910

11 12 13 14 15

08

09

10

11

12

13

14

15

COM

1

NC

+V

08

09

10

11

12

13

14

15

COM

1

A0 B0 Z0

INOUT

DC

A1 B1 Z1

INPUT

COUNTER

0 2 FUSE

DC

HIGH SPEED

OUTPUT

13OK

HSC

A0+

A0-

B0+

B0-

Z0+

Z0-

A1+

A1-

B1+

B1-

Z1+

Z1-

+V

+V

OUT

OUT

0

2

OUT

0UT

1

3

COM COM

V

V

in

in

0+

2+

I

I

in

in

0+

2+

V/I

V/I

in

in

0-

2V

CJC

in

+

3+

I

CJC

in

3+

V

V/I

in

in

1+

3-

V/I

I

in

in

1-

1+

V

V

OUT

OUT

1+

0+

I

I

OUT

in

0+

1+

COMCOM

ANALOG

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 23

Page 24

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

7. Install the 1769-SDN scanner module.

a. Make sure the scanner module’s

locking tabs are pulled out.

b. Make sure the scanner module’s

bus lever is in the unlocked

position, that is, leaning to the

right.

c. Use the upper and lower tongue-

and-groove slots to secure the

scanner module and power

supply together.

d. Move the scanner module back

along the tongue-and-groove

slots until the bus connectors line up with each other.

e. Move the scanner module’s bus

lever fully to the left until it

locks.

f. Push the locking tabs in.

24 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 25

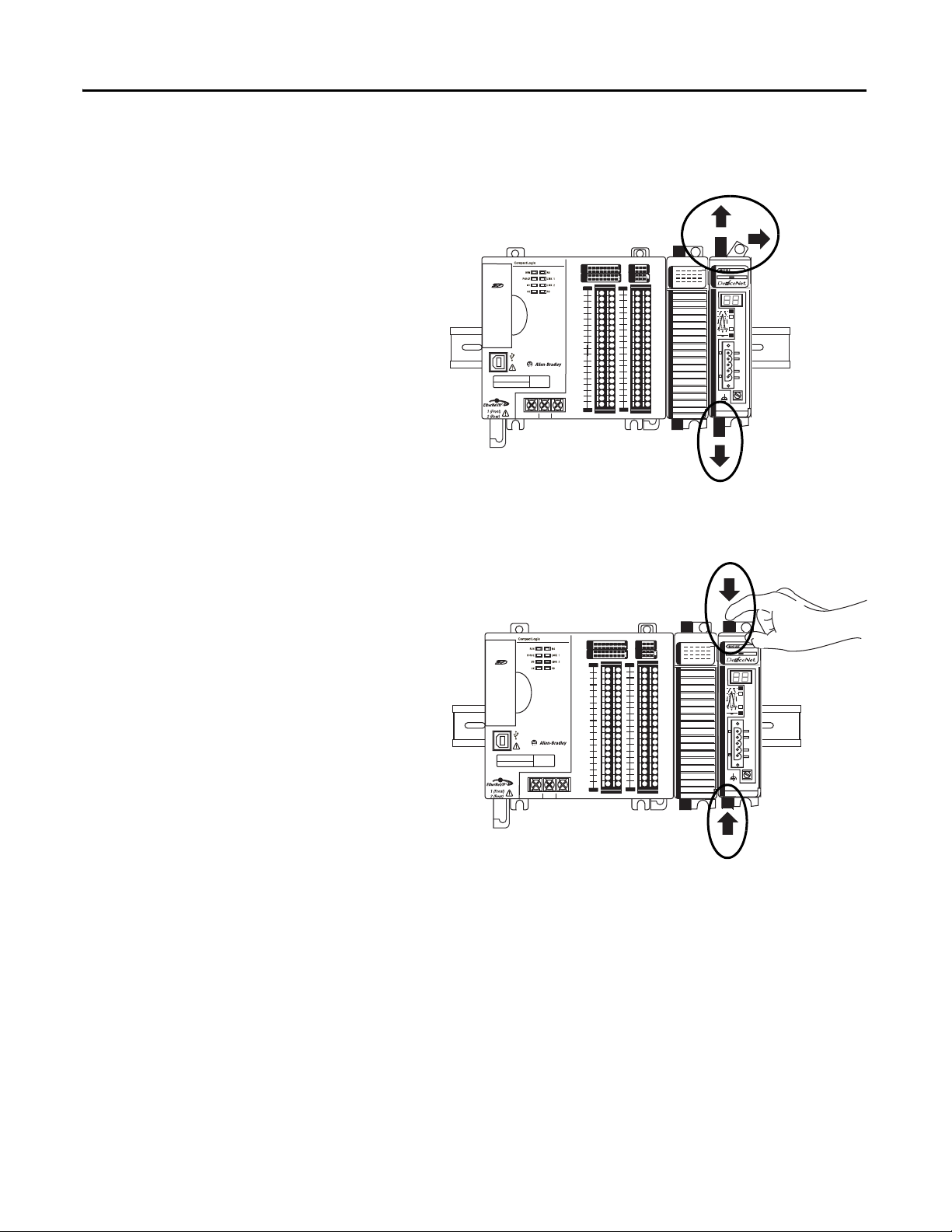

8. Install the 1769-ECR end cap

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

terminator.

a. Move the end cap terminator’s bus

lever to the unlocked position, that

is, the right.

b. Move the end cap terminator back

along the tongue-and-groove slots

with the rightmost module in the

system until the bus connectors line

up with each other.

c. Move the end cap terminator’s bus

lever fully to the left until it locks.

Prepare the CompactLogix 5370 L2 Controller Hardware Chapter 1

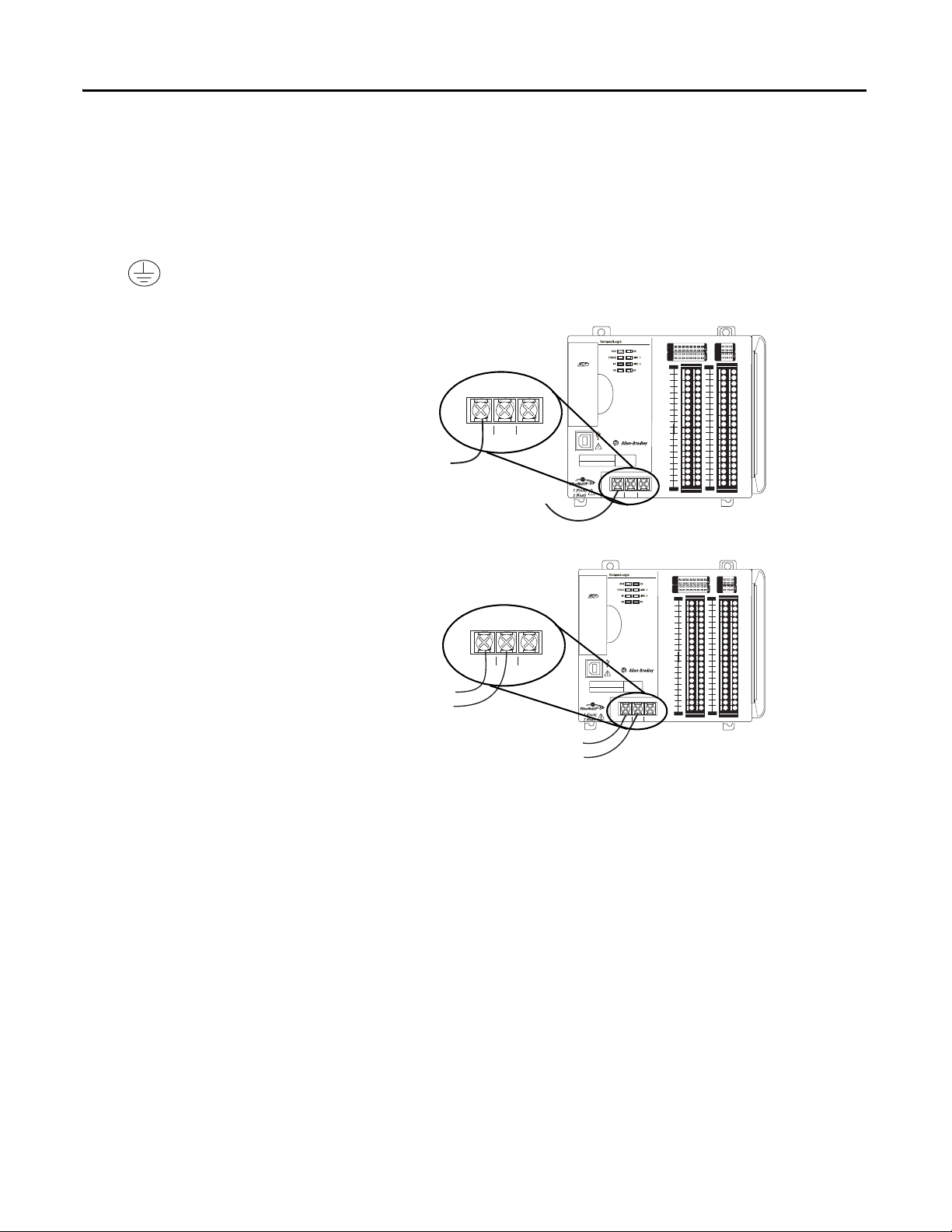

Connect Power to the Controller

The external 1606-XLDNET4 standard switched-mode power supply converts 115/230V AC

power to 24V DC to power the CompactLogix 5370 L2 controller.

1. Verify that the power setting on the external power supply is configured to match the

voltage source.

2. Mount the external power supply on the DIN rail.

3. Verify that the wire you use to connect input power to the external power supply is

not powered.

4. Remove the clear plastic finger safe cover on the front of the power terminals.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 25

Page 26

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

+24VDC COM FG

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2 FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

+24VDC COM FG

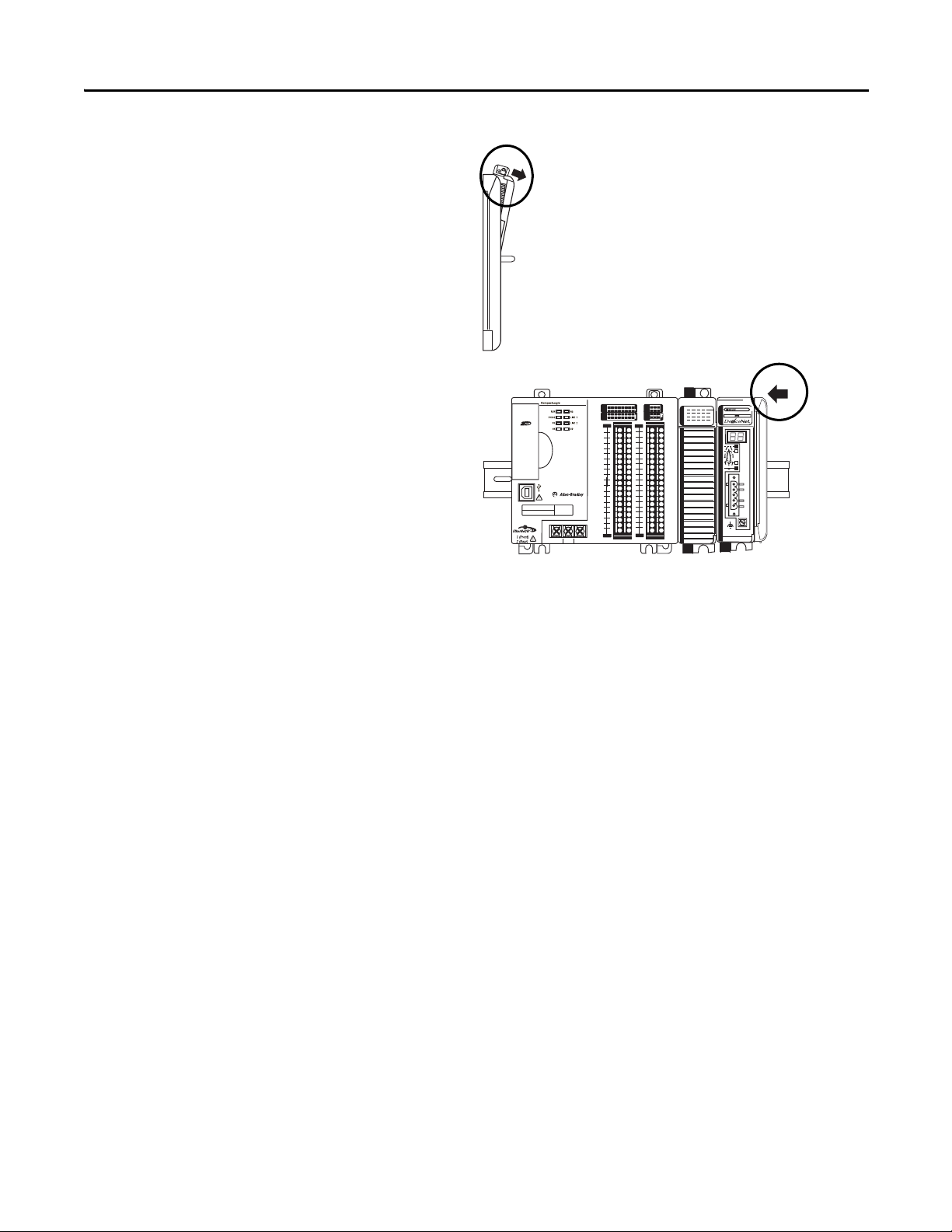

5. Wire input power to the external power supply using the following terminals:

• N (neutral)

• L (line)

• (ground)

6. Connect a wire from the + terminal

on the 1606-XLDNET4 power

supply to the +24VDC terminal on

the controller.

7. Connect the wire from the

- terminal on the external power

supply to the COM terminal on the

controller.

8. Reinstall the clear plastic finger safe

cover on the front of the power

terminals.

26 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 27

Prepare the CompactLogix 5370 L2 Controller Hardware Chapter 1

IMPORTANT

32259-M

Make Network Connections

You can make these connections to a CompactLogix 5370 L2 controller:

• Make a USB Connection

• Make an EtherNet/IP Network Connection

• Make a DeviceNet Network Connection

Make a USB Connection

You must use RSLinx Classic software, version 3.51.00 or later, with your CompactLogix 5370 L2 controllers. With this

software version, there is no need to install an RSLinx Classic software driver. The driver appears automatically in the

software when a USB cable is connected to the controller and the computer.

The controller has a USB port that uses a Type B receptacle. The port is USB 2.0-compatible and

operates at 12 Mbps.

Use a USB cable to connect your computer to the USB port. With this connection, you can

upgrade firmware and download programs to the controller directly from your computer.

ATTENTION: The USB port is intended for temporary local programming purposes only and not intended for

permanent connection.

The USB cable is not to exceed 3.0 m (9.84 ft) and must not contain hubs.

WARNING: Do not use the USB port in hazardous locations.

1. Plug the USB cable into your CompactLogix 5370 L2 controller.

2. Plug the USB cable into your

computer.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 27

Page 28

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

IMPORTANT

01234567

8 9 10 11 12 13 14 15

01234567

8910

A0 B0 Z0

A1 B1 Z1

0 2FUSE

13OK

11 12 13 14 15

HIGH SPEED

COUNTER

INOUT

DC

INPUT

24VDC

SINK\

SOURCE

24VDC

SOURCE

OUTPUT

DC

+24VDC COM FG

00

01

02

03

04

05

06

07

NC

+V

00

01

02

03

04

05

06

07

COM

0

COM

0

08

09

10

11

12

13

14

15

NC

+V

08

09

10

11

12

13

14

15

COM

1

COM

1

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

1

OUT

0

COM COM

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

0UT

3

V

in

0+

V

in

2+

V

OUT

0+

I

OUT

0+

V

OUT

1+

I

in

3+

V

in

1+

I

in

1+

I

in

1+

V

in

3+

CJC

-

CJC

+

V/I

in

1-

V/I

in

3-

V/I

in

0-

V/I

in

2-

I

in

0+

I

in

2+

OUT

2

COMCOM

DC IN

HSC

DC OUT

ANALOG

00:00:BC:2E:69:F6

L27ERM

QBFC1B

1

2

34

56

78

Make an EtherNet/IP Network Connection

ATTENTION: This section assumes you installed an EtherNet/IP network as described on page 19 and the network

includes a 1783-EMS08T switch.

This quick start describes a basic EtherNet/IP network connection. You can use

CompactLogix 5370 L2 controllers in multiple EtherNet/IP network topologies as described in

the publications listed in Table 5 on page 19

.

1. Plug a 1585J-M4TBJM-1, Ethernet cable (straight-through) into a port on the

Stratix 6000 switch.

2. Plug the other end of the Ethernet

cable into one of the Ethernet

ports on the bottom of the

controller.

WARNING: If you connect or

disconnect the communication

cable with power applied to this

module or any device on the

network, an electrical arc can

occur. This could cause an

explosion in hazardous location

installations.

Be sure that power is removed or the

area is nonhazardous before

proceeding.

Set Network IP Address

Once you connect the CompactLogix 5370 L2 controller to an EtherNet/IP network, you must

assign the controller a unique IP address. For information about how to set the network IP

address for your controller, see Chapter 3, Configure the EtherNet/IP Network on page 47

28 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

.

Page 29

Make a DeviceNet Network Connection

Input

AC 100-120/200-240V

N L

Iso

la

te

p

o

w

e

r b

e

fo

r

e

disc

o

n

n

e

ctin

g

1606-XL

POWER SUPPLY

DC

ok

Output

200W Limi

ted Power

DC 2

4V / 8A

+ –

DC ok

AC

120V

AC 240V

To other device on

network

To oth er device on

network

1606-XLDNET8

DeviceNet Power Supply

KwikLink Sealed

Te rm i na t or

KwikLink Sealed

Te rm in at o r

KwikLink Sealed

Micro Connector

1. Attach and lock the

1606-XLDNET8 DeviceNet power

supply to the DIN rail.

The power supply uses a locking tab

at the top that you push down to

secure it to the DIN rail.

2. Assemble the DeviceNet network

cable system using the KwikLink flat

cable, terminators, and sealed micro

connectors for each device.

Prepare the CompactLogix 5370 L2 Controller Hardware Chapter 1

1606-XL

AC 120V

AC 240V

Input

AC 100-120/200-240V

N L

Isolate power before disconnecting

POWER SUPPLY

Output

200W Limited Power

DC ok

DC 24V / 8A

+ –

DC ok

3. Wire a KwikLink QD Micro

4. Plug the 1769-SDN connector into the 1769-SDN scanner module.

5. Connect the other end of the KwikLink QD Micro Cordset to a KwikLink sealed micro

For more information on how to

assemble the DeviceNet network

system, see the instructions included

with these devices.

Cordset to the 1769-SDN

connector.

Connect To

Red V+

White CAN High

Bare Shield

Blue CAN Low

Black V-

connector on the network.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 29

Page 30

Chapter 1 Prepare the CompactLogix 5370 L2 Controller Hardware

Wire the DeviceNet Network Power Supply

WARNING: Verify that all incoming power is turned off before wiring power.

1. Use the information in the following table to connect incoming power to the network

power supply.

Connect To

V AC COM N (neutral)

120/240V AC L (line)

Ground

2. Place the switch in the position that matches your supply voltage.

3. Use the information in the followingtable to connect the DeviceNet power tap to the

power supply.

Connect To

Red +

White N/A

Shield N/A

Blue N/A

Black –

ATTENTION: If you have unused DeviceNet wires, make sure they do not come into contact with the other wires.

4. Connect the DeviceNet power tap to the DeviceNet network.

5. Power the 1606- XLDNET4 standard switched-mode power supply connected to the

CompactLogix 5370 L2 controller, as described in Connect Power to the Controller on

page 25.

30 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 31

Chapter 2

Prepare the Computer and Load Controller Firmware

In this chapter, you install the necessary programming and configuration software, configure

network communication on your computer, and load firmware on your controller.

Before You Begin

Before you begin, complete these tasks:

• Verify that your computer meets the software’s system requirements for installation and use

of the software listed in Ta b l e 6

• The tasks described in Chapter 1, Prepare the CompactLogix 5370 L2 Controller

.

Hardware on page 17, including the following:

– Install the EtherNet/IP network and/or the DeviceNet network.

– Install the controller and the local expansion module.

– Wire power to the controller.

– Make network connections.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 31

Page 32

Chapter 2 Prepare the Computer and Load Controller Firmware

What You Need

Ta b l e 6 lists the components you use in this chapter.

Table 6 - What You Need to Prepare the Computer

Component Description

Studio 5000 environment Environment that combines engineering and design elements into a common environment.

Logix Designer application Software used to create a project the CompactLogix 5370 L2 controller uses in your application.

RSLinx Classic software Communication server that supports multiple software applications simultaneously, establishing

communicating between devices on many different Allen-Bradley® industrial networks.

IP address A number in the form xxx.xxx.xxx.xxx where each xxx is a number from 000…254.

The IP address uniquely identifies the computer on the EtherNet/IP network.

Subnet Mask Extension of the IP address that allows a site to use a single network ID for multiple

physical networks.

If you change the subnet mask of an already-configured controller, you must cycle power to the

controller for the change to take effect.

ControlFLASH software Software used to upgrade the firmware on certain Allen-Bradley products in a CompactLogix

5370 L2 controller application.

Automatically installed with the Studio 5000 environment installation.

RSNetWorx for DeviceNet software Configuration software that creates a scanlist of devices that exchange information with the

controller over a DeviceNet network.

32 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 33

Follow These Steps

Install Additional

Software

Configure an EtherNet/IP

Driver in RSLinx Classic

Software

Optional

page 34

page 46

page 37

Install the Studio 5000

Environment

Set the IP Address for

the Computer

page 39

Load the Controller

Firmware

page 42

Prepare the Computer and Load Controller Firmware Chapter 2

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 33

Page 34

Chapter 2 Prepare the Computer and Load Controller Firmware

IMPORTANT

Install the Studio 5000 Environment

The Studio 5000 environment, version 21.00.00, installation process is configured so that,

among other software applications, RSLinx Classic software, version 3.51.00, and RSNetWorx

for DeviceNet software, version 21.00.00, are automatically installed.

The automatic installation option is enabled by default. You can change the installation settings

and install RSLinx Classic software or RSNetWorx for DeviceNet software separately. We

strongly recommend that you use the installation process default settings described in

this chapter.

The steps described in this section might vary slightly from the steps you complete during your Studio 5000

environment, version 21.00.00, installation.

1. Start the installation.

You c a n lo a d t h e s o ft wa re f rom a CD or web download.

2. Choose a language, fill in the

appropriate information, and

click Next.

34 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 35

3. Use the default selections and

click Install.

4. Read the license agreement

carefully.

Prepare the Computer and Load Controller Firmware Chapter 2

5. Click Accept All.

The installation process begins.

When installation is complete, your

computer will have the software

necessary required to complete the tasks

described in this publication.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 35

Page 36

Chapter 2 Prepare the Computer and Load Controller Firmware

Among other software, your computer will have the following :

• Studio 5000 Environment, version 21.00.00

The Studio 5000 Environment, version 21.00.00 includes Logix Designer application,

version 21.00.00.

• RSLinx Classic software, version 3.51.00

• RSNetWorx for DeviceNet, version 21.00.00

You are prompted to activate the software. For more information on software activation, see

the following:

• FactoryTalk® Activations Frequently Asked Questions, publication FTALK-FA017

• Rockwell Automation Technical Support Software Activations site http://

www.rockwellautomation.com/support/activations.html

Automatic Installation of ControlFLASH Software

ControlFLASH software is used to upgrade a CompactLogix 5370 L2 controller’s firmware

revision. ControlFLASH software is automatically installed when you install the Studio 5000

environment.

For more information on loading firmware on your controller, see Load the Controller

Firmware on page 42.

36 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 37

Configure an EtherNet/IP Driver in RSLinx Classic Software

1. Start the software.

Prepare the Computer and Load Controller Firmware Chapter 2

2. From the Communications menu,

choose Configure Drivers.

The Configure Drivers dialog box

appears.

3. From the Available Driver Types

pull-down menu, choose

EtherNet/IP Driver or Ethernet

devices and click Add New.

We re c om m e n d t h a t yo u us e

EtherNet/IP Driver.

The Add New RSLinx Classic

Driver dialog box appears.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 37

Page 38

Chapter 2 Prepare the Computer and Load Controller Firmware

4. Click OK to keep the

default name.

The Configure

driver:AB_ETHIP-x dialog box

appears. The full name of the

dialog box varies by what driver type was chosen in step 3

.

This example uses the EtherNet/IP Driver; the driver name is AB_ETHIP-1.

5. Select an Ethernet card and

click OK.

This new driver is available.

6. Verify that the driver’s Status is

Running and click Close.

38 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 39

Prepare the Computer and Load Controller Firmware Chapter 2

Set the IP Address for the Computer

Your computer requires an Internet Protocol (IP) address to operate on an EtherNet/IP

network. The IP address uniquely identifies the controller and is in the form xxx.xxx.xxx.xxx

where each xxx is a number from 000…254 with some exceptions for reserved values.

A computer’s IP address can be set automatically or manually. The manual option is typically

used with isolated networks. This section describes how to set the IP address manually.

1. On your desktop, right-click

Network and choose Properties.

2. Click adapter settings.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 39

Page 40

Chapter 2 Prepare the Computer and Load Controller Firmware

3. Right-click Local Area

Connection and

choose Properties.

4. On the Networking tab, choose

Internet Protocol Version 4

(TCP/IPv4) and click Properties.

40 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 41

5. Select Use the following IP address

and enter an IP address and Subnet

mask for your computer.

6. Record the IP address and

subnet mask.

7. Click OK.

8. Close the Local Area Connection

Properties dialog box.

Prepare the Computer and Load Controller Firmware Chapter 2

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 41

Page 42

Chapter 2 Prepare the Computer and Load Controller Firmware

IMPORTANT

Load the Controller Firmware

This section assumes that you downloaded the controller firmware from the Rockwell Automation technical support

website to install on your CompactLogix 5370 L2 controller. If not, download the firmware before following the

steps in this section.

The firmware is available with the Logix Designer application or you can download it from the support website.

Go to http://www.rockwellautomation.com/support/

This section describes how to load firmware on your CompactLogix 5370 L2 controller before setting an IP address

for the controller. In this case, you must connect from your workstation to the controller over the USB port.

With this quick start, you must use RSLinx Classic software, version 3.51.00 or later with CompactLogix 5370 L2

controllers. When the software is installed, a USB driver is automatically installed. When your computer is

connected to the CompactLogix 5370 L2 controller over a USB connection, the controller appears in the RSWho

window whenever you perform a Browse.

1. Verify that the SD card in the controller is unlocked.

2. Connect to the controller via the USB port as described in Make a USB Connection on

page 27.

The controller should be powered. If it is not, turn power on to the controller.

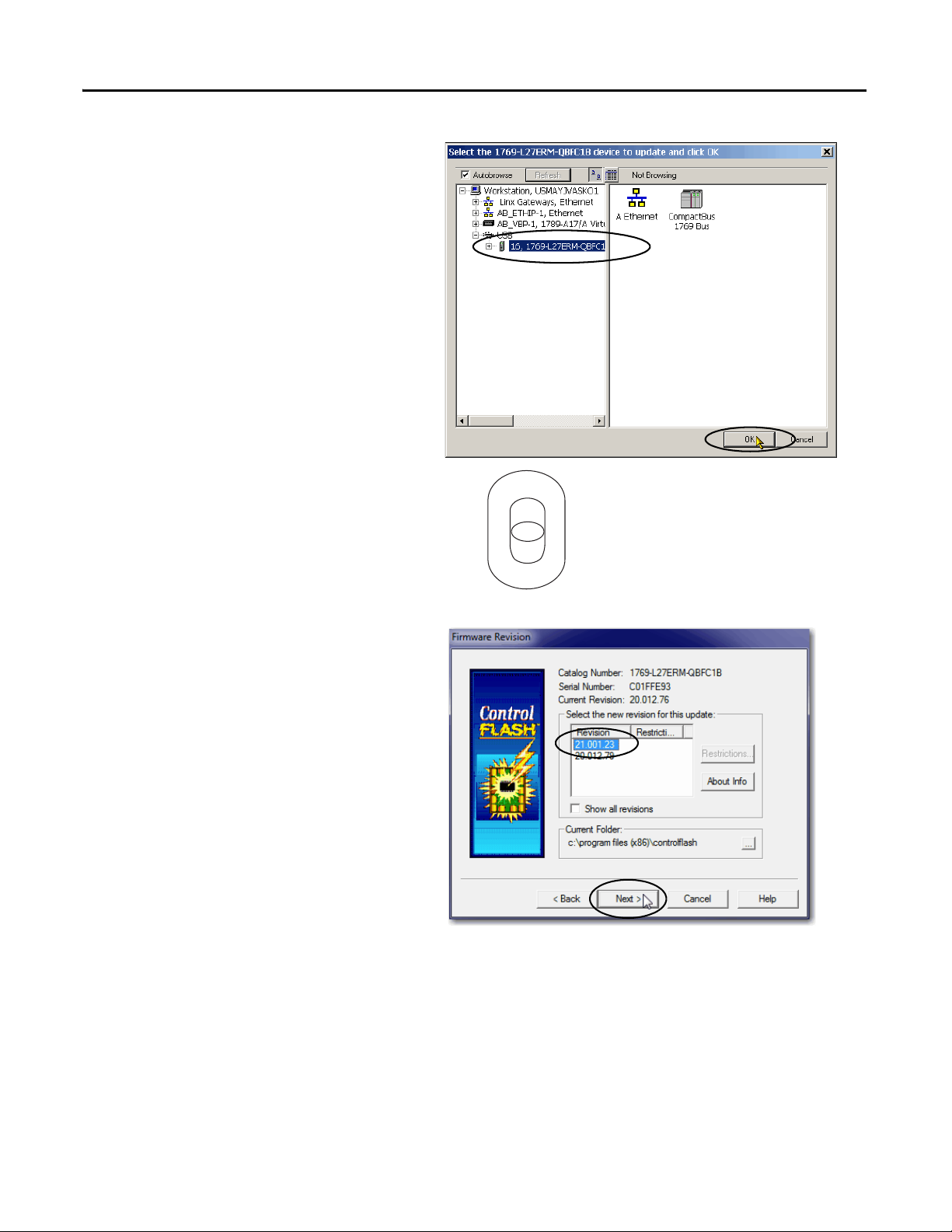

3. Start the

ControlFLASH software.

42 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 43

4. Click Next.

5. Select the controller catalog

number and click Next.

Prepare the Computer and Load Controller Firmware Chapter 2

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 43

Page 44

Chapter 2 Prepare the Computer and Load Controller Firmware

TIP

6. Expand the USB driver, and

choose your controller.

7. Click OK.

8. Verify that your controller’s mode

switch is in the REM position.

RUN

REM

PROG

9. Choose the desired firmware

revision and click Next.

Consider the following:

• If the Current Revision

matches the firmware

revision shown in the box

below it, click Cancel. You are

finished with this task.

• This example uses firmware

revision 21.001.23. Your

firmware revision may be a

different number.

You can access the latest

firmware revision at the

Rockwell Automation

Technical Support webpage.

44 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 45

10. To s ta r t th e f i rmw a re up da te , cl ic k

IMPORTANT

Finish and then click Yes.

Prepare the Computer and Load Controller Firmware Chapter 2

Before the firmware upgrade

begins, you an Attention dialog

box. Take the appropriate action

for your application. In this

example, the upgrade continues

when OK is clicked.

After the controller is updated, the

status dialog box displays the

message Update complete.

The firmware revision shown

in this quick start might not

match the firmware revisions

available for the

CompactLogix 5370 L2

controllers.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 45

Page 46

Chapter 2 Prepare the Computer and Load Controller Firmware

IMPORTANT

11. Click OK.

12. To close the ControlFLASH software, click Cancel and then click Yes.

Install Additional Software

Depending on your application, you may need to install additional software.

For example, if you are integrating a PanelView Plus terminal into your system, you must install

the following :

• RSLinx Enterprise software

You must install this software before you install any other additional software.

• FactoryTalk View Machine Edition software

46 Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012

Page 47

Chapter 3

IMPORTANT

Configure the EtherNet/IP Network

In this chapter, you assign an IP address to your CompactLogix 5370 L2 controller.

This quick start does not use other devices on the EtherNet/IP network. It is not uncommon,

however, to use other devices on an EtherNet/IP network in a CompactLogix 5370 L2 control

system. If you were to do so, for example, use PanelView Plus terminal on an EtherNet/IP

network, you need to assign an IP address to each device.

Not all tasks described in this quick start are required to complete the final task, that is, use ladder logic to test a

1769-OB16 output module as described beginning on page 63. For example, you do not need to install an

EtherNet/IP network to connect to a CompactLogix 5370 L2 controller because you can do so over a USB cable.

We expect that you might attempt to complete additional tasks with your control system by using the publications

listed on page 11 relating to using a component over an EtherNet/IP network in a Logix5000 control system. When you

use those publications, some assumptions are made. For example, if you use POINT I/O modules over an EtherNet/IP

network in a CompactLogix 5370 L2 control system, you must have already created a Logix Designer project and have an

IP address assigned to the controller.

If you complete all of the tasks described in this chapter, you can easily complete the tasks described in the publications

listed on page 11 related to using an EtherNet/IP network.

Rockwell Automation Publication IASIMP-QS025B-EN-P - December 2012 47

Page 48

Chapter 3 Configure the EtherNet/IP Network

IMPORTANT

Before You Begin