Page 1

Installation Instructions

CompactLogix Packaged Controllers

Catalog Numbers 1769-L23E-QB1B, 1769-L23E-QBFC1B, 1769-L23-QBFC1B

Topi c Pag e

Important User Information 2

Verify Compatibility 6

Before You Begin 6

Installation Checklist 8

Packaged Controller Dimensions 9

Install the Battery 11

Connect Expansion Modules (optional) 12

Panel Mount the System 14

DIN-rail Mount the System 14

Grounding Considerations 15

Wiring Power to the System 15

Wire the I/O Removable Terminal Blocks 17

Connect Using the RS-232 Connection 28

Connect Using the Ethernet Connection 28

Download and Install EDS Files 29

Download Packaged Controller Firmware 29

Use the AutoFlash Feature of RSLogix 5000 Software to Load Firmware 29

Use the ControlFLASH Utility to Load Firmware 33

Select the Packaged Controller’s Operating Mode 35

Power S upply S tatus In dicator 36

Controller Status Indicato rs 36

Additional Resources 42

Use this document as a guide to install the CompactLogix™ packaged controllers.

Page 2

2 CompactLogix Controller

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for

the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

Automation

® sales office or online at http://www.rockwellautomation.com/literature/) describes some important differences

between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibil ity or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard and recognize the

consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 3

Environment and Enclosure

WARNI NG: This equipment is intended for use in a Pollution Degree 2 industrial environment, in

overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes up to

2000 meters (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to conducted as well as radiated

disturbance.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that

is suitably designed for those specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from accessibility to live parts. The

enclosure must have suitable flame-retardant properties to prevent or minimize the spread of

flame, complying with a flame spread rating of 5VA, V2, V1, V0 (or equivalent) if non-metallic. The

interior of the enclosure must be accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific enclosure type ratings that are

required to comply with certain produc t safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley® publication 1770-4.1,

for additional installation requirements

• NEMA Standards publication 250 and IEC publication 60529, as applicable, for explanations of

the degrees of protection provided by different types of enclosure

Compac tLogix Controller 3

Prevent Electrostatic Discharge

WARNI NG: This equipment is sensitive to electrostatic discharge, which can cause internal

damage and affect normal operation. Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wrist-strap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 4

4 CompactLogix Controller

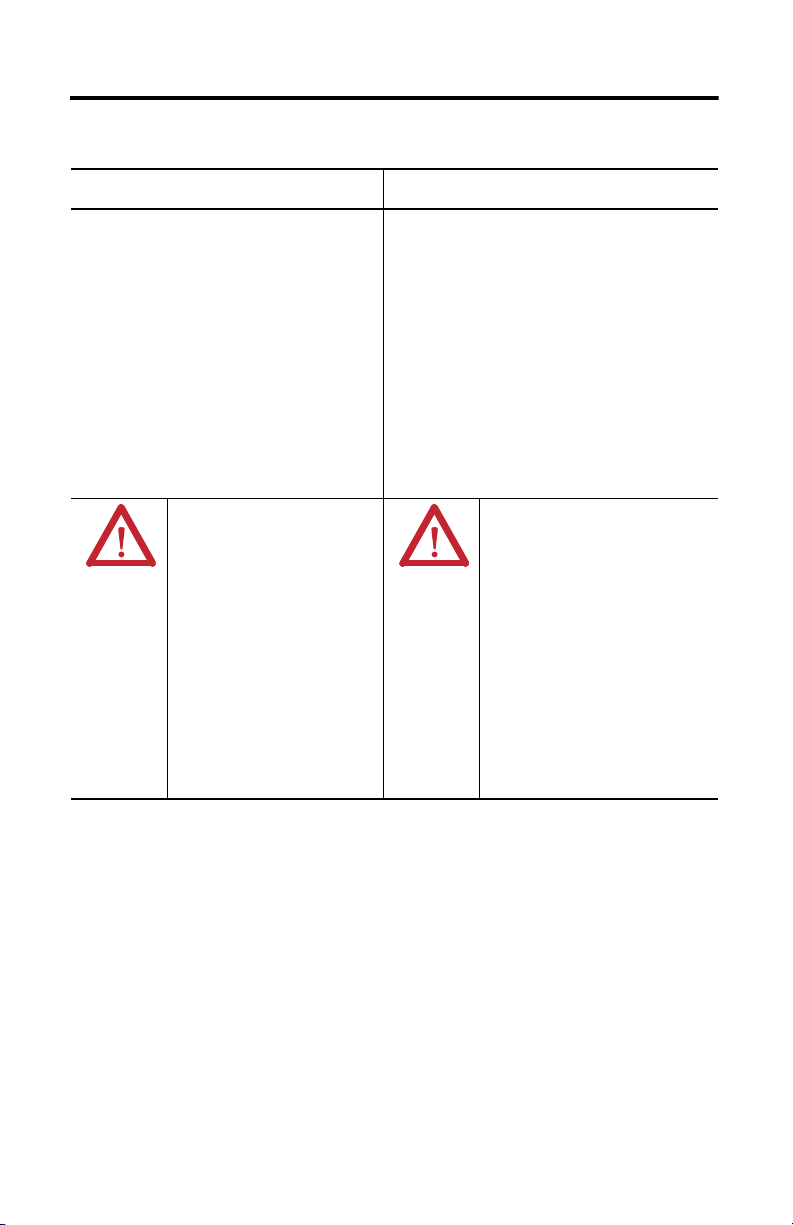

North American Hazardous Location Approval

The following information applies when operating this

equipment in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are

suitable for use in Class I Division 2 Groups A, B, C, D,

Hazardous Locations and nonhazardous locations

only. Each product is supplied with markings on the

rating nameplate indicating the hazardous location

temperature code. When combining products

within a system, the most adverse temperature

code (lowest "T" number) may be used to help

determine the overall temperature code of the

system. Combinations of equipment in your system

are subject to investigation by the local Authority

Having Jurisdiction at the time of installation.

WARNIN G:

Explosion Hazard -

• Do not disconnect equipment unless

power has been removed or the area is

known to be nonhazardous.

• Do not disconnect connections to this

equipment unless power has been

removed or the area is known to be

nonhazardous. Secure any external

connections that mate to this equipment

by using screws, sliding latches,

threaded connectors, or other means

provided with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they

must only be changed in an area known

to be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne

conviennent qu'à une utilisation en environnements de

Classe I Division 2 Groupes A, B, C, D dangereux et non

dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent

le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés

dans un système, le code de température le plus

défavorable (code de température le plus faible) peut

être utilisé pour déterminer le code de température

global du système. Les combinaisons d'équipements

dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l'installation.

AVERTISSEMENT:

Risque d’Explosion –

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer

tous les connecteurs externes reliés à cet

équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres

moyens fournis avec ce produit.

• La substitution de composants peut rendre

cet équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 5

Compac tLogix Controller 5

European Hazardous Location Approval

European Zone 2 Certification (The following applies when the product bears the Ex or EEx Marking.)

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has

been found to comply with the Essential Health and Safety Requ irements relating to the design and construction of Category 3

equipment intended for use in potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN

60079-0.

WARNI NG:

• This equipment must be installed in an enclosure providing at least IP54 protection when

applied in Zone 2 environments.

• This equipment shall be used within its specified ratings defined by Allen-Bradley.

• Provisions shall be made to prevent the rated voltage from being exceeded by transient

disturbances of more than 40% when applied in Zone 2 environments.

• Secure any external connections that mate to this equipment by using screws, sliding latches,

threaded connectors, or other means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be

nonhazardous.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 6

6 CompactLogix Controller

IMPORTANT

Verify Compatibility

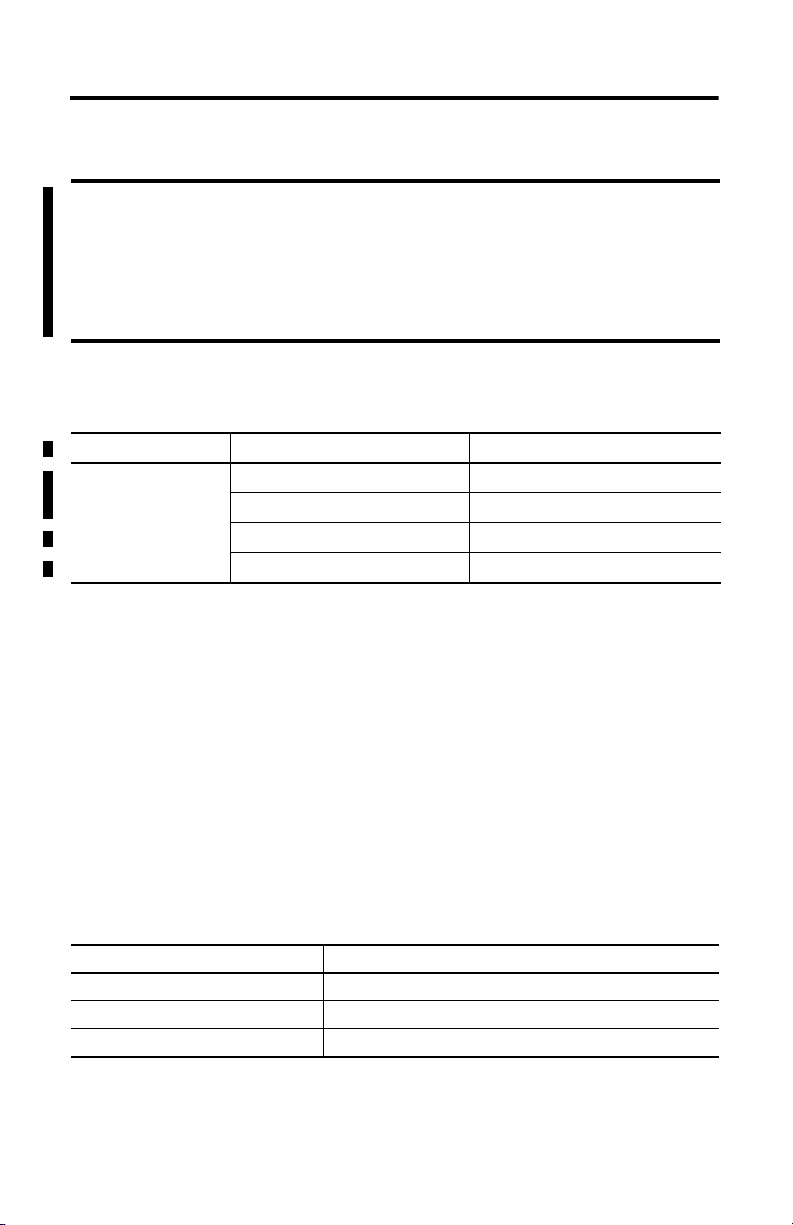

The series B controllers are compatible only with the controller firmware and the RSLogix 5000

software versions as indicated in the table below.

Attempti ng to use controllers with incompatibl e software and firmware revisions can result in

the following:

• An inability to connect to the series B controller in RSLogix 5000 software

• Unsuccessful firmware upgrades in ControlFLASH™ or AutoFlash utilities

This table shows the compatible pairs of RSLogix 5000 software versions and controller

firmware revisions.

Controller RSLogix 5000 Software Version or Later Controller Firmware Revision or Later

1769-L23E-QB1B,

1769-L23E-QBFC1B,

1769-L23-QBFC1B

16.00.00 16.023

17.01.02 17.012

19.01.00 19.015

20.01.00 20.013

Before You Begin

This section contains information you should understand before installing the CompactLogix

packaged controller.

Restrictions

The maximum amount of expansion modules that can be used with the packaged controllers is

two. Within that limit, the number of expansion I/O modules that can be attached to the

packaged controller depends on the bus current draw of the modules being attached.

Each packaged controller has a specified amount of available bus current as shown in this table.

Packaged Controller Bus Current and Expansion Module Limits

Cat. No. Total Available 5V DC Bus Current

1769-L23E-QB1B 1 A (1000 mA)

1769-L23E-QBFC1B 450 mA

1769-L23-QBFC1B 800 mA

To determine the number of expansion I/O modules you can add, total the bus current draw

(maximum) of your planned expansion I/O modules and the end cap. If your result is less than

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 7

Compac tLogix Controller 7

the packaged controller’s maximum available bus current, you are within the expansion I/O limit

of your packaged controller.

Example of Expansion I/O Calculation

In this example, these expansion I/O modules and bus current draws are planned for use with the

1769-L23E-QBFC1B packaged controller.

Planned Expansion I/O Module Bus Current Draw, max

1769-OV16 Sink Output Module 200 mA

1769-IF4 Analog Input Module 105 mA

1769-ECR End Cap 5 mA

Total Bus Current Draw 310 mA

(1) The maximum bus current draw specification for each Compact I/O™ module is available in the Compact I/ O Selection Guide, publication

. This publication also provides further explanation of and a table for the calculation of Compact I/O power supply requirements.

1769-SG002

(1)

The total bus current draw of the Compact I/O modules (310 mA) is less than the total available

bus current of the packaged controller (450 mA). These planned expansion I/O modules are

within the limits of the 1769-L23E-QBFC1B packaged controller.

Parts (included with the controller)

These components are included with your CompactLogix packaged controller.

Cat. No. Part

1747-KY Key

1769-BA Battery

1769-ECR End cap

Parts (optional, not included with the controller)

In addition to the parts included with the packaged controller, you may choose to use these

components specific to your application.

If using Then use this component

RS-232 port to connect to the packaged controller. 1756-CP3 or 1747-CP3 serial cable.

EtherNet/IP port to connect to the packaged controller. Standard Ethernet cable with an RJ45 connector, or, for industrial

Panel mount method to install the packaged controller. 4…8 M4 or #8 panhead screws (depending on the number of

grade requirements, 1585J Ethernet connectivity media.

expansion modules used).

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 8

8 CompactLogix Controller

Replacement Parts

These CompactLogix packaged controller replacement parts are available for order.

Catalog No. Description Compatible Packaged Controllers

1769-BA CompactLogix controller battery 1769-L23E-QB1B, 1769-L23E-QBFC1B, and

1769-ECR Compact right end cap 1769-L23E-QB1B, 1769-L23E-QBFC1B, and

1769-RDQB CompactLogix packaged controller door 1769-L23 E-QB1B

1769-RDQBFC CompactLogix packaged controller door 176 9-L23E-QBFC1B and 1769-L23-QBFC1B

1769-L23-QBFC1B

1769-L23-QBFC1B

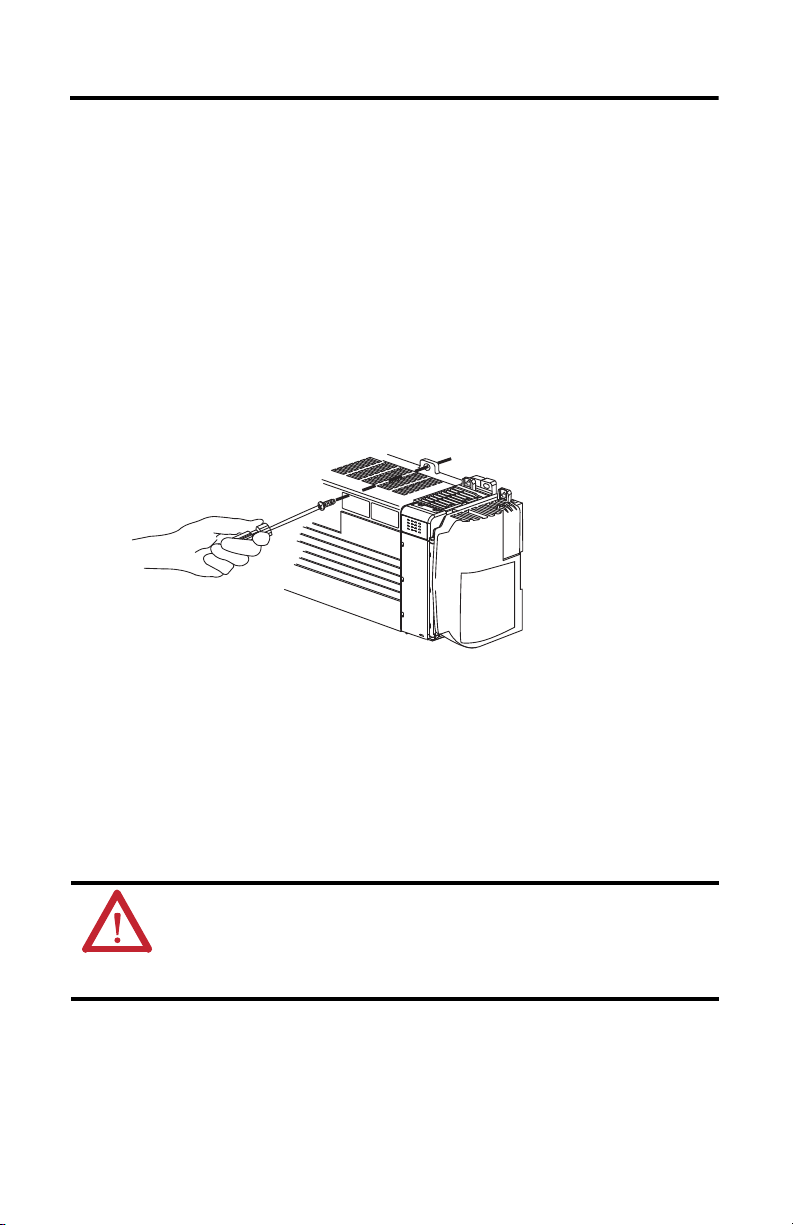

Required Tools

The only tool required for the installation of the CompactLogix packaged controller is a

medium-sized Phillips-head screwdriver.

Installation Checklist

This table lists tasks that must be completed to fully install and begin using your packaged

controller.

Installation Tasks

Install the Battery

Connect Expansion Modules (optional)

Panel Mount the System or DIN-rail Mount the System

Grounding Considerations

Wirin g Power to the Sys tem

Wire the I/O Removable Terminal Blocks

Connect Using the RS-232 Connection

Connect Using the Ethernet Connection

Download and Install EDS Files

Download Packaged Controller Firmware

Use the AutoFlash Feature of RSLogix 5000 Software to Load Firmware

or Use the ControlFLASH Utility to Load Firmware

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 9

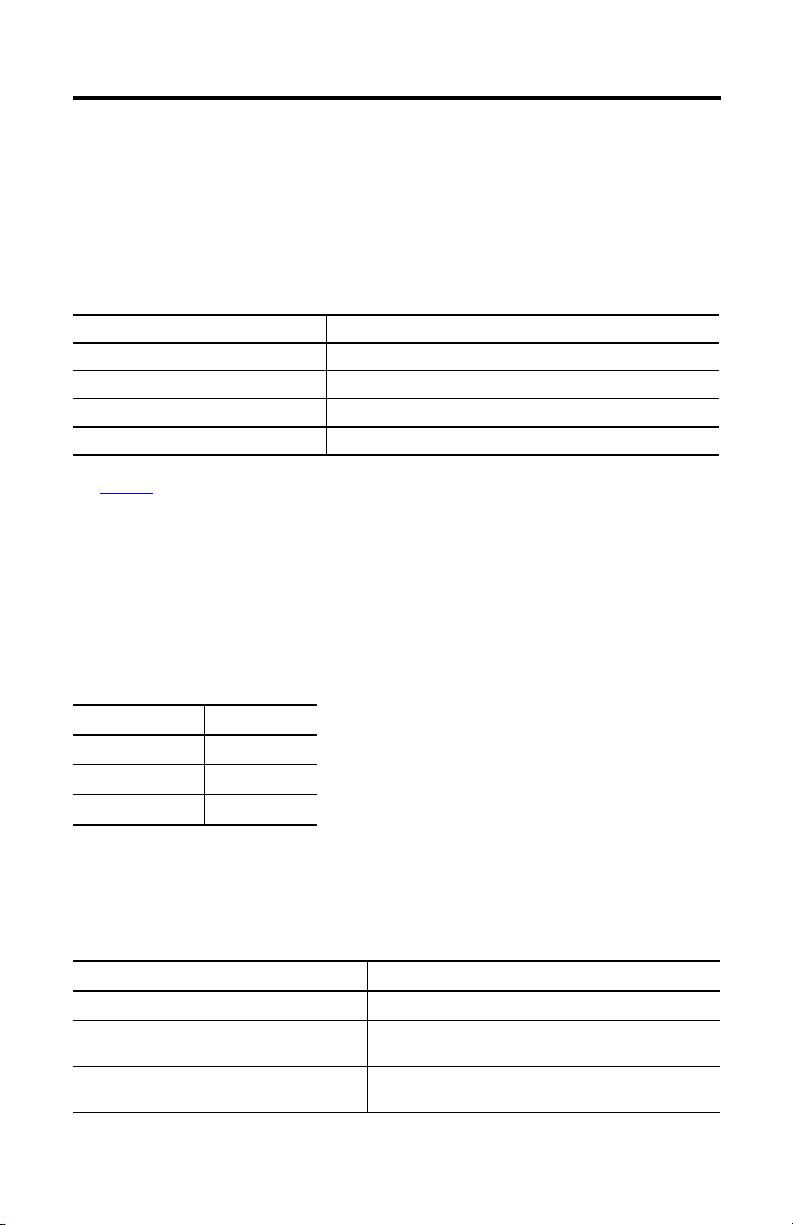

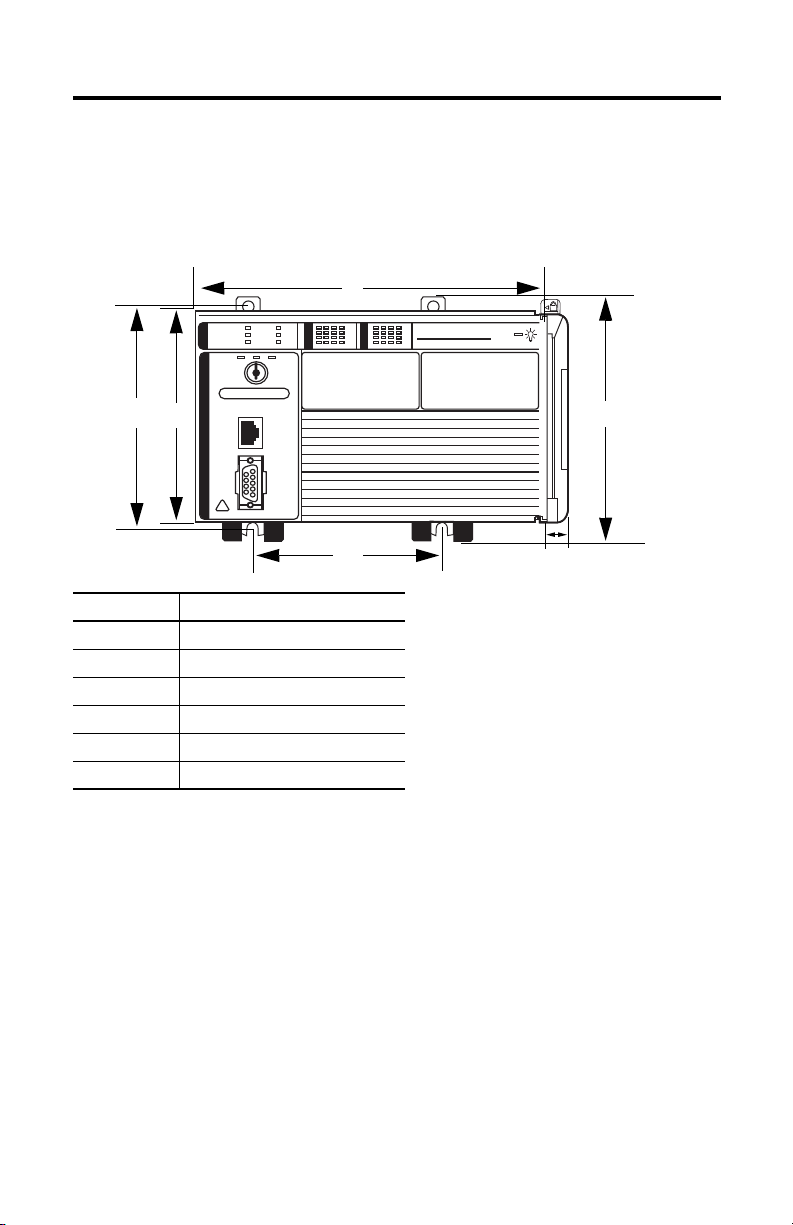

Packaged Controller Dimensions

CompactLogix L23E

a

f

b

c

d

e

1769-L23E-QB1B Packaged Controller

The 1769-L23E-QB1B controller has these approximate dimensions.

Measurement Dimension, approximate

a 185.2 mm (7.29 in.)

b 123.86 mm (4.88 in.)

c 118 mm (4.65 in.)

d 132 mm (5.20 in.)

e 132.9 mm (5.23 in.)

f 18 mm (0.71 in.)

Compac tLogix Controller 9

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

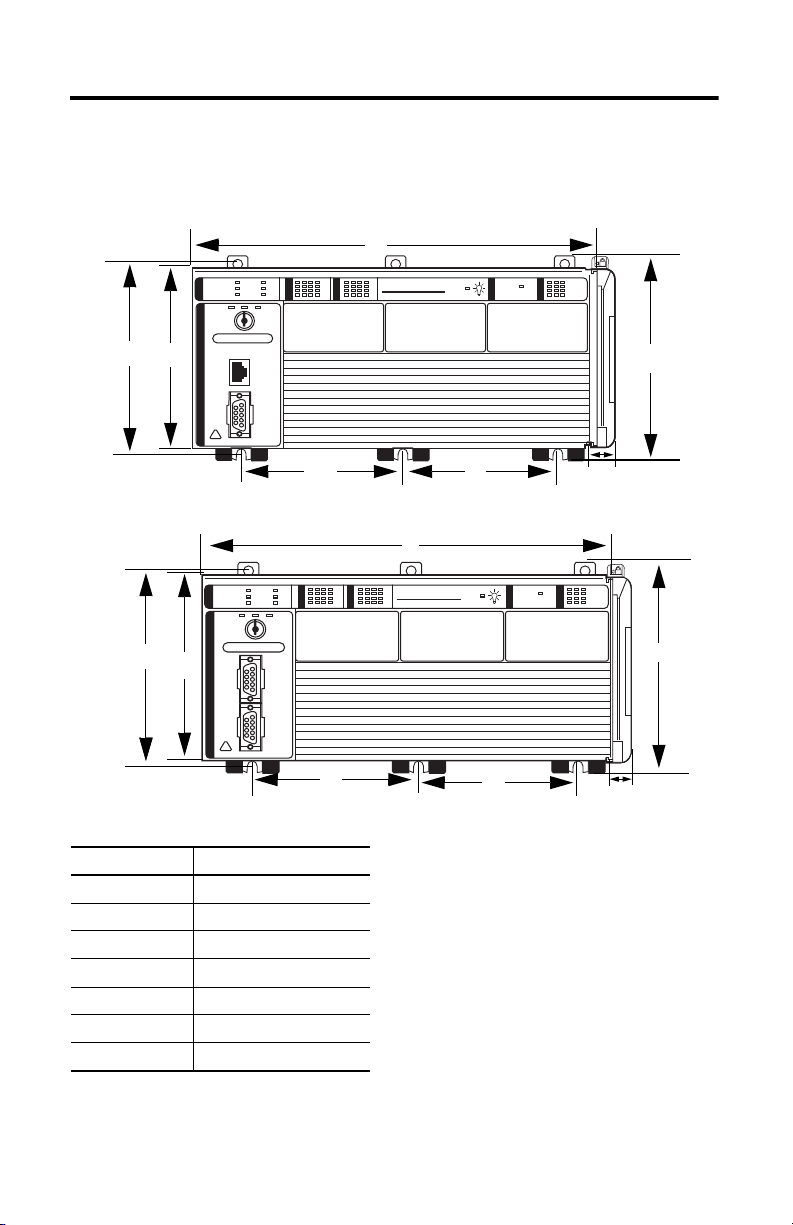

Page 10

10 CompactLogix Controller

CompactLogix L23E

g

a

b

c

e

f

d

CompactLogix L23

OK

BATT

I/O

DCH 0

FORCE

RUN

g

a

b

c

e

f

b

d

1769-L23E-QBFC1B and 1769-L23-QBFC1B Packaged Controllers

The 1769-L23E-QBFC1B and 1769-L23-QBFC1B packaged controllers have these

approximate dimensions.

Measurement

(1)

Dimension, approximate

a 249.25 mm (9.81 in.)

b 123.86 mm (4.88 in.)

c 118 mm (4.65 in.)

d 132 mm (5.20 in.)

e 98.475 mm (3.88 in.)

f 98.475 mm (3.88 in.)

g 18 mm (0.71 in.)

(1) Applies to both the 1769-L23E-QBFC1B and 1769-L23-QBFC1B

packaged controllers.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 11

CompactLogix Controller 11

CompactLogix L23

OK

BATT

I/O

DCH 0

FORCE

RUN

50 mm

(1.97 in.)

50 mm

(1.97 in.)

50 mm

(1.97 in.)

50 mm

(1.97 in.)

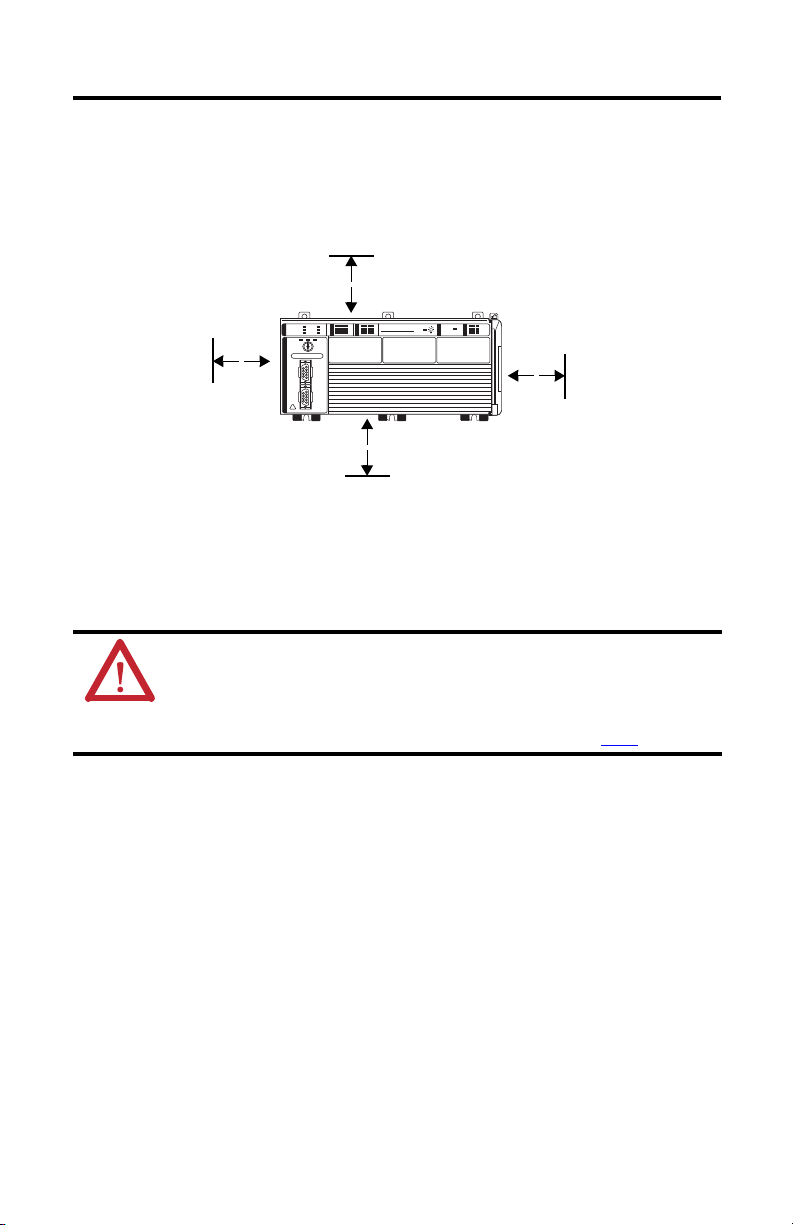

Minimum Spacing Requirements

When using any of the CompactLogix packaged controllers, maintain spacing from enclosure

walls, wireways, and adjacent equipment. Allow 50 mm (1.97 in.) of space on all sides, as shown.

This provides ventilation and electrical isolation.

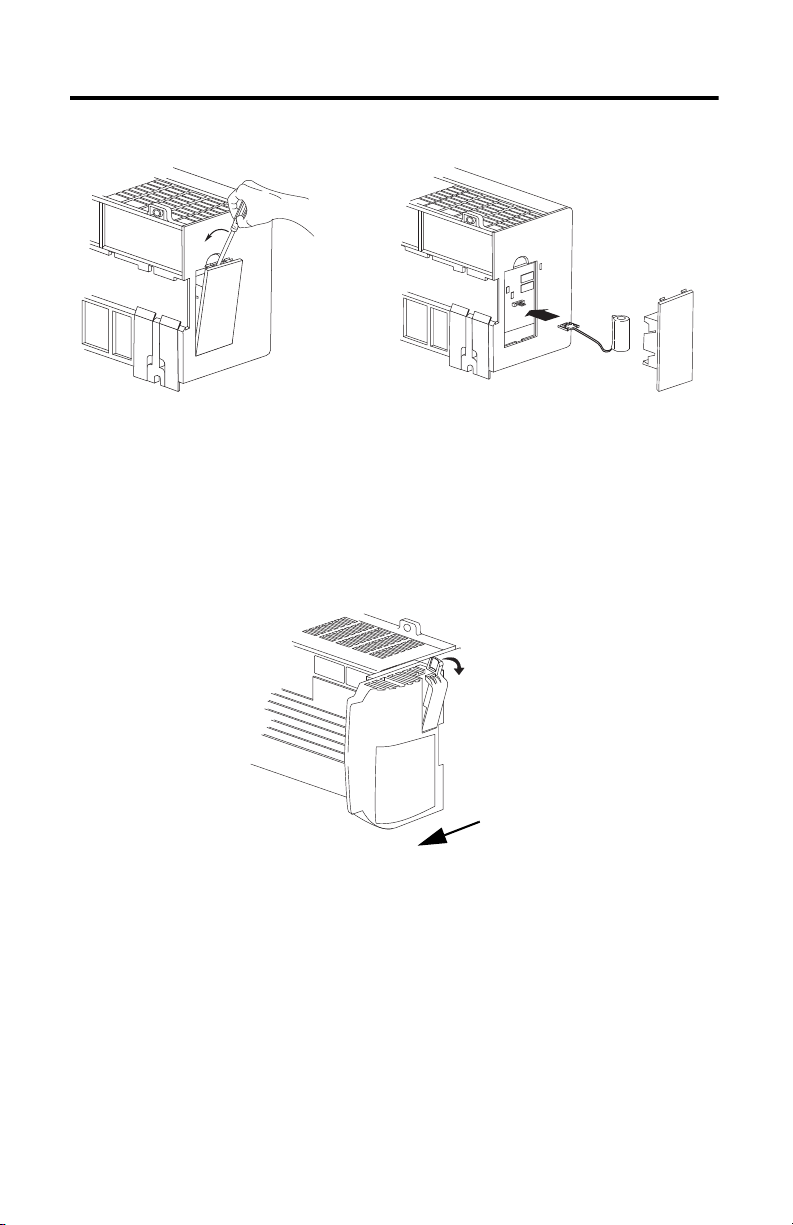

Install the Battery

Complete these steps to install the battery on your packaged controller.

WARNI NG: When you connect or disconnect the battery an electrical arc can occur. This could

cause an explosion in hazardous location installations. Be sure that the area is nonhazardous

before proceeding.

For Safety information on the handling of lithium batteries, including handling and disposal of

leaking batteries, see Guidelines for Handling Lithium Batteries, publication AG 5-4.

1. Open the battery door on the left side of the packaged controller.

2. Carefully attach the battery connector to the port located inside the packaged controller.

3. Insert the battery, wires down, in the slot on the battery door.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 12

12 CompactLogix Controller

4. Close the battery door.

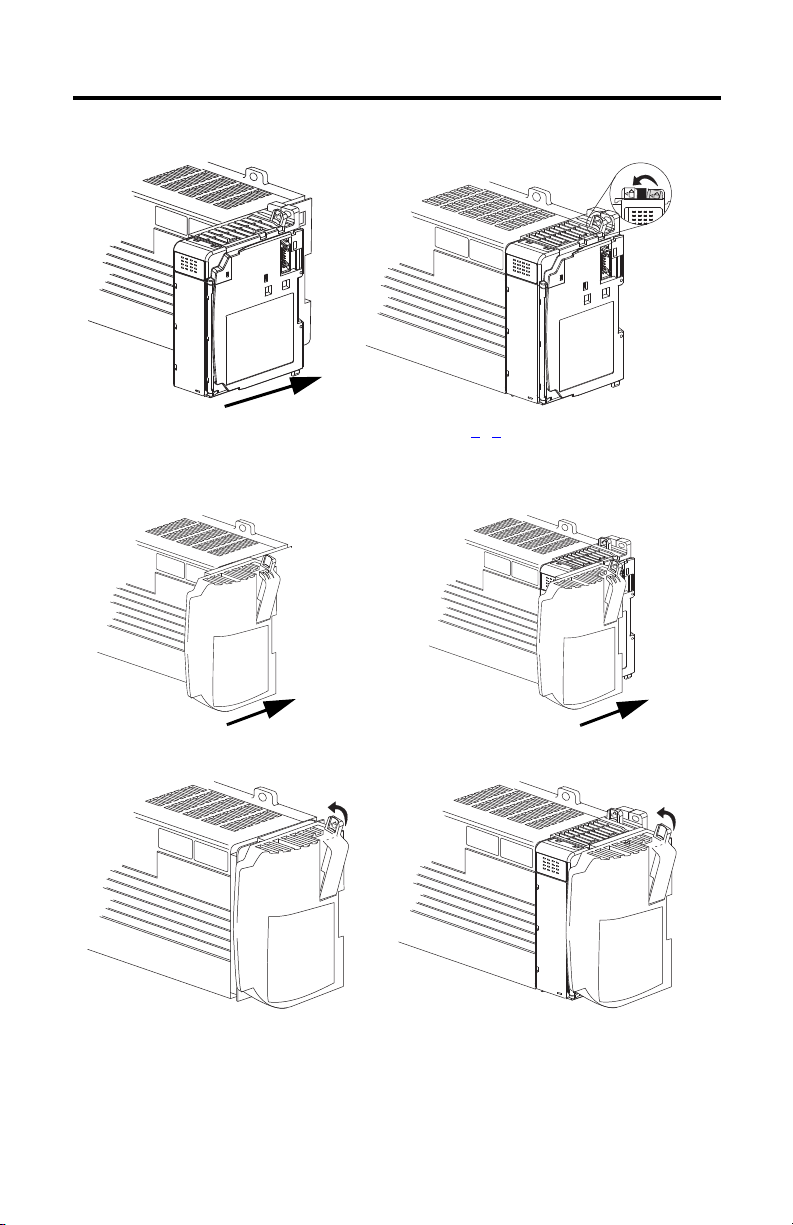

Connect Expansion Modules (optional)

If using expansion modules with your packaged controller, complete these steps to attach the

modules.

1. Remove the end cap by unlocking it and sliding it forward.

2. Align the tongue-and-groove slots of the expansion module with those on the right end

of the packaged controller.

3. Slide the module onto the packaged controller.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 13

4. Close the locking tab on the top of the module.

CompactLogix Controller 13

5. If using another expansion module, complete steps 2

6. Align the tongue-and-groove slots of the end cap with those on the right of the packaged

controller or expansion module.

7. Close the locking tab located on the top of the end cap.

…4 for the second module.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 14

14 CompactLogix Controller

Panel Mount the System

To mount your system to a panel, complete these steps.

1. Using the assembled system as a template, carefully mark the center of all mounting holes

on the panel.

2. Remove the system and drill and tap the mounting holes for the recommended M4 or #8

screws.

3. Place the grounding panel (if used) and CompactLogix system on the panel to check for

proper hole alignment.

4. Insert the recommended screws into the mounting tabs on the packaged controller and

expansion modules (if used) and tighten.

DIN-rail Mount the System

To mount your system on a DIN rail, complete these steps.

The packaged controller can be mounted on these DIN rails:

• EN 50 022 - 35 x 7.5 mm (1.38 x 0.30 in.)

• EN 50 022 - 35 x 15 mm (1.38 x 0.59 in.)

ATTENTION: When this product is grounded through the DIN rail to chassis ground, use

zinc-plated yellow-chromate steel DIN rail to assure proper grounding. The use of other DIN rail

materials (for example, aluminum or plastic) that can corrode, oxidize, or are poor conductors, can

result in improper or intermittent grounding. Secure DIN rail to mounting surface approximately

every 200 mm (7.8 in.) and use end-anchors appropriately.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 15

CompactLogix Controller 15

1. Before mounting the packaged controller on a DIN rail, close the DIN-rail latches.

2. Press the DIN-rail mounting area of the packaged controller against the DIN rail.

The latches momentarily open and lock into place on the DIN rail.

3. Press the DIN rail mounting area of the packaged controller against the DIN rail.

The latches momentarily open and lock into place on the DIN rail.

Grounding Considerations

This product is intended to be mounted to a well-grounded mounting surface such as a metal

panel. Additional grounding connections from the packaged controller’s mounting tabs or DIN

rail (if used) are not required unless the mounting surface cannot be grounded.

Refer to the Industrial Automation Wiring and Grounding Guidelines, publication 17

for additional information.

70-4.1,

Wiring Power to the System

Use this diagram as a reference when wiring the required 24V DC power to your system.

WARNI NG:

• Do not connect directly to line voltage. Line voltage must be supplied by a suitable, approved

isolating transformer or power supply having short-circuit capacity not exceeding 100VA

maximum or equivalent.

• Explos ion hazard, do not remove or replace fuses on the pack aged controll er unless po wer has

been disconnected or the area is known to be free of lb. concentrations of flammable gases or

vapors.

For more information about replacing the fuse, see the Fuse Replacement Procedure in the

Compact Expansion Power Supplies Installation Instructions, publication 1769-IN028

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

.

Page 16

16 CompactLogix Controller

IMPORTANT

CompactLogix L23E

No Connection

No Connection

+24 V DC

DC Neutral

System Power Ground

To comply with the CE Low Voltage Directive (LVD), this equipment and all connected I/O must

be powered from a source compliant with one of the following:

• safety extra low voltage (SELV)

• protected extra low voltage (PELV)

Power Wire Size and Terminal Screw Torque

Wire Type Wire Size Terminal Sc rew Torque

Solid or stranded Cu: 75 °C (167 °F) 0.25... 2.5 mm

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

2

(22...14 AWG) 1.27 Nm (11.24 lb•in)

Page 17

CompactLogix Controller 17

CompactLogix L23E

31761-M

Wire the I/O Removable Terminal Blocks

WARNI NG:

• When you connect or disconnect the Removable Terminal Block (RTB) with field side power

applied, an electrical arc can occur. This could cause an explosion in hazardous location

installations.

• If you connect or disconnect wiring while the field-side power is on, an electrical arc can occur.

This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

ATTENTION:

• Mis-wiring the removable terminal blocks to an AC power source causes damage to the

packaged controller.

• Be careful when stripping wires. Wire fragments that fall into an removable termin al block

could cause damage at power up. Once wiring is complete, ensure the removable terminal

blocks are free of all metal fragments.

• When wiring I/O removable terminal blocks, tighten terminal screws with care. Excessive

tightening can strip a screw.

To begin wiring your embedded I/O removable terminal blocks, loosen the screws at the top and

bottom of the removable terminal block and remove the removable terminal block from the

packaged controller.

I/O Removable Terminal Block Wire Size and Screw Torques

Wire Type Wire Size Terminal Screw

Tor que

Solid or

stranded

Cu: 75

°C (167 °F) 0.5... 0.8 mm

(20...18 AWG)

2

0.68 Nm (6 lb•in) 0.46 Nm (4.1 lb•in)

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Retaining Screw

Tor que

Page 18

18 CompactLogix Controller

DC Inputs Wiring Diagram

+ DC (sinking)

- DC (sourcing)

24V DC

(1)

+ DC (sinking)

- DC (sourcing)

24V DC

+ DC (sinking)

- DC (sinking)

- DC (sourcing)

+ DC (sourcing)

- DC (sinking)

+ DC (sourcing)

(1) Sinking/Sourcing Inputs - Sourcing/sin king describes the current flow between the I/O and the field device. Sourcing I/O circuits supply (source)

current to sinking field devices. Sinking I/O circuits are driven by a current sourcing field device. Field devices connected to the negative side (DC

Common) of the field power supply are sinking field devices. Field devices connected to the positive side (+V) of the field supply are sourcing field

devices. Europe: DC sinking input and sourcing output circuits are the commonly used options.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 19

CompactLogix Controller 19

+DC

24V DC (source)

-DC

DC COM

OUT 14

OUT 12

OUT 10

OUT 8

OUT 6

OUT 4

OUT 2

OUT 0

OUT 15

OUT 13

OUT 11

OUT 9

OUT 7

OUT 5

OUT 3

OUT 1

+VDC

CR

CR

CR

CR

CR

CR

CR

CR

CR

CR

DC Outputs Wiring Diagram

(1)(2)

(1) Recommended Surge Suppression - Use a 1N4004 diode reverse-wired across the load for transistor outputs switching 24V DC inductive loads. For

additional details, refer to Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley publication 1770-4.1

(2) Sourcing Output - S ource describes the current flow between the I/O and the field dev ice. Sourcing output circuits supply (source) current to

sinking field devices. Field devices connected to the negative side (DC Common) of the field power supply are sinking field dev ices. Field devices

connected to the positive side (+V) of the field su pply are sourcing field devices. Europe: DC sinking input and sourcing output circuits are the

commonly used options.

.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 20

20 CompactLogix Controller

IMPORTANT

Analog I/O Wiring Diagrams

ATTENTION: Analog outputs may fluctuate for less than a second when power is applied or

removed. This characteristic is common to most analog outputs. While the majority of loads will

not recognize the short signal, take preventive measures to ensure that connected equipment is

not affected.

In environments where high-frequency noise may be present, it may be necessary to directly

ground cable shields to earth at the removable terminal block end and via a 0.1μF capacitor at

the sensor end.

• All analog I/O commons (ANLG COM) are connected in the analog I/O card of the

packaged controller. The analog common (ANLG COM) is not connected to earth

ground inside the packaged controller.

• Analog I/O channels are not isolated from each other.

• Use Belden 8761 (or equivalent) shielded wire.

• Under normal conditions, the drain wire and shield junction must be connected to earth

ground via a panel or DIN rail mounting screw at the analog I/O removable terminal

block end. Keep the shield connection to ground as short as possible.

• To ensure optimum accuracy, limit overall cable impedance by keeping your cable as

short as possible. Plan to place the packaged controller as close to your sensors or

actuators as your application permits.

• If multiple power supplies are used with analog inputs:

• the power supply commons must be connected.

• do not exceed the specified isolation voltage.

• The embedded analog I/O does not provide loop power for analog inputs. Use a power

supply that matches the input transmitter specifications.

• Differential analog inputs are more immune to noise than single-ended analog inputs.

• Voltage outputs (Vout 0+ and Vout 1+) of the analog I/O are referenced to ANLG

COM. Load resistance for a voltage output channel must be equal to or greater than 1

K.

• Current outputs (Iout 0+ and Iout 1+) of the analog I/O source current that returns to

ANLG COM. Load resistance for a current output channel must remain between

0…300 .

• Voltages on Vin+, V/Iin-, and Iin+ of the analog I/O must be within 0 to +10V DC of

analog common.

(1)

(1) Cable length over 50 m (164.04 ft) may impact accuracy. For details, refer to the Compact Combination Analog I/O Module, publication

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

1769-UM008

.

Page 21

Differential Input Wiring Diagram

+

–

V in 1+

V in 3+

V in 0+

V/I in 0-

I in 1+

I in 3+

V/I in 1 -

I in 0+

I in 2+

V in 2 +

V/I in 3 -

V/I in 2-

ANLG Com

ANLG Com

V out 1+

I out 1+

V out 0+

I out 0+

Earth ground the

shield locally at the

module.

Differential Voltage

Tra ns mi tt er

Belden 8761 Cable (or equivalent)

+

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

+

+

-

Current

Tra ns mi tt er

Sensor/

Tra ns mi tt er

Power S upply

Voltage Transmitter

Signal

Signal

Ground

1769-IF4XOF2 Terminal Block

The sensor power supply must be rated at Class 2.

Single-ended Sensor/Transmitter Types Wiring Diagram

CompactLogix Controller 21

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 22

22 CompactLogix Controller

+

+

+

+

+

–

–

–

+

+–

–

–

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

Single-ended

Volt age

Tra ns mi tt er

Differential

Volt ag e

Tra ns mi tt er

Differential

Current

Tra ns mi tt er

2-wire

Current

Transmitter

Signal

Signal

Signal

Signal

Supply

Analog I/O Terminal Block

The sensor power supply must be rated at Class 2.

Sensor/

Tra ns mi tt er

Power Su pply

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

Volt age Lo ad

Current Load

Earth Ground

Earth Ground

Mixed-input Transmitter Wiring Diagram

Analog Outputs Wiring Diagram

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 23

CompactLogix Controller 23

IMPORTANT

High-speed Counter Wiring Diagrams

ATTENTION: Disconnect power before wiring the HSC removable terminal block. This includes

sensor and packaged controller power.

• Input and output channels are isolated from the packaged controller. Input channels are

isolated from one another; output channels are not.

• Shielded cable is required for high-speed input signals A, B, and Z. Use individually

shielded, twisted-pair cable (or the type recommended by the encoder manufacturer) for

lengths up to 300 m (1000 ft).

• Route field wiring away from any other wiring and as far as possible from sources of

electrical noise, such as motors, transformers, contactors, and AC devices.

• Routing field wiring in a grounded conduit can reduce electrical noise.

• If field wiring must cross AC or power cables, ensure that they cross at right angles.

• Make sure the system is properly grounded using these guidelines:

– This product is intended to be mounted to a well-grounded mounting surface such

as a metal panel. Additional grounding connections from the packaged controller’s

mounting tabs or DIN rail (if used) are only required when the mounting surface is

non-conductive and cannot be grounded.

– Keep the shield connection to ground as short as possible.

– Ground the shield drain wire only at the HSC input end, except where

high-frequency noise is present.

ATT EN TI ON : In environments where high-frequency noise may be present, it may be

necessary to directly ground cable shields to earth at the removable terminal block end and via

a 0.1μF capacitor at the sensor end.

• To establish optimum accuracy, limit overall cable impedance by keeping cable as short as

possible. Locate the packaged controller as close to input devices as your application

permits.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 24

24 CompactLogix Controller

A

A

B

B

Z

Z

A1(+)

A1(–)

B1(+)

B1(–)

Z1(+)

Z1(–)

GND

VS

+VDC

COM

Cable

(1)

Power

Supply

Allen-Bradley

845H Series

Differential

Encoder

Shield/housing

Connect only if housing is electronically isolated

from the motor and ground.

Shield

Inputs

Earth

HSC Differential Encoder Wiring

(1) Refer to your encoder manual for proper cabl e type. The type of cable used should be twisted pa ir, individually shielded cable with a maximum

length of 300 m (1000 ft.).

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 25

CompactLogix Controller 25

A

B

Z

A1(+)

A1(–)

B1(+)

B1(–)

Z1(+)

Z1(–)

GND

VS

+VDC

COM

R

(2)

Cable

(1)

Power

Supply

Allen-Bradley

845H Series

Single-ended

Encoder

Shield/housing

Connect only if housing is electronically

isolated from the motor and ground.

Shield

Inputs

Earth

R

V

DC Vmin–

Imin

--------------------------------------=

HSC Single-ended Encoder Wiring Diagram

(1) Refer to your encoder manual for proper cable type. The type of cable used should be twisted- pair, individually shielded cable with a maximum

length of 300 m (1000 ft.).

(2) External resistors are required if they are not internal to the encoder. The pull-up resistor (R) value depends on the power supply value. The table

below shows the maximum resistor values for typical s upply voltages. To calculate the maximum resistor value, use this formula:

Where:

R = maximum pull-up resistor value

VDC = power supply voltage

Vmin = 2.6V DC

Imin = 6.8 mA

Power Supply Voltage (V DC) Maximum Pull-up Resistor Value (R)

5V DC 352

12V DC 1382

24V DC 3147

(1) Resistance values may change, dependin g upon your application.

The minimum resistor (R) value depends on the current sinking capability of the encoder. Refer

to your encoder’s documentation for more information.

(1)

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 26

26 CompactLogix Controller

VS

A1(+)

A1(–)

B1(+)

B1(–)

Z1(+)

Z1(–)

+VDC

COM

VS

OUT

COM

OUT

COM

VS

OUT

COM

R

(1)

Power

Supply

Module Inputs

Solid-state

Switch

Proximity Sensor

Photo-electric Sensor with Open

Collec tor Sink ing Outpu t

R

V

DC Vmin–

Imin

--------------------------------------=

HSC Discrete Device Wiring

(1) External resistors are required if they are not internal to the sensor. The pull-up resistor (R) value depends on the power supply value. The table

below shows the maximum resistor values for typical supply voltages. To calculate the maximum resistor value, the following formula:

Where:

R = maximum pull-up resistor value

VDC = power supply voltage

Vmin = 2.6V DC

Imin = 6.8 mA

Power Supply Voltage (VDC) Maximum Pull-up Resistor Value (R)

5V DC 352

12V DC 1382

24V DC 3147

(1) Resistance values may change, depen ding upon your application.

The minimum resistor (R) value depends on the current sinking capability of the sensor. Refer to

your sensor’s documentation for more information.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

(1)

Page 27

CompactLogix Controller 27

+DC

+5/24V DC

-DC

Z1-

B1-

A1-

Z0-

B0-

A0-

OUT

DC COM

OUT 2

OUT 0

Z1+

B1+

A1+

Z0+

B0+

A0+

OUT 3

OUT 1

OUT DC

+5/24VDC

CR

CR

CR

HSC Output Wiring

ATTENTION: Mis-wiring the embedded HSC to an AC power source or applying reverse polarity

causes damage to the embedded HSC.

(1) (2)

(1) Recommended Surge Suppression - The embedded HSC has built-in suppression which is sufficient for most applications, however, for high-noise

applications, use a 1N4004 diode reverse-wired across the load for transistor outputs switching 24V DC inductive loads. For additional details, refer

to Industrial Automation Wiring and Grounding Guidelines, Allen- Bradley publication 1770-4.1

(2) Sourcing Output - S ource describes the current flow between the I/O and the field dev ice. Sourcing output circuits supply (source) current to

sinking field devices. Field devices connected to the negative side (DC Common) of the field power supply are sinking field dev ices. Field devices

connected to the positive side (+V) of the field su pply are sourcing field devices. Europe: DC sinking input and sourcing output circuits are the

commonly used options.

.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 28

28 CompactLogix Controller

CompactLogix L23E

8 ------ NC

7 ------ NC

6 ------ RD5 ------ NC

4 ------ NC

3 ------ RD+

2 ------ TD1 ------ TD+

Connect Using the RS-232 Connection

1769-L23E-QB1B, 1769-L23-QBFC1B, and 1769-L23E-QBFC1B Controllers

WARNI NG: If you connect or disconnect the serial cable with power applied to this module or the

serial device on the other end of the cable, an electrical arc can occur. This could cause an explosion

in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

To connect to your controller using the RS-232 (serial) connection, simply connect the 9-pin

female end of the serial cable to the serial port of the controller.

Connect Using the Ethernet Connection

1769-L23E-QB1B and 1769-L23E-QBFC1B Controllers

Complete these steps to connect to the controller using the Ethernet connection.

WARNI NG: If you connect or disconnect the Ethernet cable with power applied to this module or

any device on the network, an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

ATTENTION: Do not plug a DH-485 network cable or a NAP port cable into the Ethernet port.

Undesirable behavior and/or damage to the port may result.

1. Insert the RJ45 connector of the Ethernet cable into the Ethernet port located on the

front of the controller.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 29

CompactLogix Controller 29

IMPORTANT

2. Use the BOOTP utility or RSLogix 5000 software to assign an IP address to the

controller.

The controller ships with BOOTP functionality enabled. This means that no extra steps

must be taken to make the controller work with a BOOTP utility.

For more information about setting the controller’s IP address (a network parameter), see the

EtherNet/IP Modules in Logix5000™ Control Systems User Manual, publication

ENET-UM001

.

Download and Install EDS Files

If you have RSLinx® software, version 2.52 or later, the most current EDS files were installed with

the software.

If you are using an earlier version of RSLinx software, you need to download and install EDS files

specific to each component of the packaged controller. This includes firmware and icons specific

to the packaged controller, its Ethernet interface, virtual backplane, virtual adapter, and

embedded I/O.

EDS files are available on the RSLogix 5000 software, version 17 CD, at

http://support.rockwellautomation.com

, and at http://www.ab.com/networks/eds.

Download Packaged Controller Firmware

Packaged controller firmware is available on the RSLogix 5000 software CD or you can

download it from http://www.rockwellautomation.com/support

.

Use the AutoFlash Feature of RSLogix 5000 Software to Load Firmware

RSLogix 5000 Software lets you update your packaged controller firmware without having to

open the ControlFLASH utility. You can load firmware via an Ethernet (preferred) or serial

connection.

When upgrading your packaged controller firmware, it is extremely important to allow the

upgrade to complete without interruption.

If you interrupt the firmware upgrade either in the software or by disturbing the physical

media, you may render the packaged controller inoperable.

For more information about upgrading your CompactLogix packaged controller firmware, see

information posted at http://www.rockwellautomation.com/knowledgebase/.

1. Make sure the appropriate network connection is made and your network driver is

configured in RSLinx software.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 30

30 CompactLogix Controller

2. Use RSLogix 5000 programming software to create a packaged controller project.

3. Click RSWho to specify the controller path.

4. Select your packaged controller and click Download.

You may also choose to click Update Firmware to complete this process. If you do so,

skip to step 8.

A dialog box displays indicating that the project revision and controller firmware

revision are different.

5. Click Update Firmware.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 31

CompactLogix Controller 31

IMPORTANT

6. Use the checkbox and pull-down to select your controller and firmware revision.

7. Click Update.

8. Click Yes.

The firmware upgrade begins.

Do not interrupt the firmware upgrade once it has begun.

Interrupting the firmware upgrade may result in an inoperable packaged controller.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 32

32 CompactLogix Controller

Status Change

During the firmware upgrade you see the status change as shown below.

Continue to allow the firmware upgrade to complete without interruption.

When the firmware upgrade is complete, the Download dialog box displays and you may

continue by downloading your project to the packaged controller.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 33

CompactLogix Controller 33

IMPORTANT

Use the ControlFLASH Utility to Load Firmware

You can use the ControlFLASH utility to load firmware via an Ethernet (preferred) or serial

connection.

When upgrading your packaged controller firmware, it is extremely important to allow the

upgrade to complete without interruption.

If you interrupt the upgrade either in ControlFLASH software or by disturbing the physical

media, you may render the packaged controller inoperable.

For more information about upgrading your CompactLogix packaged controller firmware, see

information posted at http://www.rockwellautomation.com/knowledgebase/

1. Make sure the appropriate network connection is made and your network driver is

configured in RSLinx software.

2. Start the ControlFLASH utility.

3. When the Welcome dialog box appears, click Next.

4. Choose the catalog number of the packaged controller and click Next.

5. Expand the network until you see your packaged controller and select it.

.

6. Click OK.

7. Choose the revision level to which you want to update the packaged controller and click

Next .

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 34

34 CompactLogix Controller

IMPORTANT

Status

Change

Status

Change

8. Click Finish and then click Yes.

The firmware upgrade begins.

Do not interrupt the firmware upgrade once it has begun.

Interrupting the firmware upgrade may result in an inoperable packaged controller.

During the firmware upgrade you see the status change as shown below.

Continue to allow the firmware upgrade to complete without interruption.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 35

CompactLogix Controller 35

The Upgrade Status dialog box indicates that the firmware upgrade has been successfully

completed.

9. Click OK.

10. To close the ControlFLASH utility, click Cancel and then click Yes.

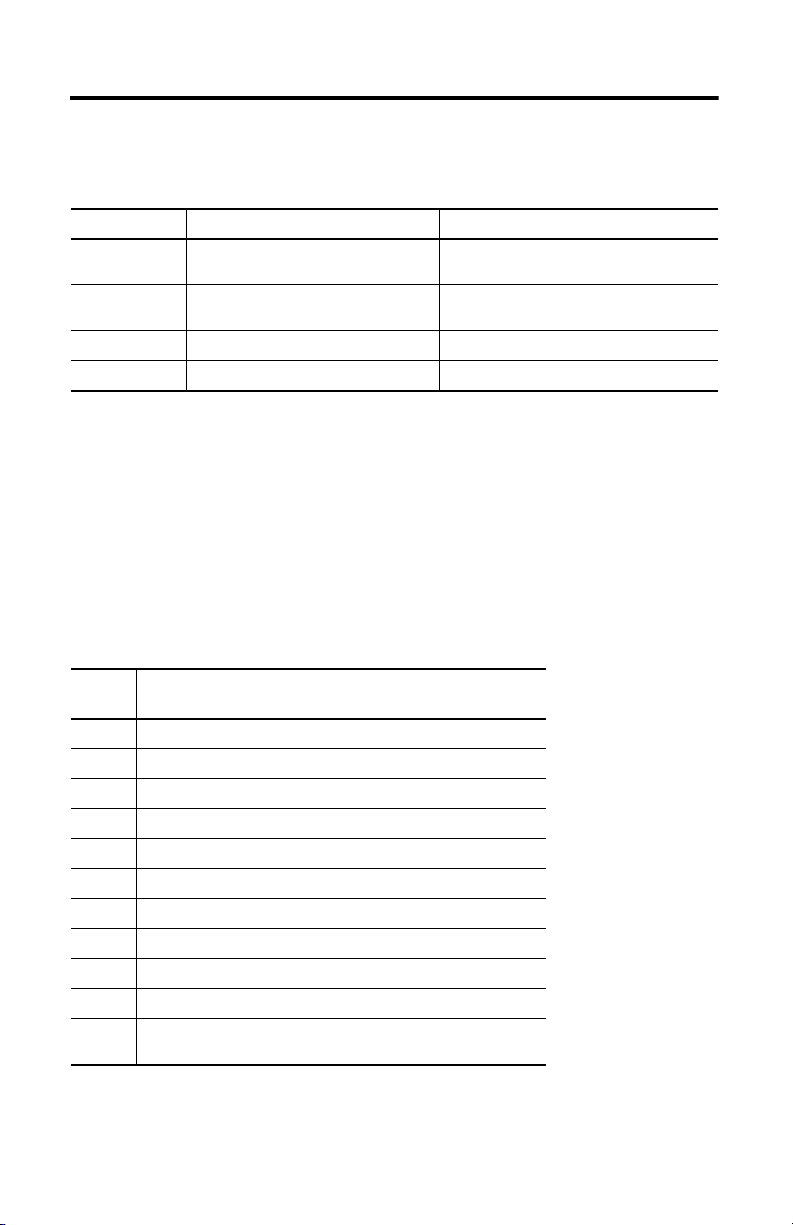

Select the Packaged Controller’s Operating Mode

Use the keyswitch on the front panel of the packaged controller to select the packaged

controller’s operating mode.

Use this

operating mode

RUN • Upload projects.

PROG • Disable outputs.

REM • Upload/download projects.

To achieve these tasks

• Run the program and enable outputs.

When the keyswitch is in the RUN position, you cannot change the operating mode by using the Controller

Status menu in RSLogix 5000 software.

• Upload/download projects.

• Create, modify, and delete tasks, programs, or routines.

• Stop the execution (scanning) of tasks. That is, the packaged controller does not execute (or scan) tasks

while the keyswitch is in the Prog position.

When the keyswitch is in the PROG position, you cannot change the operating mode by using the

Controller Status menu in RSLogix 5000 software.

• Switch between Remote Program, Remote Test, and Remote Run modes by using the Controller Status

menu in RSLogix 5000 programming software.

These Remote modes are can be selected using the Controller Status menu:

Remote Run - In this mode, the controller executes (scans) tasks, enables outputs, and enables

online edits.

Remote Program - In this mode, the controller: disables outputs, allows program and task edits

while online, downloads projects, and inhibits execution (scanning) of tasks.

Remote Test - In this mode, the controller executes tasks with outputs disabled and enables online

editing.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 36

36 CompactLogix Controller

TIP

I/O

DCH 0

FORCE

RUN

BATT

OK

Power Supply Status Indicator

The green power supply status indicator is located next to the lightbulb symbol and indicates

these power states:

• ON = +5 and +24V DC current available from power supply

• Off = No input power, power-fail enabled, or overvoltage exceeded/protection enabled

Controller Status Indicators

The six status indicators are located at the top left corner of the CompactLogix packaged

controller. Use this table as a reference when interpreting all six of the packaged controller status

indicators.

When power is first applied to the controller, the OK, NS, MS, and LNK status indicators display

a complex sequence of varying red and green states. This sequence indicates the power-up self

test and takes approximately 1…2 minutes for the packaged controller to complete.

Controller Status Indicators

Indicator Status Description

RUN Off The pac kaged controller is in Program or Test mode.

Steady green The packaged controller is in Run mode.

FORCE Off Either one of the following is true:

Steady amber Either one of the following is true:

Flashing amber One or more input or output addresses have been forced to an On or Off condition, but

BATT Off The battery supports memory.

Steady red The battery is in either one of the following states:

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

• No tags conta in I/O force values.

• I/O forces are inactive (disabled).

• I/O forces are active (enabled).

• I/O force values may or may not exist.

the forces have not been enabled.

• Not installe d

• 95% discharged and should be replaced

Page 37

Controller Status Indicators

Indicator Status Descr iption

I/O Off Either one of the following:

Steady green The packaged controller is communicating with all the devices in its I/O configuration.

Flashing green One or more devices in the I/O configuration of the packaged controller are not

Flashing red Either one of the following:

OK O ff No power is applied.

Flashing red One of the following conditions exists:

Steady red Upon power-up, the OK indicator is steadily red for a few moments. This is normal

Steady green Packaged controller is OK.

Flashing green The packaged controller is storing or loading a project to or from nonvolatile memory.

• There are no devices in the I/O configuration of the packaged controller.

• The packaged controller does not contain a project.

respond ing.

• The packaged controller is not communicating with any devices.

• The packaged controller is faulted.

• The packaged controller requires a firmware update.

• A major recoverable fault occurred on the packaged controller. To clear the fault,

perform this procedure.

• Turn the packaged controller keyswitch from PROG to RUN to PROG.

• Go online with RSLogix 5000 software.

• A nonrecoverable major fault occurred on the packaged controller. In this case, the

packaged controller:

a. OK indicator initially displays steady red.

b. Resets, clearing the project from memory.

c. Sets the OK indicator to flashing red.

d. Produces a major recoverable fault.

e. Generates a fault code in the RSLogix 5000 project.

The fault code displayed in RSLogix 5000 software and the subsequent fault recovery

method depends upon your system.

behavior and is not a fault.

If the OK indicator is steadily red for more than a few moments or changes to steadily

red while in use, then a nonrecoverable major fault has occurred and project memory

has been cleared.

To recover from a major fault, cycle power to the packaged controlle r, re-download

the project, and put the packaged controller in Run mode.

If the OK indicator remains steadily red, contact your Rockwell Automation

representative or local distributor.

CompactLogix Controller 37

Module Status (MS) Indicator

The Module Status (MS) indicator is located

under the space provided for you to write the IP

address of the packaged controller and is one of

the Ethernet/IP network status indicators.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

IP

MS

Page 38

38 CompactLogix Controller

Status Description Action

Off The packaged controller does not have power. Check the controller power supply.

Flashing green The port is in standby mode; it does not have an

Steady green The port is operating correctly. Normal operation - no action is required.

Steady red The packaged controller is holding the por t in

Flashing red The port firmware is being updated. Normal operation - no action is required.

IP address and is operating in BOOTP mode.

reset or the packaged controller has faulted.

The port is performing its power-up self test. Normal operation - no action is required.

A nonrecoverable fault has occurred. Cycle power to the controller.

Verify that the BOOTP server is running.

Clear the fault.

If the fault will not clear, replace the packaged

controller.

If the fault will not clear, replace the packaged

controller.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 39

CompactLogix Controller 39

NS

LNK

NS

LNK

Network Status (NS) Indicator

The Network Status (NS) indicator is located to the

right of the Ethernet port and is one of the EtherNet/IP

status indicators.

Status Description Action

Off The port is not initialized; it does not have an IP

Flashing green The port has an IP address, but no CIP connections

Steady green The por t has an IP address and CIP connections

Steady red The port has detected that the assigned IP address

Flashing red/green The port is performing its power-up self test. Normal operation - No action is required.

address and is operating in BOOTP mode.

are established.

(Class 1 or Class 3) are established.

is already in use.

Verify that the BOOTP server is running.

If no connections are configured, no action is

required.

If connections are configured, check connection

originator for connection error code.

Normal operation - No ac tion is required.

Verify that all IP addresses are unique.

Link Status (LNK) Indicator

The Link (LNK) status indicator is also located to the

right of the Ethernet port, below the NS indicator. It

is also an EtherNet/IP network status indicator.

Status Description Action

Off The port is not connected to a powered Ethernet device.

Flashing green The port is performing its power-up self-test. Normal operation - no action is required.

Steady green The port is connected to a powered Ethernet device.

Therefore, the port cannot communicate on the Ethernet

network.

The port is communicating on the Ethernet network.

Therefore, the port can communicate on the Ethernet

network.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Verify that all Ethernet cables are connected.

Verify that Ethernet switch is powered.

Page 40

40 CompactLogix Controller

OK

BATT

I/O

DCH 0

FORCE

RUN

CH 1

CH 0

RS-232 Serial Port Status Indicators

Two serial port status indicators (the 1769-L23-QBFC1B has three) are present on the left side

of each CompactLogix packaged controller.

Indicator Status Description

DCH0 Off Channel 0 configuration differs from the default serial configuration.

Steady green Channel 0 has the default serial configuration.

CH0 Off No RS-232 activity.

Flashing green RS-232 activity.

CH1

(1769-L23-QBFC1B only)

Off No RS-232 activity.

Flashing green RS-232 activity.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 41

CompactLogix Controller 41

CompactLogix L23E

DC Inputs DC Outputs Analog I/O HSCPower S upply S tatus

I/O Status Indicators

Digital Inputs Status Indicators

There is one status indicator for each digital input point of the CompactLogix packaged

controller. When an input is ON, the corresponding input light is on (amber).

Digital Outputs Status Indicators

There is one status indicator for each digital output point of the CompactLogix packaged

controller. When an output is ON, the corresponding output light is on (amber).

Analog I/O Status Indicator

The analog I/O have one status indicator - the OK status indicator. If the indicator is green, the

analog I/O have power, have passed internal diagnostics, and are communicating properly. If

analog I/O OK indicator is off, a fault is present.

High-speed Counter Status Indicators

The high-speed counters have 12 status indicators.

Indicator Status Description

0,1,2, and 3 Amber The corresponding output is ON.

A0, A1, B0, B1, Z0,

and Z1

FUSE Red An overcurrent condition is present.

OK Off No power to the HSC.

Amber The corresponding input is ON (amber).

Flashing red, brief The HSC is testing itself (this usually occurs at start-up).

Steady green The HSC is operating normally.

Flashing green The HSC is not in Run mode.

Steady red A fault has occurred.

Flashing red, continuous A HSC configuration error exists.

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 42

42 CompactLogix Controller

Additional Resources

These documents contain additional information concerning related Rockwell Automation

products.

Resource Description

CompactLogix Controllers Specifications Technical Data,

publication 1769-TD005

CompactLogix Packaged Controllers Quick Start and User Manual,

publication IASIMP-QS010

Logix5000 Controllers Common Procedures, publication

1756-PM001

ControlF LASH Firmware Upgrade Kit, publicatio n 1756-QS105

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

You can view or download publications at http://www.rockwellautomation.com/literature/. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Controller specifications

Procedures for using your CompactLogix packaged

controll er as well as a dditional re ference info rmation

Developing projects for Logix5000 controllers

Information and procedures for upgrading your packaged

controller firmware using the ControlFLASH utility

Ground and wire Allen-Bradley programmable controllers

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 43

Notes:

CompactLogix Controller 43

Rockwell Automation Publication 1769-IN082C-EN-P - February 2013

Page 44

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

links to software service packs, and a MySupport feature that you can customize to make the best use of these tools. You can also visit

our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

forums, software updates, and to sign up for product notification updates.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/rockwellautomation/support/overview.page

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

, you can find technical manuals, technical and application notes, sample code and

for FAQs, technical information, support chat and

SM

.

at

, or contact your

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, Rockwell Software, Rockwell Automation, CompactLogix, Compact, RSLinx , RSLogix, ControlFLASH, and TechConnect are

trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 1769-IN082C-EN-P - February 2013

Supersedes Publication 1769-IN082B-EN-P - December 2011 Copyright © 2013 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...