Page 1

Manual Title

Additional Information

be certain.

FGW900 High-temperature Furnace

Product Manual

100-231-447 A

Page 2

Copyright information © 2012 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark and MTS Criterion and MTS Insight are

trademarks of MTS Systems Corporation within the United States. These

trademarks may be protected in other countries.

Publication information

MANUAL PART NUMBER PUBLICATION DATE

100-231-447 A May 2012

2

FGW900 High-temperature Furnace Product Manual

Page 3

Contents

Preface 5

Before You Begin 5

Conventions 6

Documentation Conventions 6

Technical Support 7

How to Get Technical Support 7

Before You Contact MTS Service Representative 7

If You Contact MTS by Phone 8

After you call 9

Introduction 10

About This Manual 10

Description 11

Furnace 12

Temperature controller 12

Bracket of high temperature furnace 12

Operating condition requirements 13

Technical parameters 13

Safety Information 14

Safety 14

Hazard Placard Placement 14

Installation 16

High temperature furnace body installation 17

High-Temperature Furnace Cable Connections 20

Operation 25

Operation of High Temperature Furnace 26

FGW900 High-temperature Furnace Product Manual Contents

3

Page 4

Operation of Temperature Controller 28

Routine Maintenance 34

Routine Maintenance Overview Checklist 34

Declaration of Conformity 36

4

Contents

FGW900 High-temperature Furnace Product Manual

Page 5

Before You Begin

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the safety

information provided with your system. Improper installation, operation, or

maintenance can result in hazardous conditions that can cause severe personal

injury or death, or damage to your equipment and specimen. Again, read and

understand the safety information provided with your system before you

continue. It is very important that you remain aware of hazards that apply to your

system.

Other MTS manuals In addition to this manual, you may receive additional manuals in paper or

electronic form.

Manuals located on the product information CD will contain information that

pertains to your test system, such as:

• Hydraulic and/or mechanical accessory manuals

• Assembly drawings

• Parts lists

• Operation instructions

• Preventive maintenance tasks

Controller and application software manuals are typically included on the

software CD distribution disc(s).

FGW900 High-temperature Furnace Product Manual Preface

5

Page 6

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

not necessarily represent your actual system configuration, test application, or

software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Preface

6

FGW900 High-temperature Furnace Product Manual

Page 7

Technical Support

How to Get Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes software, look for

online help and README files that contain additional product inform ation.

If you cannot find answers to your technical questions from these sources, you

can use the Internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact Technical Support in

one of the following ways.

Outside the U.S. For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Before You Contact MTS Service Representative

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your contact

number and system

number

The contact number contains your company number and identifies your

equipment type (such as material testing or simulation). The number is typically

written on a label on your equipment before the system leaves MTS. If you do

not know your MTS contact number, contact your sales engineer.

When you have more than one MTS system, the system model number and series

number identifies your system. You can find your these number in your order

paperwork or directly on your equipment.

Identify the problem Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

FGW900 High-temperature Furnace Product Manual Technical Support

7

Page 8

If You Contact MTS by Phone

Know relevant

computer information

Know relevant

software information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and (if

available) software patch number. This information can typically be found

in the About selection in the Help menu.

• The names of other applications on your computer, such as:

– Anti-virus software

– Screen savers

– Keyboard enhancers

– Print spoolers

– Messaging applications

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical

support specialist. The agent asks you for your:

• Contact number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue

will be assigned a unique notification number.

FGW900 High-temperature Furnace Product Manual Technical Support

8

Page 9

After you call

Identify system type To enable the Call Center agent to connect you with the most qualified technical

support specialist available, identify your system as one of the following types:

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

troubleshoot

Write down relevant

information

After you call

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

MTS logs and tracks all calls to ensure that you receive assistance for your

problem or request. If you have questions about the status of your problem or

have additional information to report, please contact Technical Support again and

provide your original notification number.

FGW900 High-temperature Furnace Product Manual Technical Support

9

Page 10

About This Manual

Introduction

About This Manual

Purpose The FGW900 High Temperature Furnace provides a high-temperature testing

environment for material tests. These tests can include tension, compressing, or

bending of ceramic, metal, and compound materials. This manual provides

technical information about the high-temperature furnace in terms of its parts,

working environment, technical parameters, temperature controller, installation,

and operation.

Inappropriate Use Before you attempt to use the FGW900 MTS High Temperature Furnace, read

and understand this manual. Improper installation or operation of this product

can result in hazardous conditions that can cause sever personal injury or death,

and damage your equipment and specimen.

Contents Description 11

Operating condition requirements 13

Technical parameters 13

FGW900 High-temperature Furnace Product Manual Introduction

10

Page 11

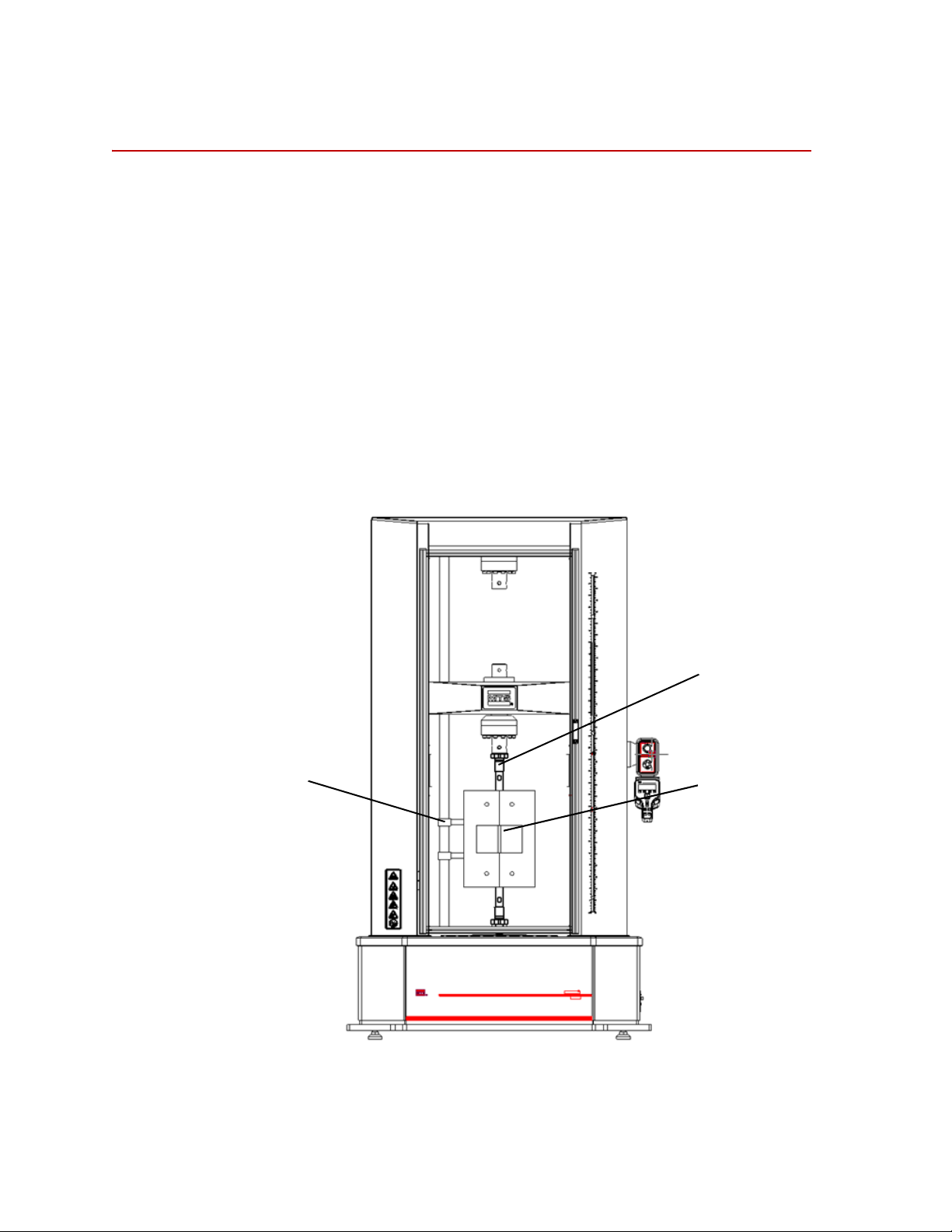

Description

Mounting Brackets

Furnace Rod

Furnace

Typical installation of high temperature furnace

Description

The FGW900 High Temperature Furnace is primarily used with the MTS Series

C45 Electronic Universal Testing Machine and the MTS Series C64 StaticHydraulic Universal Testing Machine. It provides the high temperature required

for tension tests while providing a long-term, stable, high-temperature testing

environment.

The MTS Series FGW900 High furnace let you test materials and components

within a range of temperatures, from 300~ 1100°C (572 ~ 2097°F).

Heating is accomplished with electrical heating elements.

A customer-specified temperature controller (Eurotherm2408) is mounted in the

electrical box.

The high temperature furnace provides stable test temperature conditions for high

temperature tension tests. The high temperature furnace consists of a bracket,

furnace body, temperature controller, rod.

Introduction

11

FGW900 High-temperature Furnace Product Manual

Page 12

Furnace

Controller

Furnace

Heating Element

Heating Element

Heating Element

Upper Control Signal

Middle Control Signal

Lower Control Signal

LowerThermocouple Signal

Middle Thermocouple Signal

Upper Thermocouple Signal

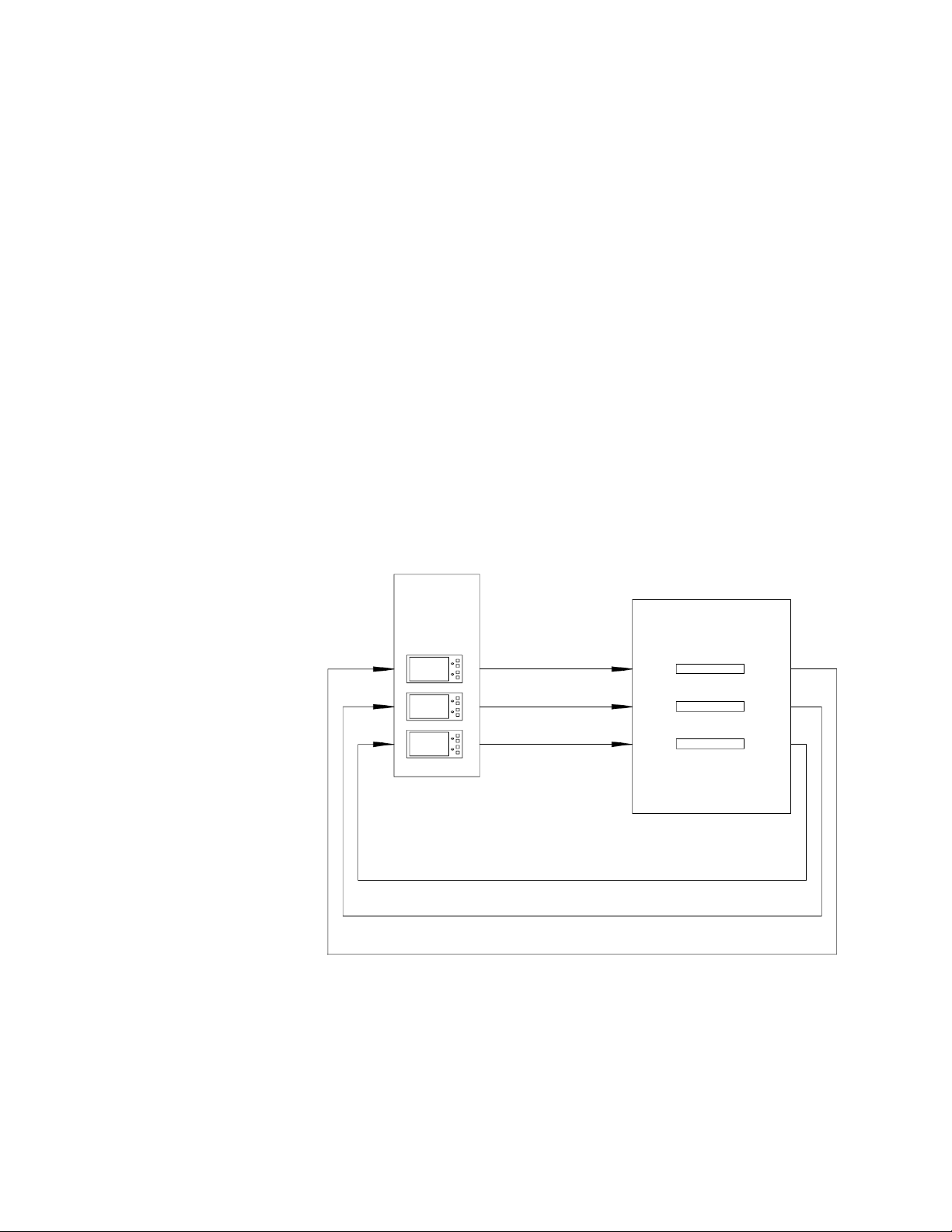

High temperature furnace control diagram

Temperature controller

Furnace

The high-temperature furnace opening provides quick sample and fixture

installation. The furnace has ports used for connecting thermocouples and hightemperature extensometers.

The cavity of the furnace uses thermal insulation material of multicrystal mullite

fiber, allowing operation at maximum temperature for extended periods of time.

The heating body is made of electro thermal alloy wire which provides fast

temperature rise, low heat loss, and long service life.

The housing is made of stainless steel in a double layer structure, ensuring a

lower surface temperature.

The high temperature furnace is monitored and controlled by the temperature

controller. The temperature controller has three high-precision Eurotherm

temperature control meters which control three heating zones. Each temperature

control meter receives the input from a thermocouple and outputs power

accordingly to its heating element. Solid-state relays are used to meet the

requirements of high-precision temperature control.

Bracket of high temperature furnace

FGW900 High-temperature Furnace Product Manual Introduction

The bracket for the furnace has an adjustable rotary bracket that allows you

toadjust the position of the furnace or easily remove it from the test space.

12

Page 13

Operating condition requirements

Operating condition requirements

Only use the high temperature furnace under the following conditions.

PARAMETER SPECIFICATION

Condition For indoor application only

Operating Temperature

Operating Humidity 5-85%, noncondensing

Maximum Altitude 2000 m (6562 ft)

Voltage Single-phase AC 200 ~ 240 V

Frequency 50 Hz / 60 Hz

Current 15 Amps

Technical parameters

M

ODEL FGW900

Scope of application C45, C64

Temperature scope (

External dimension (mm) Φ310 x 410(12.2 in x 16.1 in)

Dimension of chamber (mm) Φ100 x 320(3.9 in x 12.6 in)

Controller size (mm) 400 x 420 x 200(15.7 in x 16.5 in x 7.9 in)

Uniform temperature zone length(mm) 100(3.9 in)

°C) 300 ~ 1100(572 °F to 2097 °F)

°C (41 ~ 104 °F)

5 ~ 40

13

Temperature gradient

Heating method Three-segment controllable

Temperature fluctuation

Precision of temperature controller Class 0.3

Time to obtain operating temperature ≤50 min

Weight 25 kg(55.1lb)

Introduction

≤3

°C(≤37.4 °F)

≤± 2

°C(≤35.6 °F)

FGW900 High-temperature Furnace Product Manual

Page 14

Safety Information

Safety

Safety

Stay clear of moving

equipment/avoid crush

points

Know the causes of

unexpected crosshead

motions

Do not use RF

transmitters

Stay clear of mechanical linkages, connecting cables, and hoses that move

because you can get pinched, crushed, tangled, or dragged along with the

equipment. High forces generated by the system can pinch, cut, or crush anything

in the path of the equipment and cause serious injury. Stay clear of any potential

crush points. Most test systems can produce sudden, high-force motion. Never

assume that your reactions are fast enough to allow you to escape injury when a

system fails.

The high force and velocity capabilities of MTS systems can be destructive and

dangerous (especially if crosshead motion is unexpected). The most likely causes

of unexpected crosshead response are operator error and equipment failure due to

damage or abuse (such as broken, cut, or crushed cables and hoses; shorted wires;

overstressed feedback devices; and damaged components within the control

loop). Eliminate any condition that could cause unexpected crosshead motion.

Keep radio frequency (RF) transmitters away from the workstation computers,

remote terminals, and electronics consoles. Intense RF fields can cause erratic

operation of the more sensitive circuits in the system.

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following labels are typically located on the chamber.

L

ABEL DESCRIPTION

High temperature Furnace ID

label.

Series FEC Environmental Chamber Product Manual Safety Information

14

Page 15

Hazard Placard Placement

LABEL DESCRIPTION

Do not start, operate, or service

machine until you read and

understand the operator’s

manual.

Failure to do so could result in

serious injury.

There are no customerserviceable parts on the MTS

Criterion electromechanical

frames.

Burn hazard.

Hot surface.

Do not touch.

Allow to cool before servicing.

Hot surface hazard.

Do not touch.

Safety Information

15

Series FEC Environmental Chamber Product Manual

Page 16

Installation

The FGW900 High-T emperature Furnace is usually provided for the customer as

an accessory of a main machine, and MTS service staff installs the accessory

following defined steps. If it was purchased as a replacement or an additional

item, install it following the steps described in this section.

Installation Overview The following is an overview of furnace installation tasks:

1. Mount the furnace on the load frame.

2. Connect all electrical cables and jumpers.

3. Install the extensometer.

The extensometer, if used, is mounted independently and its extension rods

extend into the furnace through an opening filed in the front of the furnace.

Mounting

Considerations

Consider the following when mounting the furnace in the load frame:

1. When mounting ensure the specimen rod axis is in coincidence with the

furnace hearth axis.

2. When mounting ensure the vertical center of the specimen is in coincidence

with the vertical center of the high-temperature furnace.

FGW900 High-temperature Furnace Product Manual Installation

16

Page 17

High temperature furnace body installation

Bracket

Axis of Rotation

High temperature furnace body installation

Furnace body installation steps:

1. Unplug the furnace rotation axis from the hinge assembly of the furnace

2. Put the furnace onto the bracket

3. Align the high-temperature furnace hinge holes with the bracket mounting

holes;

4. Downwards insert the rotation axis , connect the high temperature furnace

with the high-temperature bracket, as shown below:

5. Furnace door switch installation

As the door switch has been adjusted in the right position in the vendor's plant,

users are not allowed to arbitrarily adjust the position when installing the furnace

for the first time. If need to replace the switch, you need follow the below steps:

FGW900 High-temperature Furnace Product Manual Installation

17

Page 18

Pressing Block

Screw

Tou c h A r m

Touch Base

Screw

Door Switch

Backing Plate

Door Switch Base

High temperature furnace body installation

5.1 Assemble the contact block and limit switch separately based on the

following figure shows:

FGW900 High-temperature Furnace Product Manual Installation

18

Page 19

High temperature furnace body installation

Furnace Bottom

Door Switch Assembly

Touch Assembly

c. Lock the door

switch assembly

four screw.

a. First ,lock touch

assembly.

b. Moving door switch

assembly so that the door

switch is closed, then moving

forward with 0.5mm.

5.2 According to the following figure shows, assemble the contact block whole

piece and limit switch whole piece to the furnace bottom front position.

5.3 Use 2 Metric M4X10 socket head cap screws to lock the contact assembly

piece, and then move the door switch assembly piece to make the door

switch closed, after that, mover forward another 0.5mm to lock the four

screws in the door switch assembly piece.

FGW900 High-temperature Furnace Product Manual Installation

19

Page 20

High-Temperature Furnace Cable Connections

High-Temperature Furnace Cable Connections

The connection between the high-temperature furnace and the temperature

controller is shown as below:

FGW900 High-temperature Furnace Product Manual Installation

20

Page 21

Connection steps: 1. Connect the thermocouple wire

To Furnace Body

Aaccording to the label sequence of J8, J9, and J10, insert thermocouple into the

upper, middle, lower jacks of the high temperature furnace side wall and tighten

the fixing screws. Insert the cable that is carried by the thermocouple into the

thermocouple outlet on the rear panel of the temperature controller.

High-Temperature Furnace Cable Connections

2. Connect the door switch wire

Insert one end of switch lead with plug into J7 jack of the temperature controller,

then connect the other end to the limit switch contact on the furnace bottom.

When installing, the furnace door switch lead has been connected together with

the limit switch. Only need to insert the other end to J7 of the temperature

controller.

3. Connect the output power cable between the furnace and the temperature

controller.

There are two power cables that connect the furnace and the temperature

controller. One is OUTPUTL, the other is OUTPUT N. The two cables have

already been connected together on the furnace. When installing, simply need to

follow the labels to insert one end with plug into the corresponding sockets on

the rear panel of the temperature controller and then tighten the fastens.

Note Do not insert or unplug this connectors group in the heating condition to

avoid personal electric shock accidents.

FGW900 High-temperature Furnace Product Manual Installation

21

Page 22

High-Temperature Furnace Cable Connections

Lock Fastener

Insert Socket

4. Connect E-STOP to the frame

When connecting insert one end of E-STOP cable with E-STOP IN label into ESTOP IN socket in the rear panel of the temperature controller , then put the other

end into E-STOP jack J14 on the frame controller. More detailed information

about E-STOP, see related contents in the MTS load frame manual.

5. Connect the communication cable to the computer

There is a reserved port J6 on the temperature controller of the furnace. When

needs to connect the computer and the temperature controller, a MTS

communication cable is required. It is through a 485 to use serial converter to

achieve the connection.

FGW900 High-temperature Furnace Product Manual Installation

22

Page 23

Temperature Controller Box

Serial

Converter

Computer

Communication cable for connection

High-Temperature Furnace Cable Connections

FGW900 High-temperature Furnace Product Manual Installation

23

Page 24

High-Temperature Furnace Cable Connections

Connected to the Customer Electrical Box and Disconnect

Connecting the Main

Power

The input voltage of the MTS FGW900 high temperature Furnace is single phase

200-240 V, 50/60 Hz. Use the cable that is provide for power input, and connect

to the customer electrical box and disconnect.

Note Local electrical codes supercede any information found here. Electrical

connections must be made by qualified personnel and is their

responsibility for using the proper power disconnect that conforms to

local codes and regulations when connecting the machine to the building

main power.

Electrical disconnect The customer is responsible for providing an electrical power disconnect that is

easy to operate and easy to reach. It must also meet IEC 60947-1 and IEC 609473 standards. Recommended circuit breaks would be ones that are of the thermal

magnetic type with characteristics suitable for large inductive loads(D-type trip

characteristic). If fuses are used it is recommended that they are of the time delay

type with dual elements. These recommendations should be followed to avoid

nuisance tripping.

FGW900 High-temperature Furnace Product Manual Installation

24

Page 25

Operation

CAUTION

Contents Operation of High Temperature Furnace 26

This section provides typical operating instructions for the high-temperature

furnace along with safety requirements. For more details about the software and

the Eurotherm temperature controller, see the software operation manual and the

Eurotherm temperature controller manual.

Operation of Temperature Controller 28

Abrasion of insulation inserts produces airborne dust.

Airborne dust from the insulation can irritate the eyes, lungs, and skin.

Use eye protection (goggles), gloves, and a high efficiency respirator if it is

necessary to work with insulating materials.

FGW900 High-temperature Furnace Product Manual Operation

25

Page 26

Operation of High Temperature Furnace

Furnace Handle

Extensometer Channel

Furnace Lock

Thermocouple Hole

Operation of High Temperature Furnace

Before starting test,you need assemble high temperature grip, open high

temperature furnace and revolve it into test space, assemble high temperature

grip into furnace body and seal pull rod hole according to requirement.

The high temperature furnace belongs to split flange high temperature furnace, of

which opening/closing is realized via lock on external wall of case shell.

The bottom of the high temperature furnace is equipped with a limit protection

switch, when the high temperature furnace is opened, this limit protection switch

will cut off the heating power, and can not self-recovery, only when to again

press the ENABLE button can be connected to the heating circuit once the door

is closed again.

If you use a high-temperature extensometer (supplied separately), its extension

guide rod is inserted into the furnace via the slot for the extensometer in front of

the furnace and contacts the testing sample. For information about the installation

and usage of the high-temperature extensometer, see the high-temperature

extensometer user manual.

FGW900 High-temperature Furnace Product Manual Operation

26

Page 27

Operation of High Temperature Furnace

WARNING

WARNING

WARNING

WARNING

Improper use can shorten the life of heater elements and insulation components.

Do not open the high-temperature furnace while it is hot or operating. Allow

sufficient time for the furnace to cool before opening the furnace. Rapid cooling

reduces heating element life.

Do not use this furnace to heat materials that pose hazards of explosion,

implosion, or the release of toxic or flammable gases

Explosions in the furnace can cause death or serious injury.

Do not operate the furnace near or above flammable materials. Allow sufficient

time for the test materials to cool before handling them.

Materials heated in the furnace are hot and can ignite flammable materials or

cause serious burns.

Do not operate the furnace near or above flammable materials. Allow sufficient

time for the test materials to cool before handling them.

Do not use the metal shell of the thermocouple when replacing the thermocouple.

Six groups of 230V AC heating wires were buried in furnace inner wall; when

thermocouple pass through the heating wires, the mental shell of thermocouple

may be charged, resulting in equipment damage or electric shock injury.

Do not use the metal shell of the thermocouple; you should use a porcelain jacket

tube thermocouple.

FGW900 High-temperature Furnace Product Manual Operation

27

Page 28

Operation of Temperature Controller

The temperature controlling system of high temperature furnace allows user to

connect it with the computer and set software parameters.

The function of the

switch and interface

Operation of Temperature Controller

.

FUNCTION DESCRIPTION

Starts the heating

Disables (stops) the heating

POWER: Power switch of the temperature controller.

COMM.: Communication interface. Furnace connects with the computer via this

interface. The required temperature and parameters can be set for a test via this

interface. Temperature information can be read through software in real time.

FGW900 High-temperature Furnace Product Manual Operation

28

Page 29

Operation of Temperature Controller

The interface use 9 pins connectors and three of them are used. Pin assignments

are as follows:

P

IN SIGNAL

1 No Contact

2 COMM A(+)

3 COMM B(-)

4 Communication GND

5 No Contact

6 No Contact

7 No Contact

8 No Contact

9 No Contact

E-STOP: The J1 connector should be connected to either J14 of the Frame

Controller or J2 of another Accessory with an Emergency Stop board.

The J2 connector will either have a jumper plug or be connected to J1 of another

Accessory with an Emergency Stop board.

J1 E-STOP pin assignments are as follows:

PIN SIGNAL

1 ESTOP3B2 No Contact

3 No Contact

4 ESTOP_OUT_MONTION+

5ESTOPB_IN+

6 ESTOP3A7ESTOPB_IN8ESTOPA_IN+

9 ESTOP3B+

10 ESTOP_OUT_MONTION11 No Contact

12 No Contact

13 ESTOPA_IN14 ESTOP3A+

15 No Contact

FGW900 High-temperature Furnace Product Manual Operation

29

Page 30

J2 E-STOP pin assignments are as follows:

P

IN SIGNAL

1 ESTOPB_OUT2 No Contact

3 ESTOP_OUT_MONTION4 ESTOP_OUT_MONTION+

5 ESTOP3B+

6 ESTOPA_OUT7 ESTOP3B8 ESTOP3A+

9 ESTOPB_OUT+

10 No Contact

11 No Contact

Operation of Temperature Controller

12 No Contact

13 ESTOP3A14 ESTOP_OUT+

15 No Contact

J4 pin assignments are as follows:

PIN SIGNAL

1 Upper heating L

2 Middle heating L

3 Lower heating L

4 GND

5 No Contact

6 No Contact

High temperature furnace heating wire N (OUTPUT N): the heating wire of hightemperature furnace temperature controller N connects the plug-in components.

The socket connects the heating wire on the furnace of N-line side.

J5 pin assignments are as follows:

PIN SIGNAL

1 No Contact

2 No Contact

FGW900 High-temperature Furnace Product Manual Operation

30

Page 31

Operation of Temperature Controller

PIN SIGNAL

3 GND

4 Upper heating N

5 Middle heating N

6 Lower heating N

The thermcouples interface (THERMCOUPLE)The three thermocouples on the

furnace are connected to the socket.J8, J9, J10 plug into the upper, middle and

lower segment of the thermocouple.

Furnace door switch: When the door is open, cut off the limit switch that's

connected to the heating power on the furnace.

This interface is a 9-pin connector, the pin function are as follows:

PIN SIGNAL

1 No Contact

2 Connected to the 2408 AC Pin

3 Connected to the E-STOP Pin ES1

4 No Contact

5 No Contact

6 No Contact

7 No Contact

8 No Contact

9 No Contact

FGW900 High-temperature Furnace Product Manual Operation

31

Page 32

Operation of Temperature Controller

Heating Output L

E-STOP

Heating Output N

Power Switch

Communication Interface

Door Switch Interface

Thermocouple Interface

Power Input

Temperature

Controller Common

Functions

The Furnace uses a Eurotherm2408 as temperature controller. The following

describes the operation of manual settings and some of its methods and

procedures. For details relating to setting test temperature and various control

parameters, refer to the attached "<<Models2404/2408 PID Controllers

Installation and Operation handbook>>". For setting test temperature and control

parameters via software, refer to the attached software application manual.

1. Setting test temperature

Press or key directly to adjust the temperature

FGW900 High-temperature Furnace Product Manual Operation

32

Page 33

Operation of Temperature Controller

The measured temperature

Set temperature

Increase and decrease key,

is used to set the

temperature and ginseng

2. Setting PID Control Parameters:

PID control parameters are the key parameters to control the temperature.

Generally, different temperatures require different PID parameters. When setting

the temperature, refer to the corresponding information to enter the correct

parameters. Based on parameters tables given in the Eurotherm manual to set

three parameters, Pb (P parameter), ti (I parameter), and td (D parameter). The

following flow chart briefly illustrates the meth ods to set the three param e ters

(PID).

FGW900 High-temperature Furnace Product Manual Operation

33

Page 34

Routine Maintenance

WARNING

This section provides information regarding service of the high-temperature

furnace.

Routine Maintenance Overview Checklist

Recommended Service

Routine Maintenance

CALENDAR TIME USING 8 HOURS RUNNING TIME RATE

PER DAY

Running time-hours 8 40 2000

Clean the furnace inside/furnace surface

area

Check the door swith and E-STOP X

Check the cable connection X

Check all the buttons function X

System Inspection

Check the cable connection MTS

System Cherks

Check E-STOP MTS

Check the door switch MTS

The surface of the furnace can become extremely hot.

DAILY WEEKLY ANNUALLY

X

Touching the furnace before it has cooled can severly burn skin.

Allow sufficient time for the furnace to cool off before servicing the furnace.

FGW900 High-temperature Furnace Product Manual Routine Maintenance

34

Page 35

Routine Maintenance

• When using the furnace, try not to make contact with the inner cavity of the

furnace during the process of installing a test sample to avoid causing

damage to the furnace cavity.

• Do not open the furnace immediately after a test is completed to avoid

serious injury and prevent damage to the furnace cavity.

• Clean the furnace cavity in a timely manner with a soft brush once a test is

completed in order to prolong the service life of the furnace.

• If the furnace is not used for a long period, preheat the furnace before using

it again. The preheating method is as follows:

1. Increase the temperature to 200°C and maintain that temperature for a

least four hours.

2. Increase the temperature to 400°C and maintain that temperature for a

least four hours.

3. Increase the temperature to 600°C and maintain that temperature for a

least four hours.

Treatment of general fault

F

AULT CONDITION REASON SOLUTION

SV window flashes

and displays “S.br”

Heatup speed is

slower than original

speed

The Temperature

controller can not start

the furnace

Temperature fails to

steady at setting

temperature

The input measuring signal

exceeds the measuring

range

The parameter are not

properly defined

The Furnace is not closed

properly or there is

something wrong with the

Furnace door switch or cable

Control parameter is

imperfect or lost

1. Check whether the

specifications of the sensor are

properly defined

2. Check whether the signal

input is broken

Check whether the parameters

of the temperature controller are

properly defined

1.Check the furnace of see if it is

closed properly

2.Check the door switch cable

and the connections to the

furnace door switch and the back

of the temperature controller

Start self-adjustment to find out

proper control parameter

FGW900 High-temperature Furnace Product Manual Routine Maintenance

35

Page 36

Declaration of Conformity

FGW900 High-temperature Furnace Product Manual Declaration of Conformity

36

Page 37

Declaration of Conformity

37

FGW900 High-temperature Furnace Product Manual

Page 38

m

MTS Systems Corporation

http://www.mts.com/en/Global/index.asp

ISO 9001 Certified QMS

Loading...

Loading...