Page 1

Series FEC Environmental Chamber

Manual Title

Additional Information

Product Manual

be certain.

100-231-448 A

Page 2

Copyright information © 2011 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark and MTS Criterion and MTS Insight are

trademarks of MTS Systems Corporation within the United States. These

trademarks may be protected in other countries.

Publication information

MANUAL PART NUMBER PUBLICATION DATE

100-231-448 A December 2011

2

Series FEC Environmental Chamber Product Manual

Page 3

Contents

Preface 5

Before You Begin 5

Conventions 6

Documentation Conventions 6

Technical Support 9

How to Get Technical Support 9

Before You Contact MTS Service Representative 9

If You Contact MTS by Phone 10

Introduction 13

About This Manual 13

Inappropriate Use 13

Description 14

Specifications 16

Operating Condition Requirements 16

Model and Specifications 16

Safety Information 17

Safety 17

Hazard Placard Placement 17

Installation 19

Installing Bracket of Environmental Chamber 20

Installing Environmental Chamber 22

Adjusting Environmental Chamber Position 24

Connecting Environmental Chamber Mains Power 26

Connecting Liquid Nitrogen to the Chamber 27

Prerequisites 27

Connecting an LN2 supply tank to the chamber: 27

Series FEC Environmental Chamber Product Manual Contents

3

Page 4

Operation 29

Installing Pull Rods and Grips 30

Operation of Temperature Controller 31

Temperature Controller Common Functions 35

Test Case 40

Routine Maintenance 43

Routine Maintenance Overview Checklist 43

Troubleshooting 44

Declaration of Conformity 45

4

Contents

Series FEC Environmental Chamber Product Manual

Page 5

Before You Begin

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the safety

information provided with your system. Improper installation, operation, or

maintenance can result in hazardous conditions that can cause severe personal

injury or death, or damage to your equipment and specimen. Again, read and

understand the safety information provided with your system before you

continue. It is very important that you remain aware of hazards that apply to your

system.

Other MTS manuals In addition to this manual, you may receive additional manuals in paper or

electronic form.

Manuals located on the product information CD will contain information that

pertains to your test system, such as:

• Hydraulic and/or mechanical accessory manuals

• Assembly drawings

• Parts lists

• Operation instructions

• Preventive maintenance tasks

Controller and application software manuals are typically included on the

software CD distribution disc(s).

Series FEC Environmental Chamber Product Manual Preface

5

Page 6

Conventions

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

DANGER

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

WARNING

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

CAUTION

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

not necessarily represent your actual system configuration, test application, or

software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Preface

6

Series FEC Environmental Chamber Product Manual

Page 7

Documentation Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Series FEC Environmental Chamber Product Manual Preface

7

Page 8

Page 9

Technical Support

How to Get Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes software, look for

online help and README files that contain additional product inform ation.

If you cannot find answers to your technical questions from these sources, you

can use the Internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact Technical Support in

one of the following ways.

Outside the U.S. For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Before You Contact MTS Service Representative

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your contact

number and system

number

The contact number contains your company number and identifies your

equipment type (such as material testing or simulation). The number is typically

written on a label on your equipment before the system leaves MTS. If you do

not know your MTS contact number, contact your sales engineer.

When you have more than one MTS system, the system model number and series

number identifies your system. You can find your these number in your order

paperwork or directly on your equipment.

Identify the problem Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Series FEC Environmental Chamber Product Manual Technical Support

9

Page 10

If You Contact MTS by Phone

Know relevant

computer information

Know relevant

software information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and (if

available) software patch number. This information can typically be found

in the About selection in the Help menu.

• The names of other applications on your computer, such as:

– Anti-virus software

– Screen savers

– Keyboard enhancers

– Print spoolers

– Messaging applications

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical

support specialist. The agent asks you for your:

• Contact number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue

will be assigned a unique notification number.

Technical Support

10

Series FEC Environmental Chamber Product Manual

Page 11

If You Contact MTS by Phone

Identify system type To enable the Call Center agent to connect you with the most qualified technical

support specialist available, identify your system as one of the following types:

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

troubleshoot

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance for your

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

problem or request. If you have questions about the status of your problem or

have additional information to report, please contact Technical Support again and

provide your original notification number.

Series FEC Environmental Chamber Product Manual Technical Support

11

Page 12

Page 13

Introduction

About This Manual

Purpose The purpose of this manual is to help you understand your environmental

Inappropriate Use

Contents Description 14

About This Manual

chamber, its capabilities, and operating requirements. This manual provides

information for MTS Series FEC Environmental Chamber. Read each section

carefully and refer to the manual whenever you need assistance.

Before you attempt to use the MTS Series FEC Environmental Chamber, read

and understand this manual. Improper installation or operation of this product

can result in hazardous conditions that can cause severe personal injury or death,

and damage your equipment and specimen.

Specifications 16

Series FEC Environmental Chamber Product Manual Introduction

13

Page 14

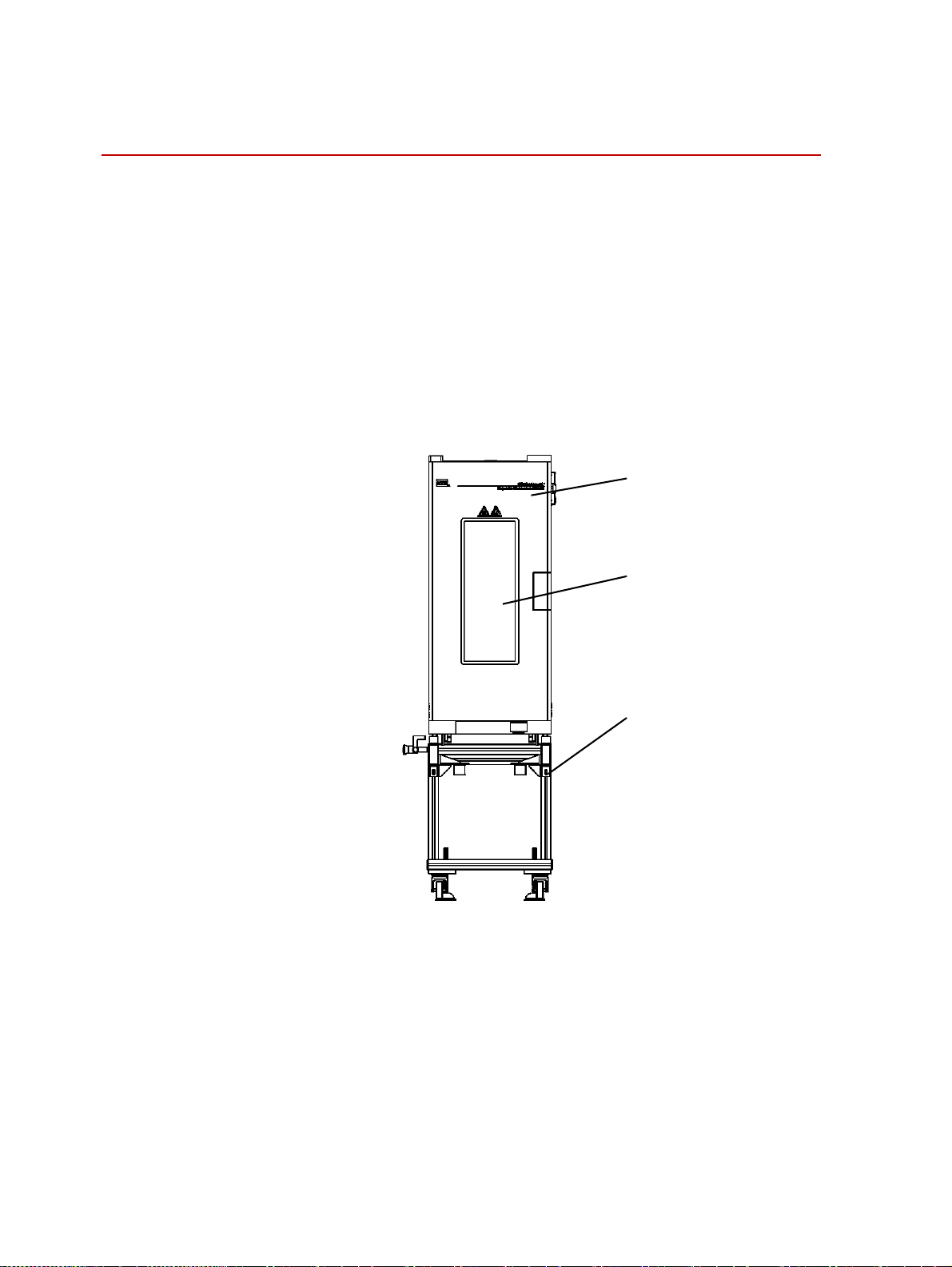

Description

Description

Series FEC environmental chambers are used for testing the mechanical

properties of metal and nonmetal materials (for example: magnesium alloy,

plastic, and rubber.) under high and low temperature conditions. Environmental

chambers can be used with Electromechanical universal testing machine.

The MTS Series FEC Environmental Chambers let you test materials and

components within a range of temperatures, from

Cooling is accomplished with the use of liquid nitrogen introduced to the

chamber. Heating is accomplished with electrical heating elements. An electric

fan and baffle diffuse the heat for uniform temperatures. A customer-specified

temperature controller (Eurotherm) is mounted in the electrical box.

-70 ~ 350°C (- 94 ~ 662°F).

Cabinet

Observation Window

Bracket

14

Introduction

Series FEC Environmental Chamber Product Manual

Page 15

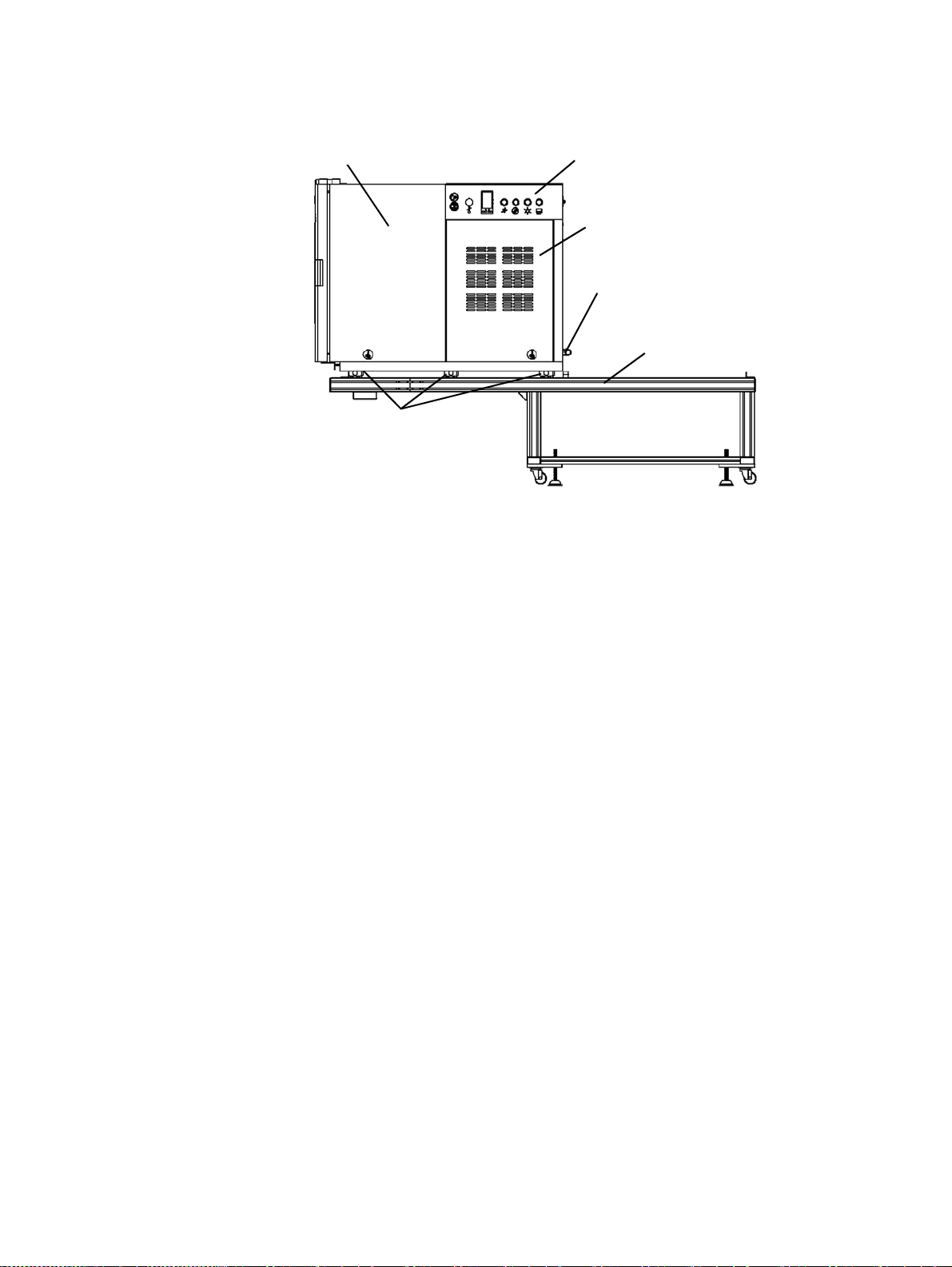

Description

Test Space

Movable Wheels

Electric Controls

Motor, Heating and

Refrigeration pipe

Liquid Nitrogen Interface

Bracket

Cabinet The surface of the cabinet is made of painted mild-steel plate, the inner wall of

the cabinet is made of stainless steel making it temperature-resistant. The front

side of the cabinet has a door with an observation window, which you can

observe tests under illumination from the lamp that is installed on the inner wall

of the cabinet. Cooling is accomplished with the use of liquid nitrogen introduced

to the chamber. Heating is accomplished with one electrical heating element. An

electric fan and baffle diffuse the heat for uniform temperatures.

Temperature control

system

Bracket for

environmental

chamber

The temperature controller unit is integrated into the backside of the cabinet,

which allows you to perform controller adjustment easily. The temperature

control system uses a Eurotherm high-precision temperature controller, and a

solid state relay as an executing element.

The bracket can be dismantled or assembled easily.You can move the chamber

back from the test zone of testing machine via rollers on the bottom of the

cabinet.

Note FEC serial chamber can only be used on MTS frames. When you want to

use it for other purpose, you should be aware of the chamber overturn

risk due to external force.

Series FEC Environmental Chamber Product Manual Introduction

15

Page 16

Specifications

Specifications

The section provides operating condition requirements and detailed specification

of the environmental chambers.

Operating Condition Requirements

Use the environmental chambers under the following conditions:

PARAMETER SPECIFICATION

Condition For indoor application only

Ambient temperature of cabinet

Relative humidity 5-85%, noncondensing

Maximum altitude 2000 m (6562 ft)

Voltage

Frequency 50 Hz / 60 Hz

Current 15 Amps

5 ~ 40

°C (41 ~ 104°F)

Single-phase AC 200 ~ 240 V

Model and Specifications

MODEL FEC1200 FEC1300

Scope of application C43.104, C43.104E, C43.304,

C43.304E, C43.504, C43.504E,

C44.104, C44.104E, C44.304,

C44.304E

Temperature scope

External dimension (W × D × H) 360 × 1060 × 795 mm

Dimension of test space

(W × D × H)

-70 ~ 350

(14.2 × 41.7 × 31.3 in)

200 × 200 × 600 mm

(7.9 × 9.4 × 23.6 in)

°C (- 94 ~ 662°F) -70 ~ 350°C (- 94 ~ 662°F)

C45.504, C45.105

C45.504E, C45.105E

460 × 1060 × 800 mm

(18.1 × 41.7× 31.5 in)

300 × 200 × 600 mm

(11.8 × 9.4× 23.6 in)

± 10%

Temperature fluctuation

Temperature deviation

Temperature uniformity

Heatup time

Cooling time

Heatup time (room

temperature~350

Weight 105 kg 120 kg

Introduction

16

°C)

≤ ±1

°C ≤ ±1°C

≤ ±2

°C ≤ ±2°C

≤ ±2

°C ≤ ±2°C

≥ 5

°C/min ≥ 5°C/min

≥ 2

°C/min ≥ 2°C/min

≤ 60 min ≤ 60 min

Series FEC Environmental Chamber Product Manual

Page 17

Safety Information

Safety

Safety

Stay clear of moving

equipment/avoid crush

points

Know the causes of

unexpected crosshead

motions

Do not use RF

transmitters

Stay clear of mechanical linkages, connecting cables, and hoses that move

because you can get pinched, crushed, tangled, or dragged along with the

equipment. High forces generated by the system can pinch, cut, or crush anything

in the path of the equipment and cause serious injury. Stay clear of any potential

crush points. Most test systems can produce sudden, high-force motion. Never

assume that your reactions are fast enough to allow you to escape injury when a

system fails.

The high force and velocity capabilities of MTS systems can be destructive and

dangerous (especially if crosshead motion is unexpected). The most likely causes

of unexpected crosshead response are operator error and equipment failure due to

damage or abuse (such as broken, cut, or crushed cables and hoses; shorted wires;

overstressed feedback devices; and damaged components within the control

loop). Eliminate any condition that could cause unexpected crosshead motion.

Keep radio frequency (RF) transmitters away from the workstation computers,

remote terminals, and electronics consoles. Intense RF fields can cause erratic

operation of the more sensitive circuits in the system.

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following labels are typically located on the chamber.

L

ABEL DESCRIPTION

Environmental Chamber ID

label.

Series FEC Environmental Chamber Product Manual Safety Information

17

Page 18

Hazard Placard Placement

LABEL DESCRIPTION

Lift the machine with straps.

Do not start, operate, or service

machine until you read and

understand the operator’s

manual.

Failure to do so could result in

serious injury.

There are no customerserviceable parts on the MTS

Criterion electromechanical

frames.

Burn hazard.

Hot surface.

Do not touch.

Allow to cool before servicing.

Hot surface hazard.

Do not touch.

Safety Information

18

Series FEC Environmental Chamber Product Manual

Page 19

Installation

Contents Installing Bracket of Environmental Chamber 20

Installing Environmental Chamber 22

Adjusting Environmental Chamber Position 24

Connecting Environmental Chamber Mains Power 26

Connecting Liquid Nitrogen to the Chamber 27

Series FEC Environmental Chamber Product Manual Installation

19

Page 20

Installing Bracket of Environmental Chamber

Installing Bracket of Environmental Chamber

Environmental chambers are installed onto different brackets that are composed

extruded aluminum and consist of front guide bracket and rear guide bracket.

During high and low temperature test, front and rear guide bracket are connected

and fixed onto testing machine.

Back Door of Enclosure

Front Door of

Enclosure

Crosshead

Environmental

Chamber

Front Guide

Bracket

Rear Guide

Bracket

20

Installation

Series FEC Environmental Chamber Product Manual

Page 21

Installing Bracket of Environmental Chamber

1. Install the front guide bracket to the accessory mounting locations on the

testing machine. Fix bracket onto the testing machine by adapter block, do

not tighten until alignment in next section is finished.

Fix bracket onto

the testing

machine by

adapter block.

Connect front and rear guide

with the guide connector.

2. Connect the front and rear guide bracket. Push the rear guide bracket

forward and connect it with the front guide bracket using connector.

Front Guide Bracket

Connect front and

rear guide with the

guide connector.

Series FEC Environmental Chamber Product Manual Installation

21

Page 22

Installing Environmental Chamber

Installing Environmental Chamber

Using a crane For safe, quick, and accurate installation, plan to use crane to lift Chamber , MTS

recommends using professional riggers experienced in moving heavy equipment.

Before you begin Before lifting the Chamber, ensure that:

• There are no loose accessories on the Chamber.

• There is adequate ceiling clearance to allow the Chamber to be lifted onto

bracket, including clearance for the crane.

• Your equipment operators have the appropriate licenses and have complied

with your local safety standards (for example, the appropriate training

required by OSHA in the U.S.).

Equipment The following items are required by the customer:

• A crane with a load rating that is double the Chamber’s gross weight.

• T wo lifting straps, each with a load rating that is double the Chamber’s gross

weight.

Procedure To lift the Chamber onto the bracket:

1. Remove all packaging material fromChamber and ensure that the Chamber

is not attached to the shipping skid.

2. Attach the two lifting straps to the base of Chamber and secure them to the

crane hook.

The Chamber may overturn suddenly when lifting the Chamber.

An overturned Chamber can cause injury or death to anyone in the

immediate area.

Ensure that all persons in the immediate area are standing away from the

Chamber during lifting.

3. Slowly lift the Chamber until it is lifted to the height which is higher than

that of the bracket.

4. Slowly lower the Chamber to the bracket so that it is standing on bracket

and can glide safely.

5. Remove the straps from Chamber.

WARNING

22

Installation

Series FEC Environmental Chamber Product Manual

Page 23

The chamber can now be positioned into its operating location and then installed

by an MTS service representative.

Oriented Stoppers

Installing Environmental Chamber

Environmental

Chamber

Lift environmental

chamber and put

onto matching

bracket.

Installation of Environmental Chamber

Bracket for Environmental

Chamber

Series FEC Environmental Chamber Product Manual Installation

23

Page 24

Adjusting Environmental Chamber Position

Adjusting Environmental Chamber Position

1. It is necessary to adjust the position of environmental chamber via upper

and lower pull rods on site.

Before fixing bracket and environmental chamber, slide the chamber from

front to back on the bracket, and adjust the position of the bracket from left

to right on testing machine to make the pull rods align to the center of the

rod hole of environmental chamber.

Rod Hole

Adjust position

of bracket.

Oriented Stops

Adjust position

of cabinet.

2. After the pull rods align to the center of pull rod hole of environmental

chamber, fix the bracket to the testing machine, and fix the stoppers to the

front bracket.

Fix the stoppers to locate the

front stopping point of

environmental chamber.

Align rod to center

of rod hole.

24

Installation

Series FEC Environmental Chamber Product Manual

Page 25

Adjusting Environmental Chamber Position

3. In order to prevent the danger of Chamber overturn, FEC serials chamber

use four anti-overturn blocks to connect the chamber body and the rail

bracket. Please fix the four anti-overturn blocks on the left and right side

wheel of the chamber after the chamber installation and adjustments are

done.

Door Switch

Anti-overturn Block

4. To ensure the safety of the chamber operation, a door switch is installed on

the bottom of it. When the door is open, the heating or cooling function will

be cut off and the stirring fan will stop working at the same time. After you

closed the door, the stirring fan will automatically run again, but the heating

or cooling function will not automatically go back to normal use until you

press "Enable" button again. After the chamber installation is done, please

make sure the door switch function works properly.

Series FEC Environmental Chamber Product Manual Installation

25

Page 26

Connecting Environmental Chamber Mains Power

Connecting Environmental Chamber Mains Power

Power connection For MTS series FEC chamber use the 3-wires cable that is provide for power

input, and connect to the customer electrical box and disconnect.

Note Local electrical codes supersede any information found here:

Voltage Single-phase AC 200-240

Current 15Amps

Frequency 50 Hz/60 Hz

Note Electrical connections must be made by qualified personnel and is their

responsibility for using the proper power disconnect that conforms to

local codes and regulations when connecting the machine to the building

main power.

Electrical disconnect The customer is responsible for providing an electrical power disconnect that is

easy to operate and easy to reach. It must also meet IEC 60947-1 and IEC 609473 standards. Recommended circuit breaks would be ones that are of the thermal

magnetic type with characteristics suitable for large inductive loads (D-type trip

characteristic). If fuses are used it is recommended that they are of the time delay

type with dual elements. These recommendations should be followed to avoid

nuisance tripping.

LN2 Input

Power Line

26

Installation

Series FEC Environmental Chamber Product Manual

Page 27

Connecting Liquid Nitrogen to the Chamber

Connecting Liquid Nitrogen to the Chamber

Prerequisites

• Review lab safety procedures and review any safety data furnished by the

LN2 supplier.

• Ensure that the area around the chamber is well ventilated.

WARNING

The environmental chamber is not rated for combustible liquids.

When heated, flammable and combustible liquids can explode an d cause

personal injury and equipment damage.

Do not use flammable or combustible liquids in the environmental chamber.

Always operate the chamber with the door closed.Do not override any safety

features.Do not modify the chamber without consulting MTS Systems

Corporation.

Connecting an LN2 supply tank to the chamber:

LN2 Input

Connect to liquid

nitrogen tank (Thread

size M20x1.5).

Power Line

Series FEC Environmental Chamber Product Manual Installation

27

Page 28

1. Connect a supply of clean, water-free liquid nitrogen to the coolant input

connector.

The cooling gas supply tank should be pressurized to 0.15 MPa (22 psi) for

LN2 cooling. If the supply tank pressure is greater than the recommended

pressure, install a pressure regulator between the supply tank and the

coolant solenoid.

WARNING

Use of LN2 gas in the chamber will result in a lack of oxygen in and around

the chamber.

A lack of oxygen can cause dizziness or blackouts.

Ensure that the area around the chamber is well ventilated.

2. Turn the liquid withdrawal valve on the supply tank on before beginning a

test.

Note When cooling is not being used, the liquid withdrawal valve on the supply

tank should be kept closed to prevent leakage of the coolant.

WARNING

Check the operating temperature range of each component in the

environmental chamber. All components must be able to operate at the

temperature of the test.

Damage to equipment can occur.

Do not set a testing temperature that is higher or lower than the temperature

rating of any component (grips, fixtures, and so forth.) inside the chamber.

Page 29

Operation

Contents Installing Pull Rods and Grips 30

This section describes routine operation of environmental chamber. For details

relating to software and temperature controllers, refer to the corresponding

software manual and temperature controllers manuals.

Only qualified and trained personnel should operate environmental chambers.

Operation of Temperature Controller 31

Temperature Controller Common Functions 35

Test Case 40

WARNING

The environmental chamber is not rated for combustible liquids.

When heated, flammable and combustible liquids can explode an d cause

personal injury and equipment damage.

Do not use flammable or combustible liquids in the environmental chamber.

Always operate the chamber with the door closed.Do not override any safety

features.Do not modify the chamber without consulting MTS Systems

Corporation.

Series FEC Environmental Chamber Product Manual Operation

29

Page 30

Installing Pull Rods and Grips

Installing Pull Rods and Grips

1. Remove the U-plugs in the top and bottom walls of the chamber.

2. Mount upper pull rod to the crosshead, and lower pull rod to the base of

testing machine.

3. Mount upper grip to upper rod, and lower grip to lower pull rod.

4. Push the environmental chamber into position so that the pull rods are

centered with respect to the access ports of the chamber.

5. Install the specimen and all of its instrumentation.

6. Reinstall the U-plugs in the chamber removed in step 1.

7. Close the front door, and you are ready to run the environmental chamber.

Upper U-plug

Lower U-plug

Remove the U-plugs,

push environmental

chamber into position.

Align rod to center

of rod hole after

assembled cabinet

completely.

30

Operation

Reinstall U-plugs

Series FEC Environmental Chamber Product Manual

Page 31

Operation of Temperature Controller

The temperature controller is located at the rear of the cabinet, which allows you

to connect it with the computer and set parameters via the software easily.

Inspect if cables are connected correctly before turning on power.

Set the test temperature in the allowable temperature range without exceeding the

minimum or maximum temperature.

Operation of Temperature Controller

FUNCTION DESCRIPTION

Alarm light-when the temperature exceeds the

maximum temperature of chamber, the light lights.

Starts the heating or cooling.

Disables (stops) the heating or cooling.

Control switch of the illuminating lamp in the

cabinet.

A switch used for removing frost on the glass

observation window during a low-temperature test.

Series FEC Environmental Chamber Product Manual Operation

31

Page 32

Operation of Temperature Controller

POWER: Power switch of environmental chamber.

COMM.: Communication interface. Environmental chamber connects with the

computer via this interface. The required temperature and parameters

can be set for a test via this interface.Temperature information can be

read through software in real time. The interface use 9 pins connectors

and three of them are used. Pin assignments are as follows:

PIN SIGNAL

1 No Contact

2 COMM A+

3 COMM B-

4 GND

5 No Contact

6 No Contact

7 No Contact

8 No Contact

9 No Contact

32

Operation

Series FEC Environmental Chamber Product Manual

Page 33

Operation of Temperature Controller

E-STOP: The J1 connector should be connected to either J14 of the Frame

Controller or J2 of another Accessory with an Emergency Stop board.

The J2 connector will either have a jumper plug or be connected to J1

of another Accessory with an Emergency Stop board.

J1 E-STOP pin assignments are as follows:

P

IN SIGNAL

1 ESTOP3B-

2 No Contact

3 No Contact

4 ESTOP_OUT_MONITOR+

5 ESTOPB_IN+

6 ESTOP3A-

7 ESTOPB_IN-

8 ESTOPA_IN+

9 ESTOP3B+

10 ESTOP_OUT_MONITOR-

11 No Contact

12 No Contact

13 ESTOPA_IN-

14 ESTOP3A+

15 No Contact

Series FEC Environmental Chamber Product Manual Operation

33

Page 34

Operation of Temperature Controller

J2 E-STOP pin assignments are as follows:

IN SIGNAL

P

1 ESTOPB_OUT-

2 No Contact

3 ESTOP_OUT_MONITOR-

4 ESTOP_OUT_MONITOR+

5 ESTOP3B+

6 ESTOPA_OUT-

7 ESTOP3B-

8 ESTOP3A+

9 ESTOPB_OUT+

10 No Contact

11 No Contact

12 No Contact

13 ESTOP3A-

14 ESTOPA_OUT+

15 No Contact

34

Operation

Series FEC Environmental Chamber Product Manual

Page 35

Temperature Controller Common Functions

Temperature Controller Common Functions

The Environmental Chamber uses a Eurotherm2408 as temperature controller.

The following describes the operation of manual settings and some of its

methods and procedures.

For details relating to setting test temperature and various control parameters,

refer to"Eurotherm Manual". For setting test temperature and control parameters

via software, refer to the attached software application manual.

1. Setting test temperature:

Press or key directly to adjust the temperature

.

Temperature Indicating

Val ue

Temperature Setting

Val ue

Arrow keys are used for

setting temperature and

parameters.

2. Setting PID control parameters:

PID control parameters are the key parameters to control the temperature.

Generally, different temperatures require different PID parameters. When

setting the temperature, refer to the corresponding information to enter the

correct parameters. Based on parameters tables given in the Eurotherm

manual to set three parameters, Pb (P pa rameter ), ti ( I para meter), an d td (D

parameter). The following flow chart briefly illustrates the methods to set

the three parameters (PID).

Series FEC Environmental Chamber Product Manual Operation

35

Page 36

Temperature Controller Common Functions

20.0

350.0

Goto

FuLL

$IWHU )X// IODVKLQJ

SUHVV

20.0

350.0

3UHVV

WLPHV WLPHV

3UHVV

WLPHV

WR H[LW

FRQWLQXRXV

SUHVV

ACCS

LISt

codE

PASS

LISt

3UHVV

ZDLW

VHFRQGV

SUHVV

WR ILQG 3

codE

0

3UHVV WLPHV

codE

1

PbPId

30

SUHVV

WR ILQG ,

60

SUHVV

WR ILQG '

tI

360

20.0 td

350.0

3. Set heating and cooling parameters:

The temperature controller uses dual channels to control the temperature.

Channel 1 is the heating channel; channel 2 is the cooling channel. Relevant

parameters have been set at the factory; do not change the parameters. If

there are some abnormal phenomena, enter the following parameters to help

it return to normal state.

conF -insT -Act = rEu

conF -1A - Func = HEAt

conF -2A - Func = CooL

The following flow chart illustrates the method to set these parameters.

SUHVV

WR H[LW

Setting PID Parameters

36

Operation

Series FEC Environmental Chamber Product Manual

Page 37

Temperature Controller Common Functions

20.0

350.0

conF

$IWHU 3$66

SUHVV

20.0

350.0

SUHVV

WR $&&6

SUHVV

2

VHW FRQ)

WR H[LW

SUHVV SUHVV

WR ,QVW SDJH

ACCS

LISt

Goto

conF

InSt

ConF

SUHVV

VHW FRG(

SUVVV

LQWR FRQ)

WR ILQG $FW

codE

1

SUHVV

LQWR

*RWR SDJH

Goto

FuLL

Act

rEu

SUHVV

LQWR $ SDJH

2A

ConF

᤹

)XQF

Func

CooL

Set Heating and Cooling Parameters

When manually setting the environmental chamber to the heating state, the

following two parameters need to be set:

FuLL - oP - Op.Lo = 0.0

FuLL - oP - Op.HI = 80.0

SUHVV

LQWR $ SDJH

WR ILQG

SUHVV

LQWR (GLW

SDJH

Func

HEAt

EdIt

YES

SUHVV

WR ILQG )XQF

5HVWDUW

FRQWUROOHU

1A

ConF

20.0

350.0

Series FEC Environmental Chamber Product Manual Operation

37

Page 38

Temperature Controller Common Functions

Below is the chart flow.

20.0

350.0

Goto

SUHVV

WLPHV

SUHVV

FuLL

$IWHU )X// IODVKLQJ

SUHVV

20.0

350.0

WR H[LW

SUHVV

WR R3

ACCS

LISt

codE

PASS

oP oP. Lo

LISt

SUHVV

ZDLW

VHFRQGV

SUHVV

WR R3/R

codE

0

SUHVV

codE

1

0.0

SUHVV

WR R3+L

20.0

350.0

Set Heating Parameters

When manually setting the temperature chamber to the cooling state, the

following two parameters need to be set:

FuLL - oP - Op.Lo = -80.0

FuLL - oP - Op.HI = 0.0

Below is the chart flow.

SUHVV

WR ([LW

oP. HI

80.0

38

Operation

Series FEC Environmental Chamber Product Manual

Page 39

Temperature Controller Common Functions

20.0

350.0

Goto

SUHVV

WLPHV

SUHVV

FuLL

$IWHU )X// IODVKLQJ

WR H[LWSUHVV

20.0

350.0

SUHVV

WR R3

ACCS

LISt

codE

PASS

oP oP. Lo

LISt

SUHVV

ZDLW

VHFRQGV

SUHVV

WR R3/R

codE

0

SUHVV

codE

1

-80.0

SUHVV

WR R3+L

20.0

350.0

Set Cooling Parameters

SUHVV

WR ([LW

oP. HI

0.0

Series FEC Environmental Chamber Product Manual Operation

39

Page 40

Test Case

Do not expose skin to the inner side of the cabinet or the sample while installing

or uninstalling the sample because the temperature of the sample or inside of the

cabinet may be very hot or cold. Install/uninstall sample using proper tools, and

perform the operation strictly according to safe operating regulations of your

laboratory.

High temperature test

procedure

To perform a high temperature test:

1. Remove the U-plugs in the top and bottom walls of the chamber.

2. Mount upper pull rod to the crosshead, and lower pull rod to the base of

testing machine.

3. Mount upper grip to upper rod, and lower grip to lower pull rod.

4. Push the environmental chamber into the test space.

5. Install the specimen and all of its instrumentation.

6. Reinstall the U-plugs into the top and bottom walls of the chamber.

7. Close the front door.

8. Press the power switch to On positioin.

9. Confirm that the temperature controller apparatus is set to the heating state.

And set the test temperature and operating parameters corresponding to the

temperature point.

Set the temperature.

10. Press the“ENABLE” button to start the chamber heating process.

11. After achieving the setting temperature and hold appointed time at the

temperature, you can start the high-temperature test via test software.

12. Press the“DISABLE” button after you have finished testing the sample.

13. Open the chamber door. Allow the specimen to return to room temperature,

if possible.

Press this button to enable the chamber

Page 41

14. Remove the specimen from the grips following the instructions in the

appropriate grip manual.

Cooling test procedure To perform a cooling test:

1. Connect liquid nitrogen tank to the environmental chambers, and ensure no

leakage.

2. Remove the U-plugs in the top and bottom walls of the chamber.

3. Mount upper pull rod to the crosshead, and lower pull rod to the base of

testing machine.

4. Mount upper grip to upper rod, and lower grip to lower pull rod.

5. Push the environmental chamber into the test space.

6. Install the specimen and all of its instumentation.

7. Replace the U-plugs into the top and bottom walls of the chamber.

8. Close the front door.

9. Press the power switch to On positioin.

Test Case

10. Confirm that the temperature controller apparatus is set to cooling state.

And set the test temperature and operating parameters corresponding to the

temperature point.

11. Press the“ENABLE” button to start the chamber cooling process.

12. After achieving the setting temperature and hold appointed time at the

temperature, you can start the low-temperature test via test software.

13. Press the“DISABLE” button after you have finished testing the sample.

14. Open the chamber door. Allow the specimen to return to room temperature,

if possible.

15. Remove the specimen from the grips following the instructions in the

appropriate grip manual.

Series FEC Environmental Chamber Product Manual Operation

41

Page 42

Test Case

42

Operation

Series FEC Environmental Chamber Product Manual

Page 43

Routine Maintenance

Routine Maintenance Overview Checklist

Recommended Service

Routine Maintenance

CALENDAR TIME USING 8 HOURS RUNNING TIME

R

ATE PER DAY

RUNNING TIME-HOURS 8 40 2000

Clean the chamber inside/chamber surface area

Check the door limit and E-stop X

Check the cable connection X

Check all the buttons function X

System Inspection

Check the cable connection MTS

System Checks

Check E-stop MTS

Check door switch MTS

Check rail bracket level MTS

Check over-temperature alarm instrument

function

Lubrication

Stirring fan bearing MTS

DAILY WEEKLY ANNUALLY

*

X

MTS

* Denotes services performed by equipment operators. Most of these procedures involve visual checks

that should not interfere with testing system operation. These checks are also completed by trained

field service engineers on each Routine Maintenance visit.

Series FEC Environmental Chamber Product Manual Routine Maintenance

43

Page 44

• Do not open the chamber immediately after a test to prevent damage or

personal injury caused by high or low temperature.

• To extend the service life of an environmental chamber, eliminate water

vapor in the cabinet or other residue left in the chamber after test.

• Do not use corrosive organic solvents when cleaning chamber.

• During test or after test, do not use any kind of shelter to cover the chamber

so as to avoid the case that the heat or water vapor can not be diffused and

damage the chamber.

Troubleshooting

Troubleshooting

YMPTOMS REASON SOLUTION

S

Routine Maintenance

Set Value window flashes and

displays “S.br” .

T emperature increase speed is

slower than original speed

Temperature rises out of

control

Temperature fails to mains at

setting temperature

Measure signal input

exceeds range.

Parameter setting may be

incorrect.

parameter setting is

incorrect.

Control parameter is

imperfect or lost.

1. Inspect if specification setting of

sensor is correct.

2. Inspect if signal input is open circuit.

Inspect if setting of temperature control

parameter is correct.

Inspect if setting of temperature control

parameter is correct.

Start self-adjustment to find out proper

control parameter.

Series FEC Environmental Chamber Product Manual Routine Maintenance

44

Page 45

Declaration of Conformity

Series FEC Environmental Chamber Product Manual Declaration of Conformity

45

Page 46

Declaration of Conformity

46

Series FEC Environmental Chamber Product Manual

Page 47

Page 48

m

MTS Systems Corporation

http://www.mts.com/en/Global/index.asp

ISO 9001 Certified QMS

Loading...

Loading...