Page 1

MTS TestSuite

Fatigue Templates User Guide

100-256-292 D be certain.

Page 2

© 2013 MTS Systems Corporation. All rights reserved.

Trademark Information

MTS, FlexTest, RPC, and TestWare are registered trademarks and MTS Acumen, MTS TestSuite, Station

Builder, and Station Manager are trademarks of MTS Systems Corporation within the United States. These

trademarks may be protected in other countries. All other trademarks are the property of their respective

holders.

Proprietary Software

Software use and license is governed by MTS’s End User License Agreement which defines all rights

retained by MTS and granted to the End User. All Software is proprietary, confidential, and owned by MTS

Systems Corporation and cannot be copied, reproduced, disassembled, decompiled, reverse engineered,

or distributed without express written consent of MTS.

Software Verification and Validation

MTS software is developed using established quality practices in accordance with the requirements detailed

in the ISO 9001 standards. Because MTS-authored software is delivered in binary format, it is not user

accessible. This software will not change over time. Many releases are written to be backwards compatible,

creating another form of verification. The status and validity of MTS’s operating software is also checked

during system verification and routine calibration of MTS hardware. These controlled calibration processes

compare the final test results after statistical analysis against the predicted response of the calibration

standards. With these established methods, MTS assures its customers that MTS products meet MTS’s

exacting quality standards when initially installed and will continue to perform as intended over time.

Manual Part Number—Publication Date—Release

100-256-292 D—August

2013—TestSuite MP 2.6 or later

100-256-292 C—September

2012—TestSuite MP 2.3

Page 3

Contents

1.0 Technical Support 9

2.0 Preface 13

3.0 Overview 17

1.1.0 How to Get Technical Support........................................................................................................9

1.2.0 Before You Contact MTS................................................................................................................9

1.3.0 If You Contact MTS by Phone......................................................................................................11

1.4.0 Problem Submittal Form in MTS Manuals...................................................................................12

2.1.0 Before You Begin..........................................................................................................................13

2.2.0 Documentation Conventions.........................................................................................................13

3.1.0 Template Overview.......................................................................................................................18

3.1.1.0 Templates........................................................................................................................18

3.1.2.0 Fatigue Templates...........................................................................................................19

3.2.0 Legacy Template Overview...........................................................................................................21

3.2.1.0 Importing Legacy Data...................................................................................................21

4.0 Test Setup 23

4.1.0 Open the Controller Station...........................................................................................................24

4.2.0 Prepare Controller Station for Operation......................................................................................24

4.3.0 Enable Manual Control.................................................................................................................24

4.4.0 Install Specimen............................................................................................................................25

4.5.0 Disable Manual Control................................................................................................................26

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template 27

5.1.0 Set Up the Test..............................................................................................................................28

5.1.1.0 ASTM Low-Cycle Fatigue (LCF) Strain Template........................................................28

5.1.2.0 Set Up a Test...................................................................................................................28

5.1.3.0 Fatigue Specimen Parameters........................................................................................29

5.2.0 Dene Test Parameters..................................................................................................................30

5.2.1.0 Strain Test Parameters....................................................................................................30

5.2.2.0 Strain Termination Parameters.......................................................................................30

5.2.3.0 Data Storage Parameters................................................................................................31

5.2.4.0 Extensometer Calibration...............................................................................................32

5.2.5.0 Verify the Extensometer.................................................................................................32

5.2.6.0 Modulus Check at Start Temperature.............................................................................33

5.3.0 Run the Test...................................................................................................................................33

MTS TestSuite 3

Page 4

5.3.1.0 Measure Modulus...........................................................................................................33

5.3.2.0 Strain-Controlled Test....................................................................................................33

5.3.3.0 Strain Test.......................................................................................................................34

5.3.4.0 Reattach Extensometer...................................................................................................35

5.3.5.0 Create a Fatigue Test Report..........................................................................................35

5.3.6.0 Test Completion.............................................................................................................35

5.4.0 View Test Results..........................................................................................................................35

5.4.1.0 Fatigue Test Results........................................................................................................36

5.5.0 Analyze Data.................................................................................................................................36

5.5.1.0 Strain View.....................................................................................................................36

5.5.2.0 Analyze the Test Runs....................................................................................................38

6.0 ASTM Low-Cycle Fatigue (LCF) Elevated Temperature Template39

6.1.0 Set Up the Test..............................................................................................................................40

6.1.1.0 ASTM Low-Cycle Fatigue (LCF) Strain Template........................................................40

6.1.2.0 Set Up a Test...................................................................................................................40

6.1.3.0 Fatigue Specimen Parameters........................................................................................41

6.2.0 Dene Test Parameters..................................................................................................................42

6.2.1.0 Temperature Parameters.................................................................................................42

6.2.2.0 Strain Test Parameters....................................................................................................42

6.2.3.0 Strain Termination Parameters.......................................................................................43

6.2.4.0 Data Storage Parameters................................................................................................43

6.2.5.0 Extensometer Calibration...............................................................................................44

6.2.6.0 Verify the Extensometer.................................................................................................45

6.3.0 Run the Test...................................................................................................................................45

6.3.1.0 Modulus Check at Start Temperature.............................................................................45

6.3.2.0 Start Temperature Strain.................................................................................................45

6.3.3.0 Measure Modulus...........................................................................................................45

6.3.4.0 Ramp to Test Temperature..............................................................................................46

6.3.5.0 Measure Thermal Strain.................................................................................................46

6.3.6.0 Measure Thermal Modulus............................................................................................46

6.3.7.0 Ramp to Start Temperature.............................................................................................47

6.3.8.0 Strain-Controlled Test....................................................................................................47

6.3.9.0 Strain Test.......................................................................................................................48

6.3.10.0 Reattach Extensometer.................................................................................................48

6.3.11.0 Create a Fatigue Test Report........................................................................................48

6.3.12.0 Test Completion...........................................................................................................49

6.4.0 View Test Results..........................................................................................................................49

6.4.1.0 Fatigue Test Results........................................................................................................49

6.5.0 Analyze Data.................................................................................................................................49

6.5.1.0 Strain Elevated Temperature Analysis Denition..........................................................49

6.5.2.0 Analyze the Test Runs....................................................................................................52

4 MTS TestSuite

Page 5

7.0 ASTM High-Cycle Fatigue (HCF) Load Test Template 53

7.1.0 Set Up the Test..............................................................................................................................54

7.1.1.0 High-Cycle Fatigue Load Test Template........................................................................54

7.1.2.0 Set Up a Test...................................................................................................................54

7.1.3.0 Fatigue Specimen Parameters........................................................................................55

7.2.0 Run the Test...................................................................................................................................56

7.2.1.0 Load Test Parameters.....................................................................................................56

7.2.2.0 Load Termination Parameters........................................................................................57

7.2.3.0 Modulus Check at Start Temperature.............................................................................57

7.2.4.0 Data Storage Parameters................................................................................................57

7.2.5.0 Extensometer Calibration...............................................................................................58

7.2.6.0 Verify the Extensometer.................................................................................................59

7.2.7.0 Measure Modulus...........................................................................................................59

7.2.8.0 Load Test........................................................................................................................60

7.2.9.0 Create a Fatigue Test Report..........................................................................................60

7.2.10.0 Test Completion...........................................................................................................60

7.3.0 View Test Results..........................................................................................................................60

7.3.1.0 Fatigue Test Results........................................................................................................60

7.4.0 Analyze Data.................................................................................................................................61

7.4.1.0 High-Cycle Fatigue Load Data Analysis Denition......................................................61

7.4.2.0 Analyze the Test Runs....................................................................................................62

8.0 Transition Test Template 65

8.1.0 Set Up the Test..............................................................................................................................66

8.1.1.0 Transition Test Template Overview...............................................................................66

8.1.2.0 Set Up a Test...................................................................................................................66

8.1.3.0 Fatigue Specimen Parameters........................................................................................66

8.2.0 Run the Test...................................................................................................................................68

8.2.1.0 Strain Test Parameters....................................................................................................68

8.2.2.0 Strain Termination Parameters.......................................................................................68

8.2.3.0 Data Storage Parameters................................................................................................69

8.2.4.0 Load Termination Parameters........................................................................................69

8.2.5.0 Transition Parameters.....................................................................................................70

8.2.6.0 Load Test Parameters.....................................................................................................70

8.2.7.0 Extensometer Calibration...............................................................................................71

8.2.8.0 Verify the Extensometer.................................................................................................71

8.2.9.0 Modulus Check at Start Temperature.............................................................................72

8.2.10.0 Measure Modulus.........................................................................................................72

8.2.11.0 Strain Test.....................................................................................................................72

8.2.12.0 Reattach Extensometer.................................................................................................73

MTS TestSuite 5

Page 6

8.2.13.0 Load Test......................................................................................................................73

8.2.14.0 Create a Fatigue Test Report........................................................................................73

8.2.15.0 Test Completion...........................................................................................................73

8.3.0 View Test Results..........................................................................................................................73

8.3.1.0 Fatigue Test Results........................................................................................................74

8.4.0 Analyze Data.................................................................................................................................74

8.4.1.0 Strain View.....................................................................................................................74

8.4.2.0 Analyze the Test Runs....................................................................................................76

9.0 Transition Test Elevated Temperature Template 77

9.1.0 Set Up the Test..............................................................................................................................78

9.1.1.0 Transition Test Elevated Temperature Template............................................................78

9.1.2.0 Set Up a Test...................................................................................................................78

9.1.3.0 Fatigue Specimen Parameters........................................................................................78

9.2.0 Run the Test...................................................................................................................................80

9.2.1.0 Temperature Parameters.................................................................................................80

9.2.2.0 Strain Termination Parameters.......................................................................................80

9.2.3.0 Data Storage Parameters................................................................................................81

9.2.4.0 Transition Parameters.....................................................................................................81

9.2.5.0 Load Test Parameters.....................................................................................................82

9.2.6.0 Load Test........................................................................................................................82

9.2.7.0 Load Termination Parameters........................................................................................82

9.2.8.0 Extensometer Calibration...............................................................................................83

9.2.9.0 Verify the Extensometer.................................................................................................84

9.2.10.0 Start Temperature Strain...............................................................................................84

9.2.11.0 Modulus Check at Start Temperature...........................................................................84

9.2.12.0 Measure Modulus.........................................................................................................84

9.2.13.0 Ramp to Test Temperature............................................................................................85

9.2.14.0 Measure Thermal Strain...............................................................................................85

9.2.15.0 Measure Thermal Modulus..........................................................................................85

9.2.16.0 Strain Test.....................................................................................................................85

9.2.17.0 Reattach Extensometer.................................................................................................86

9.2.18.0 Load Test......................................................................................................................86

9.2.19.0 Ramp to Start Temperature...........................................................................................86

9.2.20.0 Create a Fatigue Test Report........................................................................................86

9.2.21.0 Test Completion...........................................................................................................87

9.3.0 View Test Results..........................................................................................................................87

9.3.1.0 Fatigue Test Results........................................................................................................87

9.4.0 Analyze Data.................................................................................................................................87

9.4.1.0 Strain View.....................................................................................................................87

9.4.2.0 Analyze the Test Runs....................................................................................................90

6 MTS TestSuite

Page 7

10.0 ASTM Trapezoidal Strain Template 91

10.1.0 Set Up the Test............................................................................................................................92

10.1.1.0 ASTM Trapezoidal Strain Template Overview............................................................92

10.1.2.0 Set Up a Test.................................................................................................................92

10.1.3.0 Fatigue Specimen Parameters......................................................................................92

10.2.0 Run the Test.................................................................................................................................94

10.2.1.0 Strain Test Parameters..................................................................................................94

10.2.2.0 Strain Termination Parameters.....................................................................................94

10.2.3.0 Data Storage Parameters..............................................................................................95

10.2.4.0 Extensometer Calibration.............................................................................................95

10.2.5.0 Verify the Extensometer...............................................................................................96

10.2.6.0 Modulus Check at Start Temperature...........................................................................96

10.2.7.0 Measure Modulus.........................................................................................................97

10.2.8.0 Strain-Controlled Test..................................................................................................97

10.2.9.0 Strain Test.....................................................................................................................98

10.2.10.0 Reattach Extensometer...............................................................................................98

10.2.11.0 Create a Fatigue Test Report......................................................................................99

10.2.12.0 Test Completion.........................................................................................................99

10.3.0 View Test Results........................................................................................................................99

10.3.1.0 Fatigue Test Results......................................................................................................99

10.4.0 Analyze Data.............................................................................................................................100

10.4.1.0 Strain View.................................................................................................................100

10.4.2.0 Analyze the Test Runs................................................................................................102

11.0 ASTM Trapezoidal Strain Elevated Temperature Template 103

11.1.0 Set Up the Test...........................................................................................................................104

11.1.1.0 ASTM Trapezoidal Strain Elevated Temperature Template.......................................104

11.1.2.0 ASTM Low-Cycle Fatigue (LCF) Strain Template....................................................104

11.1.3.0 Set Up a Test...............................................................................................................104

11.1.4.0 Fatigue Specimen Parameters.....................................................................................105

11.2.0 Run the Test...............................................................................................................................106

11.2.1.0 Temperature Parameters.............................................................................................106

11.2.2.0 Strain Test Parameters................................................................................................107

11.2.3.0 Strain Termination Parameters...................................................................................107

11.2.4.0 Data Storage Parameters.............................................................................................107

11.2.5.0 Extensometer Calibration...........................................................................................108

11.2.6.0 Verify the Extensometer.............................................................................................109

11.2.7.0 Modulus Check at Start Temperature.........................................................................109

11.2.8.0 Measure Modulus.......................................................................................................109

11.2.9.0 Ramp to Test Temperature..........................................................................................110

MTS TestSuite 7

Page 8

11.2.10.0 Strain-Controlled Test..............................................................................................110

11.2.11.0 Measure Thermal Strain...........................................................................................111

11.2.12.0 Measure Thermal Modulus.......................................................................................111

11.2.13.0 Ramp to Start Temperature.......................................................................................112

11.2.14.0 Strain-Controlled Test..............................................................................................112

11.2.15.0 Strain Test.................................................................................................................113

11.2.16.0 Reattach Extensometer.............................................................................................113

11.2.17.0 Create a Fatigue Test Report....................................................................................113

11.2.18.0 Test Completion........................................................................................................114

11.3.0 View Test Results......................................................................................................................114

11.3.1.0 Fatigue Test Results....................................................................................................114

11.4.0 Analyze Data.............................................................................................................................114

11.4.1.0 Strain Elevated Temperature Analysis Denition......................................................114

11.4.2.0 Analyze the Test Runs................................................................................................117

8 MTS TestSuite

Page 9

1.0 Technical Support

1.1.0 How to Get Technical Support

Start with your manuals

The manuals supplied by MTS provide most of the inf ormation you need to use and maintain your equipment.

If your equipment includes software, look for online help and README files that contain additional product

information.

Technical support methods

MTS provides a full range of support services after your system is installed. If you ha ve any questions about

a system or product, contact Technical Support in one of the following ways.

Web site

Outside the U.S.

For technical support outside the United States, contact your local sales and service office. For a list of

worldwide sales and service locations and contact information, use the Global MTS link at the MTS web site:

www.mts.com > Global Presence > Choose a Region

www.mts.com > Contact Us (upper-right corner) > In the Subject field, choose

To escalate a problem; Problem Submittal Form

Worldwide: tech.support@mts.comE-mail

Europe: techsupport.europe@mts.com

Worldwide: 1 800 328 2255 - toll free in U.S.; +1 952 937 4000 - outside U.S.Telephone

Europe: +800 81002 222, International toll free in Europe

1.2.0 Before You Contact MTS

MTS can help you more efficiently if you have the following information available when you contact us for

support.

MTS TestSuite 9

Page 10

Know your site number and system number

The site number contains your company number and identifies y our equipment type (such as material testing

or simulation).The number is typically written on a label on your equipment before the system leaves MTS.

If you do not know your MTS site number, contact your sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies your system.You can find

your job number in your order paperwork.

Example system number: US1.42460

Know information from prior technical assistance

If you have contacted MTS about this problem before, we can recall your file based on the:

• MTS notification number

• Name of the person who helped you

Identify the problem

Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Know relevant computer information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant software information

For software application problems, have the following information available:

• The software application’s name , version n umber , b uild number, and (if available) software patch n umber .

This information can typically be found in the About selection in the Help menu.

• The names of other applications on your computer, such as:

• Anti-virus software

• Screen savers

10 MTS TestSuite

Page 11

• Keyboard enhancers

• Print spoolers

• Messaging applications

1.3.0 If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical support specialist.The agent

asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue will be assigned a unique

notification number.

Identify system type

To enable the Call Center agent to connect you with the most qualified technical support specialist available ,

identify your system as one of the following types:

• Electrodynamic material test system

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to troubleshoot

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an experienced user nearby to

assist you.

Write down relevant information

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

MTS TestSuite 11

Page 12

• Write down any specific instructions.

After you call

MTS logs and tracks all calls to ensure that you receive assistance for your problem or request. If you have

questions about the status of your problem or have additional information to report, please contact Technical

Support again and provide your original notification number.

1.4.0 Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with y our software, hardware, man uals, or service

that are not resolved to your satisfaction through the technical support process.The form includes check

boxes that allo w you to indicate the urgency of y our problem and y our e xpectation of an acceptable response

time.We guarantee a timely response—your feedback is important to us.

You can access the Problem Submittal Form at www.mts.com > Contact Us (upper-right corner) > In the

Subject field, choose To escalate a problem; Problem Submittal Form

12 MTS TestSuite

Page 13

2.0 Preface

2.1.0 Before You Begin

Safety first!

Before you use y our MTS product or system, read and understand the safety information provided with your

system. Improper installation, operation, or maintenance can result in hazardous conditions that can cause

severe personal injury or death, or damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very important that you remain

aware of hazards that apply to your system.

Other MTS manuals

In addition to this manual, you may receive additional manuals in paper or electronic form.

You may also receiv e an MTS System Documentation CD. It contains an electronic copy of the manuals that

pertain to your test system.

Controller and application software manuals are typically included on the software CD distribution disc(s).

2.2.0 Documentation Conventions

The following paragraphs describe some of the conventions that are used in your MTS manuals.

Hazard conventions

Hazard notices may be embedded in this manual.These notices contain safety information that is specific

to the activity to be performed. Hazard notices immediately precede the step or procedure that may lead to

an associated hazard. Read all hazard notices carefully and f ollow all directions and recommendations.Three

different levels of hazard notices may appear in your manuals. Following are examples of all three levels.

(for general safety information, see the safety information provided with your system.)

DANGER:

Danger notices indicate the presence of a hazard with a high level of risk which, if

ignored, will result in death, severe personal injury, or substantial property damage.

WARNING:

Warning notices indicate the presence of a hazard with a medium lev el of risk which,

if ignored, can result in death, severe personal injury, or substantial property damage.

MTS TestSuite 13

Page 14

CAUTION:

Caution notices indicate the presence of a hazard with a low level of risk which, if

ignored, could cause moderate or minor personal injury or equipment damage, or

could endanger test integrity.

Other special text conventions

Important:

Important notices provide information about your system that is essential to its proper

function.While not safety-related, if the important information is ignored, test results may

not be reliable, or your system may not operate properly.

Note:

Notes provide additional information about operating your system or highlight easily

overlooked information.

Recommended:

Recommended notes provide a suggested way to accomplish a task based on what MTS

has found to be most effective.

Tip:

Tips provide helpful information or a hint about how to most efficiently accomplish a task.

Access:

Access provides the route you should follow to a referenced item in the software.

Example:

Examples show specific scenarios relating to your product and appear with a shaded

background.

Special terms

The first occurrence of special terms is shown in italics.

Illustrations

Illustrations appear in this manual to clarify text.They are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual conventions

This manual is available as an electronic document in the Portable Document File (PDF) format. It can be

viewed on any computer that has Adobe Acrobat Reader installed.

14 MTS TestSuite

Page 15

Hypertext links

The electronic document has many hypertext links displayed in a blue font. All blue words in the body text,

along with all contents entries and index page numbers, are hypertext links.When you click a h ypertext link,

the application jumps to the corresponding topic.

MTS TestSuite 15

Page 16

Page 17

3.0 Overview

Topics:

•

Template Overview................................................................................................................................18

•

Legacy Template Overview....................................................................................................................21

MTS TestSuite 17

Page 18

3.0 Overview

3.1.0 Template Overview

3.1.1.0 Templates

Templates eliminate the need to re-create existing information and provide an easy wa y to run standard tests.

Test templates can come from one of several sources:

• An existing test - you open a copy of an existing test and assign it a default name (the original test is not

changed).The new test does not contain test runs or analysis runs from the source test.

• A test that is converted to a template - you can convert a test to a test template (File > Save As > Template).

With the exception of test and analysis runs, specimen definitions, and completed reports, the template

contains all other test information.

• A template supplied by MTS - MTS offers a variety of templates designed to comply with test method

standards (such as ASTM). MTS templates provide all the components you need to run a test, analyze

the test data, and create reports of the results.

Test template content

A template can include all or part of the basic test definition information for one test:

• Procedure

• Monitor displays

• Variables

• Analysis definitions

• Resources

Note:

Although a template can include test resources, if the template is designed for a particular controller

configuration, the resources may not map to (match) the test station resources in your system.

Test definitions

You can add a test definition to a test from a template.The source of the template can be any existing test

or template that has tests.With the exception of test and analysis runs, specimen definitions, and completed

reports, the new test contains all other test information.

Template locations

Projects and project templates exist on disk as folders with the .Project folder name extension.They are

typically located at C:\MTS TestSuite\Projects and C:\MTS TestSuite\Templates, respectiv ely . Report templates

are located in the C:\MTS TestSuite\Report Templates folder.

18 MTS TestSuite

Page 19

Note:Do not rename, move, or change the contents of the Projects or Templates folders outside of

the MTS TestSuite applications.To rename an open project, use the Project Summary window in any

application.

3.1.2.0 Fatigue Templates

Low-Cycle Fatigue (LCF)

The following templates are available for LCF tests and analysis:

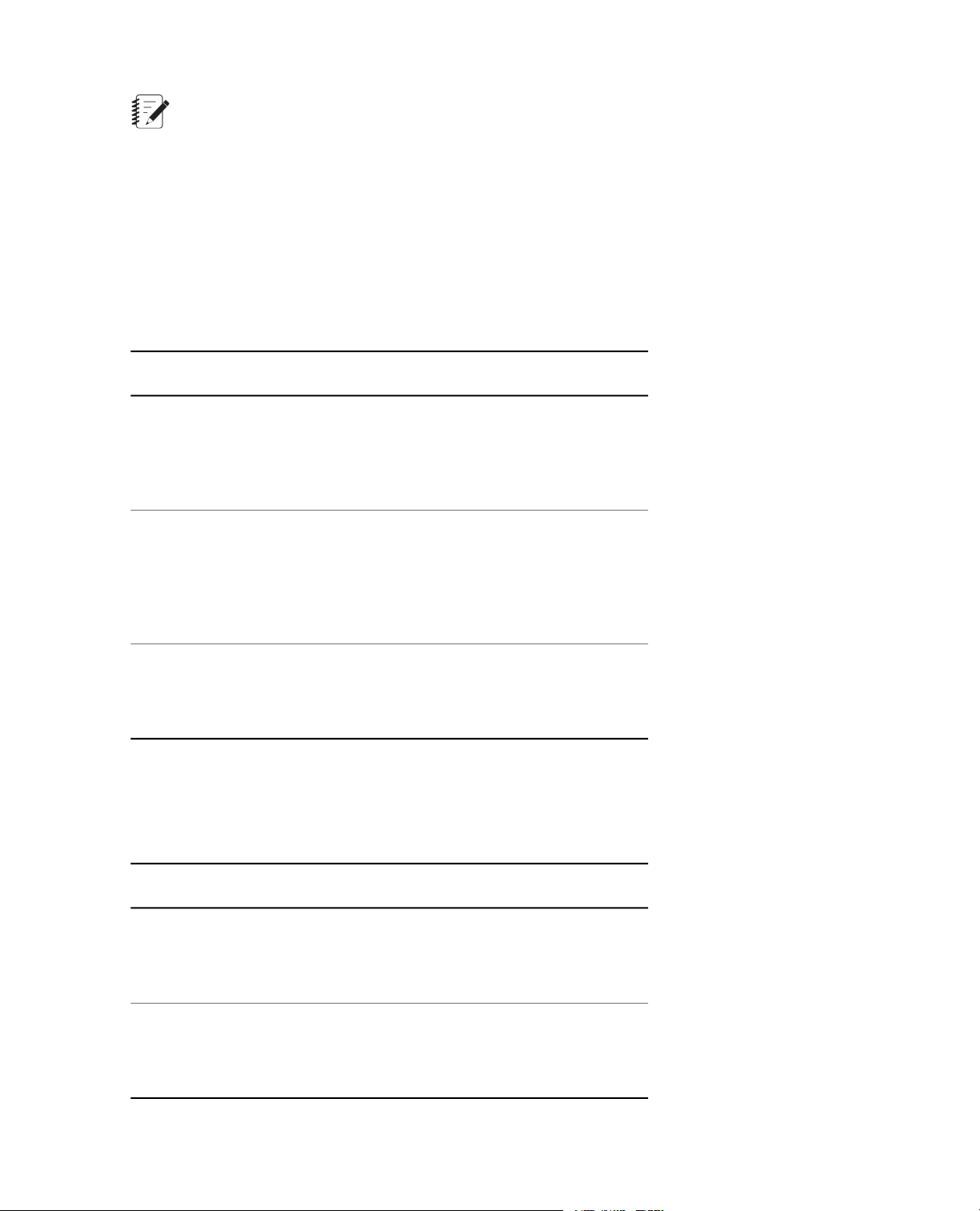

Low-Cycle Fatigue Templates

DescriptionTemplate

3.0 Overview

ASTM LCF Strain

ASTM LCF Strain

Elevated T emperature

Legacy LCF

High-Cycle Fatigue (HCF)

The following templates are available for HCF Load tests and analysis:

High-Cycle Fatigue Templates

This template complies with ASTM standard

E606-04 and ASTM standard D3479/D 3479M-96

(Reapproved 2007).The template is designed

to run LCF tests, analyze the resulting data, and

provide reports of the results.

This template complies with ASTM standard

E606-04 and ASTM standard D3479/D 3479M-96

(Reapproved 2007).The template is designed

to run LCF tests with elevated temperature,

analyze the resulting data, and provide reports

of the results.

This template is designed to analyze data

acquired from tests run with the MTS 793.20 LCF

Test application and provide reports of the

results.

ASTM HCF Load Test

Legacy HCF Displacement

DescriptionTemplate

This template complies with ASTM Standard E

466-07 and ASTM standard D3479/D 3479M-96

(Reapproved 2007).The template is designed

to determine the fatigue resistance of materials.

This template is designed to analyze data

acquired from tests run with the MTS 793.20

Advanced LCF (ADVLCF) Test application and

provide reports of the results.

MTS TestSuite 19

Page 20

3.0 Overview

Transition Test

The following templates are available for Transition tests and analysis:

Transition Test Templates

DescriptionTemplate

Transition Test

Transition Test

Elevated T emperature

Trapezoidal Strain

The following templates are available for Trapezoidal Strain tests and analysis:

Trapezoidal Strain Templates

ASTM Trapezoidal

Strain

This template complies with ASTM Standard E

606-04 and ASTM standard D3479/D 3479M-96

(Reapproved 2007).The template is designed

to run Transition Tests, analyze the resulting

data, and provide reports of the results.

This template complies with ASTM Standard E

606-04 and ASTM standard D3479/D 3479M-96

(Reapproved 2007).The template is designed

to run Transition Tests with elev ated temperature,

analyze the resulting data, and provide reports

of the results.

DescriptionTemplate

This template complies with ASTM standard

E606-04 and ASTM standard D3479/D 3479M-96

(Reapproved 2007).The template is designed

to run Trapezoidal Strain tests, analyze the

resulting data, and provide reports of the results.

ASTM Trapezoidal

Strain Elevated

Temperature (Reapproved 2007).The template is designed

20 MTS TestSuite

This template complies with ASTM standard

E606-04 and ASTM standard D3479/D 3479M-96

to run Trapezoidal Strain tests with elevated

temperature, analyze the resulting data, and

provide reports of the results.

Page 21

3.2.0 Legacy Template Overview

3.2.1.0 Importing Legacy Data

Import Legacy Data provides support in MTS TestSuite for data archived from previous software products.

The currently supported versions include:

• Model 790.20—Low-Cycle Fatigue (LCF), High-Cycle Fatigue (HCF), and Advance Low-Cycle Fatigue

(ALC) version 4.2 or later

• Model 790.40—Fatigue Crack Growth (FCG) version 4.2 or later

• Model 790.50—Fracture Toughness with J-Integral Characterization of Fracture Toughness (JIC), Linear

Elastic Plane-Strain Fracture Toughness of Metallic Materials (KIC), and E1820 Crack-Tip Opening

Displacement (CTOD) version 4.2 or later

Specialized templates map the archived data to the current format and variables for analysis:

• Advance Low-Cycle Fatigue (ALC)

• E1820 Crack-Tip Opening Displacement (CTOD)

• Fatigue Crack Growth (FCG)

• High-Cycle Fatigue (HCF)

• J-Integral Characterization of Fracture Toughness (JIC)

• Linear Elastic Plane-Strain Fracture Toughness of Metallic Materials (KIC)

• Low-Cycle Fatigue (LCF)

3.0 Overview

Legacy files

Legacy files have a similar naming convention. File names are not case-sensitive: <name><data

type>.<extension>

Legacy File Names

DescriptionItem

The user-supplied name.Name

Data Type Important:

You must select the RD file. Only the RD file is processed.

The data type is one of four following types created for an archive:

• BS—Batch-specimen data

• PR—Procedure data

• RD—Raw data

• TR—Test results

MTS TestSuite 21

Page 22

3.0 Overview

DescriptionItem

The extension indicates the type of test, such as E1820, FCG, or KIC.Extension

Import process

You can import legacy data in the Multipurpose Elite, Fatigue Analyzer, and Fracture Analyzer applications.

If you import legacy data in Multipurpose Elite, you can review the imported data in View Results .You cannot

create tests or test runs that you can run in the application.

The data is mapped from the legacy format and variables to the current format and variab les by the application.

No user intervention is required.

When the import is complete, your test is saved and the test run is initialized. In Explorer, the test run name

appears blue.The next step is to create an analysis run in an analysis application.

Properties

Import Legacy Data Properties

DescriptionItem

Show the name of the Legacy template for the test type, such as Legacy FCG.Template

Show the name of the file you select to import, such as FCG_archiverd.FCG.Files

Import Legacy Data Procedure

To import legacy data:

1. Click File > Import > Legacy Data.

2. In the Import Legacy Data window, click Select, click the Legacy template for the legacy test type, and

click OK.

3. Click Add, navigate to the location of the legacy data files, select the raw data file (nameRD.EXT), and

click the Open button.

4. Click OK.

An informational message provides the name of the specimen selected for the test.

5. Click OK to clear the success or error message.

If there was an error during the import process, the message log contains more detailed information about

the error.

22 MTS TestSuite

Page 23

4.0 Test Setup

Topics:

•

Open the Controller Station...................................................................................................................24

•

Prepare Controller Station for Operation...............................................................................................24

•

Enable Manual Control..........................................................................................................................24

•

Install Specimen.....................................................................................................................................25

•

Disable Manual Control.........................................................................................................................26

MTS TestSuite 23

Page 24

4.0 Test Setup

4.1.0 Open the Controller Station

To open the controller station:

1. Start the Station Manager application.

2. In the Open Station window, select a a configuration file.

3. Click Open to open the configuration file.

4.2.0 Prepare Controller Station for Operation

The following procedure provides a basic outline of the steps required to prepare the controller station for

specimen installation and test operation.

1. Make sure all sensors are properly calibrated.

2. Make sure the test channels are properly tuned.

3. Make sure the polarity of the sensor signals are properly set for the test.

4. Set up error detectors.

5. Set up limit detectors.

6. After the Series 793 Station Manager application is properly set up for operation, make sure the user

access level is not set to Configuration.

The test control application will not allow you to connect to a station when the Station Manager application

user access level is set to Configuration.

4.3.0 Enable Manual Control

To enable manual control of the Station Manager controller:

1. On the Station Manager Station Controls toolbar, click Manual Command.

2. Select the Enable Manual Command check box.

3. Select a control mode.

You control the actuator for specimen installation with a control knob on a control panel mounted near the

load unit. Select y our preference f or a control mode , a channel limited channel (CLC) control mode, a load

control mode, or a stroke control mode can be used.

4. Make sure error and limit detectors are set up.

Because of the potential danger of working near high-pressure hydraulic systems, you must set proper

limit and error detectors before installing specimens.

5. Apply hydraulics, and if necessary, reset interlocks.

24 MTS TestSuite

Page 25

4.0 Test Setup

Warning:

Applying hydraulics can result in sudden actuator motion.

A moving actuator can injure anyone in its path.

Always clear the actuator area before applying hydraulics.

Use the Station Manager’s Station Controls panel for the following steps.

a) Click Reset to clear interlocks.

If the interlock remains on, use the Message Logs window to identify and correct the cause of the

interlock.

b) Click HPU Power Low, and then click HPU Power High.

The buttons stop flashing when pressure is reached.

c) Click HSM Power Low, and then click HSM Power High.

When possible, use low pressure to install specimens.

4.4.0 Install Specimen

The following procedure provides a basic outline of the steps required to install a specimen. Refer to the load

unit and grip manuals for detailed instructions on installing and operating these components in your system.

1. Using manual control, move the actuator close to the specimen grips.

Warning:

Actuator movement can occur when you install a specimen.

Unexpected actuator mov ement can result in personal injury, as your hands will be in a crush

zone during this step.

Ensure that hydraulic power is turned off before placing your hands near the actuator. Read

and understand the safety information in the Safety manual, Series 793 Software manuals,

and Load Frame product manuals.

2. Install the specimen in the grips.

3. Zero the control channel sensor output signal.

4. Install the specimen gage.

5. Zero the gage sensor output signal.

MTS TestSuite 25

Page 26

4.0 Test Setup

4.5.0 Disable Manual Control

To disable manual control of the Station Manager controller:

1. In the Station Manager application, click Manual Command button in the Station Controls panel.The

Manual Command window opens.

2. Deselect the Enable Manual Command check box and close the window.

3. Turn off hydraulics in the Station Manager application.

a) Click HSM Power Off.

b) Click HPU Power Off.

26 MTS TestSuite

Page 27

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

Topics:

•

Set Up the Test......................................................................................................................................28

•

Define Test Parameters.........................................................................................................................30

•

Run the Test...........................................................................................................................................33

•

View Test Results...................................................................................................................................35

•

Analyze Data..........................................................................................................................................36

MTS TestSuite 27

Page 28

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

5.1.0 Set Up the Test

5.1.1.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

The Low-Cycle Strain template applies a small number of high-amplitude cyclic forces to the specimen to

determine the maximum load or fatigue life of a material. A variation of the template performs the test at an

elevated temperature. Both templates are designed to be in compliance with ASTM standard E606-04 and

D3479-07.

After a test run and a specimen geometry are added, a window provides access to all test parameters and

test operation steps.The buttons enable you to perform the steps to run a low-cycle fatigue test.The general

order of the buttons is left to right, from the top row to the bottom row.

As the test runs, you can stop the test to change test parameters. After the test is complete, the data can be

analyzed.

The main features of the low-cycle fatigue template include:

• Buttons enable you to:

• Set up all test parameters

• Verify and reattach the extensometer

• Measure the modulus

• Run the test

• Create a report

• End the test

• Comprehensive monitor views help you monitor test progress.

• Tabular and graphical displays help you review test results.

• Analysis definitions provide analysis results.

• Reports can be generated after the analysis is defined.

5.1.2.0 Set Up a Test

To create and run a new test:

1. Create a new test from a template.

a) Click File > New > Test from Template.

b) In the Create from Existing Test window, select a test.

c) Click OK.

The new test is automatically created and assigned a default name.You can change the name and

enter comments about the new test by clicking the Edit button and making the changes.

2. Create a new test run.

a) Click New Test Run button.

28 MTS TestSuite

Page 29

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

b) Select a specimen from the Select a Specimen window and then click OK.

To create a new specimen click Add a new item.

c) Review the variables in the Setup Variables window, modify values as necessary, and then click OK.

3. Apply hydraulic power to the system.

a) Reset the interlocks if needed.

b) Click the Low, then High, power buttons.

4. In the MTS T estSuite Custom Message windo w for the template, clic k the buttons to define test parameters,

perform setup tasks, and run tests.

5. When prompted, click Run to run the test.

5.1.3.0 Fatigue Specimen Parameters

Fatigue Specimen Parameters

DescriptionParameter

Diameter - Round

Specimens

Outer Diameter Hollow Round

Specimens

Inner Diameter Hollow round

Specimens

Width - Rectangular

Specimens

Thickness Rectangular

Specimens

Specify the diameter of the reduced cross-sectional

area on the specimen.

Diameter is a specimen variable that other

variables may use in a calculation.

Specify the outer diameter of the reduced

cross-sectional area on the specimen.

Outer Diameter is a specimen variable that other

variables may use in a calculation.

Specify the inner diameter of the reduced

cross-sectional area on the specimen.

Inner Diameter is a specimen variable that other

variables may use in a calculation.

Specify the width of the reduced cross-sectional

area on the specimen.

Width is a specimen variable that other variables

may use in a calculation.

Specify the thickness of the reduced

cross-sectional area on the specimen.

Thickness is a specimen variable that other

variables may use in a calculation.

Extensometer Gage

Length (L)

Specify the length on the specimen that has the

reduced cross-sectional area.

Extensometer Gage Length is a specimen variable

that other variables may use in a calculation.

MTS TestSuite 29

Page 30

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

DescriptionParameter

Elastic Modulus (E)

Yield Strength

Valid at Temperature

The value you specify here represents the slope

value of the material’s stress-strain curve in the

elastic deformation region.

Elastic Modulus is a specimen variable that other

variables may use in a calculation.

Specify the stress value at which permanent

deformation occurs.

Yield Strength is a specimen variable that other

variables may use in a calculation.

Specify the temperature at which Elastic Modulus

and Yield Strength are valid.

5.2.0 Define Test Parameters

5.2.1.0 Strain Test Parameters

Strain test parameters are entries you make to control the strain test. F or tests that use a sine wave command,

strain test parameters include:

• End level 1

• End level 2

• Cycle frequency

The application checks the values you enter to make sure they are within the system capabilities.

5.2.2.0 Strain Termination Parameters

Strain Termination Parameters

DescriptionItem

Cycles for Stable

Cycle

Stable Cycle

Percent

Specify the number of cycles after which the

specimen is assumed to be stable and beyond cyclic

hardening or softening.

Specify a percentage that is used to calculate

peak-valley stability.

30 MTS TestSuite

Page 31

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

DescriptionItem

Crack Initiation

Change

Load Failure

Change Percent

Peak Level

Control Change

Total Cycles

Specify a percentage that is used to calculate the

stable load range and crack initiation.

Specify a percentage that is used to calculate the

stable load range and specimen failure.

Specify a percentage that is used to calculate if the

control peak or valley occurs outside the control

range.

Specify a number of cycles for the maximum length

of the test.

5.2.3.0 Data Storage Parameters

Data Storage Parameters Properties

DescriptionItem

Ending Cycles

Sets the number of cycles to save to disk at the end

of the test or when the test stops.

Load Storage

Change

PV Nth Cycle

Stored

Starting Cycles

Time Cycles Per

Log Decade

Stored

Strain Noise Band

Percent

Displacement

Storage Change

Sets the amount of change that must occur in the

maximum load between saves to disk.

Sets the value of N, which is the rate (number) of

peak-valley cycles for a store to disk to occur. For

example, if this parameter is 100, data is saved to

disk every 100 cycles.

Sets the number of cycles to save to disk at the

beginning of the test or when the test is started.

Sets the number of cycles of time data per decade

based on a logarithm to save to disk.

Sets the number of levels between saves to disk.Number of Levels

Sets the range the data must exceed to detect the

peak-valley data.Within this range, points are

considered noise and not peak or valley data.

Sets the amount of change that must occur in the

displacement between saves to disk.

MTS TestSuite 31

Page 32

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

5.2.4.0 Extensometer Calibration

Extensometer verification

Extensometer calibration ensures accurate data collection.You should verify the extensometer calibration

before performing any testing.To verify extensometer calibration, set the system to load control and ramp to

zero load. At zero load, the strain extensometer is zeroed.

An extensometer includes a strain gage.You should verify its calibration before you run a test.You can verify

the calibration accuracy of a DC sensor/conditioner pair through shunt calibration. Shunt calibration works

by shunting a precision resistor across one arm of the sensor’s Wheatstone bridge.The resulting imbalance

provides a reference value that is recorded on the calibration data sheet that accompanies the sensor.

Note:

With systems that use Series 494 hardware, you can use the HWI Editor application to select the arm

of the bridge where the shunt calibration resistor will be applied.

A current shunt calibration value, tak en before a test, should be compared to the shunt calibration reference

value recorded when the sensor was last calibrated. If the reference value and the current value differ too

greatly, the sensor/conditioner pair should be recalibrated to establish a new shunt reference value.

Significant variations between current and reference v alues can occur if the excitation voltage has drifted, or

the sensor has been damaged or has changed in some other way. It is possible to adjust excitation to

compensate for small-to-moderate changes in the shunt calibration value.

Calibration overview

The calibration process coordinates the interaction between the transducer, a DC conditioning circuit, and a

cable. Calibration of a transducer is a two-step process:

First, a specific output of the conditioner is adjusted to a specific displacement of the transducer.This is

performed by adjusting the excitation voltage and amplification (gain) of the conditioner.

The second step verifies the output of the transducer conditioner versus a known standard displacement o ver

the entire range of measurement.

5.2.5.0 Verify the Extensometer

To verify the extensometer in the LCFS test:

1. Click Extensometer Verification in the Low-Cycle Fatigue Strain test.

A message appears: Click the Run button on the control panel to start the extensometer verification.

2. Click the Run button.

The Run button changes color and a message appears: Put the Extensometer in the zero position. Click

OK when ready.

3. Put the extensometer in the zero position and click OK.

4. Click OK.

The Verify Zero Strain Reading window appears. Accept the value or type an offset as necessary.

5. Click OK.

32 MTS TestSuite

Page 33

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

The Strain Full Scale window appears.

6. You may want to set this value to 0.1 and click OK.

The Extensometer Verification Prompt window appears.

7. Click to repeat the extensometer verification or click No to continue.

5.2.6.0 Modulus Check at Start Temperature

You should perform a modulus check before you run a test.The standard template allows you to check the

modulus at start temperature and test temperature (for elevated temperature tests). The start temperature

modulus check helps determine if the system is set up correctly. For example, if you have not pulled the zero

pin from your extensometer , the modulus is incorrect. If you type incorrect specimen dimensions , the modulus

is incorrect.

5.3.0 Run the Test

5.3.1.0 Measure Modulus

To check the modulus in the LCFS test:

1. Click Measure Modulus.

The MTS TestSuite Input Parameters window prompts you to enter a load value to ramp to for a modulus

check.

2. Enter a load value and click OK.

3. Click the Run button.

4. A window appears with the Modulus Check Result.

• Click Accept to accept the result.

• Click Reject to discard the result.

• Click Measure Modulus to perform the modulus check again.

• Click View Data Report to see the results in report form.

5.3.2.0 Strain-Controlled Test

A typical low-cycle fatigue (LCF) test sequence includes:

1. Ramp to mean level, if the mean level at the start of the test is not zero . All data recorded during the ramp

is stored in cycle number 0 (zero).

2. Identify a stable cycle for comparison with other test values.

3. Start the test cycle count, start test data collection, and run the test to completion.

4. Ramp the system to the mean load of the last cycle.

MTS TestSuite 33

Page 34

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

Cycle 0 (zero)

The application collects data for each complete cycle. A cycle starts at mean level and ends at mean level.

In most cases, mean level is zero. For cases where mean level is not zero, a ramp initially occurs to mean

level before the test actually starts.The application stores the data collected during this initial ramp in cycle

count 0.

Stable cycle determination

The application identifies the stable cycle based on user-entered parameters.

Application-determined stable cycle

For an application-determined stable cycle, a consecutive n umber of cycles must remain within the stable-cycle

deviation factor to determine the reference cycle.Typical cycle counts are from 5 to 100 cycles.

Enter the percentage deviation that consecutive cycles must be within, as compared to an initial cycle. If a

cycle deviates beyond this percentage before the stabilizing factor amount is reached, that cycle becomes

the new cycle against which following cycles are compared.Typical stable cycle deviation factors are around

1%.

Test completion

The LCF test runs until it meets one of the termination criteria. Examples of test termination criteria include:

• Non-controlling failure threshold (%)

• Peak-valley deviation

Non-controlling failure threshold (%)

For tests run in strain control, you define a percentage of stable load amplitude to use for failure detection.

When the test reaches the stable cycle, the test compares the peak loads with this cycle to determine if the

test should be terminated due to specimen failure. For tests run in load control, enter the percentage of stable

displacement for failure detection.When the stability reference cycle is reached, the test compares the peak

displacements to this cycle to determine if the test should be terminated due to specimen failure.

Crack initiation determination

After a stable cycle is identified, each subsequent cycle is compared to the stable cycle. If the non-controlling

range (force range f or a strain controlled test) de viates by the user-entered percentage, the application stores

the cycle number as the crack initiation cycle.Typical range drops are near 5%.

Peak-valley control failure

If the control value end levels are not met, the test stops.

Ramp to mean load

When the test is complete, the system changes to force control and ramps to mean load at a rate set by the

user.

5.3.3.0 Strain Test

In the LCFS test:

34 MTS TestSuite

Page 35

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

1. Click Strain Test.

The MTS TestSuite Custom Message window appears with the message:Validate test parameter on

runtime display. Click Run Test to start testing. Click Change Parameters to go back and change any

parameters.

2. Click Run Test to start the test. A message appears: Click the Run button to start the Strain test.

3. Click the Run button.The Run button changes color.

4. Click Change Parameters to view the main menu, where you can change parameters and run the test.

5.3.4.0 Reattach Extensometer

If the test stops and you want to resume it, you must reattach the extensometer. On the main menu, click

Reattach Extensometer.

A window appears that shows the End of Test Readings and the Mean Load Test Readings settings and

limits.You can click V erify Settings to see the strain and load readings again or Cancel to return to the main

menu.

5.3.5.0 Create a Fatigue Test Report

On the test main menu, click Report.

The application opens Excel.The Creating Report window shows you the progress as the application

creates a report with the test results.

You can make changes to the report and customize the output using the Reporter Add-In for Excel.

5.3.6.0 Test Completion

When the test is complete, the test stops and you can run the reports. A variety of reporting options satisfy

the standard reporting requirements.When you have generated the reports, you can end the test by clic king

Done.When you have ended the test, you cannot continue to cycle the test or generate reports without the

Reporter Add-In for Excel.

5.4.0 View Test Results

After the test run completes, you can view the test results.

1. In the Explorer panel, click the name of the test run.

2. Click Results.

3. Click on the different tabs to view different types of results.

MTS TestSuite 35

Page 36

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

5.4.1.0 Fatigue Test Results

The Test Results show the following information about the test run:

• Variable Summary shows all the parameters and their last values for the test run.

• History shows minimum-maximum or peak-valley cycle data in relation to time or an index, such as a

data group, data point, or cycle number.The Y-axis presents data values and the X-axis presents index

values.You can select variables for the chart after the test is done.

• Hysteresis shows the cyclic or group data produced during a test cycle.You can select variables for the

chart after the test is done.

• Variable Array Chart shows all data points that are collected and calculated during each test cycle and

stored in arrays.

• Data Acquisition shows data that was acquired during the test activity. A tab is available for each Data

Acquisition activity.

5.5.0 Analyze Data

5.5.1.0 Strain View

The template is preconfigured with an analysis definition that conforms to the analysis portion of the ASTM

standard.The analysis definition can be used to analyze the test run in either the Fatigue Analyzer or F racture

Analyzer application and contains the following tables and charts.

Inelastic Strain Min Max Table

The Inelastic Strain Min Max table contains the measured and calculated minimum and maximum inelastic

strain values.The table also contains the measured plastic strain range.

Modulus by Cycles Table

The Modulus by Cycles table contains these values:

• Calculated cycle modulus

• Calculated loading modulus

• Calculated unloading modulus

• Hysteresis area

• Calculated first cycle modulus

Peak Valley Data by Cycles Table

The Peak Valley Data by Cycles table contains the peak and valley values of each cycle:

• Load

• Stress

36 MTS TestSuite

Page 37

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

• Strain

• Displacement

Cycle Variables Table

The Cycle Variables table contains information about cycle variables . If the value is modified during analysis,

a check mark appears in the Modified column and the value in the Value column differs from the value in the

Original Value column. Modified values do not replace, change, or remove original test results data.

Variable Table

The Variable table contains information about test variables. If the value is modified during analysis, a check

mark appears in the Modified column and the value in the Value column differs from the value in the Original

Value column. The table includes:

• Category

• Display Name

• Value

• Unit

• Modified

• Original Value

• Dimension

• Array

• Calculation

Modified values do not replace, change, or remove original test results data.

Channels by Time

The Channels by Time table lists all data points collected in arrays during Data Acquisition activities. Click

the drop-down button to select the data acquisition activity. Specify the cycle by clicking on the Numeric or

Variable button and select one or more cycle numbers or variables. Arrays included by default include:

• Cycle Index

• Array Index

• Running Time Array

• Displacement Array

• Load Array

• Strain Array

• Elastic Strain Array

• Inelastic Strain Array

• Stress Array

• Stress Array with Ramp to Mean

• Running Time Array with Ramp to Mean

MTS TestSuite 37

Page 38

5.0 ASTM Low-Cycle Fatigue (LCF) Strain Template

Summary Data Table

The Summary Data table provides the final values of the variables defined in the Variable Editor.You can

change one or more values in this table and rerun the calculations in the same wa y described for the Analysis

Inputs table. After you refresh the values, the ones you modified have check marks in the Modified column.

The original test data is not lost and does not change.

Charts

The charts provide visual indicators of the data reported in the tables.

• Strain Peak Valley chart shows the strain peak and valley for each cycle of the test.

• Strain vs.Time chart shows changes in the strain during the test.

• Load Peak Valley chart shows the load peak and valley for each cycle of the test.

• Stress Peak Valley chart shows the stress peak and valley for each cycle of the test.

• Stress vs.Time chart shows changes in the stress during the test.

• First Cycle Modulus chart shows the modulus of the first cycle from the start point to the end point.

• Stress vs. Strain chart shows traces of the stress in relation to strain for the first modulus cycle, the third

cycle, the stable cycle, and the last strain cycle.

• Loading Unloading chart shows traces of the stress in relation to strain with markers to indicate the loading

and unloading start and end.

• Stress vs. Inelastic Strain chart shows traces of stress in relation to inelastic strain for the third cycle,

half-life cycle timed, and the last strain cycle.

• Inelastic Strain Min Max chart shows traces for minimum and maximum calculated values f or the inelastic

strain.

• Failure Cycle chart shows the traces for the selected Y-axis variable with markers to indicate the failure

point and the half-life cycle peak valley. Drop-line markers indicate the slope of the trace.

• Modulus chart shows traces for the calculated loading and unloading modulus.

• Load vs.Time chart shows changes in the load during the test.

5.5.2.0 Analyze the Test Runs

Each test that you create from an MTS template contains a default analysis definition that can be used to

analyze the test run in either the Fatigue Analyzer or Fracture Analyzer application.

T o analyz e the test runs, use one of the following methods to open the test in one of the Analyz er applications:

• From either the Fatigue Analyzer or Fracture Analyzer application, click File > Open Test and select the

test that you want to analyze.

• Open the test in the Multipurpose Elite application and on the Tools menu, click Fatigue Analyzer or

Fracture Analyzer.

The selected Analyzer application opens the test.

For more information

See the Fatigue Analyzer User Guide for information on how to create an analysis run.

38 MTS TestSuite

Page 39

6.0 ASTM Low-Cycle Fatigue (LCF) Elevated Temperature Template

Topics:

•

Set Up the Test......................................................................................................................................40

•