Page 1

be certain.

m

Model 632.85 Biaxial Extensometer

Product Information

011565200 B

Page 2

Copyright information © 2014 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. These trademarks may be protected in other countries.

All other trademarks or service marks are property of their respective owners.

Publication information

Manual Part Number Publication Date

011565200 A July 1986

011565200 B July 2014

2

Model 632.85 Biaxial Extensometer

Page 3

Contents

Introduction 5

Specifications 7

Safety Information 9

Safety Information Overview 9

Read all manuals 9

Personnel Qualifications 10

System Hazard Zones 10

Avoid Pinch and Crush Points 10

Installation 11

Specimen Mounting 11

Cabling 13

Maintenance 15

Model 632.85 Biaxial Extensometer

3

Page 4

4

Model 632.85 Biaxial Extensometer

Page 5

Introduction

The Model 632.85 Biaxial Extensometer provides axial and transverse outputs

from a single extensometer. The biaxial extensometer is typically used when

performing Poisson ratio testing, composites testing and metal formability

testing.

The extensometer consists of three sensor units. Each sensor unit uses precision

resistance-type, foil strain gages bonded to a metallic element to form a

Wheatstone bridge circuit. Each axial sensor unit uses either a half or full

Wheatstone bridge (depending upon the option selected) to measure axial

deflection. The transverse sensor unit uses a full Wheatstone bridge to measure

the transverse deflection.

Model 632.85 Biaxial Extensometer Introduction

5

Page 6

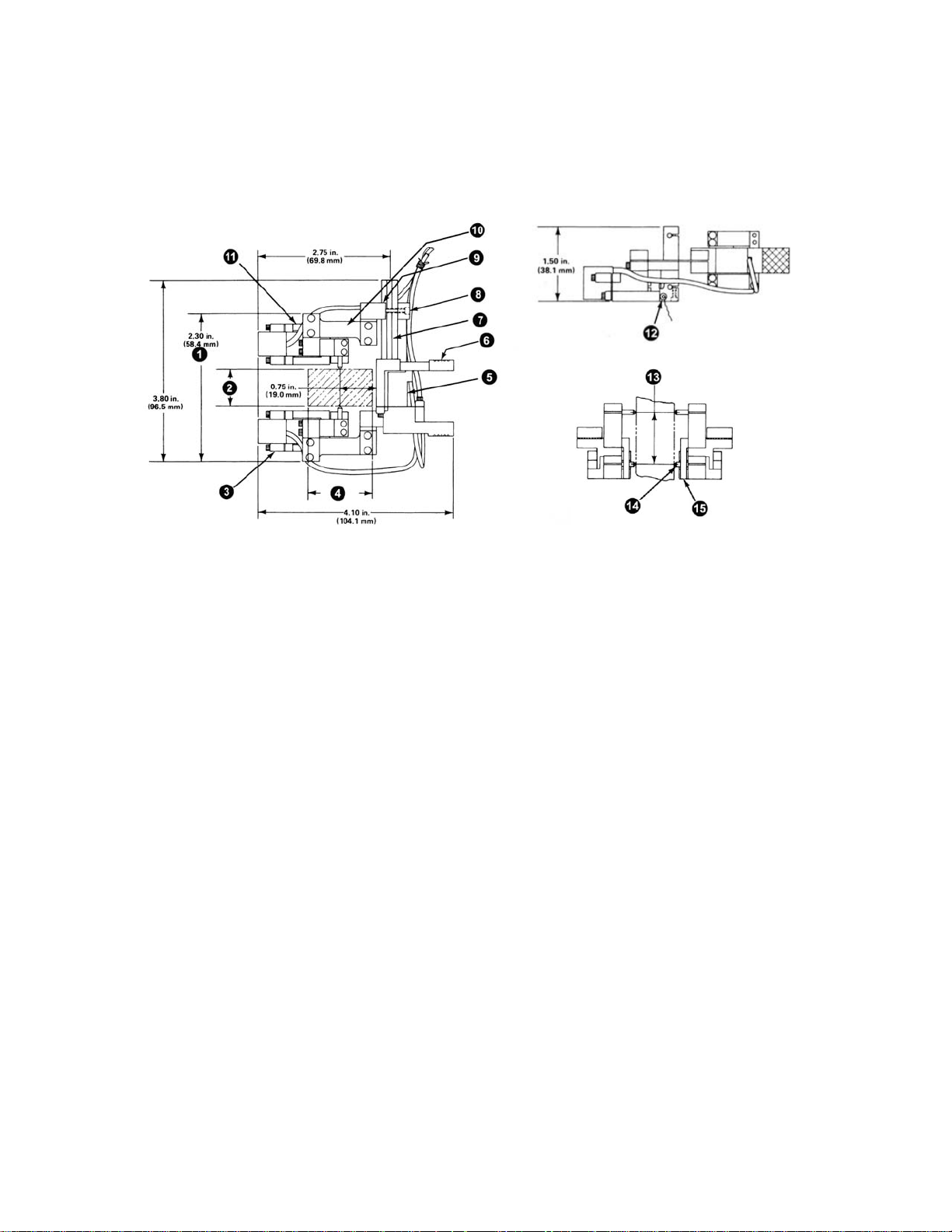

The design of the conical contact points allows the extensometer to be used on a

wide variety of specimens. These same conical points are usable on specimens

with circular as well as rectangular cross sections.

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Description

Plus specimen dimension R

Specimen dimension R

Axial sensor unit A

Specimen dimension S

Transverse sensor unit

Grip pads

Positioning arm

Loosen these screws to adjust for specimen dimension R

Slide bracket

Compliance flexure

Axial sensor unit B

Zero set pin

Axial gage length

Conical point

6

Introduction

15

Overtravel stop plate

Model 632.85 Biaxial Extensometer

Page 7

The extensometer is designed with multiple flexures for the necessary degrees of

compliance to provide for a secure, determinant attachment to the test sample.

This unique patented flexure design (covered by patent number 4,527,335)

provides approximately equal contact force to be transmitted by each of the four

conical contact points. Thus, the extensometer maintains positive contact even

with a somewhat nonuniform test sample or one which deflects somewhat

nonuniformly under static or dynamic loading.

Option 001 provides an averaged axial output to a dc conditioner. This

extensometer consists of a half Wheatstone bridge in each of the two axial sensor

units to measure the axial deflection of the specimen and a full Wheatstone

bridge in the transverse sensor unit to measure the transverse deflection of the

specimen. The two half bridges are output-matched (to within 1% of each other)

and combined into a full bridge to provide a single averaged axial output which

can be conditioned by a single dc controller or dc conditioner. The transverse

sensor unit uses a full Wheatstone bridge to measure the transverse deflection.

Two dc conditioners with their associated calibrated ranges are required to

condition the output signals from this unit.

Option 002 provides a dual axial output to the dc conditioners. This extensometer

contains a full Wheatstone bridge in each of the two axial sensor units to measure

axial deflection on both sides of the specimen independently. The transverse

deflection is also measured by a full Wheatstone bridge in the transverse sensor

unit. The output of each gage is cabled directly to its respective dc conditioner.

This configuration is particularly useful when it is necessary to measure bending

strains on the specimen. Three dc conditioners with their associated calibrated

ranges are required to condition the output signals from this unit.

Specifications

Parameter Specification - 632.85F-05

Specimen size range

Flat specimen

Dimension (R):

Dimension (S):

Round specimen

Diameter

Travel

Axial:

Transverse:

Axial gage length:

Accuracy (ISO 9513):

Temperature range:

Contact force of each contact on

specimen at mid-transverse

range:

* Specimen size range dimensions correspond to those shown in

previous figure.

*

0.5 to 51 mm

1 to 34 mm

3 to 34 mm

+1.2 to -1.5 mm

+/- 0.5 mm

25.00 mm

class 0,5

°C to +150 °C

-100

700 grams

Model 632.85 Biaxial Extensometer Introduction

7

Page 8

8

Introduction

Model 632.85 Biaxial Extensometer

Page 9

Safety Information

Safety Information Overview

Extensometers are used to provide specimen feedback in material test systems.

Operators using extensometers should be aware of the system level safety

information. Test systems are designed to generate single-axis or multi-axial

motions and forces simultaneously in a controlled laboratory environment and

impart these motions and forces into a test specimen that is secured to the system.

When you prepare to operate the system and during system operation, ensure the

following:

• Do not use or allow personnel to operate the system who are not

experienced, trained, or educated in the inherent dangers associated with

high-performance servo hydraulics and who are not experienced, trained, or

educated with regard to the intended operation as it applies to this test

system.

• Do not disable safety components or features (including limit detectors,

light curtains, or proximity switches/detectors).

• Do not attempt to operate the system without appropriate personal safety

gear (for example, hearing, hand, and eye protection).

Read all manuals

• Do not apply energy levels that exceed the maximum energies and velocities

for the system design. Refer to the system specifications.

• Do not test a specimen that exceeds the minimum (if applicable) or

maximum allowable mass. Refer to the system specifications.

• Do not use specimens that are combustible, flammable, pressurized, or

explosive.

• Do not modify the system or replace system components using parts that are

not MTS component parts or effect repairs using parts or components that

are not manufactured to MTS specifications.

• Do not operate the system in an explosive atmosphere.

• Do not use the system in a test area where uncontrolled access to the test

system is allowed when the system is in operation.

Study the contents of this manual and the other manuals provided with your

system before attempting to perform any system function for the first time.

Procedures that seem relatively simple or intuitively obvious may require a

complete understanding of system operation to avoid unsafe or dangerous

situations.

Model 632.85 Biaxial Extensometer Safety Information

9

Page 10

Personnel Qualifications

Do not allow unqualified personnel to perform any of the system

maintenance, setup, or operating procedures.

Operation and maintenance of the system by unqualified personnel can

expose them and others to hazards that can cause damage to equipment

and injury or death.

The system maintenance, setup, and operating procedures should only to be

performed by trained personnel. MTS offers training classes that provide the

necessary skills training.

System Hazard Zones

The area around and including the test system is considered hazardous.

Generally, hazards result from motions that occur during system operation.

However, there are latent pressure, overturning, and settling/unexpected

movement hazards that can occur prior to or after system operation, during

specimen installation, or during maintenance and repair.

The hazard zone includes the entire system and an additional area of at least 1

meter (3.3 feet) around the system perimeter. In addition, the hazard zone should

be extended to include the optional hydraulic power source (when purchased)

and any associated hoses, cables, and hardline.

Whenever personnel enter this defined zone they should be outfitted with

adequate and appropriate safety attire including hearing protection, safety

glasses, hard hat, and safety shoes. Never wear loose fitting clothing when in the

test area. Never enter the test area when hydraulics are on.

Avoid Pinch and Crush Points

When possible, install the extensometer on the specimen before installing the

specimen in the grips. Pinch points exist between the parts of the grip or fixture

that contact the specimen. Be aware of these pinch points when installing a

specimen or working around the grip or fixture during test setup. High forces

generated when grip pressure is activated can pinch, cut, or crush anything in the

path of the grip/ fixture specimen contact area and cause serious injury. Stay clear

of any potential pinch points.

A crush point exists between the grips. Whenever possible, use tongs or similar

tool when handling the specimen during specimen installation. Never allow any

part of your body to enter the path of machine movement or to touch moving

machinery , linkages, hoses, cables, specimens, and so forth. These present

serious crush points or pinch points.

Safety Information

10

Model 632.85 Biaxial Extensometer

Page 11

Installation

Specimen Mounting

The extensometer is mounted on the specimen by the use of the conical points.

Perform the following procedure to mount the extensometer on a specimen.

Item Description

1

2

3

4

5

6

7

8

9

10

11

12

Axial sensor unit A

R dimension

Axial sensor unit B

Compliance flexure

Remove screws on underside of compliance flexure to

separate the slide bracket form the compliance flexure.

Slide bracket

Loosen these screws to adjust for specimen dimension R

Positioning arm

Grip pads

Location for zero set spacer

Transverse sensor unit

Axial gage length

Model 632.85 Biaxial Extensometer Installation

11

Page 12

Item Description

13

14

15

16

Overtravel stop plate

Conical point contact

Conical point vertical adjustment

Zero set pin

1. Ensure the zero set pins are installed in the extensometer (refer to above

figure).

2. Slightly loosen the socket head cap screws which secure axial sensor unit B

to the positioning arm.

Note For specimens where the R dimension (refer to the specifications

section) is greater than 1.1 in. (28 mm), perform steps 3 through 5 to set

the extensometer transverse gage length. If the specimen has a R

dimension less than 1.1 in. (28 mm), proceed to step 6.

3. Remove the two socket head cap screws which secure the slide bracket to

the axial sensor unit B compliance flexure.

4. Slide the slide bracket off from the positioning arm. Turn the slide bracket

180° and slide it back onto the positioning arm. Note that the section of the

slide bracket which was secured to the top of the compliance flexure will

now be secured to the underside of the compliance flexure.

5. Place the compliance flexure in place on top of the extended side section of

the slide bracket. Replace the socket head cap screws removed in step 3 to

the underside of the slide bracket. Secure the slide bracket to the compliance

flexure by tightening the socket head cap screws.

6. Insert the zero set spacer behind the mechanical stop of the transverse

sensor. The zero set spacer is designed to hold the transverse output to zero

volts. Measure the transverse conditioner output and verify that the

conditioner output is 0 V± 2 V.

Note The extensometer might want to swing and twist very thin specimens. T o

restrain the extensometer, connect a string between the grip pad and the

load frame column.

7. Slide the axial sensor unit B along the positioning arm until the conical

points contact the specimen. Hold the extensometer in position and tighten

the socket head cap screws.

8. Remove the zero set spacer installed in step 6.

9. Adjust the placement of the conical points on the specimen to

align the upper and lower contact points on the vertical center

line of the specimen.

12

Installation

Model 632.85 Biaxial Extensometer

Page 13

Cabling

Shunt

R4

Shunt

R3

Red

Green

White

Black

+ Excitation

- Excitation

+ Output

- Output

Shield

1

2

3

4

A

B

C

D

E

F

The cable connector for the 632.85F is a PT01A-10-6P. The mating connector

should be a PT06A-10-6S. Shown below is a representation of the connector and

the wiring diagram.

Model 632.85 Biaxial Extensometer Installation

13

Page 14

14

Installation

Model 632.85 Biaxial Extensometer

Page 15

Maintenance

The conical points must be properly aligned to minimize the crosstalk between

the sensor units. Perform the following procedure to align the conical points.

Item Description

1

2

3

4

5

6

7

8

Conical point trim adjustment (lower)

Overtravel stop plate (2)

Flush adjustment of conical point

Axial gage length

Conical point trim adjustment (upper)

Conical alignment fixture shown for trim adjustment

Trim adjustment slot

Conical alignment fixture shown for flush alignment

1. Ensure the zero set pins are installed in the extensometer.

2. Refer to the installation drawing supplied with the extensometer. Check the

drawing to determine if the contact points are to be flush mounted or require

a specified trim adjustment.

Model 632.85 Biaxial Extensometer Maintenance

15

Page 16

Note If the conical points require flush mounting, perform step 3A. If the

contact points require a trim adjustment, perform step 3B.

3. Place the flat end of the alignment fixture against the side of the sensor unit

containing the replacement conical point (refer to above figure). Move the

conical point until the flat end is flush to the flat surface of the alignment

fixture.

4. Position the alignment fixture against the side of the sensor unit containing

the conical point so that the flat end of the contact point can extend into the

trim adjustment slot (refer to above figure). Move the contact point into the

trim adjust slot until the flat end is positioned as specified in the installation

drawing.

5. Firmly tighten the two conical point hold down screws.

6. Repeat this procedure for any other replacement conical point.

7. Remove the zero set pins.

16

Maintenance

Model 632.85 Biaxial Extensometer

Page 17

Page 18

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...