Page 1

be certain.

m

Series 609 Alignment Fixture

Product Information

015-031-901 E

Page 2

Copyright information © 1993, 1999, 2001, 2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

Publication information

Manual Part Number Publication Date

150319-01 A August 1993

015-031-901 B September 1999

015-031-901 C February 2001

015-031-901 D November 2001

015-031-901 E March 2008

2

Manual Template 4.3

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 6

Problem Submittal Form in MTS Manuals 7

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Introduction 13

Misalignment 15

About Concentric Misalignment 15

Adjust Concentric Alignment 16

About Angular Misalignment 17

Adjust Angular Alignment 18

Safety Information 21

Hazard Placard Placement 21

Installation 23

Series 609 Alignment Fixture Product Information Contents

3

Page 4

Specimen Preparation 29

About Gaged Specimens 29

Round Thick Diameter Specimens 31

Calculating Bending Strain—Round Thick Diameter Specimens 32

Round Thin Diameter Specimens 34

Calculating Bending Strain—Round Thin Diameter Specimens 35

Flat Thick Specimens 37

Calculating Bending Strain—Flat Thick Specimens 38

Flat Thin Specimens 40

Calculating Bending Strain—Flat Thin Specimens 41

Notched Round Thick Diameter Specimens 42

Calculating Bending Strain—Notched Round Thick Diameter Specimens 43

Notched Round Thin Diameter Specimens 44

Calculating Bending Strain—Notched Round Thin Diameter Specimens 45

Notched Flat Thick Specimens 48

Calculating Bending Strain—Notched Flat Thick Specimens 49

Notched Thin Flat Specimens 51

Calculating Bending Strain—Notched Thin Flat Specimens 52

Alignment Procedure 55

Installing a Gaged Specimen 56

Adjust the Concentric Alignment 58

Adjust the Angular Alignment 63

Check the Alignment 67

4

Contents

Series 609 Alignment Fixture Product Information

Page 5

Technical Support

How to Get Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Series 609 Alignment Fixture Product Information Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

5

Page 6

If You Contact MTS by Phone

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company, company

address, and the phone number where you can normally be reached.

Technical Support

6

Series 609 Alignment Fixture Product Information

Page 7

Problem Submittal Form in MTS Manuals

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Series 609 Alignment Fixture Product Information Technical Support

7

Page 8

Problem Submittal Form in MTS Manuals

Technical Support

8

Series 609 Alignment Fixture Product Information

Page 9

Before You Begin

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and operation and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Series 609 Alignment Fixture Product Information Preface

9

Page 10

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

Electronic manual

conventions

Preface

10

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Series 609 Alignment Fixture Product Information

Page 11

Documentation Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Series 609 Alignment Fixture Product Information Preface

11

Page 12

Documentation Conventions

12

Preface

Series 609 Alignment Fixture Product Information

Page 13

Introduction

C 0

A 0

Force Capacity

Contents Misalignment 15

The MTS Series 609 Alignment Fixture improves alignment between the upper

and lower grips of your load unit. Improving alignment reduces bending strains

in your specimen, which produces more accurate test results. This section

discusses the consequences of having misaligned grips and the two types of

adjustments that can compensate for misalignment problems:

• One set of adjustments compensates for concentric misalignment.

• One set of adjustments compensates for angular misalignment.

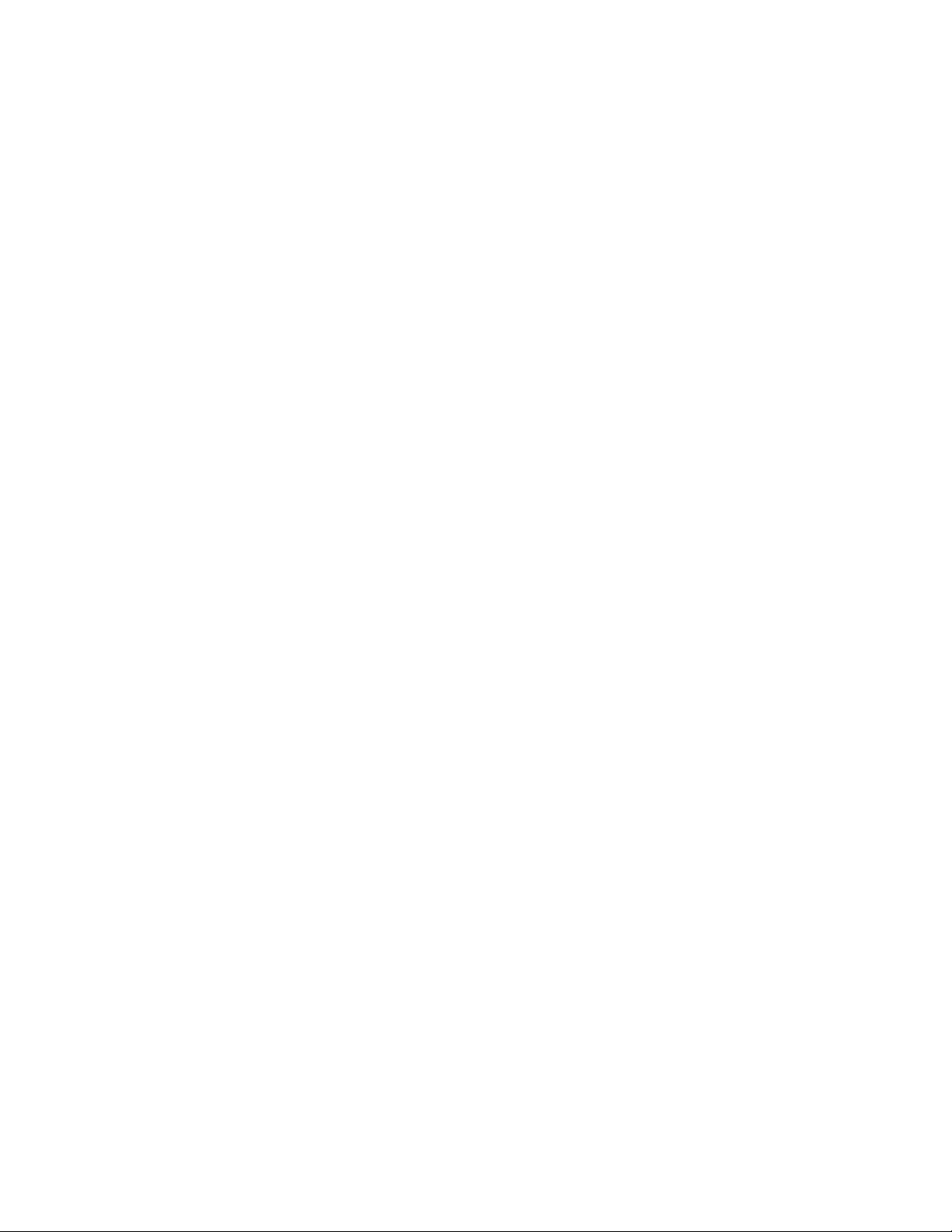

In a typical installation, the Series 609 Alignment Fixture is installed between the

force transducer and crosshead.

About Concentric Misalignment 15

About Angular Misalignment 17

Model 609 Alignment Fixture

Series 609 Alignment Fixture Product Information Introduction

13

Page 14

What you need to

know

MTS Systems Corporation assumes that you know how to use your controller.

See the appropriate manual for information about performing any controllerrelated step in the procedures in this manual. You are expected to know how to do

the following procedures:

• Turn hydraulic pressure on and off.

• Select a control mode.

• Manually adjust the actuator position.

• Install a specimen.

• Define a simple test.

• Run a test.

Related products The Series 609 Alignment Fixture is related to other products. See the following

product information manuals for product-specific information and procedures.

• Your load unit manual has information about installing the force transducer.

• Your grip manual has information about installing the grips.

• An option for the alignment fixture is an alignment software package which

is used with the fixture. See the Using 709 Easy Alignment manual.

14

Introduction

Series 609 Alignment Fixture Product Information

Page 15

Misalignment

Mounting Surface

Mounting Surface

Equal Strain Equal Strain

Loading Axis

Loading Axis

Misalignment

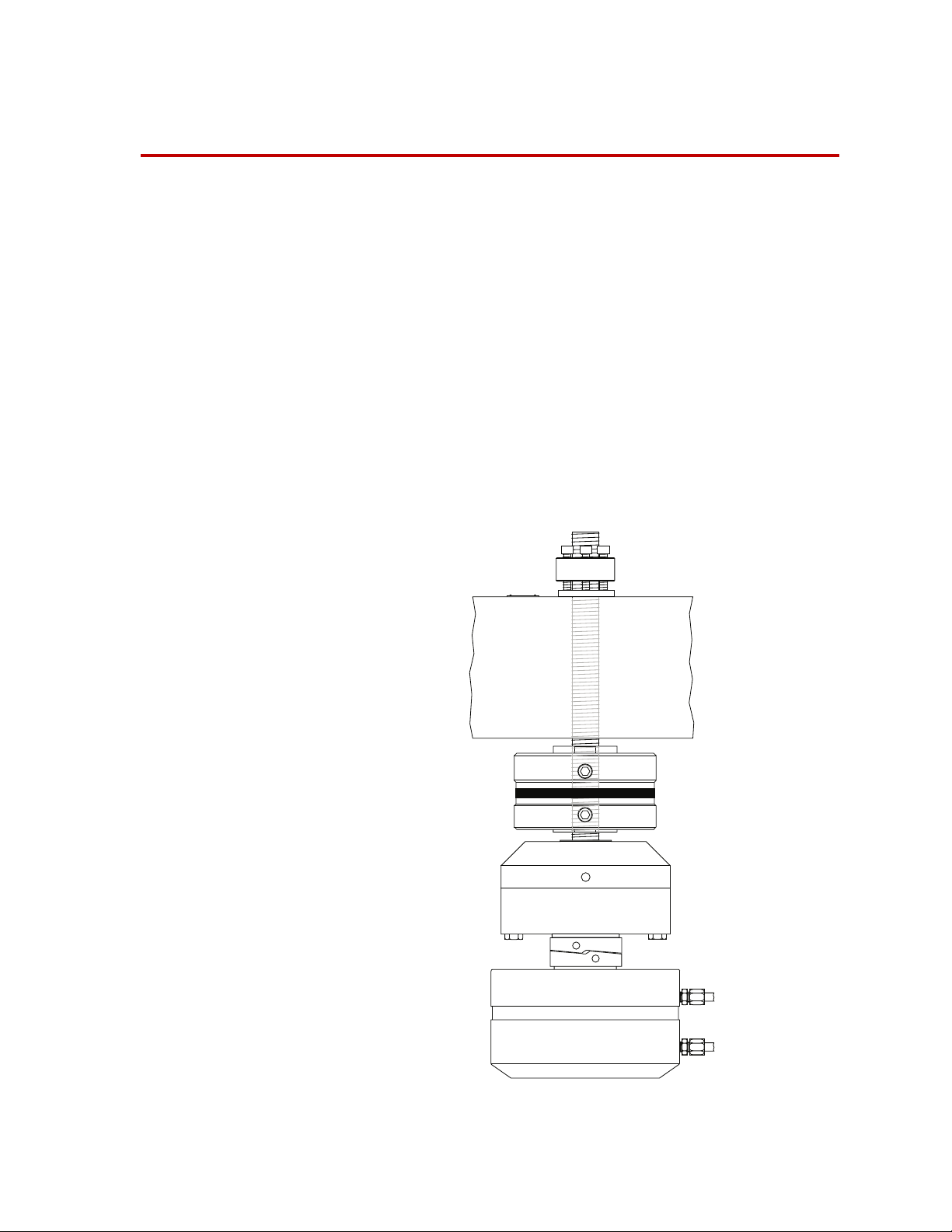

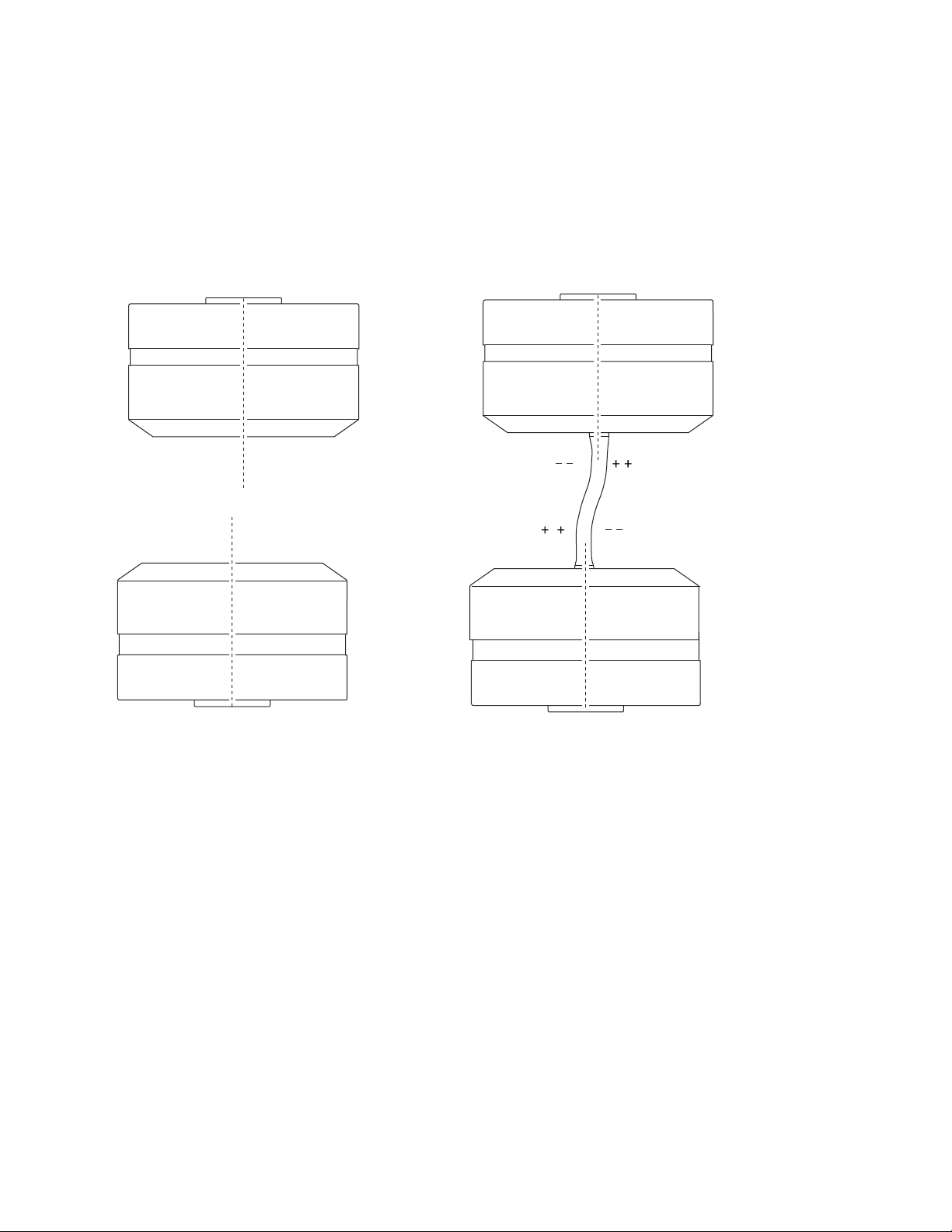

In uniaxial testing, perfectly aligned grips produce uniform axial tensile strains in

a specimen. For grips to be perfectly aligned, their loading axes must be

concentric.

Perfectly Aligned Grips Produce Uniform Axial Strains

Misalignment between the grips produces nonuniform axial strains in a

specimen. Some areas will have higher than average strains; other areas lower

than average strains. Bending strain is the difference between the average strain

and areas with higher or lower than average strains.

Many ASTM procedures limit maximum bending strains because they cause

specimens to exhibit much lower strengths than if all axial strains were uniform.

The alignment fixture lets you reduce bending strains by improving concentric

and angular alignment between the upper and lower grips.

Grips can have concentric and angular misalignments. Both can occur together

and have a combined effect on the bending strains that appear in the specimen.

About Concentric Misalignment

Concentric misalignment shifts the vertical axes of the grips laterally away from

each other. This puts an “S” shaped bend in the specimen.

A specimen with an “S” bend has a zero bending strain in the middle of its gage

section. It has higher than average bending strains at the top and bottom of its

Series 609 Alignment Fixture Product Information Introduction

15

Page 16

Adjust Concentric Alignment

Higher Than Average Strain

Lower Than Average Strain

gage section. These higher strains are on opposite sides. It also has lower than

average bending strains at the top and bottom of its gage section, opposite the

higher strains.

Actual strain readings vary with the amount of tensile load applied to the

specimen. With zero or low tensile force applied to the specimen, tensile strain

readings can be opposite compressive strain readings. Under higher tensile force,

high tensile readings can be opposite lower tensile readings.

Concentric Misalignment Produces an “S” Bend

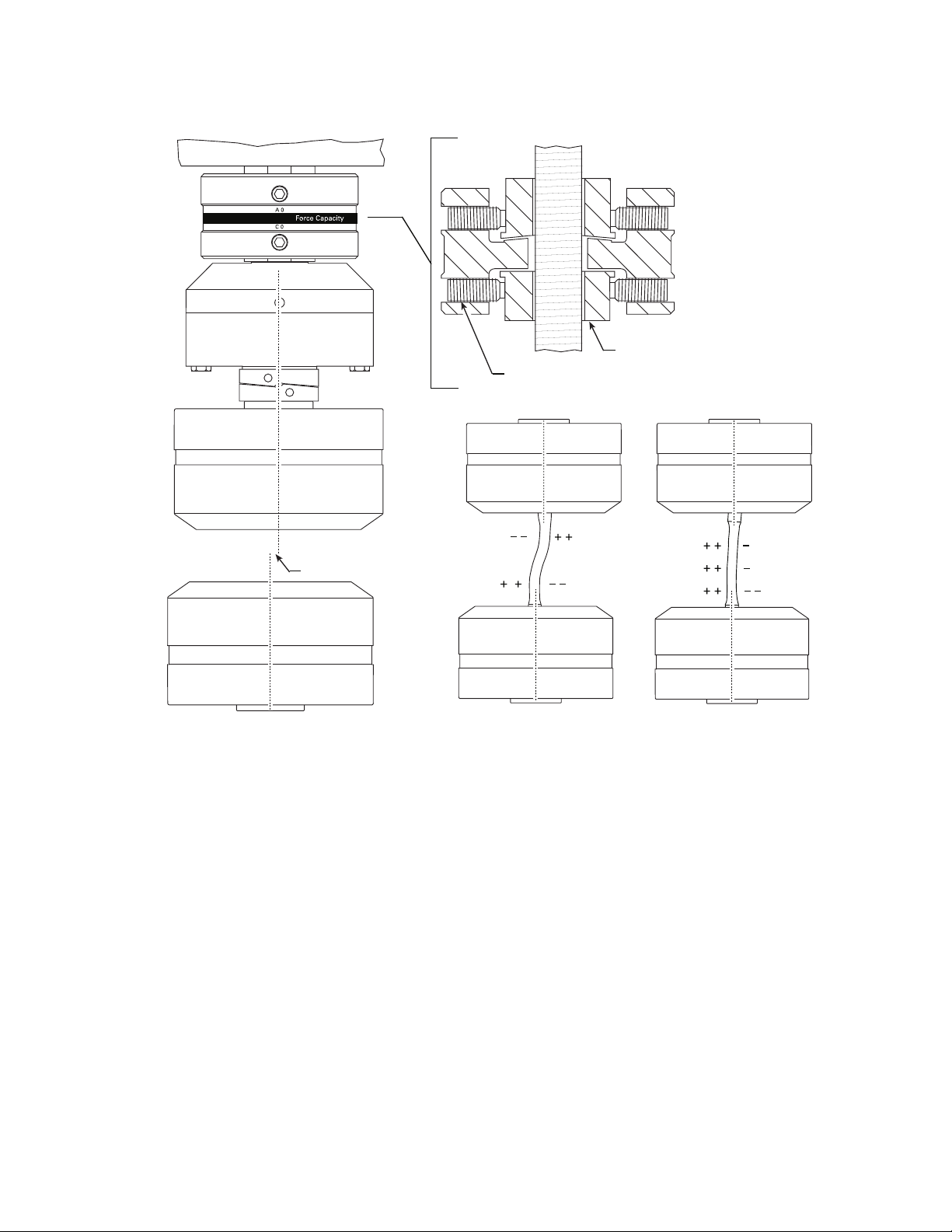

Adjust Concentric Alignment

Turning the four lower adjustment screws moves the concentricity collar. Moving

the collar laterally shifts the upper grip’s position. This aligns the grips’

centerlines, improving their concentric alignment.

The effect of improved concentricity on a specimen is to reduce its “S” bend and

the strains that go with this bend.

As “S” bend strains fade into the background, “C” bend strains come to the

foreground. (Remember that concentric and angular misalignment can occur

together, putting “S” and “C” bends into the same specimen.)

For many test procedures, removing the “S” bend alone may be enough to get

your bending strains within specifications.

Introduction

16

Series 609 Alignment Fixture Product Information

Page 17

About Angular Misalignment

Concentricity Collar

Concentricity Adjustment Screws

Before and After

Concentric

Adjustment

Misalignment

Improving Concentric Alignment

About Angular Misalignment

Angular misalignment angles the upper grip’s loading axis away from the lower

grip’s loading axis. This misalignment puts a “C”-shaped bend in the specimen.

A specimen with a “C” bend has a side with higher than average strains and a

side opposite with lower than average strains. The bending strain is uniform over

the entire gage section.

Again, actual strain readings vary with the amount of tensile load applied to the

specimen.

With zero or low tensile force applied to the specimen, you can have tensile

readings on one side of the specimen and compressive strain readings on the

other side of the specimen.

Under higher tensile force, you can have higher tensile readings on one side of

the specimen and lower tensile readings on the other side of the specimen.

Series 609 Alignment Fixture Product Information Introduction

17

Page 18

Adjust Angular Alignment

+ +

+ +

+ +

Angular Misalignment Produces a “C” Bend

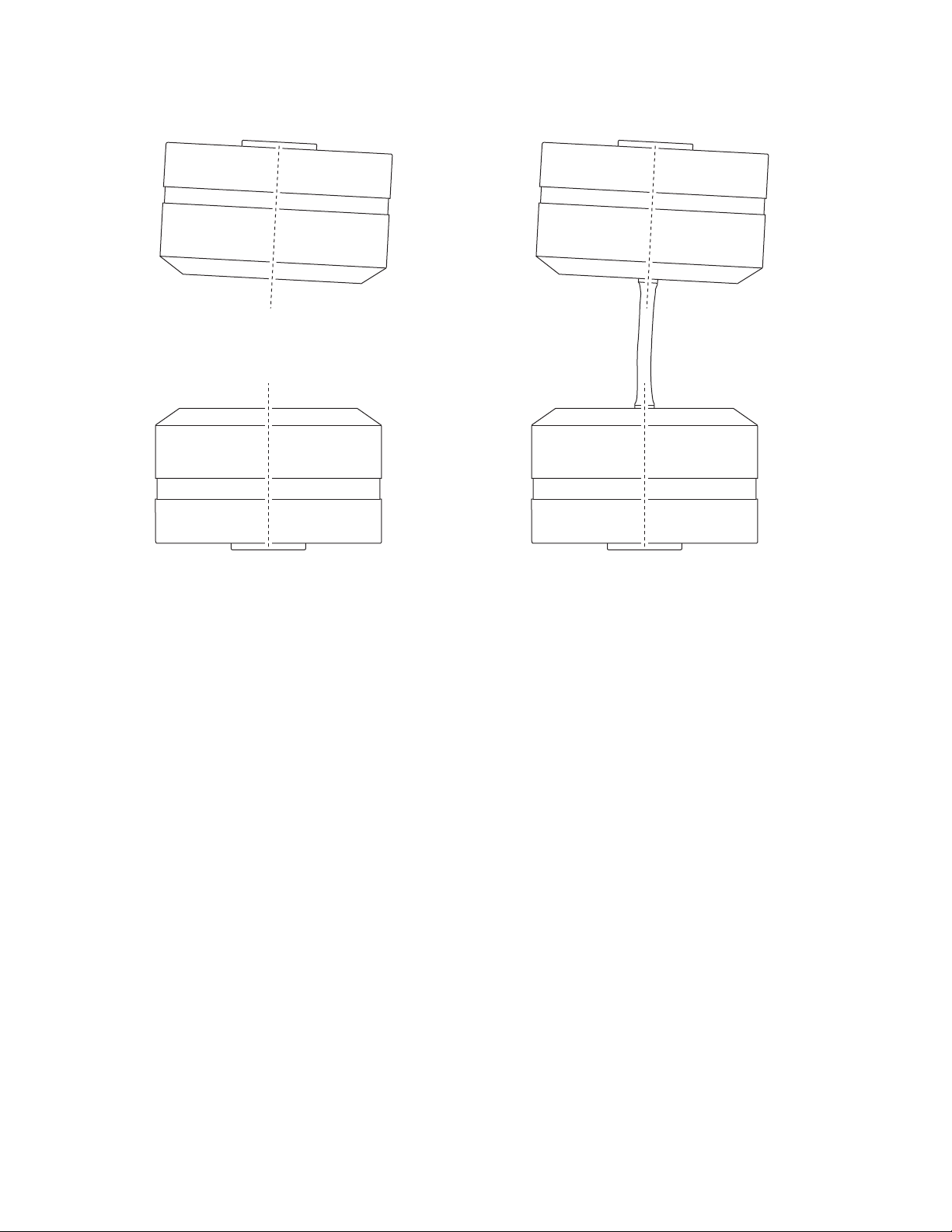

Adjust Angular Alignment

Turning the four upper adjustment screws against the angularity collar moves the

housing. The mating surfaces of the angularity collar and housing are spherical.

This tilts the housing as it moves. This tilt gets the grips’ faces parallel,

improving their angular alignment.

Improved angularity reduces the specimen’s “C” bend and the strains that go with

this bend.

Removing the “C” bend can create another “S” bend which may need to be

reduced.

You may have to go back and forth between reducing the “S” bend and reducing

the “C” bend to get the bending strain within specifications.

18

Introduction

Series 609 Alignment Fixture Product Information

Page 19

Adjust Angular Alignment

Housing

Angularity Collar

Angularity Adjustment Screws

Equal

Strain

Equal

Strain

Before and After Angular Adjustment

Misalignment

Improving Angular Alignment

Series 609 Alignment Fixture Product Information Introduction

19

Page 20

Adjust Angular Alignment

20

Introduction

Series 609 Alignment Fixture Product Information

Page 21

Safety Information

Serial No.

Rev.

Model No.

Part No.

PN 491909-01

PN 491906-01

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN USA 55344

609 Alignment Fixture

Force Capacity:

100 kN / 22 kip

Model No.

Part No.

Serial No.

Rev.

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following labels are typically located on the alignment fixture.

L

ABEL DESCRIPTION

Alignment Fixture ID label.

Hazard Placard Placement

Part # 049-190-901

Contains the following information:

• Model number

• Part number

• Serial Number

• Revision

Part # 049-190-601

Alternate ID label.

Contains the following information:

• Model number

• Part number

• Serial Number

• Revision

Series 609 Alignment Fixture Product Information Safety Information

21

Page 22

Hazard Placard Placement

Safety Information

22

Series 609 Alignment Fixture Product Information

Page 23

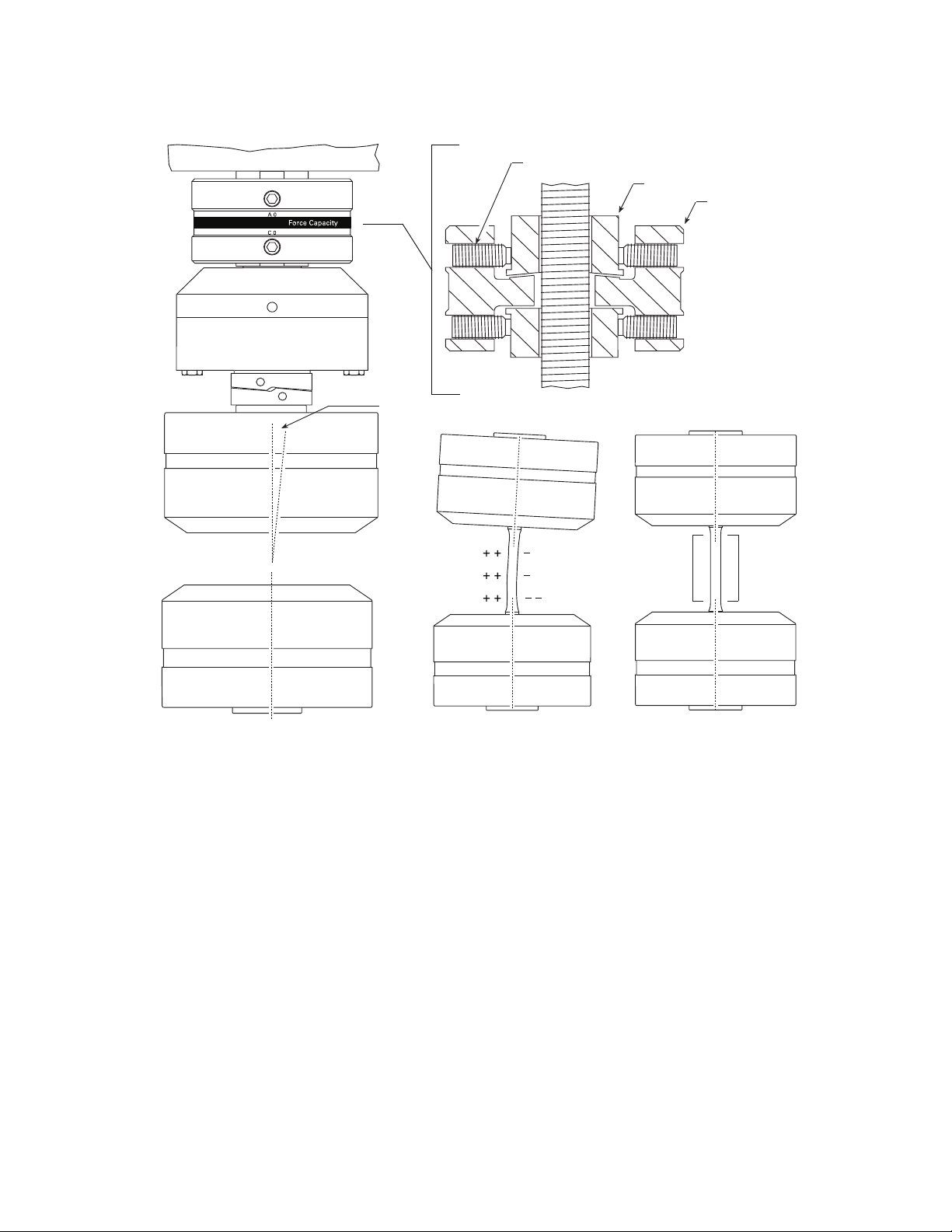

Installation

Stud

Preload Nut

Washer

Adapter Bushing

Stud

Jackbolts (6)

Preload Nut

Washer

Crosshead

Alignment Fixture

Force Transducer

Upper Grip

25 kN (5.5 kip) Installation

50 kN (11 kip) Installation

This section describes how to install the Series 609 Alignment Fixture.

As shown in the following figure, the Series 609 Alignment Fixture is installed

between the force transducer and crosshead. The mounting stud threads through

the crosshead, through the 609 Alignment Fixture, and then screws into the force

transducer.

Series 609 Alignment Fixture Product Information Installation

Alignment Fixture Components

23

Page 24

Note The following procedure assumes the force transducer is mounted to the

1

6

4

2

3

5

1

23

4

5

6

7

8

crosshead. If you have a crosshead mounted actuator, the force

transducer is mounted to the base plate. Make the appropriate changes

to the following procedure to compensate for this difference.

To install the alignment fixture:

1. If installed, remove the upper grip.

See your grip manual for procedures to remove the upper grip. Read through

the procedure before removing the grips to ensure that you understand the

process. Return to this procedure when the grip has been removed.

2. Remove the force transducer.

See your load unit manual for more information about how the force

transducer is mounted.

A. Remove the preload.

Loosen the preload nut or back off the jackbolts in 1/4 turns (using the

following sequence) to completely remove the preload.

24

Installation

B. Unscrew the force transducer from the mounting stud.

C. Unscrew the preload nut or collar. Also remove any adapters or

washers.

D. Remove the mounting stud from the crosshead (you may need to move

the crosshead to obtain clearance).

3. Install the alignment fixture.

See “Alignment Fixture Components” as a reference during this step.

A. Lubricate the stud and force transducer threads.

Series 609 Alignment Fixture Product Information

Page 25

For the jackbolts, lightly lubricate the preload collar and its washer

Lubricate

Lubricate

Lubricate

Lubricate

OR

Styrofoam Bead

with Molykote G-n paste. Remove the jackbolts and lightly lubricate

them. Reinstall the jackbolts so that they are flush with the bottom of

the collar.

For the preload nut, lubricate the washer and adapter bushing.

B. Screw the mounting stud into the top of the force transducer. A

styrofoam bead will make future stud removal easier. Do not screw the

stud all the way into the force transducer.

C. Remove grease from the surfaces of where the alignment fixture will

contact the crosshead and force transducer. Use a cleaner that leaves no

residue (like acetone).

D. Install the alignment fixture on the force transducer’s mounting stud.

Ensure that the 0° mark faces the front of the load unit.

Series 609 Alignment Fixture Product Information Installation

25

Page 26

C 0

A 0

Force Capacity

A0

WARNING

E. Install the force transducer and alignment fixture assembly into the

crosshead. Carefully lower the crosshead so that the mounting stud

goes through the crosshead.

F. Screw the preload collar or nut onto the mounting stud. Tighten the

preload collar or nut until the alignment fixture is snug against the

crosshead. Ensure that the 0° mark remains facing to the front of the

load unit.

4. Check the alignment of the force transducer and alignment fixture assembly.

If your load unit manual includes a procedure to align the force transducer,

skip this step and complete the alignment procedure in your load unit

manual.

If not, complete the following procedure:

A. Position the actuator at midstroke.

B. Move the crosshead so that there is about 360 mm (14 in) between the

top of the actuator and the bottom of the force transducer. Lock the

crosshead.

Alignment takes place in a crush zone with hydraulic pressure on.

Hands can be crushed and equipment can be damaged equipment when

hydraulics are turned on.

26

Installation

Be careful when working in a crush zone.

Series 609 Alignment Fixture Product Information

Page 27

To reduce the hazards in this procedure:

Zero

Read along

the inside edge.

360°

Zero

Read along

the edge.

360°

• Ensure that you set and enable displacement interlocks to limit the

actuator’s movement.

• Ensure that the crosshead is locked.

• Reduce the load unit’s hydraulic pressure to low.

• Keep your hands out of the crush zone except when performing the steps

needed to complete this procedure.

C. Attach the dial indicator to the actuator.

On a low profile force transducer, adjust the indicator to take the

reading along the edge of the loading surface.

On a cylindrical style force transducer, adjust the indicator so that its

stylus just touches the polished bottom edge of the transducer.

D. Zero the indicator.

E. Slowly turn the actuator to rotate the indicator 360° around the force

transducer.

Note The actuator cannot rotate on axial-torsional load units. Either disable

the antirotate hardware or move the dial indicator around the actuator.

Stop frequently to take indicator readings. Keep your hands off the

actuator and indicator when taking the readings. Compute the total

indicator runout (TIR): take the maximum dial indicator reading and

subtract the minimum dial indicator reading.

L

250 kN (55 kip) or less >0.038 mm (0.0015 in)

500 kN (100 kip) >0.051 mm (0.0020 in)

OAD UNIT RATING TIR

Series 609 Alignment Fixture Product Information Installation

27

Page 28

F. If the TIR is 0.038 mm (0.0015 in) or less, the force transducer is

1

6

4

2

5

3

1

2

3

4

5

6

7

8

accurately aligned with the actuator. Go to Step 6.

If the TIR is greater than 0.038 mm (0.0015 in), the force transducer

needs to be aligned with the actuator. Continue to Step 5.

5. Align the force transducer.

To align a force transducer to the crosshead:

A. Lightly tap the transducer with the rubber mallet to change its position

until you get a TIR of 0.038 mm (0.0015 in) or less.

B. Hand-tighten the hex nut or preload collar jackbolts.

C. Rotate the indicator to see if the TIR is still 0.038 mm (0.0015 in) or

less. If not, loosen the nut or preload collar and return to

Step A. (Loosen the preload collar using the following sequence.)

D. Once the force transducer is aligned, tighten the hex nut or preload

collar jackbolts to the final torque shown on the identification plate.

Tighten the force transducer for the following torque progression: 50%,

75%, and 100% according to the following bolt sequence.

Bolt Torque Sequence

E. Preload collar only—For uniform tightness, retorque the jackbolts or

setscrews to 100% of the final torque shown on the identification plate.

6. Install the grips.

Refer to your grip manual in order to install the grips.

Installation

28

Series 609 Alignment Fixture Product Information

Page 29

Specimen Preparation

Gage

Section

This section shows you where to place strain gages to create a gaged specimen.

Formulas are also provided as a reference during the alignment procedure.

Contents About Gaged Specimens 29

Round Thick Diameter Specimens 31

Round Thin Diameter Specimens 34

Flat Thick Specimens 37

Flat Thin Specimens 40

Notched Round Thick Diameter Specimens 42

Notched Round Thin Diameter Specimens 44

Notched Flat Thick Specimens 48

Notched Thin Flat Specimens 51

About Gaged Specimens

About Gaged Specimens

A specimen with strain gages is needed to measure and correct concentric and

angular misalignment. This specimen’s dimensions and material should match as

closely as possible the actual specimens that you will be testing.

Gages should be general purpose, single element, axial strain gage types. Place

the gages as uniaxially as possible. Tilted and crooked gages will give inaccurate

readings. Your specimen’s size and material will determine the gage size and

adhesive backing.

Series 609 Alignment Fixture Product Information Specimen Preparation

29

Page 30

About Gaged Specimens

Because misalignment produces bending strain, many test procedures verify

alignment by specifying the maximum bending strain allowed in a specimen at a

given load. This is expressed as a percent of axial strain and is usually limited to

5–10% of axial strain. Specimens with strain gages are used to measure the

maximum bending strain.

A typical gaged specimen has three levels of strain gages in its gage section. The

gages allow you to determine bending strains at each level.

In addition, the strain readings give you a picture of the “S” and “C” bends

caused by concentric and angular misalignment. Used with the formulas in this

section, they show how to move the alignment fixture to improve alignment.

Note Before beginning the alignment procedure, review the formulas in this

section. You may want to write a computer program to work through the

formulas or you can purchase the Model 709 Easy Alignment software

from MTS Systems Corporation.

Specimen Preparation

30

Series 609 Alignment Fixture Product Information

Page 31

Round Thick Diameter Specimens

1234

5678

9101112

0° 90° 180° 270°

A typical gaged specimen has three levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produce a

profile of the grip alignment.

Gage placement Use twelve gages on large diameter round specimens. Attach and number them

as shown here.

Round Thick Diameter Specimens

Series 609 Alignment Fixture Product Information Specimen Preparation

Gage Placement—Four Gage Round Specimens

• Place the gages at the top, middle, and bottom of the gage section. Space

them at 90° intervals.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section.

• Center the middle gages in the middle of the gage section.

• Place the bottom set of gages so that their lower edges just touch the lower

edge of the gage section.

31

Page 32

Calculating Bending Strain—Round Thick Diameter

Bu

x

ε1ε3–

2

----------------=

Bu

y

ε2ε4–

2

----------------=

Bm

x

ε5ε7–

2

----------------=

Bm

y

ε6ε8–

2

----------------=

Bl

x

ε9ε11–

2

------------------=

Bl

y

ε10ε12–

2

---------------------=

Middle Gages

Lower Gages

Bu Bux()2Buy()

2

+= Bm Bmx()2Bmy()

2

+= Bl Blx()2Bly()

2

+=

Upper Gages

Middle Gages Lower Gages

Calculating Bending Strain—Round Thick Diameter Specimens

This section shows how to calculate the bending strain for round specimens with

four gages at each level.

Gage Placement

1. Calculate the bending strains for each level.

Where: ε

2. Calculate the maximum bending strain for each level.

Use these formulas to find the x axis (B

) and y axis (By) bending strains of

x

each level:

through ε12 are the strain readings from gages 1 through 12

1

Bu

is the bending strain of the x axis of the upper gages

x

Bm

is the bending strain of the x axis of the middle gages

x

Bl

is the bending strain of the x axis of the lower gages

x

Bu

is the bending strain of the y axis of the upper gages

y

is the bending strain of the y axis of the middle gages

Bm

y

Bl

is the bending strain of the y axis of the lower gages

y

Do not overlook the sign of negative numbers.

Use this formula to find the maximum bending strain (B):

32

Where: Bu is the bending strain of the upper gages

Bm is the bending strain of the middle gages

Bl is the bending strain of the lower gages

3. Calculate the average axial strain for each level.

Specimen Preparation

Series 609 Alignment Fixture Product Information

Page 33

Calculating Bending Strain—Round Thick Diameter

Au

ε

1ε2ε3ε4

+++

4

---------------------------------------=

Am

ε

5ε6ε7ε8

+++

4

---------------------------------------=

Al

ε

9ε10ε11ε12

+++

4

----------------------------------------------=

Upper Gages

Middle Gages

Lower Gages

PBSu

Bu

Au

-------

100×=

PBSm

Bm

Am

--------

100×=

PBSl

Bl

Al

-----

100×=

Upper Gages

Middle Gages Lower Gages

φ arc

Bu

x

Bu

y

---------

tan=

φ arc

Bm

x

Bm

y

----------

tan=

φ arc

Bl

x

Bl

y

-------

tan=

Upper Gages

Middle Gages Lower Gages

Use this formula to find the average axial strain (A):

Where: ε

through ε12 are the strain readings from gages 1 through 12

1

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

4. Calculate the percent bending strain for each level.

Use this formula to find the percent bending strain (PBS):

Where: Bu is the bending strain of the upper gages

Bm is the bending strain of the middle gages

Bl is the bending strain of the lower gages

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

5. Calculate the direction of the maximum strain for each level.

Use this formula to find the direction (φ) of the maximum (most tensile)

bending strain:

Where: (φ) is measured from the highest reading (most tensile) strain gage toward

the second highest reading strain gage

Bu

is the highest strain of the x axis of the upper gages

x

is the highest strain of the x axis of the middle gages

Bm

x

Bl

is the highest strain of the x axis of the lower gages

x

is the highest strain of the y axis of the upper gages

Bu

y

is the highest strain of the y axis of the middle gages

Bm

y

Bl

is the highest strain of the y axis of the lower gages

y

The bending strain directions for all levels should generally agree if you

have satisfactorily removed the “S” bend.

Series 609 Alignment Fixture Product Information Specimen Preparation

33

Page 34

Round Thin Diameter Specimens

123

456

0° 120° 240°

Round Thin Diameter Specimens

A typical gaged specimen has three levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produce a

profile of the grip alignment.

Gage placement On small diameter specimens where you cannot use four gages at each level, use

three gages at each level. Attach and number the nine gages as shown here.

Specimen Preparation

34

Gage Placement—Three Gage Round Specimens

• Place the gages at the top, middle, and bottom of the gage section. Space

them at 120° intervals.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section.

• Center the middle gages in the middle of the gage section.

• Place the bottom set of gages so that their lower edges just touch the bottom

of the gage section.

Series 609 Alignment Fixture Product Information

Page 35

Calculating Bending Strain—Round Thin Diameter

Au

ε

1ε2ε3

++

3

----------------------------= Am

ε

4ε5ε6

++

3

----------------------------= Al

ε

7ε8ε9

++

3

----------------------------=

Upper Gages

Middle Gages Lower Gages

bu0°ε1A–=

bu

120°ε2

A–=

bu

240°ε3

A–=

bm

0°ε4

A–=

bm

120°ε5

A–=

bm

240°ε6

A–=

bl

0°ε7

A–=

bl

120°ε8

A–=

bl

240°ε9

A–=

Upper Gages

Middle Gages Lower Gages

Calculating Bending Strain—Round Thin Diameter Specimens

This section shows how to calculate the bending strain for round specimens with

three gages at each level.

Gage Placement

1. Calculate the average axial strain for each level.

Use this formula to find the average axial strain (A):

Where: ε

2. Calculate the bending strain for each axis and each level.

Where: ε

3. Determine the tensile direction for each level.

through ε9 are the strain readings from gages 1 through 9

1

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

Use these formulas to determine the bending strain (B):

through ε9 are the strain readings from gages 1 through 9

1

bu is the bending strain of the upper gages

bm is the bending strain of the middle gages

bl is the bending strain of the lower gages

subscript

subscript

subscript

is the bending strain of the 0° axis

0

is the bending strain of the 120° axis

120

is the bending strain of the 240° axis

240

Determine the two most positive (tensile) results for each level from Step 2.

• Call the largest b

• Call the second largest b

Series 609 Alignment Fixture Product Information Specimen Preparation

.

1

.

2

35

Page 36

Calculating Bending Strain—Round Thin Diameter

φ arc

bu

2

bu

1

-------- 0 . 5+

0.866

-----------------------

tan= φ arc

bm

2

bm

1

----------0.5+

0.866

------------------------

tan= φ arc

bl

2

bl

1

------- 0 . 5+

0.866

---------------------

tan=

Upper Gages

Middle Gages Lower Gages

Bu

b

1

θcos

------------=

Bm

b

1

θcos

------------=

Bl

b

1

θcos

------------=

Upper Gages

Middle Gages Lower Gages

PBS

Bu

Au

-------

100×=

PBS

Bm

Am

--------

100×=

PBS

Bl

Al

-----

100×=

Upper Gages

Middle Gages Lower Gages

4. Calculate the direction of the maximum strain for each level.

Use this formula to find the direction (φ) of the maximum (most tensile)

bending strain:

Where: (φ) is measured from the highest reading (most tensile) strain

gage toward the second highest reading strain gage

b

is the highest strain reading of a given level

1

b

is the second highest reading of a given level

2

The bending strain directions for all levels should generally agree if you

have satisfactorily removed the “S” bend.

5. Calculate the maximum bending strain for each level.

Use this formula to find the maximum bending strain (B) at this gage level:

Where: Bu is the bending strain of the upper gages

Bm is the bending strain of the middle gages

Bl is the bending strain of the lower gages

b

is the highest strain reading of a given level

1

6. Calculate the percent bending strain for each level.

Use this formula to find the percent bending strain (PBS):

Where: Bu is the bending strain of the upper gages

Bm is the bending strain of the middle gages

Bl is the bending strain of the lower gages

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

36

Specimen Preparation

Series 609 Alignment Fixture Product Information

Page 37

Flat Thick Specimens

1

2

34

5678

9101112

0° 90° 180° 270°

Gage placement Use twelve gages on thick flat specimens. Attach and number them as shown

Flat Thick Specimens

A typical gaged specimen has three levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produces

a profile of the grip alignment.

here.

Series 609 Alignment Fixture Product Information Specimen Preparation

Gage Placement—Thick Flat Specimens

• Place the gages in sets of four, at the top, middle, and bottom of the gage

section. Center each gage between the edges of the specimen.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section.

• Place the middle set of gages in the middle of the gage section.

• Place the bottom set of gages so that their lower edges just touch the lower

edge of the gage section.

37

Page 38

Calculating Bending Strain—Flat Thick Specimens

Bu

x

ε1ε3–

2

----------------=

Bu

y

ε2ε4–

2

----------------=

Bm

x

ε5ε7–

2

----------------=

Bm

y

ε6ε8–

2

----------------=

Bl

x

ε9ε11–

2

------------------=

Bl

y

ε10ε12–

2

---------------------=

Upper Gages

Middle Gages Lower Gages

Au

ε

1ε2ε3ε4

+++

4

---------------------------------------= Am

ε

5ε6ε7ε8

+++

4

---------------------------------------= Al

ε

9ε10ε11ε12

+++

4

----------------------------------------------=

Upper Gages

Middle Gages Lower Gages

Calculating Bending Strain—Flat Thick Specimens

This section shows how to calculate the bending strain for flat specimens with

four gages at each level.

Gage Placement

1. Calculate the bending strains for each level.

Where: ε

2. Calculate the average axial strain for each level.

Use these formulas to find the x axis (B

) and y axis (By) bending strains of

x

each level:

through ε12 are the strain readings from gages 1 through 12

1

Bu

is the bending strain of the x axis of the upper gages

x

Bm

is the bending strain of the x axis of the middle gages

x

is the bending strain of the x axis of the lower gages

Bl

x

Bu

is the bending strain of the y axis of the upper gages

y

Bm

is the bending strain of the y axis of the middle gages

y

Bl

is the bending strain of the y axis of the lower gages

y

Do not ignore the sign of negative numbers.

Use this formula to find the average axial strain (A):

Specimen Preparation

38

Where: ε

through ε12 are the strain readings from gages 1 through 12

1

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

Series 609 Alignment Fixture Product Information

Page 39

Calculating Bending Strain—Flat Thick Specimens

PBS

Bu

Au

-------

100×=

PBS

Bm

Am

--------

100×=

PBS

Bl

Al

-----

100×=

Upper Gages

Middle Gages Lower Gages

3. Calculate the percent bending strain for each level.

Use this formula to find the percent bending strain (PBS):

Where: Bu is the bending strain of the upper gages

Bm is the bending strain of the middle gages

Bl is the bending strain of the lower gages

Au is the average strain of the upper gages

Am is the average strain of the middle gages

Al is the average strain of the lower gages

Calculate the strain for both axis (PBS

and PBSy).

x

4. Determine which axis is bending.

• Bending strain along one axis (usually the y axis) can be corrected by

clamping and unclamping the specimen.

• Bending strain along the other axis (usual the x axis) can be corrected

by using the alignment fixture.

Series 609 Alignment Fixture Product Information Specimen Preparation

39

Page 40

Flat Thin Specimens

4

8

7

3

11

12

0° 90° 180° 270°

10

6

5

9

1

2

Flat Thin Specimens

Gage placement Use twelve gages on thin flat specimens. Attach and number them as shown here.

A typical gaged specimen has three levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produces

a profile of the grip alignment.

Specimen Preparation

40

Gage Placement—Thin Flat Specimens

• On thin rectangular specimens where gages can not be attached to all four

sides, use this twelve gage front-to-back arrangement. Attach and number

the gages as shown here.

• Place the gages in sets of four, at the top, middle, and bottom of the gage

section. Place each gage as close as practical to the edge of the specimen.

Keep the distance from the edge the same for all gages. Measure the

distance from the edge of the specimen to the middle of the gage. This

distance will be used in your bending strain calculations.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section. Place the middle set of gages in the middle of the gage

section. Place the bottom set of gages so that their lower edges just touch the

lower edge of the gage section.

Series 609 Alignment Fixture Product Information

Page 41

Calculating Bending Strain—Flat Thin Specimens

Bu

x

1

4

---

ε

1ε2ε3

– ε4–+()=

Bu

x

w

4

----

ε

1ε2ε3

– ε4–+

w 2d–

---------------------------------------

⎝⎠

⎛⎞

=

Bm

x

1

4

---

ε

5ε6ε7

– ε8–+()=

Bm

x

w

4

----

ε

5ε6ε7

– ε8–+

w 2d–

---------------------------------------

⎝⎠

⎛⎞

=

Bl

x

1

4

---

ε

9ε10ε11

– ε12–+()=

Bl

x

w

4

----

ε

9ε10ε11

– ε12–+

w 2d–

----------------------------------------------

⎝⎠

⎛⎞

=

Upper Gages

Middle Gages Lower Gages

PBS

x

4 Bux()

ε

1ε2ε3ε4

+++

---------------------------------------

100×= PBS

x

4 Bmx()

ε

5ε6ε7ε8

+++

---------------------------------------

100×= PBS

x

4 Blx()

ε

9ε10ε11ε12

+++

----------------------------------------------

100×=

PBS

y

4 Buy()

ε

1ε2ε3ε4

+++

---------------------------------------

100×= PBS

y

4 Bmy()

ε

5ε6ε7ε8

+++

---------------------------------------

100×= PBS

y

4 Bly()

ε

9ε10ε11ε12

+++

----------------------------------------------

100×=

Upper Gages

Middle Gages Lower Gages

Calculating Bending Strain—Flat Thin Specimens

This section shows how to calculate the bending strain for round specimens with

four gages at each level.

Gage Placement

1. Calculate the bending strains for each level.

Where: ε

2. Calculate the percent bending strain for each level.

Use these formulas to find the x axis (B

) and y axis (By) bending strains of

x

each level:

through ε12 are the strain readings from gages 1 through 12

1

w is the width of the specimen

d is the distance from the specimen edge to the middle of the gage

Bu

is the bending strain of the x axis of the upper gages

x

Bm

is the bending strain of the x axis of the middle gages

x

Bl

is the bending strain of the x axis of the lower gages

x

Bu

is the bending strain of the y axis of the upper gages

y

is the bending strain of the y axis of the middle gages

Bm

y

Bl

is the bending strain of the y axis of the lower gages

y

Do not ignore the sign of negative numbers.

Series 609 Alignment Fixture Product Information Specimen Preparation

Use this formula to find the percent bending strain (PBS):

41

Page 42

Notched Round Thick Diameter Specimens

1

2

34

567

8

0° 90° 180° 270°

Where: See the definitions above.

Notched Round Thick Diameter Specimens

A typical notched gaged specimen has two levels of strain gages. The gages

allow you to determine bending strains at each level. Analysis of the strain

readings produces a profile of the grip alignment.

Gage placement Use eight gages on large diameter round specimens. Attach and number them as

shown here.

Specimen Preparation

42

Gage Placement—Notched Four Gage Round Specimens

• Place the gages at the top, middle, and bottom of the gage section. Space

them at 90° intervals.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section.

• Center the middle gages in the middle of the gage section.

• Place the bottom set of gages so that their lower edges just touch the lower

edge of the gage section.

Series 609 Alignment Fixture Product Information

Page 43

Calculating Bending Strain—Notched Round Thick

Bu

x

ε1ε3–

2

----------------=

Bu

y

ε2ε4–

2

----------------=

Bl

x

ε5ε7–

2

----------------=

Bl

y

ε6ε8–

2

----------------=

Upper Gages Lower Gages

Bu Bux()2Buy()

2

+= Bl Blx()2Bly()

2

+=

Upper Gages Lower Gages

Calculating Bending Strain—Notched Round Thick Diameter Specimens

This section shows how to calculate the bending strain for round specimens with

four gages at each level.

Gage Placement

1. Calculate the bending strains for each level.

Where: ε

2. Calculate the maximum bending strain for each level.

Use these formulas to find the x axis (B

) and y axis (By) bending strains of

x

each level:

through ε8 are the strain readings from gages 1 through 8

1

Bu

is the bending strain of the x axis of the upper gages

x

Bl

is the bending strain of the x axis of the lower gages

x

is the bending strain of the y axis of the upper gages

Bu

y

Bl

is the bending strain of the y axis of the lower gages

y

Do not ignore the signs on negative numbers.

Use this formula to find the maximum bending strain (B):

Series 609 Alignment Fixture Product Information Specimen Preparation

Where: Bu is the bending strain of the upper gages

Bl is the bending strain of the lower gages

3. Calculate the average axial strain for each level.

Use this formula to find the average axial strain (A):

43

Page 44

Notched Round Thin Diameter Specimens

Au

ε

1ε2ε3ε4

+++

4

---------------------------------------= Al

ε5ε6ε7ε

8

+++

4

---------------------------------------=

Upper Gages Lower Gages

PBSu

Bu

Au

-------

100×=

PBSl

Bl

Al

-----

100×=

Upper Gages Lower Gages

φ arc

Bu

x

Bu

y

---------

tan=

φ arc

Bl

x

Bl

y

-------

tan=

Upper Gages Lower Gages

Where: ε

through ε8 are the strain readings from gages 1 through 8

1

Au is the average strain of the upper gages

Al is the average strain of the lower gages

4. Calculate the percent bending strain for each level.

Use this formula to find the percent bending strain (PBS):

Where: Bu is the bending strain of the upper gages

Bl is the bending strain of the lower gages

Au is the average strain of the upper gages

Al is the average strain of the lower gages

5. Calculate the direction of the maximum strain for each level.

Use this formula to find the direction (φ) of the maximum (most tensile)

bending strain:

Where: (φ) is measured from the highest reading (most tensile) strain

Notched Round Thin Diameter Specimens

Gage placement On small diameter specimens where you can not use four gages at each level, use

Specimen Preparation

44

gage toward the second highest reading strain gage

Bu

is the highest strain of the x axis of the upper gages

x

is the highest strain of the x axis of the lower gages

Bl

x

is the highest strain of the y axis of the upper gages

Bu

y

Bl

is the highest strain of the y axis of the lower gages

y

The bending strain directions for all levels should generally agree if you

have satisfactorily removed the “S” bend.

A typical gaged specimen has two levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produce a

profile of the grip alignment.

three gages at each level. Attach and number the six gages as shown here.

Series 609 Alignment Fixture Product Information

Page 45

Calculating Bending Strain—Notched Round Thin

123

456

0° 120° 240°

Calculating Bending Strain—Notched Round Thin Diameter Specimens

Gage Placement—Notched Three Gage Round Specimens

• Place the gages at the top, middle, and bottom of the gage section. Space

them at 120° intervals.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section.

• Place the bottom set of gages so that their lower edges just touch the bottom

of the gage section.

This section shows how to calculate the bending strain for round specimens with

three gages at each level.

Gage Placement

Series 609 Alignment Fixture Product Information Specimen Preparation

45

Page 46

Calculating Bending Strain—Notched Round Thin

Au

ε

1ε2ε3

++

3

----------------------------=

Am

ε

4ε5ε6

++

3

----------------------------=

Upper Gages Lower Gages

bu0°ε1A–=

bu

120°ε2

A–=

bu

240°ε3

A–=

bm

0°ε4

A–=

bm

120°ε5

A–=

bm

240°ε6

A–=

Upper Gages Lower Gages

φ arc

bu

1

bu

2

-------- 0 . 5+

0.866

-----------------------

tan=

φ arc

bl

1

bl

2

------- 0 . 5+

0.866

---------------------

tan=

Upper Gages Lower Gages

1. Calculate the average axial strain for each level.

Use this formula to find the average axial strain (A):

Where: ε

2. Calculate the bending strain for each axis and each level.

Where: ε

3. Determine the tensile direction for each level.

through ε6 are the strain readings from gages 1 through 6

1

Au is the average strain of the upper gages

Al is the average strain of the lower gages

Use these formulas to determine the bending strain (B):

through ε6 are the strain readings from gages 1 through 6

1

bu is the bending strain of the upper gages

bl is the bending strain of the lower gages

subscript

subscript

subscript

is the bending strain of the 0° axis

0

is the bending strain of the 120° axis

120

is the bending strain of the 240° axis

240

46

Specimen Preparation

Determine the two most positive (tensile) results for each level from Step 2.

• Call the largest b

• Call the second largest b

.

1

.

2

4. Calculate the direction of the maximum strain for each level.

Use this formula to find the direction (φ) of the maximum (most tensile)

bending strain:

Series 609 Alignment Fixture Product Information

Page 47

Calculating Bending Strain—Notched Round Thin

Bu

b

1

θcos

------------= Bl

b

1

θcos

------------=

Upper Gages Lower Gages

PBS

Bu

Au

-------

100×= PBS

Bl

Al

-----

100×=

Upper Gages Lower Gages

Where: (φ) is measured from the highest reading (most tensile) strain

gage toward the second highest reading strain gage

b

is the highest strain reading of a given level

1

b

is the second highest reading of a given level

2

The bending strain directions for all levels should generally agree if you

have satisfactorily removed the “S” bend.

5. Calculate the maximum bending strain for each level.

Use this formula to find the maximum bending strain (B) at this gage level:

Where: Bu is the bending strain of the upper gages

Bl is the bending strain of the lower gages

b

is the highest strain reading of a given level

1

6. Calculate the percent bending strain for each level.

Use this formula to find the percent bending strain (PBS):

Where: Bu is the bending strain of the upper gages

Bl is the bending strain of the lower gages

Au is the average strain of the upper gages

Al is the average strain of the lower gages

Series 609 Alignment Fixture Product Information Specimen Preparation

47

Page 48

Notched Flat Thick Specimens

4

3

0° 90° 180° 270°

6

5

1

2

7

8

Notched Flat Thick Specimens

A typical gaged specimen has two levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produces

a profile of the grip alignment.

Gage placement Use eight gages on thick flat specimens. Attach and number them as shown here.

Specimen Preparation

48

Gage Placement—Notched Thick Flat Specimens

• Place the gages in sets of four, at the top and bottom of the gage section.

Center each gage between the edges of the specimen.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section.

• Place the bottom set of gages so that their lower edges just touch the lower

edge of the gage section.

Series 609 Alignment Fixture Product Information

Page 49

Calculating Bending Strain—Notched Flat Thick

Bu

x

ε1ε3–

2

----------------=

Bu

y

ε2ε4–

2

----------------=

Bl

x

ε5ε7–

2

----------------=

Bl

y

ε6ε8–

2

----------------=

Upper Gages Lower Gages

Au

ε

1ε2ε3ε4

+++

4

---------------------------------------= Al

ε

5ε6ε7ε8

+++

4

---------------------------------------=

Upper Gages Lower Gages

Calculating Bending Strain—Notched Flat Thick Specimens

This section shows how to calculate the bending strain for flat specimens with

four gages at each level.

Gage Placement

1. Calculate the bending strains for each level.

Where: ε

2. Calculate the average axial strain for each level.

Use these formulas to find the x axis (B

) and y axis (By) bending strains of

x

each level:

through ε8 are the strain readings from gages 1 through 8

1

is the bending strain of the x axis of the upper gages

Bu

x

Bl

is the bending strain of the x axis of the lower gages

x

is the bending strain of the y axis of the upper gages

Bu

y

Bl

is the bending strain of the y axis of the lower gages

y

Do not ignore the sign of negative numbers.

Use this formula to find the average axial strain (A):

Series 609 Alignment Fixture Product Information Specimen Preparation

Where: ε

are the strain readings from gages 1 through 8

1–ε8

Au is the average strain of the upper gages

Al is the average strain of the lower gages

3. Calculate the percent bending strain for each level.

Use this formula to find the percent bending strain (PBS):

49

Page 50

Calculating Bending Strain—Notched Flat Thick

PBS

Bu

Au

-------

100×=

PBS

Bl

Al

-----

100×=

Upper Gages Lower Gages

Where: Bu is the bending strain of the upper gages

Bl is the bending strain of the lower gages

Au is the average strain of the upper gages

Al is the average strain of the lower gages

4. Determine which axis is bending.

• Bending strain along one axis (usually the y axis) can be corrected by

clamping and unclamping the specimen.

• Bending strain along the other axis (usually the x axis) can be corrected

by using the alignment fixture.

Specimen Preparation

50

Series 609 Alignment Fixture Product Information

Page 51

Notched Thin Flat Specimens

4

3

0° 90° 180° 270°

6

5

1

2

7

8

A notched gaged specimen has two levels of strain gages. The gages allow you to

determine bending strains at each level. Analysis of the strain readings produces

a profile of the grip alignment.

Gage placement Use eight gages on thin flat specimens. Attach and number them as shown here.

Notched Thin Flat Specimens

Series 609 Alignment Fixture Product Information Specimen Preparation

Gage Placement—Notched Thin Flat

• On thin rectangular specimens where gages cannot be attached to all four

sides, use this eight gage front-to-back arrangement. Attach and number the

gages as shown here.

• Place the gages in sets of four, at the top and bottom of the gage section.

Place each gage as close as practical to the edge of the specimen. Keep the

distance from the edge the same for all gages. Measure the distance from the

edge of the specimen to the middle of the gage. This distance will be used in

your bending strain calculations.

• Place the top set of gages so that their upper edges just touch the upper edge

of the gage section. Place the bottom set of gages so that their lower edges

just touch the lower edge of the gage section.

51

Page 52

Calculating Bending Strain—Notched Thin Flat

Bu

x

1

4

---

ε

1ε2ε3

– ε4–+()=

Bu

y

w

4

----

ε

1ε2ε3

– ε4–+

w 2d–

---------------------------------------

⎝⎠

⎛⎞

=

Bl

x

1

4

---

ε

5ε6ε7

– ε8–+()=

Bl

y

w

4

----

ε

5ε6ε7

– ε8–+

w 2d–

---------------------------------------

⎝⎠

⎛⎞

=

Upper Gages Lower Gages

PBS

x

4 Bux()

ε

1ε2ε3ε4

+++

---------------------------------------

100×= PBS

x

4 Blx()

ε

5ε6ε7ε8

+++

---------------------------------------

100×=

PBS

y

4 Buy()

ε

1ε2ε3ε4

+++

---------------------------------------

100×= PBS

y

4 Bly()

ε

5ε6ε7ε8

+++

---------------------------------------

100×=

Upper Gages Lower Gages

Calculating Bending Strain—Notched Thin Flat Specimens

This section shows how to calculate the bending strain for round specimens with

four gages at each level.

Gage Placement

1. Calculate the bending strains for each level.

Where: ε

2. Calculate the percent bending strain for each level.

Use these formulas to find the x axis (B

) and y axis (By) bending strains of

x

each level:

through ε8 are the strain readings from gages 1 through 8

1

w is the width of the specimen.

d is the distance from the specimen edge to the middle of the gage

Bu

is the bending strain of the x axis of the upper gages

x

is the bending strain of the x axis of the lower gages

Bl

x

Bu

is the bending strain of the y axis of the upper gages

y

is the bending strain of the y axis of the lower gages

Bl

y

Do not ignore the sign of negative numbers.

Use this formula to find the percent bending strain (PBS):

52

Specimen Preparation

Where: See the previous definitions.

3. Determine which axis is bending.

Series 609 Alignment Fixture Product Information

Page 53

Calculating Bending Strain—Notched Thin Flat

• Bending strain along one axis (usual the y axis) can be corrected by

clamping and unclamping the specimen.

• Bending strain along the other axis (usually the x axis y axis) can be

corrected by using the alignment fixture.

Series 609 Alignment Fixture Product Information Specimen Preparation

53

Page 54

Calculating Bending Strain—Notched Thin Flat

Specimen Preparation

54

Series 609 Alignment Fixture Product Information

Page 55

Alignment Procedure

This section covers alignment using the two most common gaged specimens.

They are the round specimen with three gage levels, four gages per level and the

thin flat specimen, also with three gage levels, four gages per level.

Note It is important to start with the force transducer and actuator aligned. The

Series 609 Alignment Fixture is a precision instrument not intended to

correct gross misalignments. Using it to correct gross misalignments can

put high stresses on its mounting stud and shorten this stud’s fatigue life.

Note Once you have completed the alignment, do not move the crosshead. If

you do, your alignment may change and you may have to repeat the

entire alignment procedure.

If you have a question about alignment using other gaged specimens, contact

MTS Systems Corporation (see the “Contact Information“ on the back of the title

page).

Contents Installing a Gaged Specimen 56

Adjust the Concentric Alignment 58

Adjust the Angular Alignment 63

Check the Alignment 67

Prerequisite You must have the grips installed in the load unit.

Series 609 Alignment Fixture Product Information Alignment Procedure

55

Page 56

Installing a Gaged Specimen

WARNING

Crosshead

Upper Grip

Lower Grip

Specimen

Actuator

Installing a Gaged Specimen

In this section, you clamp the gaged specimen and get ready to measure bending

strain.

You will be working in a crush zone when installing the gaged specimen.

If you are not careful, you could crush anything, including your hands,

between the grips.

Ensure that the crosshead is locked, appropriate limit detectors are enabled, and

tongs are used to handle the specimen.

1. Turn on electrical power at your test controller.

Alignment Procedure

56

2. Set up your controller for specimen installation.

Series 609 Alignment Fixture Product Information

Page 57

Installing a Gaged Specimen

Select force control as your active control mode. Select the most sensitive

operating range. Set and enable displacement interlocks to limit the

actuator’s movement. Or, select a channel-limited-channel control mode

that emulates the configuration described here.

3. Turn on high hydraulic power.

4. Adjust the actuator to near mid-displacement.

5. Position the crosshead so that there is room to install the specimen into the

grips. Lock the crosshead.

Note Always lower the crosshead to its final test position.

6. Position the specimen in the lower grip so that its number one gage faces

forward. Ensure that the strain gages’ leads are not inducing any bending

strain in the specimen. Clamp the specimen in the lower grip.

7. Adjust the actuator to install the specimen into the upper grip. Clamp the

specimen in the upper grip.

8. Adjust your test controller to apply zero force to the specimen.

9. Zero all the output of the specimen’s strain gages.

Note In the next two sections you will be improving concentric and angular

alignment. As you do this, check often to make sure the force applied to

the specimen stays at zero.

Series 609 Alignment Fixture Product Information Alignment Procedure

57

Page 58

Adjust the Concentric Alignment

Record all

strain readings

to find the

maximum

bending strain.

Adjust the Concentric Alignment

In this section, you move the upper grip laterally to reduce the specimen’s “S”

bend. You will probably end up with readings characteristic of a “C” bend—

tensile and compressive readings on opposite sides of the specimen.

1. Refer to your ASTM Standard Test Method (or other appropriate standard)

for the maximum bending strain permitted.

Note Your test specification permits a maximum 10% bending strain. You will

be applying an axial force to produce 1000 µS on the specimen. 100 µS

is the maximum bending strain you can have at any gage level.

2. Write down the strain readings from each gage.

Alignment Procedure

58

Find the maximum bending strain at each gage level. Use the formulas in

“Preparing a Gaged Specimen” that are appropriate for your specimen.

• If each level’s maximum bending strain falls within specifications, go

to “Checking the Alignment.”

• If any level’s maximum bending strain exceeds specifications, continue

to Step 3.

Series 609 Alignment Fixture Product Information

Page 59

Adjust the Concentric Alignment

This figure shows how

turning the concentricity

adjustment screws affects

strain gage readings.

Note If the screws can

not be adjusted,

reduce the preload

by 50%

Loosen

Tighten

Move

This reading

moves

negative

This reading

moves

positive

This reading moves positive

This reading moves negative

3. Using the following figure, determine which screws to adjust.

• If you are making minor adjustments, keep all four screws in contact

with the concentricity collar.

• If you are making adjustments of 75 µS or more, loosen the opposing

screws. Tighten one to get a reading slightly beyond your goal. Tighten

the other to reach your goal. End with all screws tight.

• If you are adjusting a round specimen, see “Round Specimens—

Reduce the “S” Bend.”

• If you are adjusting a flat specimen, see “Thin Flat Specimens –

Reduce the “S” Bend.”

You should end up with readings characteristic of the remaining “C” bend—

uniformly higher readings on one side of the specimen and uniformly lower

readings on the specimen’s opposite side.

The following figure shows typical readings before and after an adjustment.

Series 609 Alignment Fixture Product Information Alignment Procedure

59

Page 60

Adjust the Concentric Alignment

Adjust

Upper

Middle

Lower

Upper

Middle

Lower

s (typical readings before adjustment)

t (typical readings after adjustment)

Strain Readings

Alignment Procedure

60

Round Specimens—Reduce the “S” Bend

Round specimens with three gage levels, four gages per level–adjust the

concentricity adjustment screws to move the upper and lower readings toward the

middle gage readings.

If readings from the top and bottom gages cross through the middle row’s

readings, you are overadjusting the concentricity screws.

For example, you are overadjusting if the upper 0° reading moves below 13 while

the bottom 0° reading moves above 13.

Series 609 Alignment Fixture Product Information

Page 61

Adjust the Concentric Alignment

Adjust

Upper

Middle

Lower

Upper

Middle

Lower

s (typical readings before adjustment)

t (typical readings after adjustment)

Strain Readings

A

B

A side

B side

The following figure shows typical readings before and after an adjustment.

Thin Flat Specimens – Reduce the “S” Bend

If you are using thin flat specimens with three gage levels, four gages per level,

adjust the concentricity adjustment screws to move the upper and lower readings

toward the middle gage readings.

You are overadjusting the concentricity screws if the average of either the upper