Page 1

Model 512.01 Hydraulic Power Unit

Product Information Manual

015-206-301 A

Page 2

Copyright information © 2000 MTS Systems Corporation. All rights rese rved.

Trademark information MTS is a registered trademark of MTS Systems Corporation.

DTE is a registered trademark of Mobil Corporation.

Tellus is a registered tradema r k of Shell Oil Corporation.

Synasol is a registered trademark of Union Carbide Corporation.

Contact information MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information

Manual Part Number Publication Date

015-206-301 A

October 1998

Page 3

Contents

Introduction 5

Functional Description 6

Component Identification 8

Specifications 10

Dimensions 11

Installation 13

Operation 17

Maintenance 19

Reducing the Fluid Temperature 20

Adding Hydraulic Fluid 21

Resetting the Thermal Overloads 22

Adjusting the Output Pressure 23

Changing the Filter 24

Changing the Hydraulic Fluid 25

Model 512.01 Hydraulic Power Unit Contents

3

Page 4

4

Contents

Model 512.01 Hydraulic Power Unit

Page 5

Introduction

Contents

Functional Description 6

Component Identification 8

Specifications 10

This manual documents the Model 512.01 Hydraulic Power Unit (HPU),

also called a hydraulic power supply, HPS, or pump. This compact

hydraulic power unit is designed for use with low force testing systems. It

includes an air cooled heat exchanger to maintain the operating

temperature range.

l

Model 512.01 Hydraulic Power Unit

What you need to

know

Model 512.01 Hydraulic Power Unit Introduction

MTS Systems Corporation assumes that you know how to use your

controller. See the appropriate manual for information about performing

any controller-related step in this manual’s procedures. You are expected

to know how to perform the following procedures:

• Using the controller hydraulic power unit controls in conjunction with

the control located on the HPU.

• Controlling hydraulic fluid flow to other hydraulic equipment.

5

Page 6

Functional Description

The hydraulic power unit (HPU) is the mechanical source of high-pressure

hydraulic fluid required to operate the hydraulic components of a test

system. See “Component Identification” on page 8 for more information

about the components described in this section.

Pump motor

Pressure

Filtering

Heat exchanger

A motor drives a hydraulic pump which draws hydraulic fluid from a

reservoir and pressurizes it to 6.9 MPa (1000 psi). The pressurized fluid is

made available to the hydraulic components in your test system.

The HPU pressure output is adjusted with a pressure reducing valve which

is factory set to 6.9 MPa (1000 psi). If the output pressure exceeds the

pressure setting, a pressure relief valve shunts the excessive pressure to the

hydraulic return line. The output pressure can be set to 6.9 MPa (1000 psi)

or less.

The filtration system protects against silting by cleaning the hydraulic fluid

to an ISO particle count of 14/10 or better. The filter change gage indicates

when the filter needs to be changed.

A suction strainer protects the pump from larger particles when the fluid is

pumped from the reservoir. It is located in the bottom of the hydraulic fluid

reservoir.

Hydraulic fluid temperature is maintained with a heat exchanger that cools

the fluid. The heat exchanger helps keep the temperature of the hydraulic

fluid between 43–52°C (109–126°F). The temperature of the fluid is

monitored by an overtemperature switch. If the fluid temperature exceeds

55ºC (130ºF), a switch opens and shuts down the HPU. The system cannot

be restarted until the fluid cools.

6

Electronics

Introduction

The air-cooled heat exchanger cools the hydraulic fluid as it passes

through a radiator. A fan blows air through the radiator to transfer heat

from the radiator to the air.

The HPU has basic controls to turn it on and off. The HPU includes a

connector to add a remote Emergency Stop switch. The HPU requires an

Emergency Stop switch or a jumper plug to be installed in order to run.

Model 512.01 Hydraulic Power Unit

Page 7

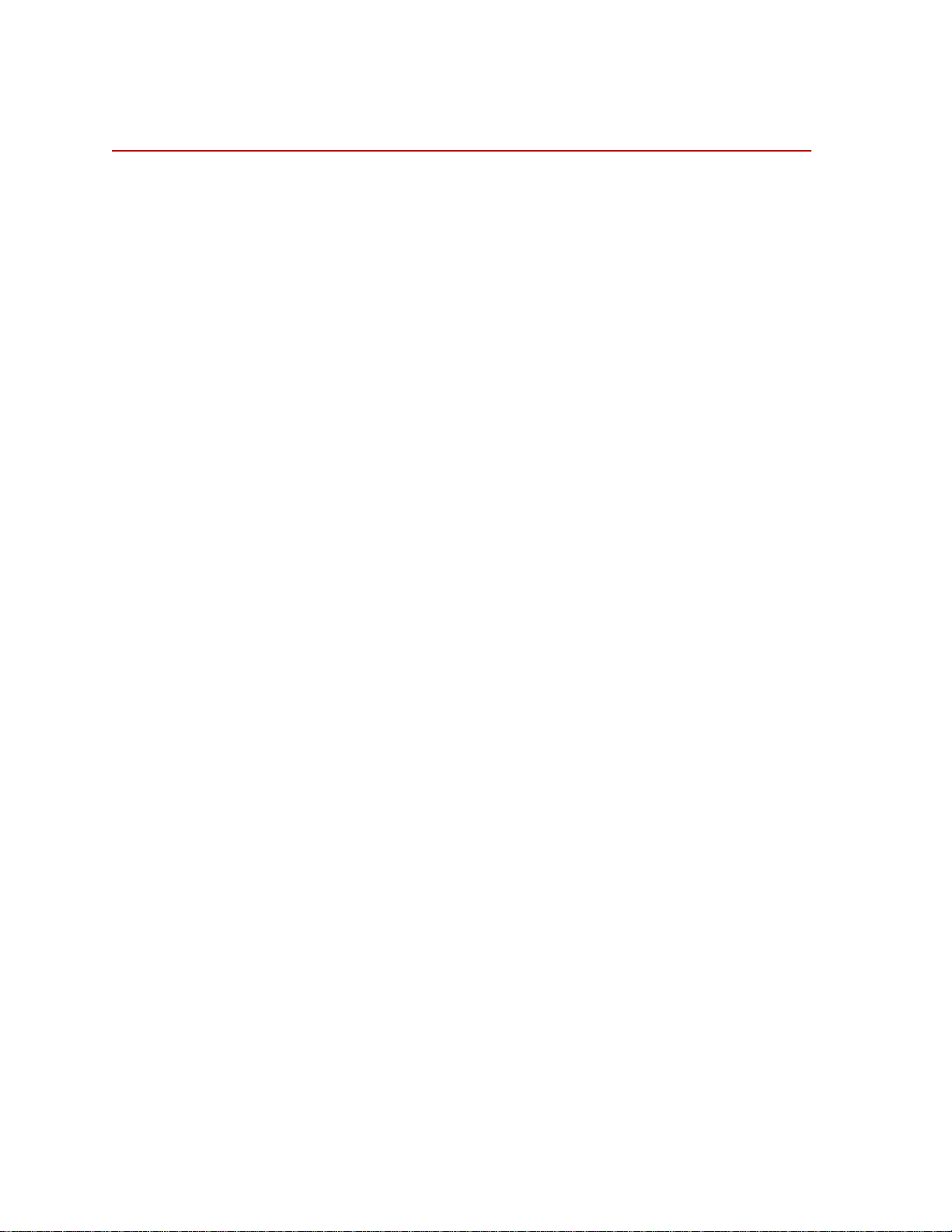

Hydraulic

schematic

Pressure

Gage

Pressure

Reducing

Valve

Motor

The hydraulic schematic shows how the hydraulic components are

connected in the Model 512.01 Hydraulic Power Unit.

Pressure -6

37° JIC Flare

Check

Valve

Set at 7 MPa

(1000 psi)

Set at 7.9 MPa

(1150 psi)

Pressure

Relief

Valve

Return -6

37° JIC Flare

Air-Cooled Heat

Exchanger

Drain -06

37° JIC Flare

1/2 NPT

Strainer

Pump

Filter

with

Bypass

Temperature Gage

Fan and Motor

Overtemperature

Switch

Set at 55°C (130°F)

Low Fluid

Switch

Model 512.01 Hydraulic Power Unit Introduction

7

Page 8

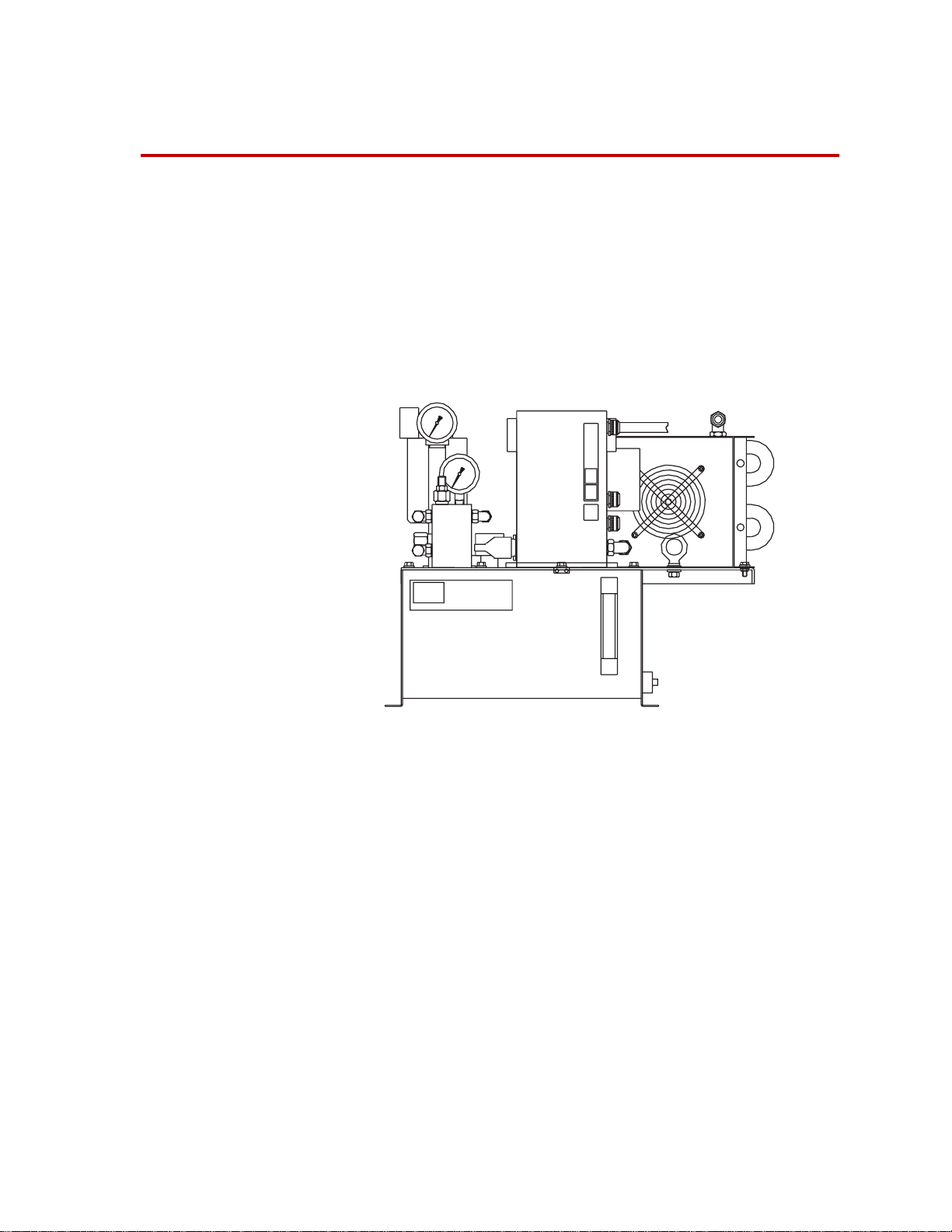

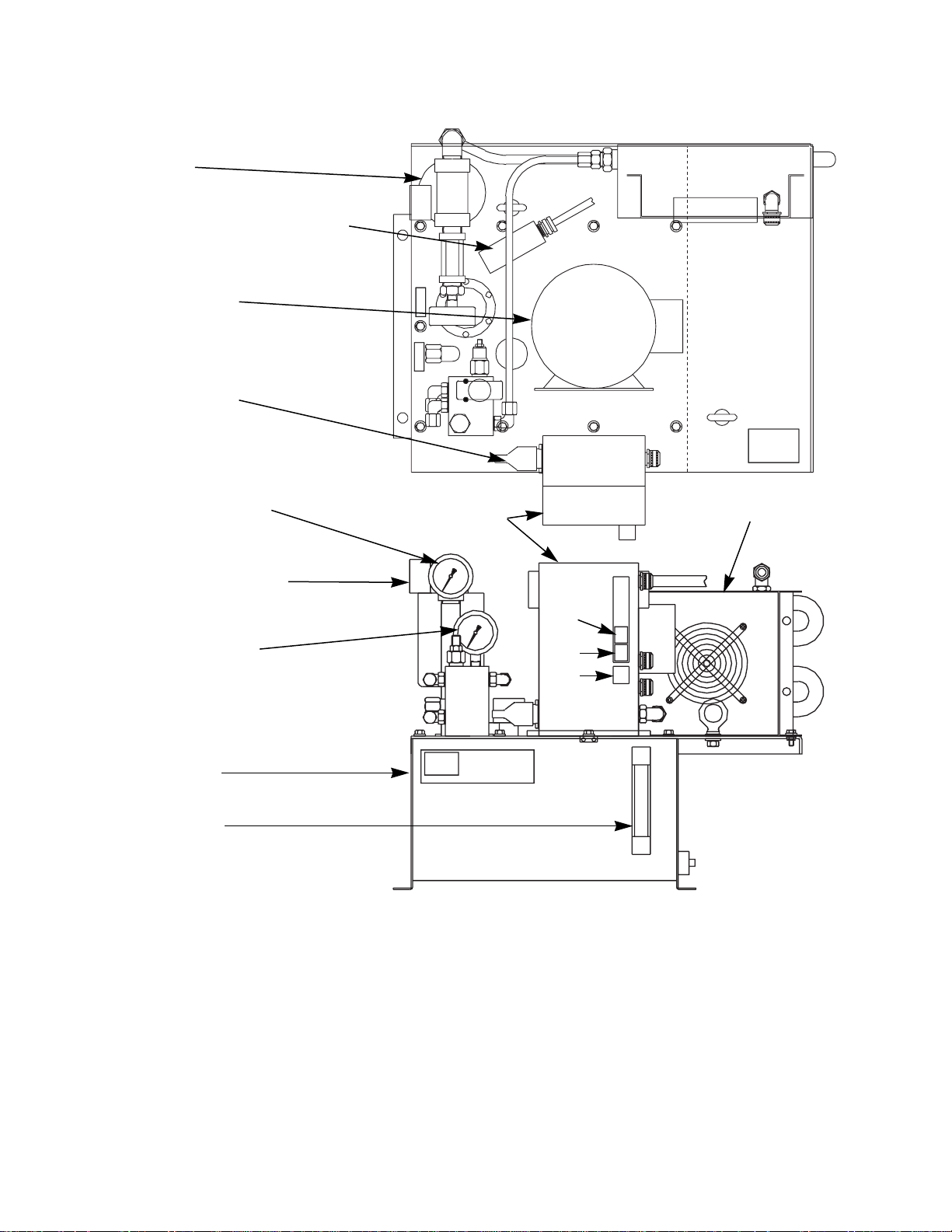

Component Identification

This table describes the components shown in the figure called

“Component Identification” on page 9.

Component Descriptions

OMPONENT

C

Filter

Low Fluid and

Overtemperature Sensor

Pump Motor

Jumper Plug

Control Box

Start Button

Stop Button

Reset Button

Heat Exchanger

Fluid Thermometer

D

ESCRIPTION

Provides 3–micron filtration to fluid returning to the reservoir (see

“Changing the Filter” on page 24).

Shuts the pump off if fluid becomes hotter than 55ºC (130ºF) or it detects

a low fluid level. See “Reducing the Fluid Temperature” on page 20 or

“Adding Hydraulic Fluid” on page 21 for more information.

Drives a fixed displacement gear pump.

Allows the HPU to run. Either the jumper plug or an external

Emergency Stop switch must be plugged into the control box before

the HPU can be started.

Houses the electronic controls for the pump, including the start button,

stop button, reset button, and the thermal overloads.

Turns the pump on. It produces an output of 6.9 MPa (1000 psi).

Turns the pump off.

Resets the thermal overloads of the HPU. See “Resetting the Thermal

Overloads” on page 22.

Cools the hydraulic fluid using an air cooled heat exchanger.

Displays the temperature of the hydraulic fluid.

Filter Change Gage

Pressure Gage

Reservoir

Sight Glass

Introduction

8

Shows when it is time to change the hydraulic filter. The gage is marked

with three zones: green, yellow, and blue.

Green—The filter is good to use.

Yellow—Change the filter soon.

Red—Do not run the HPU until you have replaced the hydraulic filter

element.

Shows the current output pressure from the HPU. The output pressure is

factory set to 6.9 MPa (1000 psi). See “Adjusting the Output Pressure” on

page 23 to change the output pressure.

Stores the hydraulic fluid. The reservoir has a 40 L (10 gal) capacity. It

includes a magnetic drain plug to help catch metal particles.

Let’s you see the hydraulic fluid. You can quickly check the hydraulic

fluid’s temperature, level, and condition (by its color).

Model 512.01 Hydraulic Power Unit

Page 9

Filter

Low Fluid/Over Temp. Sensor

Pump Motor

Jumper Plug

Fluid Thermometer

Filter Change Gage

Pressure Gage

Reservoir

Sight Glass

Control Box

Start

Stop

Reset

l

Component Identification

Heat Exchanger

Model 512.01 Hydraulic Power Unit Introduction

9

Page 10

Specifications

Model 512.01 Specifications

ARAMETER

P

Environmental

Operating temperature

Heat load

Noise rating

Pump

Flow capacity

at 6.9 MPa (1000 psi)

Motor rating

Operating voltage

Starter type

Hydraulic Fluid

Nominal temperature

Filtration (microns)

Reservoir capacity

Heat exchanger

*

†

at 1 m

PECIFICATION

S

18–35°C (65–95°F)

480 kcal/hr (1900 BTU/hr)

70 db (A)

3.8 l/m (1.0 gpm) @ 60 Hz

0.56 kW (0.75 hp)

115 V (ac) @ 13.8 A, 1 phase

Line voltage

Mobil DTE 25

®

or Shell Tellus 46

46°C (115°F)

3 µ absolute

40 L (10 gal)

Air cooled

®

Hydraulic connections

Pressure

Return

Drain

Weight

*

Specification is for 60 Hz operation.

†

Free field value [75 db (A) ≈ heavy traffic at 17m]. Your readings

each requires a 37° JIC flare

-6

-6

-6

88.5 kg (195 lb)

may be up to 10 db (A) more.

10

Introduction

Model 512.01 Hydraulic Power Unit

Page 11

Dimensions

The following figure shows those dimensions which are useful when

installing the HPU.

563 mm

(22 in)

254 mm

(10 in)

480 mm

(19 in)

l

406 mm

(16 in)

584 mm

(23 in)

Model 512.01 Hydraulic Power Unit Introduction

11

Page 12

12

Introduction

Model 512.01 Hydraulic Power Unit

Page 13

Installation

This section describes how to install the Model 512.01 Hydraulic Power

Unit (HPU). The following figure show the components referenced in the

installation procedure.

Lift Ring

Dirty Filter Gage

Pump

Drain Line Connection

Breather

Thermometer

Output Pressure Gage

Return Line Connection

Pressure Line Connection

Heat Exchanger

Power Cord

Start

Stop

Reset

E-Stop Connector

Model 512.01 Hydraulic Power Unit Installation

l

Lift Ring

Sight Gage

Component Identification

13

Page 14

1. Position the hydraulic power unit.

You should determine where to put the hydraulic power unit (HPU).

Since it is connected to the other hydraulic equipment through

hydraulic lines, the HPU can be located remotely.

• Use the lifting rings (with a crane or fork lift) to move the HPU

unit into place.

• The HPU must be located where adequate air movement is

available. A clearance of 50 mm (2 ft) is required between the

heat exchanger and a wall.

• The base of the HPU has four holes to secure the unit in place.

2. Connect an external Emergency Stop switch.

An optional Emergency Stop switch can be connected to the 14 pin

CPC connector located on the control box.

A jumper plug is required if a remote Emergency Stop switch is not

installed. The HPU will not run without an Emergency Stop switch or

a jumper plug installed.

L1

L2

Green

1

1

3

8

9

Remote

Emergency

Stop Switch

CPC-14S

A Jumper Plug is required

if a Remote Emergency

Stop Switch Not

Connected

1 A

3

8

9

3. Connect the electrical service to the HPU.

NOTE You may want to have an electrician complete this step. Also, local

electrical codes supersede any information found here.

Plug the power cord into a 115 V (ac), 60 Hz, 1 phase outlet rated for

20 A. The electrical schematic is provided if you need to check any

wiring. This unit must be grounded.

M

OL

M

OL

OL

Varistor

Fan and Motor

Stop Switch

FU1

Start

Switch

SS1

M–1

TAS

Opens at

55° (130°)

M

Low Fluid

Switch

(opens at

70% full)

OL

14

Installation

Electrical Schematic

Model 512.01 Hydraulic Power Unit

Page 15

4. Test the HPU.

A. Remove the 1/2” NPT pipe plug and install the breather in the

reservoir cover.

B. Make sure all the pressure, return, and drain port caps are in

place.

C. Press the Start button (be sure the Stop button is released).

D. Check that the output pressure is less than 6.9 MPa (1000 psi).

E. Press the Stop button.

5. Connect the hydraulic lines.

See “Component Identification” on page 13 to determine the locations

of the hydraulic connections to the HPU. See the following table to

identify the size of each hydraulic connection.

Hydraulic Connectors

15

CONNECTOR SIZE

Pressure, 37º flare -6

Return, 37º flare -6

Drain, 37º flare -6

NOTE Some maintenance procedures require you to set the HPU for a no-

flow condition (where no fluid is flowing to other hydraulic

equipment). You may want to consider plumbing in a bypass circuit

in the system hydraulic lines.

Model 512.01 Hydraulic Power Unit Installation

Page 16

16

Installation

Model 512.01 Hydraulic Power Unit

Page 17

Operation

The following procedure is a guideline, and it assumes you are starting the

hydraulic power unit (HPU) after it has been turned off for some time (the

hydraulic fluid is considered cool). You may want to incorporate portions

of this procedure into your system startup sequence.

1. Check the fluid level in the sight gage. The hydraulic fluid should be

close to the top of the sight glass. If you need to add fluid, add 1 liter

(1 quart) at a time.

Normal Level

No Fluid Visible

Check the Fluid Level

2. At your test controller, make sure hydraulic pressure is turned off.

NOTE Some controllers can remotely control the HPU. The Model 512.01

Hydraulic Power Unit does not support this feature.

3. Turn the Start button turn the HPU on and wait for the motor to get

up to speed.

4. Check the output pressure for the correct output pressure. Pressure is

factory set for 6.9 MPa (1000 psi).

If the pressure is higher or you want to reduce the pressure setting,

see “Adjusting the Output Pressure” on page 23.

After the output pressure is achieved, turn on the hydraulic pressure at

the controller.

Model 512.01 Hydraulic Power Unit Operation

17

Page 18

5. Check to make sure the filter change gage’s needle stays in the green

zone.

NOTE Cold fluid may push it temporarily into the yellow or red zone.

If the needle stays in the yellow or red zone, turn the HPU off and

change its filter (see “Changing the Filter” on page 24).

CAUTION

Do not run the HPU if the filter gage is in the red region.

When the gage needle stays in the red zone, some hydraulic fluid is

bypassing the filter. This unfiltered fluid can wear or damage hydraulic

components.

Turn the HPU off when the filter gage reaches the red zone and change the

filter.

Yellow Zone

(warning to change)

Green Zone

(normal)

Red Zone

(do not operate)

Check the Filter Change Gage

6. Run the HPU for 1 hour to get the hydraulic fluid up to the operating

temperature of 43–52°C (109–126°F).

18

Operation

7. Once the hydraulic fluid is up to the operating temperature, you can

use the hydraulic system.

8. To turn the HPU off, press the STOP switch.

Model 512.01 Hydraulic Power Unit

Page 19

Maintenance

Contents Reducing the Fluid Temperature 20

Resetting the Thermal Overloads 22

Adjusting the Output Pressure 23

Changing the Filter 24

Changing the Hydraulic Fluid 25

Maintenance Intervals

WHAT TO DO WHEN TO DO IT

Recover from an abnormal shutdown as needed–when the HPU suddenly stops running

Lower the output pressure as required by your test needs

Lubricate the pump motor every six months

Change the filter when the filter gage needle stays in the yellow or red zone;

whenever you change hydraulic fluid

Change the fluid Verify the fluid condition by analysis or if the fluid’s condition

becomes poor

Abnormal

shutdowns

Any one of the following can cause your HPU to suddenly shut down. Y ou

will not be able to restart your HPU until you correct the condition.

PROBLEM SOLUTION

The hydraulic fluid exceeds

55ºC (130ºF).

The hydraulic fluid cannot be seen in

the sight glass (or it is at a low level).

A tripped thermal overload or blown

fuse in the control box removed

power from the unit.

See “Reducing the Fluid

Temperature” on page 20.

See “Adding Hydraulic Fluid” on

page 21.

See “Resetting the Thermal

Overloads” on page 22.

Model 512.01 Hydraulic Power Unit Maintenance

19

Page 20

Reducing the Fluid Temperature

The hydraulic power unit (HPU) will be shut down if the hydraulic fluid

reaches a temperature of 55°C (130° F).

1. Check the thermometer. The HPU shuts down when fluid gets hotter

than about 55ºC (130ºF).

2. Press the Start button. Hold it down to override the overtemperature

sensor.

• If overtemperature fluid caused the shutdown, the HPU will now

start to run.

• Keep holding the Start button until the HPU stays running when

you let go of this button. This could take several minutes.

If the HPU still does not run, something else caused the shutdown.

3. Once the HPU is running, put the HPU in a no-flow condition (where

no fluid is flowing to other hydraulic equipment).

4. Let the HPU run. Wait 15 minutes for its temperature to stabilize.

Check the fluid temperature.

If the temperature is between 43 and 52ºC (109 and 126ºF), stop.

20

Maintenance

Model 512.01 Hydraulic Power Unit

Page 21

Adding Hydraulic Fluid

1. The hydraulic power unit (HPU) will shut down when fluid drops

below the sight glass. Normally, it should be close to the top of the

sight glass.

No Fluid Visible

Normal Level

CAUTION

Check the Fluid Level

Do not mix different brands of hydraulic fluid.

Mixing different brands of hydraulic fluid can contaminate your system.

Call MTS if you are not sure what brand of hydraulic fluid your system uses.

2. Open the filler cap. If you add fluid, add it 1 liter (1 quart) at a time.

NOTE Be sure the fluid you add is prefiltered since it may not be clean.

3. Replace the cover cap.

4. Start the HPU.

Model 512.01 Hydraulic Power Unit Maintenance

21

Page 22

Resetting the Thermal Overloads

The thermal overloads of the hydraulic power unit (HPU) can be tripped

by the following conditions:

• Poor motor ventilation

• The output pressure is set too high

• A pump or motor is seizing

The thermal overloads are located in the control box.

WARNING

Do not open the control box unless the line voltage is turned off. When

power is present in the control box, high voltage and amperages are also

present.

You can be electrocuted if you touch the wrong component in the control

box.

Disconnect the HPU from power before opening the control box.

1. Press RESET on the control box cover.

• If it’s tripped, reset it and try restarting the HPU.

• If it trips again, turn the

HPU off before opening

Varistor

the control panel.

2. Disconnect the HPU from its

electrical power source.

Fuse

3. Unscrew the clamps holding

the control panel’s door shut.

4. Check for a blown fuse. A

defective varistor can also

Jumper

Plug

cause this fuse to blow. The

replacement fuse must have

the same rating as the blown

fuse.

22

Maintenance

5. Shut the control box door. Use

the clamps to hold it in place.

6. Reconnect the HPU to its electrical power source.

7. Restart the HPU. If the HPU will not restart or shuts down right away,

call MTS.

Model 512.01 Hydraulic Power Unit

Page 23

Adjusting the Output Pressure

The hydraulic power unit (HPU) comes with its output pressure set at

6.9 MPa (1000 psi) and a pressure relief setting of 7.9 MPa (1150 psi).

Special testing needs may require you to lower this pressure.

Pressure Relief Valve

Factory Set to

7.9 MPa (1150 psi)

Output Pressure

Adjustment Factory

Set to 6.9 MPa

(1000 psi)

CAUTION

Pressure A djustment Locations

Do not set the output pressure higher than 6.9 MPa (1000 psi).

Setting the output pressur e abo v e 6.9 MP a (1000 psi) can damage the pump

and its motor.

Set the output pressure no higher than 6.9 MPa (1000 psi).

1. Put the HPU into a no-flow condition (where no fluid is flowing to

other hydraulic equipment).

2. Press the Start button on the control box.

3. Wait for the fluid to reach the operating temperature of 43 and 52ºC

(109 and 126ºF).

4. Hold the setscrew in the

pressure reducing valve with a

5/32–inch hex key. Loosen the

locknut with a 9/16–inch

Pressure Gage

Setscrew

Locknut

wrench.

5. Turn the setscrew while

watching the gage until you get

the output pressure you want.

6. Hold the setscrew and tighten

down the locknut.

Model 512.01 Hydraulic Power Unit Maintenance

23

Page 24

Changing the Filter

Change the filter whenever the filter change gage’s needle stays in the

yellow or red zone with the hydraulic fluid at operating temperature.

Also, change the filter whenever you change the hydraulic fluid.

Special equipment needed–

• Oil filter wrench

• 3–micron oil filter (part number 119515-21)

1. Press STOP to turn the hydraulic power unit (HPU) off.

2. Use an oil filter wrench to loosen the old filter. Screw the filter

counterclockwise to remove it.

Change Filter

CCW

3. Wet the new filter’s gasket with clean hydraulic fluid.

4. Screw the filter clockwise to install it. Turn the new filter until its

gasket touches its sealing surface. Then hand tighten the filter 1/2

turn.

NOTE Tightening the filter with a wrench will not make it seal better, but it

will make it harder to remove the next time.

5. Press the Start button to turn the HPU on. Let the HPU run a few

minutes and check for leaks.

24

Maintenance

Model 512.01 Hydraulic Power Unit

Page 25

Changing the Hydraulic Fluid

As part of your regular HPU maintenance, change the hydraulic fluid every

2,500 hours of operation or if fluid analysis indicates the fluid should be

changed. However, you must change it immediately if any of the following

is true:

• The fluid becomes very dark and has a strong burnt sugar smell

(severe overheating).

• Particles appear in the sight glass (indicate a collapsed pickup

strainer).

• Fluid becomes milky (water in the fluid–a possible leaking heat

exchanger).

It is a good idea to keep a small jar of new hydraulic fluid for comparison

purposes.

Recommended

equipment

The following equipment (or its equivalent) is needed in the for this

procedure.

• A transfer pump with a 10–micron filter

• A 125 kg (250 lb) capacity hoist

• Synasol® or a similar cleaning solvent

• Lint-free cloths or manufactured rags

• A small drain that will fit underneath the drain plug

See “Component Locations” on page 26 to identify the components called

out in the following procedure.

1. Prepare the HPU.

A. Press STOP to turn off the HPU.

B. Remove electrical power to the HPU (via the circuit breaker at the

power source or by unplugging the HPU).

C. Remove the filler cap’s strainer assembly.

2. Remove the hydraulic fluid.

A. Remove the transfer pump’s filter (you do not need to filter the

dirty hydraulic fluid when removing it).

B. Use the transfer pump to remove the old hydraulic fluid out of the

reservoir.

C. Remove the drain plug to drain any remaining fluid.

Model 512.01 Hydraulic Power Unit Maintenance

25

Page 26

Filler Cap

Reservoir

Cover Screws

Pump Filter

Lift the cover with

these lift rings)

Suction Strainer

WARNING

l

Drain

Component Locations

Synasol is toxic and flammable.

Use the Synasol solvent in a ventalat ed ar ea and keep it away from an open

flame.

Follow the cautions and warnings on its container.

26

Maintenance

Model 512.01 Hydraulic Power Unit

Page 27

3. Clean the reservoir.

A. Unscrew the cover screws attaching the cover plate to the

reservoir.

B. Attach scraps to the cover plate’s two lifting eyes. Lift the cover

plate clear of the reservoir.

C. Clean the inside of the reservoir using clean cloths dampened

with Synasol. Clean the pump and bottom of the cover plate as

well.

D. Inspect the pump’s suction strainer. Replace this strainer if it is

plugged or damaged.

E. Lower the cover plate back down onto the reservoir.

F. Wipe off the magnetic drain plug and install it.

G. Tighten the four screws that attach the cover plate to the

reservoir.

CAUTION

Do not mix different brands of hydraulic fluid.

Mixing different brands of hydraulic fluid can contaminate your system.

Call MTS if you are not sure what brand of hydraulic fluid your system uses.

4. Add new hydraulic fluid to the reservoir.

A. Install the transfer pump’s 10–micron filter.

B. Pump clean hydraulic fluid into the reservoir. Stop when the fluid

level gets close to the top of the sight glass.

C. Install the filter cap’s strainer assembly.

D. Change the filter (see “Changing the Filter” on page 24).

5. Run the HPU.

Press the Start button. Run the HPU in a no-flow condition (where not

no fluid is flowing to other hydraulic equipment) for about one hour

to filter the new hydraulic fluid.

Model 512.01 Hydraulic Power Unit Maintenance

27

Loading...

Loading...