Page 1

l

Product Manual

Model 506.62/.72

Hydraulic Power Supply

September 1996

117730-00D

Page 2

© 1996 MTS Systems Corporation. All rights reserved.

Page 3

Table of Contents

Section 1 Introduction

1.1 Functional Description ............................................................................. 1-1

1.2 Specifications.......................................................................................... 1-2

Section 2 Operation

2.1 Controls and Indicators............................................................................. 2-1

2.2 Operation Procedures............................................................................... 2-3

2.3 Supercharge Pump Operation ................................................................... 2-4

Section 3 Service

3.1 Maintenance Procedures............................................................................ 3-1

3.1.1 Filters ............................................................................................... 3-2

3.1.1.1 High-Pressure Filter Replacement................................................ 3-2

3.1.1.2 Low-Pressure Filter Replacement.................................................. 3-4

3.1.2 Hydraulic Fluid................................................................................. 3-5

3.1.3 Accumulators ..................................................................................... 3-7

3.1.3.1 Precharge Pressure-Checking Intervals ......................................... 3-7

3.1.3.2 Precharging the Accumulators ...................................................... 3-7

3.1.3.3 Changing the Accumulator Seals .................................................. 3-7

3.2 Service Adjustments ................................................................................. 3-8

3.2.1 Output Pressure Adjustment................................................................ 3-9

3.2.2 Dual-Temperature Switch Adjustments............................................. 3-10

3.2.3 Low-Level Switch Adjustment .......................................................... 3-11

3.2.4 Main Pump Low-Inlet Pressure Switch Adjustment............................. 3-12

3.3 Starter Assembly ................................................................................... 3-13

3.3.1 Abnormal HPS Shutdown................................................................. 3-14

3.3.2 Fuse Replacement............................................................................. 3-14

3.3.3 PLC Service..................................................................................... 3-15

Section 4 Installation

4.1 Hydraulic Connections ............................................................................. 4-2

4.2 Electrical Connections .............................................................................. 4-3

4.2.1 Transformer Wiring............................................................................ 4-4

4.2.2 Input Power........................................................................................ 4-5

4.3 Cooling Water Connections....................................................................... 4-6

Table of Contents i

Page 4

Section 5 Theory of Operation

5.1 Hydraulic Operation ............................................................................... 5-1

5.2 Electrical Operation ................................................................................ 5-3

5.2.1 Control .............................................................................................. 5-3

5.2.2 Interlocks........................................................................................... 5-5

Index

List of Figures

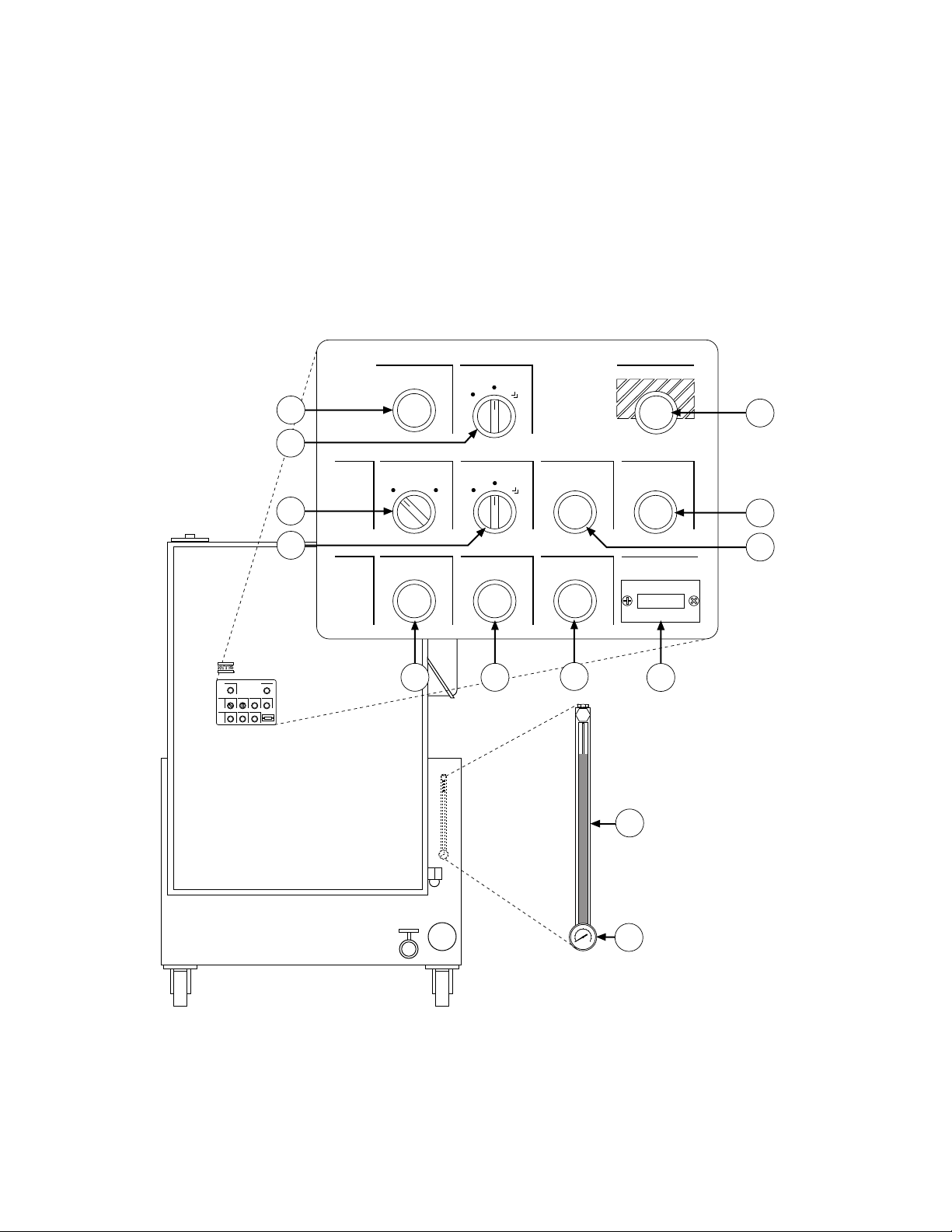

Figure 2-1 Controls and Indicators ............................................................................ 2-1

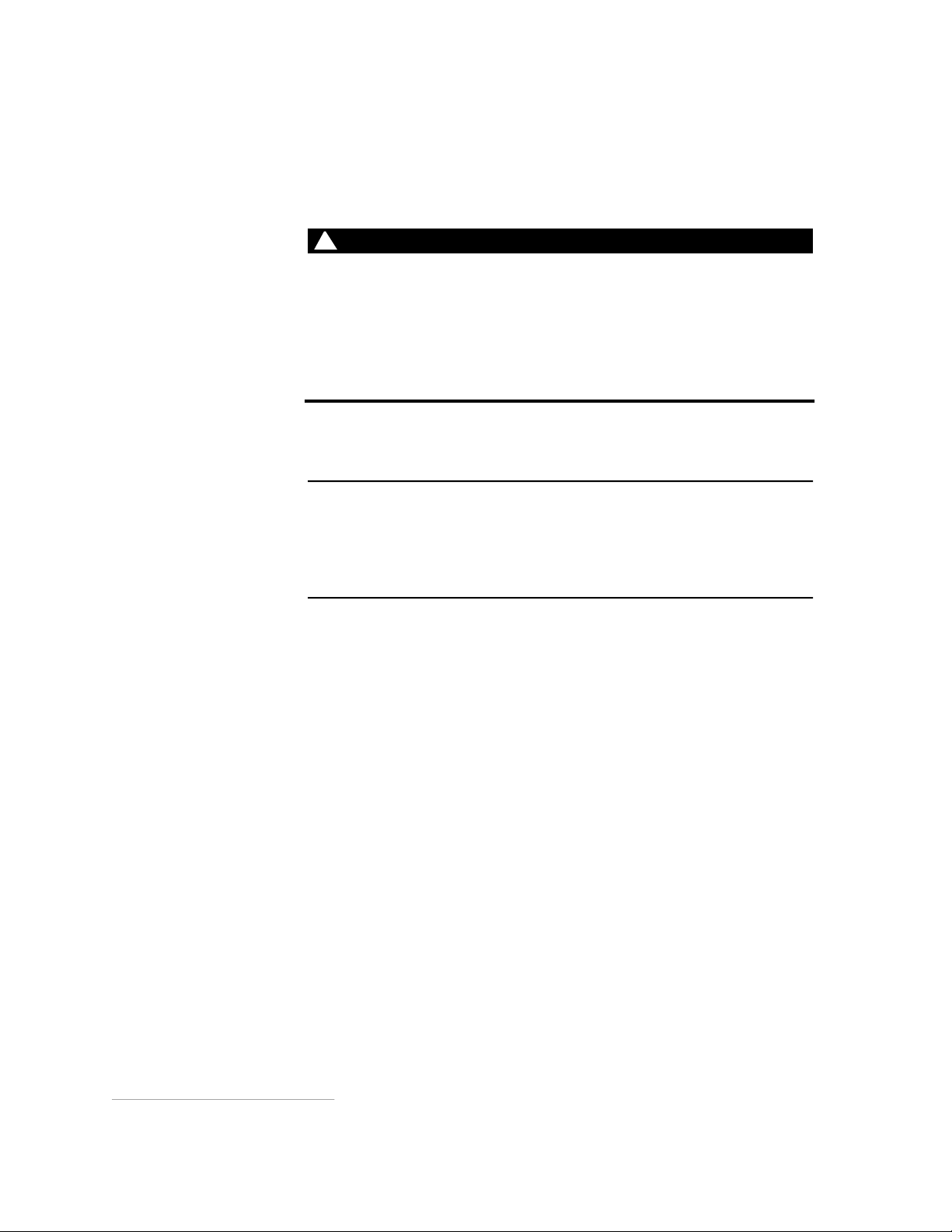

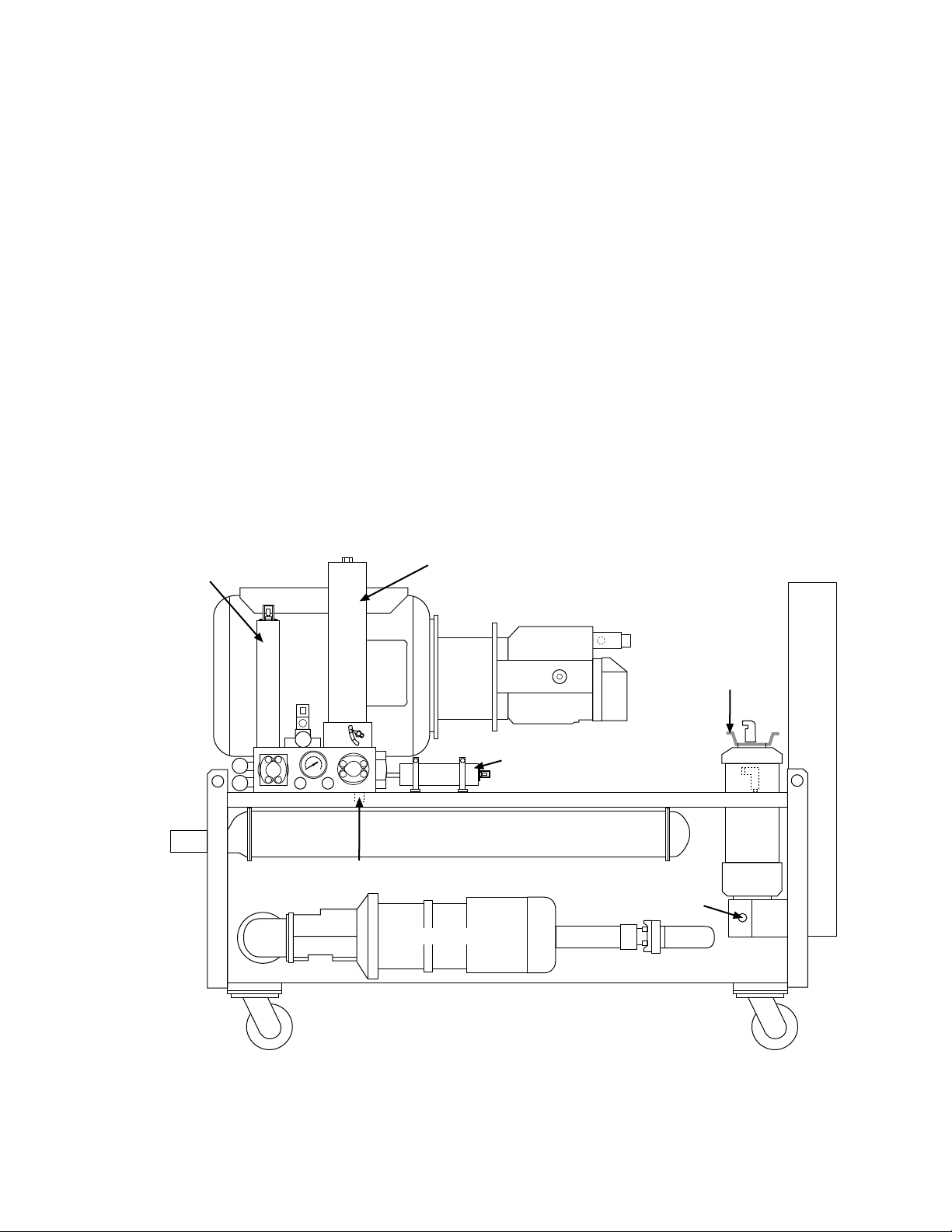

Figure 3-1 Location of Maintenance Components (HPS Side View)............................. 3-1

Figure 3-2 Location of Adjustment Components (HPS Side View)................................ 3-8

Figure 3-3 Model 506.62/.72 Starter Assembly......................................................... 3-13

Figure 4-1 Location of Remote Connector.................................................................... 4-1

Figure 4-2 Hydraulic Connections............................................................................. 4-2

Figure 4-3 Model 506.62/.72 Starter Assembly........................................................... 4-3

Figure 4-4 Standard Transformer Wiring Configuration............................................. 4-4

Figure 4-5 Typical Multi-Tap Transformer Wiring Configuration............................... 4-4

Figure 4-6 Heat Exchanger Connections..................................................................... 4-6

Figure 5-1 Hydraulic Block Diagram........................................................................ 5-1

Figure 5-2 Typical Electrical Schematic................................................................... 5-6

List of Tables

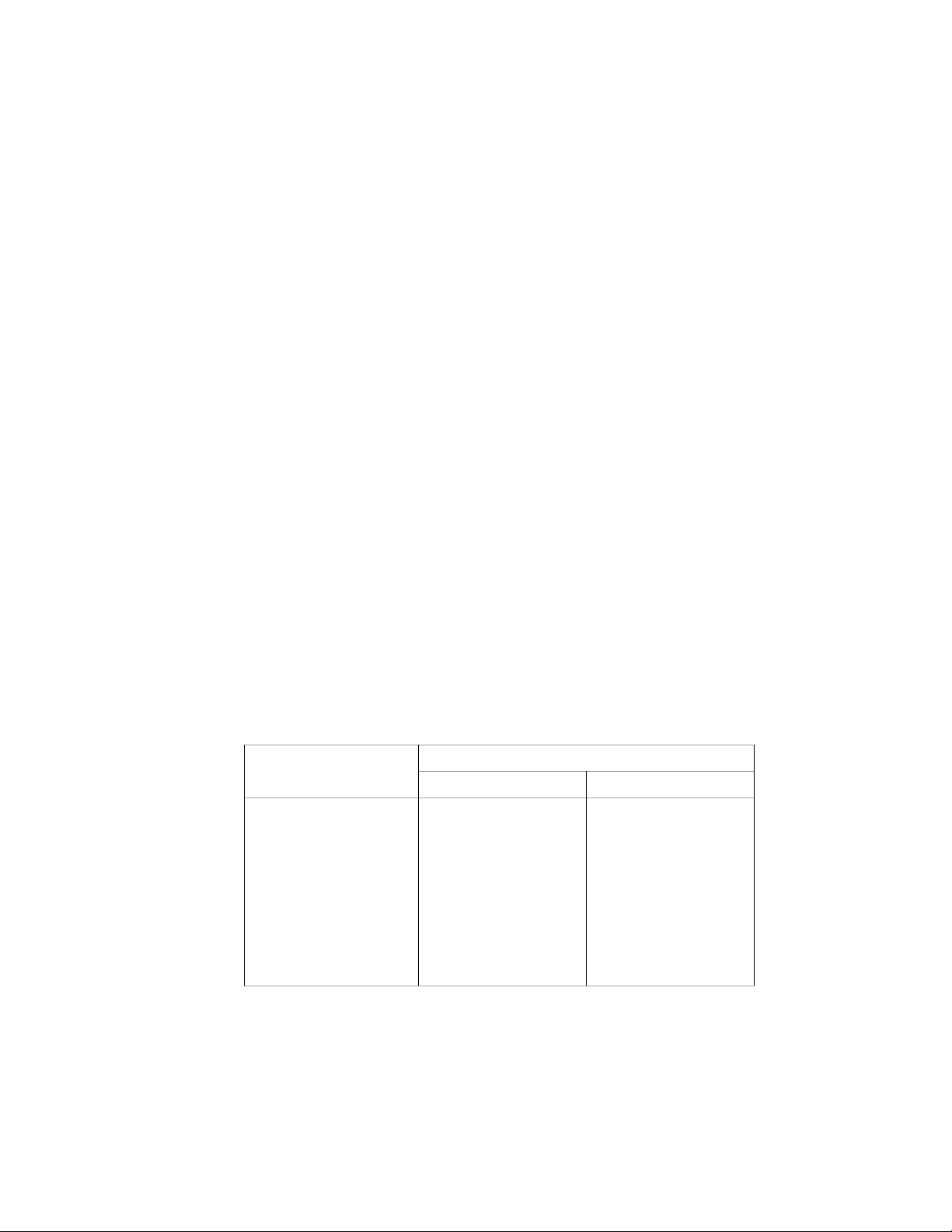

Table 1-1 Cooling Water Flow Requirements ............................................................ 1-2

Table 1-2 HPS Specifications .................................................................................. 1-3

Table 2-1 Controls and Indicators............................................................................. 2-2

Table 3-1 Maintenance Schedule.............................................................................. 3-2

Table 3-2 Starter Assembly Fuse Values................................................................. 3-14

ii Table of Contents

Page 5

Section 1

Introduction

Definition The Model 506.62/.72 Hydraulic Power Supply (HPS) uses a variable-

volume (pressure compensated) main pump, with a pressurized

(supercharged) hydraulic fluid inlet, to provide pressure to systems

with various flow requirements. The HPS is designed to be used with

servo-controlled, electro-hydraulic systems.

1.1 Functional Description

Front panel controls

and indicators

Pressure output

Front panel controls on the HPS include local operating controls for the

main pump and supercharge pump. Front panel indicators show running

time, power on, low fluid level, fluid over-temperature, and dirty filter

conditions.

Pressure output is controlled by an adjustment on the main pump and is

monitored by the output pressure gage. An adjustable back-up relief

valve limits output pressure by porting fluid back to the reservoir when

the output pressure rises above the relief valve setting. High/low

pressure operation is controlled by the high/low solenoid valves.

These valves control the main pressure control (pressure compensator)

vent ports and the backup relief valve vent port.

019-341M

Introduction 1-1

Page 6

Pressure accumulation The pump-outlet pressure accumulator smooths the HPS output and

provides additional hydraulic pressure for high instantaneous flow

demands. It is precharged with dry nitrogen to a pressure proportional

to HPS output pressure. The optional slow turn-on accumulator slows

the rate at which the backup relief valve shifts from low to high

pressure.

Temperature control A temperature gage indicates hydraulic fluid temperature. An

oil-to-water heat exchanger controls the fluid temperature. When the

temperature exceeds a preset limit, a temperature sensitive switch

turns off the HPS and lights the front panel Fluid Over-Temperature

indicator.

Fluid level indication A transparent gage indicates the level of hydraulic fluid in the HPS

reservoir. A low-level switch automatically turns off the HPS and

lights the front panel Low Fluid Level indicator if hydraulic fluid

drops below a preset level.

Programmable logic

controller

The PLC (programmable logic controller) located in the starter

assembly performs logic functions. The I/O (input/output) section of the

PLC provides an interface for various signals received from or sent to

external devices.

1.2 Specifications

Cooling water

specifications

Cooling Water Inlet Required Water Flow

Temperature 506.62 506.72

60°F (15.5°C) 30 gpm (114 L/min) 35 gpm (132 L/min)

65°F (18.5°C) 35 gpm (132 l/min) 42 gpm (159 L/min)

70°F (21.0°C) 40 gpm (151 Ll/min) 51 gpm (193 L/min)

75°F (24.0°C) 40 gpm (151 L/min) 67 gpm (254 L/min)

The required water pressure between the input and the output of the

heat exchanger is 30 to 45 psi (0.2 to 0.3 MPa). The maximum allowable

pressure is 120 psi (0.8 MPa). The flow rate (±20%) at a given

temperature is shown in the table below.

Table 1-1. Cooling Water Requirements

1-2 Introduction

80°F (26.5°C) 45 gpm (170 L/min) 90 gpm (341 L/min)

85°F (29.5°C) 63 gpm (238 L/min) 120 gpm (454 L/min)

Page 7

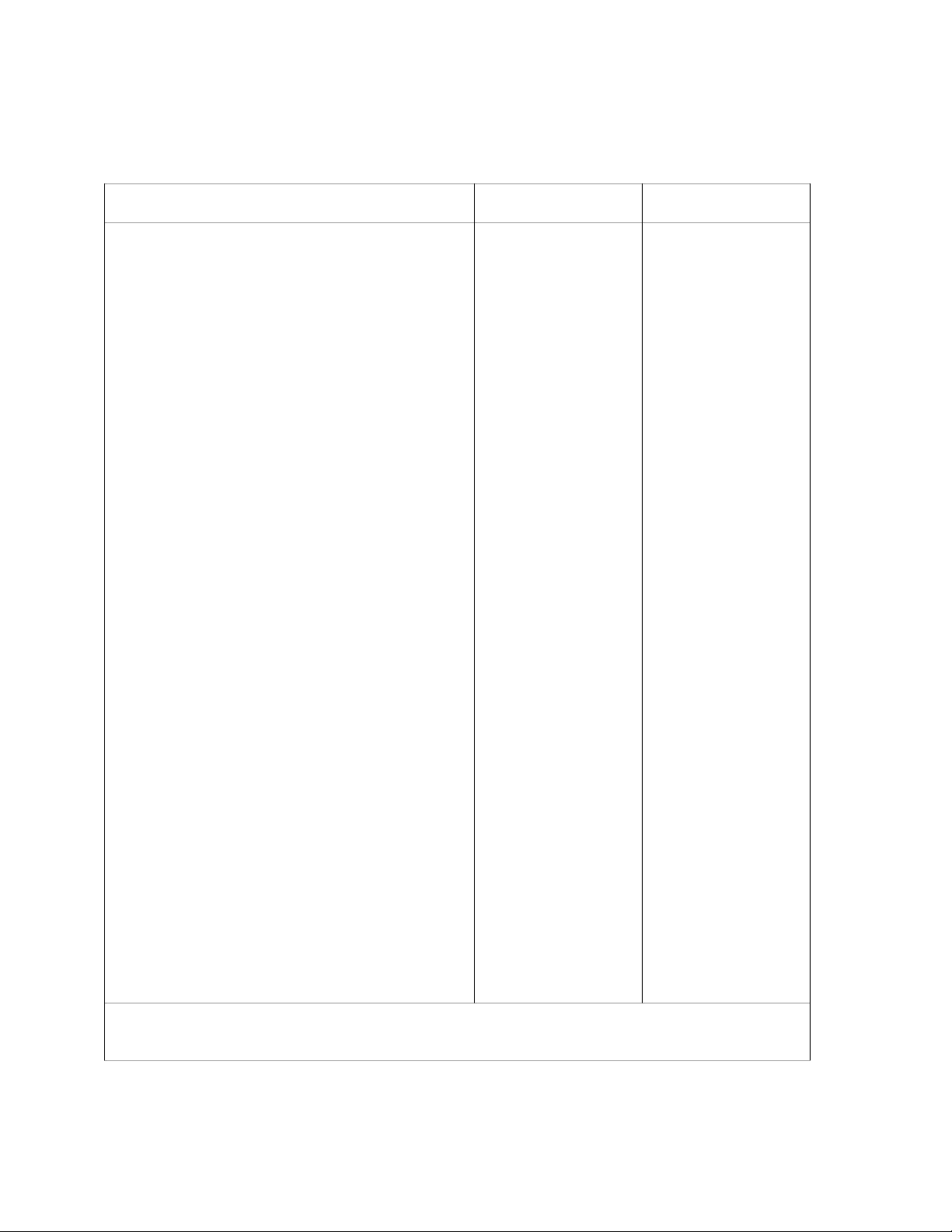

HPS specifications Table 1-2 lists the specifications for the Model 506.62/.72 HPS.

Table 1-2. HPS Specifications

Parameter Model 506.62 Model 506.72

Maximum continuous pressure 3000 psi (21 MPa) 3000 psi (21 MPa)

Maximum flow capacity 75 gpm (284 L/min) 100 gpm (380 L/min)

Noise rating at 3 ft. (0.9 m) 90 dBa 90 dBa

Reservoir capacity: 200 gpm (757 L) 280 gpm (1074 L)

Low-pressure filtration, absolute/nominal 3.0/0.45 microns 3.0/0.45 microns

High-pressure filtration 10 microns 10 microns

Fluid hose connections:

*

Pressure (SAE 4 bolt) -20 (1), -24 (1) -20 (1), -24 (1)

Return (SAE 4 bolt) -20 (1), -24 (1) -20 (1), -24 (1)

Drain (37° flare) -12 (2), -16 (1) -12 (2), -16 (1)

Main pump motor power rating (2 each) 150 hp (112 kW) 200 hp (150 kW)

Supercharge pump motor power rating 15 hp (11 kW) 20 hp (15 kW)

3-phase current 460V/60 Hz:

†

Inrush 385 A 515 A

Conti nuous 200 A 250 A

Starter type (main pump motor) Wye-delta Wye-delta

24 V external hydraulic control amps, 60 Hz 9 A 9 A

Maximum cooling water heat load:

BTU per hour 380,000 509,000

Kilocalories per hour 96,000 128,600

Atmospheric heat load

BTU per hour 27,600 37,000

Kilocalories per hour 7,000 11,100

Water inlet/outlet size 1.25 in. (38.8 mm) I.D. 1.25 in. (38.8 mm) I.D.

Maximum ambient operating temperature 104°F (40°C) 104°F (40°C)

Minimum ambient operating temperature 40°F (4.4°C) 40°F (4.4°C)

Height with casters 68 in. (1727 mm) 78 in. (1981 mm)

Length 90 in. (2286 mm) 90 in. (2286 mm)

Width 45 in. (1143 mm) 45 in. (1143 mm)

Weight with oil 6000 lb (2722 kg) 6,500 lb (2948 kg)

* The number of connections are shown in parentheses.

†

Currents listed are typical values. Maximum values may be as much as 10 to 15% higher.

Specifications are subject to change without notice. Contact MTS for verification of any critical specifications.

Introduction 1-3

Page 8

Page 9

Section 2

Operation

2.1 Controls and Indicators

The controls and indicators provided with the Model 506.62/.72

Hydraulic Power Supply (HPS) are described in Table 2-1. The

locations of these components are identified in the following figure.

Power

1

Spch Pump

Auto

Run

Start

Emergency Stop

11

2

HPS

Control

Source

Remote Local

Main Pump

High

Low

Stop

Start

3

4

Conditions Fluid Low Level

Fluid Over-Temp

65

Dirty Filter

7

Reset

10

9

Hours of Operation

8

Figure 2-1. Controls and Indicators

12

13

VW-G041C

Operation 2-1

Page 10

Table 2-1. Controls and Indicators

Item Control/Indicator Description

1 Power indicator* The Power indicator lights to indicate that electrical power is

applied to the HPS.

2 Spch Pump

Auto/Run/Start switch

To operate the supercharge pump when the main pump is not

operating, turn this spring-loaded switch to Start. After the

switch is released, it returns to the Run position — indicating

that the supercharge pump is circulating hydraulic fluid through

the heat exchanger and fine filter. If the switch is in the Auto

position, the HPS can be controlled by either the High/

Low/Start switch or the optional remote control panel.

3 Source Remote/Local

switch

If this two-position switch is in the Local position, you can

operate the HPS with the front panel controls. If it is in the

Remote position, use a remote control device to operate the HPS.

4 Main Pump

High/Low/Start switch

To apply low pressure in local control, turn this spring-loaded

switch to Start. After the switch is released, it returns to the

Low position — indicating low pressure operation. Turn the

switch to High to select high pressure.

5 Low Fluid Level

indicator*

6 Fluid Over-Temperature

indicator*

When this indicator lights, the hydraulic fluid level has

dropped below a preset value.

When this indicator lights, hydraulic fluid temperature has

exceeded a preset value.

7 Dirty Filter indicator* When this indicator lights, the low-pressure filter needs

replacement. See Subsection 3.1.1.

8 Hours of Operation

meter

This front panel meter indicates the total operating hours of the

pump.

9 Stop switch When Stop is pressed (in either local and remote control), the

HPS output first ramps to low pressure and then goes to zero

pressure. The supercharge pump continues to run for

approximately 10 seconds.

10 Reset switch This switch resets the interlock circuit if the condition causing

the interlock has been corrected.

11 Emergency Stop switch This switch operates in both local and remote control and is used

during emergency situations only. When pressed, it immediately

shuts down the HPS (the supercharge pump may continue to run

briefly to supply the main pump until they fully stop).

12 Fluid level gage This gage indicates the level of hydraulic fluid in the reservoir.

13 Temperature gage This gage indicates the temperature of the hydraulic fluid in the

HPS reservoir.

* Indicators are "push-to-test" type indicators. This means that if you push the indicator, it will light. If it does not light, the

bulb is burned out.

2-2 Operation

Page 11

2.2 Operation Procedures

WARNING

!

This section provides the local and remote operating procedures for the

506.62/.72 Hydraulic Power Supply.

Warning

Do not start the HPS if the servovalve command is not equal to

feedback (that is, zero balanced).

Failure to do this can result in sudden actuator movement which may

cause injury to persons and/or damage to equipment.

Ensure that the system is at zero balance before starting the HPS.

Before you begin Make sure that the external hydraulic system is ready for operation.

NOTE The Dirty Filter indicator may light during a cold-

start. It should turn off when the HPS reaches its

normal operating temperature. If the indicator fails to

turn off, correct the condition (Subsection 3.1.1.2) and

press Reset.

Local operation 1. Turn the Source Remote/Local switch to Local.

2. Apply electrical power to the HPS (the Power indicator will

light).

3. Press Reset.

1

4. Momentarily turn the High/Low/Start switch to Start. When you

release the switch, it returns to Low.

5. Check the HPS and external hydraulic system for leaks and

unusual sounds.

6. Turn the High/Low/Start switch to High to apply high pressure.

7. Press Stop on the HPS front panel to stop the HPS and remove

output pressure.

1

Reset must be pressed whenever electrical power to the HPS has been interrupted.

Operation 2-3

Page 12

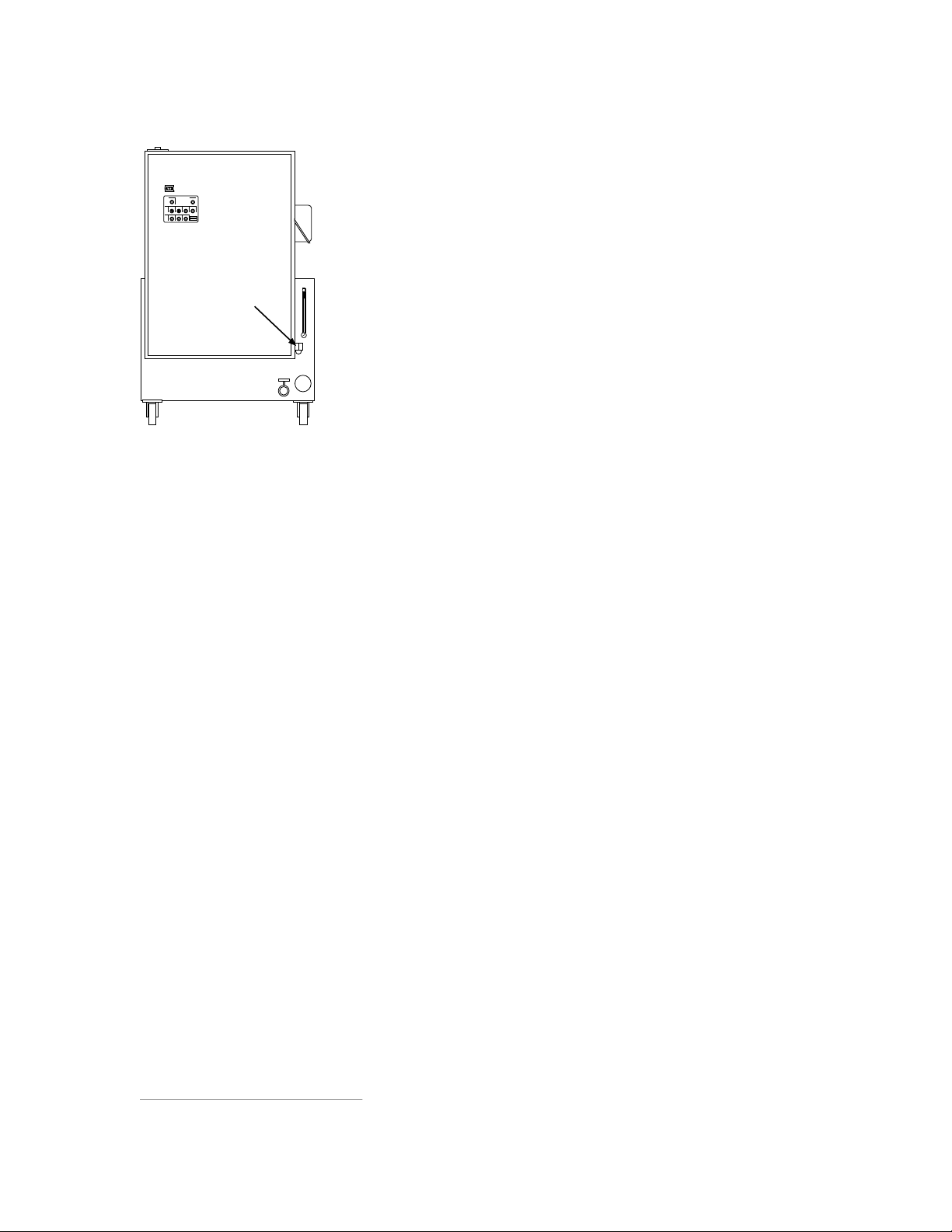

Remote Operation

1. Turn the Source Remote/Local switch to Remote. Make sure that

the remote control cable is connected to the cable connector (the

figure on the left shows the location of this connector) and to the

remote control device.

2. Apply electrical power.

1

Remote control

connector

3. Press Reset.

4. Use the remote control device to start the HPS at low pressure.

5. Check for leaks and unusual sounds.

6. Select high pressure at the remote control device.

7. Use the Off switch on the remote control device to stop the HPS

and remove output pressure.

2.3 Supercharge Pump Operation

When the temperature of the hydraulic fluid in the HPS reservoir

When to use the

supercharge pump

Cooling procedure 1. Ensure the water supply to the heat exchanger is turned on.

exceeds 140˚F (60˚C), the fluid over-temperature switch automatically

shuts down the HPS. The HPS main pumps cannot be restarted in local

or remote until the hydraulic fluid cools. The following procedure uses

the supercharge pump to hasten the cooling of the hydraulic fluid.

2. Turn the Spch Pump switch to the Start position and then release

the switch and allow it to return to the Run position. The

supercharge pump operates independently of the main pumps and

circulates hydraulic fluid through the heat exchanger to cool the

fluid.

3. When the temperature gage reads approximately 130˚F (54˚C),

turn the Spch Pump switch to the Auto position (the supercharge

pump will stop).

4. To restart the HPS, first press the Reset control on the local or

remote control panel to clear the hydraulic interlock circuit, and

then start the HPS in low pressure.

1

Reset must be pressed whenever electrical power to the HPS has been interrupted.

2-4 Operation

Page 13

Section 3

9

Service

Introduction This section contains service information for the Model 506.62/.72

Hydraulic Power Supply (HPS). It provides:

• maintenance procedures

• service adjustments

• electrical information

3.1 Maintenance Procedures

Maintenance overview The following subsections provide the routine maintenance procedures

for the HPS. Figure 3-1 shows the location of the components accessed

for the maintenance procedures. Table 3-1 lists the maintenance

schedule.

Pressure

Accumulator

High Pressure

Filter

Low Pressure

Filter

Slow Turn-on

Accumulator

Heat Exchanger

Manifold Drain

(under manifold)

Filter

Drain

Supercharge Pump

Figure 3-1. Location of Maintenance Components (HPS Side View)

VW-G06

Service 3-1

Page 14

Table 3-1. Maintenance Schedule

WARNING

!

6

Procedure Interval Subsection

Check output pressure on gage* daily

Replace high-pressure filter when the indicator points to CHANGE 3.1.1

Replace low-pressure filter when Dirty Filter indicator lights 3.1.1

Check hydraulic fluid level on gage daily 3.1.2

Check hydraulic fluid in reservoir 150 operating hours 3.1.2

Analyze hydraulic fluid 500 operating hours 3.1.2

Check accumulator precharge at established interval 3.1.3

Check hydraulic hoses monthly

*

See Subsection 3.2.1 to adjust the output pressure.

3.1.1 Filters

Fluid filtration is provided by a 10-micron high-pressure filter and a

3-micron low-pressure filter. See Figure 3-1 for the location of the

filters and their drains.

High-pressure release occurs if the system is pressurized.

High-pressure release may cause personal injury or damage equipment.

Ensure that the output pressure gage reads zero before replacing the

filters.

3.1.1.1 High-Pressure Filter Replacement

CHANGE

Replace the high-pressure filter elements whenever the DIRT ALARM

indicator mounted on the base of each high-pressure filter housing

points to CHANGE (red or yellow zone) or whenever the hydraulic

OK

DIRT ALARM

VW-GO4

fluid is replaced.

1. Press Stop on the HPS. The output pressure gage must read zero.

3-2 Service

Page 15

End Cap – Top V iew

air-bleed

unscrews

screw

unscrews

endcap

2. Loosen the air-bleed screw on top of the filter housing endcap. See

the figure on the left.

3. With a container under the manifold drain port (Figure 3-1), open

the port to drain the fluid from the filter (the pressure

accumulator also drains).

4 When the fluid is drained, close the drain port and tighten the

air-bleed screw. Discard the fluid according to company policy.

VW-G047B

5. Unscrew and remove the endcap. Remove the compression spring

plate on top of the filter elements and remove the filter elements.

air-bleed

screw

endcap

6. Remove and save the grommet between the two filter elements.

O-ring

Discard the filter elements.

7. Inspect the O-ring and back-up washer in the end-cap. If

replacement is not required, clean and lubricate them with clean

hydraulic fluid.

filter

housing

8. Inspect the filter housing for any remaining contamination.

9. Insert two clean filter elements (MTS part number 100533-05), with

the grommet between the two elements, into the filter housing.

10. Inspect the compression spring plate and replace the end-cap.

base

VW-G070

Taking care not to damage the O-ring and the back-up washer,

tighten the end-cap.

After you have finished Operate the HPS in low pressure for 5 minutes to remove air from the

filter housing. Check for leaks while doing this.

Service 3-3

Page 16

3.1.1.2 Low-Pressure Filter Replacement

The low-pressure filter element requires replacement whenever

hydraulic fluid in the HPS reservoir is replaced, or the Filter Dirty

indicator on the HPS front control panel lights.

See Figure 3-1 for the location of the filter. Refer to the figure on the

left to locate the components accessed for the following procedure.

1

Side View

cable

handle

1. Press Stop on the HPS. The output pressure gage must read zero.

2. Disconnect the cable from the filter cover.

3. Remove one of the two bleed screws at the top of the filter cover.

4. Place a container under the filter drain and drain the fluid.

bleed

screws

Dispose of the fluid according to company policy.

5. Replace and tighten the bleed screw and drain plug.

6. Hand turn the handle counterclockwise until it screws off. Remove

filter

housing

the cover.

7. Remove and discard the filter element. Inspect the filter housing

for any remaining contamination.

filter

drain

8. Insert a new filter element (MTS part number 114028-17).

9. Hand tighten the cover.

10. Reconnect the cable.

After you have finished Purge the filter housing of air and allow it to fill with fluid as follows:

1. Open the bleed screw 1-1/2 turns.

2. Press the Reset control to reset the Dirty Filter indicator.

3. Momentarily turn the Spch Pump switch to the Start position,

then immediately return it to Auto. Continue this procedure until

hydraulic fluid appears at the loosened bleed screw.

4. Close and tighten the bleed screw.

1

This indicator may light during a cold-start condition, but should extinguish when the HPS reaches its normal operating

temperature.

3-4 Service

Page 17

3.1.2 Hydraulic Fluid

Regular maintenance of hydraulic fluid maximizes the service life of

the system and its components.

Daily fluid checks Check the fluid-level in the transparent gage. A low level can indicate

a leak. A high level can indicate water contamination from the heat

exchanger. If the fluid appears to have changed significantly, obtain a

sample from the HPS reservoir and check it for the following qualities:

• Considerable darkness, burnt odor, or an opaque quality of the

fluid indicates chemical breakdown. It may also indicate that the

fluid temperature was too high. Replace the fluid.

• During operation, a milky appearance indicates water is present in

the fluid. If the system is not in operation, water separates from

the hydraulic fluid and settles at the bottom of the reservoir. If

water contamination is present, correct the source of the water

leakage and replace the hydraulic fluid.

Monthly fluid checks Perform these checks monthly or every 150 operating hours (whichever

comes first).

• Keep records of the maximum reservoir temperature. High

operating temperatures can cause the fluid to break down.

Yearly (every 500

operating hours) fluid

checks

• Check for contamination and fluid breakdown. Take a fluid sample

and test the pH level using a pH kit (available from chemical

stores). Also, check the sample for color and odor.

• Take a fluid sample and let it stand overnight. Sediment at the

bottom of the fluid indicates collapsed, ruptured or clogged filters.

Obtain a sample of the fluid and have it analyzed. The fluid tests

should include chemical analysis, particle count, and viscosity checks.

Record the results and replace the fluid if necessary.

Service 3-5

Page 18

Replacing hydraulic fluid Perform this procedure to replace the hydraulic fluid. You will need a

Front View

CAUTION

!

Model 590.01 Fluid Transfer Pump or a pump which provides at least

10-micron filtration.

1. Turn off electrical power to the HPS. Remove the reservoir filler

cap assembly.

2. Drain the hydraulic fluid into a container, while hot, through the

drain valve. Close the valve.

3. Then drain the oil from the entire system (such as from the hoses

and accumulators).

4. Dispose of the fluid according to company policy.

5. Remove the top plate from the reservoir.

6. Wipe the inside of the reservoir with a clean lint-free cloth.

Apply MOBILSOL A—a solvent for cleaning and flushing

hydraulic systems—to a clean lint-free cloth and again wipe the

reservoir. Immediately wipe away the solvent with a dry cloth.

Drain

VW-G041E

7. Replace the high-pressure filter element. See Subsection 3.1.1.1.

8. Replace the low-pressure filter element. See Subsection 3.1.1.2.

To avoid damage to the hydraulic system, follow these precautions:

Do not mix different brands of hydraulic fluid. This can create

contaminants. Ensure that the replacement hydraulic fluid is the same

brand and type as the fluid which was removed. Generally, an MTS

Hydraulic Power Supply contains Mobil DTE 25 hydraulic fluid.

Consult MTS before you use alternate fluids.

Use a transfer pump that provides 10-micron or better filtration. Most

commercial hydraulic fluids exceed the maximum amount of

contamination allowable in MTS hydraulic systems.

9. Use the transfer pump to fill the reservoir with fresh hydraulic

fluid.

10. To flush out the pipe line, connect a hose from the pressure line to

the return line of the last station, and operate the HPS at low

pressure for 2 - 4 hours.

11. Replace the high-pressure filter element if necessary (Subsection

3.1.1.1).

3-6 Service

Page 19

3.1.3 Accumulators

HPS – Side View

r

For more information

about accumulators

See the Series 111 Accumulator product manual(MTS part number

115533-XX). For other accumulators, refer to the vendor literature or

the Procedure for Checking Piston and Bladder Type Accumulator

Precharge and Precharging (MTS part number 408266-XX).

3.1.3.1 Precharge Pressure-Checking Intervals

Precharge pressure of the pressure accumulator must be checked at

regular intervals. To establish an interval time, follow this procedure:

1. Initially, check the precharge pressure after 2 weeks or 100

pressure

accumulato

operating hours.

2. If the pressure changes more than 200 psi, check the precharge

CHANGE

OK

DIRT ALARM

pressure every week or 50 operating hours.

If the pressure changes less than 200 psi, check the precharge

slow turn-on

accumulator

VW-G044J

pressure every four weeks or 200 operating hours.

Precharge pressure of the slow turn-on accumulator must be checked at

regular intervals. To establish an interval time, follow this procedure:

1. Initially, check the precharge pressure after 2 weeks or 100

operating hours.

2. If there is a pressure-level change of more than 50%, check the

precharge pressure every week or 50 operating hours.

If there is a pressure-level change of less than 50%, check the

precharge pressure every four weeks or 200 operating hours.

3.1.3.2 Precharging the Accumulators

If the pressure accumulator has a pressure-level change of ±200 psi

between checks, recharge it. If the slow turn-on accumulator has a

pressure-level change of ±50% between checks, recharge it.

The pressure and slow turn-on accumulators are typically precharged to

1000 psi (7 MPa) and 800 psi (5.5 MPa), respectively. These are the

recommended levels for an HPS output pressure of 3000 psi (21 MPa).

3.1.3.3 Changing the Accumulator Seals

When you have established a regular interval for checking the

precharge pressure, note the amount of pressure loss that occurs each

time the precharge pressure is checked. If an increase in pressure loss

occurs during the period between checks, the seals may require

replacement.

Service 3-7

Page 20

3.2 Service Adjustments

Service overview Figure 3-2 shows the location of the service components accessed for the

following procedures.

• output pressure adjustment

• dual-temperature switch adjustments

• low-level switch adjustment

• main pump low-inlet pressure switch adjustment

Pressure

control

Low level

switch

Back-up

relief valve

Heat Exchanger

Supercharge Pump

Low-inlet

pressure

switch

VW-G069B

Figure 3-2. Location of Adjustment Components (HPS Side View)

3-8 Service

Page 21

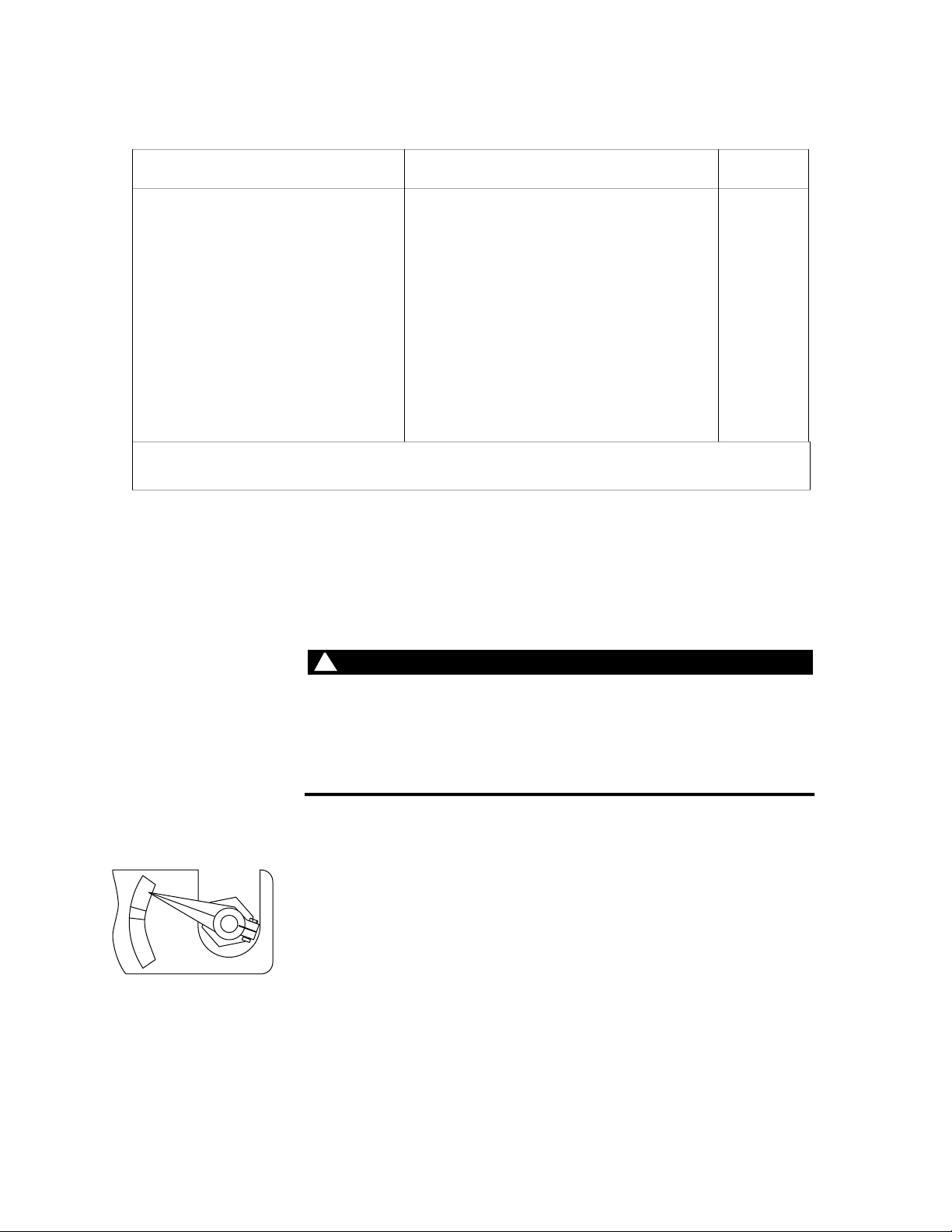

3.2.1 Output Pressure Adjustment

HPS – Side View

Top View

t

Refer to Figure 3-2 for the location of the components indicated in the

following procedure.

1. Turn off the HPS.

back-up

relief valve

CHANGE

OK

DIRT ALARM

2. Make sure that the output pressure gage reads zero (the figure on

the left shows the location of the pressure gage).

pressure

gage

VW-G044K

3. Remove the plastic cap on the pump pressure control.

4. Loosen the locknut and turn the pressure control fully

counterclockwise.

5. Loosen the locknut on the back-up relief valve and turn the

adjustment knob fully counterclockwise.

Locknut

Backup relief valve

Adjustmen

knob

TS-G072

6. Start the HPS in low pressure, then switch to high pressure.

7. Observe the pressure gage and alternately turn the back-up relief

valve adjustment and the pressure control knob clockwise.

1

Stop adjusting at approximately 500 psi (3.45 MPa) above the

desired output pressure (typically 3000 psi/21 MPa).

8. Tighten the locknut on the back-up relief valve.

9. Turn the pressure control adjustment knob counterclockwise until

the desired output pressure is reached.

10. Turn off the HPS and replace the plastic cap removed in step 3.

NOTE Whenever the output pressure is changed, the

accumulator precharge must also be checked (see

Subsection 3.1.3).

1

Adjustment increments should be approximately 500 psi (3.45 MPa) apart as indicated on the pressure gage.

Service 3-9

Page 22

3.2.2 Dual-Temperature Switch Adjustments

F

s

Definition The dual-temperature switch has two adjustment screws behind its

front protective cover. The Over Temperature adjustment turns off the

HPS if hydraulic fluid reaches a temperature of 140˚F (60˚C). The

Water Control adjustment is set at 115° F (43 °C). It controls water flow

through the heat exchanger.

Front view without cover

Adjustment

screws

Side

screw

Dual-temperature

switch

Before you begin Turn off the HPS. Loosen the screws on each side of the switch

assembly, and pull the front protective cover off. The adjustment screws

are labelled OT for over-temperature and WC for water control.

VW-G042

Over-temperature

adjustment

NOTE The fluid-level and temperature gage on the HPS is

used for reference only. Use a laboratory grade

thermometer to set the temperature switches in the

following procedure.

1. Turn the over-temperature adjustment screw (figure above) several

turns clockwise to raise the temperature limit.

2. Turn off the water supply to disable the heat exchanger.

3. Turn on the HPS and apply high pressure (see Subsection 2.2).

4. When hydraulic fluid temperature reaches 140˚F (60˚C), as

indicated on the temperature gage, turn the adjusting screw

counterclockwise until the HPS turns off.

5. Turn on the cooling water supply.

3-10 Service

Page 23

Water control

1

1. Ensure that the temperature gage reads below 90°F (32°C).

adjustment

2. Start the HPS. Turn the water control adjustment screw (figure

above) fully counterclockwise.

3. Monitor the temperature gage while the hydraulic fluid

temperature rises.

4. When the fluid temperature reaches approximately 110°F (43°C),

turn the adjustment screw clockwise until water starts to flow, then

turn it counterclockwise until water flow stops.

5. If the fluid temperature does not reach 115°F (46°C) turn the screw

a half-turn counterclockwise and note the effect after 15 minutes.

If the temperature exceeds 115°F (46°C), turn the screw clockwise.

3.2.3 Low-Level Switch Adjustment

The low fluid-level switch turns off the HPS if there is an appreciable

loss of hydraulic fluid. The factory-adjustment coincides with the

bottom of the fluid level gage and does not normally require

readjustment. Perform the following steps if readjustment is necessary.

locknut

top of

reservoir

VW-G05

1. With the HPS turned off, fill the reservoir to the correct fluid

level.

2. Turn on the HPS and apply high pressure.

3. See the figure on the left. Loosen the hand locknut on the stem of

the switch, and slowly raise the switch until the Low Fluid Level

indicator lights.

4. Lower the switch about 1.5 in. (38 mm).

5. Tighten the locknut.

6. Reset any applicable interlock circuits.

Service 3-11

Page 24

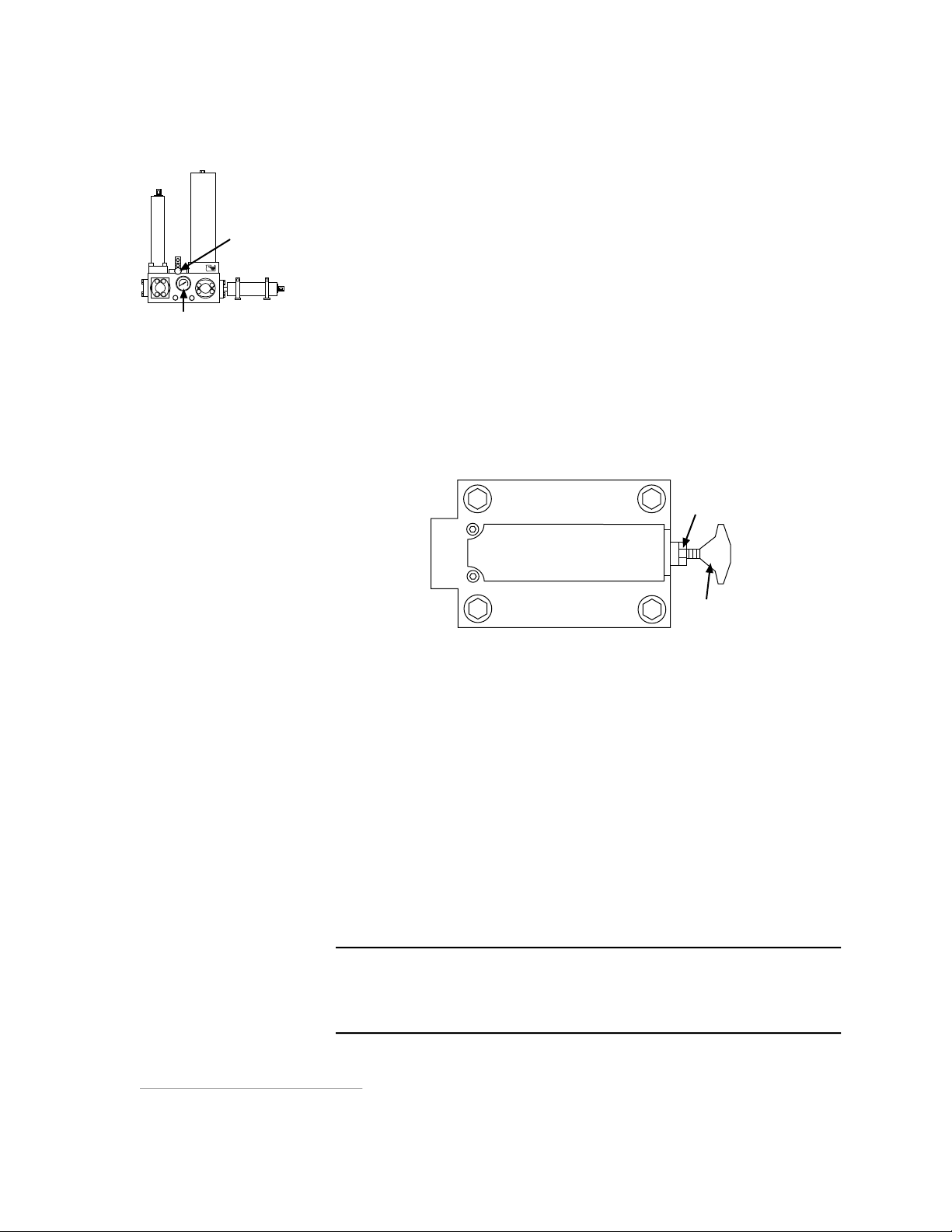

3.2.4 Main Pump Low-Inlet Pressure Switch Adjustment

Pressure Switch

(cover removed)

Adjustment knob

Indicator

Figure 3-2 shows the location of the main pump low-inlet-pressure

switch on the HPS. The switch monitors the pressure level supplied by

the supercharge pump at the input to the main pump. The switch

protects the main pump by turning off the HPS if the supercharge pump

pressure drops below the minimum level required by the main pump.

The switch is set at the factory to activate at 15 psi (0.1 MPa). This

switch may be adjusted with or without the HPS running. Use the

following procedure to adjust the switch.

1. Remove the four screws holding the cover and check the position of

the indicator.

2. If the indicator does not point to approximately 15 psi (0.1 MPa),

turn the adjustment knob located on top of the switch to increase or

decrease the pressure setting to 15 psi (0.1 MPa).

3. Re-install the cover and four screws.

VW-G052

3-12 Service

Page 25

3.3 Starter Assembly

WARNING

!

4

The starter assembly (Figure 3-3 shows the location of its components)

is located behind the starter box door. This section provides the

following information:

• Abnormal HPS Shutdown

• Fuse Replacement

• PLC (programmable logic controller) Service

WARNING

High voltage is present in the starter assembly. Do not open the starter

box door when power is applied to the HPS.

Touching components with high voltage can cause death.

Remove electrical power at the power disconnect switch before you open

the front starter box door.

Master control

relay

Programmable

logic controller

SPCH pump fuses

1FU

2FU

1M

SPCH

starter

Transformer

3FU

2M

Main

pump

starter

4FU

7FU

6FU

ground

Main pump fuses

8FU

3M 1S

5FU

Earth

9FU

Input power

10FU

PLC terminal block

Overload

relays

TS-G07

Figure 3-3. Model 506.62/.72 Starter Assembly

Service 3-13

Page 26

3.3.1 Abnormal HPS Shutdown

WARNING

!

Motor overload Sudden shutdown of the HPS may be due to circuit protection elements

in the pump motor starter assembly. If the supercharge motor

overloads, the relay opens and de-energizes the motor starter coils to

shut down the HPS. If the pump motor overloads, the pump shuts

down.

Reset procedure If a motor overloads, follow this procedure to reset it.

1. Turn off ac power at the HPS disconnect switch.

High voltage is present in the starter assembly if power is not removed.

Failure to remove power before opening the HPS starter box door may

cause death or injury.

Remove electrical power at the power disconnect switch.

2. Open the starter box door and locate the appropriate motor

overload relay (Figure 3-3).

3. Press the reset button located on the relay to enable operation.

NOTE The overload relay element may be equipped with a

3.3.2 Fuse Replacement

Table 3-2 lists the fuse values and part numbers of the fuses located in

the starter assembly. Figure 3-3 shows the location of the fuses.

switch to provide manual or automatic reset. This

switch should always be set to the manual position.

Table 3-2. Starter Assembly Fuse Values

Fuses Type MTS PN

FU 1 through FU 3 30A slo-blo 100725-05

FU 4 and FU 5 3A slo-blo 111457-06

FU 6 6A slo-blo 100524-27

FU 7 4A slo-blo 100524-04

FU 8 through FU 10 250A slo-blo 100725-52

3-14 Service

Page 27

3.3.3 PLC Service

The PLC in the 506.62/.72 HPS starter assembly has output and input

indicators shown in the figure below. These indicators are described in

the following tables.

0109 0110 0111 COM

Output indicators

(channel 1)

OUTPUT 1CH

0 1 2 3 4 5 6 7

8 9 10 11

POWER

RUN

ALARM

ERROR

Input indicators

(channel 0)

0 1 2 3 4 5 6 7

8 9 10 11 12 13 14 15

NC NC

506.62/.72 Output Indicators

Output Indicator CH1 Description

0 Remote low-level interlock/indication.

1 Remote over-temperature interlock/indication.

2 Remote dirty filter interlock/indication.

3 Remote run indication.

4 Turns on to energize main pump motor start control relay 1CR.

5 Turns on to energize main pump motor run control relay 2CR.

6 Turns on to energize main high-pressure solenoid 1SOL.

7 Turns on to energize water inlet solenoid 2SOL that allows water flow

into the heat exchanger for cooling hydraulic fluid.

8

Turns on to light front panel Low Fluid Level indicator 2LT.

0CHINPUT

24VDC 0.3A

+

VW-G073

9 Turns on to light front panel Fluid Over Temperature indicator 3LT.

10 Turns on to light front panel Dirty Filter indicator 4LT.

11 Turns on to energize supercharge motor starter 1M

Service 3-15

Page 28

506.62/.72 Input Indicators

Input Indicator CH0 Description

0 Turns off if switch 2TAS (115°F) opens. When fluid temperature exceeds a

preset limit, 2TAS opens to energize water inlet solenoid 2SOL. 2SOL

controls the water valve allowing water into the heat exchanger to cool

the fluid. (If Input 0 is off and input 13 is on, then output 7 is on.)

1 Turns off if ∆P switch 2PS (35 psi) opens to indicate the fine filter is dirty.

2 Turns on momentarily if the Remote/Local start switch is pressed.

3 Turns on if the pump is running or ready to run. Momentary "low" will shut

pump off it it is running.

4 Turns on if the front panel Main Pump High/Low/Start switch is turned to

High or high pressure is selected with a remote switch.

5 Turns on if the front panel Remote/Local switch is turned to Local.

6 Turns on if the front panel Reset switch is pressed.

7 Turns off if switch 1FS opens to indicate that the fluid level has dropped

below a preset limit.

8 Turns off if switch 1TAS (140°F) opens to indicate that the hydraulic fluid

temperature has exceeded a preset limit.

9 Turns off if motor overload relay contact 2 OL or 1 OL opens to indicate

that the supercharge or pump motor is drawing excessive current.

10 Turns on if the front panel Spch Pump switch is turned to Start. The

supercharge pump continues to run until the Spch Pump switch is turned to

Auto (i.e. if indicator 11 goes off).

11 Turns off if the front panel Spch Pump switch is turned to Auto.

12 Turns on if inlet pressure switch 1PS (15 psi) closes to start the main pump.

Inlet pressure is supplied by the supercharge pump

13 Turns on if motor relay contacts 1M close to indicate the supercharge pump

is running.

14 Turns on if motor relay contacts 3M close to indicate the main pump motor is

running.

15 Turns off if the E-Stop switch is pressed.

3-16 Service

Page 29

Section 4

Installation

Introduction This section provides the following installation information for the

Model 506.62/.72 Hydraulic Power Supply (HPS).

• hydraulic connections

• electrical connections

• water connections

Before you complete

connections

Perform these steps before you make any connections to the HPS.

1. Remove the shipping plate located under the hydraulic fluid

filler cap.

2. Make sure that the chained jumper plug is connected to the remote

control connector located on the side of the starter box door. See

the figure below.

Remote control

connector

For remote control

connection

Figure 4-1. Location of Remote Control Connector

The jumper plug may be replaced by the system cable from a remote

control device when the HPS is ready for system operation.

Installation 4-1

Page 30

4.1 Hydraulic Connections

HPS – Side View

L

The pressure, return and drain connections are located on the HPS

manifold shown in Figure 4-2. Refer to the system hydraulic

distribution drawing in the Assembly Drawings system reference

manual for hydraulic connections that are specific to your system.

Hydraulic connections Hydraulic hose connections from the HPS are made to the ports

labelled P (pressure) and R (return) on the HPS manifold. These

connections are typically made to a system servovalve manifold,

hydraulic service manifold, or hydraulic distribution manifold. The

HPS has drain ports for any drainback connections used by the system.

Pressure

ports

Return

ports

Drain

ports

VW-G044

Figure 4-2. Hydraulic Connections

NOTE Table 1-2 shows the specifications for the ports shown

in Figure 4-2.

4-2 Installation

Page 31

4.2 Electrical Connections

WARNING

!

4

The HPS is operated from a three-phase electrical power source. The

operating voltage is labeled on the outside of the starter assembly and

on the pump motor.

Before you begin

Install a fused power disconnect switch (customer supplied). This

switch removes electrical power to the HPS. Local codes dictate the

type of switch to be used. Electrical connections must be made by

qualified personnel and conform to local codes and regulations.

When the electrical connections have been made, high voltage is

present in the starter assembly when power is on. Do not open the

starter box door with power applied to the HPS.

Touching components with high voltage can cause death.

Remove electrical power at the power disconnect switch before you open

the front starter box door.

Master control

relay

Programmable

logic controller

SPCH pump fuses

1FU

2FU

1M

SPCH

starter

Transformer

3FU

2M

Main

pump

starter

4FU

7FU

6FU

ground

Main pump fuses

8FU

3M 1S

5FU

Earth

9FU

Input power

10FU

PLC terminal block

Overload

relays

Figure 4-3. Model 506.62/.72 Starter Assembly

Installation 4-3

TS-G07

Page 32

4.2.1 Transformer Wiring

460 Vac

230 Vac

6

One of two types of transformers is installed in the starter assembly.

Check the wiring configuration of the transformer before applying ac

power to the HPS.

Standard transformer

wiring

H1

X2

H3

Optional transformer

wiring

This figure shows the jumper wiring required on a standard transformer

for source voltages of 460 and 230 Vac.

jumper

H2

H4 H1

X1

X2

jumper

H3

jumper

H2

Figure 4-4. Standard Transformer Wiring Configuration

An optional multi-tap transformer may be used for source voltages other

than 230 Vac and 460 Vac. The following figure shows the typical

wiring required for various voltages. Source voltages are applied to

terminals H1 through H5 as shown. An output voltage is tapped from

terminals X1 through X4. Check the output voltage with a voltmeter.

It should be 110 Vac for systems using 50 Hz power and 115 to 120 Vac for

systems with 60 Hz.

H4

X1

VW-C03

208/220/230/240 Vac

380/400/416 Vac

440/460/480 Vac

500/550/575/600 Vac

Figure 4-5. Typical Multi-Tap Transformer Wiring Configuration

4-4 Installation

X4

H3H2H1

X3 X2 X1

H4

H5

110/120/125/130 Vac

100/110/115/120 Vac

85/91/99 Vac

VW-C037

Page 33

4.2.2 Input Power

WARNING

!

Electrical connection

procedure

Polarity check Perform this procedure to ensure that electrical power is properly

See Figure 4-3 and perform the following procedure to make the

electrical connections.

1. Connect a solid earth ground from the power disconnect switch to

the starter assembly.

2. Connect the three input leads from the disconnect switch to the

three terminals located on the starter assembly.

3. Close starter box.

connected to the HPS:

1. Apply ac power to the HPS. The Power indicator should light.

2. Jog the supercharge pump motor by turning the Spch Pump switch

to Run and then immediately returning it to the Auto position.

High voltage is present in the starter box if power is not removed.

Failure to remove power before opening the starter box may cause death

or injury.

Remove electrical power at the power disconnect switch.

3. If the supercharge motor is rotating in the direction indicated by

the arrow on the pump motor housing, electrical connections are

correct. If it is rotating in the opposite direction of the arrow,

remove ac power to the HPS and switch two of the three input

power leads to the HPS (refer to Figure 4-3).

Installation 4-5

Page 34

4.3 Cooling Water Connections

t

Shut-off

Specifications The differential pressure required between the water inlet and outlet

connections is 30 to 45 psi (0.2 to 0.3 MPa). The maximum allowable

water pressure is 120 psi (0.83 MPa). The water supply must be capable

of providing water flow at a rate indicated in Table 1-1. See Table 1-2

for the maximum cooling water heat load.

Water connections Use a 1.5 in. (38 mm) water service hose to connect the water supply and

drain to the heat exchanger water inlet and outlet connections (figure

below).

Heat Exchanger – Top View

hot fluid (from

supercharge pump)

cold fluid (to low

pressure filter)

valve

water in

water ou

VW-G055B

4-6 Installation

Page 35

Theory of Operation

This section describes the hydraulic and electrical operation of Model

506.62/.72 Hydraulic Power Supply (HPS).

5.1 Hydraulic Operation

The figure below shows a block diagram of the HPS hydraulic operation.

Section 5

Low-Inlet

Pressure

1PS

Filter Pressure

In

ER

Out

compensator

Switch

Switch 2 PS

Fluid-Level and

Temperature

Gage

Pressure

-20 JIC

M

Main Pump

set

at 3025 psi

35

psi

Optional

Water

Control

Valve

M

Pressure

-24 4 Bolt

High-Pressure

Filter

10-micron

Check

Valve

1 Sol

Low-Pressure

Fine Filter

3-micron

Heat

Exchanger

Supercharge

Pump

Output

Pressure

Gage

Filter

Bypass

Pressure

Accumulator

Bleed-down

2 SOL

24 Vdc

Supercharge and

Filter Manifold

Supercharge

Relief Valve

preset to crack

at 30 psi

Water-Control

Valve Temperature

Switch

set at 115° rising

3500 psi

Orifice

Over-Temperature

set at 140° rising

Figure 5-1. Hydraulic Block Diagram

Back-up

Relief Valve

Slow Turn-on

Accumulator

Main Manifold

Assembly

Switch

Return

-20 JIC

Low-Level

Float

Switch

Return

-24 4 Bolt

Drain

-16 JIC

-12 JIC

-12 JIC

TS-C133B

Theory of Operation 5-1

Page 36

Main and supercharge

pumps

Filters Hydraulic fluid from the low-pressure filter is routed to the main

Back-up relief valve An adjustable back-up relief valve limits output pressure by porting

High/low solenoid valve High/low pressure operation is controlled by the high/low solenoid

The HPS uses a variable-volume pressure compensated main pump,

with a pressurized (supercharged) hydraulic fluid inlet to provide

fluid flow. The supercharge pump draws hydraulic fluid from the

reservoir and forces it through a heat exchanger and a low-pressure

filter. Fluid not required by the main pump returns to the reservoir

through check valves in the low-pressure filter manifold.

pump. A low-inlet pressure switch monitors the inlet pressure

(supercharge output pressure) to the main pump.

Fluid from the main pump outlet passes through a check valve and a

10-micron high-pressure filter. The output pressure is controlled by the

pressure compensator adjustment on the main pump and is monitored by

the output pressure gage. Output volume varies automatically with

external circuit demand.

fluid back to the reservoir. When the pump compensator is operating

normally, the relief valve does not open.

valve. This valve controls the backup relief valve vent port.

With the high/low solenoid valve de-energized, the back-up relief

valve vent port is open and output volume is ported to the reservoir,

limiting output pressure to approximately 150 psi (1.03 MPa). This

low-pressure condition occurs during supply turn-on for low pressure

start-up and during power-up of the HPS.

With the high/low solenoid valve energized, the vent port is blocked

and system pressure can rise to the preset operating pressure, typically

3000 psi (21 MPa).

Fluid temperature Hydraulic fluid temperature is maintained at a recommended

operating level by a fluid-to-water heat exchanger which passes the

fluid over water-filled tubes. Water flow through the tubes is

automatically regulated by a solenoid valve which is controlled by a

programmable logic controller (PLC). If fluid temperature exceeds a

preset limit (typically 140°F), a temperature-sensitive switch turns the

HPS off.

The fluid level and temperature gage on the HPS is used for reference

only. Use a laboratory grade thermometer to set the temperature.

5-2 Theory of Operation

Page 37

Pump protection Pump protection is provided for the main pump by the main pump

low-inlet pressure switch that turns the supply off if supercharge

pressure drops below the recommended operating pressure. The

supercharge pump and main pump are protected by a fluid-level

switch, which turns the supply off if the level of hydraulic fluid in the

reservoir drops below a preset level.

Pressure accumulation The pump-outlet pressure accumulator smooths the HPS output and

provides additional hydraulic pressure for high instantaneous flow

demands. It is precharged with dry nitrogen to a pressure proportional

to HPS output pressure. The optional slow turn-on accumulator slows

the rate at which the backup relief valve shifts from low to high

pressure. The precharge must be adjusted proportionally to the HPS

output pressure. If it is above or below the recommended level, the

effect of the accumulator is reduced.

5.2 Electrical Operation

This section provides the HPS electrical theory of the operation.

Figure 5-2 is a typical electrical schematic for the 506.62/.72 HPS.

HPS operation is controlled by a PLC (programmable logic controller).

It is designed so that a desired circuit in relay ladder logic can be

programmed. The PLC provides logic functions previously

accomplished by relays, timers and sequencers. It contains an I/O

section that receives input data from various switches and contacts that

are hardwired to the input terminals. The PLC sends output commands

to motors, motor starters, solenoid valves and indicator lights that are

hardwired to the output terminals. The PLC operating program is

retained by an EPROM memory module. A back-up battery is not

required.

5.2.1 Control

When the disconnect switch is closed, the HPS control panel Power On

indicator lights to show that electrical power to the HPS is on.

Inlet pressure When the High/Low/Start switch is positioned to Start, relay 1M at

PLC output 111 energizes to start the supercharge motor. Contacts 1M

provide the supercharge motor status to PLC input 013. The

supercharge motor provides inlet pressure for the main pump. When

the inlet pressure is reached (typically 15 psi), pressure switch 1PS

(connected from the outlet of the supercharge pump to PLC input 012)

closes to start the pump motor.

Start control The start signal is sent to input 002 of the PLC. If various conditions

(such as interlocks) are satisfied, the start signal is routed to output 104

of the PLC to energize the main pump motor start control relay (1CR).

Theory of Operation 5-3

Page 38

Pump motor When 1CR contacts close, the main pump motor starts, using a

Wye-delta start. First relay 1S energizes to close 1S contacts and

energize relay 2M (1M contacts close). Relays 2M and 1S provide a wye

connection (this reduces inrush current) to start the main pump motor.

After a timing delay that the PLC provides, output 105 energizes relay

2CR. The state of all 2CR contacts change to de-energize 1S and

energize 3M. Relays 2M and 3M connect the motor windings in a delta

configuration to provide full current to the motor. A set of 3M contacts

provides the motor status to the PLC at input 014.

High pressure When the HPS High/Low/Start switch is positioned to High, high

pressure is selected by energizing high-pressure solenoid 1 SOL for the

main pump.

Stop control When stop switch 1PB at PLC input 003 is pressed, the main pump

motor is turned off. The supercharge pump motor, however, continues to

run for approximately 10 seconds.

Emergency stop control Pressing Emergency Stop turns off the HPS by de-energizing relay CRM.

CRM contacts open to cut off power to the motor starter. The

supercharge pump may continue to run briefly while the main pump

winds down.

24 Vdc operation The HPS includes a 24 Vdc electrical power supply for operating

solenoid valves, relays and the PLC. Current available for external use

is listed in the specifications table. All solenoid valves connected to

this supply must be rated at 24 Vdc. If the 115 Vac control voltage

option is required, all solenoid valves connected to the supply must also

be rated at 115 Vac.

5-4 Theory of Operation

Page 39

5.2.2 Interlocks

The HPS contains interlock circuitry to shut down the HPS when

various conditions occur—such as low level hydraulic fluid, overtemperature, low pressure, dirty filters and motor overload.

Reset When the interlock condition has been corrected and the HPS is

restarted, Reset switch 2PB at PLC input 006 must be pressed to reset

the interlock circuitry.

Low-level hydraulic fluid Low fluid level switch 1FS protects the HPS if there is an appreciable

loss of hydraulic fluid. Whenever the level of hydraulic fluid in the

HPS reservoir drops below a preset limit, switch 1FS (at PLC input 007)

opens to turn off the pump motor, and disable the supercharge pump if it

is in the Start/Run mode. PLC output 100 generates the interlock. PLC

output 108 lights the Low Fluid Level indicator on the HPS front panel.

Fluid over-temperature

condition

Low-inlet pressure Pressure switch 1PS protects the main pump if inlet pressure drops

Water control valve

temperature switch

Dirty filter The low-pressure fine filter is monitored by ∆P switch 2PS (at PLC

Whenever the temperature of the hydraulic fluid in the HPS reservoir

exceeds a preset limit, switch 1TAS (at PLC input 008) opens to turn off

the HPS pump motor. The supercharge pump can be operated in the

Start/Run mode to cool the fluid. PLC output 101 generates the

interlock. PLC output 109 lights the Fluid Over-Temperature indicator

on the HPS front panel.

below the minimum level required by the main pumps. Switch 1PS (at

PLC input 012) closes whenever low-inlet pressure drops below a preset

limit (typically 50 psi). Closing 1PS while the pump motor is

operating, turns off the HPS. The supercharge pump, however, can be

operated in the Start/Run mode.

Whenever the temperature of the hydraulic fluid exceeds a preset

limit, switch 2TAS (at PLC input 000) opens to energize water-inlet

solenoid 2SOL (at PLC output 107). This solenoid controls the water

valve allowing water into the heat exchanger to cool the hydraulic

fluid.

input 001). When a dirty filter creates excessive differential pressure

across the filter, switch 2PS opens. PLC output 102 generates the

interlock. PLC output 110 lights the Dirty Filter indicator on the HPS

front panel. If the indicator is active when the HPS shutdowns, Reset

must be pressed (after the filter is replaced) to restart the HPS.

Motor overload Thermal overload sensors detect excessive current and open the

normally closed contacts connected to the motor starter coil. Motor

overload relay contacts 1OL and 2OL at PLC input 009 open to turn off

the HPS off if the supercharge or main pump motor draws excessive

current. When an overload condition occurs, the reset button on the

motor overload relay must be pressed (see Subsection 3.3.1).

Theory of Operation 5-5

Page 40

supplied by customer

must be grounded

disconnect switches

NOTE Hydraulic power supplies are often customized for

specific applications. Actual wiring may differ from

what is shown in Figure 5-2.

The wiring schematic that is specific to your system can

be found in the product information kit. This kit is

located inside the starter box.

2OL

2M

2OL

2M

2OL

2M

3M

3M

3M

2S 2S 2S

H3 H2

H1

X1 X2

8FU

9FU

10FU

4FU

5FU

H4

HPS

2MTR

6FU7FU

1CR 2M

1S 2CR

2CR

1S

3M

1HM

red

115 – 230 Vac

115 Vac neutral

Chassis Ground

A

L

D

24 Vdc

M

CRM

white

green

E-Stop

2M

3M

1S

CRM

1LT

R

mechanical

interlock

power on

motor 1 starter

motor 1 run contactor

motor 1 start contactor

motor 1 hour meter

PLC

master control relay

1FU

2FU

3FU

1M

1M

1M

1OL

1OL

1OL

Spch

1MTR

24 Vdc

to

outputs

24 Vdc

inputs

15 Vac

1

to

to

outputs

5-6 Theory of Operation

to

PLC

input 015

to

dc

common

to

ac

common

E

Figure 5-2. Typical Electrical Schematic

Balloon with letter indicates MS connector pin

VW-C039A

VW-C039A

Page 41

from

E-stop

B

K

H

E

24 Vdc

Set at 100ºF

35 PSI

remote/local

4SS

2PB

1 TAS

2 OL

50 PSI

1M

3M

2 TAS

2 PS

low

high

start

1SS

1 FS

set at 140°F (60°C)

start

auto run

3SS

1PS

1 OL

stop

1PB

PLC inputs

0000

0001

0002

0003

0004

0005

0006

0007

0008

0009

0010

0011

0012

0013

0014

0015

common

open water valve

fine filter

common

remote start

pump run

remote/

high pressure

remote/local

reset

fluid level

fluid temperature

motor overload

spch auto

spch only

inlet pressure

spch motor status

motor 1 status

E-stop

common

dc

F

24 Vdc

115 Vac

PLC outputs

0100

0101

0102

0103

0104

0105

0106

0107

0108

0109

0110

0111

common

common

common

common

1CR

common

common

2CR

1 SOL

2 SOL

R

R

A

1M

dc

common

low level

J

over-temp

G

filter dirty

N

B

HPS on

motor 1 start relay

motor 1 run relay

main hi press sol

water inlet sol

ac common

low level interlock

over-temp interlock

dirty filter warning

supercharge motor starter

Note:

Balloon with letter indicates MS connector pin

E

Figure 5-2. Typical Electrical Schematic (Continued)

VW-C039D

Theory of Operation 5-7

Page 42

Page 43

Page 44

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...