Page 1

CH-9101 Herisau/Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

E-Mail info@metrohm.ch

Internet www.metrohm.ch

Dosing Interface USB Toolbox

Version 1.0

Reference manual

8.104.0003 06.2005 / dm

Page 2

Page 3

Table of content

Table of content

1 Overview ................................................................1

1.1 Distributed files ..............................................................................................1

1.2 The 846 Dosing Interface...............................................................................2

1.2.1 System connections.................................................................................2

1.2.2 Connectors of the 846 Dosing Interface ..................................................3

1.2.3 PC connection ..........................................................................................3

1.2.4 Dosino Connection...................................................................................4

1.3 Metrohm 700/800 Dosinos and Dosing Units...............................................5

1.3.1 Dosing/Filling the dosing cylinder............................................................6

1.3.2 Switching the valve disk ...........................................................................7

1.3.3 Port assignment .......................................................................................7

1.3.4 Standard occupancy of the Dosino ports:...............................................8

2 DLL Reference .......................................................9

2.1 Constants .......................................................................................................9

2.1.1 Return states ............................................................................................9

2.1.2 Dosino states............................................................................................9

2.1.3 Piston movement....................................................................................10

2.1.4 Valve disk................................................................................................11

2.2 Functions ..................................................................................................... 12

2.2.1 Init846 .....................................................................................................12

2.2.2 GetProgramVersion................................................................................12

2.2.3 GetInterfaceId.........................................................................................12

2.2.4 Status......................................................................................................13

2.2.5 GetCylVolume.........................................................................................13

2.2.6 DU_Cock ................................................................................................13

2.2.7 ZeroAdjust ..............................................................................................14

2.2.8 Adjust......................................................................................................14

2.2.9 GoPos.....................................................................................................14

2.2.10 DU_ToEnd ..............................................................................................15

2.2.11 DU_MakeStep ........................................................................................15

2.2.12 DU_Fill ....................................................................................................15

2.2.13 DU_Exchange.........................................................................................16

2.2.14 DosStop..................................................................................................16

2.2.15 DosHold..................................................................................................16

2.2.16 DosContinue...........................................................................................17

2.2.17 DU_Prep .................................................................................................17

2.2.18 Empty......................................................................................................17

2.2.19 GetInterfaceError ....................................................................................18

2.3 Error Messages ........................................................................................... 19

3 Annex ...................................................................20

3.1 Programming interface definitions ............................................................ 20

3.1.1 Java interface class................................................................................20

3.1.2 Java interface exception class ...............................................................28

3.1.3 C++ interface definition header file ......................................................29

3.1.4 Delphi Interface ......................................................................................36

3.1.5 Visual Basic Interface .............................................................................43

Dosing Interface USB Toolbox

Page 4

Page 5

1.1 Distributed files

1 Overview

The Liquid Handling library for Metrohm 846 Dosing Interface provides a Dynamic Link Library (DLL) for the software development for the Microsoft Win-

®

dows

2000 and XP operating systems. Based on the Metrohm Universal Serial Bus driver (metr_770.dll) the Liquid Handling Library offers all functions

necessary for free programming of liquid handling processes with the versatile

Dosino drives.

The following programming languages are supported:

• JAVA

• C++

• Delphi

• Visual Basic

For these languages programming interface definitions are available, see annex.

1.1 Distributed files

This distribution includes the following files:

DosIntFace846.dll 846 Dosing Interface driver

DosIntFace846.lib Library

DosIntFace846.def Definition file

metr_770.dll Metrohm USB driver

metr_770.inf Installation file

metr_770.sys System file

DosIntFace846.java Java interface class

DosIntFace846Exception.java Java interface exception class

DosIntFace846.html JavaDoc file

DosIntFace846Exception.html JavaDoc file

DosIntFace846.h C++ interface header file

DosIntFace846.pas Delphi interface

DosIntFace846.bas Visual Basic interface

Demo_846.exe Executable demo program

8.104.0003.pdf Reference manual

Dosing Interface USB Toolbox, Overview 1

Page 6

1.2 The 846 Dosing Interface

1.2 The 846 Dosing Interface

The 846 Dosing Interface is part of the Metrohm Titrando system as a system

component and control instrument. The instruments are controlled via USB 1.1

connections.

The four MSB connectors (MSB=Metrohm Serial Bus) of the 846 Dosing Interface enable the operation of Metrohm Dosinos (models 700 and 800) which allow complex liquid handling processes.

One or more 846 Dosing Interfaces can be controlled at the same time. Each

of them can operate up to four Metrohm 700/800 Dosinos.

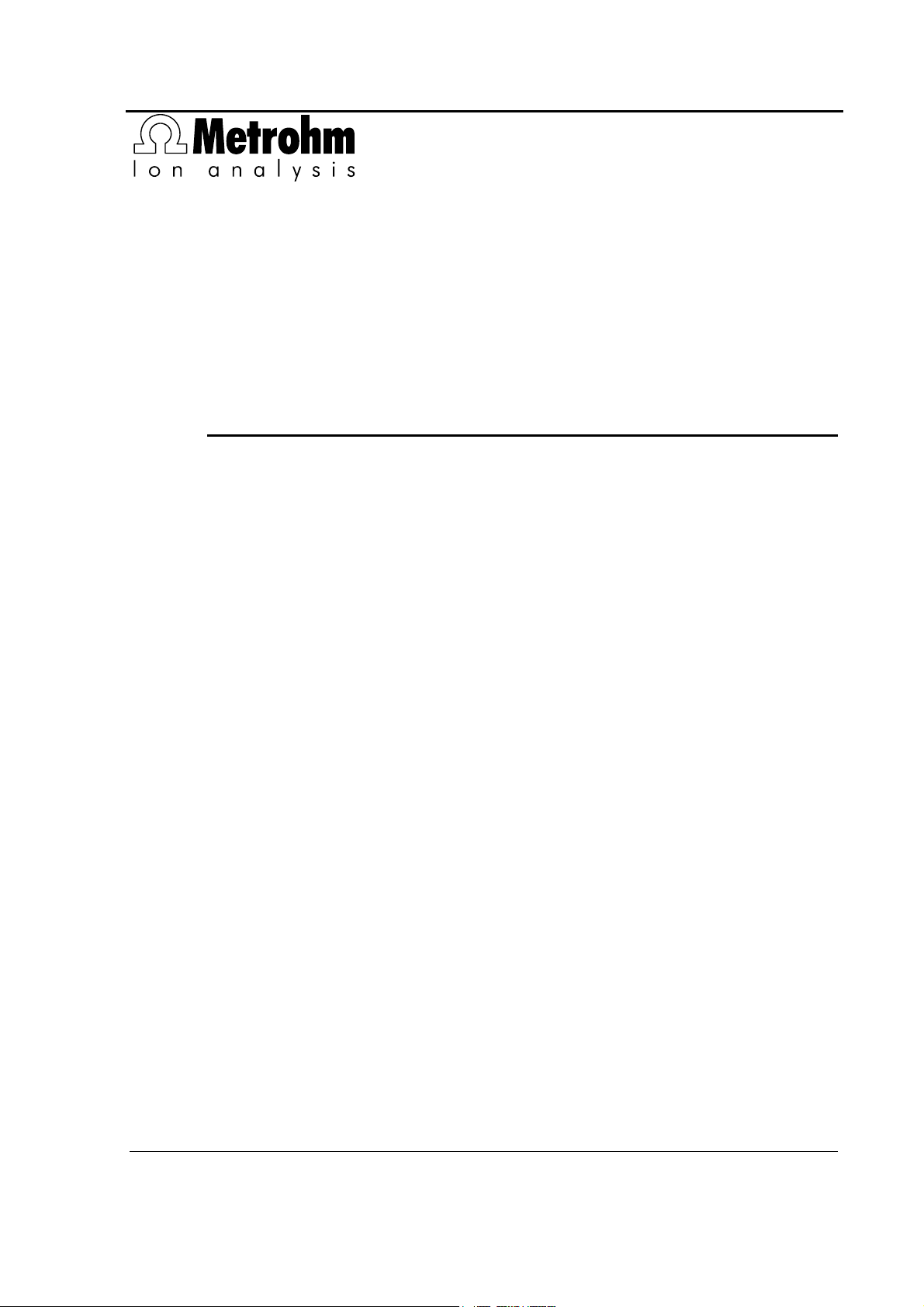

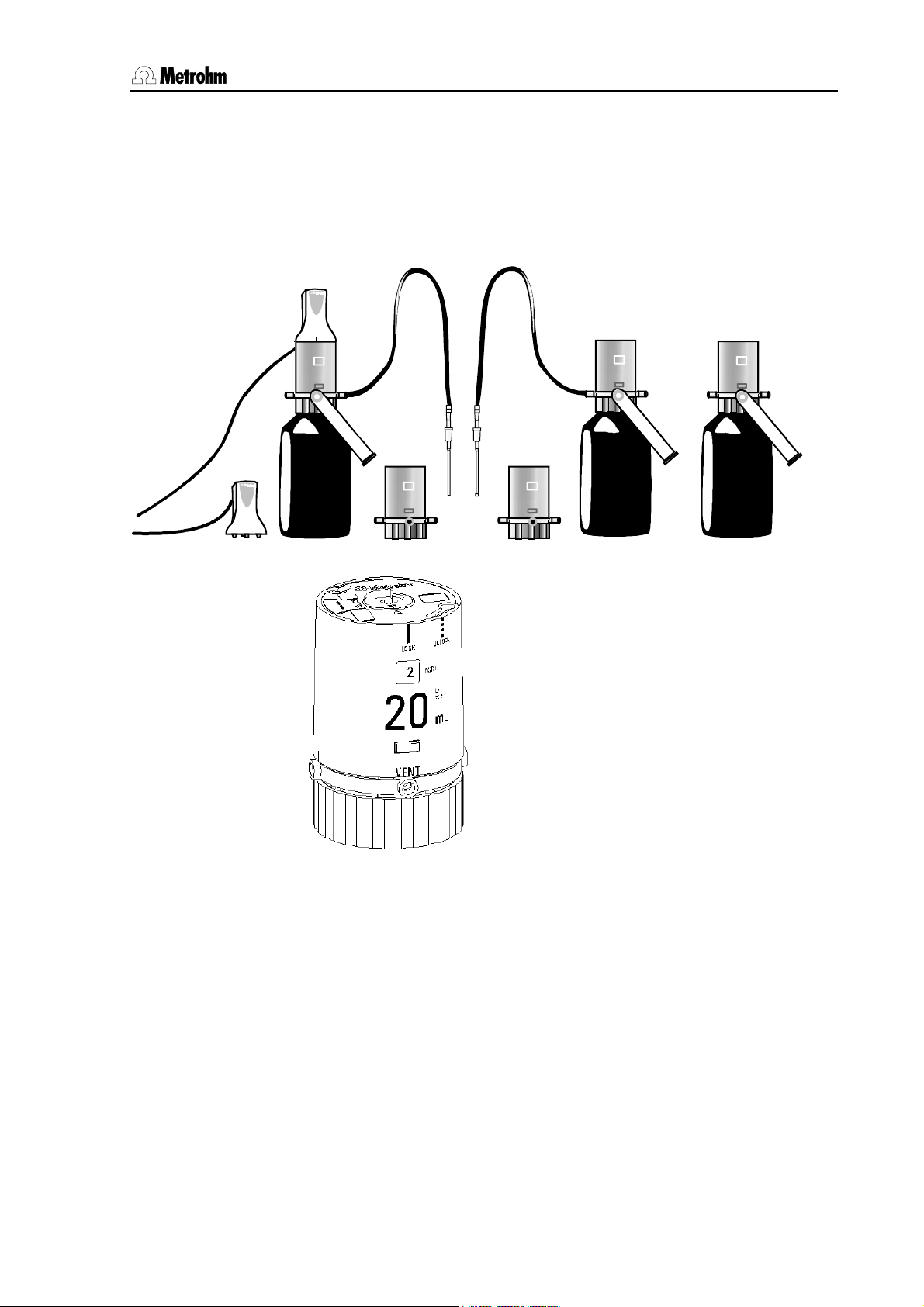

1.2.1 System connections

700/800 Dosinos

USB

700/800 Dosinos

Fig. 1 System connections

MSB1...4

846 Dosing Interface

MSB1...4

846 Dosing Interface

6.2151.000

Controller cable

USB

6.2151.000

Controller cable

USB

Several 846 Dosing Interfaces can be connected via USB in a daisy chain. All

of these instruments can be controlled by a PC software via USB. The Metrohm

USB driver (metr_770.dll) controls the basic USB data transfer. The Dosing Interface USB Toolbox provides the low level functions for controlling the Dosino

drives.

2 Dosing Interface USB Toolbox, Overview

Page 7

1.2 The 846 Dosing Interface

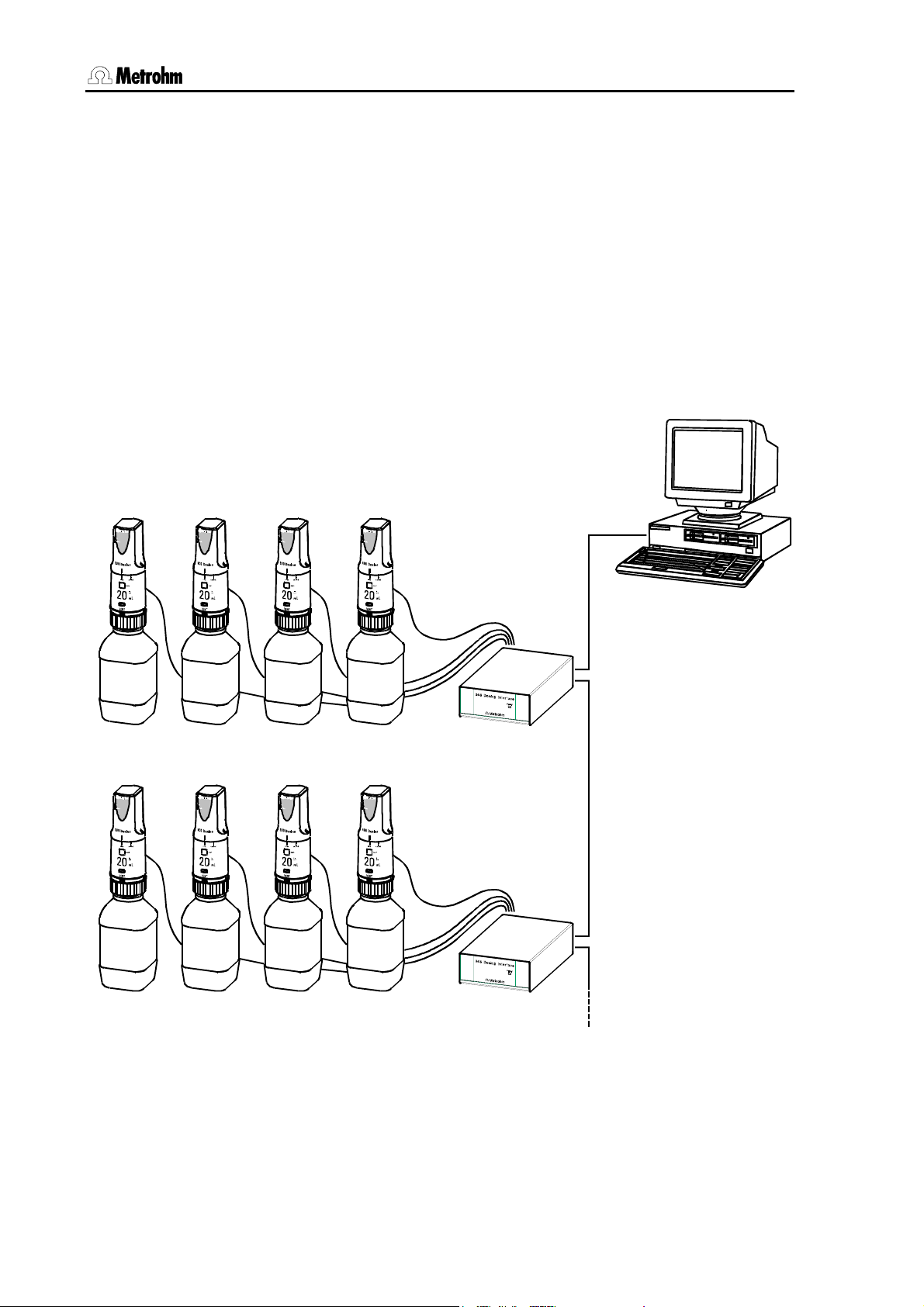

1.2.2 Connectors of the 846 Dosing Interface

3

2

1

USB1

USB2

Controller

6

Fig. 2: Rear view of the 846 Dosing Interface

1 USB connections USB 1 and USB 2

USB ports (type A) for connection of peripheral devices or further Dosing Interfaces.

2 MSB connections MSB 1 to MSB 4

Connection for dosing drives.

3 Instrument type and serial number

MSB4MSB3

MSB1 MSB2

100 - 240 V

f 50-60 Hz

P 45 W

5

Controller connection

4

Connection for PC or further Dosing interfaces.

Use 6.2151.000 controller cable.

5

Mains socket

Mains connection

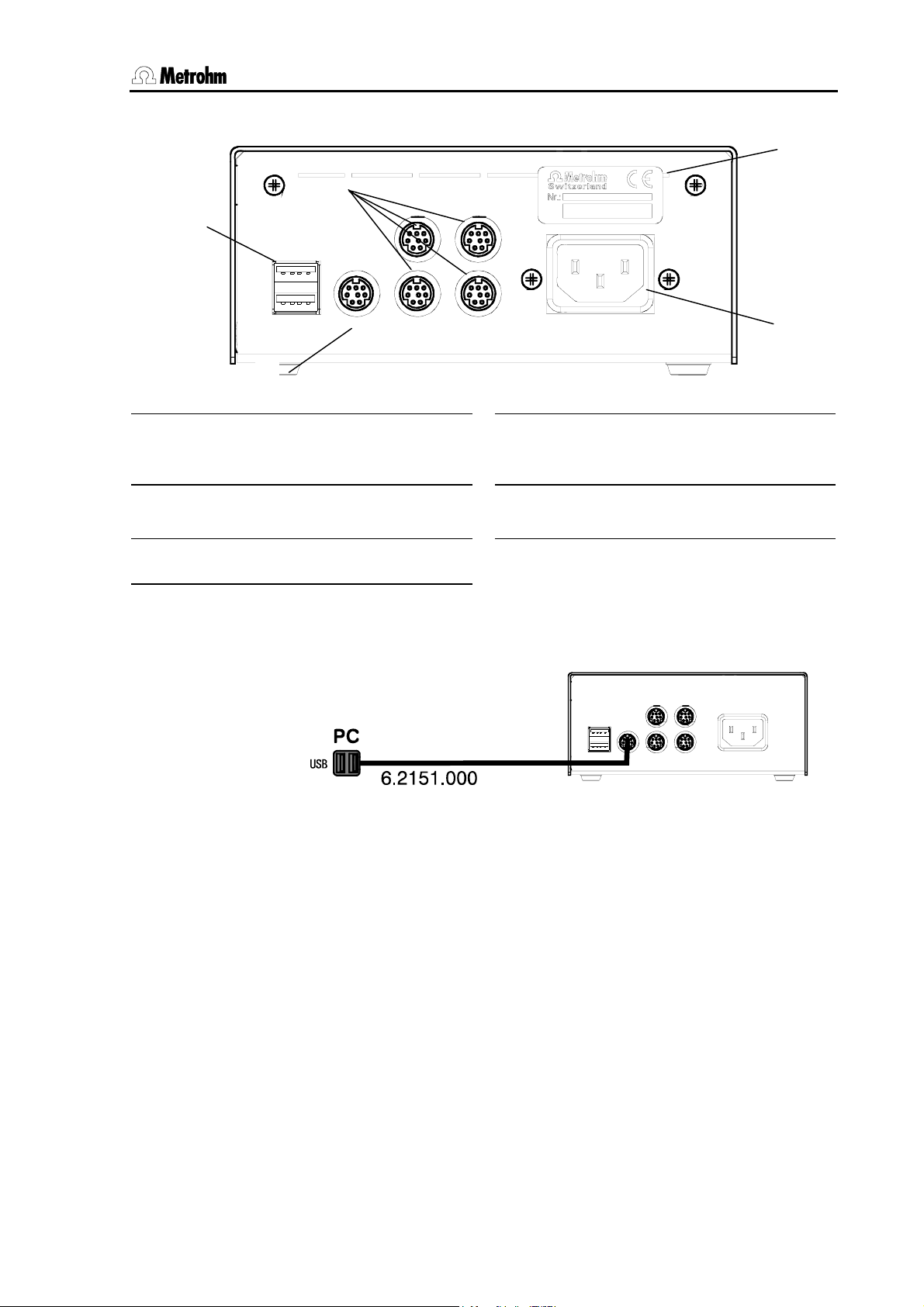

1.2.3 PC connection

Fig. 3: Dosing Interface – Personal Computer

Always use the 6.2151.000 Controller cable to connect a 846 Dosing Interface to

the USB socket of a PC or another 846 Dosing Interface.

You can extend the connection with a commercially available USB extension cable

(type A/m – type A/f). The length of the connection should not exceed 5 m. If you

require a longer connection then you need a USB signal amplifier. Up to five USB

signal amplifiers can be connected in series; this allows a maximum extension of

25 m.

Dosing Interface

Dosing Interface USB Toolbox, Overview 3

Page 8

1.2 The 846 Dosing Interface

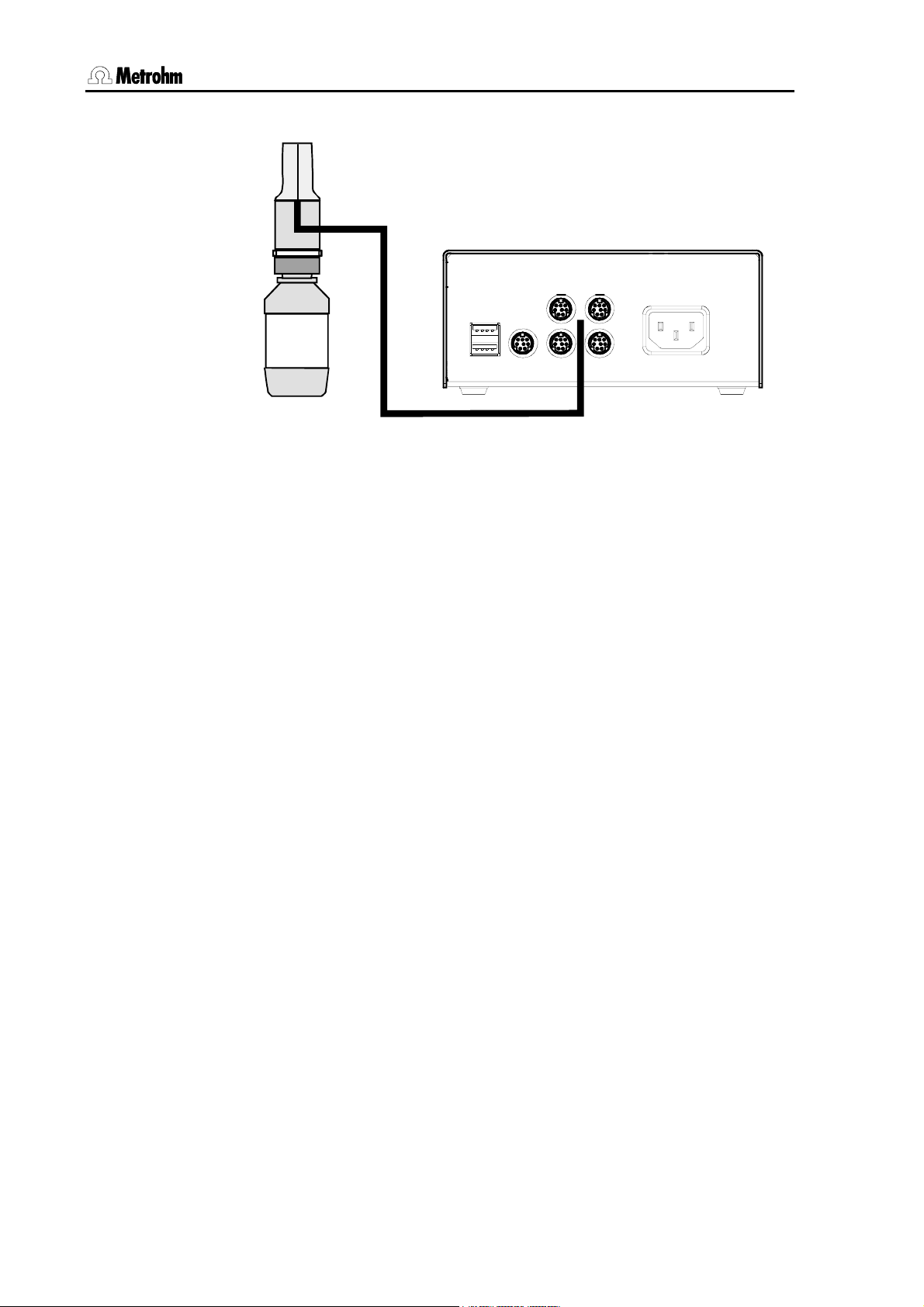

1.2.4 Dosino Connection

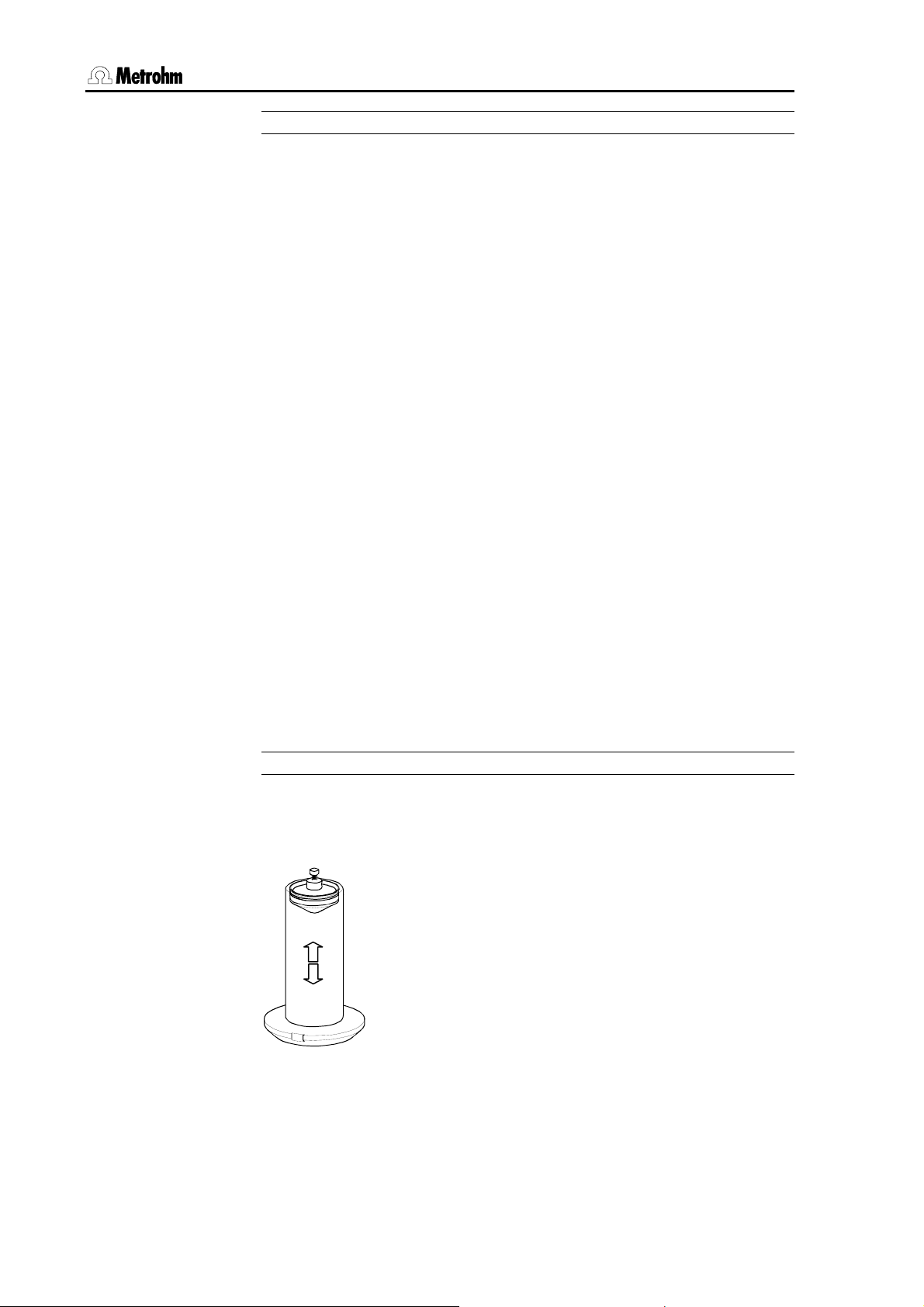

Fig. 4: Connecting a Dosino drive

700/800 Dosino drives are connected at the MSB connecters 1 to 4. A Dosino

drive can be recognized and integrated in a system by use of the

function. The MSB(…) connector specifies the Dosino number.

MSB

Dosing Interface

Init846()

4 Dosing Interface USB Toolbox, Overview

Page 9

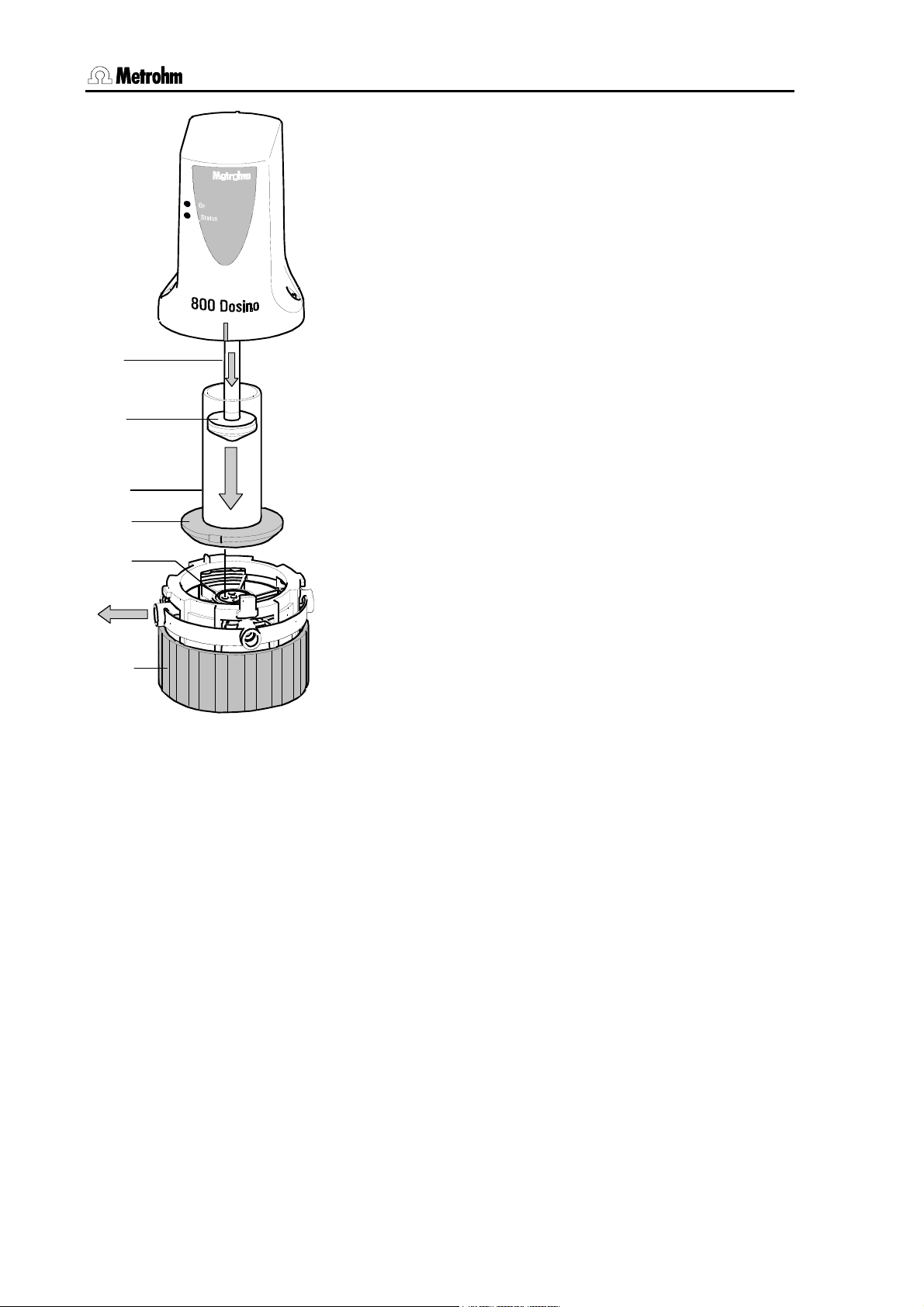

1.3 Metrohm 700/800 Dosinos and Dosing Units

1.3 Metrohm 700/800 Dosinos and Dosing Units

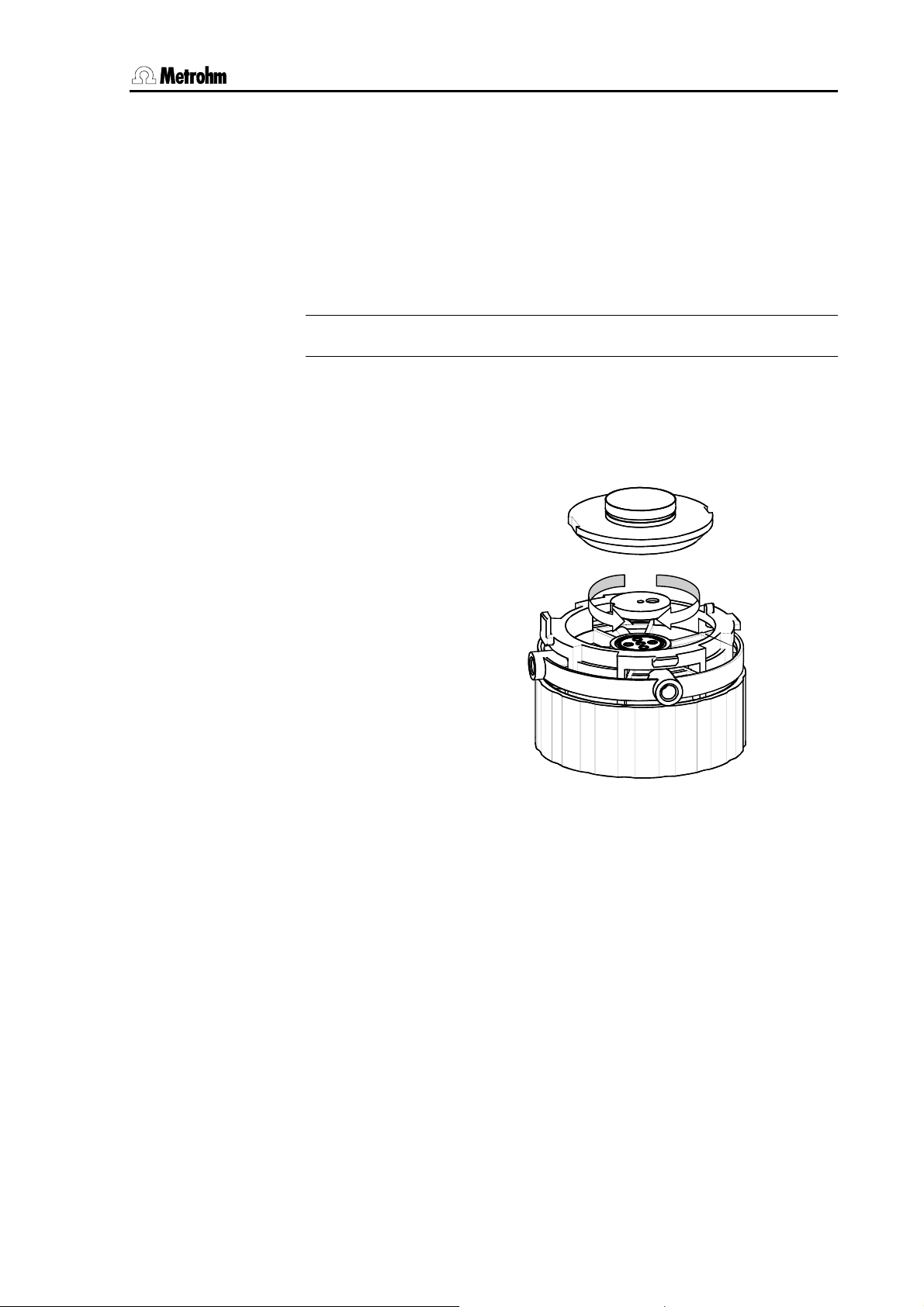

The Metrohm 800 Dosino is a versatile dosing drive which can be used with

various Metrohm dosing or titrating instruments (e.g. 808 or 809 Titrando). The

800 Dosino and its associated 807 Dosing unit are suitable for use as a buret,

not just for simple dosing tasks and titrations, etc. but also for complex automation and liquid handling applications, such as sample transfer or pipetting.

800 Dosino

800 Dosino

20

10

5

502

The 800 Dosino together with an 807 Dosing unit (available with 2, 5, 10, 20 or

50 mL cylinder) forms a buret unit for simple dosing tasks or complex liquid

handling applications.

The dosing units are normally mounted on reagent bottles and tubing is connected to the necessary dosing inlets and outlets. Four ports are available.

The 800 Dosino dosing drive can be simply attached to and removed from a

dosing unit.

When the drive is attached the dosing piston in the dosing unit is coupled to

drive rod

9 of the drive and cam 10 of the drive is guided into the recess pro-

vided for it in the centering tube of the dosing.

Dosing Interface USB Toolbox, Overview 5

Page 10

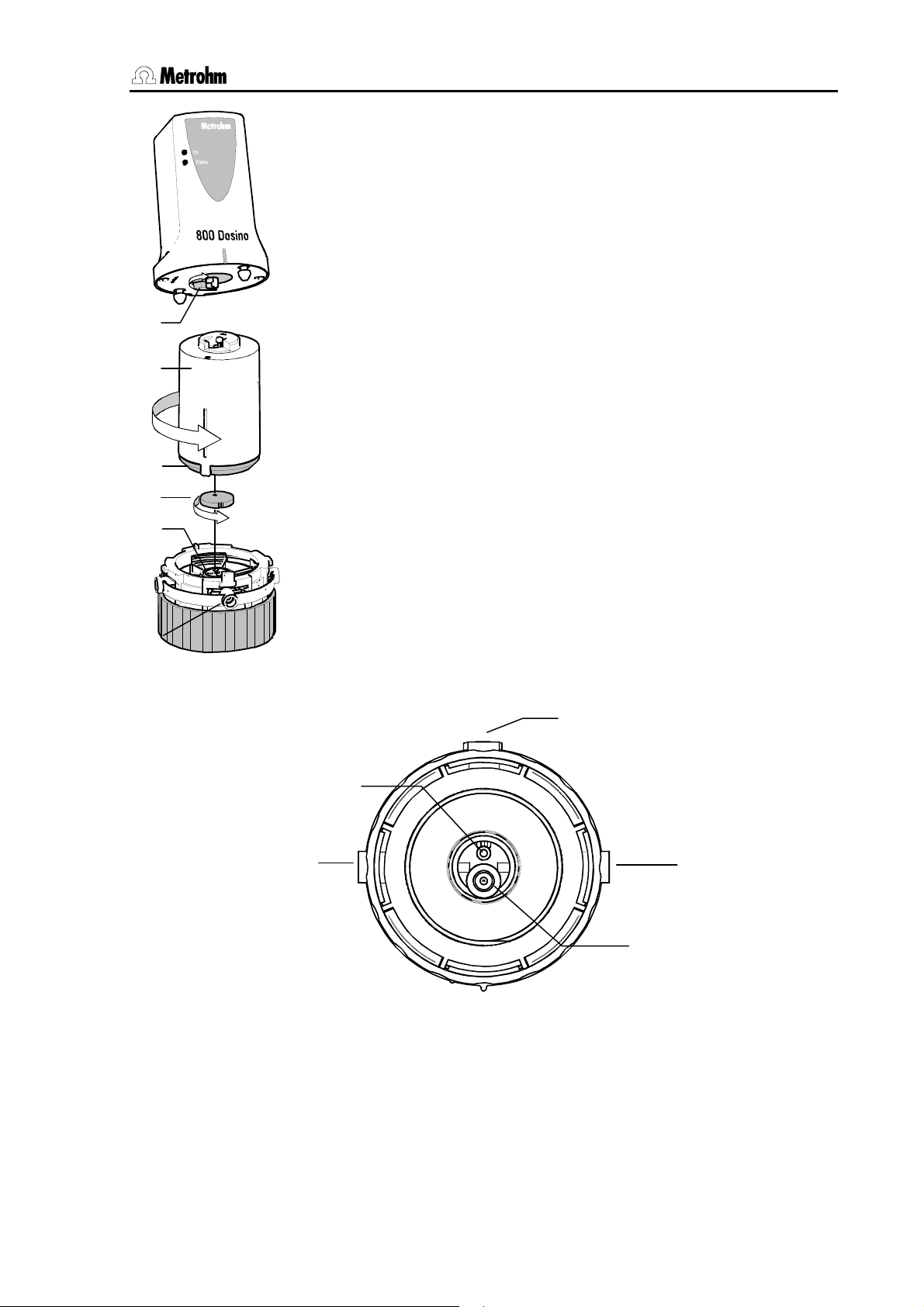

16

12

13

14

15

1.3 Metrohm 700/800 Dosinos and Dosing Units

1.3.1 Dosing/Filling the dosing cylinder

When the liquid is ejected push rod

dosing piston

12 in the cylinder downward. The liquid in cylinder 13

is forced through the valve disk in cylinder base

four openings in distributor disk

position. In distributor

17 the liquid is transferred to a dosing port

16.

9

When the valve disk has been switched (see below), i.e. rotated,

then liquid is aspirated in the opposite direction through a different

port by pulling dosing piston

12 upward with push rod 9 of the

drive.

As the dosing units are exchangeable the coupling of push rod

has a slight mechanical tolerance that comes into effect when the

direction of motion of piston

12 changes. In automated processes

the drive compensates mechanically for this tolerance.

The piston movements are controlled by the accurate electronic

precision engineering of the drive which, independent of the cylinder

volume, has a resolution of 10 000 increments throughout the whole

piston stroke.

9 of the 800 Dosino pushes

14 into one of the

15, depending on the valve disk

9

17

Fig. 5 Function: dosing/filling

6 Dosing Interface USB Toolbox, Overview

Page 11

1.3 Metrohm 700/800 Dosinos and Dosing Units

V

10

19

4

14

18

15

16

Fig. 6 Function:

switching the valve

disk

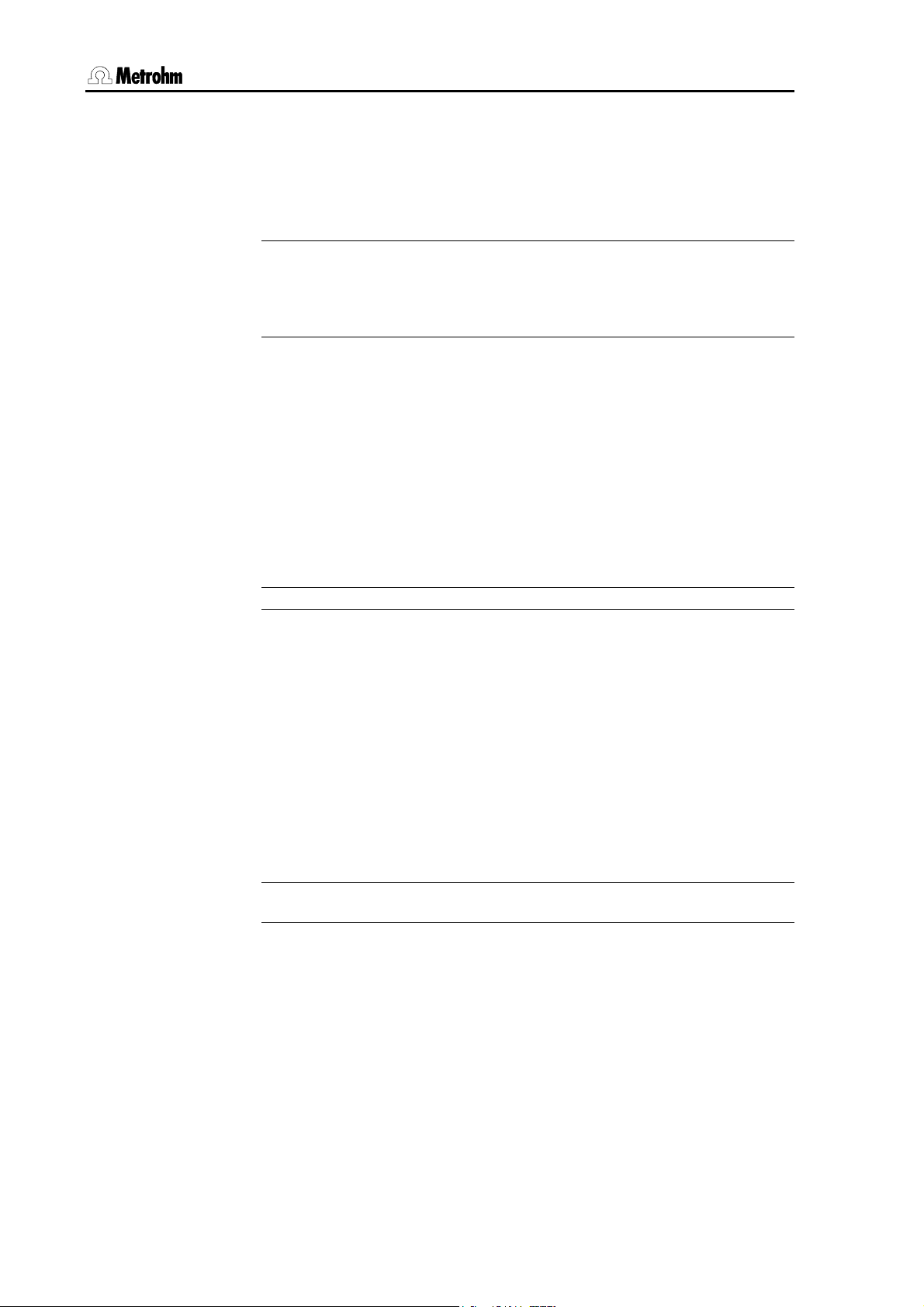

1.3.2 Switching the valve disk

The dosing unit has four ports. Two of them are on the outer housing and two

on the bottom of the dosing unit. Depending on the position of black valve

disk

distributor disk

The drive attached to the dosing unit uses cam

18 a connection between cylinder 13 and the opening of white

15 assigned to the port is made.

10 to rotate centering tube

19 and therefore the whole inner cylinder unit with cylinder base 14 and valve

disk

18 which it contains. After a rotation of the cylinder unit the opening of

valve disk

that a different port

18 points to a different opening in distributor disk 15. This means

16 has been selected for dosing (or filling).

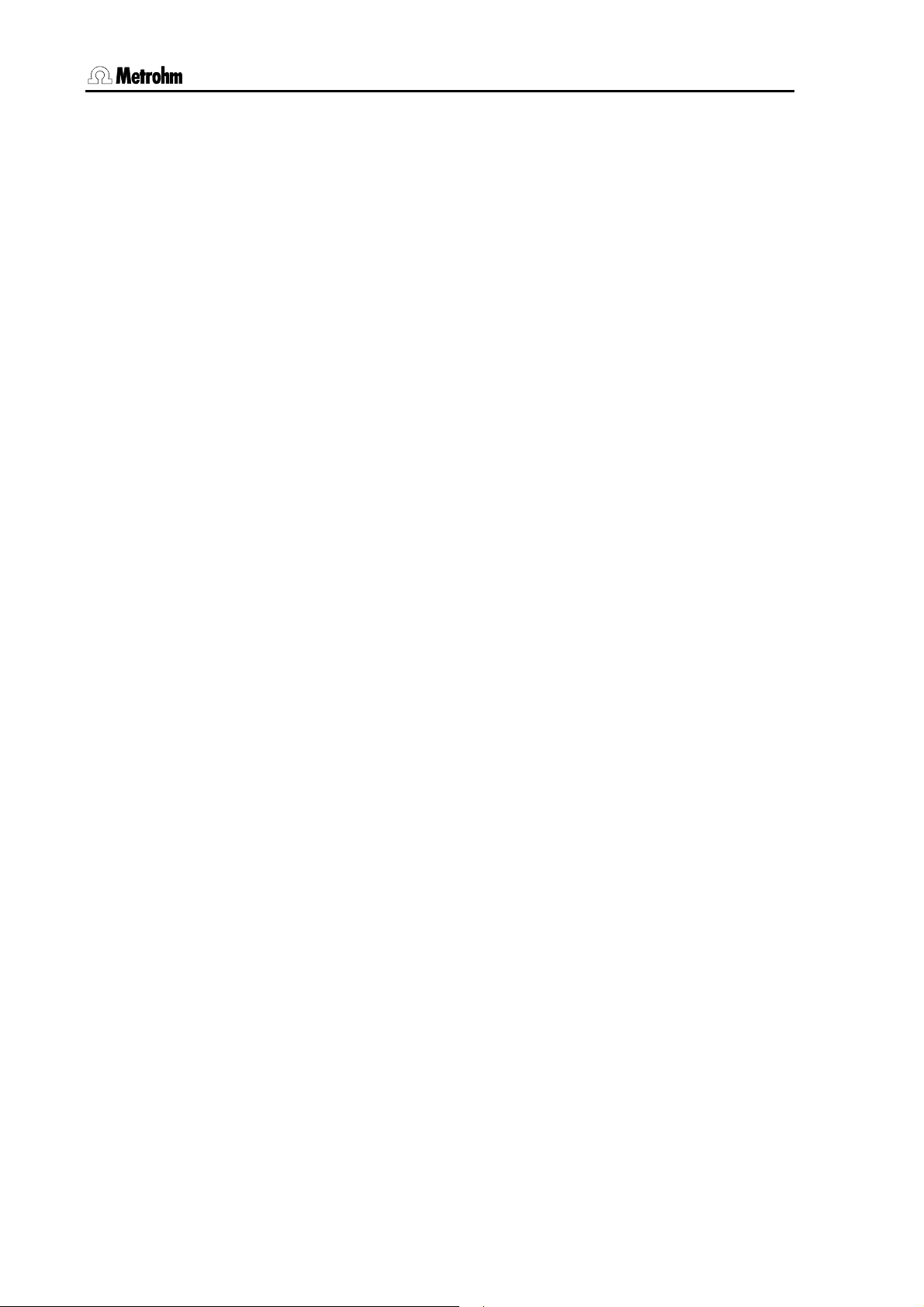

1.3.3 Port assignment

Distributor 17 of a dosing unit has four freely addressable inlets/outlets (ports)

and an additional connection which leads directly to the lower side of

distributor

disk, is responsible for venting the storage bottle and can be fitted with a

drying tube.

17. This VENT port, which cannot be addressed by the 4-way valve

ENT

Port 4

Port 1

Fig. 7 Dosing unit seen from below

The inlets and outlets (ports) of the 807 Dosing unit can be used in different

ways. This is an important precondition for complex liquid handling applications. Metrohm titrators (e.g. 808 and 809 Titrando) use a standard port assignment that is the most suitable one for titration applications.

Dosing Interface USB Toolbox, Overview 7

Port 3

Port 2

Page 12

1.3 Metrohm 700/800 Dosinos and Dosing Units

1.3.4 Standard occupancy of the Dosino ports:

Port 1 Dosing outlet; M6 threaded connection on the left-hand side of

the housing.

The liquid is ejected through a dosing tip or a titration tip.

Port 2 Filling inlet; M6 threaded connection on the base of the dosing

unit.

The liquid is aspirated from a storage container.

Port 3 Not assigned; M6 threaded connection on the right-hand side of

the housing.

Port 4 Special functions; narrow connection nipple on the base of the

dosing unit. This can be used during the 'PREP' function for

ejecting the liquid. When the dosing unit is emptied port 4 is used

as the air inlet.

VENT Vents the storage container; M6 threaded connection at the front.

A drying tube can be connected to it, e.g. filled with molecular

sieve or soda lime.

8 Dosing Interface USB Toolbox, Overview

Page 13

2.1 Constants

2 DLL Reference

This Reference applies to the interfaces of the programming languages C++,

Delphi and Visual Basic. For descriptions of the Java interface, see 3.1.1

2.1 Constants

2.1.1 Return states

enum eReturnstate

{

RET_STAT_OK = 0,

RET_STAT_nvNumber = 1,

RET_STAT_noDosino = 2,

RET_STAT_commError = 3,

RET_STAT_argError = 4,

RET_STAT_nvAction = 5

};

These are the return values of the Dosino functions, except Init846().

OK function could be set up correctly

nvNumber

noDosino

commError

argError

nvAction

not a valid 846 Dosing Interface number or Dosino number

not a valid Dosino

communication error

function arguments out of specified range

not a valid action

2.1.2 Dosino states

enum eDosinoState

{

DOS_STAT_IDLE = 0,

DOS_STAT_FILL = 1,

DOS_STAT_EXCHANGE = 2,

DOS_STAT_POSITION = 3,

DOS_STAT_ZEROADJUST = 4,

DOS_STAT_ADJUST = 5,

DOS_STAT_COCK = 6,

DOS_STAT_TOENDDOS = 7,

DOS_STAT_DOS = 8,

DOS_STAT_PREPAR = 9,

DOS_STAT_EMPTY = 10,

DOS_STAT_BUSY = 11,

DOS_STAT_HOLD_FILL = 12,

DOS_STAT_HOLD_EXCHANGE = 13,

DOS_STAT_HOLD_POSITION = 14,

DOS_STAT_HOLD_ZEROADJUST = 15,

DOS_STAT_HOLD_ADJUST = 16,

DOS_STAT_HOLD_TOENDDOS = 17,

DOS_STAT_HOLD_DOS = 18,

DOS_STAT_HOLD_PREPAR = 19,

DOS_STAT_HOLD_EMPTY = 20,

DOS_STAT_TIMEOUT = 21,

DOS_STAT_UNDEFINED = 22

};

Dosing Interface USB Toolbox, DLL Reference 9

Page 14

2.1 Constants

Status messages of a Dosino which are returned by the Status() function.

IDLE Dosino is ready to execute a function

FILL

Cylinder is being filled

EXCHANGE Dosino is executing Exchange function

POSITION Dosino is executing GoPos function

ZEROADJUST Dosino is executing ZeroAdjust function

ADJUST

COCK

TOENDDOS

DOS

PREPAR

EMPTY

BUSY

HOLD_FILL

HOLD_EXCHANGE

HOLD_POSITION

HOLD_ZEROADJUST

HOLD_ADJUST

HOLD_TOENDDOS

HOLD_DOS

HOLD_PREPAR

HOLD_EMPTY

TIMEOUT

UNDEFINED

Dosino is executing Adjust function

Dosino is executing Cock function

Dosino is executing ToEnd function

Dosino is executing MakeStep function

Dosino is executing Prep function

Dosino is executing Empty function

Dosino is busy

Dosino is halted while filling

Dosino is halted in Exchange function

Dosino is halted in GoPos function

Dosino is halted in ZeroAdjust function

Dosino is halted in Adjust function

Dosino is halted in ToEnd function

Dosino is halted in MakeStep function

Dosino is halted in Prep function

Dosino is halted in Empty function

Dosino is in timeout

Dosino is in undefined status

2.1.3 Piston movement

enum eDirection

{

DIR_fwd =0,

DIR_rev =1

};

Moving directions of a Dosino piston.

fwd Forward, dosing (0 Æ 10000 pulses)

rev Reverse, filling (10000 Æ 0 pulses)

rv

fw

10 Dosing Interface USB Toolbox, DLL Reference

Page 15

2.1 Constants

2.1.4 Valve disk

enum eCockMove

{

CK_MV_Asc =0,

CK_MV_Desc =1,

CK_MV_Auto =2,

CK_MV_NotOver =3

};

Turning mode of a Dosing Unit's valve disk. Port 1 to 4 of a Dosing Unit can be

accessed in different orders.

Asc Ascending order (Port 1 Æ 4)

Desc

Auto

NotOver

Descending order (Port 4 Æ 1)

automatic mode, shortest path

protected mode, a specified port will not

be crossed

desc.

asc.

Dosing Interface USB Toolbox, DLL Reference 11

Page 16

2.2 Functions

2.2 Functions

2.2.1 Init846

bool Init846()

Initializes all the connected Metrohm 846 Dosing Interfaces found in the USB

chain. All Dosino drives are recognized and the Dosing Units are reset. Running processes are stopped.

This function returns true if everything is initialized correctly.

Input parameters

none

Output parameters

bool

2.2.2 GetProgramVersion

GetProgramVersion(long IfNo, char* ProgramVersion, long ProgVerBufSize)

Reads the program version of the Dosing Interface firmware.

Input parameters

IfNo long Dosing Interface [1… ]

ProgVerBufSize long Number of characters

Output parameters

eReturnstate return value

ProgramVersion char* Text string of program version

2.2.3 GetInterfaceId

GetInterfaceId(long IfNo, long& InterfaceId)

Reads the serial number of a Dosing Interface. The serial number can be used

as a unique identifier of a Dosing Interface.

Input parameters

IfNo long Dosing Interface [1… ]

Output parameters

eReturnstate return value

InterfaceId long serial number of Dosing Interface

12 Dosing Interface USB Toolbox, DLL Reference

Page 17

2.2 Functions

2.2.4 Status

Status(long IfNo, long MsbNo, eDosinoState &DosinoState)

Reads the current status of a Dosino drive.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Output parameters

eReturnstate return value

DosinoState eDosinoState status of the Dosino drive

2.2.5 GetCylVolume

GetCylVolume(long IfNo, long MsbNo, long &Volume)

Returns the cylinder volume of the Dosing Unit. This function can be used for

the detection of a mounted Dosing Unit.

2.2.6 DU_Cock

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Output parameters

eReturnstate return value

&Volume

long 0, 2; 5; 10; 20; 50 mL

cylinder volume =0 means:

no Dosing Unit mounted

DU_Cock(long IfNo, long MsbNo, long Port, eCockMove Move, long

NotOver)

Turns the valve disk to the selected port. The turning direction is chosen according to "Move". If Notover is set, the "NotOverPort" will not be crossed. Otherwise this parameter is ignored.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Port long target Dosino port [1…4]

Move eCockMove turning direction of valve disk

NotOver long protected Dosino port

Output parameters

eReturnstate return value

Dosing Interface USB Toolbox, DLL Reference 13

Page 18

2.2 Functions

2.2.7 ZeroAdjust

2.2.8 Adjust

ZeroAdjust(long IfNo, long MsbNo, float RevRate)

Runs the piston of the Dosino to zero position and initializes the drive.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

RevRate float Filling speed of piston [0.01...166mL/min]

Output parameters

eReturnstate return value

Adjust(long IfNo, long MsbNo, eDirection Direction)

Eliminate slack of piston coupling. This function can be used, if the direction of

the piston movement is about to be changed.

2.2.9 GoPos

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Direction eDirection Direction of the desired piston movement.

Output parameters

eReturnstate return value

GoPos(long IfNo, long MsbNo, long Position, float Rate)

Move the piston to an absolute position. The stroke path of the piston is divided into 10000 positions.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Position long absolute piston position [0…10000]

Rate float Dosing rate [0.01…166 mL/min]

Output parameters

eReturnstate return value

14 Dosing Interface USB Toolbox, DLL Reference

Page 19

2.2 Functions

2.2.10 DU_ToEnd

DU_ToEnd(long IfNo, long MsbNo, float FwdRate)

Move piston to the mechanical end position. This function can be used to remove any air bubbles in the cylinder.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

FwdRate float Dosing rate [0.01…166 mL/min]

Output parameters

eReturnstate return value

2.2.11 DU_MakeStep

DU_MakeStep(long IfNo, long MsbNo, long FillPort, float Volume,

eDirection Direction, float FwdRate, float RevRate)

Dose a specified volume via the actual port. Dosing rate, filling rate, filling port

and piston direction of the valve disk can be chosen. With reverse piston direction it is possible to aspirate a desired volume. In this case the filling port is

used as outlet port. The dosing can be hold, continued and stopped.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

FillPort long Filling port

Volume float Dosing volume [0…99999.99 mL]

Direction eDirection Direction of piston movement

FwdRate

RevRate float Filling rate [0.01…166 mL/min]

Output parameters

eReturnstate return value

2.2.12 DU_Fill

DU_Fill(long IfNo, long MsbNo, long Port, float RevRate)

Fill the cylinder from a specified port. Filling can be hold and continued, but not

be stopped.

float Dosing rate [0.01…166 mL/min]

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Port long Dosino port to fill from [1…4]

RevRate float Filling rate [0.01…166 mL/min]

Dosing Interface USB Toolbox, DLL Reference 15

Page 20

2.2 Functions

Output parameters

eReturnstate return value

2.2.13 DU_Exchange

DU_Exchange(long IfNo, long MsbNo, long Port, float RevRate)

Prepares the Dosing Unit for exchange. The cylinder is filled from the specified

port and after that the valve disk is turned to port 2. This action can be hold

and continued, but not be stopped.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Port long Dosino port to fill from [1…4]

RevRate float Filling rate [0.01…166 mL/min]

Output parameters

eReturnstate return value

2.2.14 DosStop

DosStop(long IfNo, long MsbNo)

Stops the current Dosino action.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Output parameters

eReturnstate return value

2.2.15 DosHold

DosHold(long IfNo, long MsbNo)

Holds the current Dosino action. The halted action can be continued or finally

be stopped.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Output parameters

eReturnstate return value

16 Dosing Interface USB Toolbox, DLL Reference

Page 21

2.2 Functions

2.2.16 DosContinue

DosContinue(long IfNo, long MsbNo)

Continue a halted Dosino action.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Output parameters

eReturnstate return value

2.2.17 DU_Prep

DU_Prep(long IfNo, long MsbNo, long InPort, float InVolume,

float InRate, long OutPort, float OutVolume, float OutRate,

long SpecPort, float SpecVolume, float SpecRate)

Prepares a Dosing Unit for further use. A "Prep" cycle includes emptying the

dosing cylinder and rinsing and filling the tubings in one automated process.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

InPort long Filling port [1…4]

InVolume

InRate float Filling rate [0.01…166 mL/min]

OutPort long Output port 1 [1…4]

OutVolume float Dosing volume 1 [0…20000 µL]

OutRate float Dosing rate 1 [0.01…166 mL/min]

SpecPort long Output Port 2 [1…4]

Specvolume float Dosing volume 2 [0…20000 µL]

SpecRate float Dosing rate 2 [0.01…166 mL/min]

Output parameters

eReturnstate return value

2.2.18 Empty

Empty(long IfNo, long MsbNo, long InPort, float InVolume, float

InRate, long OutPort, float OutVolume, float OutRate, long

SpecPort, float SpecVolume, float SpecRate)

Empties the Buret Unit. Dosing cylinder and tubings are emptied in one automated process.

float Fill tube volume [0…20000 µL]

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

InPort long Filling port [1…4]

InVolume

Dosing Interface USB Toolbox, DLL Reference 17

float Fill tube volume [0…20000 µL]

Page 22

2.2 Functions

InRate float Filling rate [0.01…166 mL/min]

OutPort long Output port 1 [1…4]

OutVolume float Dosing volume 1 [0…20000 µL]

OutRate float Dosing rate 1 [0.01…166 mL/min]

SpecPort long Output Port 2 [1…4]

Specvolume float Dosing volume 2 [0…20000 µL]

SpecRate float Dosing rate 2 [0.01…166 mL/min]

Output parameters

eReturnstate return value

2.2.19 GetInterfaceError

GetInterfaceError(long IfNo, long MsbNo, long ErrorNumber,

char* ErrorCode, long ErrorBufSize)

Reads casual error messages which occur during Dosino actions.

Input parameters

IfNo long Dosing Interface [1… ]

MsbNo long Dosino at MSB[1…4]

Number long Error number [0…9]

ErrorBufSize long Number of characters

Output parameters

eReturnstate return value

ErrorCode char* Error code, format [GGG-CCC-K-III],

G = group, C = code, K = class,

I = index (1...4 or 255), see 2.3

18 Dosing Interface USB Toolbox, DLL Reference

Page 23

2.3 Error Messages

X

2.3 Error Messages

Error messages are presented in an array (Error number0…9), in which error

number 0 is always the most recent one. If more errors occur in a process,

more error entries are made. New errors always overwrite older ones, beginning with index 0.

Error messages of the function

Error message

XXX-NNN-A-I

000-001-1-255

000-002-1-255

000-003-1-255

000-004-1-255

000-005-1-255

000-006-1-255

005-001-1-X

005-002-1-X

005-003-1-X

005-004-1-X

005-005-1-X

005-006-1-X

005-007-2-X

005-008-2-X

005-009-2-X

005-010-3-X

005-011-3-X

005-012-2-X

005-013-2-X

005-015-1-X

007-001-1-X

010-001-1-X

010-003-1-X

012-001-3-255

XX=error group, NNN=Code, A=class, I=Index (mostly MSB

number)

Process already exists

Process not found

Too many processes

Wrong node

Trigger not allowed

Wrong value

Dosing device not found

Dosing device used

Check exchange/dosing unit

Empty not possible

Piston blocked

Cock blocked

Dosing rate was corrected

Filling rate was corrected

Dosing increment was corrected

Dosing unit was plugged in

Dosing unit was plugged out

Dosing unit out during reading

Dosing unit out during writing

Dosing deving connected incorr.

Stirrer not found

Remote device not found

Other devices at MSB

Manual stop of mode

GetInterfaceError:

Dosing Interface USB Toolbox, DLL Reference 19

Page 24

3.1 Programming interface definitions

3 Annex

3.1 Programming interface definitions

3.1.1 Java interface class

/*

* Copyright(c) 2004 Metrohm AG

*

* $Archive: /tools/846_usb_dll/src/java_wrapper_846/src/metr/DosIntFace846.java $

* $Date: 13.06.05 9:16 $

* $Author: Km $

* $Revision: 5 $

*/

package metr;

/**

*

* @author Michael Keller

* @version 1.2.5.0, 09/06/05

*/

/**

* DosIntFace846 class which contains all static methods to communicate with 846 Dosing

Interfaces.<br>

* Befor communicating, the init method init846 has to be called.<br>

* 846 Dosing Interfaces and Dosinos can't be hot pluged.<br>

* <br>

* If the cock move int parameter is described as eCockMove, the following description will be

used:<br>

* 0: ascending order (Port 1 --> 4) <br>

* 1: descending order (Port 4 --> 1) <br>

* 2: automatic mode, shortest path <br>

* 3: protected mode, cock will not move over specified port <br>

* <br>

* If the direction int parameter is described as eDirection, the following description will

be used:<br>

* 0: forward, dosing (0 --> 10000 pulses) <br>

* 1: reverse, filling (10000 --> 0 pulses) <br>

*

*/

public class DosIntFace846 {

// load the 846 DLL for native conaction to dosing interfaces

static{

System.loadLibrary("DosIntFace846");

}

public DosIntFace846() {}

/**

* Initializes all Metrohm 846 Dosing Interfaces found in the USB chain and sorts them

according to the serial number.

* All Dosino drives are recognized and the Dosing Units are reset.

* Running processes are stopped.

*

* @return boolean, method returns true if successful

*/

public static final native boolean init846();

/**

* Returns the cylinder volume of the Dosing Unit.

* This function can be used for the detection of a mounted Dosing Unit.

20 Dosing Interface USB Toolbox, Annex

Page 25

3.1 Programming interface definitions

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @return Volume 0; 2; 5; 10; 20; 50 mL, Cylinder volume = 0 means: no Dosing Unit

mounted!

* @throws DosIntFace846Exception

*/

public static final int getCylVolume(int ifNo, int msbNo) throws DosIntFace846Exception{

dosinoVolume = 0;

int nReturnstate = DosIntFace846.callCylVolume(ifNo, msbNo);

if (nReturnstate == 0)

return dosinoVolume;

else

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Turns the valve disk to the selected port. The turning direction is chosen

* according to "Move". If "Move" is set to protected mode, the Port specified

* in "NotOver" will not be crossed. Otherwise this parameter is ignored.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param port Target Dosino port [1... 4]

* @param move Turning direction of the valve disk [eCockMove]

* @param notOver protected Dosino port [1... 4]

* @throws DosIntFace846Exception

*/

public static final void duCock(int ifNo, int msbNo, int port, int move, int notOver)

throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callCock(ifNo, msbNo, port, move, notOver);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Moves the piston of the Dosino to zero position and initializes the drive.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param revRate Filling rate of piston [0.01...166mL/min]

* @throws DosIntFace846Exception

*/

public static final void zeroAdjust(int ifNo, int msbNo, float revRate) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callZeroAdjust(ifNo, msbNo, revRate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Eliminate slack of piston coupling.

* This function can be used, when the direction of the piston movement is about to be

changed.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param direction Direction of the desired piston movement [eDirection]

* @throws DosIntFace846Exception

*/

public static final void adjust (int ifNo, int msbNo, int direction) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callAdjust (ifNo, msbNo, direction);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

Dosing Interface USB Toolbox, Annex 21

Page 26

3.1 Programming interface definitions

* Move the piston to an absolute position. The full stroke of the piston is subdivided in

10000 positions.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param position absolut Position [0...10000]

* @param rate Dosing rate [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void goPos(int ifNo, int msbNo, int position, float rate) throws

DosIntFace846Exception{

int nReturnstate = DosIntFace846.callGoPos(ifNo, msbNo, position, rate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Move piston to the mechanical end position.

* This function can be used to remove any air bubbles from the cylinder.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param fwdRate Dosing rate [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void duToEnd(int ifNo, int msbNo, float fwdRate) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callToEnd(ifNo, msbNo, fwdRate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Dose a specified volume via the actual port. Dosing rate, filling rate, filling port

and piston direction can be chosen.

* With reverse piston direction it is possible to aspirate a desired volume. In this case

the filling port is used as outlet port.

* The dosing can be hold, continued and stopped.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param fillPort Filling port [1...4]

* @param volume Dosing volume [0... 99999.99 mL]

* @param direction Direction of piston movement [eDirection]

* @param fwdRate Dosing rate [0.01... 166 mL/min]

* @param revRate Filling rate [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void duMakeStep(int ifNo, int msbNo, int fillPort, float volume, int

direction, float fwdRate, float revRate) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callMakeStep(ifNo, msbNo, fillPort, volume, direction, fwdRate, revRate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Fill the cylinder from a specified port.

* Filling can be held and continued, but not stopped.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param port Fill port [1..4]

* @param revRate Filling rate [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void duFill(int ifNo, int msbNo, int port, float revRate) throws

DosIntFace846Exception{

int nReturnstate = DosIntFace846.callFill(ifNo, msbNo, port, revRate);

if (nReturnstate != 0)

22 Dosing Interface USB Toolbox, Annex

Page 27

3.1 Programming interface definitions

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Prepares the Dosing Unit for exchange. The cylinder is filled from the specified port

and then the valve disk is

* turned to port 2.

* This action can be held and continued, but not stopped.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param port Fill port [1..4]

* @param revRate Filling rate [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void duExchange(int ifNo, int msbNo, int port, float revRate) throws

DosIntFace846Exception{

int nReturnstate = DosIntFace846.callExchange(ifNo, msbNo, port, revRate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Reads the state of a Dosino drive.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @return 0 = Dosino is ready to execute a function, <br>

* 1 = Cylinder is being filled, <br>

* 2 = Dosino is executing Exchange function, <br>

* 3 = Dosino is executing GoPos function, <br>

* 4 = Dosino is executing ZeroAdjust function, <br>

* 5 = Dosino is executing Adjust function, <br>

* 6 = Dosino is executing Cock function, <br>

* 7 = Dosino is executing ToEnd function, <br>

* 8 = Dosino is executing MakeStep function, <br>

* 9 = Dosino is executing Prep function, <br>

* 10 = Dosino is executing Empty function, <br>

* 11 = Dosino is busy, <br>

* 12 = Dosino is halted while filling, <br>

* 13 = Dosino is halted in Exchange function, <br>

* 14 = Dosino is halted in GoPos function, <br>

* 15 = Dosino is halted in ZeroAdjust function, <br>

* 16 = Dosino is halted in Adjust function, <br>

* 17 = Dosino is halted in ToEnd function, <br>

* 18 = Dosino is halted in MakeStep function, <br>

* 19 = Dosino is halted in Prep function, <br>

* 20 = Dosino is halted in Empty function, <br>

* 21 = Dosino has timed out, <br>

* 22 = Dosino status is undefined<br>

* @throws DosIntFace846Exception

*/

public static final int status(int ifNo, int msbNo) throws DosIntFace846Exception{

dosinoState = 22;

int nReturnstate = DosIntFace846.callStatus(ifNo, msbNo);

if (nReturnstate == 0)

return dosinoState;

else

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Stops the current Dosino action.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @throws DosIntFace846Exception

*/

Dosing Interface USB Toolbox, Annex 23

Page 28

3.1 Programming interface definitions

public static final void dosStop(int ifNo, int msbNo) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callStop(ifNo, msbNo);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Holds the current Dosino action. The held action can be continued or finally stopped.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @throws DosIntFace846Exception

*/

public static final void dosHold(int ifNo, int msbNo) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callHold(ifNo, msbNo);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Continue a held Dosino action.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @throws DosIntFace846Exception

*/

public static final void dosCont(int ifNo, int msbNo) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callCont(ifNo, msbNo);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Prepares a Dosing Unit for further use. A "Prep" cycle includes emptying the dosing

cylinder and rinsing and

* filling the tubings in one automated process.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param inPort Filling port [1... 4]

* @param inVolume Fill tube volume [0... 20000 mm^3]

* @param inRate Filling rate [0.01... 166 mL/min]

* @param outPort Output port 1 [1... 4]

* @param outVolume Dosing tube volume on Output port 1 [0... 20000 mm^3]

* @param outRate Dosing rate on Output port 1 [0.01... 166 mL/min]

* @param specPort Output port 2 [1... 4]

* @param specVolume Dosing tube volume on Output port 2 [0... 20000 mm^3]

* @param specRate Dosing rate on Output port 1 [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void duPrep(int ifNo, int msbNo, int inPort, float inVolume, float

inRate,

int outPort, float outVolume, float outRate,

int specPort, float specVolume, float specRate) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callPrep(ifNo, msbNo, inPort, inVolume, inRate,

outPort, outVolume, outRate,

specPort, specVolume, specRate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Empties the Buret Unit. Dosing cylinder and tubings are emptied in one automated

process.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

24 Dosing Interface USB Toolbox, Annex

Page 29

3.1 Programming interface definitions

* @param inPort Filling port [1... 4]

* @param inVolume Fill tube volume [0... 20000 mm^3]

* @param inRate Filling rate [0.01... 166 mL/min]

* @param outPort Output port 1 [1... 4]

* @param outVolume Dosing tube volume on Output port 1 [0... 20000 mm^3]

* @param outRate Dosing rate on Output port 1 [0.01... 166 mL/min]

* @param specPort Output port 2 [1... 4]

* @param specVolume Dosing tube volume on Output port 2 [0... 20000 mm^3]

* @param specRate Dosing rate on Output port 1 [0.01... 166 mL/min]

* @throws DosIntFace846Exception

*/

public static final void duEmpty(int ifNo, int msbNo, int inPort, float inVolume, float

inRate,

int outPort, float outVolume, float outRate,

int specPort, float specVolume, float specRate) throws DosIntFace846Exception{

int nReturnstate = DosIntFace846.callEmpty(ifNo, msbNo, inPort, inVolume, inRate,

outPort, outVolume, outRate,

specPort, specVolume, specRate);

if (nReturnstate != 0)

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Reads casual error messages which occur during Dosino actions.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @param errorNumber Error number [0... 9]

* @return error code as return value [GGG-CCC-K-III], G = group, C = code, K = class, I =

index (1...4 or 255)

* @throws DosIntFace846Exception

*/

public static final String getInterfaceError(int ifNo, int msbNo, int errorNumber) throws

DosIntFace846Exception{

errorCode = "";

int nReturnstate = DosIntFace846.callInterfaceError(ifNo, msbNo, errorNumber);

if (nReturnstate == 0)

return errorCode;

else

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Reads the stop condition of a Dosino action.

*

* @param ifNo Dosing Interface [1... ?]

* @param msbNo Dosino at MSB [1... 4]

* @return Stop type of the last action

* @throws DosIntFace846Exception

*/

public static final int getStopType(int ifNo, int msbNo) throws DosIntFace846Exception{

stopType = 0;

int nReturnstate = DosIntFace846.callStopType(ifNo, msbNo);

if (nReturnstate == 0)

return stopType;

else

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Reads the serial number of a Dosing Interface. The serial number can be used as a

unique identifier of an instrument.

*

* @param ifNo Dosing Interface [1... ?]

* @return Serial number of Dosing Interface

* @throws DosIntFace846Exception

Dosing Interface USB Toolbox, Annex 25

Page 30

3.1 Programming interface definitions

*/

public static final int getInterfaceId(int ifNo) throws DosIntFace846Exception{

interfaceId = 0;

int nReturnstate = DosIntFace846.callInterfaceId(ifNo);

if (nReturnstate == 0)

return interfaceId;

else

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

/**

* Get the program version of the 846 Dosing Interface

*

* @param ifNo Dosing Interface [1... ?]

* @return string with the program version

* @throws DosIntFace846Exception

*/

public static final String getProgramVersion(int ifNo) throws DosIntFace846Exception{

programVersion = "";

int nReturnstate = DosIntFace846.callProgramVersion(ifNo);

if (nReturnstate == 0)

return programVersion;

else

throw new DosIntFace846Exception(DosIntFace846Exception.getErrorString(nReturnstate), nReturnstate);

}

//------------------------------------------------------------------------------------- //-------------------------- only for JNI, don't use it ------------------------------

/** only for JNI, don't use it */

public static final native int callCylVolume(int ifNo, int msbNo);

/** only for JNI, don't use it */

public static final void setCylVolume(int iDosinoVolume) {dosinoVolume = iDosinoVolume;}

/** only for JNI, don't use it */

public static final native int callCock(int ifNo, int msbNo, int port, int move, int

notOver);

/** only for JNI, don't use it */

public static final native int callZeroAdjust(int ifNo, int msbNo, float revRate);

/** only for JNI, don't use it */

public static final native int callAdjust (int ifNo, int msbNo, int direction);

/** only for JNI, don't use it */

public static final native int callGoPos(int ifNo, int msbNo, int position, float rate);

/** only for JNI, don't use it */

public static final native int callToEnd(int ifNo, int msbNo, float fwdRate);

/** only for JNI, don't use it */

public static final native int callMakeStep(int ifNo, int msbNo, int fillPort, float

volume, int direction, float fwdRate, float revRate);

/** only for JNI, don't use it */

public static final native int callFill(int ifNo, int msbNo, int port, float revRate);

/** only for JNI, don't use it */

public static final native int callExchange(int ifNo, int msbNo, int port, float revRate);

/** only for JNI, don't use it */

public static final native int callStop(int ifNo, int msbNo);

/** only for JNI, don't use it */

public static final native int callHold(int ifNo, int msbNo);

/** only for JNI, don't use it */

public static final native int callCont(int ifNo, int msbNo);

/** only for JNI, don't use it */

public static final native int callPrep(int ifNo, int msbNo, int inPort, float inVolume,

float inRate,

int outPort, float outVolume, float outRate,

int specPort, float specVolume, float specRate);

/** only for JNI, don't use it */

public static final native int callEmpty(int ifNo, int msbNo, int inPort, float inVolume,

float inRate,

int outPort, float outVolume, float outRate,

int specPort, float specVolume, float specRate);

26 Dosing Interface USB Toolbox, Annex

Page 31

3.1 Programming interface definitions

/** only for JNI, don't use it */

public static final native int callStatus(int ifNo, int msbNo);

/** only for JNI, don't use it */

public static final void setDosinoState(int iDosinoState) {dosinoState = iDosinoState;}

/** only for JNI, don't use it */

public static final native int callInterfaceError(int ifNo, int msbNo, int errorNumber);

/** only for JNI, don't use it */

public static final void setErrorCode(String sErrorCode) {errorCode = sErrorCode;}

/** only for JNI, don't use it */

public static final native int callStopType(int ifNo, int msbNo);

/** only for JNI, don't use it */

public static final void setStopType(int iStopType) {stopType = iStopType;}

/** only for JNI, don't use it */

public static final native int callInterfaceId(int ifNo);

/** only for JNI, don't use it */

public static final void setInterfaceId(int lInterfaceId) {interfaceId = lInterfaceId;}

/** only for JNI, don't use it */

public static final native int callProgramVersion(int ifNo);

/** only for JNI, don't use it */

public static final void setProgramVersion(String sProgramVersion) {programVersion =

sProgramVersion;}

// private data members

private static int dosinoVolume = 0;

private static int dosinoState = 0;

private static String errorCode = "";

private static int stopType = 0;

private static int interfaceId = 0;

private static String programVersion = "";

}

Dosing Interface USB Toolbox, Annex 27

Page 32

3.1 Programming interface definitions

3.1.2 Java interface exception class

/*

* Copyright(c) 2005 Metrohm AG

* created date: 09.06.2005

* $Archive:

/tools/846_usb_dll/src/java_wrapper_846/src/metr/DosIntFace846Exception.jav

a $

* $Date: 9.06.05 15:46 $

* $Author: Km $

* $Revision: 2 $

*/

package metr;

/**

*

* @author Michael Keller

* @version 1.2.5.0, 09/06/05

*/

/**

* Exception class for 846 Dosing Interface communication

* <br>

* Specification of the error code number:

* 1: not a valid 846 Dosing Interface number or Dosino number <br>

* 2: not a valid Dosino <br>

* 3: communication error <br>

* 4: function arguments out of specified range <br>

* 5: not a valid action <br>

*/

public class DosIntFace846Exception extends Exception{

private int nErrorCode;

public DosIntFace846Exception(String s,int nErrorCode) {

super(s);

this.nErrorCode = nErrorCode;

}

public int getErrorCode() {

return nErrorCode;

}

public static String getErrorString(int nErrorCode) {

switch (nErrorCode) {

case 0: return "method could be set up correctly";

case 1: return "not a valid 846 Dosing Interface number or

Dosino number";

case 2: return "not a valid Dosino";

case 3: return "communication error";

case 4: return "function arguments out of specified range";

case 5: return "not a valid action";

default: return "unknown error code";

}

}

}

/*

28 Dosing Interface USB Toolbox, Annex

Page 33

3.1 Programming interface definitions

3.1.3 C++ interface definition header file

/*******************************************************************************

Metrohm AG Switzerland. All rights reserved.

$Header:

/Tools/846_USB_DLL/src/846_Dosing_Interface/846DosingInterfaceDefinition.h 7

27.05.05 16:39 Km $

------------------------------------------------------------------------------ $Log: /Tools/846_USB_DLL/src/846_Dosing_Interface/846DosingInterfaceDefinition.h

$

*

* 7 27.05.05 16:39 Km

*

* 6 27.05.05 11:54 Km

* Change in Interface

*

* 6 12.05.05 15:30 bc, rw --> parameter names adapted

*

* 5 06.01.05 13:52 Km

*

* 4 05.01.05 10:45 Km

*

* 3 04.01.05 14:32 Km

*

* 2 03.01.05 15:29 Km

*

* 1 15.12.04 15:36 Km

$NoKeywords: $

*******************************************************************************/

#ifndef Dosinginterface846_h

#define Dosinginterface846_h

#ifdef _USRDLL

#define DllDirection __declspec( dllexport )

#else

#define DllDirection __declspec( dllimport )

#endif

enum eReturnstate

{

// function could be set up correctly

RET_STAT_OK = 0,

// not a valid 846 Dosing Interface number or Dosino number

RET_STAT_nvNumber = 1,

// not a valid Dosino

RET_STAT_noDosino = 2,

// communication error

RET_STAT_commError = 3,

// function arguments out of specified range

RET_STAT_argError = 4,

// not a valid action

RET_STAT_nvAction = 5

};

Dosing Interface USB Toolbox, Annex 29

Page 34

3.1 Programming interface definitions

enum eDosinoState

{

// Dosino is ready to execute a function

DOS_STAT_IDLE = 0,

// Cylinder is being filled

DOS_STAT_FILL = 1,

// Dosino is executing Exchange function

DOS_STAT_EXCHANGE = 2,

// Dosino is executing GoPos function

DOS_STAT_POSITION = 3,

// Dosino is executing ZeroAdjust function

DOS_STAT_ZEROADJUST = 4,

// Dosino is executing Adjust function

DOS_STAT_ADJUST = 5,

// Dosino is executing Cock function

DOS_STAT_COCK = 6,

// Dosino is executing ToEnd function

DOS_STAT_TOENDDOS = 7,

// Dosino is executing MakeStep function

DOS_STAT_DOS = 8,

// Dosino is executing Prep function

DOS_STAT_PREPAR = 9,

// Dosino is executing Empty function

DOS_STAT_EMPTY = 10,

// Dosino is busy

DOS_STAT_BUSY = 11,

// Dosino is halted while filling

DOS_STAT_HOLD_FILL = 12,

// Dosino is halted in Exchange function

DOS_STAT_HOLD_EXCHANGE = 13,

// Dosino is halted in GoPos function

DOS_STAT_HOLD_POSITION = 14,

// Dosino is halted in ZeroAdjust function

DOS_STAT_HOLD_ZEROADJUST = 15,

// Dosino is halted in Adjust function

DOS_STAT_HOLD_ADJUST = 16,

// Dosino is halted in ToEnd function

DOS_STAT_HOLD_TOENDDOS = 17,

// Dosino is halted in MakeStep function

DOS_STAT_HOLD_DOS = 18,

// Dosino is halted in Prep function

DOS_STAT_HOLD_PREPAR = 19,

// Dosino is halted in Empty function

DOS_STAT_HOLD_EMPTY = 20,

// Dosino has timed out

DOS_STAT_TIMEOUT = 21,

// Dosino status is undefined

DOS_STAT_UNDEFINED = 22

};

enum eDirection

{

// Forward, dosing (0 --> 10000 pulses)

DIR_fwd = 0,

// Reverse, filling (10000 --> 0 pulses)

DIR_rev = 1

};

enum eCockMove

{

// Ascending order (Port 1 --> 4)

CK_MV_Asc = 0,

// Descending order (Port 4 --> 1)

30 Dosing Interface USB Toolbox, Annex

Page 35

3.1 Programming interface definitions

CK_MV_Desc = 1,

// Automatic mode, shortest path

CK_MV_Auto = 2,

// Protected mode, cock will not move over specified port

CK_MV_NotOver = 3

};

#ifdef __cplusplus

// C-Declarations for C++

extern "C" {

#endif

// Initializes all Metrohm 846 Dosing Interfaces found in the USB chain.

// All Dosino drives are recognized and the Dosing Units are reset.

// Running processes are stopped.

//

// return bool Function returns true if

// successful

DllDirection bool __stdcall Init846();

// Returns the cylinder volume of the Dosing Unit. This function can be used for

// the detection of a mounted Dosing Unit.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long& Volume 0; 2; 5; 10; 20; 50 mL

// Cylinder volume = 0

// means: no Dosing Unit mounted!

// return eReturnstate

DllDirection eReturnstate __stdcall GetCylVolume(long IfNo, long MsbNo,

long &Volume);

// Turns the valve disk to the selected port. The turning direction is chosen

// according to "Move". If "Move" is set to CK_MV_NotOver, the Port specified

// in "NotOver" will not be crossed. Otherwise this parameter is ignored.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long Port Target Dosino port [1... 4]

// eCockMove Move Turning direction of the

// valve disk

// long NotOver protected Dosino port [1... 4]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_Cock(long IfNo, long MsbNo, long Port,

eCockMove Move, long NotOver);

// Moves the piston of the Dosino to zero position and initializes the drive.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// float RevRate Filling rate of piston

// [0.01...166mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall ZeroAdjust(long IfNo, long MsbNo,

float RevRate);

// Eliminate slack of piston coupling. This function can be used, when the

// direction of the piston movement is about to be changed.

//

// parameter long IfNo Dosing Interface [1... ?]

Dosing Interface USB Toolbox, Annex 31

Page 36

3.1 Programming interface definitions

// long MsbNo Dosino at MSB [1... 4]

// eDirection Direction Direction of the desired

// piston movement.

// return eReturnstate

DllDirection eReturnstate __stdcall Adjust(long IfNo, long MsbNo,

eDirection Direction);

// Move the piston to an absolute position. The full stroke of the piston is

// subdivided in 10000 positions.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long Position Absolute piston position

// [0... 10000]

// float Rate Dosing rate

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall GoPos(long IfNo, long MsbNo, long Position,

float Rate);

// Move piston to the mechanical end position. This function can be used to

// remove any air bubbles from the cylinder.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// float FwdRate Dosing rate

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_ToEnd(long IfNo, long MsbNo,

float FwdRate);

// Dose a specified volume via the actual port. Dosing rate, filling rate,

// filling port and piston direction can be chosen.

// With reverse piston direction it is possible to aspirate a desired volume.

// In this case the filling port is used as outlet port.

// The dosing can be hold, continued and stopped.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long FillPort Filling port

// float Volume Dosing volume

// [0... 99999.99 mL]

// eDirection Direction Direction of piston movement

// float FwdRate Dosing rate

// [0.01... 166 mL/min]

// float RevRate Filling rate

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_MakeStep(long IfNo, long MsbNo,

long Fillport, float Volume,

eDirection Direction,

float FwdRate, float RevRate);

// Fill the cylinder from a specified port.

// Filling can be held and continued, but not stopped.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long Port Fill port [1..4]

32 Dosing Interface USB Toolbox, Annex

Page 37

3.1 Programming interface definitions

// float RevRate Filling rate

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_Fill(long IfNo, long MsbNo, long Port,

float RevRate);

// Prepares the Dosing Unit for exchange. The cylinder is filled from the

// specified port and then the valve disk is turned to port 2.

// This action can be held and continued, but not stopped.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long Port Fill port [1..4]

// float RevRate Filling rate

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_Exchange(long IfNo, long MsbNo, long Port,

float RevRate);

// Reads the status of a Dosino drive.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// eDosinoState& DosinoState status of the Dosino drive

// return eReturnstate

DllDirection eReturnstate __stdcall Status(long IfNo, long MsbNo,

eDosinoState &DosinoState);

// Stops the current Dosino action.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// return eReturnstate

DllDirection eReturnstate __stdcall DosStop(long IfNo, long MsbNo);

// Holds the current Dosino action. The held action can be continued or

// finally stopped.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// return eReturnstate

DllDirection eReturnstate __stdcall DosHold(long IfNo, long MsbNo);

// Continue a held Dosino action.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// return eReturnstate

DllDirection eReturnstate __stdcall DosContinue(long IfNo, long MsbNo);

// Prepares a Dosing Unit for further use. A "Prep" cycle includes emptying the

// dosing cylinder and rinsing and filling the tubings in one automated process.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long InPort Filling port [1... 4]

// float InVolume Fill tube volume

Dosing Interface USB Toolbox, Annex 33

Page 38

3.1 Programming interface definitions

// [0... 20000 mm^3]

// float InRate Filling rate

// [0.01... 166 mL/min]

// long OutPort Output port 1 [1... 4]

// float OutVolume Dosing tube volume on Output

// port 1 [0... 20000 mm^3]

// float OutRate Dosing rate on Output port 1

// [0.01... 166 mL/min]

// long SpecPort Output port 2 [1... 4]

// float SpecVolume Dosing tube volume on Output

// port 2 [0... 20000 mm^3]

// float SpecRate Dosing rate on Output port 1

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_Prep(long IfNo, long MsbNo,

long InPort, float InVolume,

float InRate,

long OutPort, float OutVolume,

float OutRate,

long SpecPort, float SpecVolume,

float SpecRate);

// Empties the Buret Unit. Dosing cylinder and tubings are emptied in one

// automated process.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long InPort Filling port [1... 4]

// float InVolume Fill tube volume

// [0... 20000 mm^3]

// float InRate Filling rate

// [0.01... 166 mL/min]

// long OutPort Output port 1 [1... 4]

// float OutVolume Dosing tube volume on Output

// port 1 [0... 20000 mm^3]

// float OutRate Dosing rate on Output port 1

// [0.01... 166 mL/min]

// long SpecPort Output port 2 [1... 4]

// float SpecVolume Dosing tube volume on Output

// port 2 [0... 20000 mm^3]

// float SpecRate Dosing rate on Output port 1

// [0.01... 166 mL/min]

// return eReturnstate

DllDirection eReturnstate __stdcall DU_Empty(long IfNo, long MsbNo,

long InPort, float InVolume,

float InRate,

long OutPort, float OutVolume,

float OutRate,

long SpecPort, float SpecVolume,

float SpecRate);

// Reads casual error messages which occur during Dosino actions.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long ErrorNumber Error number [0... 9]

// char* ErrorCode Error code, format

// [GGG-CCC-K-III],

// G = group, C = code,

// K = class, I = index

// (1...4 or 255)

34 Dosing Interface USB Toolbox, Annex

Page 39

3.1 Programming interface definitions

// long ErrorBufSize Number of characters of

// ErrorCode including a

// terminating null character

// (at least 14)

// return eReturnstate

DllDirection eReturnstate __stdcall GetInterfaceError(long IfNo, long MsbNo,

long ErrorNumber,

char* ErrorCode,

long ErrorBufSize);

// Reads the stop condition of a Dosino action.

//

// parameter long IfNo Dosing Interface [1... ?]

// long MsbNo Dosino at MSB [1... 4]

// long& StopType Stop type of the last action

// return eReturnstate

DllDirection eReturnstate __stdcall GetStopType(long IfNo, long MsbNo,

long &StopType);

// Reads the serial number of a Dosing Interface. The serial number can be used

// as a unique identifier of an instrument.

//

// parameter long IfNo Dosing Interface [1... ?]

// long& InterfaceId Serial number of Dosing

// Interface

// return eReturnstate

DllDirection eReturnstate __stdcall GetInterfaceId(long IfNo,

long &InterfaceId);

// Get the program version of the 846 Dosing Interface

//

// parameter long IfNo Dosing Interface [1... ?]

// char* ProgramVersion Text string of program version

// long ProgVerBufSize Number of characters of

// ProgramVersion including a

// terminating null character

// return eReturnstate

DllDirection eReturnstate __stdcall GetProgramVersion(long IfNo,

char* ProgramVersion,

long ProgVerBufSize);

#ifdef __cplusplus

}

#endif

#endif // Dosinginterface846_h

Dosing Interface USB Toolbox, Annex 35

Page 40

3.1 Programming interface definitions

3.1.4 Delphi Interface

(*****************************************************************************)

(* *)

(* Metrohm AG Switzerland. All rights reserved. *)

(* *)

(*---------------------------------------------------------------------------*)

(* *)

(* 1 30.05.05 14:28 rw *)

(* *)

(*****************************************************************************)

UNIT DosIntFace846;

{$MINENUMSIZE 4 }

INTERFACE

CONST

dllName = '846_Dosing_Interface.dll';

TYPE

LONG = LongInt;

FLOAT = Single;

BOOL = LongBool;

eReturnState = (

(* function could be set up correctly *)

RET_STAT_OK,

(* not a valid 846 Dosing Interface number or Dosino number *)

RET_STAT_nvNumber,

(* not a valid Dosino *)

RET_STAT_noDosino,

(* communication error *)

RET_STAT_commError,

(* function arguments out of specified range *)

RET_STAT_argError,

(* not a valid action *)

RET_STAT_nvAction);

eDosinoState = (

(* Dosino is ready to execute a function *)

DOS_STAT_IDLE,

(* Cylinder is being filled *)

DOS_STAT_FILL,

(* Dosino is executing Exchange function *)

DOS_STAT_EXCHANGE,

(* Dosino is executing GoPos function *)

DOS_STAT_POSITION,

(* Dosino is executing ZeroAdjust function *)

DOS_STAT_ZEROADJUST,

(* Dosino is executing Adjust function *)

DOS_STAT_ADJUST,

(* Dosino is executing Cock function *)

DOS_STAT_COCK,

(* Dosino is executing ToEnd function *)

DOS_STAT_TOENDDOS,

(* Dosino is executing MakeStep function *)

DOS_STAT_DOS,

(* Dosino is executing Prep function *)

DOS_STAT_PREPAR,

(* Dosino is executing Empty function *)

DOS_STAT_EMPTY,

36 Dosing Interface USB Toolbox, Annex

Page 41

3.1 Programming interface definitions

(* Dosino is busy *)

DOS_STAT_BUSY,

(* Dosino is halted while filling *)

DOS_STAT_HOLD_FILL,

(* Dosino is halted in Exchange function *)

DOS_STAT_HOLD_EXCHANGE,

(* Dosino is halted in GoPos function *)

DOS_STAT_HOLD_POSITION,

(* Dosino is halted in ZeroAdjust function *)

DOS_STAT_HOLD_ZEROADJUST,

(* Dosino is halted in Adjust function *)

DOS_STAT_HOLD_ADJUST,

(* Dosino is halted in ToEnd function *)

DOS_STAT_HOLD_TOENDDOS,

(* Dosino is halted in MakeStep function *)

DOS_STAT_HOLD_DOS,

(* Dosino is halted in Prep function *)

DOS_STAT_HOLD_PREPAR,

(* Dosino is halted in Empty function *)

DOS_STAT_HOLD_EMPTY,

(* Dosino has timed out *)

DOS_STAT_TIMEOUT,

(* Dosino status is undefined *)

DOS_STAT_UNDEFINED);

eDirection = (

(* Forward, dosing (0 --> 10000 pulses) *)

DIR_fwd,

(* Reverse, filling (10000 --> 0 pulses) *)

DIR_rev);

eCockMove = (

(* Ascending order (Port 1 --> 4) *)

CK_MV_Asc,

(* Descending order (Port 4 --> 1) *)

CK_MV_Desc,

(* Automatic mode, shortest path *)

CK_MV_Auto,

(* Protected mode, cock will not move over specified port *)

CK_MV_NotOver);

(* Initializes all Metrohm 846 Dosing Interfaces found in the USB chain. *)

(* All Dosino drives are recognized and the Dosing Units are reset. *)

(* Running processes are stopped. *)

(* *)

(* return bool Function returns true if *)

(* successful *)

FUNCTION Init846 : BOOL; STDCALL; EXTERNAL dllName;

(* Returns the cylinder volume of the Dosing Unit. This function can be *)

(* used for the detection of a mounted Dosing Unit. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* LONG VAR Volume 0; 2; 5; 10; 20; 50 mL *)

(* Cylinder volume = 0 *)

(* means: no Dosing Unit mounted! *)

(* return eReturnstate *)

FUNCTION GetCylVolume(IfNo,MsbNo : LONG; VAR Volume : LONG)

: eReturnState; STDCALL; EXTERNAL dllName;

Dosing Interface USB Toolbox, Annex 37

Page 42

3.1 Programming interface definitions

(* Turns the valve disk to the selected port. The turning direction is *)

(* chosen according to "Move". If "Move" is set to CK_MV_NotOver, the Port *)

(* specified in "NotOver" will not be crossed. Otherwise this parameter is *)

(* ignored. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* LONG Port Target Dosino port [1... 4] *)

(* eCockMove Move Turning direction of the *)

(* valve disk *)

(* LONG NotOver protected Dosino port [1... 4] *)

(* return eReturnstate *)

FUNCTION DU_Cock(IfNo,MsbNo,Port : LONG; Move : eCockMove; NotOver : LONG)

: eReturnState; STDCALL; EXTERNAL dllName;

(* Moves the piston of the Dosino to zero position and initializes the drive. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* FLOAT RevRate Filling rate of piston *)

(* [0.01...166mL/min] *)

(* return eReturnstate *)

FUNCTION ZeroAdjust(IfNo,MsbNo : LONG; RevRate : FLOAT) : eReturnState;

STDCALL; EXTERNAL dllName;

(* Eliminate slack of piston coupling. This function can be used, when the *)

(* direction of the piston movement is about to be changed. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* eDirection Direction Direction of the desired *)

(* piston movement. *)

(* return eReturnstate *)

FUNCTION Adjust(IfNo,MsbNo : LONG; Direction : eDirection) : eReturnState;

STDCALL; EXTERNAL dllName;

(* Move the piston to an absolute position. The full stroke of the piston is *)

(* subdivided in 10000 positions. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* LONG Position Absolute piston position *)

(* [0... 10000] *)

(* FLOAT Rate Dosing rate *)

(* [0.01... 166 mL/min] *)

(* return eReturnstate *)

FUNCTION GoPos(IfNo,MsbNo,Position : LONG; Rate : FLOAT) : eReturnState;

STDCALL; EXTERNAL dllName;

(* Move piston to the mechanical end position. This function can be used to *)

(* remove any air bubbles from the cylinder. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* FLOAT FwdRate Dosing rate *)

(* [0.01... 166 mL/min] *)

(* return eReturnstate *)

FUNCTION DU_ToEnd(IfNo,MsbNo : LONG; FwdRate : FLOAT) : eReturnState;

38 Dosing Interface USB Toolbox, Annex

Page 43

3.1 Programming interface definitions

STDCALL; EXTERNAL dllName;

(* Dose a specified volume via the actual port. Dosing rate, filling rate, *)

(* filling port and piston direction can be chosen. *)

(* With reverse piston direction it is possible to aspirate a desired volume. *)

(* In this case the filling port is used as outlet port. *)

(* The dosing can be hold, continued and stopped. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* LONG FillPort Filling port *)

(* FLOAT Volume Dosing volume *)

(* [0... 99999.99 mL] *)

(* eDirection Direction Direction of piston movement *)

(* FLOAT FwdRate Dosing rate *)

(* [0.01... 166 mL/min] *)

(* FLOAT RevRate Filling rate *)

(* [0.01... 166 mL/min] *)

(* return eReturnstate *)

FUNCTION DU_MakeStep(IfNo,MsbNo : LONG; FillPort : LONG;

Volume : FLOAT; Direction : eDirection;

FwdRate,RevRate : FLOAT) : eReturnState;

STDCALL; EXTERNAL dllName;

(* Fill the cylinder from a specified port. *)

(* Filling can be held and continued, but not stopped. *)

(* *)

(* parameter LONG IfNo Dosing Interface [1... ?] *)

(* LONG MsbNo Dosino at MSB [1... 4] *)

(* LONG Port Fill port [1..4] *)