Page 1

845 Eluent Synthesizer

Handbuch

8.845.8001EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

845 Eluent Synthesizer

8.845.8001EN

Handbuch

08.2008 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

Contents

Table of contents

1 Introduction.................................................... 1

1.1 Instrument description ............................................................. 1

1.2 Parts and controls .................................................................... 1

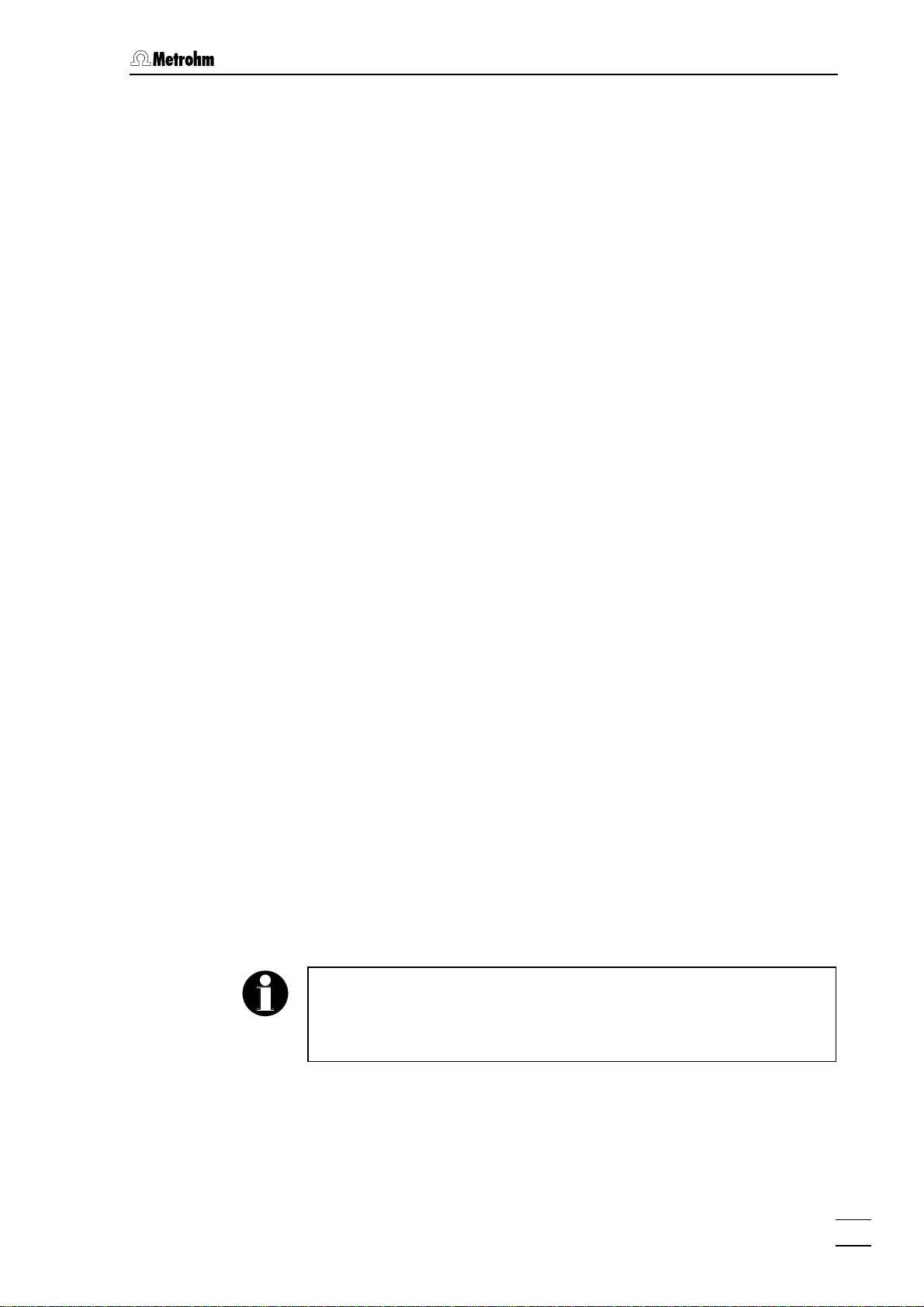

1.2.1 Front of 2.845.0010 .......................................................................2

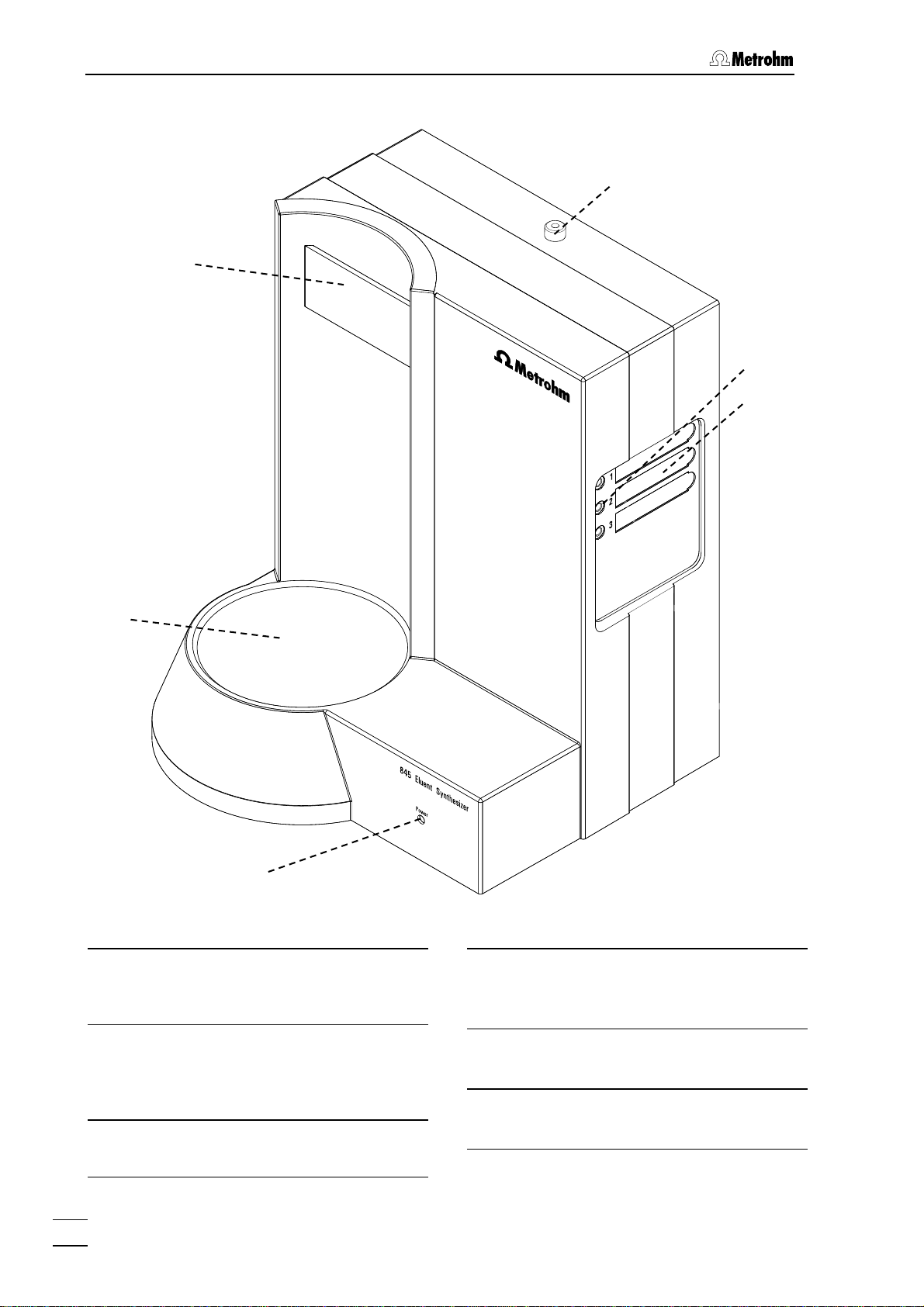

1.2.2 Front of 2.845.0020 .......................................................................3

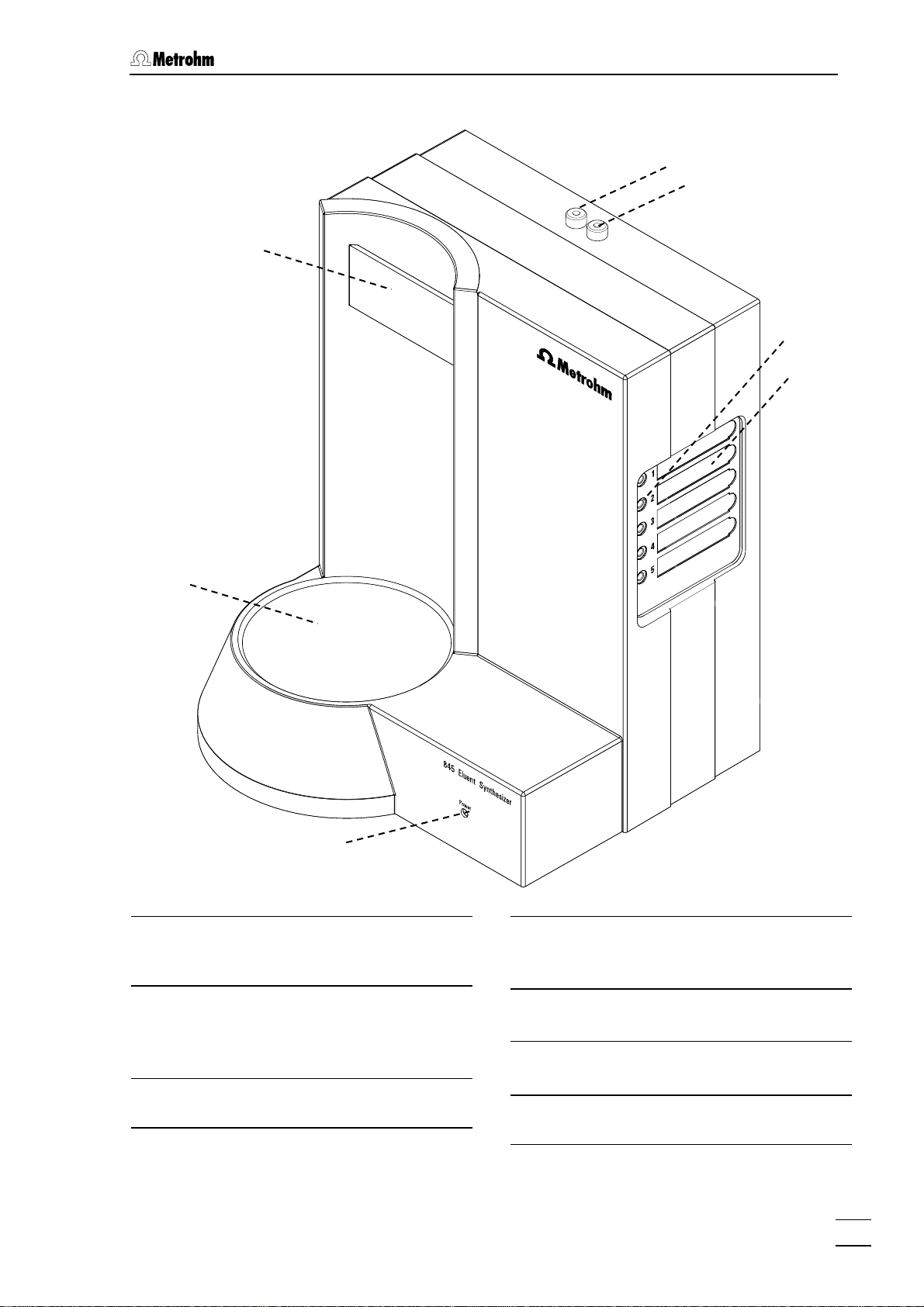

1.2.3 Rear view .......................................................................................4

1.3 Information on the Instructions for Use .................................. 6

1.3.1 Organization ..................................................................................6

1.3.2 Notation and pictograms ..............................................................7

1.4 Safety information..................................................................... 8

1.4.1 Electrical safety..............................................................................8

1.4.2 General precautionary rules .......................................................... 8

2 Installation ..................................................... 9

2.1 Setting up the instrument ......................................................... 9

2.1.1 Packaging...................................................................................... 9

2.1.2 Check.............................................................................................9

2.1.3 Location ......................................................................................... 9

2.2 Mains connection...................................................................... 9

2.3 Connection to PC.................................................................... 10

2.4 Dosino(s)/Stirrer connections................................................ 11

2.5 Tubing connections ................................................................ 11

2.5.1 Instrument with tubing connections ............................................12

2.5.2 Connecting the drainage tubing .................................................13

2.5.3 Connections to bottle adapter ....................................................13

2.5.4 Connecting the components.......................................................13

2.6 pH Controller........................................................................... 14

2.6.1 Tubing connection for pH Controller........................................... 14

2.6.2 pH Controller cable connection ..................................................15

3 «Mix Control» software................................. 16

3.1 Introduction to the software ................................................... 16

3.1.1 The principle of «Mix Control» .....................................................16

3.1.2 Procedure after the first start of «Mix Control» ............................16

3.2 Main Window........................................................................... 16

3.2.1 Menus..........................................................................................16

3.2.2 Description of the symbols .........................................................19

3.3 Method..................................................................................... 20

3.3.1 General information about methods ...........................................20

3.3.2 Parameters ..................................................................................20

3.3.3 pH Adjustment.............................................................................21

3.3.4 Creating a method.......................................................................23

3.4 Configuration .......................................................................... 23

3.4.1 Depot ........................................................................................... 23

3.4.2 Components................................................................................25

3.4.3 System Settings........................................................................... 26

3.4.4 Report Configuration ...................................................................27

3.4.5 User Administration ..................................................................... 29

3.4.6 Rinse............................................................................................33

3.5 Extras....................................................................................... 36

3.5.1 Sign methods ..............................................................................36

845 Eluent Synthesizer / Instructions for Use 8.845.8001EM

I

Page 6

Contents

3.5.2 Audit trail...................................................................................... 37

3.5.3 Window "Report List" ................................................................... 39

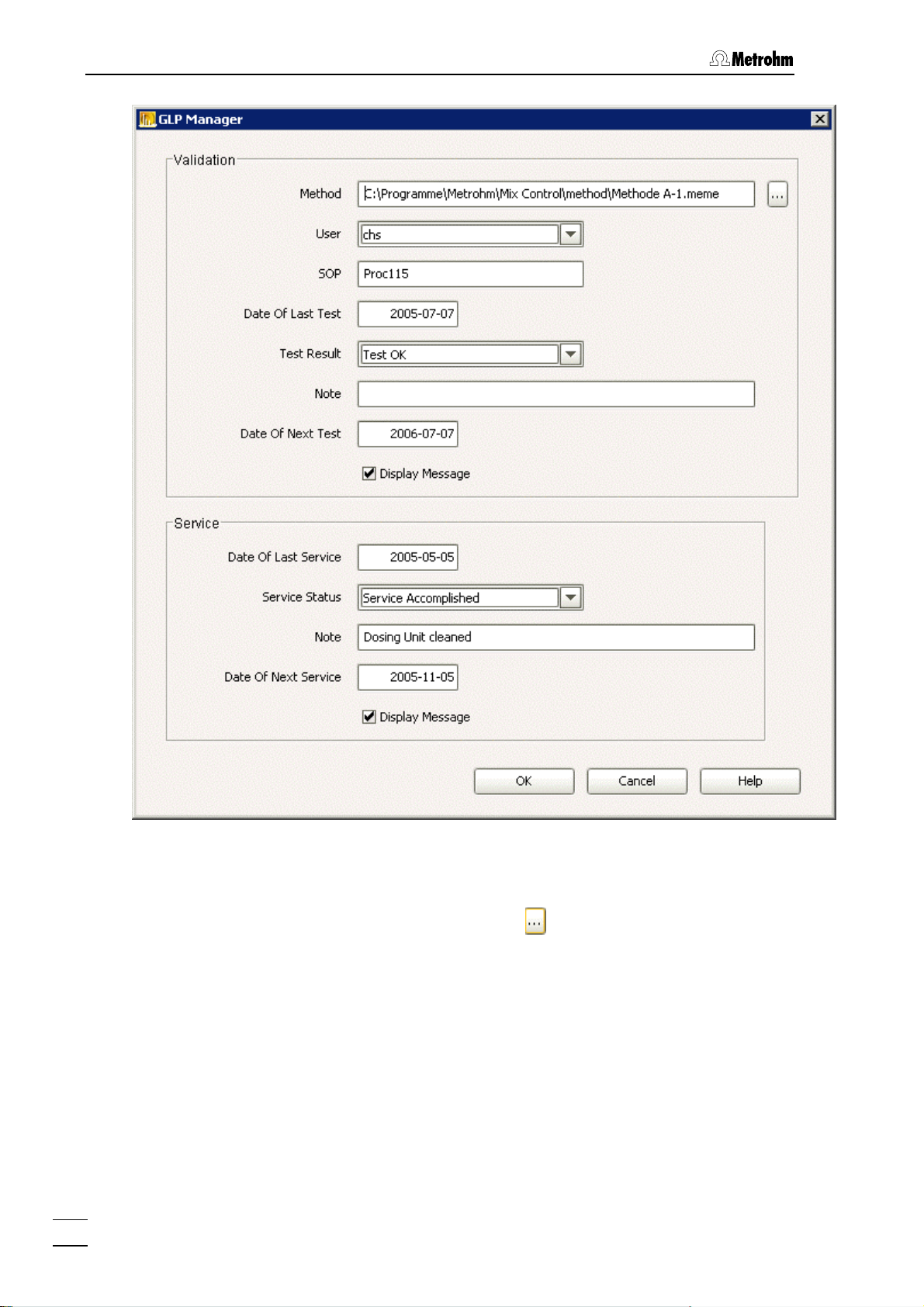

3.5.4 GLP Manager .............................................................................. 41

3.5.5 Firmware Update......................................................................... 43

3.5.6 Login Service............................................................................... 44

4 Maintenance - Troubleshooting...................45

4.1 Care .........................................................................................45

4.1.1 Decommissioning .......................................................................45

4.2 Dosing units ............................................................................ 45

4.2.1 Deinstallation............................................................................... 45

4.2.2 Cleaning ...................................................................................... 46

4.2.3 Installation ...................................................................................47

4.3 Troubleshooting...................................................................... 49

5 Annex ............................................................50

5.1 Technical data......................................................................... 50

5.1.1 Interfaces..................................................................................... 50

5.1.2 Mains connection........................................................................ 50

5.1.3 Safety specifications ...................................................................50

5.1.4 Electromagnetic compatibility (EMC) .........................................50

5.1.5 Ambient temperature ..................................................................51

5.1.6 Dosing drive ................................................................................ 51

5.1.7 Dosing Unit.................................................................................. 51

5.1.8 Reference conditions .................................................................. 51

5.1.9 Dimensions ................................................................................. 51

5.2 Standard equipment ............................................................... 52

5.2.1 Standard equipment for 2.845.0010........................................... 52

5.2.2 Standard equipment for 2.845.0020........................................... 54

5.2.3 Accessories for pH adjustment (optional) .................................. 57

5.2.4 Optional accessories ..................................................................61

5.2.5 Producers of concentrates and standards ................................. 62

5.2.6 Systems for producing ultra pure water ..................................... 62

5.3 Warranty .................................................................................. 63

5.3.1 Warranty ......................................................................................63

5.3.2 Declaration of Conformity ...........................................................64

5.3.3 Quality Management Principles .................................................. 65

5.3.4 Index............................................................................................ 66

List of figures

Figure 1: Front of 2.845.0010 ....................................................................... 2

Figure 2: Front of 2.845.0020 ....................................................................... 3

Figure 3: Rear view of 845 Eluent Synthesizer ............................................. 4

Figure 4: Tubing connections..................................................................... 12

Figure 5: Dosing unit attachment ............................................................... 46

Figure 6: Connections with one Dosino ..................................................... 47

Figure 7: Connections with two Dosinos.................................................... 48

845 Eluent Synthesizer / Instructions for Use 8.845.8001EN

II

Page 7

1.1 Instrument description

1 Introduction

The 845 Eluent Synthesizer and its associated «Mix Control» software can be used for the fully automatic preparation of solutions and

mixtures such as eluents, mobile phases, buffer solutions or standards

with the required concentration and component ratios.

The 845 Eluent Synthesizer is based on the Dosino technology which

allows high-precision dosing to be carried out. Both aqueous (acidic or

basic) and organic mixtures can be prepared. The system (with an optional extension) can also be used to adjust the pH.

1.1 Instrument description

Two versions of the instrument are available :

• 2.845.0010 845 Eluent Synthesizer with one Dosino

• 2.845.0020 845 Eluent Synthesizer with two Dosinos

The 2.845.0010 Eluent Synthesizer with one Dosino can be used to mix

together three components (of which one is the main component).

The 2.845.0020 Eluent Synthesizer with two Dosinos can be used to

mix together five components (of which one is the main component).

Both versions contain a built-in magnetic stirrer The software «Mix Control» is supplied with the instrument.

The 2.702.0120 Eluent Synthesizer Package for the automatic pH adjustment is offered as an option. In addition to a 702 Titrino this also

contains an Aquatrode, a 10 mL exchange unit and a Remote Box (see

Section

The 845 Eluent Synthesizer is connected to a PC via a USB and operated with the «Mix Control» PC software provided. The operation of the

software is described in the online help and in Section

structions for Use.

5.2.3).

1.2 Parts and controls

3 of these In-

In this Section you will find the numbers and designations of the parts

and controls of the 845 Eluent Synthesizer. The numbering applies

throughout the Instructions for Use, i.e. bold numbers in the text (e.g.

3

) refer to the parts and controls illustrated here.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

1

Page 8

1 Introduction

1.2.1 Front of 2.845.0010

4

3

5

6

2

1

Figure 1: Front of 2.845.0010

LED "Power"

1

Lights up green when the instrument is

switched on.

Place for eluent bottle

2

To place the eluent bottle while preparing the mixture. There is a built-in

magnetic stirrer beneath it.

Holder for bottle adapter

3

Holder for bottle adapter

21.

Dosino 1 outlet

4

Outlet for the components from Dosino

1.

Connections for components

5

Connections for components 1 - 3.

Recesses for magnetic labels

6

For identifying components 1 - 3.

2

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 9

1.2 Parts and controls

1.2.2 Front of 2.845.0020

7

4

3

5

6

2

1

Figure 2: Front of 2.845.0020

1 LED "Power"

Lights up green when the instrument is

switched on.

2 Place for eluent bottle

The eluent bottle is placed here for

preparing the mixture. There is a builtin magnetic stirrer beneath it.

3 Holder for bottle adapter

Holder for bottle adapter

21.

4 Dosino 1 outlet

Outlet for the components from Dosino

1.

5 Connections for components

Connections for components 1 - 5.

6 Recesses for magnetic labels

For identifying components 1 - 5.

Dosino 2 outlet

7

Outlet for components from Dosino 2.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

3

Page 10

1 Introduction

1.2.3 Rear view

19

8

9

10

11

12

13

14

Figure 3: Rear view of 845 Eluent Synthesizer

Lead-throughs for Dosino cables

8

Lead-through for stirrer cable

9

Connection "Stirrer / MSB3"

10

For connecting a stirrer (cable marked

with "Stirrer").

15

16

USB-connections USB1 and USB2

11

USB-ports (type A) for connecting devices with a USB cable.

Controller connection

12

For connecting to a PC.

18

17

4

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 11

1.2 Parts and controls

Connection "MSB1 / Dosino 1"

13

For connecting Dosino 1 (cable

marked with "Dosino 1").

Connection "MSB2 / Dosino 2"

14

For connecting Dosino 2 (cable

marked with "Dosino 2") (only for version 2.845.0020).

Connection "Remote Box / MSB4"

15

For connecting the Remote-Box for pH

adjustment with Titrino(s) (see Section

2.6.2).

Mains connection socket

16

Mains connection (see Section

Device type and serial number

17

Connection for drainage tubing

18

For draining off any liquid that has escaped inside the instrument (see Sec-

2.5.2).

tion

Rear panel

19

2.2).

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

5

Page 12

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 845 Eluent Synthesizer into operation. The Instructions for Use

contain information and warnings to which the user must pay attention

in order to assure safe operation of the instrument.

1.3.1 Organization

These Instructions for Use 8.845.1003 for the 845 Eluent Synthesizer

provide a comprehensive overview of installation, operation, maintenance, fault rectification and technical specifications of this instrument.

The Instructions for Use are organized as follows:

Sect.

1 Introduction

General description of instrument, parts and controls

and safety notes.

Sect.

2 Installation

Installation of the instrument, mains connection, connection to PC, connection of Dosino(s)/stirrer, pH

controller.

3 «Mix Control» software

Sect.

Explanation of how to use the «Mix Control» software.

Sect.

4 Maintenance - Troubleshooting

Care, cleaning the dosing units, troubleshooting.

Sect.

5 Annex

Technical data, standard equipment, options, warranty, conformity declarations, index.

To find the required information on the instruments, use either the Ta-

ble of contents or the Index at the back.

6

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 13

1.3 Information on the Instructions for Use

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

12 Part or control

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. First read the associated

directions before you continue.

Comment

This symbol marks additional information and tips.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

7

Page 14

1 Introduction

1.4 Safety information

This instrument must only be operated in accordance with the information provided in these Instructions for Use.

1.4.1 Electrical safety

While electrical safety in the handling of the 845 Eluent Synthesizer is

assured in the context of the specifications EN / IEC 61010-1, the following points should be noted:

• Electronic parts

Only qualified Metrohm technicians should carry out service work on

electronic components.

• Protection against electrostatic charges

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

8

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 15

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 845 Eluent Synthesizer is supplied together with the separately

packed accessories in special packagings containing shock-absorbing

foam linings designed to provide excellent protection. Please store all

these special packagings as only they assure transport of the

instrument free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in Section

structions in Section

5.2). In the case of transport damage, see in-

5.3.1 "Warranty".

2.1.3 Location

This instrument was developed for internal laboratory use; it should not

be used in explosion-endangered locations.

Place the instrument on a suitable vibration-free laboratory bench, protected as much as possible from corrosive atmospheres and contact

with chemicals. Choose a location where the temperature is usually between +5°C and +45°C. The instrument should be protected against

excessive variations in temperature and direct sunlight.

2.2 Mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2122.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with a grounding pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective ground (protection class 1).

Any break in the grounding inside or outside the instrument can make

it a hazard!

Mains connection

Plug the mains cable into mains connection plug

Synthesizer.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

16 of the 845 Eluent

9

Page 16

2 Installation

2.3 Connection to PC

The 845 Eluent Synthesizer is controlled by the «Mix Control» PC software (see Section

System requirements

• Processor: Pentium III

• Main memory: 256 MB RAM

• Free memory space: 100 MB for program files

• CD-ROM drive

• Connection: one free USB slot (type A)

Microsoft Windows

must be used as the operating system.

Installation

To connect the instrument and install the software proceed as follows:

3).

TM

2000 or WindowsTM XP or WindowsTM Vista

1 Installing the «Mix Control» program

• Insert installation CD in CD disk drive.

• If autostart has not

<Start> and Run. Search for the Setup.exe file on the in-

stallation CD and click on

• Click on "

Mix Control" and follow the instructions of the

been activated for the CD drive: select

<OK>.

setup program.

2 Connection 845 - PC

• Connect the 845 Eluent Synthesizer (socket "Controller" 12)

to a USB connection (type A) of your computer with the

6.2151.000 Cable (see the instruction manual for your

computer).

• A system test will automatically be carried out on the 845

Eluent Synthesizer.

• The LED "Power"

1 lights up when the system test has been

completed and the instrument is ready for use.

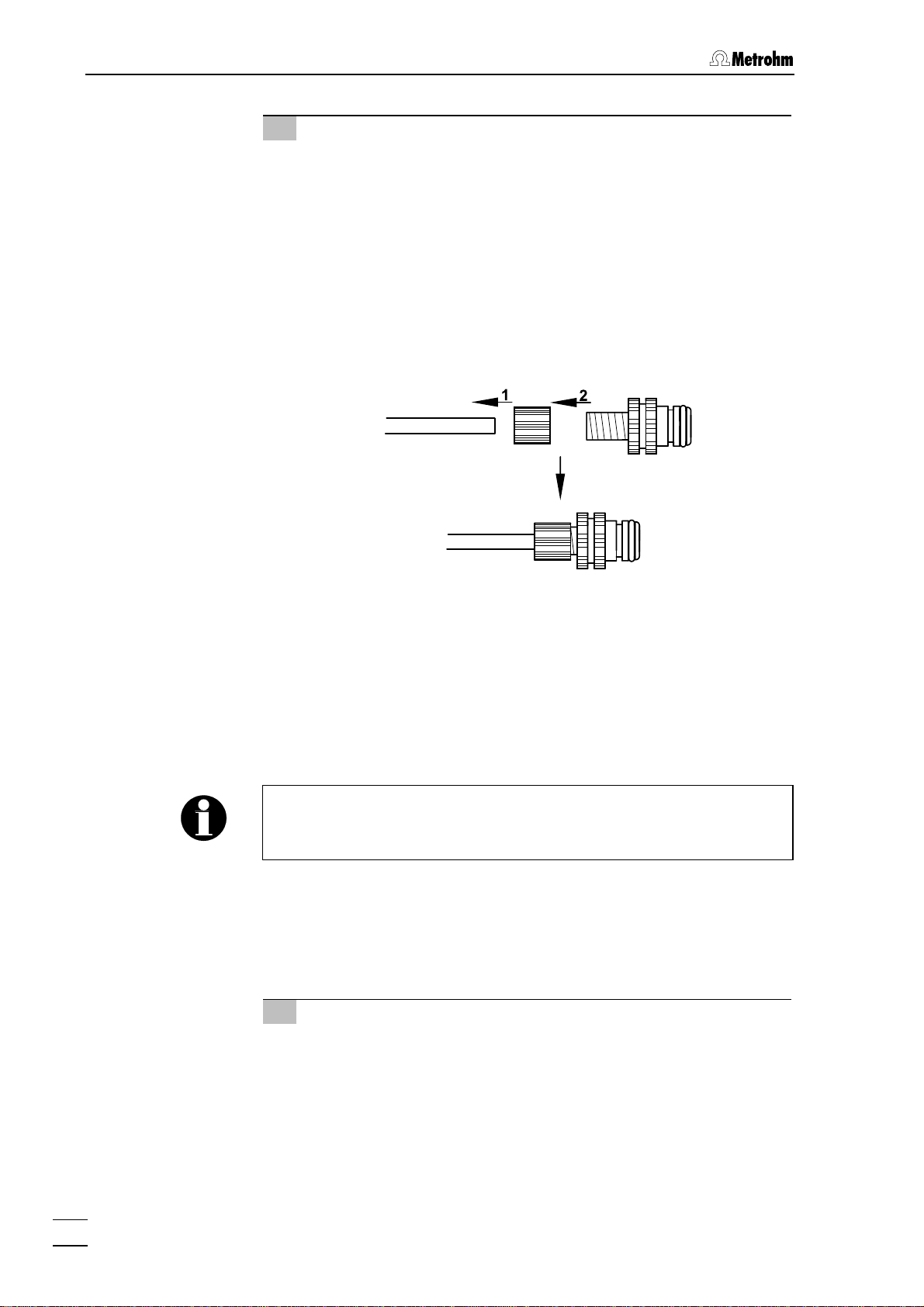

The plug for connection of the 845 Eluent Synthesizer is fitted with a

"pull-out protection device" which prevents the cable from being

pulled out accidentally. When you wish to insert or remove the plug

you must first pull back the outer plug sleeves (marked with arrows).

You can extend the connection with a commercially available USB extension cable (type A/m – type A/f). The length of the connection

should not exceed 5 m. If you require a longer connection then you

must use a USB signal amplifier. Up to five USB signal amplifiers can

be connected in series; this allows a maximum extension of 25 m.

10

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 17

2.4 Dosino(s)/Stirrer connections

3 Start the «Mix Control» program

• Double click on the icon of the «Mix Control» software.

• The device is recognized automatically.

2.4 Dosino(s)/Stirrer connections

Dosino(s) and stirrer are part of the instrument. The instrument is supplied with them already connected up; these connections should not be

altered.

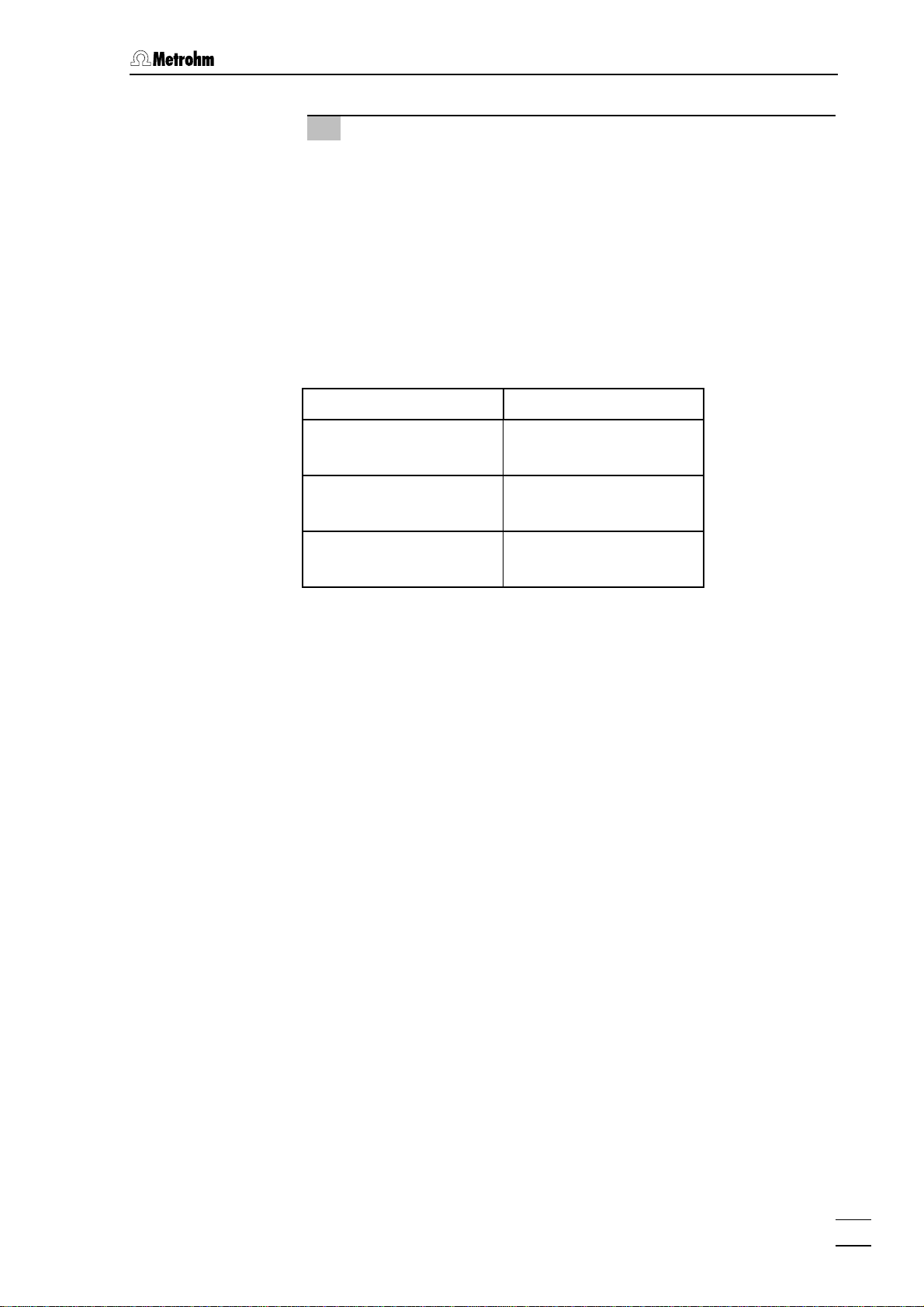

Correct connection:

Cable markings Connection markings

Dosino 1

Dosino 2

Stirrer

2.5 Tubing connections

The drainage tubing (Section 2.5.2) and the component inlets and outlets (Sections

2.5.3/2.5.4) must be connected.

MSB1

Dosino 1

MSB2

Dosino 2

Stirrer

MSB3

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

11

Page 18

2 Installation

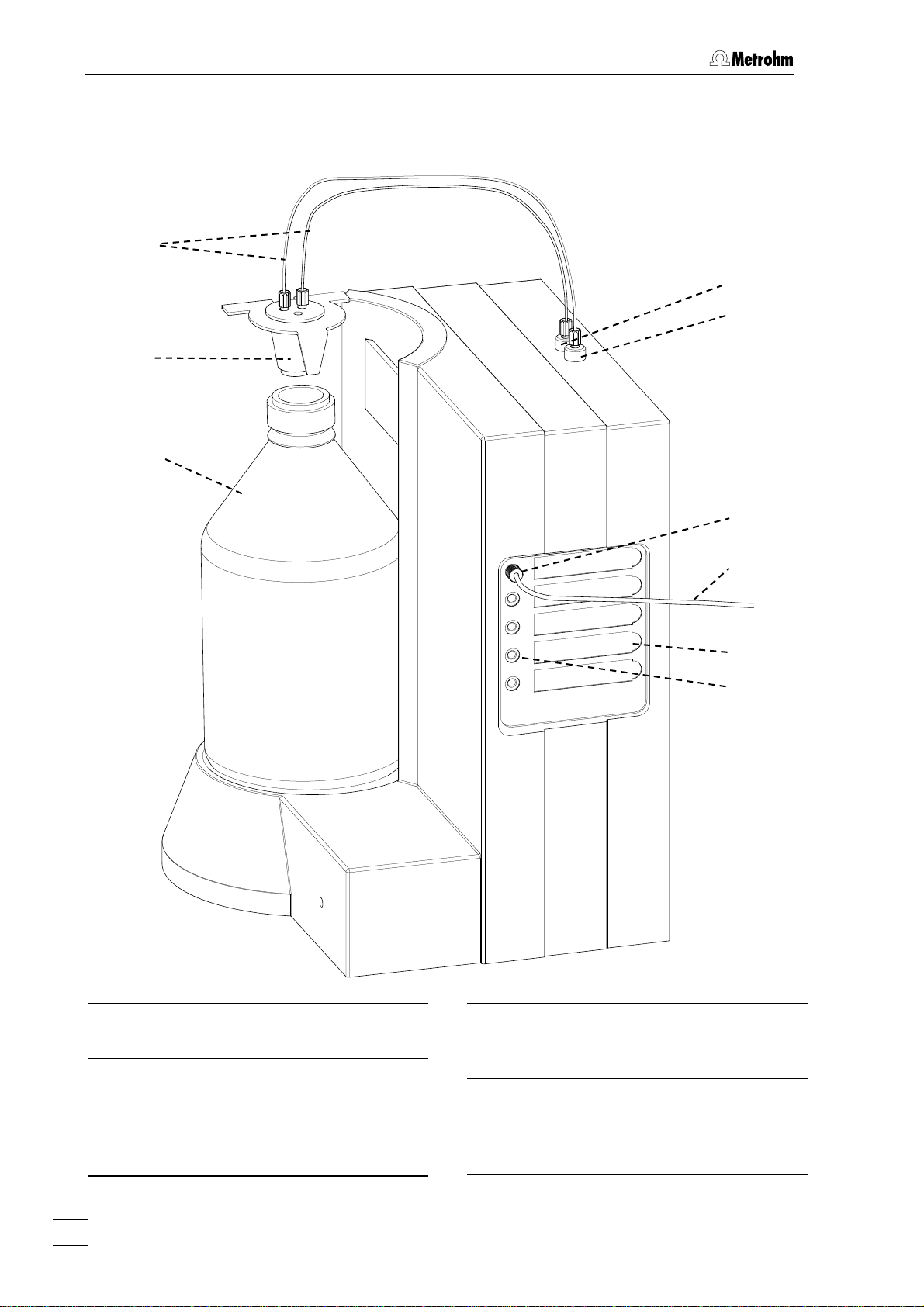

2.5.1 Instrument with tubing connections

20

7

4

21

22

23

24

6

5

Figure 4: Tubing connections

4 Dosino 1 outlet

Outlet for components from Dosino 1.

5 Connections for components

Connections for components 1 - 5.

7 Dosino 2 outlet

Outlet for components from Dosino 2

(only for version 2.845.0020).

FEP tubing connection

20

6.1838.000 Tubing connections for

6 Recesses for magnetic labels

For identifying components 1 - 5.

12

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

connecting "Dosino 1 outlet"

ino 2" outlet

7 to the bottle adapter 21.

4 / "Dos-

Page 19

2.5 Tubing connections

Bottle adapter

21

6.1602.180 Bottle adapter as connection piece between eluent bottle

and tubing connection

Eluent bottle

22

6.1608.070 Clear glass bottle for the

mixed eluent.

20.

22

23

24

2.5.2 Connecting the drainage tubing

Connect 6.1816.020 Silicone tubing to connection 18 on the rear panel

of the 845 Eluent Synthesizer and place the other end in a waste bottle.

2.5.3 Connections to bottle adapter

The tubing should not dip into the produced mixture. Make sure that

the FEP- Tubing Connection 6.1838.000

into the bottle.

2.845.0010:

Connect 6.1838.000 FEP Tubing connection

Bottle adapter and to Dosino outlet

the Eluent bottle 6.1608.070.

Pressure screw

6.2744.170 Pressure screw for connecting component capillary

component connection

PTFE capillary

6.1803.130 Capillary for connecting the

components.

20

does not loom too deep

20 to the 6.1602.180 21

4. Then, attach the Bottle adapter to

24 to

5.

2.845.0020:

Connect two 6.1838.000 FEP Tubing connections

21 Bottle adapter and to Dosino outlets 4 and 7. Then, attach the Bottle

adapter to the Eluent bottle 6.1608.070.

2.5.4 Connecting the components

The main component (e.g. water) must be connected to the component connection with the number 1 (see Section

component is used (at the end of the mixing process) to make the

volume up to the total volume given in the method (see Section

3.3).

Proceed as follows to connect the various components:

1 Connect capillary to 845

Connect 6.1803.130 PTFE capillary 24 with 6.2744.170 Pressure

screw 23 to component connection 5.

20 to the 6.1602.180

3.4.2). The main

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

13

Page 20

2 Installation

2 Connect capillary to the components

Components from a bottle:

• Insert 6.1803.130 PTFE tubing

ment into the component bottle (e.g. the combination

6.1602.160 bottle attachment GL 45 and 6.1608.030 bottle;

see Optional accessories section 5.2.4).

Components from an MPak (from Chata Biosystems, see section

5.2.5):

• Push the 6.1808.200 MPak coupling onto 6.1803.130 PTFE

tubing 24 by loosening the screw cap from the coupling

and pushing the smaller opening over the tubing. Then

screw the coupling into the cap:

24 through the bottle attach-

• Click the 6.1808.200 MPak coupling onto the lower outlet of

the MPak.

2.6 pH Controller

The pH of the prepared mixture can, if necessary, be adjusted automatically by using the (optional) extension kit. If the pH is to be adjusted

from one side then one pH Controller is required, adjustment from both

sides (without changing the titrant solution) requires two pH Controllers.

We recommend the use of 702 Titrinos as pH Controllers (for supply

package see Section

package for required accessories see Section

2.6.1 Tubing connection for pH Controller

If the pH is to be adjusted automatically after the mixing process then

adaptations are required to the tubing connections to the 845 Eluent

Synthesizer.

5.2.3). Other Titrinos can also be used (supply

5.2.3).

1 Replace bottle adapter 21

6.1602.180 Bottle adapter 21 must be replaced by 6.1602.190

Eluent bottle head.

• Screw off the 6.1838.000 FEP tubing connection(s)

6.1602.180 Bottle adapter 21.

• Screw the 6.1838.000 FEP tubing connection(s)

thread(s) of 6.1602.190 Eluent bottle head.

14

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

20 from

20 to M6

Page 21

2.6 pH Controller

2 Install tubing connection to pH Controller

6.1838.010 FEP tubing connection should be used to make

the tubing connection to the pH Controller.

• Insert the black O-ring belonging to the 6.1838.010 FEP

tubing connection into an M6 thread of 6.1602.190 Eluent

bottle head.

• Then push the tip of the 6.1838.010 FEP tubing connection

through the O-Ring and M6 thread.

• Attach the 6.2726.090 Antidiffusion micro-valve to the tip of

the 6.1838.010 FEP tubing connection.

• Connect the other end of the 6.1838.010 FEP tubing connection to the pH Controller (see Instructions for Use –

Exchange Unit).

3 Screw on bottle adapter

• Now screw 6.1602.190 Eluent bottle head onto eluent bottle

22.

806

4 Insert the Aquatrode in the Eluent bottle head

• Insert 6.0257.020 Aquatrode into the large opening of the

6.1602.190 Eluent bottle head. Watch out, that the Aquatrode looms deep enough into the mixture when the pH is

measured.

2.6.2 pH Controller cable connection

The methods at the pH Controller are started via a remote signal from

the 845 Eluent Synthesizer (see Section

ler to the 845 Eluent Synthesizer as follows:

1 Connect Remote Box

• Connect the 6.2148.010 Remote Box to connection "Remote Box / MSB4"

2 Connect pH Controller

• Connect 6.2141.210 Cable to the remote output of

6.2148.010 Remote Box.

• Connect the end of the 6.2141.210 Cable marked A

remote input of the pH Controller.

• Connect the end of the 6.2141.210 Cable marked B

remote input of the second pH Controller.

The Metrohm 702 Titrino can be used with the SET method to set the

pH to a defined value (see the Instructions for Use of the corresponding Titrino).

3.3.3). Connect the pH Control-

15.

to the

to the

The method for the pH-adjustment and the corresponding parameters

have to be defined on the pH-Controller. The pH-adjustment is started

by a remote signal sent from the 845 Eluent Synthesizer to the pHController. For the installation and operation of the pH Controllers

please refer to the corresponding Instructions for Use.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

15

Page 22

3 «Mix Control» software

3 «Mix Control» software

The 845 Eluent Synthesizer is controlled with the «Mix Control» PC

software provided. This section explains the ideas behind the software

and how to use it. For further information please consult the online help

of the software.

3.1 Introduction to the software

3.1.1 The principle of «Mix Control»

What and how much is to be mixed in which ratio is defined via Depot

(see section

Components (see section

specified. The Method is the recipe for preparing the mixture.

3.1.2 Procedure after the first start of «Mix Control»

3.4.1) and Method (see section 3.3). In the Depot the

3.4.2) connected to the instrument are

1. Define the Users (see section 3.4.5).

2. Draw up and save the configuration for the Depot (see section

3.4.1).

3. Draw up and save a Method (see section

After carrying out these steps you can already start mixing processes

(with

In the next step you should define the settings for Directories, Re-

ports, Rinsing and GLP.

).

3.2 Main Window

3.2.1 Menus

Menu File

New... Method /

For creating and configuring a new Method. The parameters of the Method are set to the default values.

3.3).

New... Depot

For creating and configuring a new Depot. The DEPOT

window opens.

Save Method /

For saving the current Method under a new name.

Save Method as...

For saving the current Method under a new name.

16

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 23

3.2 Main Window

Open... Method /

For opening a saved Method (see section 3.3).

Open... Depot

For opening a saved Depot.

Print... /

For printing the current Method. The sections selected

in the

REPORT CONFIGURATION window (without the

Produced Composition section) get printed. No preview

is shown.

Print Preview...

Opens the print preview for the current Method (without the Produced Composition section). A printout can

be made directly from the preview.

Printer Configuration...

Opens the PRINTER window. In the PRINTER window

the printer settings can be adapted.

A Report of a previous mixing process can be printed

out via the

Logout... /

Logs out the User. The LOGIN window opens so that a

(active) User can log in.

Quit...

Closes the software.

Menu Configuration

Depot...

Opens the DEPOT window (see section 3.4.1).

System...

Opens the SYSTEM SETTINGS window (see section

3.4.3).

Report...

REPORT LIST window.

Opens the REPORT CONFIGURATION window (see sec-

3.4.4).

tion

User Admin...

Opens the USER ADMINISTRATION window (see section

3.4.5).

Rinsing...

Opens the RINSE window (see section 3.4.6).

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

17

Page 24

3 «Mix Control» software

Menu Extras

Sign Method...

Opens the SIGNATURE window (see section 3.5.1).

Audit trail...

Opens the AUDIT TRAIL window (see section 3.5.2).

Report...

Opens the REPORT LIST window (see section 3.5.3).

GLP Manager

Opens the GLP MANAGER window (see section 3.5.4).

Firmware Update

Opens the FIRMWARE UPDATE window (see section

3.5.5).

Service

Opens the LOGIN SERVICE window (see section 3.5.6).

Menu Help...

Help Topics...

Info

Opens the Online Help.

Opens the ABOUT window.

18

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 25

3.2 Main Window

3.2.2 Description of the symbols

/ New... Method

For creating and configuring a new Method. The parameters of the Method (see section

default values.

/ Open... Method

For opening a saved Method.

/ Save Method

Saves the current Method.

/ Print...

For printing the current Method. The sections selected

in the

REPORT CONFIGURATION window (without the

Produced Composition section) get printed. No preview

is shown.

3.3) are set to the

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

19

Page 26

3 «Mix Control» software

/ Logout...

Logs out the user. The LOGIN window opens so that an

(active) User can log in.

/ Start

Starts the mixing process.

/ Stop

Stops all actions.

/ Rinse

Starts the rinsing process.

To move the symbol strip, click on the dotted bar and move it to the

desired position. The position is saved.

3.3 Method

3.3.1 General information about methods

The method is configured and shown on the Main Page.

The method is the recipe for preparing the mixture. The amounts/concentrations and the

fined and saved in the method. The

the pH-adjustment are also saved with the method.

Number, names and units of the Components are specified in the

Depot.

The calculated volumes of the Components (except for Component 1

see section

used to fill up to the

3.3.2 Parameters

Current Method [ ]

Description [ ]

3.4.2) are added in succession. At the end Component 1 is

Total Volume of the mixture to be produced are de-

Total Volume.

Name of the currently loaded method.

Stirrer Speed and the settings for

Notes about the currently loaded method.

Component X [ ]

Components (see section 3.4.2) with names and units

(they correspond to the Components specified in the

loaded Depot).

20

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 27

3.3 Method

Total Volume mL [ 200...5000 ; 200 ]

Volume (in mL) to be prepared in the course of a mixing

process.

Changing the Total Volume does not affect the ratio

of the Components mixed. The numerical values of

the Components given with the (absolute) unit mL are

adapted automatically.

Stirrer Speed [ -15...15 ; 4 ]

Speed of the stirrer.

/

Switch on / switch off stirrer.

3.3.3 pH Adjustment

General information about pH adjustment

pH adjustment is always carried out after the main component has

been added (i.e. at the end of the mixing process).

For automatic pH adjustment 702 Titrinos from Metrohm are intended

for use. If the pH needs to be adjusted from both sides (without

changing the pH-Controller liquid), two 702 Titrinos are required as

pH-Controllers.

In the fields pH-Adjustment and pH-Controller define whether and how

the pH is to be adjusted.

If autonomous is selected for pH-Adjustment then none must not

be selected for pH-Controller. For autonomous a pH-Controller

must be used.

When starting the mixing process (by clicking on

the stirrer is always switched on.

Opens the window PH-ADJUSTMENT CONFIGURATION.

)

Window "pH-Adjustment Configuration"

The dialog window

by clicking on the button

In the

PH-ADJUSTMENT CONFIGURATION window the pH adjustment

PH-ADJUSTMENT CONFIGURATION can be opened

in the Main Window.

procedure can be defined.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

21

Page 28

3 «Mix Control» software

No [ 1 ; display only ]

Number of the Component (see section 3.4.2).

Component

Name of the Component.

pH-Adjustment

none

No pH adjustment will take place.

with request

pH adjustment will take place. It can be carried out

manually or automatically (702 Titrinos from Metrohm

are recommended). After pH adjustment the

PLAY

window opens in which the volume added for pH

LIVE DIS-

adjustment should be entered. This added volume is

taken into account in the volume calculations of the

mixing process.

The titration volume should be below 10 mL. Titration

volumes above 10 mL result in an increased Total

Volume.

autonomous

pH adjustment will take place. It will be carried out

automatically (702 Titrinos from Metrohm are recommended). A pH-Controller must be selected. The

added volume will not be taken into account in the

volume calculations of the mixing process.

pH-Controller (see section 2.6)

none

pH adjustment is carried out manually (must not be selected if

ment

pH-Controller A

autonomous has been selected for pH-Adjust-

).

The pH is adjusted with the instrument that is connected

with the cable end marked A (of the two-headed

6.2141.210 Cable).

pH-Controller B

The pH is adjusted with the instrument that is connected

with the cable end marked B (of the two-headed

6.2141.210 Cable).

22

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 29

3.4 Configuration

Details Of pH-Adjustment

Field for notes about the pH adjustment that can be included in the report (see section

3.4.4), e.g. set pH

value, solution used, etc.

3.3.4 Creating a method

There are 2 ways of creating a method:

• Editing an existing method and saving it under a new name

• Creating a completely new method (by clicking on

menu

File, New... Method)

Procedure for configuring a method:

1. Enter the

Total Volume to be produced.

2. For all Components (except for

3.4.2) enter the desired amount/concentration.

3. Enter the

Stirrer Speed.

4. If you want to adjust the pH: configure the pH-adjustment.

5. Save the method.

3.4 Configuration

3.4.1 Depot

General information about Depot

The dialog window

The Components (see section

need to be defined in the Depot. The numbers correspond to the numbers of the Component connections

or via the

Component 1, see section

DEPOT can be opened via Configuration, Depot....

3.4.2) connected to the instrument

5 on the instrument.

Window "Depot"

Define and describe each Component connected to the instrument

under the corresponding number. Save the Depot you have drawn up

as a

.meco file. The settings in the Depot must always be edited when

alterations are made to the connected Components.

The Methods (see section

loaded when they were drawn up. This means that overwriting an existing Depot influences the Methods that are based on this Depot.

In order for the mixing process to supply the desired result, the Com-

ponents specified in the Depot must correspond to the Components physically connected to the instrument. The concentrations/-

amounts defined in the Depot will be used for the volume calculations

in the Method.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

3.3) are based on the Depot that was

23

Page 30

3 «Mix Control» software

No. [ 1...5 ; display only ]

Number of the Component.

The number under which the components are defined here must be the same as that of the connection

(

5

) which the components are connected to.

Component [ Component name ]

Name of the Component (see section 3.4.2). You can

choose it from a selection list or enter it yourself.

Only Components with a defined Component name

are displayed in the Method part of the Main Window

(see section

3.3). If the Component name is deleted,

the Component is not displayed in the Method part

of the Main Window anymore (that does not apply for

Component 1, which can not be deleted ).

Concentration [ 1...20000 ; 0.0 ] (for unit mmol/L) ; [ 1...800000 ; 0.0 ]

(for unit mg/L)

Numerical value for concentration.

Unit [ mmol/L, mg/L, %, mL ;mmol/L ]

Unit for the given concentration/amount. This Component's unit will also be adopted in the Main Window.

Manufacturer [ Name of manufacturer ]

Name of the manufacturer of the Component. You can

choose it from a selection list or enter it yourself.

Date Of Expiry [ Date ; current date ]

Expiry date of the Component. If you click on the field

the Date window opens, in which you can select the required date. If the current date is later than one of the

defined expiry dates then a message will be shown at

the start of a mixing process.

Date Of First Use [ Date ; current date ]

Date of the first use of the Component. If you click on

the field the Date window opens, in which you can select

the required date.

24

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 31

3.4 Configuration

Note [ empty ]

Notes field for the Component (e.g. for pH information).

Max. 254 characters.

3.4.2 Components

General information about components

Components are defined in the Depot (see section

3.4.1) .

Components as related to the «Mix Control» software are the liquids

which are connected to the instrument.

Relationship Dosinos - Components

Dosinos form part of the instrument and are responsible for the accurate delivery of the particular volumes of the Components. They are attached to 50 mL Dosing Units.

Whether your instrument is equipped with one or two Dosinos depends

on the particular instrument version. Version 2.845.0010 has one Dosi-

no, Version 2.845.0020 two Dosinos.

The Component connected to connection 1 ("Component 1") is the

Main Component (in the case of two Dosinos, it is the Main Component for both Dosinos). After the end of an action (mixing or rinsing) the

Dosino is always filled with the Main Component (except after a rinsing process "Empty components" with activated Main Component:

the Dosino is then empty).

Dosino 1 Dosino 2

Main Component Component 1 Component 1

Further Components

Component 2 Component 4

Component 3 Component 5

The number of the component correspond to the number of the component connection

5.

For the work with version 2.845.0020:

If two Components - in addition to the Main Component - are used,

it is recommended to connect these two Components to the same

Dosino (Connections 2 and 3, or 4 and 5).

Main Component (Component 1)

The following conditions apply for the Main Component:

• In the Depot the

Component 1 must always be defined as it is

used (at the end of each mixing process) to fill to the

given in the Method (see section

• The volume calculated in the Method for

least 70 mL if one Dosino is used; with two Dosinos it must be at

least 140 mL.

3.3).

Component 1 must be at

Total Volume

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

25

Page 32

3 «Mix Control» software

3.4.3 System Settings

General information about system settings

Check the default folders. If you wish to use different folders then, in order to save the file in the required folder, enter the Depot (

Method (

format for exporting Reports (

.meme), the raw data of the prepared mixture (.meda) and the

.pdf or .xml). You can search through the

.meco), the

workplace by clicking on the

button.

Window "System Settings"

The dialog window

tion, System...

In the

SYSTEM SETTINGS window the directories are defined in which

SYSTEM SETTINGS can be opened via Configura-

.

the generated files are to be saved. The software

also set here.

dialog language is

Depot Directory [ ]

Directory for saving a Depot (see section 3.4.1).

Method Directory [ ]

Directory for saving a Method (see section 3.3).

Raw Data Directory [ ]

Directory for saving the data of a mixing process.

Export Directory [ ]

Directory for the Export of a Report (see section 3.5.3).

Dialog language [ English, German ]

Selects the language for the software interface. Any alteration to the language will only become effective for

the Main Window after the software has been restarted.

26

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 33

3.4 Configuration

3.4.4 Report Configuration

General information about report configuration

In the

REPORT CONFIGURATION window the settings for generating

the reports are defined.

Select everything that is to appear in the report. There are two predefined presentations (

Standard / Full Report). If you want to create your

report differently you can also select the sections individually (

ized

).

You should also define what is to be done with the data when the mixture has been prepared. You can print out the data automatically or ex-

port it as a PDF- or XML-file.

Window "Report Configuration"

The dialog window

figuration, Report...

REPORT CONFIGURATION can be opened via Con-

.

Custom-

Selection box [ Standard, Full Report, Customized ]

Standard

The sections

duced Composition

Full Report

Identification, Method, Depot and Pro-

are shown in the report.

All sections are shown in the report.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

27

Page 34

3 «Mix Control» software

Customized

The activated sections are shown in the report.

Identification

Information about User, report and program version.

Depot

Information about the Depot used (see section 3.4.1).

Method

Information about Method (see section 3.3), method parameters, concentrations/amounts.

Produced Composition

Information about the mixing process.

Hardware

Information about the hardware used.

GLP Data

Logo

Print Report

Preview

Information about GLP tests and service work to be

carried out (see section

3.5.4).

The selected logo will be shown at the top right of the

report.

Selects the logo graphics (possible file formats: .jpeg or

.gif). Clicking opens the OPEN window, in which the

workplace can be searched. After selection the logo will

be shown to the left of the button.

The report is printed out on the defined default-printer

(Windows: Start/Settings/Printer) as soon as the mixture

has been prepared (if Preview has been activated a

preview

is shown before printing takes place).

print

A print preview is shown before printing takes place.

Export Report As PDF

The report is exported as soon as the mixture has been

prepared as a PDF-file into the directory chosen below.

Export Report As XML

The report is exported as soon as the mixture has been

prepared as an XML-file into the directory chosen below.

28

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 35

3.4 Configuration

After the mixture has been prepared the mixture data is saved automatically as a .meda-file in the Raw data folder. If Export Report As

PDF/XML has been activated then it will also be saved in the corresponding file format in the Export Directory selected in the window

SYSTEM SETTINGS.

If you have not activated Print Report or Export Report As

PDF/XML the reports can still be printed out or exported as a PDF- or

XML-file later via the

REPORT LIST window (see section 3.5.3).

3.4.5 User Administration

Window "User Administration"

The dialog window

guration, User Admin...

In the

USER ADMINISTRATION window the users are defined and

USER ADMINISTRATION can be opened via Confi-

.

managed.

As long as no user has been defined the software can be opened

without Login. We recommend that the users are defined immediately after the software has been opened for the first time.

User

Short name of the user. This short name is always to

be entered when the User logs in.

Full Name

First or given name and last or family name of the user.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

29

Page 36

3 «Mix Control» software

Active

Only users set to "active" can log in.

Admin.-rights

Only Administrators have the following rights:

• Depot editing (see section

• System Settings editing (see section

• Report Configuration editing (see section

3.4.1)

3.4.3)

3.4.4)

• User administration

• Drawing up and saving methods (see section

3.4.6)

• Signing methods (see section

• Audit trail opening (see section

• GLP Manager opening (see section

• Firmware update (see section

3.5.1)

3.5.2)

3.5.4)

3.5.5)

Inserts a new line in the user table in which a new user

can be defined.

Prints a list with the selected (blue highlighted) users.

Opens the

PASSWORD window.

The button Password is only active, if at least one user with Administrator rights is defined and active.

Define user

After the software has been opened for the first time define an Administrator as the first user:

1. Click on

2. Enter the

3. Activate

4. Click on [OK]. The

User and Full name.

Active and Admin.-rights.

LOGIN window opens.

5. Enter the previously defined User. Leave the

. A new line will be shown.

Password field

empty.

6. Now edit the password. Click on

PASSWORD

window opens.

. The CHANGE

7. Leave the

word under

[OK]. A return is now made to the

30

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Old Password field empty. Enter the required pass-

New Password and Confirm Passw..., and click on

LOGIN window.

Page 37

3.4 Configuration

8. Enter the previously selected password under Password and click

on [OK].

After the definition of the first user there must always be at least one

user with Administrator rights who is active.

Now (or later as necessary) define new users (with or without Administrator rights).

1. Open the

USER ADMINISTRATION window.

2. Click on

3. Enter the

User and Full Name.

4. When necessary, activate

5. Click on [OK].

The defined users can set their Passwords after they log in for the

first time.

Define if a password is required for login.

1. Click on

PASSWORD window appears.

The

2. Define if a password is required for login.

3. Define password expiry period.

Password

. A new line will be shown.

Active and Admin.-rights.

.

In the

PASSWORD window, the administrator defines whether a pass-

word is required for login.

Additionally, if a password is required for login, the administrator can

set an expiry period for the password.

This setting applies to all users and administrators.

Login with password

Login is only possible with a valid password.

At next login, a password must be created in the

CHANGE PASSWORD window.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

31

Page 38

3 «Mix Control» software

Password expires every ... days

Password expires every [365] days.

Selection box

1...[365]...999

Expiry period of the password.

If the password expires, the user/administrator will receive a message

reminding him to change the password.

Login

The

LOGIN window appears when the software is started (provided that

at least one User has already been defined), as well as for the definition of the first User (the first defined user must be an Administrator).

Login:

Enter the

User and Password and click on [OK].

Change password:

Click on

32

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

. The CHANGE PASSWORD window opens.

Page 39

3.4 Configuration

Change Password

The

CHANGE PASSWORD window opens when the but-

ton is clicked on in the

LOGIN window.

Proceed as follows to change the password:

3.4.6 Rinse

General information about rinse

Window "Rinse"

1. Enter your password under

Old Password.

2. Enter your new password under

Password

.

3. Click on [OK].

In the

RINSE window the rinsing process is defined (the rinsing pro-

cess is triggered by clicking on the

Decide which

components

mode is to be used - Prepare components or Empty

- and for which Component(s) the rinsing process is to

be carried out.

The dialog window

RINSE can be opened via Configuration, Rinsing....

New Password and Confirm

button in the Main Window).

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

33

Page 40

3 «Mix Control» software

Mode

Economy

Component X

Prepare components

The

mode "Prepare components" is used in the rinsing

process.

Empty components

The

mode "Empty components" is used in the rinsing

process.

If Economy has been activated then the Dosino contents

(is always the Main Component, after an action has

been completed) will be ejected into the component

container at the start of the rinsing process. If

my

has not been activated then the Dosino contents will

Econo-

be ejected in the usual way and can be collected in a

waste container.

Economy is intended for circumstances in which the

Main Component has to be used very sparingly.

The Components (see section 3.4.2) configured in the

Depot (see section

3.4.1) are listed. The rinsing process

is always carried out for those Component(s) that have

been set as

active.

Rinsing Mode "Empty components""

The rinsing mode "

window under the parameter

What effect has a rinsing process with

34

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Empty components" can be selected in the RINSE

Mode.

Mode "Empty components"?

Page 41

3.4 Configuration

Dosino(s) and component tubing (of the activated

Components) are emptied.

When should a rinsing process with

Mode "Empty components" be

carried out?

• When the instrument is not to be used for a long time (in

this case: activate all Components).

• When a Component is to be removed (in this case: only

activate the particular Component).

How is a rinsing process with

Mode "Empty components" trig-

gered?

1. Configure: in the Rinse window set the parameter

to

Empty components. Select the Components whose

tubing is to be emptied.

2. Start: the rinsing process is started in the Main Window

by clicking on the

button.

What happens during a rinsing process with

nents

"?

Before the start of the rinsing process disconnect all

24

Component connections

Component) from the instrument.

(except those of the Main

Mode

Mode "Empty compo-

1. The cylinder(s) of the Dosino(s) is/are completely emptied.

If in the

RINSE window the parameter Economy has

been activated then the Dosino contents will be

ejected into the component container of the Main

Component.

2. For each of the activated Components (except the

Main Component(s)) 10 mL air will be drawn in and the

Dosing unit emptied. That is done in order to empty the

tubing connections inside the instrument.

3. The Dosino(s) is/are rinsed with the Main Component.

If you have also activated the Main Component:

4. Disconnect the Main Component from the instrument.

5. From the Main Component 10 mL (per Dosino) will be

drawn in and the Dosing unit emptied. That is done in

order to empty the tubing connections inside the instrument.

"Rinsing Mode "Prepare components"

The rinsing mode "

window under the parameter

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Prepare components" can be selected in the RINSE

Mode.

35

Page 42

3 «Mix Control» software

What effect has a rinsing process with Mode "Prepare compo-

nents

"?

Air bubbles are removed by rinsing Dosino(s) and

component tubing (from the activated Components)

(see section

3.4.2).

When should a rinsing process with

be carried out?

We recommend that such a rinsing process is carried

out at least once per day, as well as each time that a

new Component has been added. Removal of air

bubbles increases the mixing accuracy.

How is a rinsing process with

Modus "Prepare components" trig-

gered?

1. Configure: in the

Prepare components. Select the Components to be

to

RINSE window set the parameter Mode

"prepared".

2. Start: the rinsing process is started in the Main Win-

dow by clicking on the

How does a rinsing process with

proceed?

1. The cylinder(s) of the Dosino(s) is/are completely emp-

tied.

If in the

RINSE window the parameter Economy is ac-

tivated then the Dosino contents will be ejected into

the component container of the Main Component.

Modus "Prepare components"

button.

Modus "Prepare components"

3.5 Extras

3.5.1 Sign methods

The dialog window SIGNATURE can be opened via Extras, Sign

Method...

In the

Enter your

reason for signing the method and click on [OK].

(only when you are logged in as Administrator).

SIGNATURE window the current Method can be signed.

2. From each of the activated Components 10 mL will be

drawn in and ejected in succession.

3. At the end the Dosino(s) will be refilled with the Main

Component.

user name and your password (see section 3.4.5), select a

36

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 43

3.5 Extras

User

Enter User name. You can also enter a user name that is

different from the currently logged in User. Prerequirement: the user is active and has Administrator rights.

Password

Reason [ Selection of standard reasons ]

Comment [ 255 Characters ]

If you change a method and save it, the signature is deleted.

3.5.2 Audit trail

The term Audit trail is used for the protocol of all user actions that

generate, edit or delete data. Each of these actions is saved as a line in

the Audit trail table together with the date, time and name of the

logged-in user.

Window "Audit trail"

AUDIT TRAIL window can be opened via Extras, Audit trail....

The

Enter the password.

Give the reason for signing the method.

Notes about the signature.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

37

Page 44

3 «Mix Control» software

Table headers:

No

Icon

Date

User

Number of the Audit trail entry.

Information about an action that is neither safety-relevant

nor altered any data.

Information about an action that is safety-relevant or with

which data has been altered.

Information about a fault or incorrect action.

Date and time of the action.

Short name of logged-in user.

Category

Program part to which the action belongs.

Action

Short description of the action.

Details

Detailed information about the action.

38

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 45

3.5 Extras

Available operations:

File, Export

Exports the Audit trail entries. The folder into which the

Audit trail entries are to be exported can be entered in

the Export window that now opens. With a search of

the workplace can be made.

File, Open

Views an Audit trail file (Log.madt).

In order to save the Audit trail file (Log.madt) a copy

must be generated via a Windows Explorer (..\Mix Control\Data).

File, Delete

Deletes all entries in the Audit trail table. Can only be

carried out when no new entries have been added after

the last Export.

File, Exit

Closes the Audit trail window.

Filter, Quick filter /

Filters the Audit trail table according to selectable criteria.

Select filter criteria:

1. Use the left-hand mouse key to click in a field

whose entry you want to use as a filter criterion,

e.g. "System":

2. Click on

The quick filter can be used again within the filtered

table so that the number of entries can be reduced

step by step.

Filter, Show all /

.

.

Cancels the Quick filter function. All Audit trail entries

are shown.

3.5.3 Window "Report List"

The REPORT LIST window can be opened via Extras, Report List....

REPORT LIST window the data of all prepared mixtures is shown.

In the

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

39

Page 46

3 «Mix Control» software

Date/Time

Method

Depot

Description

User

Date and time at which the mixture was prepared.

Name of the Method used for preparing the mixture (see

section

3.3).

Name of the Depot used for preparing the mixture (see

section

3.4.1).

Text that was entered in the Description field in the Main

Page when the mixture was prepared.

Short name of the User logged in when the mixture was

prepared.

Prints out the marked, or all (if none have been marked)

entries in the

report list.

Prints the marked Reports.

40

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 47

3.5 Extras

Exports the marked Reports as Pdf-files to the directory

defined in the

Export Directory, see section 3.4.3.

SYSTEM SETTINGS window (parameter

Exports marked Reports as XML-files to the directory defined in the

port Directory

SYSTEM SETTINGS window (parameter Ex-

).

3.5.4 GLP Manager

The dialog window GLP MANAGER can be opened via Extras, GLP

Manager

GLP validations and service work that have been carried out are en-

tered in the

The date of each validation/service work should be entered in the

GLP MANAGER window. In addition, the date for the next validation or

next service should also be entered.

.

GLP MANAGER window.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

41

Page 48

3 «Mix Control» software

Validation:

Method

Information about the Method (see section 3.3) used for

the validation. With

the workplace can be searched

through for Methods.

User

Information about the logged-in User when validation

was carried out.

SOP

Possibility of entering an SOP (Standard Operation

Procedure) name or number.

Date Of Last Test

Date of last validation.

42

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 49

3.5 Extras

Test Result [ No Test Accomplished Yet, Test OK, Test not OK ]

Information about the result of the last validation.

Note

Notes about the last validation.

Date Of Next Test

Date for the next validation.

Display Message

If activated: if the current date is later than the date given

for

Date Of Next Test then a message will be shown at

the start of a mixing process.

Service:

Date Of Last Service

Information about date of last service.

Service-Status [No Service Accomplished Yet, Service Accomplished]

Shows whether a service has been carried out.

Note

Notes about the last service.

Date Of Next Service

Date for the next service.

Display Message

If activated: if the current date is later than the date given

for the

shown at the start of a mixing process.

3.5.5 Firmware Update

The FIRMWARE UPDATE window can be opened via Extras, Firmware

Update

Via the

copied to the instrument.

.

FIRMWARE UPDATE window a current Firmware version can be

Date Of Next Service then a message will be

In order to update the instrument Firmware you should first select the

file for the

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Binary-File Path parameter that contains the current Firm-

43

Page 50

3 «Mix Control» software

ware. With you can search through the workplace. Then click on

in order to start Firmware updating.

3.5.6 Login Service

The service section of the software can be accessed via the LOGIN

SERVICE

should carry out work in the service section. It is protected by a special

service password.

window. Only service technicians from a Metrohm agency

44

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 51

4.1 Care

4 Maintenance - Troubleshooting

4.1 Care

The 845 Eluent Synthesizer requires adequate care. If it becomes excessively dirty then this could interfere with its functions and shorten the

working life of its robust mechanism and electronics.

Spilt chemicals and solvents must be wiped up immediately. The electrical connections on the rear panel of the instrument should be protected against contamination.

If aggressive media penetrate into the interior of the instrument the

mains plug should be pulled out immediately to prevent massive

damage to the electronics. If such damage does occur then please

contact Metrohm Service.

4.1.1 Decommissioning

Proceed as follows, if the instrument is not to be used for a long time:

1. Connect water to all component connections (

2. Carry out a rinsing process in the "

components should be activated for the rinsing process (see Section

3.4.6).

4.2 Dosing units

Depending on the version, the 845 Eluent Synthesizer has either one

(Version 2.845.0010) or two (Version 2.845.0020) 807 Dosing units

(each with a 50 mL glass cylinder). These are located inside the instrument, screwed onto a pull-out drawer. Each dosing unit is controlled by

an 800 Dosino.

Depending on the solutions used, the dosing units should be cleaned

every 6 to 12 months.

4.2.1 Deinstallation

In order to clean a Dosino it must first be removed from the 845 Eluent

Synthesizer.

5).

Empty components" mode. All

The procedure for deinstallation of the Dosino is as follows:

1 Empty instrument

• Use the «Mix Control» software to carry out a rinsing process in the "Empty components" mode (make sure that all

components have been activated in the RINSE window, see

Section 3.4.6).

2 Remove rear panel

• Remove rear panel 19 by using a screwdriver.

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

45

Page 52

4 Maintenance - Troubleshooting

3 Screw off tubing connections

• Screw off all tubing connections from the dosing unit.

4 Loosen attachment

• Loosen thread adapter 26 while holding the dosing unit/Dosino in your other hand.

• Also remove holder plate

27.

25

26

27

28

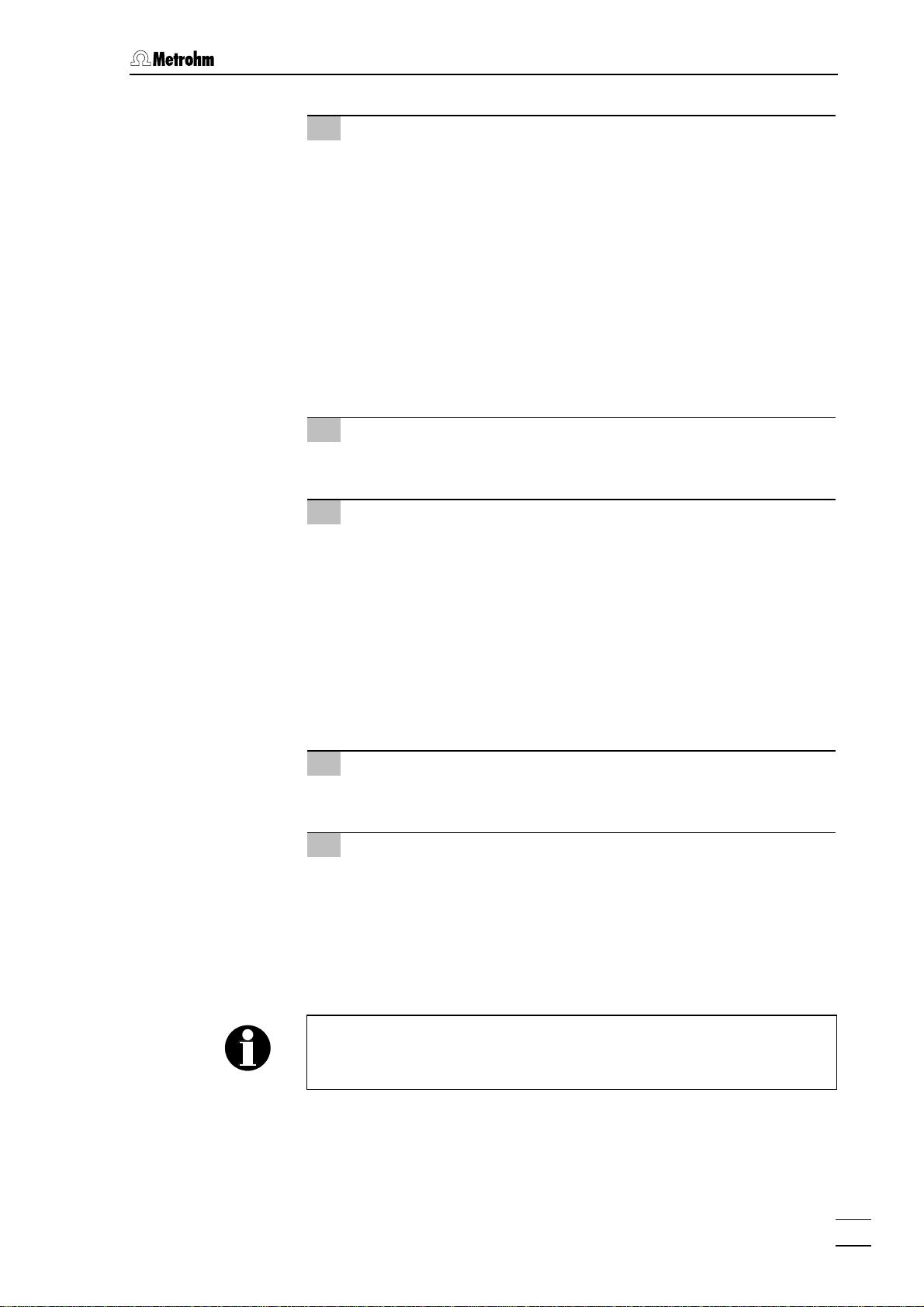

Figure 5: Dosing unit attachment

Distance ring

25

Thread adapter

26

Holder plate

27

For attaching the tubing connections to

port 2 and 4

4.2.2 Cleaning

Cleaning the 807 Dosing unit is described in the 8.807.1008 Instructions

for Use – 807 Dosing unit, Section 6.

Slip-on nipple

28

For connecting component 1 to port 4

46

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 53

4.2 Dosing units

4.2.3 Installation

After cleaning the dosing units should be reinstalled together with the

Dosinos.

Diagram showing connections with one Dosino:

(Dosing unit seen from below)

4

29

30

Figure 6: Connections with one Dosino

Component connection strip

29

Dosing unit (from below)

30

4 Dosino 1 outlet

Outlet for component to be added

(from Dosino 1).

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

47

Page 54

4 Maintenance - Troubleshooting

Diagram showing connections with two Dosinos:

(Dosing units seen from below)

Figure 7: Connections with two Dosinos

29 Component connection strip

30 Dosing unit from Dosino 1 (from

below)

Dosing unit from Dosino 2 (from

31

below)

T-piece for component 1

32

For connecting the main component

(see Section

3.4.2)

4 Dosino 1 outlet

Outlet for the component to be added

from Dosino 1.

7 Dosino 2 outlet

Outlet for the component to be added

from Dosino 2.

48

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

Page 55

4.3 Troubleshooting

4.3 Troubleshooting

Problem Cause Remedy

Liquids escaping from

drainage tubing or

from bottom of rear

panel.

Components are not

aspirated.

LED "Power" (1) does

not light up when instrument is connected.

Instrument not recognized at software startup (LED "Power" (

lights up)

1)

• Leaking connections

• Leak in instrument

• Leaking or blocked con-

nections

• Dosing units/Dosinos

defect

• Mains cable defect

• Internal power supply

defect

• Instrument not connected to USB

• USB cable defect

1. Stop the current process

2. Remove rear panel

check the connections and dosing units (see Section

1. Stop the current process

2. Check the connections outside

the instrument

3. Remove rear panel

check the connections and Dosinos/Dosing units (see Section

4.2)

• Replace the mains cable

• Contact Metrohm Service

• Connect instrument to USB of

the PC (see Section

• Replace USB cable

19 and

4.2)

19 and

2.3)

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

49

Page 56

5 Annex

5 Annex

5.1 Technical data

5.1.1 Interfaces

USB-connections

USB ports 2 USB downstream ports (type A sockets), each 500

mA, for connecting USB devices.

Controller connection

Controller port USB upstream port with additional signals (mini-DIN

socket) for connecting a computer to control the instrument (with 6.2151.000 Cable).

MSB-connections (MSB = Metrohm Serial Bus)

MSB1 Dosino For connecting Dosino 1

MSB2 Dosino For connecting Dosino 2 (if present)

MSB3 Stirrer Connection for built-in stirrer

Stirrer control: switched on/off via «Mix Control» software

(manual or in method).

Selectable speed (15 steps) and direction of rotation.

MSB4 Remote Box For connecting 6.2148.010 Remote-Box for automatic

pH adjustment (see Section

Remote boxes are used to address and control external

devices.

5.1.2 Mains connection

Voltage

Frequency

Power consumption

Fuse

100...240 V (± 10%)

50...60 Hz

max. 45 W

electronic overload protection

5.1.3 Safety specifications

Construction and testing As per EN/IEC/UL 61010-1, CSA 22.2 No. 61010-1 pro-

tection class 1

Safety information These instructions contain safety information that must

be observed by the user in order to guarantee the safe

operation of the instrument.

2.6).

5.1.4 Electromagnetic compatibility (EMC)

Emission Standards complied with:

- EN/IEC 61326

- EN 55022 / CISPR 22

Immunity Standards complied with:

- EN/IEC 61326

845 Eluent Synthesizer / Instructions for Use 8.845.1003

50

Page 57

5.1 Technical data

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-11

- EN/IEC 61000-4-14

5.1.5 Ambient temperature

Nominal working range

Automatic inner temperature

monitoring

Storage

Transport

5.1.6 Dosing drive

Resolution

Dosing/Filling rates

5.1.7 Dosing Unit

Volumes of cylinders

Chemical resistance of the

PETG housing

+5 C...+45 C (at max. 85% relative humidity)

> 70°C initial alarm

> 75°C alarm

–20°C...+60 °C

–40°C...+60 °C

10'000 increments per cylinder volume

18 seconds each per cylinder volume

50 mL

Good resistance to:

aqueous solutions, dilute acids, alcohols and hydrocarbons

Limited resistance to:

conc. organic acids, dilute aqueous alkalis (stress

cracks), acetone, isopropanol, tetrahydrofuran, hot

water

Not resistant to:

concentrated inorganic acids and bases, bromine,

chlorinated solvents, phenol, water vapor >100 °C

5.1.8 Reference conditions

Ambient temperature

Relative humidity

Instrument status

+25 °C (±3 °C)

≤ 60%

In operation for at least 30 min

5.1.9 Dimensions

Housing material Polyurethane

Width

Height

Depth

Weight

2.844.0010

2.844.0020

845 Eluent Synthesizer / Instructions for Use 8.845. 8001EN

314 mm

378 mm

280mm

6920 g

7639 g

51

Page 58

5 Annex

5.2 Standard equipment

Subject to changes!

All dimensions are given in mm.

The 845 Eluent Synthesizer is available in the following versions:

• 2.845.0010 845 Eluent Synthesizer with 1 Dosino

• 2.845.0020 845 Eluent Synthesizer with 2 Dosinos

5.2.1 Standard equipment for 2.845.0010

The following parts are supplied under the order number 2.845.0010:

Quantity Order no. Description

1 1.845.0010 Eluent Synthesizer with 1 Dosino

1 6.1546.030 Piston rod

For PTFE piston of Dosing Unit

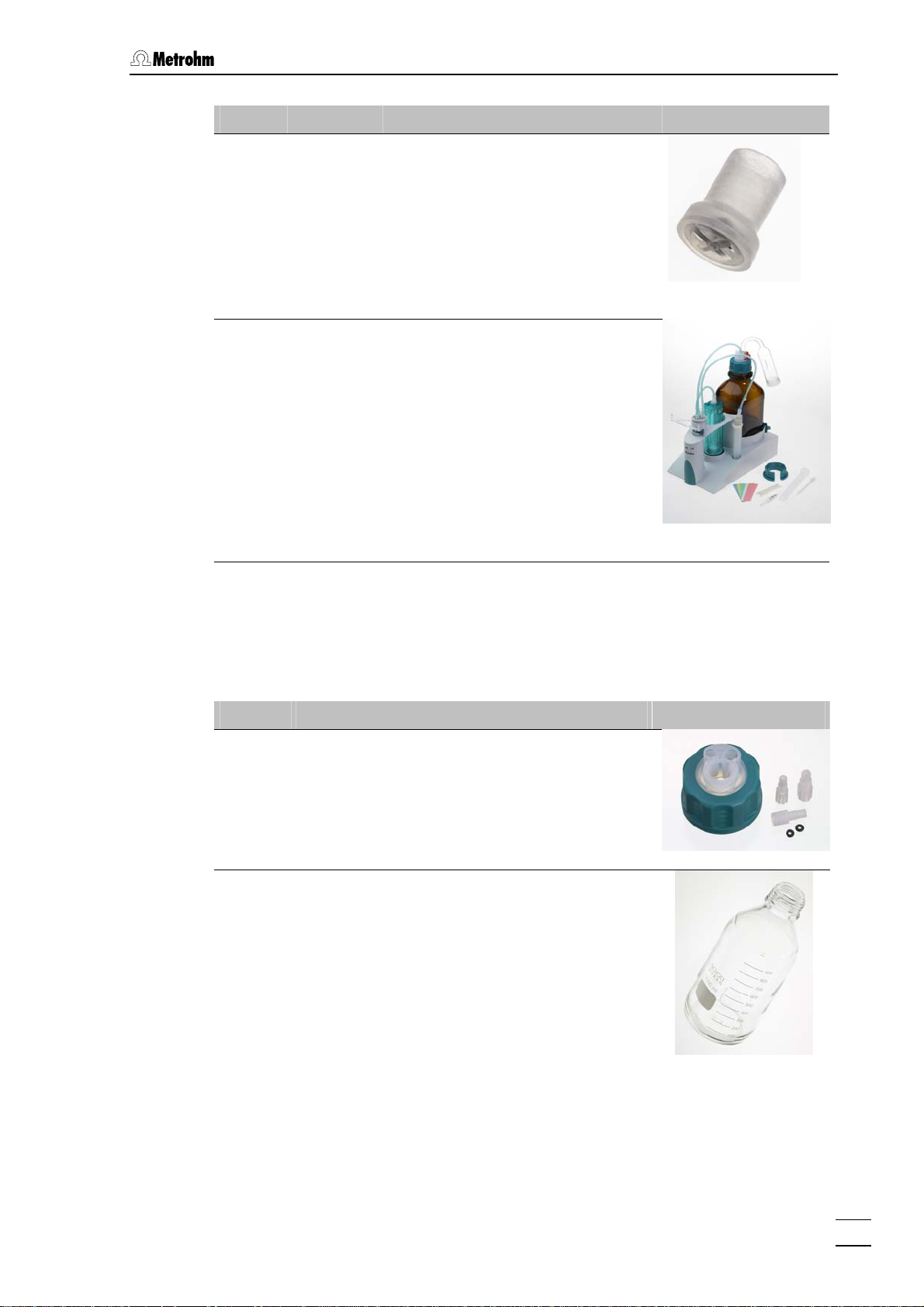

1 6.1602.180 Bottle Adaptor to 845

Adaptor to the eluent bottle of the Eluent Synthesizer without pH adjustment

1 6.1608.070 Eluent bottle / 2 L / GL 45

Material Clear glass

Height (mm) 262

Volume in mL 2000