Page 1

844 UV/VIS Compact IC

Manual

8.844.1053

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

844 UV/VIS Compact IC

Manual

8.844.1053 03.2008 chs

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

Table of contents

Table of contents

1 Introduction ................................................................ 1

1.1 Instrument description ................................................................................1

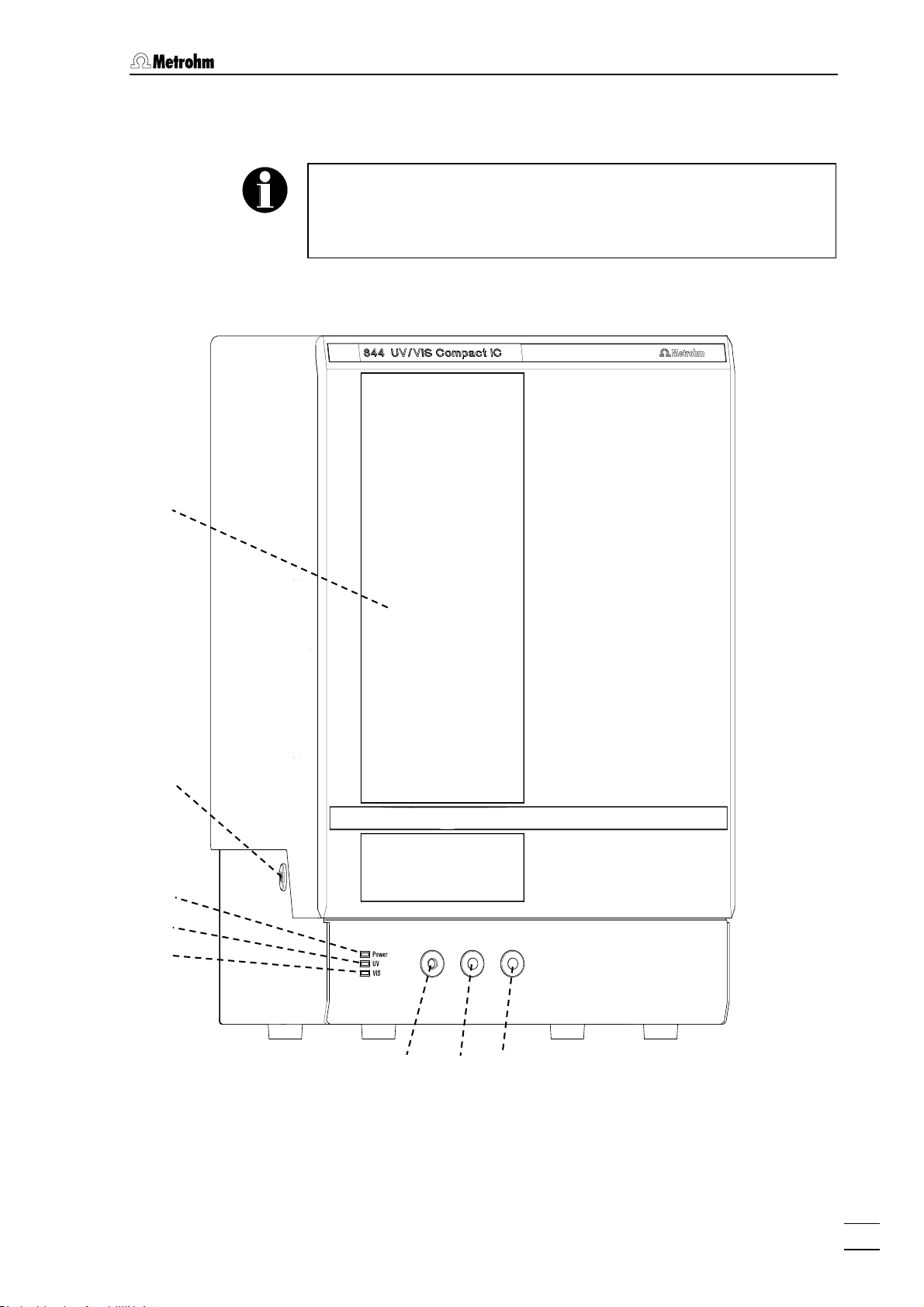

1.2 Parts and controls .......................................................................................3

1.2.1 Front.................................................................................................................... 3

1.2.2 Rear panel .......................................................................................................... 5

1.2.3 Interior PEEK versions ........................................................................................ 7

1.2.4 Interior Steel versions .........................................................................................9

1.3 Information on the Instructions for Use ...................................................11

1.3.1 Organization .....................................................................................................11

1.3.2 Notation and pictograms.................................................................................. 12

1.4 Safety notes ...............................................................................................13

1.4.1 Electrical safety................................................................................................. 13

1.4.2 General precautionary rules ............................................................................. 13

1.4.3 Recycling and disposal .................................................................................... 13

2 Installation ............................................................... 14

2.1 Overview ....................................................................................................14

2.1.1 Flow chart ......................................................................................................... 14

2.1.2 Connections in the 844 UV/VIS Compact IC.................................................... 15

2.2 Setting up the instrument..........................................................................20

2.2.1 Packaging.........................................................................................................20

2.2.2 Check................................................................................................................ 20

2.2.3 Location ............................................................................................................ 21

2.3 Attaching the accessories.........................................................................21

2.3.1 Connecting the syringe and aspirating tubing................................................. 21

2.3.2 Connecting the drainage tubing for the inner compartment ........................... 21

2.3.3 Connecting PEEK capillaries............................................................................ 21

2.3.4 Connecting Steel capillaries.............................................................................22

2.3.5 Filter unit PEEK ................................................................................................. 23

2.3.6 Filter unit Steel .................................................................................................. 24

2.4 Mains connection ......................................................................................25

2.4.1 Setting the mains voltage................................................................................. 25

2.4.2 Fuses ................................................................................................................ 26

2.4.3 Mains cable and mains connection ................................................................. 26

2.4.4 On/off switching of the instrument ...................................................................27

2.5 Connection to PC ......................................................................................27

2.5.1 Connecting cable .............................................................................................27

2.5.2 Software installation.......................................................................................... 27

2.5.3 First Login ......................................................................................................... 28

2.5.4 Create a system ............................................................................................... 28

2.6 High-pressure pump .................................................................................29

2.6.1 Removing the transport security screws.......................................................... 29

2.6.2 Installing the pulsation dampener.................................................................... 29

2.6.3 Connecting the eluent bottle ............................................................................ 31

2.6.4 Deaerating the pump and rinsing the pulsation dampener............................. 32

2.7 Post column reactor ..................................................................................34

2.7.1 Preparing the peristaltic pump......................................................................... 34

2.7.2 Installation of the post column reactor............................................................. 36

2.7.3 Post column reactor tubing connections ......................................................... 37

2.7.4 Reagent bottle connection ............................................................................... 38

2.8 Columns.....................................................................................................39

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

I

Page 6

Table of contents

2.8.1 Precolumns ...................................................................................................... 39

2.8.2 General information on separating columns ................................................... 40

2.8.3 Connecting the separating column (installation without column heating) ...... 41

2.8.4 Connecting the separating column (installation with column heating) ........... 43

2.9 Detector......................................................................................................48

2.9.1 Installing the flow-through cell ......................................................................... 48

2.9.2 Connect the lamps........................................................................................... 49

2.9.3 Flow-through cell tubing connections.............................................................. 49

2.10 Putting into operation................................................................................50

2.10.1 Putting into operation without post column reactor......................................... 50

2.10.2 Putting into operation with post column reactor.............................................. 52

2.11 Connection of external devices ................................................................55

2.11.1 Connection of the 838 Advanced Sample Processor ..................................... 55

2.11.2 Connection of the 813 Compact Autosampler ................................................ 57

3 Operation .................................................................. 59

3.1 «IC Net» - Terms.........................................................................................59

3.2 Measuring operation .................................................................................59

3.2.1 Opening a system ............................................................................................ 59

3.2.2 Defining measuring channels .......................................................................... 60

3.2.3 Connect a system ............................................................................................ 61

3.2.4 Instrument icon................................................................................................. 62

3.2.5 Hardware start/stop and baseline recording ................................................... 62

3.2.6 Determination start/stop................................................................................... 62

3.3 Settings ......................................................................................................63

3.3.1 Instrument control for connected system ........................................................ 63

3.3.2 Hardware settings ............................................................................................ 70

3.3.3 Spectrum window............................................................................................. 74

4 Notes - Maintenance - Faults ................................... 77

4.1 Practical notes on ion chromatography ...................................................77

4.1.1 Separating columns ......................................................................................... 77

4.1.2 High-pressure pump ........................................................................................ 78

4.1.3 Eluents.............................................................................................................. 78

4.1.4 Peristaltic pump................................................................................................ 79

4.1.5 Connections ..................................................................................................... 79

4.2 Maintenance and servicing .......................................................................80

4.2.1 General information.......................................................................................... 80

4.2.2 Shutdown ......................................................................................................... 80

4.2.3 Changing separating columns......................................................................... 80

4.2.4 Maintenance work at the pump head .............................................................. 82

4.2.5 Replacing the pump tubing ............................................................................. 86

4.2.6 Replacing the UV lamp .................................................................................... 87

4.3 Faults and malfunctions............................................................................89

4.3.1 Error messages ................................................................................................ 89

4.3.2 Malfunctions and their rectification .................................................................. 89

4.4 Quality Management and validation with Metrohm .................................91

5 Appendix ................................................................... 92

5.1 Technical data............................................................................................92

5.1.1 UV/VIS Detector................................................................................................ 92

5.1.2 Injection valve................................................................................................... 93

5.1.3 High-pressure pump ........................................................................................ 93

5.1.4 Peristaltic pump................................................................................................ 94

5.1.5 Leak detector ................................................................................................... 94

Page 7

Table of contents

5.1.6 Gas Sensor....................................................................................................... 94

5.1.7 RS232 interface ................................................................................................ 94

5.1.8 Remote interface .............................................................................................. 95

5.1.9 Mains connection ............................................................................................. 95

5.1.10 Analog output ...................................................................................................96

5.1.11 Control input .....................................................................................................96

5.1.12 Safety specifications......................................................................................... 96

5.1.13 Electromagnetic compatibility (EMC)............................................................... 96

5.1.14 Temperature control column heating ............................................................... 97

5.1.15 Ambient temperature........................................................................................ 97

5.1.16 Housing ............................................................................................................ 97

5.2 Standard equipment..................................................................................98

5.2.1 PEEK versions .................................................................................................. 98

5.2.2 Steel versions ................................................................................................. 103

5.3 Optional accessories ..............................................................................107

5.3.1 General accessories....................................................................................... 107

5.3.2 High-pressure pump ...................................................................................... 108

5.3.3 High-pressure pump Steel ............................................................................. 109

5.3.4 Separating columns and precolumns............................................................ 110

5.3.5 Communication .............................................................................................. 111

5.3.6 Lamps............................................................................................................. 111

5.4 Warranty and Conformity........................................................................112

5.4.1 Warranty (guarantee)...................................................................................... 112

5.4.2 Declaration of Conformity............................................................................... 113

5.4.3 Quality Management Principles ..................................................................... 114

5.5 Index.........................................................................................................115

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

III

Page 8

Table of contents

List of figures

Figure 1: Front 844 UV/VIS Compact IC................................................................... 3

Figure 2: Rear 844 UV/VIS Compact IC.................................................................... 5

Figure 3: Interior PEEK versions ............................................................................... 7

Figure 4: Interior Steel Versions................................................................................ 9

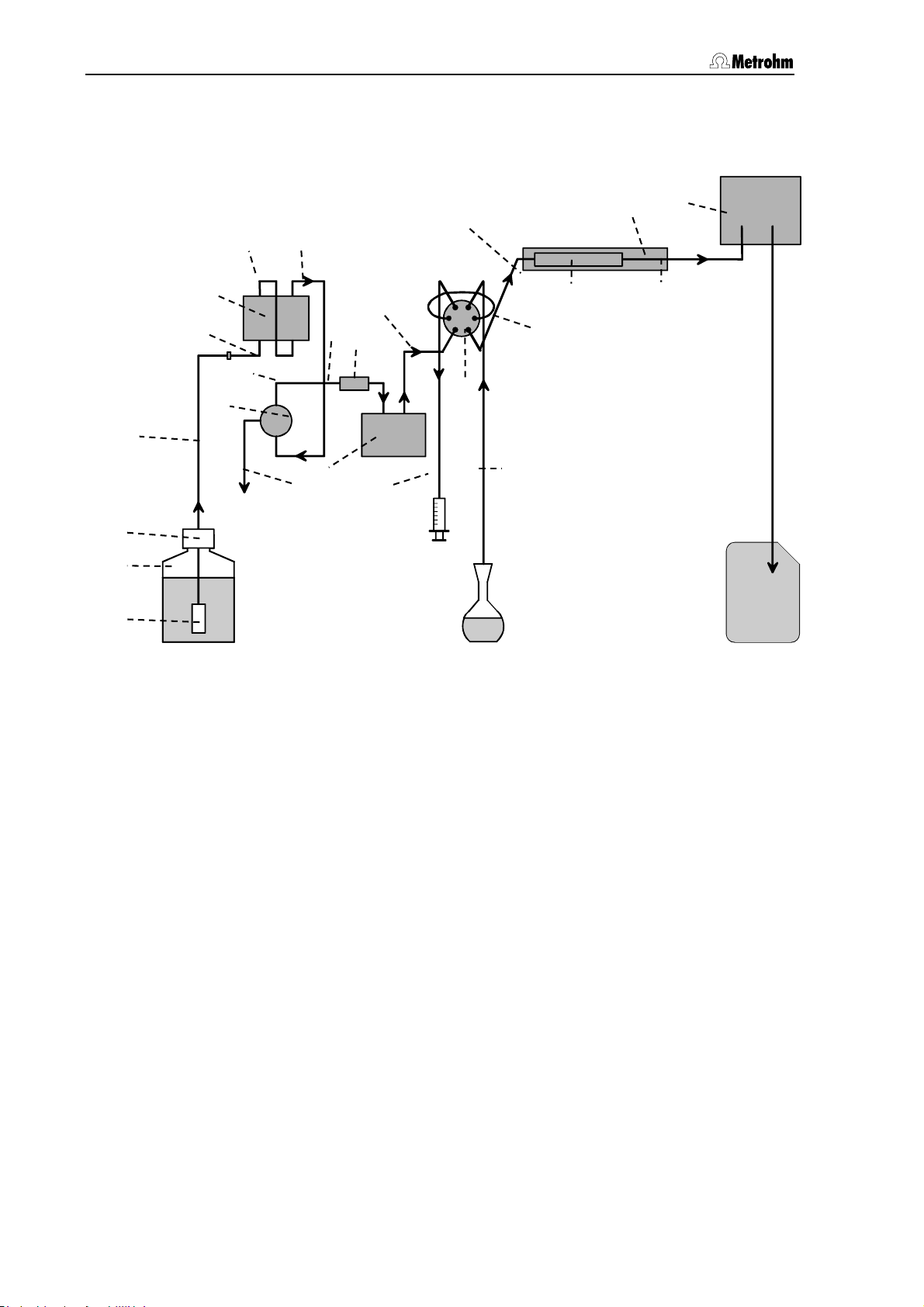

Figure 5: Connecting diagram for 844 UV/VIS Compact IC 2.844.0010 ................ 15

Figure 6: Connecting diagram for 844 UV/VIS Compact IC 2.844.0020 with

Post column reactor ................................................................................

Figure 7: Connecting diagram for 844 UV/VIS Compact IC 2.844.0030 ................ 17

Figure 8: Connecting diagram for 844 UV/VIS Compact IC 2.844.0110 with

Column heating .......................................................................................

Figure 9: Connecting diagram for 844 UV/VIS Compact IC 2.844.0120 with

Post column reactor and Column heating ..............................................

Figure 10: Connecting diagram for 844 UV/VIS Compact IC 2.844.0130 with

Column heating .......................................................................................

Figure 11: Connectors for Steel capillaries............................................................... 23

Figure 12: 6.2821.120 Filter unit PEEK ..................................................................... 24

Figure 13: 6.2620.180 Filter unit Steel ...................................................................... 24

Figure 14: Setting the mains voltage........................................................................ 26

Figure 15: Connection of the pulsation dampener................................................... 30

Figure 16: Connection of eluent bottle ..................................................................... 32

Figure 17: Installing pump tubings ........................................................................... 35

Figure 18: Attaching the post column reactor .......................................................... 37

Figure 19: Post column reactor ................................................................................ 38

Figure 20: Connection of reagent............................................................................. 39

Figure 21: Column connection without column heating........................................... 42

Figure 22: Column heating (closed) ......................................................................... 43

Figure 23: Diagram showing separating column in column heating........................ 44

Figure 24: Installing the column heating................................................................... 47

Figure 25: Flow-through cell installation................................................................... 48

Figure 26: Components of the pump head .............................................................. 83

Figure 27: Replacement of the piston seal 140 ....................................................... 84

Figure 28: Components of inlet valve 141 and outlet valve 142............................. 86

Figure 29: UV lamp (deuterium) ............................................................................... 88

Figure 30: Lamp connections (at the back of the 844 UV/VIS Compact IC) ............ 88

16

18

19

20

Page 9

Table of contents

List of numbered parts and controls

1 Door to inner compartment

34 Filter unit PEEK

2 Feedthrough

3 LED "Power"

4 LED "UV"

5 LED "VIS"

6 Connection purge valve

7 Connection for syringe

8 Feedthrough

9 Lamp cooling housing

10 VIS lamp connection

11 UV lamp connection cable

12 UV lamp connection

13 VIS lamp connection cable

14 Analog output

15 Control input

16 USB-B connection

17 USB-A connection

18 RS232 interface

19 Transport security screws

20 Mains switch

21 Mains connection plug

22 Fuse holder

23 Remote interface

24 Connection capillary

25 Connection capillary

26 Magnetic mounting rail for column

heating

27 Pump head

28 Fastening screws

29 Connection capillary

30 Aspirating capillary

31 Connection capillary purge valve

32 Purge valve

33 Connection capillary to syringe

35 Connection capillary

36 Pulsation dampener

37 Leak detector

38 Inlet capillary

39 Drainage tubing connection

40 Mounting pin

41 Aspirating tubing

42 Flow-through cell

43 UV/VIS detector

44 Mounting rail

45 Sample loop

46 Injection valve

47 Column inlet capillary without column

heating

48 Column inlet capillary with column

heating

49 Peristaltic pump

50 Snap-action lever

51 Pump drive

52 Connection capillary steel

53 Connection capillary steel

54 Pump heard steel 6.2824.040

55 Fastening screws steel

56 Connection capillary steel 6.2620.020

57 Purge valve steel

58 Filter unit steel 6.2620.180

59 Connection capillary steel 6.2620.020

60 Injection valve steel

61 UV/VIS detector steel

62 Flow-through cell steel 6.2839.100

63 Sample loop steel 6.2620.110

64 Compression fitting 6.2744.010

65 Compression fitting 6.2744.070

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

V

Page 10

Table of contents

66 Capillary

67 Ferrule (6.2620.010)

68 Ferrule (6.2620.270)

69 Pressure screw (6.2620.000)

70 Steel capillary (6.2620.020)

71 Filter screw of filter unit

72 Filter 6.2821.130

73 Filter housing

74 Steel connection capillary 6.2620.020

75 Steel filter unit 6.2620.180

76 Filter screw of filter unit

77 Filter 6.2620.190

78 Filter housing of filter unit

79 Steel connection capillary 6.2620.020

80 Connection to purge valve

81 Connection to injection valve

82 Aspirating tubing

83 Tubing nipple

84 Threaded stopper

85 Bottle attachment

86 Eluent bottle

87 Aspirating filter

88 CO2 absorber

89 Cotton wool

90 SGJ clip

91 Absorber tube

92 Aspirating tubing for reagent

93 PEEK coupling

94 Pump tubing

95 Stopper (orange-yellow)

96 Tubing cartridge

97 Contact pressure lever

98 Snap-action lever

99 PEEK coupling with filter and tubing

security device

102 PCR holder

103 Connection capillary

104 Post column reactor inlet "eluent in"

105 Post column reactor outlet "to detector"

106 Post column reactor inlet "reagent in"

107 Connection capillary

108 Bottle attachment

109 Supply bottle

110 Steel column inlet capillary

6.2620.160

111 Connection capillary 6.1831.110

112 Steel connection capillary 6.2620.160

113 Separating column

114 Column holder 6.2027.0X0

115 Feedthrough

116 Knurled screw

117 Cover of column heating

118 Connection to 844

119 Magnetic holder

120 Model plate with serial number

121 Feedthrough

122 Connection capillary

123 Connection capillary

124 Steel Connection capillary 6.2620.160

125 Holder plate

126 Capillary prewarming

127 IC Column heating

128 Column heater connection

129 Optical bank

130 Flow-through cell outlet "OUT"

131 Flow-through cell inlet "IN"

132 Knurled screws

133 Screw for piston cartridge

134 Zirconium piston

135 Spring retainer

100 Connection capillary

101 Post column reactor

136 Spring

137 Piston cartridge

Page 11

Table of contents

138 Piston guide sleeve (4.709.4380)

139 Piston guide sleeve (4.709.4370)

140 Piston seal

141 Inlet valve

142 Outlet valve

143 Screw holder

144 Special tool

145 Special tool

146 Valve housing

147 Sealing ring

148 Sleeve

149 Sapphire sleeve

150 Sapphire sphere

151 Ceramic holder for sapphire sphere

152 Seal

153 UV lamp

154 UV lamp attachment ring

155 Opening for UV lamp

156 Opening for VIS lamp

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

VII

Page 12

Page 13

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 844 UV/VIS Compact IC is a PC-controlled instrument for

chromatographic analysis that is available in the six following versions:

• 2.844.0010 UV/VIS Compact IC

• 2.844.0020 UV/VIS Compact IC with post column reactor

• 2.844.0030 UV/VIS Compact IC 844: Steel

• 2.844.0110 UV/VIS Compact IC with column heating

• 2.844.0120 UV/VIS Compact IC with post column reactor

and column heating

• 2.844.0130 UV/VIS Compact IC 844 with column heating:

Steel

All the necessary components for chromatography with UV/VIS

detection are contained in the extremely compact housing of the 844

UV/VIS Compact IC:

• Injection valve – for single injections or for use with a sample

changer, e.g. the 838 Advanced Sample Processor.

• High-pressure pump – extremely low pulsation double-piston

pump with a flow range of 0.2 … 2.5 mL/min and a maximum

pressure of 35 MPa (350 bar).

• Pulsation dampener – the pulsation dampener reliably protects

the columns from damage, even with low-level pressure variations

(not necessairy with versions 2.844.0030 and 2.844.0130).

• Column heating – the perfect insulation of the housing creates

thermally stable conditions for the columns (with Versions

2.844.0110, 2.844.0120 and 2.844.0130).

• Columns – whether anion columns, cation columns or separating

columns for organic acids – they all find space in the column

compartment of the 844 UV/VIS Compact IC.

• Post column reactor – in the post column reactor the eluate from

the column and a reagent delivered by a peristaltic pump are

mixed and transported to the detector. In this way ions that cannot

be detected are converted into (optically) detectable species (with

Versions 2.844.0020 and 2.844.0120).

• UV/VIS detector – for the determination of transitional metals with

post column derivation, chromate, bromate, nitrite and nitrate in

strongly polluted waters, as well as various organic ions.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

1

Page 14

Table of contents

The two steel versions 2.844.0030 and 2.844.0130 are used for HPLC

applications. There is an addittional componet of stel versions:.

• Gas-Sensor – the gas-sensor disrupts power supply, whenever

sovent concentration gets too high.

The operation of the 844 UV/VIS Compact IC takes place via a PC

connected to the RS232 interface with the help of the «IC Net» control

and evaluation program. This PC program can be used to create

systems for recording and evaluating chromatograms. Time programs

can also be created in which a large number of instrument functions

can be triggered for each program step. It is also possible to use programmable signals to control external instruments via the remote

interface.

The «IC Net» operating software meets all the requirements you could

place today on a modern integration software: single or multi-point

calibration, internal or external standard, selectable algorithms for nonlinear calibration, various integration modes with integration parameters

and integration events, different methods for peak recognition, peak

editor, free scaling, superimposing several chromatograms, use of

sample tables and batch reprocessing; a powerful and GLP-conform

report generator with output interfaces for monitor, printer and external

databases.

The independent «Autodatabase» PC program supplied can be used to

save and handle results and chromatograms produced by the «IC Net»

program in a database. With «Autodatabase» data can be sorted,

filtered and searched with the help of different criteria. In addition, data

and curves can be printed out according to user-defined report

templates.

The «IC Net» software can be configured and used in order to comply

with the Electronic Records and Signatures Rule, known as 21 CFR

Part 11, established by the U.S. Food and Drug Administration (FDA).

For this purpose the program contains password protection, user administration, electronic signatures, audit trail and administration of methods and results in databases. To use the 21 CFR Part 11 features of

«IC Net» the operating system Windows 2000 or Windows XP with

NTFS file system is required.

Page 15

1.2 Parts and controls

8

1.2 Parts and controls

In this Section you will find the numbers and designations of the parts

and controls of the 844 UV/VIS Compact IC. The numbering applies

throughout the Instructions for Use, i.e. bold numbers in the text (e.g.

4

) refer to the parts and controls illustrated here.

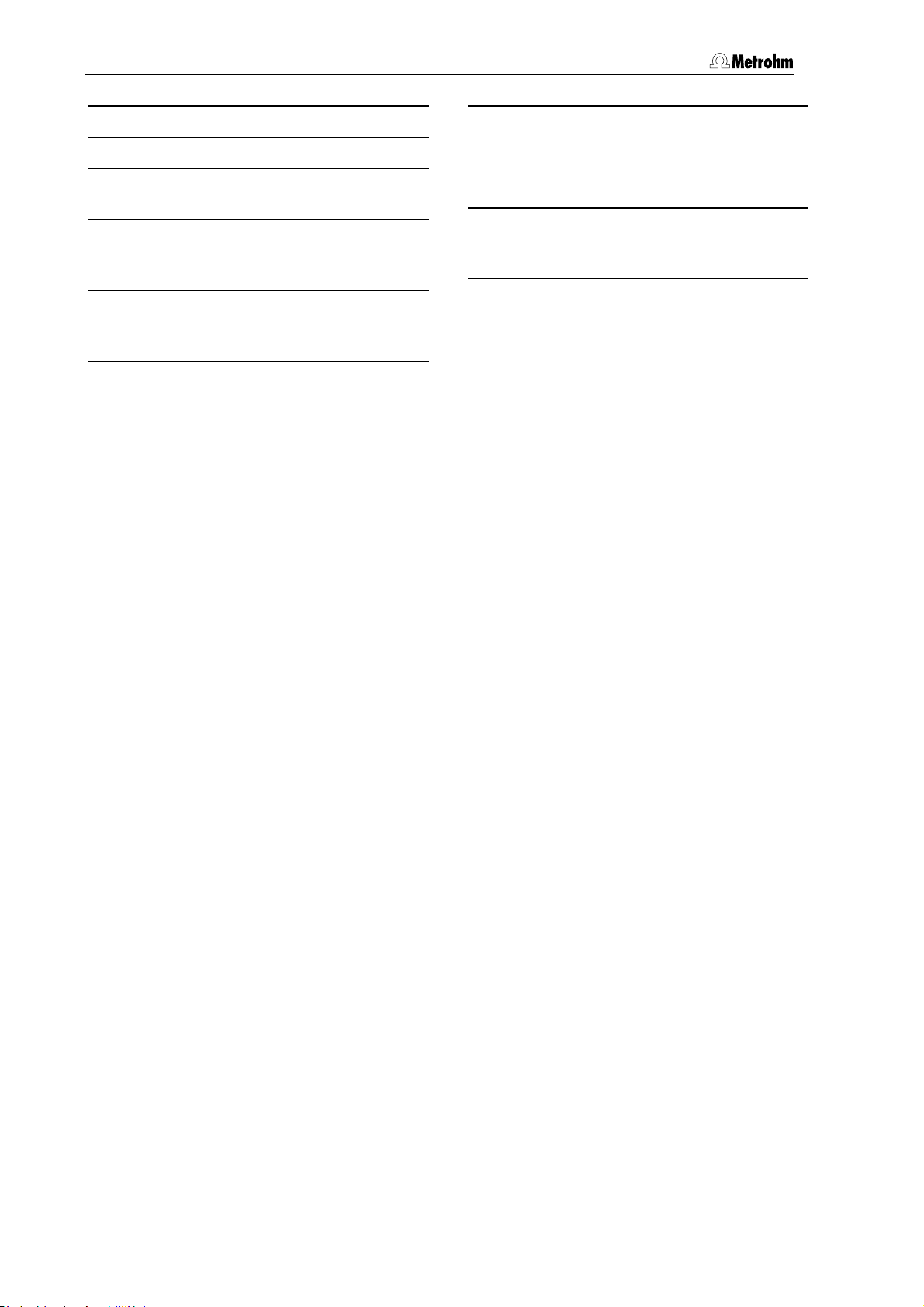

1.2.1 Front

1

2

3

4

5

6

Figure 1: Front 844 UV/VIS Compact IC

7

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

3

Page 16

Table of contents

Door to inner compartment

1

Feedthrough

2

for eluent, sample, waste, reagent...

LED "Power"

3

lights up when the instrument is

switched on.

LED "UV"

4

lights up when the UV lamp is on.

LED "VIS"

5

lights up when the VIS lamp is on.

Connection purge valve

6

Connection for 6.2816.020 syringe

7

for aspiration of the sample

Feedthrough

8

for eluent, sample, waste, reagent...

Page 17

1.2 Parts and controls

20 19 14

17

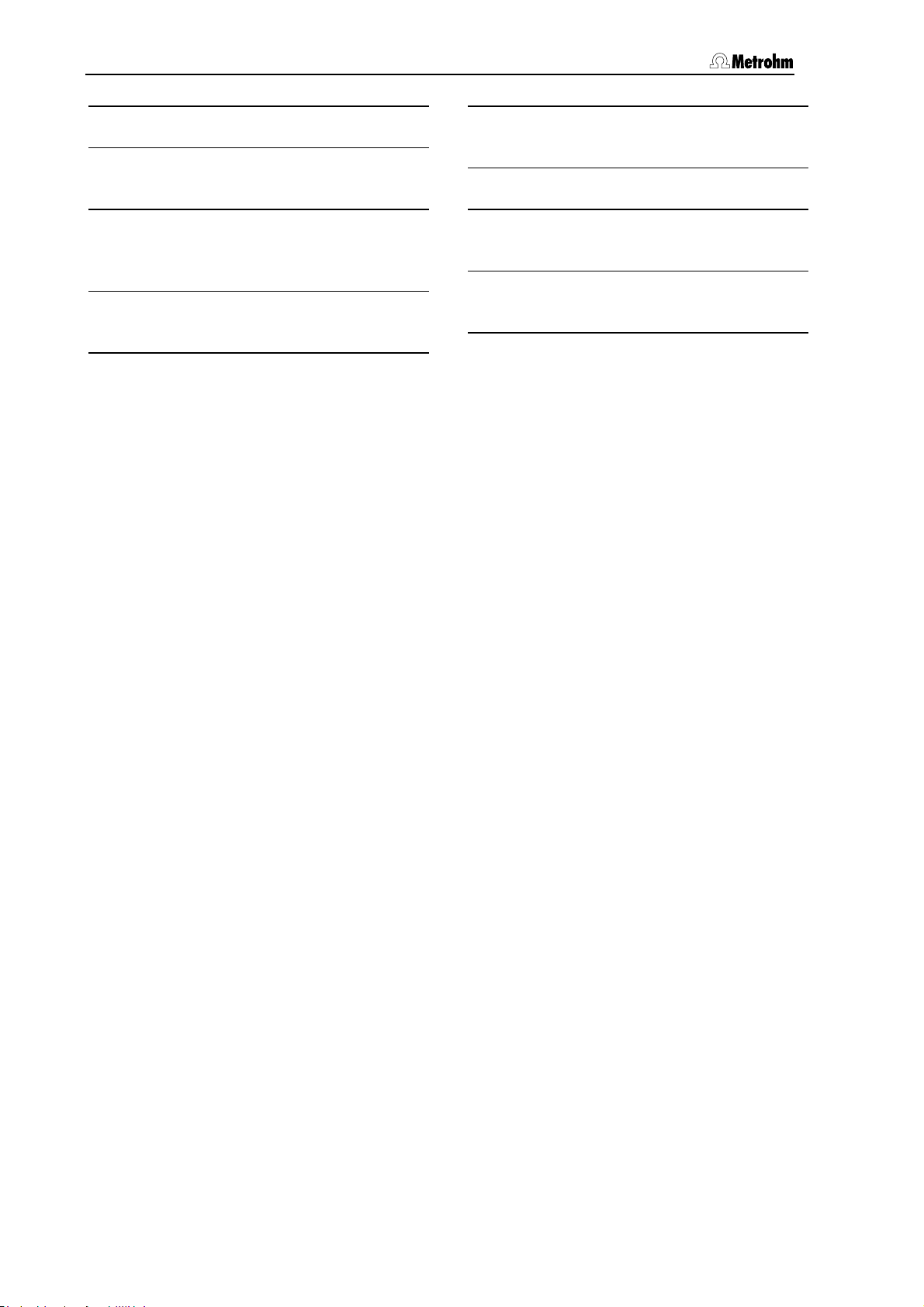

1.2.2 Rear panel

15

16

18

9

10

11

12

13

2

21

22

23

Figure 2: Rear 844 UV/VIS Compact IC

2 Feedthrough

for eluent, sample, waste, reagent...

Lamp cooling housing

9

VIS lamp connection

10

for VIS lamp connection cable

UV lamp connection cable

11

13

UV lamp connection

12

for UV lamp connection cable

VIS lamp connection cable

13

Analog output

14

output for analog signal

Control input

15

11

for control by other instruments

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

5

Page 18

Table of contents

USB-B connection

16

USB-A connection

17

RS232 interface

18

PC connection

Transport security screws

19

to secure the pump head when the

instrument is transported

Mains switch

20

to switch instrument on and off:

I = ON 0 = OFF

Mains connection plug

21

Mains connection, see Section

Fuse holder

22

Changing the fuses, see Section

Remote interface

23

Remote-I/O lines for connection of

external devices

2.4

2.4

Page 19

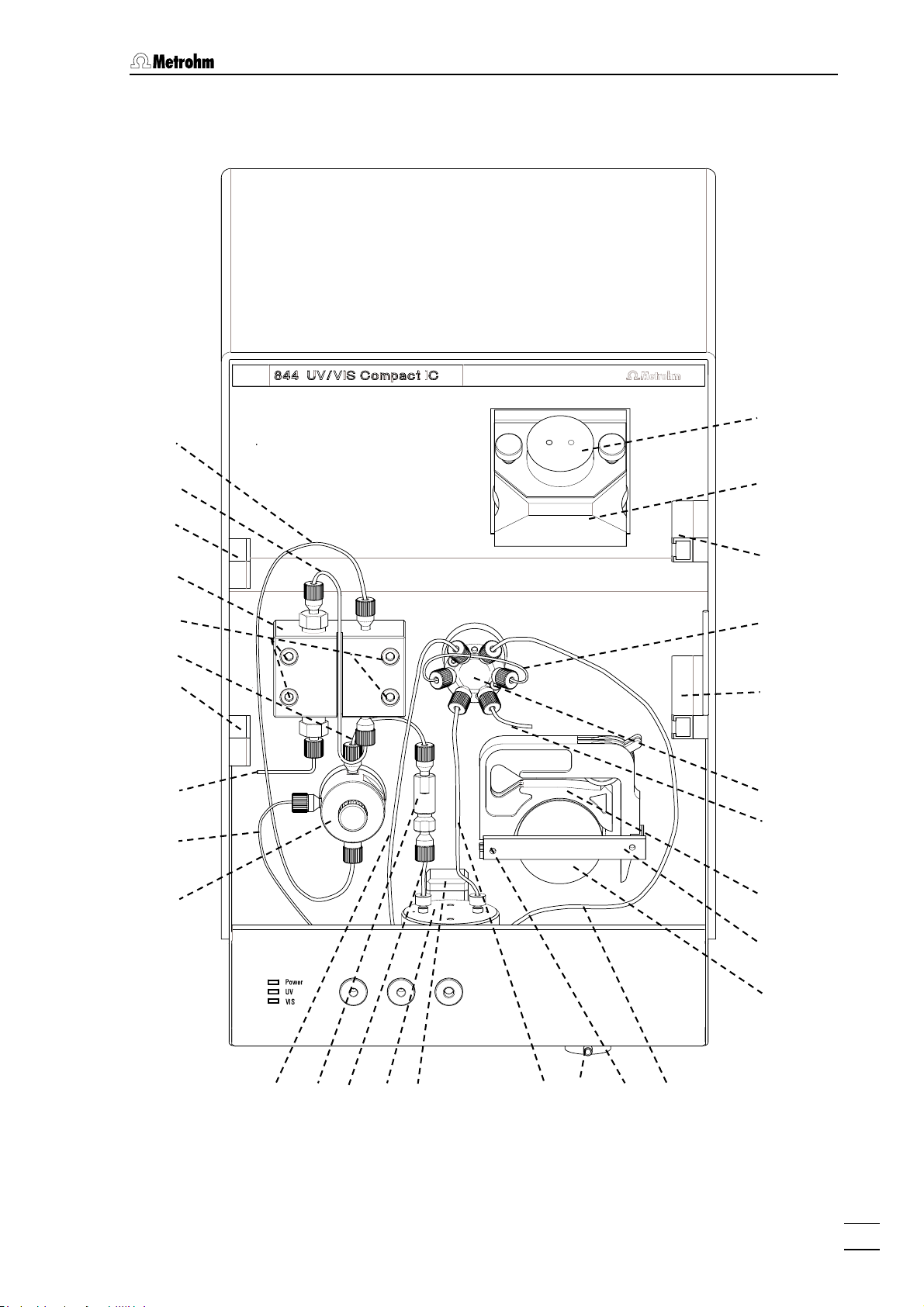

1.2 Parts and controls

44

43

51

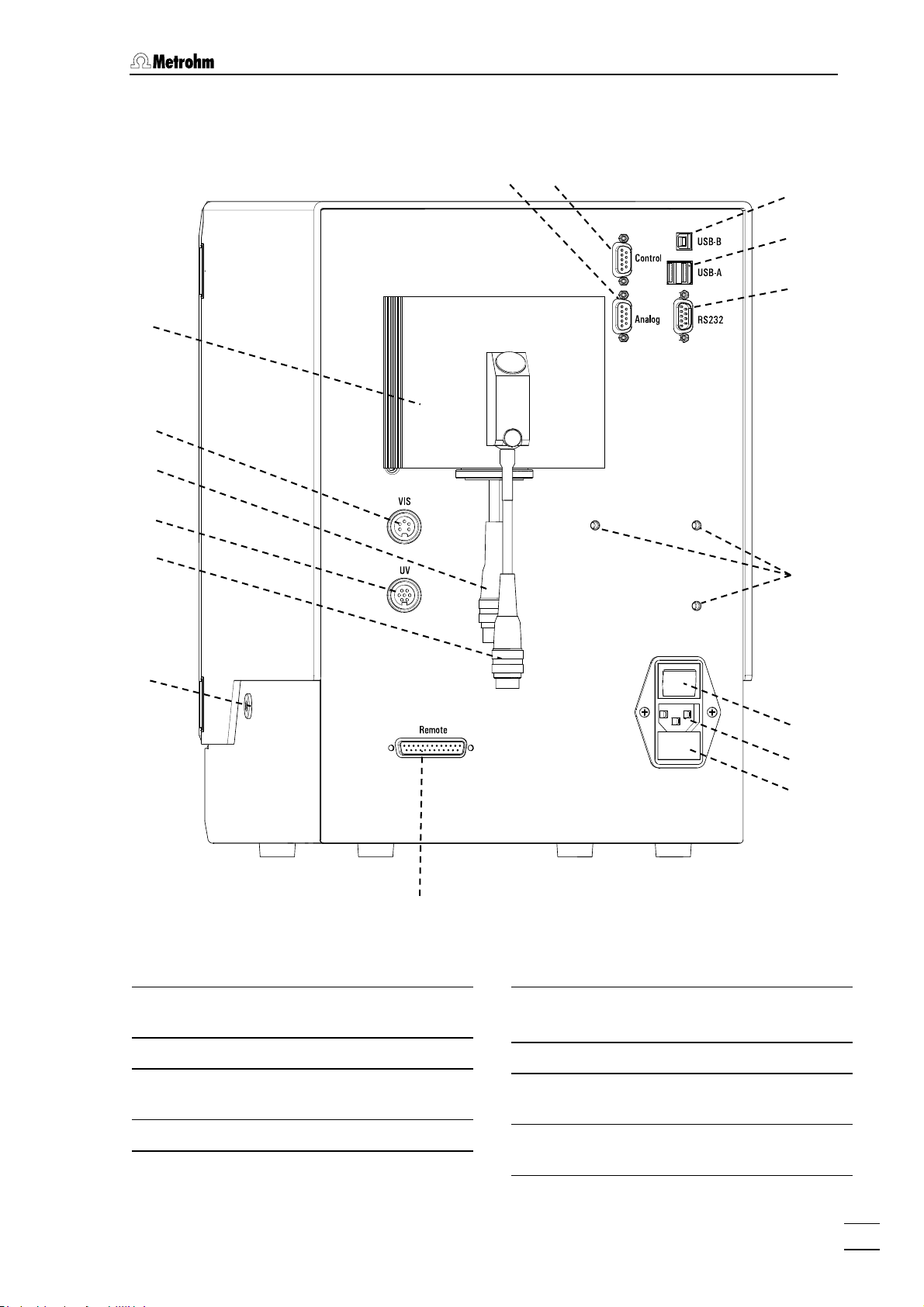

1.2.3 Interior PEEK versions

42

24

25

26

27

28

29

26

30

31

32

45

44

46

47/48

49

50

34

33

35

36

37

38

39

40

41

Figure 3: Interior PEEK versions

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

7

Page 20

Table of contents

Connection capillary

24

Connection pump head – purge

valve, fixed mounting

Connection capillary

25

in pump head, fixed mounting

Magnetic mounting rail for co-

26

lumn heating

Pump head (6.2824.100)

27

Fastening screws

28

for pump head

Connection capillary

29

27

from purge valve to Filter unit PEEK.

6.1831.010 PEEK capillary,

length L = 13 cm

Aspirating capillary

30

Connection for 6.1834.010 aspirating

tubing

Connection capillary

31

from purge valve to connection

6

Mounting pin

40

for attaching the tubing cartridges

Aspirating tubing

41

for sample;

PTFE-tubing 6.1803.020

Flow-through cell PEEK

42

6.2839.130

UV/VIS detector

43

Mounting rail

44

for 6.2027.0X0 Column holder, and

6.2057.050 PCR holder

Sample loop

45

PEEK sample loop

Injection valve

46

6.1831.110 Column inlet capillary

47

for column connection without column heating.

6.1831.110 PEEK capillary,

length L = 30 cm

Purge valve

32

Connection capillary to syringe

33

(with manual injection)

6.1803.020 PTFE tubing,

length L = 30 cm

Filter unit PEEK (6.2821.120)

34

Connection capillary

35

from Filter unit PEEK to Pulsation

dampener.

6.1831.010 PEEK capillary,

length L = 13 cm

Pulsation dampener (6.2620.150)

36

Leak detector

37

Inlet capillary for injection valve

38

PEEK capillary 6.1831.010,

length L = 24 cm

6.1831.100 Column inlet capillary

48

for column connection with column

heating.

6.1831.100 PEEK capillary,

length L = 1 m

Peristaltic pump

49

for operating the post column reactor

Holding clamp

50

for locking the tubing cartridge into

place

Pump drive

51

roller head with contact rollers

Connection for drainage tubing

39

for draining off escaped liquid

Page 21

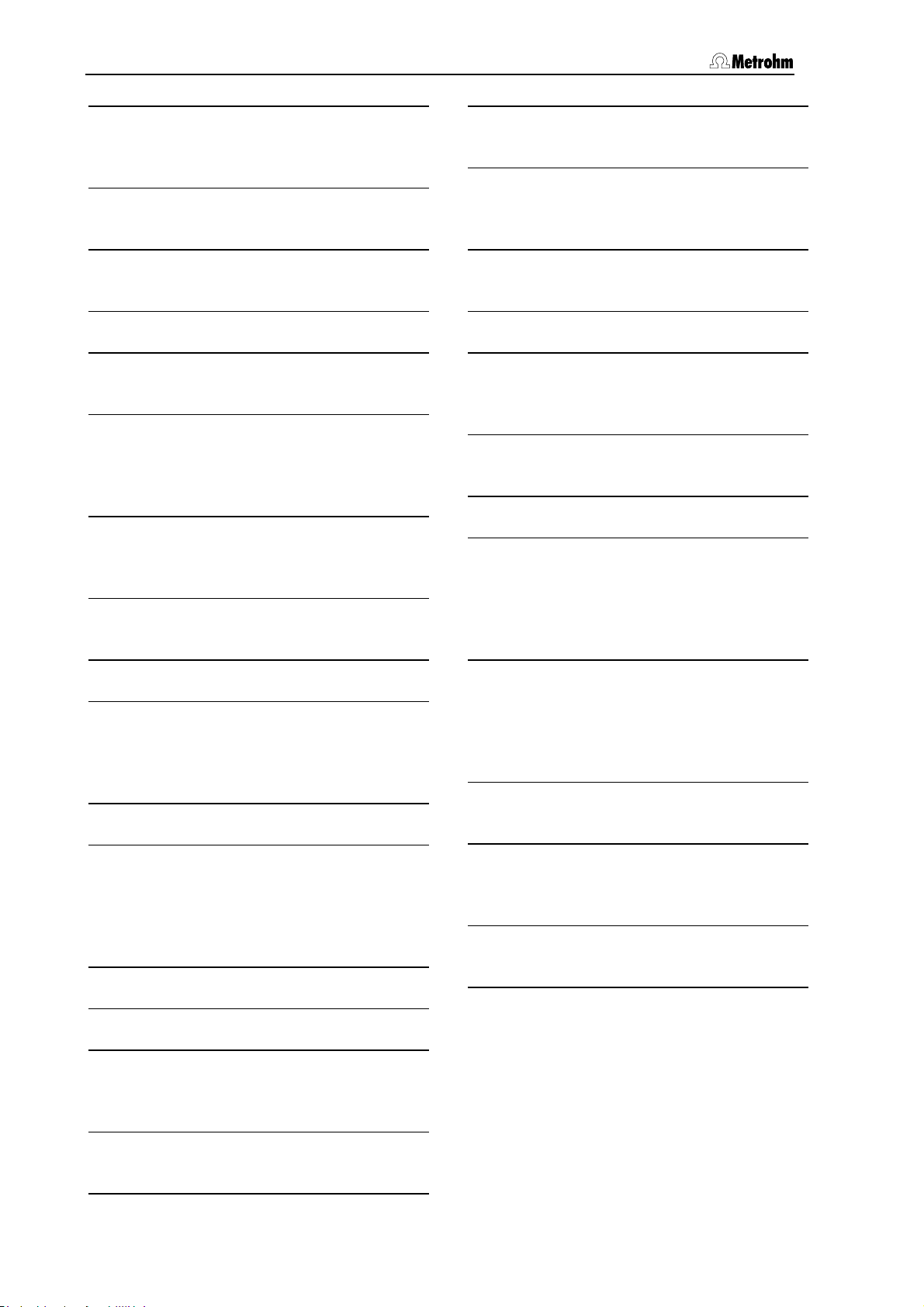

1.2 Parts and controls

61 41

1.2.4 Interior Steel versions

62

52

53

54

55

56

30

33

57

60

63

59

58

Figure 4: Interior Steel Versions

Steel connection capillary

52

Connection steel pump head – steel

Steel connection capillary

53

in pump head, fixed mounting

purge valve, fixed mounting

Steel pump head 6.2824.040

54

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

9

Page 22

Table of contents

Steel fastening screws

55

for steel pump head

Steel connection capillary

56

54

Steel capillary 6.2620.020 from steel

purge valve to steel filter unit.

Steel purge valve

57

Steel filter unit 6.2620.180

58

Steel connection capillary

59

Steel capillary 6.2620.020 from Steel

filter unit to steel injection valve.

Steel Injection valve

60

Steel UV/VIS detector

61

Steel flow-through cell 6.2839.100

62

Steel sample loop 6.2620.110

63

Page 23

1.3 Information on the Instructions for Use

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 844 UV/VIS Compact IC into operation. The Instructions for Use

contain information and warnings to which the user must pay attention

in order to assure safe operation of the instrument.

1.3.1 Organization

These Instructions for Use 8.844.1053 for the 844 UV/VIS Compact

IC provide a comprehensive overview of installation, startup procedure,

operation, fault rectification and technical specifications of this

instrument. The Instructions for Use are organized as follows:

Sect.

1 Introduction

General description of instrument, parts and controls and

safety notes

2 Installation

Sect.

Installation of instrument, accessories, external devices

and software

3 Operation

Sect.

Introduction to the operation

4 Notes - Maintenance - Faults

Sect.

Notes on ion chromatography, maintenance, fault

rectification, diagnostic tests, validation

Sect.

5 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments, use either the

Table of contents or the Index at the back.

As a supplement to the Instructions for Use, the Metrohm Monograph

8.792.5003 "Practical Ion Chromatography" is also supplied. This

provides an introduction to the theoretical fundamentals and general

information about determinations.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

11

Page 24

Table of contents

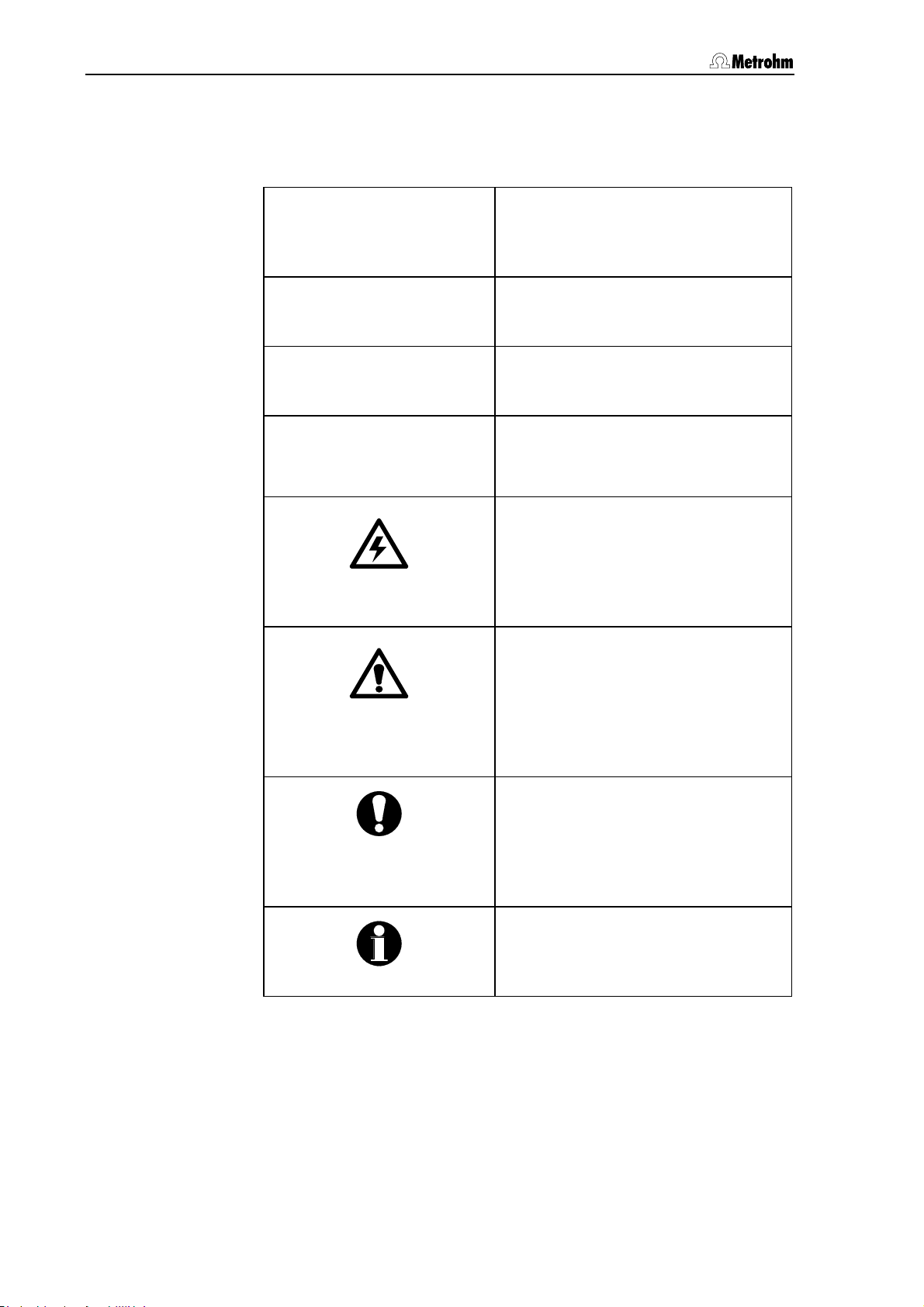

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these

Instructions for Use:

Fill Menu item, parameter or entry

value

in the software

SYSTEM STATE Program window

in the software

<OK> Button

in the software

26

Part or control of 844

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed

correctly.

Caution

This symbol marks important

information. First read the

associated directions before you

continue.

Comment

This symbol marks additional

information and tips.

Page 25

1.4 Safety notes

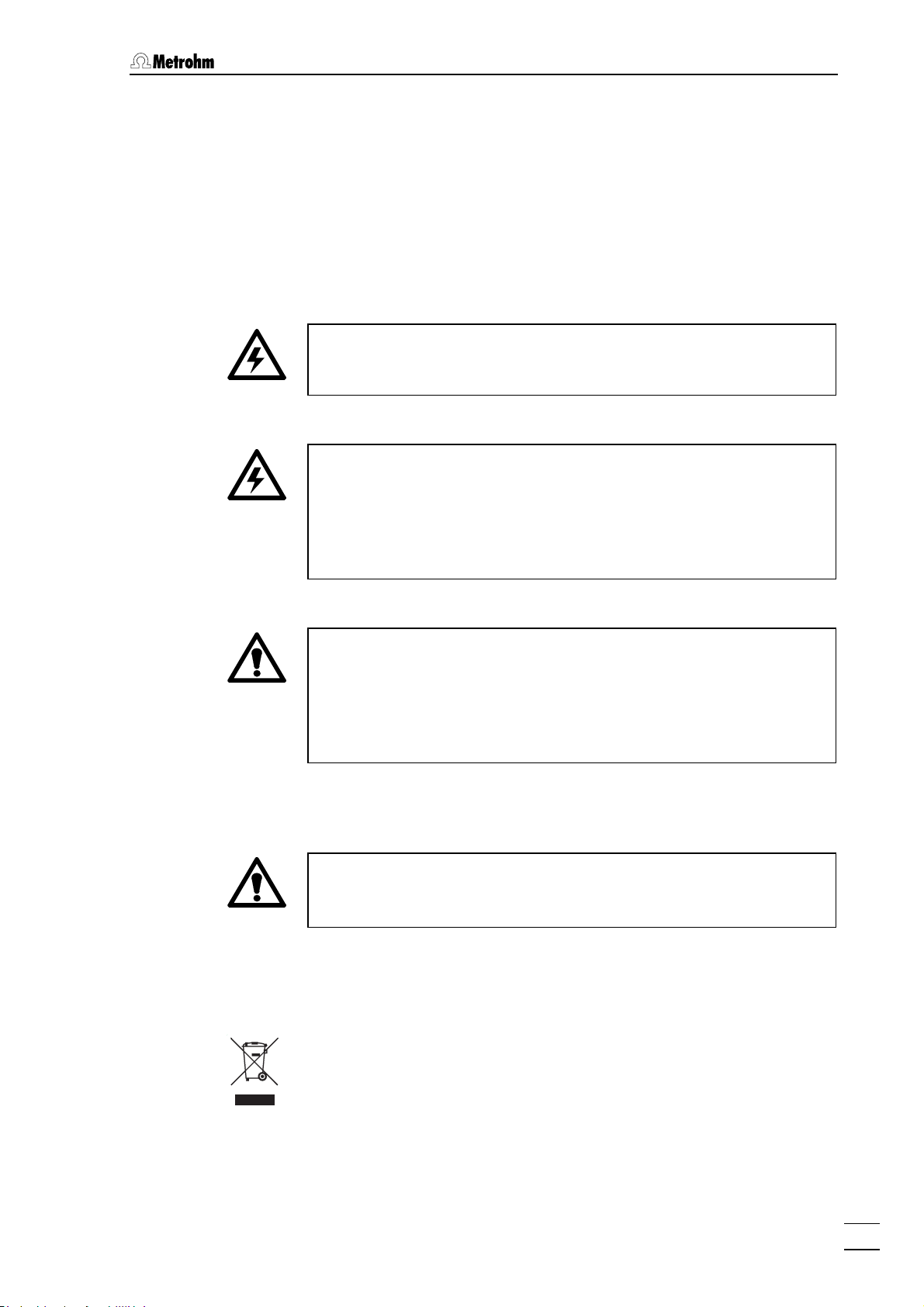

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 844 UV/VIS Compact IC is

assured in the context of the specifications EN / IEC 61010-1

(protection class

should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the

instructions in Section

• Opening the 844 UV/VIS Compact IC

If the 844 UV/VIS Compact IC is connected to the power supply, the

instrument must not be opened nor must parts be removed from it,

otherwise there is a danger of coming into contact with components

which are live. Therefore always disconnect the instrument from all

voltage sources before you open it and ensure that the mains cable

is disconnected from mains connection

I, degree of protection IP40), the following points

2.4.

21 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 844 UV/VIS Compact IC, you should ground yourself and

any tools you are using by touching a grounded object (e.g. housing

of the instrument or a radiator) to eliminate any static charges which

exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

1.4.3 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE –

Waste from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

13

Page 26

Table of contents

2 Installation

2.1 Overview

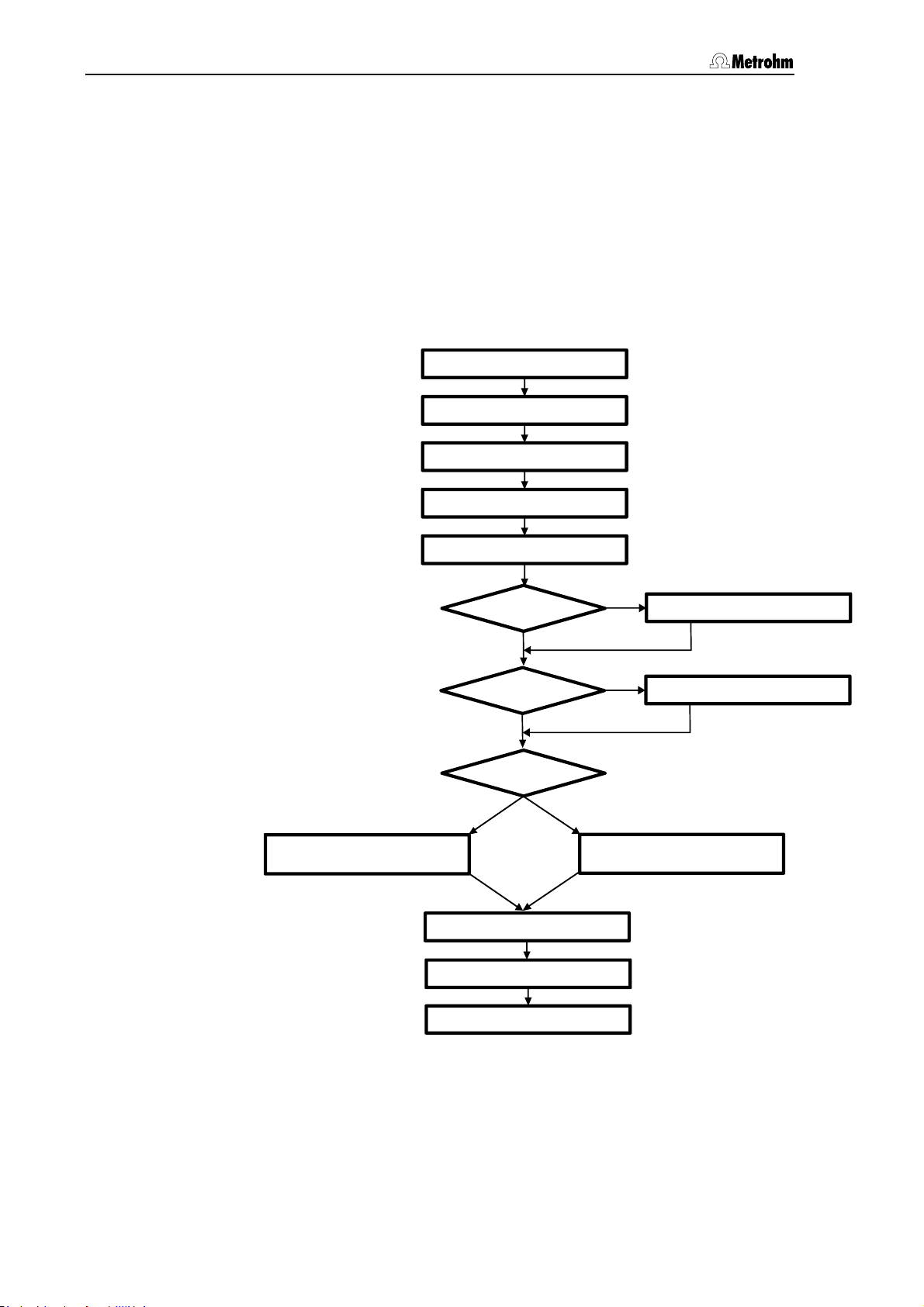

2.1.1 Flow chart

The following flow chart provides an overview of all installation work.

You will find more detailed information in the relevant Sections.

Setting up sect. 2.2

Installing accessories sect. 2.3

Mains connection sect. 2.4

Connectting PC sect. 2.5

Connecting column

Connecting high press. pump sect. 2.6

Post column reactor?

No

Precolumn?

No

Column heating?

No

sect. 2.8.3

Connecting of the detector sect. 2.9

Conditioning sect. 2.10

Yes

Yes

Install post column reactor

Yes

Connecting precolumn sect. 2.8.1

Connecting column and

column heating

sect. 2.7

sect. 2.8.4

Connecting external devices sect. 2.11

Page 27

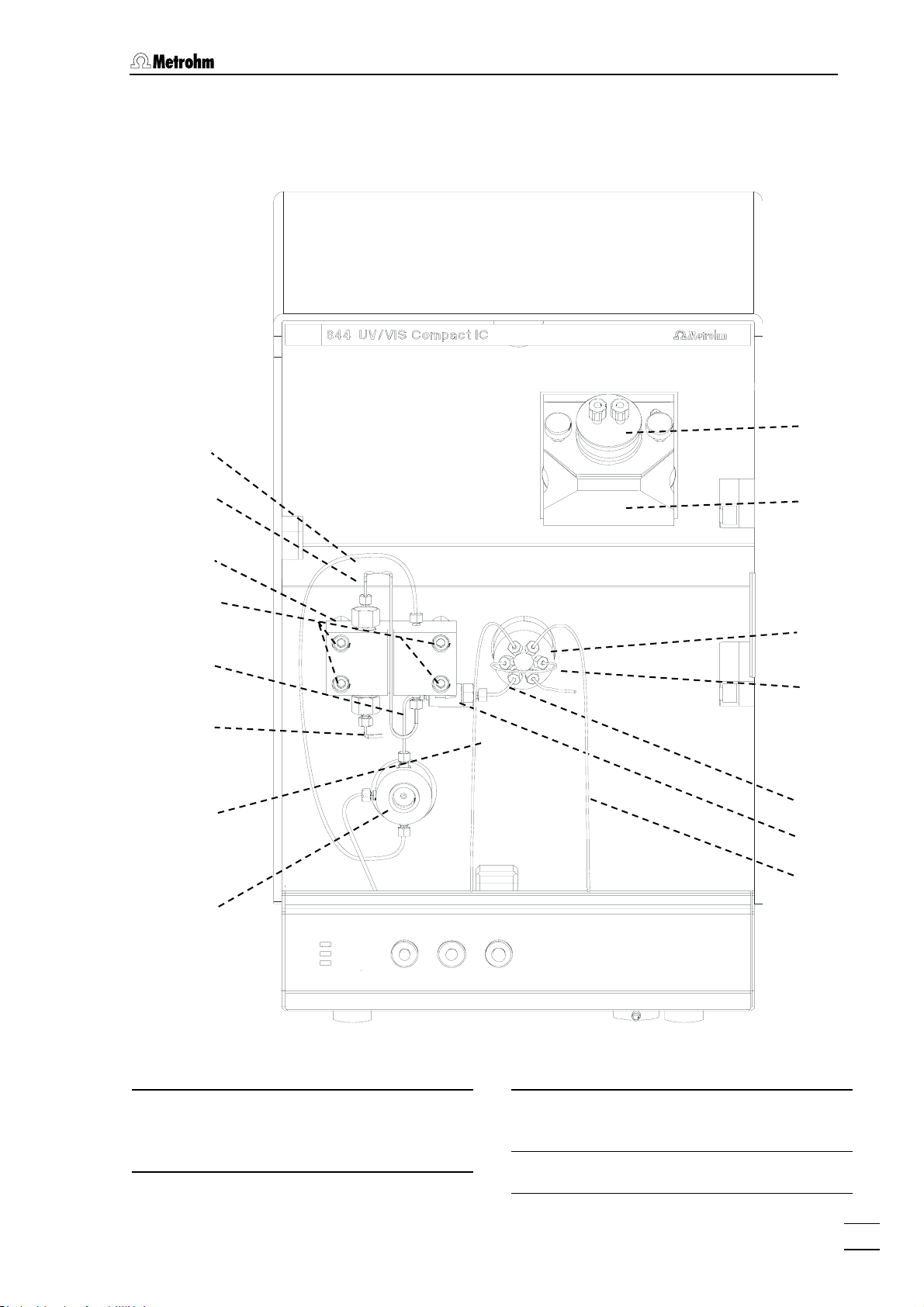

2.1 Overview

35 36 38 33 41

45

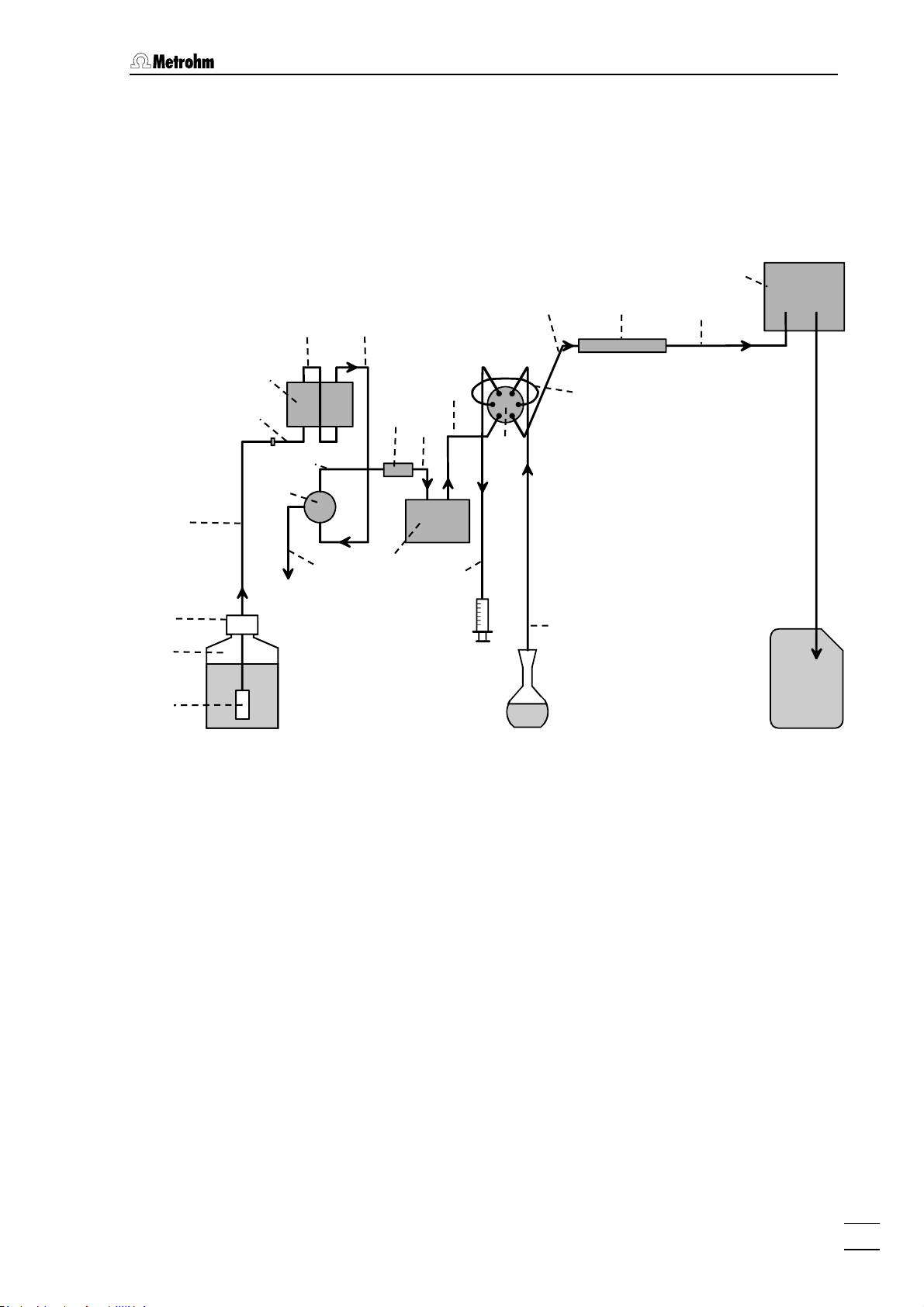

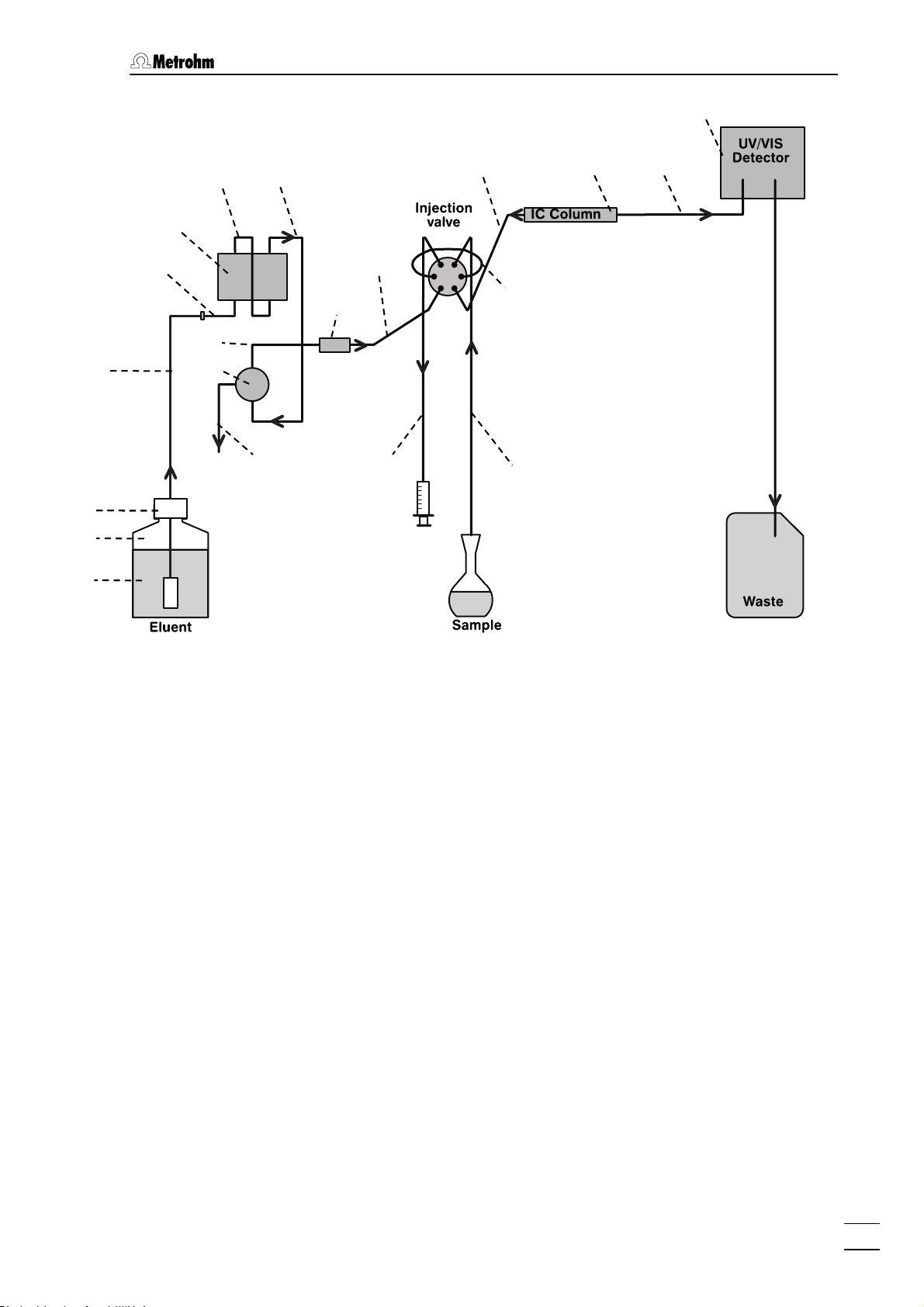

2.1.2 Connections in the 844 UV/VIS Compact IC

The following illustrations show the internal connections in the 844

UV/VIS Compact IC in schematic form. The meanings of the various

numbered components are given in the detailed illustrations and

descriptions in Sections

2.2 – 2.11.

25

24

Injection valve

47

113

IC Column

43

112

UV/VIS

Detector

27

30

29

34

46

32

82

31

85

86

87

Eluent

Sample

Waste

Figure 5: Connecting diagram for 844 UV/VIS Compact IC 2.844.0010

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

15

Page 28

Table of contents

47

94 93

41

85

86

87

82

27

30

Eluent

32

25

29

31

24

34

36

35

33

Injection

valve

46

Sample

92

108

109

47

IC Column

45

Reagent

113

103

43

107

99

UV/VIS

Detector

Post column

reactor

101

100

Waste

Figure 6: Connecting diagram for 844 UV/VIS Compact IC 2.844.0020 with

Post column reactor

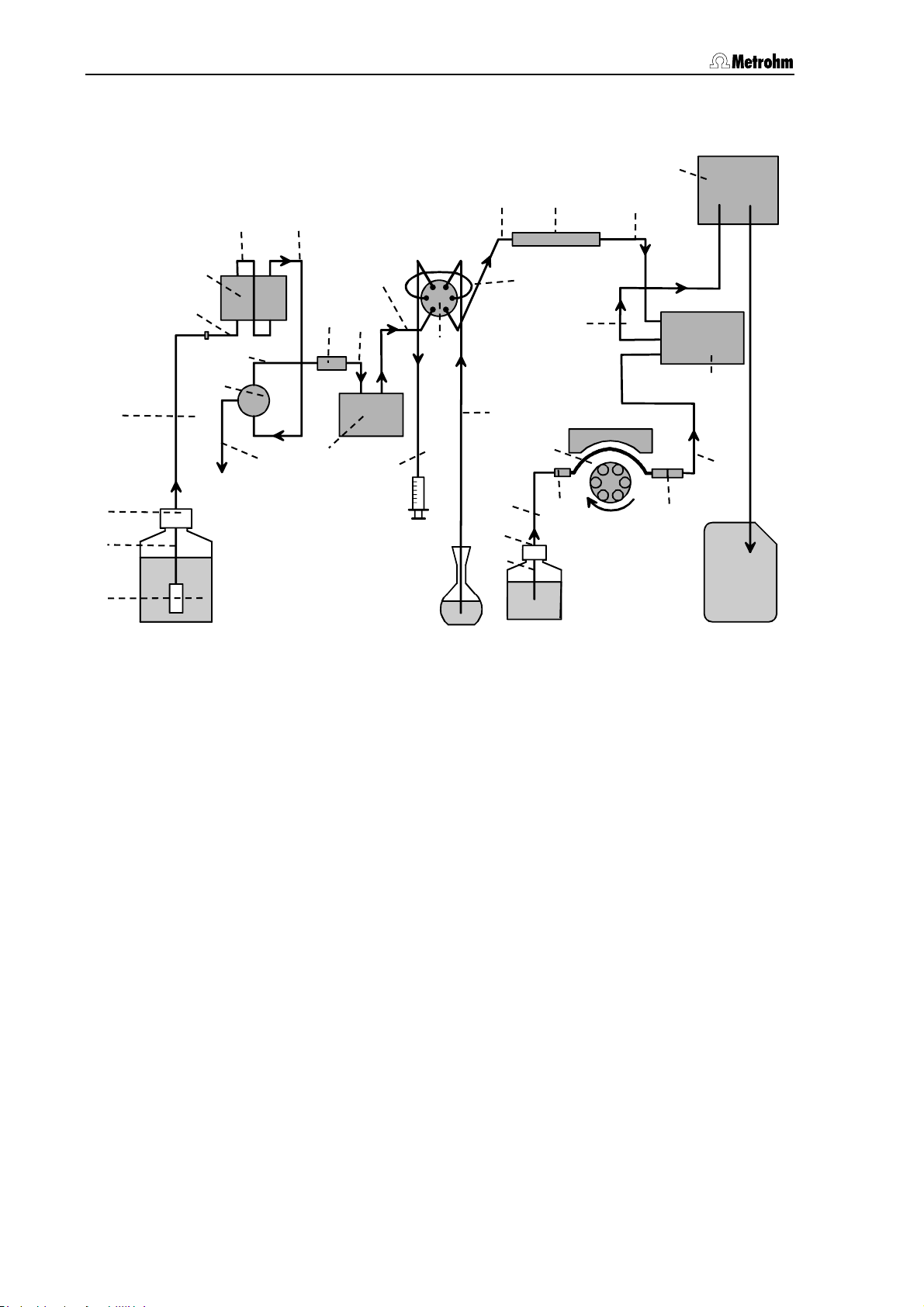

Page 29

2.1 Overview

63

61

85

Fehl

86

87

82

30

54

53

56

57

52

31

59

58

33

110 113 112

41

Figure 7: Connecting diagram for 844 UV/VIS Compact IC 2.844.0030

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

17

Page 30

Table of contents

46 45

85

86

87

82

27

30

25

24

34

35

47

48

Injection

valve

127

Column heating

IC Column

113

43

122

UV/VIS

Detector

29

32

41

31

Eluent

36

33

Waste

Sample

Figure 8: Connecting diagram for 844 UV/VIS Compact IC 2.844.0110 with

Column heating

Page 31

2.1 Overview

35 36 33 46 48

85

86

87

82

43

UV/VIS

Detector

127

Column heating

IC Column

113

45

105

104

Post column

reactor

27

30

25

24

Injection

valve

47

34

29

32

31

41

94

101

107

92

108

93

99

109

Waste

Eluent

Sample

Reagent

Figure 9: Connecting diagram for 844 UV/VIS Compact IC 2.844.0120 with

Post column reactor and Column heating

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

19

Page 32

Table of contents

63

61

85

Fehl

86

87

82

30

54

53

56

57

52

31

58

59

33

110

Column heating

Column heating

IC Column

IC Column

41

113

112

127

Eluent

Sample

Figure 10: Connecting diagram for 844 UV/VIS Compact IC

2.844.0130 with Column heating

2.2 Setting up the instrument

2.2.1 Packaging

The 844 UV/VIS Compact IC is supplied together with the separately

packed accessories in special packagings containing shock-absorbing

foam linings designed to provide excellent protection. The instrument

itself is packed in an evacuated polyethylene bag to prevent the ingress

of dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.2.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in Section

structions in Section

5.2). In the case of transport damage, see in-

5.4.1 "Warranty".

Page 33

2.3 Attaching the accessories

2.2.3 Location

Position the instrument in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

To avoid disturbing temperature influences on the insulated column

compartment, the instrument must be protected against direct sunlight.

2.3 Attaching the accessories

2.3.1 Connecting the syringe and aspirating tubing

For the manual filling of sample loop 45/63 mounted at the injection

valve the 6.2816.020 Syringe and PTFE aspirating tubing

connected to the injection valve) are required. These accessories are

attached and adjusted as follows:

1 Connecting the syringe

• Remove the plastic stopper from connection 7 on the front

panel of the 844 UV/VIS Compact IC.

• Push 6.2816.020 Syringe(without needle) into connection

until it reaches the stop.

2 Pull out the aspirating tubing

• Pull the PTFE aspirating tubing 41 connected to injection

46/61 through feedthrough 7 by hand as far as

valve

required.

41 (already

7

2.3.2 Connecting the drainage tubing for the inner compartment

The 844 UV/VIS Compact IC has a connection 39 on its front panel to

allow any escaped liquid to be drained off from the inner compartment.

A piece of drainage tubing can be attached to it. Proceed as follows:

1 Connecting the drainage tubing

• Push 6.1816.060 Silicone tubing onto the connection nipple

at the bottom right-hand side of the front panel.

2 Lead the drainage tubing into a drain

• Lead the other end of the drainage tubing into a drain and fix

it in position.

2.3.3 Connecting PEEK capillaries

With the versions 2.844.0010, 2.844.0020, 2.844.0110 and 2.844.0120,

the connections from the high-pressure pump to the detector consist of

6.1831.010 PEEK capillaries (i.d. = 0.25 mm, o.d. = 1/16"), which are

connected with either 6.2744.010 PEEK compression fitting (long) or

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

21

Page 34

Table of contents

6.2744.070 PEEK compression fitting (short). The connection pieces

are mounted on the capillaries as follows:

PEEK capillaries that are to be provided with new connection pieces

must have a perfectly flat cut surface. This is best achieved by using

the 6.2621.080 Capillary cutter available as an option.

1 Mounting the compression fitting

• At the end of capillary Fehler! Verweisquelle konnte nicht

gefunden werden. that is to be attached push either a

compression fitting Fehler! Verweisquelle konnte nicht

gefunden werden. (6.2744.010) or compression fitting Fehler!

Verweisquelle konnte nicht gefunden werden. (6.2744.070)

over the capillary as shown in Fehler! Verweisquelle konnte

nicht gefunden werden..

2 Lead the capillary into the connection

• Push the capillary end into the corresponding connection

until it reaches the stop (in order to avoid dead volume).

3 Tighten up compression fitting

• Tighten up compression fitting Fehler! Verweisquelle konnte

nicht gefunden werden. or Fehler! Verweisquelle konnte nicht

gefunden werden. by hand (do not use any tools).

64

66

65

Figure 11: Connectors for PEEK capillaries

2.3.4 Connecting Steel capillaries

With the versions 2.844.0030 and 2.844.0130, the connections from

the high-pressure pump to the detector consist of 6.2620.020 Steel

capillaries (i.d. = 0.25 mm, e.d. =

connected with the steel connectors 6.2620.010 Ferrule and

6.2620.000 Pressure screw available as an option. The connection

pieces are mounted on the capillaries as follows:

Compression fitting

64

(6.2744.010)

Compression fitting

65

(6.2744.070)

Capillary 6.1831.XXX PEEK

66

capillary

1

/16", length = 3 m), which are

Steel capillaries fitted with new connectors must have a perfectly flat

cut surface. This is best achieved by using the 6.2621.040 Capillary

tubing cutter available as an option.

Page 35

2.3 Attaching the accessories

70

1 Mount connectors

Slide a pressure screw 69 (6.2620.000) and a ferrule 68

(6.2620.010) over the end of the capillary

2 Insert capillary in connection

Push capillary end into the corresponding connection as far as it

will go (to avoid dead volume).

3 Tighten pressure screw

Tighten pressure screw 69 with the open-end spanner 1/4"

(6.2621.010) supplied.

70 to be fastened.

67

68

Figure 11: Connectors for Steel capillaries

69

70

2.3.5 Filter unit PEEK

With the versions 2.844.0010, 2.844.0020, 2.844.0110 and

2.844.0120, there is a 6.2821.120 PEEK filter unit mounted between

the high-pressure pump and injection valve

against particles.

PEEK filter unit

New filters

6.2821.130 (10 pieces).

34 consists of housing 73, filter screw 71 and filter 72.

72 are available as an option under ordering number

Ferrule (6.2620.010)

67

used in pre-installed

components only

Ferrule (6.2620.270)

68

Pressure screw (6.2620.000)

69

Capillary

6.2620.020 Steel capillary

46. It protects the valve

When connecting the filter unit please note the flow direction arrow

printed on the housing.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

23

Page 36

Table of contents

71 72 73

34

35

64

Figure 12: 6.2821.120 Filter unit PEEK

29 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

34 Filter unit PEEK (6.2821.120)

35 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

2.3.6 Filter unit Steel

With the versions 2.844.0030 and 2.844.0130, there is a Steel filter

unit 6.2620.180 mounted between the high-pressure pump and

injection valve. It protects the valve against particles.

The Steel filter unit consists of housing

New filters

6.2821.130 (10 pieces).

29

Filter screw of filter unit

71

64

Part of 6.2821.120 Filter unit

Filter 6.2821.130

72

Part of 6.2821.120 Filter unit

Filter housing of filter unit

73

Part of 6.2821.120 Filter unit

78, filter screw 76 and filter 77.

77 are available as an option under ordering number

When connecting the filter unit please note the flow direction arrow

printed on the housing.

75

74

69

67

78

77

76

67

69

79

Figure 13: 6.2620.180 Filter unit Steel

Page 37

2.4 Mains connection

Steel connection capillary

74

6.2620.020

from steel purge valve to steel filter

unit.

Steel filter unit 6.2620.180

75

Filter screw of filter unit

76

Part of 6.2620.180 Filter unit

Filter 6.2620.190

77

Part of 6.2620.180 Filter unit

2.4 Mains connection

Follow the instructions below for connecting to the power supply. If the

instrument is operated with a mains voltage set wrongly and/or wrong

mains fuse, there is a danger of fire!

Filter housing of filter unit

78

Part of 6.2620.180 Filter unit

Steel connection capillary

79

6.2620.020

from steel filter unit to steel pulsation

dampener

2.4.1 Setting the mains voltage

Before switching on the 844 UV/VIS Compact IC for the first time, check

that the mains voltage set on the instrument matches the local mains

voltage. If this is not

instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 21 of the

844 UV/VIS Compact IC.

2 Disconnect mains cable

Using a screwdriver, loosen fuse holder 22 below the mains

connection plug

3 Check and change fuse if necessary

Carefully take the fuse installed for the desired mains voltage out

of fuse holder

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100…120 V 1.6 A (slow-blow)

the case, you must reset the mains voltage on the

21 and take out completely.

22 and check its specifications (the position of the

220…240 V 0.8 A (slow-blow)

4 Insert fuse

Change fuse if necessary and reinsert in fuse holder 22.

5 Install fuse holder

Depending on the desired mains voltage, insert fuse holder 22

in the 844 UV/VIS Compact IC so that the corresponding mains

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

25

Page 38

Table of contents

V

voltage range can be read normally and the adjacent white

arrow points to the white bar imprinted below the fuse holder.

220 – 240 V

20

21

-

100

120 V

22

220 - 240 V

Figure 14: Setting the mains voltage

2.4.2 Fuses

100 – 120

20 Mains switch

to switch instrument on and off:

I = ON 0 = OFF

21 Mains connection plug

2.4.3

100 - 120 V

-

220

240 V

Mains connection, see Section

22 Fuse holder

One of the two fuses 1.6 A/slow-blow for 100…120 V or 0.8 A/slow-blow

for 220…240 V is installed in fuse holder

22 of the 844 UV/VIS Compact

IC as standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

When checking or changing fuses proceed as described in Section

2.4.1.

2.4.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with a grounding pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective ground (protection class 1).

Any break in the grounding inside or outside the instrument can make

it a hazard!

Mains connection

Plug the mains cable into mains connection plug

Compact IC.

21 of the 844 UV/VIS

Page 39

2.5 Connection to PC

2.4.4 On/off switching of the instrument

The 844 UV/VIS Compact IC is switched on and off using mains switch

20. When the instrument is switched on, the mains pilot lamp 3 lights

up.

2.5 Connection to PC

2.5.1 Connecting cable

Always switch off 844 UV/VIS Compact IC and PC before you connect

the two instruments with the 6.2134.100 Cable.

Connect the RS232 interface

serial COM port at the PC using the 6.2134.100 Cable (9-pin/9-pin). If

only a 25-pin COM interface is available on the PC then the 6.2125.110

Adapter cable or a commercially available adapter must be used.

18 at the 844 UV/VIS Compact IC to a

2.5.2 Software installation

The PC program «IC Net» (from Version 2.3 SR2) is required for operating the 844 UV/VIS Compact IC; this is included in the standard

equipment on CD 6.6034.033. This program runs under the operating

systems Windows 2000 and Windows XP and is installed as follows:

1 Install program

• Insert the installation CD 6.6034.033 into your CD-ROM drive.

• If the autorun option for the CD drive is disabled, select

<Start> and Run. Browse for the Setup.exe file on the

installation CD and click on

• Click "

2 Files

• The installation program copies the files from the

installation CD into the folder entered by you and generates the

subfolders IC Net and Autodatabase. The following subfolders are

also generated, among others:

IC Net" and follow the on-screen prompts of the Setup

program (see Instructions for Use «IC Net», Section 1.5 for a

more detailed description).

Data Folder for storage of chromatogram files

Devices Folder for storage of device files (*.dev)

Excelreport Folder for Excel reports (*.xls)

Methods Folder for storage of method files (*.mtw)

Reports Folder for storage of report files (*.txt)

Systems Folder with subfolders with system files

<OK>.

*.chw) and batch reprocessing files (*.bar)

(

and graphic files (

(

*.smt) and sample queue files (*.que).

*.wmf)

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

27

Page 40

Table of contents

The installed files (incl. system and method files) are generally not

write-protected. To prevent these files from being deleted by mistake,

switch on the write-protection or make a backup copy in another

directory.

2.5.3 First Login

Starting and closing of the Software is described in the provided

Software Instructions for Use «IC Net», Section 2.

The

Add User window (see below) opens the first time you launch the

program after installing the software and a user with Administrator

access rights is created.

2.5.4 Create a system

Create in «IC Net» a system to control the 844 UV/VIS Compact IC.

Proceed as described in Section 4.4.1 of the Software Instructions for

Use «IC Net»: System wizard. Add your version of the 844 UV/VIS

Compact IC (they are listed under "Metrohm Detectors") to the system,

and choose the port to which it is connected.

Page 41

2.6 High-pressure pump

2.6 High-pressure pump

In order to avoid damage to the pump it must never be operated dry.

Each time that the pump is switched on always first check that the

eluent supply has been connected up correctly and that sufficient

eluent is present in the eluent bottle.

2.6.1 Removing the transport security screws

In order to prevent the pump drive from being damaged during

transport the pump head is fitted with three transport security screws

19. These transport security screws must be removed before the highpressure pump is started up. Also remove the red sticker attached to

the pump head

In order to avoid damage to the pump head these three security

screws should be attached to the pump head each time that the 844

UV/VIS Compact IC is to be transported.

27/54.

2.6.2 Installing the pulsation dampener

With the PEEK versions 2.844.0010, 2.844.0020, 2.844.0110 and

2.844.0120, the 6.2620.150 Pulsation dampener MF has to be

installed between the high-pressure pump and the injection valve of the

844 UV/VIS Compact IC, to protect the column material against

pressure drops caused by the injection valve. Proceed as follows:

1 Install pulsation dampener

• Position the pulsation dampener 36 in the interior of the Com-

pact IC on the base.

2 Connection to the pump

• Unscrew PEEK capillary 35 of coupling and attach it to

connection

3 Connection to injection valve

• Unscrew PEEK capillary 38 of coupling and attach it to

connection

The pulsation dampener is filled with isopropanol and must be rinsed

with eluent before connection to a separating column (see Section

2.6.4).

80 of the pulsation dampener 36.

81 of the pulsation dampener 36.

The 6.2620.150 Pulsation dampener can be operated in both

directions.

The two steel versions 2.844.0030 and 2.844.0130 are operated

without Pulsation dampener.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

29

Page 42

Table of contents

38

46

35

29

32

34

Figure 15: Connection of the pulsation dampener

29 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

32 Purge valve

34 Filter unit PEEK (6.2821.120)

35 Connection capillary

from Filter unit PEEK to Pulsation

dampener.

6.1831.010 PEEK capillary,

length L = 13 cm

36 Pulsation dampener (6.2620.150)

80 81

36

38 Inlet capillary for injection valve

PEEK capillary 6.1831.010,

length L = 24 cm

46 Injection valve

Connection to purge valve

80

Connection to injection valve

81

Page 43

2.6 High-pressure pump

2.6.3 Connecting the eluent bottle

The eluent supply line from the storage bottle to the high-pressure

pump is connected as follows:

Only degassed (with N

, He or vacuum) and microfiltered (0.45 μm

2

filter) eluents should be used!

The 6.1608.070 Eluent bottle (2 L) supplied is not suitable for vacu-

um degassing. Use a pressure-resistant container for this.

Care must be taken that the eluent used is freely miscible with any

solvent remaining in the pump head (the pump head leaves the

factory filled with either isopropanol or methanol/water). If this is not

the case then the pump must first be rinsed with a solvent which is

miscible with both the previous eluent and the following eluent (e.g.

acetone).

1 Prepare eluent bottle

• Prepare, microfilter (0.45 μm microfilter) and degas (with N2,

He, or vacuum) the suitable eluent for the required

application and separating column.

• Fill eluent into eluent vessel

86(clear glass, 2 L).

2 Install bottle attachment

• Firmly screw threaded stopper 84 (6.1446.040; part of

6.1602.160) into the smaller threaded opening (M6) of bottle

attachment

• Firmly screw aspirating filter

• Pull the other end of aspirating tubing

threaded opening (M8) of bottle attachment

85 (6.1602.105; part of 6.1602.160).

87 onto aspirating tubing 82.

82. through the larger

85 from below.

• Push O-ring (E.301.0021; part of 6.1602.160) over the free

end of aspirating tubing

attachment

85.

• Push tubing nipple

the free end of aspirating tubing

red towards bottle attachment

larger opening of bottle attachment

• Insert aspirating tubing

82. and move it towards bottle

83 (4.420.4300; part of 6.1602.160) over

82., move it as far as requi-

85 and screw it loosely in the

85.

82. with screwed-on aspirating filter

87 into eluent bottle 86 and screw bottle attachment 85 onto

eluent bottle

• Pull aspirating tubing

86.

82. so far through the opening of tubing

nipple 83 that aspirating filter 87 is touching the bottom of

eluent bottle

• Fix aspirating tubing

nipple

86.

82. in place by screwing shut tubing

83.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

31

Page 44

Table of contents

84 85 86

3 Mount CO2 absorber tube

• First place a piece of cotton wool 89 followed by CO2

absorber

6839.1000) in the large opening of absorber tube

88 (e.g. Merck soda lime pellets with indicator, no.

91 and then

close it with the plastic lid.

• Fasten absorber tube

of SGJ clip

90.

91 to bottle attachment 85 with the aid

4 Connect aspirating tubing to pump

• Lead the free end of aspirating tubing 82. through opening 2

into the inner compartment of the 844 UV/VIS Compact IC.

• Pull aspirating tubing

82 sufficiently far into the interior of the

844 UV/VIS Compact IC, cut off to the required length and

push at least 5 mm of it onto aspirating capillary

30 of the

high-pressure pump (it may be necessary to use emery

paper).

• If necessary, fix aspirating tubing

82 in the required position

in the interior with the aid of the Y.107.0150 self-adhesive

strap.

Aspirating tubing (6.1834.010)

82

91

Tubing nipple (4.420.4300; M8)

83

with E.301.0021 O-ring

Threaded stopper (6.1446.040; M6)

84

90

82

83

89

Bottle attachment (6.1602.105)

85

88

Eluent bottle (6.1608.070)

86

Aspirating filter (6.2821.090)

87

CO2 absorber

88

Cotton wool

89

87

SGJ clip (6.2023.020)

90

Absorber tube (6.1609.000)

91

Figure 16: Connection of eluent bottle

2.6.4 Deaerating the pump and rinsing the pulsation dampener

The first time that it is started up the high-pressure pump must be deaerated. Proceed as follows:

1 Prepare for deaeration

• Open the rotary knob on purge valve 32 by approx. ½ turn in

the counterclockwise direction.

• Remove the plastic stopper from connection

6 on the front

panel of 844 UV/VIS Compact IC.

• Push 6.2816.020 Syringe (without needle) into connection

6

until the stop is reached.

Page 45

2.6 High-pressure pump

2 Open and connect system

• Start the «IC Net» PC program, if it has not already been

started (see Section

• Select

File / Open / System in the main window. Select the

system created in Section

2.5.3).

2.5.4, and click on <Open>.

• Select the

Connect to workplace item of the Control menu in this

window.

3 Set flow rate to 2 mL/min

• Double-click the 844 icon in the system window to open the

window for manual control of the 844 UV/VIS Compact IC

(see below).

• Set the flow rate to

• Click to

<Set> to send this value to the 844 UV/VIS Compact

2 mL/min in the Flow field.

IC.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

33

Page 46

Table of contents

4 Deaerate pump

• Make sure that the aspirating tubing 82 for the high-pressure

pump has been immersed into the eluent.

• Click the

<On> button for IC pump to switch on the high-pres-

sure pump.

• Use the syringe inserted into connection

6 to aspirate air until

eluent flows bubble-free into the syringe.

• Click the

<Off> button for IC pump to switch off the high-pres-

sure pump.

• Close the rotary knob on purge valve

32 by turning it in a

clockwise direction.

• Remove the syringe from connection

6.

5 Rinse pulsation dampener

• Place a beaker beneath the column connection capillary 47.

• Click the

pressure pump and rinse the pulsation dampener

<On> button for IC pump to switch on the high-

36 filled

with isopropanol for approx. 10 min with eluent.

• Click the

<Off> button for IC pump to switch off the high-pres-

sure pump.

6 Reduce flow rate

• Reset the original flow rate under Flow (e.g. 0.5 mL/min).

• Click

<Set> to send this value to the 844 UV/VIS Compact IC.

• Click <Save> to save the values.

2.7 Post column reactor

This chapter covers the two versions 2.844.0020 and

2.844.0120.

With versions 2.844.0010, 2.844.0030, 2.844.0110 or

2.844.0130 you can skip this chapter and go directly to Section

2.8.

Instrument versions 2.844.0020 and 2.844.0120 of the 844 UV/VIS

Compact IC contain the 6.2836.000 Post column reactor (see

Instructions for Use 8.108.1031 Post column reactor).

2.7.1 Preparing the peristaltic pump

Before it is started up, the accessories must be mounted on the

peristaltic pump built into the 844 UV/VIS Compact IC Proceed as

follows:

1 Remove the tubing cartridge

• Loosen tubing cartridge 96 mounted above pump drive 51 by

pressing down snap-action lever 98 from holder clip 50 and

remove it from mounting pin

40.

Page 47

2.7 Post column reactor

95

2 Attach coupling 93

• At the left-hand end of pump tubing 94 6.1826.320 push on a

coupling

93 6.2744.030. Slightly moistening the Tipp of the

coupling makes this easier.

• Fix "Aspirating tubing for reagent"

compression fitting

64 (6.2744.010).

92 to coupling 93 using

3 Attach "Coupling with filter and tubing security

device" 99

• To the right-hand end of pump tubing

94 6.1826.320

attach a "coupling with filter and tubing security device" 99

6.2744.180:

• Dismantle the tubing security device and first push the

union nut and compression piece onto the tubing.

• Push the tubing onto the coupling and screw the union

nut onto the coupling to secure the tubing.

4 Insert the pump tubing

• Insert the fitted-out pump tubing 94 into the tubing cartridge.

The middle stopper

95 should click into position in the

corresponding holder on left-hand side of the tubing

cartridge.

92

64

93

94

95

5 Reinsert the tubing cartridge

• Insert the tubing cartridge with pump tubing 94 into the front

of the holding clip. Insert the left-hand side first, then press

down the right-hand side until snap-action lever

position. Make sure that the pump tubing has no kinks.

96

98

97

99

64

98 clicks into

72

100

Figure 17: Installing pump tubings

64 Compression fitting (6.2744.010)

Aspirating tubing for reagent

92

6.1803.020 PTFE tubing

72 Filter 6.2821.130

Coupling (6.2744.030)

93

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

35

Page 48

Table of contents

Pump tubing 6.1826.320

94

for reagent

Stopper (orange-yellow)

95

Snap-action lever

98

for releasing the tubing cartridge

PEEK coupling with filter and

99

tubing security device 6.2744.180

Tubing cartridge (6.2755.000)

96

Connection capillary

100

Contact pressure lever

97

for adjusting the contact pressure

PTFE Capillary 6.1803.150,

length L = 20 cm

2.7.2 Installation of the post column reactor

The installation procedure is as follows:

1 Attach PCR holder 102

• Push the PCR holder with the strip on its rear panel onto

lower mounting rail

2 Insert post column reactor 101 in PCR holder 102

• Insert post column reactor 101 into PCR holder 102 with its

tubing connections facing upward.

• Push PCR holder

downward as possible.

44.

102 with post column reactor 101 as far

Page 49

2.7 Post column reactor

101 102

49

Figure 18: Attaching the post column reactor

49 Peristaltic pump

for operating the post column reactor

6.2836.000 Post column reactor

101

6.2057.050 PCR holder

102

Holder for post column reactor

2.7.3 Post column reactor tubing connections

The connections for the column (Section 2.8) and detector (Section 2.9)

are described later. In this first step the reagent flow is connected:

1 Connect pumping tube to inlet "reagent in" 106

• Attach connection capillary 100 6.1803.050 (20 cm) to post

column reactor inlet "reagent in"

fitting

64 (6.2744.010).

106 using a compression

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

37

Page 50

Table of contents

101

104

107

105

103

106

100

100 Connection capillary

PTFE Capillary 6.1803.050,

length L = 20 cm

101 Post column reactor 6.2836.000

Connection capillary

103

PEEK Capillary 6.1831.110,

length L = 30 cm

Post column reactor "eluent in"

104

Inlet from column

Post column reactor "to detector"

105

Outlet to detector

Post column reactor "reagent in"

106

Inlet for post column reagent from

peristaltic pump

107

101

64

Figure 19: Post column reactor

The post column reactor connections to the column and detector are

described in Section

2.8 and Section 2.9.

2.7.4 Reagent bottle connection

The reagent solution tubing from the supply bottle to the peristaltic

pump is mounted as follows:

Connection capillary

PEEK Capillary 6.1831.110,

length L = 30 cm

If a column heating is used, the

capillary

124 is connected here.

1 Preparing the supply bottle for the reagent

• Fill the reagent solution into supply bottle 109 (amber glass,

1 L) and label the bottle.

• Screw bottle attachment

108 onto supply bottle 109.

2 Connect aspirating tubing for reagent

Page 51

2.8 Columns

64

• Prepare aspirating tubing 92: cut a piece of 6.1803.020 PTFE

tubing to the required length (normally approx. 120 cm).

• Pull one end of the aspirating tubing

compression fitting

the tubing projects.

• Screw PEEK compression fitting

opening of bottle attachment

bottle for the regeneration solution and tighten it up so that

the tubing is firmly held.

• Lead the free end of aspirating tubing

of the openings 2 of the 844 UV/VIS Compact IC and pull it

sufficiently far into the inner compartment.

• Connect aspirating tubing

94 using a compression fitting 64 and a coupling 93.

64 (6.2744.010) so that approx. 30 cm of

108 mounted on the supply

92 to the inlet end of pump tubing

92 through a PEEK

64 with the tubing into one

92 from above into one

Figure 20: Connection of reagent

2.8 Columns

2.8.1 Precolumns

92

108

109

64 Compression fitting

(6.2744.010)

92 Aspirating tubing for reagent

6.1803.020 PTFE tubing

Bottle attachment

108

(6.1602.150)

Supply bottle 6.1608.020

109

The use of easily exchangeable precolumns protects the separating

columns and prolongs their lifetime. The precolumns available from

Metrohm are either real precolumns or precolumn cartridges, which are

used together with a cartridge holder. For the installation of a precolumn cartridge into the accompanying cartridge holder see the attached

leaflet.

The precolumn that is suitable for your separating column can be

found in the Metrohm IC Column Catalog which can be obtained

from your local Metrohm agency, the data sheet accompanying your

separating column, the product information about separating columns

that can be found under

chromatography products, or let your agency advise you directly.

844 UV/VIS Compact IC / Gebrauchsanweisung 8.844.1051

http://www.metrohm.com, ion

39

Page 52

Table of contents

New IC precolumns are normally filled with solution and sealed at both

ends. Before the precolumn is installed in the system, it must be

ensured that this solution is freely miscible with the eluent used

(check manufacturer's specifications).

1 Connect precolumn

• The precolumn is mounted upstream from the separating

column. Use as short a piece of 6.1831.010 PEEK capillary as

possible.

• If column heating is used (see Section

can also be placed in the inner compartment of the column

heating. Use an S-Guard for this. Other precolumns can only

be mounted outside the column heating.

When you install the column, always ensure that this is inserted

correctly in accordance with the flow direction (if existent) shown.

2 Rinse the precolumn

• Place a beaker beneath outlet capillary.

• Switch on IC Pump in «IC Net» and rinse precolumn for

approx. 10 min with eluent.

• Switch off IC Pump.

2.8.2 General information on separating columns

The precolumn that is suitable for your separating column can be

found in the Metrohm IC Column Catalog, the product information

about separating columns that can be found under

rohm.com, ion chromatography products, or let your agency advise

you directly.

2.8.4 the precolumn

http://www.met-

New IC separating columns are normally filled with solution and