Page 1

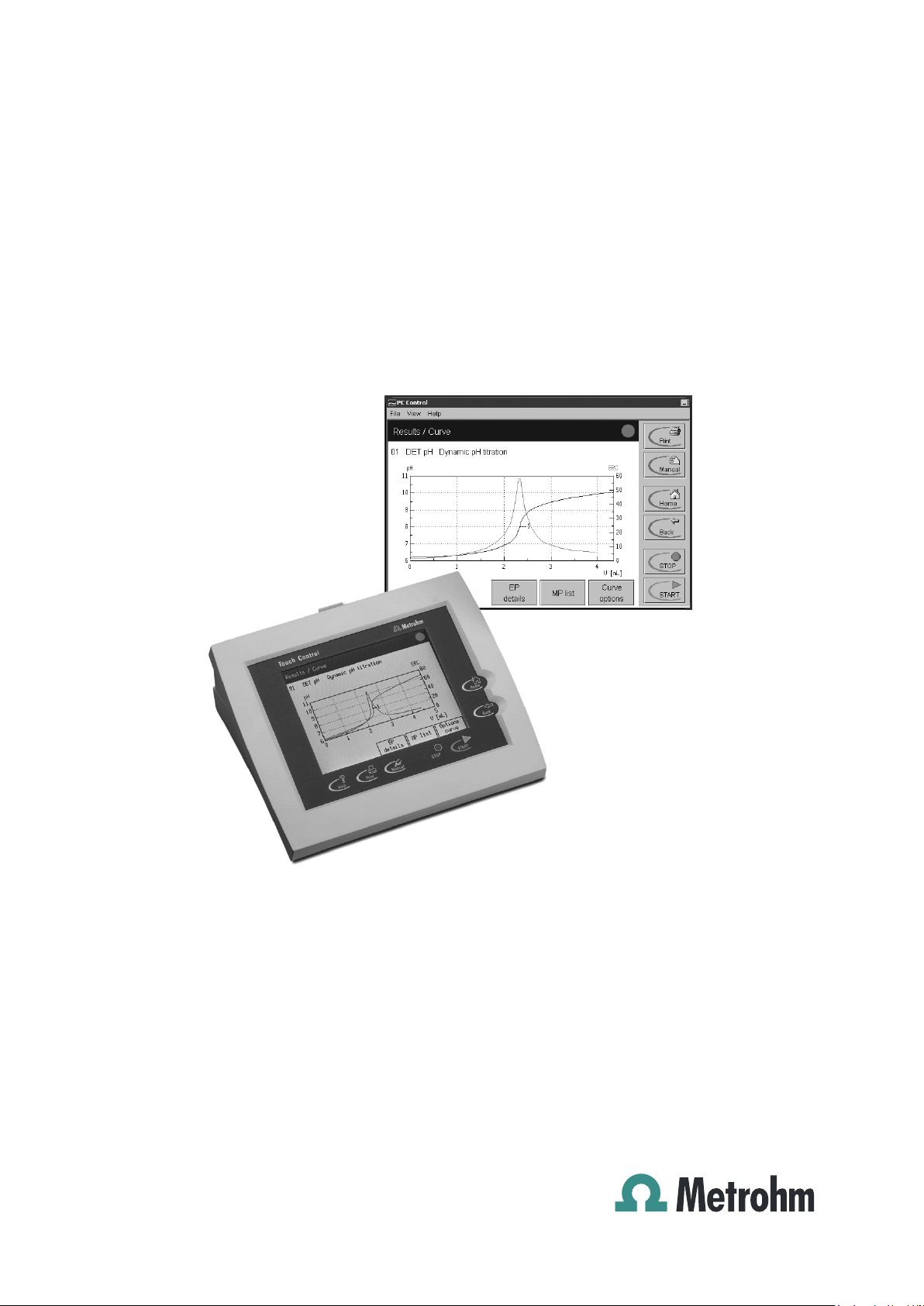

PC Control / Touch Control

Manual

8.840.8003EN

Page 2

Page 3

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

PC Control

Touch Control

Program version PC Control 5.0

Touch Control 5.840.0140

Manual

8.840.8003EN 05.2008 / jb

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been checked with great care,

errors cannot be entirely excluded. Should you notice any mistakes please send us your

comments using the address given above.

Page 5

Contents

Table of contents

1 Introduction.......................................................... 1

1.1 Instrument description...................................................................................2

1.2 About the documentation ..............................................................................3

1.2.1 Symbols and conventions........................................................................3

2 Installation ........................................................... 5

2.1 Setting up the Touch Control ........................................................................5

2.1.1 Packaging.................................................................................................5

2.1.2 Checks......................................................................................................5

2.1.3 Location....................................................................................................5

2.2 Touch Control parts and controls .................................................................6

3 Operation.............................................................. 9

3.1 Operating principles: Touch Control ............................................................9

3.1.1 Switching Touch Control on and off.........................................................9

3.1.2 Setting the display contrast of the Touch Control .................................10

3.1.3 Operating the Touch Screen..................................................................10

3.1.4 Entering text and numbers using Touch Control ...................................11

3.2 Operating principles: PC Control............................................................... 13

3.2.1 Starting and stopping the PC Control software .....................................13

3.2.2 Operating the PC Control software ........................................................13

3.3 User interface and controls ........................................................................ 14

3.3.1 User interface of the Touch Control and PC Control .............................14

3.3.2 Controls of the Touch Control and PC Control......................................15

3.3.3 Online help .............................................................................................17

3.4 Program structure ....................................................................................... 18

3.5 Login ............................................................................................................ 19

3.6 Main dialog and structure of the dialog windows..................................... 21

3.7 System settings........................................................................................... 23

3.7.1 Selecting the dialog language ...............................................................23

3.7.2 Setting the date, time and time zone .....................................................23

3.7.3 System-specific dialog options..............................................................24

3.7.4 Routine dialog: disabling functions........................................................25

3.7.5 User administration ................................................................................26

3.7.6 Creating an identification card ...............................................................29

3.7.7 Editing login options...............................................................................30

3.7.8 Audit trail.................................................................................................34

3.7.9 Measured value display .........................................................................36

3.7.10 Acoustic signals .....................................................................................37

3.8 Titrants......................................................................................................... 38

3.8.1 Configuring a titrant in a new intelligent exchange or dosing unit ........39

3.8.2 Configuring a titrant in a new non-intelligent exchange or dosing unit .40

3.8.3 Editing titrant data ..................................................................................40

3.8.4 Titer determination options and data .....................................................41

3.8.5 Exchange unit and dosing unit ..............................................................44

PC Control / Touch Control I

Page 6

Contents

3.8.6 Tubing parameters and parameters for the preparation procedure .....45

3.8.7 Rotating direction of the valve disk (Dosing unit only) ..........................48

3.8.8 Monitoring the GLP test .........................................................................49

3.8.9 Monitoring the working life .....................................................................49

3.9 Sensors........................................................................................................ 50

3.9.1 Configuring a new intelligent sensor......................................................51

3.9.2 Configuring a new non-intelligent sensor ..............................................51

3.9.3 Editing sensor data ................................................................................52

3.9.4 Calibration data (for pH and ISE electrodes only).................................52

3.9.5 Monitoring the calibration interval (for pH and ISE electrodes only).....53

3.9.6 Calibration data limits (for pH and ISE electrodes only) .......................54

3.9.7 Monitoring the working life .....................................................................54

3.10 Device manager........................................................................................... 55

3.10.1 Configuring a new device ......................................................................56

3.10.2 Editing device data ................................................................................56

3.10.3 PC Control and Touch Control...............................................................56

3.10.4 Titrando ..................................................................................................57

3.10.5 USB Sample Processor and Robotic Titrosampler ...............................58

3.10.6 Dosing Interface .....................................................................................68

3.10.7 Printer (Touch Control only) ...................................................................68

3.10.8 Balance ..................................................................................................69

3.10.9 Bluetooth devices...................................................................................71

3.10.10 RS-232/USB Box / Serial ports ..............................................................72

3.10.11 847 USB Lab Link (Touch Control only) ................................................72

3.10.12 PC/LIMS module ....................................................................................73

3.10.13 Send messages as e-mails ...................................................................74

3.10.14 PC keyboard (Touch Control only) ........................................................75

3.10.15 Barcode reader ......................................................................................76

3.11 File manager................................................................................................ 77

3.11.1 Copying files...........................................................................................81

3.11.2 File properties ........................................................................................81

3.11.3 Renaming a file ......................................................................................82

3.11.4 Saving a file ............................................................................................ 82

3.11.5 Card 1 and Card 2 .................................................................................83

3.11.6 Backup and restore................................................................................84

3.12 GLP manager............................................................................................... 87

3.12.1 Automatic system test............................................................................87

3.12.2 Test tools................................................................................................88

3.12.3 GLP tests for measurement and titration...............................................89

3.12.4 System validation ...................................................................................90

3.12.5 Service interval .......................................................................................91

3.12.6 Backup interval.......................................................................................91

3.13 Common variables ...................................................................................... 92

3.13.1 Editing common variables .....................................................................92

3.13.2 Properties of common variables............................................................94

3.13.3 Monitoring the validity ............................................................................95

3.14 Templates .................................................................................................... 96

3.14.1 Sample identification list ........................................................................96

3.14.2 Sample assignment table ......................................................................97

3.14.3 Custom results templates ......................................................................99

3.14.4 Input lines .............................................................................................100

II PC Control / Touch Control

Page 7

Contents

3.14.5 Output lines ......................................................................................... 101

3.14.6 Custom calibration buffers .................................................................. 103

3.14.7 Report header...................................................................................... 104

3.14.8 Custom electrode type........................................................................ 105

3.15 Loading methods ...................................................................................... 107

3.15.1 Loading a method ............................................................................... 107

3.15.2 Creating a new method....................................................................... 108

3.16 Editing parameters.................................................................................... 113

3.16.1 Editing commands .............................................................................. 113

3.16.2 Insert command .................................................................................. 115

3.16.3 Method options ................................................................................... 116

3.16.4 Statistics .............................................................................................. 118

3.16.5 Direct parameters................................................................................ 118

3.16.6 Sample data ........................................................................................ 119

3.16.7 Start and stop options......................................................................... 121

3.16.8 Note ..................................................................................................... 122

3.16.9 Properties ............................................................................................ 123

3.16.10 Saving the determination automat. and sending a PC/LIMS report... 123

3.16.11 Save method ....................................................................................... 125

3.17 Control ...................................................................................................... 126

3.17.1 Statistics .............................................................................................. 126

3.17.2 Sample data silo.................................................................................. 127

3.17.3 Autostart .............................................................................................. 128

3.18 Results and more determination data ..................................................... 129

3.18.1 More determination data ..................................................................... 130

3.18.2 Messages ............................................................................................ 132

3.18.3 Local common variables ..................................................................... 133

3.18.4 Determination properties..................................................................... 133

3.18.5 Save determination.............................................................................. 136

3.18.6 Load determination data ..................................................................... 136

3.18.7 Curves.................................................................................................. 139

3.18.8 Recalculation and re-evaluation.......................................................... 140

3.18.9 Export (PC Control only)...................................................................... 142

3.19 Sample data............................................................................................... 143

3.19.1 Sample data input in the main dialog ................................................. 143

3.19.2 Sample data request in the determination sequence ........................ 144

3.19.3 Sample data silo.................................................................................. 145

3.19.4 Export of sample data ......................................................................... 151

3.20 Determination sequence........................................................................... 152

3.20.1 Carrying out a single determination .................................................... 152

3.20.2 Processing a sample series ................................................................ 153

3.20.3 Stopping determinations manually ..................................................... 154

3.20.4 Live display.......................................................................................... 154

3.20.5 Main dialog "live".................................................................................. 157

3.20.6 Live parameters................................................................................... 158

3.21 Statistics .................................................................................................... 160

3.21.1 Statistical information about the result................................................ 161

3.21.2 Delete statistics data ........................................................................... 162

3.21.3 Adding a determination to a statistics series...................................... 162

3.22 Result silo.................................................................................................. 163

PC Control / Touch Control III

Page 8

Contents

3.22.1 Properties of the result silo ..................................................................164

3.22.2 Saving and loading the result silo........................................................166

3.23 Print……..................................................................................................... 167

3.23.1 Sending or saving a PC/LIMS report ...................................................174

3.23.2 Printing PDF reports.............................................................................175

3.24 Manual control........................................................................................... 176

3.24.1 Measure................................................................................................178

3.24.2 Dosing ..................................................................................................179

3.24.3 Stir ........................................................................................................184

3.24.4 Manual titration.....................................................................................185

3.24.5 Remote .................................................................................................186

3.24.6 USB Sample Processor .......................................................................187

4 Parameters ....................................................... 193

4.1 Titrations.................................................................................................... 193

4.1.1 Dynamic equivalence point titrations (DET) and monotonic equivalence

point titrations (MET)............................................................................197

4.1.2 Endpoint titrations (SET) ......................................................................206

4.1.3 Karl Fischer titrations (KFT)..................................................................212

4.1.4 STAT titrations (STAT) ..........................................................................216

4.1.5 Control device, sensor, dosing device and stirrer...............................223

4.1.6 Direct parameters.................................................................................226

4.2 Measurements (MEAS) ............................................................................. 227

4.3 Measurements (MEAS Cond) ................................................................... 230

4.4 Evaluation .................................................................................................. 231

4.4.1 Evaluation of fixed endpoints (EVAL FIX EP).......................................232

4.4.2 Evaluation of pK value and half neutralization potential

(EVAL pK/HNP) ....................................................................................233

4.4.3 Evaluation of minimum and maximum (EVAL MIN/MAX)....................234

4.4.4 Evaluation of break points (EVAL BREAK) ..........................................235

4.4.5 Rate evaluation (EVAL RATE) ..............................................................236

4.5 Calculations............................................................................................... 238

4.5.1 CALC command ..................................................................................238

4.5.2 CALC LIVE command ..........................................................................242

4.5.3 The formula editor ................................................................................243

4.5.4 Creating custom result templates........................................................246

4.5.5 Loading result templates .....................................................................246

4.5.6 Conversion table of the calculating formula for KF titrations ..............248

4.5.7 Calculable variables .............................................................................248

4.5.8 Result variables as parameters ...........................................................253

4.6 Reports ...................................................................................................... 254

4.7 Calibrating pH electrodes (CAL pH) and ISE (CAL Conc) ..................... 257

4.8 Calibrating conductivity measuring cells (CAL Cond) ........................... 263

4.9 Electrode test for pH electrodes (ELT) .................................................... 265

4.10 Dosing and liquid handling ...................................................................... 270

4.10.1 Dosing (ADD) .......................................................................................270

4.10.2 Liquid handling (LQH).......................................................................... 270

4.10.3 Preparing (PREP) and emptying (EMPTY) ..........................................272

4.10.4 Monitored dosing (DOS)......................................................................273

4.11 Communication ......................................................................................... 278

IV PC Control / Touch Control

Page 9

Contents

4.11.1 Scanning lines (SCAN)........................................................................ 278

4.11.2 Setting lines (CTRL)............................................................................. 278

4.11.3 Receive data (SCAN RS)..................................................................... 279

4.11.4 Send data (CONTROL RS).................................................................. 279

4.12 Automation ................................................................................................ 280

4.12.1 Move (MOVE) ...................................................................................... 280

4.12.2 Lift (LIFT).............................................................................................. 281

4.12.3 Pump (PUMP)...................................................................................... 281

4.12.4 Rack reset (RACK) .............................................................................. 282

4.12.5 Sample variable (SAMPLE) ................................................................. 282

4.12.6 Subsequence (SUBSEQ) .................................................................... 282

4.13 Various commands ................................................................................... 285

4.13.1 Stirring (STIR) ...................................................................................... 285

4.13.2 Waiting (WAIT) ..................................................................................... 285

4.13.3 Requesting sample data and common variables (REQUEST) .......... 286

4.13.4 Acoustic signal (BEEP)........................................................................ 286

4.13.5 Signature (SIGN) ................................................................................. 286

4.13.6 End (END) ........................................................................................... 286

5 Troubleshooting – Maintenance ...................... 287

5.1 Troubleshooting ........................................................................................ 287

5.1.1 Editing methods .................................................................................. 287

5.1.2 Sample series...................................................................................... 287

5.1.3 Results, calculations and statistics ..................................................... 288

5.1.4 SET titrations........................................................................................ 289

5.1.5 KF titrations.......................................................................................... 290

5.1.6 STAT titrations ..................................................................................... 291

5.1.7 Sensor data ......................................................................................... 292

5.1.8 Print...................................................................................................... 292

5.1.9 Manual Operation................................................................................ 293

5.1.10 USB Sample Processor....................................................................... 293

5.1.11 File manager........................................................................................ 294

5.1.12 Miscellaneous...................................................................................... 294

5.2 Diagnosis................................................................................................... 295

5.2.1 LCD test............................................................................................... 295

5.2.2 Temperature monitoring (Temperature control) ................................. 295

5.2.3 Formatting a memory card (Format card) .......................................... 296

5.2.4 PCMCIA specification (PCMCIA power selection).............................. 296

5.2.5 Service ................................................................................................. 296

5.2.6 Touch screen test................................................................................ 296

5.2.7 Software update .................................................................................. 297

5.2.8 822 Curve Simulator............................................................................ 301

5.2.9 Remove PCMCIA card 1/2 .................................................................. 302

5.3 Maintenance .............................................................................................. 303

5.3.1 Changing the batteries (Touch Control only)...................................... 303

5.3.2 RAM initialization (RAM Init, Touch Control only)................................ 304

6 Appendix ........................................................... 305

6.1 Technical data ........................................................................................... 305

6.1.1 Touch screen....................................................................................... 305

6.1.2 Interfaces ............................................................................................. 305

6.1.3 Power supply....................................................................................... 305

PC Control / Touch Control V

Page 10

Contents

6.1.4 Safety specifications ............................................................................305

6.1.5 Electromagnetic compatibility (EMC) ..................................................306

6.1.6 Ambient temperature ...........................................................................306

6.1.7 Dimensions ..........................................................................................306

6.2 Remote box................................................................................................ 307

6.2.1 Pin occupancy of the remote connection at the Remote box .............307

6.2.2 Functions of the individual remote lines ..............................................308

6.3 RS-232/USB Box........................................................................................ 309

6.3.1 RS-232 parameters ..............................................................................309

6.3.2 RS-232 pin occupancy.........................................................................310

6.4 Stored buffer series for CAL pH............................................................... 311

6.5 Liquid handling – schematic process ...................................................... 316

6.5.1 Port definitions of the dosing unit ........................................................316

6.5.2 Pipetting equipment.............................................................................316

6.5.3 Pipetting sequences ............................................................................317

6.6 Titration and measuring modes in the Titrando system......................... 320

6.7 Import of Titrino methods (PC Control only)........................................... 321

6.8 Arithmetic algorithms in the Titrando ...................................................... 324

6.9 Standard equipment.................................................................................. 326

6.9.1 840 Touch Control................................................................................326

6.9.2 PC Control software with Dongle (6.6050.400) ...................................326

6.9.3 PC Control software, demo version (6.6050.405) ...............................326

6.10 Additional devices and optional accessories ......................................... 327

6.10.1 Miscellaneous accessories..................................................................327

6.10.2 Communication....................................................................................327

6.11 Warranty and conformity .......................................................................... 329

6.11.1 Warranty ...............................................................................................329

6.11.2 Declaration of Conformity ....................................................................330

6.11.3 Declaration of Conformity ....................................................................331

6.11.4 Quality Management Principles ...........................................................332

7 Index ................................................................. 333

VI PC Control / Touch Control

Page 11

Contents

List of illustrations

Fig. 1.1: The Titrando system ...................................................................................................1

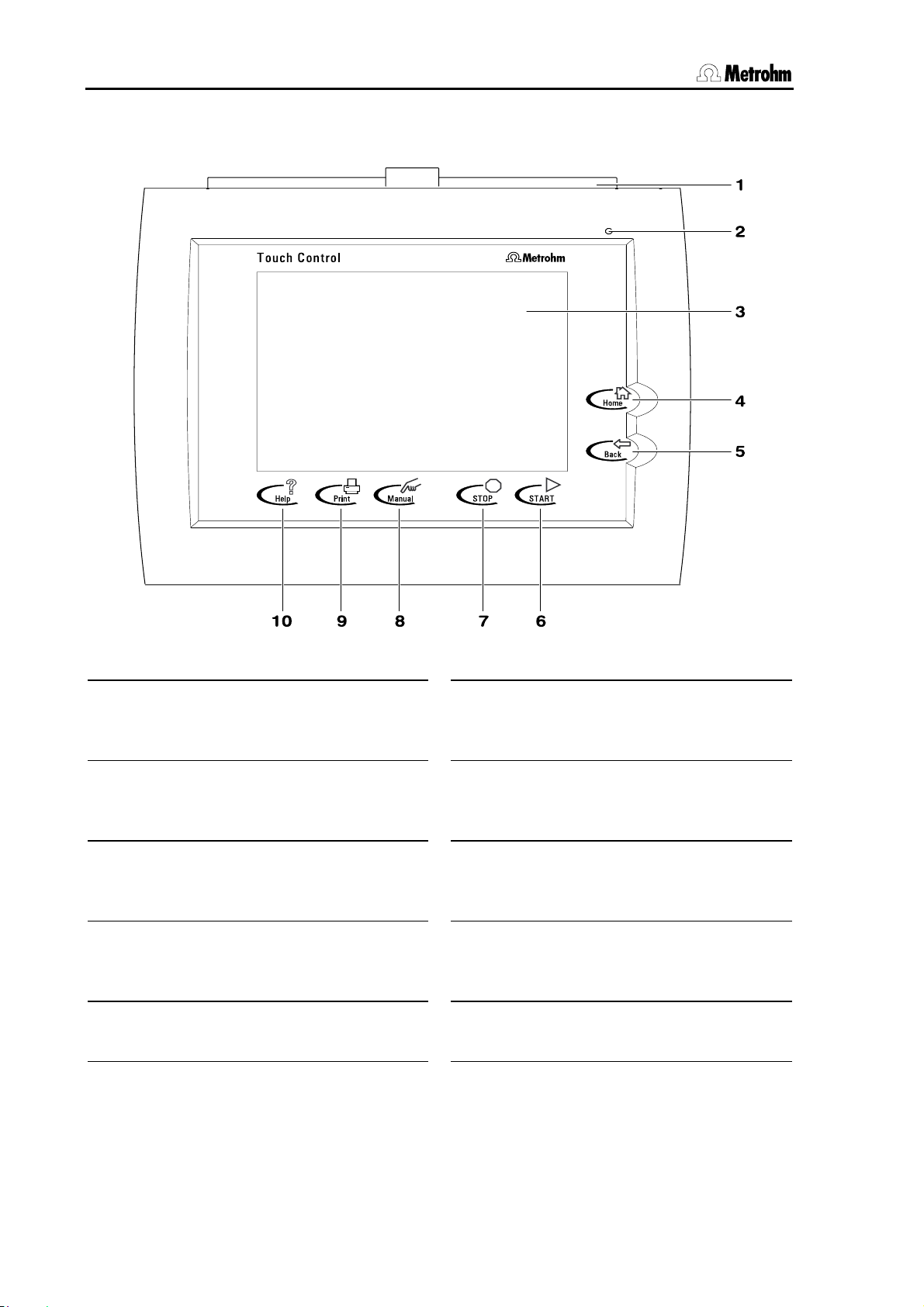

Fig. 2.1: Front view of the Touch Control.................................................................................. 6

Fig. 2.2: Rear view of the Touch Control .................................................................................. 7

Fig. 3.1: Different ways of navigation on the Touch Screen................................................... 10

Fig. 3.2: Touch Control user interface .................................................................................... 14

Fig. 3.3: PC Control user interface.......................................................................................... 14

Fig. 3.4: Online help, PC Control ............................................................................................ 17

Fig. 3.5: Program structure .....................................................................................................18

Fig. 3.6: Audit Trail .................................................................................................................. 35

Fig. 3.7: Dosing unit port occupancy and tubing connections .............................................. 45

Fig. 3.8: Exchange unit tubing connections ........................................................................... 46

Fig. 3.9: Data memory arrangement....................................................................................... 77

Fig. 3.10: PC Control: Folder structure for Card 1and Card 2 ............................................... 79

Fig. 3.11: Data transfer Backup/Restore ................................................................................ 84

Fig. 4.1: Reagent addition for DET ....................................................................................... 193

Fig. 4.2: Reagent addition for MET....................................................................................... 194

Fig. 4.3: Reagent addition for SET........................................................................................ 194

Fig. 4.4: Reagent addition for KFT........................................................................................ 195

Fig. 4.5: Reagent addition for STAT...................................................................................... 196

Fig. 4.6: Equivalence point recognition and numbering in windows ................................... 202

Fig. 4.7: Tubbs method for determining the equivalence point ........................................... 203

Fig. 4.8: Reagent addition during endpoint titrations with SET............................................ 207

Fig. 4.9: Control range size................................................................................................... 208

Fig. 4.10: Reagent addition and control range for STAT...................................................... 217

Fig. 4.11: Action "Exit method" or "Skip command".............................................................. 220

Fig. 4.12: Action "Hold" ......................................................................................................... 220

Fig. 4.13: Action "Wait" .......................................................................................................... 221

Fig. 4.14: Setting the stirring rate and speed ....................................................................... 225

Fig. 4.15: Determining the pK value from the titration curve ................................................ 233

Fig. 4.16: Evaluation of minimum and maximum ................................................................. 234

Fig. 4.17: Evaluating a breakpoint ........................................................................................ 236

Fig. 4.18: Definition of volume and dosing rate.................................................................... 273

Fig. 4.19: Definition of volume and dosing time................................................................... 274

Fig. 4.20: Definition of dosing rate and dosing time ............................................................ 274

Fig. 5.1: Changing the batteries for Touch Control .............................................................. 303

Fig. 6.1: View of the connections of the optional 6.2148.010 Remote box.......................... 307

Fig. 6.2: Pin occupancy at remote interface......................................................................... 307

Fig. 6.3: View of the connections of the optional RS-232/USB Box..................................... 309

Fig. 6.4: View of the RS-232 connections on the RS-232/USB Box..................................... 310

Fig. 6.5: Port occupancy of the Dosing unit ......................................................................... 316

PC Control / Touch Control VII

Page 12

Contents

VIII PC Control / Touch Control

Page 13

1 Introduction

1 Introduction

This manual gives you a comprehensive overview of the functions of the

Touch Control and the PC Control software for operating the Titrando

system. The Titrando system can either be operated with the Touch

Control with touch-sensitive screen as a stand-alone-system or with

the PC software PC Control. In this case the varied possibilities of a

computer can be utilized.

Figure 1.1 shows the versatility of the Titrando system. On the left a

Touch Control for operating a Titrando with external dosing devices is

shown. To the right you can see an automation system consisting of

USB Sample Processor, Titrando with internal dosing drive and Dosimat controlled by the PC Control software.

Fig. 1.1: The Titrando system

PC Control / Touch Control 1

Page 14

1.1 Instrument description

1.1 Instrument description

There are two different ways of operating the Titrando system: with

Touch Control the operation is via a touch-sensitive screen. A computer with installed PC Control software is a version with several additional features which directly utilize the communications and storage facilities of a PC. The import of Titrino methods is only possible with the

PC Control software. Both programs have a context-sensitive online

help function.

The appearance and operation of the two versions are almost identical;

this means that if you work with Touch Control then you can also use

the PC Control software without any problems and vice-versa. Methods,

determinations, sample data silos, result silos and backups are 100 %

compatible.

This manual describes the operation of the Titrando system with both

the PC Control software and Touch Control. If the description applies to

only one of these versions then this is indicated in the text.

Further documents can be found on the installation CD of PC Control.

Visit the web page http://products.metrohm.com

always find the most recent documents ready for download as PDF

files.

as well. There you will

2 PC Control / Touch Control

Page 15

1 Introduction

1.2 About the documentation

Attention!

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which have to be followed by the user in order to ensure

safe operation of the instrument.

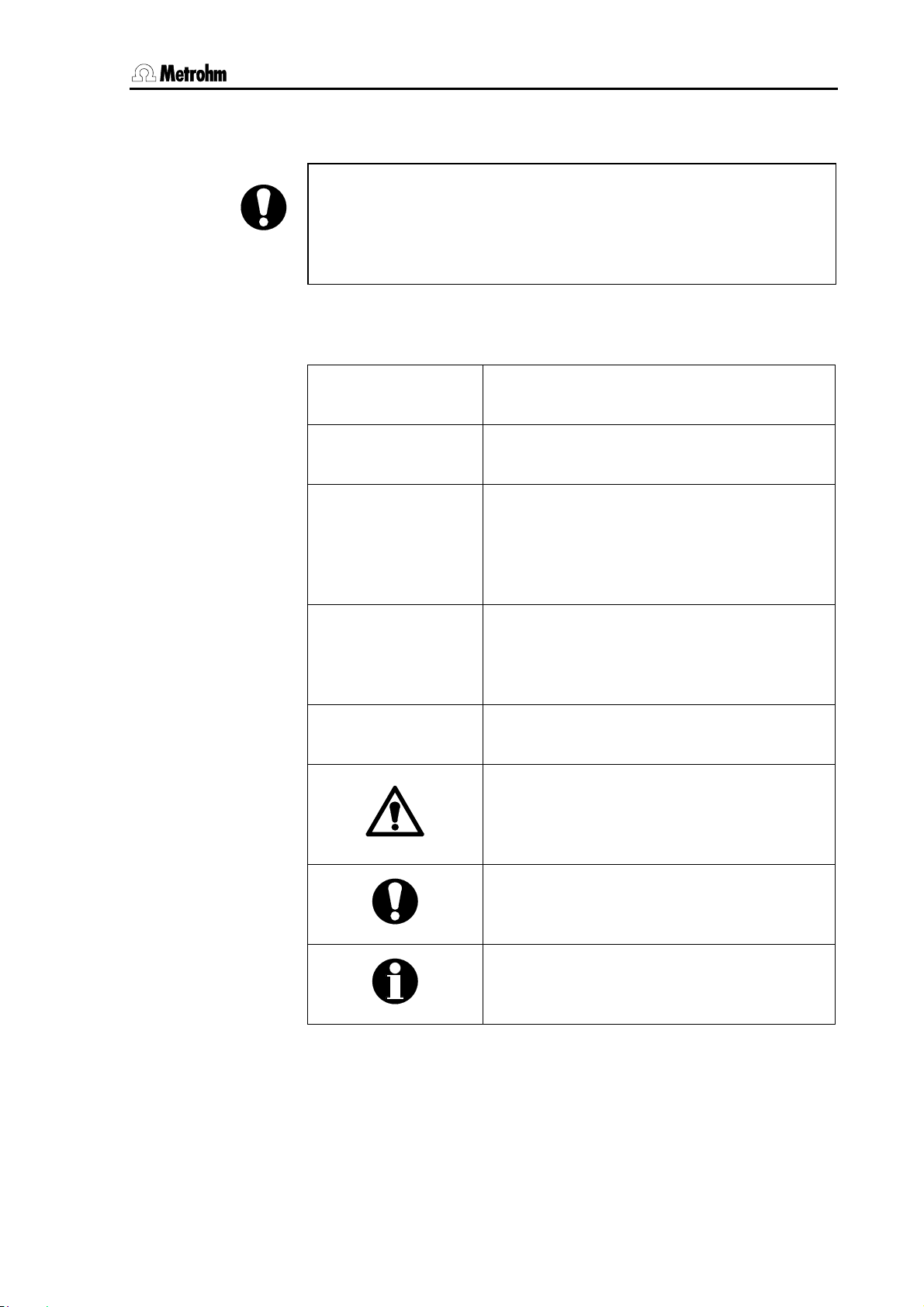

1.2.1 Symbols and conventions

The following symbols and styles are used in this documentation:

9

User

[Next]

Numbers of the parts and controls

see illustrations in Section 2.2.

Instructions

carry out the instructions step by step.

Parameters, input values

Parameters and values for parameters, dialog title.

Menu, menu item

in the PC Control software.

Button

on the user interface.

Fixed key

on the Touch Control.

<Ctrl>

Key

on the computer keyboard.

Danger/Warning

This symbol indicates a possible risk of injury to the user and possible damage to the

instrument or its components.

Attention

This symbol indicates important information

that you should read before continuing.

Information

This symbol indicates additional information

and tips that may be particularly useful.

PC Control / Touch Control 3

Page 16

1.2 About the documentation

4 PC Control / Touch Control

Page 17

2 Installation

2 Installation

Connecting the Touch Control to the Titrando is described in the

manual for the Titrando as well as the setup of the titration system with

peripheral devices such as stirrers and dosing devices.

2.1 Setting up the Touch Control

2.1.1 Packaging

The Touch Control and its specially packed accessories are supplied in

very protective special packaging. Please store this packaging in a safe

place; it is the only way in which the safe transport of the instrument can

be guaranteed.

2.1.2 Checks

Immediately after receipt, check whether the shipment has arrived

complete and without damage by comparing it with the delivery note.

2.1.3 Location

The Touch Control has been designed for internal laboratory use and

should not be used in explosion-endangered locations.

Place the instrument on a suitable vibration-free laboratory bench,

protected as much as possible from corrosive atmospheres and

contact with chemicals.

Choose a location where the temperature is usually between +5 °C and

+40 °C. The instrument should be protected against excessive

variations in temperature and direct sunlight.

PC Control / Touch Control 5

Page 18

2.2 Touch Control parts and controls

2.2 Touch Control parts and controls

1 Protective cover for card slots

Accommodates two PCMCIA or

CompactFlash memory cards.

2 “ON” LED

Lights up when instrument is switched

on.

3 Touch Screen display

4 Fixed key [Home]

Changes to main dialog.

5 Fixed key [Back]

Changes to previous dialog.

Fig. 2.1: Front view of the Touch Control

6 Fixed key [START]

Starts the current method.

7 Fixed key [STOP]

Stops the run.

8 Fixed key [Manual]

Opens the dialog for manual operation

of the titration system.

9 Fixed key [Print]

Opens the print dialog for manual

printout of a report.

10 Fixed key [Help]

Opens the context-sensitive help.

6 PC Control / Touch Control

Page 19

2 Installation

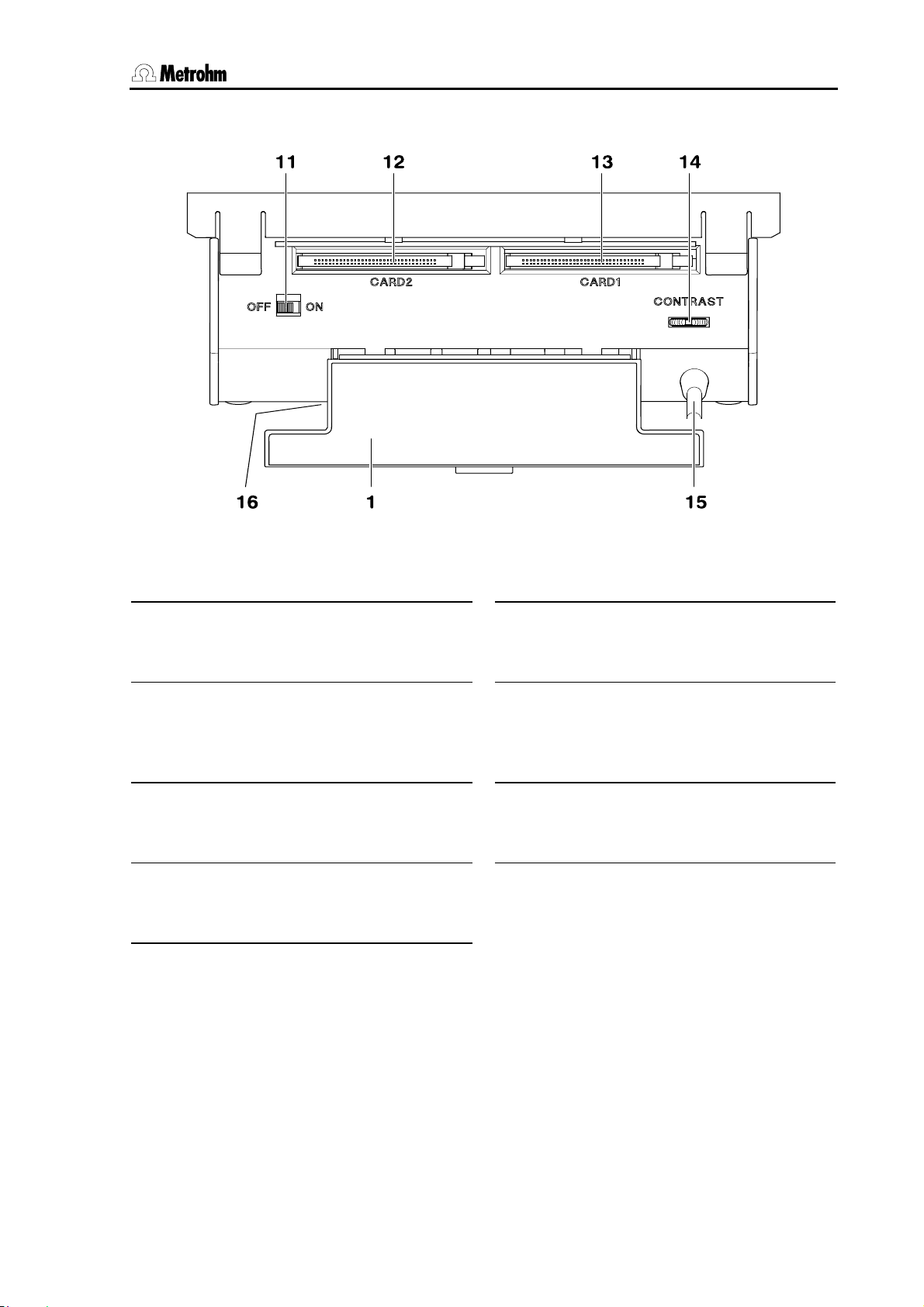

Fig. 2.2: Rear view of the Touch Control

1 Protective cover for card slots

Must be closed during operation to

protect the electronics from splashes.

11 On/Off switch

Touch Control must be shut down

properly by switching it off before the

current supply is interrupted.

12 Card slot 2

Accommodates one PCMCIA or

CompactFlash memory card.

13 Card slot 1

Accommodates one PCMCIA or

CompactFlash memory card.

Contrast controller for display

14

15 Connection cable

for connecting the Touch Control to the

Titrando ("Controller" connection).

16 Type plate

With device number and serial number

PC Control / Touch Control 7

Page 20

2.2 Touch Control parts and controls

8 PC Control / Touch Control

Page 21

3 Operation

3 Operation

The most important points concerning the operation of the Touch

Control and PC Control are described in this section. As the

appearance of the operator interface and the functions are almost

identical, only the PC Control operator interface is shown. If individual

functions are only available in Touch Control or in the PC Control

software then this is indicated accordingly in the text.

The arrangement of the program and the operating concept are

identical for Touch Control and the PC Control software. In Touch

Control operation is carried out via a touch-sensitive screen (Touch

Screen), in PC Control the software is operated by using a mouse and

the PC keyboard. This results in several system-specific operating

possibilities.

3.1 Operating principles: Touch Control

3.1.1 Switching Touch Control on and off

A Touch Control which is properly connected to a Titrando is switched

on and off with ON/OFF switch 11 on the rear panel of the instrument.

Attention!

The Touch Control must be shut down properly by switching it off

with the ON/OFF switch on the rear panel of the instrument before the

current supply is interrupted. Otherwise there is the risk that data may

be lost. As power is provided to the Touch Control via the Titrando,

the Titrando must never be separated from the mains supply (e. g. by

switching it off via a multiple outlet strip) before the Touch Control has

been switched off. When the Touch Control is switched on all the

other peripheral devices (e. g. printer) must already be switched on.

We recommend the following procedure:

Connect all the instruments (Titrando and peripheral devices) to the

mains supply via a multiple outlet strip with mains switch.

When switching on first switch on the multiple outlet strip with the

Touch Control switched off. Then switch on the Touch Control.

When switching off proceed in the reverse order. First switch off

the Touch Control. Then switch off all the peripheral devices via the

multiple outlet strip switch.

PC Control / Touch Control 9

Page 22

3.1 Operating principles: Touch Control

3.1.2 Setting the display contrast of the Touch Control

Knob 14 for setting the contrast of the Touch screen is located on the

rear panel of the instrument. Move it in one direction and hold it tight

when it reaches the stop in order to increase or reduce the contrast.

Use the fixed key [Help] in the main dialog to open the online help.

Set the contrast so that the scroll bar surface is light gray and the

margins to the left and below are dark gray (see Section

3.3.2).

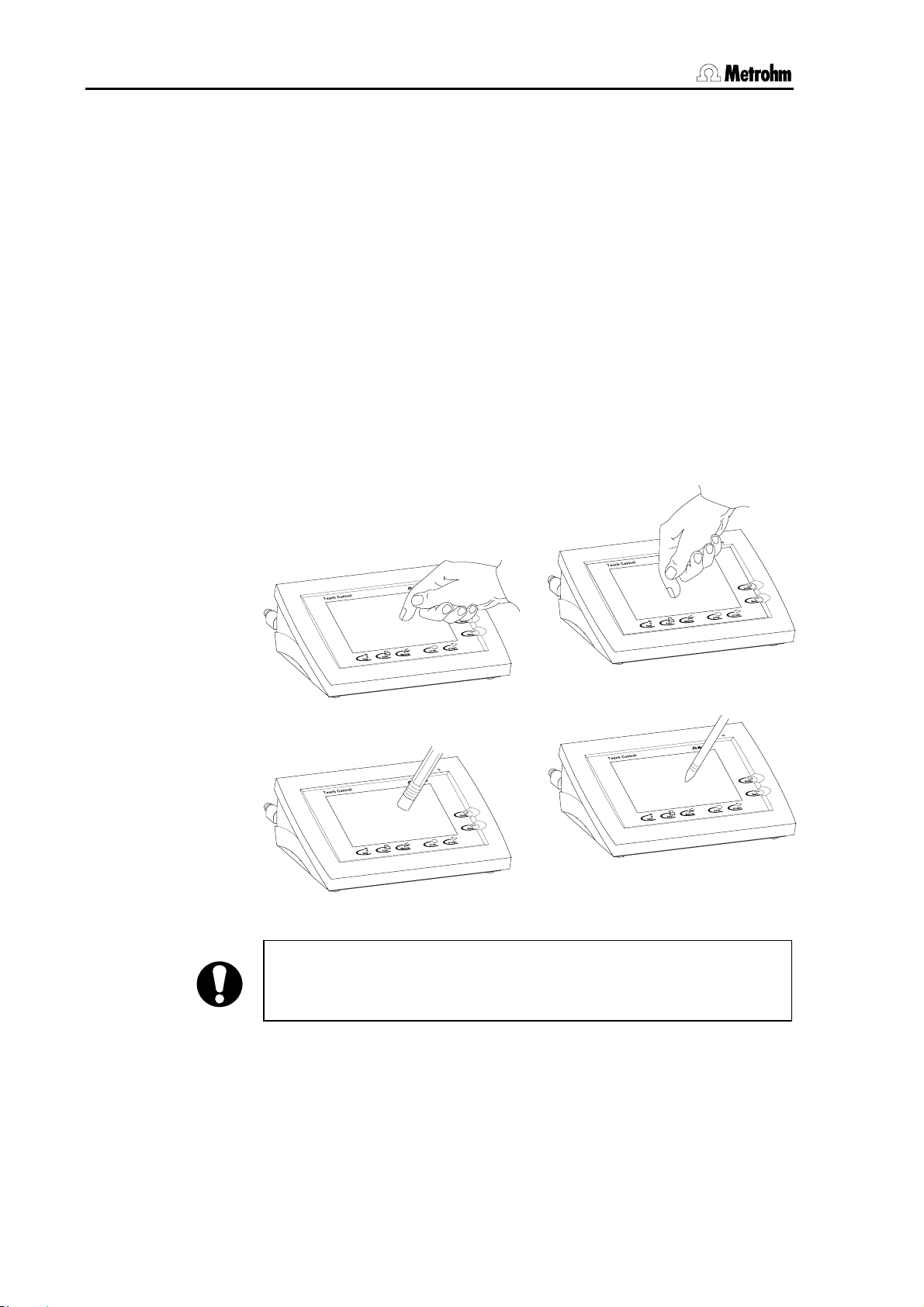

3.1.3 Operating the Touch Screen

The whole screen surface is touch-sensitive. Just touch some of the

buttons on the screen to see how to operate the Touch screen. You can

always return to the main dialog by touching [Home].

In order to activate an element on the Touch Control user interface just

touch the screen with your fingertip, finger nail, the eraser of a pencil or

a stylus (special tool for operating Touch screens); see below:

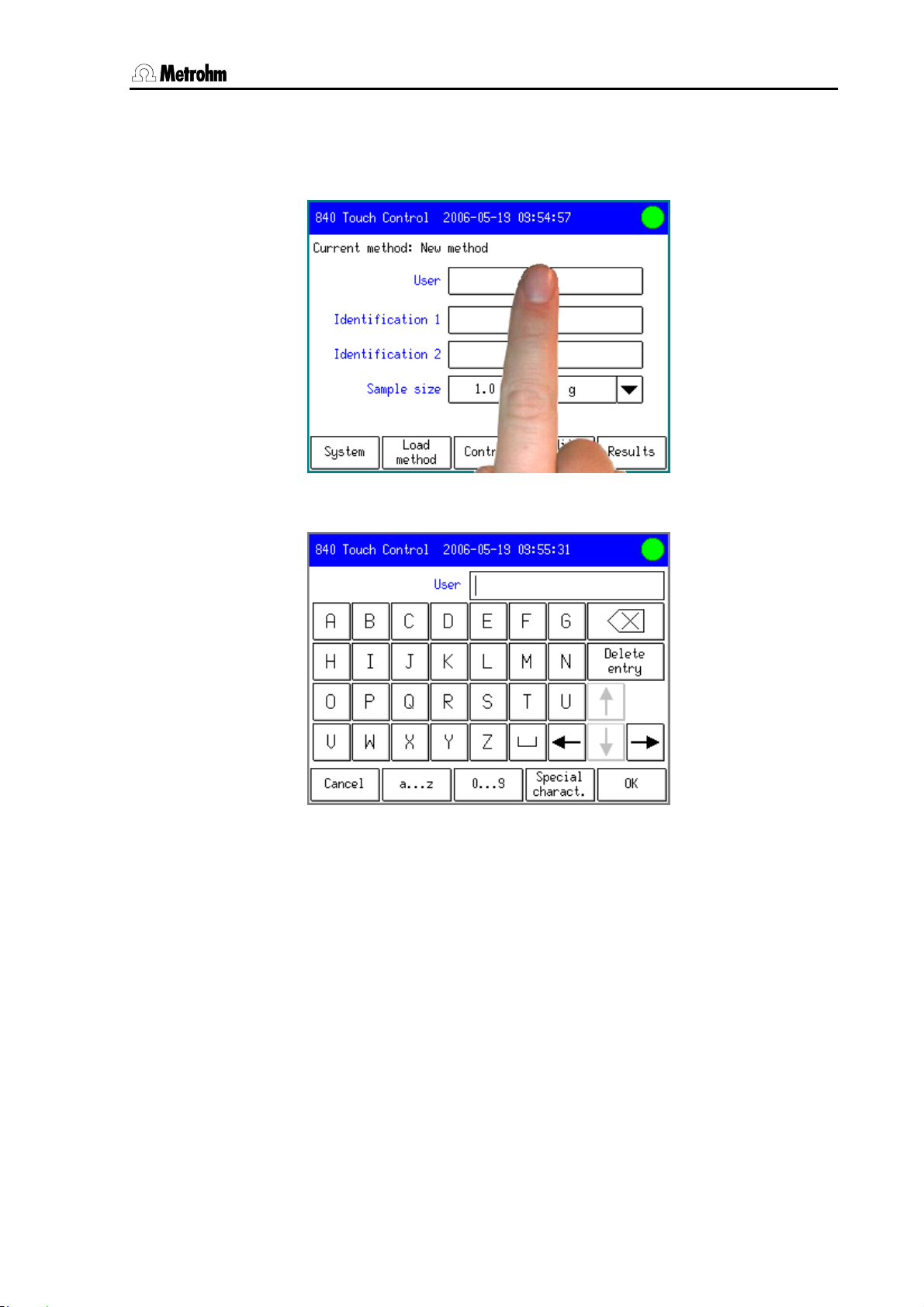

Fig. 3.1: Different ways of navigation on the Touch Screen

10 PC Control / Touch Control

Attention!

Never touch the Touch screen with a pointed or sharp object such as

a ballpoint pen.

If you use the standard settings then touching an active operating

element creates a sound.

Page 23

3 Operation

3.1.4 Entering text and numbers using Touch Control

Just touch an input field, e. g. User in the main dialog, to open the

Text editor.

In the text editor the name of the parameter is shown in front of the

input field.

Touch the required character. Apart from the capital letters which

first appear, there are also sets of characters with lower case letters,

numbers and mathematical signs as well as three blocks of special

characters. You can switch to the required set of characters with the

[a...z], [0...9] and [Special characters] buttons and

between the blocks of special characters with [More]. The

backspace button [⌫] deletes the character in front of the cursor.

[Delete entry] deletes the whole text. With the arrow buttons the

cursor can be positioned in the text.

Accept your entry with [OK] or [Back], or reject it with [Cancel].

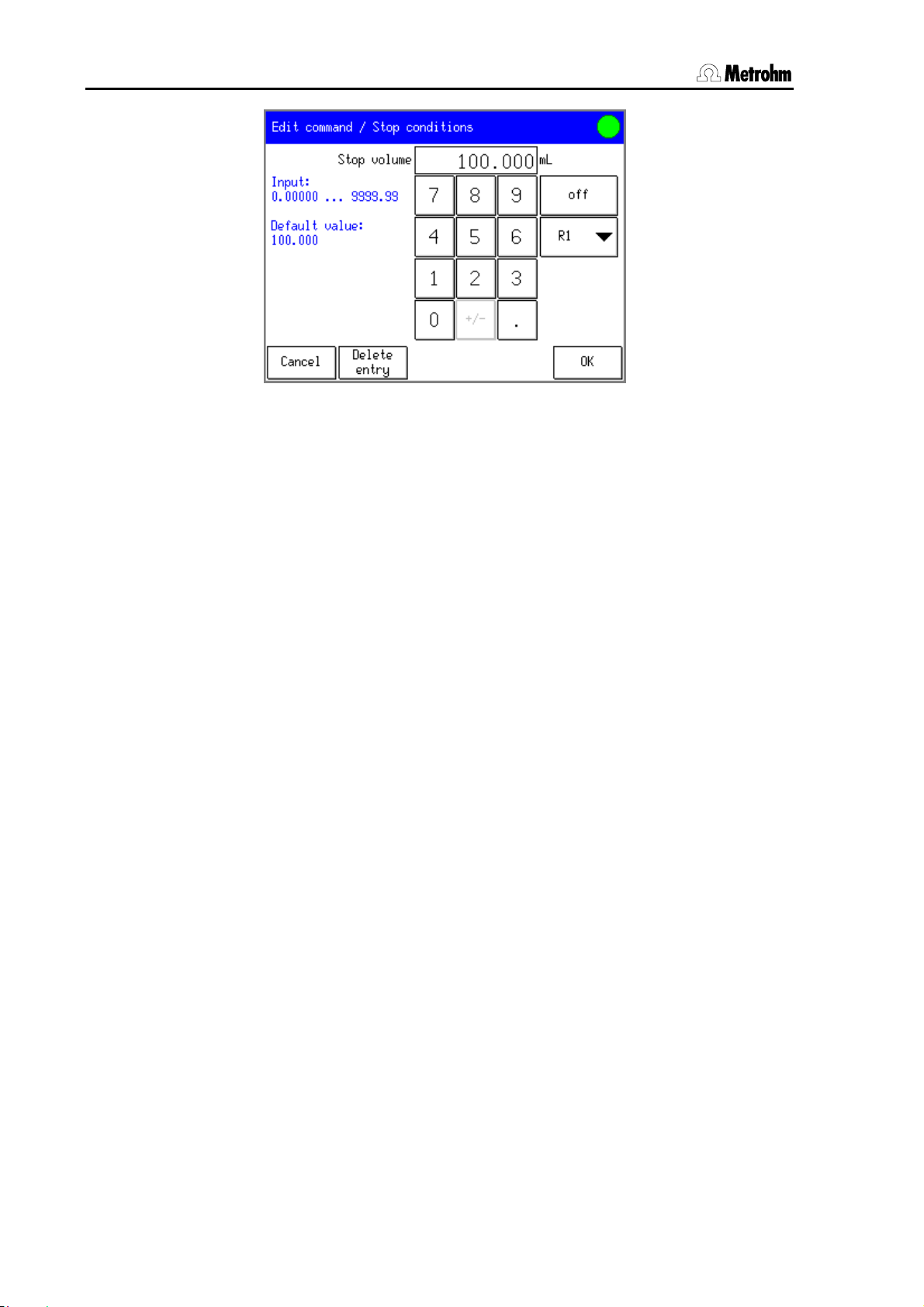

In input fields for numerical values the number editor will open. The

required value is entered directly via the indicated keys. A stop is

automatically used as the decimal separator.

For example, touch the input field for the Stop volume in a titration

command.

PC Control / Touch Control 11

Page 24

3.1 Operating principles: Touch Control

To the left of the block of numbers you can see the input range

together with its default value. If not only numbers but also special

values (e. g. off) can be entered for a parameter then the

corresponding buttons will be shown to the right of the block of

numbers. For many method parameters it is also possible to enter a

result which has previously been defined in the method sequence as a

value. The result variable can be selected under [R1] (see

Section 4.5.1).

Touch the required number or special value. The whole entry can be

deleted with [Delete entry].

Accept your entry with [OK] or [Back], or reject it with [Cancel].

To make the entry of texts and numbers easier you can also connect an

external PC keyboard with a USB connection to a Titrando system with

Touch Control (see Section

3.10.14).

12 PC Control / Touch Control

Page 25

3 Operation

3.2 Operating principles: PC Control

3.2.1 Starting and stopping the PC Control software

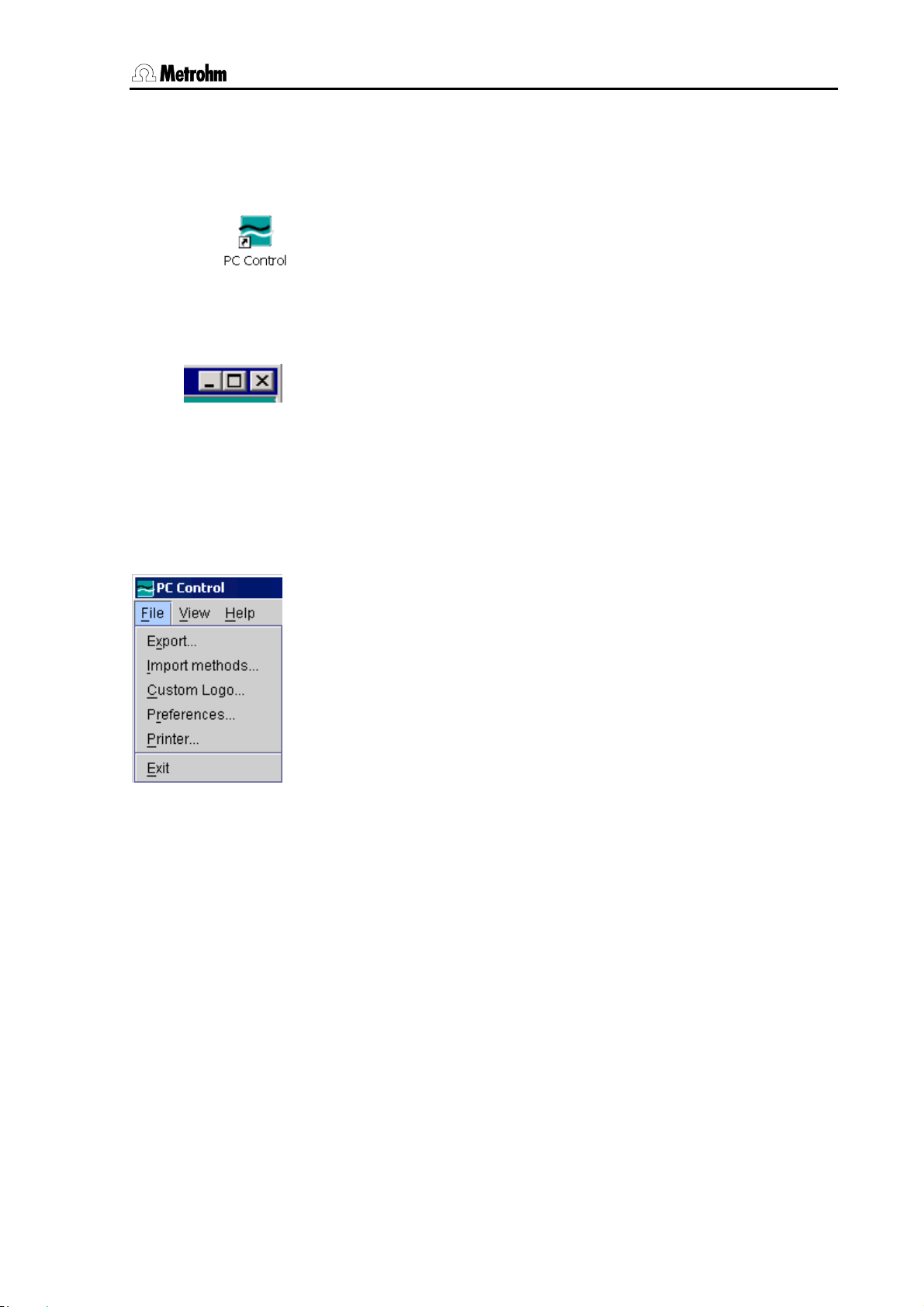

A double-click on the PC Control icon, which is automatically copied

onto the Windows desktop during installation, starts the program.

Alternatively you can start the program in the menu

Start/Program Files/Metrohm/PC Control or execute the file

PcControl.exe under C:\Program Files\Metrohm\PC Control\bin

(installation with the default path) with a double-click. After the program

start the main dialog window opens (see Section

The program can be closed by either clicking on [×] (close) in the top

right-hand corner of the program window or by clicking on the menu

item Exit in the File menu. When the PC Control software is started

the program window cannot be closed.

3.2.2 Operating the PC Control software

The PC Control program is operated within the main dialog window in

exactly the same way as Touch Control. All the elements of this

program window as well as the fixed keys can be activated or selected

with a mouse-click.

3.3).

PC Control also has a menu bar via which the specific PC Control

functions can be selected.

In addition, the controls of the main dialog display can be accessed

and operated via the PC keyboard. A cursor is provided; this can be

moved from one item to the next by using the tab key. An item selected

in this way is activated by the space bar. Input fields can be edited

directly.

PC Control / Touch Control 13

Page 26

3.3 User interface and controls

3.3 User interface and controls

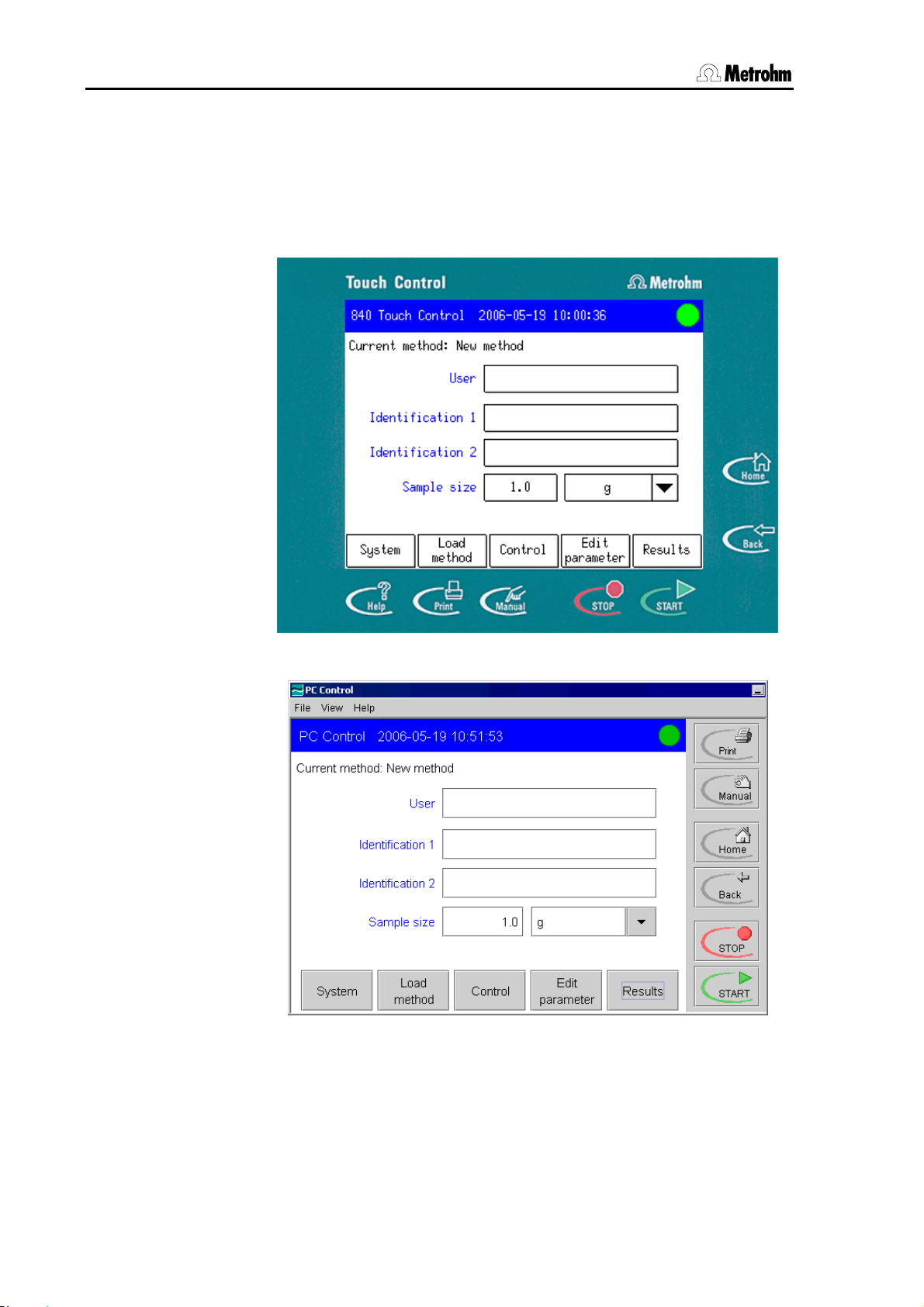

3.3.1 User interface of the Touch Control and PC Control

In both cases the user interface consists of the dialog window itself

and the fixed keys.

Fig. 3.2: Touch Control user interface

Fig. 3.3: PC Control user interface

The PC Control program has an additional menu bar.

14 PC Control / Touch Control

Page 27

3 Operation

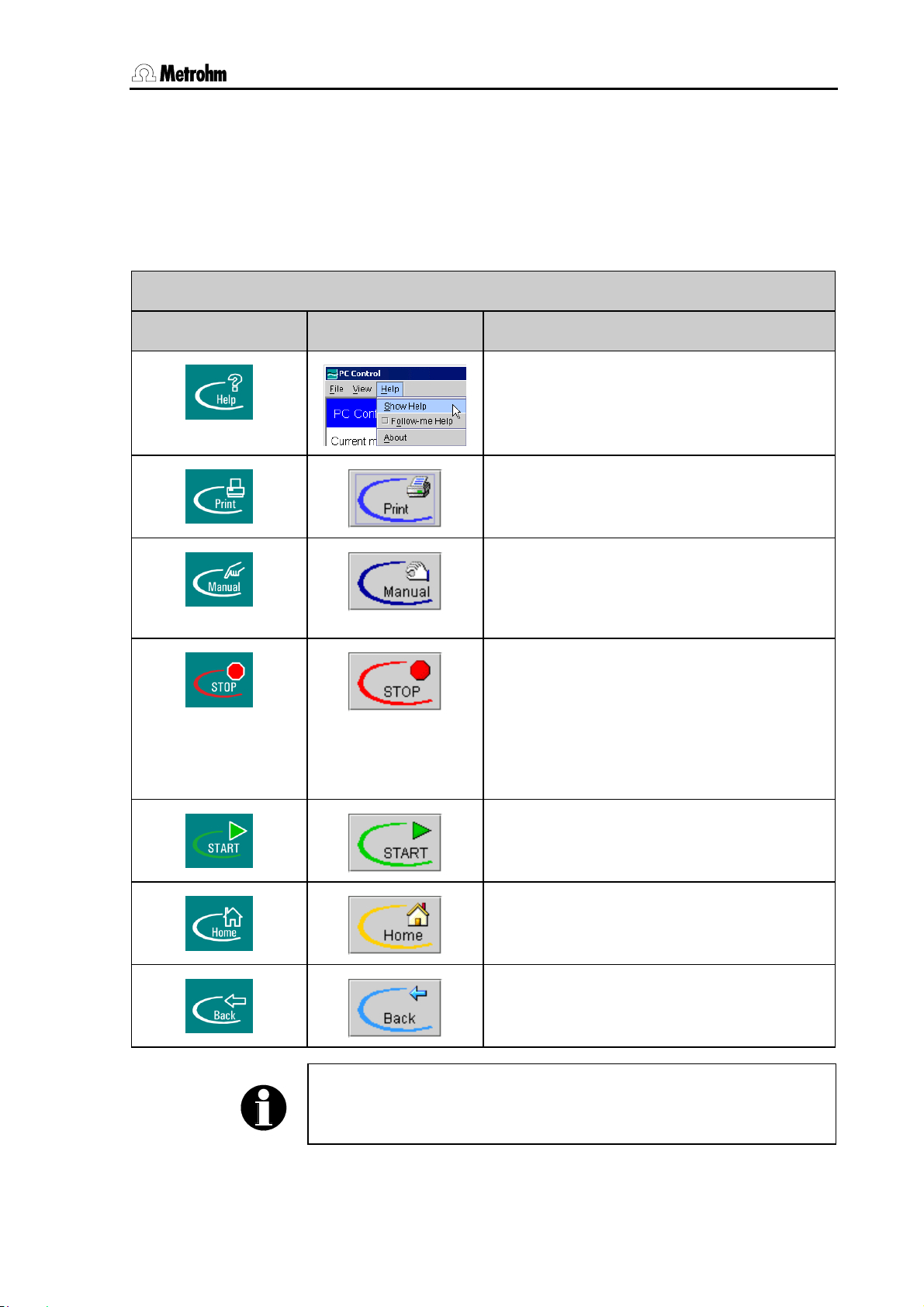

3.3.2 Controls of the Touch Control and PC Control

Both the Touch Control and the PC Control software systems have

changing controls within the dialog window and fixed keys outside the

dialog window which are accessible at all times. The following table lists

the functions of all the controls:

Fixed keys

Touch Control PC Control Fixed key function

Opens the context-sensitive online help

function (see Section

Opens the print dialog for the manual

printout of the reports (see Section

3.3.3).

3.23).

Opens the dialog for the manual operation of

the titration system (see Section

the PC Control a separate dialog window is

3.24). With

opened.

Stops the determination sequence. The

command which is currently being

processed will be stopped immediately and

the results page will be shown (see

Section

3.20.3). The following commands

(e. g. calculations, REPORT commands) will

not be carried out.

Starts the current method; this will then be

processed (see Section

3.20).

Switches to main dialog.

Switches to previous dialog.

Note!

The settings made in a dialog window with PC Control will only be

stored when the dialog is exited with [Back] or [Home].

PC Control / Touch Control 15

Page 28

3.3 User interface and controls

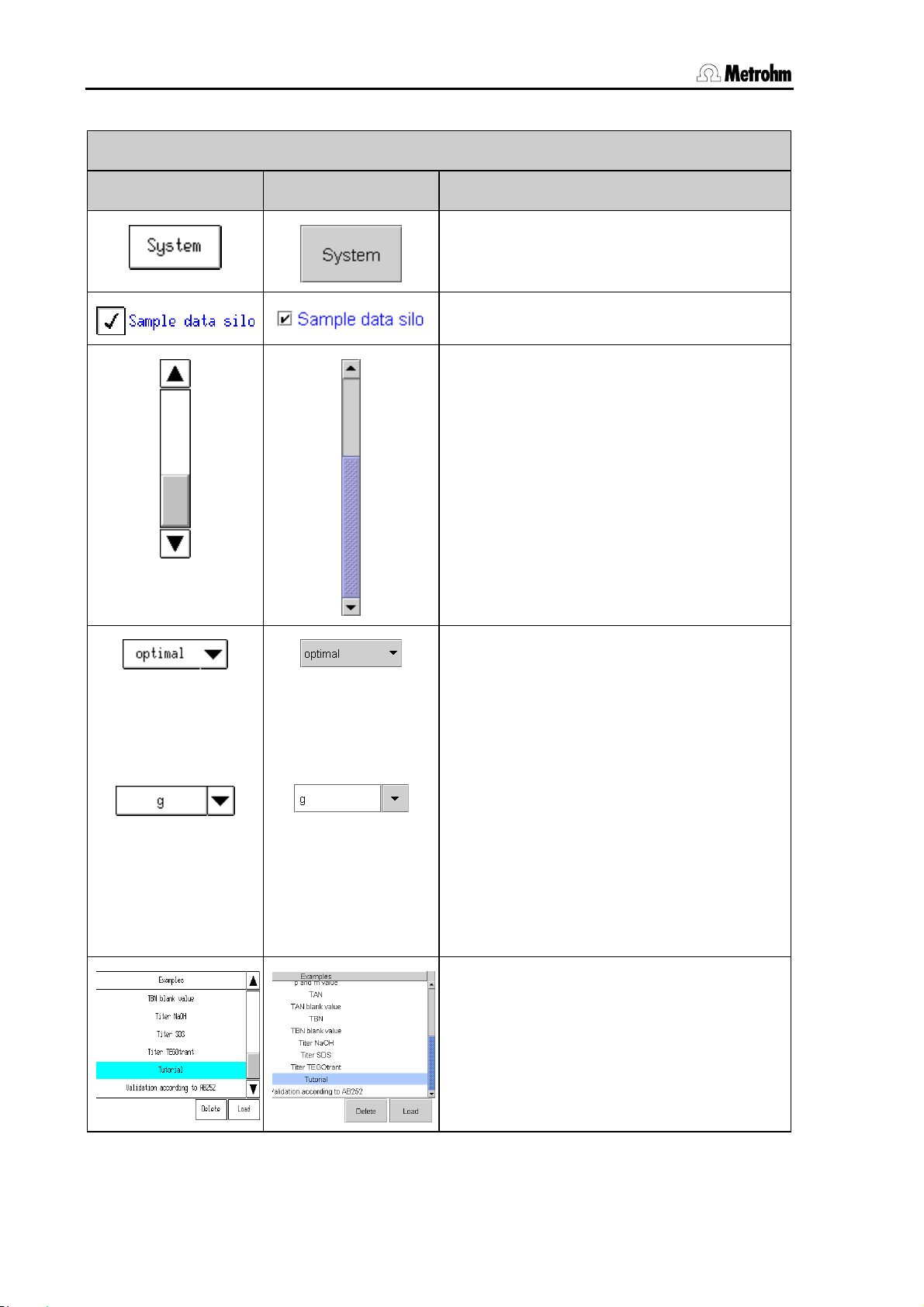

Dialog elements

Touch Control PC Control Fixed key function

Active buttons are indicated by a frame.

Inactive buttons are shown in gray.

Tip or click on a checkbox to activate it.

Use the scroll bar in order to navigate

quickly through lists or longer text displays.

To move up and down in the list push the

scroll bar up and down with your finger or

with the left-hand mouse key pressed down.

The selection list can be recognized by the

arrow to the right of the text. In an open list

the element currently selected is shown with

a background bar. Select the required

element in the list with the finger or mouse.

This entry will then be transferred directly to

the input field.

If the input field and arrow are separated by

a line then this means that you can also

make your own entries. In the Touch Control

you can open the text editor by touching the

input field. In PC Control you can click

directly on the input field and enter

text/numbers. The selection list is opened

with the arrow.

In the list the selected line is indicated by a

light blue bar. You should first mark the line

to be selected and then activate the button

for the function you want to apply to the

selected element.

16 PC Control / Touch Control

Page 29

3 Operation

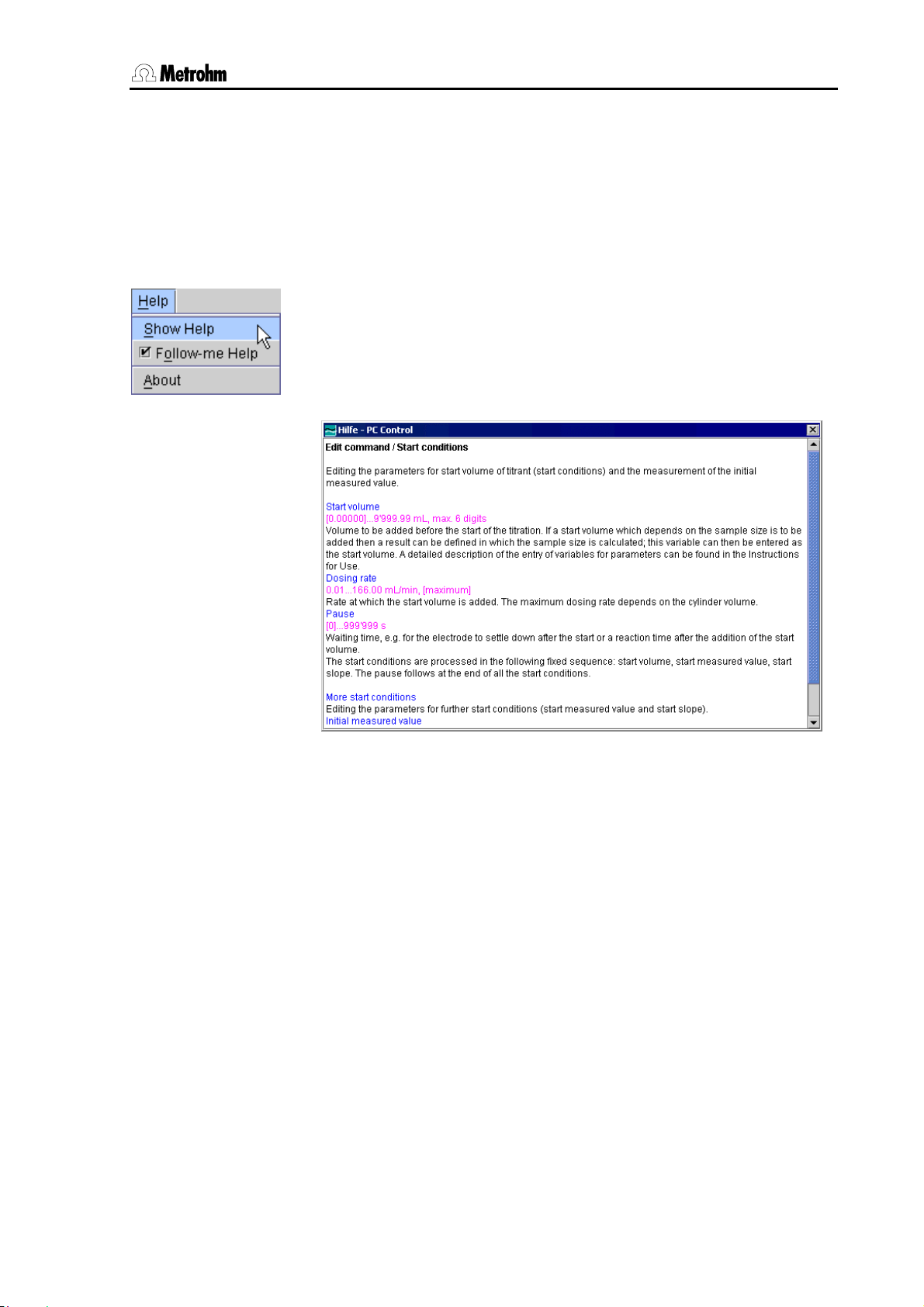

3.3.3 Online help

This manual is chiefly intended to describe the procedure for

configuring the system, carrying out a determination and evaluating and

storing the data. For further details about the individual parameters,

e. g. input ranges, you should use the context-sensitive online help,

which will rapidly provide you with the information you require at any

point.

In Touch Control you can open the online help with the [Help] fixed

key. In the PC Control software the online help is opened with the

<F1> key on the computer keyboard or started by clicking on the

menu item Show help in the Help menu. If you also activate the item

Follow-me help in this menu then the help window will be updated

each time that the dialog is changed.

Fig. 3.4: Online help, PC Control

The following markings apply to the online help for Touch Control and

PC Control:

Blue text Parameters and buttons which are explained.

Violet text Input values for the parameters.

[Value] Default value for a parameter.

PC Control / Touch Control 17

Page 30

3.4 Program structure

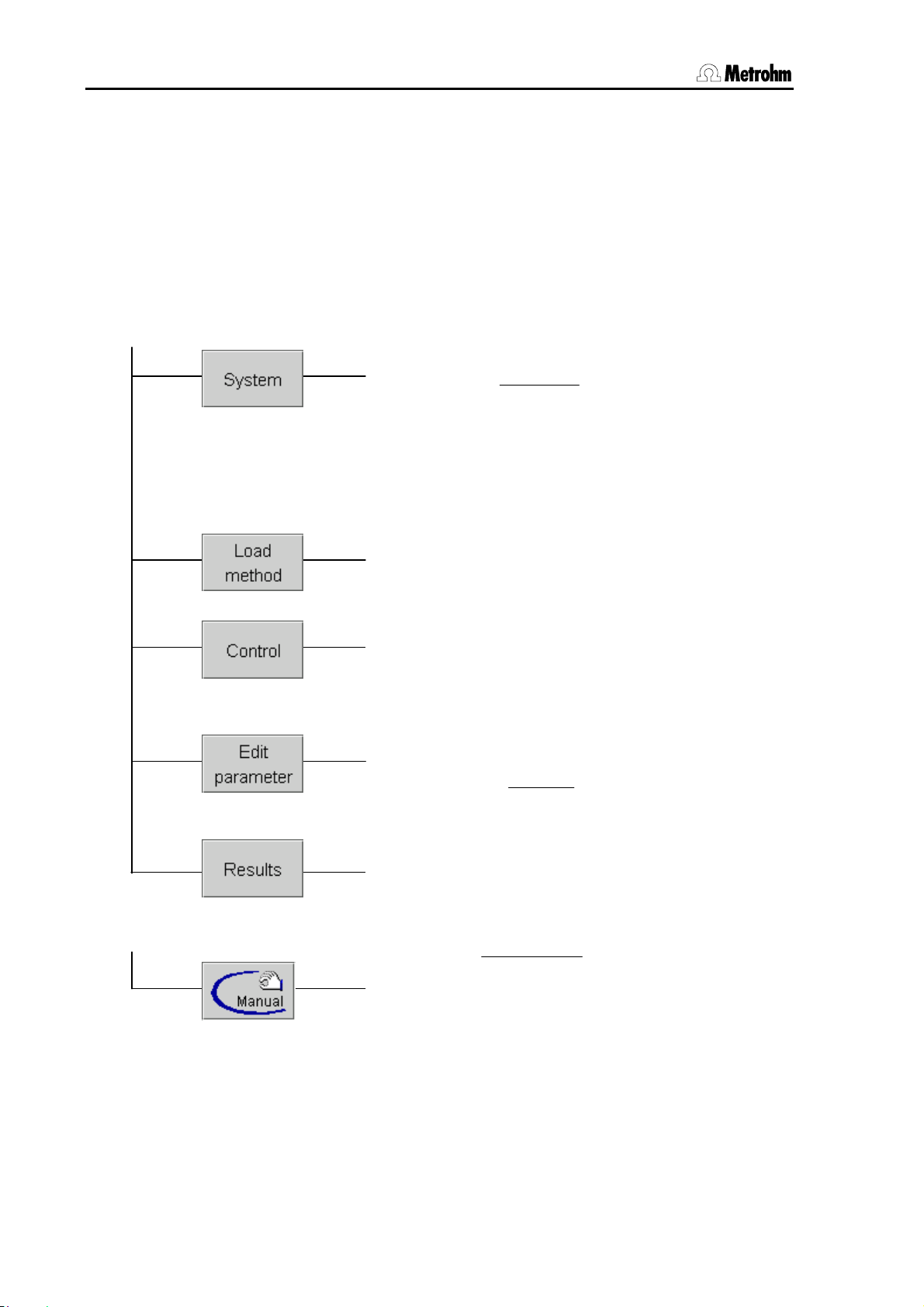

3.4 Program structure

The program structure is arranged so that the most important functions

can be accessed with only a few clicks or touches on the buttons.

Functions which are not often used in routine operation, such as

changing the system settings or editing individual parameters in a

method, can be found in lower dialog levels. In order to provide an

overview of the structure of the program we have summarized the most

important functions in the following diagram:

Main dialog

Fixed keys

├ System settings

├ Titrants

├ Sensors

├ Device manager

├ File manager

├ GLP manager

├ Common variables

├ Templates

└ Diagnosis

├ New method

├ Internal memory

├ Card 1

└ Card 2

├ Statistics

├ Sample data silo

├ Autostart

├ Sample number

└ Logout

├ Save method

├ Method options

├ Insert command

├ Delete command

└ Edit command

├ Result silo

├ Statistics

├ Recalculate

├ Curve

└ More data

├ Measure

├ Dosing

├ Stir

├ Manual titration

├ Remote

└ Sample Processor

├

Date and time

├ Language

├ User administration

└ Dialog options

├

Statistics

├ Save automatically

├ Send PC/LIMS report

├ Method note

├ Start/Stop options

└ Sample data

├

Load / Save

└ Properties

Fig. 3.5: Program structure

18 PC Control / Touch Control

Page 31

3 Operation

3.5 Login

Depending on how your Titrando system is configured, you may have

to use the User login function before you can work with the system.

User administration is carried out by a user with administrator rights

(see Section

identifying the user: by the entry of the user name or by using an

identification card, on which the user name and the routine dialog

settings are stored. If a password is required for identification then this

will be requested on login in both cases.

In the following example the user must identify himself/herself by

entering a name and password.

3.7.5 to Section 3.7.7). There are two different ways of

The first time that you log in you must first define your password with

[Change password]:

First enter the password under New password and enter it again

under Confirm password for confirmation. Please note that this

password can not be used multiple times.

Enter your password in the login dialog. If the user is defined in the

list of users and if the correct password has been entered then the

main dialog will open.

If you have to identify yourself with an identification card then you will be

requested to insert it.

PC Control / Touch Control 19

Page 32

3.5 Login

In Touch Control you must always insert your identification card in

Card slot 1. In PC Control ask your system administrator to tell you the

drive to be used. If a password additionally has to be entered then the

corresponding dialog will be opened automatically; otherwise the main

dialog will open directly.

20 PC Control / Touch Control

Page 33

3 Operation

3.6 Main dialog and structure of the dialog windows

This section provides an overview of the structure of the dialog windows

and the various dialog elements. The user interface without the fixed

keys [Help], [Print], [Manual], [STOP], [START], [Home] and [Back]

is known as the dialog window (or just dialog):

• In the status line (blue bar) the titles of the previous dialog and

current dialog are normally shown. Only in the main dialog the type

of instrument and the actual date and time are shown in this status

line. In the live display (see Section

method is shown.

• In the right top corner the current status of the system is shown:

Instrument in normal working condition (ready), i.e. a

determination can be started.

Conditioning is running (for SET and KFT titrations)

Conditioning has been manually stopped with

[Hold]. It can be continued with [Continue].

Conditioning is finished; the sample will be titrated

up to the endpoint and held there.

A determination sequence has been started.

[START] and [Print] are not active now.

3.20.4) the name of the current

The determination sequence has been interrupted

manually with [Hold] or automatically. It can be

restarted with [Continue].

PC Control / Touch Control 21

Page 34

3.6 Main dialog and structure of the dialog windows

A run has been started in the "Manual control" dialog

window.

A fault has occurred during the manual operation of

the System.

• In the main dialog you can enter or select the user if you are not

working with login (see Section

sample data (see Section

3.19.1).

3.7.5). You can also edit the

• The buttons at the lower margin of the dialog change their function

according to the dialog shown. They are usually used to open a

new dialog. You can open the following dialogs from the main

dialog:

Instrument-specific system settings, titrant and

sensor management, management and

configuration of peripheral devices, file

management, GLP functions, edits systemspecific variables, creates various templates,

diagnostic functions and software updates.

Loads a method from the method memory and

creates a new method.

Switches statistics on/off, switches sample

data silo on/off, deletes sample data silo

(Touch Control only), autostart, sample

number, system logout and deletes statistics.

Edits method command list and the

parameters of the current method.

Shows the results of the current determination,

recalculation and re-evaluation of the current

determination, views, saves and loads

determination data, views statistics results and

results silo.

22 PC Control / Touch Control

Page 35

3 Operation

3.7 System settings

A range of system-specific settings and configurations is described in

this section. You should first select the dialog language and set the

date and time. You can also configure the dialog for routine use and

create a list of users. You can make various settings concerning the

measured value display and output of acoustic signals.

3.7.1 Selecting the dialog language

Open the dialog System/System settings.

Open the selection list Dialog language with the arrow and select

the language.

Exit the dialog with [Home] so that the setting applies to all dialogs.

(From this particular dialog you can also return to the main dialog

with [Back].)

3.7.2 Setting the date, time and time zone

PC Control and Touch Control show date and time according to ISO

standard 8601.

Open the dialog System/System settings.

With PC Control the date and time will be taken directly from the

operating system of your computer. The change from Summer to

Winter time and vice versa is made automatically.

Note!

In order for the summer / winter time to be taken into account in the

Windows time display you must activate the checkbox

Automatically adjust clock for daylight saving changes under

System settings in the menu Date/Time Properties under Time Zone.

With Touch Control you should set the date and time as follows:

Open the date editor by touching the input field for the date.

Enter the actual date in the format year (4-place)-month-day. The

hyphens are already present. Confirm the entry with [OK].

PC Control / Touch Control 23

Page 36

3.7 System settings

Open the editor for the time by touching the input field for the time.

Enter the actual time in the format hours:minutes:seconds. The

entry should be made in the 24-hour format. The colons already

exist. Confirm the entry with [OK].

By entering a local time the time information becomes unambiguous.

You can enter the local time for both PC Control and Touch Control. It is

printed out in the report header together with the date and time. With

PC Control the difference to UTC (Coordinated Universal Time) is taken

automatically from the system settings of the PC.

In the local time input field you should enter the time zone based

on UTC (Universal Time) or switch off the function (example: –

05:00).

3.7.3 System-specific dialog options

The functions which a user can access can be configured specifically

for the system. You can define which method commands and fixed

keys can be used, and whether the system is to be operated in expert

dialog (all functions accessible) or in routine dialog (individual functions

disabled). The buttons to be disabled in routine dialog can also be

system-specifically defined. If an identification card is provided for each

user (see Section

stored user-specifically on the card.

3.7.6) then the routine dialog settings can also be

If you are not working with login then you can system-specifically

choose whether the system is to be operated in expert dialog or

routine dialog. In expert dialog all functions are accessible. In routine

dialog you can disable individual functions under Dialog options

/Routine dialog.

Select either Routine dialog or Expert dialog under Dialog in

System settings/Dialog options.

Exit the dialog with [Home] so that the setting applies to all dialogs.

24 PC Control / Touch Control

Page 37

3 Operation

Note!

If you have selected Routine dialog and the dialog System

settings/Dialog options is disabled for routine dialog then you can

change back to expert dialog by entering Metrohm as the user in the

main dialog. If you are using login then a user who works with expert

dialog must log in.

The selection of method commands (list of commands) and the fixed

keys ([Print] and [Manual] only) which can be used can only be

opened when the system is being operated in expert dialog.

Open the Dialog options/Command list dialog.

Disable the checkboxes for the command groups which are not to

be used. These will then be shown in gray in the method editor for

the selection of the commands. These settings apply to both expert

dialog and routine dialog.

Open the Dialog options/Fixed keys dialog. Only the [Print]

and [Manual] (manual operating of the titration system) fixed keys

can be disabled.

Disable the checkboxes for the fixed keys which are not to be used.

These settings apply to both expert dialog and routine dialog.

3.7.4 Routine dialog: disabling functions

A standard configuration which is suitable for routine dialog is stored:

methods can be loaded but not altered or newly created. Determination

data (results) can be viewed and saved, but not modified. You can

adapt this standard configuration as follows:

Open Dialog options/Routine dialog in order to deactivate

those buttons which are to be disabled in the main dialog, the live

display and in manual control. With PC Control you can also disable

individual menus. This dialog can only be opened when the system

is being used in expert dialog.

Deactivate the checkboxes for the functions which are to be

disabled in routine dialog.

You can disable individual functions in the corresponding dialogs with

the buttons at the lower margin of the dialog window ([System], [Load

PC Control / Touch Control 25

Page 38

3.7 System settings

method], [Control], [Edit parameter] and [Results]). In order for

the button to be active the corresponding checkbox must be activated

above.

Open the dialog in which you wish to disable buttons and

deactivate the checkboxes for the buttons that are to be disabled

for routine dialog.

You can also disable buttons in several subdialogs. These are indented

so that you can see which buttons belong to which dialog.

3.7.5 User administration

You can draw up a system-specific list of users who can operate the

titration system. You can use this list in two different ways: if you work

with login, i.e. if each user must log into the system before starting

work, then only those users entered in the list can log in. The user who

is currently logged in is shown in the main dialog and cannot be edited.

If you work without login then in the main dialog you can select the user

from those entered in the list and document the user of the titration

system in this way. The user name is printed out in all reports

containing determination data and stored in the determination file. Each

file always contains the name of the user who created it and the name

of the last user to edit it.

The name of the user, the dialog that the user can use to operate the

system and the status of the user are shown in the user list. If you work

with login then this dialog is only accessible to users with administrator

rights.

Open the dialog System settings/User administration.

The user list is initially empty.

Use [New] to define all the users who are allowed to operate the

system.

The dialog in which the user data can be entered is opened

automatically with [New]. For an existing user this dialog can be

opened with [Edit]. Existing users can be removed from the list with

[Delete].

26 PC Control / Touch Control

Page 39

3 Operation

Note!

If you once have worked with login and password protection then it is

no longer possible to delete users from the list even if the password

protection is switched off again.

The list of users can only be printed out in a context-sensitive situation

from the dialog System settings/User administration and its

subdialogs by using the [Print] fixed key. This means that only users

with administrator rights can print out this list.

Enter an unambiguous identification under User, for example the in-

house abbreviated form of the name or the personnel number.

Each user name can only appear once in the list of users.

Under Full name enter the proper name of the user, i.e. given

name and family name.

Select the Dialog in which the user is to operate the system.

This setting is only effective when login is used. In Expert dialog all

functions are accessible. For Routine dialog the system-specific

routine dialog configuration is normally used (see Section

user is to have separately defined routine dialog settings then you can

create an identification card for each user on which these settings are

stored (see Section

the card will be loaded automatically.

The user status normally remains active. It is a good idea to

deactivate a user when, for example, he or she is absent for a long time

or is no longer authorized to use the system. This user can then no

longer log into the system until the active status is reactivated.

You should activate the Administrator rights checkbox for each

user who is to have access to the user administration.

Note!

The last user with administrator rights cannot be deleted.

3.7.6). During login the dialog settings stored on

3.7.3). If each

By clicking on [Signature method] you can access the edit dialog for

assigning the rights for using and signing methods. These settings are

only effective when login and password is used. Only methods with the

PC Control / Touch Control 27

Page 40

3.7 System settings

status "Saved" can be signed. The status of the method is given under

Method options/Properties (see Section

3.16.9).

If use only released methods is activated then the corresponding

user can only use methods that have been released, i.e. can only start

methods that have been signed at level 2. Review methods

(signature level 1) must be activated for a user to be entitled to

sign a method at level 1. The method then receives the status

"Reviewed". To be able to sign methods at level 2 Release methods

(signature level 2) must be activated. A method can only be signed

at level 2 when it has already been signed at level 1. The same user can

sign different methods either at level 1 or at level 2, if both checkboxes

Review methods and Release Methods are activated but not the same

method at the same time at level 1 and at level 2. When the user has

signed the method at level 2 it receives the status "Released". If Delete

signatures has been activated for a user then the user is entitled to

delete signatures. However, this is possible for methods that have been

signed at level 2. All the signatures are deleted and the method

receives the status "Saved".

The methods can be signed under Method options/Properties. The

procedure is described in Section

3.16.3.

By clicking on [Signature determination] you can access the edit

dialog for assigning the rights for using and signing determinations.

These settings are only effective when login and password is used.

28 PC Control / Touch Control

Page 41

3 Operation

In a similar way to that used for methods, it is possible to state whether

a user is entitled to sign determinations at level 1, i.e. to Review

determinations, and/or is entitled to Release determinations, i.e. to

sign them at level 2. If Delete signatures has been activated for a

user then the user is entitled to delete signatures. As in the case of

methods, this is only possible when a determination has already been

signed at level 2.

Determinations can be signed under More determination

data/Properties. The procedure is described in Section

3.18.4.

Attention!

If you work with Login then User administration is only accessible

to users with administrator rights. This means that you must ensure

that at least two users have administrator rights so that one of them is

almost always available. Keep the rights of access for a user with

administrator rights in a safe place so that it is accessible in an

emergency.

3.7.6 Creating an identification card

If you have selected the version Login via identification card

under User administration/Login options (see Section

you must provide each user with an identification card. The

identification card has the User name and the current routine dialog

settings stored on it (see Section

During login with an identification card a check is made that the user is

present in the list of users and whether expert dialog or routine dialog is

to be used. After a successful login the routine dialog settings stored on

the card are loaded into the system. These define the buttons and

functions that are accessible to the user if routine dialog is used.

If you wish to provide separate routine dialog settings for each user

then you must always adapt these settings (see Section

you create the identification card for the particular user. These user-

specific routine dialog settings are stored on the identification card

with the name of the user.

3.7.7) then

3.7.4).

3.7.4) before

Touch Control

With Touch Control the identification card is always created in Card

slot 1 (13, see Fig. 2.2: Rear view of the Touch Control).

Insert the data card into Card slot 1.

In the user list, select the user for whom you would like to create the

identification card.

Press [Create ID card]. The settings are stored.

PC Control

Open the menu File/Preferences.

Define the drive in which the identification card is to be used under

Paths for Card 1 (see Section

PC Control / Touch Control 29

3.11).

Page 42

3.7 System settings

Select the disk drive if you want to use diskettes as identification cards.

You can also use a card drive with PCMCIA FlashCards or

CompactFlash cards, or a USB memory stick. With external drives you

must always check how to recognize when a storage process has been

completed in the user manual for the drive. This is usually indicated by

an LED. If you use the PCMCIA card drive of a laptop computer then

you should always trigger "Remove hardware" in the operating system

before removing a card from the drive. This is the only way that you can

be sure that the data has been stored when you remove the card.

In the user list, select the user for whom you would like to create the

identification card.

Press [Create ID card]. The settings are stored.

3.7.7 Editing login options

There are various ways of logging in to the system: either the user

name is requested or identification is carried out by using an

identification card (see Section

both versions.

Open the dialog User administration/Login options.

3.7.6). It is also possible to combine

Activate the checkbox(es) for the login option(s) that you wish to

use.

30 PC Control / Touch Control

Page 43

3 Operation

Attention!

If you select Login via identification card then you must create

an identification card for each user.

Once you have selected a login option you can then make further

settings for logging in:

If a password is to be requested as well as the user name then you

must activate the Password required checkbox. If this function is

switched on then it is no longer possible to delete users from the list

of users; they can only be deactivated. This is a requirement for

complying with FDA Guideline 21 CFR Part 11. The various

settings for entering a password are carried out under [Password

options] (see p.

Activate the Logout automatically checkbox if the user is to be

logged out of the system automatically after a certain time has

elapsed. Enter the interval after which the logout is to take place

automatically.

Note!

When you exit this dialog (User administration/Login options)

with [Back] or [Home] after you have activated one of the login

options Login via user name or Login via identification card

then you will automatically find yourself in the login dialog and will

have to log into the system. This means that you must make sure that

you have first defined all the users and produced the identification

cards before you activate login.

32).

Under [Reasons] you can draw up a selection list containing reasons

from which a selection can be made when signing and modifying

methods and determinations. Some reasons have already been

provided.

You can insert a new reason in the list with [New]. Existing reasons

can be deleted from the list with [Delete] and existing reasons can

be renamed with [Edit].

Under [Modification options] you can select in which cases a

reason is to be demanded.

PC Control / Touch Control 31

Page 44

3.7 System settings

If you activate Methods then when a modified method is being saved a

reason for the modification will be demanded. Results are altered when

a determination is recalculated. If you require a reason to be given in