Page 1

838 Advanced Sample Processor

Manual

8.838.1013

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

838 Advanced Sample Processor

8.838.1013

Manual

09.2005 dm

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

Table of Contents

1 Introduction 1

1.1 Information about these Instructions for Use..................................2

1.1.1 Note............................................................................................................2

1.1.2 Notation and pictograms ...........................................................................2

2 Operation 3

2.1 Operating principles..........................................................................3

2.1.1 Display........................................................................................................3

2.1.2 Keypad.......................................................................................................4

2.1.3 The keys .....................................................................................................5

2.1.4 Instrument dialog .....................................................................................11

2.1.5 Data input.................................................................................................13

2.1.6 Text input..................................................................................................14

2.2 Configuration .................................................................................. 16

2.2.1 Miscellaneous ..........................................................................................16

2.2.2 Tower settings..........................................................................................18

2.2.3 Rackdefinitionen ......................................................................................20

2.2.4 Dosing units .............................................................................................23

2.2.5 RS232 settings.........................................................................................24

2.3 Composition of a method .............................................................. 25

2.3.1 Run sequences and method parameters................................................25

2.3.2 Sample Processor settings......................................................................27

2.3.3 Stirrer settings ..........................................................................................28

2.3.4 Dosing drive settings ...............................................................................29

2.3.5 Behavior during timeout...........................................................................30

2.3.6 Manual stop options ................................................................................31

2.3.7 Programming of sequences ....................................................................32

2.3.8 LEARN mode ...........................................................................................32

2.3.9 TRACE-Funktion.......................................................................................33

2.4 Commands...................................................................................... 34

2.4.1 Sample Processor commands ................................................................34

2.4.2 Switching components ............................................................................38

2.4.3 Dosing drive control.................................................................................39

2.4.4 Communication commands ....................................................................41

2.4.5 Auxiliary commands.................................................................................45

2.5 Managing methods......................................................................... 46

2.5.1 User-defined methods .............................................................................46

2.5.2 POWERUP method..................................................................................47

2.6 Run control ..................................................................................... 48

Metrohm 838 Advanced Sample Processor III

Page 6

2.7 Manual operation............................................................................ 49

2.7.1 Turning the sample rack / Positioning the samples................................49

2.7.2 Moving the lift...........................................................................................49

2.7.3 Setting the sample position .....................................................................50

2.7.4 Pump control ...........................................................................................50

2.7.5 Switching the stirrers................................................................................50

2.7.6 Dosing device control..............................................................................51

2.7.7 Display interface signals.......................................................................... 51

2.7.8 Interface control .......................................................................................52

2.7.9 External pump control..............................................................................53

2.7.10 Switching the injection valve....................................................................53

2.7.11 Rack initialization .....................................................................................53

2.8 Dosing and liquid handling............................................................ 54

2.8.1 Dosimats and Dosinos ............................................................................54

2.8.2 Liquid handling functions ........................................................................59

2.8.3 The DOS command.................................................................................60

2.8.4 Pictograms...............................................................................................60

2.8.5 Liquid handling functions in detail........................................................... 61

3 Appendix 64

3.1 Sample racks .................................................................................. 64

3.1.1 Metrohm standard sample racks ............................................................64

3.1.2 Magnet codes..........................................................................................65

3.1.3 Rack data.................................................................................................65

3.2 The Remote interface ..................................................................... 68

3.2.1 Output lines..............................................................................................68

3.2.2 Input lines.................................................................................................68

3.2.3 SCN command ........................................................................................69

3.2.4 CTL-Befehl ...............................................................................................69

3.3 LEARN mode................................................................................... 70

3.3.1 Setting lift and robotic arm positions.......................................................70

3.3.2 Rack adjustment......................................................................................71

3.3.3 Parametrizing sequence commands ......................................................71

3.4 Disabling keypad functions ........................................................... 72

3.4.1 Disable whole keypad .............................................................................72

3.4.2 Disable configuration...............................................................................72

3.4.3 Disable parameter ...................................................................................72

3.4.4 Disable method storage functions ..........................................................73

3.4.5 Disable display ........................................................................................73

3.5 786 Swing Head settings ............................................................... 74

3.6 Error messages .............................................................................. 76

3.7 Initializing the working memory .................................................... 78

3.8 Standard methods .......................................................................... 80

IV Metrohm 838 Advanced Sample Processor

Page 7

3.8.1 Method "LAT"............................................................................................81

3.8.2 Methode "MLAT".......................................................................................83

3.8.3 Method "DT" .............................................................................................86

3.8.4 Method "VA"..............................................................................................88

4 Index 90

List of Illustrations

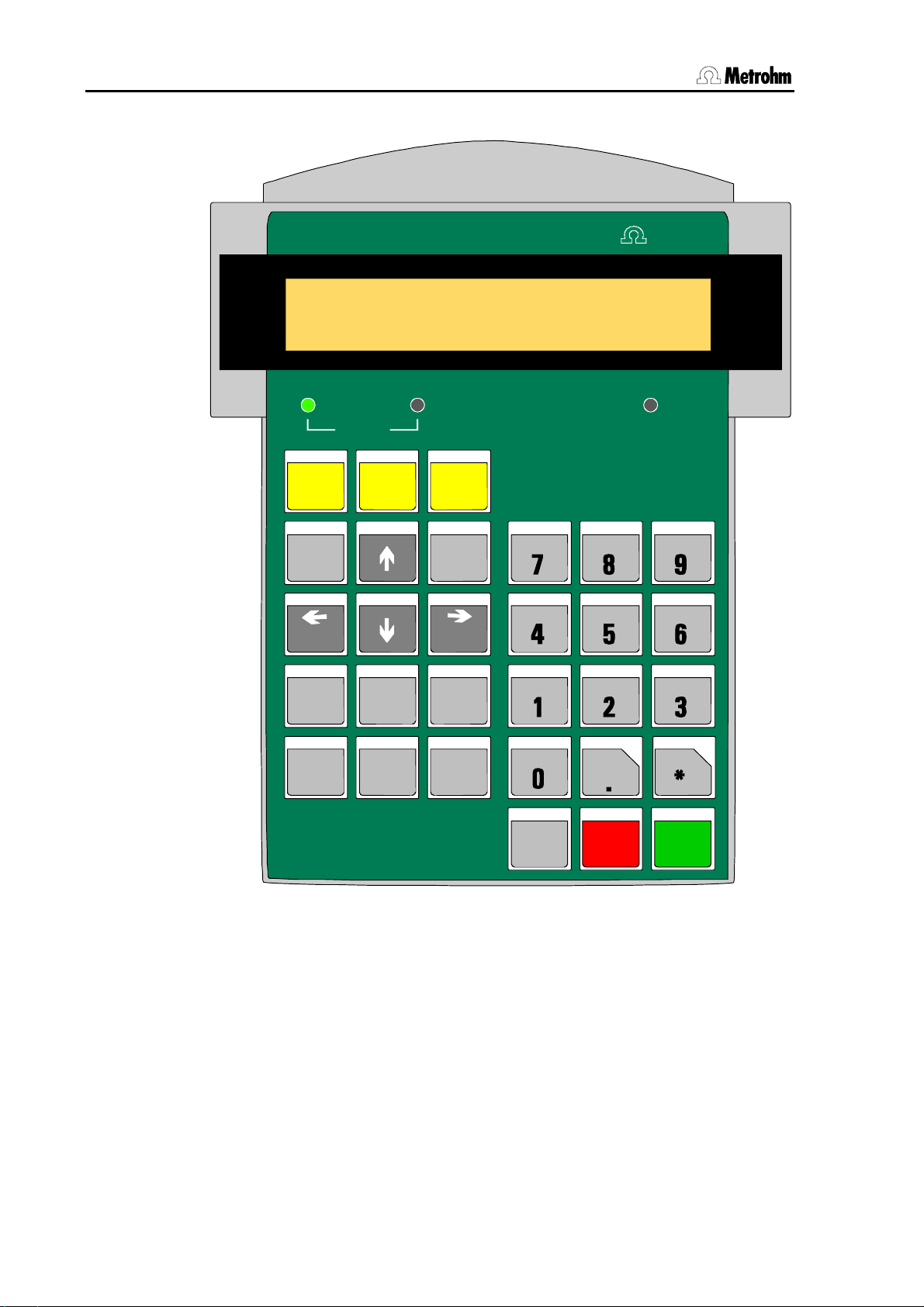

Fig. 1 Key pad....................................................................................................4

Fig. 2 Dialog arrangement ...............................................................................12

Fig. 3 Selection list...........................................................................................13

Fig. 4 Text input ...............................................................................................15

Fig. 5 Sample series ........................................................................................26

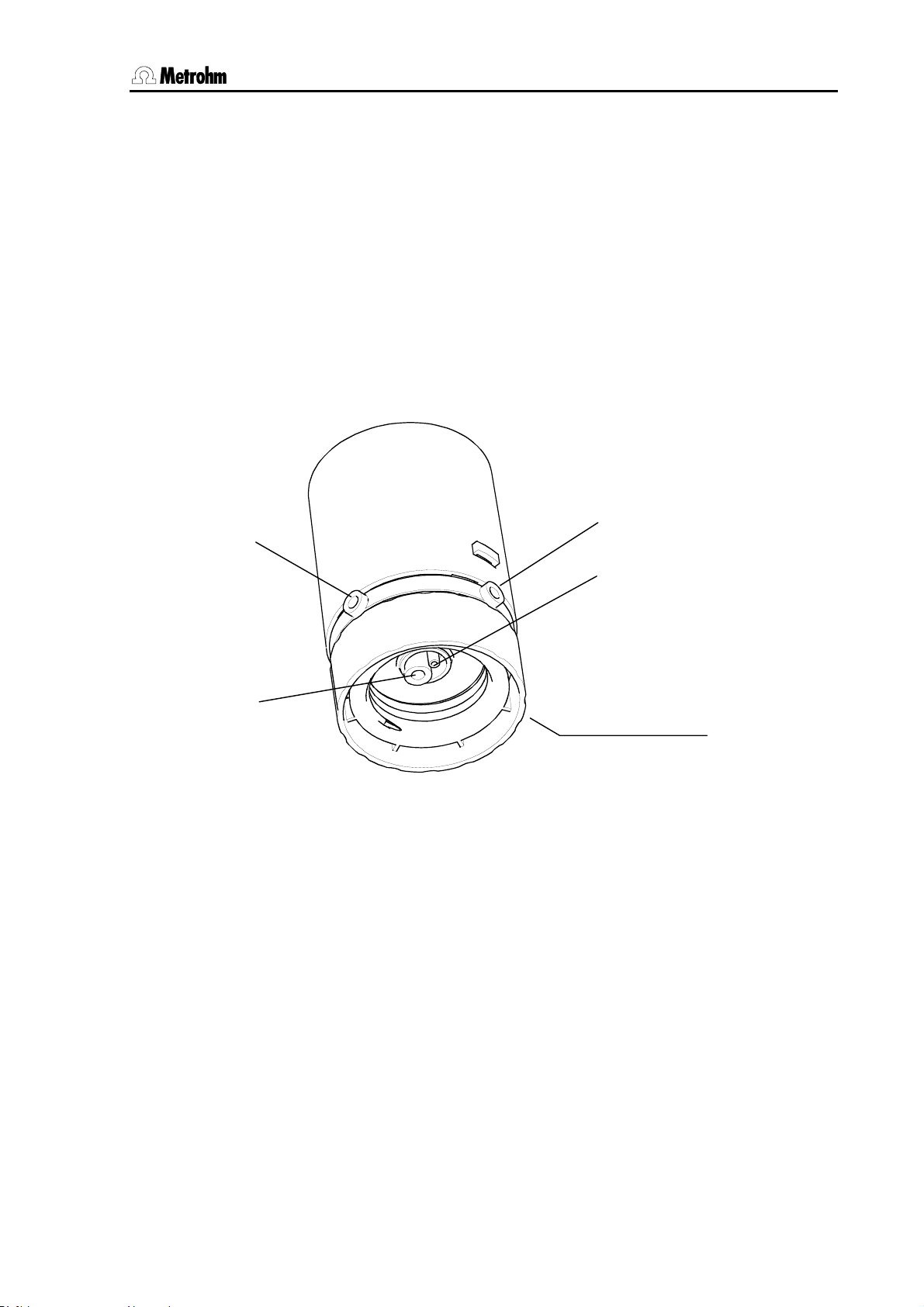

Fig. 6 Dosino 800 with Dosing units ................................................................54

Fig. 7 Dosing unit from below..........................................................................55

Fig. 8 Dosing unit - ports ................................................................................. 59

Metrohm 838 Advanced Sample Processor V

Page 8

Page 9

1.1 Information about these Instructions for Use

1 Introduction

Like all Metrohm Sample Processors, the 838 Advanced Sample Processor can be operated as stand-alone device or be controlled entirely

by a PC software (e. g. «IC Net»). In the latter case the particular functions of the instrument are invoked directly by the PC software. The

keypad of the 838 Advanced Sample Processor therefore is not necessary.

In a stand-alone system with a keypad connected, the 838 Advanced

Sample Processor can execute methods containing command sequences automatically. These sequences may be programmed freely in

a wide range. The Sample Processor can even be operated manually to

prepare a sample series.

«IC Net 2.3» (Service release 3 or later) sets a parameter in the 838

Advanced Sample Processor, which forces the Sample Processor to

reset all of it's device settings and delete all stored methods on startup (RAM init). This behavior is intended and necessary for controlling

the Sample processor with «IC Net».

If a 838 Advanced Sample Processor is to be used as a stand-alone

system with keypad control and instrument methods, which previously

was controlled by «IC Net 2.3», the setting mentioned above has to be

switched off beforehand. In «IC Net» uncheck the check box "Autoinit"

which is accessible after right-clicking the Sample Processor icon in

the working system.

The 838 Advanced Sample Processor is delivered with four standard

methods for voltammetric analysis. These can be used in the connection with the Metrohm 797 VA Computrace.

Operating and programming of the 838 Advanced Sample Processor is

described in this Instructions for Use.

Metrohm 838 Advanced Sample Processor, Introduction 1

Page 10

1.1 Information about these Instructions for Use

1.1 Information about these Instructions for Use

1.1.1 Note

Please read through these Instructions for Use carefully before you

start to use this instrument. The instructions contain information and

warnings that must be observed by the user in order to guarantee the

safe use of the instrument.

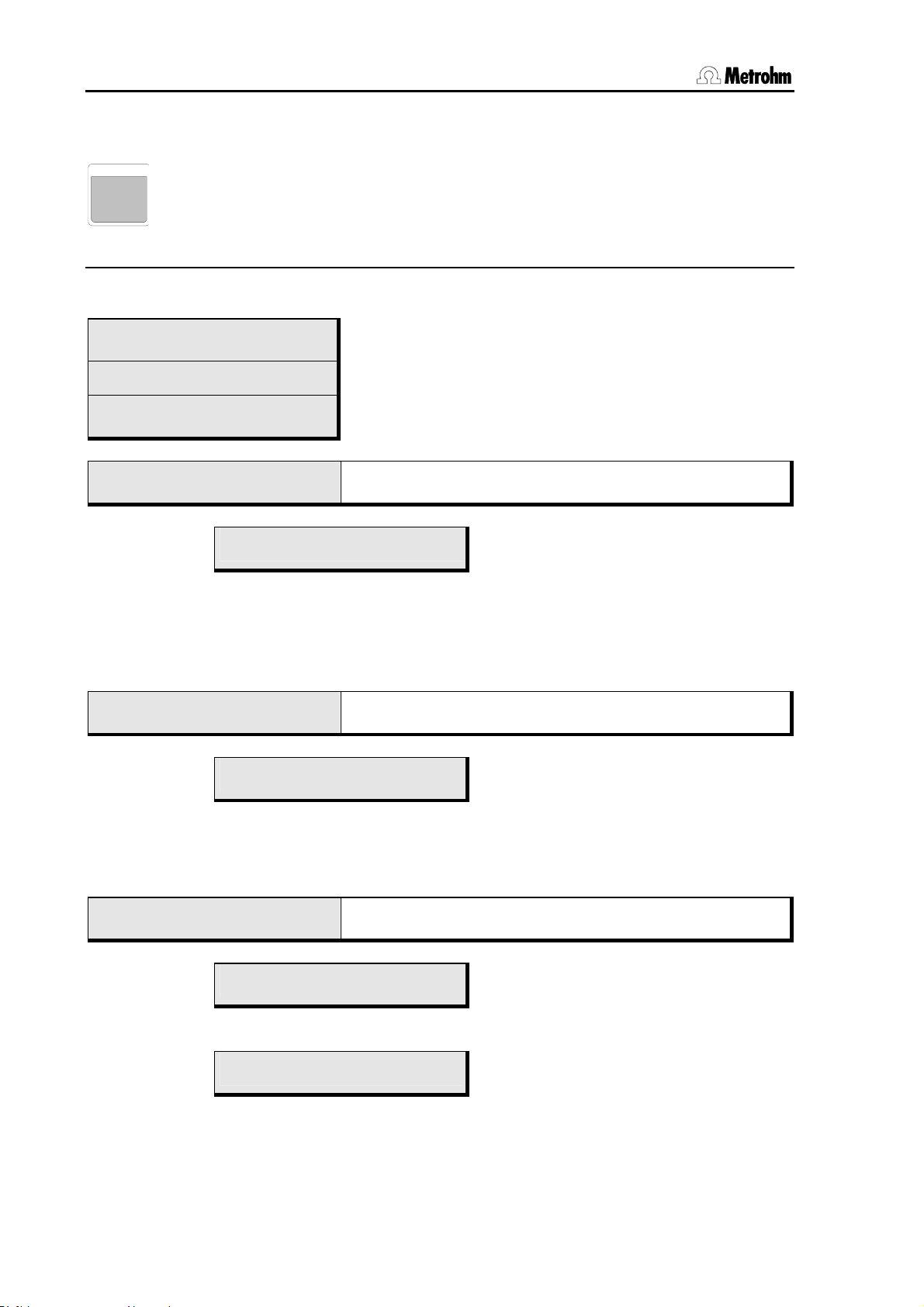

1.1.2 Notation and pictograms

The following notation and pictograms are used in these Instructions for

Use:

Location Menu item, parameter or input value

<OK> button, key

Danger

This symbol indicates a possible risk of death or injury to

the user if the instructions are not followed correctly.

Warning

This symbol indicates a possible risk of damage to the instruments or their components if the instructions are not followed correctly.

Attention

This symbol indicates important information. Read the information provided before you continue.

Remarks

This symbol indicates additional information and tips.

2 Metrohm 838 Advanced Sample Processor, Introduction

Page 11

2.1 Operating principles

2 Operation

As well as the basic functions that can be carried out manually, this section also described the configuration of the Advanced Sample Processor. Detailed descriptions of the way that run sequences are created and

how methods are managed are given.

2.1 Operating principles

2.1.1 Display

The keypad (SC Controller) display consists of two lines each with 24

characters.

The first line is used as the title line and shows the current method together with the number of processed samples. In the editing mode the

menu titles are shown here.

The second line is used as the status line and shows specific activities

that depend on the operating condition. It is used as the input line in the

editing mode.

Normal state

Method name

Pump status

Sample counter

******** counter 1/12

PUMP--++STIR+---- ready

Stirrer status

Method sequence

Running sequence

******** counter 2/12

START 03 WAIT 11 s

Current command with line number

Editing mode

Menu line or command

Menu title

>Sample sequence

1 MOVE 1 : sample

st

1

parameter

Instrument status

Parameter

nd

2

parameter

Metrohm 838 Advanced Sample Processor, Operation 3

Page 12

2.1 Operating principles

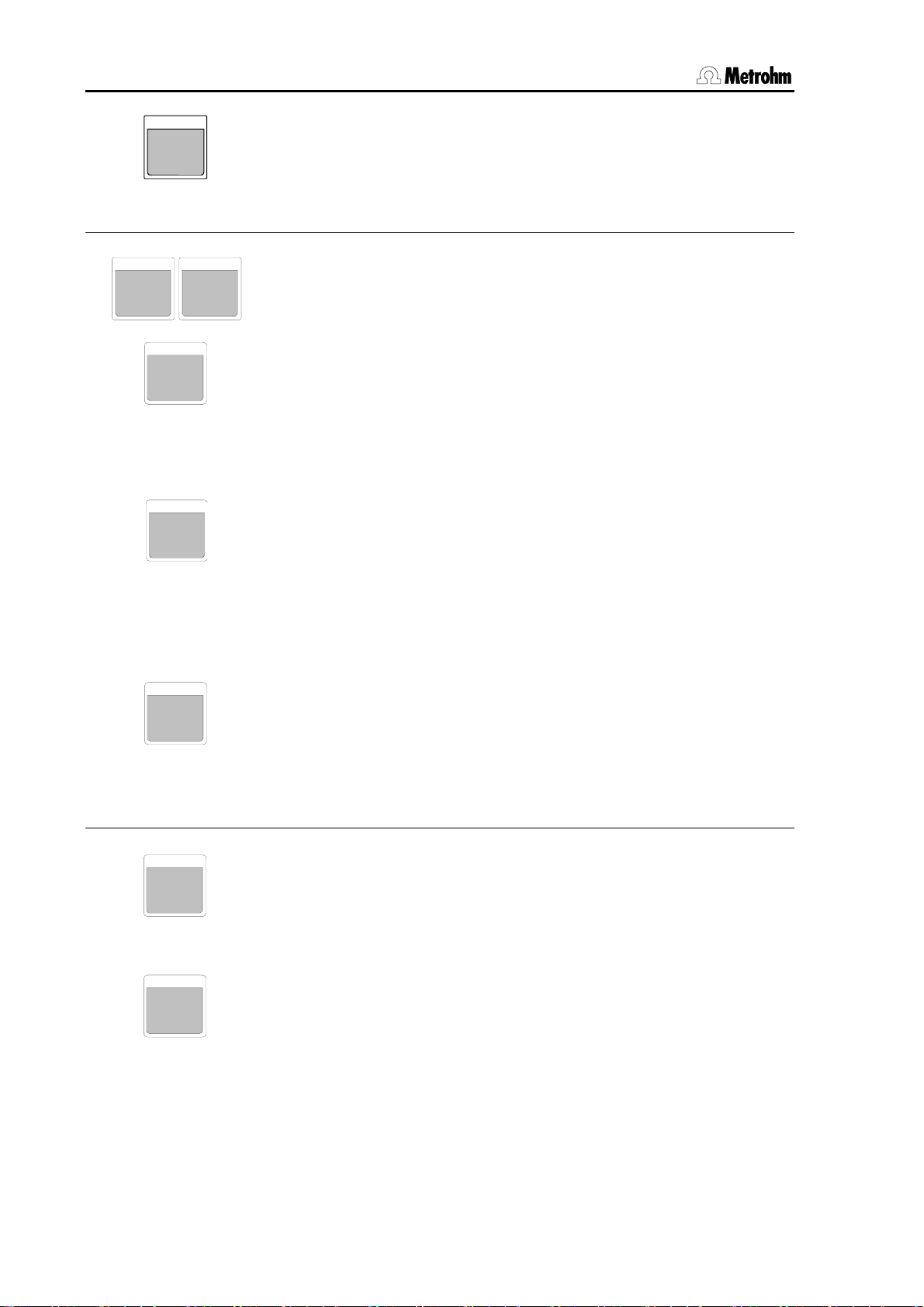

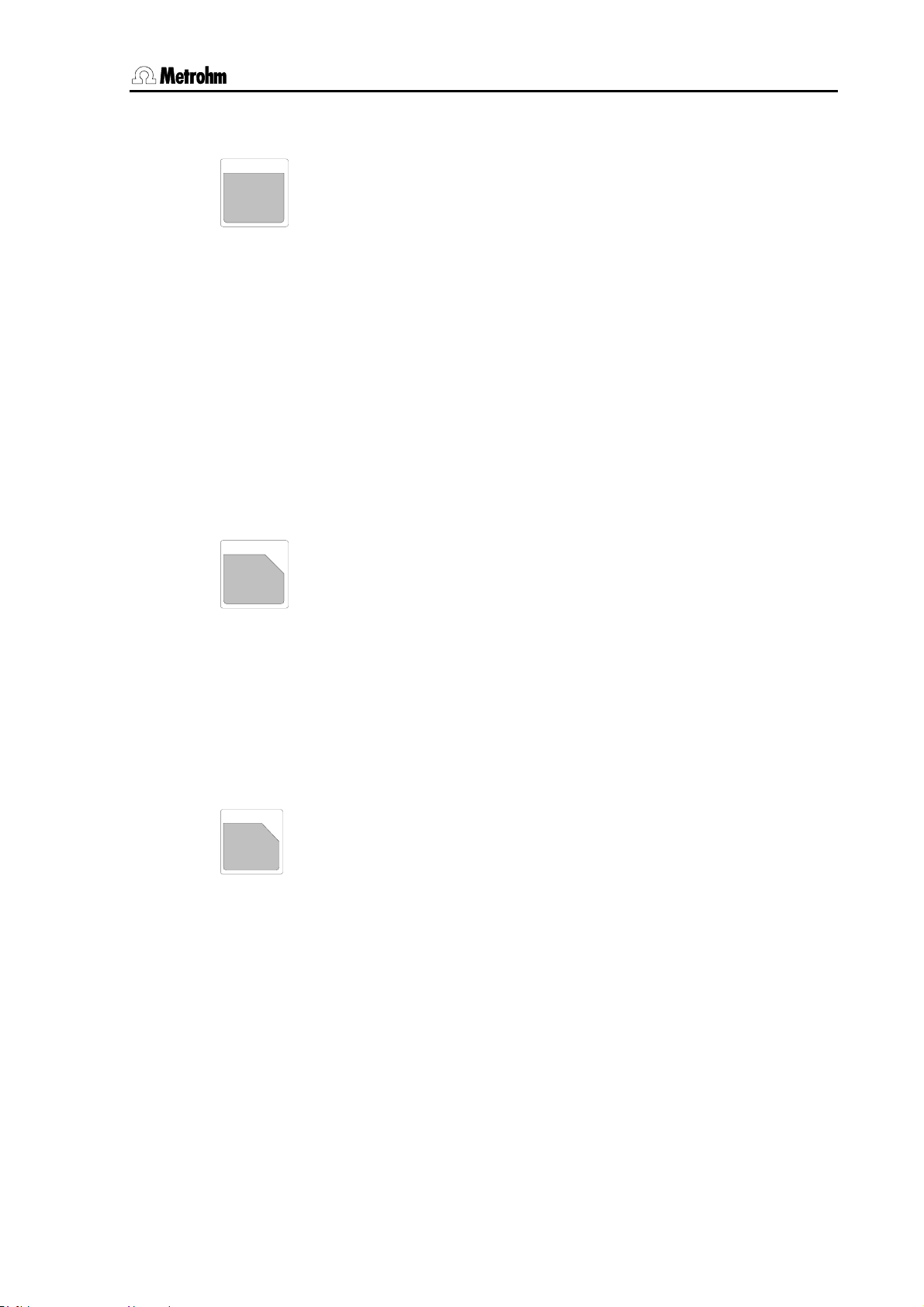

2.1.2 Keypad

Controller

******** counter 0/112

PUMP-- STIR- ready

FILL

INJECT LEAR N

VALVE

CONFIG PAR A M

HOME END

NEXT

USER

METHOD

PREV

RESET

SAM PLE MOVE LIFT

PUMP

SCA N CTRL WAIT

ST IR DOS

Me t r o h m

IN SE R T SELECT

DELETE

6.2142.050

QUIT ENTER

CLEAR

EXT

P

LEARN

HOLD

VALVE

+

STOP

<

RACK

-

START

>

Fig. 1 Key pad

Below the 2-line display there are three LEDs. The two LEDs 'FILL' and

'INJECT' indicate the current position of the injection valve. The LED

'LEARN' lights up when the learn mode is activated.

Most keys have two functions, depending on whether the Sample Processor is in the normal operating mode or in the editing mode.

Selection menus can be accessed with the upper row of keys (<CON-

FIG>, <PARAM>, <USER METHOD>). The other keys on the lefthand side of the keypad are used for navigation in the menus or for al-

4 Metrohm 838 Advanced Sample Processor, Operation

Page 13

2.1 Operating principles

2.1.3 The keys

The menu keys

CONFIG

PARAM

tering parameters. For entering parameters the numerical block on the

right-hand side of the keypad is also available.

The lowest row of keys (<HOLD>, <STOP>, <START>) are used

for the direct control of a method sequence.

If the Sample Processor is integrated in a PC-controlled automation

system and is entirely controlled via the RS232 interface, it is possible

to operate the instrument without the keypad.

The <CONFIG> key opens the selection menu for the configuration

of the Sample Processor.

The <PARAM> key opens the selection menu for editing the run sequences and method parameters.

The <User Method> key opens the selection menu for opening, sav-

USER

METHOD

ing and deleting default or user-defined methods.

Lift operation and sample positioning keys

With the <> and <> keys the lift can be moved up and down

respectively. The lowest possible lift position is defined by the configuration parameter '

max. stroke path'.

In the editing mode the arrow keys <> and <> are used

for navigation in the particular menu or submenu.

With the <HOME> key the lift is returned to the rest position (0 mm),

HOME

END

i.e. to the uppermost stop.

<END> moves the lift to the predefined working position (see p. 20).

In the editing mode the <HOME> and <END> keys move to

the first and last line of the menu or submenu respectively.

With the < NEXT> and < PREV> keys the sample rack can be

NEXT

PREV

rotated forward or backward by one position. If necessary, the lift is

automatically raised to the shifting position. When the rack position

has been reached the robotic arm will automatically be aligned to the

corresponding rack position.

During data input the <SELECT> key is used to select a pre-

defined entry from a selection list.

Metrohm 838 Advanced Sample Processor, Operation 5

Page 14

2.1 Operating principles

The <SELECT> key allows to select from a given list of entries when

editing a parameter.

SELEC T

Editing and sequence control

When editing a method sequence the <INSERT> and <DELETE>

INSERT DELETE

keys are used to insert or delete a command line.

RESET

CLEAR

QUIT

ENTE R

Command keys

SAMPL E

7

The <CLEAR/RESET> key is used to initialize the Sample Processor

and dosing devices. This corresponds to the switching-on process.

During data input the <CLEAR/RESET> key is used to de-

lete an entry or to reset the default value. In text entry mode

the last character is deleted.

During a method sequence the <QUIT> key can be used to termi-

nate the command which is currently being carried out. The following

command is executed.

During data input the <QUIT> key is used to terminate an en-

try. During navigation in a menu the <QUIT> key is used to

exit the active (sub)menu and select the next highest menu

level.

During data input the <ENTER> key is used to accept the entry.

The <SAMPLE> key is used to set the current sample position. This

has to be done before a sample series is run.

At the start of a method this position is assumed to be the first sample

in a series. If no sample position has been set then the Sample Processor will select rack position 1.

MOVE

With <MOVE> a vessel or a particular rack position can be moved to

the active tower or a robotic arm can be swung to an external position.

8

As well as the actual sample beaker a maximum of 16 possible special beakers can also be defined. A particular rack position can be

moved to directly by entering the position number (with the numerical

keys).

The direction and speed of rotation can be altered in the parameter

menu.

6 Metrohm 838 Advanced Sample Processor, Operation

Page 15

2.1 Operating principles

Important:

For safety reasons it is only possible to rotate the sample rack when

the lift or both lifts are located in the shifting position or above it. During a rack rotation the lift (or both lifts) are automatically first raised to

the predefined shift height.

When a method is started a second time, without switching off and on

again, the last accessed sample position is memorized and be applied in the next method run.

LIFT

9

PUMP

4

STIR

5

DOS

6

Raises or lowers the lift. The predefined lift positions (working position,

rest position, rinsing position, shifting position, special position) can

be selected with the <SELECT> key. They can be entered and

saved separately for each rack in the configuration menu.

As well as the predefined lift positions it is also possible to enter absolute lift positions in mm via the numerical keys.

The <PUMP> key is used for switching the peristaltic pump. The

pump rate can be selected in 15 steps. Selecting a sign (+ or –) with

the pump rate allows to set the direction of the rotation of the pump

drive.

Under <PARAM>,

>manual stop you can define whether the peri-

staltic pump should be switched off with the <STOP> key or not.

The <STIR> key is used for controlling the stirrers. A stirrer can be

switched on permanently or switched on for a given period and then

switched off again. The <SELECT> key is used to select both the

stirrer and the function. The current status of the stirrer is shown directly in the display.

Example:

STIR: T1 : ON s Display: STIR +- (+=on -=off)

STIR: MSB2 : 10 s Display: STIR 10 s

In this case in the first line the stirrer at tower 1 is switched on. The stirrer is selected with the <SELECT> key. As can be seen in the sec-

ond line, the duration of the stirring process can also be entered.

The stirring rate can be set for each stirrer in the parameter menu.

Under <PARAM>,

>manual stop you can define which stirrers can

be switched off with the <STOP> key.

The <DOS> key is used to control the connected dosing devices.

Both positive and negative volumes can be dosed. Negative volumes

are used for aspirating liquids, e.g. during pipetting.

As well as entering the volume to be dosed (with the numerical keys),

<SELECT> can also be used to select additional functions:

- Filling the dosing or exchange unit (fill)

- Initializing the exchange of a Dosing unit (release)

- Preparing the tubing systems and cylinder (prep.)

- Emptying the tubing system and the dosing cylinder (empty)

- Ejecting the cylinder contents (Eject)

Metrohm 838 Advanced Sample Processor, Operation 7

Page 16

2.1 Operating principles

- Driving the piston to the max. volume

- Compensating for the play between piston and spindle (compen.)

- Valve switching (port)

The first parameter of the DOS command stands for the number of the

dosing instrument (1…3, * = all) and the Dosino port (e. g. 1.1 stands

for Dosino 1, port 1), the second parameter for the function or the volume to be dosed.

Example:

DOS: 2.1 <ENTER> 4.51 ml <ENTER>

DOS: 2.* <ENTER> <SELECT> ... fill <ENTER>

The dosing and filling rates can be set in the parameter menu.

SCAN

1

Shows the incoming signals or data from the Remote or the serial

RS232 interfaces.

This function is used for checking the data communication with connected devices.

The first parameter shows the selected interface. The second parameter shows the signals or data that are received directly.

CTRL

2

WAIT

3

If the parallel Remote interface (Rm) is selected then the signal states

of the incoming Remote lines are shown in binary form (1=line active,

0=line inactive).

If the serial RS232 interface (RS) is selected then the data string received via this interface will be shown (14 characters per line).

Controls external devices via the Remote or RS232 interface.

The first parameter sets the interface (<SELECT>). The second parameter defines the status of the lines (Remote lines) or data (RS232

interface) to be outputted via the selected interface.

2nd parameter, for Remote interface

Binary pattern with 14 digits (0, 1 or ∗) for the 14 output lines or prede-

fined binary pattern (<SELECT> selection), e.g.

etc.

2nd parameter, for RS232 interface

Data string with up to 14 alphanumeric characters (any).

The default value "&M;$G" (for starting Metrohm instruments) can be

set with <CLEAR>.

The <WAIT> key has no function in the normal operating condition. It

is used to insert the WAIT command in a run sequence.

PUMP R/S 1, INIT

8 Metrohm 838 Advanced Sample Processor, Operation

Page 17

2.1 Operating principles

EXT

0

VALVE

<

+

.

RACK

>

-

*

Sequence control

START

The <EXT> key is used to switch on and off the pump connectors on

the rear side of the tower. On entry of the address of the connector (1

or 2) the current state of the connected pump is switched, i. e. a currently active pump is switched on.

The display indicates the current state of the pump conncectors (i. e.

PUMP–+; + means active, – means inactive).

Example:

PUMP on/off no. ? <2> display: PUMP -+--

PUMP on/off no. ? <2> display: PUMP ----

In this case pump 2 is switched on and off.

Under <PARAM>,

>manual stop you can define whether the pump

connectors should be switched off with the <STOP> key or not.

The <VALVE> key is used to switch the position of the injection

valve at the tower of the Advanced Sample Processor.

Example:

VALVE: inject

<ENTER> switches the injection valve to the displayed position.

This function is only working in the Sample Processor models

2.838.0x20 with built-in injection valve.

With the <RACK> key the sample rack can be initialized. The connected peripheral devices (e.g. Dosimats, Dosinos) are not affected

by this.

The sample rack and lift (both lifts in 2-tower versions) are moved to

the zero position and automatic rack recognition is carried out. The

SAMPLE variable (= rack position of the current sample) is reset to

1.

The <START> key starts a method. A start is only possible when the

Advanced Sample Processor is in the normal operating condition, i. e.

when the display shows

ready.

If <START> is activated after an interruption (<HOLD>, see below),

then the sequence continues with the next command.

The <START> can also be used to carry out a single command line

in a run sequence (TRACE function), see p. Fehler! Textmarke nicht

definiert..

Metrohm 838 Advanced Sample Processor, Operation 9

Page 18

2.1 Operating principles

The <STOP> key ends a method.

STOP

If a sample series is stopped manually with <STOP> then the final

sequence of a method will not be carried out. When the <STOP> key

is pressed the functions listed in the parameter menu under

stop will be carried out.

>manual

LEARN

HOLD

The <HOLD> key interrupts a method sequence.

Connected peripheral devices will not be stopped automatically. Only

the method sequence will be interrupted. In the HOLD condition a

method can be completely terminated with <STOP> or continued

with <START>.

After an error message in the method sequence the Advanced Sample Processor switches automatically to the HOLD condition after

<QUIT>.

10 Metrohm 838 Advanced Sample Processor, Operation

Page 19

2.1 Operating principles

2.1.4 Instrument dialog

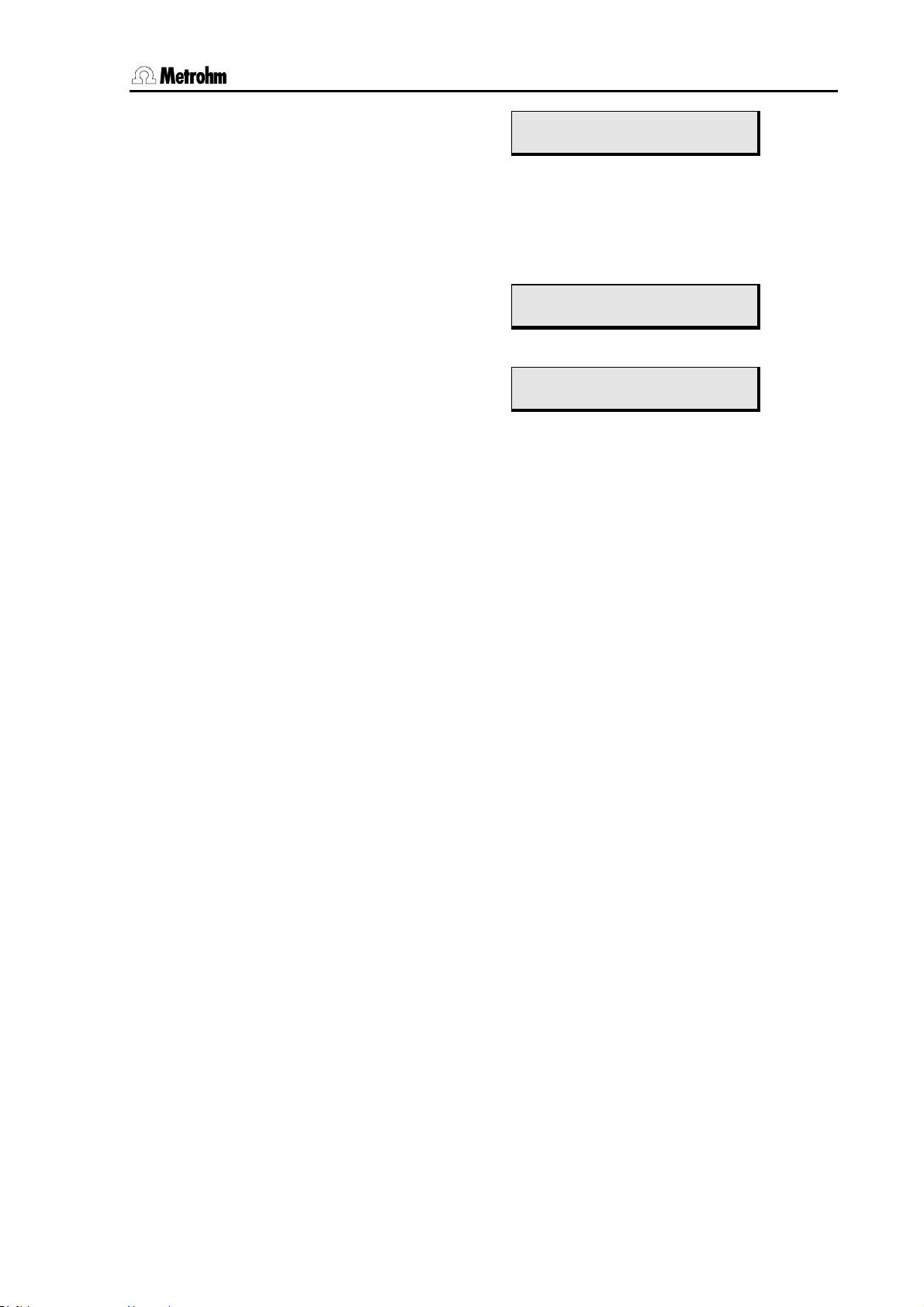

The instrument dialog of the Advanced Sample Processors is arranged

in menu levels in which the following rules apply:

Main menu

The <CONFIG>, <PARAM> and <USER METHOD> keys of the

Sample Processor open a main menu whose thematically arranged

submenus are accessed by repeatedly pressing this key or with <>.

The name of the main menu appears in the first line.

Submenu

Each submenu has its own title which is indicated by

in the lower line of the display. From the title you can use <ENTER> to

access the individual questions with which the most important instrument settings can be altered. The first line of the display always shows

the name of the active submenu.

Navigation in the menus is by the cursor keys; with <HOME> you can

access the first line of the menu and with <END> the last one.

<QUIT> exits the active menu and accesses either the next superior

menu or the normal operating condition.

">" and appears

<ENTER> always opens a submenu or confirms the data input of the

lowest menu level.

Input lines

For input lines without

":" the values can be entered by the numerical

keys. The set value is accepted with <ENTER> and the next line appears.

For input lines with

":" predefined values can be selected with the

<SELECT> key. <ENTER> accepts the set value and the next line

appears.

Depending on the parameter, <CLEAR> is used to set the initial value.

The <CLEAR> key is also used to reject incorrectly entered values.

<QUIT> exits the questions and returns to the submenu.

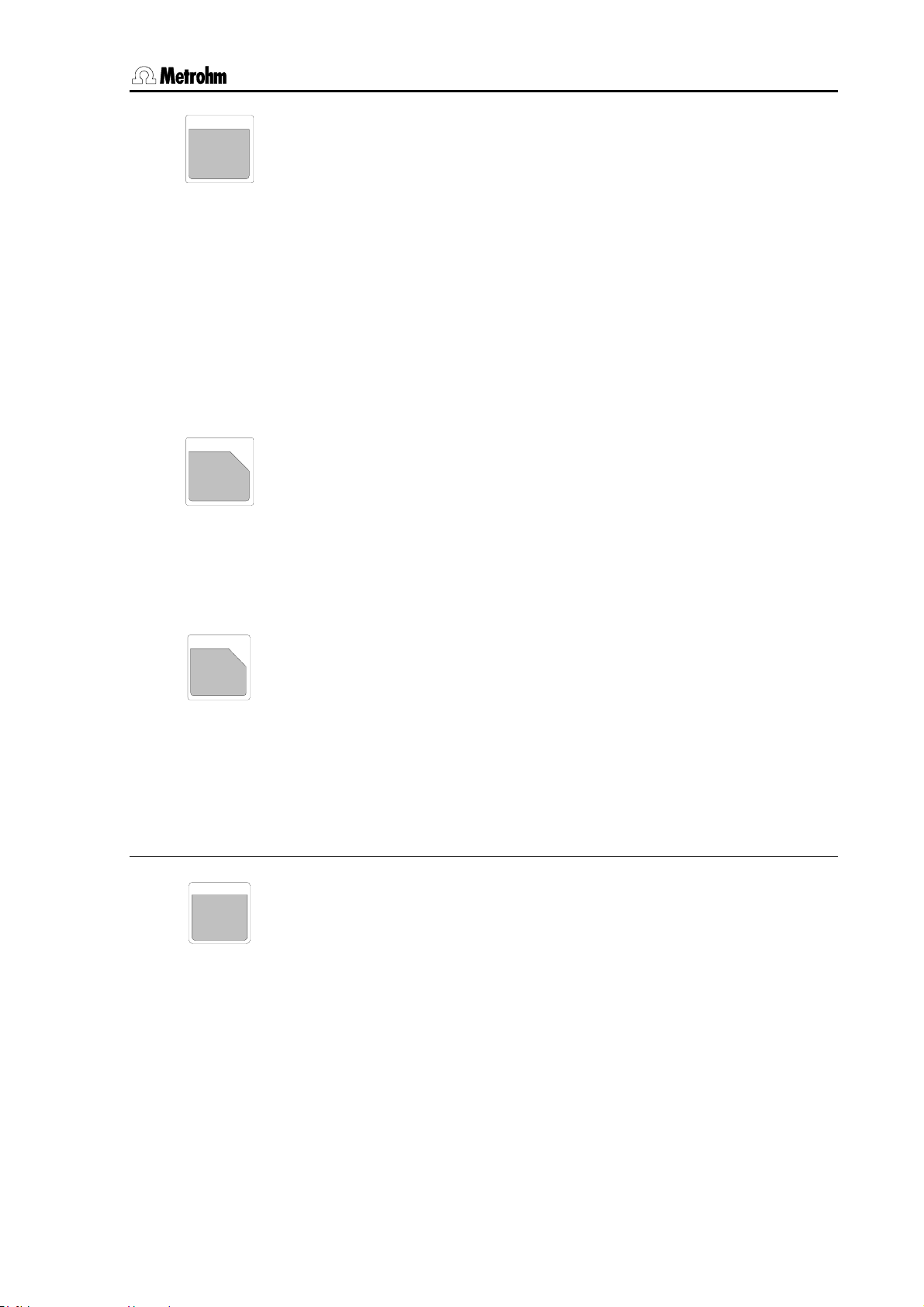

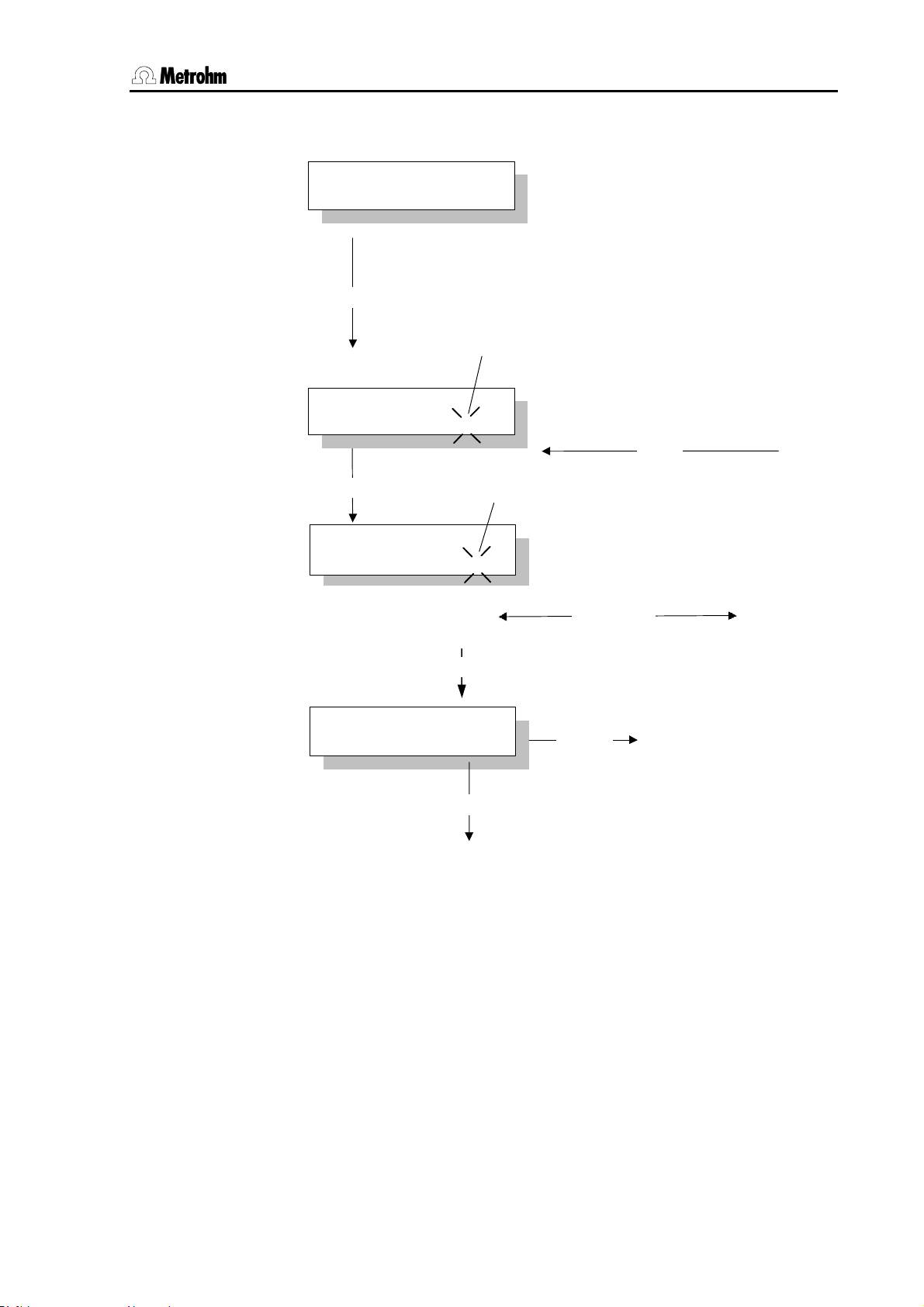

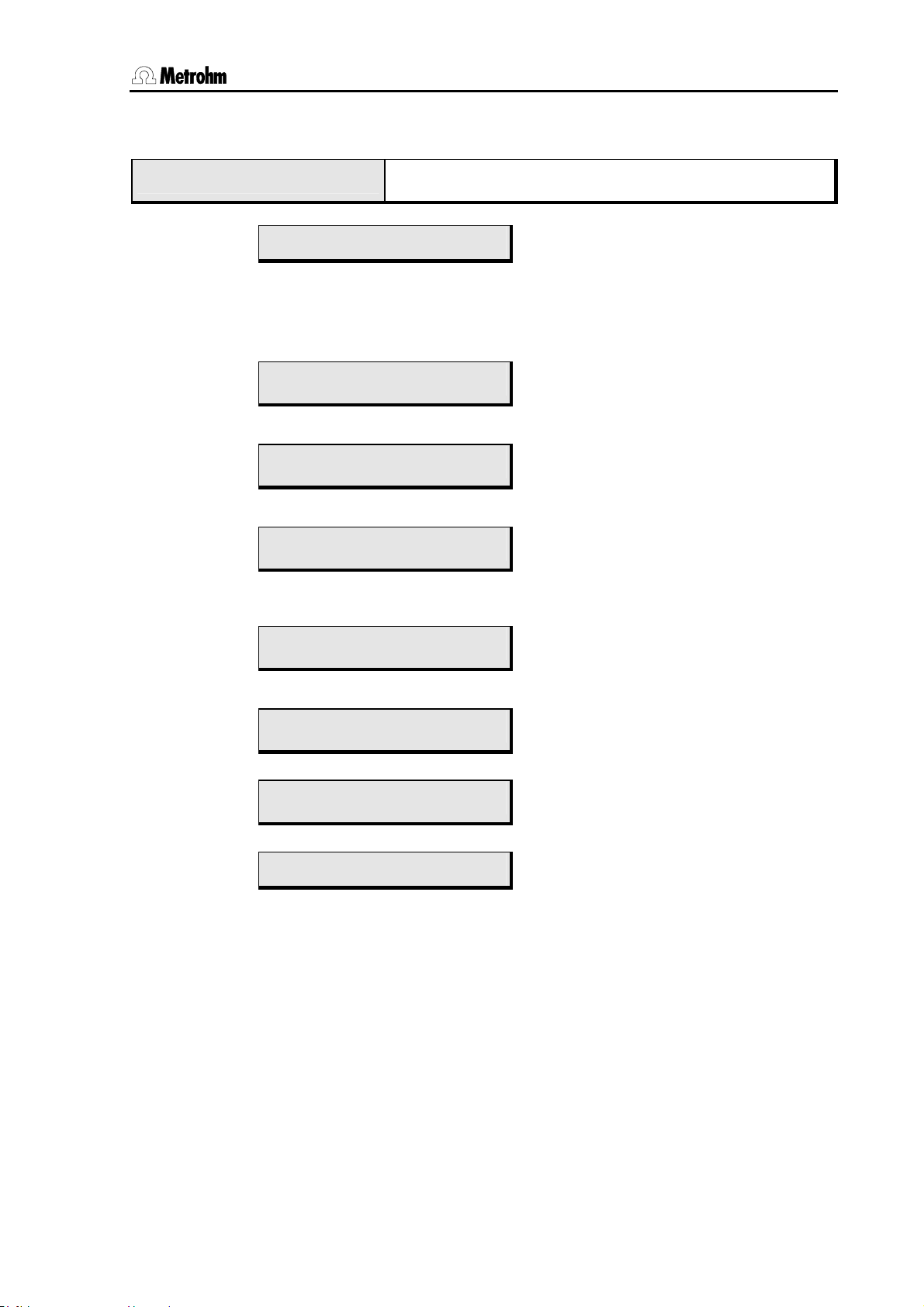

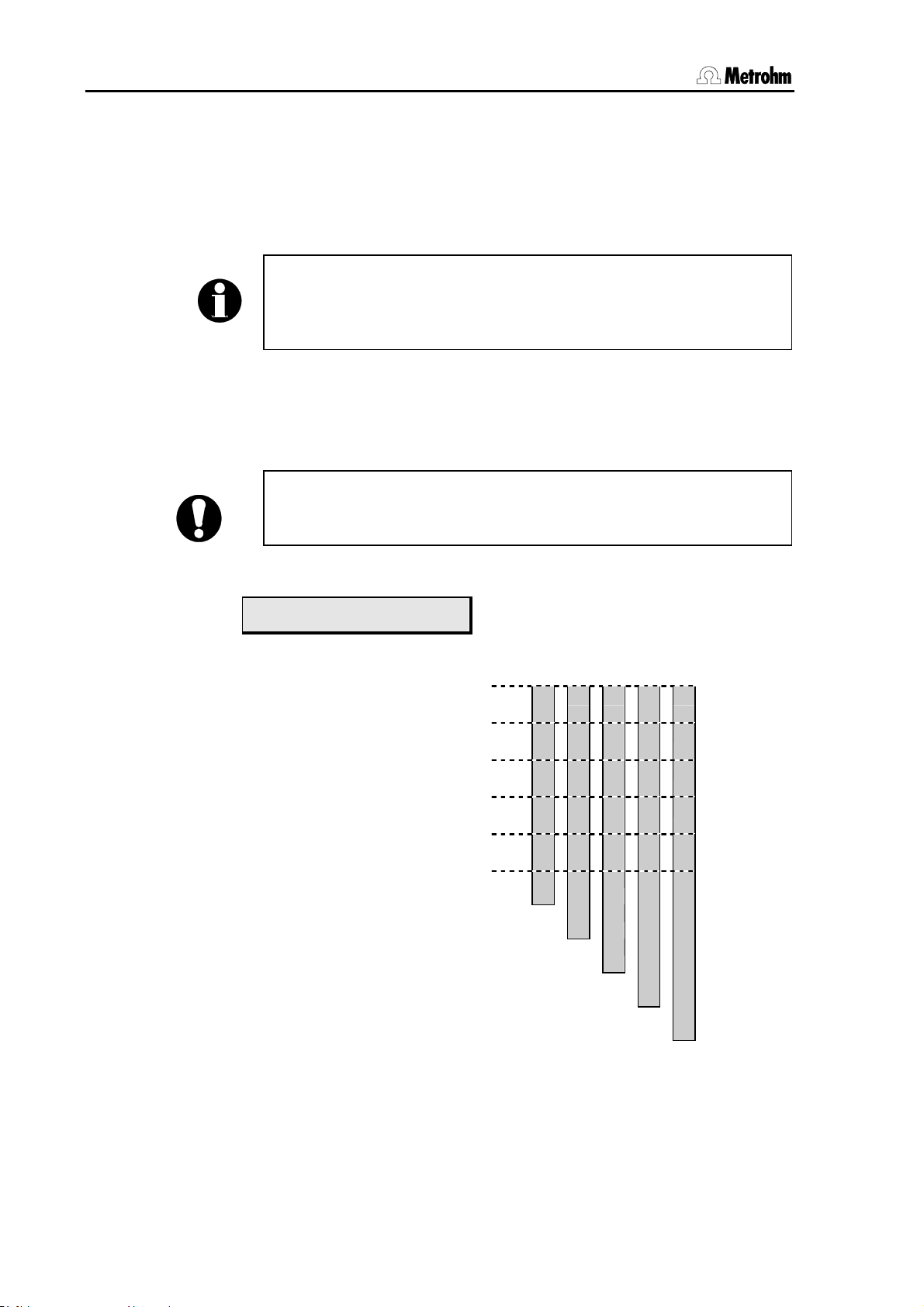

The following schematic diagram shows the instrument dialog arrangement.

Metrohm 838 Advanced Sample Processor, Operation 11

Page 20

2.1 Operating principles

Normal state

KEY

QUIT

Kex title

>Submenu 1

KEY

Key title

>Submenu 2

KEY

ENTER

ENTER

ENTER

>Submenu 1

Inquiry 1

ENTER

>Submenu 1

Inquiry 2

>Submenu 1

Inquiry n

>Submenu 2

Inquiry 1

ENTER

QUIT

QUIT

Key title

>Submenu n

KEY

Fig. 2 Dialog arrangement

ENTER

>Submenu 2

Inquiry 2

>Submenu 2

Inquiry n

12 Metrohm 838 Advanced Sample Processor, Operation

Page 21

2.1 Operating principles

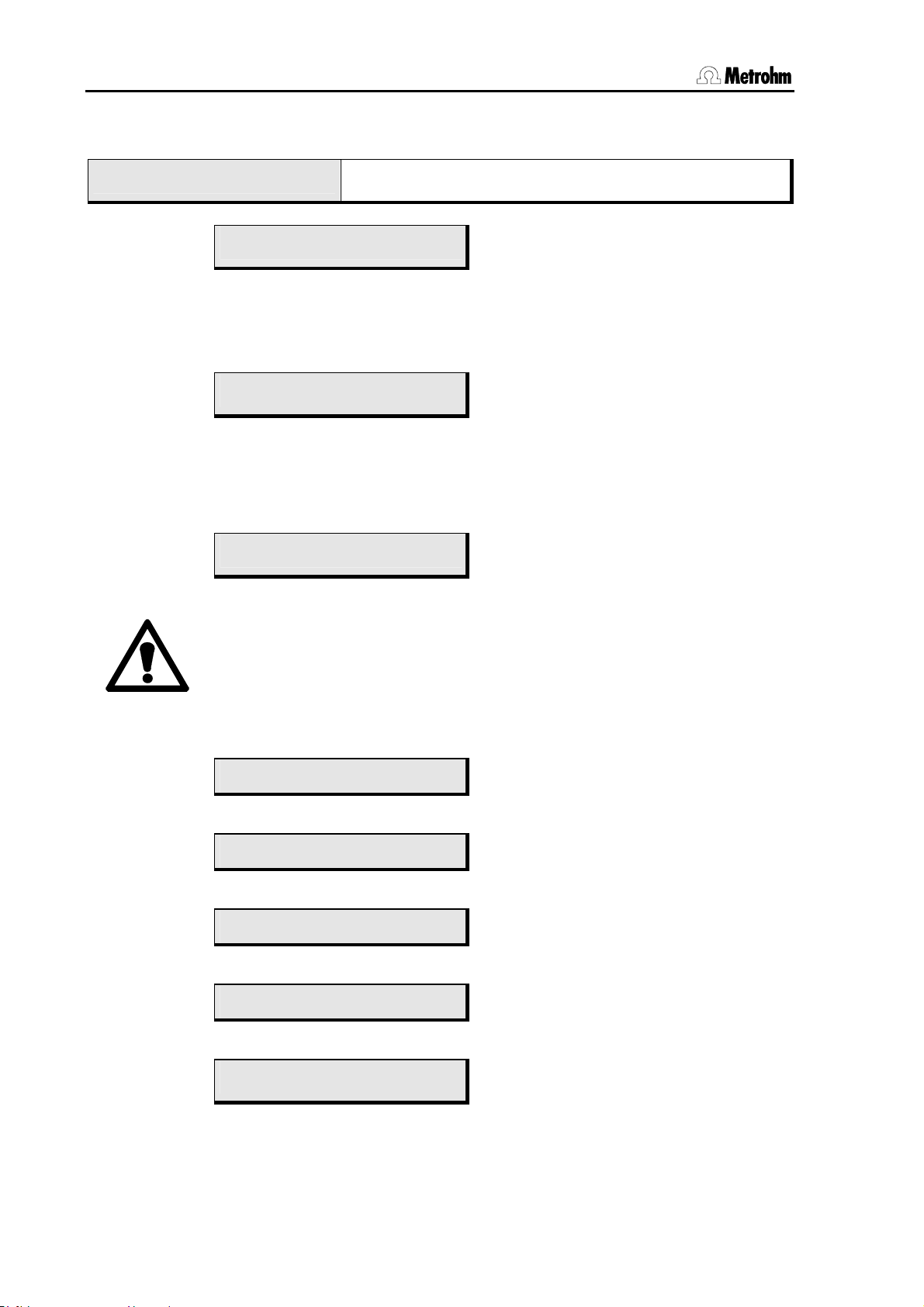

2.1.5 Data input

Input line

Either one or two parameters can be entered in a menu line or a sequence. A blinking block cursor indicates where a parameter can be

entered.

<Select> list

SELEC T

>stirring rates

stirrer tower 1 █ 3

Title line

Input line

Menu entry Cursor Parameter

>sample sequence

04 STIR █ T1 : 1 s

Command 1

st

parameter 2nd parameter

Title line

Input line

Switching between the parameters is carried out with the arrow keys

<> and <>. <ENTER> moves the cursor automatically to the

right, <QUIT> moves it to the left.

Data can usually be entered directly by the numerical keys of the keypad.

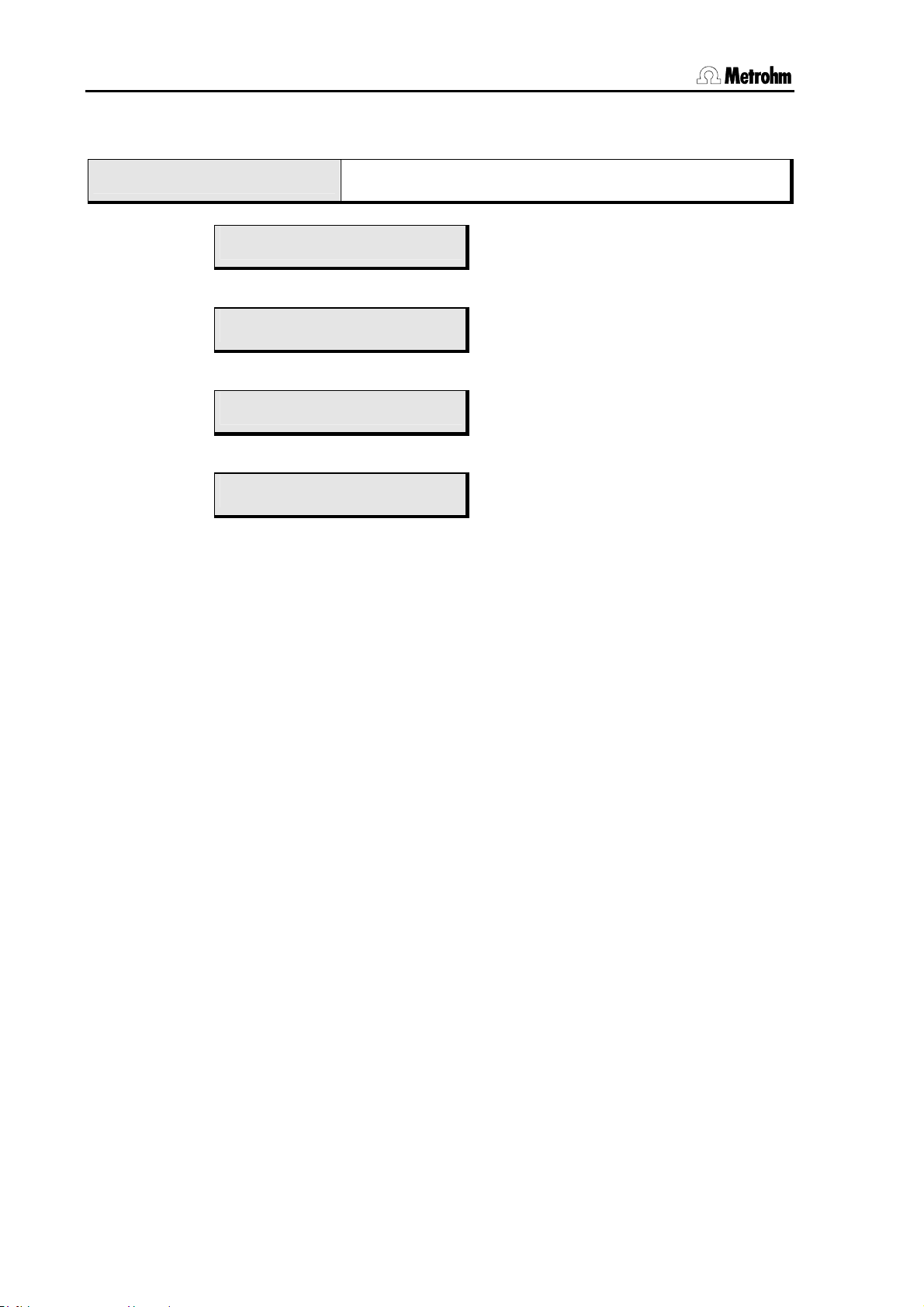

For entries marked by a colon the <SELECT> key can be used to dis-

play a selection of entries. This selection is cyclically arranged like a revolving drum.

Example:

>RS232 settings

baud rate: 9600

9600

<SELECT>

>RS232 settings

baud rate: 2400

4800

2400

1200

600

<ENTER>

Fig. 3 Selection list

Metrohm 838 Advanced Sample Processor, Operation 13

Page 22

2.1 Operating principles

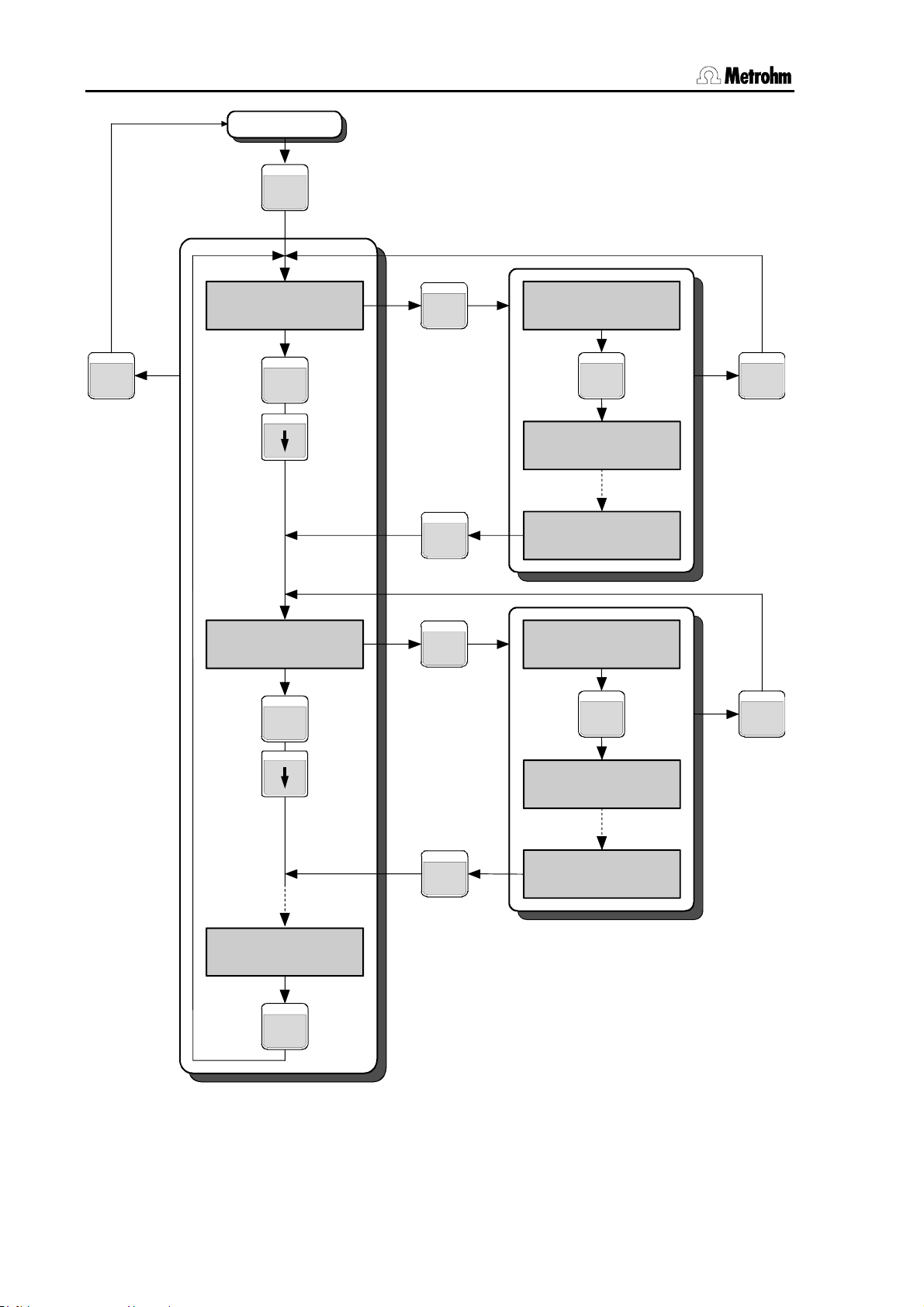

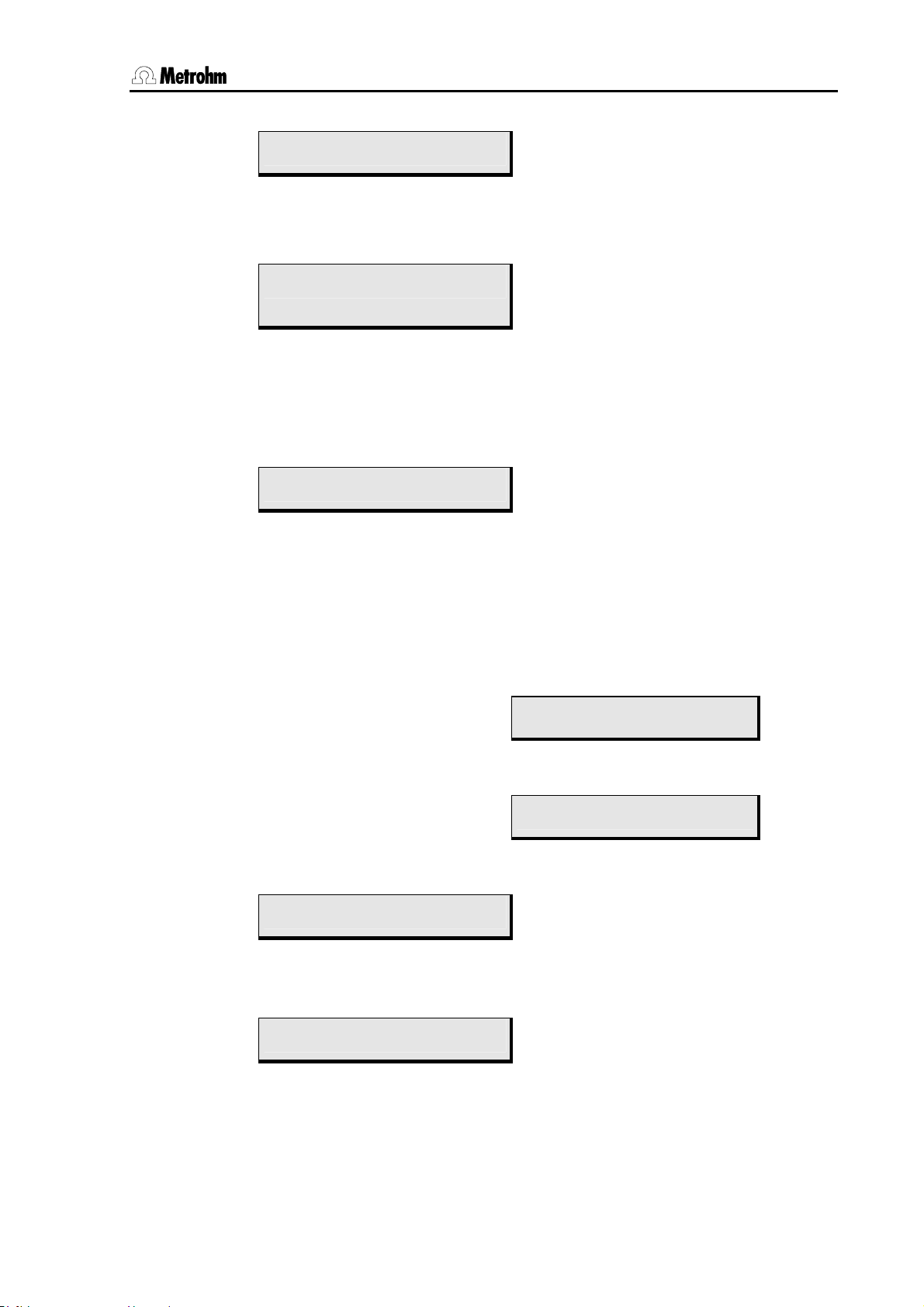

2.1.6 Text input

The text editor can be used wherever provision is made for the entry of

a text.

Numbers can be entered directly via the keypad.

PRINT

<

ENDSEQ

The "<" or ">" keys open the text editor. With "<" an existing character

>

string is deleted and the text cursor moves to the left-hand end of the

.

*

input field. With ">" an existing character string is retained, the text cursor moves to the last character of the existing text.

A character string is displayed that consists of all the characters that

can be entered in alphabetic order. The currently selected character

always blinks (text cursor).

Character selection

The "<" and ">" keys move the character string made up of all the se-

lectable characters (upper and lower case letters, numbers and special

characters, arranged alphabetically) in the selected direction past the

text cursor. Pressing either of these keys once moves the character

string in the corresponding direction by one position. Rapid character

string movement is achieved by keeping the key pressed down.

Confirming character selection

ENTE R

The <ENTER> key appends the character currently under the text

cursor to the existing text line. When the complete width of the text input field has been filled the text input mode is exited and the text line is

accepted with <ENTER>.

RESET

CLEAR

Delete character

The <CLEAR> key deletes the last character of an existing text line.

The text cursor automatically moves one character to the left.

Ending text input

QUIT

<QUIT> exits the text input mode. The displayed text line can then be

accepted with <ENTER> or rejected by pressing <QUIT> a second

time.

14 Metrohm 838 Advanced Sample Processor, Operation

Page 23

2.1 Operating principles

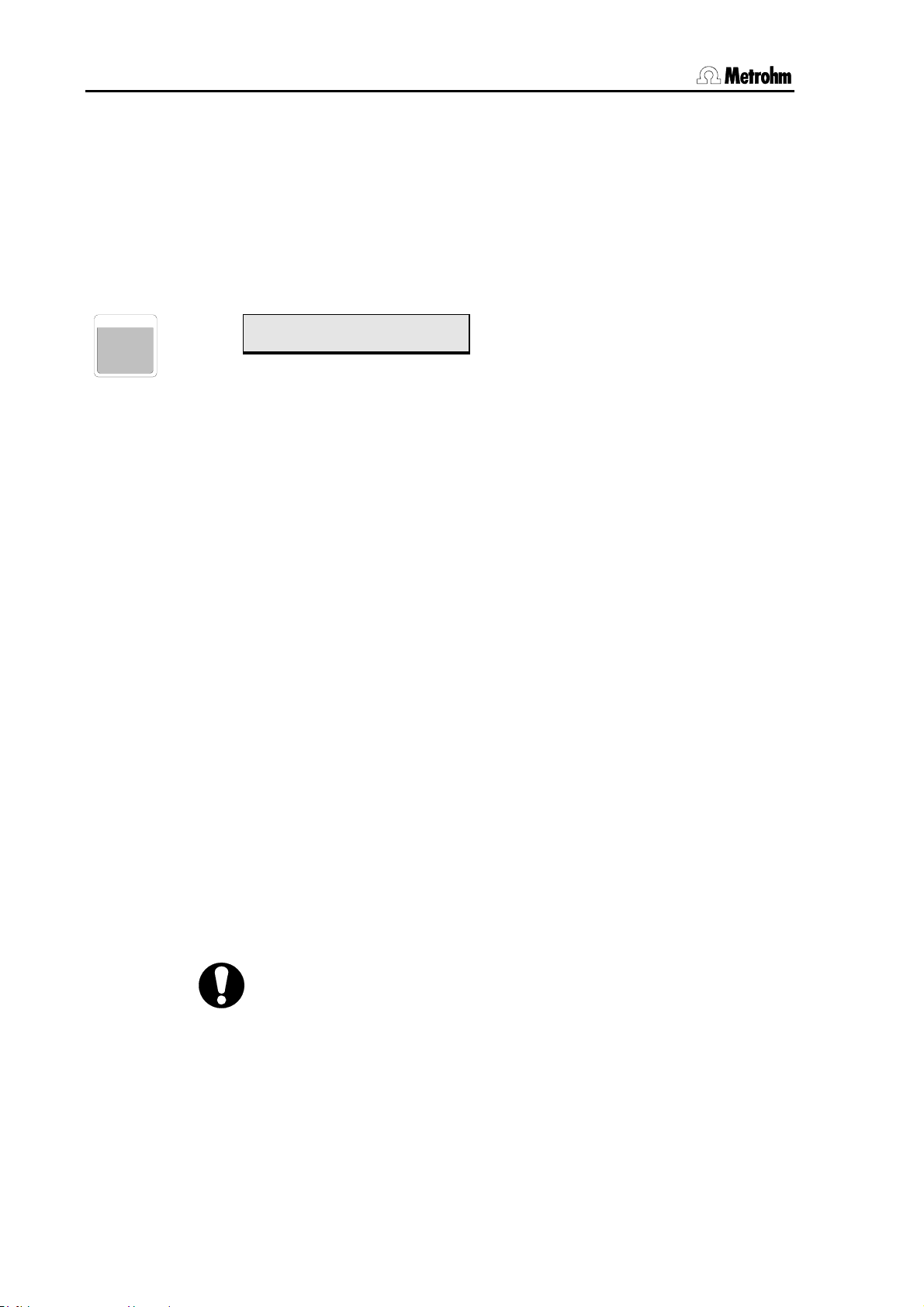

Arrangement:

>store method

method: ********

"<" or ">"

blinking text cursor

>store method

█

method:

<ENTER>

>store method

method:

>store method

method: Chloride

ABCDEFGHIJ...abcd...1234...*%&/()=...

█

DEFGHIJ...abcd...1234...*%&/()=...

CC

<QUIT>

<ENTER>

blinking text cursor

"<" or ">"

...<ENTER>...

<QUIT>

character chain

2x ">"

reject

accept

Fig. 4 Text input

The figure above shows how a character string can be entered, e.g. for

naming a method. Text input is concluded with <QUIT>. The whole of

the entered character string is then shown and can be accepted with

<ENTER> or rejected with <QUIT>.

Metrohm 838 Advanced Sample Processor, Operation 15

Page 24

2.2 Configuration

her l

l

2.2 Configuration

CONFIG

Main menu:

configuration

>auxiliaries

configuration

>tower 1

configuration

>rack definitions

configuration

>Dosing units

configuration

>RS232 settings

• Open submenu with <ENTER>

• Use <> or <> to move up and down by one

menu item

• Use <HOME> or <END> to move to the first or last

menu item

• Use <QUIT> to return to operating condition

2.2.1 Miscellaneous

configuration

>auxiliaries

>auxiliaries

dialog: english

Use <QUIT>

for next hig

eve

english, deutsch,

français, español

>auxiliaries

display contrast 3

0…3…7 0 = low contrast

>auxiliaries

beeper: ON

ON,OFF

>auxiliaries

external Start: off

on, off

Normally the Sample Processor takes over the complete run control for a

sample series as the "Master". This may be unwanted, particularly if an

automated system has been set up that includes instruments that are not

from Metrohm. This is why the Sample Processor can also be started from

any external instrument via the Remote interface.

With

external Start: ON the run sequences of the Sample Processor will

be started as soon as input line 7 is activated at the Remote interface (low

level).

Submenu for basic settings

Open the submenu with <ENTER>

Select dialog language

Set display contrast

7 = high contrast

Beep for warnings on or off

Switch on external start via Remote line

(Input 7)

16 Metrohm 838 Advanced Sample Processor, Operation

Page 25

2.2 Configuration

The run sequences of the Sample Processor will be stopped when input

line 6 is activated (low level). The technical details can be found in the

8.789.1033 Technical Reference of the Sample Processors.

>auxiliaries

>>running time meter

Shows the elapsed time

0…9999 h

Submenu for running time meter, open

with <ENTER>

>>running time meter

elapsed time 0.0 h

Warning limit for running time

meter

OFF, 0…9999 hours

>>running time meter

warning OFF h

The running time meter is used to support the regular maintenance of the Sample Processor. If a warning limit is entered then,

when this period has elapsed, a message will appear indicating

that maintenance is required.

>auxiliaries

device label

8 ASCII characters

Name of the instrument

for identification

>auxiliaries

program 5.838.0012

read only

Program version

Metrohm 838 Advanced Sample Processor, Operation 17

Page 26

2.2 Configuration

2.2.2 Tower settings

configuration

>tower 1

Submenu for basic settings for the tower

Open the submenu with <ENTER>

>tower 1

max. stroke path 125 mm

0…125…235 mm

Max. lift range for Lift 1

This max. stroke path setting is important for safety reasons. Correct entry

of this value can prevent, that i. e. an injection needle or tubing will be bent.

The working head cannot move any lower than the position entered here

(0 mm = upper stop of lift). Make these settings before you edit the rack

definitions.

>tower 1

min. beak. radius * mm

*, 1…100 mm * = any value

Sets the minimum required beaker radius for processing a sample

This is also a safety setting. In order to prevent a fully equipped, wide titration

head from trying to enter a narrow sample beaker a limit for the minimum

necessary beaker radius can be entered here. During a method sequence

the value entered here will be compared with the value given for the effective

beaker radius in the rack table before the lift is lowered and, if necessary, an

error message will be produced.

Entering * prevents a comparison from being made.

>tower 1

>>swing head 1

Submenu Swing Head

Open with <ENTER>

If a 786 Swing Head equipped with a robotic arm is mounted on the Sample

Processor then it is essential that the correct settings for the mounted robotic

arm are entered, as otherwise the instrument will not be able to position it

exactly.

Each of the following settings can be interactively defined with the LEARN

function. Press the <LEARN> key and then move the lift or robotic arm

with the arrow keys <> and <> or <> and <>. The set values

can be accepted with <ENTER> and corrected later.

For further explanations of the LEARN mode, see section 2.3.8.

Setting the rinsing height for external positions *

0…235 mm

)

>>swing head 1

rinse position 0 mm

Setting the swing height for external positions *

0…235 mm

)

>>swing head 1

shift position 0 mm

18 Metrohm 838 Advanced Sample Processor, Operation

Page 27

2.2 Configuration

Swing angle for external posi-

)

tion 1 *

Offset…84.00…max. angle+offset

>>swing head 1

external pos.1 117.00°

0° = points to rack center

The swing angle for the external positions is entered as an absolute angle. The input limits are defined by the offset of the Swing

Head drive (approx. 9°) and the set max. swing angle range.

Setting the working height for

external position 1 *

0…235 mm

)

>>swing head 1

work position1 0 mm

Swing angle for external position 2 *

… up to external pos. 4

* can be set with LEARN function

)

>>swing head 1

external pos.2 117.00°

Metrohm 838 Advanced Sample Processor, Operation 19

Page 28

2.2 Configuration

her l

l

2.2.3 Rackdefinitionen

configuration

>rack definitions

>rack definitions

>>recall rack

Use <QUIT>

for next hig

eve

In order to make a modification to the definition of a sample rack the rack

data must first be loaded. The data of the Metrohm standard racks is stored

under their ordering number.

>recall rack

name: 6.2041.450

10 ASCII characters

The <SELECT> key can be used to make a selection from the saved rack

data. The rack data is loaded with <ENTER>. The first selection to appear

is the rack name of the currently attached rack.

>recall rack

code 000001

000001…111111

The magnet code is used for the unambiguous identification of the rack. The

magnet code is recognized during the initialization of the rack. This is why

the <RACK> key should be pressed whenever a rack is changed.

For security reasons the max. stroke path should be set before modifications

of the lift positions are made, see section 2.2.1.

>recall rack

work position T1 0 mm

0…235 mm (in mm from upper stop point)

>recall rack

rinse position T1 0 mm

0…235 mm (in mm from upper stop point)

>recall rack

shift position T1 0 mm

0…235 mm (in mm from upper stop point)

>recall rack

special pos. T1 0 mm

0…235 mm (in mm from upper stop point)

>recall rack

beaker radius * mm

*, 1…100 mm * = any value

This setting is required for the check of the beaker radius, see p. 17.

Submenu for defining individual racks

Open the submenu with <ENTER>

Load rack definitions

Name of the rack to be loaded

Magnet code of the rack

See table on p. 65.

Working position for sample positions *)

Rinsing position for sample positions *)

Shifting position for sample positions *)

Special position for sample positions *)

Effective beaker radius for the sample

positions on the rack

20 Metrohm 838 Advanced Sample Processor, Operation

Page 29

2.2 Configuration

her l

l

>recall rack

beaker sensor: off

Tower, SwingH, off

Selection of the beaker sensor

Not implemented.

>recall rack

rack offset 0.00°

Correction for the rotation angle of the

sample rack *

)

-5.00…0.00…5.00°

)

*

All the above lift positions and the rack offset can be set by using the

<LEARN> function.

Special beaker positions

Use <QUIT>

for next hig

>>recall rack

>>>special positions

Submenu special beaker positions

Open with <ENTER>

Special beaker positions are predefined places on a sample rack that are not

treated as sample positions. They can be occupied by rinsing beakers or

eve

conditioning beakers and selectively addressed during a run sequence. Up

to 16 special beaker positions can be defined per rack. For each special

beaker the work position of the lift and the beaker radius can be set, see

above.

Selection of special beaker

1…16

Rack position of the special

beaker

etc. up to special beaker 16

>>>special positions

special beaker 1

>>special positions 1

rack position 0

0…number Pos.

0 = not defined

>rack definitions

>>store rack

Save rack definitions

In order to store modifications to the definition of a sample rack the submenu

>>store rack is selected.

>store rack

name: 6.2041.310

10 ASCII characters

Name of rack

With the <SELECT> key you can select one of the existing rack names. The

rack data is stored with <ENTER>. Any rack name can be used. The input

of any rack name can be made directly via the numerical keys or in the text

Metrohm 838 Advanced Sample Processor, Operation 21

Page 30

2.2 Configuration

input mode, see p. 14. Selection of the alphanumerical characters with the <

and > keys or <PRINT> and <RACK>.

>rack definitions

>>delete rack

Delete rack definitions

The submenu >>delete rack must be selected if a rack definition is to be

deleted.

>delete rack

name: 6.2041.310

Name of the rack

The <SELECT> key can be used to select one of the existing rack names.

<ENTER> confirms the selection. <QUIT> stops the deletion process.

Before the deletion a question appears.

>rack definitions

delete 6.2041.310 ?

<ENTER> confirms the deletion. <QUIT> stops the deletion process.

When the submenu '

data a request appears about saving the rack data.

>rack definitions

overwrite 6.2041.310 ?

>rack definitions' is exited without saving modified

Confirm the question (store the rack definitions) by pressing the

<ENTER> key. Reject storage with <QUIT>.

22 Metrohm 838 Advanced Sample Processor, Operation

Page 31

2.2 Configuration

her

l

l

2.2.4 Dosing units

Metrohm Exchange units (with 685 and 805 Dosimats as the dosing drive) and Dosing units for

the Dosino 700 and 800 systems can be used with the Sample Processors. The following settings are used for preparing the Dosing units (PREP function). The tubing dimensions (length

and diameter) are used for calculating the rinsing volumes.

If Exchange units are used then only the dosing and filling rate is effective (

max. rate).

configuration

>Dosing units

Submenu for the Dosing unit settings

Open the submenu with <ENTER>

Use <QUIT>

for next hig

eve

>Dosing units

Dosing unit 1

1…3

The Dosing unit selection must be confirmed with <ENTER>. It will then be

shown in the first menu line.

Selection of Dosing unit or dosing device

connection

>Dosing units 1

max. rate 1 160 ml/min

0.01…160 ml/min

Max. dosing and filling rate for Port 1

(depends on cylinder size)

>Dosing units 1

tube length 1 1000 mm

0…1000…30000 mm

Length of tubing at Dosino Port 1

>Dosing units 1

tube diameter 1 2 mm

0.1…2…20 mm

Diameter of tubing at Dosino Port 1

>Dosing units 1

max. rate 2 160 ml/min

0.01…160 ml/min

Max. dosing and filling rate for Port 2

(depends on cylinder size)

>Dosing units 1

........... to port 4

Input of tubing parameters for all four

ports of a Dosing unit.

Metrohm 838 Advanced Sample Processor, Operation 23

Page 32

2.2 Configuration

her l

l

2.2.5 RS232 settings

The correct settings of the interface parameters of the serial RS232 interface is essential for the

perfect functioning of data transmission to and from the Sample Processor. This includes the

control of the instrument by using a PC software such as «IC Net».

configuration

>RS232 settings

Submenu for serial interface settings

Open the submenu with <ENTER>

Use <QUIT>

for next hig

eve

>RS232 settings

baud rate: 9600

300,600,1200,

2400,4800,9600, 19200

Transmission rate

in baud

>RS232 settings

data bit: 8

7,8

Number of data bits

>RS232 settings

stop bit: 1

1,2

Number of stop bits

>RS232 settings

parity: none

even, odd,

none

Parity selection

>RS232 settings

handshake: HWs

HWs,SWchar,SWline,

none

Handshake selection

>RS232 settings

character set: IBM

IBM,HP,Epson,

Seiko,Citizen

Character set for printer and PC

(printer emulation)

For data transmission using personal computers you should select IBM.

>RS232 settings

RS control: ON

ON,OFF

Switch data reception on/off

If Remote control is switched off then no data will be received.

24 Metrohm 838 Advanced Sample Processor, Operation

Page 33

2.3 Composition of a method

2.3 Composition of a method

All the settings of the parameter menu form a method and can be

stored as such.

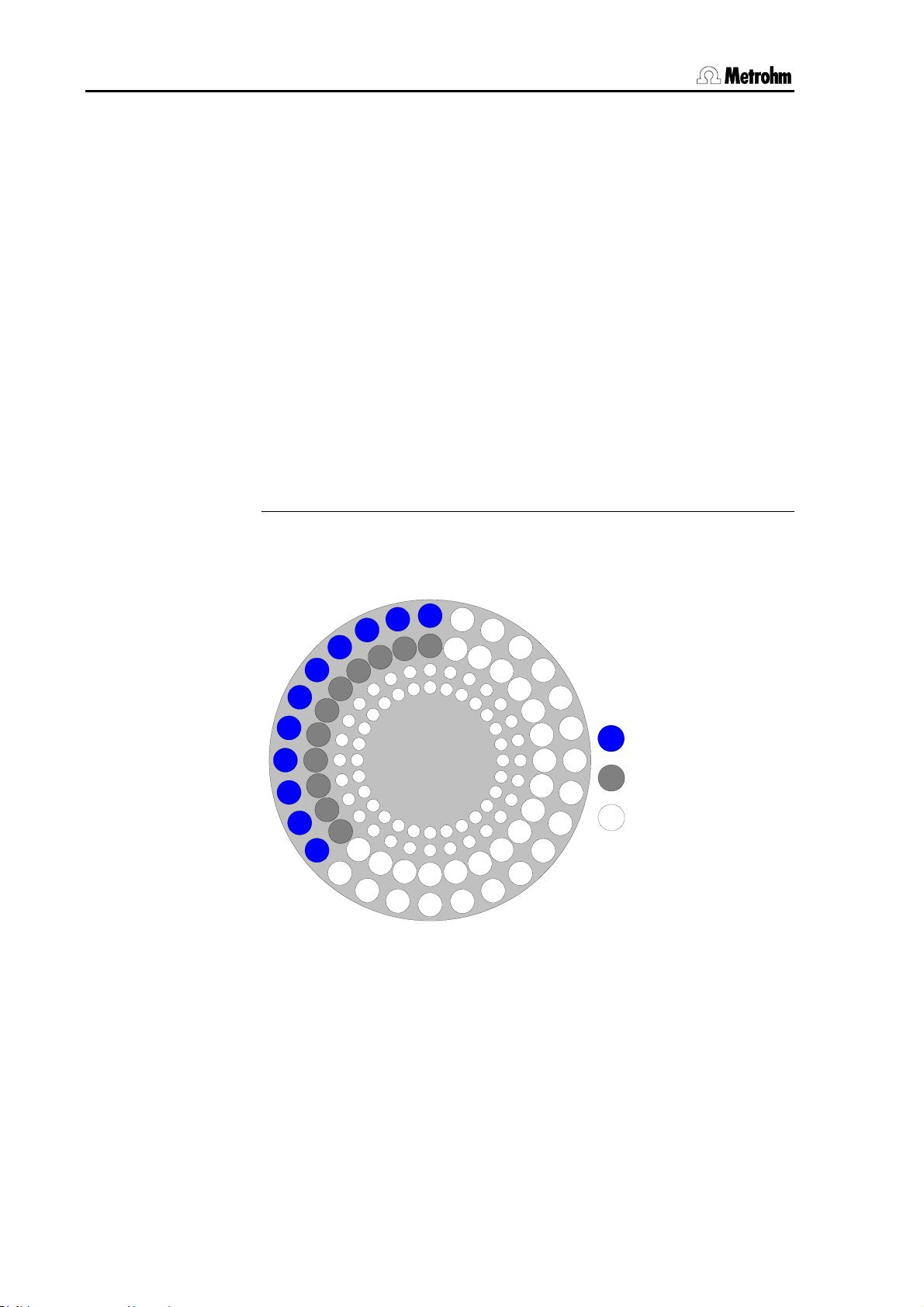

2.3.1 Run sequences and method parameters

PARAM

Main menu:

parameters

number of samples: rack

1…999,

rack,∗

Number of samples to be processed

rack = one sample rack rotation

∗ = infinite

In the rack setting all the sample positions of the current rack will be

processed (max. no. of rack positions minus number of special beakers), with only the positions occupied by sample beakers being

counted. It is important that the Sample Processor can recognize the

rack. This is only possible when the rack is in initial position. We recommend that each time a rack is changed the Sample Processor is

initialized with <RACK>.

parameters

>start sequence

parameters

>sample sequence

parameters

>final sequence

parameters

>changer settings

parameters

>stirring rate

parameters

>dosing unit def.

parameters

>timeout settings

parameters

>nanual stop

Open submenu with <ENTER>

Use <> or <> to move up and down by one menu

item

Use <HOME> or <END> to reach the first and last

menu item

Use <QUIT> to return to normal operating condition

Submenus:

In each of the submenus

>start sequence, >sample sequence and >final sequence up to 99

command lines can be entered as a run sequence. The commands can be entered directly via

the keypad. The command keys on the right-hand side of the keypad are available.

parameters

>start sequence

Commands for the start sequence of the sample series

Open the submenu with <ENTER>

The start sequence is carried out once at the start of a sample series.

Metrohm 838 Advanced Sample Processor, Operation 25

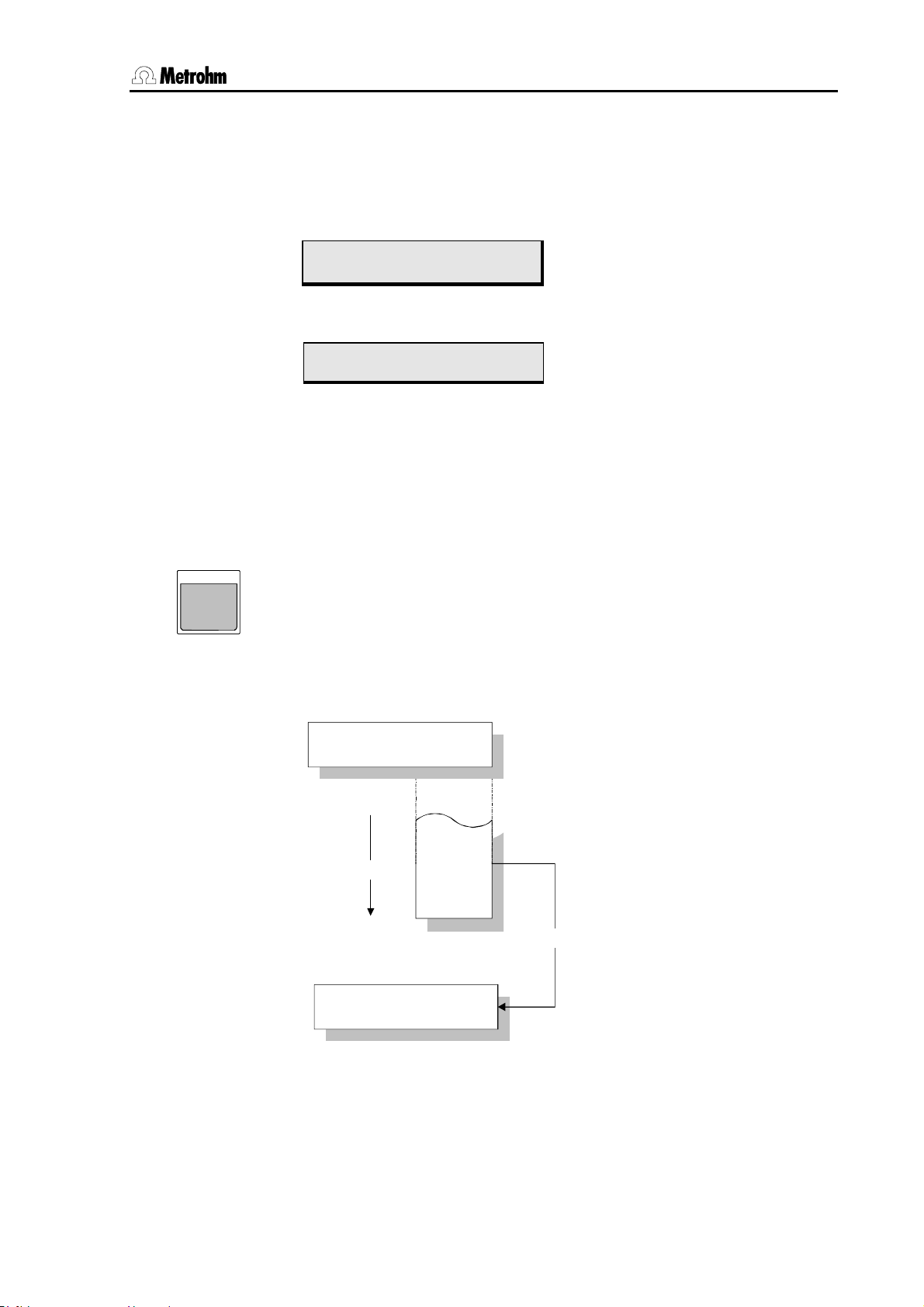

Page 34

2.3 Composition of a method

parameters

>sample sequence

parameters

>final sequence

Series operating

<START>

Commands for the processing of each sample

Open the submenu with <ENTER>

The sample sequence is carried out when each individual sample in

a sample series is processed.

Commands for the final sequence of the sample series

Open the submenu with <ENTER>

The final sequence is carried out once at the end of a sample series.

For example, it can be used to move to a rinsing or conditioning

beaker.

number

of samples

start sequence final sequence

sample sequence

normal state

Fig. 5 Sample series

Creating methods

In principle the same input rules apply for creating run sequences as for

manual operation, i. e. after selecting a command and entering the

necessary parameters the entry is confirmed with <ENTER>. The next

command line is then selected and a new command can be entered.

For more comfortable parameter input the LEARN function is available

for certain commands. It can be used to accept direct values that are

set when a single command is carried out manually. Please refer to p.

Fehler! Textmarke nicht definiert. for details.

The TRACE function can be used to execute each entered command

line individually in the editing mode. See p. 33.

Navigation in a sequence is the same as in other menus. In addition,

the <INSERT> and <DELETE> keys are available.

<INSERT> inserts a new command line above the current line of a

sequence. It is automatically occupied with the NOP command, which

has no function. The following lines move downward by one position.

<DELETE> deletes the current line of a sequence. The following lines

move upward by one position.

26 Metrohm 838 Advanced Sample Processor, Operation

Page 35

2.3 Composition of a method

2.3.2 Sample Processor settings

parameters

>changer settings

>changer settings

rack name: *

*,10 ASCII characters * = no particular rack

With this setting the user can be forced to use a particular rack for the selected method. If this is not required then

>changer settings

lift rate T1 25 mm/s

5…25 mm/s

>changer settings

shift rate 20°/s

3…20

>changer settings

shift direction: auto.

+,–,auto. auto. = the Sample Processor selects the shortest

>changer settings

rotat. increment: 5.00°

0.00…5.00…270.00°

>changer settings

swing rate T1 55°/s

10…55

Submenu for setting the Sample Processor functions

Open the submenu with <ENTER>

The sample rack assigned to the method

rack name: * must be selected.

Vertical movement rate of the lift

Speed at which the rack rotates

in degrees per second

Direction of rotation of the sample rack

path for the rotation itself.

Increment angle for the command

MOVE +/-rotate

Swing rate of the robotic arm in degrees/second

>changer settings

swing increment 10.00°

0.00…10.00…180

>changer settings

on beaker error: MOVE

Increment angle for the command

MOVE +/-swing

Definition of reaction if beaker is missing

Not implemented.

Metrohm 838 Advanced Sample Processor, Operation 27

Page 36

2.3 Composition of a method

2.3.3 Stirrer settings

parameters

>stirring rates

>stirring rates

stirrer tower 1 3

1…3…15

>stirring rates

stirrer MSB1 3

1…3…15

>stirring rates

stirrer MSB2 3

1…3…15

>stirring rates

stirrer MSB3 3

1…3…15

Submenu for the stirrer settings

Open the submenu with <ENTER>

Stirring speed of the stirrer at the tower

(stirrer models 802, 741, 722)

Stirring speed of MSB stirrer 1

(stirrer models 801, 804)

Stirring speed of MSB stirrer 2

(stirrer models 801, 804)

Stirring speed of MSB stirrer 3

(stirrer models 801, 804)

28 Metrohm 838 Advanced Sample Processor, Operation

Page 37

2.3 Composition of a method

2.3.4 Dosing drive settings

Both Dosinos (models 700 and 800, with Dosing units) and Dosimats (models 685 and 805,

with exchange units) can be used as dosing drives on an Advanced Sample Processor. However, free assignment of the ports for the various functions is only possible with Dosinos.

parameters

>Dosing unit def.

Submenu for setting the Dosing units

Open the submenu with <ENTER>

>Dosing unit def.

dosing drive 1

1…3

Selection of the dosing device, or the

connection

After entering the connection of the dosing device (see Installation instructions 8.1303) and confirming with <ENTER> the settings for the selected

dosing device should then be made.

>dosing drive 1

dos.rate max. mL/min

0.01…160 mL/min, max.

Set the dosing rate

The maximum possible dosing rate depends on the size of the dosing cylinder (rule of thumb: cylinder volume x 3.3).

>dosing drive 1

fill.rate max. mL/min

0.01…160 ml/min, max.

Set the filling rate

The maximum possible filling rate depends on the size of the dosing cylinder

(rule of thumb: cylinder volume x 3.3).

The following entries only apply to 700/800 Dosinos. Details about Dosinos

and Dosing units can be found on p. 54ff.

>dosing drive 1

dosing port 1

1…4

Define standard dosing port 1

>dosing drive 1

dosing 2 port 3

1…4

Define standard dosing port 2

>dosing drive 1

filling port 2

1…2…4

Define standard filling port

>dosing drive 1

rinsing port 2

1…2…4

Define standard rinsing inlet (if Dosing

unit is exchanged)

>dosing drive 1

preparation port 1

1…4

Define standard outlet for the preparation cycle

Metrohm 838 Advanced Sample Processor, Operation 29

Page 38

2.3 Composition of a method

>dosing drive 1

drain port 4

1…4

Define standard air inlet for emptying the

Dosing unit

>dosing drive 1

cock direction: auto

auto

not over

desc.

asc.

>dosing drive 1

not over port 4

1…4 (see above)

Direction of rotation of Dosino stopcock

= cock direction according to shortest path

= never turn beyond port given below

= cock rotation always in descending direction

= cock rotation always in ascending direction

Protected port, that it not to be moved

over during a stopcock rotation

2.3.5 Behavior during timeout

Metrohm Sample Processors are designed to communicate with other

instruments. In particular, this includes the coordination between the

Sample Processor and devices connected to it. In the method sequence the SCAN command can be used to check whether an instrument is ready or to ask for an acknowledgement after a measurement

has been made. However, it may happen sometimes that problems occur during a determination run and that the expected signal from the

connected instrument is not received. This is known as a timeout.

This means that it is possible to define a maximum waiting time that will

always be allowed to elapse if a timeout occurs. In addition, the behavior of the Sample Processor when this waiting period has elapsed

(SCAN timeout) can also be defined.

parameters

>timeout settings

>timeout settings

SCAN timeout: OFF min

off,0…999 min

When the waiting time has elapsed the function defined below will be carried

out.

>timeout settings

on SCAN timeout: error

error,continue

If

sage will be shown. Otherwise the sequence will be continued.

Submenu for behavior if a SCAN timeout occurs

Open the submenu with <ENTER>

Waiting time if a SCAN timeout occurs

Behavior if SCAN timeout occurs

error is set then the run sequence will be interrupted and an error mes-

30 Metrohm 838 Advanced Sample Processor, Operation

Page 39

2.3 Composition of a method

2.3.6 Manual stop options

The following settings can make a great contribution to the comfortable

operation of the Sample Processor. A definition is made of what is to

happen when the <STOP> key is pressed. This could be a normal

manual cancellation of a running method, or an emergency stop of the

complete system. Depending on the arrangement of the automated

system and the type of application, it can be laid down in detail how the

individual instrument components and connected instruments are to

react when the <STOP> key is pressed.

parameters

>manual stop options

>manual stop

CTL Rmt: **************

14 bit (1,0 or ∗)

Connected peripheral devices can be stopped automatically. The 14 signal

lines of the Remote interface can be set as required, see also p. 68ff.

>manual stop

CTL RS232:

14 ASCII characters default value '&M;$S' (= stops a Metrohm device)

Connected peripheral devices (e.g. Metrohm devices) can be stopped

automatically. Any character string can be transmitted. For details of the serial RS232 interface see "Technical Reference".

>manual stop

PERISTALT: cont.

cont., off, on (cont. = retain condition)

>manual stop

PUMP: cont.

cont., off, on (cont. = retain condition)

This setting applies to both pump connectors.

>manual stop

STIR T1: cont.

cont., off, on (cont. = retain condition)

>manual stop

STIR MSB1: cont.

cont., off, on (cont. = retain condition)

>manual stop

STIR MSB2: cont.

cont., off, on (cont. = retain condition)

>manual stop

STIR MSB3: cont.

cont., off, on (cont. = retain condition)

Submenu for reaction after manual stop

Open the submenu with <ENTER>

Set signal lines of the Remote interface

Command or character string, for output

via the RS232 interface

Switches the peristaltic pump

Switches the pump connectors

Switches the stirrer at the tower

Switches the stirrer at MSB connection 1

Switches the stirrer at MSB connection 2

Switches the stirrer at MSB connection 3

Metrohm 838 Advanced Sample Processor, Operation 31

Page 40

2.3 Composition of a method

2.3.7 Programming of sequences

INSERT

DELETE

The creation of sequences is done in the submenus

'>sample sequence' and '>final sequence', which are accessible via the

'>start sequence',

parameter menu.

Each sequence is organized in lines. In each line, the commands that

are on the numerical keypad as alternate functions can be used to enter

commands. After selecting a command and entering the necessary

data, the entry is accepted with <ENTER>. The line number is visible in

the display. 99 lines per sequence are possible.

Navigation in a sequence is accomplished as in the other menus. In

addition the <INSERT> and <DELETE> keys can be used.

<INSERT> adds a new command line above the current line in a

sequence. It is automatically occupied by the "NOP" command that has

no function. The following lines are shifted one line downwards.

<DELETE> deletes the current line in a sequence. The following lines

are shifted one line upwards.

The "LEARN" mode is available for the easy entry of parameters.

Furthermore the "TRACE" function can be used to execute every command line step by step.

2.3.8 LEARN mode

LEARN

HOLD

When editing a method, the parameters of a command are most easily

determined experimentally, i.e. by manual execution, and it is for this

reason that certain commands are "teachable". The LEARN function

makes the manual execution of particular changer commands possible

during the editing of a sequence. The resulting parameters (for example, the lift position or the status of the input lines) can be taken over in

the current command line. The LEARN function can be used repetitively. When times or volumes are "learned", the repetitive values are

added up.

Procedure for creating a method

• Enter a command or select an existing command line.

• Press the <LEARN> key.

"LEARN" LED goes out, edit next command line.

− Function is started, "LEARN" LED lights up.

− Press the <LEARN> key.

− Function is stopped, "LEARN" LED blinks.

− With the <ENTER> key, accept the value

(or re-start the LEARN function).

Die LEARN-Funktion steht für folgende Befehle zur Verfügung:

32 Metrohm 838 Advanced Sample Processor, Operation

Page 41

2.3 Composition of a method

Command Teachable parameter Mode of function

LIFT

PERISTALT

PUMP

WAIT

SCN Rm

SCN RS

2.3.9 TRACE-Funktion

The "TRACE" function is a valuable aid for operating through an entire

START

sequence or method (or parts thereof) for test purposes. Every command line in a sequence can be executed directly by pressing the

<START> key. Upon completion of the action the next command line

is displayed.

Tracing can be executed immediately after entry of a sequence line or

at any time after opening the parameter menu and selecting a sequence.

Lift position in mm

Pump time in sec

Pump time in sec

Waiting time in sec

absolute

additive

additive

additive

Status of the 8 remote lines "live" value

Character sequence received

"live" value

Metrohm 838 Advanced Sample Processor, Operation 33

Page 42

2.4 Commands

2.4 Commands

2.4.1 Sample Processor commands

The following commands can be programmed to form a sequence.

Most of them are also available in manual operation.

The following list applies to the programming of run sequences.

SAMPLE

SAMPL E

7

Beispiele:

>start sequence

1 SAMPLE: = 1

=,+,–

1…999

Set current sample position

1st parameter: function

nd

2

parameter: value

With the SAMPLE command you can define which sample (beaker

position on the rack) is to be regarded as being the current sample position (SAMPLE = X). This is stored in a run variable and can, for example, be altered in a sample sequence (SAMPLE + X or SAMPLE – X) in

order to selectively control a sample series.

SAMPLE: = 5

SAMPLE: + 2

SAMPLE: - 1

Sets SAMPLE variable to 5, or first sample in the series to rack position 5

Increases SAMPLE variable by 2

Decreases SAMPLE variable by 1

If in a sample sequence the SAMPLE command is not programmed,

then each run will automatically increases the SAMPLE variable by 1.

The SAMPLE command does not have to be used for simple applications. Unless anything to the contrary is required, the first sample in a

series will automatically be assumed to be in rack position 1. This is

why we recommend that special beakers are not placed on the first

rack positions, but are set on the highest rack positions.

Under manual operation the <SAMPLE> key can be used before the

start of a sample series to define the position of the first sample, provided that this has not already been defined in the method itself.

If a particular arrangement of sample beakers is always to be used for a

certain application then the position of the first beaker can be defined in

the start sequence with

SAMPLE = X and this setting can be stored in the

particular method.

The value of the SAMPLE variable remains at the end of a sample series. It is only reset to 1 when the instrument is switched on, when a

RESET command (<RESET> key) is executed or after a RACK command (<RACK> key or in in a method run).

34 Metrohm 838 Advanced Sample Processor, Operation

Page 43

MOVE

MOVE

8

2.4 Commands

>sample sequence

2 MOVE 1 : sample

1,2

sample,

ext.1…ext.4

spec.1…16

prev., next

+swing, -swing

+rotate, -rotate

1…999

+/-1…999

Position beaker / Swing robotic

arm

1st parameter: tower (Tower 2 not possible)

2nd parameter: position

With the MOVE command rack positions are moved to, i.e. the turntable rotates until the sample rack is positioned so that the selected rack

position is placed in front of Tower 1 or 2 (if present). If no 786 Swing

Head is mounted then only the rack positions of a 1-row rack can be

accessed.

With 786 Swing Head

If a 786 Swing Head is mounted then any rack positions can be moved

to. The angle of rotation of the rack is then compared with the swing

angle of the robotic arm and corrected accordingly.

Beispiele:

MOVE 1 sample

MOVE 1 ext.1

MOVE 1 spec.1

MOVE 1 5

MOVE 1 next

MOVE 1 +2

Parameters

In addition to a rack position, the robotic arm of a 786 Swing Head can

also be swung to any external position. The selectable external positions ext.1 to ext.4 can be defined in the whole swing range from 0° up

to the maximum swing angle of the robotic arm. For example, this

means that it is possible to move to a titration cell located beside the

sample rack.

Moves sample beaker (defined by SAMPLE variable) in front of the tower

Moves robotic arm to external position 1

Moves special beaker 1 in front of the tower

Moves rack position 5 in front of the tower (absolute positioning)

Moves next highest rack position in front of the tower

Depending on the current sample position (SAMPLE variable), moves the next position

but one in front of the tower (relative positioning)

sample – rack position corresponding to the current value of the SAMPLE variable, see also p. Fehler! Textmarke nicht definiert..

ext.1 to 4 – predefined angle positions of the robotic arm. These are

defined in the configuration of a tower, see also p. 17.

next, prev. – from the current rack position the next highest (next) or

the next lowest (prev.) will be moved to. Special beaker positions will be

skipped. If MOVE next is used at the highest rack position then the

move will be made to position 1. If MOVE prev. is used at rack position

1 then the highest possible position will be moved to.

spec.1 bis 16 – reserved special beaker positions on the sample rack.

These are defined in the rack configuration, see also p. 20.

Metrohm 838 Advanced Sample Processor, Operation 35

Page 44

2.4 Commands

+swing, -swing – moves the robotic arm by a certain increment angle.

The sign shows the swing direction. The value of the angle is predefined under

Parameter >changer settings.

+rotate, -rotate – moves the rack by a certain increment angle. The

sign shows the rotation direction. The value of the angle is predefined

under

Parameter >changer settings.

absolute positioning – the numbered rack position will always be

moved to, even when this is a reserved special beaker position.

relative positioning – If a numerical rack position is given with a positive or negative sign then the selected rack position will always be relative to the value of the SAMPLE variable, i.e. to the current sample

position.

Remarks

In a method sequence a MOVE command will move the lift (or both

lifts) automatically to the shifting position.

After execution of the functions +/-swing or +/-rotate the lift can be

moved without restrictions. No defined rack position is required. Thus it

is possible to cause damages if the lift is lowered without precautions.

These functions must be used with great care.

LIFT

LIFT

9

Beispiele:

LIFT: 1: work

LIFT: 1: rinse

LIFT: 1: shift

LIFT: 1: special

LIFT: 1: rest

LIFT: 1: 100 mm

The direction of rotation is normally selected automatically by the Sample Processor. In the parameter menu under

>changer settings the di-

rection and speed of rotation can be defined specifically for particular

methods.

>sample sequence

3 LIFT: 1: rest mm

1,2,∗

work,

rinse, shift,

special, rest,

0…235 mm

Lift positioning

1st parameter: tower (Tower 2 not possible)

2nd parameter: position

Raises or lowers the lift to a defined position.

Moves the lift to working position

Moves the lift to rinsing position

Moves the lift to shifting position

Moves the lift to special position

Moves the lift to uppermost position (0 mm)

Moves the lift to position 100 mm

Working, rinsing, shifting and special positions are defined specifically

for each rack in the configuration menu under

>rack definitions (see

36 Metrohm 838 Advanced Sample Processor, Operation

Page 45

2.4 Commands

p. 20). The rest position is the zero position (0 mm) of the particular lift,

i.e. its upper stop.

The lift speed can be set in the parameter menu under

changer settings or altered in a sequence with the appropriate DEF

>sample

command.

Each lift can be positioned with an accuracy of one millimeter. The

LEARN function is available for this (see p. 70).

Metrohm 838 Advanced Sample Processor, Operation 37

Page 46

2.4 Commands

2.4.2 Switching components

Pumps and stirrers can be switched as required, either together or

separately. They work independently and can be operated at the same

time as other functions are being carried out.

PERISTALT

PUMP

4

>sample sequence

4 PERISTALT: on s 3

on,off,1...999

-15…-1, 1…3…15

Pump control

1st parameter: status or duration in s

nd

2

parameter: pump rate and direction

With the PERISTALT command the peristaltic pump can be controlled.

The first parameter switches the peristaltic pump on or off. Alternatively

a particular pump duration (in seconds) can be set.

The second parameter sets the pump rate in 15 steps. The signed

value (+ or –) also defines the pump direction. If a negative signed

pump rate is set, the roller head of the pump drive revolves counterclockwise, otherwise it revolves in clockwise direction.

PUMP

EXT

0

The LEARN mode is very useful for determining the optimal pump time

(see p. 71).

>sample sequence

4 PUMP 1.1 : 1 s

1.1,1.2 1…999 s,

1.∗,2.∗ on,off

Switching the pump connectors

1st parameter: select pump connector

nd

2

parameter: status or duration

With the PUMP command one or both pump connectors (16 V, DC) on

the rear side of the tower can be controlled separately. The first parameter selects the connector.

Syntax Of the 1

1.* affects both pump connectors (

st

parameter: tower.pump

tower 2 not possible)

The connectors can be switched on or off individually or be activated for

a particular duration.

The LEARN mode is very useful for determining the optimal pump time

(see p. 71).

38 Metrohm 838 Advanced Sample Processor, Operation

Page 47

STIR

.

STIR

5

2.4 Commands

>sample sequence

5 STIR T1 : 1 s

T1, T2,T*,

MSB1…3, MSB*, ∗ ON,OFF

1…999 s

Stirrer control

1st parameter: stirrer selection

nd

2

parameter: status, duration

With the STIR command up to 4 stirrers can be controlled separately.

The first parameter selects the stirrer. With

STIR * all the stirrers can be

switched at the same time .

Selecting a stirrer

T1, T2, T* Stirrer connections as Tower 1 and 2 respectively (stirrer

models 802 / 722 / 741),

* = both connections on the tow-

ers. T2 not possible.

MSB1…3 Stirrer/Dosing device connectors in the chassis of the Sam-

ple Processor (stirrer models 801 / 803 / 804),

MSB*= all

stirrers connected to an MSB socket.

* all stirrers

The stirrers can be switched on or off selectively, or operated for a particular time.

In the parameter menu under

vidual stirrer can be defined for a particular method.

2.4.3 Dosing drive control

Connected dosing devices can be controlled separately or all at the

same time . Simultaneous addition of the same volumes or simultaneous filling of the connected dosing devices is also possible (Example:

DOS *.2 fill = fill all dosing devices via port 2).

DOS

DOS

6

>sample sequence

6 DOS 1.* : 1 ml

*.*, 1.*…3.4

fill,release, prepar

empty, eject, endVol,

compen., port,

±0.001…1…±999.999 ml

The DOS command is used for controlling Dosimats and Dosinos. Up

to 3 Dosinos or Dosimats can be addressed individually or simultaneously via the MSB bus control.

>stirring rates the speed of each indi-

Dosing device control

1st parameter: dosing device and port selection

nd

2

parameter: selects function/enters volume

The 1st parameter selects the dosing device and the corresponding

dosing port, at which the required function is to be carried out. If '*' is

entered then the default port for the corresponding function will be used

(e.g. dosing port = 1, filling port = 2, etc.).

Metrohm 838 Advanced Sample Processor, Operation 39

Page 48

2.4 Commands

Please note

After dosing the Sample Processor will not automatically fill the

dosing cylinder. If required, this can be programmed with the command

DOS: 1.* : fill, see below.

It is possible to enter the volume to be added directly as the 2

nd

parameter or to carry out specific functions of a Dosino. Negative volumes

can also be added, i.e. a certain volume can be aspirated and then

ejected again (pipetting). The minus sign is entered with the <*> key.

The functions listed below are used for complex liquid handling tasks

such as pipetting.

Dosing functions:

fill Fills the Dosimat and Dosino cylinder.

release Prepares the Dosimat or Dosino for changing the Ex-

change/Dosing unit. The dosing cylinder is filled via the

rinse port. The stopcock is turned to the exchange position (Port 2).

prepar. Preparation cycle (PREP) for Dosinos. All tubing is rinsed

and filled completely.

empty Tubing system and Dosino cylinder are emptied.