Page 1

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Titrando

Installation Instructions

8.840.1133 06.2006 / jb

Page 2

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

These instructions are protected by copyright. All rights reserved.

Although all the information given in these Instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 3

Contents

Table of contents

1 Introduction.......................................................... 1

1.1 Instrument description...................................................................................2

1.2 Information about the Installation Instructions............................................3

1.2.1 Organization .............................................................................................3

1.2.2 Notation and pictograms .........................................................................4

1.3 Parts and controls..........................................................................................5

1.4 Safety notes....................................................................................................8

1.4.1 Electrical safety.........................................................................................8

2 Installation ........................................................... 9

2.1 Overview ...................................................................................................... 10

2.2 Instrument setup ......................................................................................... 11

2.2.1 Packaging...............................................................................................11

2.2.2 Checks....................................................................................................11

2.2.3 Location ..................................................................................................11

2.3 Controller connection ................................................................................. 11

2.3.1 Touch Control connection......................................................................12

2.3.2 Computer connection.............................................................................13

2.4 Device connection at the MSB ................................................................... 14

2.4.1 Connecting stirrers and titration stands.................................................15

2.4.2 Attaching the exchange unit to the Titrando ..........................................16

2.4.3 Connecting an external dosing device ..................................................18

2.4.4 Connecting a remote box.......................................................................20

2.5 Device connection at the USB.................................................................... 21

2.5.1 Connecting a printer...............................................................................21

2.5.2 Connecting a balance ............................................................................22

2.5.3 Connecting a USB Sample Processor / Robotic Titrosampler..............24

2.5.4 Connecting additional Titrandos or Dosing Interfaces ..........................24

2.5.5 Connecting a PC keyboard (Titrando with Touch Control only)............25

2.5.6 Connecting a barcode reader................................................................25

2.5.7 Connecting a USB hub ..........................................................................26

2.5.8 Connecting a Bluetooth® adapter ..........................................................26

2.6 Sensor connection ...................................................................................... 29

2.6.1 Connecting an 854 iConnect .................................................................29

2.6.2 Differential potentiometry .......................................................................30

2.6.3 Titration vessel setup..............................................................................30

2.6.4 Assembly of the Karl Fischer titration cell ..............................................31

2.7 Update of the instrument software............................................................. 32

3 Troubleshooting ................................................. 33

3.1 Problems...................................................................................................... 33

4 Appendix ............................................................. 35

4.1 Technical data ............................................................................................. 35

4.1.1 Titration and measuring modes .............................................................35

4.1.2 Measuring interfaces..............................................................................35

Titrando Installation Instructions I

Page 4

Contents

4.1.3 Specification of the measuring inputs ...................................................36

4.1.4 Specification of the measuring inputs (857 only) ..................................36

4.1.5 Internal dosing device............................................................................37

4.1.6 Interfaces................................................................................................37

4.1.7 Mains connection...................................................................................37

4.1.8 Safety specifications ..............................................................................38

4.1.9 Electromagnetic compatibility (EMC) ....................................................38

4.1.10 Ambient temperature .............................................................................38

4.1.11 Reference conditions .............................................................................38

4.1.12 Dimensions ............................................................................................39

4.1.13 Recycling and disposal.......................................................................... 39

4.2 Standard equipment.................................................................................... 40

4.2.1 808 Titrando ...........................................................................................40

4.2.2 809 Titrando ...........................................................................................41

4.2.3 835 Titrando ...........................................................................................42

4.2.4 836 Titrando ...........................................................................................43

4.2.5 841 Titrando ...........................................................................................44

4.2.6 842 Titrando ...........................................................................................45

4.2.7 857 Titrando ...........................................................................................46

4.3 Additional instruments and optional accessories .................................... 47

4.3.1 Controller for operating the Titrando......................................................47

4.3.2 Stirrers and titration stands ....................................................................47

4.3.3 Titration equipment ................................................................................47

4.3.4 Karl Fischer titration equipment 6.5609.000..........................................48

4.3.5 Dosing devices.......................................................................................49

4.3.6 Combined pH electrodes.......................................................................50

4.3.7 Combined metal electrodes ..................................................................50

4.3.8 Ion-sensitive electrodes and surfactant electrodes............................... 50

4.3.9 Karl Fischer electrodes ..........................................................................51

4.3.10 Reference electrodes .............................................................................51

4.3.11 Temperature sensors ............................................................................. 51

4.3.12 Cables for electrodes and other accessories........................................ 52

4.3.13 Communication......................................................................................52

4.3.14 Cables for balances ...............................................................................53

4.4 Warranty and conformity ............................................................................ 54

4.4.1 Warranty .................................................................................................54

4.4.2 Declaration of Conformity for 808 Titrando ...........................................55

4.4.3 Declaration of Conformity for 809 Titrando ...........................................56

4.4.4 Declaration of Conformity for 835 Titrando ...........................................57

4.4.5 Declaration of Conformity for 836 Titrando ...........................................58

4.4.6 Declaration of Conformity for 841 Titrando ...........................................59

4.4.7 Declaration of Conformity for 842 Titrando ...........................................60

4.4.8 Declaration of Conformity for 857 Titrando ...........................................61

4.4.9 Quality Management Principles .............................................................62

5 Index ................................................................... 63

II Titrando Installation Instructions

Page 5

Contents

List of illustrations

Fig. 1: The Titrando system ...................................................................................................... 1

Fig. 2: Front view of a Titrando with internal dosing drive ........................................................ 5

Fig. 3: Front view of a Titrando for the use of external dosing devices ................................... 6

Fig. 4: Rear view of the Titrando ...............................................................................................7

Fig. 5: Titrando – Peripheral devices ........................................................................................ 9

Fig. 6: Titrando – Touch Control ............................................................................................. 12

Fig. 7: Titrando – Computer .................................................................................................... 13

Fig. 8: Overview of MSB connections..................................................................................... 14

Fig. 9: Titrando – Stirrer........................................................................................................... 15

Fig. 10: Attaching the exchange unit to the Titrando ............................................................. 16

Fig. 11: Example for connecting a dosing device: Titrando – 800 Dosino ........................... 18

Fig. 12: Example for connecting a dosing device: Titrando – 805 Dosimat......................... 19

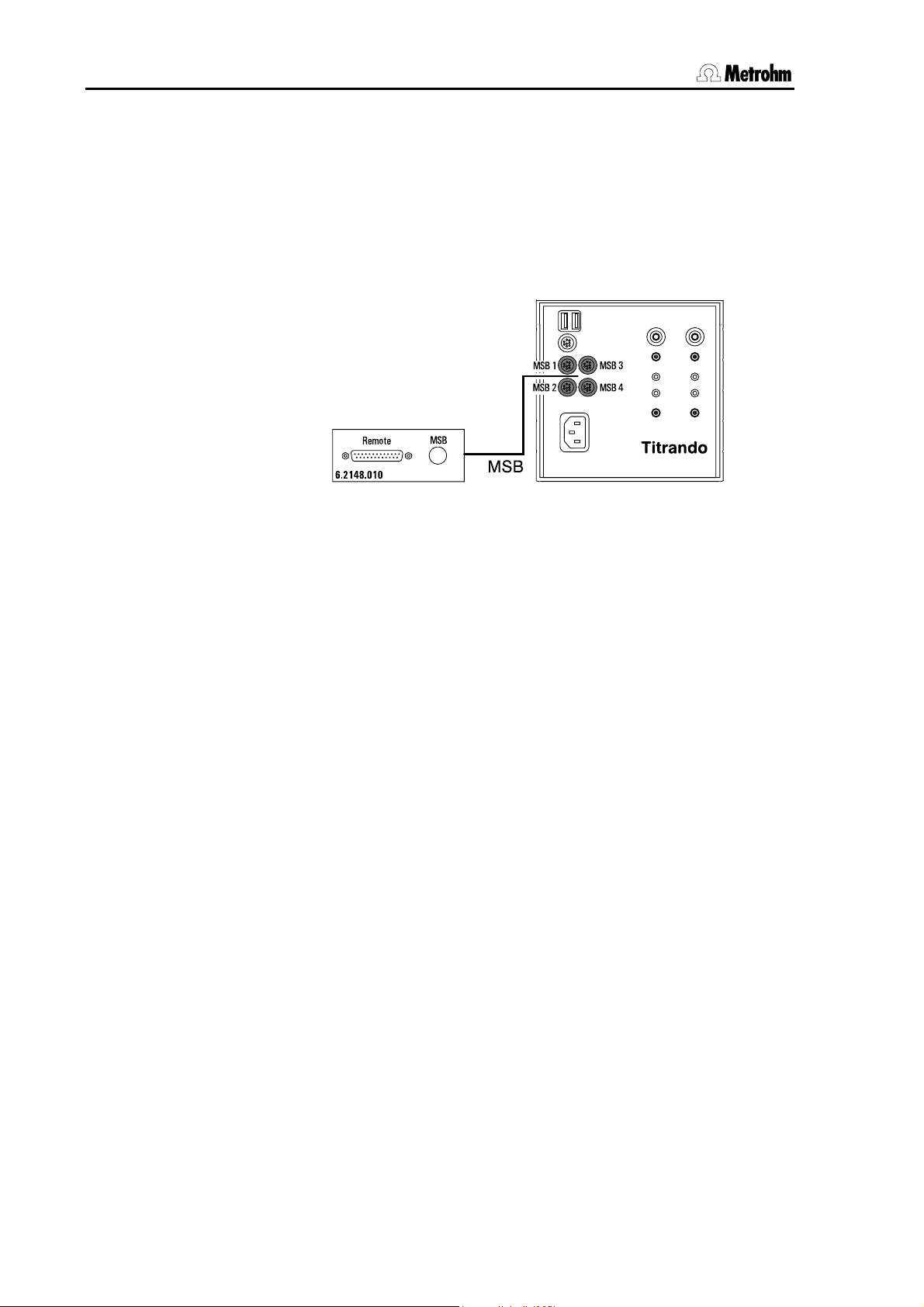

Fig. 13: Titrando – Remote box .............................................................................................. 20

Fig. 14: Titrando – Printer........................................................................................................ 21

Fig. 15: Titrando – USB-RS232 box – Balance....................................................................... 23

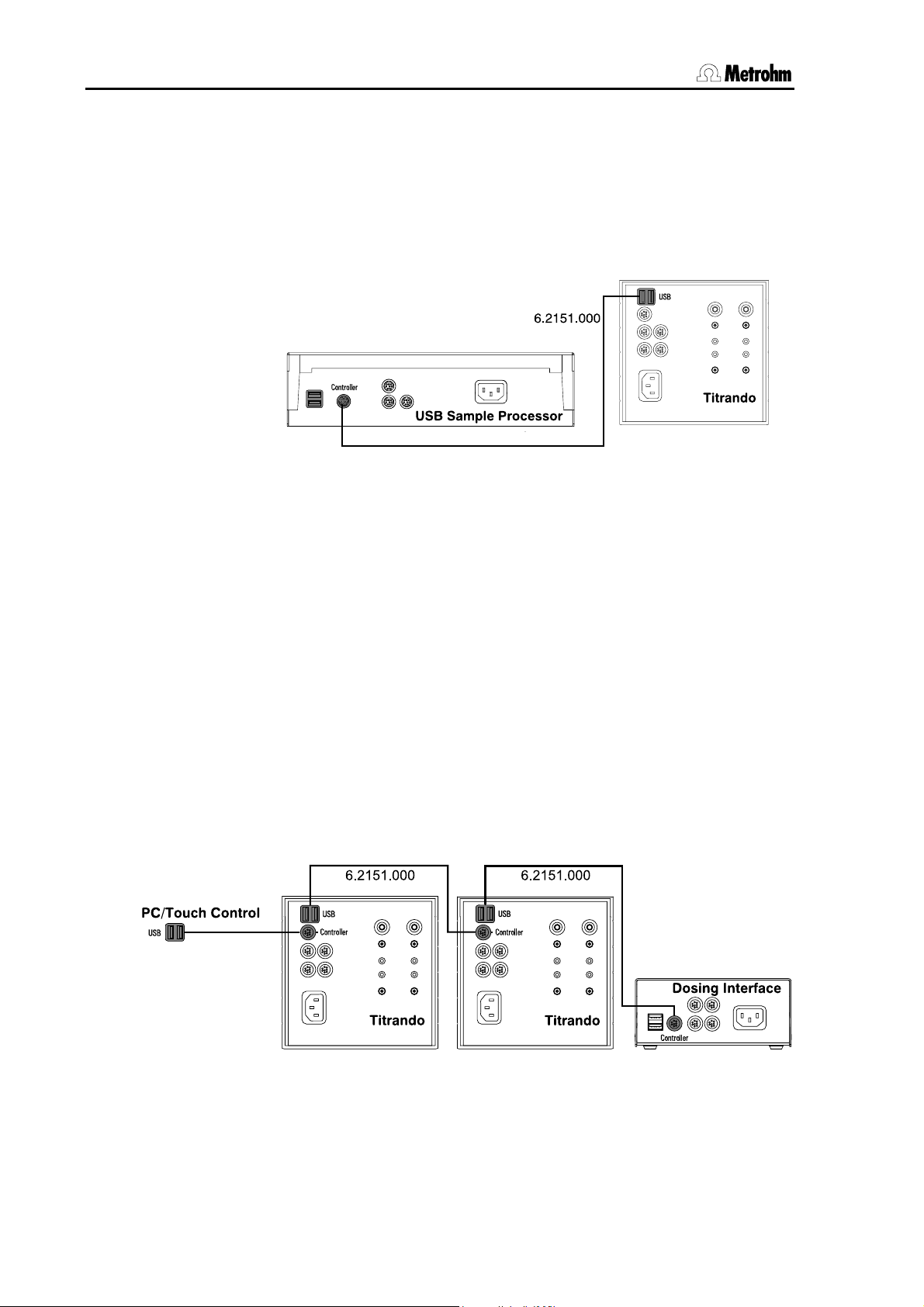

Fig. 16: Titrando –USB Sample Processor ............................................................................. 24

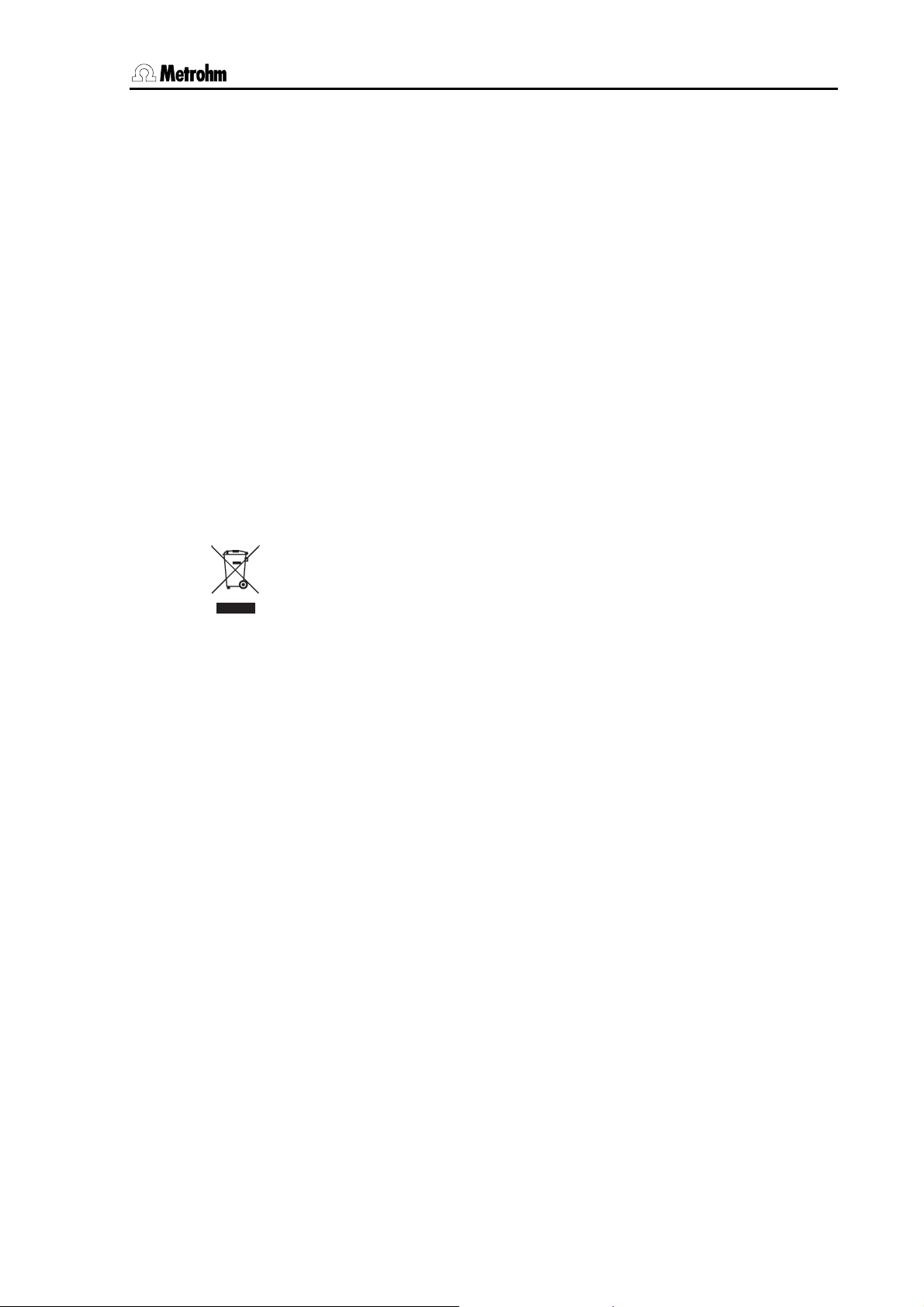

Fig. 17: Titrando – Titrando/Dosing Interface ......................................................................... 24

Fig. 18: Titrando – Sensors .....................................................................................................29

Fig. 19: Connecting the 854 iConnect .................................................................................... 29

Fig. 20: Recommended arrangement of magnetic stirring bar (1), electrode (2) and

buret tip (3) ...................................................................................................................30

Fig. 21: Drawing of the KF titration cell 6.5609.000................................................................ 31

Fig. 22: Arrangement of transport tip, buret tip and draw-off tip ........................................... 32

Titrando Installation Instructions III

Page 6

Contents

IV Titrando Installation Instructions

Page 7

1 Introduction

1 Introduction

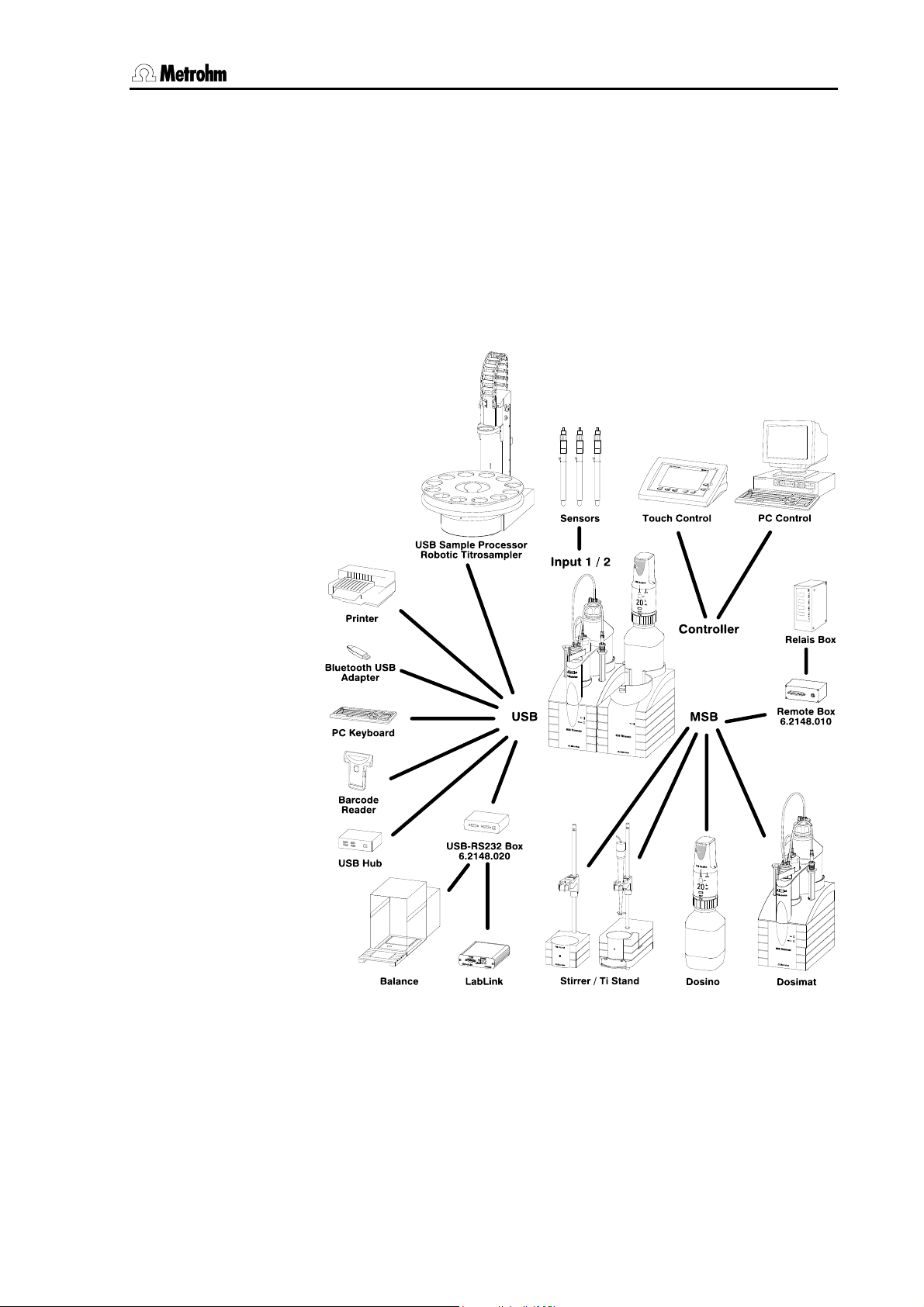

These installation instructions provide you with a comprehensive overview of the installation and specifications of the Titrando system. The

Titrando is the centerpiece of the modular Titrando system. Operation is

carried out either via a Touch Control with touch-sensitive screen

("stand-alone" titrator) or from a computer via the USB connection and

using the PC software PC Control or tiamo.

A Titrando system can integrate several, different devices. With PC

Control/Touch Control, up to three control devices (Titrandos, Dosing

Interfaces, USB Sample Processors, etc.) can be controlled via USB

connection. The tiamo software allows to expand the system with practically any number of control devices. The control devices have three to

four MSB connections (MSB = Metrohm Serial Bus), to which peripheral devices can be connected. These are mainly dosing drives

(700/800 Dosinos and 685/805 Dosimats), stirrers and titration stands,

etc.

Figure 1 shows you the flexibility of the Titrando system. On the left a Titrando is shown with external dosing devices operated by the Touch

Control. To the right of it you can see an automation system consisting

of a USB Sample Processor, a Titrando with internal dosing drive and a

Dosimat operated by the PC Control software.

Fig. 1: The Titrando system

Titrando Installation Instructions 1

Page 8

1.1 Instrument description

Additional information about the Titrando system can be found on the

Internet under www.titrando.com

Information about specific applications can be found in our "Applica-

tion Bulletins" and "Application Notes"; these can be obtained free

of charge from your local Metrohm agency or downloaded from the

Internet under www.metrohm.com.

jects of titration techniques and electrodes are also available.

.

Various monographs on the sub-

1.1 Instrument description

The Titrandos differ mainly from the kind of dosing drive. They are

equipped either with an internal dosing drive for an exchange unit (type

806 or previous) or for the use of external dosing devices (700 and 800

Dosinos with 807 dosing units).

Common features of the Titrando:

• A connection for Touch Control or for a computer with PC software

PC Control or tiamo.

• Four MSB connections (Metrohm Serial Bus) each controlling one

dosing device (Dosimat with exchange unit or Dosino with dosing

unit), a stirrer or titration stand and a remote box.

• One or two measuring interfaces. A measuring interface consists of

a high-impedance measuring input for pH, redox or ISE sensors, an

input for a separate reference electrode, a measuring input for temperature sensors (Pt1000 or NTC) and a measuring input for polarized electrodes.

• Two USB connections allow to connect, for example, a printer, keyboard, barcode reader or additional control devices (USB Sample

Processor, Titrando, Dosing Interface, etc.).

2 Titrando Installation Instructions

Page 9

1 Introduction

1.2 Information about the Installation Instructions

Attention!

Please study these Installation Instructions carefully before you start to

use the Titrando. The instructions contain information and warnings

that must be observed by the user in order to guarantee the safe use

of the instrument. Please keep these instructions near the instrument

so that they are always to hand when required.

1.2.1 Organization

These Installation Instructions for the Titrandos provide you with a comprehensive overview of the installation, startup, troubleshooting and

technical specifications of the instruments.

The Installation Instructions are arranged as follows:

Introduction

General description of the instrument, operating elements and safety information

Installation

Installation of the instrument, connection of the peripheral devices and

accessories

Troubleshooting

Description of possible errors and how to remedy them

Appendix

Technical data, standard equipment, optional accessories, warranty

and declaration of conformity

Index

In order to find the information you require about the Titrando you

should either use the Table of contents or the Index.

Titrando Installation Instructions 3

Page 10

1.2 Information about the Installation Instructions

1.2.2 Notation and pictograms

The following notation and pictograms are used in these Instructions:

9

[Continue]

Control element, instrument element

see illustrations in Section 1.3

Instruction

Carry out the instructions step by step.

Button

on the user interface

Danger

This symbol indicates a possible risk of

death or injury to the user and possible

damage to the instrument or its components by electricity.

Warning

This symbol indicates a possible risk of

damage to the instrument or its components if the given information is not properly

observed.

Attention

This symbol indicates important information

that you should read before continuing.

Information

This symbol indicates additional information

and tips that may be particularly useful.

4 Titrando Installation Instructions

Page 11

1 Introduction

1.3 Parts and controls

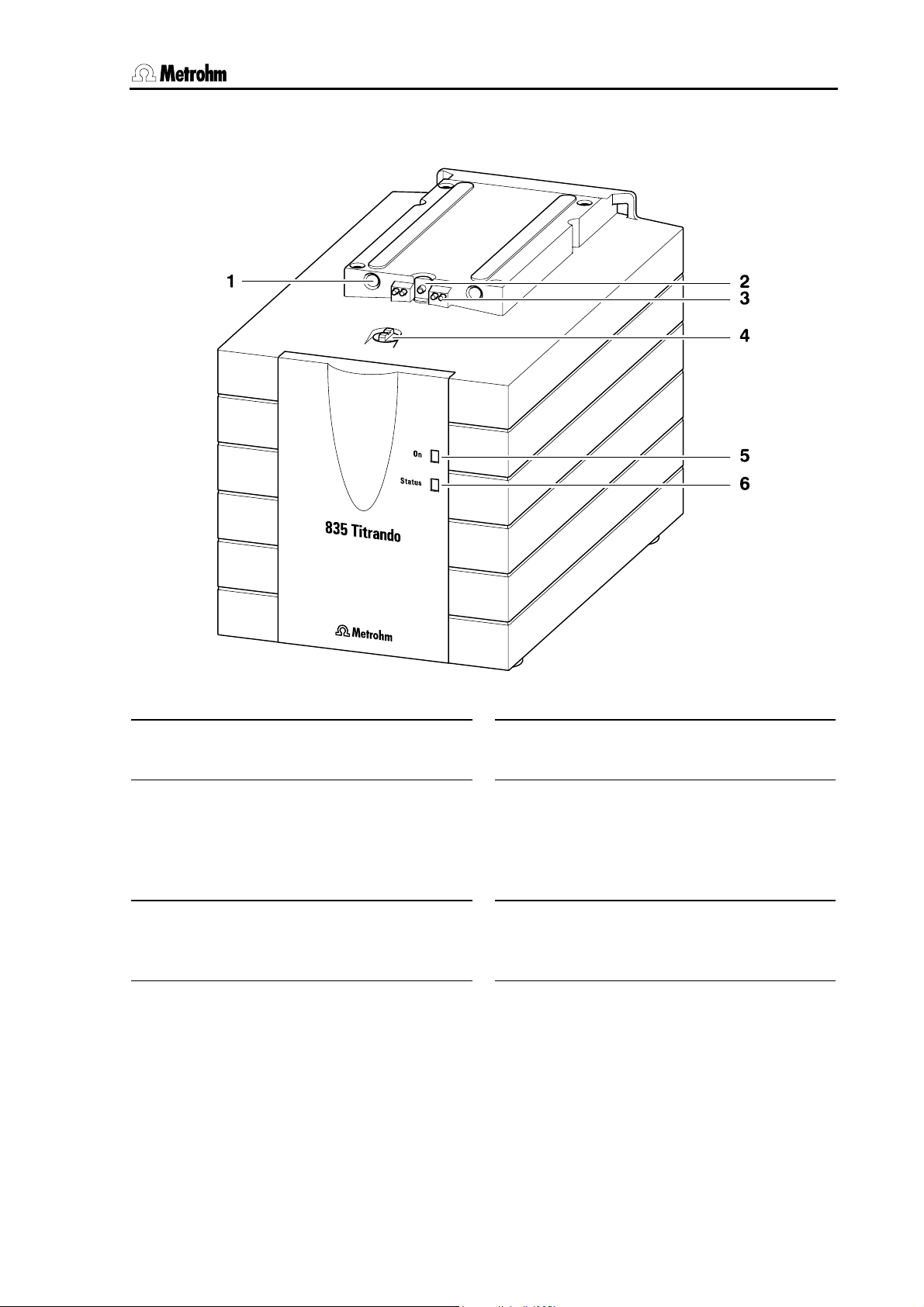

Fig. 2: Front view of a Titrando with internal dosing drive

1 Guide openings

for centering the exchange unit

2 Push rod

of the dosing drive

3 Contact pins

for the data chip

4 Coupling

for switching the flat cock

5 "On" LED

Lights up when the Titrando is connected to the mains supply and a controller (Touch Control or computer) is

connected and switched on.

6 "Status" LED

Shows the current status of the internal

dosing drive (see Section 2.4.2).

Titrando Installation Instructions 5

Page 12

1.3 Parts and controls

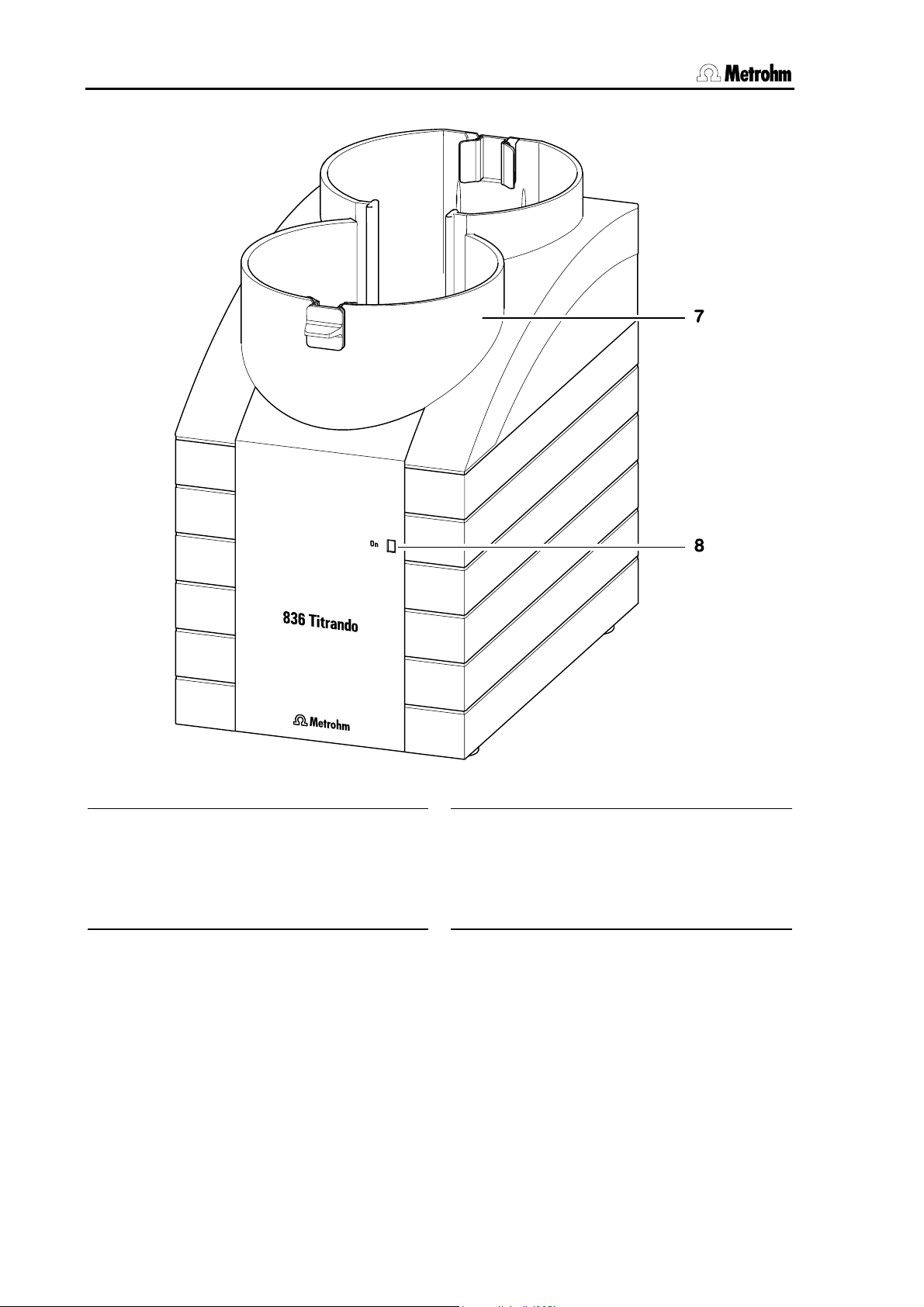

Fig. 3: Front view of a Titrando for the use of external dosing devices

7 Bottle holder

with holding clips, for two reagent bottles

8 "On" LED

Lights up when the Titrando is connected to the mains supply and a controller (Touch Control or computer) is

connected and switched on.

6 Titrando Installation Instructions

Page 13

1 Introduction

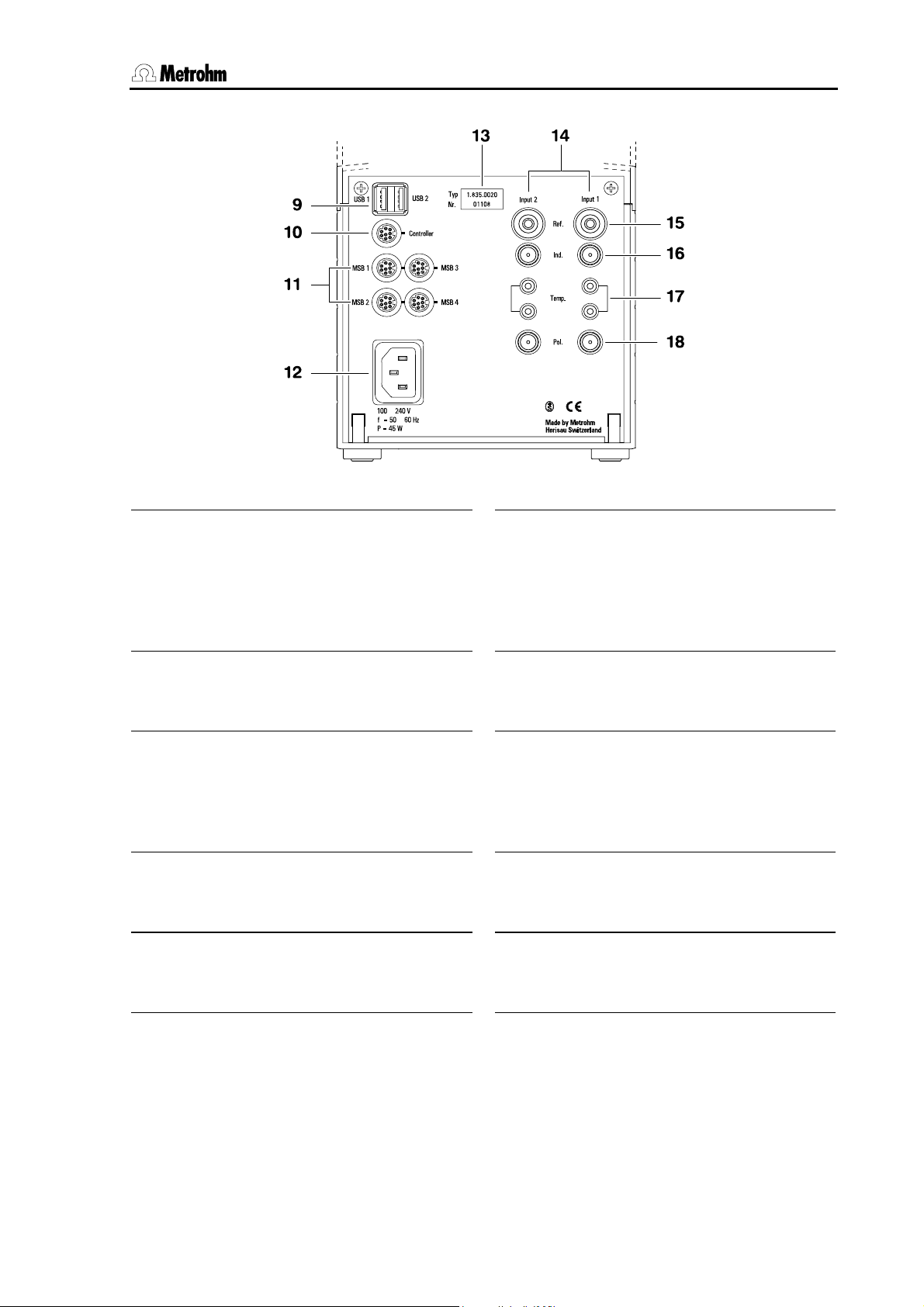

Fig. 4: Rear view of the Titrando

9 USB connections USB 1 and USB 2

USB ports (type A) for connection of

printer, keyboard, barcode reader, additional Titrandos, USB Sample Processor, etc.

10 Controller connection

Connection for Touch Control or PC

with installed PC software

11 MSB connections MSB 1 to MSB 4

Metrohm Serial Bus

Connection for external dosing device,

stirrer or remote box

12 Mains connection socket

Mains connection

13 Instrument type and serial number

14 Measuring interface 1 (Input 1) and

Measuring interface 2 (Input 2)

Models 2.8XX.0010: 1 measuring interface,

Models 2.8XX.0020: 2 measuring interfaces

15 Connection for reference electrode

(Ref.)

e. g. Ag/AgCl reference electrode

16 High-impedance measuring input

(Ind.)

Connection of pH, redox or ISE sensors with built-in or separate reference

electrode

17 Connection for temperature sen-

sors (Temp.)

Pt1000 or NTC

18 Measuring input for polarized elec-

trodes (Pol.)

e. g. double Pt electrodes

Titrando Installation Instructions 7

Page 14

1.4 Safety notes

1.4 Safety notes

Warning!

This instrument should only be used in accordance with the information given in these installation instructions.

1.4.1 Electrical safety

Please observe the following guidelines:

• Only qualified Metrohm technicians should carry out service work

on electronic components.

• Do not open the Titrando housing. This could destroy the Titrando.

Inside the housing there are no components that the user can service or exchange.

Electrical safety when handling the Titrando is guaranteed within the

framework of the IEC 61010 Standard. The following point must be observed:

Protection against electrostatic charges

Warning!

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Always remove the mains cable from

the power supply socket before setting up or breaking electrical connections on the rear panel of the instrument.

8 Titrando Installation Instructions

Page 15

2 Installation

2 Installation

This section describes what you should pay attention to when unpacking and setting up the Titrando. It also informs you about how a complete titration system – from a simple system with stirrer and printer up

to a complicated system with additional dosing devices, sample

changer and balance – is assembled.

The following illustration provides an overview of the peripheral devices

that can be connected to a Titrando:

Fig. 5: Titrando – Peripheral devices

Titrando Installation Instructions 9

Page 16

2.1 Overview

2.1 Overview

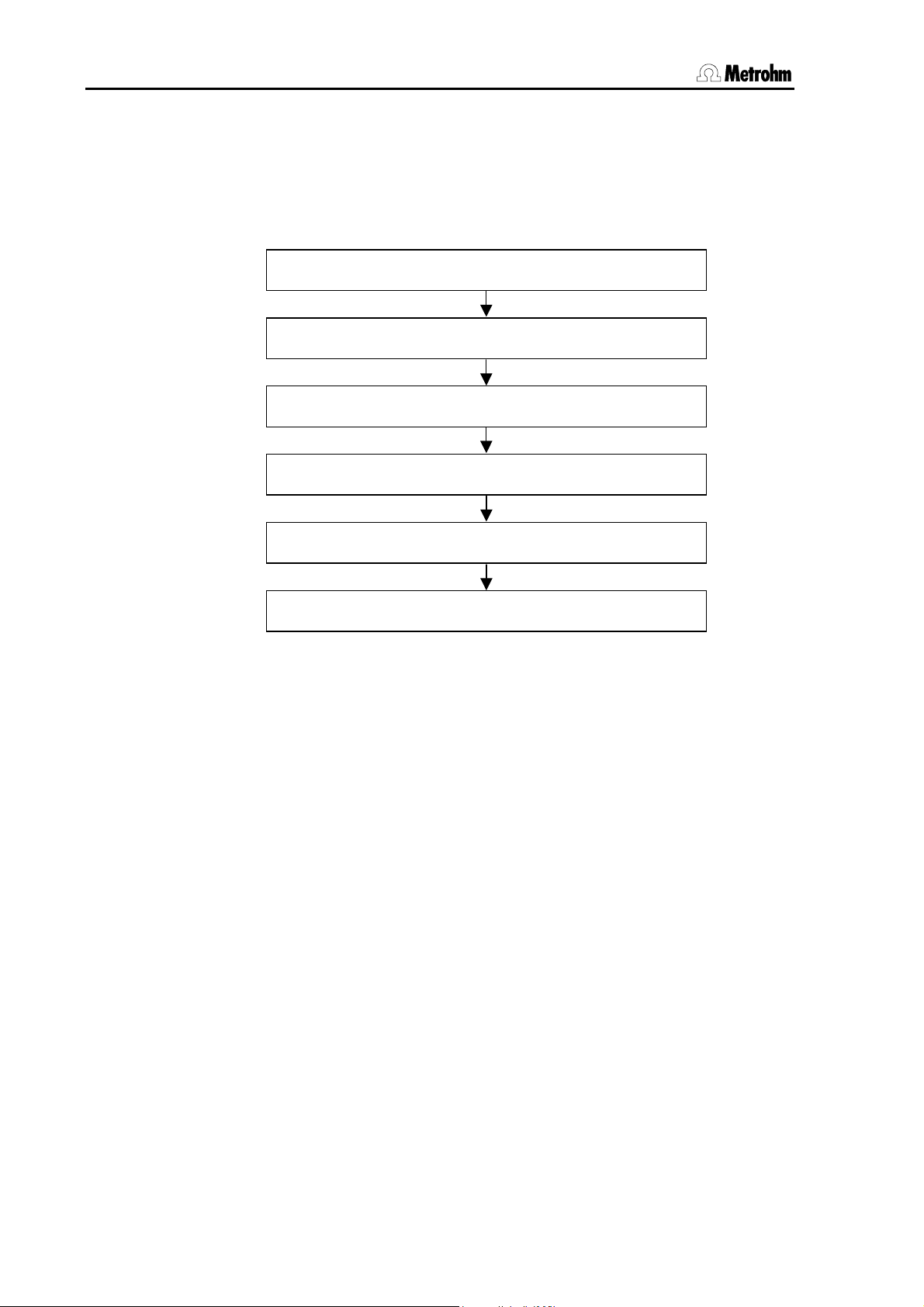

The following flow diagram provides an overview of the installation of a

simple titration system with stirrer, external dosing device, printer and

balance. More detailed information can be found in the given sections.

Setup Section 2.2

Touch Control/Computer connection Section 2.3

Stirrer/Titration stand connection Section 2.4.1

Dosing device connection Section 2.4.2 and 2.4.3

Printer connection Section 2.5.1

Balance connection Section 2.5.2

10 Titrando Installation Instructions

Page 17

2 Installation

2.2 Instrument setup

2.2.1 Packaging

The Titrando and the separately packed accessories are delivered in

special packaging that provides excellent protection. Please store this

packaging in a safe place as no other packaging can guarantee the

safe transport of the instrument.

2.2.2 Checks

Please check whether the delivery is complete and undamaged immediately on receipt (compare with delivery note and list of accessories

given in Section 4.2). If transport damage is evident please refer to the

information given in Section 4.4.1.

2.2.3 Location

The Titrando was developed for internal laboratory use; it should not be

used in explosion-endangered locations.

Place the instrument on a suitable vibration-free laboratory bench, protected as much as possible from corrosive atmospheres and contact

with chemicals.

Choose a location where the temperature is usually between +5 °C and

+45 °C. The instrument should be protected against excessive variations in temperature and direct sunlight.

2.3 Controller connection

Two different methods of controlling the Titrando are available:

• The Touch Control with contact-sensitive screen forms a “stand-

alone” titrator together with the Titrando.

• A computer can be used to control the Titrando by using the PC

software PC Control or tiamo.

Attention!

Make sure that the mains cable has been removed from the power

supply socket before setting up or breaking connections between the

instruments.

Titrando Installation Instructions 11

Page 18

2.3 Controller connection

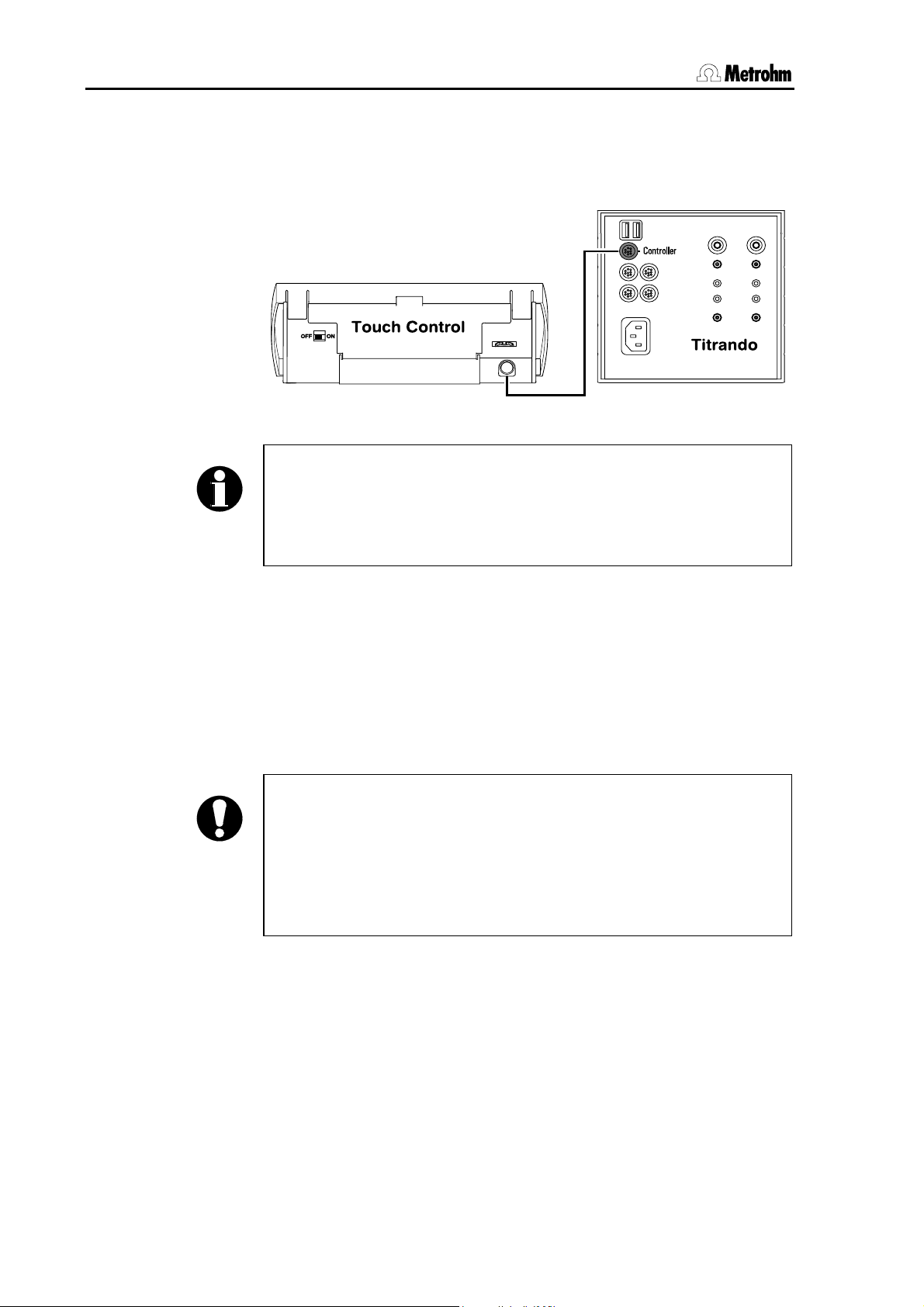

2.3.1 Touch Control connection

Connect the plug of the Touch Control connection cable to the con-

troller socket.

Fig. 6: Titrando – Touch Control

Note!

The plug is fitted with a "pull-out protection device" that prevents the

cable from being pulled out accidentally. When you wish to insert or

remove the plug you must first pull back the outer plug sleeves

(marked with arrows).

Connect all peripheral devices (see Section 2.4 and 2.5) before you

switch on the Touch Control.

Power for the Touch Control is provided by the Titrando.

Connect the Titrando to the mains supply and switch on the Touch

Control.

After switch-on automatic system tests are carried out on both the Titrando and the Touch Control. The "On" LED on the Titrando lights up

when the system test is finished and the instrument is ready for use.

Attention!

The Touch Control has to be shut down properly with the ON/OFF

switch at the back of the instrument before the power supply is interrupted. Otherwise data can be lost. Since the power for the Touch

Control is supplied by the Titrando, never disconnect the Titrando

from the mains connection (e. g. by switching it off via a mains distributor), before you have switched off the Touch Control.

If you do not want to place the Touch Control directly alongside the Titrando then you can extend the connection between the Titrando and

Touch Control with the 6.2151.010 Cable. The connection length must

not exceed 5 m.

12 Titrando Installation Instructions

Page 19

2 Installation

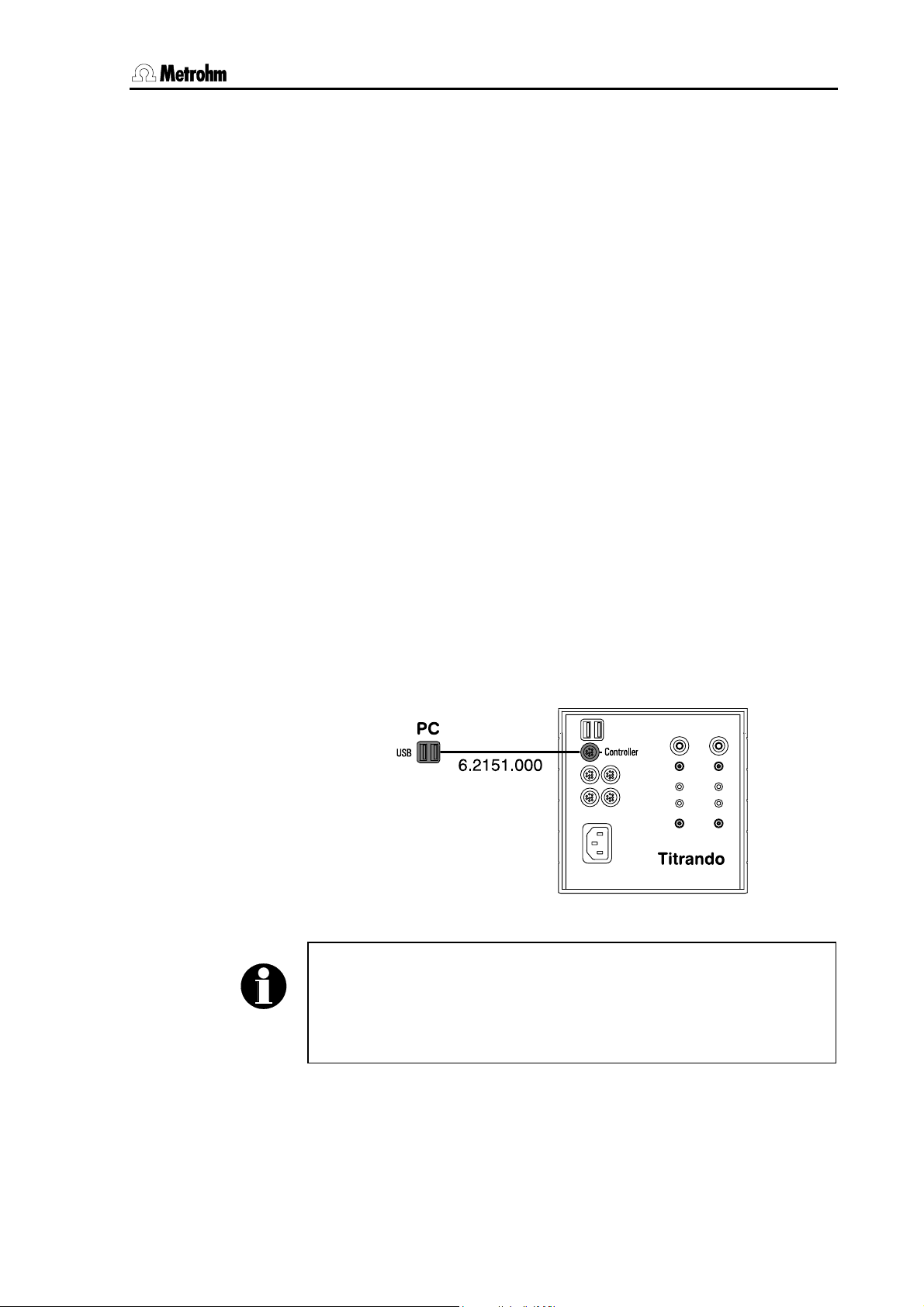

2.3.2 Computer connection

Install the PC Control or tiamo software on your computer. Quit

the program if you have started it after the installation.

Connect all peripheral devices (see Section 2.4 and 2.5) before you

connect the Titrando to the mains supply.

Connect the Titrando to the mains supply. The LED "On" on the Ti-

trando will not yet light up!

Connect the Titrando to a USB connection (type A) on your com-

puter with the 6.2151.000 cable (see the instruction manual for your

computer).

Windows 2000: The Titrando will be recognized and the driver will be

installed automatically. Windows XP: The Titrando will be recognized

and the wizard for the installation of the driver will be started automatically. Select the option "Install the software automatically" and click on

[Next]. End the wizard with [Finish].

PC Control

Connect the USB dongle ("authorization plug") supplied with the full

version of the PC Control software to any USB socket (type A) of the

computer or Titrando.

Windows 2000: The USB dongle will be recognized and the driver will

be installed automatically. Windows XP: The USB dongle will be recognized and the wizard for the installation of the driver will be started

automatically. Select the option "Install the software automatically" and

click on [Next]. End the wizard with [Finish].

Fig. 7: Titrando – Computer

Note!

The plug for connecting to the Titrando is fitted with a "pull-out protection device" that prevents the cable from being pulled out accidentally.

When you wish to insert or remove the plug you must first pull back

the outer plug sleeves (marked with arrows).

You can extend the connection with a commercially available USB extension cable (type A/m – type A/f). The length of the connection should

not exceed 5 m. If you require a longer connection then you must use a

commercially available USB signal amplifier. Up to five USB signal am-

Titrando Installation Instructions 13

Page 20

2.4 Device connection at the MSB

plifiers can be connected in series; this allows a maximum extension of

25 m.

Start the PC Control or tiamo software.

The Titrando will be recognized automatically. When the PC Control or

tiamo software is started a system test will be carried out automatically

on the Titrando. The LED "On" on the Titrando lights up when the system test is finished and the instrument is ready for use.

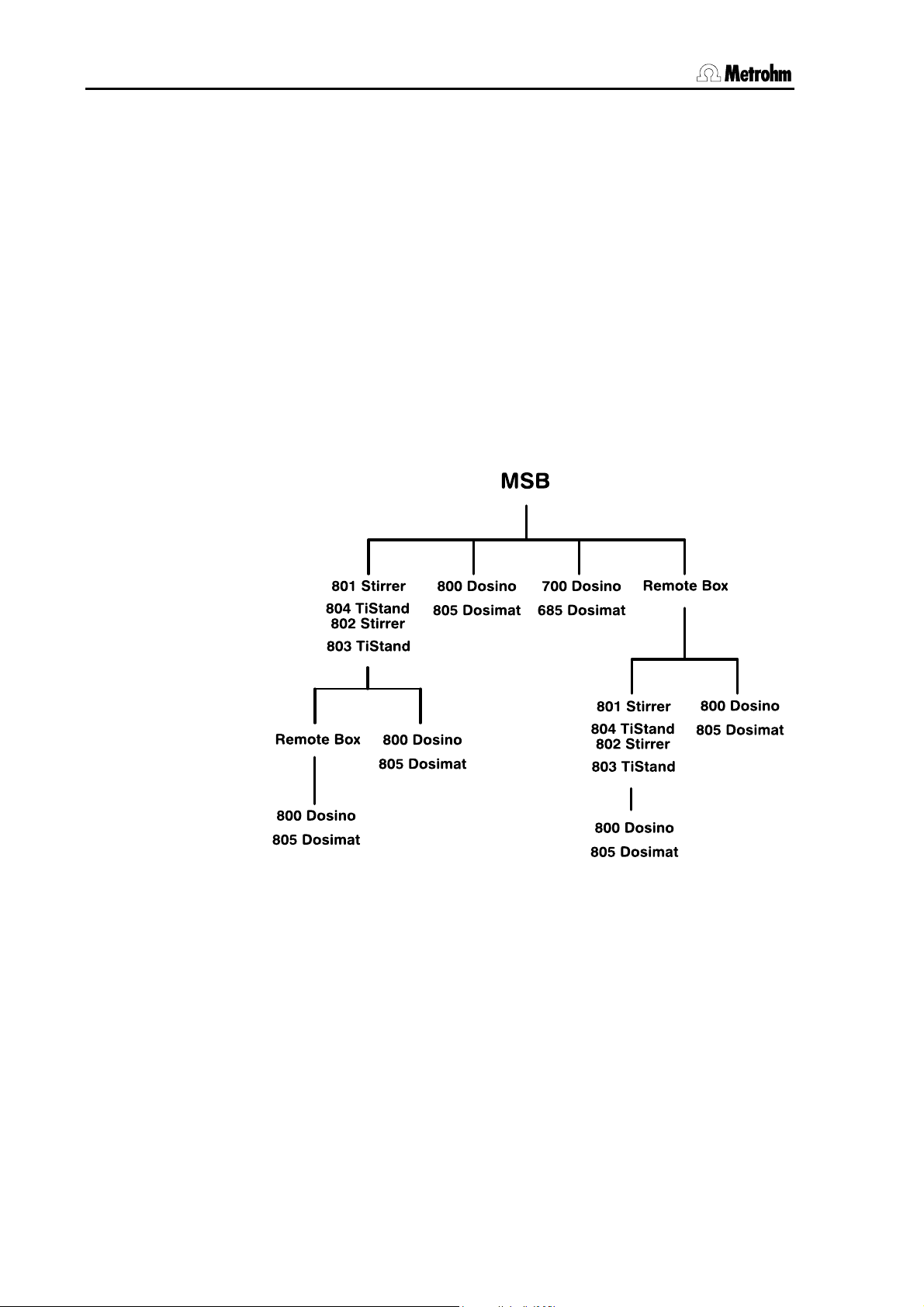

2.4 Device connection at the MSB

The following devices can be connected via each of the four MSB connections (Metrohm Serial Bus): one stirrer or titration stand, one Dosimat or Dosino dosing device and one remote box. The stirrers and

remote boxes each have an MSB output so that the devices can be

switched sequentially ("daisy chain"). The following illustration provides

an overview of the devices that can be connected to an MSB.

Fig. 8: Overview of MSB connections

The MSB 1 of the Titrando with internal dosing drive is occupied by the

internal dosing drive. This means that only a stirrer and a remote box

can be connected to MSB 1.

First connect all peripheral devices and then connect the Titrando to the

mains supply. MSB connections can be extended with the 6.2151.010

cable. The maximum length of the connection is 15 m.

The Titrando automatically recognizes which device has been connected to which MSB connection. The Touch Control or the PC software

(PC Control or tiamo) shows the connected devices in the device manager or the configuration dialog respectively. All devices connected to

the MSB are operated by the Touch Control or PC Control/tiamo.

14 Titrando Installation Instructions

Page 21

2 Installation

Attention!

If you are operating the Titrando with the Touch Control then make

sure that the Touch Control is switched off while you are setting up or

breaking connections between the instruments. If you are operating

the Titrando with the PC software then pull out the plug from the

power supply socket before setting up or breaking MSB connections.

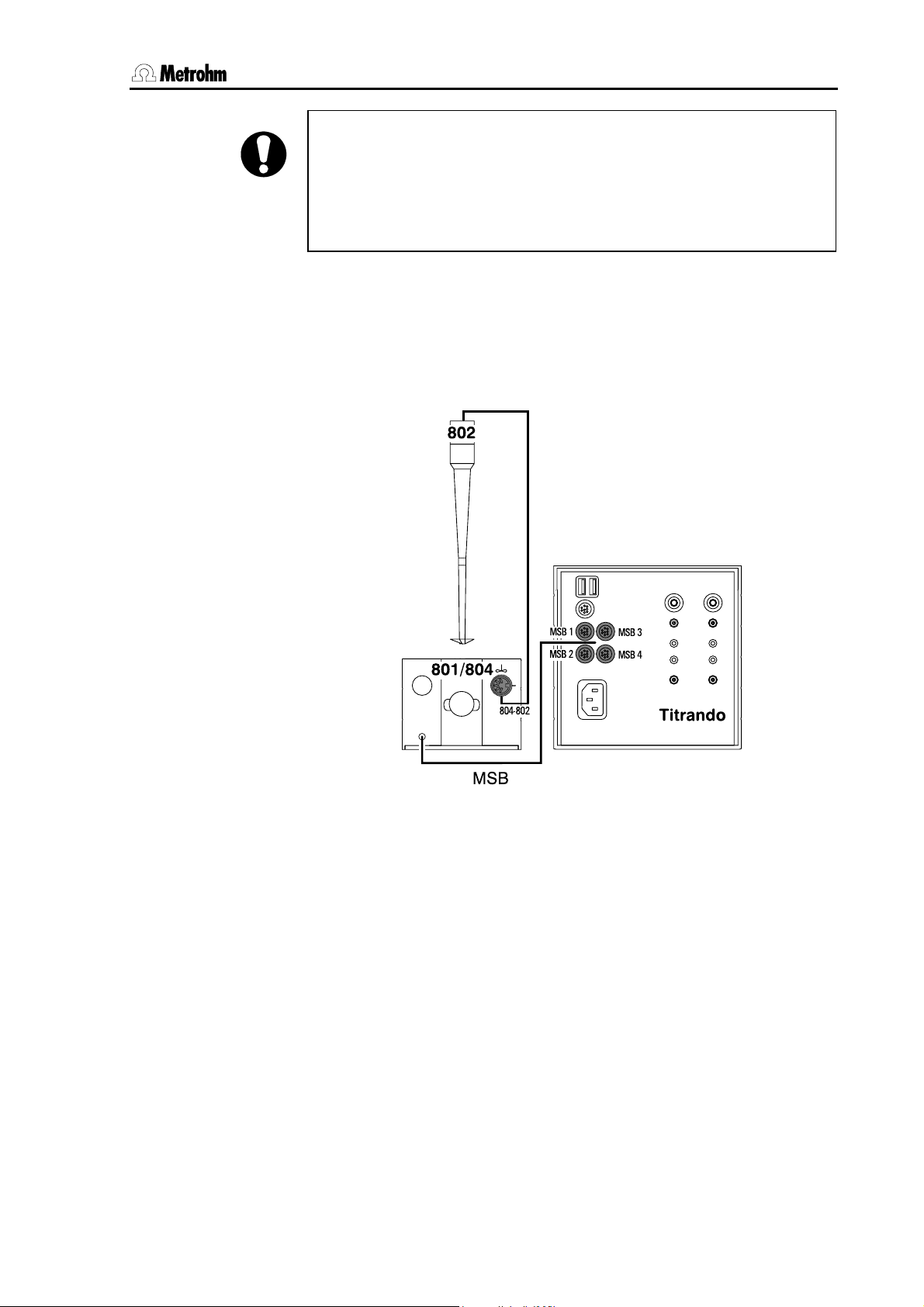

2.4.1 Connecting stirrers and titration stands

You can use the 801 Magnetic Stirrer, the 803 Titration Stand (stirring from below) or the 804 Titration Stand with 802 Rod Stirrer (stirring from above).

Connect the appropriate stirrer as follows:

Fig. 9: Titrando – Stirrer

You can connect a maximum of one 801 Stirrer, one 804 Titration Stand

with 802 Rod Stirrer or one 803 Titration Stand to each MSB socket. The

801 Stirrer as well as the 804 and 803 Titration Stands has a MSB connection to which an additional device, e. g. a dosing device, can be

connected. We recommend that the stirrer is connected to MSB 1, as

this corresponds to the default setting in the methods.

The stand and the stand support are included with the stirrer or titration

stand. Fasten the stand support to the base of the Titrando with the four

screws supplied. Decide whether you want to attach the stirrer to the

right or left of the Titrando. The assembly of the support rod and the

stirrer or titration stand is described in the Instructions for Use of the

801 Stirrer and the 804 Titration Stand or the 803 Titration Stand.

Titrando Installation Instructions 15

Page 22

2.4 Device connection at the MSB

2.4.2 Attaching the exchange unit to the Titrando

Type 806 exchange units have a built-in data chip that allows the storage of data concerning the exchange unit and the reagent. Data is edited in the Touch Control or in the PC Control/tiamo software. The assembly of the exchange unit is described in the Instructions for Use of

the exchange unit.

Fig. 10: Attaching the exchange unit to the Titrando

Slide the exchange unit onto the Titrando so that it snaps into posi-

tion and the "Status" LED slowly blinks.

If the exchange unit has been properly positioned then the exchange

unit guide bolts will operate a microswitch and trigger the exchange unit

initialization. The exchange unit will be recognized and the data is

automatically read out from the data chip. The "Status" LED then lights

up constantly.

The following table provides an overview of the operating statuses of

the internal dosing device that can be indicated by the "Status" LED:

16 Titrando Installation Instructions

Page 23

2 Installation

"Status" LED Dosing device operating status

off There is no exchange unit at-

tached.

constant illumination The Titrando is ready for dosing

or titrating. The exchange unit

has been attached correctly and

recognized and is now in the

change position, i. e. the exchange unit can be removed.

blinks slowly The Titrando is currently dosing

or filling or the exchange unit is

not in the change position.

An intelligent 806 Exchange unit

has been attached and the data

on the built-in data chip is currently being read out or written.

blinks rapidly Dosing drive error (see Sec-

tion 3, Troubleshooting)

Titrando Installation Instructions 17

Page 24

2.4 Device connection at the MSB

2.4.3 Connecting an external dosing device

Three dosing devices of the type 805 or 685 Dosimat or 800 or

700 Dosino can be connected to Titrandos with an internal dosing

drive and four of them to Titrandos without internal dosing drive. MSB 1

is occupied by the built-in dosing drive on the Titrando with internal

dosing drive.

Connect the dosing drive as shown in Fig. 11 and Fig. 12.

Fig. 11: Example for connecting a dosing device:

Titrando – 800 Dosino

18 Titrando Installation Instructions

Page 25

2 Installation

Fig. 12: Example for connecting a dosing device:

Titrando – 805 Dosimat

The 685 Dosimat is connected to the Titrando with the 6.2134.030 cable. 685 Dosimat and 700 Dosino types must be connected directly to

the MSB socket of the Titrando (see Fig. 8: Overview of MSB connections). If you want to connect a stirrer (see Section 2.4.1) and an external 800 Dosino (or 805 Dosimat) dosing device to a Titrando without internal dosing drive then we recommend that the stirrer is connected to

MSB 1 and the dosing device to the MSB connection of the stirrer as

this corresponds to the standard settings in the methods.

Type 806 Exchange units for the 805 Dosimat and type 807 Dosing

units for the 800 Dosino have a built-in data chip that allows the storage

of data about the exchange or dosing unit and the reagent. This data is

automatically read out or updated by Touch Control or PC Control/tiamo when the exchange or dosing unit is attached to the dosing

device. The data is edited in the Touch Control or in the PC Control/tiamo software.

Titrando Installation Instructions 19

Page 26

2.4 Device connection at the MSB

2.4.4 Connecting a remote box

Instruments that are controlled by remote lines or can transmit signals

to the Titrando via remote lines can be connected to the Titrando via the

6.2148.010 Remote box. The pin occupancy of the remote socket is

described in the Instructions for Use for PC Control / Touch Control.

Connect the remote box to an MSB connection on the Titrando in

the following way:

Fig. 13: Titrando – Remote box

For example, you can connect the 849 Level Control to the remote interface of the remote box. The remote box also has an MSB output, to

which an additional instrument, e. g. a dosing device or stirrer, can be

connected.

During a method run remote output lines are set automatically and the

setting of input lines by a peripheral device can automatically trigger

commands (e. g. start or stop). An exact description of the signals is

given in the Instructions for Use for PC Control / Touch Control.

PC Control / Touch Control

If you have several remote boxes connected then you must remember

that the particular remote box that is recognized first by the software

(Touch Control or PC Control) will automatically be used as the "Control

remote box". This means that lines will be set up and scanned automatically on this remote box. The current Control remote box is shown

in the device manager under the Touch Control or PC Control properties (see Instructions for Use for PC Control / Touch Control).

20 Titrando Installation Instructions

Page 27

2 Installation

2.5 Device connection at the USB

The Titrando has two USB connections (type A sockets) for connecting

peripheral devices with a USB interface. The Titrando functions as the

USB hub (distributor), regardless of whether you are using it with Touch

Control or PC Control/tiamo. If you wish to attach more than two devices to a USB then you can also use an additional commercially available USB hub (see Section 2.5.7).

Attention!

If you are operating the Titrando with Touch Control then make sure

that the Touch Control is switched off while you are setting up or

breaking the connections between the instruments. If you are operating the Titrando with the PC software, end the program before setting

up or breaking USB connections.

2.5.1 Connecting a printer

Printers to be connected to the Titrando operated by Touch Control

must meet the following requirements:

• Printer language: HP-PCL, Canon BJL Commands or Epson ESC

P/2

• Printer resolution 300 dpi or 360 dpi (Epson)

• A4 paper, single page feed.

Current printer models that can be connected are listed on the Internet

under www.titrando.com

To connect the printer proceed as follows:

Switch off Touch Control.

Use the 6.2151.020 cable to connect the USB connection of the Ti-

trando (type A) to the USB connection of the printer (type B, see

printer’s operating manual).

.

First switch on the printer and then the Touch Control.

Configure the printer in the device manager of the Touch Control as

described in the Instructions for Use for PC Control / Touch Control.

Fig. 14: Titrando – Printer

Titrando Installation Instructions 21

Page 28

2.5 Device connection at the USB

2.5.2 Connecting a balance

If you are operating the Titrando with the PC Control/tiamo software

then connect the balance directly to the serial interface (COM) of the

computer. This is normally 9-pin and marked with the symbol IOIOI. If

you are operating the Titrando with the Touch Control then you need

the 6.2148.020 USB-RS232 box to connect a balance.

The following table gives an overview of the balances that can be used

together with the Titrando system and which cables you will need to

connect the balance to the RS232 interface:

Balance Cables

AND

6.2125.020 + 6.2125.010

ER-60, 120, 180, 182

FR-200, 300

FX 200, 300, 320

with RS232 interface (OP-03)

Mettler AB, AG, PR (LC-RS9) Supplied with balance

Mettler AM, PM, PE with interface

option 016

or

Mettler AJ, PJ with interface option 018

6.2146.020 + 6.2125.010

additionally from Mettler:

ME 47473 Adapter and either

ME 42500 Hand switch or

ME 46278 Foot switch

Mettler AT 6.2146.020 + 6.2125.010

additionally from Mettler:

ME 42500 Hand switch or

ME 46278 Foot switch

Mettler AX, MX, UMX, PG, AB-S,

6.2134.120

PB-S

Mettler AE with interface option

011 or 012

6.2125.020 + 6.2125.010

additionally from Mettler:

ME 42500 Hand switch or

ME 46278 Foot switch

Ohaus

Cable AS017-09 from Ohaus

Voyager, Explorer, Analytical Plus

Precisa

6.2125.080 + 6.2125.010

balances with RS232C interface

Sartorius MP8, MC1 6.2134.060

Shimadzu BX, BW 6.2125.080 + 6.2125.010

22 Titrando Installation Instructions

Page 29

2 Installation

Operation with Touch Control

Use the 6.2151.030 cable to connect the USB connection of the Ti-

trando (type A) to the USB connection of the USB-RS232 box

(type B).

Connect one of the RS interfaces of the USB-RS232 box with the

RS232 interface of the balance (see Table for cables).

Fig. 15: Titrando – USB-RS232 box – Balance

Switch on the Touch Control.

Switch on the balance.

Configure the RS232 interface of the balance.

Configure the RS232 interface of the USB-RS232 box in the device

manager of the Touch Control (see Instructions for Use for PC Control / Touch Control).

Operation with PC Control/tiamo

Connect the RS232 interface of the computer with the RS232 inter-

face of the balance (see Table for cables).

Switch on the balance.

Configure the RS232 interface of the balance.

Configure the RS232 interface of the computer in the device man-

ager of the PC Control software (see Instructions for Use for PC

Control / Touch Control) or in the configuration dialog of tiamo.

Titrando Installation Instructions 23

Page 30

2.5 Device connection at the USB

2.5.3 Connecting a USB Sample Processor / Robotic Titrosampler

A USB Sample Processor or a Robotic Titrosampler can be controlled

by Touch Control or PC Control/tiamo.

Use the 6.2151.000 cable to connect the USB connection of the Ti-

trando (type A) with the controller socket of the USB Sample Processors / Robotic Titrosampler.

Fig. 16: Titrando –USB Sample Processor

Start the PC Control/tiamo software or switch on the Touch Control.

The USB Sample Processor / Robotic Titrosampler will be recognized automatically and entered in the device list of PC Control/tiamo or Touch Control.

Configure the USB Sample Processor / Robotic Titrosampler in the

device manager or the configuration dialog as described in the Instructions for Use for PC Control / Touch Control or tiamo respectively.

2.5.4 Connecting additional Titrandos or Dosing Interfaces

With the Touch Control or the PC Control software you can control up to

three Titrandos or Dosing Interfaces. The tiamo software allows to expand the system with practically any number of control devices.

Use the 6.2151.000 cable to connect the USB connection of the first

Titrando / Dosing Interface (type A) with the controller socket of the

second Titrando / Dosing Interface.

Fig. 17: Titrando – Titrando/Dosing Interface

Switch on the Touch Control or start the PC Control/tiamo software.

The Titrando / Dosing Interface will be recognized automatically and

entered in the device list of PC Control/tiamo or Touch Control.

24 Titrando Installation Instructions

Page 31

2 Installation

Configure the Titrando / Dosing Interface in the device manager or

the configuration dialog as described in the Instructions for Use for

PC Control / Touch Control or tiamo respectively.

You can connect another Titrando or Dosing Interface in the manner

described above.

Attention!

Connecting Titrandos/Dosing Interfaces via a commercially available

USB hub is not possible.

2.5.5 Connecting a PC keyboard (Titrando with Touch Control only)

The PC keyboard is used as an aid for entering text and numbers. If you

are operating the Titrando with the Touch Control then you can connect

a PC keyboard with USB interface to the Titrando. Current keyboard

models that can be connected are listed on the Internet under

www.titrando.com

Connect the USB plug of the keyboard (type A) to one of the USB

sockets of the Titrando.

Switch on the Touch Control. The keyboard will be automatically

recognized and entered in the device manager.

Configure the keyboard in the device manager of the Touch Control

as described in the Instructions for Use for PC Control / Touch Control.

.

2.5.6 Connecting a barcode reader

The barcode reader is used as an aid for entering text and numbers.

You can connect a barcode reader with USB-interface. Current barcode

reader models that can be connected are listed on the Internet under

www.titrando.com

Operation with Touch Control

Connect the USB plug of the barcode reader (type A) to one of the

USB sockets of the Titrando.

Switch on the Touch Control. The barcode reader will be automati-

cally recognized and entered in the device manager of the Touch

Control.

Configure the barcode reader in the device manager as described

in the Instructions for Use for PC Control / Touch Control.

Operation with PC Control/tiamo

Connect the USB plug of the barcode reader (type A) to one of the

USB sockets of the Titrando or the computer.

Start the PC Control or tiamo software.

Configure the barcode reader in the device manager or the configu-

ration dialog as described in the Instructions for Use for PC Control / Touch Control or tiamo respectively.

.

Titrando Installation Instructions 25

Page 32

2.5 Device connection at the USB

Settings on the barcode reader:

The operating instructions of the barcode reader describe the programming of the barcode reader.

Bring the barcode reader into the programming mode.

Set the required keyboard layout (USA, Germany, France, Spain,

Switzerland (German)). This setting must be the same as the setting

in the device manager (see Instructions for Use for PC Control / Touch Control).

Make sure that the barcode reader is set so that Ctrl-characters

(ASCII 00 to 31) can be transmitted.

Program the barcode reader so that ASCII character 02 (STX or

Ctrl B) is the first character to be transmitted. This first character is

normally known as the "Preamble" or "Prefix code".

Program the barcode reader so that ASCII character 04 (EOT or

Ctrl D) is the last character to be transmitted. This last character is

normally known as the "Postamble", "Record suffix" or "Postfix code".

Terminate the programming mode.

2.5.7 Connecting a USB hub

If you would like to connect more than two devices to the USB connection of the Titrando then you can use an additional commercially available USB hub (distributor). If you are operating the Titrando with the

Touch Control then you should use a self-powered USB hub.

Switch off the Touch Control or close the PC Control/tiamo software.

Use the 6.2151.020 cable to connect the USB connection of the Ti-

trando (type A) with the USB connection of the hub (type B, see operating instructions of hub).

Switch on the Touch Control or start the PC Control/tiamo software.

The USB hub will be recognized automatically.

2.5.8 Connecting a Bluetooth® adapter

Printers and balances (or other instruments with RS232 connection) can

be connected optionally via a wireless Bluetooth

of printers and balances with integrated Bluetooth

ommended for this. Bluetooth

Bluetooth

are commercially available.

Note!

Bluetooth

Special Interest Group (Bluetooth

®

serial adapters for RS232 connections (e. g. for balances)

®

is a registered and protected trademark of the Bluetooth®

®

®

connection. Models

®

functionality are rec-

printer adapters for the USB port and

®

SIG, Inc.).

26 Titrando Installation Instructions

Page 33

2 Installation

PC Control and tiamo

If the Titrando system is operated with the PC Control/tiamo software, a

Bluetooth USB adapter can be connected to a USB port of the computer (or of the Titrando/USB Sample Processor). The driver software

(for MS Windows 2000/XP), supplied by the manufacturer of the Bluetooth adapter, must be installed as specified in the related instructions.

A Bluetooth USB adapter must support the Bluetooth specifications

HCRP (Hardcopy Cable Replacement Profile for printers) and/or

SPP (Serial Port Profile for balances or RS232 connections). Printer

drivers must be configured before installation of the Bluetooth adapter.

Touch Control

If the Titrando system is operated as a stand-alone system with an

840 Touch Control, the Metrohm Bluetooth USB Adapter for 840

(6.2162.000, Bluetooth

for a Bluetooth connection.

®

V1.1 qualified Class 2 device) will be required

Note!

The Metrohm Bluetooth USB Adapter cannot be operated on a

computer. The adapter is designed exclusively for use in a Titrando

system in stand-alone mode, i. e. with a 840 Touch Control as control

unit. The version 5.840.0130 or higher of the Touch Control software is

required.

The Metrohm Bluetooth USB adapter guarantees wireless data transfer

over a distance of up to 10 m and is easy to install.

Connect the Bluetooth adapter to a free USB port on the rear of the

Titrando/USB Sample Processor.

Switch on the Touch Control. The Bluetooth USB adapter is recog-

nized automatically.

Configure the adapter in the device manager of the Touch Control

as described in the Instructions for Use for PC Control/Touch Control.

Printers and Bluetooth

A Bluetooth-enabled printer or a Bluetooth printer adapter must support

the HCRP Hardcopy Cable Replacement Profile.

Please refer to the printer's User Manual for the settings required for a

Bluetooth-enabled printer. Bluetooth printer adapters can normally be

connected to the USB port of the relevant printer without the need for

configuration. Please note what is said in the printer adapter's documentation. The printer type is defined in the device manager of Touch

Control.

Balances and Bluetooth

A Bluetooth-enabled balance or a Bluetooth serial adapter must comply

with the SPP Serial Port Profile in accordance with the Bluetooth

specifications. If the manufacturer of the balance offers a specific Blue-

Titrando Installation Instructions 27

Page 34

2.5 Device connection at the USB

tooth serial adapter, this should be used instead of a commercially

available adapter.

Bluetooth serial adapters must be configured on the PC using the utility

program supplied by the manufacturer. The data transfer parameters of

instrument and adapter must agree with each other. The Bluetooth serial adapter must be defined as Acceptor and not as Initiator of a serial

connection. Authentication with a PIN code is not supported.

28 Titrando Installation Instructions

Page 35

2 Installation

2.6 Sensor connection

One measuring interface consists of a high-impedance measuring input

(Ind.) for pH, redox or ISE sensors, an input for a separate reference

electrode (Ref.), a measuring input for temperature sensors (Temp.),

e. g. Pt1000 or NTC and a measuring input for polarized electrodes

(Pol.).

Fig. 18: Titrando – Sensors

2.6.1 Connecting an 854 iConnect

One or two external 854 iConnect measuring interfaces can be connected to an 857 Titrando depending on the Titrando's version.

Connect the iConnect plug of the 854 iConnect to the socket "iCon-

nect" of the 857 Titrando. Make sure that the mark on the plug

points to the mark on the Titrando as shown in the figure.

Fig. 19: Connecting the 854 iConnect

The 854 iConnect is recognized automatically and entered as

measuring input in the device properties of the Titrando.

The connection of sensors is described in the Instructions for Use of the

854 iConnect.

Titrando Installation Instructions 29

Page 36

2.6 Sensor connection

2.6.2 Differential potentiometry

During potentiometric measurements in poorly conducting media, highimpedance measuring sensors are affected by electrostatic and electromagnetic interferences. Use our Solvotrode 6.0229.100 or any other

special electrode for pH measurements in organic solvents. If this does

not help then you can connect a Differential amplifier 6.5104.030

(230 V) or 6.5104.040 (115 V).

The Differential amplifier is connected to the high-impedance measuring input (Ind.).

2.6.3 Titration vessel setup

In titration it is important that the solution is thoroughly mixed. The stirring rate should be high enough for a small vortex to be formed. If the

stirring rate is too high then air bubbles will be entrained. This results in

incorrect measurements. If the stirring rate is too low then the solution

at the electrode will not be correctly mixed. To ensure that the measurement is made in a thoroughly mixed solution after titrant addition the

buret tip should be located where the turbulence is greatest. In addition, the distance between the spot where the titrant is added and the

electrode should be as large as possible. When positioning the electrode and buret tip you must also take the stirring direction into account.

1

2

3

Fig. 20: Recommended arrangement of magnetic stirring bar (1),

electrode (2) and buret tip (3)

30 Titrando Installation Instructions

Page 37

2 Installation

2.6.4 Assembly of the Karl Fischer titration cell

Install the titration cell for volumetric KF titrations according to the following figures:

Fig. 21: Drawing of the KF titration cell 6.5609.000

Titrando Installation Instructions 31

Page 38

2.7 Update of the instrument software

Fig. 22: Arrangement of transport tip, buret tip and draw-off tip

1 Position of the transport tip for sol-

vent

2 Position of the buret tip for KF re-

agent

3 Position of the draw-off tip

2.7 Update of the instrument software

The Update of the instrument software is described in the Instructions

for Use for PC Control / Touch Control or in the tiamo help.

32 Titrando Installation Instructions

Page 39

3 Troubleshooting

3 Troubleshooting

3.1 Problems

Problem Possible cause Measures

"On" LED does not

light up although the

Titrando is connected to the mains

supply.

Titrando with internal

dosing drive only:

"Status" LED does

not light up although

an exchange unit is

in place.

Titrando with internal

dosing drive only:

The exchange unit

cannot be pushed

into position.

Either the Touch Control or

the computer is not switched

on, or the plugs are not

plugged in correctly.

The exchange unit has not

been attached correctly.

The exchange unit flat cock

is not in the change position.

The piston rod in the exchange unit is not in the correct position.

Check the plug connections and

switch on the Touch Control or the

computer.

Remove the exchange unit and

push it on again until it clicks into

position. The LED blinks while the

data is being read out from an intelligent exchange unit (806) and is on

continuously when the exchange

unit has been recognized correctly.

Move the flat cock manually to the

change position (switch lever pointing to the right).

Move the piston rod to the correct

position (see exchange unit Instructions for Use, Section "Attaching

the exchange unit").

Titrando with internal

dosing drive only:

The exchange unit

cannot be removed

and the "Status" LED

blinks slowly.

Dosing or filling is currently

taking place and / or the Titrando is not in the change

position.

Stop the run or carry out a "Fill"

step.

Titrando Installation Instructions 33

Page 40

3.1 Problems

Problem Possible cause Measures

Titrando with internal

dosing drive only:

"Status" LED blinks

rapidly.

The dosing drive is overloaded because the flat cock

is blocked.

The dosing drive is overloaded because the piston is

blocked. The fault is indicated by the software (Touch

Control or PC Control/tiamo).

Switch off the Touch Control or end

PC Control/tiamo. Check whether

the exchange unit can be removed.

If it cannot be removed then check

whether the flat cock can still be

rotated. Move it manually to the

change position by turning it to the

right (see Instructions for Use of

exchange unit). Remove the exchange unit and proceed as described in the Instructions for Use

in the section "Servicing a blocked

flat cock".

Switch the control device off and

then on again. The dosing device is

initialized when switching on. Remove the exchange unit and clean

it as described in the Instructions

for Use in the section "Care and

maintenance". Contact Metrohm

Service if it is not possible to remove the exchange unit.

The exchange unit data can

no longer be read as the

data chip has been damaged mechanically or by

chemicals.

Have the data chip replaced by

Metrohm Service personnel.

In order to be able to use the exchange unit until the data chip is

replaced you can remove the data

chip yourself. The cylinder volume

will still be recognized automatically, but data can no longer be

read from or stored in the exchange unit.

34 Titrando Installation Instructions

Page 41

4 Appendix

4 Appendix

In this section you will find the most important technical data of the Titrando, a list of standard and optional accessories and the warranty

and conformity declarations.

4.1 Technical data

Provided that nothing to the contrary is mentioned, the published values are typical technical data for the Titrandos with internal and external

dosing drive.

4.1.1 Titration and measuring modes

DET Dynamic equivalence point titration

Controlled titrant addition with variable volume increments

MET Monotonic equivalence point titration

Titrant addition with fixed volume increments

SET Titration to one or two predefined endpoints

KFT Karl Fischer titration

STAT Endpoint titration while holding the measured value constant

MEAS Measurement (pH, potential, temperature, current (Upol), poten-

tial(Ipol) and concentration)

4.1.2 Measuring interfaces

1 or 2 galvanically separated measuring interfaces

Potentiometry

1 high-impedance measuring input for pH, redox and ISE electrodes

1 reference input for separate reference electrode

Input resistance

Offset current

Temperature

1 measuring input for temperature sensors (Pt1000 or NTC)

Automatic temperature compensation, for NTC sensors R (25 °C) and B

configured.

> 1 * 10

< 1 * 10

(under reference conditions)

12

Ohm

–12

A

25/50

can be

Polarizer

1 measuring input for polarized electrodes

Polarization current Ipol

Polarization potential Upol

Titrando Installation Instructions 35

–125.0 ... +125.0 µA in 2.5 µA steps

–1250 ... +1250 mV in 25 mV steps

Page 42

4.1 Technical data

Polarizer (857 only)

1 measuring input for polarized electrodes

Polarization current Ipol

Polarization potential Upol

1)

–125.0 / +125.0 µA: values not guaranteed, dependent on reference potential

1)

–122.5 ... +122.5 µA in 2.5 µA steps

2)

–1225 ... +1225 mV in 25 mV steps

+2.5 V

2)

–1250 / +1250 mV: values not guaranteed, dependent on reference potential

+2.5 V

4.1.3 Specification of the measuring inputs

Measuring range Resolution Measuring accuracy 1)

pH –20.000 ... +20.000 0.001 pH ± pH 0.003

Potential 2) –2000 mV ... +2000 mV 0.1 mV ± 0.2 mV

Current 3) –200 µA ... +200 µA 0.01 µA −

Temperature

Pt1000

NTC

1)

± 1 digit, without sensor error, under reference conditions

2)

potentiometric and voltametric

3)

amperometric

4)

for a NTC-Sensor with R (25 °C) = 30'000 Ohm and B (25/50) = 4100 K.

–150 °C ... +250 °C

–20 °C ... +250 °C

0.1 °C

4)

0.1 °C

± 0.2 °C (Pt1000: –20 °C ...

+150 °C)

Measuring cycle: 100 ms for all measuring ranges

4.1.4 Specification of the measuring inputs (857 only)

Measuring range Resolution Measuring accuracy 1)

pH –13.000 ... +20.000 0.001 pH ± pH 0.003

Potential 2) –1200 mV ... +1200 mV 0.1 mV ± 0.2 mV

Current 3) –120 µA ... +120 µA 0.01 µA −

Temperature

Pt1000

NTC

–150 °C ... +250 °C

–5 °C ... +250 °C

4)

0.1 °C

0.1 °C

± 0.2 °C (–20 °C... +150 °C)

± 0.6 °C (+10 °C... +40 °C)

1)

± 1 digit, without sensor error, under reference conditions

2)

potentiometric and voltametric

3)

amperometric

4)

for a NTC-Sensor with R (25 °C) = 30'000 Ohm and B (25/50) = 4100 K.

Measuring cycle: 100 ms for all measuring ranges

36 Titrando Installation Instructions

Page 43

4 Appendix

4.1.5 Internal dosing device

Cylinder volume

Exchange unit resolution

Accuracy

4.1.6 Interfaces

USB connections

USB ports 2 USB downstream ports (type A sockets), 500 mA

Controller connection

Controller port USB upstream port with additional signals (mini DIN

Touch Control connection With built-in Touch Control cable

Computer connection With 6.2151.000 cable

MSB connections (MSB = Metrohm Serial Bus)

1 mL, 5 mL, 10 mL, 20 mL or 50 mL

20'000 steps per cylinder volume

0.025% (typical)

Complies with ISO/DIN Standard 8655-3

each, for connection of peripheral devices such as

printer, keyboard, barcode reader or USB-RS232 box

(Metrohm Ordering no. 6.2148.020)

socket) for the connection of Touch Control or computer to control the Titrando.

Dosing device Connection of max. 3 external dosing devices of the

Stirrer Connection of max. 4 stirrers

Remote box Connection of max. 4 remote boxes

4.1.7 Mains connection

Voltage

Frequency

Power consumption

Fuses

type Dosimat or Dosino to Titrandos with internal dosing drive (MSB 2 to MSB 4) or 4 external dosing devices of the type Dosimat or Dosino to Titrandos without internal dosing drive (MSB 1 to MSB 4).

Stirrer control: on/off; manual or coordinated with the

titration procedure.

15 steps for speed and direction of rotation selectable.

Remote boxes are used to select and control external

devices.

100 ... 240 V (± 10%)

50 ... 60 Hz

45 W

electronic overload protection

Titrando Installation Instructions 37

Page 44

4.1 Technical data

4.1.8 Safety specifications

Construction and testing According to EN/IEC/UL 61010-1, CSA-C22.2 No.

61010-1 protection class I

Safety information The Installation Instructions contain safety information

that must be observed by the user in order to ensure

the safe operation of the instrument.

4.1.9 Electromagnetic compatibility (EMC)

Emission Standards complied with:

- EN/IEC 61326

- EN 55022 / CISPR 22

Immunity Standards complied with:

- EN/IEC 61326

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-11

4.1.10 Ambient temperature

Nominal working range

Automatic inside temperature monitoring

Storage

Transport

+5 °C ... +45 °C (at max. 85 % rel. humidity)

> 70 °C pre-alarm, > 75 °C alarm

–20 °C ... +60 °C

–40 °C ... +60 °C

4.1.11 Reference conditions

Ambient temperature

Rel. humidity

Warmed-up condition

Validity of data

+25 °C (±3 °C)

≤ 60 %

Instrument in operation for at least 30 min

After adjustment

38 Titrando Installation Instructions

Page 45

4 Appendix

4.1.12 Dimensions

Titrando with internal dosing drive

Housing material Polybutylene terephthalate (PBT)

Width

Height (without exch. unit)

Height (with exch. unit)

Depth

Weight (without exch. unit) 2948 g

Titrando without internal dosing drive

Housing material Polybutylene terephthalate (PBT)

Width

Height

Depth

Weight 2817 g

142 mm

164 mm

approx. 450 mm

239 mm

142 mm

227 mm

231 mm

4.1.13 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

Titrando Installation Instructions 39

Page 46

4.2 Standard equipment

4.2 Standard equipment

Immediately upon receipt of the Titrando please check that the delivery

is complete. The illustrations in the accessory lists are not to the same

scale.

4.2.1 808 Titrando

The 808 Titrando is available in the 2 following versions:

• 2.808.0010 808 Titrando with one measuring interface

• 2.808.0020 808 Titrando with two galvanically separated

measuring interfaces

The information given in brackets refers to 2.808.0020.

No. Order No. Description

1 1.808.0010

or

1.808.0020

1 6.0262.100 Ecotrode Plus

1 6.2104.020 Connection cable for Metrohm electrodes with plug head

1 6.2739.010 Key for exchange units

1 (2)

1 (2)

1

6.2103.130

6.2103.140

6.2122.020

6.2122.040

6.2122.070

808 Titrando with one measuring interface

or

808 Titrando with two galvanically separated measuring interfaces

Combined LL pH glass electrode with fixed ground-joint diaphragm

length 1 m

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

40 Titrando Installation Instructions

Page 47

4 Appendix

4.2.2 809 Titrando

The 809 Titrando is available in the 2 following versions:

• 2.809.0010 809 Titrando with one measuring interface

• 2.809.0020 809 Titrando with two galvanically separated

measuring interfaces

The information given in brackets refers to 2.809.0020.

No. Order no. Description

1 1.809.0010

or

1.809.0020

809 Titrando with one measuring interface

or

809 Titrando with two galvanically separated measuring interfaces

1 6.0262.100 Ecotrode Plus

Combined LL pH glass electrode with fixed ground-joint diaphragm

1 6.2104.020 Connection cable for Metrohm electrodes with plug head

length 1 m

2 6.2043.005 Holding clip for bottle

1 (2)

1 (2)

6.2103.130

6.2103.140

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

1

6.2122.020

6.2122.040

6.2122.070

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

Titrando Installation Instructions 41

Page 48

4.2 Standard equipment

4.2.3 835 Titrando

The 835 Titrando is available in the 2 following versions:

• 2.835.0010 835 Titrando with one measuring interface

• 2.835.0020 835 Titrando with two galvanically separated

measuring interfaces

The information given in brackets refers to 2.835.0020.

No. Order No. Description

1 1.835.0010

or

1.835.0020

835 Titrando with one measuring interface

or

835 Titrando with two galvanically separated measuring interfaces

1 6.0262.100 Ecotrode Plus

Combined LL pH glass electrode with fixed ground-joint diaphragm

1 6.2104.020 Connection cable for Metrohm electrodes with plug head

length 1 m

1 6.2739.010 Key for exchange units

1 (2)

1 (2)

6.2103.130

6.2103.140

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

1

6.2122.020

6.2122.040

6.2122.070

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

42 Titrando Installation Instructions

Page 49

4 Appendix

4.2.4 836 Titrando

The 836 Titrando is available in the 2 following versions:

• 2.836.0010 836 Titrando with one measuring interface

• 2.836.0020 836 Titrando with two galvanically separated

measuring interfaces

The information given in brackets refers to 2.836.0020.

No. Order no. Description

1 1.836.0010

or

1.836.0020

836 Titrando with one measuring interface

or

836 Titrando with two galvanically separated measuring interfaces

1 6.0262.100 Ecotrode Plus

Combined LL pH glass electrode with fixed ground-joint diaphragm

1 6.2104.020 Connection cable for Metrohm electrodes with plug head

length 1 m

2 6.2043.005 Holding clip for bottle

1 (2)

1 (2)

6.2103.130

6.2103.140

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

1

6.2122.020

6.2122.040

6.2122.070

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

Titrando Installation Instructions 43

Page 50

4.2 Standard equipment

4.2.5 841 Titrando

The 841 Titrando is available in the following version:

• 2.841.0010 841 Titrando with one measuring interface

No. Order no. Description

1 1.841.0010 841 Titrando with one measuring interface

1 6.5609.000 Karl Fischer titration equipment (see Section 4.3.4 and Fig. 21)

2 6.2043.005 Holding clip for bottle

1

1

6.2103.130

6.2103.140

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

1

6.2122.020

6.2122.040

6.2122.070

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

44 Titrando Installation Instructions

Page 51

4 Appendix

4.2.6 842 Titrando

The 842 Titrando is available in the following version:

• 2.842.0010 842 Titrando with one measuring interface

No. Order no. Description

1 1.842.0010 842 Titrando with one measuring interface

1 6.0262.100 Ecotrode Plus

Combined LL pH glass electrode with fixed ground-joint diaphragm

1 6.2104.020 Connection cable for Metrohm electrodes with plug head

length 1 m

2 6.2043.005 Holding clip for bottle

1

1

6.2103.130

6.2103.140

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

1

6.2122.020

6.2122.040

6.2122.070

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

Titrando Installation Instructions 45

Page 52

4.2 Standard equipment

4.2.7 857 Titrando

The 857 Titrando is available in the 2 following versions:

• 2.857.0010 857 Titrando with one measuring interface for 854

iConnect

• 2.857.0020 857 Titrando with two galvanically separated

measuring interfaces (one for 854 iConnect, one for

854 iConnect and conventional sensors)

The information given in brackets refers to 2.857.0020.

No. Order no. Description

1 1.857.0010

or

1.857.0020

857 Titrando with one measuring interface

or

857 Titrando with two galvanically separated measuring interfaces

1 1.854.0010 854 iConnect

measuring input

2 6.2043.005 Holding clip for bottle

1

1

6.2103.130

6.2103.140

for 2.857.0020 only:

Adapter red

Adapter black

for temperature sensor

2 mm plug / 4 mm socket

1

6.2122.020

6.2122.040

6.2122.070

Mains cable (plug to customer’s specification)

Type SEV 12 (Switzerland)

Type CEE(7), VII (Germany,...)

Type NEMA/ASA (USA,...)

1 8.840.1133 Installation Instructions for Titrando

46 Titrando Installation Instructions

Page 53

4 Appendix

4.3 Additional instruments and optional accessories

4.3.1 Controller for operating the Titrando

Order no. Description

2.840.0100 Touch Control

with touch-sensitive screen

6.6050.310 PC Control Software 4.1 for Titrando

4.3.2 Stirrers and titration stands

Order no. Description

2.801.0040 801 Magnetic stirrer

with stand and electrode holder for mounting on Titrando

2.801.0010 801 Magnetic stirrer

without stand

2.804.0040 804 Titration stand

for 802 Rod stirrer, with stand and electrode holder for mounting on Titrando

2.804.0010 804 Titration stand

for 802 Rod stirrer, without stand

2.802.0040 802 Rod stirrer for 804 Titration stand

6.1909.010 Propeller stirrer, polypropylene

(length from lower edge of SGJ: 96 mm)

2.803.0010 803 Titration stand

with magnetic stirrer and pump

4.3.3 Titration equipment

Order no. Description

6.5609.000 Karl Fischer titration equipment (see Fig. 21)

6.5613.000 Eco titration equipment

6.1414.010 Titration vessel upper part

for titration vessels 6.1415.xxx and

6.1418.xxx

5 openings, made of PPS

Titrando Installation Instructions 47

Page 54

4.3 Additional instruments and optional accessories

Order no. Description

6.1415.22x Titration vessel, 20 ... 90 ml

6.1415.220 clear glass

6.1415.223 amber glass

6.1415.25x Titration vessel, 50 ... 150 ml

6.1415.250 clear glass

6.1415.253 amber glass

6.2021.020 Electrode holder,

plastic

6.2013.010 Clamping ring

for 10 mm diameter support rods

6.1602.190 Bottle adapter for tandem dosing

1 x NS14, 4 x M6

4.3.4 Karl Fischer titration equipment 6.5609.000

Order no. Description

6.0338.100 Double platinum wire electrode

6.1244.040 Sealing rings for 6.1414.030

6.1403.040 Drying tube with cover and O-ring

6.1414.030 KF titration vessel upper part

6.1415.220 Titration vessel 20 ... 90 mL

6.1415.250 Titration vessel 50 ... 150 mL

6.1448.010 Septum

6.1903.020 PTFE-stirring bar 16 mm

6.1903.030 PTFE-stirring bar 25 mm

48 Titrando Installation Instructions

Page 55

4 Appendix

Order no. Description

6.2104.020 Electrode cable with F plug length 1 m

6.2412.000 Glass weighing spoon with protective tube

6.2730.010 Screw nipple

6.2730.020 Septum stopper 18 mm with O-ring

6.2730.030 Stopper with nipple and O-ring

6.2811.000 Molecular sieve 250 g; pore dimension: 0.3 nm

4.3.5 Dosing devices

Order no. Description

2.805.0010 805 Dosimat

6.3026.110 806 Exchange unit with 1 mL glass cylinder

6.3026.150 806 Exchange unit with 5 mL glass cylinder

6.3026.210 806 Exchange unit with 10 mL glass cylinder

6.3026.220 806 Exchange unit with 20 mL glass cylinder

6.3026.250 806 Exchange unit with 50 mL glass cylinder

6.2244.020 Cards for 806 Exchange unit (10 pieces, assorted)

2.800.0010 800 Dosino

6.3032.120 807 Dosing unit with 2 mL glass cylinder

6.3032.150 807 Dosing unit with 5 mL glass cylinder

6.3032.210 807 Dosing unit with 10 mL glass cylinder

6.3032.220 807 Dosing unit with 20 mL glass cylinder

6.3032.250 807 Dosing unit with 50 mL glass cylinder

6.2061.010 Bottle holder for Dosinos (Reagent Organizer)

for 2 bottles

Titrando Installation Instructions 49

Page 56

4.3 Additional instruments and optional accessories

4.3.6 Combined pH electrodes

Order no. Description

6.0262.100 Ecotrode Plus

Combined LL pH glass electrode with fixed ground-joint diaphragm

6.0256.100 Flat membrane electrode