Page 1

833 IC Liquid Handling Unit

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Instructions for Use

8.833.1003

Page 2

Page 3

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

833 IC Liquid Handling Unit

Instructions for Use

8.833.1003 10.2003 / pkl

Page 4

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

1st Edition 2003

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 5

Table of contents

Table of contents

1 Introduction ................................................................ 1

1.1 Instrument description ................................................................................1

1.1.1 833 IC Liquid Handling Pump Unit..................................................................... 1

1.1.2 833 IC Liquid Handling Suppressor Unit ........................................................... 2

1.1.3 833 IC Liquid Handling Sample Preparation Unit.............................................. 3

1.1.4 833 IC Liquid Handling Dialysis Unit.................................................................. 4

1.1.5 833 IC Liquid Handling Ultrafiltration Unit.......................................................... 5

1.2 Parts and controls .......................................................................................6

1.3 Information about these Instructions for Use ............................................8

1.3.1 Arrangement....................................................................................................... 8

1.3.2 Notation and pictograms.................................................................................... 9

1.4 Safety information .....................................................................................10

1.4.1 Electrical safety................................................................................................. 10

1.4.2 General safety rules.......................................................................................... 10

2 Installation ............................................................... 11

2.1 Instrument setup .......................................................................................11

2.1.1 Packaging......................................................................................................... 11

2.1.2 Checks.............................................................................................................. 11

2.1.3 Location ............................................................................................................ 11

2.1.4 Arranging the instruments ................................................................................ 11

2.2 Mains connection ......................................................................................12

2.2.1 Setting the mains voltage................................................................................. 12

2.2.2 Fuses ................................................................................................................ 13

2.2.3 Mains cable ...................................................................................................... 13

2.2.4 Switching the instrument on/off........................................................................ 13

3 Basic instrument ...................................................... 14

3.1 Electrical connection.................................................................................14

3.1.1 Connecting to 761 Compact IC ....................................................................... 14

3.1.2 Connecting to 819 IC Detector......................................................................... 16

3.1.3 Connecting to 830 IC Interface ........................................................................ 18

3.2 Assembly the pump tubing .......................................................................19

3.3 Operation ...................................................................................................23

3.3.1 Switching the instrument on/off........................................................................ 23

3.3.2 Program settings .............................................................................................. 23

4 833 IC Liquid Handling Pump Unit........................... 27

4.1 Connection of the suppressor module ....................................................27

5 833 IC Liquid Handling Suppressor Unit ................. 31

5.1 Connection of the Suppressor module ....................................................31

5.2 Handling the suppressor module .............................................................35

6 833 IC Liquid Handling Sample Preparation Unit ... 36

6.1 Connection to modular IC system for neutralization .............................36

6.1.1 Electrical connections ...................................................................................... 37

6.1.2 Connection of the sample preparation module ............................................... 38

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

I

Page 6

Table of contents

6.2 Connection to modular IC system for cation separation ........................43

6.2.2 Settings in IC Net.............................................................................................. 47

6.3 Handling the sample preparation module................................................49

7 833 IC Liquid Handling Dialysis Unit .......................50

7.1 Flow diagram for dialysis..........................................................................51

7.2 Electrical connection.................................................................................52

7.2.1 Dialysis without suppression............................................................................ 52

7.2.2 Dialysis with suppression................................................................................. 53

7.3 Settings in IC Net.......................................................................................54

7.3.1 Dialysis without suppression............................................................................ 54

7.3.2 Dialysis with suppression................................................................................. 55

7.4 Assembling the dialysis cell .....................................................................56

7.5 Making the capillary connections.............................................................57

7.5.1 Preparing the 820 IC Separation Center.......................................................... 57

7.5.2 Connection of the dialysis cell ......................................................................... 58

7.6 Optimizing the dialysis..............................................................................63

7.6.1 Determining the rinsing time ............................................................................ 63

7.6.2 Determining the transfer time........................................................................... 63

7.6.3 Determining the dialysis time........................................................................... 64

7.7 Dialysis procedure ....................................................................................66

8 833 IC Liquid Handling Ultrafiltration Unit.............. 68

8.2 Assembling the ultrafiltration cell.............................................................69

8.3 Connect filtration cell ................................................................................70

8.4 Filtration .....................................................................................................74

8.4.1 Selection of possible sample types ................................................................. 74

8.4.2 Filter working life............................................................................................... 74

8.4.3 Filter membrane selection................................................................................ 75

9 Troubleshooting - maintenance............................... 76

9.1 Faults and their remedies .........................................................................76

9.2 Care and maintenance ..............................................................................79

9.2.1 Instrument care ................................................................................................ 79

9.2.2 Maintenance by Metrohm service.................................................................... 79

9.2.3 Shut down ........................................................................................................ 79

9.2.4 Replacing the pump tubing ............................................................................. 80

9.2.5 Changing the filter ............................................................................................ 81

9.2.6 Suppressor module / Sample preparation module ......................................... 82

9.2.7 Dialysis cell....................................................................................................... 88

9.2.8 Ultrafiltration cell ............................................................................................... 90

10 Appendix ................................................................... 91

10.1 Technical data............................................................................................91

10.1.1 Basic instrument: 833 IC Liquid Handling Unit 1.833.0010............................. 91

10.1.2 6.2729.100 Dialysis cell.................................................................................... 94

10.1.3 6.2729.110 Ultrafiltration cell............................................................................ 94

10.2 Standard equipment ..................................................................................95

10.2.1 833 IC Liquid Handling Pump Unit .................................................................. 95

10.2.2 833 IC Liquid Handling Suppressor Unit ......................................................... 96

10.2.3 833 IC Liquid Handling Sample Preparation Unit............................................ 97

10.2.4 833 IC Liquid Handling Dialysis Unit ............................................................... 98

10.2.5 833 IC Liquid Handling Ultrafiltration Unit...................................................... 100

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

II

Page 7

Table of contents

10.3 Optional accessories ..............................................................................103

10.3.1 Connection cables ......................................................................................... 103

10.3.2 Pumps............................................................................................................. 104

10.3.3 Modules .......................................................................................................... 106

10.4 Validation / GLP .......................................................................................107

10.5 Warranty and Conformity ........................................................................108

10.5.1 Warranty.......................................................................................................... 108

10.5.2 Declaration of Conformity............................................................................... 109

10.5.3 Quality Management Principles ..................................................................... 110

10.6 Index .....................................................................................................111

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

III

Page 8

Table of contents

List of figures

Fig. 1: Front panel of 833 IC Liquid Handling Unit ............................................... 6

Fig. 2: Rear panelof 833 IC Liquid Handling Unit................................................. 7

Fig. 3: Setting the mains voltage........................................................................ 13

Fig. 4: Connecting the 833 IC Liquid Handling Unit to 761 Compact IC ........... 14

Fig. 5: Connecting the 833 IC Liquid Handling Unit to 819 IC Detector............. 16

Fig. 6: Connecting the 833 IC Liquid Handling Unit to 830 IC Interface ............ 18

Fig. 7: Assembly the pump tubing ..................................................................... 19

Fig. 8: Connections to suppressor module of 820 Separation Center............... 27

Fig. 9: Suppressor module 1.753.0100 .............................................................. 31

Fig. 10: Suppressor module connections for

833 IC Liquid Handling Suppressor Unit................................................. 32

Fig. 11: 1.793.0110 Sample Preparation Module................................................. 36

Fig. 12: Electrical connections for 833 IC Liquid Handling Sample

Preparation Unit and modular IC system for neutralization..................... 37

Fig. 13: Connections at sample preparation module of

the 833 IC Liquid Handling Sample Preparation Unit.............................. 39

Fig. 14: Connection of 833 IC Liquid Handling Sample Preparation Unit

to modular IC system for cation separation ............................................ 44

Fig. 15: 6.2729.100 Dialysis Cell .......................................................................... 50

Fig. 16: Connecting the 833 IC Liquid Handling Dialysis Unit

to a modular dialysis system without suppression ................................. 52

Fig. 17: Connecting the 833 IC Liquid Handling Dialysis Unit

to a modular dialysis system with suppression....................................... 53

Fig. 18: Time program for dialysis without suppression ...................................... 54

Fig. 19: Time program for dialysis with suppression............................................ 55

Fig. 20 Inserting the dialysis cell in the holder..................................................... 57

Fig. 21: Tubing connection system ...................................................................... 58

Fig. 22: 6.2729.110 Ultrafiltration cell ................................................................... 68

Fig. 23 Inserting the ultrafiltration cell in the holder ............................................. 70

Fig. 24: Tubing connection system ...................................................................... 71

Fig. 25: Filter unit PEEK 6.2821.120 ..................................................................... 81

Fig. 26: Actuator assembly................................................................................... 84

Fig. 27: Adjusting the actuator step ..................................................................... 88

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

IV

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

Within the modular Advanced IC Systems the 833 IC Liquid Handling

Unit is the universal building block for the preliminary preparation and

post-treatment of samples and for transporting auxiliary and rinsing

solutions. It is available in 5 versions that are matched to the most

frequently required applications:

• 2.833.0010 833 IC Liquid Handling Pump Unit

• 2.833.0020 833 IC Liquid Handling Suppressor Unit

• 2.833.0030 833 IC Liquid Handling Sample Preparation Unit

• 2.833.0040 833 IC Liquid Handling Dialysis Unit

• 2.833.0050 833 IC Liquid Handling Ultrafiltration Unit

1.1.1 833 IC Liquid Handling Pump Unit

The 833 IC Liquid Handling Pump Unit corresponds to the basic

instrument. It has a 2-channel peristaltic pump and can be included in a

modular Metrohm IC system via a remote interface and remotely

controlled by the IC Net software.

It can transport two solutions simultaneously and is particularly suitable

for the operation of the suppressor module in the 2.820.0230 IC

Separation Center for supplying regeneration and rinsing solution.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

1

Page 10

1 Introduction

1.1.2 833 IC Liquid Handling Suppressor Unit

As well as the basic instrument, the 833 IC Liquid Handling

Suppressor Unit includes a suppressor module connected to the

basic instrument and also remotely controlled by IC Net.

With the suppressor included in the suppressor module analyses by

ion chromatography with chemical suppression can be carried out. The

suppressor consists of a total of 3 suppressor units which are used in

rotation for suppression, regeneration with sulfuric acid and rinsing with

water. In order that each new chromatogram is recorded under

comparable conditions a freshly regenerated suppressor unit is

normally used. Switching takes place automatically.

The 833 IC Liquid Handling Suppressor Unit is particularly suitable

for retrofitting existing IC systems for chemical suppression in a simple

way. For example, this means that the 833 IC Liquid Handling

Suppressor Unit can be used together with two 819 IC Detectors, two

818 IC Pumps and an 820 IC Separation Center without suppressor

(2.820.0220) to realize a complete 2-channel IC system with only a

single Separation Center.

2

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 11

1.1 Instrument description

1.1.3 833 IC Liquid Handling Sample Preparation Unit

As well as the basic instrument, the 833 IC Liquid Handling Unit

includes a reactor block (sample preparation module) that is

connected to the basic instrument and also remotely controlled by IC

Net.

With the cation exchanger built-into the sample preparation module

such inline sample preparation steps as neutralization and cation

separation can be carried out for analyses by ion chromatography.

The sample preparation module contains a total of three units which are

used in rotation for cation exchange, regenerated with acid and rinsed

with water. In order that each new chromatogram is recorded under

comparable conditions a freshly regenerated cation exchanger is

normally used. Switching takes place either automatically by the IC

system or manually. As sulfate could interfere with the subsequent IC

analysis, the cation exchanger of the sample preparation module

usually uses perchloric acid (HClO

regeneration.

) instead of sulfuric acid (H2SO4) for

4

The 833 IC Liquid Handling Sample Preparation Unit is particularly

suitable for retrofitting a modular IC system for anion analysis for

sample preparation in a simple way. Two typical applications

(neutralization: exchange of e.g. Na

exchange of e.g. heavy metals for H

Instructions for Use. Although the cation exchange technique used is

comparable with the principle of suppression of the 833 IC Liquid

Handling Suppressor Unit, the 833 IC Liquid Handling Sample

Preparation Unit is not suitable for chemical suppression after the

separation of anions by ion chromatography.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

+

for H+ and cation separation:

+

) are described in detail in the

3

Page 12

1 Introduction

1.1.4 833 IC Liquid Handling Dialysis Unit

As well as the basic instrument, the IC Liquid Handling Dialysis Unit

833 includes a dialysis cell upstream from the sample injector.

The 833 IC Liquid Handling Dialysis Unit is used for online sample

preparation in ion chromatography and allows the use of automatic

sample dialysis immediately before sample injection. As well as the 2channel peristaltic pump of the basic instrument for transferring the

sample and acceptor solution from the dialysis cell itself, the ions from

the flowing sample solution are enriched in the stationary acceptor

solution and then injected directly into the IC system. As a result of this

special stopped flow technique, for which an application for a patent

has been made by Metrohm, 100% sample concentration can be

achieved in the acceptor solution and in this way it is possible to carry

out calibration with external standards in a very easy manner.

The operation of the 833 IC Liquid Handling Dialysis Unit requires

the use of an 820 IC Separation Center with one injector and an

additional 833 IC Liquid Handling Pump Unit for the sample tramsport.

These systems, which are described in the Instructions for Use, require

the following instruments:

Operation without

2.819.0110 IC Detector

2.820.0210 IC Separation Center

2.818.0110 IC Pump

2.833.0040 IC Liquid Handling

Dialysis Unit

2.833.0010 IC Liquid Handling

Pump Unit

suppressor

Operation with suppressor

2.819.0110 IC Detector

2.820.0230 IC Separation Center

2.818.0110 IC Pump

2.833.0040 IC Liquid Handling

Dialysis Unit

2.833.0010 IC Liquid Handling

Pump Unit (2 x)

4

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 13

1.1 Instrument description

1.1.5 833 IC Liquid Handling Ultrafiltration Unit

As well as the basic instrument, the IC Liquid Handling Ultrafiltration

Unit 833 includes a filtration cell upstream from the sample injector.

The 833 IC Liquid Handling Ultrafiltration Unit is an instrument for

online sample preparation in ion chromatography that allows the inline

filtration of the sample immediately before it is injected.

The 833 IC Liquid Handling Ultrafiltration Unit is designed for the

filtration of difficult samples that place special demands on the filtration

effects and sample throughput.

Of course, all versions of the 833 IC Liquid Handling Unit can also be

used with any other commercially available HPLC components.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

5

Page 14

1 Introduction

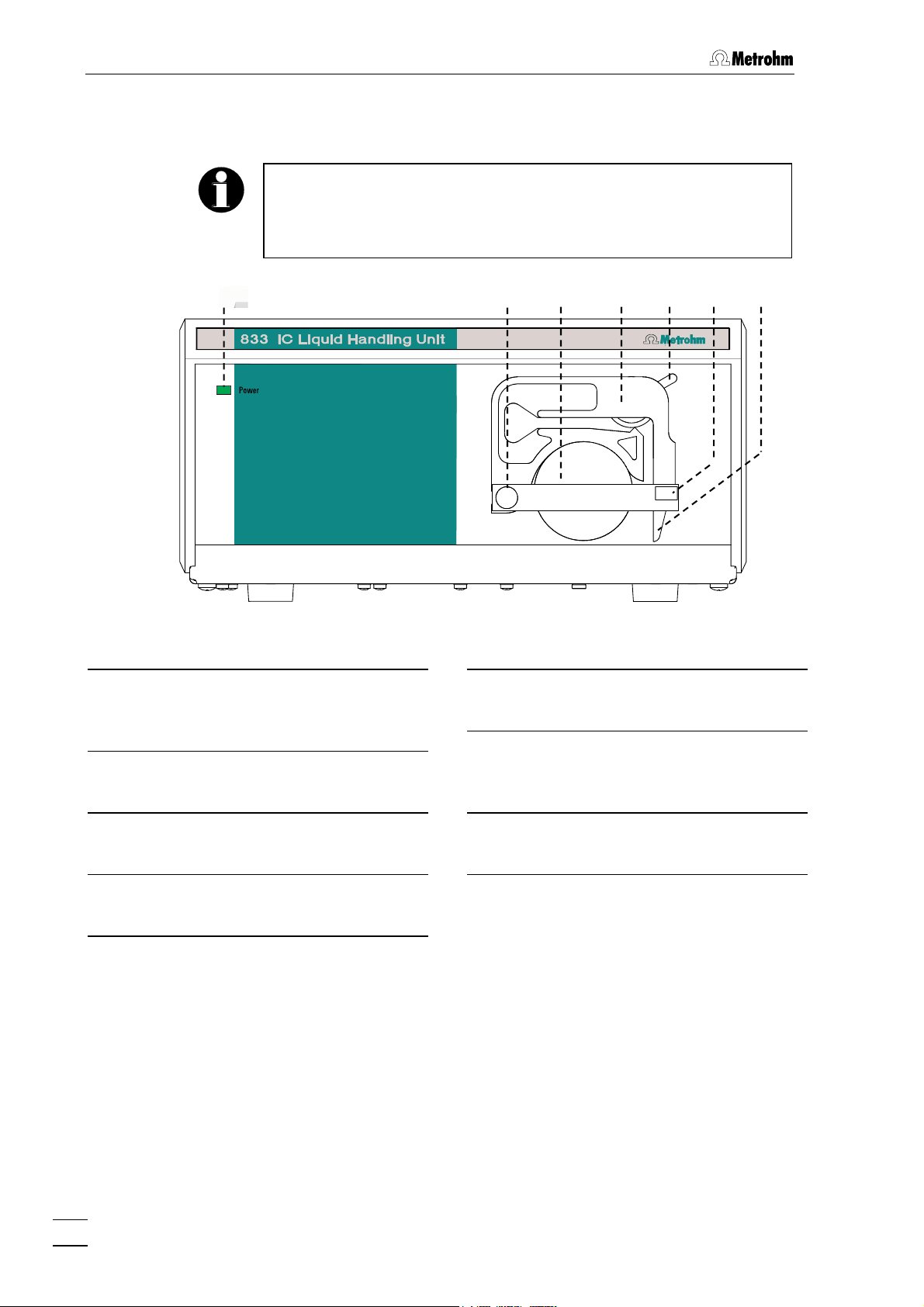

1.2 Parts and controls

In this section you will find the numbers and names of the parts and

controls of the 833 IC Liquid Handling Unit. The numbering is valid for

the whole of these Instructions for Use, i.e. bold numbers in the text

(e.g.

9

) refer to the parts and controls shown here.

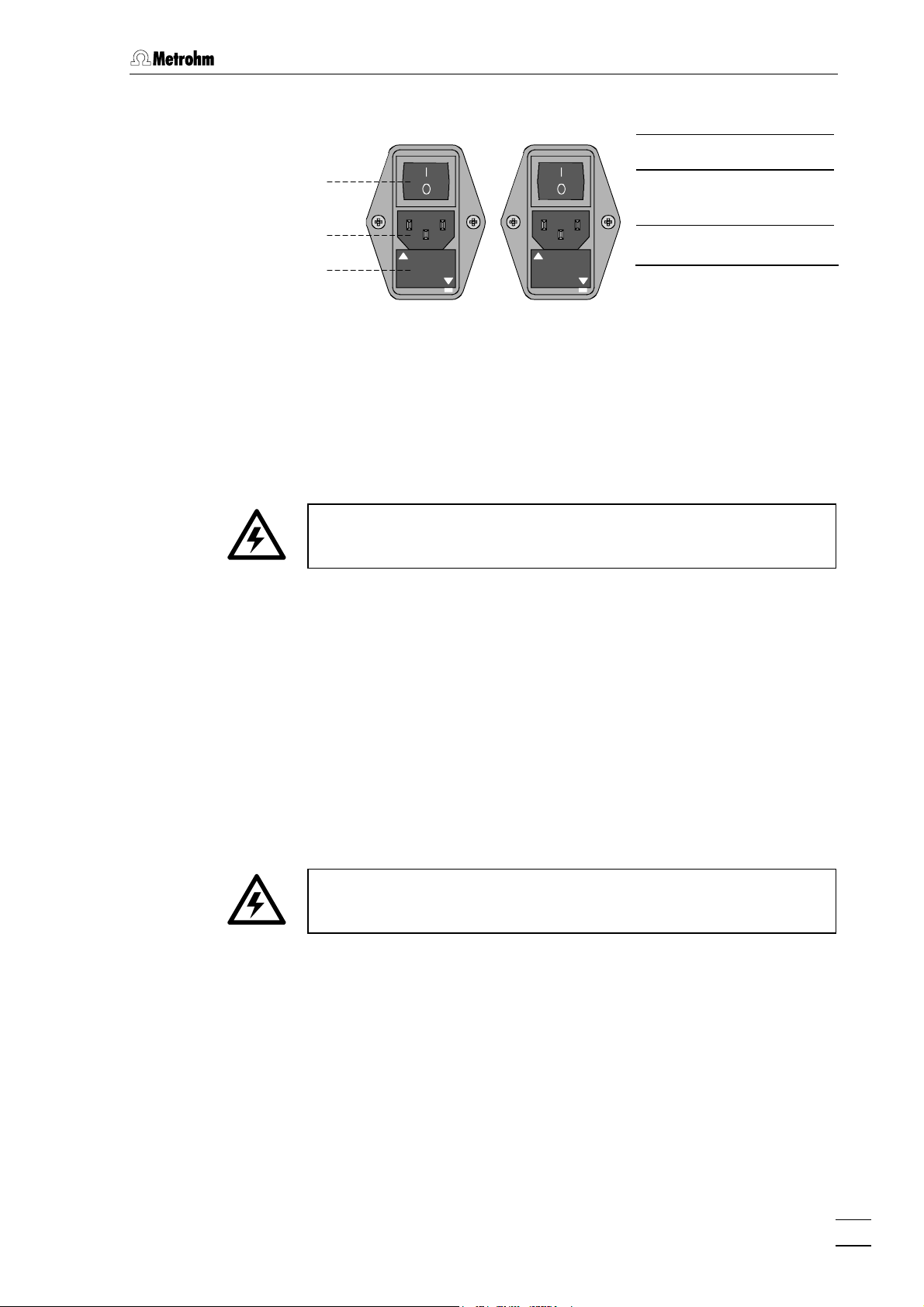

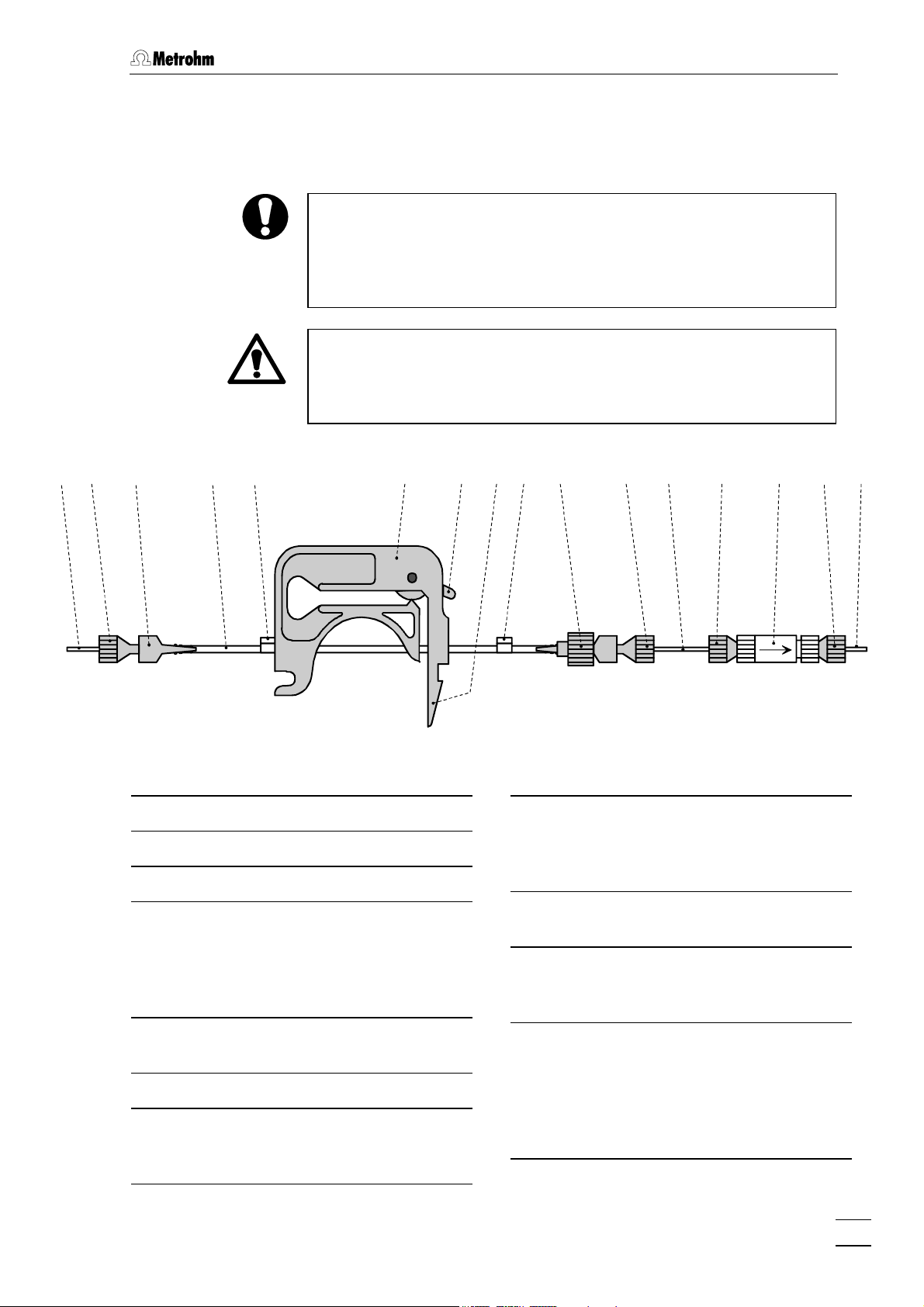

Fig. 1: Front panel of 833 IC Liquid Handling Unit

Mains lamp

1

Lights up when instrument is switched

on

Holding pin

2

For inserting the tubing cassettes

32 4 5 6

Contact lever

5

For controlling the contact pressure

Holding clip

6

For clicking the tubing cassette in

place

7

Pump drive

3

Roller head with contact rollers

Tubing cassette

4

For 6.1826.0X0 Pump tubing

6

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Spring lever

7

For releasing the tubing cassette

Page 15

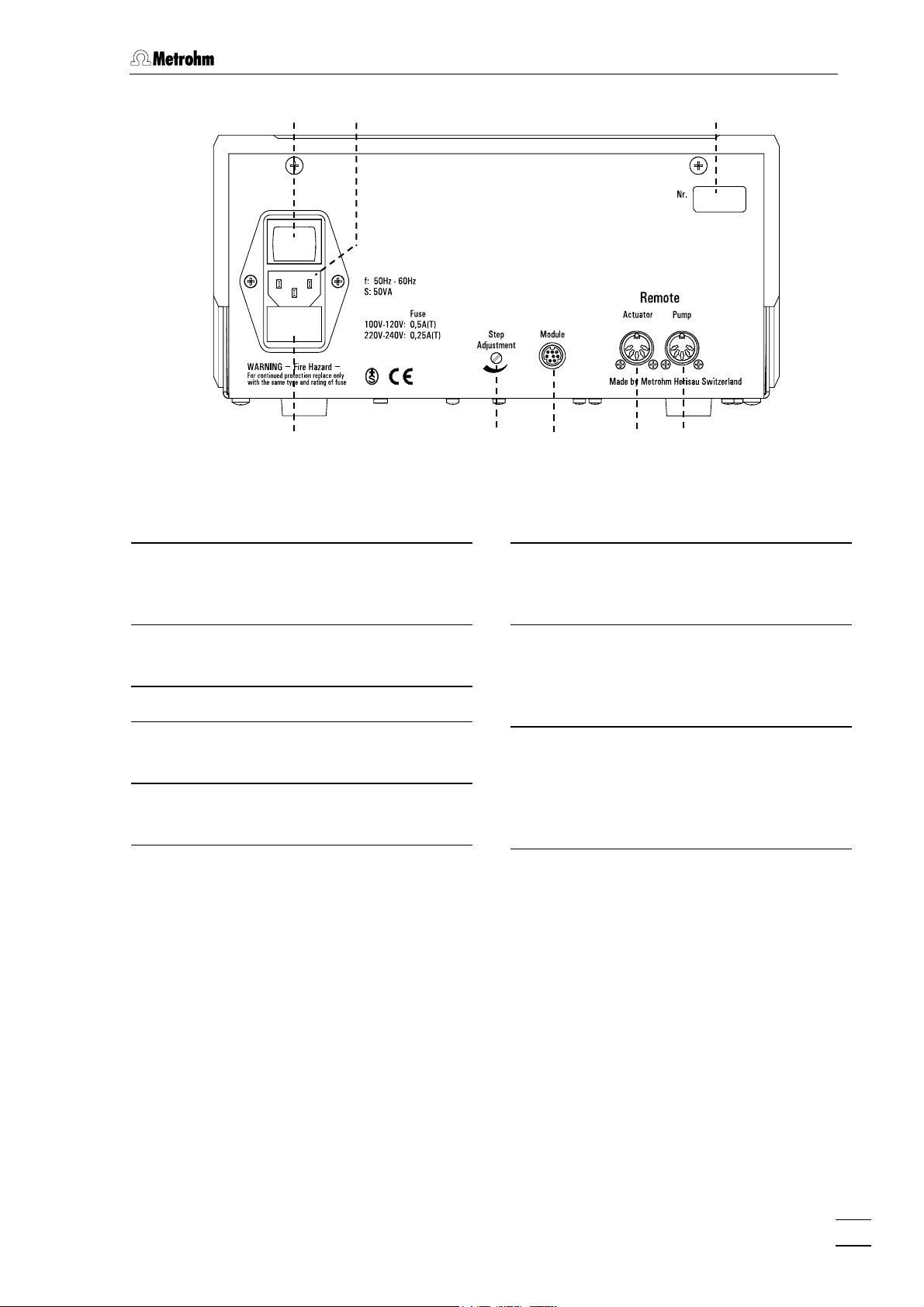

1.2 Parts and controls

8

9

11

Fig. 2: Rear panelof 833 IC Liquid Handling Unit

Mains switch

8

Switch for switching instrument on/off:

I = ON 0 = OFF

12 13 14

Module

13

Connection for suppressor module

and sample preparation module

10

15

Mains connection

9

Mains connection: see Section 2.2

Serial number

10

Fuse holder

11

Changing the fuses: see Section 2.2.2.

Step adjustment

12

Adjusts the actuator rotor

REMOTE actuator

14

Remote interface for actuator

Connection to 761 Compact IC, 819 IC

Detector or 830 IC Interface

REMOTE pump

15

Remote interface for pump

Connection to 761 Compact IC,

732/819 IC Detector or 762/830 IC

Interface

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

7

Page 16

1 Introduction

1.3 Information about these Instructions for Use

Please read through these Instructions for Use carefully before you

start to use the 833 IC Liquid Handling Unit. The instructions contain

information and warnings that must be observed by the user in order

to guarantee the safe use of the instrument.

1.3.1 Arrangement

These 8.833.1003 Instructions for Use for the 833 IC Liquid

Handling Unit provide a comprehensive overview of the installation,

start-up, operation and technical specifications of this instrument. They

are arranged in the following way:

Sect. 1 Introduction

General description of the instrument, numbers and

names of the parts and controls, safety information

Sect. 2 Installation

Instrument setup, mains connection

Sect. 3 Basic instrument

Instrument connection, mounting the pump tubing,

control via «IC Net»

Sect. 4 833 IC Liquid Handling Pump Unit

Instrument connection

Sect. 5 833 IC Liquid Handling Suppressor Unit

Instrument connection, suppressor module handling

Sect. 6 833 IC Liquid Handling Sample Preparation Unit

Instrument connection to modular system for cation

separation and modular system for neutralization, sample

preparation module handling

Sect. 7 833 IC Liquid Handling Dialysis Unit

Instrument connection to modular system with manual

sample injection, dialysis procedure, dialysis optimization

Sect. 8 833 IC Liquid Handling Ultrafiltration Unit

Instrument connection, general information about filtration

Sect. 9 Troubleshooting -

Troubleshooting and remedies, care and maintenance

Sect. 10 Appendix

Technical data, standard equipment, options, warranty,

conformity declarations, index

Please use either the Table of Contents or the Index to find any

information you may require.

8

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 17

1.3 Information about these Instructions for Use

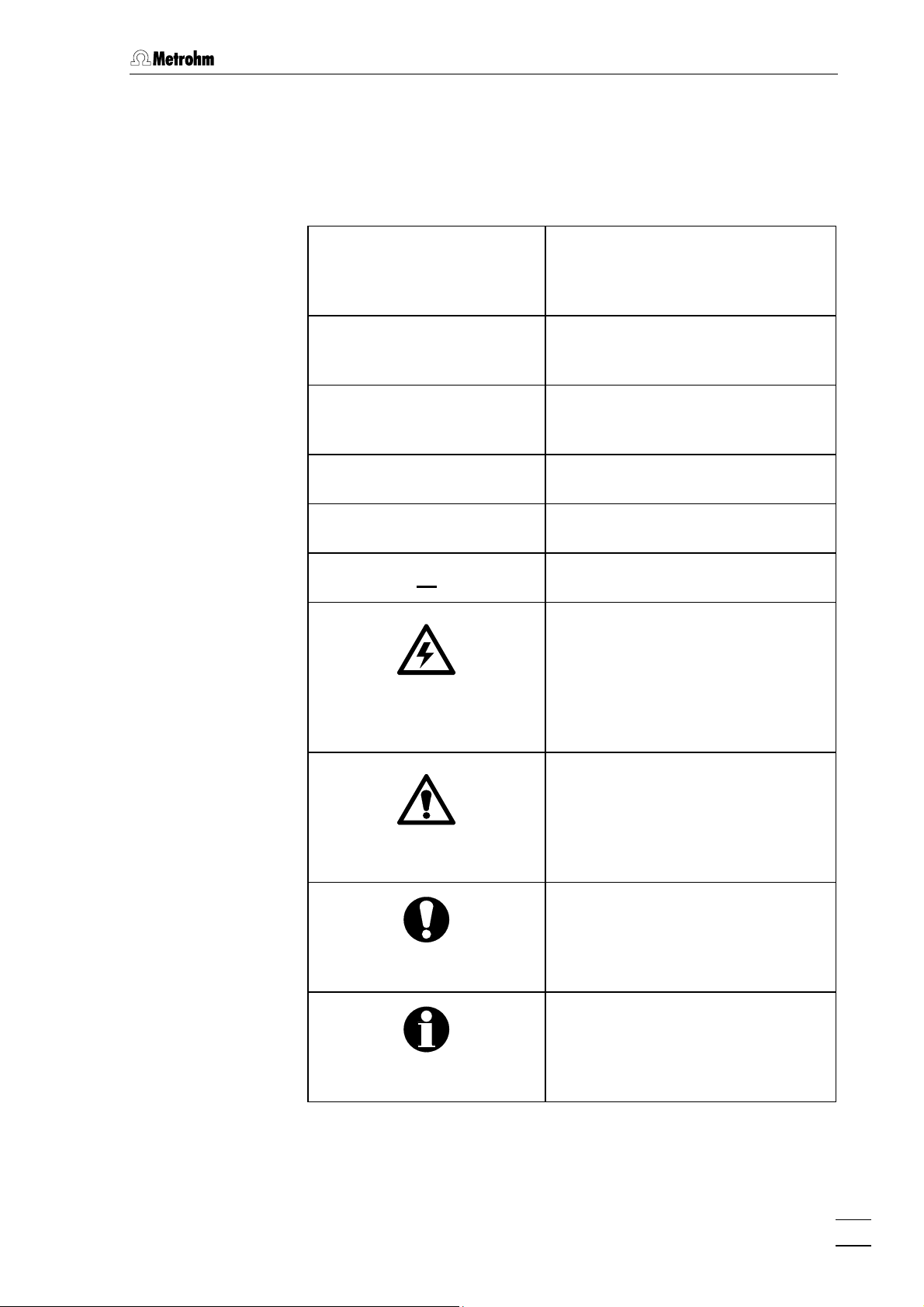

1.3.2 Notation and pictograms

The following notation and pictograms (symbols) are used in these

Instructions for Use:

Pump Menu item, parameter or input

value

in «IC Net» program

SYSTEM STATE Program window

in «IC Net» program

<OK> Button

in «IC Net» program

[ RUN/STOP ] Switch or key

10 Part or control of 833

14 Part or control of 819/820

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components by

electric current.

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components.

Attention

This symbol indicates important

information that you should read

before continuing.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Information

This symbol indicates additional

information and tips which may be

of particular use to you.

9

Page 18

1 Introduction

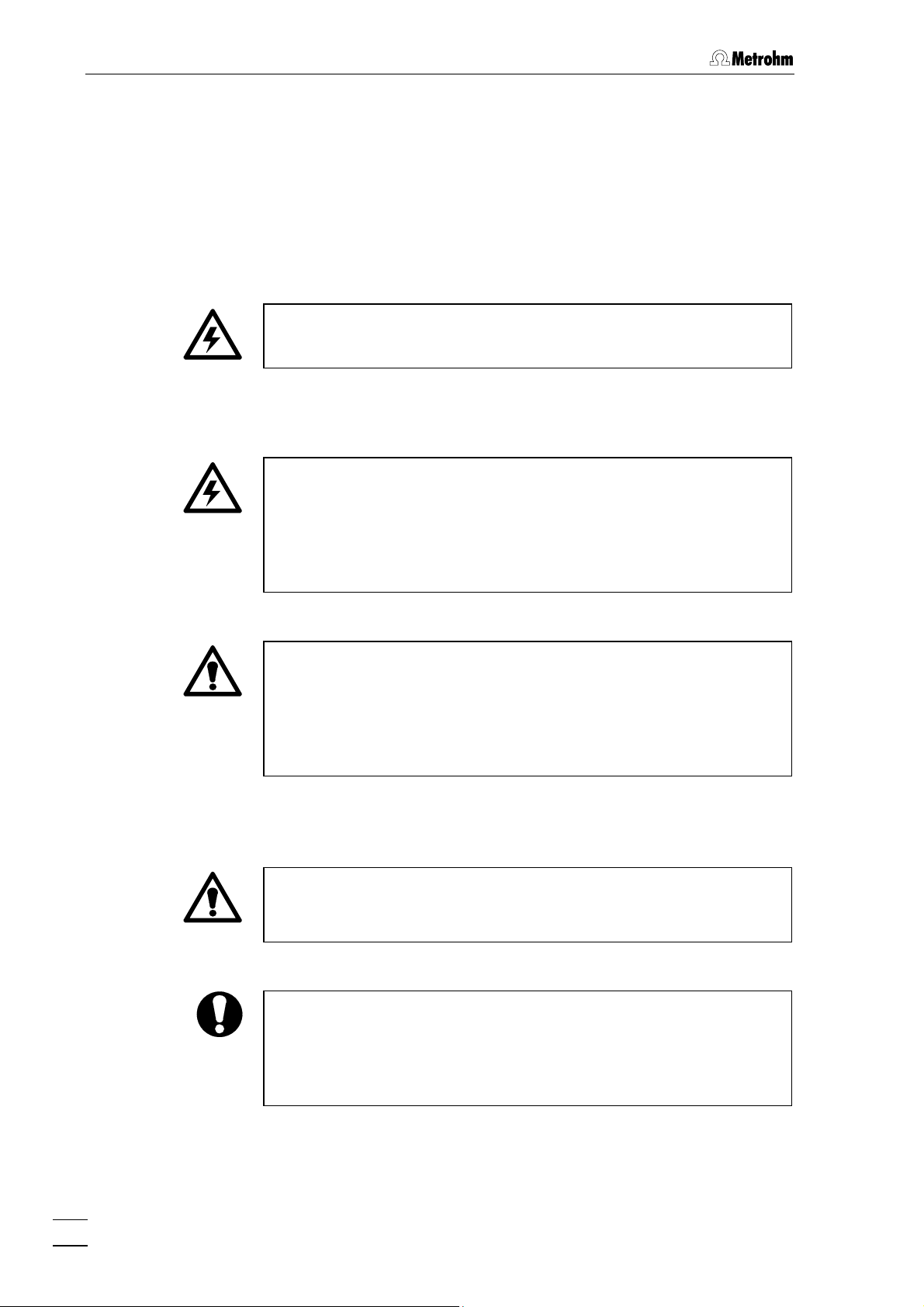

1.4 Safety information

1.4.1 Electrical safety

Electrical safety when handling the 833 IC Liquid Handling Unit is

guaranteed within the scope of Standard IEC 1010-1 (protection class

1, protection code IP40). The following points must be observed:

• Mains connection

The mains connection must be made in accordance with the

instructions given in Section 2.2.

• Opening the instrument

The housing contains no components which could be set or adjusted

by the user .

When the 833 IC Liquid Handling Unit is connected to the mains

supply the instrument must not be opened, nor should any of its

components be dismantled as otherwise you could come into contact

with current-carrying components. Before opening the instrument

separate it from all current sources and make sure that mains cable

9

has been removed from mains connection socket

!

• Protection against electrostatic charges

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Before you touch any electronic

components of the 833 IC Liquid Handling Unit you should ground

you and your tools by grasping a grounded object (e.g. the instrument

housing or a radiator) in order to eliminate any electrostatic charges

that may be present.

1.4.2 General safety rules

• Solvent handling

Check the pump tubing and inlet and outlet connections for leaks at

regular intervals. Observe the relevant regulations when handling and

disposing of flammable and/or toxic solutions.

• Regular replacement of pump tubing

Pump tubing is a consumable and must be replaced from time to

time (see Section 9.2.4). Take suitable measures to ensure that any

leak in the pump tubing or connections during unattended and

continuous operation cannot cause any damage (placing the

instrument in a low position, collection trough for escaping liquid).

10

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 19

2.1 Instrument setup

2 Installation

2.1 Instrument setup

2.1.1 Packaging

The 833 IC Liquid Handling Unit and its separately packed accessories

are supplied in very protective special packaging. These contain

impact-absorbing plastic foam linings contained inside a blue plastic

film; these are molded to fit the individual components. The instrument

itself is contained in a dustproof evacuated polyethylene bag. Please

store all this special packaging; it is the only way in which the safe

transport of the instrument can be guaranteed.

2.1.2 Checks

Please check that the delivery is complete and undamaged

immediately on receipt (compare with delivery note and list of

accessories given in Section 10.2). If transport damage is evident

please refer to the information given in Section 10.5.1 "Warranty".

2.1.3 Location

Place the instrument on a vibration-free bench in a favorable position

for operation and protected from corrosive atmospheres and

contamination by chemicals.

2.1.4 Arranging the instruments

Other IC instruments (e.g. 818, 819, 820) can be stacked on top of the

833 IC Liquid Handling Unit. It is best to place it beside the modular IC

system or at the bottom of the stack.

The 833 IC Liquid Handling Unit should always be at the bottom so

that any leaks which may occur in the pump tubing or connections

cannot cause any great damage by escaping liquids (e.g. acids).

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

11

Page 20

2 Installation

2.2 Mains connection

Please observe the following rules when connecting the instrument to

the electricity supply. If the instrument is operated with an incorrectly

set mains voltage and/or an incorrect mains fuse then it represents a

fire hazard!

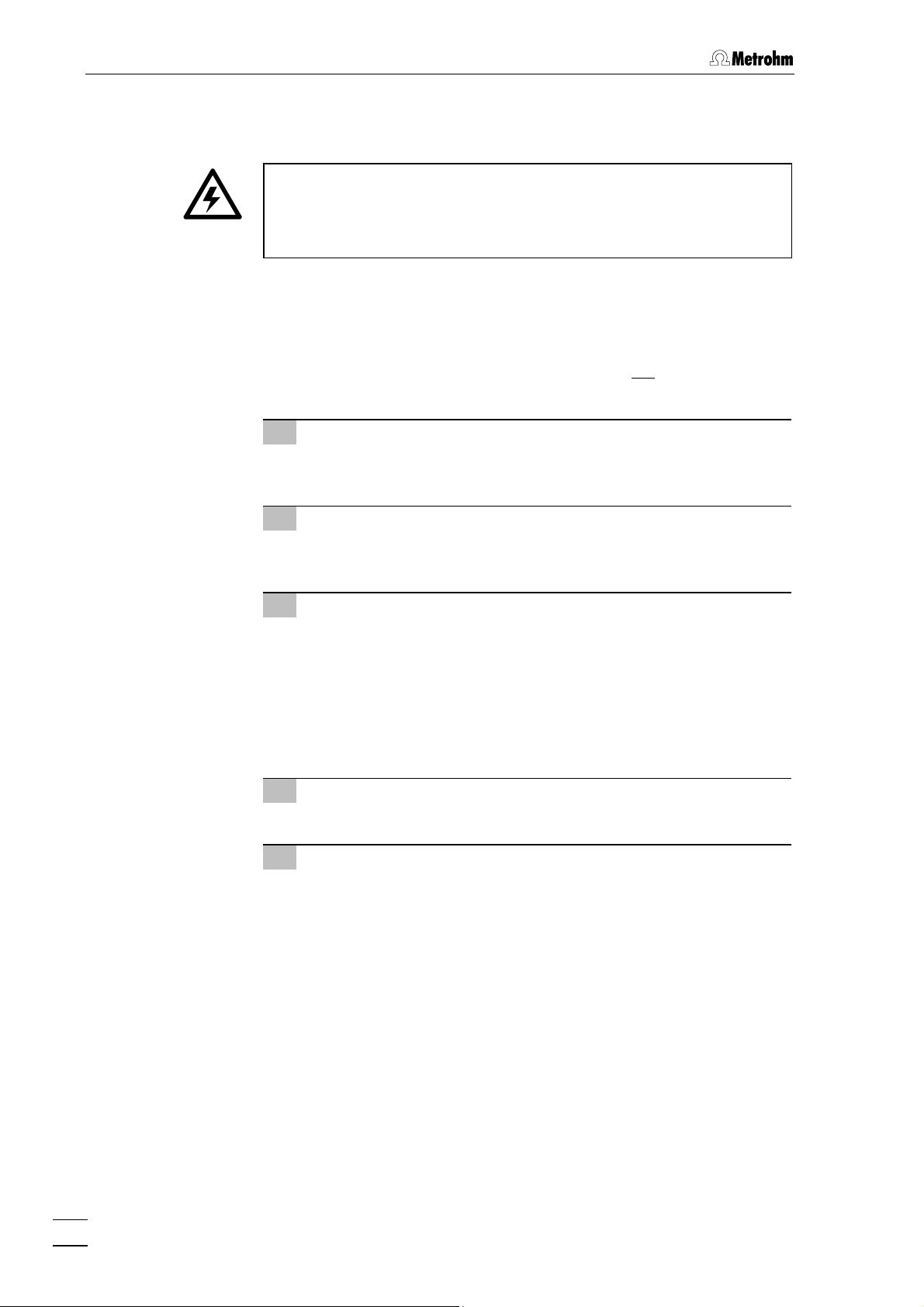

2.2.1 Setting the mains voltage

Before you switch on the 833 Liquid Handling Unit for the first time

please check that the mains voltage set on the instrument (see Fig. 3)

corresponds to your local mains voltage. If this is not

must alter the mains voltage as follows:

1 Pull out mains cable

Remove the mains cable from mains supply connection 9 of the

833 IC Liquid Handling.

the case then you

2 Remove the fuse holder

Use a screwdriver to loosen fuse holder 11 beneath the mains

supply connection and remove it completely.

3 Check the fuse

Carefully remove the built-in fuse for the intended voltage from

the fuse holder and check its specifications (the position of the

fuse in the fuse holder is indicated by the white arrow beside the

voltage range):

100…120 V 0.5 A (slow blow) Metrohm No. U.600.0013

220…240 V 0.25 A (slow blow) Metrohm No. U.600.0010

4 Insert fuse

Exchange the fuse if necessary and replace it in the fuse holder.

5 Insert fuse holder

Depending on the required mains voltage, insert the fuse holder

in the 833 IC Liquid Handling Unit 833 so that the appropriate

voltage range can be read normally and the adjacent white

arrow points to the white bar printed beneath the fuse holder

(see Fig. 3).

12

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 21

2.2 Mains connection

–

V

V

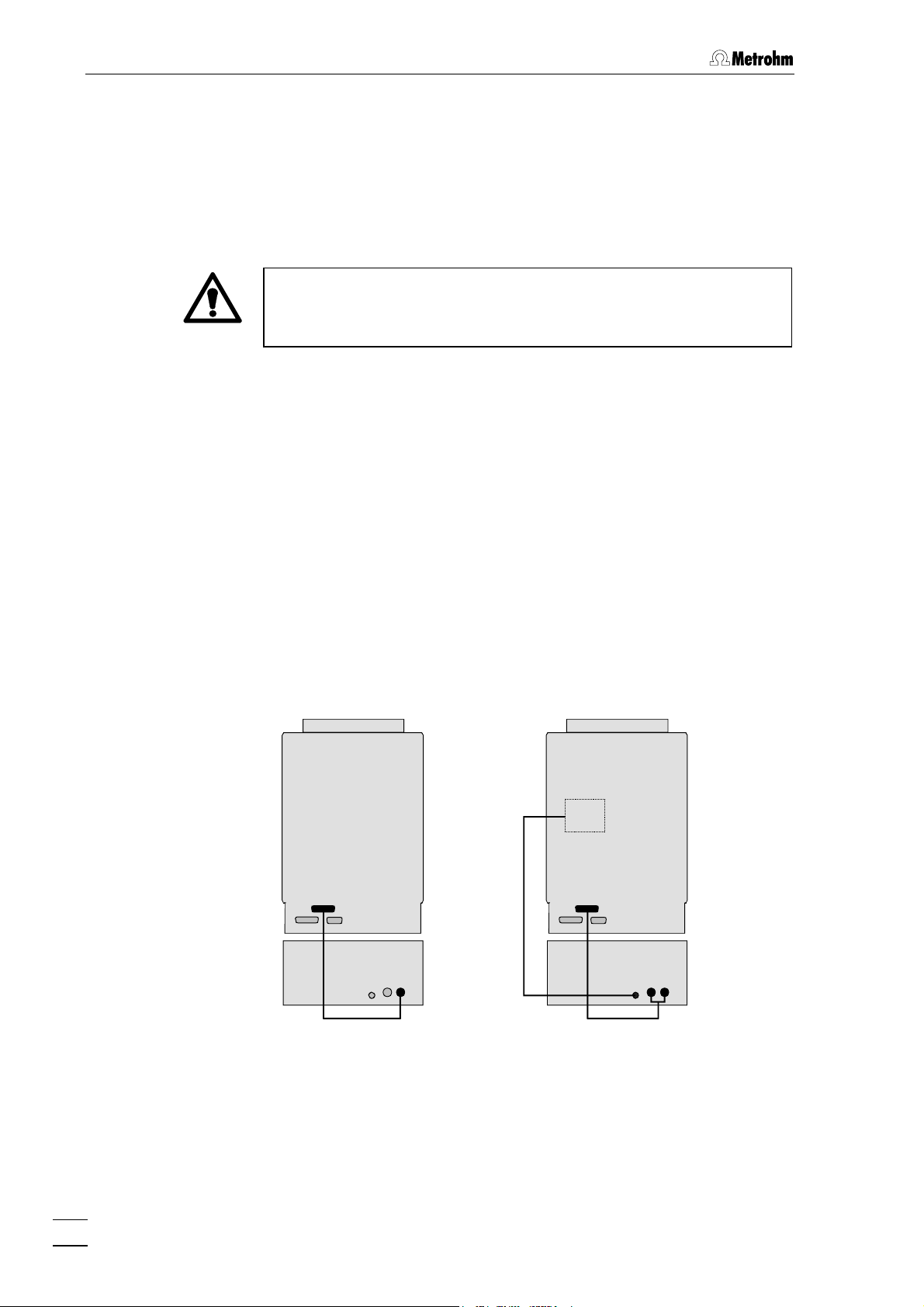

Fig. 3: Setting the mains voltage

2.2.2 Fuses

220 –240

100

120

8 Mains switch

8

9 Mains

connection

9

11

220 - 240 V

100 - 120 V

-

220

240 V

-

100

120 V

11 Fuse holder

The fuse holder of the 833 IC Liquid Handling Unit contains one of the

two fuses 0.5 A/slow blow for 100…120 V or 0.25 A/slow blow for

220…240 V.

Make sure that the instrument is never operated with a different type of

fuse as otherwise it represents a fire hazard!

Checking and replacing a fuse is described in Section 2.2.1.

2.2.3 Mains cable

The instrument is supplied with one of the following mains cables:

• 6.2122.020 with SEV 12 plug (Switzerland, …)

• 6.2122.040 with CEE(7), VII plug (Germany, …)

• 6.2133.070 with NEMA 5-15 (USA, …)

which has 3 wires and is fitted with a plug with a grounding pin. If a

different plug has to be attached then the yellow/green wire (IEC

standard) must be connection to the grounding pin.

Any break in the grounding inside or outside the instrument will make

it dangerous!

Insert the mains cable plug in mains connection 9 of the 833 IC Liquid

Handling Unit (see Fig. 2).

2.2.4 Switching the instrument on/off

The 833 IC Liquid Handling Unit is switched on and off with mains

switch 8 (see Fig. 2). When the instrument is switched on mains lamp 1

lights up.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

13

Page 22

3 Basic instrument

3 Basic instrument

3.1 Electrical connection

Always switch off the 833 IC Liquid Handling Unit and the instrument

to which the Liquid Handling Unit is to be connected before you make

an electrical connection.

The 833 Liquid Handling Unit can be operated and remotely controlled

by a 761 Compact IC, an 819 IC Detector and in a modular system

via the 830 IC Interface.

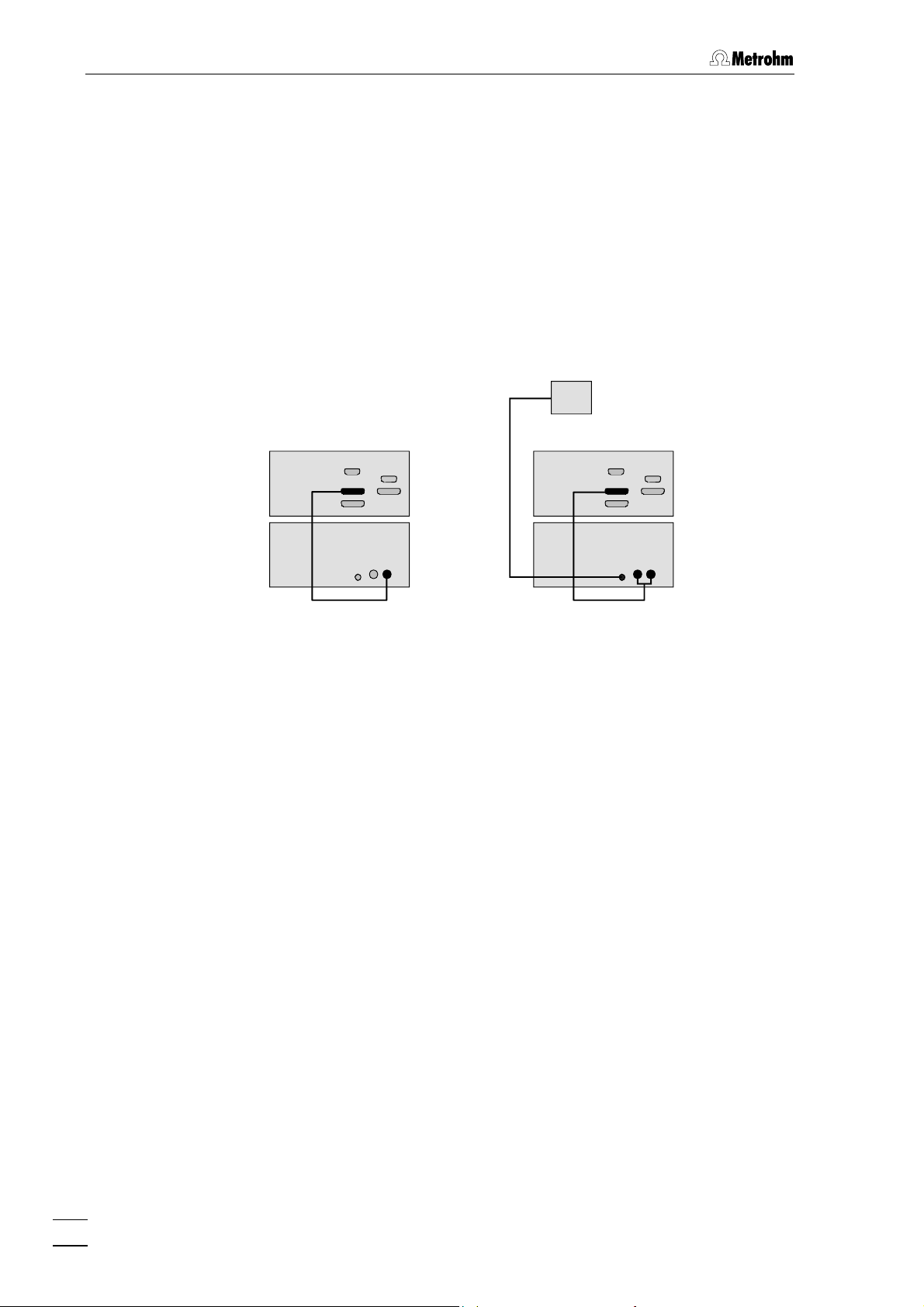

3.1.1 Connecting to 761 Compact IC

Connect the remote connection of the 761 Compact IC with the

required remote connections 14 and 15 on the 833 IC Liquid Handling

Unit. The peristaltic pump of the Liquid Handling Unit is controlled via

remote connection Remote Pump 15, this must always be connected.

The connection Remote Actuator 14 is only required for the 833 IC

Liquid Handling Suppressor Unit and the 833 IC Liquid Handling

Sample Preparation Unit; it is used to switch the suppressor or

sample preparation module. The particular modules are connected

to the socket Module 13.

761

833

816

Cable

to

Module

761

833

816

6.2143.200

6.2143.210

Fig. 4: Connecting the 833 IC Liquid Handling Unit to 761 Compact IC

14

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 23

3.1 Electrical connection

The following cables are available for these connections:

• 6.2143.200 Cable for one remote connection via

Remote line 1.

To connect a Liquid Handling Unit with a peristaltic pump, e.g.:

2.833.0010 IC Liquid Handling Pump Unit

2.833.0050 IC Liquid Handling Ultrafiltration Unit

• 6.2143.210 Cable for two remote connections via

Remote lines 1 and 2.

To connect a Liquid Handling Unit with a peristaltic pump and a

suppressor or sample preparation module, e.g.:

2.833.0020 IC Liquid Handling Suppressor Unit

2.833.0030 IC Liquid Handling Sample Preparation Unit

or

To connect two peristaltic pumps, e.g. for dialysis:

2.833.0010 IC Liquid Handling Pump Unit

2.833.0040 IC Liquid Handling Dialysis Unit

• 6.2143.220 Cable for three remote connections via

Remote lines 1, 2 and 4.

To connect up to three Liquid Handling Units, e.g. for dialysis with

suppression:

2x 2.833.0010 IC Liquid Handling Pump Unit

and 1x 2.833.0040 IC Liquid Handling Dialysis Unit

(three peristaltic pumps are switched on and off)

or

Ultrafiltration with suppression

1x 2.833.0020 IC Liquid Handling Suppressor Unit

and 1x 2.833.0050 IC Liquid Handling Ultrafiltration Unit

(two peristaltic pumps are switched on and off

and the sample preparation module is switched

on)

The remote line via which the control of the Liquid Handling Unit takes

place is determined by the wiring of the cable. The active remote line is

printed on the 833-end of the cable. This remote line must be set

accordingly in the control software «761 Compact IC» or «IC Net», see

Section 4.3.7 In the «761 Compact IC» Instructions for Use and Section

6.5.3 in the «IC Net» Instructions for Use.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

15

Page 24

3 Basic instrument

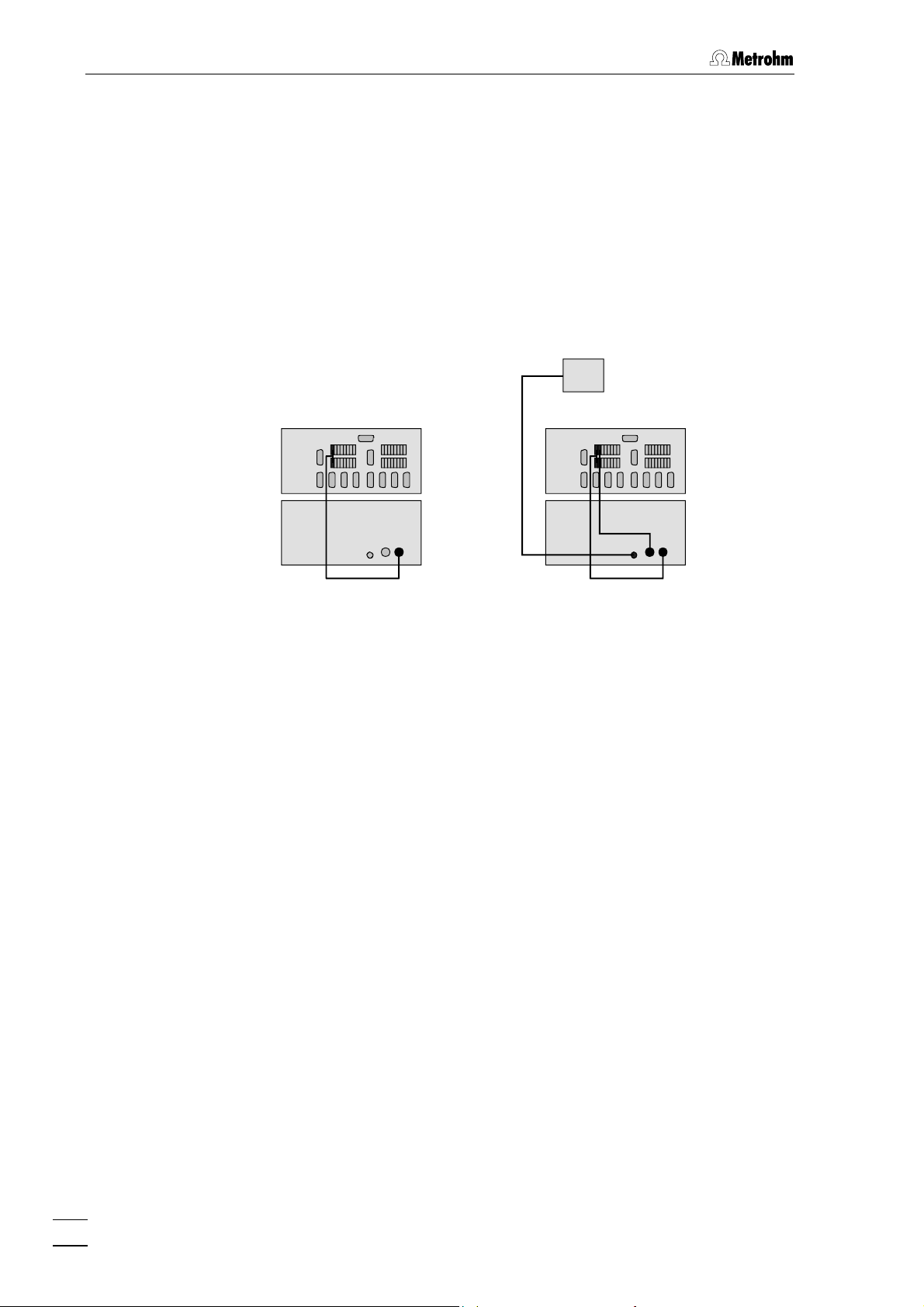

3.1.2 Connecting to 819 IC Detector

Connect the remote connection of the 819 IC Detector to the necessary

remote connections 14 and 15 on the 833 IC Liquid Handling Unit. The

peristaltic pump of the Liquid Handling Unit is controlled via remote

connection Remote Pump 15, this must always be connected. The

connection Remote Actuator 14 is only required for the 833 IC Liquid

Handling Suppressor Unit and the 833 IC Liquid Handling Sample

Preparation Unit; it is used to switch the suppressor or sample

preparation module. The particular modules are connected to the

socket Module 13.

819 819

833

816

6.2143.200

Cable

to

Module

833

816

6.2143.210

Fig. 5: Connecting the 833 IC Liquid Handling Unit to 819 IC Detector

The following cables are available for these connections:

• 6.2143.200 Cable for one remote connection via

Remote line 1.

To connect a Liquid Handling Unit with a peristaltic pump, e.g.:

2.833.0010 IC Liquid Handling Pump Unit

2.833.0050 IC Liquid Handling Ultrafiltration Unit

• 6.2143.210 Cable for two remote connections via

Remote lines 1 and 2.

To connect a Liquid Handling Unit with a peristaltic pump and a

suppressor or sample preparation module, e.g.:

2.833.0020 IC Liquid Handling Suppressor Unit

2.833.0030 IC Liquid Handling Sample Preparation Unit

or

To connect two peristaltic pumps, e.g. for dialysis:

2.833.0010 IC Liquid Handling Pump Unit

2.833.0040 IC Liquid Handling Dialysis Unit

16

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 25

3.1 Electrical connection

• 6.2143.220 Cable for three remote connections via

Remote lines 1, 2 and 4.

To connect up to three Liquid Handling Units, e.g. for dialysis with

suppression:

2x 2.833.0010 IC Liquid Handling Pump Unit

and 1x 2.833.0040 IC Liquid Handling Dialysis Unit

(three peristaltic pumps are switched on and off)

or

Ultrafiltration with suppression

1x 2.833.0020 IC Liquid Handling Suppressor Unit

and 1x 2.833.0050 IC Liquid Handling Ultrafiltration Unit

(two peristaltic pumps are switched on and off

and the sample preparation module is switched

on)

The remote line via which the control of the Liquid Handling Unit takes

place is determined by the wiring of the cable. The active remote line is

printed on the 833-end of the cable. This remote line must be set

accordingly in the control software «IC Net», see Section 6.4.3 of the

«IC Net» Instructions for Use.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

17

Page 26

3 Basic instrument

3.1.3 Connecting to 830 IC Interface

Connect one of the event lines of the 830 IC Interface with one of the

required remote connections 14 and 15 on the 833 IC Liquid Handling

Unit. The peristaltic pump of the Liquid Handling Unit is controlled via

remote connection Remote Pump 15, this must always be connected.

The connection Remote Actuator 14 is only required for the 833 IC

Liquid Handling Suppressor Unit and the 833 IC Liquid Handling

Sample Preparation Unit; it is used to switch the suppressor or

sample preparation module. The particular modules are connected

to the socket Module 13.

830

833

816

Cable

to

Module

6.2128.180

830

833

816

6.2128.180

6.2128.180

Fig. 6: Connecting the 833 IC Liquid Handling Unit to 830 IC Interface

For each remote connection one 6.2128.180 Cable is required. At the

830 IC Interface 2 × 7 remote connections can be assembled. Which

event lines are used for this does not matter; when a system is set up

the assignment must only be given correctly in the «IC Net» software

when creating a system, see Section 6.1 of the «IC Net» Instructions for

Use.

18

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 27

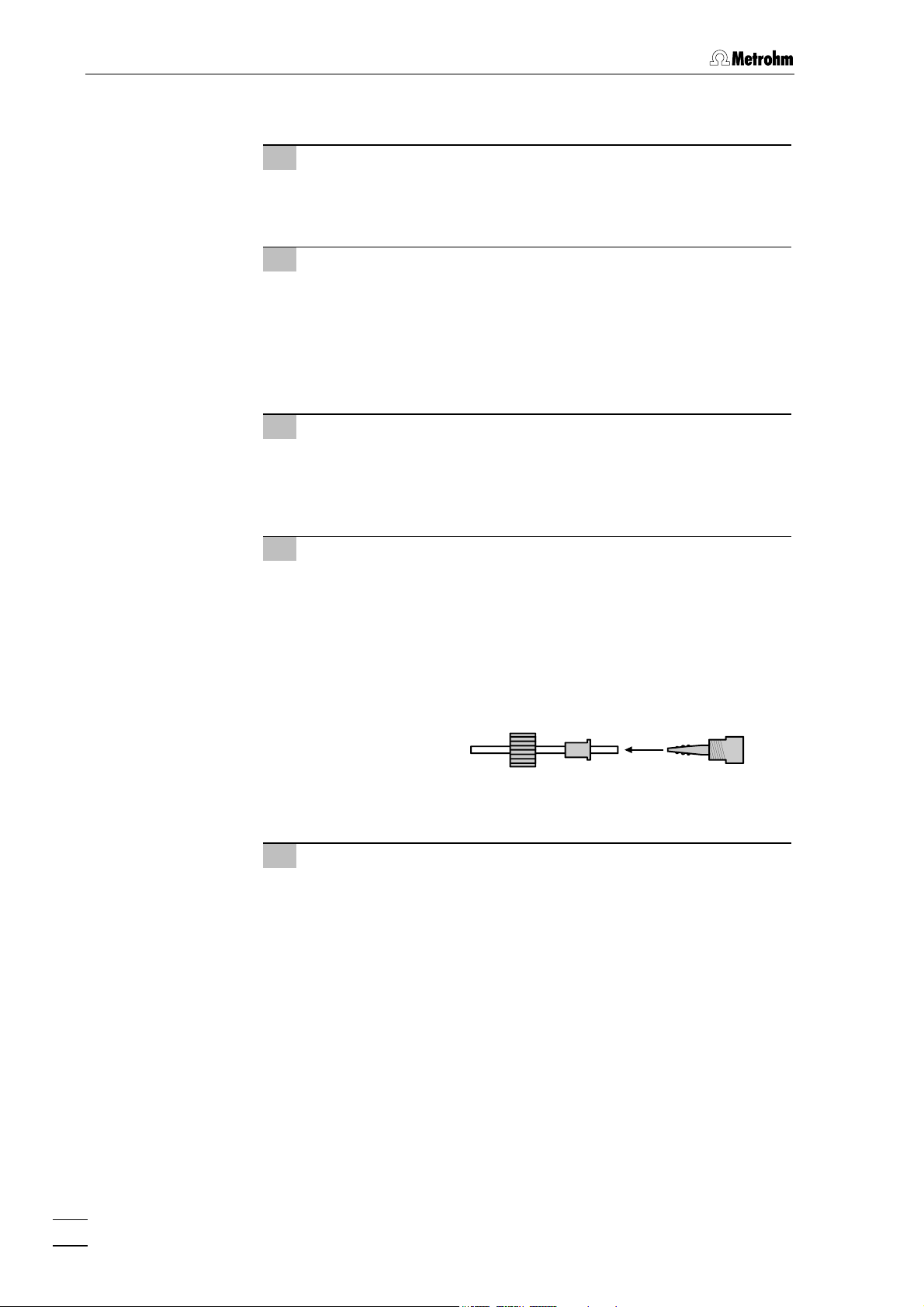

3.2 Assembly the pump tubing

3.2 Assembly the pump tubing

Pump tubing is a consumable whose working life depends on the

contact pressure. This is why when the pump is switched off for a long

time, the tubing cassette should be lifted by fully loosening spring

lever

7

on the right-hand side (in this way the correctly set optimal

contact pressure is retained).

The 6.1826.0X0 Pump tubing consists of PVC or PP and must

therefore not be rinsed with solvents that contain acetone. In this case

you should either use different pump tubing or use a different pump

for rinsing.

18 17 16 4 519

Tubing cassette

4

Contact lever

5

Spring lever

7

6.1803.0X0 Aspiration

16

tubeing/capillary

PTFE tubing/capillary, depends on

version, see Section 10.2 Standard

equipment

20 22 21 20 17

Fig. 7: Assembly the pump tubing

7

Stopper

20

The color of the stopper indicates the

material and dimensions of the pump

tubing, see Tab. 1.

6.2744.160 PEEK Coupling

21

with tubing security device

6.2821.120 PEEK Filter unit

22

not contained in all versions, see

Section 10.2 Standard equipment

17 1716

23

6.2744.010 PEEK compression

17

fitting

6.2744.034 PEEK coupling

18

6.1826.0X0 Pump tubing

19

various tubing is available, depending

on the application, see Tab. 1.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Discharge capillary

23

delivery side for connection to:

suppressor module

sample preparation module

dialysis cell

ultrafiltration cell

19

Page 28

3 Basic instrument

1 Remove tubing cassettes

• Loosen the two tubing cassettes 4 by pressing in spring lever

7 of holding clip 6 and unhinge them from holding pin 2 of

the 833 IC Liquid Handling Unit (see Fig. 1).

2 Insert pump tubing

• Press contact lever 5 on the two tubing cassettes down as far

it will go.

• Insert pump tubing into each tubing cassette as shown in

Fig. 7.

Stopper must click into position in the corresponding holder

on the left-hand side of the tubing cassette.

3 Attach tubing cassettes

• Hinge the tubing cassettes on holding pin and press down

on the right –hand side until spring lever clicks into position

in holding clip 6. Take care that the pump tubing does not

kink.

4 Attach coupling to pump tubing

• Attach PEEK coupling 18 to the aspiration end of pump

tubing 19 for both channels (see Fig. 7).

•

Mount PEEK coupling 21 with the tubing security device

(6.2744.160) to the delivery end of pump tubing 19 for both

channels.

This is done by dismantling the tubing security device and

first pushing the sleeve nut and the compression piece onto

the tubing.

Attach the tubing to the PEEK coupling and screw the sleeve

nut onto the coupling in order to secure the tubing.

5 Mounting of filter unit

• If contained in the standard equipment (see Section 10.2

Standard equipment), screw 6.2821.120 PEEK filter unit 22

onto PEEK coupling 21 (6.2744.160) by using two PEEK

compression fittings 17 (6.2744.010) and a piece of

aspiration tubing/capillary 16 (6.1803.0X0) at the delivery end

of pump tubing 19.

Setting the contact pressure correctly:

Press contact lever 5 until the solutions are just aspirated. Then press

the contact lever up by 1 further click to achieve the optimum contact

pressure.

20

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 29

3.2 Assembly the pump tubing

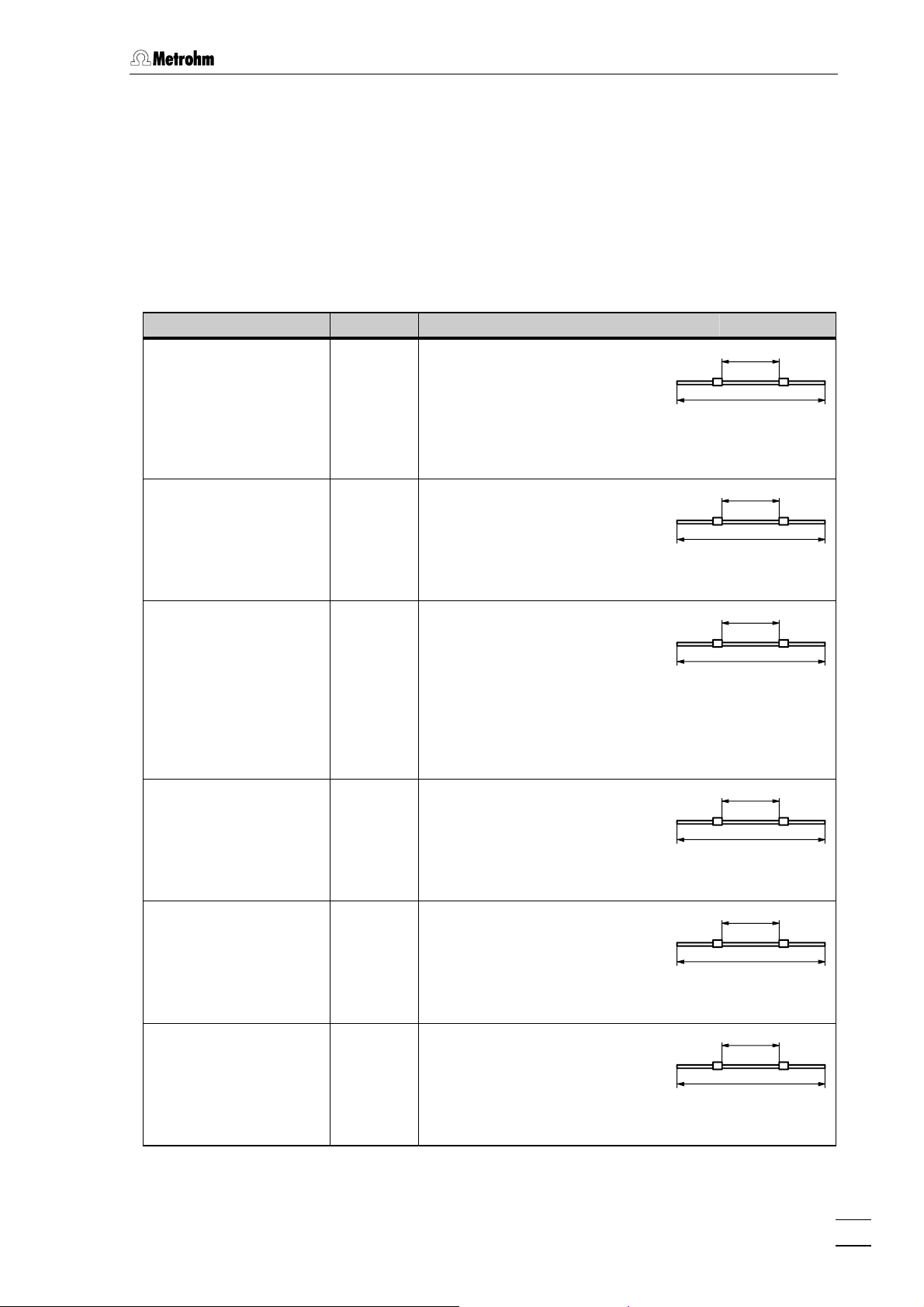

In addition to the correct contact pressure, the delivery rate of the 833

IC Liquid Handling Unit depends primarily on the inner diameter of

pump tubing 19. Different pump tubing can be used depending on the

application.

The following table provides information about the properties and use

of the available pump tubing.

Tab. 1: Using 6.1826.0X0 Pump tubing

Used with Order no. Description

2.833.0030 IC Liquid

Handling Sample

Preparation Unit:

both channels

6.1826.010 Pump tubing

PVC (Tygon

ST) with 2 permanently

mounted white-white stoppers;

i.d. = 1.02 mm ± 0.05 mm,

Delivery rate

1.41 mL/min (20 min

1.69 mL/min (24 min

optional 6.1826.020 Pump tubing

PVC (Tygon

ST) with 2 permanently

mounted blue-blue stoppers;

i.d. = 1.65 mm ± 0.05 mm,

Delivery rate

3.75 mL/min (20 min

4.50 mL/min (24 min

2.833.0040 IC Liquid

Handling Dialysis Unit:

channel for supplying

acceptor solution

2.833.0050 IC Liquid

Handling Ultrafiltration

Unit:

channel for transferring

filtrate to sample loop

2.833.0040 IC Liquid

Handling Dialysis Unit:

channel for supplying

sample

6.1826.030 Pump tubing

PVC (Tygon

ST) with 2 permanently

mounted orange-yellow stoppers;

i.d. = 0.51 mm ± 0.05 mm,

Delivery rate

0.40 mL/min (20 min

0.48 mL/min (24 min

6.1826.040 Pump tubing

PVC (Tygon

mounted black-black stoppers;

i.d. = 0.76 mm ± 0.05 mm,

Delivery rate

ST) with 2 permanently

0.75 mL/min (20 min

0.90 mL/min (24 min

150

-1

)

-1

)

-1

)

-1

)

-1

)

-1

)

-1

)

-1

)

400

150

400

150

400

150

400

2.833.0010 IC Liquid

Handling Pump Unit,

2.833.0020 IC Liquid

Handling Suppressor

Unit:

both channels

6.1826.050 Pump tubing

PVC (Tygon

mounted white-yellow stoppers;

i.d. = 0.57 mm ± 0.05 mm,

Delivery rate

0.52 mL/min (24 min

optional 6.1826.060 Pump tubing

PP (PharMed

mounted orange-yellow stoppers;

i.d. = 0.51 mm ± 0.05 mm,

Delivery rate

0.56 mL/min (24 min

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

ST) with 2 permanently

0.43 mL/min (20 min

) with 2 permanently

0.47 mL/min (20 min

150

-1

)

-1

)

-1

)

-1

)

400

150

400

21

Page 30

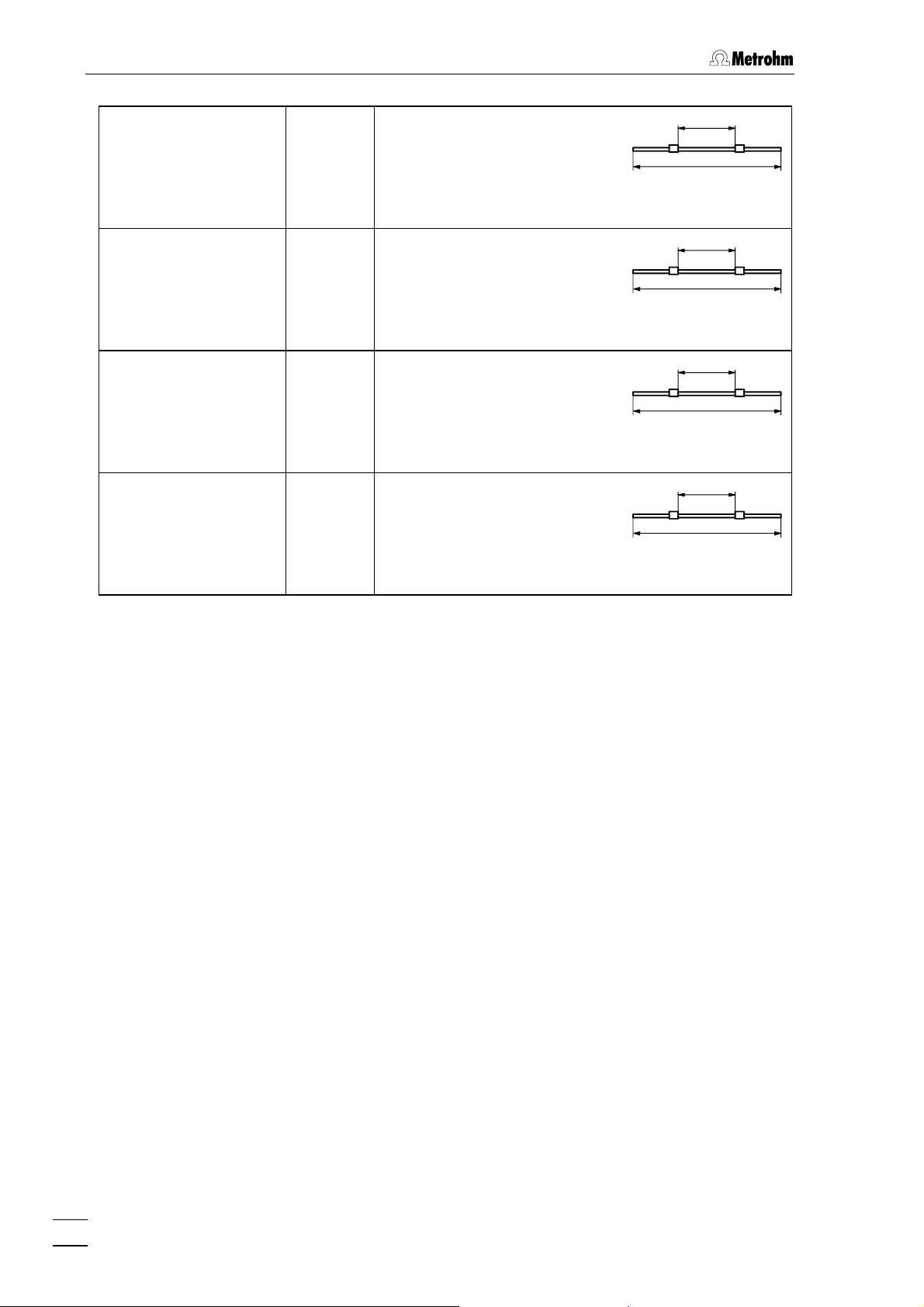

3 Basic instrument

2.833.0050 IC Liquid

Handling Ultrafiltration

Unit:

channel for transferring

sample to ultrafiltration cell

6.1826.070 Pump tubing

PVC (Tygon

ST) with 2 permanently

mounted yellow-yellow stoppers;

i.d. = 1.42 mm ± 0.05 mm,

Delivery rate

2.55 mL/min (20 min

3.06 mL/min (24 min

optional 6.1826.110 Pump tubing long-life

PVC (Tygon

mounted orange-yellow stoppers;

i.d. = 0.51 mm ± 0.0102 mm,

Delivery rate

LFL) with 2 permanently

0.40 mL/min (20 min

0.48 mL/min (24 min

optional 6.1826.120 Pump tubing long-life

PVC (Tygon

mounted orange-white stoppers;

i.d. = 0.59 mm ± 0.05 mm,

Delivery rate

LFL) with 2 permanently

0.44 mL/min (20 min

0.53 mL/min (24 min

optional 6.1826.130 Pump tubing long-life

PVC (Tygon

mounted white-white stoppers;

i.d. = 1.02 mm ± 0.0127 mm,

Delivery rate

LFL) with 2 permanently

1.41 mL/min (20 min

1.69 mL/min (24 min

150

-1

)

-1

)

-1

)

-1

)

-1

)

-1

)

-1

)

-1

)

400

150

400

150

400

150

400

22

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 31

3.3 Operation

R

3.3 Operation

The 833 IC Liquid Handling Unit is operated completely via the

Metrohm «IC Net» software.

This Section only described the most important functions and settings

for operating the 833 IC Liquid Handling Unit. Further information is

given in the Instructions for Use of the «IC Net» and in the online help

for the program.

3.3.1 Switching the instrument on/off

Remote control of the 833 IC Liquid Handling Unit by the software

requires that the instruments has been installed correctly as described

in Section 2.

Switching the instrument on/off

The 833 IC Liquid Handling Unit is switched on and off with

mains switch 8 on the rear panel of the instrument (see Fig. 2):

I Instrument switched on

0 Instrument switched off

POWE

When the instrument has been switched on mains lamp 1 lights

up to show that it is ready for use.

3.3.2 Program settings

The 833 IC Liquid Handling Unit is operated completely via the

Metrohm «IC Net» software.

This section only describes the most important functions and settings

for operating the 833 IC Liquid Handling Unit. Further information is

given in the Instructions for Use of the «IC Net» and in the online help

for the program.

3.3.2.1 833 IC Liquid Handling Unit icon

2.833.00X0 IC Liquid Handling Unit

For differentiating between which version of the 833 is indicated by the

instrument icon a tool tip with the name of the corresponding

instrument appears when the mouse cursor is placed on the particular

icon.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

23

Page 32

3 Basic instrument

3.3.2.2 Settings in the window "833 IC Liquid Handling Unit"

Selection of this menu item with the right-hand mouse key or a doubleclick on the 833 instrument icon opens the window

Unit for parameter settings. It consists of three tabs: Manual, Program

Links.

and

833 IC Liquid Handling

Depending on the version, the title line of the parameter settings

window shows

Preparation Unit

833 IC Pump Unit, 833 IC Suppressor Unit, 833 IC Sample

, 833 IC Dialysis Unit or 833 IC Ultrafiltration Unit and (in

brackets) the name of the system folder and the system file.

Manual

The tab

Manual of the window 833 IC Liquid Handling Unit is used for

manually operating the peristaltic pump and the suppressor or sample

prep module.

Pump (available with all versions)

<On> Start pump drive.

<Off> Stop pump drive.

Suppressor (only available with 833 IC Suppressor Unit)

<Step> Rotate suppressor to the next position. The

time since the last step action is displayed in

the field beside the

Actuator (only available with 833 IC Sample Preparation

Unit)

<Step> Rotate sample preparation module to the next

<Step> button.

position. The time since the last step action is

displayed in the field beside the

24

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

<Step> button.

Page 33

3.3 Operation

Start pump with startup hardware

Automatic start of pump drive with Startup

hardware

.

Time program

A user-specific time program can be entered on the tab

833 IC Liquid Handling Unit window. Depending on the settings made in

Start mode window (for details see Section 4.4.3 8.110.8281

the

Program in the

Instructions for Use for the Metrodata «IC Net 2.3» software), this

program is started automatically either at the start of the determination

(

Start with determination) or when the sample is injected (Start with inject).

Time (1st column) Time at which program instruction is applied.

Entry range:

0.0 ... 999.9 min

If no time is entered, the program instruction is

applied together with the last instruction with

time entry.

Command (2nd. column) Program instruction (see below).

Parameter (3rd column) Parameter for program instruction (see below).

ENABLED Enable program start (a disabled program is

not started).

<Add> Add new program instruction.

<Delete> Delete selected program instruction.

<Verify> Test the time program (error messages are

displayed if program is wrong).

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

25

Page 34

3 Basic instrument

List of program instructions

The following program instructions can be added to the time

program on the

Instruction Parameter entry Meaning

Pump on, off Switch on or off the pump drive.

Step Rotate suppressor or sample prep

Program page:

(available for

all versions)

module to the next position.

(only available for

Unit and 833 IC Sample Prep Unit)

833 IC Suppressor

Links

Links tab of the 833 IC Pump Unit is used for Event line selection (for

The

details see Instructions for Use of «IC Net»).

26

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 35

4.1 Connection of the suppressor module

4 833 IC Liquid

Handling Pump Unit

This version is mainly used for supplying a Metrohm Suppressor

Module MSM built into a 2.820.0X30 IC Separation Center with

regeneration and rinsing solutions. The Metrohm Suppressor Module

MSM is described in detail in Section 2.9.7 of the 819/820 Instructions

for Use.

4.1 Connection of the suppressor module

In order to protect the suppressor module against foreign particles an

inline filter is mounted between the 833 IC Liquid Handling Unit and

the inlet capillary of the suppressor module, see Fig. 7. The most

suitable unit is the 6.2821.120 Filter unit PEEK included in the

standard equipment.

H2SO4

Waste

The suppressor module is connected to the 833 IC Liquid Handling

Pump Unit in accordance with Section 2.9.7 of the 819/820 Instructions

for Use. The most important points are described again below, with

underlined numbers ##

819/820 Instructions for Use:

Eluent

64

65

66

1

2

3

67

Waste

69

68

referring to the parts and controls in the

64

Suppressor inlet

capillary for eluent

65 Suppressor inlet

Detector

H2O

capillary for H

66 Suppressor outlet

capillary for H

67 Suppressor outlet

capillary for H

68 Suppressor inlet

capillary for H

69 Suppressor outlet

capillary for eluent

2SO4

2SO4

2

2

O

O

Fig. 8: Connections to suppressor module of 820 Separation Center

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

27

Page 36

4 833 IC Liquid Handling Pump Unit

1 Connect column to injector

• Remove end caps from column 53.

• without column heating:

Screw inlet end of separating column 53

to column connection capillary 50

(note flow direction)

mounted on the injector.

• with column heating:

Prepare column heating according to Section 2.9.2 of the

819/820 Instructions for Use and screw column connection

capillary 50

compression fitting to injection valve 51

(see Fig. 20, 819/820 Instructions for Use) with a

.

• With precolumn:

Install precolumn according to the supplied leaflet between

inlet of the separating column and the injection valve.

2 Rinse column

• Place a beaker beneath the column outlet.

• Start 818 IC Pump in «IC Net» with suitable flow (see leaflet of

the column) and rinse column for ca. 10 min with eluent.

• Stop 818 IC Pump.

3 Connect column to suppressor module (Suppressor

connection 1)

• Cut inlet capillary 64

module 70

to the required length. Use the 6.2126.080

(marked with "Eluent") of suppressor

Capillary cutter available as an option.

• without column heating

Screw inlet capillary 64

column 53

using a 6.2744.010 compression fitting.

on to the outlet end of separating

• with column heating

Connect capillary 52

at the outlet of the separating column

(see Fig. 20, 819/820 Instructions for Use) to the inlet

capillary 64

using the 6.2744.040 Coupling.

4 Fix column

• without column heating

Insert one or two column holders 59

or 6.2027.050) in the mounting rails 58

(6.2027.030, 6.2027.040

and fasten separating

column in the column holder.

• with column heating

Insert column heating according to Fig. 10 (819/820

Instructions for Use) into the Separation Center.

28

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 37

4.1 Connection of the suppressor module

5 Connect suppressor module to detector block

(Suppressor connection 1)

• Cut outlet capillary 69

module 70

to the required length. Use the 6.2126.080

(marked with “Detector”) of suppressor

Capillary cutter available as an option.

• Screw outlet capillary 69

on to coupling 71 by using a

6.2744.010 Pressure screw.

• Screw inlet capillary 56

end of coupling 71

of detector block 57 on to the other

.

6 Mount pump tubing on 833 Pump Unit

• Mount the two lengths of 6.1826.050 Pump tubing (white-

yellow stopper) with aspirating tube 16 and filter unit PEEK

22 6.2821.120 as described in Section 3.2, see Fig. 7.

7 Suppressor connection 2: H2SO4

• Pull inlet capillary 65 (marked with "H2SO4") by hand as far as

required through one of the feedthroughs 14

to the outside

(see Fig. 23 and Fig.24, 819/820 Instructions for Use).

• Screw the filter unit PEEK contained in the standard

equipment of the 833 IC LH Pump Unit on to PEEK coupling

21 (6.2744.160) as described in Section 3.2 at the outlet end

of the first piece of pump tubing 19.

• Fasten inlet capillary 65

(23 in Fig. 7) to filter unit PEEK

(6.2821.120) by using a compression fitting 17 (6.2744.010)

(see Fig. 7).

• At the inlet end of the first piece of tubing 19 fasten a suitably

long piece of PTFE tubing 16 (6.1803.020) to coupling 18

(6.2744.034) by using a compression fitting 17 (6.2744.010).

• Immerse the other end of the aspiration tubing in a container

with regeneration solution (normally 50 mmol/L H

2SO4

) and fix

it in position.

• Pull outlet capillary 66 of the suppressor module (marked

with "Waste") through opening 18

on the rear panel, lead it

into a sufficiently large waste bottle and fix it in position.

8 Suppressor connection 3: H2O

• Pull inlet capillary 68 (marked with "H2SO4") by hand as far as

required through one of the feedthroughs 14

(see Fig. 23 and Fig.24, 819/820 Instructions for Use).

• Screw the filter unit PEEK contained in the standard

equipment of the 83 IC LH Pump Unit on to PEEK coupling

21 (6.2744.160) as described in Section 3.2 at the outlet end

of the second piece of pump tubing 19.

• Fasten inlet capillary 68

(6.2821.120) by using a compression fitting 17 (6.2744.010)

(see Fig. 7).

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

to the outside

(23 in Fig. 7) to the filter unit PEEK

29

Page 38

4 833 IC Liquid Handling Pump Unit

• At the inlet end of the second piece of tubing 19 fasten a

suitably long piece of PTFE tubing 16 (6.1803.020) to

coupling 18 (6.2744.034) by using a compression fitting 17

(6.2744.010).

• Immerse the other end of the aspiration tubing in a container

with rinsing solution (normally dist. H

• Pull outlet capillary 67

of the suppressor module (marked

with "Waste") through opening 18

O) and fix it in position.

2

on the rear panel, lead it

into a sufficiently large waste bottle and fix it in position.

9 Start up the 833 Pump Unit

• Switch on the 833 Pump Unit with mains switch 8.

• Set the contact pressure for both cassettes: press contact

lever 5 until the solutions are just aspirated. Then press the

contact lever up by 1 further click to achieve the optimum

contact pressure.

• Check all the tubing from the storage containers to the 833 IC

Liquid Handling Unit and the suppressor module through to

the waste bottles for leaks. If any liquid should be leaking

then the corresponding connection must be tightened up or

replaced.

30

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 39

5.1 Connection of the Suppressor module

5 833 IC Liquid

Handling

Suppressor Unit

This instrument version can be used for retrofitting a 2.820.0X20 IC

Separation Center with two injectors or a 2.761.0010 Compact IC for

chemical suppression in an easy way. It consists of the 833 IC Liquid

Handling Unit basic instrument and the 1.753.0100 Metrohm

Suppressor Module MSM.

Suppressor module

24

Suppressor connection

25

with permanently attached inlet

and outlet capillaries

1

2

3

26 25 24

Fig. 9: Suppressor module 1.753.0100

Connection cable

26

connection cable to 833 IC Liquid

Handling Unit

5.1 Connection of the Suppressor module

The 1.753.0100 Suppressor module must first be inserted in the

2.820.0X20 IC Separation Center and connected to the 833 IC Liquid

Handling Unit. Connections are then made to the inlet and outlet

capillaries mounted on the suppressor. Proceed as follows (underlined

numbers ##

Use):

1 Insert suppressor module

refer to parts and controls in the 819/820 Instructions for

• 820.0X20 IC Separation Center (2-channel system):

Place suppressor module 24 inside the chamber on the floor,

see Fig. 24, 819/820 Instructions for Use).

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

31

Page 40

5 833 IC Liquid Handling Suppressor Unit

2 Connect suppressor module

• 820.0X20 IC Separation Center (2-channel system):

Remove plastic stopper from rear panel opening 18

of the

820 IC Separation Center and lead cable 26 of suppressor

module 24 out through one of the openings in the rear panel

of the IC Separation Center.

• Connect cable 26 to connection 13 (“Module” of the 833 IC

Liquid Handling Unit (see Fig. 2).

3 Connect the column to the injector

• Remove end caps from column 53

• without column heating:

Screw inlet end of separating column 53

to column connection capillary 50

(note flow direction)

mounted on the injector.

• with column heating:

Prepare column heating according to Section 2.9.2 of the

819/820 Instructions for Use and screw column connection

capillary 50

compression fitting to injection valve 51

(see Fig. 20, 819/820 Instructions for Use) with a

.

• With precolumn:

Install precolumn according to the supplied leaflet between

inlet of the separating column and the injection valve.

H2SO4

Waste

28

29

4 Rinse column

• Place a beaker beneath the column outlet.

• Start 818 IC Pumpe 818 in «IC Net» with suitable flow (see

leaflet of the column) and rinse column for ca. 10 min with

eluent.

• Stop 818 IC Pump.

Eluent

27

32

1

2

3

31

30

Waste

Detector

H2O

Suppressor inlet capillary for

27

eluent

Suppressor inlet capillary for

28

H

Suppressor outlet capillary for

29

H

Suppressor outlet capillary for

30

H

Suppressor inlet capillary for

31

H

Suppressor outlet capillary for

32

2SO4

2SO4

O

2

O

2

eluent

Fig. 10: Suppressor module connections for 833 IC Liquid Handling

Suppressor Unit

32

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 41

5.1 Connection of the Suppressor module

5 Connect column to suppressor module (Suppressor

connection 1)

• Cut inlet capillary 27 (marked with “Eluent”) at suppressor

connection 25 (see Fig. 9) to the required length. Use the

6.2126.080 Capillary cutter available as an option.

• without column heating

Screw inlet capillary 27 on to the outlet end of separating

column 53

using a 6.2744.010 compression fitting.

• with column heating

Connect capillary 52

at the outlet of the separating column

(see Fig. 20, 819/820 Instructions for Use) to the inlet

capillary 27 using the 6.2744.040 Coupling supplied with the

820 standard equipment.

6 Fix column

• without column heating

Insert one or two column holders 59

or 6.2027.050) in the mounting rails 58

(6.2027.030, 6.2027.040

and fasten separating

column in the column holder.

• with column heating

Insert column heating according to Fig. 10 (819/820

Instructions for Use) into the Separation Center.

7 Connect suppressor module to detector block

(Suppressor connection 1)

• Cut outlet capillary 32 (marked with “Detector”) at suppressor

connection 25 (see Fig. 9) to coupling 71

(6.2620.060) to the

required length. Use the 6.2126.080 Capillary cutter available

as an option.

• Screw outlet capillary 32 on to coupling 71

by using a

6.2744.010 compression fitting.

• Screw inlet capillary 56

end of coupling 71

of detector block 57 on to the other

.

8 Attach pump tubing to 833 Liquid Handling Unit

• Mount both the 6.1826.050 Pump tubing (white-yellow

stopper) as described in Section 3.2, see Fig. 7.

9 Suppressor connection 2: H2SO4

• Pull inlet capillary 28 (marked with “H2SO4”) at suppressor

connection 25 (see Fig. 9) through one of the openings 18

the rear panel of the 820 IC Separation Center.

• Attach inlet capillary 28 (23 in Fig. 7) to the filter unit PEEK 22

(6.2821.120) of the first pump tubing using a compression

fitting 17 (6.2744.010), see Fig. 7.

• Mount aspiration tubing: cut a piece of PTFE tubing 16

(6.1803.020) to the required length.

• Attach a PEEK compression fitting 17 (6.2744.010) to one

end of the PTFE tubing 16 and screw this on to coupling 18.

on

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

33

Page 42

5 833 IC Liquid Handling Suppressor Unit

• Immerse the other end of the aspiration tubing in a container

with regeneration solution (normally 50 mmol/L H

2SO4

) and fix

it in position.

• Pull outlet capillary 29 (marked with “Waste”) through one of

the openings 41

or 43 in the rear panel of the 820 IC

Separation Center.

• Lead outlet capillary 29 into a sufficiently large waste bottle

and fix it in position.

10 Suppressor connection 3: H2O

• Pull inlet capillary 31 (marked with “H2O”) at suppressor

connection 25 (see Fig. 9) through one of the openings 18

in

the rear panel of the 820 IC Separation Center.

• Fasten inlet capillary 31 (23 in Fig. 7) to filter unit PEEK 22

(6.2821.120) of the second pump tubing using a

compression fitting 17 (6.2744.010), see Fig. 7.

• Mount aspiration tubing: cut a piece of PTFE tubing 16

(6.1803.020) to the required length.

• Attach a PEEK compression fitting 17 (6.2744.010) to one

end of the PTFE tubing 16 and screw this on to coupling 18.

• Immerse the other end of the aspiration tubing in a container

with rinsing solution (normally dist. H

O) and fix it in position.

2

• Pull outlet capillary 30 (marked with “Waste”) through one of

the openings 41

or 43 in the rear panel of the 820 IC

Separation Center.

• Lead outlet capillary 30 into a sufficiently large waste bottle

and fix it in position.

11 Start up 833 IC Liquid Handling Suppressor Unit

• Switch on 833 Pump Unit with mains switch 8.

• Set the contact pressure for both cassettes: press contact

lever 5 until the solutions are just aspirated. Then press the

contact lever up by 1 further click to achieve the optimum

contact pressure.

• Before switching the suppressor to the next position for the

first time (see Section 5.2) rinse the three suppressor units

with solution for 5 minutes.

• Check all the tubing from the storage containers to the 833 IC

Liquid Handling Unit and the suppressor module through to

the waste bottles for leaks. If any liquid should be leaking

then the corresponding connection must be tightened up or

replaced.

34

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 43

5.2 Handling the suppressor module

5.2 Handling the suppressor module

General

The Metrohm Suppressor Module MSM of the 833 IC Liquid

Handling Suppressor Unit consists of a total of three suppressor

units, which are used in sequence for suppression, regenerated with

sulfuric acid and rinsed with water. In order to be able to record each

chromatogram under comparable conditions, work is normally carried

out with a freshly regenerated suppressor. Switching takes place either

automatically together with the valve switching or manually.

Correct connection

The three suppressor inlets and outlets numbered 1…3 each have two

permanently attached PTFE capillaries that must be connected as

described in Section 5.1 (see Fig. 10).

Flow direction

The suppressor units must never be regenerated with H

same direction as which the eluent is transported. This is why the inlet

and outlet capillaries must always be mounted as described in

Section 5.1 and shown in Fig. 10.

Never switch to the next position when dry

The suppressor module must never be switched to the next position

when it is dry, as there is a risk that it could be blocked.

No recycling

The recycling method (return of the eluent to the storage container)

must not be used with the suppressor.

2SO4

in the

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

35

Page 44

6 833 IC Liquid Handling Sample Preparation Unit

6 833 IC Liquid

Handling Sample

Preparation Unit

This instrument version consists of the 833 IC Liquid Handling Unit

basic instrument and the 1.793.0110 Sample Preparation Module.

Sample preparation module

33

Sample preparation

34

connection

1

2

3

with permanently attached inlet

and outlet capillaries

Connection cable

35

3534 33

Fig. 11: 1.793.0110 Sample Preparation Module

connection cable to 833 IC Liquid

Handling Unit

6.1 Connection to modular IC system for neutralization

The 833 IC Liquid Handling Sample Preparation Unit is frequently used

for the neutralization of an alkaline sample for anion determination with

chemical suppression. Excessive amounts of strong bases (e.g. 30%

NaOH) should not be fed into the sample preparation module. In order

to ensure an adequate capacity for the exchange of Na

ions under all circumstances only a small fraction of the sample is fed

into the sample preparation module through a sample loop (e.g. 20 µL).

The analyte anions are retained on a downstream enrichment column,

then re-eluted with the eluent in counterflow and transferred to the

separating column.

This means that the necessary instrument configuration corresponds to

the Modular IC System 6 (MIC 6 Advanced: anion system with

chemical suppression, enrichment and matrix elimination), extended by

the 833 IC Liquid Handling Sample Preparation Unit. Samples with

a low load for the capacity of the sample preparation module can also

be added directly to the sample preparation module and transferred to

the sample loop. Switching then corresponds to the system described

in Section 6.2.

+

ions for H+

36

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

Page 45

6.1 Connection to modular IC system for neutralization

The electrical connections of this system to the 766 IC Sample

Processor with complete control by the «IC Net 2.3» software is

described below.

6.1.1 Electrical connections

The electrical connections of the system, consisting of 819 IC Detector,

820 IC Separation Center (2-channel; 2.820.0X20), 818 IC Pump, 833 IC

Liquid Handling Pump Unit (2.833.0010), 833 IC Liquid Handling

Suppressor Unit (2.833.0020), 833 IC Liquid Handling Sample

Preparation Unit (2.833.0030) and 830 IC Interface are shown in Fig. 12:

6.2125.120

6.2143.210

6.2143.200

819

6.2125.090

820

B (LOOP) A (PCC)

6.2128.180

818

6.2141.110

830

6.2134.130

6.2134.040

6.2128.180

PC

6.2134.100

833 Sample Prep

833 Suppressor

6.2115.070

833 Pump

6.2128.180

6.2134.090

Fig. 12: Electrical connections for 833 IC Liquid Handling Sample

Preparation Unit and modular IC system for neutralization

766

6.2134.080

Please note that the signal for switching the connected 833 IC Liquid

Handling Suppressor Unit to the next position is not controlled by the

program of the 766 Sample Changer. Instead the remote connection 14

of the 833 IC Liquid Handling Suppressor Unit for the

Suppressor/Actuator is connected by 6.2128.180 cable with the event

line “Fill” of valve B (sample loop before the sample preparation

module) to the 820. In this way a move to the next position of the

suppressor is triggered by the “Fill” setting of this valve.

833 IC Liquid Handling Unit / Instructions for Use 8.833.1003

37

Page 46

6 833 IC Liquid Handling Sample Preparation Unit

A

6.1.2 Connection of the sample preparation module

The following description assumes the use of a 2.820.0X20 IC

Separation Center (2-channel system).

The 1.793.0110 Sample Preparation Module must first be inserted in the

820 IC Separation Center and then connected to the basic instrument