Page 1

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

832 KF Thermoprep

Instructions for Use

8.832.1023 10.2004/ dm

Page 2

Teachware

Metrohm AG

Oberdorfstr. 68

CH-9101 Herisau

teachware@metrohm.com

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great

care, errors cannot be entirely excluded. Should you notice any mistakes please

inform the author at the address given above.

© Metrohm Ltd. 2002

Printed in Switzerland

II 832 KF Thermoprep

Page 3

Table of contents

1 Introduction 1

1.1 Description of the instrument ..........................................................1

1.2 Information about these Instructions for Use.................................2

1.3 Parts and controls ............................................................................3

1.3.1 Individual parts and standard accessories ..............................................3

1.3.2 Rear view...................................................................................................4

1.3.3 Temperature controller..............................................................................5

1.3.4 Sample holder for standard vials ..............................................................5

2 Safety information 6

2.1 General..............................................................................................6

2.2 Electrical safety ................................................................................6

3 Installation 7

3.1 Instrument setup...............................................................................8

3.1.1 Packaging .................................................................................................8

3.1.2 Checks ......................................................................................................8

3.1.3 Location.....................................................................................................8

3.2 Mains connection .............................................................................8

3.3 Assembling the 832 KF Thermoprep............................................ 10

3.3.1 Assembling the needles..........................................................................10

3.3.2 Attaching the drying bottles ....................................................................11

3.3.3 Attaching the dust filter ...........................................................................11

3.4 Assembling the coulometric cell .................................................. 12

3.5 Assembling the titration vessel for volumetric KF titrators ........ 12

4 Operation 13

4.1 Inserting and removing sample vials ........................................... 13

4.2 Needle penetration ........................................................................ 13

4.3 The pump ....................................................................................... 14

4.4 The temperature controller ........................................................... 15

4.4.1 Two set temperatures .............................................................................15

4.4.2 Setting a temperature..............................................................................15

4.4.3 Self-optimization of the control parameters............................................16

4.4.4 Key lock function.....................................................................................16

4.5 Working procedure........................................................................ 17

4.5.1 Preparing the 832 KF Thermoprep/756/831 Coulometer system ..........18

4.5.2 Determination with blank value subtraction............................................18

4.5.3 Determination without blank value subtraction.......................................19

4.6 Practical information ..................................................................... 20

5 Maintenance information 21

6 GLP validation 21

832 KF Thermoprep III

Page 4

7 Troubleshooting 22

7.1 Problems ........................................................................................ 22

8 Annex 23

8.1 Technical data................................................................................ 23

8.1.1 Oven........................................................................................................23

8.1.2 Air pump..................................................................................................23

8.1.3 Temperature controller............................................................................23

8.1.4 Power supply ..........................................................................................23

8.1.5 Safety specifications ...............................................................................23

8.1.6 Electromagnetic compatibility (EMC) .....................................................24

8.1.7 Ambient temperature ..............................................................................24

8.1.8 Dimensions and materials ......................................................................24

8.2 Standard equipment ...................................................................... 25

8.2.1 832 KF Thermoprep................................................................................25

8.3 Optional accessories..................................................................... 27

8.3.1 Sample vials............................................................................................27

8.4 Warranty and conformity............................................................... 28

8.4.1 Warranty ..................................................................................................28

8.4.2 EU Declaration of Conformity for 832 KF Thermoprep ..........................29

8.4.3 Declaration of Conformity .......................................................................30

Index 31

List of illustrations

Fig. 1 Front view ...................................................................................................................3

Fig. 2 Rear view ....................................................................................................................4

Fig. 3 Temperature controller ...............................................................................................5

Fig. 4 Sample holder .......................................................................................................... 5

Fig. 5: 832 KF Thermoprep – peripheral devices ..................................................................7

Fig. 6 Fuse holder.................................................................................................................9

Fig. 7 Needle assembly ...................................................................................................... 10

Fig. 8 Guide head with needles..........................................................................................10

Fig. 9 Coulometer cell......................................................................................................... 12

Fig. 10 Volumetric KF cell ..................................................................................................... 12

Fig. 11 Crimping pliers.......................................................................................................... 13

Fig. 12 Loosening the guide head........................................................................................13

Fig. 13 Needle in lowered position ....................................................................................... 14

IV 832 KF Thermoprep

Page 5

1.1 Description of the instrument

1 Introduction

Thanks to its reliability and simple handling, the Metrohm 832 KF Thermoprep is a very versatile instrument. It has been designed for use in

production and laboratories and covers a wide range of applications.

The 832 KF Thermoprep can be used wherever it is necessary to heat

up a solid or liquid sample and/or to drive off water by the application of

heat.

When combined with a coulometric or volumetric KF titrator, the 832 KF

Thermoprep forms the ideal analytical system for determining the water

content of samples which contain interfering components or which only

release their moisture slowly.

Among the decisive advantages of the KF Thermoprep is the reduction

of sample preparation to a minimum. By using hermetically sealed

sample vessels (headspace vials) the samples can be filled directly on

site. The PTFE-coated septa guarantee a constant and true water content, even when the sample have been allowed to stand for a long time.

1.1 Description of the instrument

The 832 KF Thermoprep has been designed primarily for the determination of moisture by the oven method. The samples are heated in the

oven block and release their moisture in the form of water vapor; this is

transferred to a measuring cell by a carrier gas. The carrier gas stream

is produced by a built-in air pump. An inlet valve is also provided for the

use of nitrogen or other inert gases. The determination of moisture in

the measuring cell can be carried out either coulometrically or volumetrically according to the Karl Fischer method.

The 832 KF Thermoprep is characterized by its compact construction;

the oven heating block, air pump, temperature controller, flowmeter and

flow controller as well as the drying bottles are already built in.

832 KF Thermoprep, Introduction 1

Page 6

1.2 Information about these Instructions for Use

1.2 Information about these Instructions for Use

Please read through these Instructions for Use before you start to use

the 832 KF Thermoprep.

The following notations and pictograms are used in these instructions:

35

Operating element

The operating elements are explained on

pages 3ff.

Danger

This symbol indicates a possible risk of

death or injury to the user and possible

damage to the instrument or its components by electricity.

Danger/Warning

This symbol indicates a possible risk of

death or injury to the user and possible

damage to the instrument or its components.

Attention

This symbol indicates important information. Read the information provided before

you continue.

2 832 KF Thermoprep, Introduction

Page 7

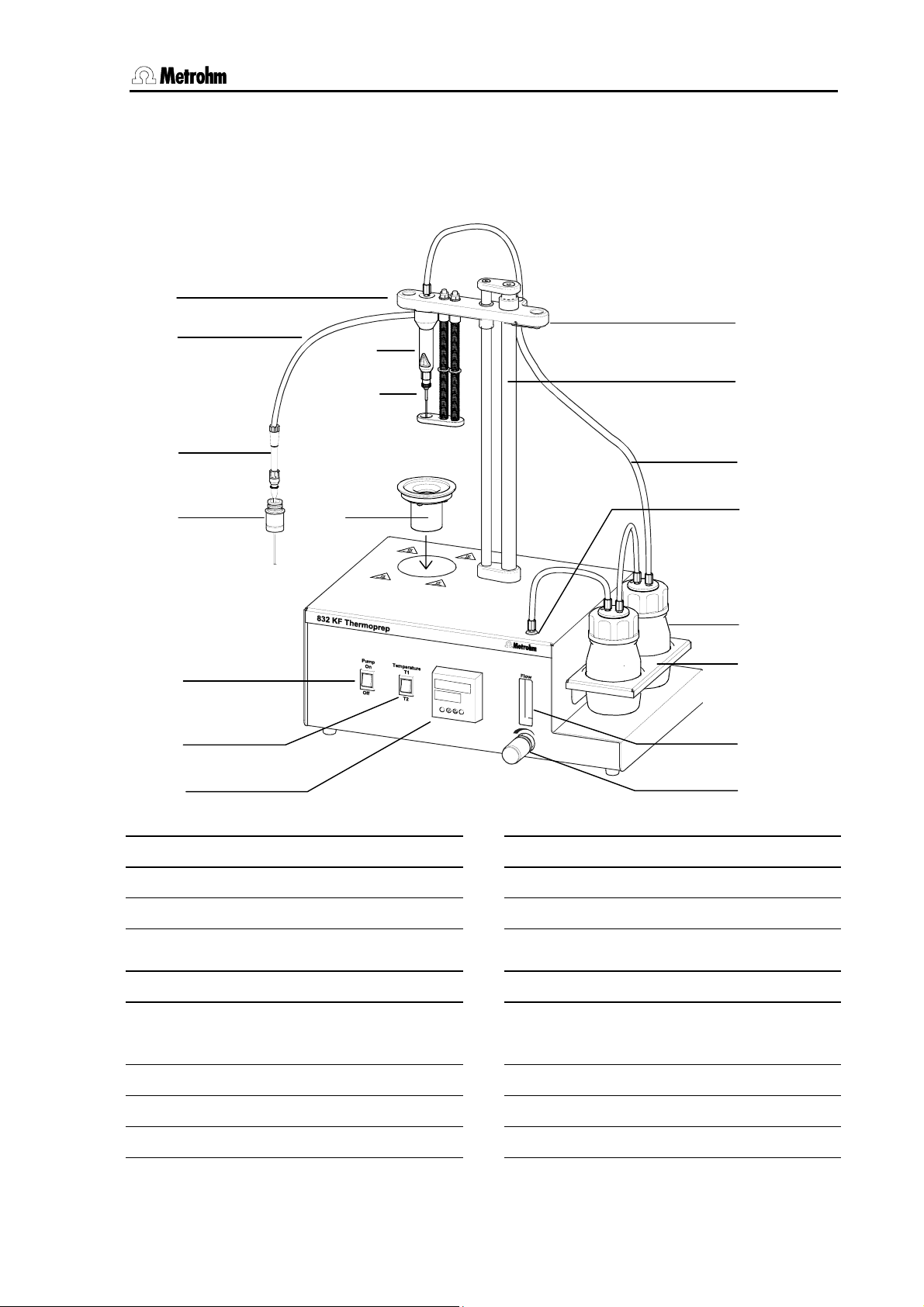

1.3 Parts and controls

1.3 Parts and controls

1.3.1 Individual parts and standard accessories

1

2

3

11

5

6

8

9

10

4

7

Fig. 1 Front view

12

13

14

15

16

17

18

Guide head

1

Transfer tubing 6.1805.460

2

Spacer 4.832.4190

3

Penetration and outlet needle

4

6.2816.070 and 6.2816.080

Dosing tip 6.1543.060

5

Septum stopper 6.2730.050

6

Sample holder

7

Pump switch

8

Temperature selection switch

9

832 KF Thermoprep, Introduction 3

10

11

12

13

14

15

16

17

18

Temperature controller

Clamping lever

Guide rod

Inlet tubing 6.1805.020

Air/Nitrogen outlet

Drying bottles 6.1608.050

With 6.1602.140 inset, filled with

6.2811.000 molecular sieve

Bottle holder

Flow indicator

Flow controller

Page 8

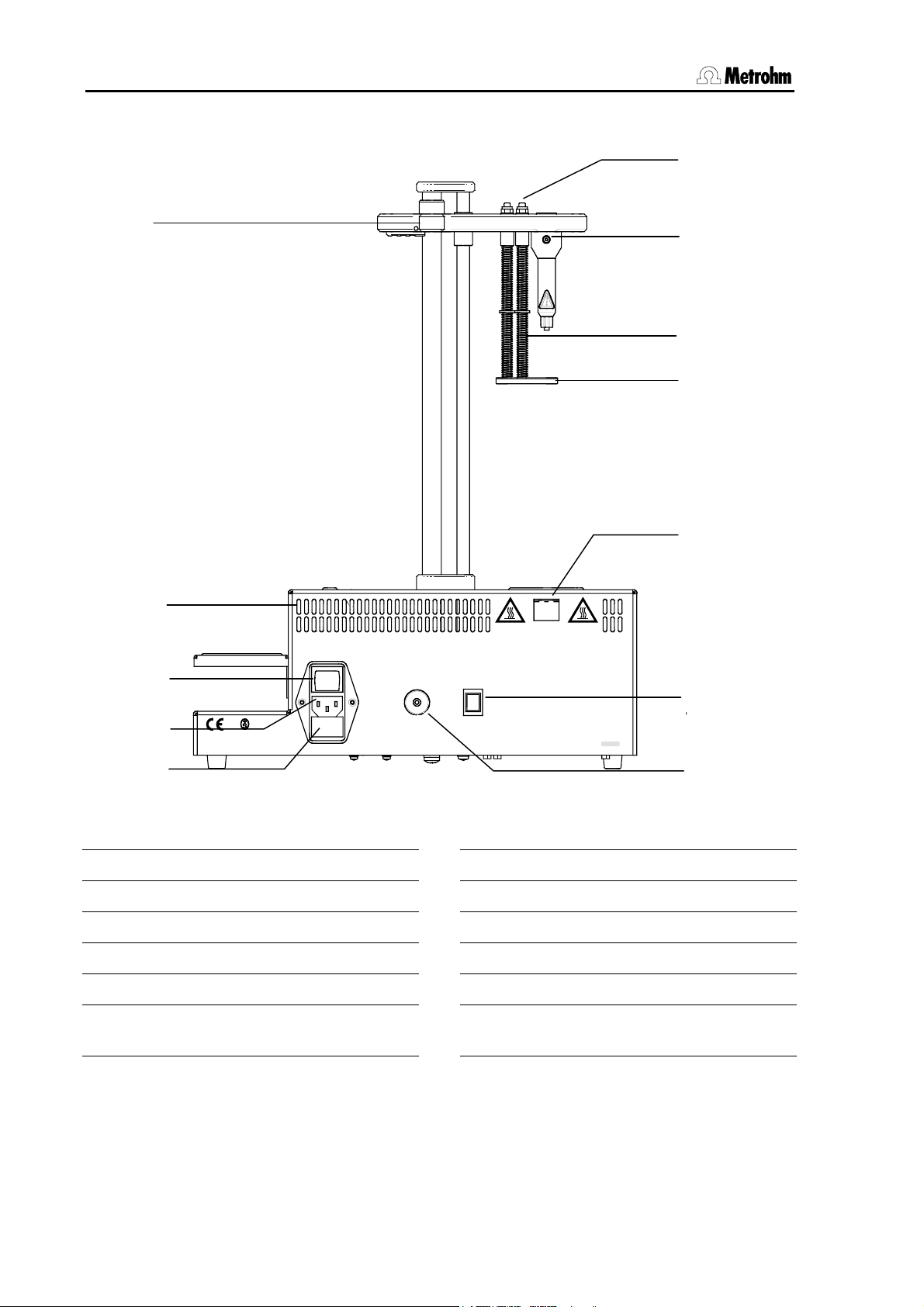

1.3 Parts and controls

1.3.2 Rear view

19

20

21

22

23

WARNING - Fire Hazard -

for conti nued pro tection replac e only

with the same ty pe and rating of fuse

100 - 120 V: 4 A (T)

220 - 240 V: 2 A (T)

f = 50/60 Hz

S = 350 VA

Inlet filt er

Key lock

On

Off

Fig. 2 Rear view

Vorsicht: Heisse Gehäuseteile

(üb er 60° C)

Attention: Hot parts

(a bove 6 0°C)

Cuidado: Partes calientes

(mas de 60°C)

Attention: Parties chaudes

(p lus de 60°C)

Type 1.832.0010 Nr.

Made by Metrohm Switzerland

0010/01104

24

25

26

27

28

29

30

Tubing guide

19

Ventilation slots

20

Mains switch

21

Mains connection

22

Fuse holder

23

Adjustment nuts

24

25

26

27

28

29

30

Transfer tubing connection

Guide spring

Needle base

Hot air outlet

Key lock switch

Air/nitrogen outlet

Connection for dust filter (6.2724.010)

4 832 KF Thermoprep, Introduction

Page 9

1.3 Parts and controls

1.3.3 Temperature controller

31

32

33

34

Actual value display

31

red, 4-place

Set value display

32

green, 4-place

Program key

33

for selecting the parameters

Decrement key

34

for changing values

Fig. 3 Temperature controller

35

36

37

38

Output status display

yellow, for outputs 1 to 3

(K1 and K3: oven heating, K2: fan)

LED for ramp/program function

green, lights if configured

EXIT key

to exit the dialog levels

Increment key

for changing values

35

36

37

38

1.3.4 Sample holder for standard vials

The dimensions of the 6.2063.000 sample holder are optimized for the

Metrohm 6.2419.007 standard sample vials (6 mL). This ensures the

highest possible heat flow from the oven to the sample.

If other sample containers with different dimensions shall be used

custom made sample holders can be delivered. For this the precise

dimensions (incl. dimensional tolerances) must be known.

The measures of non-standard sample containers must vary within the

following dimensional limits:

Diameter 10.0 … 32.0 mm

Fig. 4 Sample holder

832 KF Thermoprep, Introduction 5

Depth of immersion 20.0 … 45.0 mm

Page 10

2.1 General

2 Safety information

Warning!

This instrument should only be used in accordance with the information

given in these Instructions for Use.

2.1 General

This instrument left our works in perfect condition from the point of view

of its operational safety (see Technical data, safety specification). To

keep it in this condition and to continue to operate safely the following

information must be carefully observed.

2.2 Electrical safety

Please observe the following guidelines:

• Only qualified Metrohm personnel should carry out service work on

electronic components.

• Do not open the instrument housing as this could damage the instrument. The housing contains no components which could be

serviced or exchanged by the user.

Electrical safety when handling the instrument is guaranteed within the

scope of Standard IEC 61010. However, please observe the following

point:

Protection against electrostatic charges

Warning!

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Always remove the mains connection

cable from socket 12 before making or breaking electrical connections

on the rear panel of the instrument.

Connection to the electricity supply:

This instrument must only be operated at the specified mains voltage.

Repair and maintenance:

If faults or malfunctions occur while using the 832 KF Thermoprep we

recommended that you first check that the connection to the control instrument has been made correctly.

The instrument must not be opened. This is reserved exclusively for

authorized service personnel.

6 832 KF Thermoprep, Safety information

Page 11

2.2 Electrical safety

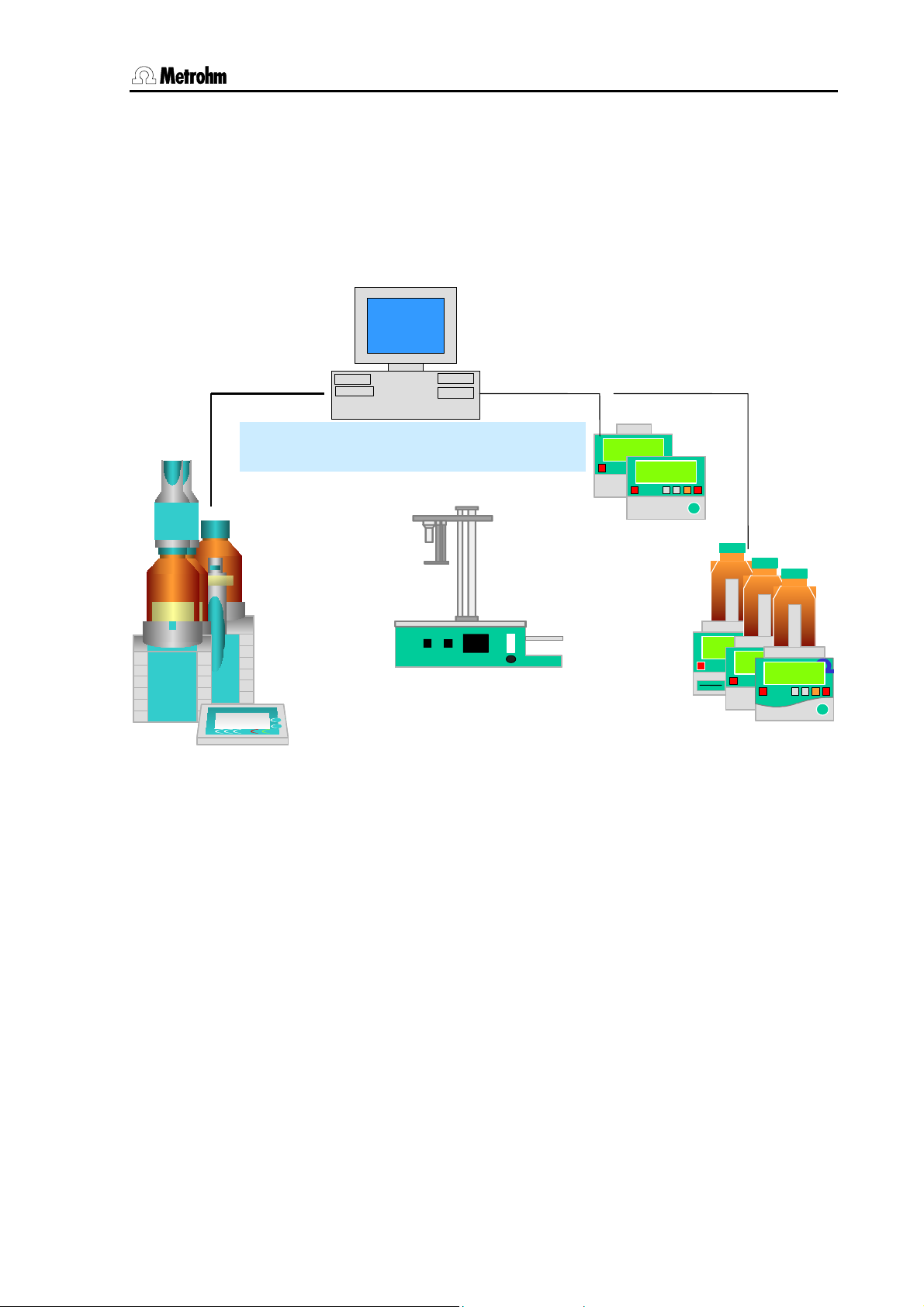

3 Installation

This section describes the things you should pay attention to when unpacking and starting up the 832 KF Thermoprep. It also tells you how a

complete automation system is built up.

The following illustration provides an overview of the peripheral devices

which can be used with an 832 KF Thermoprep:

PC

PC

800

800

800

800

800

800

800

800

Dosino

Dosino

Dosino

Dosino

Dosino

Dosino

Dosino

Dosino

Titriermittel

KF

Titriermittel

KF

Titriermittel

Titriermittel

KF

KF

835

835

835

Titrando

Titrando

Titrando

836

836

836

Titrando

Titrando

Titrando

Titrandos

USB

PC Control tiamo

KF

KFKF

Touch ControlTouch Control

Fig. 5: 832 KF Thermoprep – peripheral devices

LPT 1

LPT 1

USB

PC Software

COM 1

COM 1

COM 2

COM 2

USB

RS232

Tinet 2.x / VESUV 3.0

832 TP832 TP

832 Thermoprep

RS232

756 KF756 KF

831 KF831 KF

KF Coulometer

831 / 756

Titrierm ittelTitrierm ittel

Titrierm ittelTitrierm ittel

Titrierm ittel

Titrierm ittel

KFD 758

KFD 758

KFP 785

KFP 785

KFP 795KFP 795

KF Titrino

795 / 787 / 758

832 KF Thermoprep, Installation 7

Page 12

3.1 Instrument setup

3.1 Instrument setup

3.1.1 Packaging

The 832 KF Thermoprep and its specially packed accessories are supplied in very protective special packaging. Please store this packaging

in a safe place; it is the only way in which the safe transport of the instrument can be guaranteed.

3.1.2 Checks

Please check that the delivery is complete and undamaged immediately on receipt (compare with delivery note and list of accessories

given in Section 8.28.2). If transport damage is evident please refer to

the information given in Section 8.4.1 “Warranty”.

3.1.3 Location

The 832 KF Thermoprep has been developed for use indoors and must

not be used in explosion-endangered surroundings.

Place the instrument on a suitable vibration-free laboratory bench, protected as much as possible from corrosive atmospheres and contamination by chemicals.

Select a location in which the ambient temperature is normally between

+5 °C and +45 °C. The instrument should be protected against excessive variations in temperature and direct sunshine.

If an instrument which has been stored under cold conditions is

brought into a warm room then the atmospheric humidity may condense inside the instrument and form water. In order to avoid damaging

the instrument please wait for at least one hour before switching it on.

3.2 Mains connection

Please observe the following rules when connecting the instrument to

the electricity supply. If the instrument is operated with an incorrectly set

mains voltage and/or an incorrect mains fuse then it represents a fire

hazard!

Setting the mains voltage

Before you switch on the 832 KF Thermoprep for the first time please

check that the mains voltage set on the instrument (see illustration on

the following page) corresponds to your local mains voltage. If this is

not the case then you must alter the mains voltage as follows:

8 832 KF Thermoprep, Installation

Page 13

3.2 Mains connection

• Pull out mains cable

Remove the mains cable from the mains supply connection of the 832

KF Thermoprep.

• Remove the fuse holder

Use a screwdriver to loosen the fuse holder beside the mains supply

connection and remove it completely.

• Check the fuse and replace it

Carefully remove the built-in fuse for the intended voltage from the fuse

holder and check its specifications (the position of the fuse in the fuse

holder is indicated by the white arrow beside the voltage range):

100…120 V 4 A (slow blow) Metrohm-No. U.600.0022

220…240 V 2 A (slow blow) Metrohm No. U.600.0019

• Insert fuse

Exchange the fuse if necessary and replace it in the fuse holder.

• Insert fuse holder

Depending on the required mains voltage, insert the fuse holder so that

the white arrow of the corresponding voltage range points to the white

bar; this is to the right of the fuse holder (see below).

220 – 240 V 100 – 120 V

Mains switch

Mains connection

Fuse holder

100 - 120 V

220 - 240 V

Fig. 6 Fuse holder

220 - 240 V

100 - 120 V

832 KF Thermoprep, Installation 9

Page 14

3.3 Assembling the 832 KF Thermoprep

3.3 Assembling the 832 KF Thermoprep

3.3.1 Assembling the needles

41

3

39

• Screw spacer 3 (4.832.4190, L=58 mm) into distributor 39. For special

requirements, e.g. different sample vials, custom-made spacers can

be supplied, see p. 27.

• Place PTFE distance ring 41 (supplied with the needle) on penetration

needle 42 (6.2816.070) and insert this into distributor 39 from above

(see left). Pull penetration needle 42 down as far as it will go.

• Slide hollow outlet needle 43 over penetration needle 42 from below

and fasten it to Luer-lock connector of the spacer 3.

• Connect inlet tubing 13 (6.1805.020, 52 cm) to distributor 39 from

above and fasten it. This fixes penetration needle 42 in the proper

position.

44

13

Fig. 7

Needle assembly

43

12

42

27

Fig. 8 Guide head with needles

To prevent possible injury the height of needle base 27, which protects

the tip of penetration needle 42, can be adjusted. Screw adjustment

nuts 44 of guide rod 12 until the needle tip is flush with the lower side of

needle base 27.

10 832 KF Thermoprep, Installation

Page 15

3.3 Assembling the 832 KF Thermoprep

3.3.2 Attaching the drying bottles

1. Fill 6.1608.050 drying bottles 15 with 6.2811.000 molecular sieve

and place 6.1821.040 outlet tube (with 6.2821.090 filter) in

6.1602.140 screw cap. Screw the screw caps onto the drying bottles.

14

16

When attaching the tubing please

observe the following:

To filter the carrier gas before leaving

the drying bottle, it must be led

through the outlet tube to the outlet

connection.

2. Place drying bottles 15 in holder 16 of the

oven. Screw the 6.1805.180 Tubing (16 cm) to

the inlet tubing connection of the front drying

bottle. The carrier gas must enter the drying

15

bottle at the top of the bottle. Connect the other

end of the tubing to the air/nitrogen outlet 14

(see drawing).

3. The rear drying bottle is connected to the front

bottle using 6.1805.010 Tubing (13 cm). Screw

the tubing onto the outlet tube of the front bottle

and connect the other end to the inlet connection of the rear drying bottle. The carrier gas

must enter the rear drying bottle at the top of

the bottle.

4. Screw 6.1805.020 Tubing (52 cm) onto the

outlet tube of the rear drying bottle and lead it

through the tubing guide on the guide head of

the 832 KF Thermoprep. The free end of the

tubing is screwed onto the connection provided

for it on the guide head.

5. 6.1805.460 Transfer tubing (27 cm) is screwed onto the back of the

distributor piece. Attach 6.1543.060 Dosing tip to the other end of

the tubing and insert it into the titration vessel.

3.3.3 Attaching the dust filter

Attach 6.2724.010 Dust filter to the 'Inlet filter' connection on the rear

panel of the instrument.

If nitrogen is to be used as the carrier gas then the nitrogen inlet tubing

can be attached directly to the dust filter tubing nozzle.

832 KF Thermoprep, Installation 11

Page 16

3.4 Assembling the coulometric cell

3.4 Assembling the coulometric cell

Generator electrode

Fig. 9 Coulometer cell

with drying tube

Indicator electrode

6.1543.060 Tip

Screw nipple of

6.2730.030

6.1446.060 Stopper

The coulometer cell is setup for the gas inlet as

follows:

6.1543.060 Tip is screwed into the 6.1446.060 Stopper

by using the screw nipple (screw nipple of 6.2730.030

with O-ring) and the stopper is inserted into the SGJ

14/15 opening.

If simultaneous aspiration is necessary while gas is

being led in then the gas inlet tubing must be inserted

into the side inlet. This requires the use of the following

parts:

Tip 6.1543.060

Screw cap 6.2701.0

40

Sealing ring A.254.0104

A titration vessel with 2 side-mounted inlets is also

available: order number 6.1465.320.

3.5 Assembling the titration vessel for volumetric KF titrators

The titration vessel is adapted for the gas inlet in the

following way:

Instead of the 6.2730.020 Septum stopper, the

6.2730.050 Stopper is used with 6.1543.060 Tip. (Nipple

and O-ring of 6.2730.030 from the Titrino accessories.)

Fig. 10 Volumetric KF cell

12 832 KF Thermoprep, Installation

Page 17

4.1 Inserting and removing sample vials

4 Operation

This section describes the basic principles of handling the 832 KF Thermoprep.

4.1 Inserting and removing sample vials

As the oven of the 832 KF Thermoprep can reach a temperature of

250 °C, vials must only be inserted in or removed from the oven by using crimping pliers or other tools. Hot vials should only be placed on

temperature-resistant surfaces.

Fig. 11 Crimping pliers

4.2 Needle penetration

Always lower guide head 1 by using both hands. In this way you can

avoid injuring yourself on the needle.

Fig. 12 Loosening the guide head

Clamping lever

11

832 KF Thermoprep, Operation 13

Page 18

4.3 The pump

Loosen the red clamping lever by pressing it strongly and lower the

guide head and needle by using both hands. Penetrate the vial septum

with the needle and lower the guide head until it reaches the bottom

stop.

4.3 The pump

The 832 KF Thermoprep is equipped with a powerful air pump, with

which the released humidity of the sample can be transferred to a titration cell in a constant carrier gas stream.

Atach a 6.2724.010 dust filter to the air inlet 30 on the instrument's rear

side. Avoid the intrusion of dust particles.

The dust filter must be replaced in a regular equipment service.

If thermal unstable samples, which may decompose at higher temperatures are treated, the use of nitrogen as carrier gas is highly recommended. Connect the nitrogen supply pipe to the hose olive of the dust

filter. The maximum pressure of the nitrogen supply must not exceed

1 bar.

Fig. 13 Needle in lowered position

14 832 KF Thermoprep, Operation

Page 19

4.4 The temperature controller

4.4 The temperature controller

The best proven dTron 16.1 (JUMO) temperature controller of the 832

KF Thermoprep is very easy to use for routine operation of the instrument. Fine adjustment of the control parameters is possible but not

normally necessary. Unappropriate parameters of configuration settings

may cause faults of the instrument. The default settings can be used

without any problems. The temperature controller 10 also has a comfortable and simple self-optimization function which can be used if necessary.

4.4.1 Two set temperatures

The temperature controller of the 832 KF Thermoprep can store two set temperatures (T1 and T2).

You can switch between these two set temperatures by using the temperature selection switch.

The oven starts to heat up as soon as the instrument is switched on

and is controlled at the set temperature (T1 or T2). If a switch is made

from one set temperature to the other one then this will be adopted immediately by the temperature controller, i.e. the oven will immediately

heat up or cool down until the set temperature has been reached.

4.4.2 Setting a temperature

The desired temperature (T1 or T2) is easily set by using the two arrow

keys (increment key 38) and (decrement key 34) of the temperature controller. The set temperature can be altered at any time, regardless of whether the set temperature has been reached or not.

Please observe the green set value display 32. This always refers to the

set temperature T1 or T2 which has been selected. Longer pressure on

an arrow key changes the set value more quickly.

Altered set values are immediately accepted by the temperature controller.

If the key lock function (tumbler switch 29 on the rear panel of the housing) is switched on then no settings can be made.

Temperature display

The display indicates the real value and the set

value (T1 or T2).

832 KF Thermoprep, Operation 15

Page 20

4.4 The temperature controller

4.4.3 Self-optimization of the control parameters

Self-optimization should only be used when the set temperature cannot

be achieved by the temperature controller or when the actual temperature varies about the set temperature by more than 2…5 °C (overshooting).

Preparation

Set the same conditions as would be used in a real determination.

• Set the temperature (T1 or T2) to a value corresponding to a real

determination (e.g. 120 °C).

• Wait until the oven has reached the set temperature.

• Insert a sealed sample vial containing a sample in the oven.

• Lower the work head and completely penetrate the sample vial sep-

tum with the needle.

• Switch on the pump (or open the nitrogen valve) and set the gas

flow to a realistic value which would be used during a proper determination.

Self-optimization

• Start the self-optimization process with EXIT (keep key 37 pressed

down for at least 2s!).

During the self-optimization process "tunE" blinks in the display 31.

When the blinking stops the process is finished. Self-optimization normally takes 1 to 5 minutes. The duration depends on the selected temperature, i.e. the higher the temperature the shorter it takes.

•

• Save the control parameters which have been determined by press-

ing the EXIT key 37 for 2 seconds.

The self-optimization process can be canceled by pressing the EXIT

key 37 briefly.

4.4.4 Key lock function

The temperature controller settings can be protected against accidental

alteration. On the rear panel of the 832 KF Thermoprep the 'Key Lock'

tumbler switch 29 can be switched to 'On'.

If the key lock function is switched on the 'Temperature' tumbler switch

9 can still be used to select the two set temperatures T1 and T2. It is

also possible to switch the pump on and off (key 8).

However, no alteration can be made to the temperature controller 10

with the key lock function switched on.

16 832 KF Thermoprep, Operation

Page 21

4.5 Working procedure

4.5 Working procedure

Warning!

As both the sample vials and the oven become very hot the sample

vials must be removed from the oven by using the crimping pliers. The

sample vials should only be placed on a heat-resistant surface.

In principle two different methods can be used.

For samples with a low water content one (or more) blank values

must be determined and subtracted from the water content determined

for the sample. Sample vials contain a considerable amount of atmospheric humidity, e.g. Metrohm standard vials with a volume of 6 mL can

contain 60…150 µg water. While the determination is being carried out

atmospheric moisture can also enter the coulometer cell as a result of

leaks, etc.

For samples with a high water content blank value determinations

are not necessary as the atmospheric humidity contained in the vial is

negligible when compared with the moisture contained in the sample. If

no blank determinations are carried out then the whole procedure is

simplified and takes less time.

Determinations with the 832 KF Thermoprep basically take part in three

phases:

1. Preparing / Conditioning the system

2. Possibly determining the blank value

3. Determination of the sample

The procedure for determinations with the 756/831 Coulometer is described below. A similar procedure can be used with a volumetric KF titrator (e.g. 795 KFT Titrino).

Note

When using either a coulometer or a volumetric KF titrator it is absolutely essential that an extraction time of at least 300 s is observed per

determination. More details are given in the Instructions for Use of the

particular instrument.

832 KF Thermoprep, Operation 17

Page 22

4.5 Working procedure

4.5.1 Preparing the 832 KF Thermoprep/756/831 Coulometer system

1. Switch on the 832 KF Thermoprep. The oven heats up automatically to set temperature T1 or T2.

2. If necessary use the set value switch to alter set temperature T1 or

T2.

3. Place an empty sealed vial in the oven.

4. Lower the needle until the stop is reached. Both hands should be

used for safety reasons.

5. Switch on air pump (if N

is used open the nitrogen valve).

2

6. Check the gas flow at the flowmeter 17 and alter it if necessary

(optimal range: 40…60 mL/min).

7. Start the 756/831 Coulometer and allow it to be conditioned.

8. Let the oven heat up until the set temperature is reached and the

coulometer cell is conditioned.

4.5.2 Determination with blank value subtraction

Determination of blank value(s)

1. Load a method for a blank value determination (e.g. Blank) into the

coulometer. The mean value of the blank value determinations

should be stored as a common variable. Set the extraction time to

300 s.

2. Start conditioning the coulometer (with the <START> key).

3. Wait until the set temperature has been reached and the coulometer cell is conditioned.

4. Start the blank determination at the coulometer with <START>.

5. Raise the needle fully and remove the conditioning vial from the

oven with the crimping pliers.

6. Insert an empty sealed vial (blank sample) in the oven using the

crimping pliers.

7. Lower the needle until it reaches the stop and pierce the septum

cap.

8. After the determination wait for post-conditioning to be completed

and, if necessary, carry out further blank value determinations, i.e.

repeat the procedure from item 3 onward.

Sample determination

1. Load a method for a sample determination into the coulometer.

The mean blank value, stored as a common variable, is to be subtracted from the sample result. Set the extraction time to 300 s.

2. Start conditioning the coulometer (with the <START> key).

3. Wait until the set temperature has been reached and the coulometer cell is conditioned.

4. Start the determination at the coulometer with <START>.

18 832 KF Thermoprep, Operation

Page 23

4.5 Working procedure

5. Raise the needle fully and remove the blank sample vial from the

oven with the crimping pliers.

6. Insert the sealed sample vial in the oven using the crimping pliers.

7. Lower the needle until it reaches the stop. Enter the sample size at

the coulometer and confirm it with <ENTER>.

8. After the determination wait for post-conditioning to be completed

and, if necessary, carry out further determinations.

4.5.3 Determination without blank value subtraction

Sample determination

1. Load a method for a sample determination into the coulometer. The

result calculation must not contain any blank value subtraction. Set

the extraction time to 300 s. 'Value' must be entered under

'>Preselection' | 'Request sample size'.

2. Start conditioning the coulometer (with the <START> key).

3. Wait until the set temperature has been reached and the coulometer

cell is conditioned.

4. Start the determination at the coulometer with the <START> key.

5. Raise the needle fully and remove the conditioning vial from the

oven with the crimping pliers.

6. Insert the sealed sample vial) in the oven using the crimping pliers.

7. Lower the needle until it reaches the stop. Enter the sample size at

the coulometer and confirm it with <ENTER>.

8. After the determination wait for post-conditioning to be completed

and, if necessary, carry out further determinations.

832 KF Thermoprep, Operation 19

Page 24

4.6 Practical information

4.6 Practical information

Selecting the carrier gas

Nitrogen (N

sitive to air or oxygen (decomposition) or releases substances which interfere with the KF reaction.

Temperature setting

Select as high a temperature as the sample allows (high temperature =

short analysis time). However, the sample must not decompose. It

should not release any other oxidizable substances than water. The

temperature shown on the temperature controller refers to the temperature in the aluminum heating block and not to the sample temperature.

Depending on the size of vial used and the temperature setting, the

sample temperature could vary by up to 10%.

Gas flow

The gas flow is set on the flow controller on the front panel of the 832

KF Thermoprep and passes through the drying bottles. The gas flow

should be kept as low as possible. With very moist samples in particular

care must be taken that large amounts of water do not enter the titration

vessel too quickly. The solution in cell must be able to absorb the

driven-off moisture. A flow rate of 40…60 mL/min is normally optimal.

If the needle is inserted in the sample bottle until the stop is reached

then the flow of gas through the sample will be transferred to the titration vessel via the outlet needle. The moisture is then titrated in the titration vessel.

Extraction time

An extraction time of at least 5 min should be set on the connected titrator, in order to prevent the titration from being stopped before all the

sample has released all its moisture.

Conditioning the system

Before a measurement the system must be conditioned with an empty

sealed sample vial (conditioning vessel).

Literature

• Hydranal

de Haën, 1987

• The following Metrohm Application Bulletins can be obtained free of

charge:

should be used as the carrier gas if the hot sample is sen-

2)

®

Manual, Water reagents for Karl-Fischer-Titration, Riedel-

No. 109 Karl Fischer water determination with the KF drying

oven

No. 145 Determination of low water contents in plastics using

the KF oven method

No. 217 Karl Fischer water determination in pharmaceuticals using the oven method

20 832 KF Thermoprep, Operation

Page 25

4.6 Practical information

5 Maintenance information

The 832 KF Thermoprep does not need a lot of care. Ensure that it does

not become excessively dirty and is not exposed to corrosive atmospheres.

• Renew used-up molecular sieve in good time. The molecular sieve

should be exchanged as soon as increased drift values occur in the

Karl Fischer cell.

• Rinse the tubing and the distributor occasionally and carefully dry

the tubing.

• Clean the oven compartment at regular intervals.

• Replace the dust filter on the rear panel when necessary.

6 GLP validation

Each instrument produced by Metrohm undergoes a rigorous quality

control check before delivery.

GLP (Good Laboratory Practice) requires, among other things, that the

precision and correctness of analytical instruments are checked at

regular intervals by using SOPs (Standard Operating Procedure).

Recommended literature

• Metrohm leaflets "Quality Management with Metrohm", detailed information about the principles and procedures of Good Laboratory

Practice

• Metrohm Application Bulletin 252/1 "Validation of Metrohm titrators

according to GLP/ISO 9001"

832 KF Thermoprep, Maintenance information 21

Page 26

7.1 Problems

s

s

7 Troubleshooting

7.1 Problems

Problem Possible cause Remedy

Titration results

widely scattered.

Drift too high.

Titration time too

long.

Molecular sieve in the

drying bottles is used

up.

Condensate in the outlet

tubing.

Gas flow too high. Reduce gas flow

Inhomogeneous

sample.

Not all the moisture has

been driven out.

Leaky tubing connections.

Molecular sieve in the

drying bottles is used

up.

Leaky titration vessel Orings.

Leaky septum cap. Replace septum cap.

Inhomogeneous

sample.

Replace molecular sieve. (If the

molecular sieve in the front bottle is

till OK then this bottle can be used

as the rear bottle. The "freshest“ molecular sieve belongs in the front bottle.)

Dry the tubing. Reduce gas flow.

Possibly lower the temperature.

Reduce sample particle size before

weighing.

Set "harder" switch-off conditions at

the titrator: Lower stop drift, increased

switch-off delay.

Check tubing and replace if neces-

sary.

Replace molecular sieve. (If the

molecular sieve in the front bottle is

till OK then this bottle can be used

as the rear bottle. The "freshest“ molecular sieve belongs in the front bottle.)

Replace O-rings.

Reduce sample particle size before

weighing.

22 832 KF Thermoprep, Troubleshooting

Page 27

8.1 Technical data

8 Annex

In this section you will find the most important technical data of the 832

KF Thermoprep, a list of standard and optional accessories and the

warranty and conformity declarations.

8.1 Technical data

8.1.1 Oven

Temperature range

Correction range

Heating power

Heating rate

50…250 °C

-10…+10 °C

200 VA

15 °C/min

8.1.2 Air pump

Delivery rate

Adjustment range

0…300 mL/min (0…18 L/h)

0…80 mL/min (0…4.8 L/h)

8.1.3 Temperature controller

Make

Temperature control

Display

JUMO dTRON 16.1

Self-optimizing microprocessor controller, can be used as

2-point, 3-point or continuous controller

2x 7-segment digital display of set and actual values

8.1.4 Power supply

Voltage

Frequency

Power consumption

100...120 V, 220...240 V

50...60 Hz

220 VA

8.1.5 Safety specifications

Construction and testing According to IEC 61010, EN 61010, EN50093, protection

class 3

Safety information The Instructions for Use contains safety information that

must be observed by the user in order to ensure the safe

operation of the instrument.

832 KF Thermoprep, Annex 23

Page 28

8.1 Technical data

8.1.6 Electromagnetic compatibility (EMC)

Emission Standards fulfilled:

- EN/IEC 61326-1

- EN 55022 class B

- CISPR 22 class B

- EN/IEC 61000-3-2 class A

- EN/IEC 61000-3-3

- Namur

Immunity Standards fulfilled:

- EN/IEC 61326-1

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-8

- EN/IEC 61000-4-11

- Namur

8.1.7 Ambient temperature

Nominal working range

Storage

Transport

+5…+45 °C

(at max. 85% relative humidity)

-20 °C…+60 °C

-40 °C…+60 °C

8.1.8 Dimensions and materials

Height

Width

Depth

Weight approx. 8.9 kg (without accessories)

Housing material Metal housing, surface-refined

49.5 cm

35.5 cm

22.0 cm

24 832 KF Thermoprep, Annex

Page 29

8.2 Standard equipment

8.2 Standard equipment

Immediately upon receipt of the instrument please check that the delivery is complete.

8.2.1 832 KF Thermoprep

Order no. 2.832.0020

No. Order no. Description

1 1.832.0020 832 KF Thermoprep

KF oven for processing single samples in sealed vials.

The following accessories are supplied as standard:

1 6.1543.060 ETFE/FEP dosing tip

2 6.1602.145 Drying bottle insert

2 6.1608.050 Clear glass bottle GL 45, 100 mL

1 6.1805.010 FEP tubing, M6, L=13 cm

1 6.1805.020 FEP tubing, M6, L=52 cm

1 6.1805.180 FEP tubing, M6, L=16 cm

1 6.1805.460 FEP tubing, M6, L=27 cm

832 KF Thermoprep, Annex 25

Page 30

8.2 Standard equipment

2 6.1821.040 Inlet tube for drying bottle, with filter,

L=92 mm

1 6.2049.030 Spacer with Luer-Lock needle

connector, L=58mm

1 6.2063.000 Sample holder for 6.2419.007

sample vials (6 mL)

1 6.2621.110 Crimping pliers

1 6.2724.010 Dust filter, 32 mm diameter

1 6.2730.050 Stopper for dosing tip, M10, with

O-ring

1 6.2739.000 Tubing nipple wrench

1 6.2811.000 Molecular sieve, 250 g

1 6.2816.070 Penetration needle

1 6.2816.080 Outlet needle

100 6.2419.007 Sample vials, 6 mL

100 6.1448.057 Septum seals for sample vial 6.2419.007

1 8.800.1023 Instructions for Use for 832 KF Thermoprep

26 832 KF Thermoprep, Annex

Page 31

8.3 Optional accessories

8.3 Optional accessories

8.3.1 Sample vials

Order no. Description

6.2419.000 Sample vials , 6 mL, 1000 ea.

6.1448.050 Septum seals for sample vial, 1000 ea.

In order to use other sample vials with different dimensions the sample

holder of the 832 KF Thermoprep must be replaced. Please contact

your Metrohm distributor.

For further accessories please see Metrohm Accessories Catalog.

832 KF Thermoprep, Annex 27

Page 32

8.4 Warranty and conformity

8.4 Warranty and conformity

8.4.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In this case, the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty period. For parts of

outside manufacture insofar as these constitute an appreciable part of

our instrument, the warranty stipulations of the manufacturer in question

apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the orderer has no rights or claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedment in

wood shavings or similar material, the parts must be packed in a dustproof package (for instruments, use of a plastic bag is imperative). If

open assemblies are enclosed in the scope of delivery that are sensitive to electromagnetic voltages (e.g. data interfaces etc.) these must

be returned in the associated original protective packaging (e.g. conductive protective bag). (Exception: assemblies with built-in voltage

source belong in a non-conductive protective packaging).

No warranty responsibility whatsoever will be accepted by Metrohm for

damage which arises as a result of non-compliance with these instructions.

28 832 KF Thermoprep, Annex

Page 33

8.4 Warranty and conformity

8.4.2 EU Declaration of Conformity for 832 KF Thermoprep

EU Declaration of Conformity

The Metrohm Ltd. company, Herisau, Switzerland hereby certifies, that the instrument:

832 KF Thermoprep

meets the requirements of EU Directives 89/336/EEC and 73/23/EEC.

Source of specifications:

EN 61326-1 Electromagnetic compatibility, basic specification Emitted In-

terference, Interference Immunity

EN 61010-1 Safety requirements for electrical laboratory measurement

and control equipment

Description of the instrument:

Instrument with sample heating block, temperature controller and air pump for

processing samples according to the Karl Fischer oven method.

Herisau, May 30, 2002

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

832 KF Thermoprep, Annex 29

Page 34

8.4 Warranty and conformity

8.4.3 Declaration of Conformity

Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for electrical appliances

and accessories, as well as to the standard specifications for security and to system

validation issued by the manufacturing company.

Name of commodity: 832 KF Thermoprep

Manufacturer: Metrohm Ltd., Herisau, Switzerland

Technical specifications: Distribution voltage:

100…120, 220…240 V

Frequency: 50…60 Hz

The instrument was manufactured and tested according to the following

standards:

Electromagnetic compatibility:

Emission

IEC 61326-1, EN 55022 class B, CISPR 22 class B EN/IEC 61000-3-2 class A,

EN/IEC 61000-3-3

Immunity

EN/IEC 61326-1, EN/IEC 61000-4-2, EN/IEC 61000-4-3, EN/IEC 61000-4-4, EN/IEC

61000-4-5, EN/IEC 61000-4-6, EN/IEC 61000-4-8, EN/IEC 61000-4-11, EN/IEC

61000-4-14

Security specifications

EN/IEC 61010-1, UL 3101-1

It has also been certified by the Swiss Electrotechnical Association (SEV), which is

member of the International Certification Body (CB/IEC).

The technical specifications are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for quality

assurance in design/development, production, installation and servicing.

Herisau, May 30, 2002

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

30 832 KF Thermoprep, Annex

Page 35

Index

Index

<ENTER> ............................. 19

<START>........................18, 19

A

Accessories ............................26

Actual value display ..................5

Adjustment nuts..................4, 10

Air inlet ....................................14

Air outlet................................3, 4

Air pump .................................14

Ambient temperature ..........8, 24

Assembling .............................10

Atmospheric humidity...............8

B

Blank value..............................18

Bottle holder..............................3

C

Care ........................................21

Carrier gas ........................14, 20

Certificate................................30

Clamping lever....................3, 14

Cleaning..................................21

Condensation .........................22

Conformity ..............................29

Connection ...............................6

Corrosive atmospheres ..........21

Coulometric cell ......................12

Crimping pliers..................13, 17

D

Danger ......................................2

Declaration of conformity........29

Decomposition .......................20

Decrement key....................5, 15

Delivery rate ............................23

Depth of immersion ..................5

Diameter ...................................5

Dimensions...............................5

Dirty......................................... 21

Display ....................................23

Distance ring........................... 10

Distributor ...............................10

Dosing tip..................................3

Drift too high ...........................22

Drying bottle .............................3

Drying bottles..........................11

dTron 16.1 (JUMO).................15

Dust filter.................4, 11, 14, 21

E

Electrical safety.........................6

Electricity supply...................6, 8

Electromagnetic compatibility ....

.....................................24, 30

Electrostatic charges ................6

Emission ...........................24, 30

EU Declaration........................ 29

EXIT key ....................................5

Extraction time ..................17, 20

F

Faults ........................................6

Flow controller ..........................3

Flow indicator............................3

Flowmeter ...............................18

Fuse ..........................................9

Fuse holder...........................4, 9

G

Gas flow..................................20

GLP .........................................21

Good Laboratory Practice ......21

Guide head ...................3, 10, 13

Guide rod..................................3

Guide spring .............................4

H

Handling .................................13

Heating rate ............................23

High water content..................17

Hollow needle .........................10

Hot air outlet .............................4

I

Immunity ...........................24, 30

Increment key .....................5, 15

Information................................2

Inlet filter..................................11

Inlet tubing ..........................3, 10

Inserting sample vials .............13

Installation............................. 7, 8

J

JUMO...................................... 15

K

Karl Fischer.............................20

Key lock function ....................16

Key lock switch .........................4

L

Leaking ...................................22

LED ...........................................5

Literature .................................20

Location ....................................8

Low water content...................17

Luer-lock adapter....................10

M

Mains connection .................4, 8

Mains switch .............................4

Maintenance ...........................21

Malfunctions .............................6

Materials .................................24

Maximum pressure .................14

Molecular sieve.................11, 21

N

Needle assembly ....................10

Needle base..............................4

Needle penetration .................13

Needles...................................10

Nitrogen ............................14, 20

Nitrogen outlet ......................3, 4

Notations...................................2

O

Operation ................................13

Outlet needle ......................3, 10

Output status display................5

Oven .........................................3

Overshooting ..........................16

P

Packaging.................................8

Parts.......................................... 3

Penetration needle..............3, 10

Peripheral devices ....................7

Pictograms................................2

Power consumption................23

Power supply ..........................23

Practical information ...............20

Preparing ................................18

Pressure..................................14

Problems.................................22

Procedure ...............................17

Program key..............................5

Pump switch .............................3

Q

Quality control......................... 21

R

Rear view ..................................4

Relative humidity.....................24

Removing sample vials...........13

Repair........................................6

S

Safety information...............6, 23

Sample containers....................5

Sample determination.............19

Sample holder.......................3, 5

Sample vials......................26, 27

Sealing ring.............................12

Security specifications ............30

Self-optimization .....................16

Septum seals ....................26, 27

Septum stopper ........................3

Service-personnel .....................6

Set temperatures ....................15

Set value display................. 5, 15

Setup.........................................8

832 KF Thermoprep, Index 31

Page 36

Index

SOP ........................................21

Spacer ....................................10

Standard accessories............... 3

Standard equipment...............25

Standards ............................... 24

System conditioning ...............20

T

T1, T2......................................15

Technical data ........................23

Temperature controller ...3, 5, 15

Display/Control parts................5

Temperature display...............15

Temperature selection switch.....

.......................................3, 15

Temperature setting ...............20

Titration vessel........................12

Tolerances ................................ 5

Transfer tubing..........................3

Transfer tubing connection....... 4

Transport damage..................28

Troubleshooting...................... 22

Tubing guide............................. 4

V

Validation ................................ 21

Ventilation slots......................... 4

Voltage.................................. 8, 9

Volumetric KF cell...................12

W

Warning.....................................2

Warranty.................................. 28

Water content .........................17

32 832 KF Thermoprep, Index

Loading...

Loading...