Page 1

830 IC Interface

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Instuctions for Use

8.830.1003

Page 2

Page 3

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

830 IC Interface

5.830.0020 Program

Instructions for Use

8.830.1003 07.2003 / pkl

Page 4

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

st

Edition 2003

1

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 5

Table of contents

Table of contents

1 Introduction.................................................... 1

1.1 Instrument description ............................................................. 1

1.2 Parts and controls..................................................................... 2

1.3 Information on the Instructions for Use................................... 4

1.3.1 Organization ..................................................................................4

1.3.2 Notation and pictograms ..............................................................5

1.4 Safety notes .............................................................................. 6

2 Installation ..................................................... 7

2.1 Setting up the instrument ......................................................... 7

2.1.1 Packaging......................................................................................7

2.1.2 Check.............................................................................................7

2.1.3 Location ......................................................................................... 7

2.1.4 Arrangement of the instruments....................................................7

2.2 Mains connection...................................................................... 8

2.2.1 Mains voltage and fuses ...............................................................8

2.2.2 Mains cable ...................................................................................8

2.2.3 Switching the instrument on/off.....................................................8

2.3 Connection to the PC................................................................ 9

2.3.1 Connecting cable ..........................................................................9

2.3.2 Software installation ......................................................................9

2.4 Connection of external instruments....................................... 10

2.4.1 General information.....................................................................10

2.4.2 819 IC Detector, 820 IC Separation Center, 818 IC Pump .........12

2.4.3 833 IC Liquid Handling Pump Unit .............................................13

2.4.4 833 IC Liquid Handling Suppressor-Unit .................................... 14

2.4.5 833 IC Liquid Handling Sample Prep Unit .................................. 15

2.4.6 833 IC Liquid Handling Dialysis Unit...........................................16

2.4.7 833 IC Liquid Handling Ultra Filtration Unit.................................17

2.4.8 Triathlon Autosampler .................................................................18

2.4.9 766 IC Sample Processor ...........................................................19

2.4.10 791 IC VA Detector ......................................................................20

2.4.11 761 Compact IC ..........................................................................21

2.4.12 812 IC Valve Unit and 817 Bioscan............................................. 22

2.4.13 816 IC Eluent Selector ................................................................. 23

2.4.14 828 IC Dual Suppressor ..............................................................24

2.4.15 837 IC Combi Degasser..............................................................25

3 Operation...................................................... 26

3.1 Switch instrument on/off ........................................................ 26

3.2 Settings in the "830 IC Interface" window.............................. 27

3.2.1 Event output lines ........................................................................ 30

4 Appendix ....................................................... 34

4.1 Technical data......................................................................... 34

4.2 Scope of delivery .................................................................... 38

4.3 Optional accessories.............................................................. 39

4.4 Validation / GLP ...................................................................... 40

4.5 Warranty and Conformity ....................................................... 41

830 IC Interface / 8.830.1003 Instructions for Use

I

Page 6

Table of contents

4.5.1 Warranty ......................................................................................41

4.5.2 Declaration of Conformity ...........................................................42

4.5.3 Quality Management Principles .................................................. 43

4.6 Index ........................................................................................ 44

List of illustrations

Fig. 1: Connection possibilities at 830 IC Interface .............................................. 1

Fig. 2: Front of 830 IC Interface............................................................................ 2

Fig. 3: Rear of 830 IC Interface............................................................................. 3

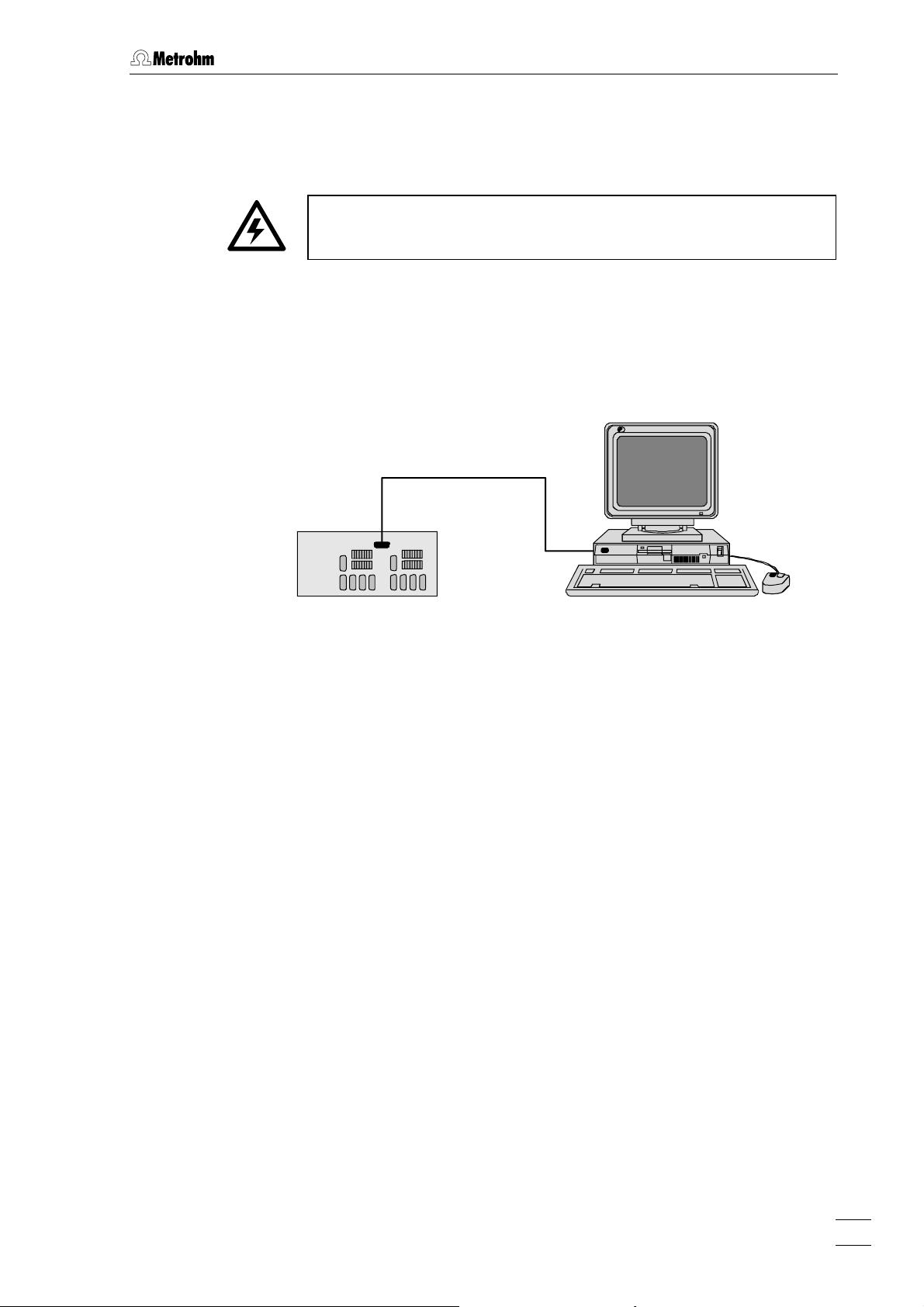

Fig. 4: Connection of 830 IC Interface to PC........................................................ 9

Fig. 5: Connection of 819, 820 and 818 (MIC 1) ................................................ 12

Fig. 6: Connection of 820, 819, 818 and 833(Pump Unit) (MIC 2) ..................... 13

Fig. 7: Connection of 2×819, 820, 2×818 and 833 (Suppressor Unit) (MIC 3).. 14

Fig. 8: Connection of 833 (Sample Prep Unit) to MIC 6 for Neutralization......... 15

Fig. 9: Connection of 819, 820, 818, 833 (Suppressor Unit)

and 833 (Dialysis Unit)

............................................................................ 16

Fig. 10: Connection of 819, 820, 818, 833 (Suppressor Unit)

and 833 (Ultra Filtration Unit)

................................................................... 17

Fig. 11: Connection of 819, 820, 818 and Triathlon ............................................. 18

Fig. 12: Connection of 819, 820, 818 and 766 ..................................................... 19

Fig. 13: Connection of 819, 820, 818 and 791 ..................................................... 20

Fig. 14: Connection of 819, 820, 818 and 761 ..................................................... 21

Fig. 15: Connection of 817, 812 and 818 (MIC 8) ................................................ 22

Fig. 16: Connection to 819, 820, 818 and 816 ..................................................... 23

Fig. 17: Connection to 819, 820, 2x818 and 828 (MIC 10)................................... 24

Fig. 18: Connection to 819, 820, 818 and 837 ..................................................... 25

830 IC Interface / 8.830.1003 Instructions for Use

II

Page 7

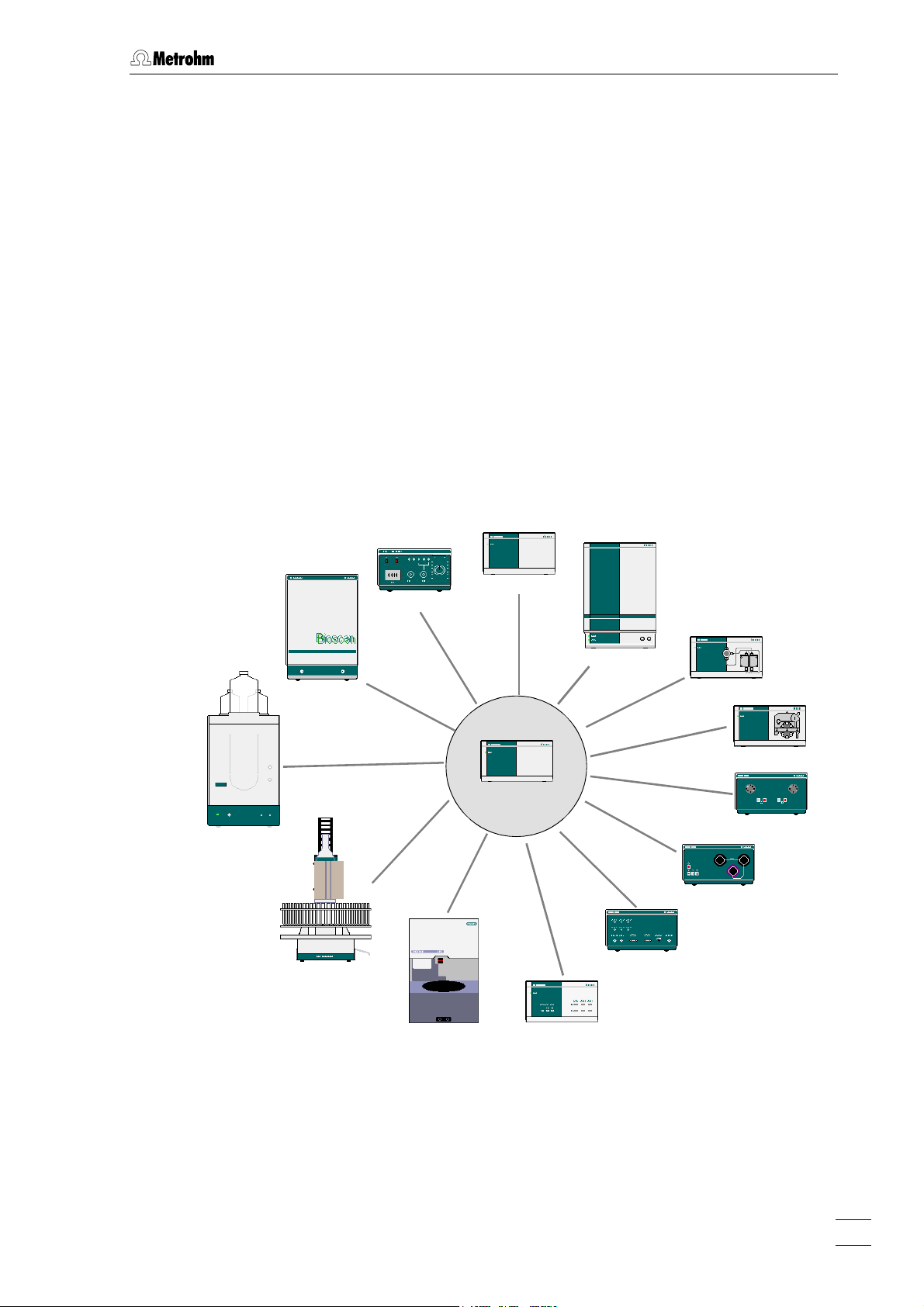

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 830 IC Interface provides the connection between the PC and external IC or HPLC peripheral instruments. Up to 16 instruments including 4 detectors can be connected to the 830 IC Interface and controlled

by means of the «IC Net» PC software. The 830 IC Interface can also

record and convert the analog signals from a maximum of 4 channels

(two at once) which are processed at very high resolution.

Fig. 1 shows an overview of all the Metrohm instruments which can be

connected to the 830 IC Interface and are described in these ‘Instructions for Use’. It is also possible to connect Bischoff instruments;

please refer to the «IC Net» on-line program help as well as the relevant

Bischoff instruction manuals.

761 Compact IC

766/788 IC Sample Processor

817 Bioscan

791 IC VA Detector

Triathlon Autosampler

819 IC Detector

820 IC Separation Center

818 IC Pump

833 IC Liquid Handling Unit

830 IC Interface

812 IC Valve Unit

816 IC Eluent Selector

828 IC Dual Suppressor

837 IC Inline Degasser

Fig. 1: Connection possibilities at 830 IC Interface

830 IC Interface / 8.830.1003 Instructions for Use

1

Page 8

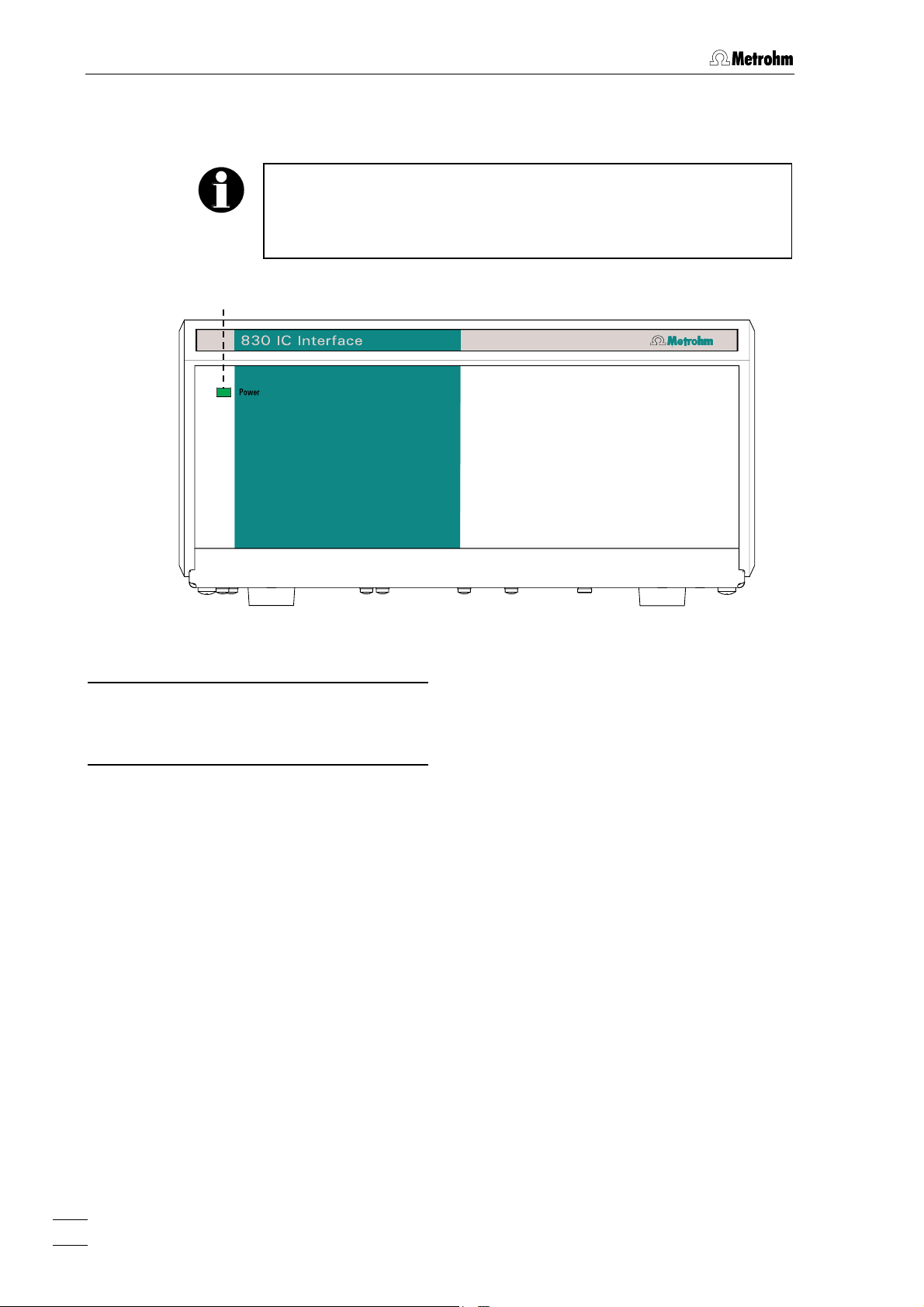

1 Introduction

1.2 Parts and controls

In this section you will find the numbers and designations of the parts

and controls of the 830 IC Interface. The numbering applies throughout the instructions for use, i.e. bold numbers in the text (e.g.

to the parts and controls illustrated here.

1

5

) refer

Fig. 2: Front of 830 IC Interface

Mains pilot lamp

1

Lights up when instrument is switched

on

2

830 IC Interface / 8.830.1003 Instructions for Use

Page 9

1.2 Parts and controls

2 3 4 5

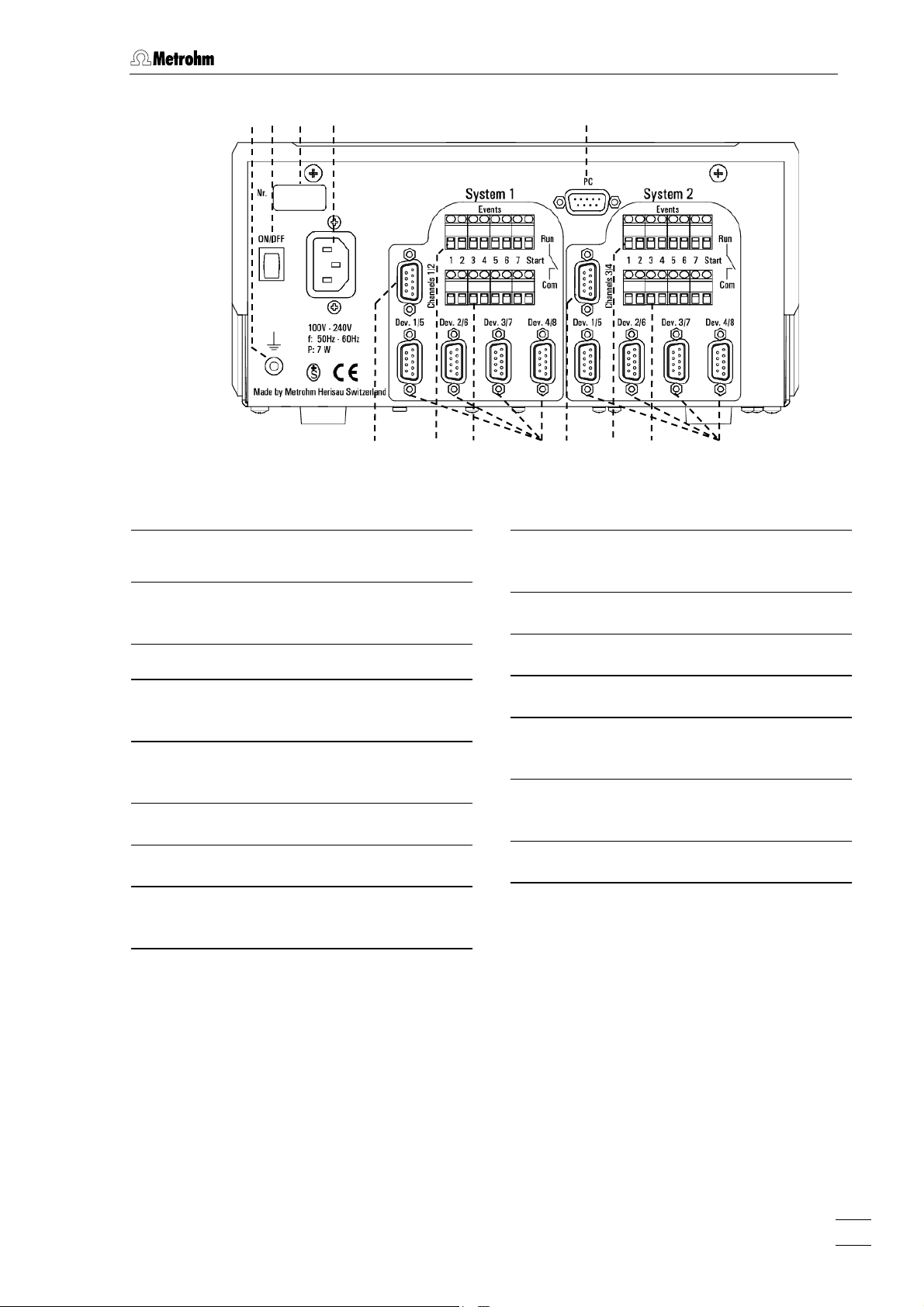

Fig. 3: Rear of 830 IC Interface

Earthing socket

2

Mains switch

3

For switching the instrument on/off.

Serial number

4

6

7 8 9 10 11 12 13 14

Remote input/output lines connec-

9

tion (COM)

RS232 interfaces

10

System 2

Mains connection plug

5

Mains connection see section 2.2

PC connection

6

RS232 interface

System 1

Analog signal connection

7

Remote input/output lines connec-

8

tion (RUN)

Analog signal connection

11

Remote input/output lines connec-

12

tion (RUN)

Remote input/output lines connec-

13

tion (COM)

RS232 interfaces

14

830 IC Interface / 8.830.1003 Instructions for Use

3

Page 10

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 830 IC Interface into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instrument.

1.3.1 Organization

These 8.830.1003 Instructions for Use for the 830 IC Interface provide a comprehensive overview of the installation, startup procedure,

operation and technical specifications of this instrument. The Instructions for Use are organized as follows:

Section 1 Introduction

Section 2 Installation

General description of instrument, parts and controls and safety notes

Mains connection, connection to PC,

connection of external instruments

Section 3 Operation

Operation via «IC Net»

Section 4 Appendix

Technical data, standard equipment, options, warranty, declarations of conformity, index

To find the required information on the instruments you will find it an

advantage to use either the Table of contents or the Index at the

back.

4

830 IC Interface / 8.830.1003 Instructions for Use

Page 11

1.3 Information on the Instructions for Use

1.3.2 Notation and pictograms

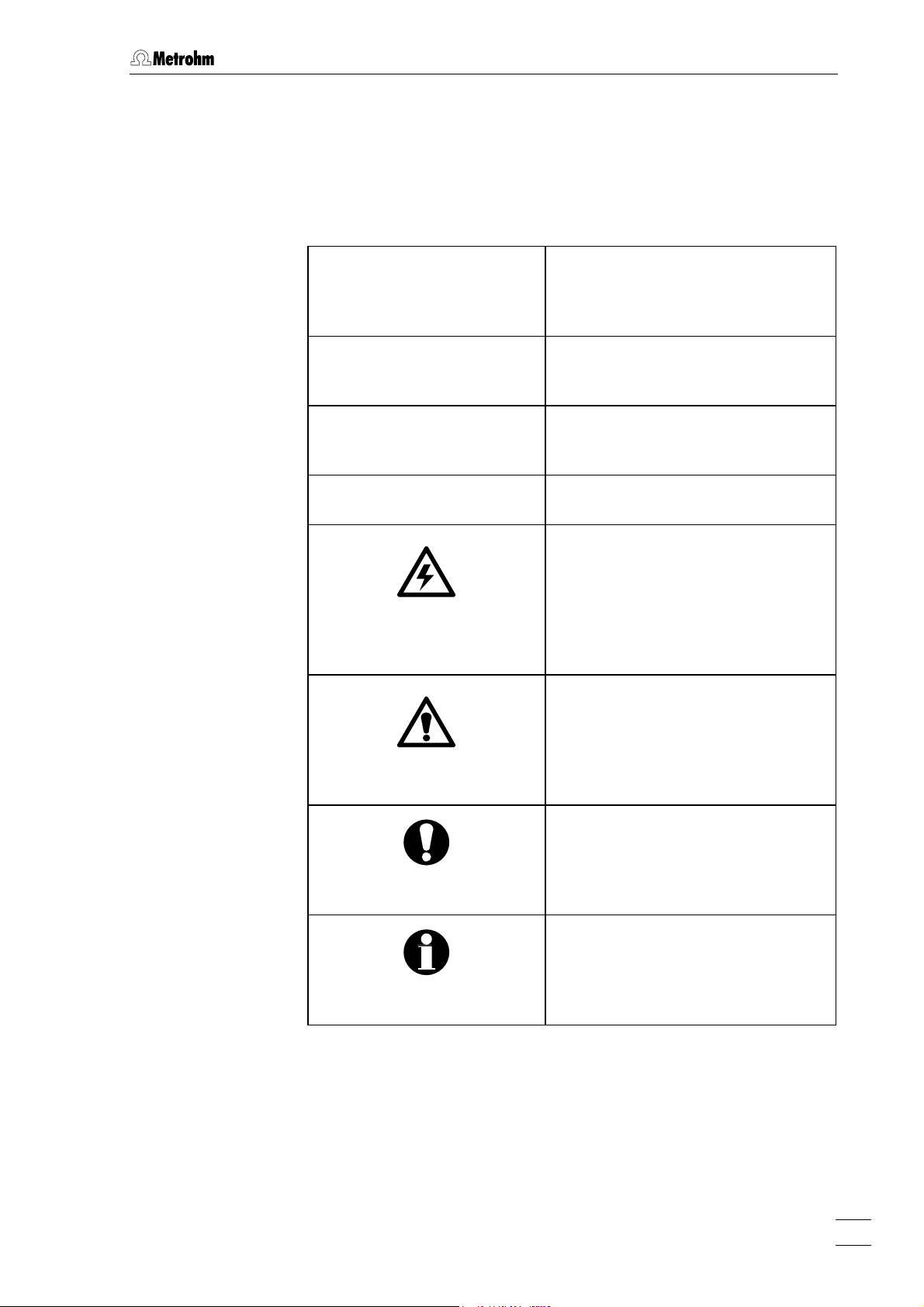

The following notations and pictograms (symbols) are used in these Instructions for Use:

Range Menu item, parameter or entry

value

in «IC Net» program

SYSTEM STATE Program window

in «IC Net» program

<OK> Button

in «IC Net» program

4 Part or control of 830

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components by

electricity.

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components.

Attention

This symbol indicates important

information that you should read

before continuing.

Information

This symbol indicates additional

information and tips which may be

of particular use to you.

830 IC Interface / 8.830.1003 Instructions for Use

5

Page 12

1 Introduction

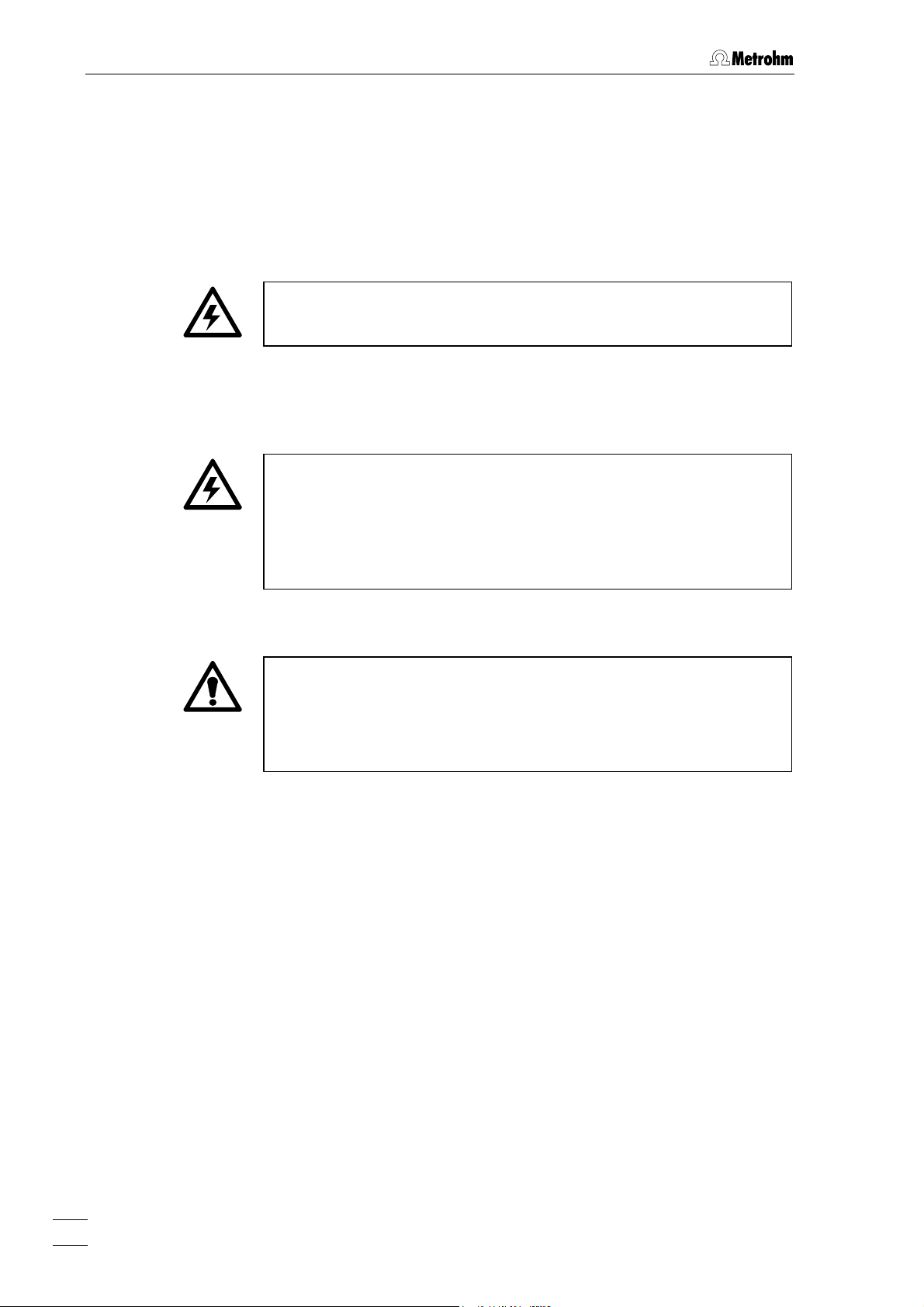

1.4 Safety notes

While electrical safety in the handling of the 830 IC Interface is assured

in the context of the specifications IEC 1010-1 (protection class 1, degree of protection IP40), the following points should be noted:

• Mains connection

The mains connection must be effected in accordance with the

instructions in section 2.2.

• Opening the instrument

Inside the instrument there are no parts which must be set or adjusted

by the user.

If the 830 IC Interface is connected to the power supply, the instrument must not be opened nor must parts be removed from it, otherwise there is a danger of coming into contact with components which

are live. Hence, always disconnect the instrument from all voltage

sources before you open it and ensure that the mains cable is

5

disconnected from mains connection

!

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 830 IC Interface, you should earth yourself and any tools

you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

6

830 IC Interface / 8.830.1003 Instructions for Use

Page 13

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 830 IC Interface is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The instrument itself is

packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 4.2). In the case of transport damage, see

instructions in section 4.5.1 "Warranty".

2.1.3 Location

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

2.1.4 Arrangement of the instruments

The modular IC instruments can be piled up in any order. The best

place for the 830 IC Interface is on top of a modular IC system.

The 830 IC Interface should always be placed above components

carrying liquids so that any leaks which may occur in the tubing or

connections cannot cause damage by leakage of liquids (e.g. acid).

830 IC Interface / 8.830.1003 Instructions for Use

7

Page 14

2 Installation

2.2 Mains connection

2.2.1 Mains voltage and fuses

The 830 Interface has a power supply which automatically adjusts itself

to the existing mains voltage (100…240 V) and frequency (50…60 Hz).

It is equipped with an electronic overload protection device and also

has two fuses; however, these should only be exchanged by Metrohm

service technicians.

2.2.2 Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to the earthing socket 2 (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Plug the mains cable into mains connection plug 5 at the 830 IC Interface (see Fig. 3).

2.2.3 Switching the instrument on/off

The 830 IC Interface is switched on and off using mains switch 3 (see

Fig. 3). When the instrument is switched on a start-up check routine is

running the mains pilot lamp 1 flashes twice slowly and remains on.

8

830 IC Interface / 8.830.1003 Instructions for Use

Page 15

2.3 Connection to the PC

2.3 Connection to the PC

2.3.1 Connecting cable

Always switch off 830 IC Interface and PC before you connect the two

instruments with the 6.2134.100 Cable

Connect the PC connection 6 at the 830 IC Interface to one of the serial

COM ports at the PC using the 6.2134.100 Cable (9 pin/9 pin). If only a

25-pin COM interface is available on the PC then the 6.2125.110

Adapter cable or a commercially available adapter must be used.

6.2134.100

830

Fig. 4: Connection of 830 IC Interface to PC

2.3.2 Software installation

The PC program «IC Net 2.3» is required for the operation of the 830 IC

Interface; this is contained on the 6.6034.033 CD included in the accessories. This program runs under Windows 2000 and Windows XP operating systems and is installed according to section 1.4.2 of the «IC Net»

Instructions for Use.

830 IC Interface / 8.830.1003 Instructions for Use

9

Page 16

2 Installation

2.4 Connection of external instruments

2.4.1 General information

Before an external instrument is connected to the 830 IC Interface, the

3

830 IC Interface must always be switched off using mains switch

Each system of the two versions of the 830 IC Interface has four RS232

interfaces 10 or 14 for connection of a maximum of 8 external instruments, an 7 or 11 interface for analog signals from a maximum of 2 detectors and 8 remote output lines 8/9 or 12/13 for controlling external

instruments by making contacts or impulses (see Fig. 3). Information

about the technical data of these interfaces is given in section 4.1.

For installation and startup of external instruments proceed as follows:

1 Switch off all instruments

!

• Switch off 830 IC Interface and all external instruments using

the mains switch.

2 Connect instruments

• Connect the instruments to the 830 IC Interface according to

the connection diagrams shown in sections 2.4.2 to 2.4.15 by

using the cables named in the diagrams. Other instrument

combinations can be set up by using these examples as a

guide.

3 Switch on all instruments

• Switch on 830 IC Interface and all external instruments using

the mains switch.

4 Instrument settings

Operation with the 830 IC Interface requires that the following

settings must be made:

• Advanced IC instruments:

818 IC Pump

819 IC Detector

820 IC Separation Center

833 IC Liquid Handling Unit

These instruments are already pre-configured, no additional

settings must be made.

Also all other Metrohm IC instruments can be operated with the

830 IC Interface, for the settings of the instruments please refer

to the respective instructions for use.

• 732 IC Detector:

>CONFIG/RS settings

handshake: SWchar

10

830 IC Interface / 8.830.1003 Instructions for Use

Page 17

2.4 Connection of external instruments

>CONFIG/RS settings

RS control: on

• 709 IC Pump:

Switch on external control of the 709 IC Pump using the

[ EXT. ] key.

• 752 IC Pump Unit, 753 IC Suppressor Module,

754 IC Dialysis Unit:

Switch on external control via remote interface using the

[ Remote ] switch.

• 817 Bioscan:

This instrument is already pre-configured, no additional settings must be made.

• 761 Compact IC:

This instrument is already pre-configured, no additional settings must be made.

• 750 IC Autosampler:

Always switch on the 830 IC Interface first and then the 750

Autosampler.

• 766 IC Sample Processor:

>RS232 settings

handshake: SWchar

>RS232 settings

RS control: on

• Triathlon Autosampler:

This instrument is already pre-configured, no additional settings must be made.

• 812 IC Valve Unit:

This instrument is already pre-configured, no additional settings must be made.

• 816 IC Eluent Selector:

Switch on external control via RS232 interface using the

[ EXT ] switch..

• 828 IC Dual Suppresso:

Switch on external control via remote interface using the

[ Remote ] switch.

• 837 IC Degasser:

This instrument is already pre-configured, no additional settings must be made.

5 Create new system in «IC Net»

• Start the «IC Net» program.

• Create a new system file with the selected instruments (de-

830 IC Interface / 8.830.1003 Instructions for Use

tails see IC Net Instructions for Use).

11

Page 18

2 Installation

2.4.2 819 IC Detector, 820 IC Separation Center, 818 IC Pump

Example

Analysis of anions or cations on a modular system with electronic suppression.

Instruments

The setup of the instruments corresponds to the Modular IC System 1

(MIC 1 Advanced).

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center with 1 injector and

column heater

• 2.818.0110 818 IC Pump

819

6.2134.130

820

6.2115.070

PC

6.2134.100

818830

6.2134.040

6.2134.090

Interconncection

Fig. 5: Connection of 819, 820 and 818 (MIC 1)

6.2125.090

12

830 IC Interface / 8.830.1003 Instructions for Use

Page 19

2.4 Connection of external instruments

2.4.3 833 IC Liquid Handling Pump Unit

Example

Analysis of anions or cations on a modular system with chemical suppression.

Instruments

The setup of the instruments corresponds to the Modular IC System 2

(MIC 2 Advanced).

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0230 820 IC Separation Center with 1 injector,

suppressor module and column heater

• 2.818.0110 818 IC Pump

• 2.833.0010 833 IC Liquid Handling Pump Unit

819

6.2134.130

820

6.2125.090

6.2115.070

PC

6.2134.100

818830

6.2134.040

6.2134.090

6.2128.180

833

Interconnection

Fig. 6: Connection of 820, 819, 818 and 833(Pump Unit) (MIC 2)

830 IC Interface / 8.830.1003 Instructions for Use

13

Page 20

2 Installation

2.4.4 833 IC Liquid Handling Suppressor-Unit

Example

Simultaneous analysis of cations and anions on a modular system with

two independent detectors.

Instruments

The setup of the instruments corresponds to the Modular IC System 3

(MIC 3 Advanced).

• 2.830.0020 830 IC Interface

• 2.819.0010 819 IC Detector for System 1 (cations)

• 2.819.0110 819IC Detector für System 2 (anions)

• 2.820.0220 820 IC Separation Center with 2 injectors and

column heater

• 2.818.0110 818 IC Pump, for System 1 (cations)

• 2.818.0110 818 IC Pumpe, for System 2 (anions)

• 2.833.0020 833 IC Liquid Handling Suppressor Unit,

for System 2 (anions)

PC

Interconnection

6.2134.100

6.2134.130

6.2134.130

6.2134.040

6.2134.090

819-1

820

6.2115.070

818-1830

6.2125.090

6.2115.070

819-2

6.2125.090

818-2

833

6.2143.200

6.2134.090

6.2128.180

Fig. 7: Connection of 2

×

819, 820, 2×818 and 833 (Suppressor Unit)

(MIC 3)

14

830 IC Interface / 8.830.1003 Instructions for Use

Page 21

2.4 Connection of external instruments

2.4.5 833 IC Liquid Handling Sample Prep Unit

Example

Neutralization of an alkaline sample for anion determination with chemical suppression.

Instruments

The setup of the instruments corresponds to the Modular IC System 6

(MIC 6) enhanced by the IC Liquid Handling Sample Prep Module

833 (2.833.0030).

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0220 820 IC Separation Center with 2 injectors and

column heater

• 2.818.0110 818 IC Pump

• 2.833.0010 833 IC Liquid Handling Pump Unit

• 2.833.0020 833 IC Liquid Handling Suppressor Unit

• 2.833.0030 833 IC Liquid Handling Sample Prep Unit

Interconnection

830

6.2134.130

6.2134.040

6.2128.180

PC

6.2134.100

6.2134.090

833 Sample Prep

833 Suppressor

6.2115.070

833 Pump

6.2128.180

6.2143.210

6.2143.200

819

820

B (LOOP) A (PCC)

6.2128.180

818

6.2125.120

6.2141.110

6.2125.090

766

6.2134.090

Fig. 8: Connection of 833 (Sample Prep Unit) to MIC 6 for Neutralization

830 IC Interface / 8.830.1003 Instructions for Use

15

Page 22

2 Installation

2.4.6 833 IC Liquid Handling Dialysis Unit

Example

Analysis of anions on a modular system with chemical suppression after preceding sample dialysis.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0220 820 IC Separation Center 820 with 2 injectors and

column heater

• 2.818.0110 818 IC Pump

• 2.833.0020 833 IC Liquid Handling Suppressor Unit

• 2.833.0040 833 IC Liquid Handling Dialysis Unit

Interconnection

819

6.2134.130

6.2143.220

820

6.2125.090

6.2115.070

833 Dialysis

PC

6.2134.100

818830

6.2134.040

6.2134.090

833 Suppressor

Fig. 9: Connection of 819, 820, 818, 833 (Suppressor Unit) and

833 (Dialysis Unit)

16

830 IC Interface / 8.830.1003 Instructions for Use

Page 23

2.4 Connection of external instruments

2.4.7 833 IC Liquid Handling Ultra Filtration Unit

Example

Analysis of anions on a modular system with chemical suppression after preceding sample filtration, for strongly contaminated samples.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center 820 with 1 injector and

column heater

• 2.818.0110 818 IC Pump

• 2.833.0020 833 IC Liquid Handling Suppressor Unit

• 2.833.0050 833 IC Liquid Handling Ultra Filtration Unit

Interconnection

819

6.2134.130

6.2143.220

820

6.2125.090

6.2115.070

833 Ultra Filtration

PC

6.2134.100

818830

6.2134.040

6.2134.090

833 Suppressor

Fig. 10: Connection of 819, 820, 818, 833 (Suppressor Unit) and

833 (Ultra Filtration Unit)

830 IC Interface / 8.830.1003 Instructions for Use

17

Page 24

2 Installation

2.4.8 Triathlon Autosampler

Example

Automatic analysis of anions or cations on a modular system with electronic suppression using the Triathlon Autosampler.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center 820 with 1 injector and

column heater

• 2.818.0110 818 IC Pump

• 2.135.0100 Triathlon Autosampler

Interconnection

819

6.2134.130

820

6.2125.090

6.2115.070

Triathlon

PC

6.2134.100

818830

6.2134.040

6.2134.090

6.2134.000

Fig. 11: Connection of 819, 820, 818 and Triathlon

18

830 IC Interface / 8.830.1003 Instructions for Use

Page 25

2.4 Connection of external instruments

2.4.9 766 IC Sample Processor

Example

Automatic analysis of anions or cations on a modular system with electronic suppression using the 766 IC Sample Processor.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center 820 with 1 injector and

column heater

• 2.818.0110 818 IC Pump

• 2.766.0010 766 IC Sample Processor

Interconnection

819

6.2134.130

820

6.2125.090

6.2115.070

PC

6.2134.100

818830

766

6.2134.040

6.2134.090

6.2134.080

6.2141.110

Fig. 12: Connection of 819, 820, 818 and 766

830 IC Interface / 8.830.1003 Instructions for Use

19

Page 26

2 Installation

2.4.10 791 IC VA Detector

Example

Analysis of anions or cations on a modular system with electronic suppression and with simultaneous conductometric and electrochemical

detection.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center with 1 injector and

column heater

• 2.818.0110 818 IC Pump

• 2.791.0020 791 IC VA Detector

Interconnection

819

6.2134.130

820

6.2125.090

6.2115.070

6.2134.100

6.2134.040

PC

818830

6.2134.090

6.2128.130

791

Fig. 13: Connection of 819, 820, 818 and 791

20

830 IC Interface / 8.830.1003 Instructions for Use

Page 27

2.4 Connection of external instruments

2.4.11 761 Compact IC

Example

Connection of a modular system and a 761 Compact IC to a 830 IC Interface (if not enough COM ports are available at the PC).

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center with 1 injector and

column heater

• 2.818.0110 818 IC Pump

• 2.761.0020 761 Compact IC with suppressor module

Interconnection

819

6.2134.130

820

6.2125.090

6.2115.070

761

PC

6.2134.100

818830

6.2134.040

6.2134.090

6.2134.100

Fig. 14: Connection of 819, 820, 818 and 761

830 IC Interface / 8.830.1003 Instructions for Use

21

Page 28

2 Installation

2.4.12 812 IC Valve Unit and 817 Bioscan

Example

Modular system for sugar analysis.

Instruments

The setup of the instruments corresponds to the Modular IC System 8

(MIC 8 Advanced) enhanced by the 830 IC Interface.

• 2.830.0020 830 IC Interface

• 2.817.0010 817 Bioscan

• 2.812.0010 812 IC Valve Unit 812 with 1 valve

• 2.818.0110 818 IC Pump

Interconnection

817

1

AUX 1

AUX 2

1 2 3 4 5 6 7 8 9

2

+ Adapter 6.2125.150

812

PC

6.2134.100

830

6.2134.090

6.2128.100

818

Fig. 15: Connection of 817, 812 and 818 (MIC 8)

Ground

Fill

Inject

22

830 IC Interface / 8.830.1003 Instructions for Use

Page 29

2.4 Connection of external instruments

2.4.13 816 IC Eluent Selector

Example

Analysis of anions on a modular system with chemical suppression and

step gradients.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0230 820 IC Separation Center with 1 injector,

suppressor module and column heater

• 2.818.0110 818 IC Pump

• 2.816.0010 816 IC Eluent Selector

Interconnection

819

6.2134.130

820

6.2115.070

PC

6.2134.100

818830

6.2134.040

6.2134.090

6.2134.080

Fig. 16: Connection to 819, 820, 818 and 816

6.2125.090

816

830 IC Interface / 8.830.1003 Instructions for Use

23

Page 30

2 Installation

2.4.14 828 IC Dual Suppressor

Example

Analysis of anions on a modular system using binary high-pressure

gradients with chemical suppression.

Instruments

The setup of the instruments corresponds to the Modular IC System 10 (MIC 10 Advanced)

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0210 820 IC Separation Center with 1 injector,

suppressor module and column heater

• 2.818.0110 818 IC Pump, 2 devices

• 2.828.0010 828 IC Dual Suppressor

PC

6.2134.100

830

6.2134.130

819

6.2125.090

820

6.2134.040

6.2115.070

828

6.2128.180

818

6.2134.090

818

6.2134.080

Interconnection

Fig. 17: Connection to 819, 820, 2x818 and 828 (MIC 10)

24

830 IC Interface / 8.830.1003 Instructions for Use

Page 31

2.4 Connection of external instruments

2.4.15 837 IC Combi Degasser

Example

Analysis of anions on a modular system with chemical suppression and

automatic degassing of sample and eluent.

Instruments

• 2.830.0020 830 IC Interface

• 2.819.0110 819 IC Detector

• 2.820.0230 820 IC Separation Center with 1 injector and

suppressor module and column heater

• 2.818.0010 818 IC Pump

• 2.837.0030 837 IC Combi Degasser

Interconnection

819

6.2134.130

820

6.2115.070

PC

6.2134.100

818830

6.2134.040

6.2134.090

6.2128.180

Fig. 18: Connection to 819, 820, 818 and 837

6.2125.090

837

830 IC Interface / 8.830.1003 Instructions for Use

25

Page 32

3 Operation

3 Operation

The operation of 830 IC Interface is made completely via the Metrohm

software «IC Net».

This section describes only the most important points concerning the

operation of the 830 IC Interface. For further details please refer to the

«IC Net» Instructions for Use and to the on-line help in the PC program.

3.1 Switch instrument on/off

The 830 IC Interface is switched on and off using mains switch 3 on the

rear of the instrument (see Fig. 3).

After the instrument has been switched on a self-test is running. The

mains pilot lamp 1 flashes twice slowly and remains on to show that the

instrument is ready for use, if an error ocurrs the mains pilot lamp 1

starts flashing fast.

If the mains pilot lamp is flashing fast after the instrument is switched

on an error occured. Switch the instrument off and on, if the error

remains, refer to the Metrohm service.

26

830 IC Interface / 8.830.1003 Instructions for Use

Page 33

3.2 Settings in the "830 IC Interface" window

3.2 Settings in the "830 IC Interface" window

By clicking the 830 icon in the toolbar with the left mouse button or by

Open

Init

clicking this icon with the right mouse button and selecting the

menu item the

It consists of three tabs

830 IC Interface window for parameter settings is opened.

Init, RS settings, and Links.

The Init tab of the 830 IC Interface window contains data acquisition parameters for the 830 IC Interface.

Label Optional label to name the interface with

maximum 8 characters.

ROM version Instrument program version number .

Measuring per second Number of data points measured per s.

Entry range: 10, 20, 30, 50, 60 points/s

Range Range for AD converter .

Example: converts ± 2500 mV to 224 bits

Entry range:

39.062 mV

<SET> Send current parameters to 830 IC Interface.

2500, 1250, 625, 312.5, 156.25, 78.125,

830 IC Interface / 8.830.1003 Instructions for Use

27

Page 34

3 Operation

RS settings

The

RS settings tab of the 830 IC Interface window contains RS232 pa-

rameters for the 830 IC Interface.

Protected Protocol

Data transfer with Protected Protocol between

830 IC Interface and PC for enhanced data secu-

rity.

Data transfer without Protected Protocol be-

tween

if there is a problem with the RS communication

using the Protected Protocol.

Baud Rate Display of the baud rate of the device.

Parity Display of the parity check .

Handshake Display of the software handshake mode.

FIFO size Display of the intermediate memory in byte.

The values are displayed correctly only if the 830 IC Interface is connected and switched on.

830 IC Interface and PC, select this option

28

830 IC Interface / 8.830.1003 Instructions for Use

Page 35

3.2 Settings in the "830 IC Interface" window

Links

The

Links tab of the 830 IC Interface is used for RS232 interface (COM

port) selection and settings.

Alias Name of the instrument.

COM # If this entry is clicked with the right mouse but-

ton, the following menu appears:

Put on desktop Possibility for setting RS232 interface parame-

ters (details see on-line help).

Change Possibility for changing the RS232 interface.

The following window is opened, where the

COM port can be changed by clicking on the

desired entry.

830 IC Interface / 8.830.1003 Instructions for Use

29

Page 36

3 Operation

3.2.1 Event output lines

830 System [1] or 830 System [2] window are available in the SYSTEM

The

window if the

Install existing devices option. The 830 System [#] window with pro-

the

grams and settings for the seven event output lines is opened by selecting the

clicking the

tabs

Time program

On the

program for the event output lines of the 830 IC Interface can be entered. This program is started automatically as defined in the

window either at the moment the determination is started (

termination

Program and Events setup.

Program tab of the 830 System [#] window a user-defined time

830 System [1] or 830 System [2] have been installed with

Open menu item with the right mouse button or by double-

830 icon added to the SYSTEM window. It consists of the

Start mode

Start with de-

) or at the moment the sample is injected (Start with inject).

The Program tab contains the two following subpages::

Program Main time program with all program steps.

Events configuration Possibility for creation of user-defined remote

commands.

30

830 IC Interface / 8.830.1003 Instructions for Use

Page 37

3.2 Settings in the "830 IC Interface" window

Program

On the

Program subpage, program steps including time, program in-

struction and parameter can be entered.

Erste Spalte Time at which program instruction is applied.

Entry range:

0.0 ... 999.9 min

If no time is entered, the program instruction is

applied together with the last instruction with

time entry.

Zweite Spalte Program instruction (see below).

In addition to these predefined instructions,

user-defined remote commands can be entered if activated on the

Dritte Spalte Parameter for program instruction (see below).

ENABLED Enable program start (a disabled program is

Events configuration tab.

not started).

<Add> Add new program instruction.

<Delete> Delete selected program instruction.

<Verify> Test the time program (error messages are dis-

played if program is wrong).

List of program instructions

The following program instructions can be added to the time program

on the

Instruction

Events 0, 1, p, * Set event output lines 1...7 to the desired

Program subpage:

Entry Meaning

values. For entry of the first value, enter

or

*. For entry of the other values, move the

1, 0, p

cursor in front of the value to be changed and

enter

1, 0, p or *.

Program END, RESET The END flag can be used to end a program,

especially if the program time should be longer

than the chromatogram duration. Additional

steps after this flag are not allowed. The

RESET

flag is used to reset the parameters to the

system startup values.

830 IC Interface / 8.830.1003 Instructions for Use

31

Page 38

3 Operation

Events configuration

On the

Events configuration subtab user-defined event commands can

be defined, which can be inserted into a time program after being activated with

<Activate>.

Name (1st column) User-definable name of the event command

(e.g.

Start_766).

Remotebefehl (2nd column)

Setting the event output lines 1…7.

Selection:

0 (line off, inactive, open)

1 (line on, active, 0 V)

p (pulse, pulse length 150 ms)

* (leave line in current status)

For entry of the first value, enter

entry of the other values, move the cursor in

front of the value to be changed and enter

p or *.

<Add> Add new remote command.

<Delete> Delete selected remote command.

<Activate> Activate the defined remote commands for in-

sertion into the time program.

1, 0, p or *. For

1, 0,

32

830 IC Interface / 8.830.1003 Instructions for Use

Page 39

3.2 Settings in the "830 IC Interface" window

Events setup

The

Events setup tab of the 830 System [#] window contains the startup

values for the seven event output lines of system 1 or system 2 of the

830 IC Interface. These startup values are sent each time the system is

connected or a determination is started.

Each event output line can be set to the following values:

0 Line off, inactive (open)

1 Line on, active (0 V)

For technical data to the event output lines see section 4.1.

830 IC Interface / 8.830.1003 Instructions for Use

33

Page 40

4 Appendix

4 Appendix

4.1 Technical data

Mains connection

Voltage 100...240 V

Frequency 50...60 Hz

Power consumption 7 W

Fuse 2 × 1 ATH (to be replaced by Metrohm Service

PC interface (RS232)

Connector Dsub connector 9 pin (male)

Baud rate 1'200…115'200

Provided that nothing to the contrary is mentioned, the

published data are typical values for the 830 IC Interface

at an ambient temperature of 25°C.

only using the same type)

Additional electronic overload protection

15

96

Data bits 8

Stop bits 1

Handshake Xon/Xoff, none

Parity none, even, odd

FIFO 0…16 Bytes

Pin assignment

Pin 1,4,6: internally connected

Pin 2: RxD (Received Data)

Pin 3: TxD (Transmitted Data)

Pin 5: GND (Signal Ground)

Pin 7,8: internally connected

34

830 IC Interface / 8.830.1003 Instructions for Use

Page 41

4.1 Technical data

t

Rs232 interfaces

Connector Dsub connector 9 pin (male)

15

96

Baud rate 1'200…115'200 (für Dev. 8 1'200…19'200)

Data bits 7, 8

Stop bits 1, 2

Handshake Xon/Xoff, none

Parity none, even, odd

FIFO 0…16 Bytes (für Dev. 8 not available)

Pin assignment

Remote interface (Events)

Output lines

Input lines

Pin 2: RxD (Received Data) for Dev. 1…4

Pin 3: TxD (Transmitted Data) for Dev. 1…4

Pin 5: GND (Signal Ground) for Dev. 1…4

Pin 7: TxD (Transmitted Data) for Dev. 5…8

Pin 8: RxD (Received Data) for Dev. 5…8

Pin 9: GND (Signal Ground) for Dev. 5…8

7 potential-free relay contacts per system for

controlling external instruments.

RUN

Maximum contact load:

30 V / 1 A DC

COM

1 digital input per system for external method

start.

+5V

470k

47k

RUN

Ext. Star

COM

Maximum load for external contact:

approx. 0.1 mA at max. cut-off voltage of approx.

5 V

830 IC Interface / 8.830.1003 Instructions for Use

35

Page 42

4 Appendix

Analog signal interface

Function

2 potential-free analog signal inputs per system.

Connector Dsub connector 9 pin (female)

15

69

Input voltage range ± 2.5 V

Input amplification 1, 2, 4, 8, 16, 32, 64 (selectable)

Sampling rate 10, 20, 30, 50, 60 measuring pooints/s

Resolution 24 bit (1 LSP = 0.298 µV at amplification 1)

Noise < 20 µVpp

< 3 µVrms (at 0 V input voltage, amplification 1

and sampling rate 10 Hz)

Zero error ± 2.5 mV

Pin assignment

Pin 1,4,5,8,9: GND (ground, connected to

housing)

Pin 2: Analog 1+

Pin 3: Analog 1–

Pin 6: Analog 2+

Pin 7: Analog 2–

Safety specifications

Construction/testing according to EN/IEC 61010-1 / UL 3101-1,

protection class 1, degree of protection IP40

Safety directions The Instructions for Use include information and

warnings which must be heeded by the user to

assure safe operation of the instrument.

Electromagnetic compatibility (EMC)

Emitted interference Standards met:

- EN/IEC 61326

- EN 55022

- CISPR 22

Immunity to interference Standards met:

- EN/IEC 61326

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-8

- EN/IEC 61000-4-11

- EN/IEC 61000-4-14

- NAMUR

36

830 IC Interface / 8.830.1003 Instructions for Use

Page 43

4.1 Technical data

Ambient temperature

Nominal operating range +5…+45°C

(at 20…80 % atmospheric humidity)

Storage, transport –20…+70°C

Housing

Material of cover Polyurethane rigid foam (PUR) with fire protection

for fire class UL94VO, CFC-free

Material of base Steel, enameled

Dimensions

Width 260 mm

Height 130 mm

Depth 340 mm

Weight (with accessories) 4.8 kg

830 IC Interface / 8.830.1003 Instructions for Use

37

Page 44

4 Appendix

4.2 Scope of delivery

Subject to changes !

The 830 IC Interface 2.830.0020 for 2 IC systems includes the following

parts:

Quant. Order-No. Description

2 6.2115.070 Remote Connection cable

Connection cable 830 IC Interface –

820 IC Separation Center

2 6.2134.130 Connection cable

Connection cable 830 IC Interface –

819 IC Detrector

2 6.2134.090 RS232 connection cable

Connection cable 830 IC Interface –

2 external devices (818, 819, 766,

etc.)

1 6.2134.100 RS232 connection cable

Connection cable 830 IC Interface –

PC

1 6.6034.033 Software CD «IC Net 2.3»

1 6.2122.0X0 Mains cable

according to customer's specification:

Cable socket

Type IEC 320/C 13 Type SEV 12 (CH…) ............................... 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…)........................... 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) ...................... 6.2122.070

1 8.830.1003 Instructions for Use (english)

for 830 IC Interface

1 8.110.8283 Instructions for Use «IC Net» (english)

for PC program «IC Net 2.3»

1 8.110.8293 Compliance White Paper (english)

for PC program «IC Net 2.3»

1 8.110.8303 Administrator Manual «IC Cap 1.0» (english)

for PC program «IC Cap 1.0»

Cable plug

1 8.110.8309 User Manual «IC Cap 1.0» (english)

for PC program «IC Cap 1.0»

38

830 IC Interface / 8.830.1003 Instructions for Use

Page 45

4.3 Optional accessories

1 8.110.8213 Instructions for Use «Autodatabase» (english)

for PC program «Autodatabase 1.0»

1 8.110.8207 Registration card

4.3 Optional accessories

Order-No. Description

6.2128.130 Connection cable

Connection cable 830 IC Interface – 732

analog output (channel 1/2 or 3/4)

6.2128.180 Remote connection cable

Connection cable 830 IC Interface – 833

6.2134.000 RS232 connection cable

Connection cable 830 IC Interface –

Triathlon Autosampler

6.2134.080 RS232 connection cable

Connection cable 830 IC Interface –

1 external device (818, 819, 766, etc.)

6.2141.110 Connection cable

Connection cable 830 IC Interface –

819 IC Detector– 766/788 IC Sample

Processor (accessory part of 766/788)

830 IC Interface / 8.830.1003 Instructions for Use

39

Page 46

4 Appendix

4.4 Validation / GLP

GLP (Good Laboratory Practice) requires, among other things, that the

precision and correctness of analytical instruments is checked at regular intervals by using SOPs (Standard Operating Procedures, SOP). An

example of such a standard operating procedure is available from

Metrohm under the title «Application Bulletin No. 277 – Validation of

Metrohm Ion Chromatography Systems by using Standard Operating Procedures (SOP)». This SOP can be adapted for your ion

chromatography system and used for its validation.

The 830 IC Interface must be included as a part of the whole ion chromatography system, whose most important components include the

pumps, separation columns, detector and evaluation system, in the allembracing validation of the whole system.

Please contact your local Metrohm agency in order to receive support in

validating your 830 IC Interface. It can also provide you with validation

documentation which will help you to carry out your installation qualification (IQ) and operational qualification (OQ).

Further information about QA, GLP and validation can also be found in

the brochure «Quality management with Metrohm» which is also obtainable from your local Metrohm agency.

Checking the electronic and mechanical assemblies of Metrohm instruments can and should be undertaken within the framework of regular servicing by Metrohm technicians. All Metrohm instruments are

equipped with start-up check routines which check that the relevant assemblies are functioning perfectly when the instrument is switched on. If

no error message appears it can be assumed that the instrument is

functioning properly.

The 830 IC Interface also contains a built-in diagnosis program which

allows the service technicians to check the functioning of particular assemblies should faults or malfunctions occur and to localize them.

40

830 IC Interface / 8.830.1003 Instructions for Use

Page 47

4.5 Warranty and Conformity

4.5 Warranty and Conformity

4.5.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In this case, the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty period. For parts of

outside manufacture insofar as these constitute an appreciable part of

our instrument, the warranty stipulations of the manufacturer in question

apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the orderer has no rights or claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedment in

wood shavings or similar material, the parts must be packed in a dustproof package (for instruments, use of a plastic bag is imperative). If

open assemblies are enclosed in the scope of delivery that are sensitive to electromagnetic voltages (e.g. data interfaces etc.) these must

be returned in the associated original protective packaging (e.g. conductive protective bag). (Exception: assemblies with built-in voltage

source belong in a non-conductive protective packaging).

No warranty responsibility whatsoever will be accepted by Metrohm for

damage which arises as a result of non-compliance with these instructions.

830 IC Interface / 8.830.1003 Instructions for Use

41

Page 48

4 Appendix

4.5.2 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well

as to the standard specifications for security and to

system validation issued by the manufacturing company.

Name of commodity 830 IC Interface

System software Stored in ROMs

Name of manufacturer Metrohm Ltd., Herisau, Switzerland

Description

PC controlled chromatography data system for remote control of IC instruments and

for automatic evaluation of chromatograms.

This Metrohm instrument has been built and has undergone final type testing according to the

standards:

CH-9101 Herisau, Switzerland

Tel. +41 71 353 85 85

Fax +41 71 353 89 01

www.metrohm.com

Electromagnetic compatibility: Emission

EN/IEC 61326, EN 55022 / CISPR 22

Electromagnetic compatibility: Immunity

EN/IEC 61326, EN/IEC 61000-4-2, EN/IEC 61000-4-3, EN/IEC 61000-4-4, EN/IEC 61000-4-5, EN/IEC

61000-4-6, EN/IEC 61000-4-8, EN/IEC 61000-4-11, EN/IEC 61000-4-14, NAMUR

Safety specifications

EN/IEC 61010-1, UL 3101-1 protection class I

It has also been certified by ElectroSuisse, which is member of the International Certification Body

(CB/IEC).

The instrument meets the requirements of the CE mark as contained in the EU directives 89/336/EEC

and 73/23/EEC and fulfils the following specifications:

EN 61326 Electrical equipment for measurement, control and laboratory use – EMC requirements

EN 61010-1 Safety requirements for electrical equipment for measurement, control and laboratory

use

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for quality assurance in

design/development, production, installation and servicing.

The system software, stored in Read Only Memories (ROMs) has been validated in connection

with standard operating procedures in respect to functionality and performance.

The technical specifications are documented in the instruction manual.

Herisau, May 28, 2003

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

42

830 IC Interface / 8.830.1003 Instructions for Use

Page 49

4.5 Warranty and Conformity

4.5.3 Quality Management Principles

Metrohm Ltd., CH-9101 Herisau, Switzerland

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Metrohm Ltd. holds the ISO 9001 Certificate, registration number 10872-02, issued by

SQS (Swiss Association for Quality and Management Systems). Internal and external audits are carried out periodically to assure that the standards defined by Metrohm’s QM

Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments are fully

documented and the resulting reports are archived for ten years. The development of

software for PCs and instruments is also duly documented and the documents and

source codes are archived. Both remain the possession of Metrohm. A non-disclosure

agreement may be asked to be provided by those requiring access to them.

The implementation of the ISO 9001

quality system is described in Metrohm’s

QM Manual, which comprises detailed

instructions on the following fields of

activity:

Instrument development

The organisation of the instrument

design, its planning and the intermediate

controls are fully documented and

traceable. Laboratory testing accompanies all phases of instrument development.

Software development

Software development occurs in terms of

the software life cycle. Tests are

performed to detect programming errors

and to assess the program’s functionality in a laboratory environment.

Components

All components used in the Metrohm

instruments have to satisfy the quality

standards that are defined and implemented for our products. Suppliers of

components are audited by Metrohm as

the need arises.

Manufacture

The measures put into practice in the

production of our instruments guarantee

a constant quality standard. Production

planning and manufacturing procedures,

maintenance of production means and

testing of components, intermediate and

finished products are prescribed.

Customer support and service

Customer support involves all phases of

instrument acquisition and use by the

customer, i.e. consulting to define the

adequate equipment for the analytical

problem at hand, delivery of the equipment, user manuals, training, after-sales

service and processing of customer

complaints. The Metrohm service organisation is equipped to support customers in implementing standards such

as GLP, GMP, ISO 900X, in performing

Operational Qualification and Performance Verification of the system components or in carrying out the System

Validation for the quantitative determination of a substance in a given matrix.

830 IC Interface / 8.830.1003 Instructions for Use

43

Page 50

4 Appendix

4.6 Index

7

709 IC Pump

Settings ....................................10

732 IC Detector

Settings ....................................10

750 IC Autosampler

Settings ....................................10

752 IC Pump Unit

Settings ....................................10

753 IC Suppressor Module

Settings ....................................10

754 IC Dialysis Unit

Settings ....................................10

761 Compact IC

Connection to 830 ................... 21

Settings ....................................10

766 IC Sample Processor

Connection to 830 ................... 19

Settings ....................................10

791 IC VA Detector

Connection to 830 ................... 20

8

812 IC Valve Unit

Connection to 830 ................... 22

Settings ....................................10

816 IC Eluent Selector

Connection to 830 ................... 23

Settings ....................................10

817 Bioscan

Connection to 830 ................... 22

Settings ....................................10

818 IC Pump

Connection to 830 ................... 12

Settings ....................................10

819 IC Detector

Connection to 830 ................... 12

Settings ....................................10

820 IC Separation Center

Connection to 830 ................... 12

Settings ....................................10

828 IC Dual Suppressor

Connection to 830 ................... 24

Settings ....................................10

833 IC Liquid Handling Unit

Dialysis Unit

Connection to 830 ............. 16

Pump Unit

Connection to 830 ............. 13

Sample Prep Unit

Connection to 830 ............. 15

Settings ....................................10

Suppressor Unit

Connection to 830 ............. 14

Ultra Filtration Unit

Connection to 830 ............. 17

837 IC Degasser

Connection to 830 ................... 25

Settings ....................................10

A

<Activate> ................................... 32

AD converter ................................27

<Add>.................................... 31, 32

Advanced IC instruments

Settings ....................................10

Alias ..............................................29

Ambient temperature ...................37

Analog connection

11

Figure...................................3

Technical Data...................36

7

Figure...................................3

Technical Data...................36

Analog signal interface.................36

Appendix ......................................34

Arrangement of the instruments ....7

Attention .........................................5

B

Baud Rate .....................................28

C

Cable

6.2125.070................................38

6.2125.110..................................9

6.2128.130................................39

6.2128.180................................39

6.2134.000..........................38, 39

6.2134.080................................39

6.2134.100............................9, 38

6.2134.130................................38

6.2141.110................................39

CE mark........................................ 42

Change .........................................29

Check .............................................7

COM # ..........................................29

Compliance White Paper

IC Net 2.3 8.110.8193 ..............38

Connection possibilities ................. 1

Connections

Figure .........................................3

Technical Data .....................34 ff

to external instruments.............10

to PC........................................... 9

Contents .......................................... I

D

Danger............................................ 5

Declaration of Conformity ............42

Degree of protection ................6, 36

<Delete> ................................ 31, 32

Dimensions ..................................37

E

Earthing ......................................6, 8

Earthing socket 2

Figure .........................................3

Electrical safety ..............................6

Electromagnetic compatibility...... 36

EMC.............................................. 36

Emitted interference ..................... 36

ENABLED ......................................31

END............................................... 31

Event output lines......................... 30

Events ........................................... 31

Events configuration .....................32

Events setup..................................33

External instruments .....................10

External start .................................35

F

FIFO size .......................................28

Front................................................2

Fuse ..............................................34

G

GLP ........................................ 40, 43

GMP..............................................43

H

Handshake ....................................28

Housing ........................................37

I

Illustrations

List ..............................................II

Immunity to interference...............36

Information......................................5

Information on the Instructions for

Use..................................................4

Init .................................................27

Installation.......................................7

Instructions for Use

830 IC Interface 8.830.1003 .4, 38

Autodatabase 8.110.8213........39

IC Cap 1.0 8.110.8303 .............38

IC Cap 1.0 8.110.8309 .............38

IC Net 2.3 8.110.8193 ..............38

Instrument

Description .................................1

Switch on/off.............................26

Introduction.....................................1

IQ ..................................................40

ISO 9100.......................................42

L

Label .............................................27

leakage ...........................................7

Links..............................................29

List

of illustrations..............................II

List of program instructions..........31

Location ..........................................7

M

Mains cable

Mains connection .......................8

Ordering designation ...............38

Mains connection

Procedure ...................................8

Safety notes................................6

Mains connection plug 5

Figure..........................................3

Mains connection .......................8

Mains frequency ...........................34

828 IC Dual Suppressor/ Gebrauchsanweisung 8.828.1001

44

Page 51

4.6 Index

Mains pilot lamp 1

Error ..........................................26

Figure..........................................2

Ready for use display...........8, 26

Mains switch 3

Figure..........................................3

Switching the instrument

on/off.....................................8, 26

Mains voltage ...........................8, 34

Measuring per second ..................27

MIC 1 ............................................12

MIC 2 ............................................13

MIC 3 ............................................14

MIC 6 ............................................15

MIC 8 ............................................22

MIC 10 ..........................................24

N

Name the interface .......................27

Notation ..........................................5

Number of data points .................27

O

Opening the instrument..................6

Operation

via IC Net ..................................26

Optional accessories....................39

OQ ................................................40

Organization ...................................4

P

Packaging.......................................7

Parity.............................................28

Parity check ..................................28

Parts and controls ..........................2

PC connection 6

Connection to the PC .................9

Figure..........................................3

PC interface 6

Technical Data..........................34

Pictograms .....................................5

Power consumption .....................34

Program ..................................30, 31

Program instruction ......................31

Program step ............................... 31

Programm version number.......... 27

Protected Protocol........................ 28

Protection class ................... 6, 8, 36

Protective earth.............................. 8

Pulse ............................................ 32

Put on desktop ............................. 29

Q

QA ................................................ 40

Quality assurance ........................ 40

Quality Management ................... 43

R

Range ........................................... 27

Rear................................................ 3

Registration card 8.110.8207 ...... 39

Remote connection

12

Figure .................................. 3

13

Figure .................................. 3

8

Figure .................................. 3

Technical Data .................. 35

9

Figure .................................. 3

Remote connection 12

Technical Data......................... 35

Remote connection 13

Technical Data......................... 35

Remote connection 9

Technical Data......................... 35

Remote input lines ....................... 35

Remote output lines............... 30, 35

RESET .......................................... 31

ROM version................................. 27

RS settings................................... 28

RS232 interface 10

Figure......................................... 3

Technical Data......................... 35

RS232 interface 14

Figure......................................... 3

Technical Data......................... 35

RS232 parameters....................... 28

S

Safety directions........................... 36

Safety notes ................................... 6

Safety specifications .................... 36

Scope of delivery ......................... 38

Serial number 4

Figure ......................................... 3

<SET>.......................................... 27

Setting up the instrument............... 7

Settings ........................................27

Software CD 6.6034.033.............. 38

Software installation ....................... 9

SOP .............................................. 40

Standard operating procedures ..40

Static charges ................................6

Storage......................................... 37

Switch instrument on/off ..............26

Switching on/off the instrument .....8

T

Technical data.............................. 34

Time program............................... 30

Transport........................................ 7

Transport damage .......................41

Triathlon Autosampler

Connection to Triathlon............ 18

Settings ....................................10

U

User-defined event commands ... 32

V

Validation...................................... 40

<Verify> ....................................... 31

W

Warning .......................................... 5

Warranty ....................................... 41

830 IC Interface / 8.830.1003 Instructions for Use

45

Loading...

Loading...