Page 1

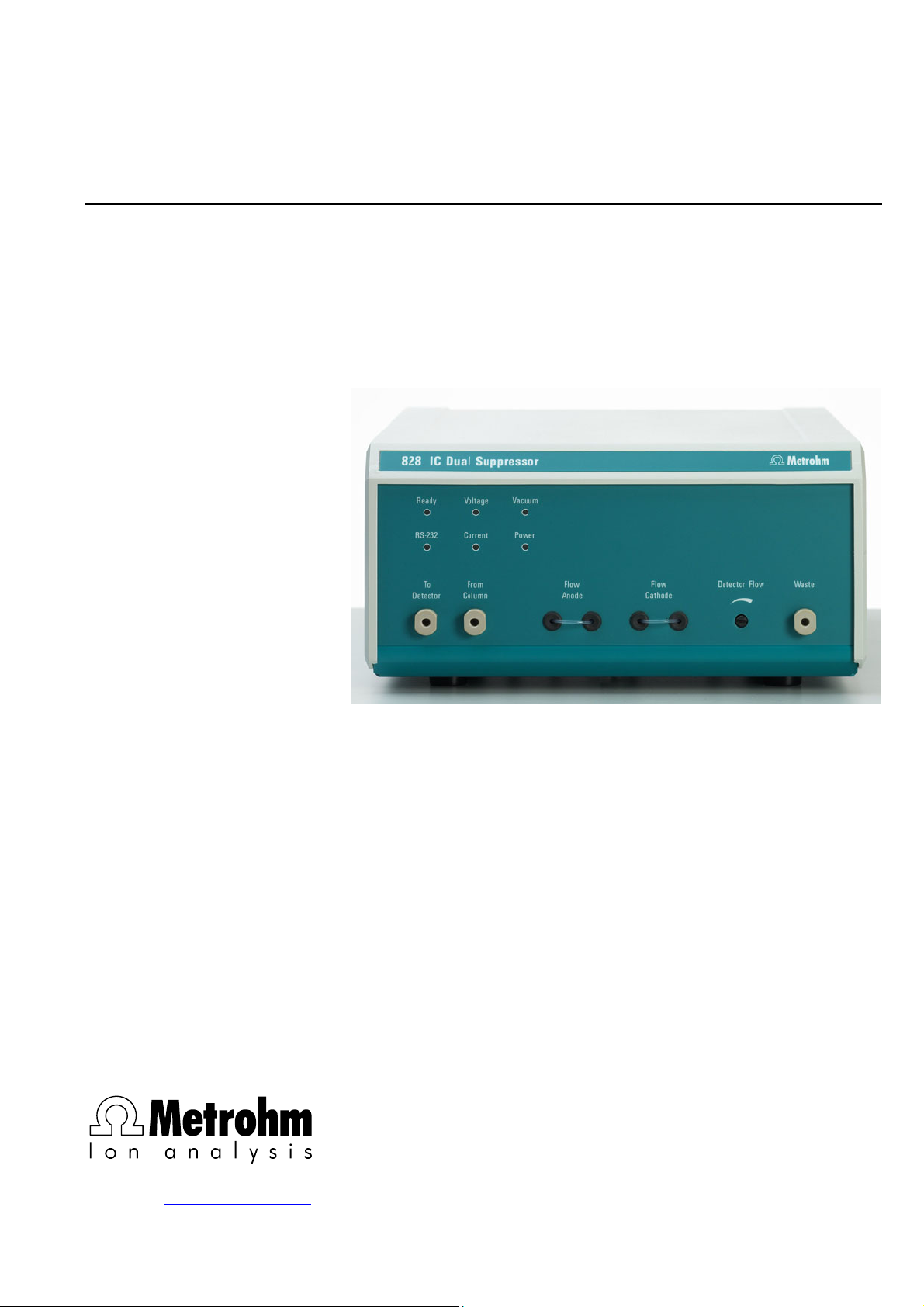

828 IC Dual Suppressor

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Instructions for Use

8.828.1003

Page 2

Page 3

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

828 IC Dual Suppressor

Instructions for Use

8.828.1003 09.2002 / pkl

Page 4

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

1st Edition 2002

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 5

Contents

Table of contents

1 Introduction.................................................... 1

1.1 Instrument description ............................................................. 1

1.2 How it works.............................................................................. 2

1.3 Parts and controls .................................................................... 4

1.4 Information about the Instructions for Use ............................. 7

1.4.1 Organization ..................................................................................7

1.4.2 Notation and pictograms ..............................................................8

1.5 Safety notes ..............................................................................9

1.5.1 Electrical safety..............................................................................9

1.5.2 General safety measures ..............................................................9

2 Installation ................................................... 10

2.1 Instrument setup..................................................................... 10

2.1.1 Packaging.................................................................................... 10

2.1.2 Checks.........................................................................................10

2.1.3 Location ....................................................................................... 10

2.2 Connecting the accessories................................................... 11

2.2.1 Attaching the CO2 absorber cartridge ........................................11

2.3 Mains connection.................................................................... 12

2.3.1 Mains voltage ..............................................................................12

2.3.2 Fuse.............................................................................................12

2.3.3 Mains cable and mains connection ............................................13

2.3.4 Switching the instrument on/off...................................................13

2.4 Connecting to a modular gradient IC system ....................... 14

2.4.1 Electrical connections .................................................................14

2.4.2 Connecting the IC Dual Suppressor ...........................................15

2.4.3 Settings in IC Net 2.1...................................................................17

2.5 Connecting to the 761 Compact IC........................................ 19

2.5.1 Electrical connection ...................................................................19

2.5.2 Connecting the IC Dual Suppressor ...........................................19

2.5.3 Settings for control by the 761 PC Software 1.1 ......................... 20

3 Operation...................................................... 22

3.1 General information................................................................ 22

3.2 Eluent....................................................................................... 23

3.3 Capacity................................................................................... 23

3.4 Degassing unit and CO2 absorber cartridge ......................... 23

3.5 Flow rate ratio ......................................................................... 24

3.5.1 Setting the flow rates ................................................................... 24

3.6 Routine operation ................................................................... 26

3.6.1 Manual operation ........................................................................26

3.6.2 Software control...........................................................................27

4 Troubleshooting - Problems......................... 30

4.1 Remedying faults and problems ............................................ 30

4.2 Chromatography problems .................................................... 30

4.3 Instrument problems ..............................................................32

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

I

Page 6

Contents

5 Care and maintenance ................................33

5.1 Instrument care ....................................................................... 33

5.2 Maintenance by Metrohm Service ......................................... 33

5.3 Shutdown ................................................................................ 33

5.4 Regular maintenance.............................................................. 33

5.4.1 Replacing the CO2 absorber cartridge .......................................34

5.5 Unplanned maintenance work................................................ 34

5.5.1 Regenerating the cation exchanger............................................ 34

5.5.2 Replacing the suppressor cell .................................................... 35

6 Appendix ....................................................... 39

6.1 Technical data......................................................................... 39

6.1.1 Suppressor cell ...........................................................................39

6.1.2 RS 232 interface.......................................................................... 39

6.1.3 Remote interface ......................................................................... 39

6.1.4 Fault switch, ready output........................................................... 40

6.1.5 Mains connection........................................................................ 40

6.1.6 Safety specifications ...................................................................40

6.1.7 Electromagnetic compatibility (EMC) ......................................... 41

6.1.8 Ambient temperature ..................................................................41

6.1.9 Housing ....................................................................................... 41

6.2 Standard equipment ............................................................... 42

6.3 Optional accessories .............................................................. 44

6.4 Validation / GLP ...................................................................... 45

6.5 Warranty and conformity ........................................................ 46

6.5.1 Warranty ......................................................................................46

6.5.2 EU Declaration of Conformity .....................................................47

6.5.3 Certificate of conformity and system validation.......................... 48

6.6 Index ........................................................................................ 49

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

II

Page 7

Contents

List of illustrations

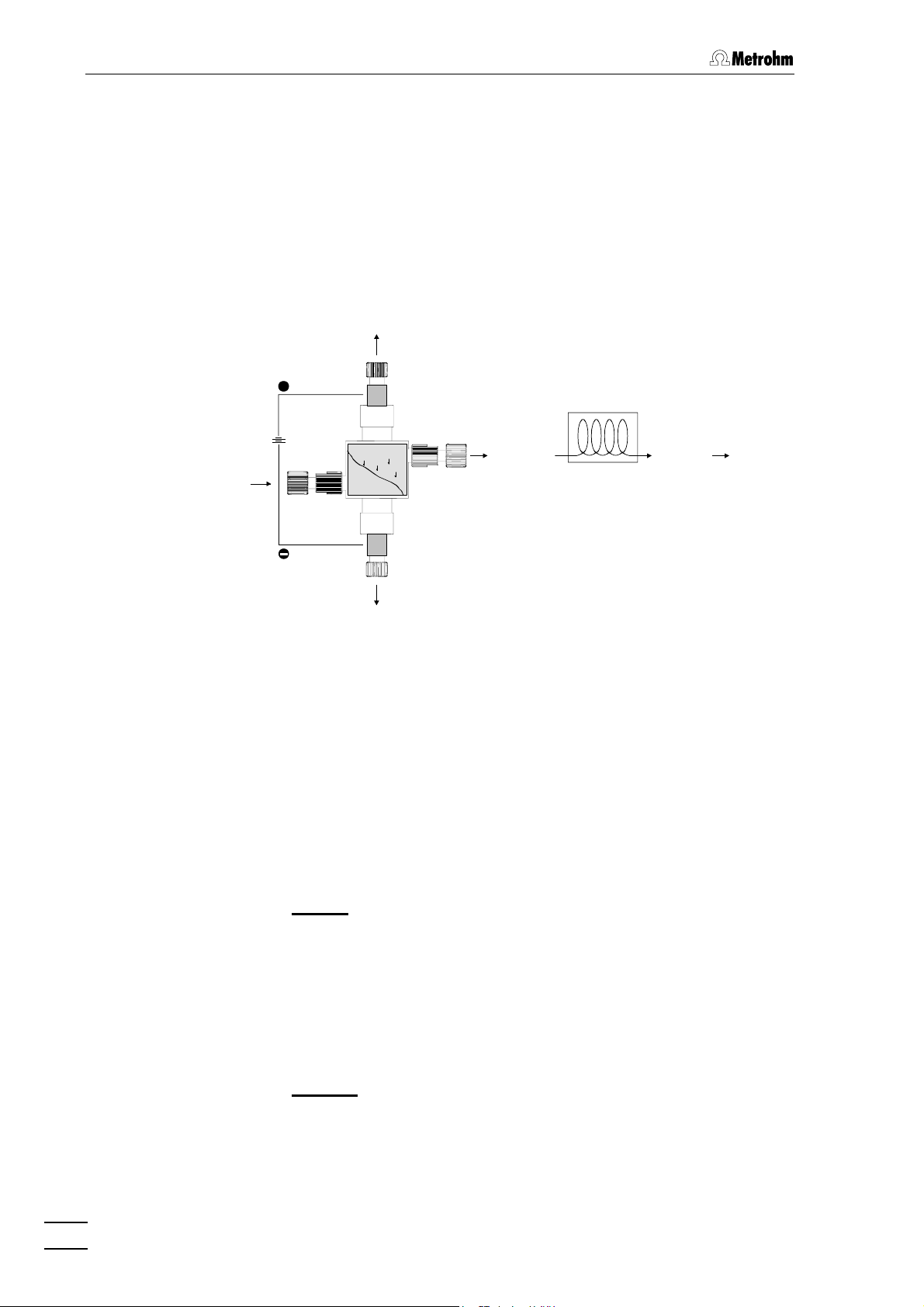

Figure 1: Dual suppressor flow diagram............................................. 2

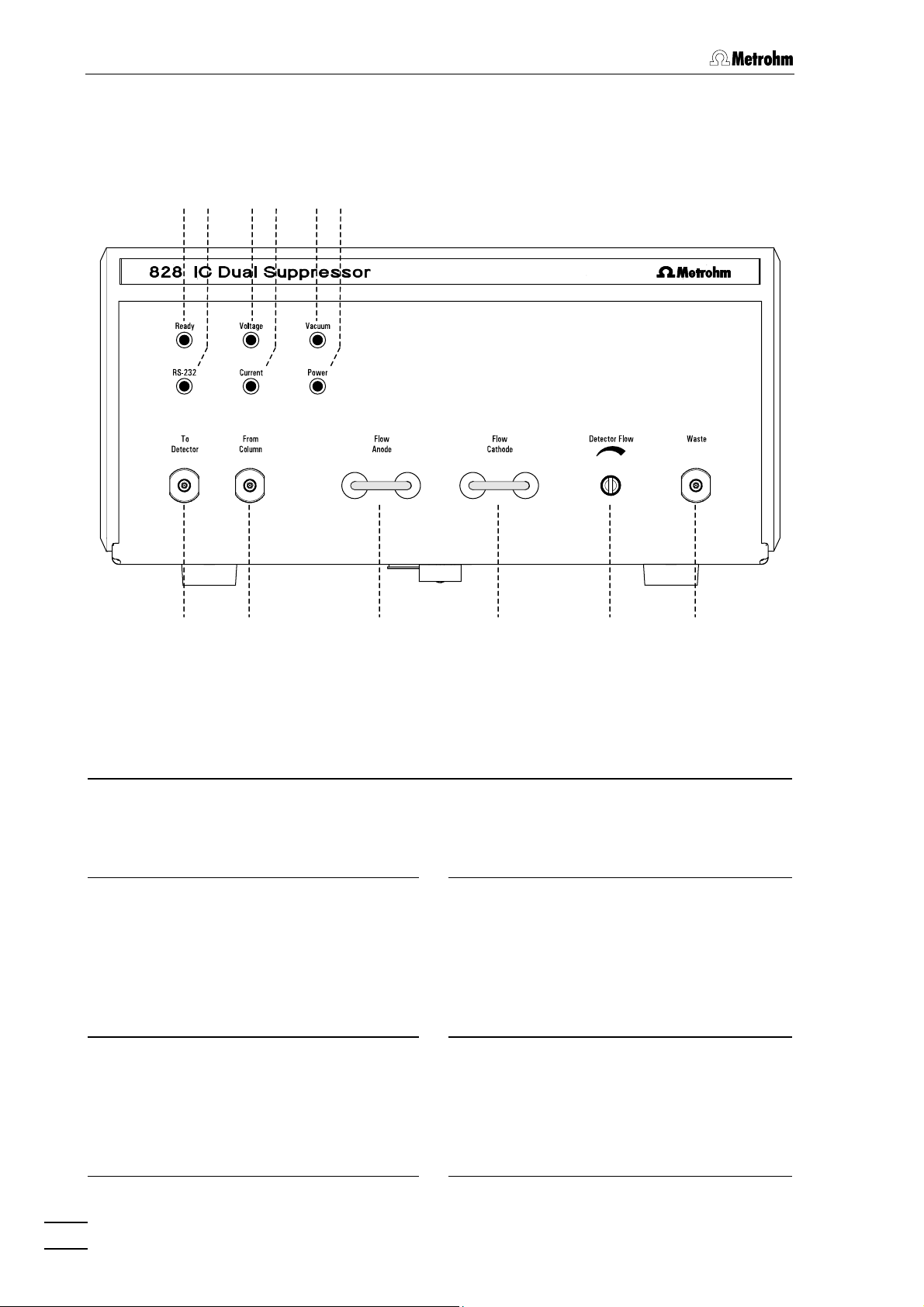

Figure 2: Front panel of the 828 IC Dual Suppressor ......................... 4

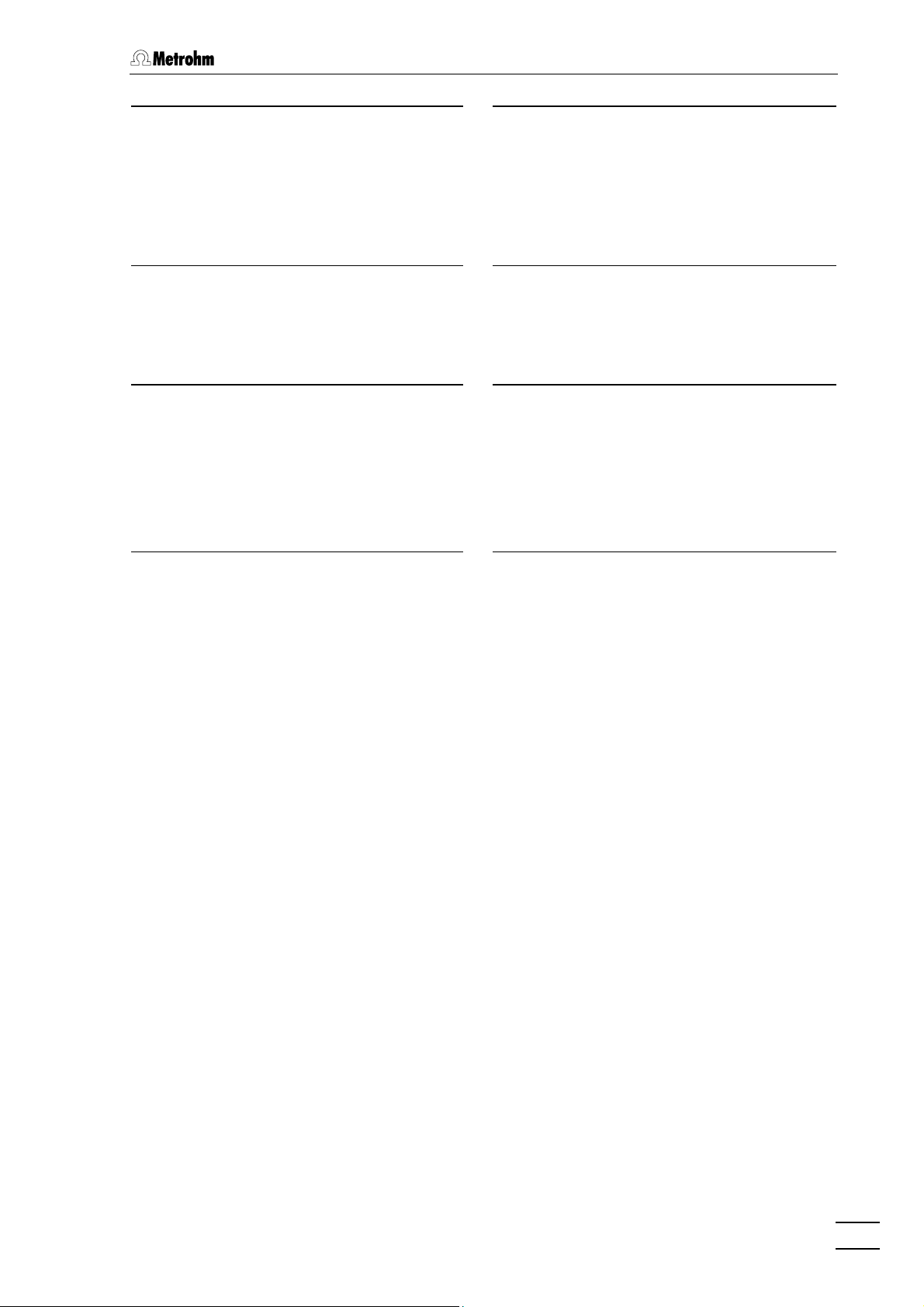

Figure 3: Rear panel of the 828 IC Dual Suppressor .......................... 6

Figure 4: Attaching the CO2 absorber cartridge................................ 11

Figure 5: Electrical connections in the MIC 10 system ..................... 14

Figure 6: Flow diagram of the MIC 10............................................... 15

Figure 7: Connecting the 828 IC Dual Suppressor to

the 761 Compact IC ........................................................... 19

Figure 8: Opening the instrument ..................................................... 36

Figure 9: Opened IC Dual Suppressor.............................................. 37

Figure 10: Suppressor cell position, front view ................................... 38

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

III

Page 8

Contents

List of numbered

parts and controls

LEDs

1 Ready ..................................................................................................... 4

2 RS 232.................................................................................................... 4

3 Voltage ................................................................................................... 4

4 Current................................................................................................... 4

5 Vacuum .................................................................................................. 4

6 Power ..................................................................................................... 4

7 Connection To Detector ........................................................................ 5

8 Connection From Column..................................................................... 5

9 Flow anode............................................................................................ 5

10 Flow cathode......................................................................................... 5

11 Detector flow setting screw .................................................................. 5

12 Connection for Waste............................................................................. 5

13 RS-232 interface..................................................................................... 6

14 Holder for CO

15 Remote switch ...................................................................................... 6

16 Fuse holder, mains switch, mains connection ................................ 6

17 Vacuum pump inlet .............................................................................. 6

18 Ready Output interface ......................................................................... 6

19 Type and serial number....................................................................... 6

20 Drain....................................................................................................... 6

21 Remote interface.................................................................................... 6

22 Vacuum pump exhaust ........................................................................ 6

23 Front housing screws........................................................................ 36

24 Rear housing screws......................................................................... 36

25 Housing cover .................................................................................... 36

26 Suppressor cell ..............................................................................36,37

Trap Cartridge ............................................................. 6

2

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

IV

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 828 IC Dual Suppressor is a continuous, regeneration-free solid

phase suppressor which is used to increase the sensitivity of the

detection of anions in ion chromatography.

As well as the usual chemical suppression of the

carbonate/bicarbonate background, in a second suppression step the

suppressor also removes dissolved CO

background conductivity of the mobile phase even further. This results

in an improved signal-to-noise ratio; peak areas in the ppm-range and

above are increased by approx. 30%. At the same time the areas of the

injection peak (water dip) and the system peak are reduced to a

minimum. The reduction of the injection peak means that the detection

of early-eluting anions is improved; the reduction of the system peak

allows the detection of anions which coelute with the system peak. The

baseline drift is also minimized when carbonate/bicarbonate gradients

are used.

in order to reduce the

2

In Metrohm IC systems the 828 IC Dual Suppressor can be remotely

controlled via a remote interface. It can also be combined with all other

commercially available HPLC systems.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

1

Page 10

1 Introduction

X

X

1.2 How it works

The 828 IC Dual Suppressor is used to increase the sensitivity of the

detection of anions in conductivity measurements. It is installed

between the separation column and the conductivity detector. The IC

Dual Suppressor consists of a suppressor cell, a direct current source

and a degassing unit. After it enters the suppressor cell the eluent

containing the sample ions is split proportionally toward the detector,

anode and cathode as shown in Figure 1.

NaHCO

/Na2CO3 + MX

3

+ O2+ H

2 H

2CO3

Anode

+

+

H+

Na+ form

Resin

IN

Cathode

NaOH + MOH + H2+ NaX

2 H2O 4 H++ O2+ 4 e

H+

H+

H+

OUT

2 H2O + 2 e

-

H2CO3+ HX

+2 OH

H

2

-

Degassing Unit

CO2 + H2O

H

2CO3

-

M = Cations (Na+, K+, Mg2+, etc.)

= Anions

H

O + HX

2

To Detector

Figure 1: Dual suppressor flow diagram

Three processes take place simultaneously in the 828 IC Dual

Suppressor:

1. As the eluent and the sample ions emerge from the separation

column an acid/base reaction converts them to their protonated

forms. The cell is packed with a strong cation exchanger which is

present in protonated form. The following exchange reactions occur

in the suppressor:

Eluent:

NaOH + Resin-SO

-H+

Resin-SO

3

-Na+

3

+ H2O

or

NaHCO

/Na2CO3 + Resin-SO

3

-H+

Resin-SO

3

-Na+

3

+ H2CO3

Sample:

MX + Resin-SO

-H+

Resin-SO

3

-M+

3

+ HX

-

-

, NO

X = Cl

, Br-, etc.

3

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

2

Page 11

1.2 How it works

The counter ions (Na+) of the eluent are exchanged for the hydrogen

+

ions (H

water will be formed; if NaHCO

) of the resin in the cell. If NaOH is used as the eluent then

/Na2CO3 is used as the eluent then

3

carbon dioxide is produced. At the same time the counter ions of the

sample (M

+

= metal cation) are exchanged for protons from the resin.

Together with the sample anions these form acids which have an

increased conductivity, e.g. hydrochloric acid, nitric acid, etc. This

provides an improved signal-to-noise ratio and an improved detection

sensitivity.

2. During the operation of the 828 IC Dual Suppressor a direct current

is constantly applied to the suppressor cell electrodes.

Water in the cell is electrolyzed and the following electrode

reactions take place:

Anode: 2 H

O 4 H+ + O2(g) + 4 e-

2

Cathode: 2 H

O + 2 e- 2 OH- + H2(g)

2

At the anode hydrogen ions and gaseous oxygen are produced; at

the cathode hydroxide ions and gaseous hydrogen. In this way the

hydrogen ions produced at the anode continuously regenerate the

cation exchanger. The sodium cations of the eluent and the cations

of the sample wander toward the cathode in the direct current field.

The eluate that leaves the suppressor cell on the cathode side

contains the hydroxide salts of these cations, gaseous hydrogen

and some sample anions (in the form of their sodium salts). The

eluate at the anode side contains carbonic acid or water together

with gaseous oxygen and some sample ions (protonated form). The

protonated sample anions are eluted toward the detector with

carbonic acid or water.

3. After leaving the suppressor cell all eluates pass through a

degassing unit. Oxygen and hydrogen are removed from the eluate

flows at the anode and cathode sides respectively before they

reach the waste container. The eluate at the OUT connection (see

Figure 1, Figure 10) contains the sample anions and carbonic acid

(if a carbonate/bicarbonate eluent is used) and passes the

degassing unit before reaching the conductivity detector. In the

degassing unit the carbonic acid dissociates to form carbon dioxide

and water. Carbon dioxide is removed and water remains.

This further reduces the background conductivity of the eluate to

provide improved sensitivity and a more stable baseline. This

means that it is possible to use carbonate/bicarbonate gradients.

The injection peak (water dip), which is often overlapped by quickly

eluting anions, and the system peak, which interferes with the

detection of anions which coelute with it, are eliminated.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

3

Page 12

1 Introduction

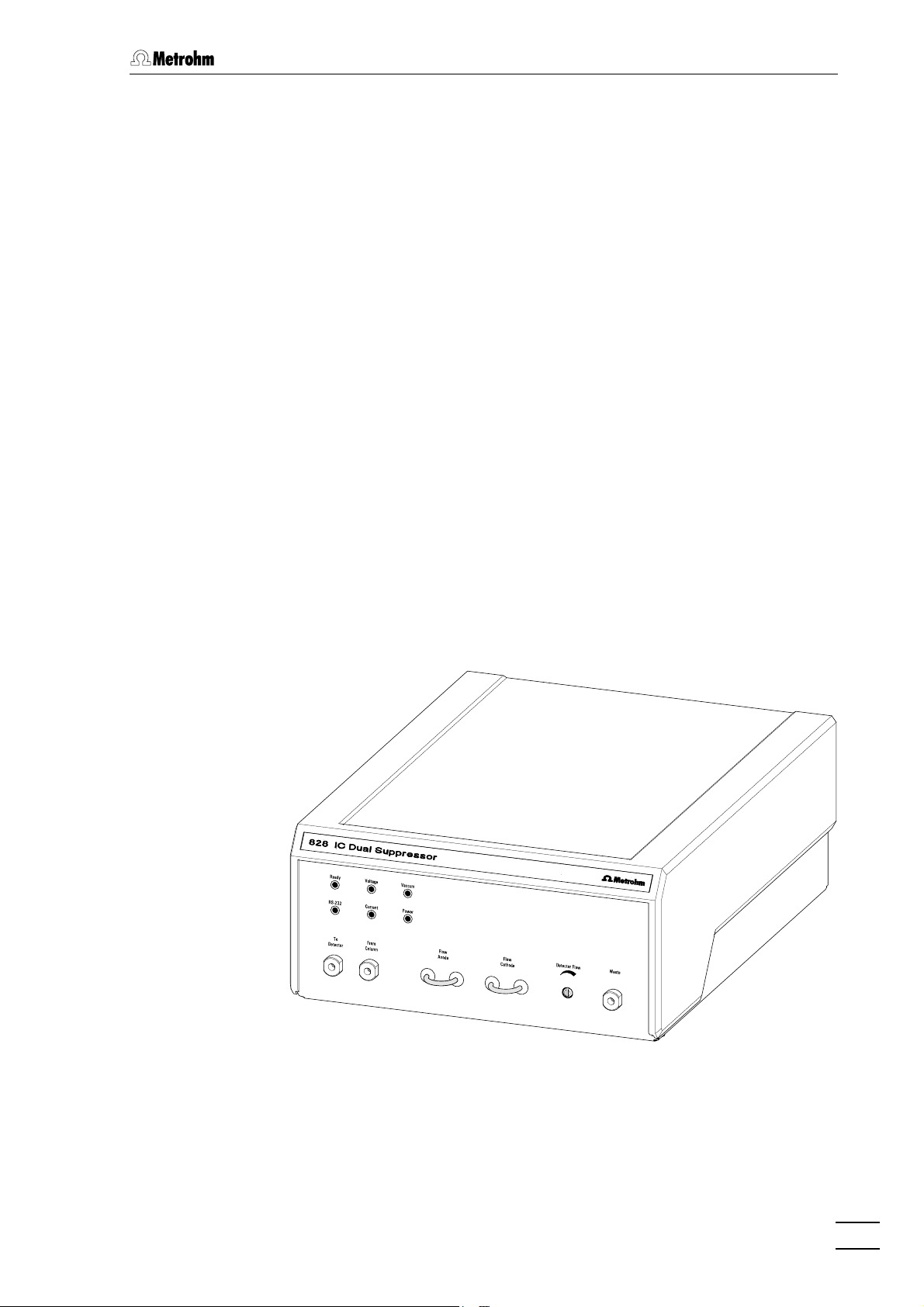

1.3 Parts and controls

12 34 56

78 9 10 11 12

LEDs

The color of the LED indicates the instrument status.

Ready

1

Green: the suppressor is ready for an

analysis.

Red: an error has occurred.

RS-232

2

Green: data transfer via RS 232

connection 13, only for service

purposes.

Figure 2: Front panel of the 828 IC Dual Suppressor

4

5

Current

Green: current is flowing across the

suppressor cell.

Vacuum

Green: the vacuum has operating

pressure.

Red: insufficient vacuum. A leak is

present or the set value has not been

reached within 30 minutes of the

instrument being switched on.

Voltage

3

Green: the voltage applied to the

suppressor cell is within the limits for

normal operation.

Red: the voltage is outside the

operating limits.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

4

6

Power

Green: the Dual Suppressor is

switched on, mains voltage is applied.

Page 13

1.3 Parts and controls

To Detector

7

Inlet connection to detector,

connection for 6.1831.010 PEEK

Capillary with 6.2744.010 PEEK

Pressure screw

From Column

8

Outlet connection from column,

connection for 6.1831.010 PEEK

Capillary with 6.2744.010 PEEK

Pressure screw

9 Flow Anode

For a visual check of the anode

eluate. The liquid from the anode

passes through the FEP tubing before

entering the degassing unit. In normal

operation oxygen bubbles should be

seen regularly.

10

Flow Cathode

For a visual check of the cathode

eluate. The liquid from the cathode

passes through the FEP tubing before

entering the degassing unit. In normal

operation hydrogen bubbles should be

seen regularly.

11

Detector Flow

The flow to the detector can be

regulated with a screwdriver.

12 Waste

Outlet to waste container, connection

for 6.1803.020 PTFE Tubing with

6.2744.010 PEEK Pressure screw

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

5

Page 14

1 Introduction

13 14 15 16

17

18 19 20 21 22

Figure 3: Rear panel of the 828 IC Dual Suppressor

RS 232

13

Interface for service purposes

18

Ready Output

6-pin connector, used as fault switch,

carries status signals (ready/not ready)

to external instruments.

CO

14

Trap Cartridge

2

Holder for CO

absorber-cartridge for

2

19 Type and serial number

cleaning the incoming air

Remote switch

15

Activates the remote control of the

20

Drain

Drain port outlet for liquids

Dual Suppressor via the Remote

connector:

I = ON 0 = OFF

Fuse holder

16

For slow blow fuse 1.0 AT, U.600.0016

Mains switch

21

Remote

Remote interface for remote control by

external instruments.

For switching instrument on/off:

I = ON 0 = OFF

Mains connector

For mains connection see Section 2.3

Vacuum pump inlet

17

Connected to 6.2837.000,

22

Vacuum pump exhaust

see Section 2.2.1

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

6

Page 15

1.4 Information about the Instructions for Use

1.4 Information about the Instructions for Use

Please study these Instructions for Use carefully before you start to

use the 828 IC Dual Suppressor. The instructions contain information

and warnings that must be observed by the user in order to guarantee

the safe use of the instrument. Please keep these instructions near the

instrument so that they are always to hand when required.

1.4.1 Organization

These 8.828.1003 Instructions for Use for the 828 IC Dual

Suppressor provide you with a comprehensive overview of the

installation, startup, troubleshooting and technical specifications of the

instrument. The installation instructions are arranged as follows:

Sect. 1 Introduction

General description of the instrument, operating parts

and controls, and safety notes

Sect. 2 Installation

Installation of the instrument, mains connection,

connection of the accessories, connection to IC system

Sect. 3 Operation

Information about the operation of the 828 IC Dual

Suppressor

Sect. 4 Troubleshooting - Problems

Possible faults and their remedies

Sect. 5 Care and maintenance

Care and maintenance of the instrument

Sect. 6 Appendix

Technical data, standard equipment, optional

accessories, warranty and declaration of conformity,

index

In order to find the information you require about the 828 Dual

Suppressor you should either use the Contents or the Index.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

7

Page 16

1 Introduction

1.4.2 Notation and pictograms

The following notation and pictograms (symbols) are used in these

Instructions:

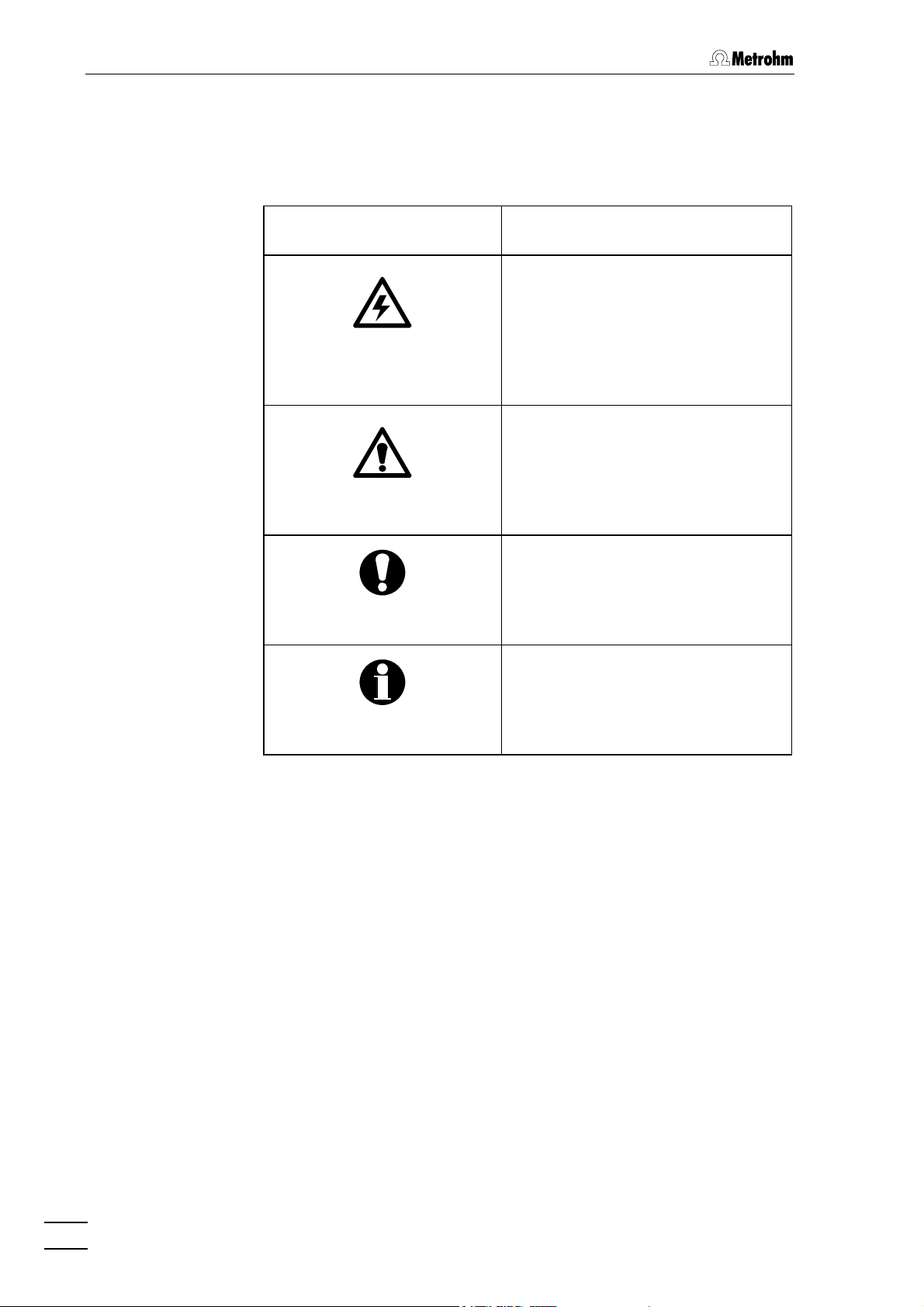

15 828 parts and controls

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components by

electricity.

Danger/Warning

This symbol indicates a possible

risk of death or injury to the user

and possible damage to the

instrument or its components.

Attention

This symbol indicates important

information that you should read

before continuing.

Information

This symbol indicates additional

information and tips which may be

of particular use to you.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

8

Page 17

1.5 Safety notes

1.5 Safety notes

Warning!

This instrument should only be used in accordance with the

information given in these Instructions for Use.

1.5.1 Electrical safety

Electrical safety when handling the 828 IC Dual Suppressor is

guaranteed within the scope of Standard IEC 61010. However, please

observe the following points:

• Mains connection

The mains connection and checking the mains fuse must be

carried out according to the information given in Section 2.3.

• Opening the 828 IC Dual Suppressor

If the 828 IC Dual Suppressor is connected to the mains supply then it

must neither be opened nor should any parts be removed from it, as

otherwise the risk of contact with current-carrying assemblies exists.

This is why the instrument should be separated from all voltage

sources before being opened. Please make sure that the mains

cable is pulled out from mains connector 16!

• Protection against electrostatic charges

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Before touching any assembly within

the 828 IC Dual Suppressor you should ground yourself and any tool

you are using by grasping a grounded object (e.g. the instrument

housing or a radiator) in order to eliminate any electrostatic charge

which may be present.

1.5.2 General safety measures

• Liquid handling

Check all inlet and outlet tubing for leaks at regular intervals. Observe

the appropriate regulations concerning the handling of flammable

and/or toxic solutions and their disposal.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

9

Page 18

2 Installation

2 Installation

2.1 Instrument setup

2.1.1 Packaging

The 828 IC Dual Suppressor and its specially packed accessories are

supplied in very protective special packaging which contains a shockabsorbing plastic foam lining. The instrument itself is contained in an

dustproof evacuated polyethylene bag. Please store this packaging in a

safe place; it is the only way in which the safe transport of the

instrument can be guaranteed.

2.1.2 Checks

Please check that the delivery is complete and undamaged

immediately on receipt (compare with delivery note and list of

accessories given in Section 6.2). If transport damage is evident please

refer to the information given in Section 6.4 “Warranty”.

2.1.3 Location

Place the instrument on a suitable vibration-free laboratory bench,

protected as much as possible from corrosive atmospheres and

contact with chemicals.

Choose a location where the temperature is usually between +5 °C and

+45 °C. The instrument should be protected against excessive

variations in temperature and direct sunlight.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

10

Page 19

2.2 Connecting the accessories

2.2 Connecting the accessories

2.2.1 Attaching the CO2 absorber cartridge

A 6.2837.000 CO

accessories of the IC Dual Suppressor. It is attached as follows:

Mount Cartridge Holders 6.2027.070

1

• Remove the lower screws of the holders 14 with a Philips

screwdriver.

• Insert the Cartridge holders 6.2027.070 into the holders 14

from below.

• Reattach the screws.

Attach CO2 Absorber Cartridge

2

• Push the CO2 Absorber Cartridge into the clamps of the

cartridge holders.

Absorber Cartridge is included in the standard

2

• Remove the yellow stopper which seals the cartridge inlet and

connect the CO

absorber cartridge to vacuum inlet 17 using

2

the 6.1816.030 Silicone tubing.

Figure 4: Attaching the CO

Use the yellow stopper to close off the CO

whenever the 828 IC Dual Suppressor is not to be used for a longer

period. This increases the working life of the cartridge.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

absorber cartridge

2

absorber cartridge inlet

2

11

Page 20

2 Installation

2.3 Mains connection

Please observe the following rules when connecting the instrument to

the electricity supply. If the instrument is operated with an incorrectly

set mains voltage and/or an incorrect mains fuse then it represents a

fire hazard!

2.3.1 Mains voltage

All power supplies from 100 V to 240 V with 50/60 Hz can be connected

to the mains input of the 828 IC Dual Suppressor. Adaptation to the

mains supply used is carried out automatically.

2.3.2 Fuse

A 1.0 A fuse (slow blow) is contained in the fuse holder of the 828 IC

Dual Suppressor.

Make sure that the instrument is never operated with a different type of

fuse as otherwise it represents a fire hazard!

Changing the fuse

Pull out mains cable

1

Switch off the instrument and remove the mains cable from mains

supply connection 16 of the 828 IC Dual Suppressor.

Remove the fuse holder

2

Use a screwdriver to loosen the fuse holder beside the mains

supply connection (see Figure 3) and remove it completely.

Changing the fuse

3

Change the fuse if necessary and replace it in the fuse holder.

Use only a fuse with the following specifications.

1.0 A fuse (slow blow) Metrohm No. U.600.0016

Re-insert fuse holder

4

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

12

Page 21

2.3 Mains connection

2.3.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of the following mains cables

• 6.2122.020 with SEV 12 plug (Switzerland, …)

• 6.2122.040 with CEE(7), VII plug (Germany, …)

• 6.2133.070 with NEMA 5-15 plug (USA, …)

which has three wires and is fitted with a plug with a grounding pin. If a

different plug has to be used then the yellow/green wire (IEC standard)

must be connected to the grounding pin (Protection class I).

Any interruption to the grounding inside or outside the instrument can

represent a hazard!

Mains connection

Insert the mains cable into mains connector 16 of the 828 IC Dual

Suppressor.

2.3.4 Switching the instrument on/off

The 828 IC Dual Suppressor is switched on and off with mains switch

16. When the instrument is switched on the "Power" 6 LED lights up.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

13

Page 22

2 Installation

2.4 Connecting to a modular gradient IC system

The 828 IC Dual Suppressor allows the sensible use of the gradient

technique with carbonate/bicarbonate eluents for the first time. The

installation of the 828 IC Dual Suppressor in the system that is most

frequently used, a binary gradient system, is described below.

The required instrument configuration corresponds to the Modular IC

System 10 (MIC 10), an anion system using binary high-pressure

gradients with chemical suppression. It consists of the 762 IC Interface,

732 IC Detector, 733 IC Separation Center (1-channel), 828 IC Dual

Suppressor, two 709 IC Pumps and a gradient mixing spiral with Tpiece and downline pulsation dampener.

The electrical and wet-chemistry connections of this system and its

control using the «IC Net 2.1» software are described below.

2.4.1 Electrical connections

PC

6.2134.100

762

6.2128.130

732

6.2125.090

733

A (LOOP)

6.2115.070

828

6.2128.180

709

6.2134.090

709

6.2134.080

Figure 5: Electrical connections in the MIC 10 system

The electrical connections in the system consisting of the 762 IC

Interface, 732 IC Detector, 733 IC Separation Center (1-channel), 828 IC

Dual Suppressor and two 709 IC Pumps are shown in Figure 5:

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

14

Page 23

2.4 Connecting to a modular gradient IC system

2.4.2 Connecting the IC Dual Suppressor

The following diagram shows how the system is arranged:

Sample

Gradient

mixing capillary

A Trap column

Valve

IC Pumps

Sample

loop

Separation

column

Inline filter

T-connector

Pulsation

dampener

IC Detector

IC Dual Suppressor

Figure 6: Flow diagram of the MIC 10

All the components should be connected as shown in Figure 6, which

also provides a flow diagram for the sample.

The installation of the other components is described in detail in the

appropriate Instructions for Use.

The 828 IC Dual Suppressor is inserted between the separation column

and the detector. The following connections must be made:

Please ensure that the liquid connections between the separation

column outlet, the Dual Suppressor and the detector inlet are as short

as possible and use a narrow diameter capillary, e.g. 6.1831.010

PEEK Capillary (included as standard). In this way you minimize the

dead volumes and reduce the peak broadening of the signal.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

15

Page 24

2 Installation

From Column

1

• Connect the outlet of the separation column in the 733 IC

Separation Center with the inlet of the 828 IC Dual

Suppressor "From Column" 8. Use a 6.1831.010 PEEK

Capillary (i.d. = 0.25 mm, o.d. = 1/16") and a 6.2744.010

Pressure screw for this (both included in standard

equipment).

To Detector

2

• Use another piece of 6.1831.010 PEEK Capillary (i.d. =

0.25 mm, o.d. = 1/16"), further 6.2744.010 Pressure

screws and a 6.2744.040 Coupling (all included in

standard equipment) to connect the outlet of the 828 IC Dual

Suppressor "To Detector" 7 with the inlet of the conductivity

detector in the 732 IC Detector.

Detector outlet

3

• Mount the 6.1803.090 PTFE Capillary (i.d. = 1/16", o.d. =

0.25 mm, 15 m) as a backpressure capillary between the

detector outlet and the waste container. Use a 6.2744.010

Pressure screw and a 6.2744.040 Coupling (all included in

standard equipment) for this.

The backpressure capillary is required to ensure the correct ratio

between the flow rates at the outlets of the suppressor cell, see

Section 3.5.

Check this ratio the first time that a system in which the 828 IC Dual

Suppressor has been newly installed is started up; a detailed

description is given in Section 3.5.1.

To Waste

4

• Connect outlet "Waste" 12 of the 828 IC Dual Suppressor to a

waste container. Use the 6.1803.020 PTFE Tubing (i.d. =

0.97 mm, o.d. = 1.57 mm) and a 6.2744.010 Pressure

screw (both included in standard equipment) for this.

PEEK capillaries that are to be provided with new connections must

have a perfect and plane cutting surface. This is best obtained by

using the optionally available 6.2621.080 Capillary cutter .

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

16

Page 25

2.4 Connecting to a modular gradient IC system

2.4.3 Settings in IC Net 2.1

On the rear panel of the 828 IC Dual Suppressor switch remote switch

15 to "ON" and also switch mains switch 16 to "ON". The Dual

Suppressor can now be controlled by an external instrument.

Start the IC Net 2.1 software and open the "New System Wizard"

under “File/ New/System....”. This wizard will guide you through the

installation of a new system. Use it to create a system file, e.g.

"Gradient.smt" for your modular gradient system. During the installation

you will be asked about the components of your system. Enter the 762

IC Interface, 732 IC Detector, 733 IC Separation Center (1-channel) and

the two 709 IC Pumps as a Solvent Delivery Unit (SDU) with two pumps

to the system. A detailed description of this procedure is given in the

8.110.8221 Instructions for Use for the Metrodata «IC Net 2.1»

software.

The 828 IC Dual Suppressor has not yet been integrated into the

Version 2.1 of this software and cannot be selected from the list of

devices. This means that you should configure the system without it; its

control commands must then be entered manually.

When you have created the system file "Gradient.smt" the IC Net

window will appear as follows:

The instrument symbols of your detector, the Separation Center and the

two pumps will already appear in your "Gradient.smt" system. As the

Dual Suppressor is controlled via the 762 IC Interface, see Figure 5, you

only have to integrate and configure the interface in the existing system:

• Select the 762 IC Interface under Setup/New devices/Link to

existing device. The instrument symbol will be added to your

system.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

17

Page 26

2 Installation

• Double-click on the instrument symbol of the 762 IC Interface to

open its configuration menu and select the file card Events setup.

• The value of the event line, via which the Dual Suppressor will be

controlled, must be set to 1. In this example this is Event Line 1, see

Figure 5.

• Set Event Line 1 to the value 1 and confirm with OK.

The 828 IC Dual Suppressor is now included in the system and will be

controlled by the Metrodata IC Net 2.1 software. It is started together

with the other hardware of the system "Gradient.smt" with SYSTEM

/Control/Startup hardware and shut down with SYSTEM

/Control/Shutdown hardware.

In Metrodata IC Net software versions with version numbers higher

than 2.1 the 828 IC Dual Suppressor will be preconfigured in the

software just like all other Metrohm IC instruments. It can then be

immediately installed in the New System Wizard. A detailed

description can be found in the corresponding Instructions for Use of

the software.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

18

Page 27

2.5 Connecting to the 761 Compact IC

2.5 Connecting to the 761 Compact IC

The installation of the 828 IC Dual Suppressor with the 761 Compact IC

and control via the «761 PC Software 1.1» software is described

below.

2.5.1 Electrical connection

The electrical connections of the system consisting of the 761 Compact

IC and the 828 IC Dual Suppressor are made according to Figure 7:

761

6.2134.100

PC

828

Figure 7: Connecting the 828 IC Dual Suppressor

to the 761 Compact IC

2.5.2 Connecting the IC Dual Suppressor

Please ensure that the liquid connections between the separation

column outlet, the Dual Suppressor and the detector inlet are as short

as possible and use a narrow diameter capillary, e.g. 6.1831.010

PEEK Capillary (included as standard). In this way you minimize the

dead volumes and reduce the peak broadening of the signal.

From Column

1

• Connect the outlet of the separation column in the 761

Compact IC to the inlet of the 828 IC Dual Suppressor "From

Column" 8. Use a 6.1831.010 PEEK Capillary (i.d. = 0.25

mm, o.d. = 1/16") and a 6.2744.010 Pressure screw (both

included as standard) for this.

6.2143.200

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

19

Page 28

2 Installation

To Detector

2

• Use another piece of 6.1831.010 PEEK Capillary (i.d. =

0.25 mm, o.d. = 1/16"), further 6.2744.010 Pressure

screws and a 6.2744.040 Coupling (all included in

standard equipment) to connect the outlet of the 828 IC Dual

Suppressor "To Detector" 7 with the inlet of the conductivity

detector in the 761 Compact IC.

Detector outlet

3

• Mount the 6.1803.090 PTFE Capillary (i.d. = 1/16", o.d. =

0.25 mm, 15 m) as a backpressure capillary between the

detector outlet and the waste container. Use a 6.2744.010

Pressure screw and a 6.2744.040 Coupling (all included in

standard equipment) for this.

The backpressure capillary is required to ensure the correct ratio

between the flow rates at the outlets of the suppressor cell, see

Section 3.5.

Check this ratio the first time that a system in which the 828 IC Dual

Suppressor has been newly installed is started up; a detailed

description is given in Section 3.5.1.

To Waste

4

• Connect outlet "Waste" 12 of the 828 IC Dual Suppressor to a

waste container. Use the 6.1803.020 PTFE Tubing (i.d. =

0.97 mm, o.d. = 1.57 mm) and a 6.2744.010 Pressure

screw (both included in standard equipment) for this.

PEEK capillaries that are to be provided with new connections must

have a perfect and plane cutting surface. This is best obtained by

using the optionally available 6.2621.080 Capillary cutter .

2.5.3 Settings for control by the 761 PC Software 1.1

On the 828 IC Dual Suppressor switch remote switch 15 to "ON" and

also switch mains switch 16 to "ON". The Dual Suppressor can now

be controlled by an external instrument.

In the 761 PC Software 1.1 you must make the following settings:

• Start the 761 PC Software 1.1 and select your system.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

20

Page 29

2.5 Connecting to the 761 Compact IC

• Open the instrument control with a double-click on the instrument

symbol of the Compact IC.

If your system is not yet connected to your workplace then the left-hand

window will open, otherwise the right-hand window will open. In each

case the procedure is the same:

• Set the value for Remote Line 1 to 1.

• Save the setting with "Save".

The 828 IC Dual Suppressor is now included in the system and will be

controlled by the 761 PC Software 1.1. The 828 IC Dual Suppressor will

be started as soon as your system is connected to the workplace and

will be shut down together with the 761 Compact IC hardware with

System/Control/Shutdown hardware.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

21

Page 30

3 Operation

3 Operation

3.1 General information

No eluent should be pumped through the IC Dual Suppressor when it

is switched off, or if an error occurs. Errors are indicated by red LEDs

on the front panel. Faults which may occur during operation affect the

voltage and the vacuum, which may be outside their specified values.

Details can be found in Section 4 Troubleshooting - Problems.

• During the starting sequence of the instrument (Section 3.6.1) wait

until the vacuum LED lights up green before switching on the eluent

pump.

• A pressure sensor in the instrument is used as the on/off switch for

the electrolysis current of the cell. The current will only be switched

on when a defined pressure has been achieved in the system after

the instrument has been switched on, i.e. if no leaks are present. The

"Current" 4 LED lights up green. If the pressure falls below the

preset value for some time then the current will be switched off.

This ensures that current will only be applied to the cell when liquid

is flowing through the suppressor. This means that the 828 IC Dual

Suppressor can remain switched on even when no eluent is flowing

through it without being damaged. However, in such a case we do

recommend that the IC Dual Suppressor is switched off.

• The 828 IC Dual Suppressor is designed for operation with a total

flow rate of between 0.5 and 2.0 mL/min. Operating the suppressor

with flow rates outside this range may either damage it or produce

unsatisfactory results. At flow rates below 0.5 mL/min the built-up

pressure may not be sufficient to switch on the current. This can

cause the suppressor cell to become exhausted. Flow rates above

2.0 mL/min can create an overpressure in the system and alter the

ratio between the eluates at the anode, cathode and detector outlet

of the cell.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

22

Page 31

3.2 Eluent

3.2 Eluent

The cation exchanger resin of the 828 IC Dual Suppressor allows the

use of all the eluents normally used for suppressed ion

chromatography such as hydroxide, borate and carbonate/bicarbonate

eluents, although carbonate/bicarbonate eluents offer the greatest

benefits when used with the 828 IC Dual Suppressor because of the

removal of CO

.

2

In order to achieve the best results you should only use ultrapure

reagents and ultrapure water to prepare your eluents .

3.3 Capacity

The exchange capacity of the suppressor cell of the 828 IC Dual

Suppressor is 50 mmol/L NaOH or 25 mmol/L Na

1 mL/min.

at a flow rate of

2CO3

Check whether the concentration of your eluent and the selected flow

rate are appropriate for the capacity of the suppressor before you start

to use it.

Calculate the maximum "Total cation flow" for your eluent or gradient

and your flow rate in milli-equivalents of cations that pass through the

cell per minute (meq/min). The total amount of 0.05 meq/min must not

be exceeded.

Example

An eluent with 5 mmol/L Na

/5 mmol/L NaHCO3 and a flow rate of

2CO3

1.5 mL/min gives a value of 0.0225 meq/min for the total cation flow

and is therefore within the capacity of the suppressor cell.

3.4 Degassing unit and CO2 absorber cartridge

A further improvement of the signal from the 828 IC Dual Suppressor is

achieved with carbonate/bicarbonate eluents by degassing the

suppressor eluate before detection. Dissolved CO

suppressor eluate with the result that the background conductivity is

reduced, the signal-to-noise ratio is improved, the injection peak (water

dip) and system peak are eliminated and the rise in the background

conductivity with carbonate/bicarbonate gradients is suppressed.

is removed from the

2

The degassing unit consists of a vacuum pump, a vacuum chamber

and a CO

absorber cartridge. In the vacuum chamber carbonic acid

2

dissociates to form water and carbon dioxide. In order to prevent the

formation of an equilibrium between the dissolved and gaseous CO

the vacuum chamber, the vacuum pump works with a gas ballast. A

small amount of ambient air is drawn in by the pump and passes

through the vacuum chamber so that any CO

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

in

2

evolved is continuously

2

23

Page 32

3 Operation

removed and the equilibrium for the breakdown of the carbonic acid is

displaced even further toward the dissociated products. The CO

absorber cartridge is required to remove CO

and humidity from the

2

drawn-in ambient air before it enters the degassing system. Exchanging

the CO

absorber cartridge is described in Section 5.4.1.

2

The vacuum pump works at a constant speed and as soon as the

vacuum reaches the preset working pressure LED "Vacuum" 5 lights up

green.

3.5 Flow rate ratio

Please ensure that the backpressure capillary is mounted at the outlet

of the detector used, see Section 2.4.2, Section 2.5.2; it is required for

the correct ratio between the flow rates.

Check this ratio between the flow rates before starting up the 828 IC

Dual Suppressor for the first time.

2

The 828 IC Dual Suppressor achieves its optimal performance when

40% of the total flow is eluted to the detector. The 828 IC Dual

Suppressor is preadjusted for a total flow rate of 1 mL/min. At a total

flow rate in the working range of 0.5 - 2.0 mL/min this flow ratio only

changes slightly, but you should nevertheless check it when you alter

the total flow rate.

If more than one detector is used in series downstream the IC Dual

Suppressor then the ratio between the flow rates must be adjusted in

order to compensate for the additional backpressures of the other

detectors.

3.5.1 Setting the flow rates

The IC Dual Suppressor is designed to work at a flow rate to the

detector of 40% ± 5% of a total flow rate of 1 mL/min.

The following instructions describe in detail how you can check the ratio

between the flow rates and alter it if necessary:

Preparation

1

Set the flow rate at the pump to 1 mL/min and wait for 10 minutes.

Measurement

2

Measure the volume V or the weight m of the liquid which elutes

from the backpressure capillary in 3 minutes.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

24

Page 33

3.5 Flow rate ratio

Calculation

3

Use the following equation to calculate the fraction of the flow to

the detector compared with the total flow rate of 1 mL/min:

Detector flow fraction (in %) = (V/3 mL) x 100

or = (m/3 g) x 100

If you check the detector flow for other total flow rates than 1

mL/min then change the denominator in the formulae accordingly.

Adjustment

4

If the detector flow fraction is not within the limits of

40% ± 5% then the ratio between the flow rates must be adjusted.

This is done by adjusting the setting screw "Detector Flow" 11

with a screwdriver.

• A clockwise rotation increases the detector flow rate fraction of

the total flow rate.

• A counterclockwise rotation decreases the detector flow rate

fraction of the total flow rate.

Proceed according to items 2 and 3 to check again whether the

ratio between the flow rates is now correctly adjusted.

If it is impossible to set the correct ratio this indicates a blockage

in the flow path, see Section 4 Troubleshooting - Problems.

The ratio between the flow rates can also be checked at the "Waste" 12

outlet of the 828 IC Dual Suppressor, where the eluates from the anode

and cathode outlets of the suppressor cell escape. These flows should

have a fraction of the total flow rate of 60% ± 5%.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

25

Page 34

3 Operation

3.6 Routine operation

3.6.1 Manual operation

Start sequence

Installation

1

Install the 828 IC Dual Suppressor as described in Section 2.

• The remote connection from the suppressor to the 762 IC

Interface (6.2128.180 Cable, Figure 5) or to the 761 Compact

IC (6.2143.200 Cable, Figure 7) are not necessary for manual

operation.

• The IC Dual Suppressor must be switched to manual operation, remote switch 15 = OFF.

Switch on suppressor

2

• Switch on the instrument with mains switch 16.

The vacuum pump starts up and the LED "Vacuum" 5 will light

up green as soon as the set working pressure is reached.

Wait until the LED "Vacuum" 5 lights up green before continuing with

step 3.

Switch on pump

3

• Switch on the high pressure pump.

After a short time the pump will build up pressure and, when

the value set for the pressure sensor has been reached (see

page 22), current is applied to the suppressor cell.

The LED "Current" 4 lights up green. This process takes about

1 minute, but this time may vary depending on the set flow rate

and the backpressure of the system. When the cell voltage lies

within the given range then LED "Voltage" 3, followed by LED

"Ready" 1, will light up green.

Equilibrate

4

• Wait 20-30 minutes until the 828 IC Dual Suppressor is

equilibrated.

The suppressor is fully equilibrated when the background conductivity remains constant and a stable baseline is obtained.

When you change the eluent you should first rinse the separation

column without connecting the 828 IC Dual Suppressor. Pump the

eluent through the system for about 5 min.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

26

Page 35

3.6 Routine operation

If you change the eluent type, particularly when changing from a

strong to a weak eluent, then it may take longer to equilibrate the

suppressor.

The system is now ready to carry out an analysis

5

Stop sequence

Switch off pump

1

Step 2 is only necessary when the suppressor will not be used for

more than one week; otherwise continue with step 3.

Rinse suppressor

2

• Leave the suppressor switched on and rinse it with pure water

for 15 min (1 mL/min).

Switch off suppressor

3

• Switch off the suppressor at mains switch 16.

You can also leave the 828 IC Dual Suppressor switched on when it is

not being used; this will not damage the instrument. However, when it

is switched on the vacuum pump operates continuously. This is why

we recommend that the 828 IC Dual Suppressor is always switched

off when it is not being used in order not to unnecessarily shorten the

working lives of the vacuum pump and CO

You should also seal the inlet of the CO

absorber cartridge when the

2

absorber cartridge.

2

828 IC Dual Suppressor is not to be used for a longer period.

Storage

4

These measures are only necessary when the IC Dual Suppressor

will not be used for a long time.

• Remove the connections from the following inlets and outlets:

"To Detector" 7, "From Column" 8 and "To Waste" 12 and

seal them with the original closures supplied with the

instrument.

3.6.2 Software control

The operation and functions of the two control programs IC Net 2.1

and 761 PC Software 1.1 are identical in many respects. Where

differences occur these are described separately for the particular

software.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

27

Page 36

3 Operation

Start sequence

Installation

1

Install the 828 IC Dual Suppressor as described in Section 2.

• The IC Dual Suppressor must be switched on, mains switch

16 = ON, and also switched for remote operation, remote

switch 15 = ON.

Start software

2

• Start the IC Net 2.1 software or 761 PC Software 1.1, open

your system and connect it to the workplace.

761 PC Software 1.1:

The suppressor starts, the vacuum pump runs and, as soon as

the set working pressure has been achieved, LED "Vacuum" 5

lights up green.

• Start your system with Control/Startup hardware.

The system is run up, the high pressure pump starts working

and the system is equilibrated.

IC Net 2.1:

The suppressor is started together with the rest of the system,

the vacuum pump runs and, as soon as the set working

pressure has been achieved, LED "Vacuum" 5 lights up green.

After a short time the pump will build up pressure and, when the

value set for the pressure sensor has been reached (see page

22), current is applied to the suppressor cell. The LED "Current" 4

lights up green. This process takes about 1 minute, but this time

may vary depending on the set flow rate and the backpressure of

the system. When the cell voltage lies within the given range then

LED "Voltage" 3, followed by LED "Ready" 1, will light up green.

Please make sure that you always start your system with

Control/Startup hardware. This is the only way to ensure that the

828 IC Dual Suppressor is controlled properly.

If you start the high pressure pump directly in the instrument window

then the suppressor will not start up automatically with it. If this is not

noticed for a long time there is the risk that the cation exchanger will

become exhausted and have to be regenerated manually, see Section

5.5.1.

Equilibrate

3

• Wait 20-30 minutes until the 828 IC Dual Suppressor is equilibrated.

The suppressor is fully equilibrated when the background conductivity remains constant and a stable baseline is obtained.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

28

Page 37

3.6 Routine operation

When you change the eluent you should first rinse the separation

column without connecting the 828 IC Dual Suppressor. Pump the

eluent through the system for about 5 min.

If you change the eluent type, particularly when changing from a

strong to a weak eluent, then it may take longer to equilibrate the

suppressor.

The system is now ready to carry out an analysis

4

Stop sequence

Switch off system

1

• Shut down the system with Control/Shutdown hardware. On

the 828 IC Dual Suppressor the current to the suppressor cell

and the vacuum pump are switched off.

If the IC Dual Suppressor is to be used again within a few days

then no further measures are necessary.

The following steps are only necessary if the suppressor will not be

used for more than one week.

Rinse suppressor

2

• Before switch-off let the system run with pure water for 15 min

(1 mL/min); the suppressor must be working.

Switch off suppressor

3

• Shut down the system with Control/Shutdown hardware. On

the 828 IC Dual Suppressor the current to the suppressor cell

and the vacuum pump is switched off.

• Switch off the suppressor at mains switch 16.

Seal the inlet of the CO

Suppressor is not to be used for a longer period.

Storage

4

absorber cartridge when the 828 IC Dual

2

These measures are only necessary when the IC Dual Suppressor

will not be used for a long time.

• Remove the connections from the following inlets and outlets:

"To Detector" 7, "From Column" 8 and "To Waste" 12 and

seal them with the original closures supplied with the

instrument.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

29

Page 38

4 Troubleshooting - Problems

4 Troubleshooting - Problems

4.1 Remedying faults and problems

If difficulties occur during analyses with your IC system then it is best to

search for their causes in the following sequence: column → pump →

eluent → IC system. In the Instructions for Use of your MIC 10

Modular IC system or 761 Compact IC you will find an overview of

possible faults together with their causes and remedies.

In addition to these general problems, the following section covers

those problems which could arise from the use of the 828 IC Dual

Suppressor.

4.2 Chromatography problems

Problem Cause Remedy

Poor peak shape

Poor retention time

reproducibility

• Dead volume in system.

• Weak eluent, unsuitable

gradient program.

• Space inside the suppressor

cell.

• Leak in the instrument.

• Flow rate ratio not correct.

• Blockage in flow path.

• High pressure in system.

• Check that the capillary connections are

tight. Keep the length of the PEEK

capillaries between the column and IC

Dual Suppressor and between the IC Dual

Suppressor and detector as short as

possible and make sure that a capillary

with the correct inner diameter is used

(6.1831.010).

• Make up a new eluent, correct the

gradient.

• Exchange suppressor cell, see Section

5.5.2.

• Check whether liquid is escaping from

drain 20, replace leaking connections.

• Check the flow rate ratio, Section 3.5.

• See Section 4.3.

• See Section 4.3.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

30

Page 39

4.2 Chromatography problems

Noisy or unstable baseline

Background conductivity

too high

• Suppressor cell is not yet

properly equilibrated with the

eluent.

• CO

absorber cartridge is

2

exhausted.

• Fraction of volatile organic

modifiers in eluent is too high.

• Flow rate ratio not correct.

• Leak in the instrument.

• Blockage in flow path.

• Eluent concentration incorrect.

• Eluent contaminated.

• CO

absorber cartridge is

2

exhausted.

• Flow rate ratio not correct.

• Suppressor cell is exhausted.

• Let the system run and wait until the

suppressor is equilibrated.

• Exchange the 6.2827.000 CO

absorber

2

cartridge, see Section 5.4.1.

• Make up a new eluent, refer to Section

3.2.

• Check the flow rate ratio, Section 3.5.

• Check whether liquid is escaping from

drain 20, replace leaking connections.

• See Section 4.3.

• Make up a new eluent, take the capacity

of the suppressor into account, see

Section 3.3.

• Make up a new eluent, see Section 3.2.

• Exchange the 6.2827.000 CO

absorber

2

cartridge, see Section 5.4.1.

• Check the flow rate ratio, Section 3.5.

• Regenerate the cell, proceed as

described in Section 5.5.1.

• Blockage in flow path.

• See Section 4.3.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

31

Page 40

4 Troubleshooting - Problems

4.3 Instrument problems

Problem Cause Remedy

LED "Power" 1 does not

light up / no LED lights up

No flow at "Flow Anode" 9

or "Flow Cathode" 10

High pressure in system

Blockage in flow path

Liquid escapes from drain

20

• Remote switch 15 switched to

ON despite manual operation.

• Mains cable not connected.

• Fuse blown.

• Electronics fault.

• Blockage in flow path.

• Pressure screws tightened up

too much.

• Blockage in flow path.

• A capillary is blocked.

• The suppressor cell is blocked.

• Leak inside the instrument. • Replace leaking connections, if the

• Switch off remote switch 15 = OFF.

• Connect the IC Dual Suppressor to the

mains supply.

• Replace fuse, see Section 2.3.2

• Contact Metrohm Service.

• See next box but one.

• Loosen pressure screws a little or replace

connection.

• See next box.

• Contact Metrohm Service; it may be

necessary to replace the suppressor cell

as described in Section 5.5.2.

suppressor cell is leaking replace it as

described in Section 5.5.2.

LED "Vacuum" 5 is red

LED "Current" 4 is not

green

LED "Voltage" 3 is red

• Leak in the vacuum chamber.

• Vacuum pump not working

properly.

• The pressure sensor (page

22) is not switching the

electrolysis current on.

• Suppressor cell not installed

correctly.

• The suppressor cell is

exhausted.

• The suppressor cell is faulty.

• Contact Metrohm Service.

• Contact Metrohm Service.

• Check whether the high pressure pump is

running and that the set flow rate is

correct, see Section 3.1.

• Check for leaks in the liquid connections

and replace the connections if necessary.

• Install the suppressor as described in

Section 5.5.2.

• Regenerate the cell, proceed as

described in Section 5.5.1.

• Exchange the suppressor cell as

described in Section 5.5.2.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

32

Page 41

5.1 Instrument care

5 Care and maintenance

5.1 Instrument care

The 828 IC Dual Suppressor requires adequate care. Excessive

contamination of the instrument could interfere with its functions and

reduce the working life of the really robust mechanism and electronics.

Spilt chemicals and solvents should be removed immediately. The

connections on the rear panel (and the mains connection in particular)

should be protected against contamination.

Although the design prevents liquid penetration to a great extent, if

aggressive media should enter the housing then pull out the mains

plug of the 828 IC Dual Suppressor immediately, in order to prevent

massive damage to the instrument’s electronics. In such a case

please contact the Metrohm Service Department.

The instrument should only be opened by experienced users. Please

observe the safety information given in Section 1.5.1.

5.2 Maintenance by Metrohm Service

The maintenance of the 828 IC Dual Suppressor should take place

within the framework of an annual service carried out by trained

Metrohm technicians.

The Metrohm Service Department will provide competent advice about

the care and maintenance of all Metrohm instruments.

5.3 Shutdown

If the 828 IC Dual Suppressor is not to be used for a long time then it

should be rinsed with ultrapure water, see Sections 3.6.1 and 3.6.2

Stop sequence.

5.4 Regular maintenance

The 828 IC Dual Suppressor is a very robust instrument intended for

virtually maintenance-free work. If it is used properly then only the CO

absorber cartridge needs to be replaced at regular intervals.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

2

33

Page 42

5 Care and maintenance

5.4.1 Replacing the CO2 absorber cartridge

The CO2 absorber cartridge must be replaced at regular intervals. The

replacement interval depends on the operating time of the 828 IC Dual

Suppressor and the laboratory surroundings. A color change indicates

when the absorber material is exhausted. An exhausted cartridge is

also indicated by an increased background conductivity and an

unstable baseline.

The CO

absorber cartridge contains alkali hydroxides. Please

2

observe the appropriate regulations when handling and disposing of

these chemicals.

Attaching the CO

absorber cartridge is described in Section 2.2.1.

2

• Remove the exhausted cartridge in the opposite sequence to that

described in Section 2.2.1 Point 2.

• Attach a new CO

absorber cartridge.

2

5.5 Unplanned maintenance work

If problems occur when using the 828 IC Dual Suppressor then it may

be necessary to carry out the following maintenance work. Details

about problems and their remedies are given in Section 4.1 Remedying

faults and problems.

5.5.1 Regenerating the cation exchanger

The cation exchanger in the suppressor cell may become exhausted if

the exchange capacity of the 828 IC Dual Suppressor is exceeded or if

a fault occurs during operation. The following steps should be carried

out to regenerate the cation exchanger.

Prepare the system

1

• Remove the column from the system and connect the

suppressor to the high pressure pump.

• Switch off the 828 IC Dual Suppressor at mains switch 16.

Regenerate the cation exchanger

2

1. Rinse the system with ultrapure water for 15 min (1 mL/min)

with the suppressor switched off (mains switch 16 = OFF).

2. Pump 25 mM sulfuric acid at 1 mL/min through the system for

30 min, the suppressor remains switched off (mains switch

16 = OFF).

3. Rinse the system with ultrapure water for 15 min (1 mL/min)

with the suppressor switched off (mains switch 16 = OFF).

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

34

Page 43

5.5 Unplanned maintenance work

4. Pump ultrapure water at 1 mL/min through the system with the

suppressor switched on (mains switch 16 = ON).

When LED "Voltage" 3 lights up green continue for a further 30

min; the suppressor is then regenerated.

If LED "Voltage" 3 turns red again then repeat rinsing step 3.

and continue with 4. If the LED "Voltage" 3 still remains red

then regeneration procedure 2. - 4. must be repeated.

If the suppressor cannot be regenerated then the suppressor

cell must be replaced.

5.5.2 Replacing the suppressor cell

If the suppressor cell can no longer be regenerated then it must be

replaced.

As replacing the suppressor cell requires the instrument to be

opened, this should only be carried out by experienced users. Please

observe the safety information given in Section 1.5.1.

If the 828 IC Dual Suppressor is connected to the mains supply then it

must neither be opened nor should any parts be removed from it, as

otherwise the risk of contact with current-carrying assemblies exists.

This is why the instrument should be separated from all voltage

sources before being opened. Please make sure that the mains

cable is pulled out from mains connector 16!

Required tools:

1 Phillips screwdriver

1 Pliers

Preparation

1

• Switch off the 828 IC Dual Suppressor at mains switch 16.

• Remove the mains cable from connection 16.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

35

Page 44

5 Care and maintenance

Figure 8: Opening the instrument

23 Front housing screws 24 Rear housing screws

25 Housing cover 26 Suppressor cell

Open the instrument

2

• Loosen the two front housing screws 23 on the base of the

IC Dual Suppressor, see Figure 8.

• Loosen the two housing screws 24 at the top of the rear

panel of the IC Dual Suppressor.

• Lift off housing cover 25 upward.

Remove the suppressor cell

3

• Loosen the pressure screws on all four of the capillaries

connected to suppressor cell 26, see Figure 9.

• The suppressor cell 26 can be pulled forward out of the

electrode clamp holders.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

36

Page 45

5.5 Unplanned maintenance work

Figure 9: Opened IC Dual Suppressor

Replace the suppressor cell

4

• Reconnect the capillaries to the appropriate connections of the

new 6.2838.000 Suppressor cell 26.

The electrode connections are kept waterproof by flat seals.

Tighten them up by hand and then use the pliers to tighten

them by a further 1/8 turn.

The suppressor cell connections and capillaries are marked;

the suppressor cell position and the assignment of the

capillaries is shown in Figure 10.

• Press the connected-up suppressor cell back into the

electrode clamp holders.

Take care that you do not touch the suppressor cell electrodes with

your bare fingers as this could cause contact problems. If you do

accidentally touch the electrodes then they must be degreased with a

little ethanol.

Reassemble the instrument and connect it up

5

• Reattach housing cover 25 by carrying out the steps given in

item 2 in the reverse order.

• Connect the Dual Suppressor to the mains supply and switch it

on. If you have removed the suppressor from your system then

reinstall it as described in Section 2.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

37

Page 46

5 Care and maintenance

Start up the suppressor

6

• No further work is necessary before start-up. However, before

the first measurement is made with the IC Dual Suppressor we

recommend that it is allowed to run overnight to equilibrate the

new cell.

"Anode" capillary

"Outlet" capillary

"Inlet" capillary

"Cathode"capillary

Figure 10: Suppressor cell position, front view

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

38

Page 47

6.1 Technical data

6 Appendix

6.1 Technical data

6.1.1 Suppressor cell

Total flow rate 0.5...2.0 mL/min, optimal value 1.0 mL/min

Flow rate ratio 40% ± 5% of total flow to detector

Exchange capacity 0.05 meq/min, see Section 3.3

Eluent Aqueous eluents, see Section 3.2

6.1.2 RS 232 interface

Connection D-sub connection 9-pin (male)

Function Only for service purposes

6.1.3 Remote interface

Connection

Purpose

Pin occupancy

DIN connection 5-pin (female)

Remote operation of suppressor (on/off)

+5V

330

828

Pin

Current flow: on

No current flow: off

2

+

-

5

external

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

39

Page 48

6 Appendix

6.1.4 Fault switch, ready output

Connection

Purpose

Pin occupancy

6-pin (male)

NC normally closed

COM common

NO normally open

Pins 1-3 and 4-6 form two independent fault

switches which indicate an instrument error (an

LED lights up red).

Ready status:

• Open between NC and COM

• Closed between NO and COM

Not Ready status:

An impulse of 1 s is outputted; during this time

the pin switching is reversed.

• Closed between NC and COM

• Open between NO and COM

6.1.5 Mains connection

Voltage 100...240 V

Frequency 50...60 Hz

Power consumption 25 W

Fuse 5 mm dia., 20 mm long

6.1.6 Safety specifications

Construction and testing According to EN/IEC 61010-1 / UL 3101-1,

Safety instructions The Instructions for Use contain safety

automatic voltage adaptation in instrument

see Section 2.3.1

1.0 AT (slow blow); must only be replaced by the

same type

protection class 1

information that must be observed by the user in

order to ensure the safe operation of the

instrument.

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

40

Page 49

6.1 Technical data

6.1.7 Electromagnetic compatibility (EMC)

Emission Standards fulfilled:

- EN/IEC 61326-1

- EN 55022

- CISPR 22

Immunity Standards fulfilled:

- EN/IEC 61326-1

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-11

- EN/IEC 61000-4-14

- Namur

6.1.8 Ambient temperature

Nominal working range +5…+45 °C

Transport

Storage

6.1.9 Housing

Cover material Rigid polyurethane foam (PUR) with flame

Base material Steel, enameled

Width 260 mm

Height 129 mm

Depth 366 mm

Weight 5.6 kg (with accessories)

(at 20…80% relative humidity)

–40…+70 °C

–20…+70 °C

protection to flammability class UL94VO, CFCfree

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

41

Page 50

6 Appendix

⁄

⁄

6.2 Standard equipment

We reserve the right to make alterations!

All dimensions given in mm.

The 2.828.0010 IC Dual Suppressor includes the following accessories:

No. Order. no. Description

1 1.828.0010 IC Dual Suppressor

1 6.21220X0 Mains cable

to customer’s requirements:

Cable socket Cable plug

Type IEC 320/C 13 Type SEV 12 (CH…) 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…) 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) 6.2122.070

1 6.2128.180 Remote connection cable

Connection cable IC Interface 762 –

752, 753, 754, 793 or 828.

1 6.2140.40 Connection block

For ready output interface, 6-pin

1 6.1831.010 PEEK capillary

Length = 3 m

2.5

1

16"

1 6.1803.020 PTFE capillary tubing

Length = 5 m

1 6.1803.090 PTFE capillary

Backpressure capillary,

0.97

2.5

length = 15 m

1 6.2744.010 PEEK pressure screw

For connecting 1⁄16" capillaries,

set of 5 pieces

26

1 6.2744.014 PEEK pressure screw

For connecting

1

⁄16" capillaries,

set of 2 pieces

26

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

42

1.57

1

16"

Page 51

6.2 Standard equipment

2 6.2744.040 PEEK coupling

1

For connecting

⁄16" capillaries

9.5

24

1 6.1816.030 Silicone tubing

Connection tubing for CO

cartridge, length = 7 cm

absorber

2

4 6

1 6.2027.070 Column holder

Holder for the CO2 absorber cartridge,

diameter d = 25.0 mm, 2 pieces

42

d

1 6.2837.000 CO2 absorber cartridge

1 8.828.1003 Instructions for Use (English)

for 828 IC Dual Suppressor

828 IC Dual Suppressor/ 8.828.1003 Instructions for Use

43

Page 52

6 Appendix

6.3 Optional accessories

No. Order. no. Description

1 6.2143.200 Remote connection cable

761 Compact IC - 828, length = 2 m

1 6.2838.000 IC Dual Suppressor cell

1 U.600.0016 Fuse

1.0 AT slow blow

1 6.2621.080 Capillary cutter for plastic

capillaries

for 6.1831.010 PEEK capillaries and

6.1822.010 PTFE microcapillaries

with 5 spare cutting blades

25 pol.

2 m

55

118