Page 1

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

824 Easy Sample Changer

Program version 5.824.0010

Instructions for Use

8.824.1003 08.2002/ dm

Page 2

Contents

Teachware

Metrohm AG

Oberdorfstr. 68

CH-9101 Herisau

teachware@metrohm.com

1st Edition 2002

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great

care, errors cannot be entirely excluded. Should you notice any mistakes please

inform the author at the address given above.

© Metrohm Ltd. 2002

Printed in Switzerland

II 824 Easy Sample Changer, Contents

Page 3

Contents

Table of contents

1 Introduction ..................................................1

1.1 Instrument description...................................................................... 1

1.1.1 Two versions ............................................................................... 1

1.2 Information about these Instructions for Use ................................ 3

1.3 Parts and controls ............................................................................. 4

1.3.1 The keypad ................................................................................. 4

1.3.2 Individual parts and standard accessories ................................5

1.4 Safety information ............................................................................. 7

1.4.1 General:....................................................................................... 7

1.4.2 Electrical safety ........................................................................... 7

2 Installation.................................................... 8

2.1 Instrument setup ............................................................................... 9

2.1.1 Packaging ................................................................................... 9

2.1.2 Checks ........................................................................................ 9

2.1.3 Location ...................................................................................... 9

2.2 Mains connection .............................................................................. 9

2.3 Keyboard connection...................................................................... 10

2.4 Attaching and equipping a titration head ..................................... 11

2.4.1 Attaching and equipping the KF titration head ........................ 12

2.4.2 Attaching the splash protector ................................................. 13

2.4.3 741 Magnetic Stirrer.................................................................. 13

2.5 Attaching the 759 Swing Head ....................................................... 14

2.5.1 Procedure.................................................................................. 14

2.6 Connecting devices to the Remote socket................................... 15

2.6.1 Remote connections................................................................. 15

2.7 Serial connection (RS232) .............................................................. 18

2.8 Sample racks ................................................................................... 19

2.8.1 Positioning a sample rack ........................................................ 20

3 Operation ....................................................21

3.1 The <SELECT> key.......................................................................... 21

3.2 Settings............................................................................................. 22

3.2.1 Setting the working position of the lift....................................... 22

3.2.2 Setting the rinsing position of the lift......................................... 22

3.2.3 Setting the shifting position of the lift........................................ 23

3.2.4 Setting the stirrer rate................................................................ 23

3.3 Manual operation............................................................................. 24

3.3.1 Moving the lift............................................................................ 24

3.3.2 Rotating the sample rack.......................................................... 24

3.3.3 Switching the stirrer on/off ........................................................ 24

3.3.4 Operating the pumps................................................................ 24

3.4 Automatic operation........................................................................ 25

3.4.1 Preparing a sample series........................................................ 25

3.4.2 Method selection ...................................................................... 25

3.4.3 Starting a method ..................................................................... 25

3.4.4 Interrupting a method run ......................................................... 26

3.4.5 Canceling a method run ........................................................... 26

824 Easy Sample Changer, Contents III

Page 4

Contents

3.5 Functions of the LEDs..................................................................... 27

3.5.1 The Status LED ......................................................................... 27

3.5.2 The [SELECT] LEDs ................................................................. 27

3.5.3 LEDs 1 to 4 ............................................................................... 27

4 Standard methods ......................................29

4.1 Information about the methods...................................................... 29

4.2 Method labels ................................................................................... 30

4.3 Method 1 ........................................................................................... 30

4.4 Method 2 ........................................................................................... 31

4.5 Method 3 ........................................................................................... 32

4.6 Method 4 ........................................................................................... 33

4.6.1 Editing methods........................................................................ 34

5 Maintenance information ...........................35

5.1 Maintenance / Service ..................................................................... 35

5.2 Care / Maintenance .......................................................................... 35

6 GLP validation.............................................36

7 Troubleshooting .......................................... 37

7.1 Error messages................................................................................ 37

8 Annex...........................................................39

8.1 Technical data.................................................................................. 39

8.1.1 Interfaces .................................................................................. 39

8.1.2 Pump connections.................................................................... 39

8.1.3 Lift ............................................................................................. 39

8.1.4 Turntable................................................................................... 39

8.1.5 Stirrer......................................................................................... 39

8.1.6 Power supply ............................................................................ 40

8.1.7 Safety Specifications ................................................................ 40

8.1.8 Electromagnetic compatibility (EMC)....................................... 40

8.1.9 Ambient temperature................................................................ 40

8.1.10 Dimensions and materials........................................................ 41

8.2 Method listings................................................................................. 42

8.2.1 Method 1................................................................................... 42

8.2.2 Method 2................................................................................... 43

8.2.3 Method 3................................................................................... 44

8.2.4 Method 4................................................................................... 45

8.3 Connecting external pumps ...........................................................46

8.4 Connecting rinsing and aspirating equipment............................. 47

8.4.1 Attaching the distributor and tubing......................................... 47

8.4.2 Spray nozzles ........................................................................... 47

8.4.3 Aspiration tip............................................................................. 49

8.5 Sample beakers for Karl Fischer titrations ................................... 49

8.6 Standard equipment ........................................................................ 50

8.6.1 824 Easy Sample Changer....................................................... 50

IV 824 Easy Sample Changer, Contents

Page 5

Contents

8.7 Optional accessories ...................................................................... 53

8.7.1 6.5610.020 KFT Equipment...................................................... 53

8.7.2 772 Pump Unit (2.772.0020)..................................................... 54

8.7.3 772 Pump Unit (2.772.0030)..................................................... 56

8.7.4 Optional accessories and instruments..................................... 57

8.7.5 Connection cables.................................................................... 57

8.7.6 Sample racks and sample beakers.......................................... 58

8.7.7 Electrodes for Sample Changers ............................................. 59

8.8 Warranty and conformity................................................................ 60

8.8.1 Warranty .................................................................................... 60

8.8.2 EU Declaration of Conformity for 824 Easy Sample Changer . 61

8.8.3 Declaration of Conformity: 824 Easy Sample Changer ...........62

Index............................................................ 63

List of illustrations

Fig. 1 Keypad ....................................................................................................................... 4

Fig. 2 Side view of 824 Easy Sample Changer .................................................................... 5

Fig. 3 Rear view .................................................................................................................... 6

Fig. 4 824 Easy Sample Changer – peripheral devices ....................................................... 8

Fig. 5 Fuse holder............................................................................................................... 10

Fig. 6 Rear panel of instrument .......................................................................................... 10

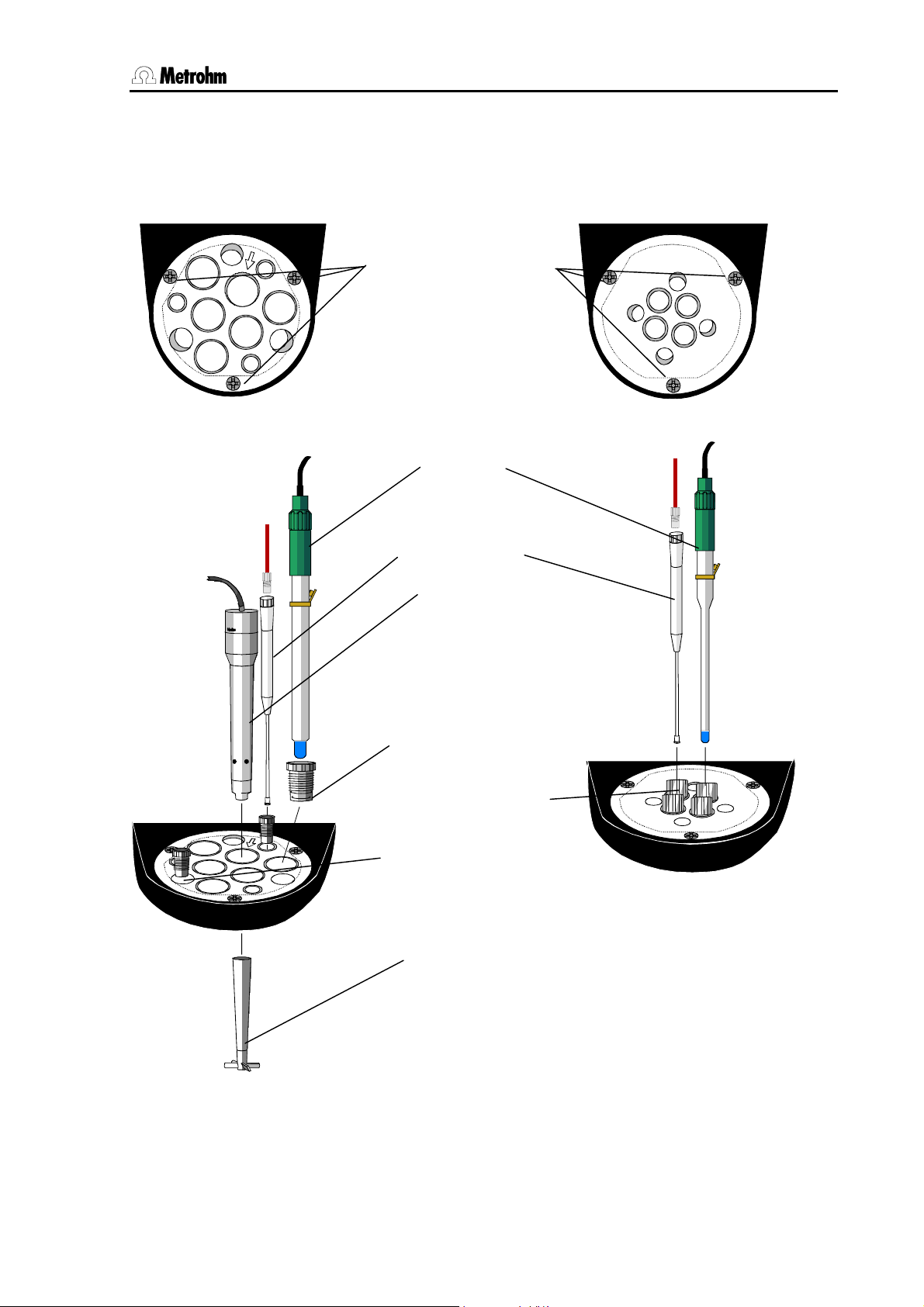

Fig. 7 Macro-titration head ................................................................................................. 11

Fig. 8 Micro-titration head .................................................................................................. 11

Fig. 9 KF Titration head ...................................................................................................... 12

Fig. 10 Attaching the splash protector ................................................................................. 13

Fig. 11 Attaching the magnetic stirrer .................................................................................. 13

Fig. 12 Attaching the 759 Swing Head................................................................................. 14

Fig. 13 Connecting a 7xx Titrino ........................................................................................... 15

Fig. 14 Connecting an 8xx Titrando...................................................................................... 16

Fig. 15 Connecting a Titrino and Dosimat............................................................................ 16

Fig. 16 Connecting a 780/781 pH Meter .............................................................................. 17

Fig. 17 Connecting the 759 Swing Head ............................................................................. 17

Fig. 18 Connecting a computer............................................................................................ 18

Fig. 19 Attaching a sample rack........................................................................................... 20

Fig. 20 6.2142.010 Keypad for sample changer ................................................................. 34

Fig. 21 Pump connections ................................................................................................... 46

Fig. 22 Distributor ................................................................................................................. 47

Fig. 23 Attaching the spray nozzles and the aspiration tip .................................................. 48

Fig. 24 Titration head with aspiration and rinsing equipment .............................................. 48

Fig. 25 Function of the spray nozzles................................................................................... 48

Fig. 26 Karl Fischer sample beaker...................................................................................... 49

824 Easy Sample Changer, Contents V

Page 6

Page 7

1.1 Instrument description

1 Introduction

The Metrohm 824 Easy Sample Changer is an instrument for numerous

applications. It was specially developed for the industrial or analytical

laboratory and therefore covers a wide spectrum of applications. It provides indispensable support when processing a large sample series

throughout the whole titration sector, for various measurement jobs, or

for other analytical purposes.

Due to the well-developed communication interfaces (parallel remote

control and serial RS 232), not only can it communicate with the large

range of Metrohm titration and dosing instruments but it can also control or be controlled by a personal computer. For this purpose Metrohm

offers the versatile Tinet titration software. These capabilities predestine

it for all conceivable automation jobs in a modern laboratory, even in

conjunction with highly integrated laboratory data systems.

1.1 Instrument description

The greatest advantage of the 824 Easy Sample Changer lies in its very

easy user operation. For carrying out simple applications the predefined standard methods may be used without any modifications being

needed. The simple keyboard allows the use of all the functions used in

the daily routine tasks of the 824 Easy Sample Changer.

1.1.1 Two versions

The 824 Easy Sample Changer is supplied in two different versions.

Macro-version

The 2.824.0010 version includes a complete set of accessories for

working with the supplied macro-titration head to process large- to medium-size sample vessels.

Micro-version

The 2.824.0020 version includes a complete set of accessories for

working with the supplied micro-titration head to process smaller sample vessels.

Both versions are supplied with a sample rack and suitable sample

vessels as standard. A particularly suitable set of KFT equipment can

be ordered for carrying out Karl Fischer titrations with the 824 Easy

Sample Changer.

Pump control

For rinsing the electrodes and for aspiration of the sample solutions either one or two peristaltic pumps can be connected directly to the 824

Easy Sample Changer. The Metrohm 772 Pump Unit is also available in

versions with accessories for aspiration or rinsing.

824 Easy Sample Changer, Introduction 1

Page 8

1.1 Instrument description

Standard sample racks

Exchangeable standard sample racks are available for a wide range of

different sized vessels. Each rack has a predefined "special beaker" position. This is used for placing a rinsing or conditioning beaker on the

rack. In this way, for example, it is possible to condition or rinse an electrode after each titration.

Standard methods

The predefined standard methods of the 824 Easy Sample Changer not

only have an optimized sample processing sequence but also have

both a start sequence and a final sequence which are carried out before and after a series of samples respectively.

759 Swing Head

For processing a larger number of samples the 759 Swing Head can be

installed on the sample changer. This drive is used instead of the standard titration head and can, for example, be fitted with a titration head

for direct titration in the sample vessels. By using the 759 Swing Head it

is possible to use multi-row sample racks and therefore to process larger numbers of samples within a very short time.

The basis

The 824 Easy Sample Changer was developed on the basis of the timeproven Metrohm 730 Sample Changer and therefore offers the possibility of the free definition of run sequences, method parameters and rack

data throughout a very wide range. This requires the use of the

“6.21.42.010 SC Controller” Sample changer keypad.

2 824 Easy Sample Changer, Introduction

Page 9

1.2 Information about these Instructions for Use

1.2 Information about these Instructions for Use

Please read through these Instructions for Use before you start to use

the 824 Easy Sample Changer.

The following notations and pictograms are used in these instructions:

35 Operating element

The operating elements are explained on

pages 4ff.

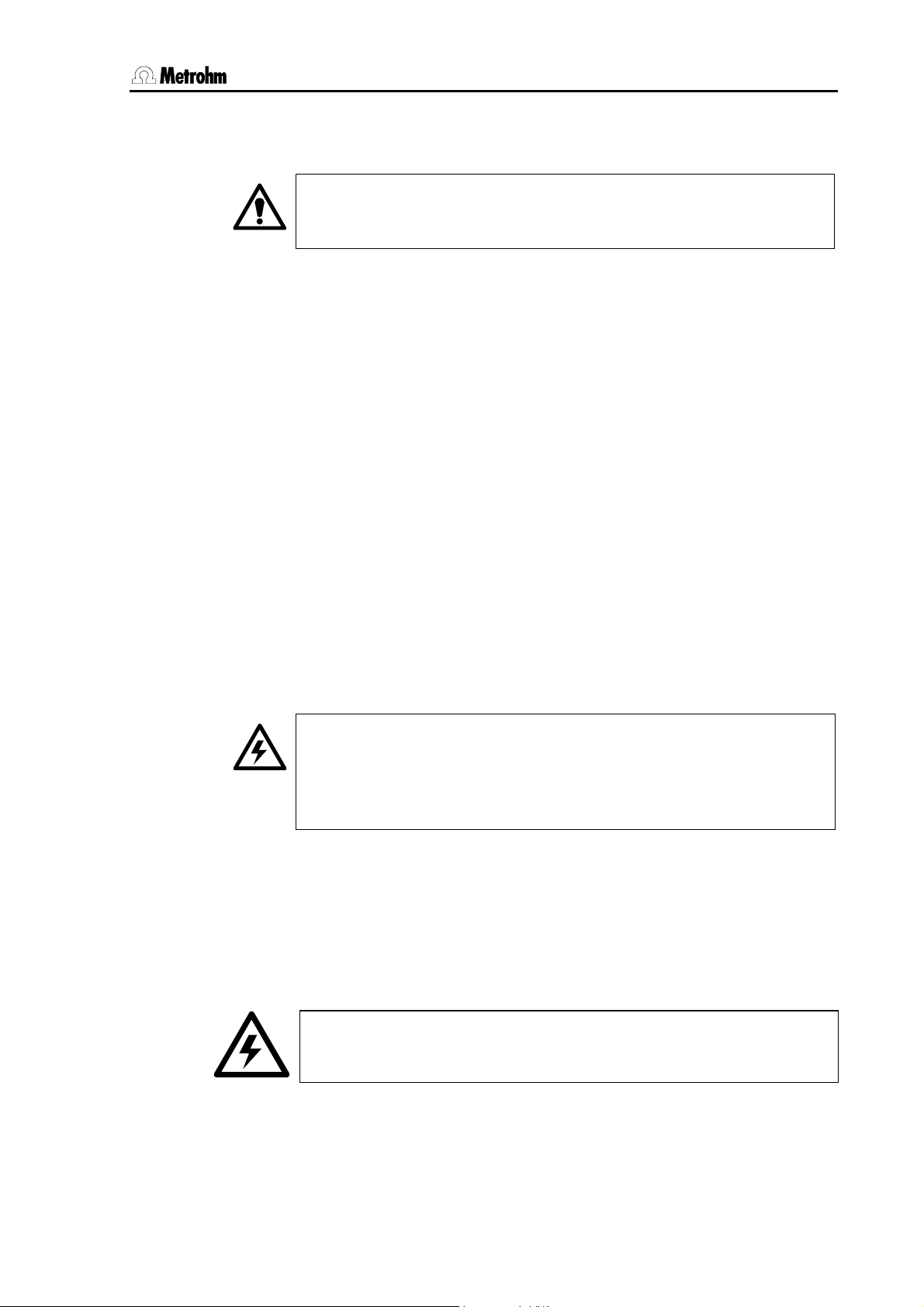

Danger

This symbol indicates a possible risk of

death or injury to the user and possible

damage to the instrument or its components by electricity.

Danger/Warning

This symbol indicates a possible risk of

death or injury to the user and possible

damage to the instrument or its components.

Attention

This symbol indicates important information. Read the information provided before

you continue.

Information

This symbol indicates additional information

and tips which may be of particular use to

you.

824 Easy Sample Changer, Introduction 3

Page 10

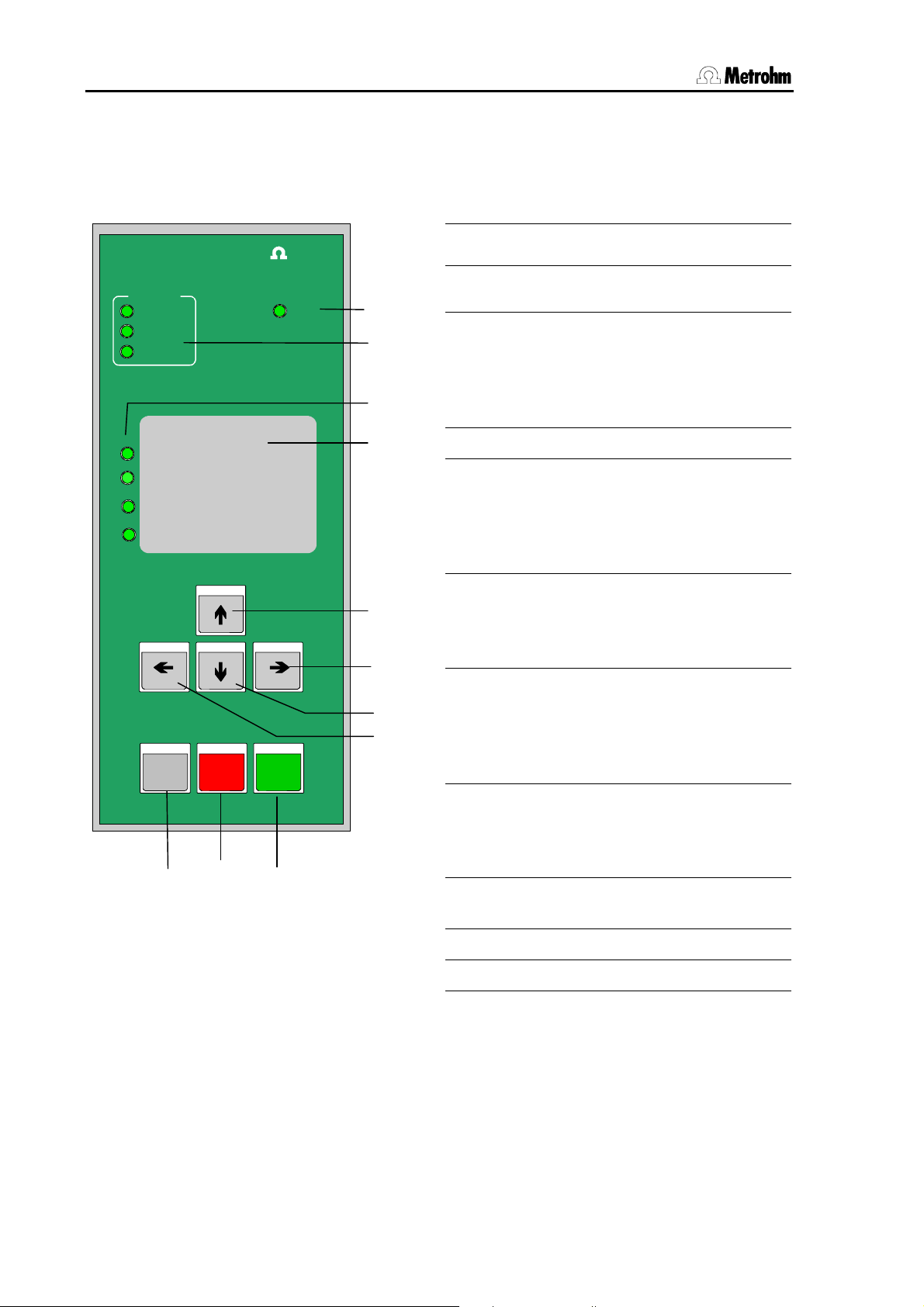

1.3 Parts and controls

1.3 Parts and controls

1.3.1 The keypad

1 Status LED

Easy Controller

SELECT

Method

PUMP/STIR

Config

Methods

1 ________________________

2 ________________________

3 ________________________

4 ________________________

STIR 1

PUMP 1 PUMP 2

STIR 2

Met ro h m

Status

2

3

4

5

6

2 SELECT LEDs

Indicate the user mode

3 LEDs 1 to 4

• Method selection

• Stirrer/Pump status

• Configuration steps

• Error display

4 Labeling field for methods

5 Arrow key up / Stirrer 1

• Lift up

• Method selection

• Stirrer 1 on/off

• Sets lift position and stirrer rate

6 Arrow key right / Pump 2

• Rotates rack clockwise

• Pump 2 on/off

• Next configuration step

7 Arrow key down / Stirrer 2

HOLD STOP

6.2142.110

9

Fig. 1 Keypad

RESETSELECT

10

START

11

7

8

• Lift down

• Method selection

• Stirrer 2 on/off

• Sets lift position and stirrer rate

8 Arrow key left / Pump 1

• Rotates rack counterclockwise

• Pump 1 on/off

• Previous configuration step

9 User mode / Interrupt method /

Acknowledge error message

10 Initialize changer / Cancel method

11 Start method / Continue method

4 824 Easy Sample Changer, Introduction

Page 11

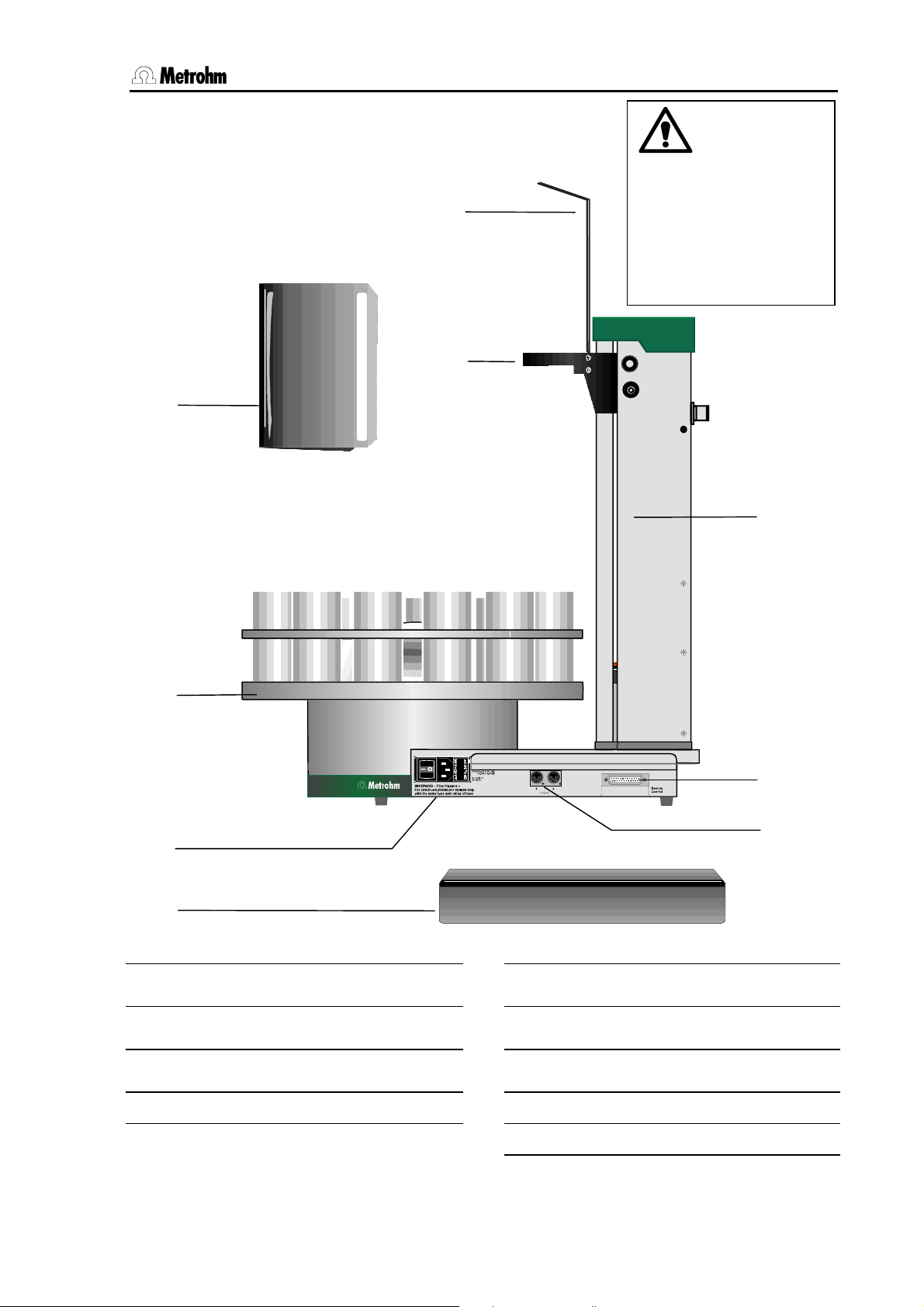

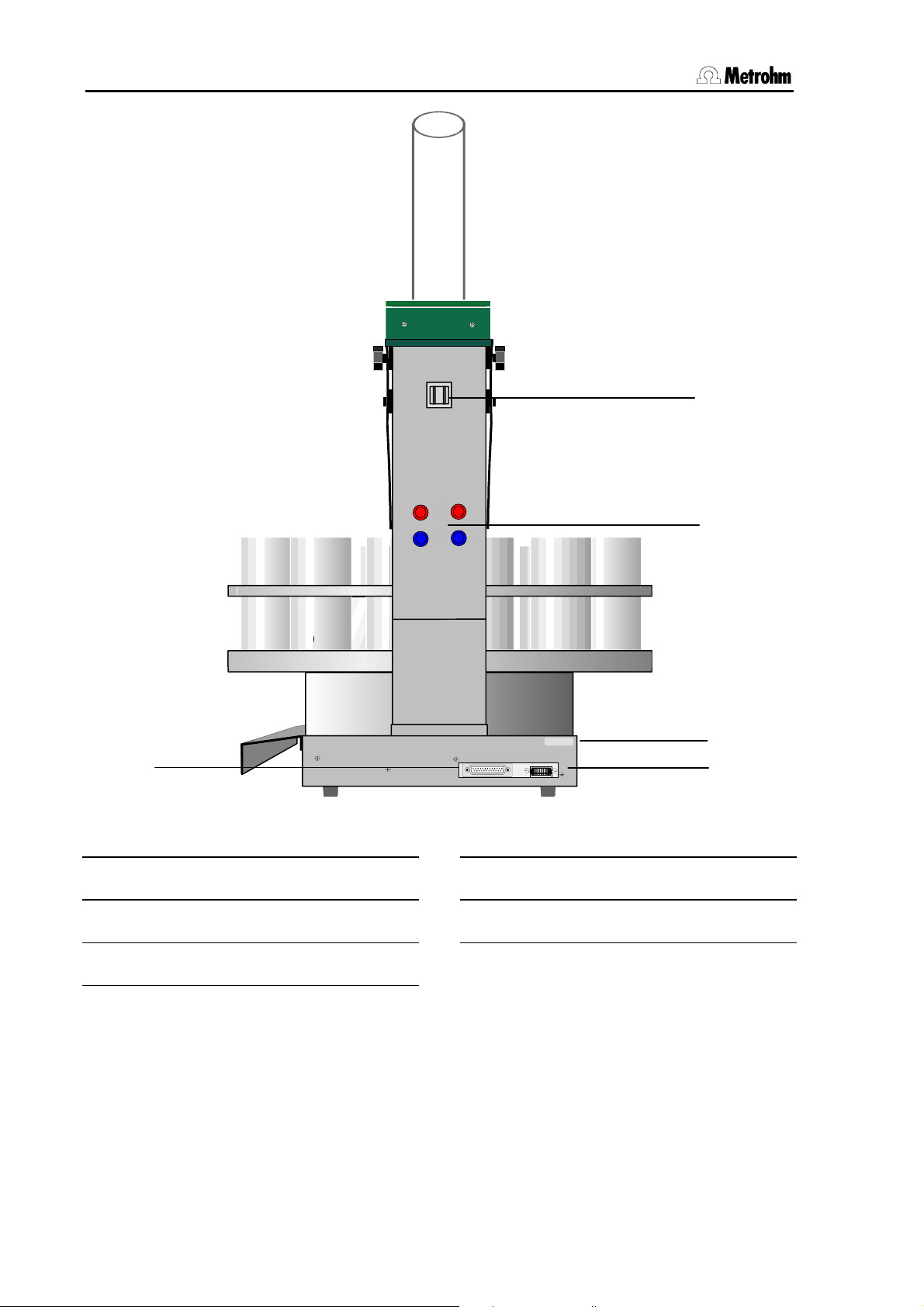

1.3 Parts and controls

1.3.2 Individual parts and standard accessories

12

14

13

The 824 Easy Sample

Changer must not be

operated without the

splash protector 13 and

connections cover 17 in

position.

18

15

19

20

16

17

Fig. 2 Side view of 824 Easy Sample Changer

12 Tubing guide 16 Mains switch and fuse holder

13 Splash protector 6.2751.010 17 Connections cover 6.2752.010

14 Lift 18 Tower

15 Sample rack e. g. 6.2041.310 19 Remote interface

20 Stirrer connection

824 Easy Sample Changer, Introduction 5

Page 12

1.3 Parts and controls

21

Ext.

Ext.

Pump 1

Pump 2

22

16 V

16 V

max. 300 mA

max. 300 mA

25

Line sleeve

21

Pump connectors

22

Manufacturing number

23

RS 232 Keybo ard

Made by Metrohm Herisau Switzerland

Fig. 3 Rear view

24

25

Type 1.824.0010 Nr.

0010/01104

Keyboard connector

RS232 connector

23

24

6 824 Easy Sample Changer, Introduction

Page 13

1.4 Safety information

1.4 Safety information

Warning!

This instrument should only be used in accordance with the information

given in these Instructions for Use.

1.4.1 General:

This instrument left our works in perfect condition from the point of view

of its operational safety (see Technical data, safety specification). To

keep it in this condition and to continue to operate safely the following

information must be carefully observed.

1.4.2 Electrical safety

Please observe the following guidelines:

• Only qualified Metrohm personnel should carry out service work on

electronic components.

• Do not open the instrument housing as this could damage the in-

strument. The housing contains no components which could be

serviced or exchanged by the user.

Electrical safety when handling the instrument is guaranteed within the

scope of Standard IEC 61010-1. However, please observe the following

point:

Protection against electrostatic charges

Warning!

Electronic components are sensitive to electrostatic charges and can

be destroyed by a discharge. Always remove the mains connection

cable from socket 12 before making or breaking electrical connections

on the rear panel of the instrument.

Connection to the electricity supply:

This instrument must only be operated at the specified mains voltage.

Repair and maintenance:

If faults or malfunctions occur while using the 824 Easy Sample

Changer we recommended that you first check that the connection to

the control instrument has been made correctly.

The instrument must not be opened. This is reserved exclusively for

authorized service personnel.

824 Easy Sample Changer, Introduction 7

Page 14

1.4 Safety information

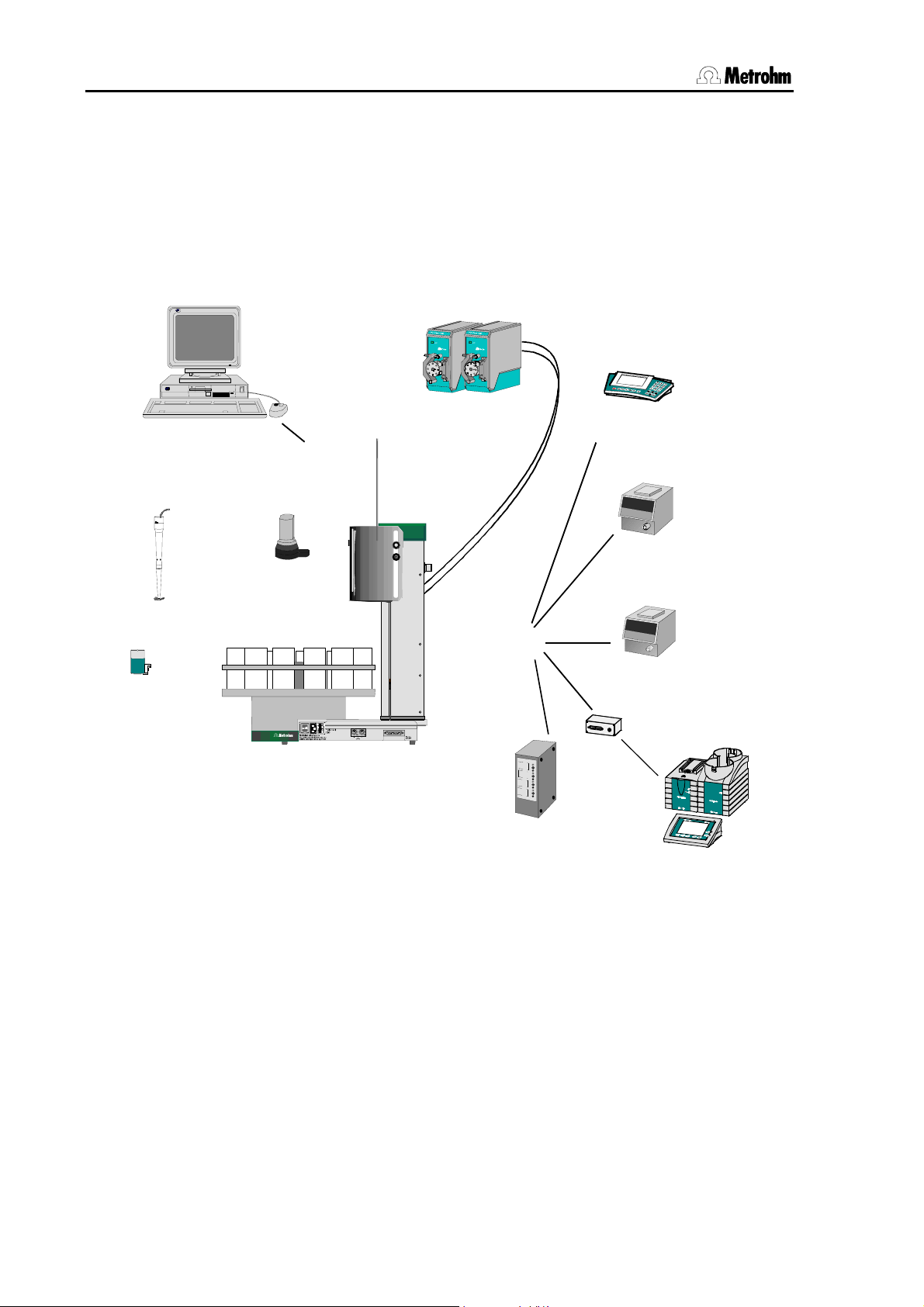

2 Installation

This section describes the things you should pay attention to when unpacking and starting up the 824 Easy Sample Changer. It also tells you

how a complete automation system is built up.

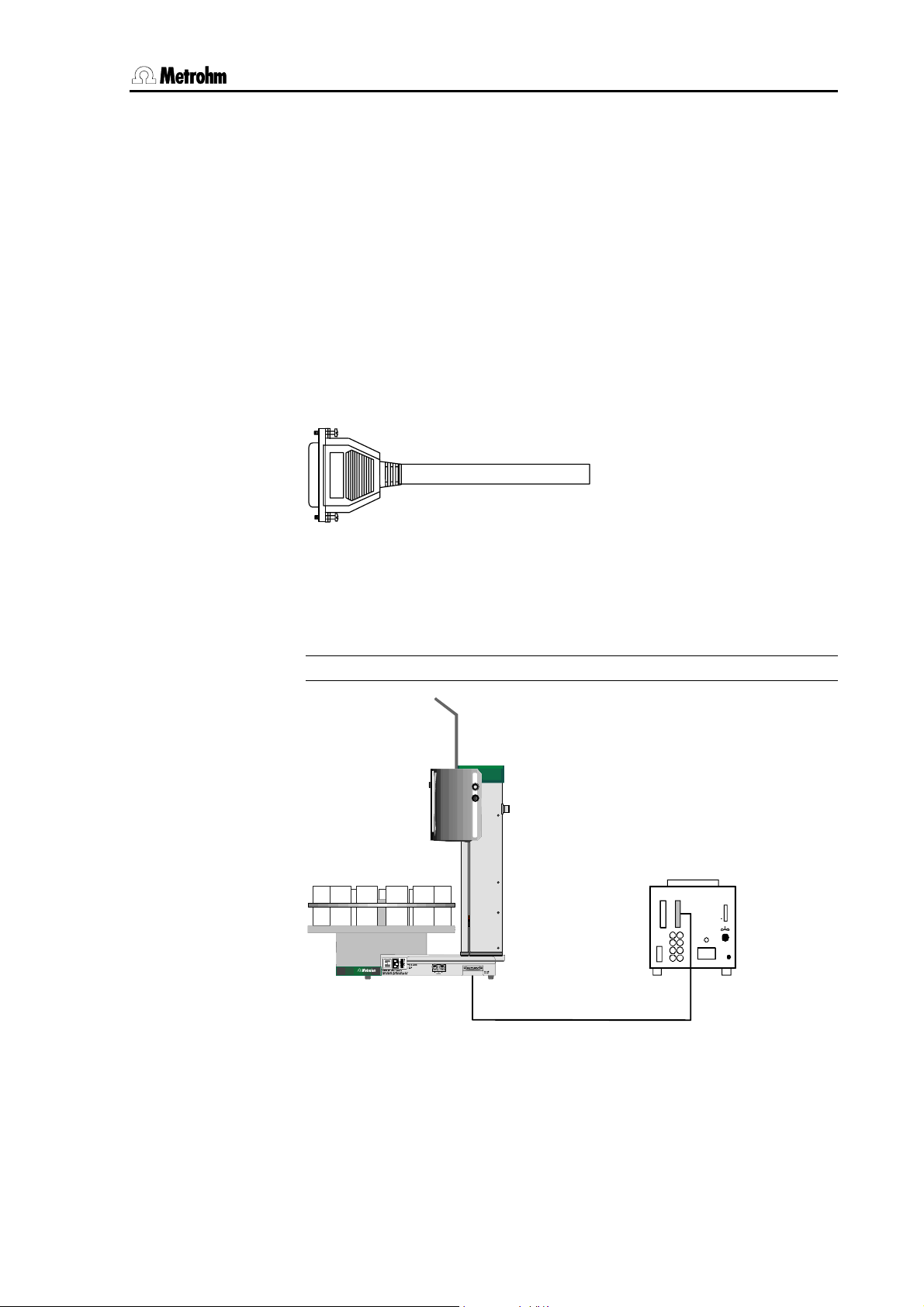

The following illustration provides an overview of the peripheral devices

which can be attached to an 824 Easy Sample Changer:

691

780

692

781

712

713

665

725

765

775

776

Personal Computer

759 Swing Head

RS232

772 Pump Unit

pH Meter / Ion meter

Conductometer

Dosimat

722/802 Rod stirrer

741 Magnetic stirrer

824 Easy Sample Changer

Remote

Remote Box MSB

731 Relay Box

Fig. 4 824 Easy Sample Changer – peripheral devices

7xx

Titrino

family

808/809

Titrando

8 824 Easy Sample Changer, Installation

Page 15

2.1 Instrument setup

2.1 Instrument setup

2.1.1 Packaging

The 824 Easy Sample Changer and its specially packed accessories

are supplied in very protective special packaging. Please store this

packaging in a safe place; it is the only way in which the safe transport

of the instrument can be guaranteed.

2.1.2 Checks

Please check that the delivery is complete and undamaged immediately on receipt (compare with delivery note and list of accessories

given in Section 8.6). If transport damage is evident please refer to the

information given in Section 8.8.1 ''Warranty'.

2.1.3 Location

The 824 Easy Sample Changer has been developed for indoors use

and must not be used in explosion-endangered surroundings.

Place the instrument on a suitable vibration-free laboratory bench, protected as much as possible from corrosive atmospheres and contamination by chemicals.

Select a location in which the ambient temperature is normally between

+5 °C and +45 °C. The instrument should be protected against excessive variations in temperature and direct sunshine.

If an instrument which has been stored under cold conditions is

brought into a warm room then the atmospheric humidity may condense inside the instrument and form water. In order to avoid damaging

the instrument please wait for at least one hour before switching it on.

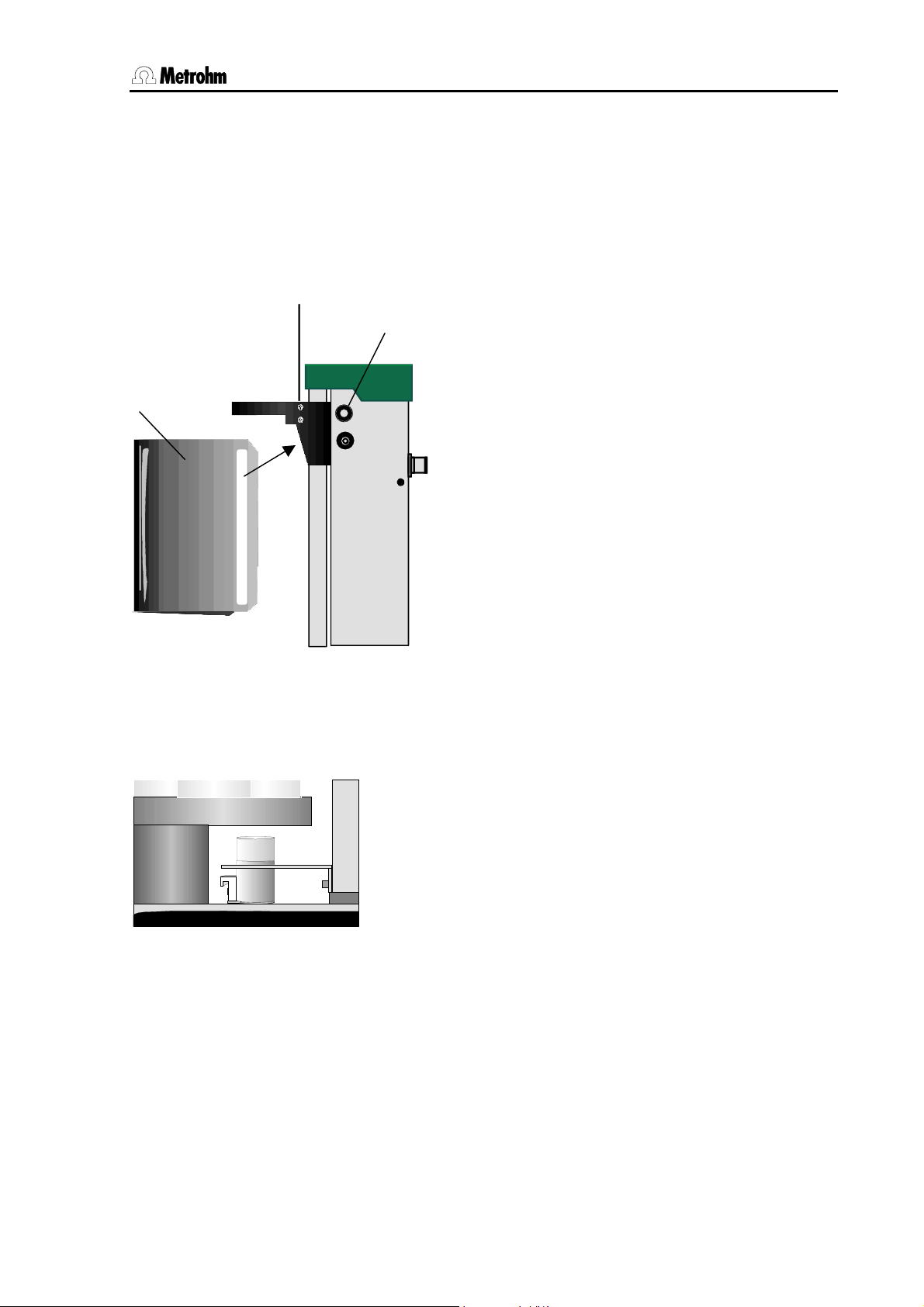

2.2 Mains connection

Please observe the following rules when connecting the instrument to

the electricity supply. If the instrument is operated with an incorrectly set

mains voltage and/or an incorrect mains fuse then it represents a fire

hazard!

Setting the mains voltage

Before you switch on the 824 Easy Sample Changer for the first time

please check that the mains voltage set on the instrument (see illustration on the following page) corresponds to your local mains voltage. If

this is not the case then you must alter the mains voltage as follows:

824 Easy Sample Changer, Installation 9

Page 16

2.3 Keyboard connection

• Pull out mains cable

Remove the mains cable from the mains supply connection of the 824

Easy Sample Changer.

• Remove the fuse holder

Use a screwdriver to loosen the fuse holder beside the mains supply

connection and remove it completely.

• Check the fuse and replace it

Carefully remove the built-in fuse for the intended voltage from the fuse

holder and check its specifications (the position of the fuse in the fuse

holder is indicated by the white arrow beside the voltage range):

100…120 V 0.5 A (slow blow) Metrohm-No. U.600.0014

220…240 V 0.25 A (slow blow) Metrohm No. U.600.0011

• Insert fuse

Exchange the fuse if necessary and replace it in the fuse holder.

• Insert fuse holder

Depending on the required mains voltage, insert the fuse holder so that

the white arrow of the corresponding voltage range points to the white

bar; this is to the right of the fuse holder (see below).

220 – 240 V

100

-

120 V

240 V

-

220

100 – 120 V

220

-

240 V

120 V

-

100

Fig. 5 Fuse holder

Mains switch

Mains connection

Fuse holder

• Attach connections cover

Position the connections cover in the guide rail above the connections

strip. The connections cover protects the connections from spilt chemicals.

2.3 Keyboard connection

Type 1.824.0010 Nr.

RS 232 Keyboard

Made by Metrohm Herisau Switzerland

Fig. 6 Rear panel of instrument

10 824 Easy Sample Changer, Installation

0010/01104

The keyboard is attached to the connection 24

provided for it on the rear panel of the instrument. To

remove the connection press both sides of it together.

Page 17

2.4 Attaching and equipping a titration head

2.4 Attaching and equipping a titration head

Macro-titration head

6.1458.010

Attachment screws

SGJ14 Sleeve

SGJ9 Guiding sleeve

Propeller stirrer

Fig. 7 Macro-titration

Note about the Macro-titration head

Micro-titration head

Electrode

Buret tip

Rod stirrer

2.802.0020

6.1236.020

Screw nipple

4.658.0180

6.2709.070

6.1909.020

head

6.1458.020

Fig. 8 Micro-titration head

Only special micro-electrodes

can be used with the microtitration head; see list of

accessories, p. 46.

The SGJ14 opening marked by an arrow is bored at a slight angle so that a rod stirrer or an

electrode can be centered in narrow titration vessels.

824 Easy Sample Changer, Installation 11

Page 18

2.4 Attaching and equipping a titration head

A

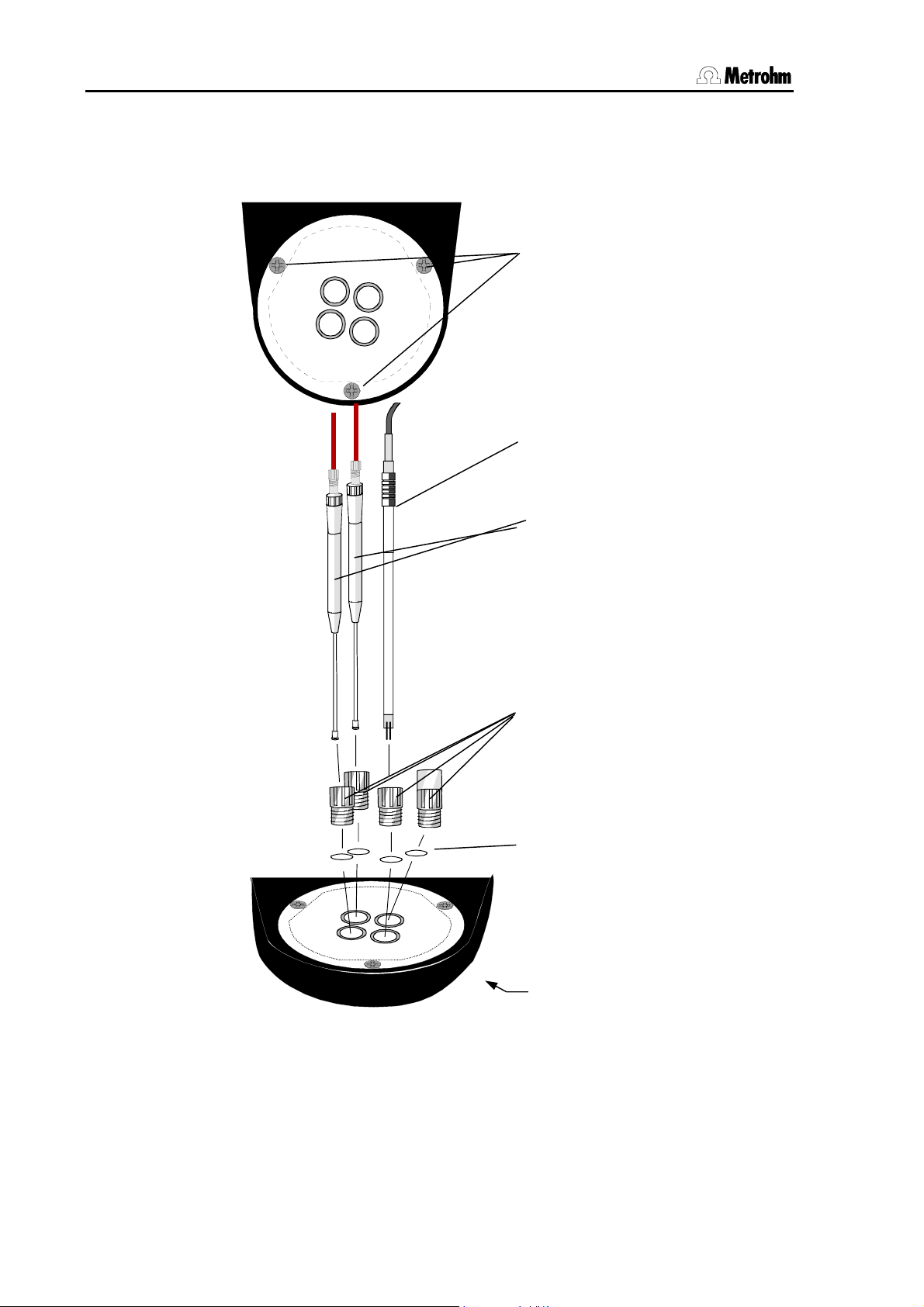

2.4.1 Attaching and equipping the KF titration head

KFT Titration head

6.1458.030

ttachment screws

Double Pt-electrode

6.0340.000

Buret tips

6.1543.200

Screw nipple

4.658.0180

O-Rings

E.301.0022

O-Ring (below)

E.301.0080

Fig. 9 KF Titration head

Note:

In order to ensure an optimal seal of the titration vessel the M10 threads

should be inserted into the titration head together with the O-rings.

12 824 Easy Sample Changer, Installation

Page 19

2.4 Attaching and equipping a titration head

When attaching the tubing and cable connections these should be led

from the titration head through the tubing guide in order not to restrict

the range of movement of the lift. Take care that the tubing is long

enough to accommodate the whole range of movement of the lift.

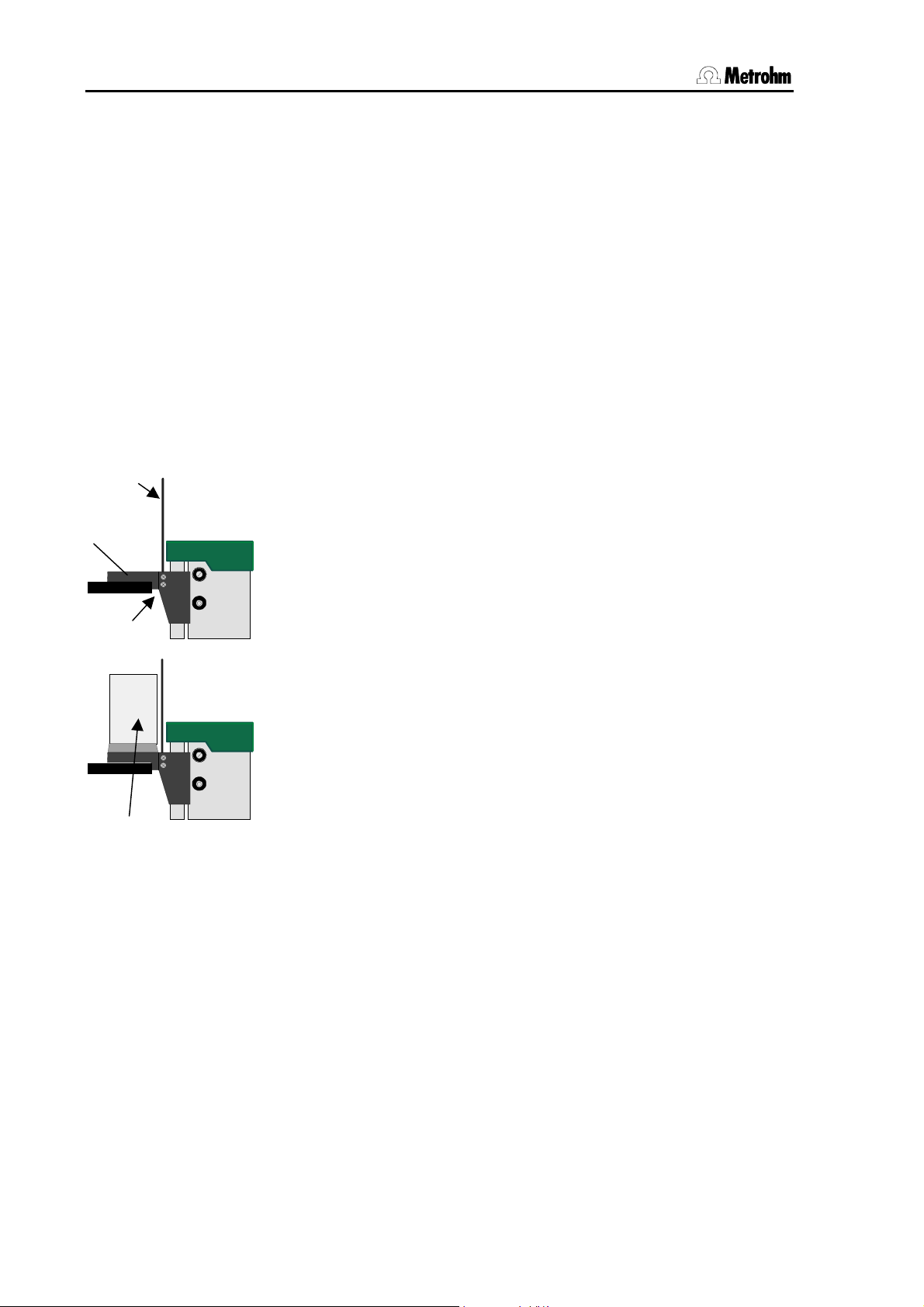

2.4.2 Attaching the splash protector

For safety reasons the 824 Easy Sample Changer should not be operated unless the splash protector is in its proper position.

13

Fig. 10 Attaching the splash protector

2.4.3 741 Magnetic Stirrer

Fig. 11 Attaching the magnetic stirrer

26

• On both sides of the tower loosen knurled nuts

26.

• Slip the slot-shaped openings of the splash

protector 13 over the attachment screws and

tighten up knurled nuts 26 again.

• If the knurled nuts 26 are loosened slightly it is

easy to adjust the height of the splash protector

13.

Apart from the micro-titration head, the

2.824.020 version also includes a 741 Magnetic

Stirrer.

The use of the 741 Magnetic Stirrer is particularly

recommended for Karl Fischer titrations.

The 2.741.0010 Magnetic Stirrer can be attached

to the tower by using the holder (6.2034.020)

and supplied screws as shown in the drawing

alongside.

824 Easy Sample Changer, Installation 13

Page 20

2.5 Attaching the 759 Swing Head

2.5 Attaching the 759 Swing Head

In order to accurately move to the individual sample vessels when multirow sample racks are used (see p. 19), the 759 Swing Head can be

used instead of a normal titration head. It is equipped with either a titration head (Model 2.759.0020) or with a transfer head (Model

2.759.0010).

The 759 Swing Head with titration head can be used with the 2-row

sample rack M48-1. The swing head version with the transfer head is intended for use with the 3-row sample racks M128-2, M129-2 and M142-

2.

2.5.1 Procedure

• Switch off instrument.

12

• Remove the titration head 14 by loosening the four screws on both

the outer sides of the lift.

14

Loosen

759 Swing

Head

Fig. 12

Attaching the 759

Swing Head

• Screw off the tubing guide from the titration head 14.

• Attach the new titration head (6.1462.020) or the transfer head

(6.1462.010) to the bottom of the swing head by using the three

screws provided.

• Screw the tubing guide 12 onto the new titration or transfer head.

• Attach new titration or transfer head to the lift and fasten it with the

four screws.

• Connect the 759 Swing Head to the Remote socket 19 of the 824

Easy Sample Changer, see also p. 17.

• Place a multi-row sample rack on the turntable of the sample

changer.

• Switch on instrument.

• If the swing head moves when the instrument is switched on then

this means that it has been recognized by the 824 Easy Sample

Changer and is ready for use.

• If the swing head does not move when the instrument is switched on

then switch the instrument off and then on again.

14 824 Easy Sample Changer, Installation

Page 21

2.6 Connecting devices to the Remote socket

2.6 Connecting devices to the Remote socket

Connection cable

If the 824 Easy Sample Changer is to be connected to other devices

then only Metrohm cables should be used as these are the only cables

that guarantee perfect data transfer.

Note:

The Remote cable for the 824 Easy Sample Changer have a marking at

each end which indicates the instrument for which the particular end is

intended to be used and the connection to which it is to be connected.

Example (standard Remote cable):

Titrino B

692 / 712 / 713

Before peripheral devices are connected the sample changer must be

switched off as otherwise the instruments could be damaged.

2.6.1 Remote connections

Sample changer — Titrino

with standard cable

824

Fig. 13 Connecting a 7xx Titrino

Cable 6.2141.020

B

A

Titrino

C

D

824 Easy Sample Changer, Installation 15

Page 22

2.6 Connecting devices to the Remote socket

Sample changer — Titrando

with standard cable and 6.2148.010 Remote Box

Remote box

6.2148.010

MSB 3

MSB 1

MSB 4

MSB 1

824

MSB

808 / 809 Titrando

6.2141.020 Cable

Fig. 14 Connecting an 8xx Titrando

Sample changer — Titrino — 765/776 Dosimat

B

A

Titri no

824

C

D

6.2141.040 Cable

A

665

D

B

C

Fig. 15 Connecting a Titrino and Dosimat

16 824 Easy Sample Changer, Installation

Page 23

2.6 Connecting devices to the Remote socket

Sample changer — 780/781 pH-Meter

with standard cable and 6.2148.010 Remote box

Remote box

6.2148.010

824

6.2141.020 Cable

MSB

Fig. 16 Connecting a 780/781 pH Meter

Sample changer with 759 Swing Head

824

Connecting further devices via

Remote cables

Fig. 17 Connecting the 759 Swing Head

The swing head is connected to the Remote interface of the 824 Easy

Sample Changer. The connection of the 759 Swing Head allows the

connection of further devices via Remote lines; 4 lines (Input 7 and

Output 11–13) are occupied by the swing head. These four lines are not

led any further through the connection.

824 Easy Sample Changer, Installation 17

Page 24

2.7 Serial connection (RS232)

2.7 Serial connection (RS232)

A personal computer can be connected to the serial RS232 interface

25. In this way the 824 Easy Sample Changer can be remotely controlled (in the same way as the Metrohm 730 Sample Changer), provided that a suitable software such as Tinet 2.5 is installed.

824

Fig. 18 Connecting a computer

A requirement for correct data transfer is that the transmission parameters are correctly set; these must correspond to the settings at the interface of the connected device.

The standard transmission parameters for the 824 Easy Sample

Changer are:

Baud Rate: 9600 Baud

Data Bit. 8

Stop Bit: 1

Parity: none

Handshake: HWs

Cable 6.2125.060 (25p/25p)

oder 6.2125.110 (25p/9p)

18 824 Easy Sample Changer, Installation

Page 25

2.8 Sample racks

2.8 Sample racks

A sample rack is a turntable which accommodates sample vessels and

which is placed on the sample changer. As in titrations or measurements various sizes of sample vessels are normal or necessary, different types of easily exchangeable sample racks can be used. The number of sample vessels which can be accommodated on a sample rack

depends on their diameters.

When used with the 824 Easy Sample Changer the highest rack position is intended to be used for a special beaker for rinsing or conditioning/dipping.

Metrohm supplies the following standard sample racks:

Type No. of

samples

M12-0 12 250 mL Metrohm titration beaker 000001 6.2041.310

M16-0 16 150 mL beaker 000010 6.2041.320

M24-0 24 75 mL Metrohm titration beaker 001000 6.2041.340

M12-0 12 150 mL beaker or

M14-0 14 200 mL disposable beaker (Euro) 000011 6.2041.370

M14-0 14 8 oz disposable beaker (US) 000101 6.2041.380

M16-0 16 120 mL disposable beaker (US) 100001 6.2041.390

Sample racks for use with the 759 Swing Head:

M48-1 48 * 75 mL Metrohm titration beaker 010000 6.2041.350

M128-2 128 15 mL test tubes+

M142-2 142 15 mL test tubes +

M129-2 129 11 mL test tubes +

*Special beaker at position 24

Type of sample vessel Predefined

magnet code

100000 6.2041.360

200 mL disposable beaker (Euro)

000110 6.2041.400

2 x 250 mL titration beaker

001010 6.2041.410

1 x 500 mL beaker

010001 6.2041.430

2 x 300 mL beaker

Ordering

number.

Each sample rack is unambiguously identified by a magnet code. Magnetic pins, attached to the base of the rack, provide a 6-place binary

code. This means that the magnet sensor can automatically recognize

the rack that is attached when the first beaker position is in front of the

tower.

824 Easy Sample Changer, Installation 19

Page 26

2.8 Sample racks

2.8.1 Positioning a sample rack

After a sample rack has been positioned the sample changer must be

initialized with <RESET> so that the

Magnet holder

Magnet sensor

magnet code of the rack can be read

in. This makes the unambiguous recognition of the rack possible and

therefore the correct positioning of the

beakers.

Fig. 19 Attaching a sample rack

20 824 Easy Sample Changer, Installation

Page 27

3.1 The <SELECT> key

3 Operation

This section contains the basic principles for using the 824 Easy Sample Changer.

As well as processing a series of samples automatically, the 824 Easy

Sample Changer can also be operated manually in order, for example,

to rinse the electrode in a special beaker during the preparation of a series of samples.

In order to load methods or use functions which are not available in the

normal operating status the <SELECT> key must be activated.

3.1 The <SELECT> key

SELECT

HOLD

<SELECT>

<SELECT>

<SELECT>

<SELECT>

The <SELECT> key is used to switch between the different operating

levels of the 824 Easy Sample Changer. Each pressure on the key

SELECT

Met ho d

PUMP/STIR

Conf ig

SELECT

Met hod

PUMP/STIR

Conf ig

SELECT

Met ho d

PUMP/STIR

Conf ig

SELECT

Met ho d

PUMP/STIR

Conf ig

switches from one mode to the next. The LEDs (see left) indicate the

selected mode.

The individual modes and their functions are as follows:

• Normal operating mode

o Controls the lift and the sample rack.

o Starts a method.

• Method selection

o Selects one of four predefined basic methods or modified meth-

ods

• Pump and stirrer control

o Switches two external pumps on/off

o Switches stirrer 1 and 2 on/off

• Sample changer settings

o Sets the lift working height

o Sets the rinsing height of the lift

o Sets the shifting position of the lift

o Sets the stirring rate

SELECT

Met ho d

PUMP/STIR

Conf ig

<SELECT> returns to the normal operating mode.

824 Easy Sample Changer, Operation 21

Page 28

3.2 Settings

3.2 Settings

In order to be able to work comfortably with the 824 Easy Sample

Changer a few settings must first be made.

• The various lift settings depend on the rack used; this means that

they must be made for each sample rack according to the size of the

sample vessels used.

• The stirrer rate is method-specific and is stored in the active method.

If you use different methods then the stirrer speed must be optimized

separately for each method.

3x

HOLD

SELECT

SELECT

Met ho d

PUMP/STIR

Conf ig

Place a sample rack on the turntable and press <STOP/RESET>.

Place a filled sample beaker at the rack position in front of the lift in

order to make the following settings.

Press the <SELECT> key three times.

The SELECT LEDs show that the 824 Easy Sample Changer is now in

the configuration mode.

You can now use the <Í> and <Î> keys to switch between the four

possible settings in this mode.

3.2.1 Setting the working position of the lift

1

2

3

4

STIR 1

STIR 2

The lift with the titration head can be easily moved up and down with

the <Ï> and <Ð> keys respectively.

Set the working height of the lift so that the electrode is immersed and

the stirrer can work efficiently.

Accept/ continue with <Î>.

3.2.2 Setting the rinsing position of the lift

1

2

3

4

STIR 1

STIR 2

The lift with the titration head can be easily moved up and down with the

<Ï> and <Ð> keys respectively.

If standard method 4 is used then the rinsing position of the lift is

required for aspirating the used sample. Set the rinsing position of the

lift so that the sample vessel can be emptied completely. A rinsing

position which is lower than the working height can be selected. The

mounting position of the aspiration tubing can be selected as required.

Accept/ continue with <Î>.

22 824 Easy Sample Changer, Operation

Page 29

3.2 Settings

3.2.3 Setting the shifting position of the lift

1

STIR 1

2

3

4

STIR 2

The lift with the titration head can be easily moved up and down with the

<Ï> and <Ð> keys respectively.

Set the shift height of the lift so that the sample rack can rotate freely.

The electrode must fully emerge from the sample beaker.

Accept/ continue with <Î>.

3.2.4 Setting the stirrer rate

1

2

3

4

STIR 1

STIR 2

The stirrer rate (applies to both stirrer outputs) can be easily increased

or reduced in 15 steps with the <Ï> and <Ð> keys respectively.

The standard setting is step 3.

Accept/ continue with <Î>.

824 Easy Sample Changer, Operation 23

Page 30

3.3 Manual operation

3.3 Manual operation

When it has been switched on the 824 Easy Sample Changer is in the

normal operating mode. The most important functions for manual operation can be carried out by pressing a key.

3.3.1 Moving the lift

In normal operating

mode

STIR 1

STIR 2

The lift with the titration head can be easily moved up and down with

the <Ï> and <Ð> keys respectively.

Please note that the lift must be located above a valid rack position. If,

because of a possible mechanical influence, the rack is no longer in its

correct position then press the <RESET/STOP> key.

3.3.2 Rotating the sample rack

In normal operating

mode

PUMP 1

PUMP 2

The sample rack can be rotated counterclockwise with the <Í> key

and clockwise with the <Î> key.

For safety reasons the lift must be at or above the set rotating position

when the rack is rotated, so first move the lift upward or press the

<RESET/STOP> key.

3.3.3 Switching the stirrer on/off

2x <SELECT>

STIR 1

STIR 2

After the <SELECT> key has been pressed twice the <STIR 1> and

<STIR 2> keys can be used to switch the stirrers on and off. The

stirring rate of both stirrers can first be set under 'SELECT / Config’, see

below.

LEDs LED 1 and LED 2 show the status of stirrer connections 1 and 2

respectively (LED lit up = on).

3.3.4 Operating the pumps

2x <SELECT>

PUMP 1

PUMP 2

After the <SELECT> key has been pressed twice the pump connections 1 and 2 (each ±16 V) can be switched on and off with the

<PUMP 1> and <PUMP 2> keys respectively.

LEDs LED 3 and LED 4 show the status of pump connections 1 and 2

respectively (LED lit up = on).

24 824 Easy Sample Changer, Operation

Page 31

3.4 Automatic operation

3.4 Automatic operation

3.4.1 Preparing a sample series

• Prepare all the samples to be processed. Select the sample vessel

size according to your type of sample rack. The setting for the predefined lift position must be matched to the size of your sample

vessels.

• Place the sample vessels on the rack. Start with rack position 1.

• Do not forget to place a rinsing/conditioning beaker at the highest

rack position. Most sample changer methods require a special

beaker, see method description p. 29ff.

In order to process a series of samples a suitable method must first be

loaded, see below.

3.4.2 Method selection

1x <SELECT>

STIR 1

3x <SELECT>

STIR 2

After pressing the <SELECT> key a method can be selected by using

the <Ð> and <Ï> keys. Four predefined simple standard methods are

available (Methods 1,2,3 and 4).

LEDs LED 1 to 4 show the selected method. The selected method is

accepted with <SELECT>.

Return to the normal operating mode with 2x <SELECT>.

3.4.3 Starting a method

A method is started with the <START> key.

START

• When a method is started the sample changer is first initialized, i.e.

the lift is moved upward as far as it will go and the sample rack is

moved to the starting position. The magnet code of the rack is read

in and the corresponding rack table, in which the beaker positions

on the rack are defined, is loaded.

• While the method is running the status LED blinks slowly (once per

second).

• After the start of the method the starting sequence is carried out

once. This contains commands for preparing for a series of samples.

• When all rack positions have been processed the final sequence is

carried out.

824 Easy Sample Changer, Operation 25

Page 32

3.4 Automatic operation

3.4.4 Interrupting a method run

SELECT

HOLD

Press the <HOLD> key to briefly interrupt a method run.

• In the HOLD condition the status LED blinks more quickly.

• The run can be continued from the same position by pressing the

<START> key.

3.4.5 Canceling a method run

RESET

STOP

A method run is canceled with the <STOP> key.

• The sample changer switches back to the normal operating mode.

The status LED lights up permanently.

• After the manual cancelation of a method the final sequence is not

carried out.

26 824 Easy Sample Changer, Operation

Page 33

3.5 Functions of the LEDs

3.5 Functions of the LEDs

The 824 Easy Sample Changer has several green LEDs (LED) which indicate the status of the instrument.

3.5.1 The Status LED

Status

Status LED 1 shows the complete status of the sample changer.

The LED lights up… when the 824 Easy Sample Changer is in the normal operating

mode.

The LED does not light up… when a fault has occurred.

The LED blinks slowly… while a method is running.

The LED blinks quickly… when the 824 Easy Sample Changer is in the HOLD condition. An

interrupted method can be continued with <START> or canceled

with <STOP>.

3.5.2 The [SELECT] LEDs

SELECT

Met ho d

PUMP/STIR

Conf ig

’Method’ LED lights up… during the selection of a method.

‘PUMP/STIR’ LED lights up … when the external pumps and stirrers are being operated

‘Config’ LED lights up … when setting the lift positions and the stirrer rate.

The LEDs in the [SELECT] field indicate the status when the settings

are changed.

manually.

3.5.3 LEDs 1 to 4

Depending on the instrument mode, LEDs 1 to 4 have different functions.

In the normal operating mode

Shows the active method.

During method selection

Shows the method to be loaded from the method memory.

824 Easy Sample Changer, Operation 27

Page 34

3.5 Functions of the LEDs

During manual operation

Shows the switching status of the pumps and stirrers.

LED 1 : lights up when Stirrer 1 is running

LED 2 : lights up when Stirrer 2 is running

LED 3 : lights up when Pump 1 is running

LED 4 : lights up when Pump 2 is running

During the configuration of the sample changer settings

Shows the possible settings.

LED 1 : lights up when setting the working position of the lift

LED 2 : lights up when setting the rinsing position of the lift

LED 3 : lights up when setting the shifting position of the lift

LED 4 : lights up when setting the stirrer rate

28 824 Easy Sample Changer, Operation

Page 35

4.1 Information about the methods

4 Standard methods

On delivery the 824 Easy Sample Changer already contains four optimized standard methods for processing series of samples. Simple titration tasks can be carried out with these methods without having to

make complicated settings.

4.1 Information about the methods

The Metrohm sample changer methods consist of three different sequences for different purposes and a series of specific settings.

Sequences are made up of a series of individual commands with which

the functions of the sample changer can be programmed. For example,

the command 'LIFT 1 work' causes the Lift 1 of a sample changer to

move to the predefined working height.

Metrohm sample changer methods differentiate between three different sequences:

• Start sequence

The start sequence is carried out once at the start of a series of

samples.

• Sample sequence

The sample sequence is carried out once for each sample.

• Final sequence

The final sequence is carried out once at the end of a series of

samples.

Series operating

number

of samples

<START>

start sequence final sequence

The number of samples is limited only by the capacity of the sample

rack. In principle, in the standard methods of the 824 Easy Sample

Changer all the positions of a sample rack are processed. Empty rack

positions are automatically jumped over.

The standard methods of the 824 Easy Sample Changer can be used

with all Metrohm standard sample racks. In all these methods the

highest (last) rack position is used for a rinsing or conditioning beaker.

Make sure that a sufficiently large vessel is always placed in this position.

824 Easy Sample Changer, Standard methods 29

sample sequence

normal state

Page 36

4.2 Method labels

4.2 Method labels

On the keyboard covering film you will find a gray marking field with 4

lines. You can enter a short description for each of the four sample

changer methods.

Use a soft pencil or waterproof marker for the labels.

When choosing a marker make sure that the writing can easily be

wiped off with alcohol. Pencil markings can be removed with a soft

rubber.

A brief description of the standard methods of the 824 Easy Sample

Changer is given below.

4.3 Method 1

Use:

For simple titrations (including KF titrations) or pH measurements (without calibration). The initial addition of auxiliary reagents or solvents is

possible.

Required instruments:

• Metrohm titrator (Titrino or Titrando) or pH meter

• Metrohm Dosimat (optional)

• Metrohm 802 Rod Stirrer or 741 Magnetic Stirrer

Features:

No electrode rinsing after sample processing. The electrode is immersed in the conditioning beaker at the end of a series of samples.

Preparation:

Fill a sufficiently large conditioning vessel with a suitable solvent and

place it in the highest rack position.

Procedure:

• (Start sequence) Initialize the sample changer

• Move to sample and lower lift to working position

• Switch on stirrer

• If a Dosimat is connected (optional): add auxiliary reagent or sol-

vent and wait until addition is completed

• Start titration/measurement and wait until it is completed

• Switch off stirrer

• Move lift to rotating position and allow electrode to drip

• (Final sequence) Move to conditioning beaker and immerse elec-

trode

30 824 Easy Sample Changer, Standard methods

Page 37

4.4 Method 2

4.4 Method 2

Use:

For simple titrations (including KF titrations) or pH measurements (without calibration). The initial addition of auxiliary reagents or solvents is

possible.

Required instruments:

Features:

After each determination the electrode is briefly immersed in the conditioning beaker (dipping). The direction of the rack rotation is controlled

so that samples which have not yet been processed are not contaminated by drops falling from the electrode.

Preparation:

Fill a sufficiently large conditioning vessel with a suitable solvent and

place it in the highest rack position.

Procedure:

• Metrohm titrator (Titrino or Titrando) or pH meter

• Metrohm Dosimat (optional)

• Metrohm 802 Rod Stirrer or 741 Magnetic Stirrer

• (Start sequence) Initialize the sample changer

• Move to sample and lower lift to working position

• Switch on stirrer

• If a Dosimat is connected (optional): add auxiliary reagent or sol-

vent and wait until addition is completed

• Start titration/measurement and wait until it is completed

• Switch off stirrer

• Move lift to rotating position and allow electrode to drip

• Move to conditioning beaker in front of the tower and immerse

electrode

• Stir 5 seconds

• Move lift to rotating position and allow electrode to drip

• (Final sequence) Move to conditioning beaker and immerse elec-

trode

824 Easy Sample Changer, Standard methods 31

Page 38

4.5 Method 3

4.5 Method 3

Use:

For simple titrations (including KF titrations) or pH measurements (without calibration). The initial addition of auxiliary reagents or solvents is

possible.

Required instruments:

• Metrohm titrator (Titrino or Titrando) or pH meter

• Metrohm Dosimat (optional)

• Metrohm 802 Rod Stirrer or 741 Magnetic Stirrer

• External pump (e.g. Metrohm 772 Pump Unit)

Features:

After each determination the electrode is rinsed in the sample vessel

using a pump and spray nozzle. A separate spraying height must be

defined for the rack.

Preparation:

Fill a sufficiently large conditioning vessel with a suitable solvent and

place it in the highest rack position.

Procedure:

• (Start sequence) Initialize the sample changer

• Move to sample and lower lift to working position

• Switch on stirrer

• If a Dosimat is connected (optional): add auxiliary reagent or sol-

vent and wait until addition is completed

• Start titration/measurement and wait until it is completed

• Switch off stirrer

• Move lift to rinsing position and allow electrode to drip

• Rinse electrode for 3 seconds

• Move lift to rotating position and allow electrode to drip

• (Final sequence) Move to conditioning beaker and immerse elec-

trode

32 824 Easy Sample Changer, Standard methods

Page 39

4.6 Method 4

4.6 Method 4

Use:

For simple titrations (including KF titrations) or pH measurements (without calibration). The initial addition of auxiliary reagents or solvents is

possible.

Required instruments:

Features:

After each determination the sample vessel is emptied by Pump 1 and

then the electrode is rinsed by Pump 2. The sample vessel is then emptied again by Pump 1.

Preparation:

Fill a sufficiently large conditioning vessel with a suitable solvent and

place it in the highest rack position.

Procedure:

• Metrohm titrator (Titrino or Titrando) or pH meter

• Metrohm Dosimat (optional)

• Metrohm 722/802 Rod Stirrer or 741 Magnetic Stirrer

• 2 external pumps (e.g. Metrohm 772 Pump Unit; Pump 1 for rins-

ing, Pump 2 for aspirating

• (Start sequence) Initialize the sample changer

• Move to sample and lower lift to working position

• Switch on stirrer

• If a Dosimat is connected (optional): add auxiliary reagent or sol-

vent and wait until addition is completed

• Start titration/measurement and wait until it is completed

• Switch off stirrer

• Move lift to rinsing position and empty sample vessel

• Rinse electrode and empty sample vessel again

• Move lift to rotating position and allow electrode to drip

• (Final sequence) Move to conditioning beaker and immerse elec-

trode

824 Easy Sample Changer, Standard methods 33

Page 40

4.6 Method 4

4.6.1 Editing methods

The preinstalled standard methods of the 824 Easy Sample Changer

are suitable for most simple measuring and titration tasks. The open

method concept of this universal sample changer also allows adaptation of the standard methods, other methods to be loaded (e.g.

Metrohm 730 Sample Changer methods) or completely new method

sequences to be created.

By using the "6.2142.010 SC Controller" sample

changer keypad, which has a 2-line display and 30

keys, it is possible to edit all the settings of the 824

Easy Sample Changer in detail and to create, edit and

save methods in an easy way.

This keypad can be obtained from Metrohm under the

Fig. 20 6.2142.010 Keypad for

sample changer

Ordering No. 6.2142.010 and can be connected to

the 824 Easy Sample Changer instead of the

conventional keypad.

Information

How to create sample changer methods is described in the Instructions for Use of the Metrohm 730 Sample Changer (Ordering No.

8.730.1101).

Note

If edited methods are later to be loaded by using the conventional

keypad of the 824 Easy Sample Changer then they must be saved

under the method names 1, 2, 3 or 4.

34 824 Easy Sample Changer, Standard methods

Page 41

5.1 Maintenance / Service

5 Maintenance information

5.1 Maintenance / Service

The maintenance of the 824 Easy Sample Changer should take place

within the framework of an annual service carried out by trained

Metrohm technicians. If harsh and corrosive chemicals are frequently

used then shorter maintenance intervals are necessary.

The Metrohm Service Department will provide competent advice about

the care and maintenance of all Metrohm instruments.

5.2 Care / Maintenance

Not only highly sensitive measuring instruments but also sample

changers need adequate care. Excessive contamination of the instrument could interfere with its functions and reduce the working life of the

really robust mechanism and electronics of the sample changer.

Excessive contamination of the titration head can influence the results

obtained. This can largely be prevented by cleaning the exposed parts

regularly.

Spilt chemicals and solvents should be removed immediately. The connections strip (and the mains connection in particular) should be protected against contamination. Never use the sample changer without

the connections cover and splash protector in position.

Although the design prevents liquid penetration to a great extent, if aggressive media should enter the housing then pull out the mains plug

immediately, in order to prevent massive damage to the instrument’s

electronics. In such a case please contact your distributor's service department.

Warning

The instrument must not be opened by untrained personnel!

824 Easy Sample Changer, Maintenance information 35

Page 42

5.2 Care / Maintenance

6 GLP validation

Each Metrohm instrument undergoes a rigorous quality control process

before dispatch.

GLP (Good Laboratory Practice) requires, among other things, that

the precision and correctness of analytical instruments is checked at

regular intervals by using SOPs (Standard Operating Procedure, SOP).

As this instrument is not an analytical instrument as such, we recommend the user to include the 824 Easy Sample Changer as part of an

analytical system in its all-embracing validation.

If the sample changer is primarily used for titrations then the validation

of the titrator is best carried out by using the sample changer. In this

way any interference (e.g. carryover of titrant or sample solution), which

could influence the results obtained, in included within the framework of

the evaluation of the complete titration system.

Checking the electronic and mechanical assemblies of Metrohm instruments can and should be undertaken within the framework of regular servicing by Metrohm technicians. All Metrohm instruments are

equipped with start-up check routines which check that the relevant assemblies are functioning perfectly when the instrument is switched on. If

no error message appears it can be assumed that the instrument is

functioning properly. Metrohm also supplies the instruments with built-in

diagnosis programs which allow the service technicians to check the

functioning of particular assemblies should faults or malfunctions occur

and to localize them.

Recommended literature

• Metrohm booklets "Quality management with Metrohm"; detailed in-

formation about the principles and methods of Good Laboratory

Practice

• Metrohm Application Bulletin 252/1 "Validation of Metrohm titrators

according to GLP/ISO 9001"

36 824 Easy Sample Changer, GLP validation

Page 43

7.1 Error messages

7 Troubleshooting

7.1 Error messages

If a fault or error occurs then LEDs 1 to 4 start to blink in particular

combinations (binary error code). The status LED goes out.

SELECT

HOLD

<START>

or

<STOP>

LED 1…4 Description / Remedy

Instrument error messages (blinking LEDs 1…4) must be acknowledged with the <HOLD> key. The 824 Easy Sample Changer then

enters the HOLD mode.

When the fault has been remedied then the run can be continued with

the <START> key or canceled with the <STOP> key.

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Error 1:

Error 2:

Error 3:

Error 4:

Beaker missing

After a rack rotation no beaker is found at the moved-to position.

Remedy: Press <HOLD>. Position beaker and press <START> or

cancel sample series with <STOP>.

Lift not in rotating position

The sample rack must be at or above the predefined rotating position

before it can rotate.

Remedy: Press <HOLD> and <STOP>. Move lift upward with <Ï>

and then rotate rack again with <Í> or <Î>.

Sample rack error

An incorrect or no sample rack at all is in position. Possibly the magnet

code of the rack cannot be read or the instrument does not recognize

the magnet code.

Press <HOLD>. Position Metrohm standard sample rack. Press

<STOP> or <START>.

Invalid rack position

An attempt has been made to move to an invalid rack position (method

error).

Remedy: Press <HOLD> and <STOP>. Check method.

1

Error 5:

2

3

4

824 Easy Sample Changer, Troubleshooting 37

Sample changer not ready

The 824 Easy Sample Changer cannot carry out the command as it is

busy doing something else.

Remedy: Press <HOLD> and <STOP>. Wait and then repeat command.

Page 44

7.1 Error messages

Error 6:

1

2

3

4

Error 10:

1

2

3

4

Error 11:

1

2

3

4

1

2

3

4

Error 12:

Sample rack and swing head not compatible

The positioned sample rack cannot be used together with the swing

head and vice versa. Multi-row sample racks must be used with the

swing head, single row racks without the swing head.

Remedy: Press <HOLD> and <STOP>. Change rack and press

<STOP/RESET>.

Mains overload

The power supply cannot cope with the simultaneous use of all

components (stirrers, pumps, lift).

Remedy: Press <HOLD> and <STOP>. Switch off a stirrer or a pump.

If necessary, switch the instrument off and on again.

Method store full

The memory for the user-defined methods is full.

Remedy: Switch the instrument off and on again. Delete any methods

which are no longer required from the memory (via RS232 interface or

with the "6.2142.010 SC Controller" keypad).

Sample changer overload

Load or resistance is too large to carry out the selected action.

Remedy: Press <HOLD> and <STOP>. Remove the mechanical

hindrance to the lift or sample rack.

1

2

3

4

1

2

3

4

1

2

3

4

Error 13:

Error 14:

Error 15:

RS232 error, interface error

Error during data transfer or control by a PC.

Remedy: Press <HOLD> and <STOP>. Observe the PC software

display. Check the interface parameters. If necessary, consult the PC

software manual.

Exceptional instrument error

An exceptional fault has occurred in the 824 Easy Sample Changer

hardware.

Remedy: Switch the instrument off and on again. If the fault occurs

again please contact the service department of your local Metrohm

agency.

Program stopped (trap error)

An unexpected and non-recoverable program error has occurred.

Remedy: Switch the instrument off and on again. If the fault occurs

again please contact the service department of your local Metrohm

agency.

38 824 Easy Sample Changer, Troubleshooting

Page 45

8.1 Technical data

8 Annex

In this section you will find the most important technical data of the 824

Easy Sample Changer. Furthermore there are listings of the four standard methods, the standard and optional accessories as well as the

declaration of conformity and warranty.

8.1 Technical data

8.1.1 Interfaces

RS232 interface 25

Remote Interface 19

14 1

0 Vo lt

+5 Volt

Output 5

Output 3

Output 1

Output 12

Output 13

Input 0

Input 2

Input 4

Input 6

0 Vo lt

1325

Outp ut 6

Outp ut 7

Outp ut 4

Outp ut 2

Outp ut 0

Outp ut 8

Outp ut 9

Output 10

Inp ut 1

Inp ut 3

Inp ut 5

Inp ut 7

Output 11

For the connection of computers

Universal parallel interface for synchronizing with external

devices, 14 signal lines (8x input, 14x output), TTL-level

Input:

t

p

t

>20 ms

p

+5V

t

p

t

Output:

I

V

CEO

C

>200 ms

p

= 40 V

= 20 mA

+5 V: max. charge = 20 mA

8.1.2 Pump connections

Pump outputs 2x ±16 VDC, max. 300 mA , for ground–free load

active = low

inactive = high

active = low

inactive = high

8.1.3 Lift

Max. lift stroke

Max. load

Stroke speed

approx. 235 mm

approx. 10 N

adjustable, 3...25 mm/s

8.1.4 Turntable

Turning speed adjustable, 3...20 angular degrees/s

8.1.5 Stirrer

Stirring speed

824 Easy Sample Changer, Annex 39

adjustable in 15 steps

- magnetic stirrer 180/min...2600/min

- rod stirrer 180/min...3000/min

Page 46

8.1 Technical data

8.1.6 Power supply

Voltage

Frequency

Power input

Fuses

100...120 V, 220...240 V

50...60 Hz

40 W

0.5 AT (110 V), 0.25 AT (220 V)

8.1.7 Safety Specifications

Construction and testing According to EN/IEC 61010-1, UL 3101-1

Safety instructions The Instructions for Use contain safety information that

must be observed by the user in order to ensure the safe

operation of the instrument.

8.1.8 Electromagnetic compatibility (EMC)

Emission Standards fulfilled:

- EN/IEC 61326-1

- EN 55022

- CISPR 22

Immunity Standards fulfilled:

- EN/IEC 61326-1

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

- EN/IEC 61000-4-8

- EN/IEC 61000-4-11

- EN/IEC 61000-4-14

8.1.9 Ambient temperature

Nominal working range

Storage

Transport

+5…+45 °C (at max. 85% relative humidity)

-20 °C…+60 °C

-40 °C…+60 °C

60 °C relative humidity <60%

50 °C " " <85%

40 °C " " <95%

40 824 Easy Sample Changer, Annex

Page 47

8.1 Technical data

8.1.10 Dimensions and materials

Height

Width

Depth

Weight

Materials

- Housing

- Keyboard case

- Keyboard film

- Sample rack

- Splash protection

74 cm

28 cm

48 cm

12.5 kg (without accessories)

metal housing, surface refined

PBTP

PETP, resistant to chemicals

PVC

PMMA

824 Easy Sample Changer, Annex 41

Page 48

8.2 Method listings

8.2 Method listings

8.2.1 Method 1

824 Easy Sample Chan. 5.824.0010

Parameters

method 1

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 MOVE 1 : sample

2 LIFT: 1 : work mm

3 STIR: * : ON s

4 CTL:Rm: START dos*

5 WAIT 10 s

6 CTL:Rm: START device1

7 SCN:Rm : End1

8 STIR: * : OFF s

9 LIFT: 1 : shift mm

10 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 1 25 mm/s

shift rate 20

shift direction: auto.

beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>manual stop

CTL Rmt: STOP device1

CTL RS232:

¬ Report header with program version

¬ Method name

¬ No. of samples (whole sample rack)

¬ Initialize remote interface

¬ Initialize sample

position

¬ Move next sample in front of tower

¬ Move lift to working position

¬ Switch on stirrer

¬ Start addition

¬ Waiting time

¬ Start instrument/titrator

¬ Wait for end of determination [EOD]

¬ Switch off stirrer

¬ Move lift to rotating position

¬ Waiting time: 3 s for drips

¬ Move conditioning beaker in front of tower

¬ Immerse electrode

------ Sample changer settings --------

¬ If sample beaker is missing then the

next one will be moved to automatically

------ Stirring rates ---------------------------

------ Reaction to manual stop --------------

¬ Stop instrument/titrator

42 824 Easy Sample Changer, Annex

Page 49

8.2 Method listings

8.2.2 Method 2

824 Easy Sample Chan. 5.824.0010

Parameters

method 2

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 SHIFTRATE: + 20

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 STIR: * : ON s

5 CTL:Rm: START dos*

6 WAIT 10 s

7 CTL:Rm: START device1

8 SCN:Rm : End1

9 STIR: * : OFF s

10 LIFT: 1 : shift mm

11 WAIT 3 s

12 SHIFTRATE: - 20

13 MOVE 1 : spec.1

14 LIFT: 1 : work mm

15 STIR: * : ON s

16 WAIT 5 s

17 STIR: * : OFF s

18 LIFT: 1 : shift mm

19 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 1 25 mm/s

shift rate 20

shift direction: auto.

beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>manual stop

CTL Rmt: STOP device1

CTL RS232:

¬ Report header with program version

¬ Method name

¬ No. of samples (whole sample rack)

¬ Initialize remote interface

¬ Initialize the

sample position

¬ Rack direction of rotation (clockwise)

¬ Move next sample in front of tower

¬ Move lift to working position

¬ Switch on stirrer

¬ Start addition

¬ Waiting time

¬ Start instrument/titrator

¬ Wait for end of determination [EOD]

¬ Switch off stirrer

¬ Move lift to rotating position

¬ Waiting time: 3 s for drips

¬ Rack direction of rotation (counterclockwise)

¬ Move conditioning beaker in front of tower

¬ Move lift to working position

¬ Switch on stirrer

¬ Waiting time

¬ Switch off stirrer

¬ Move lift to rotating position

¬ Waiting time: 3 s for drips

¬ Move conditioning beaker in front of tower

¬ Immerse electrode

------ Sample changer settings --------

¬ If sample beaker is missing then the

next one will be moved to automatically

------ Stirring rates ---------------------------

------ Reaction to manual stop -------------¬ Stop instrument/titrator

824 Easy Sample Changer, Annex 43

Page 50

8.2 Method listings

8.2.3 Method 3

824 Easy Sample Chan. 5.824.0010

parameters

method 3

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 SHIFTRATE: + 20

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 STIR: * : ON s

5 CTL:Rm: START dos*

6 WAIT 10 s

7 CTL:Rm: START device1

8 SCN:Rm : End1

9 STIR: * : OFF s

10 LIFT: 1 : rinse mm

11 WAIT 3 s

12 PUMP 1.1 : 3 s

13 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 1 25 mm/s

shift rate 20

shift direction: auto.

beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>manual stop

CTL Rmt: STOP device1

CTL RS232:

¬ Report header with program version

¬ Method name

¬ No. of samples (whole sample rack)

¬ Initialize remote interface

¬ Initialize

sample position

¬ Rack direction of rotation (clockwise)

¬ Move next sample in front of tower

¬ Move lift to working position

¬ Switch on stirrer

¬ Start addition

¬ Waiting time

¬ Start instrument/titrator

¬ Wait for end of determination [EOD]

¬ Switch off stirrer

¬ Move lift to rinsing position

¬ Waiting time: 3 s for drips

¬ Switch on pump, 3 s for rinsing

¬ Waiting time: 3 s for drips

¬ Move rinsing beaker in front of tower

¬ Immerse electrode

------ Sample changer settings --------

¬ If sample beaker is missing then the

next one will be moved to automatically

------ Stirring rates ---------------------------

------ Reaction to manual stop -------------¬ Stop instrument/titrator

44 824 Easy Sample Changer, Annex

Page 51

8.2 Method listings

8.2.4 Method 4

824 Easy Sample Chan. 5.824.0010

Parameters

method 4

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 MOVE 1 : sample

2 LIFT: 1 : work mm

3 STIR: * : ON s

4 CTL:Rm: START dos*

5 WAIT 10 s

6 CTL:Rm: START device1

7 SCN:Rm : End1

8 STIR: * : OFF s

9 LIFT: 1 : rinse mm

10 PUMP 1.2 : 10 s

11 PUMP 1.1 : 5 s

12 PUMP 1.2 : 5 s

13 LIFT: 1 : shift mm

14 WAIT 3 s