Page 1

822 Titration Curve Simulator

Manual

8.822.1013

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

822 Titration Curve Simulator

8.822.1013

Manual

06.2006 jb

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

Contents

Table of contents

1 Introduction.......................................................... 1

1.1 Instrument description...................................................................................1

1.2 Parts and controls..........................................................................................1

1.3 Functional principle .......................................................................................2

2 Connection ........................................................... 3

2.1 Connection to the MSB interface ..................................................................3

2.1.1 Connection to Titrandos with internal dosing drive .................................3

2.1.2 Connection to Titrandos by using an external dosing device .................4

2.2 Connection to the dosing interface ..............................................................5

2.2.1 Connection to Titrinos by using an external dosing device.....................5

2.2.2 Connection to Titroprocessors.................................................................6

2.3 Connection to the remote interface ..............................................................6

2.3.1 Connection to Titrinos with internal dosing drive.....................................6

3 Description of the titration curves ...................... 8

3.1 Acid-Base titration .........................................................................................8

3.2 Titration of citric acid .....................................................................................8

3.3 Conditioning and Karl Fischer titration ........................................................9

4 Appendix ............................................................. 11

4.1 Description of the curves ........................................................................... 11

4.1.1 Recorder control.....................................................................................11

4.1.2 Diagonal .................................................................................................11

4.1.3 D/A – converter test................................................................................12

4.1.4 Testing department – test ......................................................................13

4.2 Meaning of the LEDs................................................................................... 13

4.2.1 Serial 8-bit...............................................................................................13

4.2.2 Serial 25 bit.............................................................................................14

4.3 Technical data ............................................................................................. 18

4.3.1 Control ....................................................................................................18

4.3.2 Curves.....................................................................................................18

4.3.3 Analog output .........................................................................................18

4.3.4 Resolution...............................................................................................19

4.3.5 Supply.....................................................................................................19

4.3.6 Safety specifications ..............................................................................19

4.3.7 Electromagnetic compatibility (EMC) ....................................................19

4.3.8 Ambient temperature..............................................................................19

4.3.9 Reference conditions .............................................................................19

4.3.10 Dimensions.............................................................................................19

4.4 Standard equipment ................................................................................... 20

4.4.1 822 Titration Curve Simulator.................................................................20

4.5 Warranty and conformity ............................................................................ 21

4.5.1 Warranty .................................................................................................21

4.5.2 Declaration of Conformity.......................................................................22

822 Titration Curve Simulator, Instructions for Use I

Page 6

Contents

4.5.3 Quality Management Principles .............................................................23

5 Index ................................................................... 24

II 822 Titration Curve Simulator, Instructions for Use

Page 7

Contents

List of illustrations

Fig. 1: Front view of the Curve Simulator................................................................................ 1

Fig. 2: Rear view of the Curve Simulator................................................................................. 2

822 Titration Curve Simulator, Instructions for Use III

Page 8

Page 9

1 Introduction

1 Introduction

These Instructions for Use give you a overview of the applications and

the functionality of the 822 Titration Curve Simulator.

First, the device as such and the simulation of the titration curves are

explained. The description of the additional curves, the explanation of

the LEDs and the technical data are summarized in the appendix.

1.1 Instrument description

The 822 Titration Curve Simulator is a diagnostic tool that allows

Metrohm service technicians to check titrators. With this simulator a

possible malfunction of the titration or dosing device or even the electrode can be identified quickly and easily. This is done by connecting

the 822 Titration Curve Simulator instead of an electrode. During the

test it simulates a titration, i.e. the user gets a titration curve without using electrodes or chemicals.

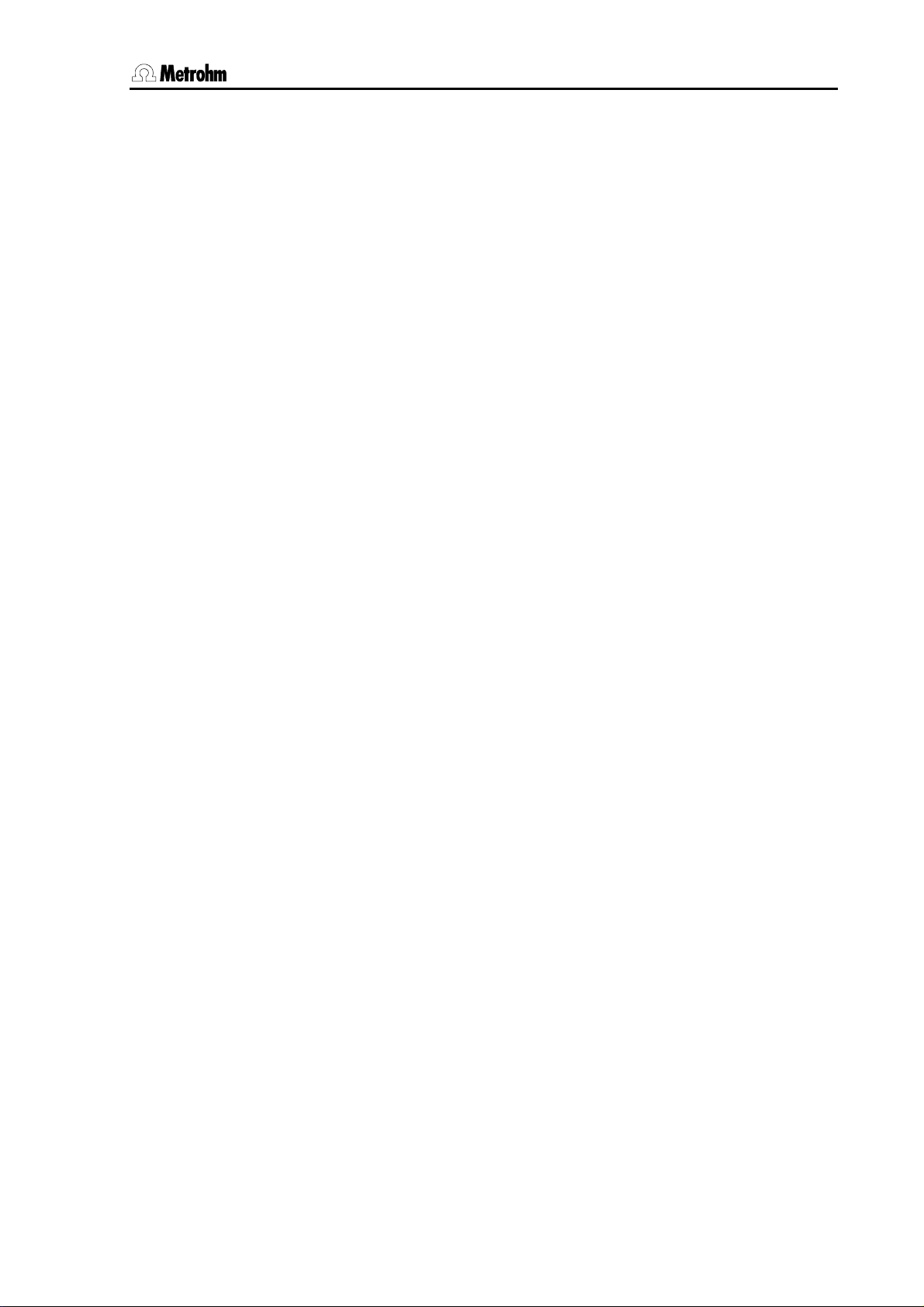

1.2 Parts and controls

Fig. 1: Front view of the Curve Simulator

1 Communication protocol

for adjusting communication type;

depends on the external dosing device

2 Curve selector

for adjusting the desired titration curve

3 Sample addition key for KF titra-

tions

simulates the sample addition after

conditioning

822 Titration Curve Simulator, Instructions for Use 1

Page 10

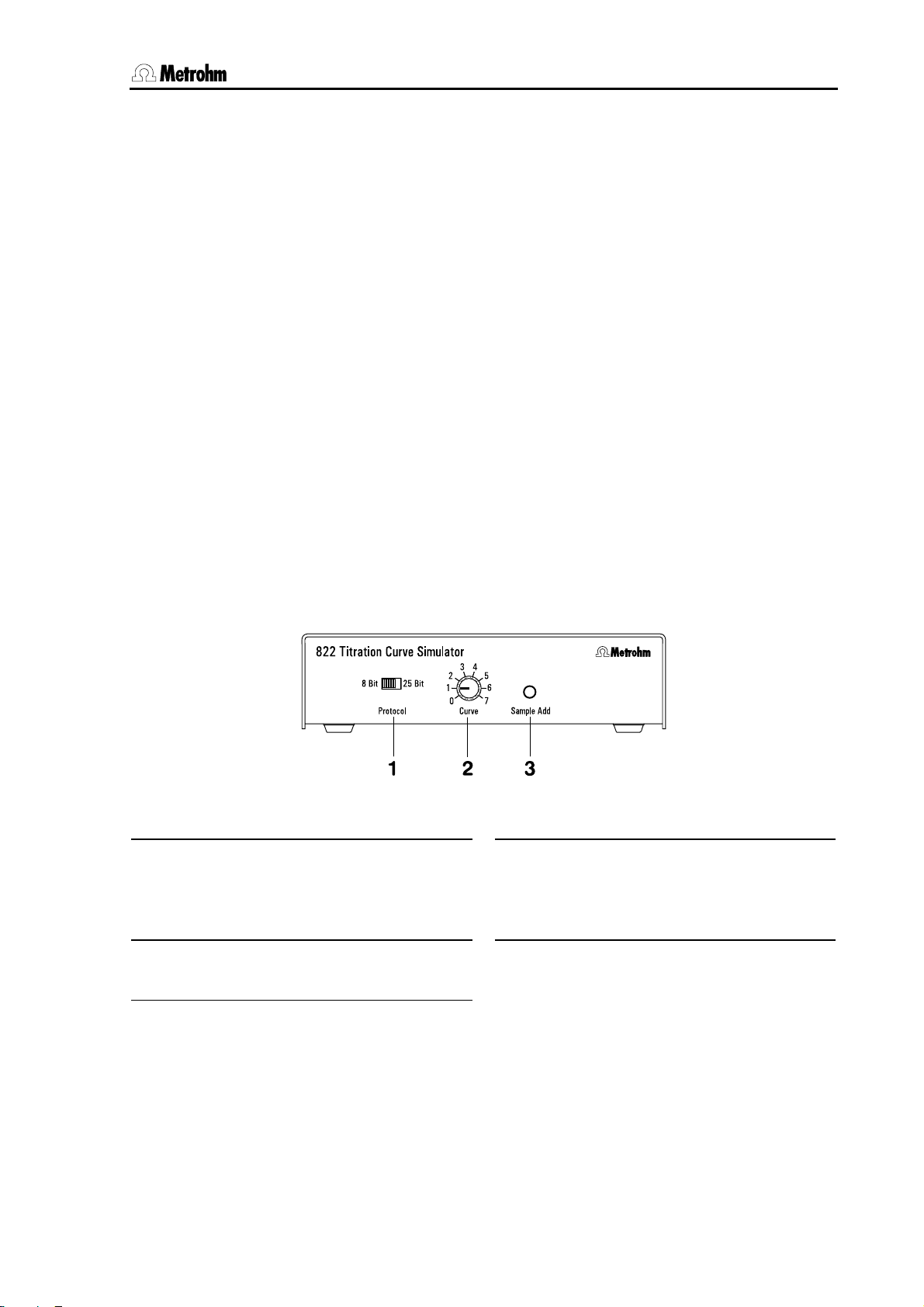

1.3 Functional principle

Fig. 2: Rear view of the Curve Simulator

4 Connector cable

connection to the titrator (MSB, Dosing

or Remote)

5 Serial number digit 1 and 2 identify

the device series, digit 3 to 5 the device

number

1.3 Functional principle

The 822 Titration Curve Simulator uses the dosing pulses of the titrator

to output, as the volume increases, an analog signal corresponding to

the titration curve selected. These values are evaluated again by the titrator and the equivalence points found are displayed. The data sets of

the titration curves are stored digitally in the Curve Simulator. This allows to achieve an excellent reproducibility of the equivalence points.

6 Connector for dosing device

directly or with 6.2134.020 adapter

cable

7 Connector for measuring signal

cable

connection to the measuring interface

with 6.2116.020 cable (2x plug type F)

2 822 Titration Curve Simulator, Instructions for Use

Page 11

2 Connection

2 Connection

Titrators with internal dosing drive do not need an additional dosing device. Titrators without internal dosing drive (e. g. 809/836 Titrando,

726/796 Titroprocessor) need a connected dosing device

(685/805 Dosimat or 700/800 Dosino). The Curve Simulator is connected between titrator and dosing device.

A detailed list of the connecting combinations can be found in the drawings given below.

Note!

The 822 Titration Curve Simulator does not replace a dosing device!

The communication protocol 1 has to be adjusted depending on the

type of the external dosing device connected. The setting is not important for internal dosing drives.

2.1 Connection to the MSB interface

2.1.1 Connection to Titrandos with internal dosing drive

Connect the 822 Titration Curve Simulator with the connector cable

4 to the MSB 2 connection of the Titrando.

Connect the measuring input of the Titrando with the Analog Output

7 of the 822 Titration Curve Simulator using the 6.2116.020 cable.

Adjust the communication protocol 1 to 25 bit.

Signals for the internal dosing drive can only be read at MSB 2. Therefore you have to activate the checkbox Send dosing signals to

MSB 2 under System/Diagnosis/822 Curve Simulator. This

setting will only be deactivated when restarting the PC Control software

or switching off and on the Touch Control.

822 Titration Curve Simulator, Instructions for Use 3

Page 12

2.1 Connection to the MSB interface

Note!

No dosing device may be connected to the 822 Titration Curve

Simulator in this case.

2.1.2 Connection to Titrandos by using an external dosing device

Connect the 822 Titration Curve Simulator with the connector cable

4 to any of the four MSB connections of the Titrando.

Connect the dosing device to the Dosing device connection 6 of the

822 Titration Curve Simulator.

Connect the Analog Output 7 with the measuring input of the Ti-

trando using the 6.2116.020 cable.

The communication protocol 1 has to be adjusted depending on

the type of external dosing device connected. 25 bit is needed for

dosing devices type 8XX, 8 bit by using a 685 Dosimat or a

700 Dosino.

variant 1:

variant 2:

4 822 Titration Curve Simulator, Instructions for Use

Page 13

2 Connection

700 Dosino

The 700 Dosino with the 8-pin MiniDIN plug type (2.700.0020) can be

connected directly to the 822 Titration Curve Simulator. If you have a

700 Dosino with a 9-pin Sub-D plug type (2.700.0010) you need the

6.2134.020 adapter cable.

Note!

With Titrandos with internal dosing drive (e. g. 808/835 Titrando) the

822 Titration Curve Simulator can only be connected to MSB 2 – MSB

4 because MSB 1 is occupied by the internal dosing drive.

2.2 Connection to the dosing interface

2.2.1 Connection to Titrinos by using an external dosing device

Connect the 822 Titration Curve Simulator with the connector cable

4 to the dosing input Dos 1 or Dos 2 of the Titrino.

Connect the dosing device to the Dosing device connection 6 of the

822 Titration Curve Simulator.

Connect the Analog Output 7 with the measuring input of the Titrino

using the 6.2116.020 cable.

Adjust the communication protocol 1 to 8 bit.

700 Dosino

The 700 Dosino with the 8-pin MiniDIN plug type (2.700.0020) can be

connected directly to the 822 Titration Curve Simulator. If you have a

700 Dosino with a 9-pin Sub-D plug type (2.700.0010) you need the

6.2134.020 adapter cable.

The endpoint volume of certain Titrino models 736, 751 and 758 is

approx. 50 % lower than the one specified for the curves. Please ask

the Metrohm service to remedy this or use the internal dosing drive.

822 Titration Curve Simulator, Instructions for Use 5

Page 14

2.3 Connection to the remote interface

2.2.2 Connection to Titroprocessors

Connect the 822 Titration Curve Simulator to the 6.2134.010 adapter

box with the connector cable 4. Connect the adapter box with one

of the dosing interfaces Dos. A1...4 of the Titroprocessor.

Connect the dosing device to the Dosing device connection 6 of the

822 Titration Curve Simulator.

Connect the Analog Output 7 with the measuring input of the Titro-

processor with the 6.2116.020 cable.

Adjust the communication protocol 1 to 8 bit.

700 Dosino

The 700 Dosino with the 8-pin MiniDIN plug type (2.700.0020) can be

connected directly to the 822 Titration Curve Simulator. If you have a

700 Dosino with a 9-pin Sub-D plug type (2.700.0010) you need the

6.2134.020 adapter cable.

2.3 Connection to the remote interface

2.3.1 Connection to Titrinos with internal dosing drive

Connect the 822 Titration Curve Simulator with the connector cable

4 to the remote interface of the Titrino.

Connect the Analog Output 7 with the measuring input of the Titrino

with the 6.2116.020 cable.

The adjustment of the communication protocol 1 does not matter in

this case.

Switch on the activation pulse of the Titrino under parame-

ters>preselections.

Note!

The parameter activate pulse does not exist for the 701 and 787

Titrinos. The conditioning must therefore be switched off so that a KF

titration can be simulated.

6 822 Titration Curve Simulator, Instructions for Use

Page 15

2 Connection

The Titrinos 701, 702, 716, 718, 719, 720, 721, 736, 787 and 794 work

with only 6000 pulses per cylinder volume. This means that the EP volumes received have to be multiplied by 0.6.

The 751 and 758 Titrinos with program version 0020 do not provide the

required pulses on the remote interface. For this device combination

you either need an update of the Titrino program software or you have

to use the 6.2148.000 remote box.

822 Titration Curve Simulator, Instructions for Use 7

Page 16

3.1 Acid-Base titration

3 Description of the titration

curves

3.1 Acid-Base titration

If you turn the curve selector to position "0", an acid-base titration with

one endpoint is simulated. Program a corresponding method and start

the titration. The illustration below shows an example of a simulated

curve.

Endpoint at (50.00 ± 0.03) % of the cylinder volume

parameters: DET pH with standard parameters

5 mL exchange unit

Stop EP: 1

Volume after EP: 0.5 mL

3.2 Titration of citric acid

If you turn the curve selector to position "1", the titration of citric acid

with three endpoints is simulated:

8 822 Titration Curve Simulator, Instructions for Use

Page 17

3 Description of the titration curves

st

1

endpoint at (17.50 ± 0.15) % of the cylinder volume

nd

endpoint at (35.0 ± 0.1) % of the cylinder volume

2

rd

3

endpoint at (52.50 ± 0.02) % of the cylinder volume

parameters: DET pH with standard parameters

5 mL exchange unit

Stop EP: 3

Volume after EP: 0.5 mL

3.3 Conditioning and Karl Fischer titration

Turn the curve selector 2 to position "3" for simulating a Karl Fischer titration (except with 701, 787 Titrino; see following page).

Program a Karl Fischer method with conditioning and sample data request. Start the conditioning. Start the titration as soon as "Conditioning

OK" is displayed. The cylinder will be filled again. Now press the key

"Sample Add" 3 and confirm the sample weight. The curve simulator

changes internally automatically to curve "4". The illustration below

shows an example of a simulated curve.

Endpoint at (26.15 ± 0.10) % of the cylinder volume

parameters: KFT Ipol with standard parameters

5 mL exchange unit

822 Titration Curve Simulator, Instructions for Use 9

Page 18

3.3 Conditioning and Karl Fischer titration

Procedure with 701, 787 Titrino:

Turn the curve selector 2 to position "4".

Program a Karl Fischer method without conditioning but with sample

data request. Start the titration and confirm the sample weight.

Note!

The endpoint of the conditioning curve "3" is at 10 % of the piston

stroke with Curve Simulators of the series 02 and 03 but at 8.4 % for

those from series 04 (see serial number, page 2). By reconditioning

with Curve Simulators of the series 02 and 03 the status "Conditioning

OK" will never be reached because the cylinder will be filled at 10 % of

the piston stroke.

10 822 Titration Curve Simulator, Instructions for Use

Page 19

4 Appendix

4 Appendix

In this section you will find the description of the additional curves of the

822 Titration Curve Simulator (for Metrohm Service technicians only) as

well as the most important technical data, a list with standard accessories and the warranty and conformity declarations.

4.1 Description of the curves

4.1.1 Recorder control

A connected recorder can be checked with curve "2". The full voltage

range is passed through twice. The range is –2.5 V to +2.5 V for devices of the series 02 and 03 (see serial number, page 2) and –2 V to

+2 V for devices from series 04.

4.1.2 Diagonal

With curve "5" the whole voltage range is run through in the form of a

diagonal. The range is –2.5 V to +2.5 V for devices of the series 02 and

03 (see serial number, page 2) and –2 V to +2 V for devices from series

04.

recorder control

2.0

1.5

1.0

0.5

0.0

-0.5

0 102030405060708090100

voltage [V]

-1.0

-1.5

-2.0

piston stroke [%]

Excel diagram from original data

822 Titration Curve Simulator, Instructions for Use 11

Page 20

4.1 Description of the curves

parameters: DET U with standard parameters

5 mL exchange unit

stop volume: 5.0 mL

4.1.3 D/A – converter test

Curve "6" checks the D/A converter in the entire voltage range from

-2.5 V to +2.5 V. The 822 Titration Curve Simulator produces the following curve:

parameters: DET U with standard parameters

5 mL exchange unit

stop volume: 5.0 mL

The A/D converter input of the titrators ranges only from –2 V to +2 V.

The area below and above is cut off.

12 822 Titration Curve Simulator, Instructions for Use

Page 21

4 Appendix

4.1.4 Testing department – test

A ramp in the voltage range of –2 V to +2 V is run through with curve

"7".

2.0

1.5

1.0

0.5

0.0

-0.5

0 5000 10000 15000 20000 25000 30000

voltage [V]

-1.0

-1.5

-2.0

Excel diagram from original data

test curve

pulse number

4.2 Meaning of the LEDs

The green LEDs represent the commands (more exactly: the single bits)

from the control device for the dosing device. The red LEDs represent

the reply i.e. the single bits from the dosing device to the control device.

Labeling on the device:

Red LEDs

serial out (SER_OUT)

serial 8-bit serial 25-bit bit-No. serial 25-bit serial 8-bit

e. g.:

685 Dosimat

700 Dosino

Reply from the dosing device 0 ... 24 Commands for the dosing device

Status information from 822 --- Status information from 822

4.2.1 Serial 8-bit

With the 8-bit transmission the single bits 0...7 have the following meanings:

e. g.:

805 Dosimat,

800 Dosino

Green LEDs

serial in (SER_IN)

e. g.:

805 Dosimat,

800 Dosino

e. g.:

685 Dosimat,

700 Dosino

Reply from the dosing device:

SER_OUT - bit 0:

BUSY

Status message for active cock

switching

SER_OUT - bit 1:

STOP

Status message if difference counter

= zero

SER_OUT - bit 2:

ESU

End switch down: cylinder at minimal

stroke

SER_OUT - bit 3:

822 Titration Curve Simulator, Instructions for Use 13

EXP0

Bit 0 for coding the cylinder volume

Page 22

4.2 Meaning of the LEDs

SER_OUT - bit 4:

SER_OUT - bit 5:

SER_OUT - bit 6:

SER_OUT - bit 7:

Commands for dosing device:

SER_IN - bit 0:

SER_IN - bit 1:

SER_IN - bit 2:

SER_IN - bit 3:

SER_IN - bit 4:

SER_IN - bit 5:

SER_IN - bit 6:

SER_IN - bit 7:

4.2.2 Serial 25 bit

EXP1

EXP2

LOCK

DOS_TYP1

POS0

POS1

DOWN

UP

NRES

POS2

R_NRW

DIR

Bit 1 for coding the cylinder volume

Bit 2 for coding the cylinder volume

Exchange unit present

Bit 1 definition of the chip function

(formerly "GTYP")

Bit 0 for the default of the desired

cock position

Bit 1 for the default of the desired

cock position

Dosing impulses for spindle motor

Filling impulses for spindle motor

Reset for the Dosimat controller

(L active)

Bit 2 for the default of the desired

cock position

Use data or set STROBE impulse

Definition of the direction of rotation

of the cock motor

With the 25 bit transmission the single bits 0...24 have the following

meanings:

Reply from the dosing device:

SER_OUT - bit 0:

STOP

Status message if difference

counter = zero

SER_OUT - bit 1:

ESU

End switch down: cylinder at

minimal stroke

SER_OUT - bit 2:

HOTLOCK

Bit for prompting the "Hot Plug

& Play" of the exchange unit

SER_OUT - bit 3:

ESO

End switch up: cylinder at

maximum stroke

SER_OUT - bit 4:

SER_OUT - bit 5:

LOCK

MOT_D0/IN0

Exchange unit present

Bit 0 D/A converter or digital

input IN0

SER_OUT - bit 6:

MOT_D1/IN1

Bit 1 D/A converter or digital

input IN1

SER_OUT - bit 7:

MOT_D2/IN2

Bit 2 D/A converter or digital

input IN2

SER_OUT - bit 8:

MOT_D3/NHWR

Bit 3 D/A converter or status

message of the reset signal

SER_OUT - bit 9:

MOT_D4/NPOR

Bit 4 D/A converter or of the

power-on-reset

SER_OUT - bit 10:

MOT_SN/OVERL

Algebraic sign of D/A converter

or motor overload

14 822 Titration Curve Simulator, Instructions for Use

Page 23

4 Appendix

SER_OUT - bit 11:

SER_OUT - bit 12:

SER_OUT - bit 13:

SER_OUT - bit 14:

SER_OUT - bit 15:

SER_OUT - bit 16:

SER_OUT - bit 17:

SER_OUT - bit 18:

SER_OUT - bit 19:

SER_OUT - bit 20:

SER_OUT - bit 21:

SER_OUT - bit 22:

SER_OUT - bit 23:

SER_OUT - bit 24:

MOT_INFO

MOT_INFO = L:

MOT_INFO = H:

BUSY

STOP_O

ESM

ISTPOS0/EXP0

ISTPOS1/EXP1

ISTPOS2/EXP2

DOS_TYP0

DOS_TYP1

DOS_TYP2

DOS_TYP3

P10000

P20000

PWR

Definition of the signals

SER_OUT bit 5 ... 10, 15 ... 17

Information about current

speed of the spindle motor

(MOT_D0…SN) and cock

position (ISTPOS0…2)

Information of the digital inputs

IN0…2, NHWR, NPOR, OVERL,

EXP0…2

Status message for active cock

switching

Driver stage spindle or cock

motor inactive

End switch middle

Bit 0 for cock position or coding

the cylinder volume

Bit 1 for cock position or coding

the cylinder volume

Bit 2 for cock position or coding

the cylinder volume

Bit 0 definition of the chip

function

Bit 1 definition of the chip

function (formerly "GTYP")

Bit 2 definition of the chip

function

Bit 3 definition of the chip

function

Bit 0 for stating the number of

pulses for the total volume

Bit 1 for stating the number of

pulses for the total volume

Enables "Hot Plug & Play" of

the device and recognize

temporally unusual supply and

control data

Commands for dosing device:

SER_IN - bit 0:

UP

Filling impulses for spindle

motor

SER_IN - bit 1:

DOWN

Dosing impulses for spindle

motor

SER_IN - bit 2:

R_NRW

Use data or set STROBE

impulse

822 Titration Curve Simulator, Instructions for Use 15

Page 24

4.2 Meaning of the LEDs

SER_IN - bit 3:

SER_IN - bit 4:

SER_IN - bit 5:

SER_IN - bit 6:

SER_IN - bit 7:

SER_IN - bit 8:

SER_IN - bit 9:

SER_IN - bit 10:

SER_IN - bit 11:

SER_IN - bit 12:

SER_IN - bit 13:

SER_IN - bit 14:

SER_IN - bit 15:

SER_IN - bit 16:

SER_IN - bit 17:

SER_IN - bit 18:

SER_IN - bit 19:

SER_IN - bit 20:

SER_IN - bit 21:

SER_IN - bit 22:

SER_IN - bit 23:

SER_IN - bit 24:

MOT_INFO

MOT_INFO = L:

MOT_INFO = H:

NRES

OUT0

OUT1

OUT2

POS0

POS1

POS2

DIR

STOP_HM

STOP_SM

P10000

P20000

TITR_NLIQ

SET_HOTLOCK

EXT_D0

EXT_D1

EXT_D2

EXT_D3

EXT_D4

EXT_SN

SET_PWR

Definition of the digital signals

SER_OUT bit 5 ... 10, 15 ... 17

Information about current

speed of the spindle motor

(MOT_D0…SN) and cock

position (ISTPOS0…2)

Information of the digital inputs

IN0…2, NHWR, NPOR, OVERL,

EXP0…2

Reset for dosimat controller

(L active)

Bit 0 digital output

Bit 1 digital output

Bit 2 digital output

Bit 0 for the default of the

desired cock position

Bit 1 for the default of the

desired cock position

Bit 2 for the default of the

desired cock position

Definition of the direction of

rotation of the cock motor

Signal to switch off the driver

stage of the cock motor

Signal to switch off the driver

stage of the spindle motor

Bit 0 for stating the number of

pulses for the total volume

Bit 1 for stating the number of

pulses for the total volume

Definition of the mechanism of

the motor controller

Enables "Hot Plug & Play" of

the exchange unit

Bit 0 for the theoretical speed

of the spindle motor

Bit 1 for the theoretical speed

of the spindle motor

Bit 2 for the theoretical speed

of the spindle motor

Bit 3 for the theoretical speed

of the spindle motor

Bit 4 for the theoretical speed

of the spindle motor

SIGN for the specification of the

direction of rotation of the

spindle motor

Enables "Hot Plug & Play" of

the device and recognize

temporally unusual supply and

control data

16 822 Titration Curve Simulator, Instructions for Use

Page 25

4 Appendix

Meaning of the red status LEDs:

DAISY:

With the serial protocol several devices can be at the same bus one after the other in a so-called daisy-chain configuration but only one of

them is active. The so-called daisy signal is produced with SHIFT,

STROBE and the momentary condition of SER_IN to switch to the next

device.

COND.:

When "Conditioning OK" is displayed on the titrator, no further pulses

are coming from the titrator and the voltage at the "Analog Output" 7

remains at the same level. The air humidity is not simulated. After pressing "Sample Add" 3 the LED "COND" is switched on to show that the

Karl Fischer curve is running now.

SIMI NOT OK:

When switching on the titrator a self test of the internal reference and

supply voltages is carried out in the 822 Titration Curve Simulator. The

self test is carried out also at a reset of the Curve Simulator caused by

rotating the cock at the dosing device or a reset command on a serial

transmission. After the self test the display changes to "SIMI OK".

Meaning of the green status LEDs:

CURVE STATE:

If the 822 Titration Curve Simulator recognizes pulses for ejecting at the

dosing device, the LED "CURVE STATE" starts blinking i.e. it stays dark

for 500 pulses and bright for the next 500 pulses and so on.

CURVE 6000:

not in use

CURVE 20000:

If dosing is done with a 805 Dosimat or with the internal dosing drive of

the Titrando and a stroke with 20'000 pulses is ejected, this LED is

blinking synchronously with the LED "CURVE STATE".

SIMI OK:

see SIMI NOT OK

822 Titration Curve Simulator, Instructions for Use 17

Page 26

4.3 Technical data

4.3 Technical data

4.3.1 Control

parallel

serial

4.3.2 Curves

Curve memory

Number of curves

Flash

Curve types

Acid-Base

Citric acid

Recorder control

Conditioning

Karl Fischer

Diagonal

D/A converter test

Testing department test

Remote

8 bit / 25 bit

8

4 Mbit

+240 mV ... –300 mV

Endpoint at (50.00 ± 0.03) % of the cylinder volume

+250 mV ... –300 mV

st

endpoint at (17.50 ± 0.15) % of the cylinder volume

1

nd

endpoint at (35.0 ± 0.1) % of the cylinder volume

2

rd

endpoint at (52.50 ± 0.02) % of the cylinder volume

3

steps of 200 mV per 2.5 % of the cylinder volume over

the whole voltage range

series 02, 03: –2.5 V ... +2.5 V ... –2.5 V

from series 04: –2 V ... +2 V ... –2 V

series 02, 03: end at 10 % of the cylinder volume

from series 04: end at 8.4 % of the cylinder volume

Endpoint at (26.15 ± 0.10) % of the cylinder volume

series 02, 03: –2.5 V ... +2.5 V

from series 04: –2 V ... +2 V

–2.5 V ... +2.5 V

–2.0 V ... +2.0 V

Reproducibility of the endpoints (volume)

Acid-Base

Citric Acid

st

endpoint

1

nd

endpoint

2

rd

endpoint

3

Karl Fischer

99.9 %

97.5 %

99.5 %

99.95 %

99.5 %

4.3.3 Analog output

Range

18 822 Titration Curve Simulator, Instructions for Use

–2.5 V ... +2.5 V

Page 27

4 Appendix

4.3.4 Resolution

D/A converter

LSB

Curve

16 bit

76.3 µV

20'000 Word

4.3.5 Supply

Voltage

Power consumption

+5 V / +12 V

0.1 W

4.3.6 Safety specifications

Construction and testing According to EN/IEC 61010-1, UL3101-1

4.3.7 Electromagnetic compatibility (EMC)

Emission Standards complied with:

- EN/IEC 61326

- EN 55022 / CISPR 22

Immunity Standards complied with:

- EN/IEC 61326

- EN/IEC 61000-4-2

- EN/IEC 61000-4-3

- EN/IEC 61000-4-4

- EN/IEC 61000-4-5

- EN/IEC 61000-4-6

4.3.8 Ambient temperature

Nominal working range

Storage

Transport

+5 °C...+45 °C (at max. 85% rel. humidity)

–40 °C...+70 °C

–40 °C...+70 °C

4.3.9 Reference conditions

Ambient temperature

Rel. humidity

Warmed-up condition

+25 °C (±3 °C)

≤60%

Instrument in operation for at least 30 min

4.3.10 Dimensions

Housing material Sheet steel 1 mm

Width

Height

Depth

Weight 704 g

150 mm

41 mm

118 mm

822 Titration Curve Simulator, Instructions for Use 19

Page 28

4.4 Standard equipment

4.4 Standard equipment

4.4.1 822 Titration Curve Simulator

No. Order No. Description

1 1.822.0010 822 Titration Curve Simulator

1 6.2116.020 Cable for connection to the meas-

uring input; 2 plugs type F (1 m)

1 6.2134.010 Adapter box DB9 plug / Mini-DIN8

socket

1 6.2134.020 Adapter cable DB9 socket / Mini-

DIN8 plug for connecting a

685 Dosimat and 700 Dosino with

9-pin Sub-D plug (1.700.0010)

1 6.2151.040 Connecting cable Curve simulator –

Titrino (Remote interface)

1 8.822.1011 Instructions for Use for 822 Titration Curve Simulator

20 822 Titration Curve Simulator, Instructions for Use

Page 29

4 Appendix

4.5 Warranty and conformity

4.5.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing fault which occur within 12

months from the day of delivery. In this case the defects will be rectified

in our workshops free of charge. Transport costs are to be paid by the

customer.

For day and night operation the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which are not a result of material or manufacturing faults are also charged during the warranty period. For parts from

outside manufacturers, insofar as these constitute an appreciable part

of our instrument, the warranty stipulations of the manufacturer in question apply.

With the regard to the guarantee of accuracy the technical specifications in the instruction manual are authoritative.

Concerning defects in materials, construction or design as well as the

absence of guaranteed features the purchaser has no rights or claims

except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

Lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned then the original packaging should be used if at all possible. This applies above all to instruments, electrodes, buret cylinders and PTFE pistons. Before embedment in wood shavings or similar material, the parts must be packed in

a dustproof package (for instruments the use of a plastic bag is essential). If open assemblies are included that are sensitive to electromagnetic interferences [fields] (e. g. data interfaces, etc.) then these must

be returned in the associated original protective packaging (e. g. conductive protective bag). (Exception: assemblies with a built-in voltage

source belong in non-conductive protective packaging.)

For damage which arises as a result of non-compliance with these instructions, no warranty responsibility whatsoever will be accepted by

Metrohm.

822 Titration Curve Simulator, Instructions for Use 21

Page 30

4.5 Warranty and conformity

4.5.2 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical appliances and accessories,

as well as to the standard specifications for security and to system validation issued by the manufacturing company.

Name of commodity

822 Titration Curve Simulator

Description GLP test device for system check. Different types of curves can be simulated for

verification of dosing output, electrode input and titration software.

This instrument has been built and has undergone final type testing according to the standards:

Electromagnetic compatibility: Emission

EN/IEC 61326, EN 55022 / CISPR 22

Electromagnetic compatibility: Immunity

EN/IEC 61326, EN/IEC 61000-4-2, EN/IEC 61000-4-3, EN/IEC 61000-4-4, EN/IEC 61000-4-5,

EN/IEC 61000-4-6

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

www.metrohm.com

Safety specifications

EN/IEC 61010-1, UL3101-1

The instrument meets the requirements of the CE mark as contained in the EU directives 89/336/EEC and 73/23/EEC and fulfils the following specifications:

EN 61326 Electrical equipment for measurement, control and laboratory use – EMC requirements

EN 61010-1 Safety requirements for electrical equipment for measurement, control and laboratory

use

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for quality assurance in

design/development, production, installation and servicing.

The system software, stored in Read Only Memories (ROMs) has been validated in connection with

standard operating procedures in respect to functionality and performance.

The technical specifications are documented in the instruction manual.

Herisau, February 28, 2002

Dr. J. Frank Ch. Buchmann

Vice President Vice President

Head of R&D Head of Production

Responsible for Quality Assurance

22 822 Titration Curve Simulator, Instructions for Use

Page 31

4 Appendix

4.5.3 Quality Management Principles

Metrohm Ltd., CH-9101 Herisau, Switzerland

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Metrohm Ltd. holds the ISO 9001 Certificate, registration number 10872-02, issued by

SQS (Swiss Association for Quality and Management Systems). Internal and external audits are carried out periodically to assure that the standards defined by Metrohm’s QM

Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments are fully

documented and the resulting reports are archived for ten years. The development of

software for PCs and instruments is also duly documented and the documents and

source codes are archived. Both remain the possession of Metrohm. A non-disclosure

agreement may be asked to be provided by those requiring access to them.

The implementation of the ISO 9001

quality system is described in Metrohm’s

QM Manual, which comprises detailed

instructions on the following fields of

activity:

Instrument development

The organization of the instrument

design, its planning and the intermediate

controls are fully documented and

traceable. Laboratory testing accompanies all phases of instrument development.

Software development

Software development occurs in terms of

the software life cycle. Tests are

performed to detect programming errors

and to assess the program’s functionality in a laboratory environment.

Components

All components used in the Metrohm

instruments have to satisfy the quality

standards that are defined and implemented for our products. Suppliers of

components are audited by Metrohm as

the need arises.

Manufacture

The measures put into practice in the

production of our instruments guarantee

a constant quality standard. Production

planning and manufacturing procedures,

maintenance of production means and

testing of components, intermediate and

finished products are prescribed.

Customer support and service

Customer support involves all phases of

instrument acquisition and use by the

customer, i.e. consulting to define the

adequate equipment for the analytical

problem at hand, delivery of the equipment, user manuals, training, after-sales

service and processing of customer

complaints. The Metrohm service organization is equipped to support customers in implementing standards such

as GLP, GMP, ISO 900X, in performing

Operational Qualification and Performance Verification of the system components or in carrying out the System

Validation for the quantitative determination of a substance in a given matrix.

822 Titration Curve Simulator, Instructions for Use 23

Page 32

5 Index

5 Index

A

Ambient temperature......... 19

Analog output ....................18

Appendix............................ 11

C

Communication protocol..... 1

Connection

Device.......................... 3

Dosing device .............2

Dosing interface ..........5

Measuring signal cable

.....................................2

MSB interface.............. 3

Remote interface......... 6

to Titrandos .............3, 4

to Titrinos.................5, 6

to Titroprocessors ....... 6

Connector cable .................. 2

Control ...............................18

Curve

Curve memory........... 18

Curve types ............... 18

Curve description ..........8, 11

Curve selector...................... 1

Curves................................ 18

D

D/A - converter test............ 12

Description

Curves ...................8, 11

Diagonal.............................11

Dimensions........................19

E

Electromagnetic compatibility

...........................................19

EMC ...................................19

F

Front view.............................1

Functional principle .............2

I

Instrument description.........1

Introduction..........................1

P

Parts and controls ...............1

R

Rear view .............................2

Recorder control ................11

Reference conditions.........19

Reproducibility

Endpoints ..................18

Resolution ..........................19

S

Safety specifications..........19

Sample addition key ............1

Serial number.......................2

Simulation

Acid-Base titration .......8

Karl Fischer titration.....9

Titration of citric acid ...8

Standard equipment..........20

Status LED

Meaning.....................13

Serial 25 bit ................14

Serial 8 bit ..................13

Supply ................................19

T

Testing department test.....13

Transport damage .............21

W

Warranty.............................21

24 822 Titration Curve Simulator, Instructions for Use

Loading...

Loading...