Page 1

817 Bioscan

Bioscan817

Bioscan

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

Instructions for Use

8.817.1003

Page 2

Page 3

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

817 Bioscan

Instructions for Use

8.817.1003 09.2001 / up

Page 4

Page 5

Contents

Contents

1 Introduction............................................................................................ 1

1.1 Instrument description............................................................................. 1

1.2 Parts and controls .................................................................................... 2

1.3 Information about the Instructions for Use .......................................... 8

1.3.1 Organization.................................................................................. 8

1.3.2 Notation and pictograms.............................................................. 9

1.4 Safety notes ............................................................................................. 10

1.4.1 Electrical safety........................................................................... 10

1.4.2 General precautionary rules ....................................................... 10

2 Installation........................................................................................... 11

2.1 Setting up the instruments.................................................................... 11

2.1.1 Packaging ................................................................................... 11

2.1.2 Check.......................................................................................... 11

2.1.3 Location ...................................................................................... 12

2.1.4 Arrangement of the instruments................................................. 12

2.2 Mains connection ................................................................................... 12

2.2.1 Setting the mains voltage ........................................................... 12

2.2.2 Fuses .......................................................................................... 13

2.2.3 Mains cable and mains connection ........................................... 14

2.2.4 On/Off switching ......................................................................... 14

2.3 Capillary connections ............................................................................ 15

2.3.1 Connection of the 6.5324.000 Bottle Rack (option)................... 15

2.3.2 Connection of the pulsation absorber........................................ 15

2.3.3 Connection of the injection valve ............................................... 16

2.3.4 Mounting the column.................................................................. 16

2.3.5 Connection of the flow cell ......................................................... 17

2.3.6 Connecting the waste tubing...................................................... 18

2.3.7 Rinsing the tubing....................................................................... 19

2.3.8 Rinsing the column ..................................................................... 19

2.4 System for sugar analysis – MIC 8 ...................................................... 20

2.4.1 Electrical connections................................................................. 20

2.4.2 Settings in «IC Net 2.1» ............................................................. 21

2.4.3 Connecting a sample changer ................................................... 22

2.5 System for the analysis of anions and sugars – MIC 9.................... 24

2.5.1 Electrical connections................................................................. 24

2.5.2 Capillary connections ................................................................. 25

2.5.3 Configuration in «IC Net 2.1» ..................................................... 27

2.6 Preparing the 817 Bioscan for the analysis ....................................... 32

2.6.1 System switch-on........................................................................ 32

2.6.2 Start pump .................................................................................. 32

2.6.3 Set operating mode.................................................................... 33

817 Bioscan

I

Page 6

Contents

3 Operation............................................................................................... 35

3.1 Handling the 817 Bioscan ..................................................................... 35

3.2 Operation using «IC Net 2.1» ................................................................ 36

3.2.1 817 Bioscan icon.........................................................................36

3.2.2 817 Bioscan window ...................................................................37

4 Basic principles............................................................................. 47

4.1 Introduction ............................................................................................. 47

4.2 Measuring conditions ............................................................................ 48

4.3 Pulsed amperometric detection........................................................... 49

4.3.1 Optimization of the PAD parameters ..........................................49

4.4 Optimization of the measuring potential ............................................ 51

5 Notes – Maintenance – Faults....................................... 55

5.1 Practical notes on ion chromatography ............................................. 55

5.1.1 Separating columns ....................................................................55

5.1.2 High-pressure pump ...................................................................56

5.1.3 Eluents .........................................................................................57

5.1.4 Connections ................................................................................57

5.2 Maintenance and servicing................................................................... 58

5.2.1 General information .....................................................................58

5.2.2 Shutdown.....................................................................................58

5.2.3 Cleaning the working electrode ..................................................59

5.2.4 Changing separating columns....................................................60

5.3 Faults and malfunctions ........................................................................ 61

5.3.1 Malfunctions and their rectification .............................................61

5.4 Instrument test with the dummy cell ................................................... 63

5.5 Validation / GLP ...................................................................................... 64

6 Appendix................................................................................................. 65

6.1 Technical data......................................................................................... 65

6.2 Standard equipment............................................................................... 69

6.3 Warranty and conformity....................................................................... 71

6.3.1 Warranty.......................................................................................71

6.3.2 EU declaration of conformity.......................................................72

6.3.3 Certificate of conformity and system validation ..........................73

6.4 Index ......................................................................................................... 75

II

817 Bioscan

Page 7

Contents

List of illustrations

Fig. 1: Front of the 817 Bioscan................................................................................... 3

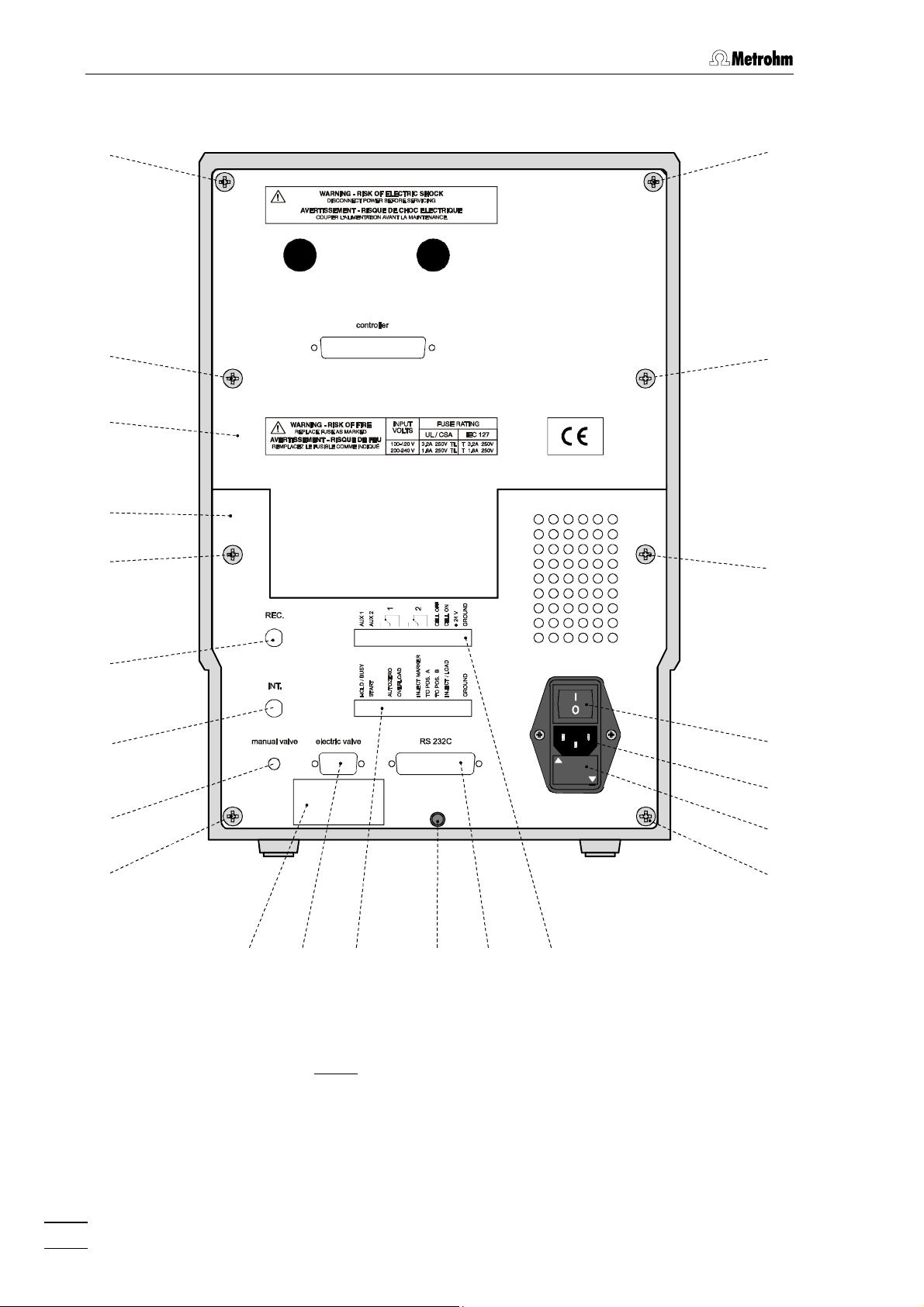

Fig. 2

: Rear of the 817 Bioscan.................................................................................... 4

Fig. 3

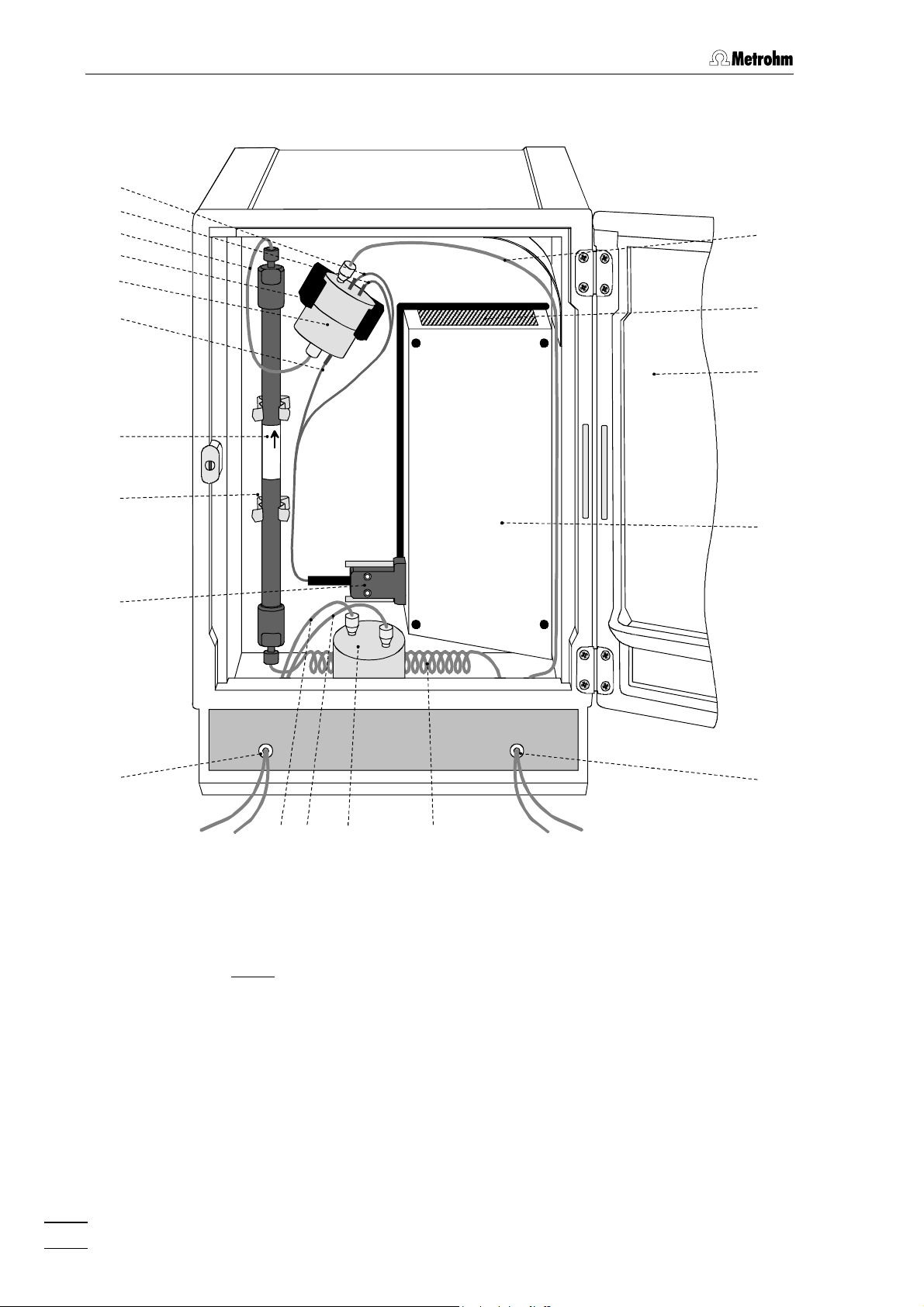

: Interior of the 817 Bioscan (with permanently attached accessories) .. 6

Fig. 4

: Setting the mains voltage ............................................................................... 13

Fig. 5

: Connections at the injection valve of the 2.812.0010 Valve Unit ......... 16

Fig. 6

: Connections at flowcell ............................................................................... 17

Fig. 7

: Connecting up a simple modular IC system

with the 817 Bioscan – MIC 8

Fig. 8

: Connecting up a simple MIC 8 system

including a sample changer

Fig. 9

: Connections with a 817 Bioscan as second detector

with a modular IC system – MIC 9

..................................................................... 20

....................................................................... 22

............................................................. 24

Fig. 10

: Connections of injection valves A and B in the IC Separation

Center (2.733.0120)

Fig. 11

: Potentials applied during pulsed amperometric detection (PAD). ...... 49

Fig. 12

: Example of a hydrodynamic voltammogram of a

..................................................................................... 26

substance (A) with additional presentation of the

measured values for the pure eluent (B)

Fig. 13

: Example of a scan of a substance (A) with additional

presentation of the scan of the pure eluent (B)

.................................................. 51

...................................... 52

817 Bioscan

III

Page 8

Contents

IV

817 Bioscan

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 2.817.0010 Bioscan is a PC-controlled measuring instrument for

the sensitive analysis of carbohydrates by ion chromatography using

pulsed amperometric detection. The compact housing of the 817 Bioscan contains several IC system components:

• Detector – flow-through cell with three-electrode arrangement for

amperometric detection in the Pulse, DC and Scan modes.

• Column compartment – the perfect insulation of the housing cre-

ates not only stable thermal conditions for the separating columns,

but also shields the system from electromagnetic interference; in

addition to the column it also contains the detection cell, pulsation

absorber and preheating capillary.

• Oven – amperometric determinations require extremely stable

thermal conditions. The built-in column compartment oven ensures

that all important components can be set exactly to a temperature

from 10°C above room temperature to 60 °C with a stability of

0.1°C.

• All components that come into contact with the eluent and the

sample, except the electrodes, are metal-free.

• Signal converter – the 817 Bioscan contains its own analog/ digi-

tal converter for the detector signal. This means that complete control of the instrument is possible from a PC via an RS232 interface.

Together with the 709 IC Pump and the 812 Valve Unit, the 817 Bio-

scan forms a complete IC system for carbohydrate analysis. Operation is via a PC connected to the RS232 interface and uses the in-

cluded «IC Net 2.1» control and evaluation program. This software

fulfills all the demands which are placed today on a modern integration

software: 1-point or multi-point calibration, internal or external standard,

selectable algorithms for non-linear calibration, numerous Integration

modes with selectable parameters and integration events, various peak

recognition methods, peak editor, free scaling, superimposition of several chromatograms, post-treatment of chromatograms, high-performance GLP-conform report generator with output interfaces for monitor,

printer and external databases.

817 Bioscan

1

Page 10

1 Introduction

817 Bioscan

2

Page 11

1.2 Parts and controls

1.2 Parts and controls

Bioscan817

Bioscan

1 2 3

: Front of the 817 Bioscan

Fig. 1

Door to interior 3 Feed through for tubing

1

e.g. connection of injection valve and preheating capillary or connection to waste

2 Feed through for tubing

e.g. connection of 709 IC Pump and

pulsation absorber

817 Bioscan

3

Page 12

1 Introduction

4

4

4

4

5

6

4

4

7

8

18

17

9

16

4

10

11 14

12 13 15

Fig. 2

: Rear of the 817 Bioscan

4

817 Bioscan

4

Page 13

1.2 Parts and controls

Mounting screw

4

for fastening the rear panels 5 / 6

12 Lower connections for remote lines

(not used with IC Net)

Detachable rear panel

5

access to top part of the inner compartment

6 Detachable rear panel

access to bottom part of the inner

compartment

7 Analog signal (REC.)

AD/DA-converted signal

(not used with IC Net; see chapter 6.1

for details)

8 Analog signal (Int.)

Original signal

(not used with IC Net; see chapter 6.1

for details)

9 Manual valve

(not used with IC Net)

10 Model plate

with technical data serial number

13 Outlet for spilled liquid

for discharge of spilled liquid from the

inner compartment

14 RS232 interface

connection of the PC; see chapter 6.1

for details

15 Upper connections for remote lines

Aux 1, Aux 2 as well as 1 and 2 are

only

used with IC Net

16 Fuse holder

changing the fuses, see section 2.2.1

17 Mains connection plug

mains connection, see section 2.2

18 Mains switch

to switch instrument on and off:

I = ON 0 = OFF

11 Electric valve

(not used with IC Net)

817 Bioscan

5

Page 14

1 Introduction

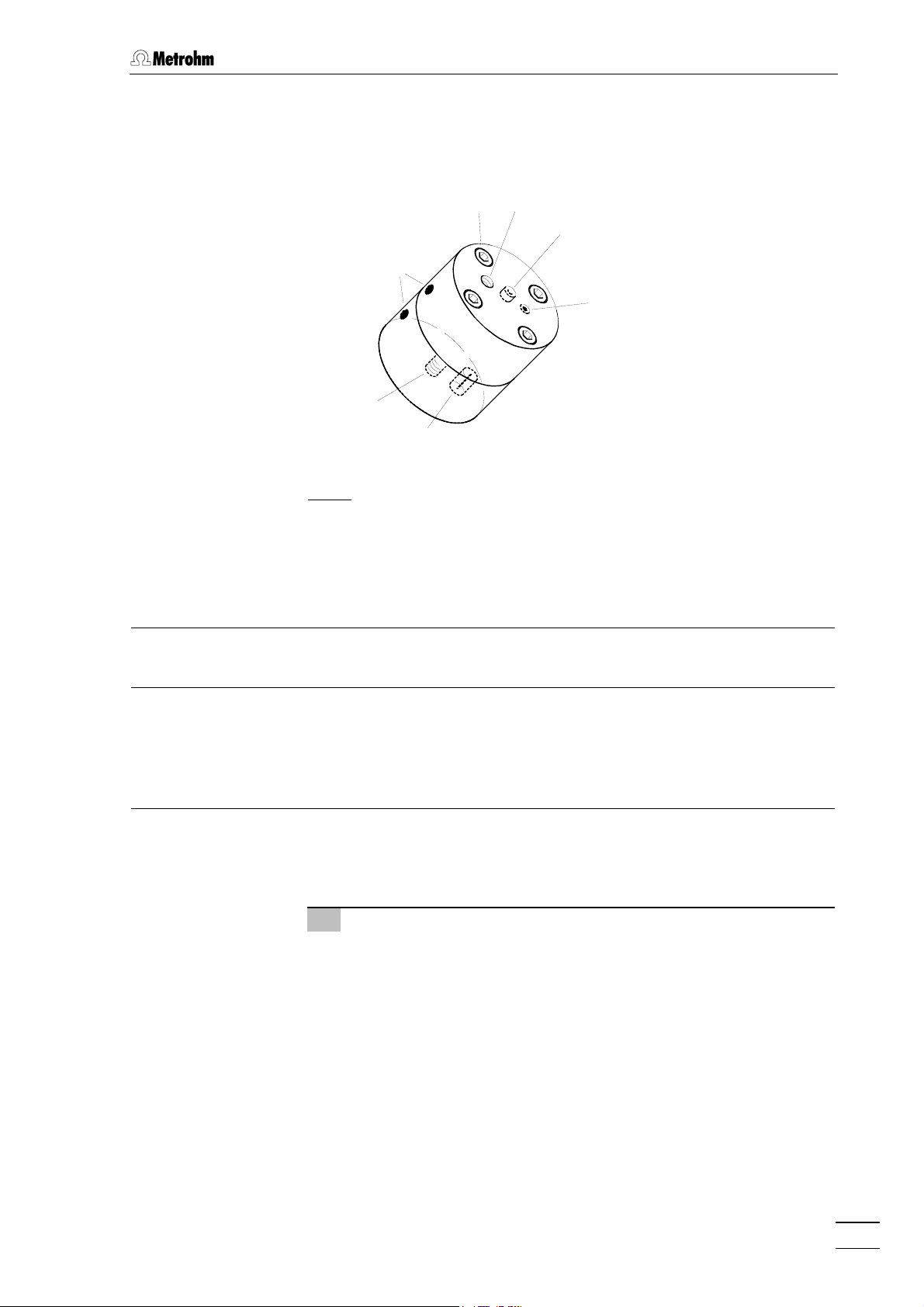

19

20

21

34

22

23

24

25

26

27

33

1

Metrosep

Carb 1

32

2

29 31

28

: Interior of the 817 Bioscan

Fig. 3

30

(with permanently attached accessories)

3

817 Bioscan

6

Page 15

1.2 Parts and controls

Electrode cable (red)

19

connection for working electrode

27 Connection for elektrode cable

connection '1'

Electrode cable (blue)

20

connection for auxiliary electrode

28 Connection capillary

connection 709 IC Pump – pulsation

absorber

21 Column connection capillary

PEEK capillary

29 Connection capillary

connection pulsation absorber –

injection valve

22 Measuring cell holder 30 Pulsation absorber

6.2620.150

23 Au - Flow cell

6.1254.010

24 Electrode cable (black)

connection for reference electrode

25 IC column

e.g. Metrosep Carb 1 (6.1013.000)

31 Preheating capillary

6.1836.010, length: 3 m

32 Oven

33 Oven heating fan

for carbohydrate analysis

26 Column holder

34 Connection capillary

connection flow cell – waste

817 Bioscan

7

Page 16

1 Introduction

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 817 Bioscan into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instruments.

1.3.1 Organization

These Instructions for Use 8.817.1003 for the 817 Bioscan provide a

comprehensive overview of the startup procedure, operation, fault rectification and technical specifications of these instruments. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instruments, parts and controls

and safety notes

Section 2 Installation

Setting up, mains connection, attachment of accessories, connection to IC system

Section 3 Operation

Detailed description of the operation

Section 4 Basics

Information about the pulsed amperometric detection

Section 5 Notes – Maintenance – Faults

Notes on ion chromatography, maintenance, fault rectification, diagnostic tests, validation

Section 6 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instrument, you will find it an advantage to use either the Table of contents or the Index at the back.

As a supplement to the Instructions for Use, the 8.732.2003 Metrohm

Monograph "Ion chromatography" is also supplied. This provides an

introduction to the theoretical fundamentals and general information on

separating columns and sample pretreatment.

The 8.792.5003 Metrohm Monograph "Practical Ion Chromato-

graphy" is a practical textbook, which provides an illustrative introduction to the basic principles of ion chromatography and also describes

22 experiments covering the whole world of ion chromatography.

IC Application Notes for different applications of Metrohm IC systems

are also supplied.

8

817 Bioscan

Page 17

1.3 Information about the Instructions for Use

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

<PARAM> Key

'Range' Parameter or entry value

35 Part or control of 817

22 Part or control of 709

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important

information. First read the associated directions before you continue.

Comment

This symbol marks additional

information and tips.

817 Bioscan

9

Page 18

1 Introduction

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 817 Bioscan is assured in

the context of the specifications EN61010-1 / IEC61010-1, the following

points should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.4.

• Opening the 817 Bioscan

If the 817 Bioscan is connected to the power supply, the instrument

must not be opened (apart from the front door) nor must parts be

removed from it, otherwise there is a danger of coming into contact

with components which are live. Hence, always disconnect the

instrument from all voltage sources before you open it and ensure that

the mains cable is disconnected from mains connection 17 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 817 Bioscan, you should earth yourself and any tools you

are using by touching an earthed object (e.g. housing of the instrument or a radiator) to eliminate any static charges which exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

• Never block drain opening for spilled liquids

On the bottom of the interior directly below the front door there is a

drain opening 1. Spilled liquids can flow directly to the outlet 13 on

the back. Due to safety consideration, take care that these openings

may never be blocked.

10

817 Bioscan

Page 19

2.1 Setting up the instrument

2 Installation

The 817 Bioscan is an electrochemical detector and can be included in

a modular IC system in two different ways:

1) The 817 Bioscan as the only detector in an IC system.

Apart from the 709 IC Pump, you also require an 812 Valve Unit with

one injection valve. In this MIC-8 modular IC system the 817 Bioscan is

intended for the analysis of sugars only.

2) The 817 Bioscan is included in an IC system as the second

detector. An example of this is given in Section 2.5 where an IC system

(MIC-9) is described for the simultaneous determination of sugars and

anions with chemical suppression.

These modular IC system configurations (MIC-1, MIC-2, etc.) are possible instrument combinations that have been properly tested. Under

www.metrohm.com

updated.

you will find further examples; these are continually

Following the general information about the installation of the

instruments, Sections 2.4 and 2.5 describe the two configurations

mentioned above including their control by the «IC Net 2.1» software.

2.1 Setting up the instrument

2.1.1 Packaging

The 817 Bioscan is supplied together with the separately packed

accessories in special packaging containing shock-absorbing foam

linings designed to provide excellent protection. The actual instruments

are packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all this special packaging as only it can assure

transport of the instruments free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 6.2). In the case of transport damage, see

instructions in section 6.3.1 "Warranty".

817 Bioscan

11

Page 20

2 Installation

2.1.3 Location

Position the instruments in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals. The same applies to all

other components of the IC system.

To avoid disturbing temperature influences on the insulated column

compartment, the entire system including pump and eluent reservoir

must be protected against direct sunlight.

2.1.4 Arrangement of the instruments

If the 817 Bioscan is used as a single detector (see chapter 2.4), the

709 IC Pump, 812 Valve Unit and 817 Bioscan are best stacked on top

of one another in this order.

In a two-channel system (see chapter 2.5), the optimum arrangement

(1, 2 or 3 towers) depends on the laboratory space available.

In general, the IC pumps should be set up at the very bottom and the

IC detectors at the very top.

2.2 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

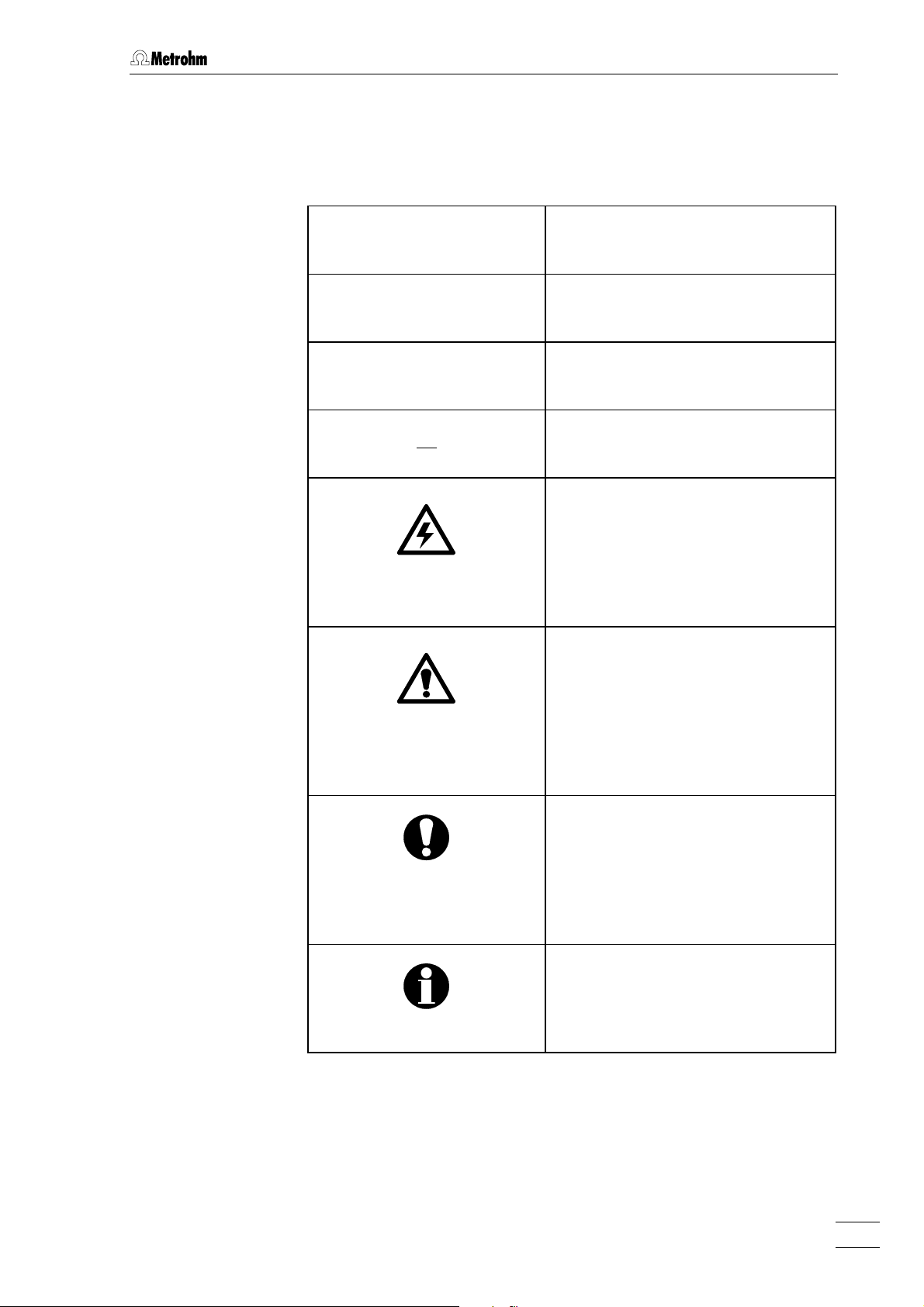

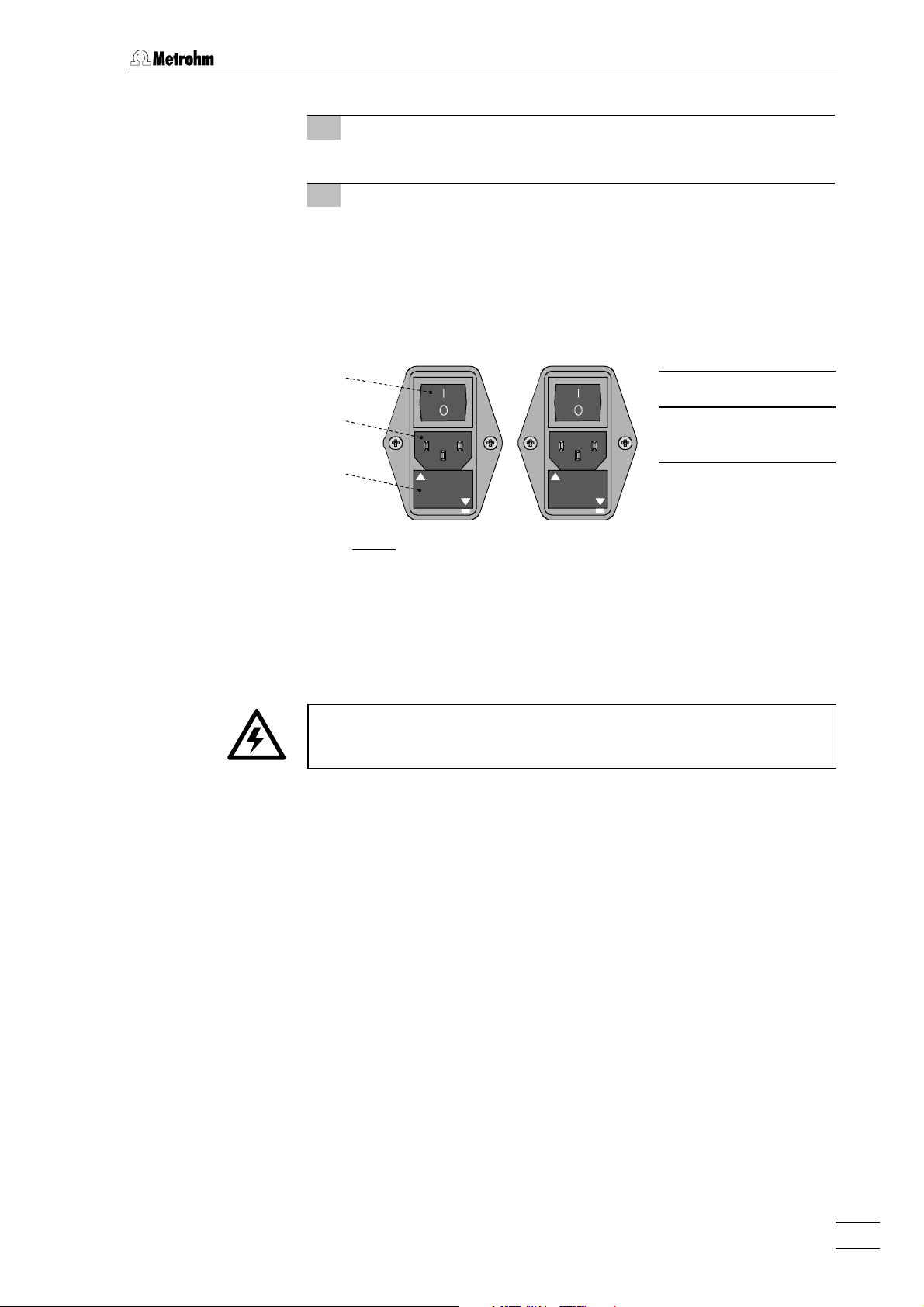

2.2.1 Setting the mains voltage

Before switching on the 817 Bioscan for the first time, check that the

mains voltage set on the instrument (see Fig. 4) matches the local

mains voltage. If this is not

on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 17.

the case, you must reset the mains voltage

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 16 below the mains

connection plug and take out completely.

3 Check and change fuse if necessary

Carefully take the fuses installed for the desired mains voltage

out of fuse holder and check their specifications:

100…120 V 3.15 A (slow-blow) Metrohm No. U.600.0021

220…240 V 1.6 A (slow-blow) Metrohm No. U.600.0018

817 Bioscan

12

Page 21

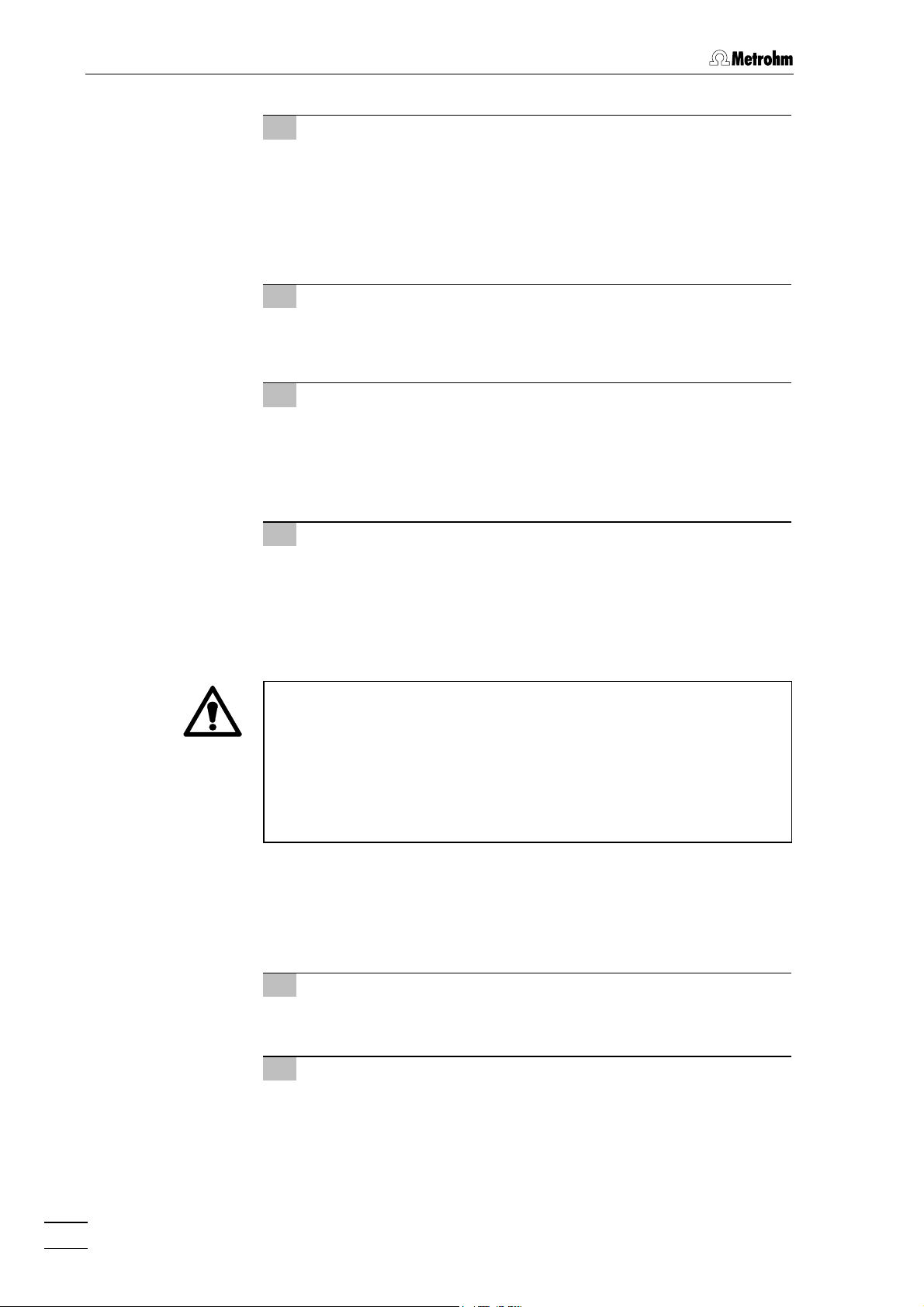

2.2 Mains connection

V

V

4 Insert fuse

Change fuses if necessary and reinsert in fuse holder.

5 Install fuse holder

Depending on the necessary mains voltage, insert fuse holder in

the 817 Bioscan so that the corresponding mains voltage range

can be read normally and the adjacent white arrow points to the

white bar imprinted below the fuse holder (see Fig. 4).

2.2.2 Fuses

18

17

100 – 120

220 – 240

18 Mains switch

17 Mains connec-

tion plug

16

220 - 240 V

100 - 120 V

100 - 120 V

220 - 240 V

16 Fuse holder

Fig. 4

: Setting the mains voltage

Two fuses 3.15 A/slow-blow for 100…120 V or 1.6 A/slow-blow for

220…240 V are installed in fuse holder 16 of the 817 Bioscan as standard.

Ensure that the instrument is never put into operation with fuses of a

different type as this could cause a fire!

817 Bioscan

For checking or changing fuses, proceed as described in section 2.2.1.

13

Page 22

2 Installation

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 17 of the 817 Bioscan

(see Fig. 2).

2.2.4 On/off switching of the instruments

The 817 Bioscan is switched on and off using mains switch 18. Do not

switch the IC components on before all cable connections have been

established.

817 Bioscan

14

Page 23

2.3 Capillary connections

2.3 Capillary connections

The capillary connections described below are necessary for operating

the 817 Bioscan in a simple IC system for carbohydrate analysis (MIC-

8). The electronic connections and control by IC Net 2.1 are described

in Section 2.4.

Section 2.5 contains the description of a combination of this IC system

with an IC system for the determination of anions with chemical suppression (MIC-9). The necessary changes to the capillary connections

are described there.

2.3.1 Connection of the 6.5324.000 Bottle rack (option)

The optionally available 6.5324.000 Bottle rack for supply vessels can

be placed on top of the 817 Bioscan. The tubing connections to the 709

IC Pump are described in the corresponding leaflet.

2.3.2 Connecting the pulsation absorber

To protect the column material from any pressure shocks which the injection may cause we recommend the insertion of the 6.2620.150 MF

Pulsation absorber between the high-pressure pump and the injection valve. This is done as follows (see Fig. 3):

1 Connect the pulsation absorber

• Place pulsation absorber 30 on the floor in the interior of the

817 Bioscan.

2 Connection to pump

• Connect the 6.2821.100 PEEK Filter unit described in

Section 2.3.5 of the 8.709.1021 ‘Instructions for Use’ to connection 23

• Lead PEEK capillary 28 or 43

the filter unit outwards through opening 2 of the Bioscan and

attach it to one of the 52 connections on the top side of the

pulsation absorber.

3 Connection to injection valve

• Connect PEEK capillary 29 to the second connection 30 of

the pulsation absorber, lead it out through 2 of the Bioscan

and connection it to the injection valve on the 812 Valve Unit

(connection 17).

The pulsation absorber is filled with isopropanol and must be rinsed

with eluent before a separating column is connected (see Section

2.3.7).

of the 709 Pump by using PEEK capillary 22.

from connection piece 47 of

817 Bioscan

The 6.2620.150 Pulsation absorber can be operated in both directions.

15

Page 24

2 Installation

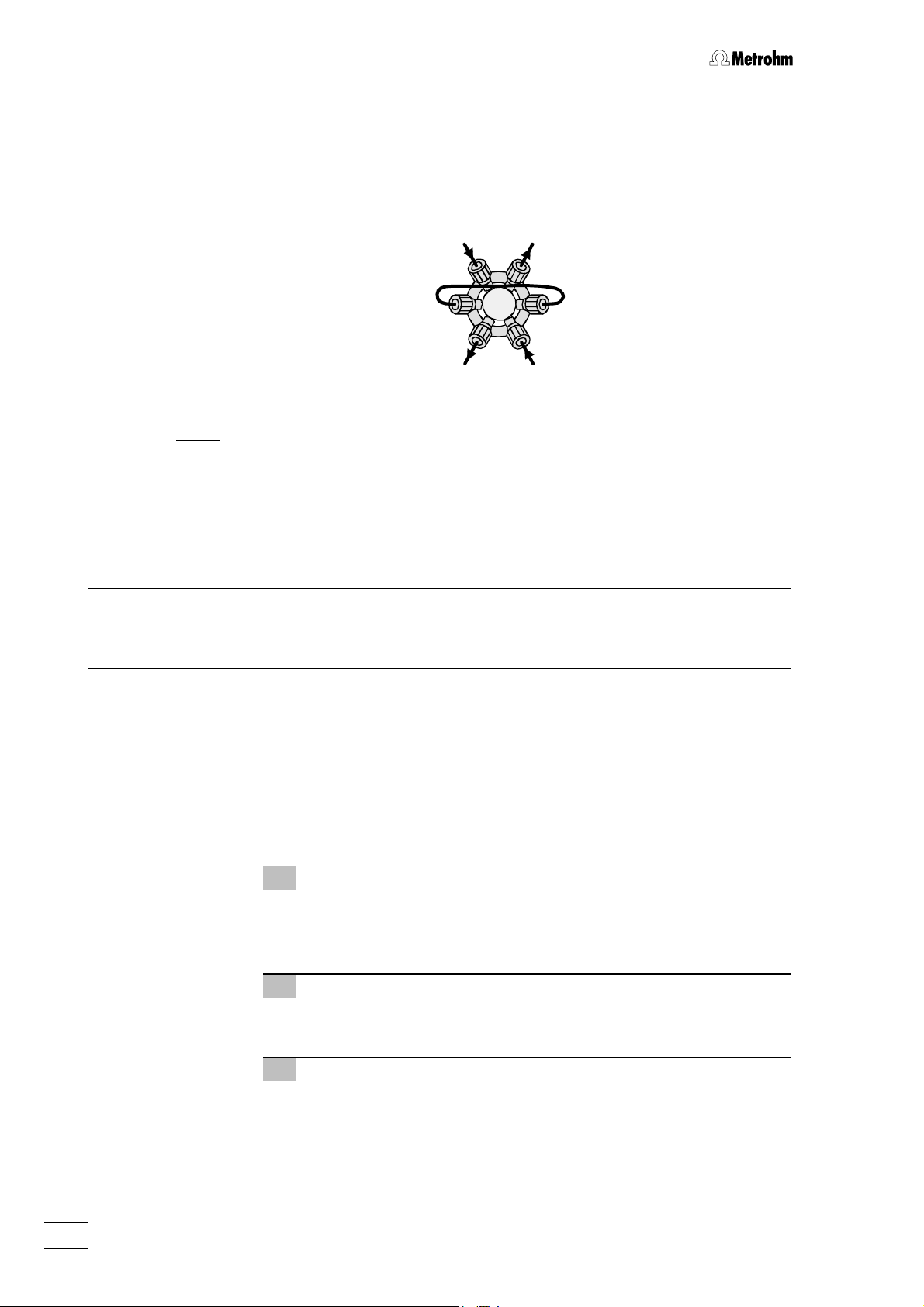

2.3.3 Connection of the injection valve

Connect all capillaries to the injection valve according to the following

description:

46 45

45

36

21

4447

Fig. 5

: Connections at the injection valve of 2.812.0010 valve unit

Connection for syringe tubing

42

PTFE tubing with coupling

(6.2744.120) and syringe (6.2816.020,

without needle)

43

Connection for aspirating tubing

PTFE tubing for aspirating sample

44 Connection for sample loop

20 µL PEEK sample loop (6.1825.210)

2.3.4 Mounting the column

The IC separating column (e.g. Metrosep Carb 1, 6.1013.000) is first

mounted in the 817 Bioscan as follows (see Fig. 3):

42 43

45 Eluent outlet

Connection to preheating capillary 31

(PEEK, 6.1836.010)

46 Eluent inlet

PEEK capillary connection 29 to

pulsation absorber

47 Connection for sample loop

20 µL PEEK sample loop (6.1825.210)

1 Connect column to the preheating capillary

• Remove the caps from column 25.

• Screw eluent outlet of preheating capillary 31 on to the inlet

end of the column (observe flow direction) .

2 Connect column to flow-through measuring cell

• Screw outlet end of column 25 on to eluent inlet 41 of the

flow-through cell using the 6.2744.130 KELF pressure screw.

3 Fix column

• Fix the column in column holder 26.

817 Bioscan

16

Page 25

2.3 Capillary connections

2.3.5 Connection of the flowcell

The Flowcell (6.1254.010) is a part of the standard equipment of the

817 Bioscan. It is already mounted and ready to use.

37

36

38

35

39

41

40

: Connections at flowcell

Fig. 6

Check marks

35

For correct orientation of the top and

bottom part of the flow-cell

36

Mounting screws (4x)

37 Outlet for eluent

Connection of PEEK capillary by

6.2744.130 KELF pressure screw .

PEEK pressure screws may damage

the threads of the cell.

38 Working electrode connection

for red electrode cable 19

39 Auxiliary electrode connection

for blue electrode cable 20

40 Reference electrode connection

for black electrode cable 24

41 Inlet for eluent

Connection of PEEK capillary by

6.2744.130 KELF pressure screw.

PEEK pressure screws may damage

the threads of the cell.

817 Bioscan

1 Before starting up check all screws 36

• Use the Allen key provided to loosen all four of the 36 screws

by one rotation.

• Then slightly tighten the screws again, e.g. by holding the

Allen key between the thumb and index finger only.

• Finally tighten all four screws by a quarter rotation.

• Always tighten opposing screws, i.e. tighten one screw and

then the opposite screw.

• Avoid overtightening the screws as this could damage the

6.1254.020 Distance piece!

17

Page 26

2 Installation

2 Connect the electrode cable

• The included 6.2156.000 Cable for connecting the measur-

ing cell is attached to connections 38, 39 and 40 of the

measuring cell using the three connectors 19, 20 and 24

(see Fig. 6).

• The other end of the cable is inserted into connection '1' of

the 817 Bioscan 817 with connector 27 (see Fig 3).

3 Connect the column

• Screw column connection capillary 21 of the column on to

eluent inlet 41 of the flow-through measuring cell using the

6.2744.130 Pressure screw.

4 Connect the waste container

• In order to ensure an adequate backpressure, screw a PEEK

capillary (approx. 1 m) on to eluent outlet 37 of the measuring

cell.

• Lead the end through opening 3 into a sufficiently large waste

container and attach it there.

5 Mount the measuring cell

• Attach the flow-through measuring cell to the holder 22 817

Bioscan which is provided for it (see Fig. 3).

• Rotate the holder and the cell so that the cell outlet is located

as high as possible. In this way it is easier for any air bubbles

that may occur to escape from the cell.

Never switch on the flow-through cell when this is

(a) not being rinsed through with a conducting eluent at the

time,

(b) not completely connected up, or

(c) when its outside is moist so that so a short circuit could

occur between the connections of working electrode 38

and auxiliary electrode 39!

2.3.6 Connecting the waste tubing

The 817 Bioscan has an outlet 13 on its rear panel for discharged

liquids to which the waste tubing can be attached. Proceed as follows:

1 Connect the waste tubing

• Attach matching tubing (e.g. Silicone tubing, optional) into

outlet 13 (see Fig. 2).

2 Lead the waste tubing to a drain

• Place the other end of the waste tubing in a drain and attach

it there.

817 Bioscan

18

Page 27

2.3 Capillary connections

2.3.7 Rinsing the tubing

The pulsation absorber is supplied permanently mounted and is filled

with isopropanol. In order to remove this and any air that may be present in the capillaries and the measuring cell all the eluent-carrying tubing or capillary connections must first be installed; the column and the

flow cell must not be connected during the beginning of the process.

Proceed as follows:

1 Deconnect preheating capillary from column

• Deconnect the eluent outlet of preheating capillary 31 from

the column and fix it at a waste bottle.

2 Set injection valve to “Inject”

• Press the <INJECT> key on the 812 Valve unit, which should

not yet be connected to the 817 Bioscan. The green LED in

the key lights up to show that the injection valve is in the “Inject” position.

3 Vent 709 IC Pump before start up

• Proceed according to Section 2.7 of the ‘Instructions for Use’

of the 709 IC Pump.

4 Rinse with dist. H2O

• Immerse the aspiration capillary of the 709 IC Pump in distilled or deionized water.

• Switch on the 709 IC Pump, rinse the IC system for approx.

10 min. and switch off the 709 IC Pump.

5 Rinse with eluent

• Immerse the aspiration capillary of the 709 IC Pump in the

eluent to be used (e.g. 100 mM NaOH).

• Switch on the 709 IC Pump, rinse the IC system for approx.

10 min. and switch off the 709 IC Pump.

6 Connect flowcell and rinse with eluent

• Connect the preheating capillary 31 to flowcell using column

connection capillary 21 and 6.2620.060 Coupling.

• Switch on the 709 IC Pump, rinse the IC system for approx.

10 min. with eluent and switch off the 709 IC Pump.

7 Remove the coupling

• Remove the 6.2620.060 Coupling between column connection capillary 21 and preheating capillary 31.

• Remount the column between column connection capillary

21 and preheating capillary 31 as show in Fig. 3.

2.3.8 Rinsing the column

In order to rinse or precondition the column the connection capillary 21

to flowcell must be unscrewed from the column. Proceed as described

in point 3 and 4 in section 5.2.4.

817 Bioscan

19

Page 28

2 Installation

2.4 System for sugar analysis – MIC-8

The MIC-8 system with manual sample injection is described below. Of

course, you can also install a Metrohm sample changer. This is described in Section 2.5 or in the ‘Instructions for Use’ of the sample

changer.

In order to connect a sample changer and control it completely you

need a further free COM port on your PC. However, we recommend the

use of the 762 IC Interface, to which you can then also connect the 709

IC Pump to be controlled by IC Net 2.1.

2.4.1 Electrical connections

The electrical connections of the MIC-8 system, which consists of the

817 Bioscan, the 812 Valve unit and the 709 IC Pump, are made according to Figure 7:

817

812

709

6.2128.100

6.2125.160

PC

1

AUX 1

AUX 2

123456789

Ground

Fill

2

Inject

: Connecting up a simple modular IC system with the 817

Fig. 7

Bioscan – MIC 8

817 Bioscan

20

Page 29

2.4 System for sugar analysis – MIC-8

2.4.2 Settings in «IC Net 2.1»

1 System

As in this configuration only the 817 Bioscan is to be directly

controlled by IC Net then only this instrument is to be installed as

the detector with the help of the system assistant

wizard

.

2 Method

You should first select the standard method supplied for use

with your particular column (e.g. for Metrosep Carb 1:

CARB1_250.mtw). You can save any alterations under a different

file name.

3 Data source

Select: Cell( 817 BioScan) as the signal source.

4 Save system

Then save the system (e.g. 817_MIC-8.smt).

The following system window should now appear:

New system

5 Connect system and workplace

Under SYSTEM / Control / Connect to workplace connect the

new system with the workplace.

At the same time the symbol will appear in the symbol

bar.

6 Check measuring cell

If the 817 Bioscan is switched on without the flow-through cell

being constantly rinsed by a conducting eluent (e.g. 0.1 M

NaOH) then the measuring cell must not be switched on!

You should now check this in the instrument window of the 817

Bioscan (accessed with a double-click with the mouse on instrument symbol) under

Manual / Cell.

7 Check start mode

Make sure that in this system the 817 Bioscan is standing under

Start with determination under Setup / Start mode.

.

817 Bioscan

21

Page 30

2 Installation

2.4.3 Connecting a sample changer

If the MIC-8 system described above is to be operated with a Metrohm

sample changer then the following connections and settings must be

made:

817

1

AUX 1

AUX 2

1 2 3456789

2

CELL OFF

CELL ON

+ 24 V

GROUND

10 11 12

6.2141.140

766/78 8/813

6.2141.140

812

709

6.2128.100

6.2125.160

PC

Ground

Fill

Inject

Fig. 8: Connecting a simple MIC 8 system including a sample

changer

The IC Sample Processor 766, the IC Filtration Sample Processor

788 or the Compact Autosampler 813 can be used as the sample

changer. In this combination of the MIC-8 system the 817 Bioscan is

operated as the "Master". The start impulse for the instrument methods

to the connected sample changer is transferred via the remote connection (6.2141.140, optional). You can then select any instrument method

at the sample changer that is described as being for control with the PC

as master. Information about this is given in the corresponding ‘Instructions for Use’.

If a second COM port on the PC or a 762 IC Interface is available for an

RS232 connection then the 766 IC Sample Processor or the 788 IC Filtration Sample Processor can be connected up via this connection. In

this way you can generate your own time programs in IC Net 2.1 for

these sample changers. Details are given in the ‘Instructions for Use’ for

the particular instrument.

817 Bioscan

22

Page 31

2.4 System for sugar analysis – MIC-8

Creating the time program

In order to control the 766 IC Sample Processor and the 788 IC Filtration Processor the following program is created in the Bioscan:

In this way shortly after the injection valve has been switched to 'Fill' at

the 812 Valve unit, the first remote line 'AUX 1' (see Fig. 6) will be

switched briefly to 'ON'. This signal will be scanned at the start of the

suitable sample changer programs.

Terminate the program entry by activating the program with

store it in the system with

Save.

Enable and

The control of the 813 Compact Autosampler is carried out similarly.

The only thing to be done here is to set the remote lines to the required

times as described above for each of the three working steps: autosampler start, pump start and pump stop in order for a brief impulse to

be transferred.

In order for the connection Autosampler – 817 Bioscan to function

properly the program must first be started at the sample changer and

then the "Sample queue" in IC Net 2.1.

817 Bioscan

23

Page 32

2 Installation

2.5 System for the analysis of anions and sugars – MIC-9

The combination of an anion system with chemical suppression with the

IC system for sugar analysis is described as an example of a complete

IC system for the simultaneous determination of anions and sugars.

As ideally the two sample loops for the different separation pathways

should be connected by as short a piece of capillary as possible for

sample injection, a 733 IC Separation Center with two injectors

(2.733.0120) is used. This means that the 812 Valve Unit is no longer

required for sample injection for the Bioscan. The MSM Suppressor

Module, which is frequently located in the 733 IC Separation Center, is

then replaced by the 753 IC Suppressor Module which is used instead

of the 752 IC Pump Unit.

2.5.1 Electrical connections

The electrical connection of the system, consisting for example of two

709 IC Pumps, 817 Bioscan, 732 IC Detector, 733 IC Separation Center

(2 injectors), 753 IC Suppressor Module, 762 IC Interface and 766 IC

Sample Processor is made according to the Figure 9:

6.2125 .120

6.2128.130

PC

6.2134.100

6.2128.180

6.2115.070

817

709762

6.2134.090

732

733

709

753

MSM

6.2125.090

6.2141.110

6.2143.210

AB

6.2134.080

Fig. 9

: Connections with a Bioscan 817 as second detector with

a modular IC system – MIC 9

817 Bioscan

24

Page 33

2.5 System for the analysis of anions and sugars – MIC-9

2.5.2 Capillary connections

This section describes the capillary connections required for the combination of the IC system for sugar analysis (MIC-8) with an anion system with chemical suppression (e.g. MIC-2). It is assumed that the capillary connections for the anion system are already known.

Arrange the necessary components as shown in Fig. 9. Please also observe the recommendations about the arrangement of the IC modules

given in Section 2.1.4. The capillary connections for the 817 Bioscan

correspond to a large extent to the connections described in Section

2.3. Only the connection of the injection valve to the 812 Valve Unit is

not necessary. Instead the second injection valve B of the 733 IC Separation Center is connected for injecting the sample for the sugar determination (see below).

For the components for determination of the anions the typical arrangement of the capillaries for such an anion system is assumed to be

present. The necessary alterations concern the injection valve A in the

733 IC Separation Center, which must be connected for injection valve

B so that the two sample loops can be filled simultaneously. In addition

the MSM Suppressor Module connections must be transferred to the

753 IC Suppressor Module if the 752 IC Pump Unit has previously been

used with the MSM Module contained in the 733 IC Separation Center.

The necessary modifications are described below. Injections valves A

and B are designated as follows:

Injection valve A: sample injection for anion determination

Injection valve B: sample injection for sugar determination

All the connections for the two injection valves are shown in Figure 10

on the following page.

1 Connection injection valve A – injection valve B

For simultaneously filling the two sample loops as short as

possible piece of PEEK capillary is attached to sample outlet 48

of injection valve A and sample inlet 55 of injection valve B.

2 Connection pulsation absorber – injection valve B

Connect PEEK capillary 29 to pulsation absorber 52 in the

Bioscan, lead it out through opening 2 or 3 of the Bioscan, and

in through opening 27

or 28 of the 733 IC Separation Center

and connect it to injection valve B (eluent inlet 58).

3 Connection injection valve B – preheating capillary

Connect PEEK capillary at injection valve B (eluent outlet 57),

lead it out through opening 27

or 28 of the 733 IC Separation

Center and in through opening 2 or 3 of the Bioscan and use a

PEEK coupling to connect it to preheating capillary 31.

817 Bioscan

25

Page 34

2 Installation

49 48

A

51 52

Fig. 10

Injection Valve A

48 Sample outlet

PEEK capillary connection to injection

valve B

49 Sample inlet

PEEK capillary connection to sample

processor (18 in Instructions for Use

for 766 IC Sample Processor)

: Connections of injection valves A and B

in the IC Separation Center (2.733.0120)

- Anions -

55 54

12

63

54

5350

57 58

54 Sample outlet

PTFE tubing connection to waste

55 Sample inlet

PEEK capillary connection to injection

valve A

12

63

B

54

5956

Injection Valve B

- Carbohydrates -

50 Connection for sample loop

PEEK sample loop for anion analysis

51 Eluent outlet

PEEK capillary connection to anion

separation column

52 Eluent inlet

PEEK capillary connection, e.g. to

pulsation absorber for anion eluent

53 Connection for sample loop

PEEK sample loop for anion analysis

56 Connection for sample loop

20 µL PEEK sample loop (6.1825.210)

57 Eluent outlet

Connection of preheating capillary 31

(PEEK, 6.1836.010)

58 Eluent inlet

PEEL capillary connection 29 to

pulsation absorber

59 Connection for sample loop

20 µL PEEK sample loop (6.1825.210)

817 Bioscan

26

Page 35

2.5 System for the analysis of anions and sugars – MIC-9

2.5.3 Configuration in IC Net 2.1

The complete IC system is installed in IC Net using the New system

wizard

:

1 762 IC Interface

2 732 IC Detector

3 817 Bioscan

4 709 IC Pump

817 Bioscan

27

Page 36

2 Installation

5 709 IC Pump

6 766 IC Sample Processor

7 733 IC Separation Center

8 753 Suppressor Module

817 Bioscan

28

Page 37

2.5 System for the analysis of anions and sugars – MIC-9

9 Second data recorder

10 Anion method and data source

11 System overview

12 Final settings

In the system window of the 753 Suppressor Module the option

Start pump with hardware should be activated under Manual.

817 Bioscan

29

Page 38

2 Installation

13 Bioscan method and data source

The Bioscan method and corresponding data source must be

selected in the

Setup menu which can be accessed by a right-

hand mouse click on the second data recorder symbol.

14 Connect system with workplace

Under SYSTEM / Control / Connect to workplace connect the

new system with the workplace.

At the same time the symbol

appears in the symbol bar.

15 Check measuring cell

If the 817 Bioscan is switched on without the flow-through cell

being constantly rinsed by a conducting eluent (e.g. 0.1 M

NaOH) then the measuring cell must not be switched on!

You should now check this in the instrument window of the 817

Bioscan (accessed with a double-click with the mouse on instrument symbol) under

Manual / Cell.

16 Check connections

You can now check the electronic connections to all modules.

This is done by double-clicking with the left-hand mouse key on

each instrument symbol. If the connection is functioning properly

then the current status of the instrument parameters will be

shown.

Remarks

• The event-line for the suppressor of the 753 Suppressor Module

is only set up as a "dummy connection" (Step 8). The real command for switching the suppressor further is made by the 766

Sample Changer via a remote line.

• For the installation described above the option

Stacked recorder icons

Options / Global preferences. This is why only a symbol for the

must be activated in IC Net 2.1 under

System face /

data recorder is visible in the system overview. With a right-hand

mouse click and the offered

Setup option the setting possibili-

ties described for both recorders man (Step 10 and Step 13)

can be accessed.

817 Bioscan

30

Page 39

2.5 System for the analysis of anions and sugars – MIC-9

Creating the time program

1. Input of the program for the 766 IC Sample Processor (Master):

001 Ctrl INIT

002 Move sample

003 Lift work

004 Ctrl ZERO 1

005 Ctrl FILL A 1

006 Ctrl STEP MSM 753

007 Ctrl FILL B/Step 1

008 Pump 120 s

009 Ctrl INJECT A 1

010 Ctrl INJECT B 1

− Initialize remote interface

− Move needle to sample position

− Move lift with needle to working height

− Trigger Autozero on 732 IC Detector

− Switch injection valve A on 733 to "Fill"

− Switch on 753 Suppressor-Module

− Switch injection valve B on 733 to "Fill"

− Fill sample loops A + B with sample for 120 s

− Switch injection valve A on 733 to "Inject"

− Switch injection valve B on 733 to "Inject"

1. Terminate the program entry by activating the program with

and store it in the system with

Save.

Enable

2. Finally check that in the IC system the 766 Sample Processor is entered under

Start with inject under Setup / Start mode.

Remarks

If only one of the detection pathways is to be used in this IC system

then the modules which are not required can be removed from the system (remove recorder and instrument symbols with the right-hand

mouse key and

However, please note that in this instrument configuration the recording

of the Bioscan data nevertheless begins only when the injection valve A

on the 733 IC Separation Center is switched from

is only a corresponding connection to the 762 IC Interface from this

valve (see Fig. 9). This means that even if only sugar analysis is to be

carried out, the 733 IC Separation Center and the 732 IC Detector must

still form part of the system described above. The program described

above for the 766 IC Sample Processor must then remain unchanged.

Unlink) and save the system under a new name.

Fill to Inject, as there

817 Bioscan

31

Page 40

2 Installation

2.6 Preparing the 817 Bioscan for the analysis

This section describes the necessary steps for preparing the 817 Bioscan to carry out an analysis. A more detailed description of the operation of the 817 Bioscan using IC Net 2.1 can be found in Section 3 and

in the ‘Instructions for Use’ of the 8.110.8221 Metrodata IC Net 2.1

software.

2.6.1 System switch-on

1 Mains on

Start up the individual instruments and the IC Net program in the

following sequence:

1. Computer

2. IC instruments

3. IC Net 2.1

2 Check measuring cell

For safety reasons check the status of the measuring cell in the

instrument window of the Bioscan (accessed by a double-click

with the mouse on the instrument symbol) under

Manual / Cell.

If the 817 Bioscan is switched on without the flow-through

measuring cell being constantly rinsed through a conducting

eluent (e.g. 0.1 M NaOH) or correctly connected up then the

measuring cell must not be switched on!

3 Check the external control of the 709 IC Pump

Depending on the control of the 709 IC Pump (MIC-8: manual;

combination with 762 IC Interface: external) the setting of the

external control of the IC Pump should be checked with key 8

<EXT.>.

2.6.2 Start pump

1 Column/ Eluent

With the Metrosep Carb 1 (6.1013.000) column use 0.1 M NaOH

(quality) as the eluent for sugar analysis. This should be made

up and degassed freshly every day; it should at least be degassed before use each day.

2 Flow rates / Pressure

The Metrosep Carb 1 column should not be subjected to large

variations in pressure. For this reason each time that the eluent

is used it should be pumped for a period of 10 minutes both

before and after use at 0.3 mL/min. For normal operation a flow

rate of1.0 mL/min is used.

Set a maximum pressure P

0.1 M NaOH this should establish a pressure of approx. 9 - 10

MPa with the Metrosep Carb 1.

817 Bioscan

32

of 15 MPa. At 1 mL/min and with

max

Page 41

2.6 Preparing the 817 Bioscan for the analysis

2.6.3 Set operating mode

1 Manual control of the 817Bioscan

• In the instrument window of the Bioscan (double-click with the

mouse on the instrument symbol) select

Mode: Pulse for

pulse amperometric detection.

• The cell must remain deactivated for as long no eluent flows

through the flow-through measuring cell.

• The oven is set to e.g. 32 °C. In general this temperature

should be at least 10 °C higher than the ambient room temperature.

817 Bioscan

33

Page 42

2 Installation

2 Parameters for the pulse mode

• Set these method parameters for the pulse mode. Please

note that this menu can only be accessed when the option

Pulse has been selected for Mode under Manual (see above).

• Finally transfer the current parameters to Bioscan with <

and use

System / Save to save them in the system file (*.smt).

The IC system with the 817 Bioscan is now ready for use.

Set>

817 Bioscan

34

Page 43

3.1 Handling the 817 Bioscan

3 Operation

3.1 Handling the 817 Bioscan

General

Amperometric detection takes place with a flowing current and therefore with a chemical conversion of the analyte. The course of a chemical reaction depends directly on various physical parameters, among

other things. In order to obtain optimum measuring conditions (e.g.

stable baseline or reproducible signals) it is necessary to take the following points into consideration. Further information can be found in

Section 4.2.

Constant temperature

The 817 Bioscan allows the interior of the instrument to be kept at a

constant temperature of up to max. 60°C. The lower limit is the ambient

temperature plus 10 °C. Under IC Net you should activate the appropriate oven-operating mode in the 817 method parameters and define the

temperature (see Section 3.2.2)

Constant pH

The characteristic current/potential curves of all electrochemically reactive substances depend very strongly on the pH of the pH eluent used.

This means that you should prepare the eluent very carefully and check

its pH at regular intervals.

Pulsation-free eluent flow

Changes to the eluent flow should be avoided as far as is possible. The

6.2620.150 Pulsation Absorber is available for this purpose; it is

mounted between the 709 IC Pump and the injection valve as described in Section 2.3.2.

Never make dry measurements

The flow-through measuring cell must not be switched on if it is not

being rinsed constantly by the eluent or if the measuring cell is not

connected up properly!

817 Bioscan

35

Page 44

3 Operation

3.2 Operation using «IC Net 2.1»

3.2.1 817 Bioscan icon

The 817 icon is available in the system window if an 817 Bio-

scan

has been installed with the New system wizard or by us-

ing the Setup/New devices/Install new device option of the

SYSTEM window (see section 2.4.2).

If the system is connected and the 817 icon is clicked with

the right-hand mouse button then the following menu appears:

Open Opens the 817 Bioscan window for parameter set-

tings (this window can also be opened by double-clicking the icon).

Unlink Deletes the 817 icon from the system.

817 Bioscan

36

Page 45

3.2 Operation using «IC Net 2.1»

3.2.2 817 Bioscan window

817 icon / Open

The 817 Bioscan window for parameter settings is opened by

selecting this menu option with the right-hand mouse button

or by double-clicking the 817 icon in the SYSTEM window. It

consists of the four tabs Manual, Method parameters, Program,

and Links.

Manual

The Manual tab of the 817 Bioscan window is only available

for a connected system.

817 Bioscan

Mode Selection of detector mode:

DC In the DC mode a constant potential is ap-

plied; the analytes are oxidized or reduced

in accordance with their electrochemical

properties.

Pulse The Pulse mode works with three different

potentials that are applied cyclically. This

frees the electrode surface from any adhering reaction products during each sweep

and an activated surface is produced for

the next measurement.

Scan The Scan mode allows potential/current

curves to be recorded.

37

Page 46

3 Operation

Cell Manual control of amperometric detector

cell:

<On> Switches on detector cell.

<Off> Switches off detector cell.

Attention

Switch on the detector cell only if a conducting eluent is being pumped through it continuously!

Oven Manual control of column oven (heater):

<On> Switches on oven.

<Off> Switches off oven.

Temperature Temperature of column oven.

Range:

15 ... 60 °C (> room temp. + 10 °C)

Control Manual setting of 4 remote lines.

<Set> Sets remote lines to selected states.

Aux1, Aux2, Cont1, Cont2

Setting of 4 remote lines.

Selection:

Valve Manual switching of the injection valve,

0, 1, *

e.g. at the 812 Valve Unit:

<Fill> Switches injection valve to "Fill" position

(control line Cont1 is set to 0).

<Inject> Switches injection valve to "Inject" position

(control line Cont1 is set to 1).

Analog output

Manual setting of the analog output signal

to zero. For RS232 data the full-scale range

(see next page) is shifted until the signal is

located in the center of this range again (s.

also Chapter 6.1).

<Zero> Triggers the autozero function.

Actual

Display of actual values.

Mode Display of current detector mode.

Cell Display of current cell state.

Oven

Control

817 Bioscan

38

Display of current oven state.

Display of current control line settings.

Page 47

3.2 Operation using «IC Net 2.1»

Method parameters

DC mode

The DC mode subtab of the Method parameters tab on the 817

Bioscan

window is used to set the parameters for the DC

mode. This window is only available if Mode has been set to

DC on the Manual tab.

Method data

Cell potential Electric potential applied to the amperomet-

ric detector cell in V

Range:

Oven Switches column oven on/off and sets op-

-2 ... +2 V.

erating temperature.

Range: 15 ... 60 °C (> room temp. + 10 °C)

Range Selection of measuring range:

pA 10 ... 5000 pA.

nA 0.1 ... 50 nA.

µA 0.01 ... 5 µA.

Full scale The full-scale range (operating range) sets

the desired sensitivity for the analog output.

The possible values of the full-scale range

depend on the preset measuring Range. For

RS232 data (IC Net 2.1), always the maximum settings should be used.

817 Bioscan

39

Page 48

3 Operation

Filter Electronic damping of the analog output

(REC) and RS232 signal.

Selection: 0.1, 0.2, 0.5, 1, 2, 5 s

Offset

Offset of the zero point.

Selection: -50 ... +50 % (in steps of 10 %)

Actual

Cell potential Display of current cell potential in V

Oven Display of current oven state.

Range Display of current measuring range.

Full scale Display of current full-scale range.

Filter Display of current damping constant.

Offset Display of current offset.

<Set> Sends current parameters immediately to

the 817 Bioscan. Parameters are not stored

in the system file (*.smt) as long as the file

is not saved.

817 Bioscan

40

Page 49

3.2 Operation using «IC Net 2.1»

Pulse mode

The Pulse mode subtab of the Method parameters tab on the

817 Bioscan window is used to set the parameters for the

pulse mode. This window is only available if Mode has been

set to Pulse on the Manual tab.

Method data

Cell Definition of three different working poten-

tials that are applied to the amperometric

detector cell cyclically. The set potentials

are graphically displayed if the Method option is enabled above the graphic window.

E1, E2, E3 Potentials.

Range: -2 ... +2 V.

t1, t2, t3 Time duration to apply the potentials.

Range: 0.01 ... 2 s

Sample time

Measuring time at the end of working po-

tential E1.

Selection: 20, 40, 60, 80, 100 ms

Oven Switches column oven on/off and sets op-

erating temperature.

Range: 15 ... 60 °C (> room temp. + 10 °C)

Range Selection of measuring range:

pA 10 ... 5000 pA.

nA 0.1 ... 50 nA.

µA 0.01 ... 5 µA.

817 Bioscan

In the Pulse mode, always the µA range

should be selected.

41

Page 50

3 Operation

Full scale The full-scale range (operating range) sets

the desired sensitivity for the analog output.

The possible values of the full-scale range

depend on the preset measuring

Range. For

RS232 data (IC Net 2.1), always the maximum settings should be used.

Offset Offset of the zero point.

Selection: -50 ... +50 % (in steps of 10 %)

Actual

E1, E2, E3 Display of current potentials in V.

t1, t2, t3 Display of current time durations for poten-

tials in s.

Sample time Display of current sample time in ms.

Oven Display of current oven state.

Range Display of current measuring range.

Full scale Display of current full-scale range.

Offset Display of current offset.

Cycle potentials Graphical display of cycle potentials.

Method Display of potentials set in the Method data

frame.

Actual Display of current potentials.

<Set> Sends current parameters immediately to

the 817 Bioscan. Parameters are not stored

in the system file (*.smt) as long as the file

is not saved.

817 Bioscan

42

Page 51

3.2 Operation using «IC Net 2.1»

Scan mode Parameters

The Scan mode subtab of the Method parameters tab on the

817 Bioscan window is used for parameter setting and curve

display for the scan mode. This window is only available if

Mode has been set to Scan on the Manual tab.

Method data

Cell potential Definition of start and end potential for a

user-defined potential sweep that is applied

to the amperometric detector cell.

E1 Start potential for sweep.

Range: -2 ... +2 V.

E2 End potential for sweep.

Range: -2 ... +2 V.

Scan cycle Definition of scan cycle:

full double scan E1 ... E2 ... E1

half single scan E1 ... E2

Selection: full, half

Scan rate Definition of scan rate in mV/s.

Selection: 1, 2, 5, 10, 20, 50 mV/s

Oven Switches column oven on/off and sets op-

erating temperature.

Range: 15 ... 60 °C (> room temp. + 10 °C)

Range Selection of measuring range:

pA 10 ... 5000 pA.

nA 0.1 ... 50 nA.

µA 0.01 ... 5 µA.

817 Bioscan

43

Page 52

3 Operation

Full scale The full-scale range (operating range) sets

the desired sensitivity for the analog output.

The possible values of the full-scale range

depend on the preset measuring

Range. For

RS232 data (IC Net 2.1), always the maximum settings should be used.

Offset Offset of the zero point.

Selection: -50 ... +50 % (in steps of 10 %)

Actual

E1, E2 Display of current start and end potentials

in V.

Scan cycle Display of current scan cycle mode.

Scan rate Display of current scan rate in mV/s.

Oven Display of current oven state.

Range Display of current measuring range.

Full scale Display of current full-scale range.

Offset Display of current offset.

<Set> Sends current parameters immediately to

Scan mode Operations

the 817 Bioscan. Parameters are not stored

in the system file (*.smt) as long as the file

is not saved.

817 Bioscan

44

Page 53

3.2 Operation using «IC Net 2.1»

Caption Possibility of entering a title that is written

at the head of the scan mode graphics

window.

Program

<Add date & time>

The current date and time are added to

the title defined in the Caption field.

State Display of current state.

<Start> Starts scan mode sweep.

<Stop> Stops scan mode sweep.

<Copy to clipboard> Copies the content of the scan mode

graphics window to the clipboard.

On the Program subpage, program steps including time,

program instruction and parameter can be entered.

First column Time at which program instruction is

applied.

Entry range: 0.0 ... 999.9 min

If no time is entered, the program instruction is applied to-

gether with the last instruction with time

entry.

Second column Program instruction (see below).

Third column Parameter for program instruction (see

below).

ENABLED Enable program start (a disabled pro-

gram is not started).

<Add> Add new program instruction.

<Delete> Delete selected program instruction.

<Verify> Test the time program (error messages

are displayed if program is wrong).

817 Bioscan

45

Page 54

3 Operation

List of program instructions

The following program instructions can be added to the time

program on the

Program subpage:

Instruction Parameter entry Meaning

Mode DC, Pulse, Scan

Cell On, Off Switch cell on/off.

Outputs 0, 1, * Set remote lines Aux1, Aux2, Cont1

Select detector mode.

and Cont2 to desired values. For entry

of the first value, enter

1, 0 or *. For

entry of the other values, move the

cursor in front of the value to be

changed and enter

Range pA: 10 pA – 5 nA

nA: 0.1 nA – 50 nA

µA: 10 nA – 5 µA

Offset -50, -40, -30,…50 % Set offset for measuring signal.

Valve Fill, Inject Switch connected injection valve.

Oven off, 15 ... 60 °C Set column oven temperature.

Autozero Trigger analog output signal auto

Set measuring range.

1, 0 or *.

zero.

DC_E -2 ... +2 V Set measuring potential (DC).

Filter 0.1, 0.2, 0.5 ... 5 s Set electronic damping for the

analog output signal.

Scan_E1 -2 ... +2 V Set sweep start potential E1.

Scan_E2 -2 ... +2 V Set sweep end potential E2.

Scan_Cycle half, full Select scan cycle type.

Scan_Rate 1, 2, 5, … 50 mV/s Set scan rate.

Links

The Links tab of the 817 Bioscan is used for COM port selection and settings (details see Section 5.2.4 in the Software

Manual for IC Net 2.1).

817 Bioscan

46

Page 55

4.1 Introduction

4 Basic principles

4.1 Introduction

The 817 Bioscan can be operated as an amperometric detector in

three different working modes:

• DC mode A constant potential is applied to the working elec-

trode. The analyte substances are oxidized or reduced according to their electrochemical properties.

The current that is produced is measured.

• Scan mode Current-potential curves are recorded in order to de-

termine the optimum parameters for pulsed amperometric detection. This is done by passing a solution that contains only the substance of interest

through the measuring cell and recording a currentpotential curve.

• Pulse mode Three different potentials are applied cyclically to

the working electrode. This frees the electrode surface from any adhering reaction products and reactivates it for the next measurement. As this is the

operating mode that is primarily used with the 817

Bioscan for carbohydrate analysis it is described in

detail in Section 4.2.

817 Bioscan

47

Page 56

4 Basic principles

4.2 Measuring conditions

Amperometric detection takes place with a flowing current and therefore with a chemical conversion of the analyte. The course of a chemical reaction depends directly on various physical parameters, among

other things. In order to obtain optimum measuring conditions (e.g.

stable baseline or reproducible signals) it is necessary to take the following points into consideration:

• Temperature The reactions occurring at the working electrode

(oxidation and reduction) are influenced by the temperature. However, this applies not only to the conversion of the analyte, but also for interfering reactions that produce the background current. This is

the reason why a constant temperature is a necessary precondition for obtaining a stable baseline

and reproducible signals. For the determination of

carbohydrates, lower temperatures (30 °C – 35 °C)

are suitable. Furthermore, the flowcell should not be

operated above 45 °C over a longer time period.

• pH Just like the temperature, the pH of the eluent also

has a direct influence on the electrochemical reactions at the working electrode. pH alterations cause

a displacement of the characteristic current/potential curves (voltammograms). Possible results are

the reduction of the signal intensity and lower signal/noise ratios. In order to ensure that a stable

baseline and reproducible measuring conditions are

obtained care should be taken that the pH of the

eluent is correct.

• Pulsation Electrochemical reactions at the electrode surfaces

depend on the transport of the reacting substances

to the electrode. This is why a constant eluent flow

is crucial, both for a stable baseline and also for reproducible signals. This is why pulsation-free eluent

supply must be ensured. You should use the pulsation absorber provided (see Section 2.3.2).

817 Bioscan

48

Page 57

4.3 Pulsed amperometric detection

4.3 Pulsed amperometric detection

During an amperometric determination the reaction products formed on

the working electrode can alter its surface properties by adsorption. In

pulsed amperometric detection (PAD) it is possible to apply further potentials cyclically in addition to the detection potential in order to ensure

a constant electrode surface. In this way the electrode surface is renewed after each current measurement and remains in this activated

condition.

The exact potential steps are shown in Fig. 11 as a function of time.

Fig. 11: Potentials applied during pulsed amperometric detection (PAD)

The working potential E1 is applied during the time t1 with the signal

being measured in ts. The high positive potential E2 causes the oxidative removement of reaction products from the electrode surface, which

is reduced to a pure Au-surface during t3.

4.3.1 Optimization of the PAD parameters

When adapting the method parameters the preset parameters should

initially be used. Descriptions of various applications are available from

Metrohm AG in the form of Application Works and Application Notes.

These can be obtained from your local Metrohm agency or on the Internet under www.metrohm.com

The potential profile shown in Fig. 11 must always be matched to the

analyte under investigation. 7 parameters must be taken into account:

potentials E1, E2 and E3, time intervals t1, t2 and t3 and the measuring

time ts. Some basic conditions are preset; this makes configuration

easier. These are described below.

.

2.0 1.0

817 Bioscan

49

Page 58

4 Basic principles

Measuring interval (E1, t1 and ts)

The measuring potential depends on the substance being investigated.

If no data is available in the literature that can initially be used for optimization then you can determine these parameters yourself. For this

reason Bioscan has the scan mode available, among other things. Recording the corresponding voltammograms is described in Section 4.4.

As each change in potential can cause a higher charging current to occur at the working electrode, the current measurement itself is only

started when the signal has stabilized itself to a large extent. This time

is defined as t1 – ts (see Fig. 11). It influences the level of the background current and should therefore be selected so that it is not too

small. In practice a time of 0.1 to 0.4 s is frequently used.

The measuring interval ts can be set to 20, 40, 60, 80 or 100 ms. These

values correspond to multiples of 50 Hertz. In this way possible interference from the mains current supply can be avoided.

Regeneration interval (E2, E3, t2 and t3)

The potentials E2 and E3 which are required for the regeneration of the

electrode surface are primarily determined by the material of the working electrode.

With the gold electrode used the oxide layer is already formed at E2 >

+200 mV (Ag/AgCl) under alkaline conditions. Higher potentials accelerate oxide formation, therefore in practice E2 = +750 mV and t2 = 0.2

s are often selected.

For example, –800 mV at 0.2 s or –150 mV at 0.4 s can be selected for

E3 and t3.

Measuring frequency

In pulsed amperometric detection the total of the three individual intervals (t1 + t2 + t3) represents the duration of one measuring cycle. The

reciprocal of this cycle duration (in seconds) gives the pulse fre-

quency. Please note that the measured value is outputted from the detector at this pulse frequency. The sampling frequency which otherwise has to be set under IC Net for data acquisition (

M

ethod setup / Measure / Sampling rate and Frequency divisor) is

automatically adapted accordingly.

IC NET / Method /

817 Bioscan

50

Page 59

4.4 Optimization of the measuring potential

4.4 Optimization of the measuring potential

An optimization of the measuring potential for amperometric detection

may bring benefits in the following situations:

a) The sensitivity of the detection of the analyte is to be increased

against the background signal.

b) The selectivity of the detection is negatively affected by the analyte

peak overlapping with a second substance peak that has not been

optimally separated by chromatography.

If there are no suitable literature data available, this requires the recording of a voltammogram. This is a curve showing the relationship

between the given potential and the measured current. It is characteristic for individual chemical substances or even whole classes of substances.

There are two different types of voltammograms, each of which is suitable for solving a different problem: a hydrodynamic voltammogram

and a scan voltammogram.

Fig. 12

A hydrodynamic voltammogram is made of several chromatograms

recorded in the DC mode. This involves recording a chromatogram of

the substance under investigation, dissolved in eluent, at a constant potential. The potential is now varied several times and the process is repeated. Finally the height of the current peak obtained is evaluated and

plotted against the particular potential. Fig. 12 shows a schematic example of such a hydrodynamic voltammogram:

I

: Example of a hydrodynamic voltammogram of a substance (A)