Page 1

CH-9101 Herisau/Schweiz

Internet www.metrohm.com

E-Mail info@metrohm.ch

812 Valve Unit

812 Valve Unit

Metrohm

FILL IN JECT

A

FILL IN JECT

B

8.812.1003 Instructions for Use

16.11.2001 / dö

Page 2

Table of contents

Table of contents

1 Introduction ..................................................................................1

1.1 Instrument description .................................................................1

1.2 Parts and controls.........................................................................2

1.3 Information on the Instructions for Use.....................................4

1.3.1 Organization .........................................................................4

1.3.2 Notation and pictograms......................................................5

1.4 Safety notes ...................................................................................6

2 Installation.....................................................................................7

2.1 Setting up the instrument ............................................................7

2.1.1 Packaging.............................................................................7

2.1.2 Check ...................................................................................7

2.1.3 Location................................................................................7

2.1.4 Arrangement of the instruments...........................................7

2.2 Mains connection ..........................................................................8

2.3 Electrical connection ....................................................................8

2.3.1 Connection at the 762 IC Interface.......................................8

2.3.2 Connection at 817 Bioscan ..................................................9

2.4 Connections at injection valve..................................................10

2.4.1 General information ............................................................ 10

2.4.2 Attaching standard accessories.........................................10

2.5 Software installation ...................................................................12

3 Operation......................................................................................13

3.1 Manual operation.........................................................................13

3.2 Operation via «IC Net»................................................................14

3.2.1 812 Valve Unit icon.............................................................14

3.2.2 Settings in the "812 Valve Unit" window..............................14

4 Appendix .......................................................................................17

4.1 Technical data..............................................................................17

4.2 Standard equipment....................................................................19

4.3 Optional accessories ..................................................................20

4.4 Warranty and conformity ...........................................................21

4.4.1 Warranty .............................................................................21

4.4.2 EU Declaration of conformity..............................................22

4.4.3 Certificate of conformity and system validation .................23

4.4 Index ..............................................................................................24

812 Valve Unit

I

Page 3

Table of contents

List of figures

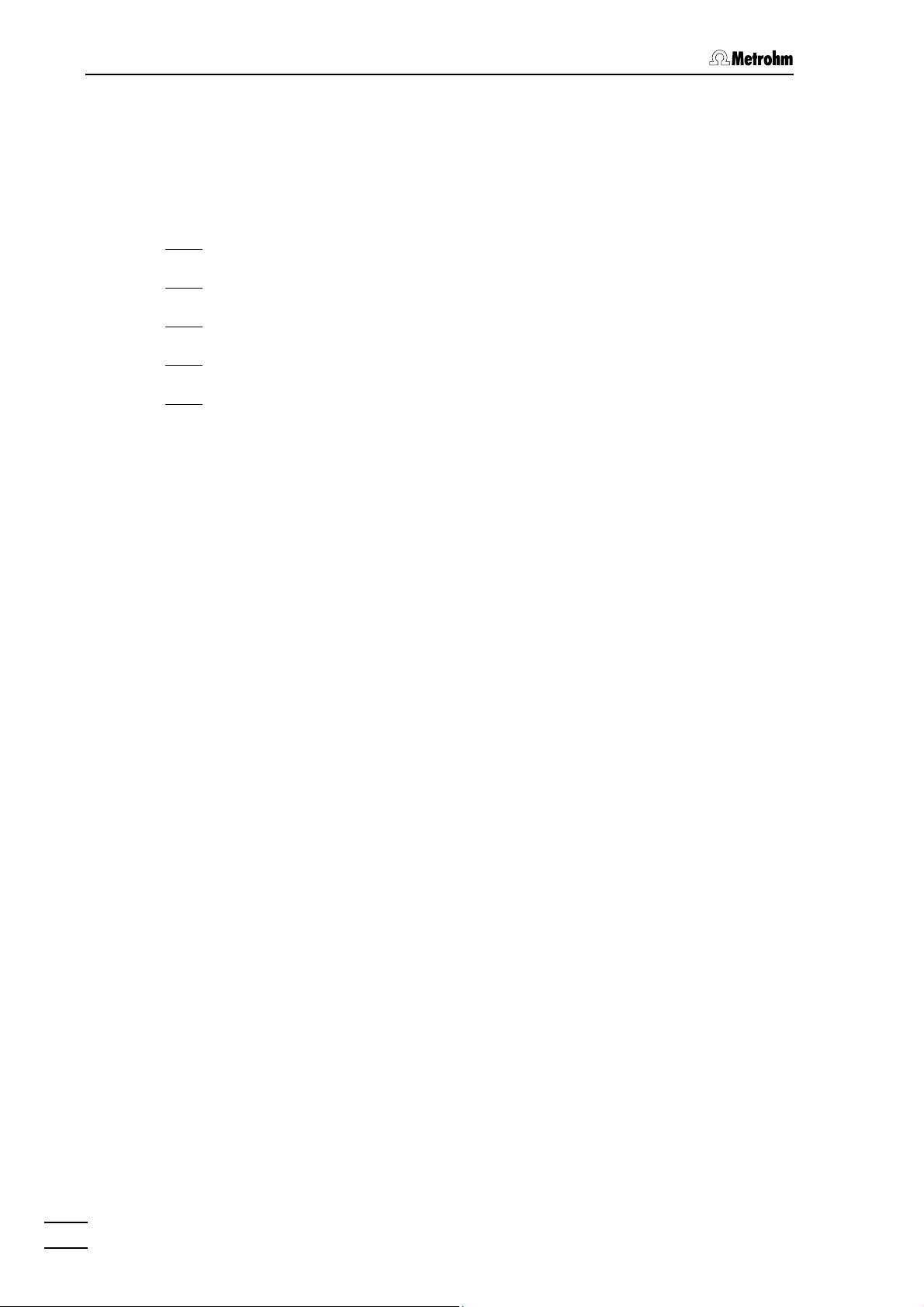

Fig. 1: Front of 812 Valve Unit........................................................................... 2

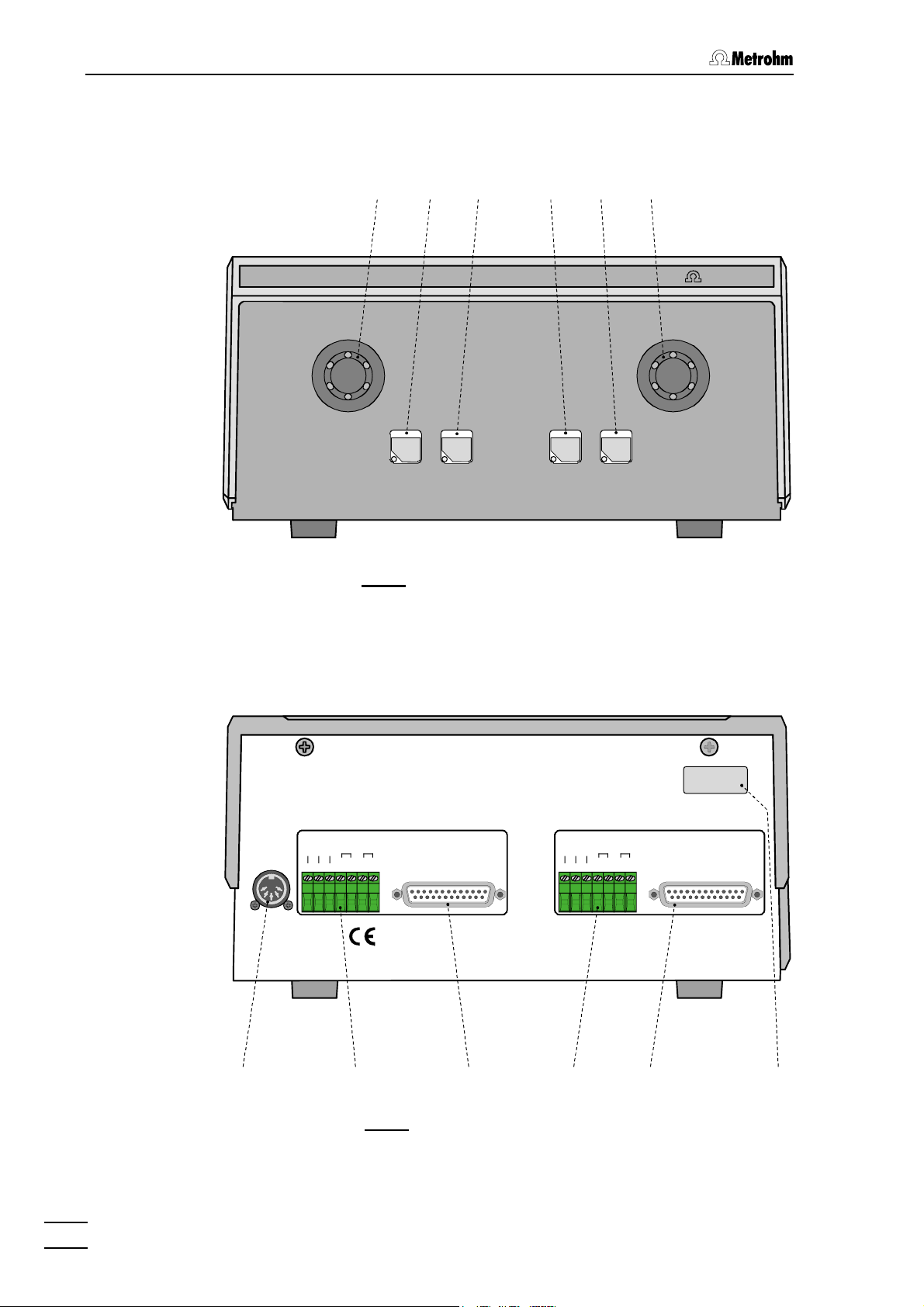

Fig. 2

: Rear of 812 Valve Unit ........................................................................... 2

Fig. 3

: Connection of 812 Valve Unit at 762 IC Interface...................................... 9

Fig. 4

: Switching of injection valves................................................................. 10

Fig. 5

: Connection at injection valve................................................................ 11

812 Valve Unit

II

Page 4

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 812 Valve Unit is an instrument with one or two electrically driven

ein 6-port injector valves. Two different versions of the 812 Valve Unit

are available:

2.812.0010 Valve Unit with 1 valve

2.812.0020 Valve Unit with 2 valves

Valve parts in contact with the eluent are manufactured out of PEEK

material. The instrument is equipped with an external power supply so it

can be operated as a stand alone unit and is independent of other

Metrohm devices.

The 812 Valve Unit can be used for a variety of different applications:

• In combination with the 817 Bioscan or the 791 VA Detec-

tor, the 812 Valve Unit is used as the injector for the systems.

• With the 812 Valve Unit, a 761 Compact IC can be up-

graded to be a combined anion an cation system.

• In combination with the 816 Eluent Selector, the 2-port

version can be used for automatic column switching with

an intermediate rinsing step.

• The 812 Valve Unit can also be used in a large variety of

sample preparation techniques, like for cutting techniques, or switching between different sample streams.

812 Valve Unit

1

Page 5

1 Introduction

1.2 Parts and controls

812 Valve Unit

3

21 4

FILL INJECT

A

: Front of 812 Valve Unit

Fig. 1

65

Metrohm

FILL INJECT

B

Type: 1.812.00X0

Nr.: XX XXX

External

Power

24VDC/2A

5VDC/0,5A

.

d

n

u

o

r

G

r

t

g

t

.

r

e

s

c

a

l

t

l

l

l

i

F

t

o

e

i

j

n

S

F

I

P

n

I

M

N

M

N

O

U

O

U

R

C

R

732 IC Detector

C

B

978

d

n

u

o

r

G

10 11 12

.

r

t

g

t

.

r

e

s

c

a

l

t

l

l

l

i

F

t

o

e

i

j

n

S

F

I

P

n

I

N

M

M

N

U

O

O

U

R

C

C

R

Made by Metrohm Herisau Switzerland

A

732 IC Detector

Fig. 2

: Rear of 812 Valve Unit

812 Valve Unit

2

Page 6

1.2 Parts and controls

1 Valve A 7 Connection for external supply

connection of power supply unit

(5 V, 0.5 A / 24 V, 2 A)

2 "FILL" key for valve A 8 Terminal block for valve B

(without function for 2.812.0010

instrument version)

Ground, Fill, Inject:

inputs for control of the valve

Pos.Fill:

output signal on switching of the

valve to position "FILL"

Integr.Start:

output signal on switching of the

valve to position "INJECT"

3 "INJECT" key for valve A 9 Connection for 732 IC Detector B

(without function for 2.812.0010

instrument version)

4 "FILL" key for valve B

(without function for 2.812.0010

instrument version)

10 Terminal block for valve A

Ground, Fill, Inject:

inputs for control of the valve

Pos.Fill:

output signal on switching of the

valve to position "FILL"

Integr.Start:

output signal on switching of the

valve to position "INJECT"

5 "INJECT" key for valve B

11 Connection for 732 IC Detector A

(without function for 2.812.0010

instrument version)

6 Ventil B

(not available for 2.812.0010

12 Model plate

with serial number

instrument version)

812 Valve Unit

3

Page 7

1 Introduction

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 812 Valve Unit into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instrument.

1.3.1 Organization

These 8.812.1003 Instructions for Use for the 812 Valve Unit provide

a comprehensive overview of the installation, startup procedure, operation and technical specifications of this instrument. The Instructions for

Use are organized as follows:

Section 1 Introduction

General description of instrument, parts and controls

and safety notes

Section 2 Installation

Mains connection, electrical connection,

connection of accessories

Section 3 Operation

Manual operation and operation via «IC Net»

Section 4 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments you will find it an

advantage to use either the Table of contents or the Index at the

back.

812 Valve Unit

4

Page 8

1.3 Information on the Instructions for Use

1.3.2 Notation and pictograms

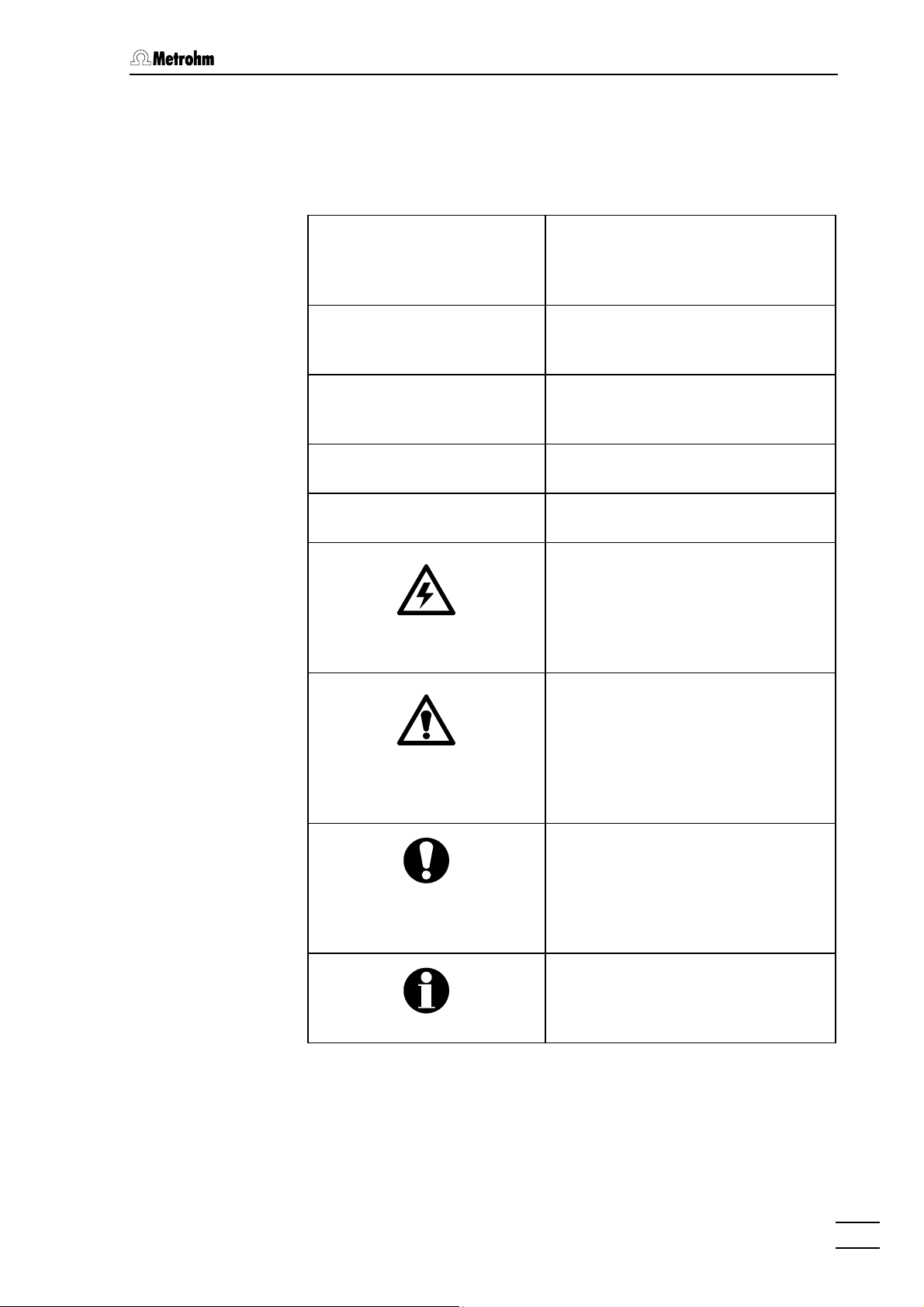

The following notations and pictograms (symbols) are used in these Instructions for Use:

Range Menu item, parameter or entry

value

in «IC Net» program

SYSTEM STATE Program window

in «IC Net» program

<OK> Button

in «IC Net» program

[ FILL ] Switch or key

7 Part or control of 812

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important

information. First read the associated directions before you continue.

812 Valve Unit

Comment

This symbol marks additional

information and tips.

5

Page 9

1 Introduction

1.4 Safety notes

While electrical safety in the handling of the 812 Valve Unit is assured in

the context of the specifications IEC 61010-1 (protection class 1), the

following points should be noted:

• Mains connection

The mains connection must be effected in accordance with the

instructions in section 2.2.

• Opening the instrument

Inside the instrument there are no parts which must be set or adjusted

by the user.

If the 812 Valve Unit is connected to the power supply, the instrument

must not be opened nor must parts be removed from it. Hence,

before opening the instrument, always ensure that the power supply

unit is disconnected from connection 7!

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 812 Valve Unit, you should earth yourself and any tools you

are using by touching an earthed object (e.g. housing of the instrument or a radiator) to eliminate any static charges which exist.

812 Valve Unit

6

Page 10

2.1 Setting up the instrument

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 812 Valve Unit is supplied together with the separately packed accessories in special packagings containing shock-absorbing foam linings designed to provide excellent protection. The instrument itself is

packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of accessories in section 4.2). In the case of transport damage, see instructions in section 4.4.1 "Warranty".

2.1.3 Location

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

2.1.4 Arrangement of the instruments

The 812 Valve Unit can be piled up together with other IC instruments

(e.g. 732, 733, 709).

812 Valve Unit

7

Page 11

2 Installation

2.2 Mains connection

The 812 Valve Unit is operated with the 6.2152.000 Power supply unit

which automatically adjusts itself to the existing mains voltage

(100…240 V) and frequency (50…60 Hz).

The power supply unit is connected to the mains using one of the following mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin.

The cable permanently mounted to the power supply unit is plugged

into connection 7 at the 812 Valve Unit (see Fig. 2). The operational

readiness is shown by the LEDs lighting up on the "FILL" or "INJECT"

keys.

2.3 Electrical connection

2.3.1 Connection at the 762 IC Interface

Always switch off 762 IC Interface and 812 Valve Unit before you

connect the two instruments.

The connection of the 812 Valve Unit at the 762 IC Interface enables the

three following functions:

• Control of valve A by the 762 IC Interface

via remote line

• Control of valve B by the 762 IC Interface

via remote line

• Automatic start of data acquisition at the

762 IC Interface by switching valve A or valve B

to the "INJECT" position

For instrument connection proceed as follows (see Fig. 3):

1 Connection for control of valve A

• Connect the plugs inscribed with "GND", "INJECT" and "FILL"

of the 6.2128.100 cable to the connections "Ground", "Fill"

and "Inject" on the terminal block 10 of the 812 Valve Unit

(see Fig. 2).

• Connect the plug inscribed with "Inject NO" of the 6.2128.100

cable to the desired remote line 1...7 "Events - Run" at the

762 IC Interface and the plug inscribed with "Inject COM" to

the same remote line "Events - COM" (see Fig. 5 Instructions

for use 762).

812 Valve Unit

8

Page 12

2.3 Electrical connection

6.2128.100

6.2128.100

6.2115.070

BA

812762

Fig. 3

: Connection of 812 Valve Unit 812 at 762 IC Interface

• Connect the plug inscribed with "LOAD NO" of the

6.2128.100 cable at the desired remote line 1...7 "Events -

Run" at the 762 IC Interface and the plug inscribed with

"LOAD COM" to the same remote line "Events - COM" (see

Fig. 5 Instructions for use 762).

2 Connection for control of valve B

• Connect the plugs inscribed with "GND", "INJECT" and "FILL"

of the 6.2128.100 cable to the connections "Ground", "Fill"

and "Inject" on the terminal block 8 of the 812 Valve Unit (see

Fig. 2).

• Connect the plug inscribed with "Inject NO" of the 6.2128.100

cable to the desired remote line 1...7 "Events - Run" at the

762 IC Interface and the plug inscribed with "Inject COM" to

the same remote line "Events - COM" (see Fig. 5 Instructions

for use 762).

• Connect the plug inscribed with "LOAD NO" of the

6.2128.100 cable at the desired remote line 1...7 "Events -

Run" at the 762 IC Interface and the plug inscribed with

"LOAD COM" to the same remote line "Events - COM" (see

Fig. 5 Instructions for use 762).

3 Connection for external start (option)

• Connect the 6.2115.070 cable to the connections "Integr.

Start - RUN" and "Integr. Start - COM" on the terminal block

10 (valve A) or 8 (valve B) of the 812 Valve Unit (see Fig. 2).

• Connect the other end of the 6.2115.070 cable to the remote

lines "Events - Start - Run" and "Events - Start - Com" at

the 762 IC Interface (see Fig. 5 Instructions for use 762).

2.3.2 Connection at 817 Bioscan

The connection of the 812 Valve Unit to the 817 Bioscan is described in

detail in the Instructions for Use 817.

812 Valve Unit

9

Page 13

2 Installation

2.4 Connections at injection valve

2.4.1 General information

The two six-way valves at the 812 Valve Unit each have 6 connections

for capillaries which are switched as follows:

Fill

45

36

12

: Switching of injection valves

Fig. 4

Connections 1 and 2 of the valve are normally used for supply of sample solution, connections 4 and 5 for eluent supply, and connections 3

and 6 for sample loop installation. For solution supply in the low pressure range (sample feed by use of a syringe or a peristaltic pump), the

6.1803.020 PTFE capillary (i.d. 0.97 mm) is used; in the high pressure

range, the 6.1831.010 PEEK capillary (i.d. 0.25 mm) is used. For both

capillaries, a 6.2744.010 PEEK compression fitting is used as connector.

Inject

45

36

12

2.4.2 Attaching standard accessories

The standard accessories supplied with the 812 Valve Unit can be used

to equip one valve for manual filling of the sample loop. Proceed as follows (see Fig. 5):

1 Connecting the syringe

• Cut off a piece of the 6.1803.020 PTFE capillary to the de-

sired length (at best using the optionally available 6.2621.080

tubing cutter) and fit it on both sides with a 6.2744.010 PEEK

compression fitting (do not tighten too firmly).

• Screw one end of the PTFE capillary 13 to connection 1 of

the injection valve.

• Screw the other end of the PTFE capillary 13 to the

6.2744.120 coupling.

• Push 6.2816.020 syringe (without needle) as far as it will go

into the connection of the 6.2744.120 coupling.

812 Valve Unit

10

Page 14

2.4 Connections at injection valve

17 16

Fig. 5

Syringe tubing

13

6.1803.020 PTFE tubing with

6.2744.120 coupling and

6.2816.020 syringe

14 Aspirating tubing

6.1803.020 PTFE tubing for

aspirating the sample

15 Sample loop

6.1825.210 PEEK sample

loop (20 µL )

45

15

36

21

13 14

: Connection at injection valve

16 Eluent outlet

6.1831.010 PEEK

capillary

17 Eluent inlet

6.1831.010 PEEK

capillary

2 Connecting the aspirating tubing

• Cut off a piece of the 6.1803.020 PTFE capillary to the de-

sired length (at best using the optionally available 6.2621.080

tubing cutter) and fit it on one side with a 6.2744.010 PEEK

compression fitting (do not tighten too firmly).

• Screw this end of the aspirating tubing 14 to connection 2 of

the injection valve.

3 Connecting the sample loop

• Fit the 6.1825.210 sample loop on both sides with a

6.2744.010 compression fitting.

• Screw the sample loop 15 (20 µL) to connections 3 and 6 of

the injection valve.

4 Connecting the eluent supply

• Screw the PEEK capillary 17 for eluent supply from the high

pressure pump to connection 5 of the injection valve.

5 Connecting the separating column

• Screw the PEEK capillary 16 for eluent supply to the separat-

ing column to connection 4 of the injection valve.

812 Valve Unit

11

Page 15

2 Installation

2.5 Software installation

The PC program «IC Net 2.1» is required for the operation of the 812

Valve Unit by a PC. This program runs under Windows 95, Windows 98,

Windows NT and Windows 2000 operating systems and is installed according to section 1.4.2 of the «IC Net» Instructions for Use.

The installation of the 812 Valve Unit is described in section 6.11 of the

«IC Net» Instructions for Use.

812 Valve Unit

12

Page 16

3.1 Manual operation

3 Operation

3.1 Manual operation

FILL

Switch instrument on/off

The 812 Valve Unit is switched on and off by connecting/disconnecting the 6.2152.000 power supply unit attached to

connection 7 (see section 2.2).

After the instrument has been connected to the mains the LEDs

on the "FILL" or "INJECT" keys light up and show that the

instrument is ready for use.

Switch to "FILL" position

By pressing the "FILL" key, the injection valve A or B is switched

to the "FILL" position.

Lighting up of the LED in the "FILL" key indicates the "FILL"

position.

Fill

45

36

12

INJECT

Switch to "INJECT" position

By pressing the "INJECT" key, the injection valve A or B is

switched to the "INJECT" position.

Lighting up of the LED in the "INJECT" key indicates the "INJECT"

position.

Inject

45

36

12

812 Valve Unit

13

Page 17

3 Operation

3.2 Operation via «IC Net»

This section describes only the most important points concerning the

operation of the 812 Valve Unit. For further details please refer to the

«IC Net» Instructions for Use and to the on-line help in the PC program.

3.2.1 812 Valve Unit icon

2.812.0010 Valve Unit

with 1 injector

2.812.0020 Valve Unit

with 2 injectors

3.2.2 Settings in the "812 Valve Unit" window

The 812 Valve Unit window for parameter settings is opened by selecting

Open menu option with the right mouse button or by double-clicking

the

the 812 icon in the system window. It consists of the three tabs

Program and Links.

Manual

The Manual tab of the 812 Valve Unit window is used for manual operation of the injection valves.

Manual,

812 Valve Unit

14

Page 18

3.2 Operation via «IC Net»

Valve A

<Fill> Switch valve A to "FILL" position.

<Inject> Switch valve A to "INJECT" position.

Valve B

<Fill> Switch valve B to "FILL" position.

<Inject> Switch valve B to "INJECT" position.

Time program

On the Program tab of the 812 Valve Unit window a user-defined time

program can be entered. This program starts automatically as defined

Start mode window either at the moment the determination is star-

in the

Start with determination) or at the moment the sample is injected

ted (

Start with inject).

(

Time (1st column) Time at which program instruction is applied.

Range:

If no time is entered, the program instruction is

applied together with the last instruction with

time entry.

Instruction (2nd column) Program instruction (see below).

Parameter (3rd column) Parameter for program instruction (see below).

ENABLED Enable program start (a disabled program is

not started).

<Add> Add new program instruction.

<Delete> Delete selected program instruction.

<Verify> Test the time program (error messages are dis-

played if program is wrong).

0.0 ... 999.9 min

812 Valve Unit

15

Page 19

3 Operation

List of program instructions

The following program instructions can be added to the time program

on the

Instruction Parameter entry Meaning

ValveA fill, inject Switch injection valve A to "inject" or

ValveB fill, inject Switch injection valve B to "inject" or

Program page:

"

fill" position.

"

fill" position.

Links

The Links tab of the 812 Valve Unit window is used for COM port selection and settings (details see IC Net Instructions for Use).

812 Valve Unit

16

Page 20

4.1 Technical data

4 Appendix

4.1 Technical data

Parts and controls

Keypad

Chemically resistant membrane keypad made of

polyester with function keys

Indicators LEDs for display of valve position

Power supply

External External supply via DIN connector:

5 V / 0.5 A

24 V / 2 A (transient, 200…300 ms)

6

3

5

7

1

4

2

1 +5 V DC / 0.5 A

2 not assigned

3 +24 V DC / 2 A

4 0 V (digital) *

5 0 V (analog) *

6 Ground

7 Ground

* Pin 4 and Pin 5 must be

connected in the vicinity

of the power source ("zero

point of star")

Valve interfaces

Connection Function

Inputs

0V

10k

10k

Ω

Ω

Ground Ground

+5V

Fill

+5V

Inject

Valve → "FILL"

Valve is switched to the "FILL"

position

Valve → "INJECT"

Valve is switched to the "INJECT"

position

H

L

H

L

> 2 ms

t

P

> 2 ms

t

P

Outputs

COM

RUN

COM

RUN

Position "Fill"

A pulse is outputted when the

valve is switched to the "FILL"

position.

Integrator Start

A pulse is outputted when the

valve is switched to the "INJECT"

position.

H

L

H

L

≅ 250 ms

t

P

≅ 250 ms

t

P

812 Valve Unit

17

Page 21

4 Appendix

Safety specifications

Safety notes The Instructions for Use include information and

warnings, which must be heeded by the user to

assure safe operation of the instrument.

Electromagnetic compatibility (EMC)

Emitted interference Standards met:

EN 50081-1/2, EN55022 (class B)

Immunity to interference Standards met:

EN50082-1

IEC61000-4-2 (class 3)

IEC61000-4-4 (class 4)

IEC61000-4-11

IEC61000-4-14 (class 3)

Ambient temperature

Nominal operating range +5…+45°C

(at 20…80 % atmospheric humidity)

Storage, Transport –40…+70°C

Housing

Material of cover Polyurethane rigid foam (PUR) with fire protection

for fire class UL94VO, FCH-free

Material of base Steel, enameled

Dimensions

Width 255 mm

Height 128 mm

Depth 365 mm

Weight (with accessories) 2.812.0010: 4.3 kg

2.812.0020: 5.1 kg

812 Valve Unit

18

Page 22

4.2 Standard equipment

4.2 Standard equipment

Subject to changes !

All dimensions are given in mm.

The 812 Valve Unit is available in two versions:

• 2.812.0010 Valve Unit with 1 valve

• 2.812.0020 Valve Unit with 2 valves

These instruments include the following parts:

Quant. Order No. Description

2.812.0010

2.812.0020

1 - 1.812.0010 Valve Unit with 1 valve

- 1 1.812.0020 Valve Unit with 2 valves

1 1 6.1803.020 PTFE capillary

Length L = 5 m

1 1 6.1825.210 Sample loop aus PEEK (20 µL)

for injection valve; incl. 2 PEEK

compression fittings (6.2744.010)

1 1 6.1831.010 PEEK capillary

Length L = 3 m

Diameter d = 0.25 mm

812 Valve Unit

1 1 6.2122.0X0 Mains cable

to customer's specifications:

Cable socket

Type IEC 320/C 13 Type SEV 12 (CH…)............................... 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…)........................... 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) ...................... 6.2122.070

1 2 6.2128.100 Connecting cable

For connection 812 – 762/817

1 1 6.2152.000 Power supply unit

1 2 6.2744.010 PEEK compression fitting

For the connection of 6.1831.010 PEEK

capillaries or 6.1803.020 PTFE capillaries,

set of 5

Cable connector

26

19

Page 23

4 Appendix

Quant. Order No. Description

2.812.0010

2.812.0020

1 1 6.2744.120 Coupling 1⁄16" – Luer

Coupling between 6.2744.010 PEEK

compression fitting and 6.2816.020

Syringe

1 1 6.2816.020 Syringe

made of PP, volume = 10 mL;

for manual filling of the sample loop

1 1 8.812.1003 Instructions for Use (English)

for 812 Valve Unit

22

76

4.3 Optional accessories

Order No. Description

6.1825.XXX Sample loop made of PEEK

For injection valve; incl. 2 PEEK compression

fittings (6.2744.010)

6.1825.230: volume = 10 µL

6.1825.210: volume = 20 µL

6.1825.220: volume = 100 µL

6.2115.070 Cable

Connection cable 812/762 for external start

6.2621.080 Capillary tubing cutter

for 6.1831.010 PEEK capillaries and

6.1803.020 PTFE capillaries

incl. 5 additional blades

55

118

812 Valve Unit

20

Page 24

4.4 Warranty and conformity

4.4 Warranty and conformity

4.4.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error that occur within 12

months from the day of delivery. In this case, the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks, which are not a result of material or manufacturing faults, are also charged during the warranty period. For parts of

outside manufacture insofar as these constitute an appreciable part of

our instrument, the warranty stipulations of the manufacturer in question

apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as the

absence of guaranteed features, the orderer has no rights or claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report demanded.

Lack of an official damage report releases Metrohm from any liability to

pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedment in

wood shavings or similar material, the parts must be packed in a dustproof package (for instruments, use of a plastic bag is imperative). If

open assemblies are enclosed in the scope of delivery that are sensitive to electromagnetic voltages (e.g. data interfaces etc.) these must

be returned in the associated original protective packaging (e.g. conductive protective bag). (Exception: assemblies with built-in voltage

source belong in a non-conductive protective packaging). For damage,

which arises as a result of non-compliance with these instructions, no

warranty responsibility whatsoever will be accepted by Metrohm.

812 Valve Unit

21

Page 25

4 Appendix

4.4.2 EU Declaration of conformity

EU Declaration of Conformity

The METROHM AG company, Herisau, Switzerland hereby certifies, that the

instrument:

812 Valve Unit

meets the requirements of EC Directives 89/336/EEC and 73/23/EEC..

Source of the specifications:

EN 50081-1/2 Electromagnetic compatibility, basic specification;

Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification;

Interference Immunity

Description of the instrument:

Instrument with 1 or 2 electrically driven six-way valves.

Herisau, April 4, 2001

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

812 Valve Unit

22

Page 26

4.4 Warranty and conformity

4.4.3 Certificate of conformity and system validation

Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well as to the standard specifications for security and

to system validation issued by the manufacturing company.

Name of commodity: 812 Valve Unit

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

Principal technical information: Voltages: 100-240 V

Frequency: 50-60 Hz

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

EN50081-1/2, EN50082-1, EN55022 (class B), IEC61000-4-2 (class 3),

IEC61000-4-4 (class 4), IEC61000-4-11, IEC61000-4-14 (class 3)

— Electromagnetic compatibility

It has also been certified by the Swiss Electrotechnical Association (SEV), which

is member of the International Certification Body (CB/IEC).

The technical specifications are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for

quality assurance in design/development, production, installation and servicing.

Herisau, April 4, 2001

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

812 Valve Unit

23

Page 27

4 Appendix

4.5 Index

A

Ambient temperature............................ 18

Appendix............................................... 17

Arrangement of the instruments..............7

Aspirating tubing 14

Figure................................................ 11

Installation......................................... 11

Attaching standard accessories .......... 10

C

Cable (6.2115.070)............................ 9,20

Cable (6.2128.100)......................... 8,9,19

Capillary tubing cutter

(6.2621.080) ................................ 10,20

Caution ....................................................5

Certificate of conformity and

system validation.............................. 23

Check ......................................................7

Comment.................................................5

Conformity ............................................ 22

Connection

Aspirating tubing .............................. 11

Bioscan 817.........................................9

Eluent supply.................................... 11

Sample loop ..................................... 11

Separating column ........................... 11

Syringe.............................................. 10

Connection 7

Connect power supply unit .................8

Figure...................................................3

Connection 9

Figure...................................................3

Connection 11

Figure...................................................3

Connections at injection valve ............. 10

Coupling (6.2744.120).......................... 20

D

Declaration of conformity ..................... 22

Dimensions........................................... 18

E

Earthing ............................................... 6,8

Electrical connection ...............................8

Electrical safety........................................6

Electromagnetic compatibility.............. 18

Eluent inlet 17

Figure................................................ 11

Eluent outlet 16

Figure................................................ 11

EMC ...................................................... 18

Emitted interference ............................. 18

EU Declaration of conformity ............... 22

F

Front ........................................................2

H

Hazard.....................................................5

Housing .................................................18

I

Immunity to interference .......................18

Information on the

Instructions for Use ............................. 4

Installation ...............................................7

Instructions for Use 8.812.1003..............4

Instrument description ............................1

Introduction .............................................1

K

Key 2 (FILL)

Figure ..................................................3

Operation ..........................................13

Key 3 (INJECT)

Figure ..................................................3

Operation ..........................................13

Key 4 (FILL)

Figure ..................................................3

Operation ..........................................13

Key 5 (INJECT)

Figure ..................................................3

Operation ..........................................13

Keypad .................................................. 17

L

Links ......................................................16

List of program instructions ..................16

Location................................................... 7

M

Mains cable ...........................................19

Mains connection

Procedure............................................ 8

Safety notes.........................................6

Manual operation ..................................13

Model plate 12

Figure ..................................................3

N

Notation ...................................................5

O

Opening the instrument ..........................6

Operation...............................................13

Operation via IC Net.............................. 14

Optional accessories ............................20

Organization ............................................4

P

Packaging ...............................................7

Parts and controls ................................... 2

PEEK capillary (6.1831.010) ............10,19

PEEK compression fitting

(6.2744.010).................................10,19

Pictograms .............................................. 5

Power supply ........................................17

Power supply unit..........................8,13,19

Program instructions............................. 16

Protection class....................................... 6

PTFE capillary (6.1803.020)............. 10,19

R

Rear......................................................... 2

S

Safety notes ............................................6

Safety specifications ............................. 18

Sample loop 15

Figure ................................................ 11

Installation ......................................... 11

Ordering designation ........................ 19

Sample loop (6.1825.XXX).................... 20

Setting up the instrument........................ 7

Software installation .............................. 12

Standard equipment ............................. 19

Static charges .........................................6

Storage.................................................. 18

Switch instrument on/off .......................13

Switching of injection valves ................. 10

Syringe (6.2816.020)........................ 10,20

Syringe tubing 13

Figure ................................................ 11

Installation ......................................... 10

T

Technical data....................................... 17

Terminal block 8

Connection of 6. 2115.070 cable .......9

Connection of 6.2128.100 cable ........9

Figure .................................................. 3

Technical data................................... 17

Terminal block 10

Connection of 6. 2115.070 cable .......9

Connection of 6.2128.100 cable ........8

Figure .................................................. 3

Technical data................................... 17

Time program........................................15

Transport................................................. 7

Transport damage ................................21

V

Valve 1 (A)

Figure .................................................. 3

Operation ..........................................13

Valve 6 (B)

Figure .................................................. 3

Operation ..........................................13

Valve A..............................................15,16

Valve B.............................................. 15,16

Valve interfaces ..................................... 17

W

Warning ................................................... 5

812 Valve Unit

24

Loading...

Loading...