Page 1

807 Dosing Unit

Manual

8.807.8002EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

807 Dosing Unit

8.807.8002EN

Manual

01.2011 dm/ek

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Model versions ...................................................................... 1

1.3 About the documentation ................................................... 2

1.3.1 Symbols and conventions ........................................................ 2

1.4 Safety instructions ................................................................ 3

1.4.1 Tubing and capillary connections ............................................. 3

1.4.2 Flammable solvents and chemicals ........................................... 3

1.5 Recycling and disposal ......................................................... 4

2 Construction of the 807 Dosing Unit 5

2.1 Total view .............................................................................. 5

2.2 Components of the 807 Dosing Unit .................................. 6

Table of contents

2.3 Cylinder unit .......................................................................... 8

2.4 Connectors (ports) of the 807 Dosing Unit ........................ 9

3 Installation 10

3.1 Greasing the dosing unit .................................................... 10

3.2 Mounting the storage vessel and the holder ................... 11

3.3 Mounting the adsorber tube ............................................. 14

3.4 Mounting filling tubes ........................................................ 15

3.5 Mounting the dosing unit onto the bottle ....................... 15

3.5.1 Mounting the dosing unit onto the bottle .............................. 15

3.5.2 Mounting the dosing tubing and buret tips ............................ 17

3.5.3 Buret tips ............................................................................... 18

3.6 Avoiding air bubbles .......................................................... 19

3.7 Disassembling the dosing unit .......................................... 21

3.7.1 Disassembling the dosing unit ................................................ 21

3.8 Assembling the dosing unit ............................................... 26

3.8.1 Inserting the dosing piston .................................................... 26

3.8.2 Attaching cylinder unit in distributor ...................................... 28

3.8.3 Attaching the housing ........................................................... 28

807 Dosing Unit

4 Handling and maintenance 31

4.1 Care and upkeep ................................................................. 31

4.1.1 Cleaning dosing cylinder and dosing piston ........................... 31

4.1.2 Cleaning valve disc and distributor disc .................................. 32

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.1.3 Discs adhere to one another .................................................. 33

4.1.4 Resistance and materials ........................................................ 34

4.2 Quality Management and validation with Metrohm ....... 35

4.3 GLP - Validation .................................................................. 36

5 Troubleshooting 37

5.1 Problems ............................................................................. 37

6 Appendix 40

6.1 Buret data ........................................................................... 40

6.2 Dosing accuracy .................................................................. 41

6.2.1 Typical measurement deviation .............................................. 41

6.2.2 The ISO/EN/DIN standard 8655-3 ........................................... 41

7 Accessories 43

7.1 Scope of delivery ................................................................ 43

7.1.1 807 Dosing Unit 6.3032.xxx .................................................. 43

7.2 Optional accessories ........................................................... 47

Index 54

■■■■■■■■

IV

807 Dosing Unit

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 807 Dosing Unit ................................................................................ 5

Figure 2 807 Dosing Unit - Components ......................................................... 6

Figure 3 Cylinder unit ...................................................................................... 8

Figure 4 807 Dosing Unit - Ports ..................................................................... 9

Figure 5 Removing the housing ..................................................................... 10

Figure 6 Greasing the centering tube and interior edges of the housing ........ 11

Figure 7 Mounting the storage vessel and the holder .................................... 12

Figure 8 Marking rib on housing and distributor ............................................ 13

Figure 9 Locking the housing ........................................................................ 13

Figure 10 Mounting the adsorber tube ........................................................... 14

Figure 11 Mounting filling tubes ..................................................................... 15

Figure 12 Dosing unit on the reagent bottle .................................................... 16

Figure 13 Mounting the tubing and the buret tip ............................................ 17

Figure 14 Air bubbles in the cylinder ............................................................... 20

Figure 15 Removing the housing ..................................................................... 22

Figure 16 Cylinder unit on the distributor ........................................................ 23

Figure 17 Dosing cylinder damaged ................................................................ 23

Figure 18 Dosing cylinder with dosing piston .................................................. 25

Figure 19 Inserting the dosing piston .............................................................. 26

Figure 20 Centering tube on the dosing cylinder ............................................. 27

Figure 21 Stopper of the dosing piston flush with the upper edge of the hous-

ing .................................................................................................. 27

Figure 22 Marking ribs on the centering tube and edge of the distributor ....... 28

Figure 23 Marking rib on housing and distributor ............................................ 29

Figure 24 Locking the housing ........................................................................ 29

Figure 25 Piston stopper flush with the upper edge of the housing ................. 30

Figure 26 Triangles on the upper side of the dosing unit when the stopcock is set

correctly .......................................................................................... 30

Figure 27 Dosing unit completely mounted ..................................................... 30

Figure 28 Valve disc in the cylinder base ......................................................... 32

Figure 29 Distributor disc with 4 ports (in the distributor) ................................ 32

Figure 30 Data chip and contact pin ............................................................... 41

Table of figures

807 Dosing Unit

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 807 Dosing Unit is a versatile buret unit which can be operated with a

700 Dosino or 800 Dosino dosing drive. The 807 Dosing Unit is suitable

for precise dosings, titrations, pipetting procedures, sample transfers, etc.

The four inputs and outputs (ports) are designed for flexible use (presuming the presence of a suitable control device).

Thanks to the transparent housing of the 807 Dosing Unit, piston movements and stopcock rotations are visible. This means that even complex

liquid handling applications are easy to monitor. The unobstructed view

into the dosing cylinder also ensures that solutions can be monitored with

respect to the absence of bubbles and the leak-tightness of the cylinder

unit.

1 Introduction

Specifications concerning the dosing unit and the reagent can be stored in

the integrated data chip. This data can be extracted and updated by a

suitable control device.

1.2 Model versions

The 807 Dosing Unit is available with cylinder sizes of 2 mL, 5 mL, 10 mL,

20 mL and 50 mL. In addition to glass cylinders, plastic cylinders (ETFE)

specially manufactured for alkali and other aggressive solutions are also

available.

Table 1

Volume Order number

2 mL 6.3032.120

5 mL 6.3032.150

10 mL 6.3032.210

20 mL 6.3032.220

50 mL 6.3032.250

807 Dosing Unit with glass cylinder

807 Dosing Unit

Table 2 807 Dosing Unit with ETFE cylinder

Volume Order number

2 mL 6.1575.120

■■■■■■■■

1

Page 10

1.3 About the documentation

Volume Order number

5 mL 6.1575.150

10 mL 6.1575.210

20 mL 6.1575.220

50 mL 6.1575.250

1.3 About the documentation

CAUTION

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

■■■■■■■■■■■■■■■■■■■■■■

1.3.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

■■■■■■■■

2

Warning

This symbol draws attention to a possible biological

hazard.

807 Dosing Unit

Page 11

■■■■■■■■■■■■■■■■■■■■■■

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.4 Safety instructions

1.4.1 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

1 Introduction

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.4.2 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled fluids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

807 Dosing Unit

■■■■■■■■

3

Page 12

1.5 Recycling and disposal

1.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

4

807 Dosing Unit

Page 13

■■■■■■■■■■■■■■■■■■■■■■

2

1

2

3

4

5

6

7

8

9

10

11

12

2 Construction of the 807 Dosing Unit

2 Construction of the 807 Dosing Unit

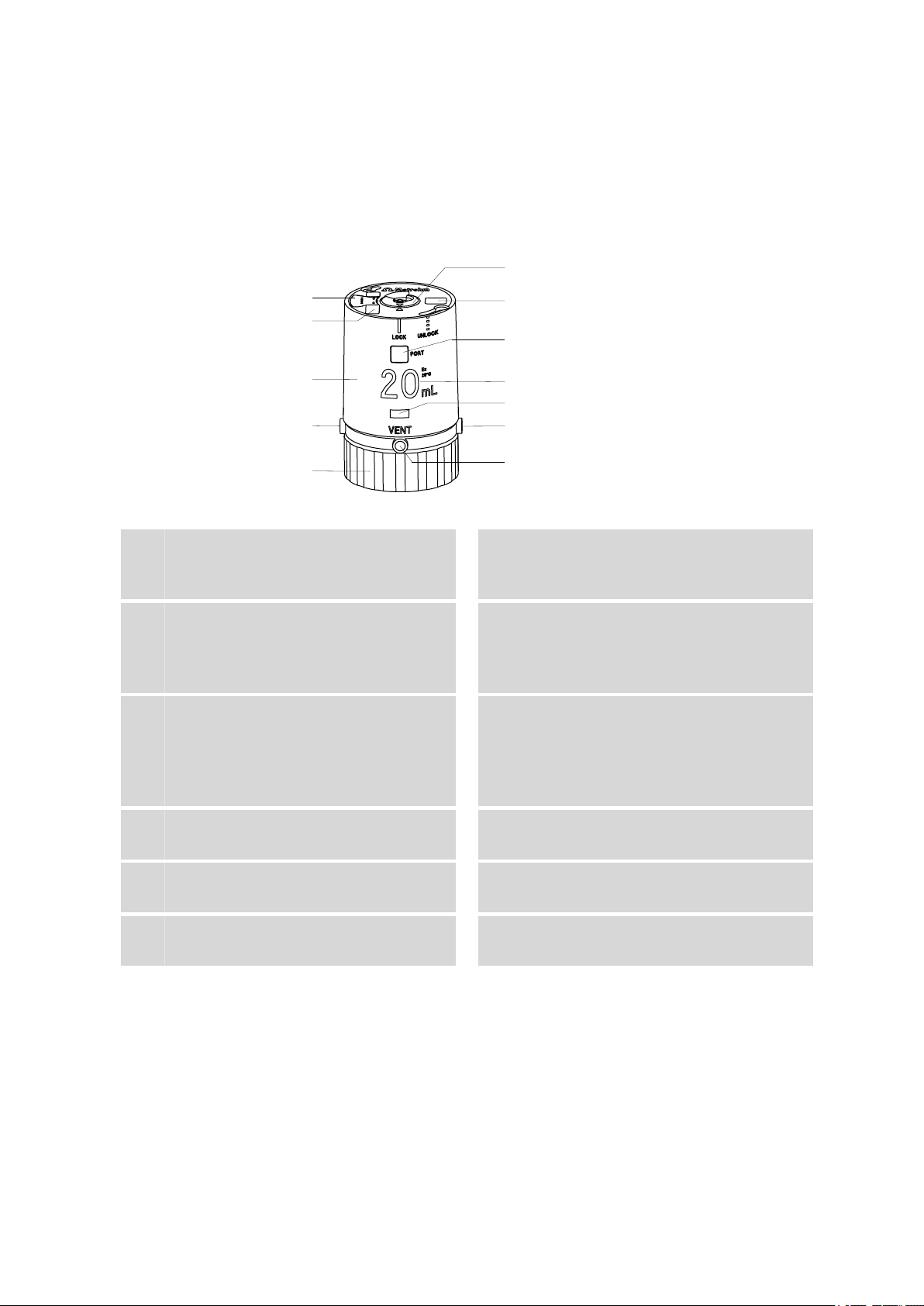

2.1 Total view

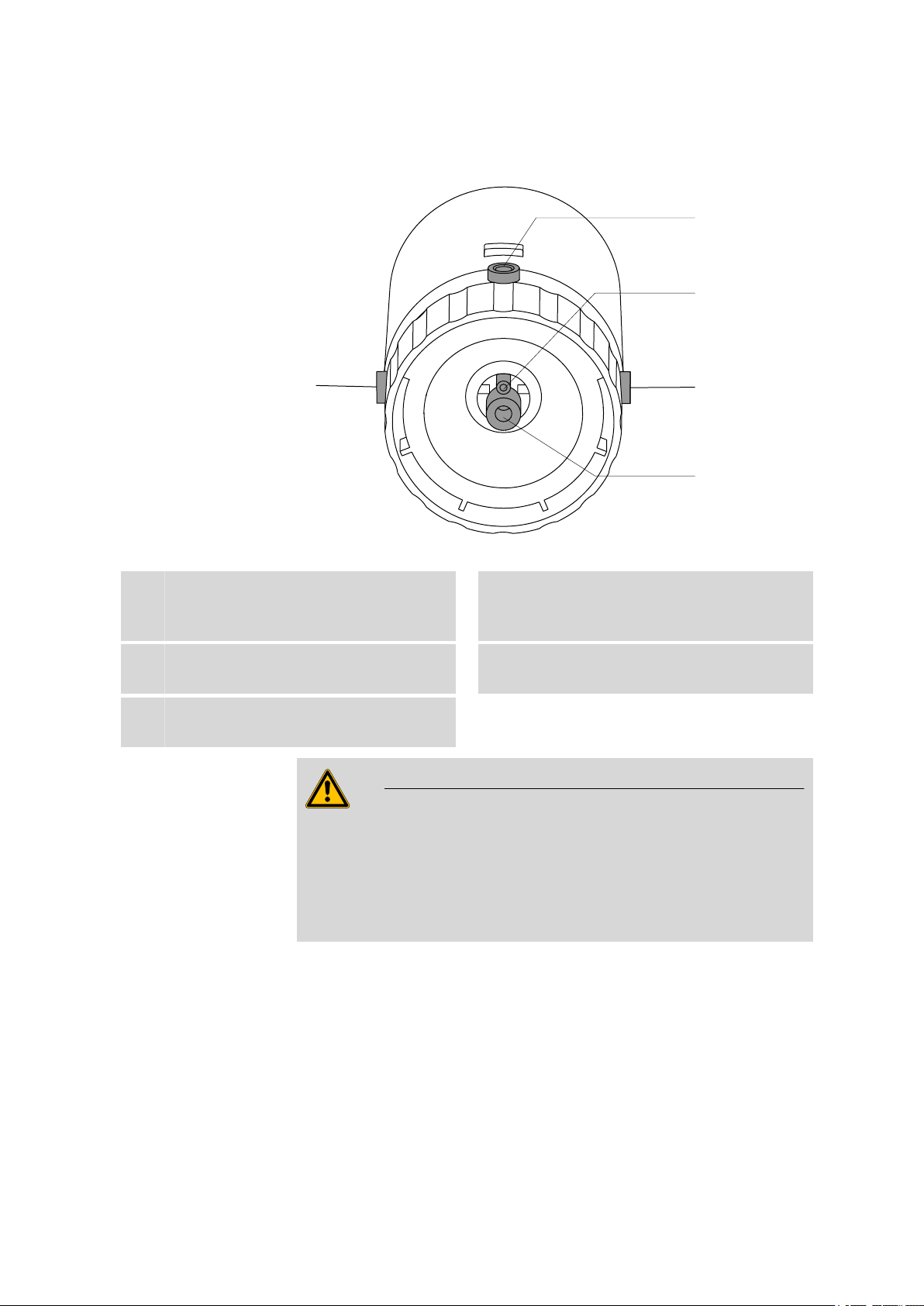

Figure 1 807 Dosing Unit

Data chip

1

Contains all specifications for the dosing

unit.

Housing

3

With data chip, coding magnets, locking

button and specifications concerning the

dosing unit.

Fixing ring

5

For fastening the dosing unit onto a reagent

bottle.

Serial number, order number and bar-

7

code

Nominal volume

9

Volume of the dosing cylinder.

Port 3

11

Dosing port 2. Dosing output for solution.

Coding magnet

2

For automatic recognition of the volume of

the dosing unit.

Port 1

4

Dosing port 1. Dosing output for solution.

Centering tube

6

Is actuated by Dosino and rotates the entire

inner cylinder unit, together with dosing cylinder, cylinder base and the integrated valve

disc.

Port display

8

Displays the port currently opened.

Locking button

10

For locking and unlocking the housing.

VENT port

12

For deaerating the reagent bottle.

807 Dosing Unit

■■■■■■■■

5

Page 14

2.2 Components of the 807 Dosing Unit

1

2

3

4

5

6

7

8

9

10

11

■■■■■■■■■■■■■■■■■■■■■■

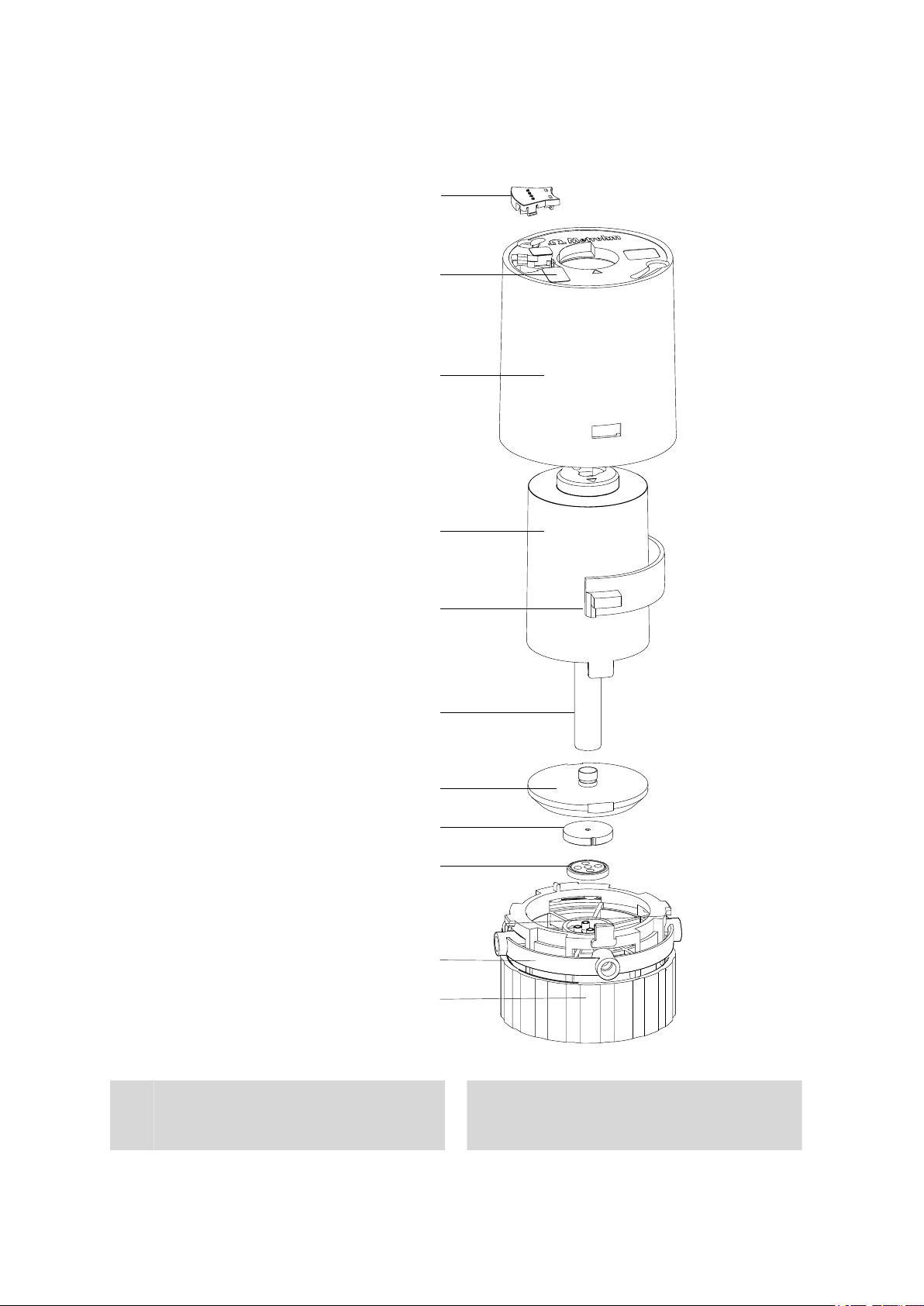

2.2 Components of the 807 Dosing Unit

6

Data chip

1

Contains all specifications for the dosing

unit.

■■■■■■■■

Figure 2 807 Dosing Unit - Components

Coding magnet(s)

2

For automatic recognition of the volume of

the dosing unit.

807 Dosing Unit

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2 Construction of the 807 Dosing Unit

Housing

3

With data chip, coding magnets, locking

button and specifications concerning the

dosing unit.

Material: PETG or PVDF

Spring clip

5

Material: PETG or PVDF

Cylinder base

7

Seals the dosing cylinder and contains the

valve disc.

Material: PTFE / Graphite

Distributor disc

9

The four holes in the distributor disc each

set up a connection with one of the four

ports (input/output) of the dosing unit.

Material: Al 2 O 3 ceramic

Centering tube

4

Is actuated by Dosino and rotates the entire

inner cylinder unit, together with dosing cylinder, cylinder base and the integrated valve

disc.

Material: PETG or PVDF

Dosing cylinder

6

Contains the solution for dosing. Volume

2 mL , 5 mL , 10 mL , 20 mL or 50 mL .

Material: Borosilicate 3.3 or ETFE

Valve disc

8

A hole in the valve disc guides the solution

into one (of four) selected openings in the

distributor disc.

Material: Silicone carbide ceramic

Distributor

10

Contains four ports (input/output) for solutions. The ports are actuated by the distributor disc in the distributor and the valve disc

in the base of the cylinder.

Material: ETFE

Fixing ring

11

For fastening the dosing unit onto a reagent

bottle.

Material: PVDF

807 Dosing Unit

■■■■■■■■

7

Page 16

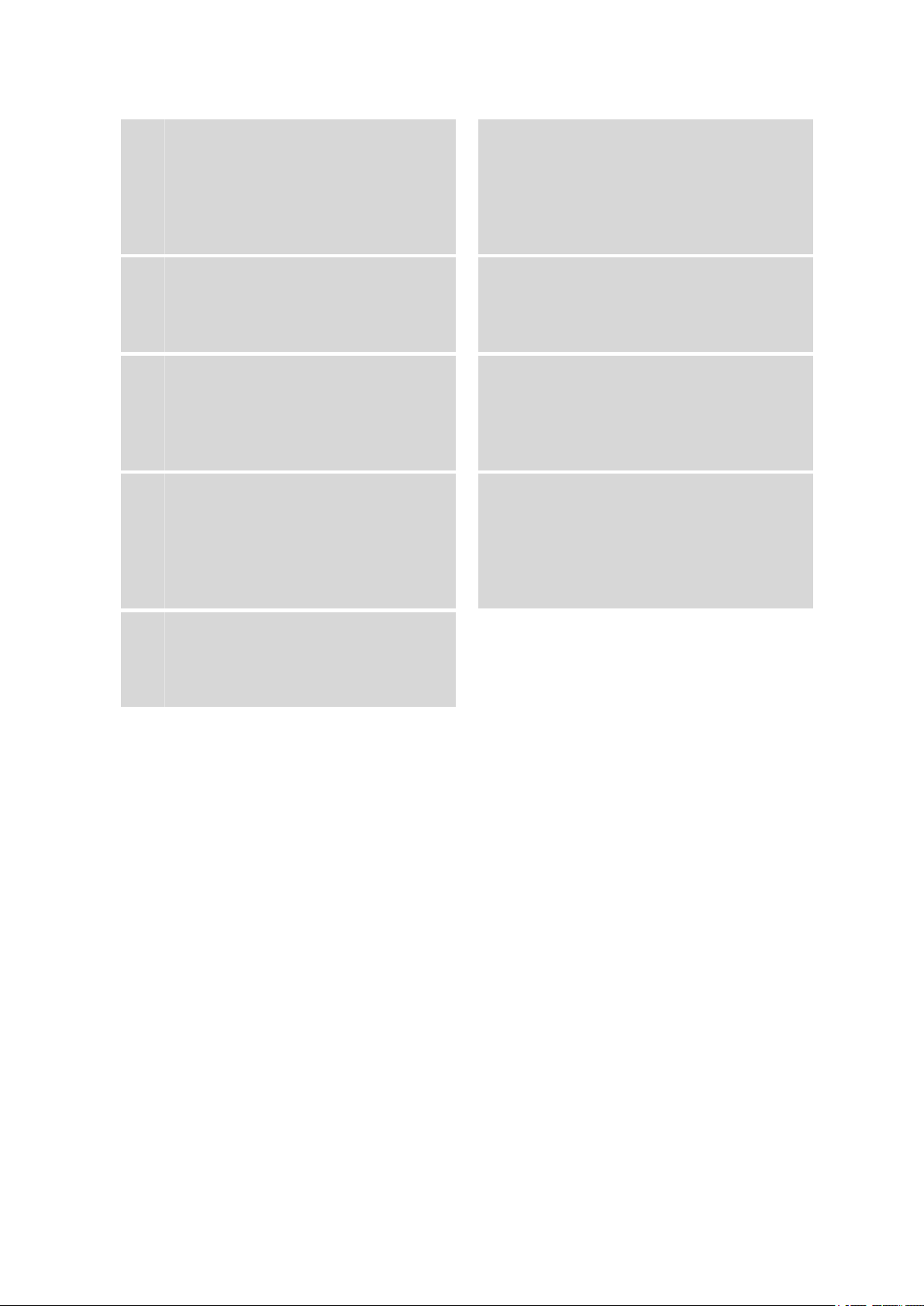

2.3 Cylinder unit

1

2

3

4

5

2.3 Cylinder unit

Figure 3 Cylinder unit

■■■■■■■■■■■■■■■■■■■■■■

Piston stopper

1

Coupling for the piston rod of the Dosino.

Dosing cylinder (Glass: 6.1574.XXX,

3

ETFE: 6.1575.XXX)

Contains the solution for dosing. Volume

2 mL , 5 mL, 10 mL, 20 mL or 50 mL.

Material: Borosilicate 3.3 or ETFE

Cylinder base

5

Seals the dosing cylinder and contains the

valve disc.

Material: PTFE / Graphite

Dosing piston

2

For ejecting and aspirating a solution.

Material: ETFE

Centering tube

4

Is actuated by Dosino and rotates the entire

inner cylinder unit, together with dosing cylinder, cylinder base and the valve disc

mounted within.

Material: PETG or PVDF

■■■■■■■■

8

807 Dosing Unit

Page 17

■■■■■■■■■■■■■■■■■■■■■■

1

3

4

5

2

2 Construction of the 807 Dosing Unit

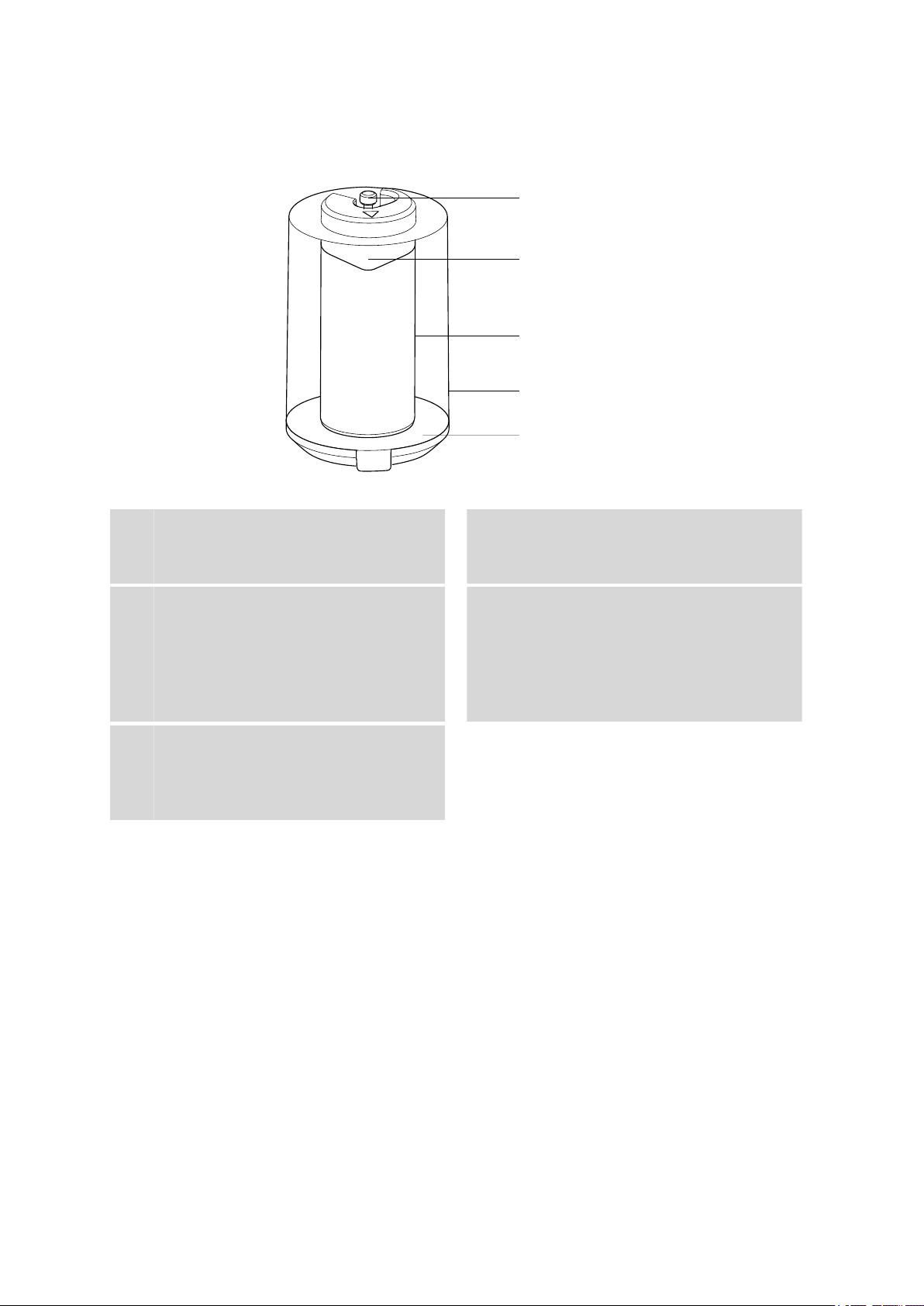

2.4 Connectors (ports) of the 807 Dosing Unit

Figure 4 807 Dosing Unit - Ports

Port 1

1

Connector (M6) for the dosing tubing.

Port 4

3

Special port, waste port or recycling port.

Port 2

5

Connector (M6) for the filling tubing.

Port 2 is the fill port in the default configuration. Take care to ensure

that the tubing is firmly screwed in place in order that no air bubbles

will be able to enter during aspiration of the reagent solution. Always

use the 6.2739.000 wrench provided for tightening and unscrewing

tubing connections.

WARNING

VENT

2

Deaeration, connection (M6) for adsorber

tube.

Port 3

4

Connector (M6) for a second dosing tubing.

807 Dosing Unit

■■■■■■■■

9

Page 18

3.1 Greasing the dosing unit

3 Installation

3.1 Greasing the dosing unit

We recommend that the upper side of the centering tube and interior

edges of the upper side of the housing be greased with paraffin grease

6.2803.010 before the dosing unit is used for the first time. This measure

will reduce friction resistance when the centering tube is rotated.

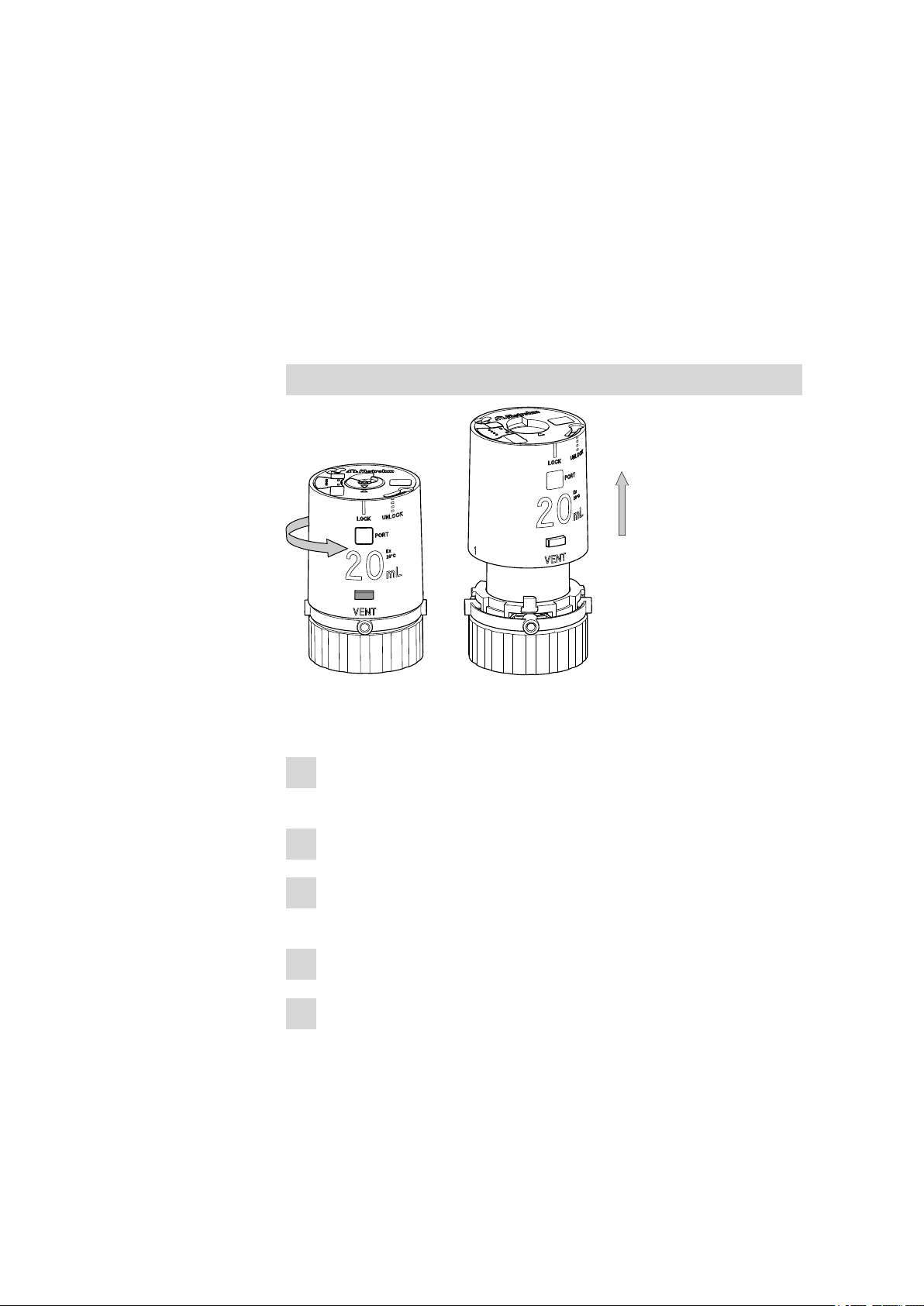

Removing the housing

■■■■■■■■■■■■■■■■■■■■■■

Figure 5

Removing the housing

Remove the housing of the dosing unit as follows:

Place the dosing unit on a flat, level surface so that the lettering of

1

the volume specification faces towards the front.

Keep the locking button pressed down.

2

Rotate the housing of the dosing unit by ca. 1 cm to the right (in

3

counterclockwise direction).

Release the locking button.

4

Carefully raise the housing upward.

5

When removing the housing, take care to ensure that the spring clip

on the interior side of the housing does not slide out of place.

■■■■■■■■

10

807 Dosing Unit

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1

1

2

3 Installation

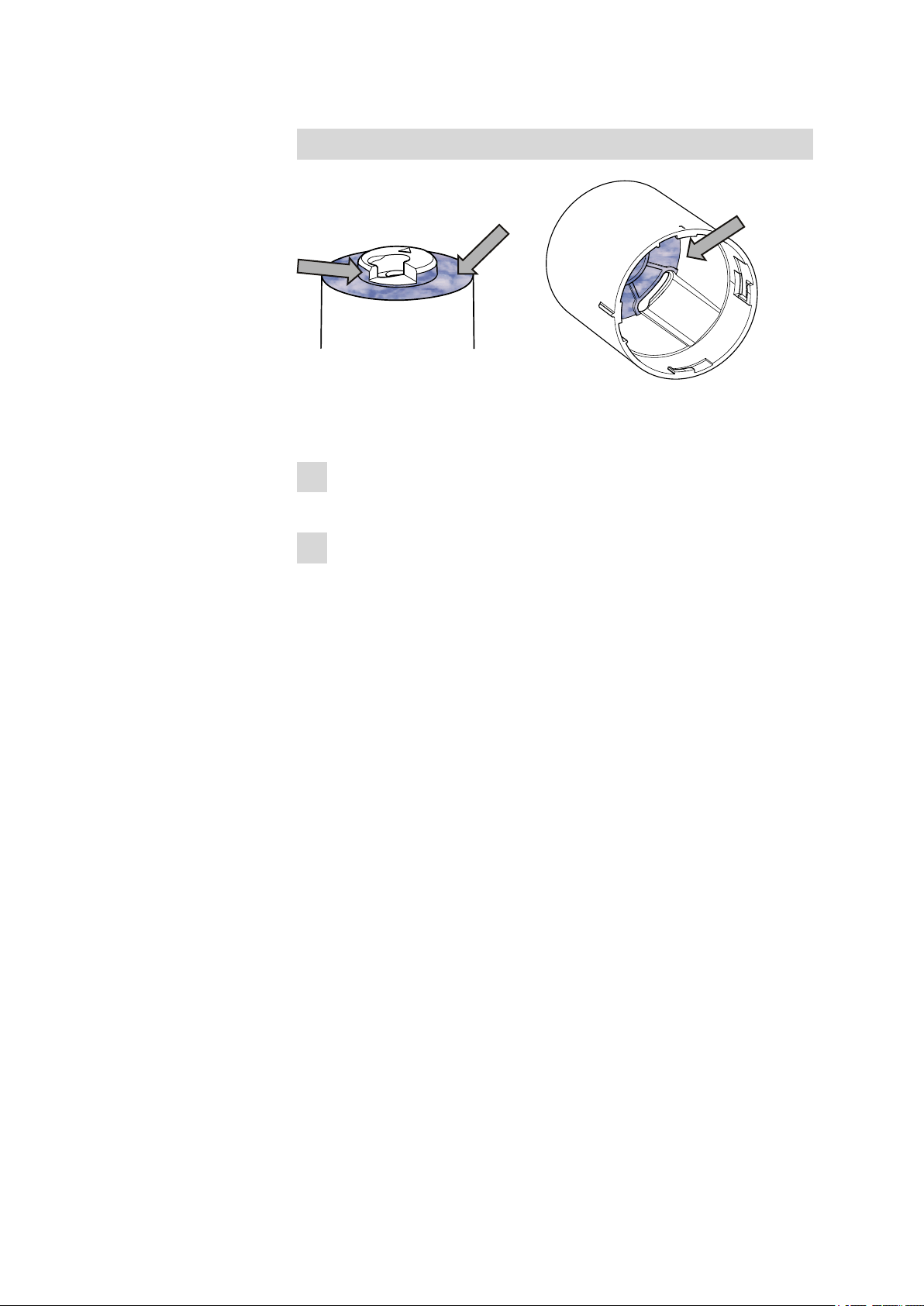

Greasing the centering tube and housing

Figure 6 Greasing the centering tube and interior edges of the housing

Grease the centering tube and housing as follows:

Grease the sliding surfaces on the upper side of the centering tube

1

with paraffin grease 6.2803.010.

Grease the sliding surfaces on the interior edge of the housing with

2

paraffin grease 6.2803.010.

3.2 Mounting the storage vessel and the holder

The dosing unit comes equipped with a storage vessel 6.2008.030 with

holder 6.2008.050 for the storage of the buret tip. It should be mounted

when the device is started up for the first time.

The storage vessel serves as a storage container for the buret tip when the

dosing unit is not in use.

The associated holder is used at the same time for mounting a name plate

with the designation of the reagent in the dosing unit. Name plates can

be reordered under the order number 6.2244.020 from any Metrohm

agent.

The dosing unit housing must be removed in order to assemble the storage vessel holder (see "Removing the housing", page 10).

807 Dosing Unit

■■■■■■■■

11

Page 20

3.2 Mounting the storage vessel and the holder

6.2008.030

6.2008.050

6.2244.020

2

3

4

5

1

Mounting the storage vessel and the holder

Figure 7 Mounting the storage vessel and the holder

■■■■■■■■■■■■■■■■■■■■■■

Mount the storage vessel and the holder on the dosing unit as follows:

Rotate the centering tube on the distributor in such a way that the

1

marking rib on the centering tube is lined up with the marking rib on

the edge of the distributor.

Place the holder 6.2008.050 on the edge of the distributor.

2

Place the storage vessel 6.2008.030 for the buret tip in the holder.

3

In order to ensure perfect seating, the rib on the storage vessel must

be guided into the groove on the holder and pushed downward.

The holder can be placed at any one of four positions on the ring of

the distributor.

Slide the name plate 6.2244.020, which has the designation of the

4

reagent in the dosing unit, into the holder.

Slide the housing of the dosing unit onto the centering tube.

5

The centering tube with the cylinder unit must be in correct position

when the housing is attached. You will find a positioning aid on the

rear side of the dosing unit.

■■■■■■■■

12

807 Dosing Unit

Page 21

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

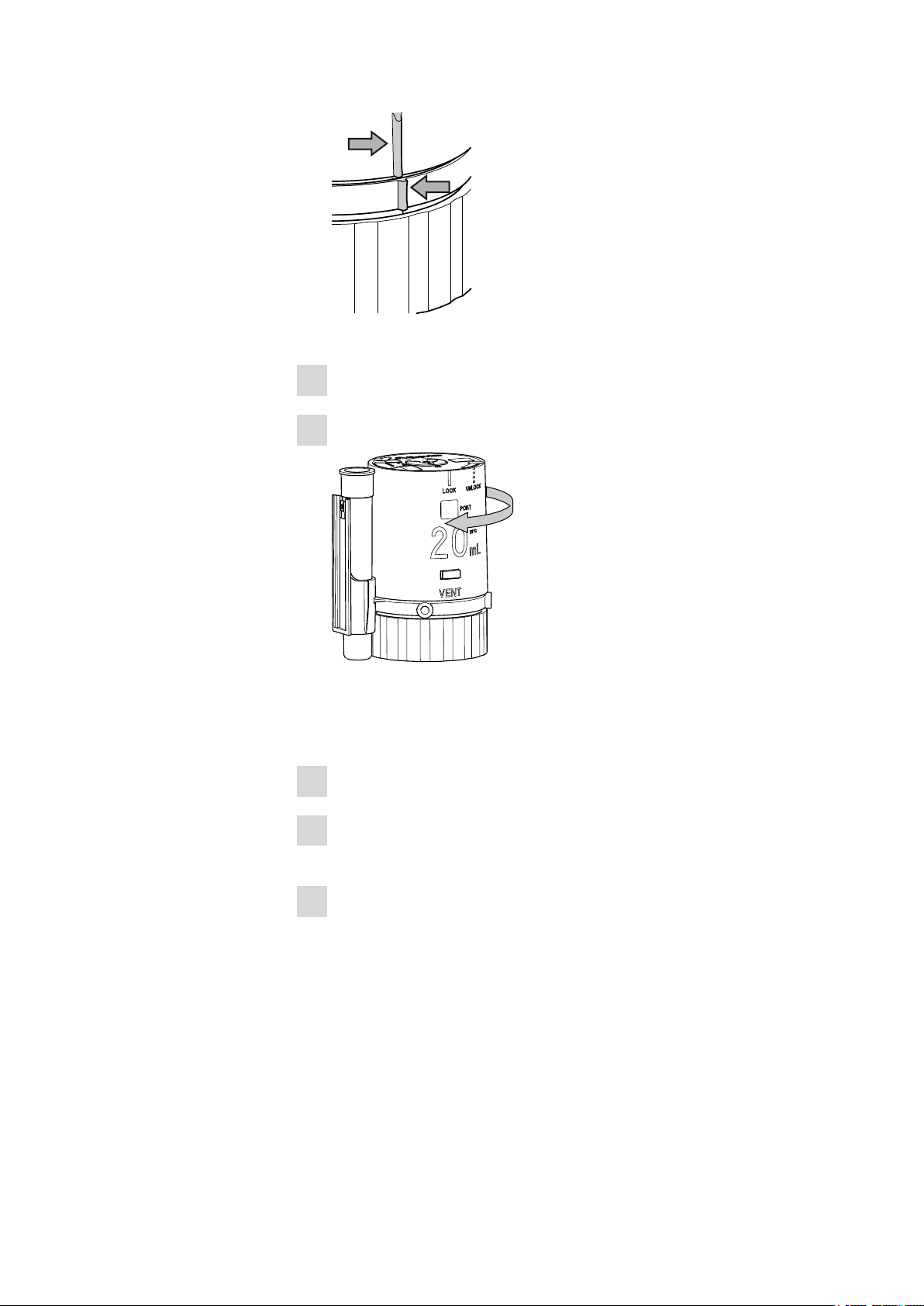

Figure 8 Marking rib on housing and distributor

Locking the housing

Figure 9

Locking the housing

Lock the housing as follows:

Hold the distributor in place.

1

Rotate the housing to the left (in clockwise direction).

2

Once all the parts are lined up with one another, the housing will

snap into place.

807 Dosing Unit

■■■■■■■■

13

Page 22

3.3 Mounting the adsorber tube

6.1619.00

3.3 Mounting the adsorber tube

Figure 10 Mounting the adsorber tube

Mount the adsorber tube as follows:

Fill the adsorber tube 6.1619.000 with an adsorption material

1

required for the reagent.

■■■■■■■■■■■■■■■■■■■■■■

■ Molecular sieve for moisture-sensitive solutions ( e.g. KF solu-

tions).

■ Soda lime for sodium hydroxide solution (CO

Seal the adsorber tube with the appropriate cover.

2

adsorption)

2

A minimum pressure compensation remains ensured.

Screw the adsorber tube to the deaeration port (VENT) of the dos-

3

ing unit.

The adsorber tube should be screwed on a bottle in hanging position

after the assembly of the dosing unit.

The VENT connector deaerates the reagent bottle. It should never be

entirely sealed off. If no adsorber material is required, then the adsorber

tube can be filled with cotton and used as a dust filter.

■■■■■■■■

14

807 Dosing Unit

Page 23

■■■■■■■■■■■■■■■■■■■■■■

6.1829.010

3.4 Mounting filling tubes

3 Installation

Figure 11 Mounting filling tubes

Mount the tubing as follows:

Screw the aspiration tubing 6.1829.010 onto the connector with

1

inner thread (Port 2) on the underside of the dosing unit.

3.5 Mounting the dosing unit onto the bottle

3.5.1 Mounting the dosing unit onto the bottle

A variety of different bottles can be used as storage containers. Amber

glass bottles 6.1608.023, clear glass bottles 6.1608.030 or PE bottles

6.1608.040 of 1 liter volume and GL45 thread.

Suitable thread adapters are available for bottles with other threads (see

Chapter 7.2, page 47).

WARNING

The lip of the bottle should have a plastic decanting ring. Do not use

any mechanical aids for mounting the dosing unit. The upper part of

the housing should still be easy to turn by hand.

807 Dosing Unit

■■■■■■■■

15

Page 24

3.5 Mounting the dosing unit onto the bottle

■■■■■■■■■■■■■■■■■■■■■■

Figure 12 Dosing unit on the reagent bottle

Mount the dosing unit as follows:

Rotate the adsorber tube upward.

1

Fasten the dosing unit onto the filled reagent bottle.

2

After the dosing unit has been screwed tigh, rotate the adsorber

3

tube back into hanging position.

■■■■■■■■

16

807 Dosing Unit

Page 25

■■■■■■■■■■■■■■■■■■■■■■

6.1805.100

6.1543.060/

6.1543.200

6.2739.000

3.5.2 Mounting the dosing tubing and buret tips

Figure 13 Mounting the tubing and the buret tip

Mount the tubing and the buret tip as follows:

3 Installation

Screw the dosing tubing 6.1805.100 (40 cm) on the left-hand side to

1

Port 1 of the dosing unit.

Tighten the connection nipple with the wrench 6.2739.000.

2

Screw the open dosing tip 6.1543.060 or the antidiffusion tip

3

6.1543.200 onto the dosing tubing.

The link stopper 6.1446.030 included in the scope of delivery can be

used to fix the tip in place in a ground joint opening NS14/15.

Insert the buret tip into the storage vessel provided for this purpose.

4

Details concerning the selection of the buret tip (see Chapter 3.5.3, page

18).

The first-time filling of the dosing unit requires no special measures. Each

Metrohm control device (e.g. Titrando, Titrino or Sample Processor) is

equipped with a PREP/Preparing function with which the filling of the

dosing cylinder and the rinsing of the dosing unit tubing can be readily

accomplished in an automated sequence.

807 Dosing Unit

■■■■■■■■

17

Page 26

3.5 Mounting the dosing unit onto the bottle

6.1543.200

6.1543.060

3.5.3 Buret tips

The following buret tips are included in the standard equipment of the

dosing unit:

Open dosing tip 6.1543.060

For tasks during which the top is not immersed, e.g. dosings.

The buret tip can be stored in the same solvent as the one contained in

the reagent in order to prevent reagent crystallization.

We recommend that the storage vessel be filled with solvent and that the

buret tip be placed inside it. In the event that KF reagent is used as the

titrant, use methanol or ethanol for storing the dosing tip.

■■■■■■■■■■■■■■■■■■■■■■

Antidiffusion tip 6.1543.200

It is used for work requiring the immersion of the tip, e.g. titrations.

This tip prevents the diffusion of liquids into the buret tip.

The pressure of the surrounding liquid and the internal stress of the membrane press on the tubing end, thus sealing off the opening.

The backpressure of the dosed liquid is overcome during the dosing process. The membrane opens up the tubing end. The tubing end is sealed off

again automatically after the dosing is completed.

CAUTION

18

■■■■■■■■

Do not disassemble the antidiffusion tip.

807 Dosing Unit

Page 27

■■■■■■■■■■■■■■■■■■■■■■

3.6 Avoiding air bubbles

Air bubbles could collect in the dosing cylinder as the result of leaking tubing connections or the degassing of air released in the liquid to be dosed.

Make sure that the tubing connections are always leak-proof. Check to

make sure that the ends of the tubing are not damaged before assembly.

Always pull the screw nipple tight with the wrench 6.2739.000. Take care

to ensure however that you do not damage the tubing ends while doing

so.

All Metrohm devices which support Dosinos as dosing drives offer a

PREP/Preparing function. This function is a preparatory step which automatically fills cylinders and tubing with liquid.

The specification of length and diameter of all of the connected filling and

dosing tubing is required in order for the control device to be able to calculate the necessary rinsing volume correctly. This is accomplished in the

configuration of the dosing units of the respective device. The data is

stored in the data chip of the dosing unit.

3 Installation

CAUTION

Apply the PREP/Preparing function in each case prior to the first use

of a dosing unit. This means that whenever you begin a new sample

series (at least once per day), first execute the PREP function. You will

find more detailed information in this connection in the manual for

your Metrohm device.

NOTE

The contents present in the cylinder will be expelled completely during

the PREP/Preparing function. The piston moves past the regular end

position and is pressed against the base of the cylinder. The contour of

the base of the cylinder will however never be able to be filled out completely by the piston, which means that a small air bubble might still

remain in place.

807 Dosing Unit

■■■■■■■■

19

Page 28

3.6 Avoiding air bubbles

A

B

■■■■■■■■■■■■■■■■■■■■■■

CAUTION

A small air bubble will also always be present on the piston after a

PREP-Preparing step. It will however not be expelled during the dosing.

An air bubble of that small size will not have any effect on the precision

of a dosing! (see Figure 14, page 20)

Figure 14 Air bubbles in the cylinder

The end position A (end volume) will never be exceeded by the piston during dosing procedures. It is only with the PREP function that the piston

will be moved all the way to the stop (PREP Position B).

A dead volume will always remain after dosing which is greater in size

than any air bubble which might remain following the execution of the

PREP/Preparing function (see arrow). This means that the latter cannot

exit into the tubing system and impair the precision of the dosing. The air

bubble remains in the dosing cylinder.

Conclusion

The design and mode of operation of the dosing unit is constructed in

such a way that air bubbles which could possibly arise in the system will

not be able to escape unchecked. They can be expelled efficiently prior to

the dosing with the PREP function. Any small air bubbles which might

form will be held back in a bubble trap. They exercise no influence over

the dosing.

■■■■■■■■

20

807 Dosing Unit

Page 29

■■■■■■■■■■■■■■■■■■■■■■

3.7 Disassembling the dosing unit

Generally speaking, it is not necessary to disassemble the dosing unit

when reagents are replaced. Thanks to the low exchange volume of only

a few microliters, and thanks to the EMPTY/Emptying and PREP/Pre-

paring functions, which every control unit for the Dosino has, a reagent

in a dosing unit can be replaced readily and without any large loss of

reagent.

We recommend that inspections of pistons and cylinders be carried out

regularly for each dosing unit (e.g. every six months). If alkali, corrosive or

highly concentrated reagents are used, then shorter (possibly weekly)

intervals will be called for. The glass cylinder itself could become corroded

by aggressive alkalis, or solids could crystallize out of the solution. In the

case of alkali reagents, the use of dosing units with ETFE cylinders is to be

recommended.

3.7.1 Disassembling the dosing unit

3 Installation

Dismantling the dosing system

Empty the dosing cylinder with the EMPTY/Emptying function of

1

the control device.

Rotate the Dosino on the dosing unit to the right all the way to the

2

UNLOCK marking.

Lift the Dosino.

3

Loosen the dosing unit on the bottle.

4

Remove the filling tubing.

5

Remove the storage vessel and the holder.

6

807 Dosing Unit

■■■■■■■■

21

Page 30

3.7 Disassembling the dosing unit

Removing the housing

Figure 15 Removing the housing

Remove the housing of the dosing unit as follows:

Place the dosing unit on a flat, level surface.

1

■■■■■■■■■■■■■■■■■■■■■■

The lettering of the volume specification faces towards the front.

Keep the locking button of the spring clip pressed down.

2

Rotate the housing by approx. 1 cm to the right (in counterclockwise

3

direction).

Release the locking button.

4

Carefully raise the housing upward.

5

You will now see the complete cylinder unit with the transparent

centering tube which rotates on the distributor with the interior dosing cylinder when the flat stopcock is switched.

■■■■■■■■

22

807 Dosing Unit

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Figure 16 Cylinder unit on the distributor

Removing the centering tube

Remove the centering tube as follows:

Remove the cylinder unit, comprised of centering tube, black cylinder

1

base, valve disc, dosing cylinder and dosing piston, from the distributor.

Carefully pull out the centering tube on the black cylinder base in an

2

upward direction.

3 Installation

You will now see the dosing cylinder on the black cylinder base with

the integrated valve disk.

You can now inspect the condition of the cylinder and the piston.

The glass cylinder should not exhibit any signs of corrosion. The plastic coating PTFE of the piston should not be damaged in any way.

Figure 17 Dosing cylinder damaged

807 Dosing Unit

■■■■■■■■

23

Page 32

3.7 Disassembling the dosing unit

6.1546.030

■■■■■■■■■■■■■■■■■■■■■■

CAUTION

Do not dismantle the piston, cylinder and cylinder base any further

unnecessarily. You should do that only if parts require cleaning, care or

replacement. Damage to individual parts will impair the leak-tightness

and accuracy of the dosing unit.

The dosing piston and the cylinder should always be replaced together.

Complete cylinder units can be ordered under 6.1574.XXX or

6.1566.XXX(see Chapter 7.2, page 47)

Pulling out the dosing piston

■■■■■■■■

24

NOTE

Use caution when handling the 2 mL cylinder! In contrast to the larger

dosing cylinders, here the dosing cylinder can be pulled out completely.

Pull the dosing piston out of the cylinder as follows:

Press down on the white grip of the piston tongs 6.1546.030.

1

807 Dosing Unit

Page 33

■■■■■■■■■■■■■■■■■■■■■■

Two wire loops will appear at the tip of the piston tongs.

Arrange the piston tongs in such a way that the wire loops surround

2

the piston stopper.

Carefully let go of the grip.

3

The wire loops will snap shut.

Carefully pull out the dosing piston with the white grip, applying a

4

certain amount of force while doing so.

Release the piston tongs by pressing on the white grip.

5

3 Installation

Figure 18 Dosing cylinder with dosing piston

Now the dosing cylinder and the piston can be cleaned separately (see

Chapter 4.1, page 31).

CAUTION

Never disconnect the dosing cylinder from the cylinder base. There is a

danger of the sensitive material in the cylinder base (particularly the

edges) becoming damaged when the cylinder is attached by hand.

807 Dosing Unit

■■■■■■■■

25

Page 34

3.8 Assembling the dosing unit

3.8 Assembling the dosing unit

CAUTION

Dosing cylinders and pistons, and in particular their sealing lips, should

not be permitted to become damaged during assembly.

3.8.1 Inserting the dosing piston

Inserting the dosing piston

■■■■■■■■■■■■■■■■■■■■■■

Figure 19

Inserting the dosing piston

Insert the dosing piston as follows:

Place the dosing piston horizontally on the cylinder.

1

Carefully press the dosing piston inward by approximately 1-2 mm.

2

Fitting the stoppers

Fit the stoppers as follows:

Place the centering tube over the dosing cylinder.

1

Fit the narrow and the wider guide blades on the lower edge of the

2

centering tube into the corresponding recesses of the cylinder base.

■■■■■■■■

26

807 Dosing Unit

Page 35

■■■■■■■■■■■■■■■■■■■■■■

The centering tube stopper fits into the opening of the centering

tube.

Figure 20 Centering tube on the dosing cylinder

Slide the housing onto the centering tube.

3

Press the housing onto the tabletop.

4

3 Installation

The dosing piston is pressed into the cylinder until the stopper is flush

with the upper edge of the housing.

Figure 21 Stopper of the dosing piston flush with the upper edge

of the housing

Afterwards, remove the housing once again.

5

807 Dosing Unit

■■■■■■■■

27

Page 36

3.8 Assembling the dosing unit

3.8.2 Attaching cylinder unit in distributor

Attach the cylinder unit in the distributor as follows:

Place the distributor on a flat, level surface.

1

Place the complete cylinder unit in the distributor.

2

Rotate the cylinder unit in such a way that the marking rib on the

3

centering tube is lined up with the marking rib on the edge of the

distributor.

■■■■■■■■■■■■■■■■■■■■■■

Figure 22 Marking ribs on the centering tube and edge of the dis-

The centering tube must be in correct position for the following assembly

of the housing.

3.8.3 Attaching the housing

Attach the housing as follows:

Check whether the interior spring clip is positioned correctly in its

1

guide groove.

It must be able to move readily when the exterior locking button is

pressed.

Slide the housing of the dosing unit onto the centering tube.

2

The marking rib on the housing must be lined up with the marking

rib on the edge of the distributor and the centering tube must fit into

the opening on the upper side of the housing.

tributor

■■■■■■■■

28

807 Dosing Unit

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Figure 23 Marking rib on housing and distributor

Hold the distributor firmly.

3

Rotate the housing to the left (in clockwise direction).

4

3 Installation

Figure 24 Locking the housing

Once all the parts are lined up with one another, the housing will

snap into place.

Check the seating of the housing.

5

Check whether the piston and the centering tube are correctly posi-

6

tioned.

Press the entire dosing unit against a tabletop in upside-down posi-

7

tion.

The piston stopper must be flush with the upper edge of the housing.

807 Dosing Unit

■■■■■■■■

29

Page 38

3.8 Assembling the dosing unit

■■■■■■■■■■■■■■■■■■■■■■

Figure 25 Piston stopper flush with the upper edge of the housing

Check the stopcock setting.

8

Rotate the centering tube (interior) until the two triangles on the

9

upper side of the dosing unit are lined up with one another.

Figure 26 Triangles on the upper side of the dosing unit when the

stopcock is set correctly

Screw on all tubings and the adsorber tube.

10

Figure 27 Dosing unit completely mounted

■■■■■■■■

30

807 Dosing Unit

Page 39

■■■■■■■■■■■■■■■■■■■■■■

4 Handling and maintenance

4.1 Care and upkeep

In contrast to the Dosino drive, dosing units require regular care.

If aggressive reagents are dosed with dosing units, then such units should

be rinsed with an inert solvent when not in use ( 'PREP/Preparing function) and then subsequently emptied ( 'EMPTY/Emptying function). In

the event of that the dosing unit is not in use for > 2 days, the dosing unit

should be emptied without fail, because even water can corrode the buret

glass in the event of prolonged periods of disuse. Remove the dosing drive

in the event of prolonged periods of disuse (longer than one week).

NOTE

4 Handling and maintenance

Dosing units require regular inspections and must be disassembled

down to the cylinder unit from time to time and cleaned as necessary.

WARNING

Monthly or even weekly inspections are called for in the event that

alkali, corrosive or high-concentration reagents are used. If non-problematic reagents are used, then the inspection intervals can be extended to between six and twelve months.

4.1.1 Cleaning dosing cylinder and dosing piston

CAUTION

Never disconnect the cylinder from the cylinder base. Neither the cylinder nor the piston should ever be placed in a dishwasher!

■ Check the leak-tightness of the dosing piston and cylinder. Inspect the

dosing piston for deformations or damage to the sealing lips. The pis-

ton and the cylinder must be replaced in the event that any changes

are discovered.

■ Degreasing the piston and the glass cylinder are part of the cleaning

procedure. Use a cloth to wipe down the piston.

807 Dosing Unit

■■■■■■■■

31

Page 40

4.1 Care and upkeep

■ Clean the dosing cylinder and piston with a liquid cleaning agent. Do

not use any abrasive cleaning powder which could scratch the cylinder.

Afterwards, rinse the individual parts with plenty of deionised (or distilled) water.

■ Check the piston and cylinder for any changes once more before

assembling the dosing unit. If the dosing cylinder should exhibit

scratches or rough areas, then it must be replaced together with the

piston.

■ You should grease the dosing piston lightly in order to guarantee pre-

cise dosings. Using your finger, carefully apply a trace of paraffin

grease 6.2803.010 to the exterior of the sealing lips of the piston.

Wipe off excess grease with a soft, lint-free cloth.

4.1.2 Cleaning valve disc and distributor disc

■■■■■■■■■■■■■■■■■■■■■■

Figure 28

Valve disc in the cylinder base

Figure 29 Distributor disc with 4 ports (in the distributor)

The valve disc and distributor disc must also be checked regularly. Blockage of the valve opening or of the outlet port is to be avoided under all

circumstances.

Disassembling the dosing unit (see Chapter 3.7, page 21).

■■■■■■■■

32

807 Dosing Unit

Page 41

■■■■■■■■■■■■■■■■■■■■■■

CAUTION

Do not under any circumstances remove the black valve disc from the

cylinder base or the white distributor disc from the distributor.

4.1.2.1 Cleaning contact surfaces

CAUTION

Do not damage the valve disc under any circumstances. Even small

scratches could lead to leakage!

■ Use a liquid cleaning agent and a soft cloth for polishing the contact

surfaces of the two discs. Abrasive cleaning powders are unsuitable

and could scratch the valve disk.

■ Rinse the discs thoroughly with plenty of water.

■ Dry the discs with a soft, lint-free cloth.

4 Handling and maintenance

4.1.3 Discs adhere to one another

A film of liquid must always be present between the valve disc and the

distributor disc. If the dosing unit is used with solvent or pure water, it

could happen that this film of liquid will dry out during prolonged periods

of disuse. This could then lead to the valve disc and the distributor disc

adhering to one another so strongly that the dosing unit is no longer able

to function. It will no longer be possible to switch the stopcock position in

such cases. The control device will announce that the dosing drive is overloaded.

CAUTION

Do not attempt to use excessive force to separate the cylinder from the

distributor.

Separating the valve disc and distributor discs from one

another

Proceed as follows:

Removing the housing.

1

Remove the centering tube.

2

807 Dosing Unit

■■■■■■■■

33

Page 42

4.1 Care and upkeep

Place the dosing unit with the dosing cylinder in water (possibly with

3

a small amount of dishwashing detergent) for a few minutes.

Carefully release the cylinder base from the distributor by hand (with-

4

out rotating it) in order to separate the two discs from one another.

If the discs cannot be separated this way, inform the Metrohm Service Dept.

Should it happen that the discs repeatedly adhere to one another, then

the contact surfaces of the valve disc and the distributor disc can be

greased with a small amount of paraffin grease 6.2803.010. This is however not to be generally recommended.

4.1.4 Resistance and materials

■■■■■■■■■■■■■■■■■■■■■■

4.1.4.1

Solvent

Conventional reagents and media can be dosed without difficulty with the

807 Dosing Unit. The materials of the individual components (see Chapter

4.1.4, page 34) used which come into contact with the liquid being dosed

have been selected for maximum resistance to chemicals and functionality.

It can however not be assumed that all types of aggressive or high-concentration reagents can be conveyed without difficulty. It is the responsibility of the user to determine the resistance of the various individual components to specific, aggressive media.

WARNING

Reagents which corrode glass, e.g. hydrofluoric acid HF or strong inorganic alkalis, should be applied in diluted concentrations only. Caution

is also called for with concentrated solutions which are subject to crystallization.

Many problems involving aggressive media can be prevented by regular

cleaning and inspections. It is possible that frequent replacement of the

cylinder unit (piston/cylinder/cylinder base with valve disc) will be required.

■■■■■■■■

34

The temperature of the dosing material may not exceed 50°C. The dosing

unit and its components cannot be autoclaved. The sterility of a germ-free

dosing material cannot be guaranteed.

807 Dosing Unit

Page 43

■■■■■■■■■■■■■■■■■■■■■■

4.1.4.2 PETG housing

In contrast to the other components of the dosing unit, the transparent

housing has only limited resistance to chemicals.

Good resistance Aqueous solutions, diluted acids, alcohols and

Limited resistance Concentrated organic acids, diluted aqueous

Non-resistant Concentrated inorganic acids and bases, bro-

The PETG housing is not dishwasher-safe, but it can be cleaned readily

with lukewarm water and a dishwashing detergent.

4 Handling and maintenance

hydrocarbons

alkalis (cold cracking), acetone, isopropanol, tetrahydrofuran, hot water

mine, chlorinated solvents, phenol, water vapor

>100°C

4.1.4.3

Materials

Housing PETG (polyethylene terephthalate, glycol-modi-

fied) or PVDF

Centering tube PETG or PVDF

Dosing piston PTFE (polytetrafluoroethylene)

Dosing cylinder Borosilicate 3.3 or ETFE

Valve disc Silicone carbide ceramic

Distributor disc Al 2 O 3 ceramic

Distributor chan-

ETFE

nels

4.2 Quality Management and validation with Metrohm

Quality Management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure «Quality Management with

Metrohm» available from your local Metrohm agent.

807 Dosing Unit

Validation

Please contact your local Metrohm agent for support in validating instruments and software. Here you can also obtain validation documentation

to provide help for carrying out the Installation Qualification (IQ) and

the Operational Qualification (OQ). IQ and OQ are also offered as a

service by the Metrohm agents. In addition, various application bulletins

■■■■■■■■

35

Page 44

4.3 GLP - Validation

are also available on the subject, which also contain Standard Operating Procedures (SOP) for testing analytical measuring instruments for

reproducibility and correctness.

Maintenance

Electronic and mechanical functional groups in Metrohm instruments can

and should be checked as part of regular maintenance by specialist personnel from Metrohm. Please ask your local Metrohm agent regarding the

precise terms and conditions involved in concluding a corresponding

maintenance agreement.

You can find information on the subjects of quality management, validation and maintenance as well as an overview of the documents currently available at www.metrohm.com/com/ under Support.

4.3 GLP - Validation

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Every dosing unit manufactured by the Metrohm company is subjected to

rigorous quality controls prior to shipment. Every dosing unit is issued a

quality certificate attesting to conformance with the strict quality criteria

of Metrohm GLP(Good Laboratory Practice) requires, among other

things, periodic inspection of analytical measuring devices with respect to

precision and correctness on the basis of standard operating procedures

Standard Operating P rocedure, SOP). This may also include an inspection of dosing accuracy.

Recommended literature

■ Metrohm brochure "Quality management with Metrohm", detailed

information concerning the principles and procedural methods of

Good Laboratory Practice

■ Metrohm Application Bulletin 283/1 "Validation of Metrohm burets"

The validation of burets is carried out by the Metrohm-Service with a special software.

The Metrohm agents worldwide offer the possibility of on-site inspections

and certifications of dosing units and Dosinos with respect toaccuracy. It is

recommended that an accuracy inspection be performed when the dosing

cylinders and dosing pistons of a dosing unit are replaced.

■■■■■■■■

36

807 Dosing Unit

Page 45

■■■■■■■■■■■■■■■■■■■■■■

5 Troubleshooting

5.1 Problems

Problem Cause Remedy

5 Troubleshooting

Adsorber tube is

jammed

Air bubbles in the

cylinder or in the

dosing tubing

Using your thumb or the balls of your hand,

apply forceful pressure to the center of rotation of the adsorber tube, while at the same

time carefully rotating it counterclockwise until

the screw nipple releases.

Leaking connection ■ Check the ends of the tubing, in particular

that of the aspiration tubing.

■ Tighten all of the tubing connections with

the wrench 6.2739.000.

■ Check the locking mechanism of the hous-

ing. Suggestion: Remove the housing and

then reattach it.

The reagent degasses

excessively, e.g. released

air forms bubbles.

■ Carry out [PREP] / [Preparing]

■ Reduce the filling rate.

■ Suggestion: Degas the reagent with ultra-

sound, nitrogen or in a vacuum.

Wear Replacing piston and cylinder.

[PREP] / [Preparing] is

not carried out or false

■ Carry out [PREP] / [Preparing]

■ Correct tubing length and diameter.

parameters-

An incorrect volume

is dosed

Data of the dosing

unit cannot be read.

807 Dosing Unit

Dosing unit either mounted

or assembled incorrectly.

Data chip of the dosing

unit mechanically damaged or impaired by chemicals.

■ Remove the dosing unit and then reattach

it.

■ Check whether the nominal volume on the

housing and the effective cylinder volume

match one another.

■ Remove the dosing drive and then reattach

it.

■ Clean the data chip and the contact sur-

faces.

■ Have the data chip replaced by the

Metrohm Service Dept.

■■■■■■■■

37

Page 46

5.1 Problems

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Dosing cylinder does

not fit into the centering tube

Dosing unit has a

leak on the distribu-

Dosing cylinder is canted

or attached at an angle on

the base of the cylinder.

Distributor disc shows leakage.

tor

Dosing unit recognized either not at

The dosing drive was not

attached correctly.

all or incorrectly.

Dosing unit incorrectly

assembled.

Dosino becomes hot Dosing drive is overloaded.

Valve disc or dosing piston

is blocked.

Dismantle the cylinder and reassemble the

dosing unit.

Clean valve disc and distributor disc (see Chap-

ter 4.1.2, page 32).

■ Remove the dosing drive and then reattach

it once again.

■ Check whether the dosing drive is correctly

seated.

■ Switch the control instrument off and on

again.

■ If necessary contact Metrohm Service Dept.

Check whether the nominal volume on the

housing and the effective cylinder volume

match one another.

■ Switch off the instrument immediately.

■ Disconnect dosing unit from the bottle and

tighten only slightly (see "Dismantling the

dosing system", page 21).

■ Disassemble the dosing unit and clean all

of the individual parts (see Chapter 3.7,

page 21). Replace defective parts.

Fluid above the dosing piston

Housing cannot be

closed.

Liquid drips into the

bottle

Worn-out or defective dos-

Replace dosing piston and cylinder.

ing piston and/or cylinder.

Spring clip inserted incorrectly.

Remove the housing and insert the spring clip

correctly.

There is air in the cylinder. ■ Check the ends of the tubing, in particular

that of the aspiration tubing.

■ Tighten all of the tubing connections with

the wrench 6.2739.000.

■ Check the locking mechanism of the hous-

ing. Suggestion: Remove the housing and

then reattach it.

The reagent degasses

excessively, e.g. released

air forms bubbles.

■ Carry out [PREP] / [Preparing]

■ Reduce the filling rate.

■ Suggestion: Degas the reagent with ultra-

sound, nitrogen or in a vacuum.

■■■■■■■■

38

807 Dosing Unit

Page 47

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

Wear Replace dosing piston and cylinder.

5 Troubleshooting

No dosing takes

place at all

Not possible to

rotate the stopcock

[PREP] / [Preparing] is

not carried out or false

parameters-

Tubing connections are

blocked or dosing unit is

not assembled correctly.

Valve disc and distributor

disc stick to one another.

■ Carry out [PREP] / [Preparing]

■ Correct tubing length and diameter.

■ Check whether the dosing tip is blocked.

■ Check whether the dosing tubing is con-

nected to the correct port.

■ Check whether the dosing port is sealed off

with a stopper.

■ Check whether the VENT port is sealed off

with a stopper (vacuum in the supply bottle!). The VENT port must be open for pressure compensation.

■ Remove dosing drive and check whether

the dosing piston is connected to the dosing drive. The piston stopper must be flush

with the upper side of the housing.

■ Check whether the connection cable is

attached to the dosing drive.

Clean valve disc and distributor disc (see Chap-

ter 4.1.2, page 32).

807 Dosing Unit

■■■■■■■■

39

Page 48

6.1 Buret data

6 Appendix

6.1 Buret data

The 807 Dosing Unit is equipped with a data chip which contains the

specifications for the dosing unit, the tubing connections and the reagent

used. The data chip can be read and overwritten by an 800 Dosino.

Indications on dosing unit / tubing connections

■ Order number of the dosing unit

■ Serial number of the dosing unit

■ Serial number of the dosing cylinder

■ Length and diameter of the tubings on the dosing ports

■ Validation date

■ etc.

Indications on the reagent

■■■■■■■■■■■■■■■■■■■■■■

■ Name of the reagent

■ Titer of the reagent

■ Concentration of the reagent

■ Production and expiry date of the reagent

■ etc

The 807 Dosing Unit makes it possible to read and overwrite data with the

aid of a suitable device (e.g. Titrando). Consult the respective manual in

order to determine whether the Metrohm device which you are using is

capable of accomplishing this. The contact surfaces for data exchange

with the data chip are made of titanium and are exceptionally resistant to

both chemicals and abrasion.

CAUTION

Take care to ensure that the contact surfaces do not become contaminated. Wipe off any contaminations at once. In the event of more serious contamination, the underside of the 807 Dosing Unit can be

cleaned with a moist cloth (possibly with a small amount of dishwashing detergent or ethanol).

■■■■■■■■

40

807 Dosing Unit

Page 49

■■■■■■■■■■■■■■■■■■■■■■

2

1

6 Appendix

Figure 30 Data chip and contact pin

Contact surfaces

1

on the 800 Dosino

6.2 Dosing accuracy

Every dosing unit is subjected to a strict quality inspection prior to shipment. Every dosing unit is issued a quality certificate attesting conformance with the quality criteria of Metrohm.

6.2.1 Typical measurement deviation

The accuracy of dosing units can be seen in the following table. The values listed are to be regarded as typical values which can be achieved with

a 700 Dosino or an 800 Dosino.

Table 3

Cylinder volume max. systematic deviation

2 mL ± 6 µL

5 mL ± 15 µL

10 mL ± 20 µL

Typical measurement deviation of Metrohm dosing units

Data chip with contact pins

2

on the 807 Dosing Unit

20 mL ± 30 µL

50 mL ± 50 µL

6.2.2 The ISO/EN/DIN standard 8655-3

The Metrohm dosing units fulfil the requirements of the ISO/EN/DIN

standard 8655-3 Volume measurement instruments with pistons –

Part 3: Piston burets. Metrohm guarantees that its dosing units are in

compliance with the following limit values at the time of shipment:

807 Dosing Unit

■■■■■■■■

41

Page 50

6.2 Dosing accuracy

■■■■■■■■■■■■■■■■■■■■■■

Table 4 Permissible limit values as per ISO/EN/DIN 8655-3

Cylinder

volume

max. systematic

Measurement deviation

max. permissible

Measurement deviation

(mL)

2 ± 0.5 % ± 10 µL ± 0.1 % ± 2 µL

5 ± 0.3 % ± 15 µL ± 0.1 % ± 5 µL

10 ± 0.2 % ± 20 µL ± 0.07 % ± 7 µL

20 ± 0.2 % ± 40 µL ± 0.07 % ± 14 µL

50 ± 0.2 % ± 100 µL ± 0.05 % ± 25 µL

The Metrohm agents worldwide offer the possibility of on-site dosing unit

inspections and certifications with respect to accuracy. We recommend

that an accuracy inspection be performed when the dosing cylinders and

dosing pistons of a dosing unit are replaced.

■■■■■■■■

42

807 Dosing Unit

Page 51

■■■■■■■■■■■■■■■■■■■■■■

7 Accessories

7.1 Scope of delivery

NOTE

Subject to change without notice.

7.1.1 807 Dosing Unit 6.3032.xxx

7 Accessories

Qty.

Order no. Description

1 6.3032.xxx 807 Dosing Unit

Dosing unit with data chip. With 2, 5, 10, 20 or 50 mL glass cylinder

and light protection, mountable to a reagent bottle with ISO/DIN

GL45 glass thread, FEP tubing connection and antidiffusion buret tip.

6.3032.120: 2 mL

6.3032.150: 5 mL

6.3032.210: 10 mL

6.3032.220: 20 mL

6.3032.250: 50 mL

1 6.1446.030 Link stopper / B-14/(15)

For the flexible holding of buret tips in titration vessels

Material: ETFE

Height (mm): 31.5

SGJ size: B-14/(15)

807 Dosing Unit

■■■■■■■■

43

Page 52

7.1 Scope of delivery

Qty. Order no. Description

1 6.1446.040 Threaded stopper / M6

Material: PVDF

Height (mm): 21.5

Outer diameter (mm): 4.9

1 6.1543.060 Tip / Thread M6

Tip with M6 thread. Together with the 6.1805.160 capillary tubing

and the 6.1446.030 link stopper it provides the entire 6.1537.010

buret tip.

Material: ETFE/FEP

Length (mm): 151

■■■■■■■■■■■■■■■■■■■■■■

1 6.1543.200 Antidiffusion tip / Thread M6

Material: ETFE/FEP

Length (mm): 151

■■■■■■■■

44

807 Dosing Unit

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.1619.000 Adsorber tube for dosing unit

Material: PMP

Height (mm): 88

Inner diameter (mm): 19

1 6.1805.100 FEP tubing / M6 / 40 cm

Protected against light and kink.

Material: FEP

Inner diameter (mm): 2

Length (mm): 400

7 Accessories

1 6.1829.010 FEP aspiration tubing / M6 / 0.25 m

With M6 thread. For dosing units

Material: FEP

Inner diameter (mm): 2

Length (mm): 250

1 6.2008.030 Buret tip storage vessel for dosing unit

Together with the 6.2008.050 storage vessel holder it provides a

holder for the buret tip on the 6.3032.XXX dosing unit.

807 Dosing Unit

■■■■■■■■

45

Page 54

7.1 Scope of delivery

Qty. Order no. Description

1 6.2008.050 Storage vessel holder for dosing unit

Together with the 6.2008.030 buret tip storage vessel it provides a

holder for the buret tip on the 6.3032.XXX dosing unit.

Material: PP

1 6.2244.020 Labeling plates for intelligent exchange unit

Set of 10 pieces, in various colors.

■■■■■■■■■■■■■■■■■■■■■■

1 6.2739.000 Wrench

For tightening connectors

Length (mm): 68

1 6.2803.010 Grease (2 g)

Special quality (silicone-free). For grease-free ground joint connections, see 6.2713.XXX

1 8.807.8002EN Manual 807 Dosing Unit

■■■■■■■■

46

807 Dosing Unit

Page 55

■■■■■■■■■■■■■■■■■■■■■■

7.2 Optional accessories

Order no. Description

6.1574.120 Glass cylinder unit / 2 mL

Glass cylinder unit complete with cylinder, piston, cylinder base, valve disc and

centering tube.

Material: Clear glass

Volume (mL): 2

6.1574.150 Glass cylinder unit / 5 mL

Glass cylinder unit complete with cylinder, piston, cylinder base, valve disc and

centering tube.

Material: Clear glass

Volume (mL): 5

7 Accessories

6.1574.210 Glass cylinder unit / 10 mL

Glass cylinder unit complete with cylinder, piston, cylinder base, valve disc and

centering tube.

Material: Clear glass

Volume (mL): 10

6.1574.220 Glass cylinder unit / 20 mL

Glass cylinder unit complete with cylinder, piston, cylinder base, valve disc and

centering tube.

Material: Clear glass

Volume (mL): 20

807 Dosing Unit

■■■■■■■■

47

Page 56

7.2 Optional accessories

Order no. Description

6.1574.250 Glass cylinder unit / 50 mL

Glass cylinder unit complete with cylinder, piston, cylinder base, valve disc and

centering tube.

Material: Clear glass

Volume (mL): 50

6.1575.120 Dosing unit complete / 2 mL

For dosing solvents or solutions with Dosinos

Material (Cylinder): ETFE

Material (Housing): PVDF

Volume (mL): 2

■■■■■■■■■■■■■■■■■■■■■■

6.1575.150 Dosing unit complete / 5 mL

For dosing solvents or solutions with Dosinos

Material (Cylinder): ETFE

Material (Housing): PVDF

Volume (mL): 5

6.1575.210 Dosing unit complete / 10 mL

For dosing solvents or solutions with Dosinos

Material (Cylinder): ETFE

Material (Housing): PVDF

Volume (mL): 10

■■■■■■■■

48

807 Dosing Unit

Page 57

■■■■■■■■■■■■■■■■■■■■■■

Order no. Description

6.1575.220 Dosing unit complete / 20 mL

For dosing solvents or solutions with Dosinos

Material (Cylinder): ETFE

Material (Housing): PVDF

Volume (mL): 20

6.1575.250 Dosing unit complete / 50 mL

For dosing solvents or solutions with Dosinos

Material (Cylinder): ETFE

Material (Housing): PVDF

Volume (mL): 50

7 Accessories

6.1608.023 Amber glass bottle / 1000 ml / GL 45

For exchange units. Bottle for auxiliary solutions

Material: Amber glass

Width (mm): 96

Height (mm): 223

Volume (mL): 1000

6.1608.030 Round glass bottle / 1000 mL / GL 45

Material: Clear glass

Height (mm): 223

Volume (mL): 1000

807 Dosing Unit

■■■■■■■■

49

Page 58

7.2 Optional accessories

Order no. Description

6.1608.040 PE bottle / 1000 mL / GL 45

For exchange units. Bottle for auxiliary solutions

Material: PE

Width (mm): 96

Height (mm): 223

Volume (mL): 1000

6.1608.050 Drying flask / 100 mL / GL 45

Material: Clear glass

Height (mm): 100

Outer diameter (mm): 56

Volume (mL): 100

■■■■■■■■■■■■■■■■■■■■■■

6.1608.060 Bottle / 1000 mL / GL 45

Material: PE

Width (mm): 48

Depth (mm): 48

Volume (mL): 100

6.1618.000 Thread adapter / 32 mm on GL 45

Adapter for bottles with 32 mm thread (Fluka, Riedel de-Haen 500 mL...) on

GL45

■■■■■■■■

50

807 Dosing Unit

Page 59

■■■■■■■■■■■■■■■■■■■■■■

Order no. Description

6.1618.010 Thread adapter / 28 mm on GL 45

Adapter for bottles with 28 mm thread (Fisher...) on GL45

6.1618.020 Thread adapter / S40 on GL 45

Adapter for bottles with S40 / thread (Merck...) on GL45.

6.1618.050 Thread adapter / 40 mm on GL 45

Adapter for bottles with 40 mm thread on GL45.

7 Accessories

6.1618.060 Thread adapter / GL45 on GL45

Thread adapters (GL45 to GL45); for reagent bottles with raised flange, among

others

6.1622.000 Support ring for the dosing unit

For improving the contact between the neck of the bottle and the lower part of

the Dosino

807 Dosing Unit

■■■■■■■■

51

Page 60

7.2 Optional accessories

Order no. Description

6.1805.030 FEP tubing / M6 / 150 cm

Protected against light and kink.

Material: FEP

Inner diameter (mm): 2

Length (mm): 1500

6.1805.110 FEP tubing / M6 / 80 cm

Protected against light and kink.

Material: FEP

Inner diameter (mm): 2

Length (mm): 800

■■■■■■■■■■■■■■■■■■■■■■

6.1808.000 Coupling bush M6

Material: ETFE

Outer diameter (mm): 10

Length (mm): 25

■■■■■■■■

52

807 Dosing Unit

Page 61

■■■■■■■■■■■■■■■■■■■■■■

Order no. Description

6.1808.020 Tubing adapter olive / M6 inner

With inner thread M6 and 1 olive for tubings. Part of the screw connections of

exchange units and stability measurement instruments.

Material: PCTFE

Length (mm): 30

6.1808.030 Tubing coupling for grounded buret tip

Results in the completely grounded buret tip 6.1540.010 when used together

with buret tip 6.1541.010. For titrations in non-aqueous solvents.

6.1808.060 T connection / M6 inner

7 Accessories

3 times M6 inner thread

Material: PCTFE

6.1829.020 FEP aspiration tubing / M6 / 0.5 m

For dosing unit

Material: FEP

Inner diameter (mm): 2

Length (mm): 500

807 Dosing Unit

■■■■■■■■

53

Page 62

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

A

Accuracy .................................. 36

Acids ........................................ 35

Adhering .................................. 33

Adsorber tube .............. 21, 28, 37

Air bubbles ............................... 19

Antidiffusion tip .................. 17, 18

Aqueous alkalis ........................ 35

Aqueous solution ..................... 35

Aspiration tubing ...................... 37

B

Bubble trap .............................. 19

Buret data ................................ 40

Buret tip ............................. 17, 18

Crystallizing ........................ 18

Selection ............................ 17

Storage .............................. 18

C

Care ......................................... 31

Centering tube

Attaching ........................... 28

Material .............................. 35

Certification .............................. 36

Checks ..................................... 31

Cleaning

Contact surface .................. 33

Distributor disc ................... 32

Dosing cylinder ................... 31

Dosing piston ..................... 31

Valve disc ........................... 32

Cleaning agent ................... 31, 33

Contact surface ........................ 40

Cleaning ............................. 33

Contact surfaces ....................... 33

Contamination ......................... 40

Corrosion ........................... 21, 31

Crystallization ..................... 21, 34

Crystallizing .............................. 18

D

Data chip ........................... 19, 40

Data exchange ......................... 40

Dead volume ............................ 19

Degassing ................................ 19

Distributor channels

Material .............................. 35

Distributor disc

Cleaning ............................. 32

Material .............................. 35

Dosing accuracy ....................... 36

Dosing cylinder

Air bubbles ......................... 19

Cleaning ............................. 31

Degreasing ......................... 31

Fill ...................................... 17

Dosing piston

Attaching ........................... 26

Cleaning ............................. 31

Degreasing ......................... 31

Greasing ............................. 31

Leak-tightness .................... 31

Material ........................ 34, 35

Scratches ............................ 31

Stopper .............................. 26

Dosing tip ................................ 17

Open .................................. 18

Dosing tubing

Mounting ........................... 17

Dosing unit

Checks ............................... 31

Disassembling ..................... 21

Non-use ............................. 31

Opening ............................. 21

Dosino ............................... 19, 21

E

EMPTY ............................... 21, 31

Emptying ............................ 21, 31

End position ............................. 19

ETFE

Distributor channels ............ 35

Dosing cylinder ................... 21

Exchange volume ..................... 21

F

Fill

Dosing cylinder ................... 17

Dosing unit ......................... 17

Filling tubing

Removing ........................... 21

G

Glass cylinder ..................... 21, 31

GLP .................................... 35, 36

Good Laboratory Practice ......... 36

Ground joint opening ............... 17

Guide groove ........................... 28

H

Housing ................................... 35

Attaching ........................... 28

Closing ............................... 28

Locking .............................. 28

Material .............................. 35

Opening ............................. 21

Resistance to chemicals ...... 35

L

Leak-tightness .......................... 31

Leakage ................................... 33

Link stopper ............................. 17

Locking .................................... 28

Locking button ................... 21, 28

M

Marking rib .............................. 28

O

Order number .......................... 40

P

Paraffin grease ................... 31, 33

PETG ........................................ 35

Precision ................................... 19

PREP ....................... 17, 19, 21, 31

PREP-Position ........................... 19

Preparation .............................. 31

Preparation step ....................... 19

Preparing ............................ 19, 21

Production date ........................ 40

Q

Quality certificate ..................... 36

Quality control ......................... 36

Quality Management ................ 35

R

Reagent

Aggressive .......................... 31

Concentrated ..................... 34

Concentration .................... 40

Crystallizing ........................ 18

Expiry date ......................... 40

Name ................................. 40

Production date .................. 40

Titer ................................... 40

Reagent replacement ................ 21

■■■■■■■■

54

807 Dosing Unit

Page 63

■■■■■■■■■■■■■■■■■■■■■■

Index

Resistance to chemicals

Acetone ............................. 34

Acids/bases ........................ 34

Alcohols ............................. 34

Halogens ............................ 34

Hydrocarbons ..................... 34

Rib ........................................... 28

Rinsing volume ......................... 19

S

Sample series ............................ 19

Scratches .................................. 33

Sealing lip ........................... 26, 31

Serial number ........................... 40

Service Agreement ................... 35

SOP .......................................... 36

Spring clip .......................... 21, 28

Sterility ..................................... 34

Stopcock setting ................. 28, 33

Storage vessel .......................... 18

T

Temperature

Dosing material .................. 34

Triangles ................................... 28

Tubing

Filling ................................. 19

Tubing diameter ................. 19, 40

Tubing length ..................... 19, 40

Tubings

Rinsing ............................... 17

U

Upkeep .................................... 31

V

Validation ........................... 35, 36

Validation date ......................... 40

Valve disc

Cleaning ............................. 32

Material .............................. 35

Scratches ............................ 33

807 Dosing Unit

■■■■■■■■

55

Loading...

Loading...