Liebherr ER 954 C User Manual

Excavators Electric |

ER 934 C - ER 954 C |

|

Material Handlers |

||

|

||

|

|

|

|

ER 934 C Operating Weight: 38,050 – 39,450 kg |

|

|

ER 944 C Operating Weight: 52,050 – 53,750 kg |

|

|

ER 954 C Operating Weight: 63,900 – 76,200 kg |

ER 934 C

Operating Weight: 38,050 – 39,450 kg Engine Capacity: 160 kW / 218 PS

ER 954 C

Operating Weight: 63,900 – 76,200 kg Engine Capacity: 250 kW / 340 PS

ER 944 C

Operating Weight: 52,050 – 53,750 kg Engine Capacity: 200 kW / 272 PS

2 ER 934 C ER 944 C ER 954 C Material Handlers

Performance

These new electric Material Handlers have been designed to meet the specific needs of industrial handling. A wide range of equipment and uppercarriages optimized for long working radius provide the ideal answer to all the demands which arise in the industry.

The performance of the kinematic chain formed from components from our in-house production, combined with the power of the electric motor, maximize the performance of the machine when it comes to lifting power, precision, and speed of operation. The equipment’s performance is enhanced by the mobility provided by the crawler undercarriage.

Comfort

Helping the operator to concentrate on his work and get the best out of his machine is achieved by providing a comfortable driving position, good visibility, and a highly ergonomic layout of the controls. The new electric Material Handlers offer the same level of comfort as on the mobile excavators (arrangement of the controls, driver’s seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks to the low noise emissions and absence of vibration. For Liebherr, comfort also means ease of daily maintenance of the machine in terms of access to the service and inspection points, so as to minimize down time.

Reliability

Backed by more than 30 years experience in the construction of electric excavators, Liebherr designed the new ER 934 C, ER 944 C and ER 954 C with the aim of providing top performance whatever the challenge might be. The structure of the machine, using components from our own manufacture for the electric drive, has been completely rethought, and so moves away from simply being an adaptation of a diesel-engine machine. Being intended for key functions in the organization of industrial sites, Liebherr electric Material Handlers provide a very

high level of reliability. The service life of the hydraulic components has also been increased, thanks to the smoother movement of the electric drive. The concept of the single actuator (one single electric motor for all the hydraulic functions) allows

all the low-voltage functions to be concentrated in a single box.

Economy

Investing in the acquisition of an electric Material Handler is a great long-term advantage. Constant increases in the costs of conventional energy sources are pushing up operating charges, and reducing profi t margins considerably. Environmental criteria, in particular CO2 emissions, are also playing a constantly greater part in the choice of power systems and working methods. With the electric drive, Liebherr offers an economical alternative to conventional diesel-engine machines, and a solution with real respect for the environment. Also, the excavator is permanently available, with no need to refill. There are no constraints (e.g. DPF or AdBlue).

ER 934 C ER 944 C ER 954 C Material Handlers |

3 |

Side or rear cable opening for freely positioning the cable on the ground

•Power supply through multicore wiring cable entrance (funnel-shaped) especially designed for travelling machines

•For longer distances a cable reel can be proposed as an option

•Heavy duty connecting box fitted on the middle piece of the undercarriage with switching system

4 ER 934 C ER 944 C ER 954 C Material Handlers

Performance

These new electric Material Handlers have been designed to meet the specifi c needs of industrial handling. A wide range of equipment and uppercarriages optimized for long working radius provide the ideal answer to all the demands which arise in the industry. The performance of the kinematic chain formed from components from our in-house production, combined with the power of the electric motor, maximize the performance of the machine when it comes to lifting power, precision, and speed of operation. The equipment’s performance is enhanced by the mobility provided by the crawler undercarriage.

Exceptional lift capacity |

Thanks to optimized kinematics and uppercarriage, |

|

the machines offer extended reach and balance |

|

with a better absorption of mechanical forces. |

Excellent Working |

Designed for the most demanding applications, the |

Radius |

machines offer extended reach and lift capacity in |

|

wide working radius. |

Fast work cycles |

The ER 934 C, ER 944 C and ER 954 C electric |

|

excavators are fitted with the Liebherr Torque Con- |

|

trol system. The hydraulic guidance system on the |

|

excavator operates as a closed circuit, and does |

|

not affect the speed of movement of the equip- |

|

ment during the working cycle. The high torque and |

|

high oil delivery from the guide pump maximize the |

|

excavator swing speed. |

|

A two-pump hydraulic system allows for operating |

|

speeds to be reached which are unequalled any- |

|

where. Regeneration on the circuits for the equip- |

|

ment allows for optimization of the hydraulic power |

|

available and minimizing response time to the opera- |

|

tor’s commands. |

Precision |

The hydraulic control allows for exceptional preci- |

|

sion - even at extended reach - contributing to the |

|

confidence of the operator and achieving high perfor- |

|

mance as a result. |

Distributor

•Fine response of hydraulic control for maximum working precision

•Immediate response to operator‘s commands

•Three-pump hydraulic system, one of which is a closed circuit dedicated to uppercarriage swing

High strenght structure

•High strength steel sheet at points subject to severe stress.

•Stable mounting of equipment elements

•Exceptional strength, even under intense loading

ER 934 C ER 944 C ER 954 C Material Handlers |

5 |

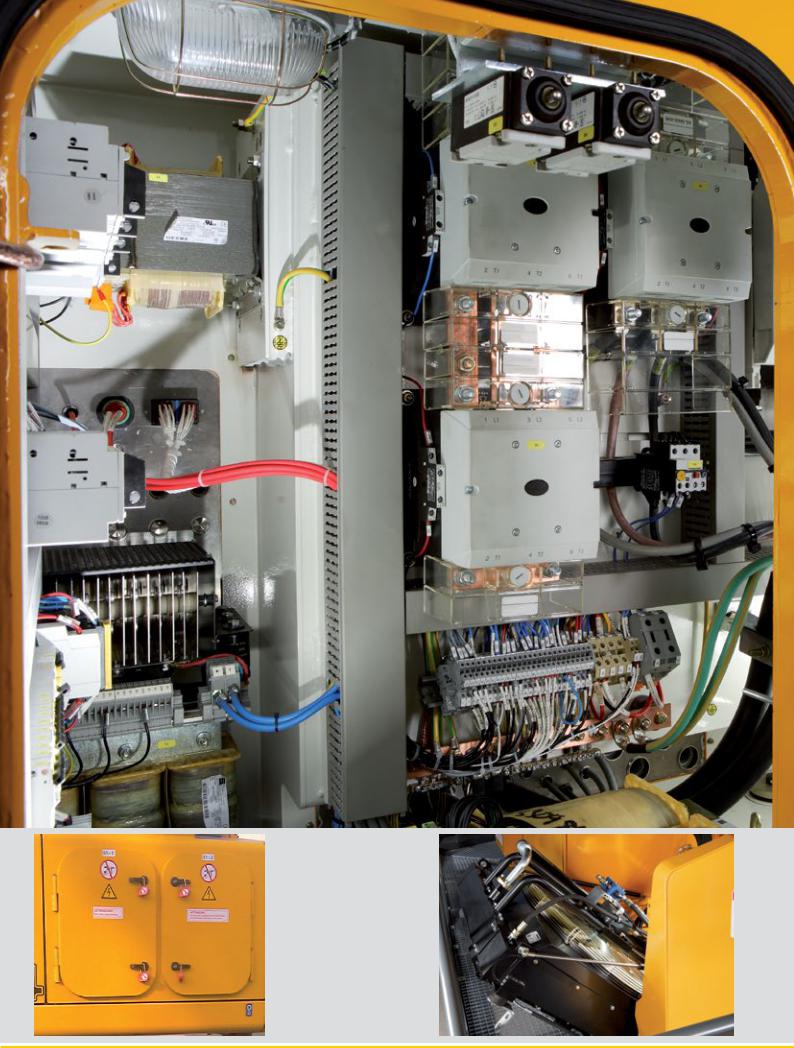

Reliability - Safety

•Automatic Power cut off if the cabinet doors are opened

•Automatic power cut off in the event of any anomalies (electric motor or its bearings overheating)

•Active safety on the transformers in the electric cabinet

•Possible to lock with padlock

6 ER 934 C ER 944 C ER 954 C Material Handlers

Reliability

Backed by more than 30 years experience in the construction of electric excavators, Liebherr designed the new ER 934 C, ER 944 C and ER 954 C with the aim of providing top performance whatever the challenge might be. The structure of the machine, using components from our own manufacture for the electric drive, has been completely rethought, and so moves away from simply being an adaptation of a diesel-engine machine. Being intended for key functions in the organization of industrial sites, Liebherr electric Material Handlers provide a very high level of reliability. The service life of the hydraulic components has also been increased, thanks to the smoother movement of the electric drive. The concept of the single actuator (one single electric motor for all the hydraulic functions) allows all the low-voltage functions to be concentrated in a single box.

Electrical |

Totally integrated into the structure of the uppercarriages |

system |

and accommodated in a metal container, the electric cabinet |

|

provides a three-fold level of protection to the components |

|

of the electrical system: |

|

- Mechanical (insulation from vibrations and from the pos- |

|

sible impact of falling objects) |

|

- Heat (maintains a constant temperature thanks to the heat- |

|

ing resistors which prevent corrosion from condensation) |

|

- Electrical earthing of the structure and disconnection from |

|

current is controlled from the cab by way of a motorised |

|

circuit-breaker. |

Protected |

The electric cabinet, such as the collecting pipe, provides |

electric cabinet |

IP55 class protection. A filtered ventilation system which |

|

avoids any dust penetration and, with permanent ventila- |

|

tion, ensures the thermal balance of all the components. |

Electric motor |

Liebherr electric excavators are equipped with motors espe- |

|

cially designed for really tough applications. The dimensions |

|

of the motor allow for the full power to be drawn from the |

|

kinematic chain, and so maximises the performance of the |

|

machine especially in the combined movements. The motor |

|

can resist a momentary overload of up to +25 % of its rated |

|

capacities. Protected against penetration by water and dust, |

|

its properties correspond to protection class IP55. |

|

The temperature of the roller bearings and other bearing |

|

elements is constantly monitored, and, in the event of over- |

|

heating, the operator is warned of malfunction on the con- |

|

sole at the driving position. |

Cooling system |

|

Undercarriage |

|

||

• Generous dimensions |

|

• The undercarriages are those of the EW |

for high cooling capacity |

|

or S-EW diesel machines for industrial |

• Vertical arrangement for increased |

|

applications, flat or ribbed tiles |

|

|

|

efficiency and minimal incursion of |

|

• The undercarriages are designed and |

foreign bodies |

|

built especially for electric excavators: |

• Powered by a thermostatically |

|

- side cable opening |

|

- armoured junction box |

|

regulated hydraulic motor |

|

|

|

- electrical collecting pipe |

|

|

|

|

• Hinged to allow for complete |

|

|

cleaning |

|

|

• Reversible actuation of the fan |

|

|

(without time limit) as option |

|

|

|

|

|

|

|

|

|

|

|

ER 934 C ER 944 C ER 954 C Material Handlers |

7 |

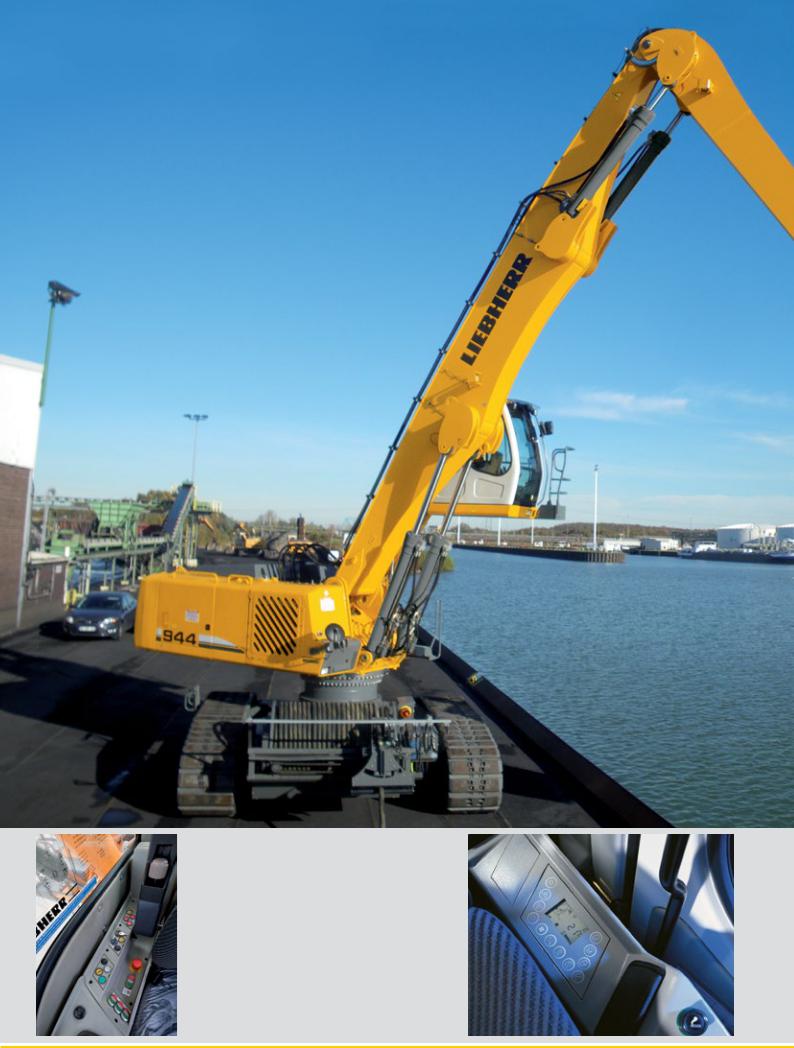

Cab with control panel

•The command arrangement for putting the electrical system under voltage is progressive (3 functions) and the emergency stop button allows for the general cutting of the electric cabinet supply

•Available as an option is a cut off system deriving from one source point, which can be activated from the driving position via an additional rotating joint

8 ER 934 C ER 944 C ER 954 C Material Handlers

Comfort

Helping the operator to concentrate on his work and get the best out of his machine is achieved by providing a comfortable driving position, good visibility, and a highly ergonomic layout of the controls. The new electric Material Handlers offer the same level of comfort as on the mobile excavators (arrangement of the controls, driver’s seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks to the low noise emissions and absence of vibration. For Liebherr, comfort also means ease of daily maintenance of the machine in terms of access to the service and inspection points, so as to minimize down time.

Driving position |

Mounted as standard on a fixed platform of |

|

1,200 mm ( 2,000 mm or hydraulic platform on re- |

|

quest), the new cab on the electric excavators |

|

meets all safety standards in force ( 24 V supply in |

|

the operator’s compartment), comfort, panoramic |

|

visibility, and ergonomic arrangement of the con- |

|

trols for perfect control of the machine. |

Low noise emissions |

Liebherr electric excavators are really quiet in op- |

|

eration. Their measured acoustic level is from 4 to |

|

5 dB lower than an equivalent diesel-engine version. |

|

The level of noise intensity from a Liebherr electric |

|

excavator represents less than a third of the noise |

|

generated by a diesel-engine unit. |

Carbon gas emission |

Zero grams of CO2 emitted per tonne of product |

|

handled! |

Climate control entirely automatic

•Automatic climate control ensures a level of comfort similar to a private car

•Two sensors for precise temperature regulation

•Ventilation flaps can be adjusted at the touch of a button

•Rapid demisting and defrosting of the windscreen thanks to the «reheat“ function

Parallelogram hydraulic lift

•Improved visibility of the operator over his workspace

ER 934 C ER 944 C ER 954 C Material Handlers |

9 |

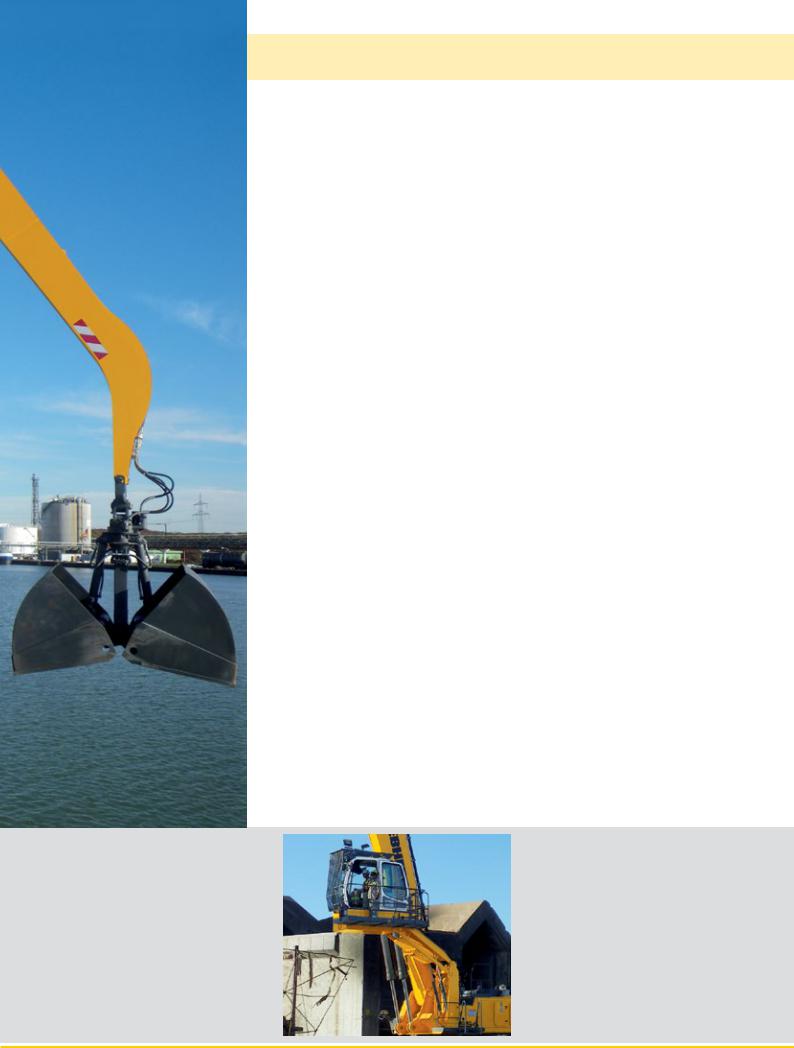

Wide range of solutions

•Modular arrangement for rapid changeover

•Liebherr quick-coupling system, mechanical and hydraulic, for efficient equipment changeover

•Quick-coupling arrangement for hydraulic lines (Multi-Coupler)

•Complete range of grapples

•Range of different wood grapples and grab buckets from Liebherr

10 ER 934 C ER 944 C ER 954 C Material Handlers

Economy

Investing in the acquisition of an electric Material Handler is a great long-term advantage. Constant increases in the costs of conventional energy sources are pushing up operating charges, and reducing profit margins considerably. Environmental criteria, in particular CO2 emissions, are also playing a constantly greater part in the choice of power systems and working methods. With the electric drive, Liebherr offers an economical alternative to conventional diesel-engine machines, and a solution with real respect for the environment. Also, the excavator is permanently available, with no need to refill. There are no constraints (e.g. DPF or AdBlue).

Flexibility and versatility |

Liebherr electric Material Handlers are multi-tasking |

|

machines. With a wide range of tools, which can be |

|

combined with Liebherr quick-coupling systems, |

|

they can create a degree of flexibility and versatility |

|

which has no comparison anywhere. |

Energy costs cut |

The energy yield from an electric motor is greater |

|

than that of a diesel-engine. Delivering the same kW |

|

output in hydraulic power costs three to five times |

|

less with an electric excavator than with a diesel-en- |

|

gine unit. Liebherr excavators deliver the full power |

|

from their kinematic chain and at a lot less cost. |

Increased service life |

The smooth actuation of the electric drive and the |

|

reliability of Liebherr hydraulic components mean |

|

that the maintenance costs of the excavator can be |

|

reduced considerably. |

|

The absence of vibrations and variations in output |

|

from a motor, which operates on a torque principle |

|

and at constant output, means that the stress on |

|

the kinematic chain can be reduced and the option- |

|

al pre-heating of the hydraulic system allows for the |

|

hydraulic oil to be kept at an optimum temperature |

|

right from the start. |

Maximum availability |

The costs associated with maintenance operations |

|

are reduced to a minimum, and that also cuts down- |

|

times. The electric motor does not require any main- |

|

tenance beyond lubrication of the bearings every |

|

3,000 hours. No filters (air, oil) to be changed and no |

|

draining of engine oil throughout the entire service |

|

life of the machine. |

Kinematic chain made by Liebherr

•Constant provision of power for the kinematic chain

•Reduced wear of hydraulic components

•Optimum exploitation of the hydraulic power potential of the system

Backhoe stick with sorting grapple

•Numerous combinations are associated with Liebherr’s wide range of tools (straight and angled mono boom, sticks and industrial sticks, etc.)

ER 934 C ER 944 C ER 954 C Material Handlers 11

Loading...

Loading...