Liebherr Face shovel User Manual

The Liebherr

Working Tools

Tool-System for a variety of jobs

Liebherr working tools for excavators were designed as problem solvers for the most varied applications. The carefully balanced program ranges from standard buckets for digging and loading of loosened material to buckets for heavy-duty jobs in the mining industry with extreme break-out forces and high wear and tear. Equipped with effective, to the relating ground matching teeth the Liebherr digging tools provide a maximum productivity and longevity.

Performance

Liebherr digging tools are particularly productive excavator components at the very latest technological level. Special bucket shapes, permit maximum transmission of power, provide the best penetrationand outstanding digging characteristics. Optimized bucket capacities and improved heap-cones provide the best turn-over performance.

Reliability

Liebherr digging tools are in-house designed and manufactured. Specific material selection, specialized heat treatment and lowest machining tolerances are utilized in order to achieve the especially toughness and the high longevity. The convincing result: outstanding dependability under the most severe job conditions.

Comfort

The careful and precise calibration of bucket shape and tooth selection provides the ideal digging tool for each job. The proven and reliable quickchange system LIKUFIX permits the split-second, safe exchange of mechanical and hydraulic attaching tools by the press of a button from the cab. LIKUFIX attaching tools also work on hydraulic excavators with Liebherr quick change adapters without LIKUFIX - that means full flexibility and high comfort in every situation.

Efficiency

Liebherr digging tools provide a maximum of profitability. The Liebherr quick change systems increase productivity especially in applications with varying attaching tools. The 24/7 availability of wear parts and the easy exchange procedure safe time and money as well. Because of the modular design, the change systems and tools are very suitable for future tasks.

2

3

Bucket options

Whether loose dirt, abrasive material or hard rock – quality and effectiveness of every excavator job are affected by the targeted selection of the suitable bucket. Therefore, Liebherr has designed a wide range of bucket options, which are especially suitable for an applicable job due to the shape, material selection and technical fittings. Practical experience and continued attention to product development assure that Liebherr buckets are always state-of-the-art technology.

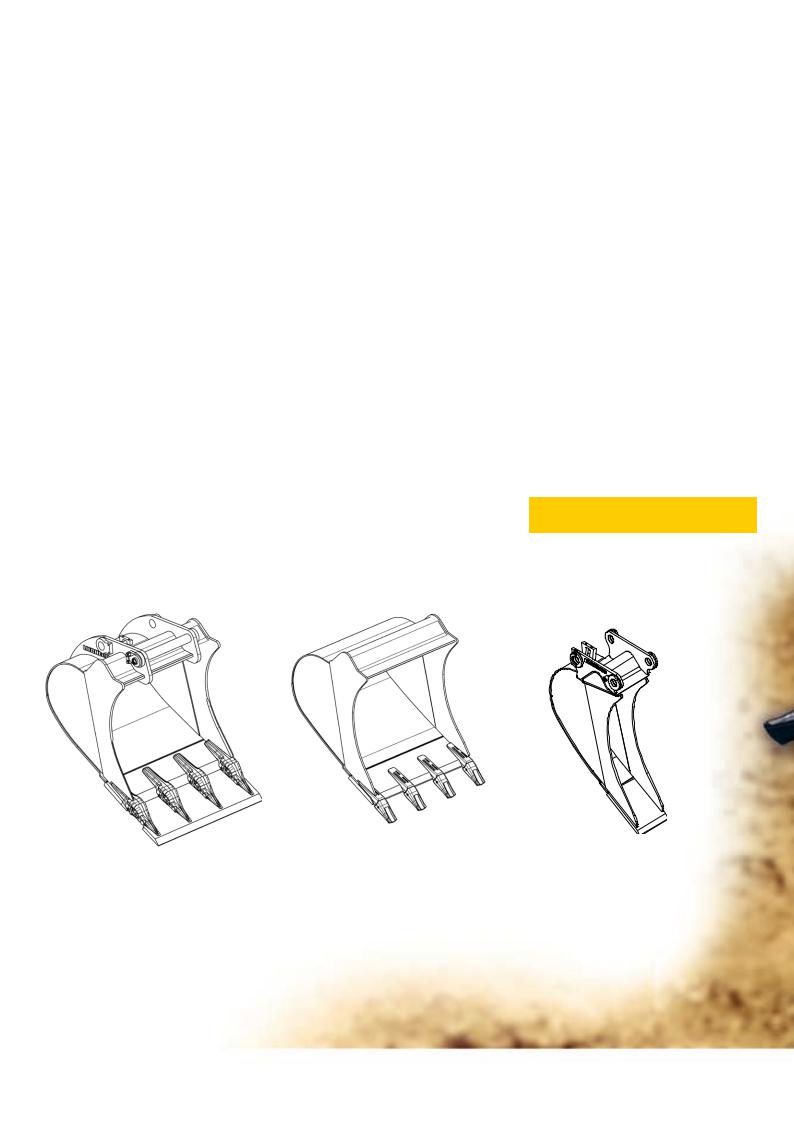

Backhoe bucket |

|

Backhoe bucket |

with teeth |

|

with cutting edge |

Suitable for digging up hard ground |

|

Optimum penetration due to low digging resistance |

HD-backhoe bucket

Suitable for very abrasive materials due to wear protection and side reinforcement

Backhoe bucket |

|

Backhoe bucket with univer- |

|

Backhoe bucket with |

with clip-on cutting edge |

|

sal mounting bracket |

|

limited digging depth |

A backhoe bucket with teeth that can be |

|

Suitable for any rapid-change systems |

|

If the rapid-change slot of a backhoe bucket is |

equipped with a cutter if required |

|

|

|

wider than the backhoe bucket itself, this limits the |

|

|

|

|

digging depth. |

|

|

|

|

For cases such as this Liebherr offers backhoe |

|

|

|

|

buckets with an extended basic shape. This |

|

|

|

|

increases the maximum digging depth. |

4

Tiltable ditch |

|

Tilt bucket |

cleaning bucket |

|

|

|

|

Suitable for shaping, levelling and grading earth walls Suitable for levelling and excavation

Rigid ditch cleaning bucket

Ideal when using a tilt rotator

5

Backhoe buckets

Backhoe buckets are essential tools for Liebherr excavators. Due to their well thought-out geometry, the weight optimized genuine buckets are well matched to the Liebherr excavators. Good penetration characteristics and high productivity are the results.

Backhoe bucket with teeth (technical data on page 35)

Applications

•Typical utility jobs with medium to high break-out forces

•Digging and loading of loosened material, e.g. dirt or clay

Features

•Weld-on tooth adapters

•Generous cutting lip thickness

•Bucket back reinforcement with wear resistant material

Benefits

•Buckets are optimally matched to excavator model

•Versatility

•Good penetration characteristic

•easy filling and dumping due to improved bucket geometry

•effortless eroding possible due to long bucket base

Backhoe bucket with cutting edge

(technical data on page 35)

Applications

•General civil engineering

•Utility

•Gardenand landscaping work

•Loading

Features

•Weld-on cutting lip

•Bucket-back reinforcements with wear resistant material

Benefits

•Efficient operation

•easy grading of surfaces

•easy filling and dumping due to improved bucket geometry

•effortless eroding possible due to long bucket base

•low digging resistance as a backhoe bucket with clip-on cutting edge with identical bucket radius

•high fuel efficiency

Backhoe bucket with teeth

6

|

|

Backhoe bucket with clip-on cutting edge |

Backhoe bucket with cutting edge |

||

7

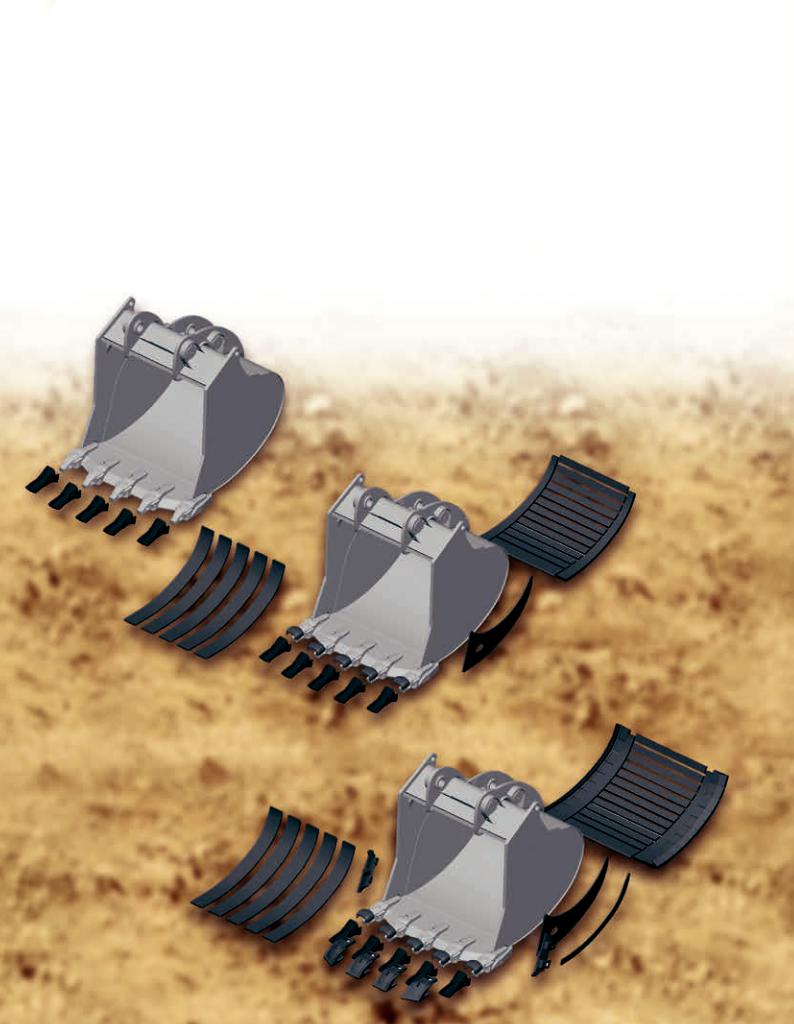

Various bucket shapes

starting R 936 (R 934) and for large machines

L-shape*

With a longer bottom and strongly curved side cutters. Suitable for rocky ground conditions as well as loading of hard and coarse material (large boulders) and to place rip-rap for embankment construction.

Cutting edge shapes

Straight edge*

With straight cutting lips for general loading jobs. Good floor maintenance capability.

Delta edge**

With the pointed V-shaped cutting lip and pull-up single tooth at the center for difficult to break, layered material. Optimal penetration characteristics for severe ripping jobs.

V-delta edge**

With the trapezoidal cutting lip and pulled-up teeth in the center for difficult to break, layered material. Optimal penetration characteristics, low torsion due to center target, limited floor maintenance capability.

L-shape

V-delta |

Delta |

Straight |

8

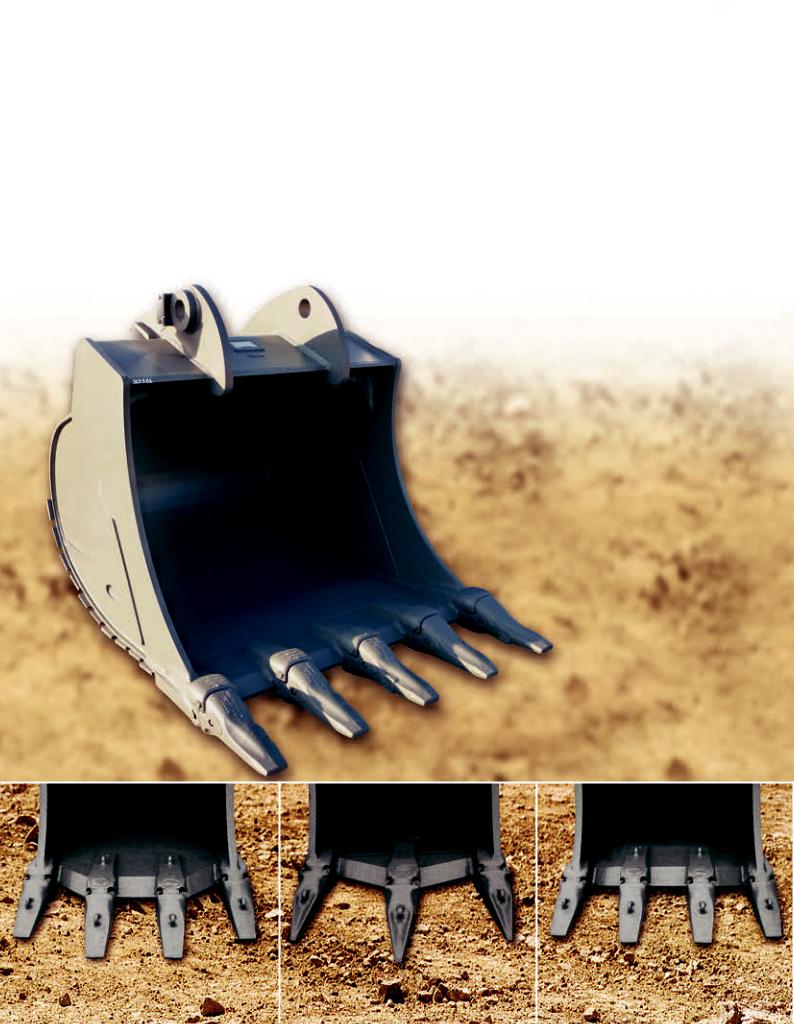

Bucket versions

Standard*

Wear resistance cutting edge and bottom with weld-on tooth adapter. Suitable for general utility, for digging and loading of matured and loosened but not abrasive material such as top soil, clay etc..

Standard

HD

HD*

Additional back- (wearand denting protection) and side reinforcements, weld-on tooth adapters for excavator jobs with a higher use. Suitable for digging and loading of harder and abrasive materials such as topsoil, rock, sand/clay, sand/gravel and limestone with low to medium quality.

HDV**

Additional backand side reinforcement, weld-on tooth adapter, reinforced cutting lip and additional wear parts. Suitable for extreme excavator jobs such as quarry or demolition, for digging and loading of mixed soil with high share of rock and other abrasive material such as rock, slag, quartz etc..

*starting R 936 (R 934) **only for large excavators

HDV

9

The right tooth

for every application

The economic use of a hydraulic excavator is only possible if the tooth shape matches the relating application. Liebherr offers a broad tooth program with tooth shapes for every task.

Liebherr Uni tooth system:

A 910 Compact (A 309) - A 918 (A 900) / R 918 - R 920

(technical data on page 42)

Due to its low overall heigth and the slim, self-sharpening tooth shape the Liebherr U-system stands for best diggning behavior at lowest penetration resistance. Highly wear-resistant steel provides familiar reliability under hard conditions, which has already stood the test on wheel loaders. The lateral rolled pin fastening allows a simple and safe change of teeth.

Standard tooth

Features:

symetric caps with cut-out at the front, self sharpening, reversible.

Application:

for friable and medium-weight friable soils (loamy sand, gravel, soft brown coal, soft/ medium clay etc.).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HD-tooth |

|

Pointed tooth |

|||

|

|

|

|

|

|

|

Features: |

Features: |

|||||

Cap with high share of material for long service |

Pointed tooth for good penetration, reversible. |

|||||

life in wear-intensive applications. |

|

|

||||

|

|

|

|

|

Application: |

|

Application: |

for very hard and frozen soil, non-friable rock |

|||||

for extremely abrasive soils (granite, basalt, |

(limestone, shale, brown coal, mining of wall |

|||||

sandstone, rocks with high share of silica etc.). |

gravel etc.). |

|||||

10

Liebherr Z tooth system: A 918 (A 900) / R 920 - R 980 SME

(technical data on page 43)

The optimized tooth design leads to efficiency increase of the Liebherr Z-system on the jobsite. The low digging resistance, the self-sharpening tooth shape or the simple hammer-free change of teeth speak for the Liebherr Z-system. The teeth are made out of high-strength steel which distinguishes itself through highest wear resistance and long service life.

C-tooth

Features:

The conical shape allows for very good penetration capacity in non-cohesive soils.

Application:

Friable soils and weak non-cohesive soils, such as loose, loamy sand, fine to medium gravels, and wet or soft clay.

|

|

|

|

|

|

|

|

CL-tooth |

|

|

CR-tooth |

||

|

|

|

|

|

|

|

Features:

Long-drawn pointed shape with sharp cutting edge for very good penetration properties.

Application:

Medium-weight friable and non-cohesive soil types up to soils with medium plasticity, such as hard, loamy sand, medium-hard clay, and fine to medium gravel.

Features:

The long drawn tip allows for good penetration in broken ground and debris. The wide, thick sole of the tooth provides for a long service life even under intensive wear conditions.

Application:

Abrasive soils and rocks, such as granite, basalt, and sandstone. Predominantly in combination with bottom dump bucket operations.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R-tooth |

|

|

P-tooth |

||||

|

|

|

|

|

|

|

|

|

|

Features: |

Features: |

||||||||

Narrow cutting width and high wear volume for |

Pointed tooth with good penetration properties |

||||||||

high penetrating forces and extended life. |

even in hard stone and rocky applications. |

||||||||

Application: |

Application: |

||||||||

Hard-to-penetrate ground, particularly abrasive |

Very hard, frozen ground, non-friable rock such |

||||||||

materials, rock, i. e. limestone, shale, very hard |

as compacted, unweathered clay schist |

||||||||

clay, lignite. |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PF-tooth

Features:

Fork tip with excellent penetration properties in extremely compact soils. Can be fitted as a supplement to the P-tips on the bucket corners in order to retain the inclination angle.

Application:

Very hard, frozen ground, non-friable rock such as compacted, non-weathered clay schist, heavy ores with medium and weak cleavage, slag heaps at steel plants.

Wearing cap

Wearing caps are designed to increase lifetimes of adapters in extreme abrasive applications

Shrouds

Reduces exposure of the bucket to impacts and abrasion, extending ist wear life. Allows you to carry more material and to increase penetration, thereby improving productivity of the machine.

|

|

|

|

Tooth holder |

|

Tooth holder |

|

single bracket |

|

double bracket |

|

For precise jobs where the terrain surface |

|

For tougher applications |

|

must be left smooth |

|

|

|

11

Buckets for special application

starting R 936 (R 934)

Liebherr provides its customers with buckets in the very best material quality and outstanding workmanship.

Far more than in pure earthmoving applications, they prove their worth day after day in mining operations, demolition jobs, marine engineering and a string of other special applications.

With performance, dependability and profitability, they set the standard as effective excavator tools in these extraordinary jobs.

Backhoe bucket in marine engineering |

Backhoe bucket in demolition |

12

Loading...

Loading...