Liebherr Downloads User Manual

2012

Exhibition News

InnoTrans 2012

September 18 -21 - Berlin

Liebherr-Transportation

Systems

Liebherr-Aerospace

© DB AG, Airbus

2 Editorial

Francis Niss

Dear Reader,

InnoTrans in Berlin is an event of utmost importance for Liebherr. As in the past, we are participating with enthusiasm this year to present the products and the technologies we have developed for the rail industry.

The industry is currently facing a downturn. Indeed, the global economic and financial conditions restrain the implementation of new train projects and the replacement of rolling stock. Even in China, the world’s most important market for the rail industry, several new programs have suddenly been frozen.

Nevertheless, we continue to experience sustainable growth thanks to our long-term development strategy.

We have decided to concentrate our engineering skills at our main site in Korneuburg (Austria) in order to consolidate efficiency. We have launched a promising process for product standardization as well as for the reduction of lead-time and development cost. In Korneuburg, we are establishing engineering and production expertise for highly efficient hydraulic systems derived from the technologies we developed for the aerospace industry.

Of course, we continue to invest in environmentally friendly technologies such as air cycle and CO2 air conditioning as well as in other solutions for the reduction of noise emissions, on-board weight and energy consumption.

A modern and competitive production center in Bulgaria and a joint venture in China complement the Korneuburg site. Our customer service activities show substantial growth thanks to dynamic commercial action and our global presence.

Thus, Liebherr is well prepared to meet the future challenges of the rail industry, which still shows considerable growth potential in the medium and long term.

We hope you enjoy reading this new edition of our exhibition news and have a successful InnoTrans 2012.

Best regards,

Francis Niss

President, Liebherr-Aerospace & Transportation SAS

Contents 3

Editorial |

2 |

Liebherr-Transportation Systems |

4 |

A Strong Network ................................................... |

6 |

Air Cycle Air Conditioning Technology...................... |

8 |

Electro-Hydraulic Actuation..................................... |

10 |

Saline Provides Services |

|

for Rail Vehicle Industry .......................................... |

12 |

News From Around the World ................................ |

14 |

Liebherr-Aerospace |

16 |

Major Investments |

18 |

Liebherr-Aerospace in the Americas........................ |

20 |

A Supplier to Airbus from the Very Beginning......... |

22 |

CSeries: Landing Gear and |

|

Air Management Systems ..................................... |

24 |

AW189, Global 7000 / 8000 Program .................... |

25 |

Vast Array of Products for the Aviation Industry ..... |

26 |

Liebherr Group News |

28 |

Growth in the Business Year 2011.......................... |

30 |

Domestic Appliances Receive Awards .................. |

33 |

New Liebherr T 284 Mining Truck ......................... |

34 |

Publisher’s Address .............................................. |

36 |

© Bombardier Transportation

Liebhe

rr-Transportation Systems

6 Transportation Systems

Liebherr’s Transportation Systems Division,

a Strong Network

The railway industry shows growth perspectives in the medium term, even if it seems that the dynamics have slightly slowed down in the last few months. While countries that were hit particularly hard by the current economic and debt crisis cancelled or postponed several projects, the railway industry as a whole continues to grow.

The driving forces behind this growth are new railway projects on the one hand, and modernization measures in the fields of long-distance traffic for the main routes, subways and streetcars on the other hand. Additionally, this development is supported by new environmental protection requirements and the highly congested transfer routes in metropolitan areas.

Within its long-term strategy LiebherrTransportation Systems continues to promote the expansion of its organization in selected new markets or market regions like North America, Russia or Brazil with the aim of local presence. At the same time Liebherr-Transportation Systems has reinforced the sales

and service teams in its core markets France, Germany and United Kingdom.

The process-based organization of Liebherr-Transportation Systems has been further developed in order to improve smooth collaboration across the different sites and to ensure that every individual part of the organization remains responsible for its tasks while contributing to the achievement of the company’s overall objectives. By enhancing simultaneous engineering the lead time of the projects could be shortened even further. Thus, product quality, customer satisfaction and sustainability have been further increased.

Moreover, Liebherr-Transportation Systems has started to concentrate all heating, ventilation and air conditioning (HVAC) product development activities at its main site in Korneuburg (Austria). The aim is to benefit from synergies that the utilization of engineering resources and infrastructure, the standardization of business processes, the existing in-house production as well as test facilities offer.

Furthermore, the collaboration with the development and project management departments is being improved in order to meet customer needs in an even more suitable manner and to implement the sales and service strategy, which was defined for the entire transportation field. Here the standardization of processes across all LiebherrTransportation Systems sites has especially proven its worth.

The organizational alignment of the hydraulic systems area has been completed: Liebherr-Transportation Systems further established its responsibility regarding marketing, sales and customer service (including repair and overhaul) of hydraulic systems and equipment, within the framework of a close collaboration with Liebherr-Aerospace Lindenberg GmbH (Germany). The strategic alignment of the manufacturing network, which was kicked off some years ago, was also further advanced.

Transportation Systems |

7 |

|

|

The manufacturing site of LiebherrTransportation Systems in Radinovo (Bulgaria) has expanded its operation. The local company called LiebherrTransportation Systems Marica EOOD is in charge of the series production of all large-scale European HVAC projects.

The joint venture in China’s Zhejiang province, Liebherr Zhongche Transportation Systems Co., Ltd., has successfully increased its production program in the field of HVAC systems for Chinese car manufacturers, who contribute to projects in and beyond China.

In addition, the plant of Liebherr- Transportation Systems GmbH & Co KG in Korneuburg has been further developed in order to optimize performance and quality, flexibility and high-speed reaction time, which contributes to the division’s competitiveness. The range of products manufactured in Korneuburg is subsequently being enlarged.

Liebherr-Transportation Systems is being prepared to launch the assembly and test of hydraulic products in the near future, which will complement the traditional HVAC systems railway application.

All employees work hard to make one vision come true: that of LiebherrTransportation Systems becoming a

Liebherr-Transportation

Systems GmbH & Co KG

in Korneuburg, Austria

global player and a worldwide reference in the fields of HVAC, hydraulics and power supply systems for the railway industry. A major achievement in this context was the renewal of the IRIS (International Railway Industry Standard) certification of the Liebherr-Transportation Systems’ sites in Korneuburg, Mannheim and Radinovo in autumn 2011.

Service specialists checking an air conditioning unit

8 Transportation Systems

The Eco-Friendly Solution

The Eco-Friendly Solution

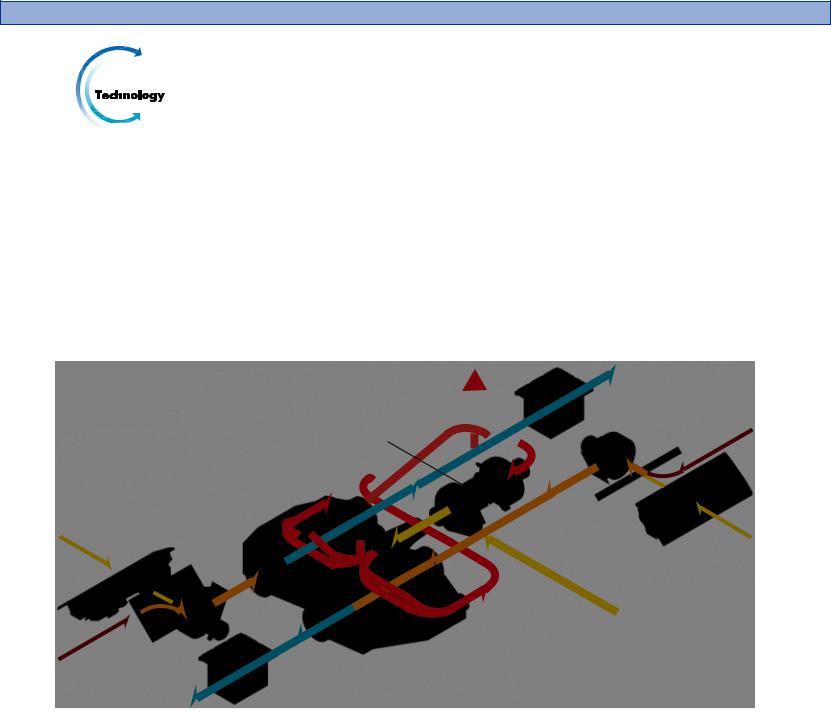

for Air Conditioning in Trains

Liebherr’s air cycle air conditioning system simply uses air as refrigerant to provide a comfortable climate for passengers. The system operates with an open loop process and draws the air required for the cooling process from the environment. The air expands and thus cools. Then the cool air runs through the heat exchanger and is subsequently returned to the ambience.

When developing the system, Liebherr took advantage of its long-term experience in the aircraft industry: air cycle air conditioning systems made by Liebherr have been installed on board of numerous aircraft.

The system for application in rail vehicles complies with all common passenger comfort requirements such as UIC 553,

EN13129 and EN14750, and – as a real alternative to chemical refrigerants – helps to reduce the greenhouse effect according to worldwide HFC regulations. As the system does not use any other refrigerant than air, there is no risk of refrigerant leakage and the compliance with any future legislation regarding refrigerants in air conditioning systems is absolute and unlimited.

Exhaust |

|

|

Supply Air |

Process Air |

|

Heater |

|

|

|

||

|

|

|

|

MCT |

|

Fan |

Return Air |

|

|

|

|

|

|

|

|

Filter

Fresh Air

Fresh Air

Filter

Fresh Process Air

Return Air |

Fan |

Heater |

Heat Exchanger |

Supply Air

Liebherr’s Air Cycle Air Conditioning Technology Gives Proof of its Qualities

Liebherr-Transportation Systems’ cut- ting-edge eco-friendly technology for air conditioning of railway vehicles – the air cycle air conditioning system – has proven its outstanding performance in daily service. During the past seven years, application in ICE 3 high speed trains has demonstrated that this future-proof technology derived from Liebherr’s aerospace branch is superior to traditional vapor cycle air conditioning con-

cepts in terms of eco-friendliness, total cost of ownership and enhanced passenger comfort.

Liebherr's air cycle air conditioning technology features significantly reduced life cycle costs compared to common vapor cycle systems. Life cycle costs of traditional air conditioning systems consist of several items, the most significant ones being the direct maintenance on the system,

unscheduled vehicle downtime due to system failure, spare part administration and power consumption. Additional operating costs related to the refrigerant circuit such as refrigerant handling and disposal, retrofit of refrigerant in order to comply with future regulations, or refrigerant emptying / refilling times also contribute to the high life cycle costs of traditional techno logies, increasing the attractiveness of the air cycle technology.

Transportation Systems |

9 |

|

|

Thanks to the reduced number of its key components, which is based on the fact that the refrigerant channel does not need to be sealed, the system offers higher reliability. Moreover, failed components can be isolated and exchanged much faster on an air cycle system than on a traditional system, which normally requires the replacement of the complete cooling unit. Therefore maintenance operations are significantly simpler.

In all, the reliability of Liebherr’s air cycle air conditioning system helps to save direct maintenance costs and leads to considerably reduced vehicle downtimes. In the case of maintenance the reduced number of parts in the system ease any maintenance and repair, while simplified accessibility guarantees efficient time-saving service. Maintenance

does not require EG 303/2008 refriger- ant-trained and certified personnel any more. Moreover, storage, handling and future accounting of refrigerant on site are no longer necessary. Furthermore, with a view to a future ban of chemical refrigerants, the air cycle air conditioning units will not need to be retrofitted or adapted, thus accounting for an additional cost advantage when compared to vapor cycle units.

A key advantage of the air cycle system technology is its ability to continue operating even when external temperatures are extremely severe and beyond normal operating conditions. For example, it even continues generating cool air under high external temperatures. In contrast to this, the vapor cycle system stops operating due to the refrigerant

overpressure switch. This key feature guarantees that the air cycle air conditioning systems works when it is most needed, thus preventing inside cabin temperatures from exceeding outside temperatures.

Other benefits this technology offers to passengers are the low measured noise and vibration levels in the car and on the platform. Liebherr-Transportation Systems is the only supplier in the industry to develop the air cycle machine / cooling turbine in-house, which guarantees the long-term availability of this next generation technology for railway applications.

From September 18 - 21, 2012, Liebherr-Transportation Systems will present numerous innovative solutions at InnoTrans in Berlin (Germany) at booth no. 232 in hall 3.1. Energy-efficient and environmentally friendly air conditioning systems, reliable hydraulic actuation systems and electronic compo-

nents, or a high-performance railroad excavator with rail bogies – the variety of products and services on display represent Liebherr’s comprehensive know-how in the transportation sector.

Outdoor display at InnoTrans

10 Transportation Systems

Electro-Hydraulic Actuators −

an Intelligent Solution for Rail Transport

Electro-hydraulic actuators (EHA) work |

Liebherr performs their assembly, fill- |

as compact, high-performance “power |

ing and final testing under extremely |

houses” in rail vehicles, and are pro- |

clean conditions and thus ensures they |

duced by Liebherr to meet specific cus- |

will achieve many years of service in the |

tomer requirements in a wide range of |

tough environment of rail transport. The |

applications. |

car manufacturer fits the Liebherr EHA |

Twindexx Express

© Bombardier Transportation

These applications include active lateral suspension and active lateral centering systems, car positioning systems, active radial control, active wheelset control and tilt technology. Among other attributes, EHA make a valuable contribution to reducing the burden on the environment and preventing wear while increasing performance.

At train speeds of up to 350 km/h EHA have to move heavy loads of several tons into the position specified by intelligent control units, or counteract vibrations occurring on the vehicle. They not only make faster train speeds possible, but also increase passenger comfort.

A further key advantage of EHA is that they reduce car and infrastructure wear enormously. Initially rather high investment costs are recouped very quickly through lower maintenance expenses, reduced total energy costs and higher carrying capacity compared with conventional hydraulic systems. EHA are self-contained hydraulic systems.

to the vehicle and installs the cable connection for the energy supply and control systems. The time-consuming installation work required on conventional hydraulic systems to route the lines, fill

and vent the circuit is thus eliminated. This also removes the risk of contaminating the hydraulic fluid through incorrect installation work and, as a result, damaging the actuator. The system could almost be described as having ‘plug and play’ functionality.

EHA from Liebherr are fundamentally maintenance-free. If, nevertheless, a fault should occur, the entire unit can be quickly replaced without any hydraulic expertise, thus avoiding prolonged vehicle downtime.

The innovative EHA systems are regulated by a controller which communicates with the vehicle control unit via CAN bus. This controller was also developed by Liebherr.

Liebherr’s EHA can be adapted for all customer requirements and ensure fast, comfortable, and above all safe arrivals at the destinations.

Above: Active yaw damper system Below: Actuator for tilting technology

Transportation Systems |

11 |

|

|

The new Bombardier

V300 ZEFIRO high-speed train

© Bombardier Transportation

New Generation of Compact,

Reliable and Service-Friendly Actuators

Last year, Liebherr-Transportation Systems developed a new type of electro-hydraulic drive system for rail vehicles for Bombardier Transportation. In the first stage, concepts for two versions of this new actuator type were drawn up. One version is used for active roll compensation on the new InterCity double-decker coaches of Swiss Federal Railways (SBB). The other version is used for active yaw compensation on Bombardier’s new V300 ZEFIRO Italia high-speed train.

The new actuator type is part of a new platform strategy, for which Liebherr is developing customer-specific actuators for as broad a range of applications as possible. These include elements for active rotational damping, active lateral suspension, lateral compensation, tilt technology and level control.

The new generation of actuators differs from the electro-hydraulic actuators developed by Liebherr in the past in that the electronics are now integrated into the device. They now assume the task of regulating and monitoring the individual actuator. The computer in the vehicle is merely responsible for coordinating the individual actuators among each other. Communications with this computer are conducted using a robust CAN bus

signal, allowing the number of electrical connections needed in the overall system to be substantially reduced. Another advantage of bus communications is that the parameters specific to the vehicle or the actuator can be made available through the bus system. Therefore an actuator can, for example, be used in different vehicles without any modifications to its software. Equally, it is possible to change the mechanical or hydraulic para meters of the actuator without software modifications.

Another feature of Liebherr's new actuator type is the complete integration into the bogie frame. The actuator is simply slid sideways into the opening provided in the frame. This guarantees optimal accessibility to the actuator when it is installed, and allows the complete electronics or individual hydraulic valves to be exchanged within a very short space of time without removal of the device. Direct thermal contact means that the bogie frame can also act as a cooler for the actuator.

Not only in its installation attention was paid to optimal service friendliness, but also in its design. For example, all components which could potentially fail can be quickly and simply replaced. The num-

ber of parts subject to wear has been reduced to small assembly modules, and a paint finish has been deliberately omitted, keeping the follow-on costs incurred during an overhaul to a minimum.

With the new generation of compact, reliable and service-friendly actuators, Liebherr-Transportation Systems has developed a highly versatile basis for a wide range of future applications. Fundamentally, these are configured as highly dynamic, power-regulated components. Versions with travel control circuit are, however, also possible. The design was configured to allow additional expansion stages to be realized. That permits the actuator to be expanded by a second controlling element, for example, retaining use of many individual components. One actuator controlling element can thus tilt the coach frame while the second radially adjusts the axis to the specific radius of the bend.

Loading...

Loading...