LG LWM1860BCP, LWN2120BHG, LWN2123BHG, LWM2130AAG, LWN2131BAG Service Manual

...

website http://biz.LGservice.com

e-mail http://www.LGEservice.com/techsup.html

Room Air Conditioner

SERVICE MANUAL

MODELS: LWM1860BCG/BCL/QCG/QCL/QAG/BAG

LWN1860BCG/BCL/QCG/QCL

LWN2260BCG/BCL/QCG/QCL

LWM1820BCG/BCL/QCG/QCL

LWM1821BCG/BCL/QCG/QCL

LWN2120BCG/BCL/QCG/QCL

LWN2123BCG

LWM1830BCG/BCL/QCG/QCL

LWN2130BCG/BCL/QCG/QCL,BXN

LWN2131BAG

LWM2130AAG/BAG

LWM1860BCP

LWN2120BHG/BHP/QHG

LWN2123BHG

CAUTION

-BEFORE SERVICING THE UNIT, READ THE "SAFETY PRECAUTIONS" IN THIS MANUAL.

-ONLY FOR AUTHORIZED SERVICE.

CONTENTS

1. PREFACE |

|

1.1 SAFETY PRECAUTIONS ............................... |

2 |

1.2 INSULATION RESISTANCE TEST................. |

2 |

1.3 SPECIFICATIONS .......................................... |

3 |

1.4 FEATURES ..................................................... |

6 |

1.5 CONTROL LOCATIONS ................................. |

6 |

1.5.1 COOLING ONLY MODEL ...................... |

6 |

1.5.2 HEAT PUMP MODEL ............................ |

7 |

1.5.3 COOLING ONLY MODEL WITH REMOTE |

|

CONTROL AND TOUCH TYPE................. |

8 |

2. DISASSEMBLY INSTRUCTIONS |

|

2.1 MECHANICAL PARTS.................................. |

10 |

2.1.1 FRONT GRILLE ................................... |

10 |

2.1.2 CABINET.............................................. |

10 |

2.1.3 CONTROL BOX ................................... |

10 |

2.2 AIR HANDLING PARTS................................ |

11 |

2.2.1 COVER (AT THE TOP)........................ |

11 |

2.2.2 BLOWER.............................................. |

11 |

2.2.3 FAN ...................................................... |

11 |

2.2.4 SHROUD.............................................. |

12 |

2.3 ELECTRICAL PARTS ................................... |

12 |

2.3.1 MOTOR................................................ |

12 |

2.3.2 COMPRESSOR ................................... |

12 |

2.3.3 CAPACITOR ........................................ |

13 |

2.3.4 POWER CORD .................................... |

13 |

2.3.5 THERMOSTAT .................................... |

13 |

2.3.6 ROTARY SWITCH ............................... |

14 |

2.3.7 SYNCHRONOUS MOTOR .................. |

14 |

2.4 REFRIGERATION CYCLE................................. |

15 |

2.4.1 CONDENSER ...................................... |

15 |

2.4.2 EVAPORATOR .................................... |

15 |

2.4.3 CAPILLARY TUBE............................... |

15 |

3. TROUBLESHOOTING GUIDE |

|

3.1 OUTSIDE DIMENSIONS............................... |

18 |

3.2 PIPING SYSTEM .......................................... |

18 |

3.3 TROUBLESHOOTING GUIDE...................... |

19 |

4. SCHEMATIC DIAGRAM |

|

4.1 CIRCUIT DIAGRAM ...................................... |

29 |

4.2 ELECTROING CONTROL DEVICE .............. |

31 |

4.3 COMPONENTS LOCATION |

|

(OF MAIN P.C.B ASM).................................. |

32 |

4.4 COMPONENTS LOCATION |

|

(FOR DISPLAY P.C.B ASM) ......................... |

33 |

5. EXPLODED VIEW.................................. |

34 |

6. REPLACEMENT PARTS LIST ....... |

36 |

1. PREFACE

This SERVICE MANUAL provides various service information, including the mechanical and electrical parts etc. This room air conditioner was manufactured and assembled under a strict quality control system. The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS |

1.2 INSULATION RESISTANCE TEST |

1.When servicing the unit, set the ROTARY SWITCH or POWER SWITCH to OFF and unplug the power cord.

2.Observe the original lead dress.

If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

3.After servicing the unit, make an insulation resistance test to protect the customer from being exposed to shock hazards.

—2—

1.Unplug the power cord and connect a jumper between 2 pins (black and white).

2.The grounding conductor (green or green & yellow) is to be open.

3.Measure the resistance value with an ohm meter between the jumpered lead and each exposed metallic part on the equipment at all the positions (except OFF or O) of the ROTARY SWITCH.

4.The value should be over 1MΩ .

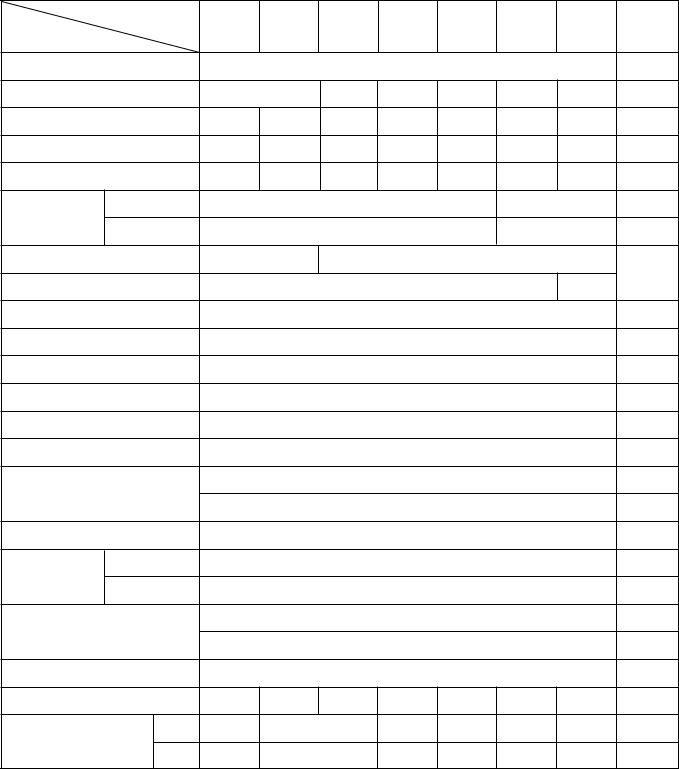

1.3 SPECIFICATIONS

1.3.1 FOR LWM1860BCG(BCL)/LWN1860BCG(BCL)/LWN2260BCG(BCL)/LWM1820BCG(BCL)LWM1821BCG(BCL) LWN2120BCG(BCL)/LWM1830BCG(BCL)/LWN2130BCG(BCL)/LWN2123BCG/BAG / LWM2130AAG/BAG

|

|

|

MODELS |

LWM1860 |

LWN1860 |

LWN2260 |

LWN1820/1 |

LWN2120 |

|

LWN2123 |

|

LWM2130 |

LWN1830 |

LWN2130 |

REMARK |

||||||||

ITEMS |

|

|

|

|

BCG(BCL) |

BCG |

BCG |

BCG |

|

BCG |

|

BCG |

|

AAG/ |

|

BCG |

BCG(BCL) |

||||||

|

|

|

|

BAG/BCP |

(BCL) |

(BCL) |

(BCL) |

|

(BCL) |

|

|

BAG |

|

(BCL) |

LWN2131BAG |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

POWER SUPPLY |

|

|

|

1Ø, 220-240V, 50Hz |

|

1Ø, 220V, 60Hz |

|

|

|

|

1Ø, 208-230V, 60Hz |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

COOLING CAPACITY |

17,500/18,000 |

|

21,500/22,000 |

18,000 |

|

|

21,000 |

|

|

24,000 |

|

22,000 |

|

18,000 |

|

21,000 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

INPUT |

|

|

|

(W) |

2,035/2,100 |

2,190/2250 |

|

2,810/2,890 |

2,090/2,000 |

|

|

2,440 |

|

2,470 |

|

2,000 |

|

2,470 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

RUNNING CURRENT |

|

(A) |

9.3/8.6 |

10.6/10.1 |

|

13.5/12.8 |

9.8/9.0 |

|

|

11.5 |

|

10.8 |

|

9.0 |

|

12 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

REFRIGERANT (R-22) CHARGE(g) |

690 |

610 |

|

600 |

630 |

|

|

700 |

|

710 |

|

740 |

|

1,090 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPERATING |

|

INDOOR (°C) |

|

|

|

27(DB), 19(WB) |

|

|

|

|

|

|

|

26.55(DB), 19.35(WB) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEMPERATURE |

OUTDOOR (°C) |

|

|

|

35(DB), 24(WB) |

|

|

|

|

|

|

|

34.85(DB), 23.75(WB) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EVAPORATOR |

|

|

|

|

2 ROW 15 STACKS |

|

|

|

|

|

|

|

3 ROW 15 STACKS |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONDENSER |

|

|

|

|

|

|

|

2 ROW 19 STACKS, L-BENDED TYPE |

|

|

|

|

2 ROW 16 STACKS, |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

L-BENDING TYPE |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN, INDOOR |

|

|

|

|

|

|

|

|

|

|

|

BLOWER |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

FAN, OUTDOOR |

|

|

|

|

|

|

PROPELLER TYPE FAN WITH SLINGER-RING |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

FAN SPEEDS, FAN/COOLING |

|

|

|

|

|

|

|

2/3 |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

FAN MOTOR |

|

|

|

|

|

|

|

|

|

|

|

6 POLES |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

OPERATION CONTROL |

|

|

|

|

ROTARY SWITCH |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

ROOM TEMP. CONTROL |

|

|

|

|

THERMOSTAT |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

AIR DIRECTION CONTROL |

|

|

|

|

VERTICAL LOUVER(RIGHT & LEFT) |

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

HORIZONTAL LOUVER(UP & DOWN) |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

CONSTRUCTION |

|

|

|

|

|

|

|

SLIDE IN-OUT CHASSIS |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

PROTECTOR |

|

COMPRESSOR |

|

|

|

|

INTERNAL OVERLOAD PROTECTOR |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN MOTOR |

|

|

|

|

INTERNAL THERMAL PROTECTOR |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

POWER CORD |

|

|

|

|

|

|

1.6m (3 WIRE WITH GROUNDING) |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

CORD-CONNECTED TYPE (ATTACHMENT PLUG: OPTION) |

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

DRAIN SYSTEM |

|

|

|

|

|

|

DRAIN PIPE OR SPLASHED BY FAN SLINGER |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NET WEIGHT |

|

|

(lbs/kg) |

132/60 |

143/65 |

|

148/67 |

121/55 |

|

|

|

|

|

148/67 |

|

|

121/55 |

|

143/65 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

OUTSIDE DIMENSION |

|

(inch) |

26x1627/32 x269/16 |

26x1627/32 x305/16 |

26x1627/32 x269/16 |

|

|

|

|

|

26x1627/32 x305/16 |

|

|

26x1627/32 x269/16 |

|

26x1627/32 x305/16 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

(W x H x D) |

|

|

|

(mm) |

660 x 428 x 675 |

660 x 428 x 770 |

660 x 428 x 675 |

|

|

|

|

|

660 x 428 x 770 |

|

|

660 x 428 x 675 |

|

660 x 428 x 770 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

—3—

1.3.2 FOR LWM1860QCG(QCL, QAG)/LWN1860QCG(QCL)/LWN2260QCG(QCL)/LWM1820QCG(QCL) |

||||||||||

LWM1821QCG(QCL)/LWN2120QCG(QCL)/LWM1830QCG(QCL)/LWN2130QCG(QCL) |

|

|||||||||

|

MODELS |

LWM1860 |

LWN1860 |

LWN2260 |

LWM1820/1 |

LWN2120 |

LWM1830 |

LWN2130 |

REMARK |

|

|

QCG |

|||||||||

|

|

|

QCG(QCL) |

QCG(QCL) |

QCG(QCL) |

QCG(QCL) |

QCG(QCL) |

QCG(QCL) |

||

ITEMS |

|

|

(QCL, QAG) |

|

||||||

POWER SUPPLY |

|

|

1Ø, 220-240V, 50Hz |

|

1Ø, 220V, 60Hz |

|

|

|||

COOLING CAPACITY |

|

17,500/18,000 |

21,500/22,000 |

18,000 |

21,000 |

18,000 |

21,000 |

|

||

INPUT |

|

(W) |

2,035/2,100 |

2,190/2,250 |

2,810/2,890 |

2,090/2,000 |

2,440 |

2,000 |

2,470 |

|

RUNNING CURRENT |

(A) |

9.3/8.6 |

10.6/10.1 |

13.5/12.8 |

9.8/9.0 |

11.5 |

9.0 |

12 |

|

|

REFRIGERANT (R-22) CHARGE(g) |

690 |

610 |

600 |

630 |

700 |

740 |

1,090 |

|

||

OPERATING |

INDOOR (°C) |

|

|

27(DB), 19(WB) |

|

26.55(DB), 19.35(WB) |

|

|||

TEMPERATURE |

OUTDOOR (°C) |

|

|

35(DB), 24(WB) |

|

34.85(DB), 23.75(WB) |

|

|||

EVAPORATOR |

|

|

2 ROW 15 STACKS |

|

3 ROW 15 STACKS |

|

|

|||

CONDENSER |

|

|

|

2 ROW 19 STACKS, L-BENDED TYPE |

|

2 ROW 16 STACKS, |

|

|||

|

|

|

|

L-BENDING TYPE |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

FAN, INDOOR |

|

|

|

|

|

BLOWER |

|

|

|

|

FAN, OUTDOOR |

|

|

|

PROPELLER TYPE FAN WITH SLINGER-RING |

|

|

||||

FAN SPEEDS, FAN/COOLING |

|

|

|

2/2 |

|

|

|

|

||

FAN MOTOR |

|

|

|

|

|

6 POLES |

|

|

|

|

OPERATION CONTROL |

|

|

WIRELESS REMOCON |

|

|

|

||||

ROOM TEMP. CONTROL |

|

|

|

THERMISTOR |

|

|

|

|

||

AIR DIRECTION CONTROL |

|

|

VERTICAL LOUVER(RIGHT & LEFT) |

|

|

|

||||

|

|

HORIZONTAL LOUVER(UP & DOWN) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||

CONSTRUCTION |

|

|

|

SLIDE IN-OUT CHASSIS |

|

|

|

|||

PROTECTOR |

COMPRESSOR |

|

|

INTERNAL OVERLOAD PROTECTOR |

|

|

|

|||

FAN MOTOR |

|

|

INTERNAL THERMAL PROTECTOR |

|

|

|

||||

|

|

|

|

|

|

|||||

POWER CORD |

|

|

|

|

1.6m (3 WIRE WITH GROUNDING) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CORD-CONNECTED TYPE (ATTACHMENT PLUG: OPTION) |

|

|

||||

DRAIN SYSTEM |

|

|

|

DRAIN PIPE OR SPLASHED BY FAN SLINGER |

|

|

||||

NET WEIGHT |

|

(lbs/kg) |

132/60 |

143/65 |

148/67 |

121/55 |

148/67 |

121/55 |

143/65 |

|

OUTSIDE DIMENSION (inch) |

26 x 1627/32 x 269/16 |

26 x 1627/32 x 305/16 |

26 x 1627/32 x 269/16 |

26 x 1627/32 x 305/16 |

26 x 1627/32 x 269/16 |

26 x 1627/32 x 305/16 |

|

|||

(W x H x D) |

|

(mm) |

660 x 428 x 675 |

660 x 428 x 770 |

660 x 428 x 675 |

660 x 428 x 770 660 x 428 x 675 |

660 x 428 x 770 |

|

||

|

|

|

|

|

—4— |

|

|

|

|

|

1.3.3 FOR LWN2120BHG/BHP/QHG, LWN2123BHG

|

|

|

|

|

MODELS |

LWN2120BHG/BHP |

|

LWN2120QHG |

|

LWN2123BHG |

||

ITEMS |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

POWER SUPPLY |

|

|

|

|

|

|

|

1ø, 220V, 60Hz |

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

CAPACITY |

|

(BTU/H) |

|

24,000 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

COOLING |

INPUT |

|

|

|

|

(W) |

|

2,560 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

RUNNING CURRENT (A) |

|

12.3 |

|

|

||||||||

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E.E.R |

|

|

(BTU/W.h) |

|

|

|

- |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

CAPACITY |

|

(BTU/h) |

|

24,000 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

HEATING |

INPUT |

|

|

|

|

(W) |

|

2,560 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

RUNNING CURRENT (A) |

|

12.3 |

|

|

||||||||

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

E.E.R |

|

|

(BTU/W.h) |

|

9.4 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

OPERATING |

COOLING |

INDOOR |

(°C) |

|

|

27 (DB)* |

19 (WB)** |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR (°C) |

|

|

35 (DB) |

24 (WB) |

|

||||||

TEMPERA- |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

HEATING |

INDOOR |

(°C) |

|

|

20 (DB) |

15 (WB) |

|

|||||

TURE |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR (°C) |

|

|

7 (DB) |

6 (WB) |

|

||||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||

REFRIGERANT (R-22) CHARGE |

|

|

1200g (42.3 Oz) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||

EVAPORATOR |

|

|

|

|

|

3ROW 15STACKS, LOUVERED-FIN TYPE |

||||||

|

|

|

|

|

|

|

|

|

|

|||

CONDENSER |

|

|

|

|

|

2ROW 16STACKS, LOUVERED-FIN TYPE |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN, INDOOR |

|

|

|

|

|

|

|

TURBO FAN |

|

|||

|

|

|

|

|

|

|

|

|

|

|||

FAN, OUTDOOR |

|

|

|

|

|

PROPELLER TYPE FAN WITH SLINGER-RING |

||||||

|

|

|

|

|

|

|

|

|

|

|||

FAN SPEEDS, FAN/COOLING/HEATING |

1/2/2 |

|

2/2/2 |

|

1/2/2 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN MOTOR |

|

|

|

|

|

|

|

6 POLES |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

OPERATION CONTROL |

|

|

|

ROTARY SWITCH |

|

WIRELESS REMOCON |

|

ROTARY SWITCH |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

ROOM TEMP. CONTROL |

|

|

|

THERMOSTAT |

|

THERMISTOR |

|

THERMOSTAT |

||||

|

|

|

|

|

|

|

|

|

||||

AIR DIRECTION CONTROL |

|

VERTICAL LOUVER (RIGHT & LEFT) |

||||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

HORIZONTAL LOUVER (UP & DOWN) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

CONSTRUCTION |

|

|

|

|

|

|

SLIDE IN-OUT CHASSIS |

|

||||

|

|

|

|

|

|

|

|

|

|

|||

PROTECTOR |

COMPRESSOR |

|

OVERLOAD PROTECTOR |

|

||||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

FAN MOTOR |

INTERNAL THERMAL PROTECTOR |

||||||||

|

|

|

|

|

|

|

|

|

|

|||

POWER CORD |

|

|

|

|

|

1.8m (7") (3 WIRE WITH GROUDING) |

||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

ATTACHMENT PLUG (CORD-CONNECTED TYPE) |

|||||

|

|

|

|

|

|

|

|

|

|

|||

DRAIN SYSTEM |

|

|

|

|

|

DRAIN PAN OR SPLASHED BY FAN SLINGER |

||||||

|

|

|

|

|

|

|

|

|

|

|

||

NET WEIGHT |

|

|

|

(lbs/kg) |

|

147.7(67) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

OUTSIDE DIMENSION |

|

(inch) |

|

|

23 x 1627/32 x 305/16 |

|

||||||

(W X H X D) |

|

|

|

|

(mm) |

|

|

660 x 428 x 770 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

* DB : dry bulb |

|

|

|

|

|

|

|

|

|

|

|

|

** WB : wet bulb |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

—5— |

|

|

|

|

|

1.4 FEATURES

•Designed for cooling only.

•Powerful and quiet cooling.

•Slide-in and slide-out chassis for the simple installation and service.

•Reversible inlet grille.

•Side air-intake, side cooled-air discharge.

•Built in adjustable THERMOSTAT.

•Washable one-touch filter.

•Compact size.

1.5 CONTROL LOCATIONS

1.5.1 COOLING ONLY MODEL

•VENTILATION

The ventilation lever must be in the CLOSE position in order to maintain the best cooling conditions. When a fresh air is necessary in the room, set the ventilation lever to the OPEN position.

The damper is opened and room air is exhausted.

NOTE: Before using the ventilation feature, make the lever, as shown. First, pull down part  to horizontal line with part

to horizontal line with part  .

.

•THERMOSTAT

Thermostat will automatically control the temperature of the room. Select the higher number for the lower temperature of the room. The temperature is selected by positioning the knob to the desired position.

The 5 or 6 position is a normal setting for average conditions.

•OPERATION

O |

|

|

|

( 0 |

) |

: Turns the air conditioner off. |

MED FAN |

|

( |

) |

: Permits the medium fan speed |

||

|

|

|

|

|

|

operation without cooling. |

LOW FAN |

|

( |

) |

: Permits the low fan speed |

||

|

|

|

|

|

|

operation without cooling. |

HIGH COOL |

( |

) |

: Permits cooling with the |

|||

|

|

|

|

|

|

high fan speed operation. |

MED COOL |

( |

) |

: Permits cooling with the |

|||

|

|

|

|

|

|

medium fan speed |

|

|

|

|

|

|

operation. |

LOW COOL |

( |

) |

: Permits cooling with the low |

|||

|

|

|

|

|

|

fan speed operation. |

• AUTO SWING |

|

|

||||

ON |

( |

|

): Air swing is operated while OPERATION |

|||

|

|

|

knob is set to the COOL position. |

|||

OFF |

( |

|

): Stops the operation of air swing. |

|||

|

||||||

—6—

Part B

Part A

CLOSE  VENT

VENT  OPEN

OPEN

|

Thermostat |

Auto Swing |

|

Operation |

|

5 |

|

Off |

|

|

|

|

||

4 |

6 |

|

Med |

High |

|

Off |

On |

||

|

|

|

Fan |

Cool |

3 |

7 |

|

|

|

2 |

8 |

|

|

|

1 |

9 |

|

Low |

Med |

|

Fan |

Cool |

Low Cool

0

1.5.2 HEAT PUMP MODEL

• CAUTION

When the air conditioner has been performing its cooling operation and is turned off or set to the fan position, wait at least 3 minutes before resetting to the cooling operation again.

• THERMOSTAT

Turn the thermostat control to the desired setting. The control position is a normal setting for average conditions. You can change this setting, if necessary, in accordance with your temperature preference.

The thermostat automatically controls cooling or heating, but the fan runs continuously whenever the air conditioner is in operation. If the room is too warm, turn the thermostat control clockwise. If the room is too cool, turn the thermostat control counterclockwise.

• HEATER LAMP

When the unit sets heating operation condition, the green lamp is lighted.

When the frost settles on the heat exchanger of the outside, defrosting is made automatically and the green lamp is turned off. The unit may give a hiss and the fan motor stops for 1 to 10 minutes.

This should not be regarded as a problem.

After defrosting, the heating operation begins again.

• OPERATION |

|

|

|||

OFF |

|

|

( |

O ) |

: Turns the air conditioner off. |

LOW FAN |

( |

) |

: Permits the low fan speed |

||

|

|

|

|

|

operation without cooling (heating). |

LOW COOL ( |

) |

: Permits cooling with the low fan |

|||

|

|

|

|

|

speed operation. |

HIGH COOL ( |

) |

: Permits cooling with the high fan |

|||

|

|

|

|

|

speed operation. |

LOW HEAT |

( |

) |

: Permits heating with the low fan |

||

|

|

|

|

|

speed operation. |

HIGH HEAT ( |

) |

: Permits heating with the high fan |

|||

|

|

|

|

|

speed operation. |

• AUTO SWING |

|

||||

ON |

( |

|

) |

: Air swing is operated while |

|

|

|

|

|

OPERATION knob is set to the COOL |

|

|

|

|

|

or HEAT position. |

|

OFF |

( |

|

) |

: Stops the operation of air swing. |

|

|

|||||

— 7—

1.5.3 COOLING ONLY MODEL WITH REMOTE CONTROL AND TOUCH TYPE

DISPLAY |

|

REMOTE CONTROL |

3

2

4

5

3

2

4

5

Mode Sleep

Mode Sleep

Fan Cool On

Fan Speed |

Temp |

Auto

Modo Apagado

Modo Apagado

Ventilacion Frio Encendido

Deshumedad

Velocidad Temp

|

Auto Restart |

On |

Off |

Auto Swing |

Power |

Re-inicio

Automatico

Si No

Auto Encendido

Deflector

8 |

|

|

|

6 |

7 |

1 |

|

|

|||

|

|

||

1 |

3 |

|

|

|

5 |

||

|

2 |

||

7 |

|

||

|

|

||

|

1 |

4 |

|

|

|

||

8 |

5 |

3 |

|

2 |

|||

|

|||

6 |

4 |

7 |

|

|

|||

1 |

|

|

|

7 |

|

|

Precaution: The Remote Control unit will not function properly if strong light strikes the sensor window of the air conditioner or if there are obstacles between the Remote Control unit and the air conditioner.

POWER BUTTON

Operation starts, when this button is pressed and stops when you press the button again.

OPERATION MODE SELECTION BUTTON

Select Cooling, or Fan or Dehumid mode with button. (Dehumid mode is not to all models.)

ON/OFF TIMER BUTTON

Set the time of starting and stopping operation. The timer is set by 1 hour.

FAN SPEED SELECTOR

FAN SPEED SELECTOR

Everytime you push this button it is set as follows. [High(F3) → Low(F1) → Med(F2) → High(F3)...].

ROOM TEMPERATURE SETTING BUTTON

Control the room temperature within a range of 16°C to 30°C.

6AUTO RESTART SWITCH (NOT TO ALL MODELS)

In failure of electric power, if the switch is set to "ON", the unit runs as previous setting operation when power returns.

7AUTO SWING BUTTON

Control the horizontal air direcion by air swing system.

8 SIGNAL RECEIVER

— 8—

DISPLAY |

|

REMOTE CONTROL |

2 3

7

1

4 |

2 |

3 |

5 |

6 |

7

1

4 |

5 |

6 |

6

2 |

4 |

5 |

|

6 |

|

3 |

2 |

3 |

1 |

4 |

1 |

|

5 |

|

Precaution: The Remote Control unit will not function properly if strong light strikes the sensor window of the air conditioner or it there are obstacles between the Remote Control unit and the air conditioner.

POWER BUTTON

Operation starts, when this button is pressed and stops when you press the button again.

OPERATION MODE SELECTION BUTTON

OPERATION MODE SELECTION BUTTON

Select Cooling, Heating, Fan or Dehumidification(Dry) mode with this button.

ON/OFF TIMER BUTTON

Set the time of starting and stopping operation.

The timer is set by 1 hour.

FAN SPEED SELECTOR

FAN SPEED SELECTOR

Select the fan speed

-Cooling Model: High[F3] Low[F1] Med[F2] High[F3] ....

-Heating Model: High[F2] Low[F1] High[F2] ....

ROOM TEMPERATURE SETTING BUTTON

Control the room temperature within a range of 16°C to 30°C.

The unit takes an average of 30 minutes to adjust the room temperature by 1°C (1.8°F).

Temperature increases only by 2°C and no longer increase thereafter.

6AUTO SWING

The vertical louver swings horizontally by the automatic system and stops when you press the button again.

7SIGNAL RECEIVER

—9—

2. DISASSEMBLY INSTRUCTIONS

— Before the following disassembly, POWER SWITCH is set to OFF and disconnected the power cord.

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Open the inlet grille upward or downward.

2. Remove the screw which fastens the front grille.

3. Pull the front grille from the right side.

4. Remove the front grille. (See Fig. 1)

5. Re-install the component by referring to the removal procedure.

NOTE: Mark "  "of inlet grille means opening direction.

"of inlet grille means opening direction.

Figure 1

2.1.2 CABINET

1.After disassembling the FRONT GRILLE, remove the screws which fasten the cabinet at both sides.

2.Remove the two screws which fasten the cabinet at back. (See Fig. 2)

3.Pull the base pan forward.

2.1.3 CONTROL BOX

1.Remove the front grille. (Refer to section 2.1.1)

2.Pull the base pan forward so that you can remove the 2 screws which fasten the cover control at the right side. (See Fig. 3)

3.Remove the 3 screws which fasten the control box. (See Fig. 3)

4.Discharge the capacitor by placing a 20,000 ohm resistor across the capacitor terminals.

5.Disconnect two wire housings in the control box.

6.Pull the control box forward completely.

7.Re-install the components by referring to the removal procedure. (See Fig. 3)

(Refer to the circuit diagram found on page 19 in this manual and on the control box.)

Figure 2

Figure 3

— 10—

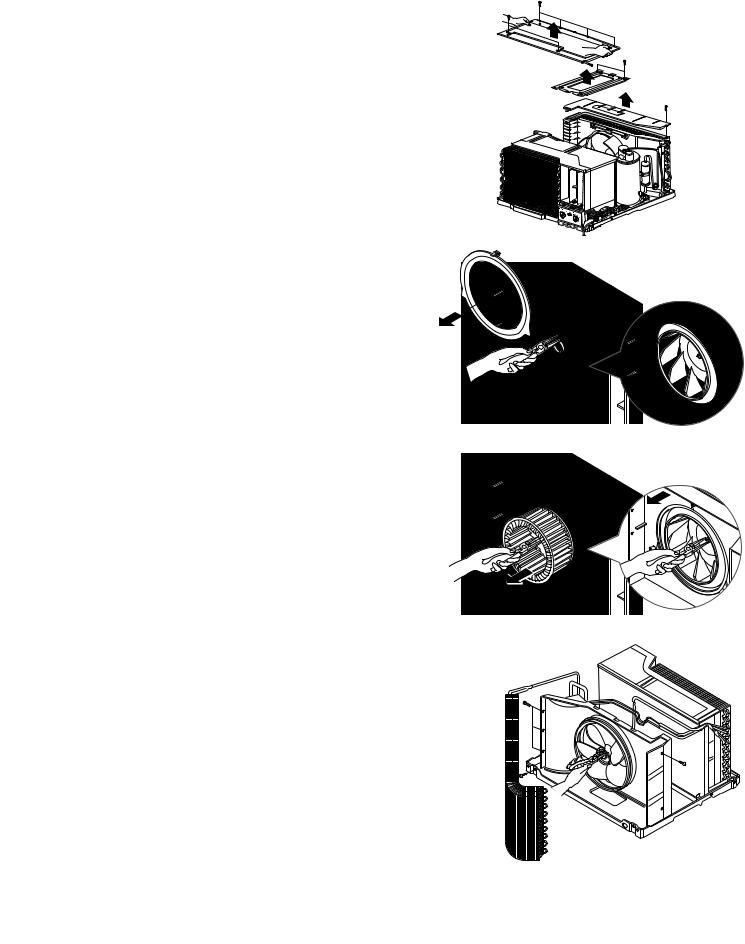

2.2 AIR HANDLING PARTS

2.2.1 COVER (AT THE TOP)

1.Remove the front grille. (Refer to section 2.1.1)

2.Remove the cabinet. (Refer to section 2.1.2)

3.Remove 11 screws which fasten the brace and covers.

4.Remove the covers and the brace. (See Fig. 4)

5.Re-install the components by referring to the removal procedure, above.

2.2.2 BLOWER

1.Remove the cover. (Refer to section 2.2.1)

2.Remove the 3 screws which fasten the evaporator at the left side and the top side.

3.Move the evaporator sideward carefully.

4.Remove the orifice from the air guide carefully.

5.Remove the clamp which secures the blower with plier. (See Fig. 5)

6.Remove the blower with plier or your hand without touching blades. (See Fig. 6)

7.Re-install the components by referring to the removal procedure, above.

2.2.3 FAN

1.Remove the cabinet. (Refer to section 2.1.2)

2.Remove the brace and shroud cover. (Refer to section 2.2.1)

3.Remove the 5 screws which fasten the condenser.

4.Move the condenser sideways carefully.

5.Remove the clamp which secures the fan.

6.Remove the fan. (See Fig. 7)

7.Re-install the components by referring to the removal procedure, above.

Figure 4

Figure 5

Figure 6

Figure 7

—11—

2.2.4 SHROUD

1. Remove the fan. (Refer to section 2.2.3)

2. Remove the 2 screws which fasten the shroud.

3. Remove the shroud. (See Fig. 8)

4. Re-install the component by referring to the removal procedure, above.

Figure 8

2.3 ELECTRICAL PARTS

2.3.1 MOTOR

1.Remove the cabinet. (Refer to section 2.1.2)

2.Remove the cover control and disconnect a wire

|

housing in control box. (Refer to section 2.1.3) |

|

3. |

Remove the blower. (Refer to section 2.2.2) |

|

4. |

Remove the fan. (Refer to section 2.2.3) |

|

5. |

Remove the 4 screws which fasten the motor. |

|

|

(See Fig. 9) |

|

6. |

Remove the motor. |

|

7. |

Re-install the components by referring to the |

|

|

removal procedure, above. |

Figure 9 |

|

|

2.3.2 COMPRESSOR

1.Remove the cabinet. (Refer to section 2.1.2)

2.Discharge the refrigerant system using FreonTM Recovery System.

If there is no valve to attach the recovery system, install one (such as a WATCO A-1) before venting the FreonTM . Leave the valve in place after servicing the system.

3.Disconnect the 3 leads from the compressor.

4.After purging the unit completely, unbrace the suction and discharge tubes at the compressor connections.

5.Remove the 3 nuts and the 3 washers which fasten the compressor.

6.Remove the compressor. (See Fig. 10)

7.Re-instill the components by referring to the removal procedure, above.

Figure 10

— 12—

2.3.3 CAPACITOR

1.Remove the control box. (Refer to section 2.1.3)

2.Remove the screw and knobs which fasten the display panel.

3. Disconnect the 2 leads from the rocker switch and remove the panel.

4. Remove a screw and unfold the control box. (See Fig. 11)

5. Remove the screw and the clamp which fastens the capacitor. (See Fig. 11)

6. Disconnect all the leads of capacitor terminals. 7. Re-install the components by referring to the

removal procedure, above.

Figure 11

2.3.4 POWER CORD

1.Remove the control box. (Refer to section 2.1.3)

2.Unfold the control box. (Refer to section 2.3.3)

3.Disconnect the grounding screw from the control

|

box. |

|

4. |

Disconnect 2 receptacles. |

|

5. |

Remove a screw which fastens the clip cord. |

|

6. |

Pull the power cord. (See Fig. 12) |

|

7. |

Re-install the component by referring to the |

|

|

removal procedure, above. |

|

|

(Use only one ground-marked hole |

for ground |

|

connection.) |

|

8. |

If the supply cord of this appliance is damaged, it |

|

must be replaced by the special cord. |

|

|

(The special cord means the cord which has the |

Figure 12 |

|

same specification marked on the supply cord |

||

|

||

fitted to the unit.) |

|

2.3.5 THERMOSTAT

1. Remove the control box. (Refer to section 2.1.3)

2. Unfold the control box. (Refer to section 2.3.3)

3. Remove the 2 screws which fasten the thermostat.

4. Disconnect all the leads of thermostat terminals.

5. Remove the thermostat. (See Fig. 13)

6. Re-install the components by referring to the removal procedure, above.

Figure 13

— 13—

Loading...

Loading...