LG LWD3063ST Installation Manual

ESPAÑOL ENGLISH

Installation Manual

Electric CONVECTION

BUILT-IN Oven

Please read these instructions thoroughly before installing and operating the oven.

LWS3081ST |

LWS3010ST |

LWS3063ST |

LSWS306ST |

LWS3063BD |

LWD3081ST |

LWD3010ST |

LWD3063ST |

LSWD306ST |

LWD3063BD |

www.lg.com

MFL51224802_09

Part 1 |

SAFETY |

1

BEFORE BEGINNING

BEFORE BEGINNING

Remove all tape and packing materials before using the oven. Dispose of all plastic bags after unpacking the oven. Never allow children to play with packing materials.

You can download an installation manual at http://www.lg.com.

IMPORTANT SAFETY INSTRUCTIONS

Read and follow all instructions before using the oven to prevent the risk of fire, electric shock, injury to persons, or damage when using the oven. This guide does not cover all possible conditions that may occur. For further assistance contact the service agent or manufacturer.

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others. All safety messages will follow the safety alert symbol and either the word “WARNING” or “CAUTION”. These words mean :

WARNING

WARNING

CAUTION

CAUTION

This symbol will alert you to hazards or unsafe practices which could cause serious bodily harm or death.

This symbol will alert you to hazards or unsafe practices which could cause bodily injury or property damage.

WARNING

WARNING

• The information in this manual should be followed exactly.

-Failure to do so could result in fire or electrical shock, causing property damage, personal injury or death.

•DO NOT put any weight on the oven door. Never allow anyone to climb, sit, stand or hang on the oven door.

-The oven could be tipped and injury might result from contact with hot food or the oven itself.

• The electrical power must be shut off while the electrical connections are being made.

-Failure to do so can result in severe personal injury, death or electrical shock.

•New branch-circuit installations (1996 NEC), mobile homes, recreational vehicles, or installations where local codes prohibit grounding through the neutral conductor require 4-wire branch-circuit connection.

•Improper connection of aluminum house wiring to copper leads can result in an electrical hazard or fire. Use only connectors designed for joining copper to aluminum and follow the manufacturer’s recommended procedure closely.

•Mounting screws must be used.

- Failure to do so can result in the oven falling out of the cabinet causing serious injury.

CAUTION

CAUTION

•Make sure the cabinets and wall coverings around the oven can withstand the temperature (up to 194˚F[90˚C]) generated by the oven.

- Discoloration, delamination or melting may occur.

• DO NOT remove spacers on the side walls of the built-in oven.

- These spacers center the oven in the space provided.The oven must be centered to prevent excess heat buildup that may result in heat damage or fire.

• DO NOT block the oven air exhaust located at the bottom of the oven.

-Blocking the exhaust may cause cabinet damage and product malfunction.

-2 -

Part 1 |

SAFETY |

IMPORTANT NOTE

This installation must be completed by a qualified installer or technician.

•Please read the entire Installation Instructions prior to installation.

•Remove all packing materials from the oven compartments before connecting the electrical supply to the oven.

•Installer: please retain these instructions for local inspector’s reference, then leave them with the consumer.

•Consumer: please read and keep these instructions for future reference and be sure to read the entire OWNER’S MANUAL prior to use.

•Do not use the parts except for provided components when you install the product.

WARNING

WARNING

• The information in this manual should be followed exactly.

-Failure to do so could result in fire or electrical shock, causing property damage, personal injury or death.

IMPORTANT NOTE

Proper installation is the responsibility of the installer and product failure due to improper installation is NOT covered under warranty.

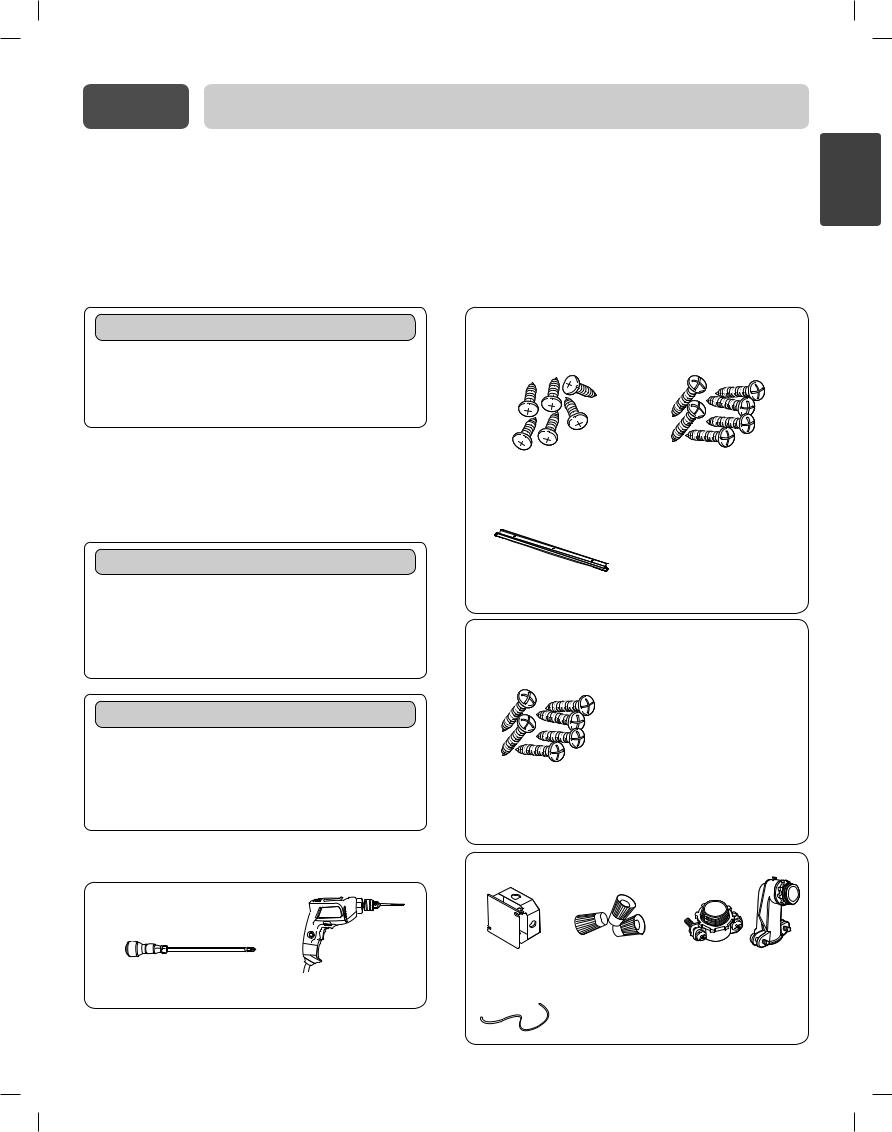

MATERIALS INCLUDED

(For Model : LWS3081ST, LWD3081ST, LWS3010ST, LWD3010ST)

4X8 |

4X14 |

6 Screws For |

6 Wood Screws |

Bottom Trim |

For Mounting |

(3 needed for installation |

(4 needed for installation |

and 3 extra’s) |

and 2 extra’s) |

WARNING

WARNING

•DO NOT put any weight on the oven door. Never allow anyone to climb,

sit, stand or hang on the oven door.

-The oven could tip and injury might result from contact with hot food or the oven itself.

WARNING

WARNING

•The electrical power must be shut off while the electrical connections are

being made.

-Failure to do so can result in severe personal injury, death or electrical shock.

REQUIRED TOOLS

30’ (76.2 cm) Metal Bottom Trim

MATERIALS INCLUDED

(For Model : LWS3063ST, LWD3063ST, LSWS306ST, LSWD306ST, LWS3063BD, LWD3063BD)

4X14

6 Wood Screws

For Mounting

(4 needed for installation and 2 extra’s)

MATERIALS NEEDED

ENGLISH

|

Junction Box |

Wire Nuts |

3/4” Conduit |

Phillips Screwdriver |

Drill |

|

Connector |

36” (91 cm) of String

- 3 -

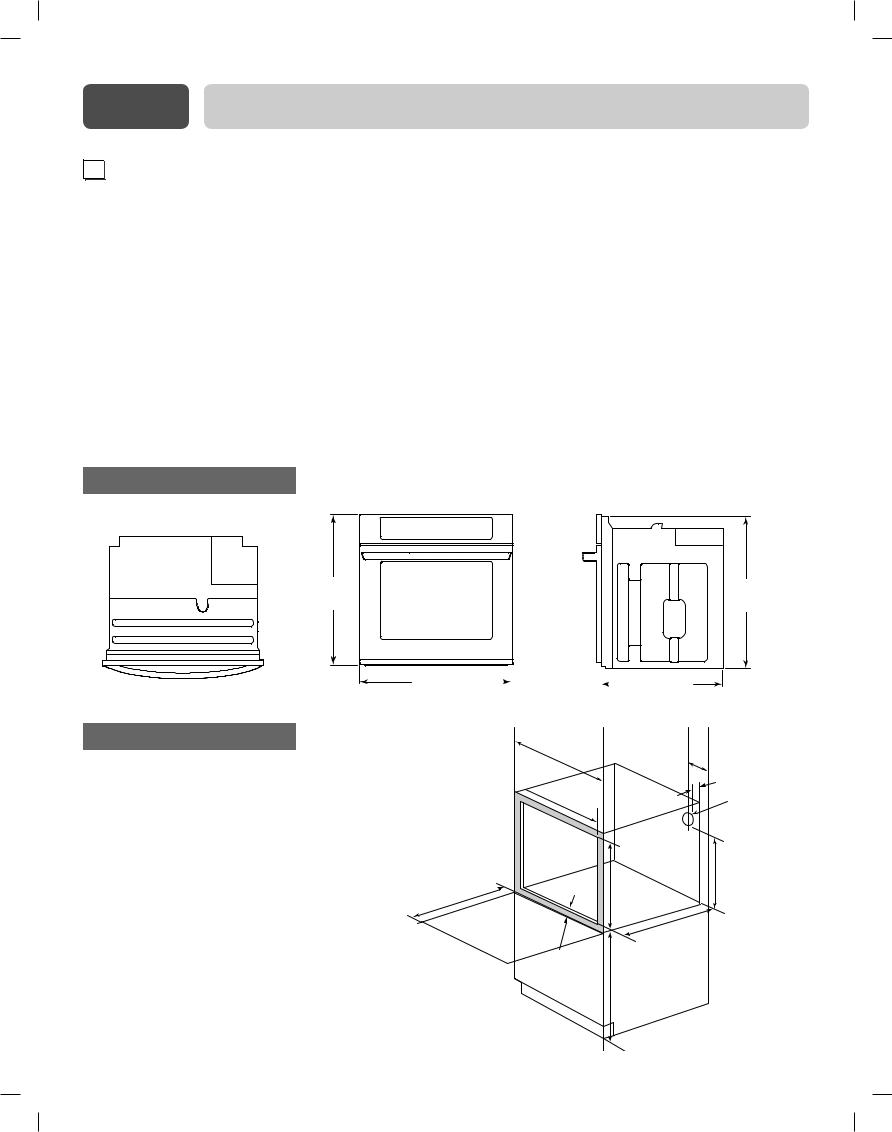

Part 2 INSTALLATION REQUIREMENTS

1

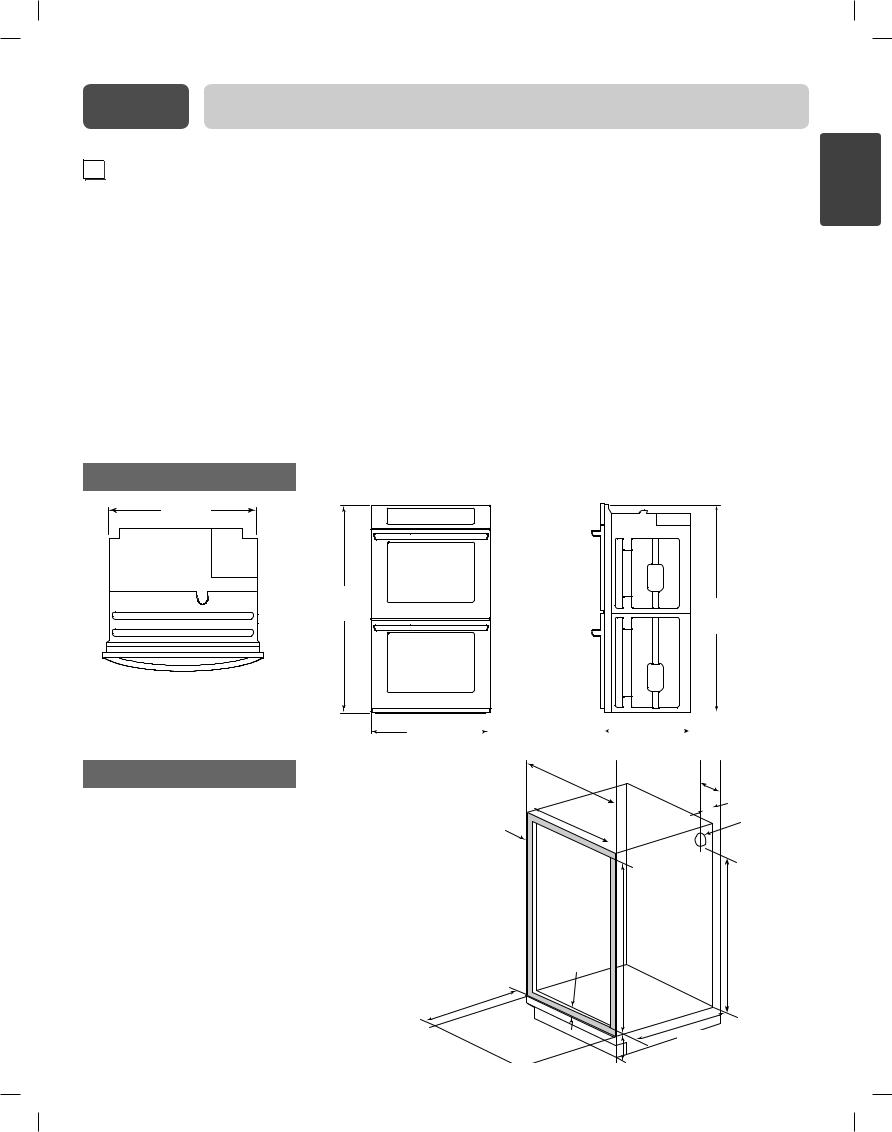

INSTALLATION DRAWINGS (FOR 30” SINGLE BUILTIN OVEN)

INSTALLATION DRAWINGS (FOR 30” SINGLE BUILTIN OVEN)

The first step of the installation is measure the current cutout dimensions and compare them to the cutout dimensions shown below. Little or no cabinet work may be necessary.

IMPORTANT NOTE

•The cabinet base platform must be able to support 190lbs (86kg). If the cabinet does not have a solid bottom, two braces or runners must be installed level with the bottom of the cutout to support the weight of the oven. Make sure the base is level and the front of the cabinet is square. If the cabinet base is not level, the oven glides will tend to slide out when opening the door.

•If marks, blemishes or the cutout opening are visible above the installed oven, it may be necessary to add wood shims under the runners and front trim until the marks or opening are covered.

•If the cabinet does not have a front frame and the sides are less than 3/4” (1.9 cm) thick, shim both sides equally to establish the cutout width.

•The junction box must be flush with the rear wall of the cabinet as shown below.

•Allow at least a 23” clearance for the door depth when it is open.

•Kitchen cabinets in contact with the oven must be heat resistant up to 194°F (90°C), and fronts of nearby units up to at least 158°F (70°C).

Product dimensions

27 3/8”

(69.5 cm)

(69.5 cm)

29 5/16” |

28 7/8” |

(74.5 cm) |

(73.3 cm) |

|

|

|

|

|

|

|

29 3/4” |

|

|

|

|

|

23 3/8” |

|

||||||

(75.5 cm) |

|

|

|

|

|

(59.3 cm) |

Cutout dimensions

Cabinet Width |

30” (762 mm) |

|

Recommended |

|

|

Minimum |

|

|

Cutout Location |

|

|

from Floor |

31” (787.4 mm) |

|

Cutout Depth |

23 |

1/2” Min. (596.9 mm) |

Cutout Width |

28 |

1/2” Min. (723.9 mm) |

|

28 |

5/8” Max. (727 mm) |

Cutout Height |

28 |

15/16” Min. (735 mm) |

|

29” Max. (736.6 mm) |

|

Allow 1”  minimum for overlap of oven

minimum for overlap of oven

23”

30”

28 1/2” Min.

28 5/8” Max.

Allow 1” minimum for overlap of oven

5”

Junction Box

Location

23 1/2”

28 15/16” Min. 29” Max.

23 1/2”

Minimum cutout location from floor 31”

- 4 -

Part 2 INSTALLATION REQUIREMENTS

2

INSTALLATION DRAWINGS (FOR 30” DOUBLE BUILTIN OVEN)

INSTALLATION DRAWINGS (FOR 30” DOUBLE BUILTIN OVEN)

The first step of the installation is measure the current cutout dimensions and compare them to the cutout dimensions shown below. Little or no cabinet work may be necessary.

IMPORTANT NOTE

•The cabinet base platform must be able to support 325lbs (147kg). If the cabinet does not have a solid bottom, two braces or runners must be installed level with the bottom of the cutout to support the weight of the oven.

Make sure the base is level and the front of the cabinet is square. If the cabinet base is not level, the oven glides will tend to slide out when opening the door.

•If marks, blemishes or the cutout opening are visible above the installed oven, it may be necessary to add wood shims under the runners and front trim until the marks or opening are covered.

•If the cabinet does not have a front frame and the sides are less than 3/4” (1.9 cm) thick, shim both sides equally to establish the cutout width.

•The junction box must be flush with the rear wall of the cabinet as shown below.

•Allow at least a 23” clearance for the door depth when it is open.

•Kitchen cabinets in contact with the oven must be heat resistant up to 194°F (90°C), and fronts of nearby units up to at least 158°F (70°C).

Product dimensions

27 3/8”

(69.5 cm)

52 1/16”

(132.2 cm)

Cutout dimensions

Cabinet Width |

30” (762 mm) |

|

Recommended |

|

|

Minimum |

|

|

Cutout Location |

|

|

from Floor |

12” (304.8 mm) |

|

Cutout Depth |

23 |

1/2” Min. (596.9 mm) |

Cutout Width |

28 |

1/2” Min. (723.9 mm) |

|

28 |

5/8” Max. (727 mm) |

Cutout Height |

51 |

13/16” Min. (1316 mm) |

|

51 |

15/16” Max. (1319.2 mm) |

51 5/8”

(131.0 cm)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29 3/4” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 3/8” |

|

|

|

|

|

|

|

(75.5 cm) |

|

|

|

|

|

|

|

(59.3 cm) |

|

|

|

|||||

|

|

|

|

|

30” |

|

|

|

|

5” |

||||||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

||||||||

Allow 1” |

|

1/2” Min. |

|

|

|

|

|

|

Junction Box |

|||||||

|

28 |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|||||||||||

|

28 |

5/8” Max. |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

Location |

|||||||||

minimum for |

|

|

|

|

|

|

|

|

|

|

|

|

||||

overlap of oven |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Allow 1” |

51 |

13/16” Min. |

47” |

minimum for |

|

||

51 |

15/16” Max. |

|

|

overlap of oven |

|

||

|

|

|

|

23” |

|

|

|

- 5 - |

|

23 1/2” |

|

Minimum cutout location from floor 12” |

|||

ENGLISH

Part 2 INSTALLATION REQUIREMENTS

3

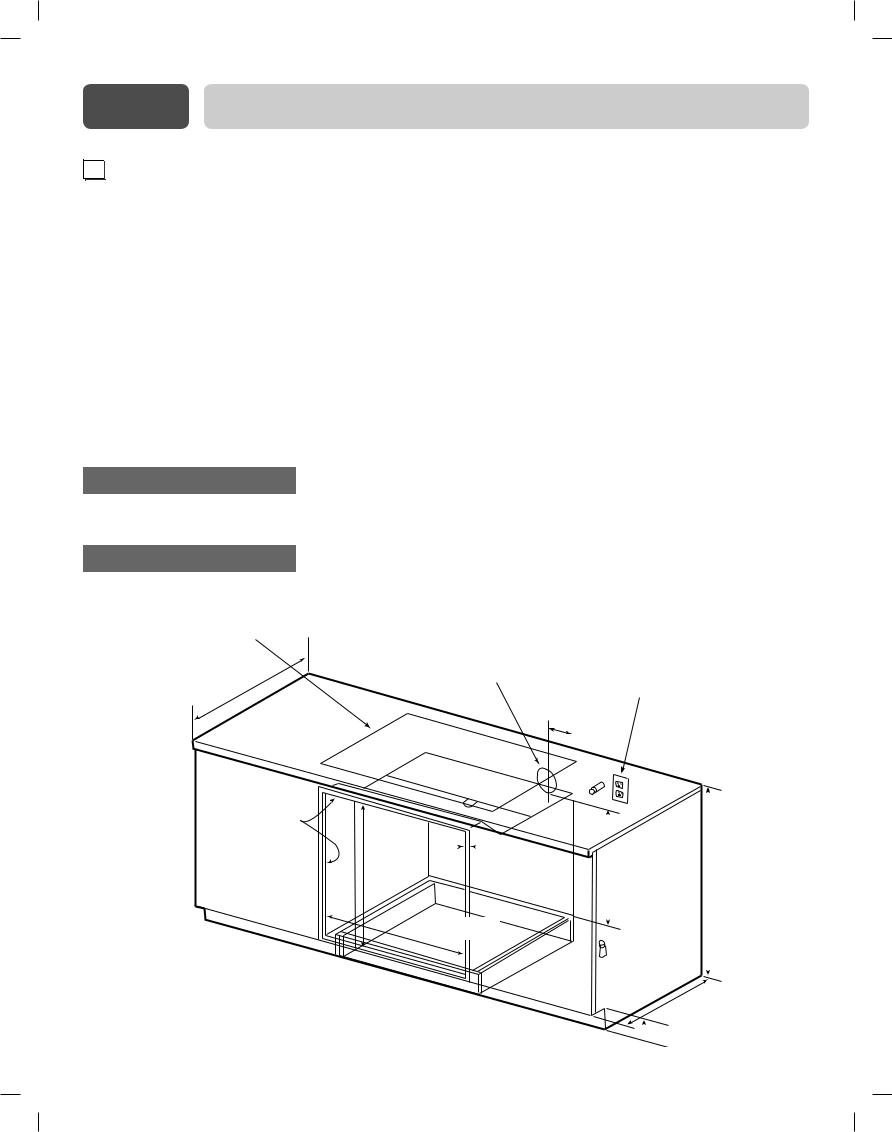

INSTALLATION DRAWINGS (FOR 30” SINGLE BUILTIN OVEN UNDERCOUNTER)

INSTALLATION DRAWINGS (FOR 30” SINGLE BUILTIN OVEN UNDERCOUNTER)

The first step of the installation is measure the current cutout dimensions and compare them to the cutout dimensions shown below. Little or no cabinet work may be necessary.

IMPORTANT NOTE

•The cabinet base platform must be able to support 190lbs (86kg). If the cabinet does not have a solid bottom, two braces or runners must be installed level with the bottom of the cutout to support the weight of the oven.

Make sure the base is level and the front of the cabinet is square. If the cabinet base is not level, the oven glides will tend to slide out when opening the door.

•If marks, blemishes or the cutout opening are visible above the installed oven, it may be necessary to add wood shims under the runners and front trim until the marks or opening are covered.

•If the cabinet does not have a front frame and the sides are less than 3/4” (1.9 cm) thick, shim both sides equally to establish the cutout width.

•The junction box must be flush with the rear wall of the cabinet as shown below.

•This oven is only approved to be installed under the specific models as labeled on this unit.

•Kitchen cabinets in contact with the oven must be heat resistant up to 194°F (90°C), and fronts of nearby units up to at least 158°F (70°C).

Product dimensions

Dimensions are the same as the single built-in oven on page 4.

Cutout dimensions

Gas or electric cooktops may be installed over this oven. See cooktop installation instructions for cutout size. See label on top of oven for approved cooktop models.

25” (63.5 cm)

Top and/or side fillers may be necessary if unit is positioned between existing cabinets. Be sure they are attached securely since, they will anchor the oven in the cabinets.

240 V / 208 V Junction Box Location (Junction box may be in adjacent cabinet)

Gas and electrical connections for

30” (76.2 cm) gas cooktop must be located in an adjacent accessible location to the right. For a 36” (91.4 cm) gas cooktop, the connections may be made to the left.

5”

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Allow 1” (2.5 cm) |

|

|

|

|

|

|

|

|

|

|

|

||||

28 15/16” (73.5 cm) Min. |

|

|

|

overlap top of oven, |

|

23 1/2” (59.7 cm) Min. |

36” (91.4 cm) |

|||

29” (73.7 cm) Max. |

|

|

|

1 1/16” (1.8 cm) overlap |

|

|||||

|

|

|

|

Above Support |

||||||

|

|

|

|

|

|

side edges of cutout |

|

Typical |

||

|

|

|

|

|

|

|

Platform |

|||

|

|

|

|

|

|

and 1 1/4” (3.2 cm) |

|

Countertop |

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

overlap bottom of oven. |

|

|

Height |

|

|

|

|

|

|

|

|

||||

28 1/2” (72.4 cm) Min. |

|

|

|

|||||||

|

|

|||||||||

28 5/8” (72.7 cm) Max. |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

24” (61 cm)

2 3/4”(7 cm) ~ 4”(10.2 cm)

2 3/4”(7 cm) ~ 4”(10.2 cm)

- 6 -

Part 2 INSTALLATION REQUIREMENTS

4

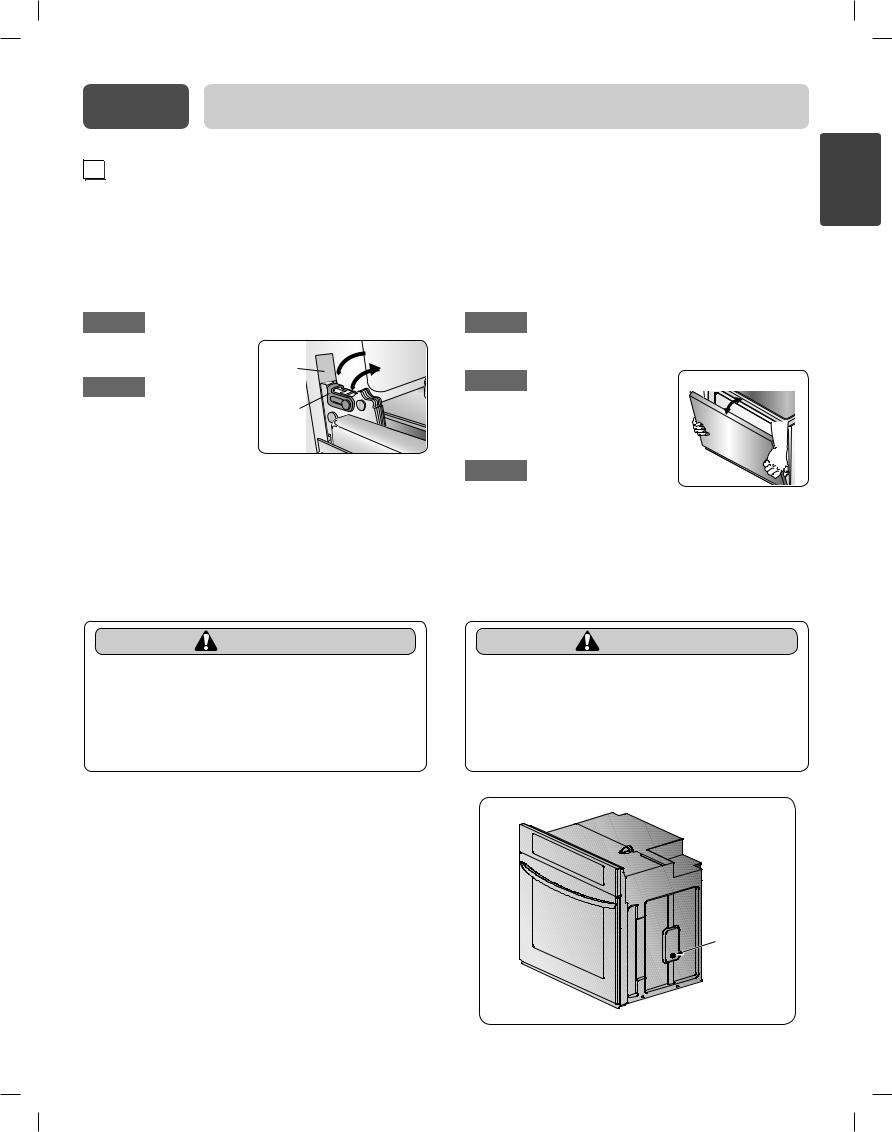

PREPARATION FOR MOVING THE OVEN

PREPARATION FOR MOVING THE OVEN

The second step of the installation is to remove any packing material from the oven before installing the oven.

1.Remove all tape from around the oven.

2.Open the oven door and remove packaging materials and oven racks inside the oven.

3.Door removal is not a requirement for installation of the oven, but is an added convenience. To remove the door, follow the steps below.

Step. 1

Fully open the door.

Step. 2

Pull the hinge locks up towards the door's frame, to the unlocked position.

Lock

Slot  Unlock

Unlock

Hinge

lock

Step. 3

Firmly grasp both sides of the door at the top.

Step. 4 |

about 5 |

Close door to the door removal position, which is approximately

5 degrees.

Step. 5

Lift door up and out until the hinge arm is clear of the slot.

4.Place the oven on a table or platform even with the cutout opening. (The table or platform must support 190 lbs

[86 Kg] for a single built-in oven, 325 lbs [147 Kg] for a double built-in oven.)

5.Remove the metal bottom trim from the oven. It will be installed at the end of the installation process. The trim is wrapped separately and taped to the top of the unit.

CAUTION |

CAUTION |

•Make sure the cabinets and wall coverings around the oven can withstand the temperature (up to

194 °F [90 °C]) generated by the oven.

- Discoloration, delamination or melting may occur.

IMPORTANT NOTE

•Do not lift the door by the handle. The oven door is very heavy. Firmly grasp the door by the sides before lifting it off the hinges.

•Do not lay the oven door on its handle. Doing so may cause dents or scratches.

•Use two or more people to lift or move the oven into the cabinet opening. Use caution when lifting the oven and wear gloves to protect hands from any sharp edges. Failure to follow these instructions may result in injury.

• DO NOT remove spacers on the side walls of the built-in oven.

-These spacers center the oven in the space provided. The oven must be centered to prevent excess heat buildup that may result in heat damage or fire.

Spacer

ENGLISH

- 7 -

Part 3 ELECTRICAL CONNECTIONS

1

ELECTRICAL CONNECTION REQUIREMENTS

ELECTRICAL CONNECTION REQUIREMENTS

The third step of the installation is to follow the electrical connection requirements below.

Ensure that dedicated circuit protection is prepared as recommended and that the oven is grounded properly.

IMPORTANT NOTE

Be sure the wall oven is installed and grounded properly by a qualified installer or service technician.

•This wall oven must be electrically grounded in accordance with local codes or, in their absence, with the National Electrical Code ANSI/NFPA No.70latest edition* in United States, or with CSA Standard C22.1-1982 and C22.2 No.01982 (or latest edition)**, Canadian Electrical Code, Part1, and all local codes and ordinances.

•This wall oven must be supplied with the proper voltage and frequency, and connected to an individual, properly grounded branch circuit, protected by a circuit breaker or fuse. To know the circuit breaker or fuse required by this model, see the rating plate to find the wattage consumption and refer to the table below to get the circuit breaker or fuse amperage.

Appliance Rating |

Protection Circuit |

Appliance Rating |

Protection Circuit |

Watts 240 V |

recommended |

Watts 208 V |

recommended |

|

|

|

|

less than 4800 W |

20 A |

less than 4100 W |

20 A |

|

|

|

|

4800 W - 7200 W |

30 A |

4100 W - 6200 W |

30 A |

|

|

|

|

7200 W - 9600 W |

40 A |

6200 W - 8300 W |

40 A |

|

|

|

|

9600 and + |

50 A |

8300 and + |

50 A |

|

|

|

|

•A double wall oven can consume up to 7,800 W at 240 VAC.

A 40 Amp circuit breaker with wire gauge #8 AWG must be used.

•A single wall oven can consume up to 4,100 W at 240 VAC.

A 30 Amp circuit breaker with wire gauge at least #10 AWG must be used.

IMPORTANT NOTE

•Do Not ground to a gas pipe.

•Do Not have a fuse in the neutral or grounding circuit.

•A U.L.-listed conduit connector must be provided at the junction box.

WARNING

WARNING

•New branch-circuit installations (1996 NEC), mobile homes, recreational vehicles, or installations where local codes prohibit grounding through the neutral conductor require 4-wire branch-circuit connection.

WARNING

WARNING

•Improper connection of aluminum house wiring to copper leads can result in an electrical hazard or fire. Use only connectors designed for joining copper to aluminum and follow the manufacturer’s recommended procedure closely.

- 8 -

Part 3 ELECTRICAL CONNECTIONS

2

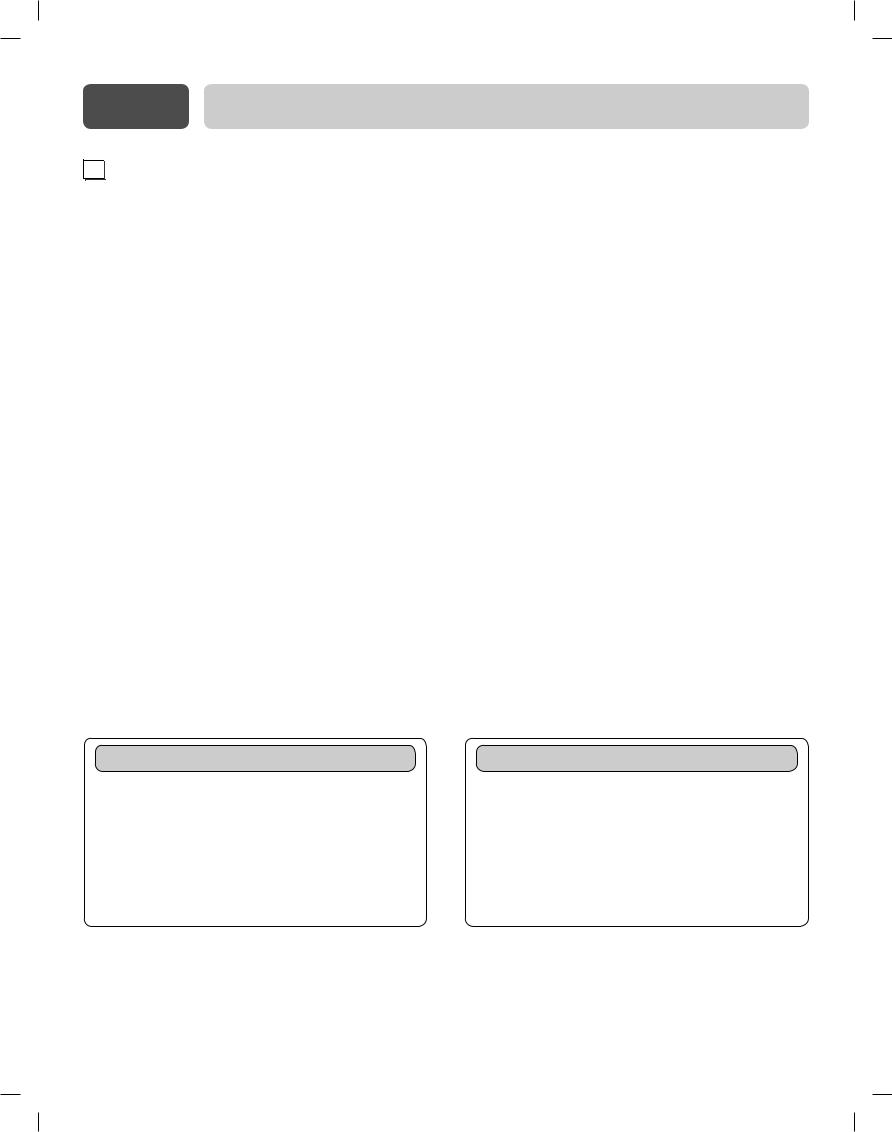

ELECTRICAL CONNECTION

ELECTRICAL CONNECTION

The fourth step of the installation is to prepare the electrical connection as follows:

1.Turn off the circuit breaker or remove fuses to the oven branch circuit.

2.With the oven positioned directly in front of the cabinet opening, connect the flexible conduit to the electrical junction box as shown below. Position the conduit in such a manner that it will lie on top of the oven in a natural loop when the oven is installed.

5” Min

Junction Box

Location

22” Min for single wall oven 42” Min for double wall oven

Junction Box must be recessed and conduit connector must be used at Junction Box.

ENGLISH

3.If local codes permit connection of the frame grounding conductor to the neutral(white) wire, follow the instructions for a 3-wire circuit connection on page 10.

If used in mobile homes or new construction, or a recreational vehicle, or local codes do not permit connection of the frame grounding conductor to the neutral(white) wire, follow the instructions for a 4-wire circuit connection on page 10.

IMPORTANT NOTE

•The wall ovens must be hard wired (direct wired) into an approved junction box. A plug and receptacle is not permitted on these products.

•DO NOT shorten the flexible conduit. The conduit connector must be securely attached to the junction box and the flexible conduit must be securely attached to the conduit connector. If the flexible conduit will not fit within the connector, do not install the oven until a connector of the proper size is obtained.

NOTE TO ELECTRICIAN

The power leads supplied with the appliance are UL, CSA recognized for connection to larger gauge household wiring. The insulation of these leads is rated at temperatures much higher than the temperature rating of household wiring. The current carrying capacity of the conductor is governed by the wire gauge and the temperature rating of the insulation around the wire.

- 9 -

Loading...

Loading...