LG LZ-H100GXN4 INSTALLATION INSTRUCTIONS

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product. Installation work must be performed in accordance with the national wiring standards by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

VENTILATOR

Original instruction

[Representative] LG Electronics Inc. EU Representative : LG Electronics European Shared Service Center B.V. Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro, Seongsan-gu, Changwon-si, Gyeongsangnam-do, KOREA

For more information, Refer to the CD or LG Web site (www.lg.com).

www.lg.com

<![endif]>ROMÂNĂ LIMBA POLSKI NEDERLANDS ČEŠTINA ΕΛΛΗΝΙΚΆ DEUTSCH FRANÇAIS ESPAÑOL ITALIANO ENGLISH

P/NO : MFL69268904

Ventilator Installation Manual

TABLE OF CONTENTS

Installation |

|

Requirements |

|

Safety Precaution................. |

3 |

Introduction.......................... |

8 |

Feature Dimension |

|

Diagram............................... |

8 |

Standard drawing of installa- |

|

tion ........................................ |

9 |

Installation.......................... |

11 |

Selection of the best |

|

location .............................. |

11 |

Ceiling dimension and hang- |

|

ing bolt location ................. |

12 |

Indoor Unit Installation....... |

13 |

Drain Piping and Water Sup- |

|

ply Work.............................. |

15 |

Check the drainage ........... |

16 |

Install the water supply |

|

piping................................. |

16 |

Insulate all piping that |

|

passes indoors .................. |

17 |

Duct Connection ................ |

18 |

Connecting Pipes............... |

19 |

Preparation of Piping......... |

19 |

Connecting the pipings to the |

|

indoor unit and drain hose to |

|

drain pipe........................... |

20 |

Insulation, Others .............. |

20 |

Wiring Connection............. |

21 |

Electrical Wiring.................. |

21 |

Method to Connect Wiring... |

23 |

Wiring for the Humidity Regu- |

|

lator (Locally Procured) ..... |

25 |

Wiring Example ................. |

26 |

Installer Setting and |

|

Test Run............................... |

27 |

Installer setting - How to enter |

|

installer setting mode......... |

27 |

Installer Setting – Function |

|

explanation ........................ |

29 |

Run the humidifier ............. |

31 |

In case of finding a problem at |

|

a test run.............................. |

32 |

Airborne Noise Emission ..... |

32 |

Limiting concentration .......... |

32 |

Required Parts

•Screws

•Nuts

•Ceiling Fixing Bolt(M10~12)

•Washer

•Aluminium Tape

•Screws

Required Tools

•Screw Driver

•Spanner

•Cutter

•Cutter

•Screw Driver

2 Ventilator

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the following indications.

CAUTION This symbol indicates the possibility of injury or damage.

CAUTION This symbol indicates the possibility of injury or damage.

WARNING

WARNING

Installation

Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

•There is risk of fire or electric shock.

For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized Service Center.

•Do not disassemble or repair the product.

There is risk of fire or electric shock.

Always ground the product.

•There is risk of fire or electric shock.

Install the panel and the cover of control box securely.

•There is risk of fire or electric shock.

Do not modify or extend the power cable.

•There is risk of fire or electric shock.

Always install a dedi- |

Use the correctly rated |

cated circuit and |

breaker or fuse. |

breaker. |

|

• Improper wiring or |

• There is risk of fire or |

installation may cause |

electric shock. |

fire or electric shock |

|

Do not install, |

Be cautious when |

remove, or re-install |

unpacking and |

the unit by yourself |

installing the prod- |

(customer). |

uct. |

• There is risk of fire, |

• Sharp edges could |

electric shock, explo- |

cause injury. |

sion, or injury. |

|

<![endif]>ENGLISH

Installation Manual 3

Safety Precautions

For installation, always |

Do not install the |

contact the dealer or |

product on a defec- |

an Authorized Service |

tive installation |

Center. |

stand. |

• There is risk of fire, |

• It may cause injury, |

electric shock, explo- |

accident, or damage to |

sion, or injury. |

the product. |

Do not let the product run for a long time when the humidity is very high and a door or a window is left open.

•Moisture may condense and wet or damage furniture.

For re-installation of the installed product, always contact the dealer or an Authorized Service Center.

Do not open the maintenance cover of the main body during operation.

• There is risk of fire, |

• Otherwise, it may cause |

electric shock, explosion |

electrical shock. |

or injury. |

|

Use the outdoor air suction hole with the net installed to ensure that birds could not come in.

•Remove estrange things like the bird’s nest. Otherwise, it may cause scarcity of indoor oxygen.

Install the air intake where polluted air can not be directly sucked in.

Do not install this product in a refrigerated warehouse, heated swimming pool or other location where the temperature and humidity are significantly different.

•It may cause various accidents, including suffocation, due to the suction of harmful gasses(CO, etc.)

•There is risk of electrical shock, malfunctioning.

Install this product in an environment where the temperature ranges from –15°C to +45°C and the relative humidity is less than 80%. It condensation is expected to form, heat up the fresh outside air using a duct heater etc.

4 Ventilator

Safety Precautions

Install this product in and environments where the outside air intake meets the following conditions: temperature range is between –15°C and +40°C and the relative humidity is 80% or less.

Use the designated electrical wires for the terminal board connections, and connect the wires securely so that they will not become disconnected. (Failure to ensure proper connections may cause fire.)

When passing metal ducts through wooden buildings clad with metal laths, wire laths or metal, these ducts must be installed in such a way that they will not make electrical contact with the metal laths, wire laths or metal sheets. (Power leakage can cause ignition)

|

Operation |

|

|

|

|

|

Don't touch a dedicat- |

||

|

Avoid fire equipment |

When the product is |

||

|

|

|

soaked (flooded or |

ed circuit or breaker |

|

|

|

submerged), contact |

with wet hands. |

|

|

|

an Authorized Service |

|

|

|

|

Center. |

|

• There is risk of fire. |

• There is risk of fire or |

• There is risk of electric |

||

|

|

|

eletric shock. |

shock. |

|

When the product is |

Do not store or use |

When flammable gas |

|

|

not be used for a long |

flammable gas or |

leaks, turn off the gas |

|

|

time, disconnect the |

combustibles near |

and open a window |

|

|

power supply plug or |

the product. |

for ventilation before |

|

|

turn off the breaker. |

|

turn the product on. |

|

• There is risk of product |

• There is risk of fire or |

• Do not use the tele- |

||

|

damage or failure, or |

failure of product. |

phone or turn switches |

|

|

unintended operation. |

|

on or off. There is risk |

|

|

|

|

|

of explosion or fire |

<![endif]>ENGLISH

Installation Manual 5

Safety Precautions

Be cautious that |

Turn the breaker off |

water could not enter |

when cleaning or |

the product. |

maintaining the prod- |

|

uct. |

• There is risk of fire, |

• There is risk of electric |

electric shock, or prod- |

shock. |

uct damage. |

|

The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from the ventilator unit, and properly insulated. (The entry of rain water may cause power leaks, fire or damage to household property.)

Glove should be worn when doing the installation work. (There is risk of injury.)

CAUTION

CAUTION

Installation

Don't connect the ground wire to the window frame or water cock.

•There is risk of electric shock.

Do not install the prod- |

Install the product in |

uct at a smoky and oily |

an insulated space |

place like kitchen or |

from outdoor air. |

factory. |

|

•Otherwise. oil may adhere to the filter or heating exchanger and cause trouble.

•In case of installing the product outside of the insulated layer, dewing occurs inside of the main body in winter.And it causes electrical shock or falling of condensed water.

6 Ventilator

Safety Precautions

Keep level even when |

Use two or more peo- |

installing the prod- |

ple to lift and trans- |

uct. |

port the product. |

• To avoid vibration or |

• Avoid personal injury. |

water leakage. |

|

Do not install the product where it will be exposed to sea wind (salt spray) directly.

•It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator fins, could cause product malfunction or inefficient operation.

Do not install the ventilation unit alone for controlling room temperature.

• If this is needed, install with another Indoor unit (air conditioner).

Operation

Use a soft cloth to clean. Do not use harsh detergents, wax or thinner, etc.

•Otherwise, color or surface of the oroduct mav deteriorate.

Clean the filter and the heat exchanger regularly and use the gloves for cleaning.

•Adhering to a mass of dust may cause the deterioration of air volume.

Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a consumer ventilator, not a precision refrigeration system.

•There is risk of damage or loss of property.

Do not block the inlet or outlet of |

Do not step on or put anyting on |

air flow. |

the product. |

• It may cause product failure. |

• There is risk of personal injury and |

|

failure of product. |

<![endif]>ENGLISH

Installation Manual 7

Introduction

Introduction

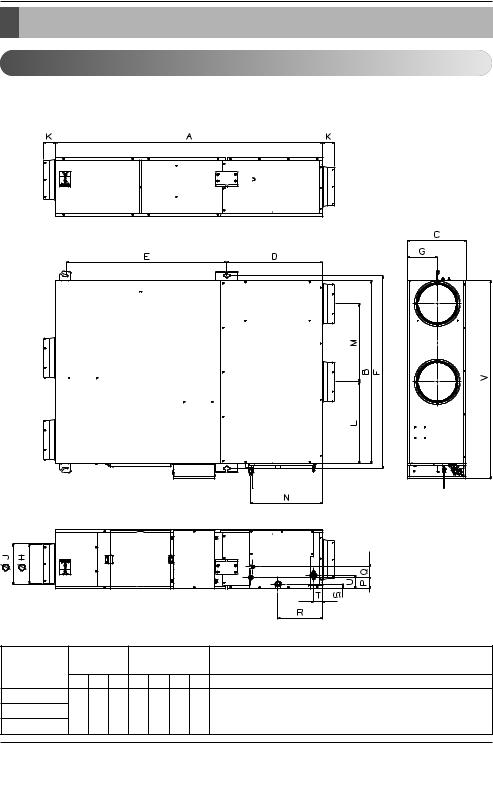

Feature Dimension Diagram

Model : LZ-H050GXN4, LZ-H080GXN4, LZ-H100GXN4

LZ-H050GXH4, LZ-H080GXH4, LZ-H100GXH4

Application tools |

(CMH) |

Unit : mm

|

Figure |

Pitch of Suspension |

|

Model |

Fixture |

||

|

|||

A |

B C D E F G |

||

LZ-H050GXN4/LZ-H050GXH4

LZ-H080GXN4/LZ-H080GXH4 1667 1140 365 599 1006 1204 185

LZ-H100GXN4/LZ-H100GXH4

Duct Connection |

Duct Pitch |

Pipe Connec- |

Drain Hose |

WaterSupplyPip- |

Width |

Wei- |

|||||||||

|

Flange |

|

|

|

|

tion |

|

Connection |

ingConnection |

|

ght |

||||

H |

J |

|

K |

L |

M |

N |

P |

Q |

R |

S |

T |

U |

V |

kg |

|

242 |

|

252 |

|

74 |

510 |

488 |

449 |

70 |

67 |

278 |

29 |

55 |

83 |

1239 |

105 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 Ventilator

Standard drawing of installation

Standard drawing of installation

LZ-H050GXN4 / LZ-H080GXN4 / LZ-H100GXN4

|

Ceiling suspension |

|

|

|

|

|

|

Air supply grille |

|

bolts position |

|

|

|

|

|

|

(user-supplied) |

|

|

|

A |

|

|

|

|

Air return grille |

EA |

|

|

|

|

|

|

|

(user-supplied) |

|

|

|

|

|

|

|

|

|

(Exaust air outlet) |

|

|

|

|

|

|

|

|

OA |

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>B |

(Fresh air outlet) |

|

|

|

|

|

|

|

Y duct connecting |

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>600 |

|

|

|

|

|

|

(user-supplied) |

|

<![if ! IE]> <![endif]>150~250 |

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>Morethan |

Inspection |

Inspection |

<![if ! IE]> <![endif]>600 |

||||

|

|

|

hatch |

|

|

hatch |

|

|

|

|

|

600 |

|

150~200 |

600 |

|

|

|

|

|

|

|

Maintenance space |

|

|

|

|

|

|

( |

Total heat Exchanger |

) |

|

||

|

|

|

|

Air Filter |

|

|

||

|

|

|

|

|

|

Ceiling Fixing Bolt |

||

Duct normal diameter |

|

|

|

|

|

(user-supplied) |

||

|

|

|

|

|

|

|

|

|

ØC(user-supplied) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Refrigerant piping (Liquid pipe) |

|||

|

|

|

|

|

(Φ 6.35 Flare connection) |

|||

|

<![if ! IE]> <![endif]>C |

|

|

|

|

|

|

<![if ! IE]> <![endif]>C |

EA |

|

|

|

|

|

Drain pipe |

||

|

|

|

|

|

(Inner diameter : 25.4) |

|||

(Exaust air outlet) |

OA |

Refrigerant piping (Gas pipe) |

Sloping downwards at a |

|||||

|

(Φ12.7 Flare connection) |

|

|

|||||

|

|

|

Gradient of the 1/100 |

|||||

(Fresh air outlet) |

|

|

|

|

|

|

|

|

Inspection part |

Air return grille |

|

Air supply grille |

|

450( |

600) |

RA |

SA |

SA |

|

|

|||

|

|

(Return air) |

(Supply air) |

(Supply air) |

Duct slope: More than 1/30(toward the wall) Obtaining of right distance (preventing penetration of rain water)

<![endif]>ENGLISH

|

|

|

[Unit : mm] |

Model |

A |

B |

C |

|

|

|

|

LZ-H050GXN4 |

|

|

|

LZ-H080GXN4 |

1006 |

1204 |

250 |

LZ-H100GXN4 |

|

|

|

|

|

|

|

Installation Manual 9

Standard drawing of installation

LZ-H050GXH4 / LZ-H080GXH4 / LZ-H100GXH4

EA

(Exaust air outlet)

OA

(Fresh air outlet)

Ceiling suspension bolts position

A

| <![if ! IE]> <![endif]>More than 600 |

<![if ! IE]> <![endif]>150~250 |

Inspection |

Inspection |

hatch |

hatch |

600 150~200 600

Maintenance space

(Total heat Exchanger ) Air Filter

Air supply grille (user-supplied)

Air return grille (user-supplied)

<![if ! IE]><![endif]>B

Y duct connecting (user-supplied)

<![if ! IE]><![endif]>600

|

|

Cistern Tank |

|

|

|

|

|

|

Ceiling Fixing Bolt |

Duct normal diameter |

|

|

|

(user-supplied) |

|

|

|

|

|

ØC(user-supplied) |

|

|

|

|

|

|

Strainer |

|

|

|

|

(user-supplied) |

Refrigerant piping (Liquid pipe) |

|

|

|

|

|

(Ø 6.35 Flare connection) |

|

|

Drain valve |

Refrigerant piping (Gas pipe) |

|

|

|

(user-supplied) |

||

|

|

Water supply |

(Ø12.7 Flare connection) |

|

|

|

shut-off valve |

|

|

|

|

(user-supplied) |

|

|

|

|

<![if ! IE]> <![endif]>C |

|

<![if ! IE]> <![endif]>C |

EA |

|

|

|

Feed water pipe |

(Exaust air outlet) |

OA |

|

|

|

|

|

(Φ6.35 Flare connection) |

||

|

Sloping downwards at a |

|

||

|

|

Drain pipe |

||

(Fresh air outlet) |

Gradient of the 1/100 |

|

(Inner diameter : 25.4) |

|

|

|

|||

Inspection hatch

Duct slope: More than 1/30(toward the wall) Obtaining of right distance (preventing penetration of rain water)

|

|

Air return grille |

|

|

|

Air supply grille |

RA |

SA |

SA |

||||

(Return air) |

(Supply air) |

(Supply air) |

||||

|

|

|

[Unit : mm] |

Model |

A |

B |

C |

|

|

|

|

LZ-H050GXH4 |

|

|

|

LZ-H080GXH4 |

1006 |

1204 |

250 |

LZ-H100GXH4 |

|

|

|

|

|

|

|

10 Ventilator

Loading...

Loading...